Page 1

MGC+50/MGC+100

Getting Started Guide

Version

9.0.4

| August 2010 | DOC2231A

Page 2

Trademark Information

Polycom®, the Polycom “Triangles” logo, and the names and marks associated with Polycom’s

products are trademarks and/or service marks of Polycom, Inc., and are registered and/or

common-law marks in the United States and various other countries.

All other trademarks are the property of their respective owners.

Patent Information

The accompanying product is protected by one or more U.S. and foreign patents and/or pending

patent applications held by Polycom, Inc.

© 2010 Polycom, Inc. All rights reserved.

Polycom, Inc.

4750 Willow Road

Pleasanton, CA 94588-2708

USA

No part of this document may be reproduced or transmitted in any form or by any means,

electronic or mechanical, for any purpose, without the express written permission of Polycom, Inc.

Under the law, reproducing includes translating into another language or format.

As between the parties, Polycom, Inc., retains title to and ownership of all proprietary rights with

respect to the software contained within its products. The software is protected by United States

copyright laws and international treaty provision. Therefore, you must treat the software like any

other copyrighted material (e.g., a book or sound recording).

Every effort has been made to ensure that the information in this manual is accurate. Polycom, Inc.,

is not responsible for printing or clerical errors. Information in this document is subject to change

without notice.

Page 3

Regulatory Notices

United States Federal Communication

Commission (FCC)

Part 15: Class A Statement. This equipment has

been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC

Rules. T est limits are designed to provide reasonable

protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate

radio-frequency energy and, if not installed and used

in accordance with the instruction manuals, may

cause harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the

user will be required to correct the interference at his

or her own expense.

Part 68: Network Registration Number. This

equipment is registered with the FCC in accordance

with Part 68 of the FCC Rules. This equipment is

identified by the FCC registration number.

If requested, the FCC registration Number and REN

must be provided to the telephone company.

Any repairs to this equipment must be carried out by

Polycom Inc. or our designated agent. This

stipulation is required by the FCC and applies during

and after the warranty period.

United States Safety Construction Details:

• Unit is intended for RESTRICTED ACCESS

LOCATION.

• Unit is to be installed in accordance with the

National Electrical Code.

• The branch circuit overcurrent protection shall

be rated 20 A for the AC system.

• This equipment has a maximum operating

ambient of 40°C, the ambient temperature in

the rack shall not exceed this temperature.

• To eliminate the risk of battery explosion, the

battery should not be replaced by an incorrect

type.

Dispose of used batteries according to their

instructions.

CE Mark R&TTE Directive

Polycom Inc., declares that the MGC+50 and

MGC+100 with NET-8 card is in conformity with the

following relevant harmonized standards:

EN 60950: 1992 Including Amendments 1,2,3 & 4

EN 55022: 1994

EN 50082: 1997

Following the provisions of the Council Directive

1999/CE on radio and telecommunication terminal

equipment and the recognition of its conformity.

Canadian Department of Communications

This Class [A] digital apparatus complies with

Canadian ICES-003.

Notice: The Industry Canada label identifies certified

equipment. This certification means that the

equipment meets telecommunication network

protective, operational and safety requirements as

prescribed in the appropriate Terminal Equipment

Technical Requirements document(s). The

Department does not guarantee the equipment will

operate to the user's satisfaction.

Before installing this equipment, users should ensure

that it is permissible to be connected to the facilities

of the local telecommunications company. The

equipment must also be installed using an acceptable

method of connection. The customer should be

aware that compliance with the above conditions may

not prevent degradation of service in some situations.

Repairs to certified equipment malfunctions, may give

the telecommunications company cause to request

the user to disconnect the equipment.

Users should ensure for their own protection that the

electrical ground connections of the power utility,

telephone lines and internal metallic water pipe

system, if present, are connected together. This

precaution may be particularly important in rural

areas.

Caution: Users should not attempt to make such

connections themselves but should contact the

appropriate electric inspection authority or electrician,

as appropriate.

Page 4

Regulatory Notices

Singapore Certificate

MGC+100 --- Complies with IDA standards G1260-05

MGC+50 --- Complies with IDA standards G1261-05

Taiwan Certificate

Russian Communication Certificate

The MGC+100 and MGC+50 comply with the

Russian Ministry of Communication requirements

stated in certificate OC/1-MM-15.

Page 5

Table of Contents

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Network Equipment, Numbers and Addresses . . . . . . . . . . . . . . . . . . 1-2

Overview of the Getting Started Guide . . . . . . . . . . . . . . . . . . . . . . . 1-3

Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

MGC+100 Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Inspecting the MGC+/ReadiManager IAM Package Contents . . 2-2

System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Rack Mount Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Polycom MGC+/ReadiManager Precautions . . . . . . . . . . . . . . . 2-3

Unpacking and Positioning the MGC+100 . . . . . . . . . . . . . . . . . 2-4

Mounting the MGC+100 in a 23” Rack . . . . . . . . . . . . . . . . . . . 2-6

MGC+50 Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Unpacking and Positioning the MGC+50 . . . . . . . . . . . . . . . . . . 2-7

Mounting the MGC+50 on a Rack . . . . . . . . . . . . . . . . . . . . . . . 2-9

Connecting and Setting Up the MGC+100/MGC+50 . . . . . . . . . . . 2-10

Connecting to the Power Source . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Connecting the MGC+100/MGC+50 to the Local Network . . . 2-11

Connecting the MGC+ to the Conferencing Network . . . . . . . . 2-11

Connecting the MGC+ to the ISDN/ T1-CAS Network . . . 2-11

Connecting the MGC+ to the IP Network . . . . . . . . . . . . . 2-13

First Entry MGC+ Control Unit (CU) IP Configuration . . . . . . . . . 2-14

Using the Compact Flash Disk with the LAN.CFG File . . . . . . 2-14

Using a Cross-over Hub Cable and a Laptop to Connect to the MCU

Locally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Using a Keyboard and Monitor Attached to the MGC+ unit . . 2-19

MGC+ Softw a re In s ta l la tion and Configuratio n . . . . . . . . . . 3-1

Initial ReadiManager IAM Configuration . . . . . . . . . . . . . . . . . . . . . 3-1

Installing the MGC Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Starting the MGC Manager Application . . . . . . . . . . . . . . . . . . . . . . . 3-4

MGC+50/MGC+100 Getting Started Guide

i

Page 6

Defining the MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Connecting to an MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Configuring the Network Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Defining the Network Services . . . . . . . . . . . . . . . . . . . . . . 3-8

About Conferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

On-Demand (Reservation-less) Conferencing . . . . . . . . . . . . . . . . . . 4-1

Ad Hoc Conferencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Meeting Rooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Scheduled Conferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Video Conference Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Entry Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Reservation Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Default Reservation Tem plates . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Starting a Conference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Viewing the Conference Dial-in Properties . . . . . . . . . . . . . . . . 5-4

Connecting to a Conference/Entry Queue . . . . . . . . . . . . . . . . . . . . . 5-5

Dialing-in to a Conference/Entry Queue . . . . . . . . . . . . . . . . . . 5-5

Monitoring On Going Conferences . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

General Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Monitoring a Conference . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Listing Participants in the Browser and Status Panes . . . . 5-10

Participant Level Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Operations Performed During On Going Conferences . . . . . . . . . . 5-13

Adding a Participant to a Conference . . . . . . . . . . . . . . . . . . . . 5-13

Defining Dial-out Participants . . . . . . . . . . . . . . . . . . . . . . 5-13

Making Dial-Out Connections . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Disconnecting Participants . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Muting a Participant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Locking and Unlocking a Conference . . . . . . . . . . . . . . . . . . . 5-21

Changing the Conference Duration . . . . . . . . . . . . . . . . . . 5-22

Terminating a Conference Manually . . . . . . . . . . . . . . . . . 5-24

Changing the Layout in a Continuous Presence Conference . . 5-25

ii

Page 7

MGC+50/MGC+100 Getting Started Guide

Defining a New Audio Conference . . . . . . . . . . . . . . . . . . . . . 6-1

Defining a New Audio Only Entry Queue . . . . . . . . . . . . . . . . . . . . . 6-1

Defining an On Going Audio Conference . . . . . . . . . . . . . . . . . . . . . 6-5

Defining a New Audio Only Meeting Room . . . . . . . . . . . . . . . . . . . 6-9

Defining a New Video Conference . . . . . . . . . . . . . . . . . . . . . 7-1

Defining a New Video Entry Queue . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Setting an Entry Queue as Default . . . . . . . . . . . . . . . . . . . . . . . 7-4

Creating a Target Conference from an Entry Queue . . . . . . . . . . . . . 7-5

Creating an On Going Video Conference . . . . . . . . . . . . . . . . . . . . . . 7-6

Defining a New Video Meeting Room . . . . . . . . . . . . . . . . . . . . . . . 7-12

Management Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Resource Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Resources Report - Network Resources . . . . . . . . . . . . . . . . . . . 8-3

Resource Report - Network Resources Details . . . . . . . . . . . 8-4

Resources Report - Media Resources . . . . . . . . . . . . . . . . . . . . . 8-5

Media Resources Area Parameters Description . . . . . . . . . . 8-5

Port-Unit Allocation Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Listing the Installed Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

MCU Faults Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Reset MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Obtaining Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

iii

Page 8

iv

Page 9

Before You Begin

This Getting Started Guide provides information on the installation and

basic operation of your MGC+50/100. For more information on defining

and running conferences, defining IVR services and managing the system,

refer to the MGC Manager User’s Guide Volumes I & II and the MGC

Administrator’s Guide. References to the relevant chapters of these guides

are included throughout this Getting Started Guide

The term ReadiConvene, used in this documen tation, refers to t he combined

MGC+ unit with the installed Polycom® ReadiManager™ Integrated

Application Module (IAM). It provides func tionalit y of both the MGC+ uni t

and the ReadiManager™.

System Overview

The MGC+50 and MGC+100 are high performance, high capacity multinetwork solutions that provides you with feature-rich, and easy-to-use

multipoint voice, video and gateway conferencing.

The system meets International Telecommunication Union Telecommunication Standardization Sector, (ITU-T, formerly CCITT)

standards for multipoint multimedia bridging devices, and meets ETSI

standards for telecommunication products.

The flexible architecture in the system is designed to accommodate users’

changing multipoint needs. This system utilizes a modular “universal slot”

platform that allows the formation of different configurations based on

users’ individual port capacity and functionality requirements.

1

1-1

Page 10

Chapter 1 - Before You Begin

Network Equipment, Numbers and Addresses

Obtain the following information from your network administrato r:

• IP address for the MGC+50/MGC+100

• Subnet Mask for the MGC+50/MGC+100

• Default Gateway IP address (optional)

• Gatekeeper IP address, if applicable

• DNS IP address, if applicable

• SIP server IP address, if applicable

For ISDN configurations, obtain the following equipment and information

from your network service provider:

• PRI line(s) or Leased Line(s)

• Directory number range(s)

• Switch Type

• Line Coding

• Line Framing

• Numbering Plan

• Numbering Type

1-2

If the MGC+50/100 ha s to be conn ected to the public ISDN network, an external

CSU or similar equipment is needed.

Page 11

MGC+50/MGC+100 Getting Started Guide

Overview of the Getting Started Guide

The MGC+50/MGC+1 00 Getting Started Guide includes the following

topics:

Chapter 1 - Before You Begin

This chapter includes the following:

• System Overview

• System Specifications

• General Site Requirements - Ne twork Equipment, N umbers and

Addresses

Chapter 2 - MGC+ Unit Hardware Installation

This chapter includes instructions on how to:

• Unpacking and install the MGC+ unit

• Configure the initial IP of the system

Chapter 3 - Software Installation and Configuration

This chapter includes instructions on how to:

• Install the MGC Manager

• Configure the MGC Manager to work with your MGC+50/MGC+100

• Configure the network services for ISDN and IP connections

Chapter 4 - Conference Types

This chapter describes the major types of conferences that can be scheduled

on the MCU, such as Reservationl ess (Ad Hoc) confer ences, Meeting Rooms,

video conferences, Audio Only conferences and Entry Queues.

Chapter 5 - Basic Operation

This chapter includes instructions on how to:

• Start a conference from the default conference templates

• Monitor On Going Conferences

• Perform basic operations during an On Going Conference

1-3

Page 12

Chapter 1 - Before You Begin

Chapter 6 - Defining a New Audio Conference

This chapter includes instructions on how to:

• Define the basic parameters of a new Audio Only Entry Queue

• Define a new Standard Audio Only conference

• Define an Audio Only Meeting Room

Chapter 7 - Defining a New Video Conference

This chapter includes instructions on how to:

• Define the basic parameters of a new Video Entry Queue

• Define the basic parameters of a new Video Conference

• Define a Me eting Room

Chapter 8 - Management Tools

This chapter describes the basic management tools for the MGC+50/

MGC+100:

• Resource Report

• Cards Management

• MCU Faults report

• Reset MCU.

1-4

This is an example of the notes that you may encounter throughout this guide.

Page 13

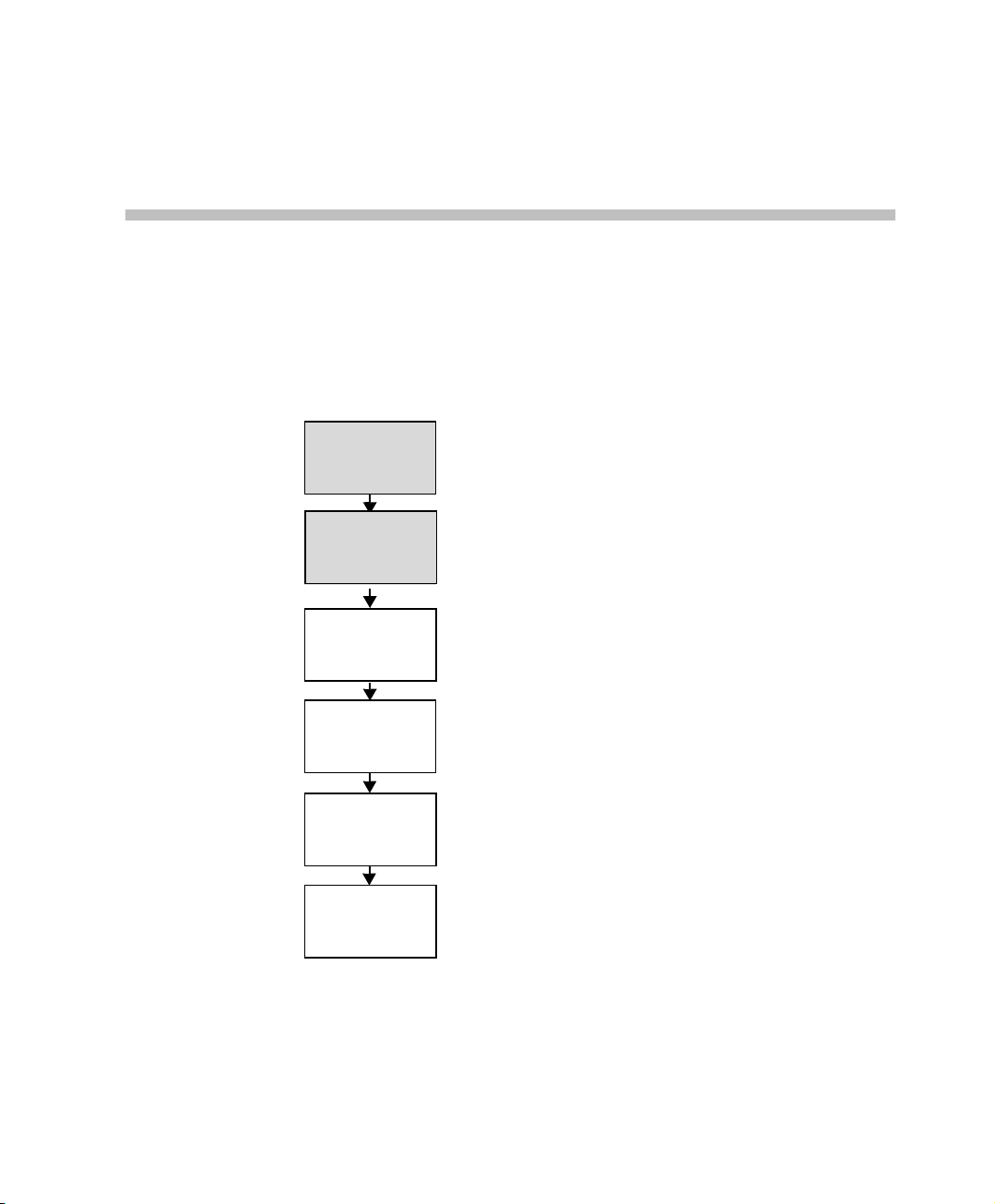

Hardware Installation

This chapter describes the unpacking and connection of both the MGC+50

and the MGC+100, to the ISDN, T1-CAS, IP, MPI (seria l) network(s) and to

the operator workstation (P C).

2

Hardware

Installation

First Entry MCU

IP Configuration

MGC Manager

Software

Installation

MGC Unit

Definition in the

MGC Manager

Network Services

Definition

Database

Configuration

MGC+ Getting Started Guide, Chapter 2

MGC+ Getting Started Guide, Chapter 2

MGC+ Getting Started Guide, Chapter 3

MGC+ Getting Started Guide, Chapter 3

MGC+ Getting Started Guide, Chapter 3

MGC+ User’s Guide - Volume II,

Chapter 6

Figure 2-1: Installation and Configuration Workflow - Hardware Installation

2-1

Page 14

Chapter 2 - Hardware Installation

MGC+100 Hardware Installation

Inspecting the MGC+/ReadiManager IAM Package Contents

You should inspect the shipped box and note if it was damaged in any way. If

the box items show damage, you should file a damage claim with the carrier

who delivered it.

When deciding on a setup location for the MGC+, refer to the section

“System Safety” on page 2-2.

Disclaimer

Polycom is not responsible for damage sustained during shipment of this

product.

System Safety

This section includes the foll ow topics related to system safety:

• “General Safety Precautions” on page 2-2

• “Rack Mount Safety Precautions” on page 2-3

• “Polycom MGC+/ReadiManager Precautions” on page 2-3

General Safety Precautions

Follow these rules to ensure general safety:

• Keep the area around the Polycom ReadiConvene clean and free of

clutter.

• The MGC+50 weighs approximately 24 kg (53 lbs) and the MGC+100

weighs approximately 48 kg (106 lbs). When lifting the system, two

people at either end should lift slowly with their feet spread out to

distribute the weight. Always keep your back straight and lift with your

legs.

2-2

Page 15

Rack Mount Safety Precautions

The following precautions should be followed with regards to rack mount

safety:

• Decide on a suitable location for the equipment rack that will hold the

MGC+ unit. It should be situated in a clean, dust-free area that is well

ventilated. Avoid areas where heat, electrical noise and electromagnetic

fields are generated. You will also need it placed near a grounded power

outlet.

• Ensure that the leveling jacks on the bottom of the rack are fully

extended to the floor with the full weight of the rack resting on them.

• In a single rack installation, stabilizers should be attached to the rack.

• In multiple rack installations, the racks should be coupled together.

• Always make sure the rack is stable before extending a component from

the rack.

• You should extend only one component at a time - extending two or more

simultaneously may cause the rack to become unstable.

• Before you install the rails, determine the placement of each component

in the rack.

• Install the heaviest server compone nts on the bottom of the rack firs t, and

then work up.

• Allow the power supply units to cool before touching them.

• Always keep the rack’s front door and all the blade’s panels and

components closed when not servicing, to maintain proper cooling.

MGC+50/MGC+100 Getting Started Guide

Polycom MGC+/ReadiManager Precautions

The following precautions should be followed with regards to installation of

the ReadiConvene:

Use a regulating uninterruptable power supply (UPS) to protect the MGC+

from power surges and voltage spikes, to keep your MCU and Readi Manag er

IAM operating in case of a power failure.

2-3

Page 16

Chapter 2 - Hardware Installation

C

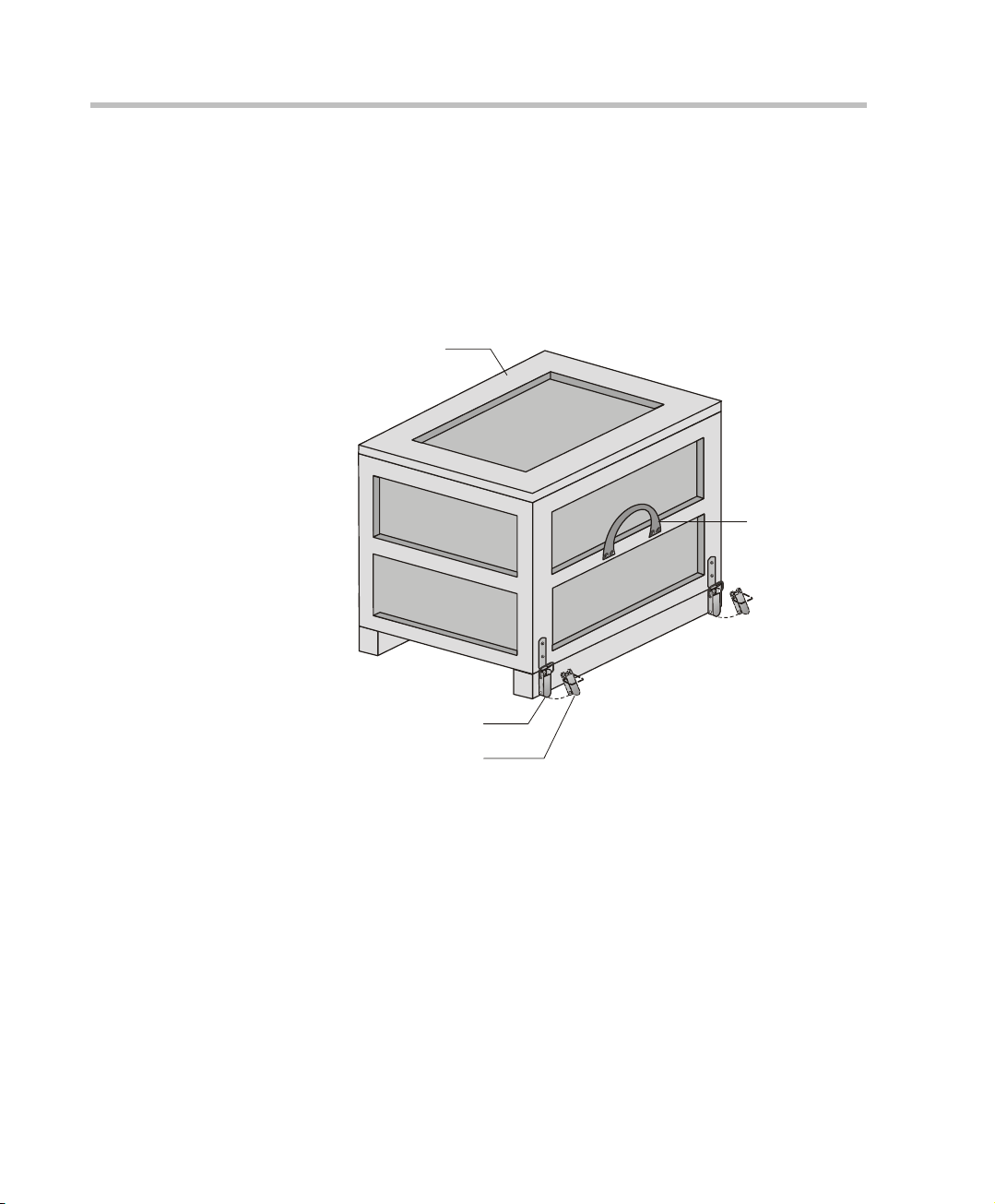

Unpacking and Positioning the MGC+100

To unpack and position the MGC+100:

1. When you receive your MGC+100, inspect the equipment for damage

and verify that the components match the packing slip. If you did not

receive a component or if there is damage to the system, notify your

service representative immediately.

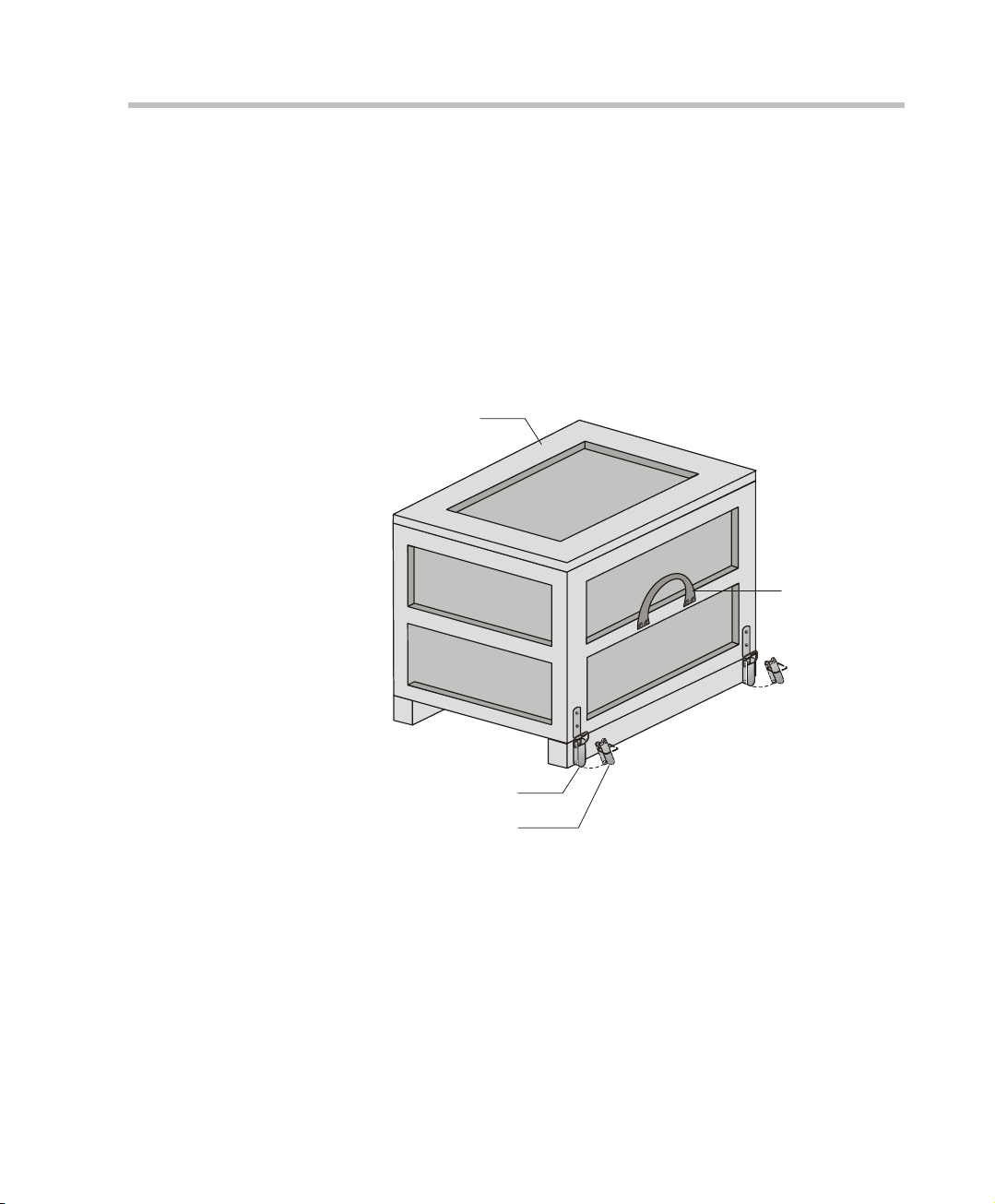

Wood Packing

Lock in Closed Position

Lock in Open Position

Figure 2-1: MGC+100 package

ase

Carrying Strap

2. Place the MGC+100 unit on a stable flat surface in a location that meets

the MGC+ environment requirements, which are:

2-4

— Operating temperature: 10°–40°C (50°–104°F) or 10°–35°C

(50°–95°F) when installed in a 19” rack

— Humidity: 15%–90% non-condensing

— Altitude: Up to 3,000m (10,000ft)

— ESD: +8 kV

Page 17

MGC+50/MGC+100 Getting Started Guide

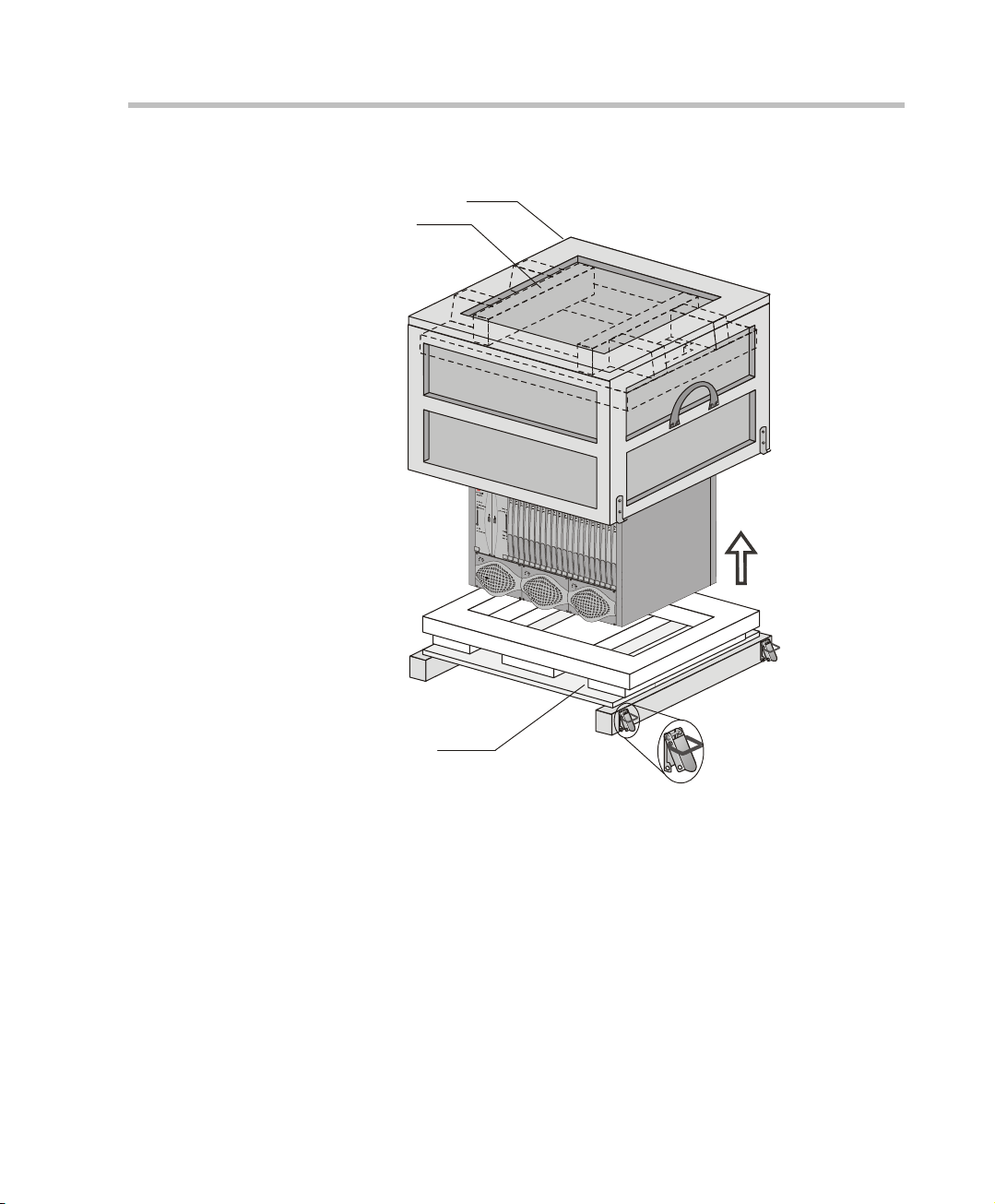

C

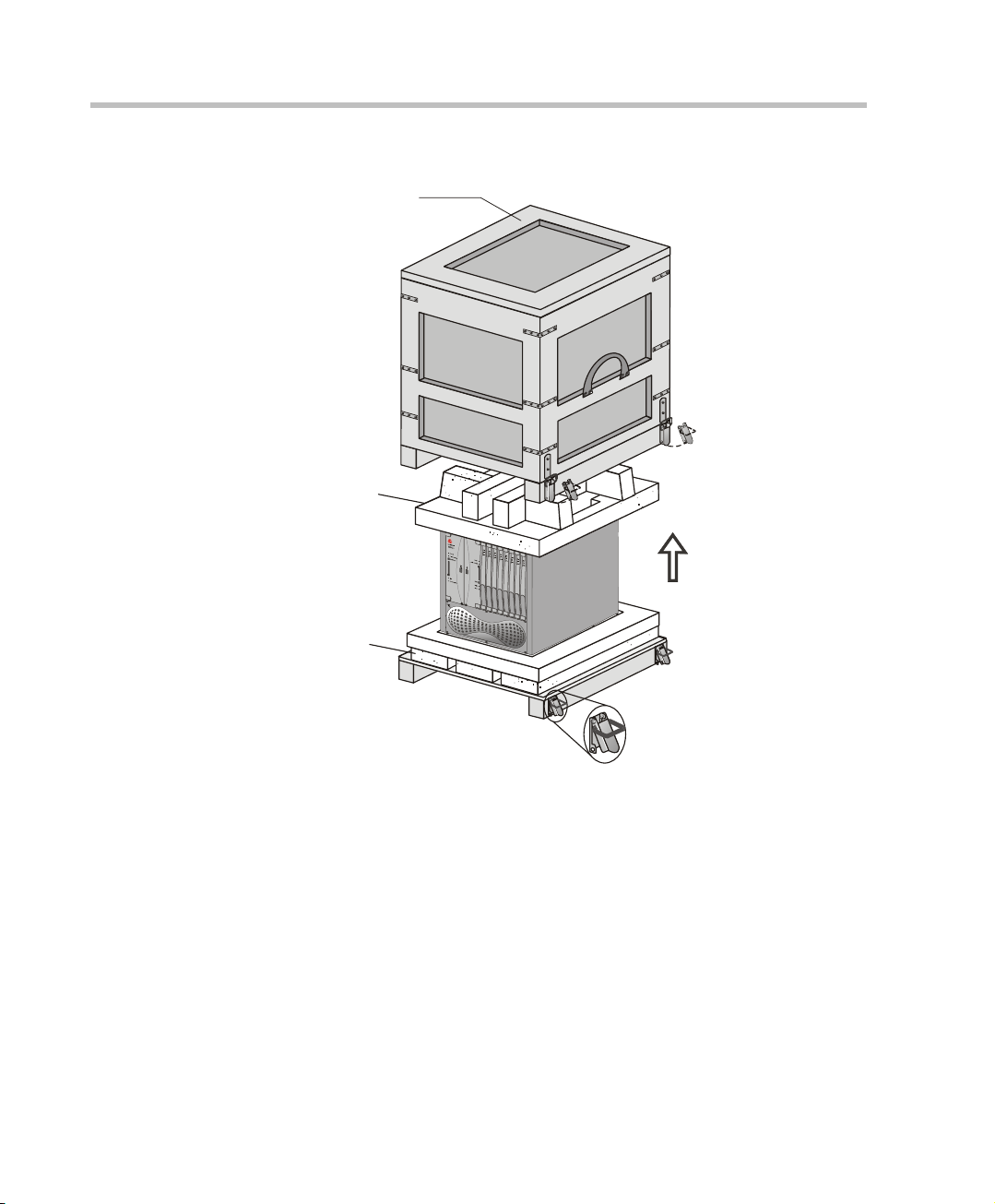

3. Release the clasp locks at the bottom, and lift the MGC+100 top cover.

Wood Packing

Foam Block

ase

Foam Block

Figure 2-2: Unpacking the MGC+100

4. Lift the MGC+100 unit and remove the packaging material.

5. Lower the MGC+100 unit, placing it on the surface.

If the MGC+100 is a standalone unit, place it on a flat surface. If you are

rack mounting the MGC+100, allow a minimum clearance of 3” above

the unit.

2-5

Page 18

Chapter 2 - Hardware Installation

Mounting the MGC+100 in a 23” Rack

The MGC+100 can be mounted in a 23” rack using the two mounting plates

that are pre-installed on the unit.

1. Make sure that the MCU is turned OFF and it is disconnected from the

AC power.

2. Place the MCU in a 23” rack and support i t, screw the mounting brackets

to the rack securing it with bolts and

self-locking nuts (which the client provides).

When the unit is installed on a rack, the rack must be properly grounded to the

central office ground. The rack must be grounded with two-hole compressiontype connectors using copper conductors (tinned or untinned). Wire, bus bar or

braided strap connectors are acceptable.

If the MGC+100 was shipped without the two mounting plates that are

usually pre-installe d, refer to the MGC+ Hardware and Installation Manual,

Chapter 2 for a detailed description of the installation process.

For a detailed description of mounting the MGC+100 in a 19” rack, see the

MGC+ Hardw are and Installation Manual, Chapter 2 .

2-6

Page 19

MGC+50 Hardware Installation

C

Unpacking and Positioning the MGC+50

To unpack and position the MGC+50:

1. When you receive your MGC+50, inspect the equipment for damage and

verify that the components match the packing slip. If you did not receive

a component or if there is damage to the system, notify Polycom

immediately.

MGC+50/MGC+100 Getting Started Guide

Wood Packing

Lock in Closed Position

Lock in Open Position

Figure 2-3: MGC+50 package

ase

Carrying Strap

2. Place the MGC+50 unit on a stable flat surface in a location that meets

the MGC+50’s environment requirements, which are:

— Operating temperature: 10°–40°C (50°–104°F)

— Humidity: 15%–90% noncondensing

— Altitude: Up to 3,000m (10,000ft)

— ESD: +8 kV

2-7

Page 20

Chapter 2 - Hardware Installation

C

3. Release the clasp locks at the bottom, and lift the MGC+50 top cover.

Wood Packing

Foam Block

Foam Block

ase

2-8

Figure 2-4: Unpacking the MGC+50

4. Lift the MGC+50 unit and remove the package base.

5. Lower the MGC+50 unit, placing it on the surface.

If you are rack mounting the MGC+50, allow a minimum clearance of 3

inches above the unit.

Page 21

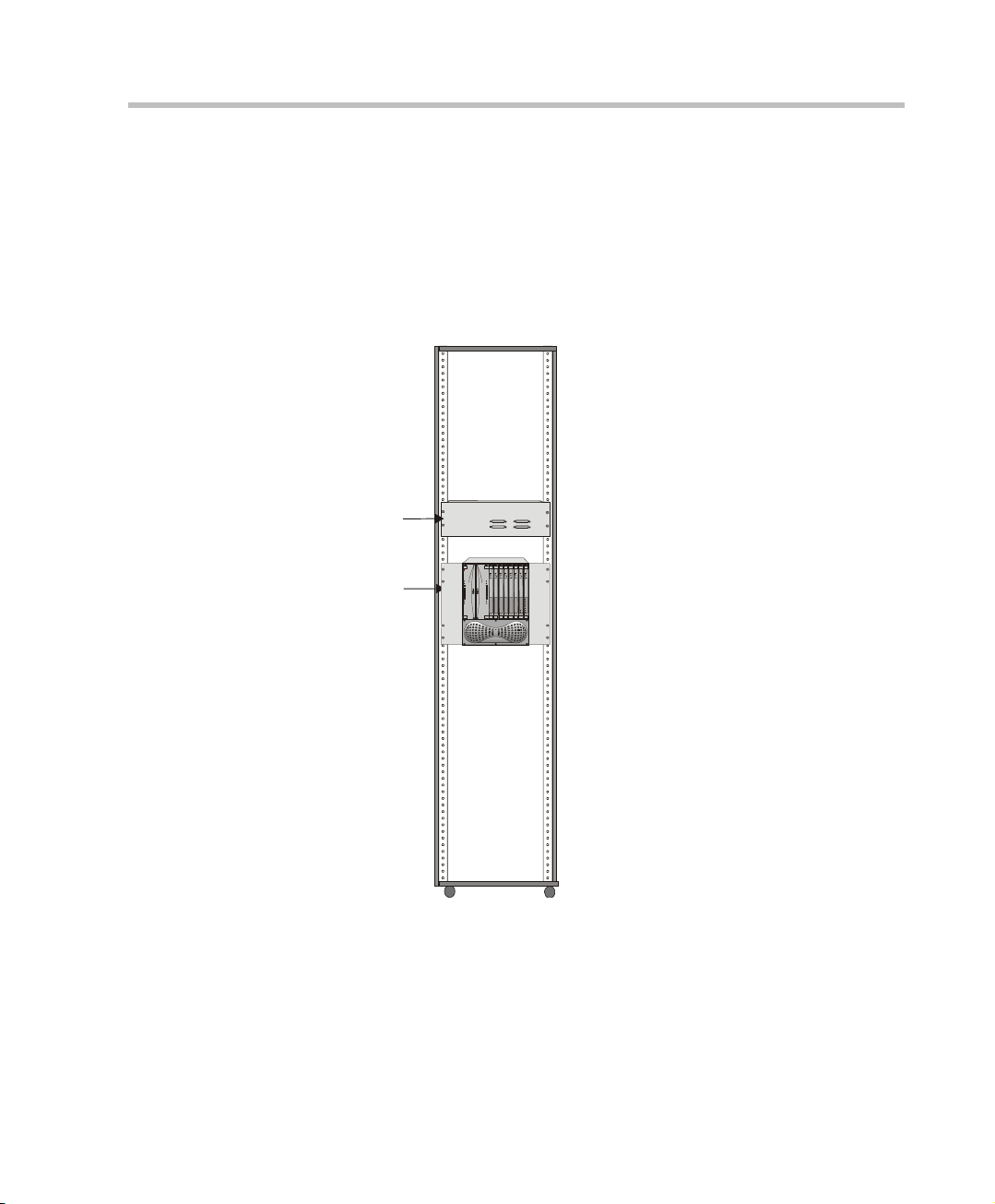

Mounting the MGC+50 on a Rack

The MGC+50 can be mounted in a 19” rack using the two mounting plates

that are usually pre-installed.

To install and mount the MGC+50:

• Place the MGC+50 in a 19” rack and while supporting it, screw the

mounting brackets to the rack securing it with nuts.

MPI Box

R

POLYCOM

MGC+

Power

Power

Flash Memory

Flash Memory

Mounting

Plate

Shut Down

Reset

HD

Major

Remove Server

Minor

Power

Out

MGC+50/MGC+100 Getting Started Guide

Line 1

Line 2

Line 3

Line 4

Line 5

Line 6

Line 1

Line 7

Line 8

Line 2

2-9

Page 22

Chapter 2 - Hardware Installation

Connecting and Setting Up the MGC+100/ MGC+50

To Connect the MGC+100/ MGC+50 to the network and power source and

set up the system the following procedures are performed:

• Connecting the MGC+ uni t to the power source (AC inlet)

• Connecting the MGC+ unit to the LAN Network

• Connecting the MGC+ unit to the network(s)

Connecting to the Power Source

You can connect to an AC Inlet power supply at your site. It is important to

follow these steps.

The following restrictio ns apply to the c onducto rs and connectors t hat may be

used to ground the unit when rack mounted:

• When using bare conductors, they must be coated with an appropriate

antioxidant compound before crimp connections are made. Tinned,

solder-plated or silver-plated connectors do not have to be prepared in

this manner.

• The same bolt assemblies should not secure multiple connectors.

• Listed fastening hardware must be compatible with the materials being

joined and must be preclude l oosening, deteri oration and e lectrochemical

corrosion of the hardware and joint materials.

2-10

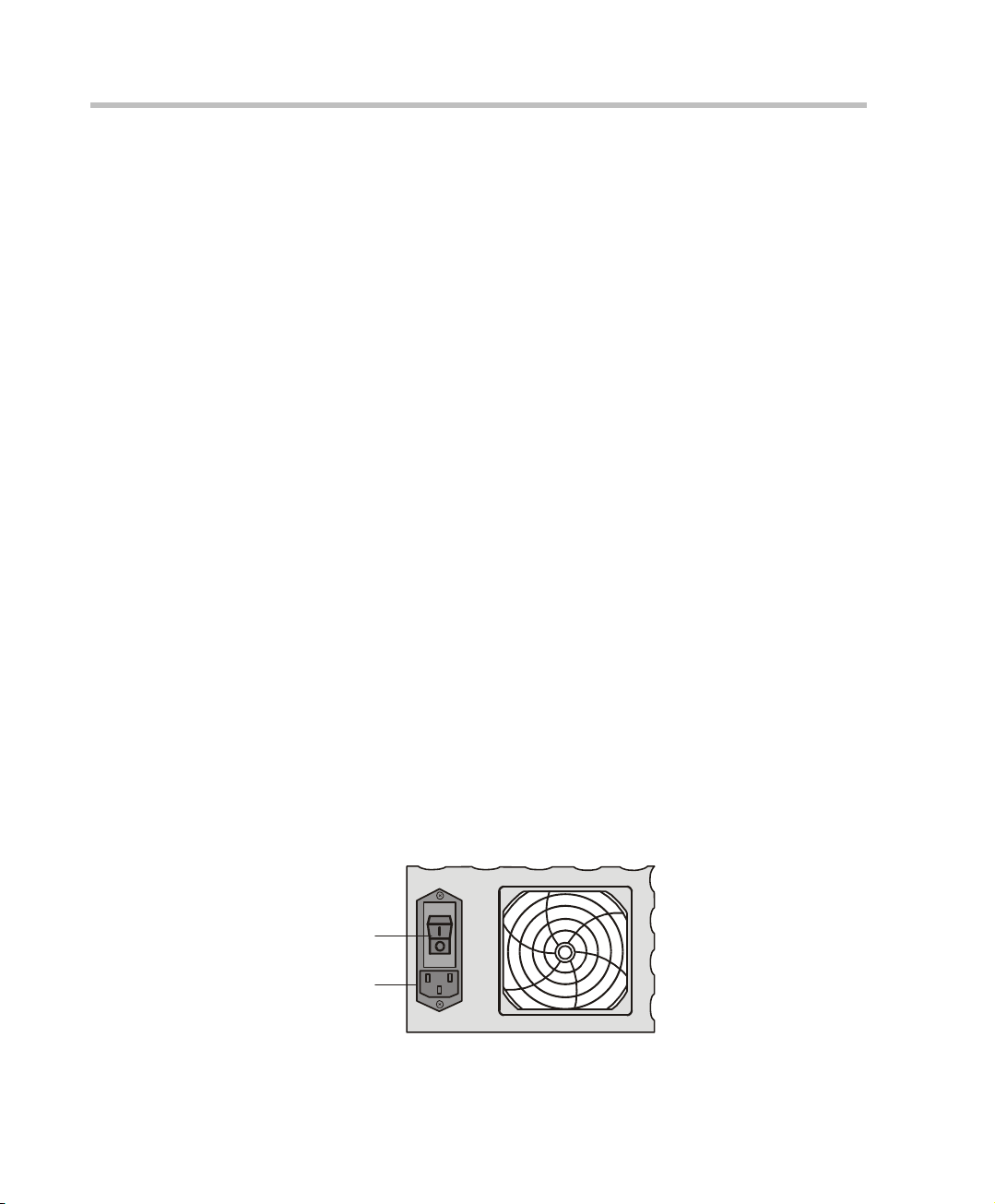

To connect to the AC Inlet:

1. Make sure the power switch is OFF. Insert the power cable into the

power connector on the rear panel of the MGC+100 unit.

Main Switch

AC Inlet

2. Insert the power cable into the power source socket.

Page 23

MGC+50/MGC+100 Getting Started Guide

3. Turn on the power by pressing on the power switch located on the rear

panel of the MGC+100/ MGC+50 unit.

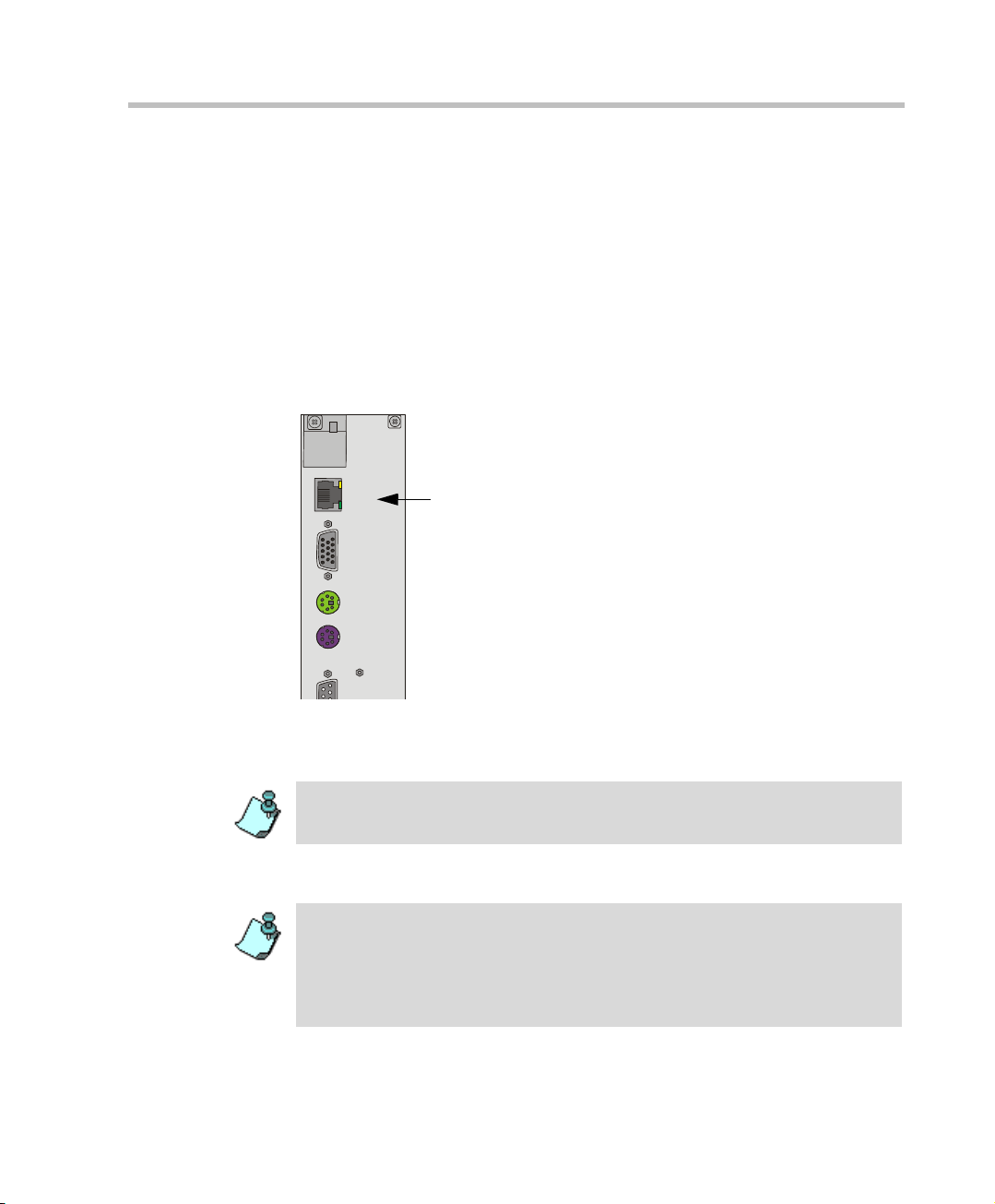

Connecting the MGC+100/MGC+50 to the Local Network

The MGC+ must be connected to the local LAN network to enable

communication between the MGC+ unit and the PC workstations running the

MGC Manager application.

Connect one end of a network cable to the LAN connector on the rear I/O

panel of the MGC+ Control Module and the other end to the network.

LAN

VGA

MOUSE

KEYBOARD

Connecting the MGC+ to the Conferencing Network

The installati on of th e M PI box on the MGC+ unit and the c onn ec tion to the MPI

Network module are described in the MGC+ Hardware and Installation Manual,

Chapter 2.

Connecting the MGC+ to the ISDN/ T1-CAS Network

The ISDN network is optional. If the MGC+ has to be connected to the public

ISDN network then an external CSU or similar equipment is needed.

T1-CAS network is optional. It allows you to connect Audio Only participants to

conferences via T1-CAS lines. It uses the same network connections as ISDN

and the procedure described below is applicable to both ISDN and T1-CAS

lines.

2-11

Page 24

Chapter 2 - Hardware Installation

p

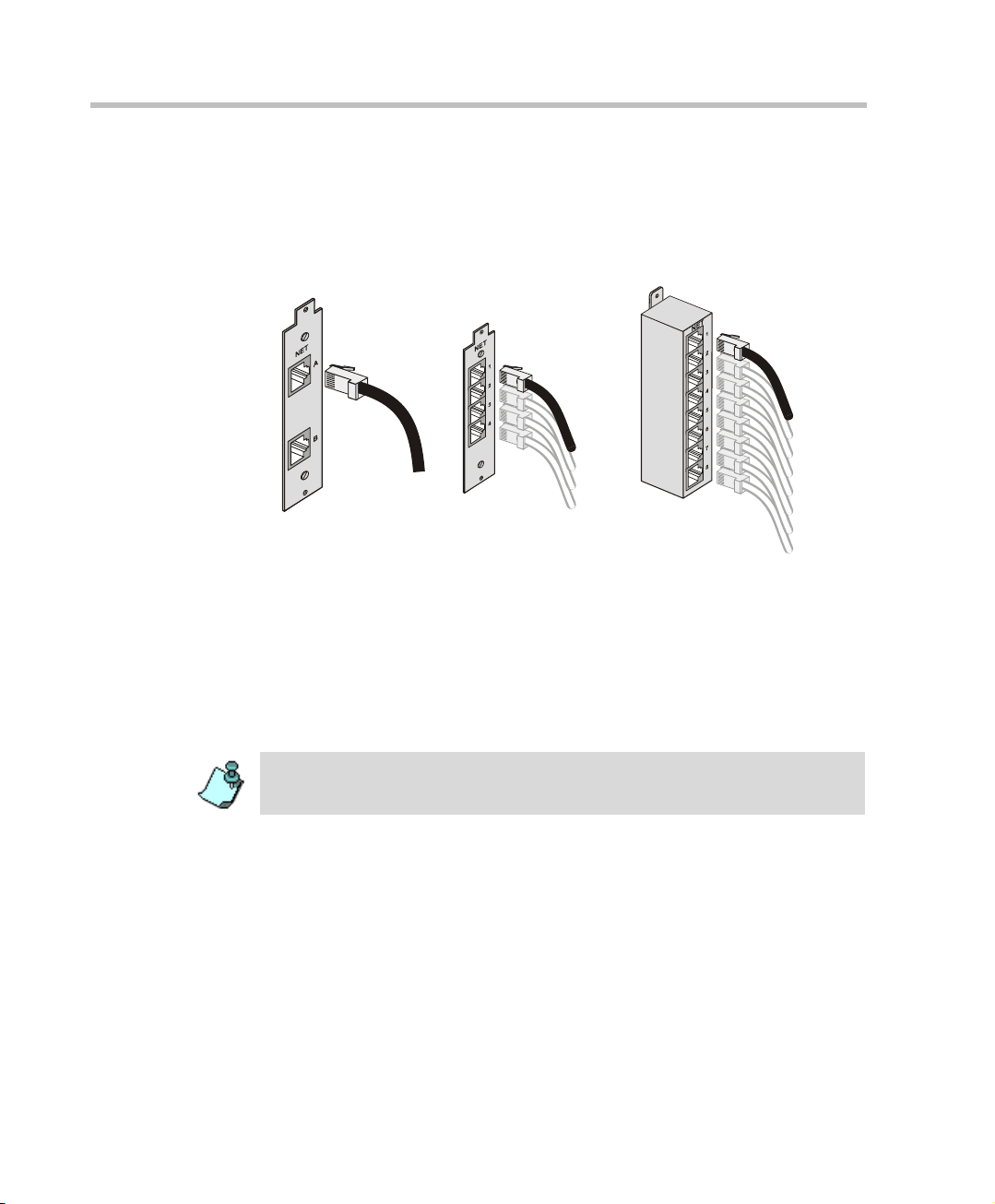

To connect the MGC+ to the ISDN network or T1-CAS Network:

• Connect the 8-pin RJ-45 connector of the network cable to the NET

RJ-45 jack on the rear panel of the MGC+. Repeat this step for each of

the ISDN network lines to be connected to the Network Interface card

installed in the MCU.

ISDN network

connection

ISDN Network connection

for 4 spans

ISDN Network connection

for 8 s

ans

Figure 2-5: ISDN network conne ction

Leased lines should be connected using an adapter with a screw

connector with solid conductor wires or a similar adapter.

• Connect one side of the adapter to the NET RJ-45 jack on the rear panel

of the MGC+. Then connect the leased line wires to the other side of the

adapter.

The ISDN and T1-CAS network properties must be defined in the Network

Services. For details, see the MGC+ Administrator’s Guide, Chapter 3.

2-12

Page 25

MGC+50/MGC+100 Getting Started Guide

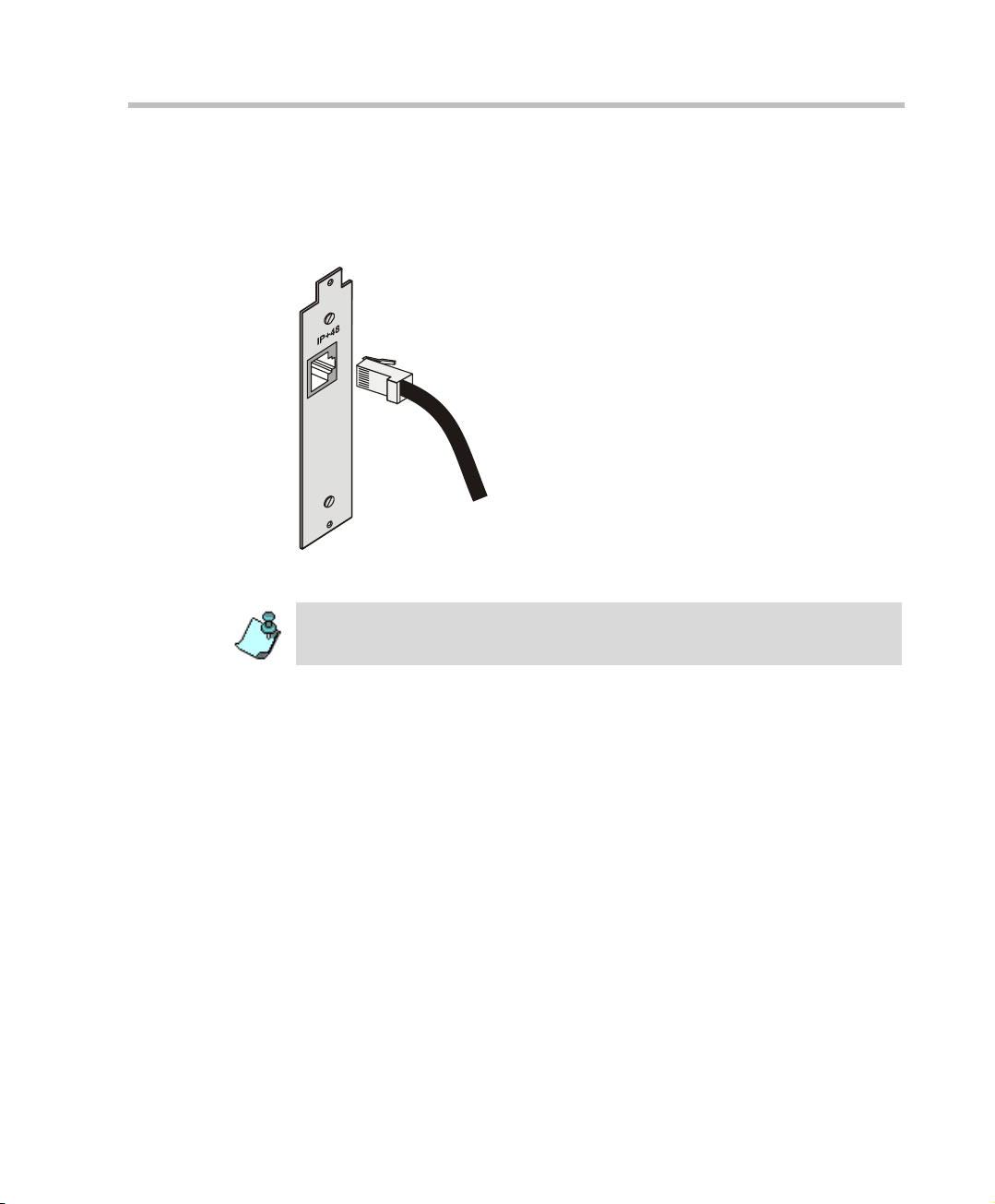

Connecting the MGC+ to the IP Network

If an IP network Interface card is installed in the MGC+, connect the 8-pin

RJ-45 connector of the LAN networ k cable to the LAN-32 3 RJ-45 jac k on the

rear panel of the MGC+.

Figure 2-6: LAN IP network connection

The IP network properti es mu st be defined in the Network Servic es , Fo r de t ail s,

see MGC+ Administrator’s Guide, Chapter 3.

2-13

Page 26

Chapter 2 - Hardware Installation

First Entry MGC+ Control Unit (CU) IP Configuration

The MCU is delivered with a default IP address: 129.254.4.8. At this point

you cannot communicate with the MCU f rom th e MGC Manager ap plica tion,

as the IP address is incorrect. You must change this IP address to the IP

address appropriate for your site’s network. There are three methods to

modify the default IP address:

• Using the Compact Flash with an updated LAN.CFG file

• Using a cross-over hub cable and a laptop to connect to the MCU locally

• Using a keyboard and monitor attached to the MCU

Using the Compact Flash Disk with the LAN.CFG File

The MCU is delivered with a Compact Flash disk t hat contains a LAN.cfg file

with the default IP address. Using a USB to Compact F lash ada ptor (suppl i ed

with the MGC+ accessory kit) connect to any PC and alter the LAN.cfg file.

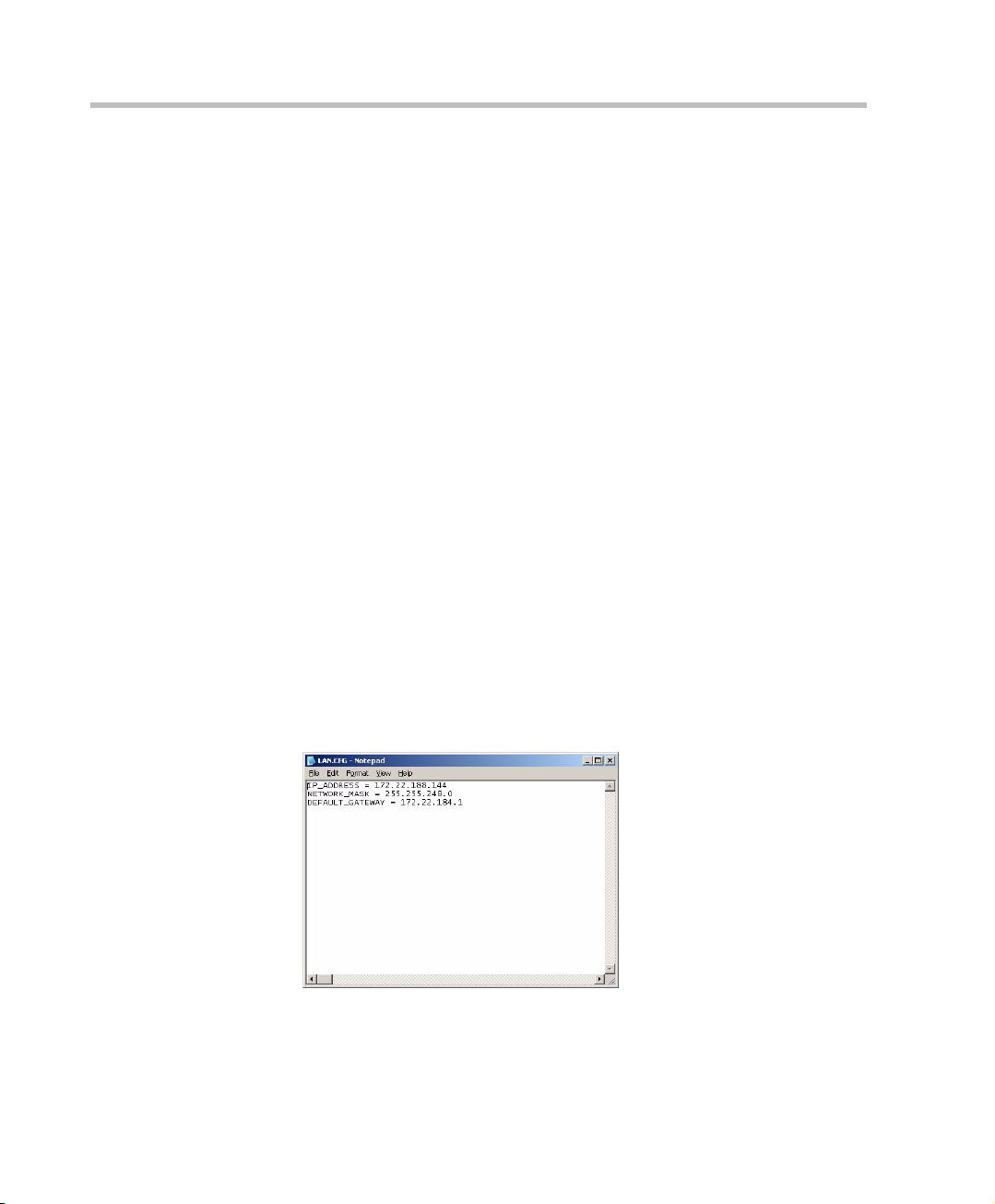

To update the LAN.cfg File:

1. Insert the Compact Flash disk into the Compact Flash adaptor and using

a text editor application, open the LAN.cfg file stored on the Compact

Flash disk.

2-14

2. Using a text editor application, edit the following parameters:

:

Page 27

MGC+50/MGC+100 Getting Started Guide

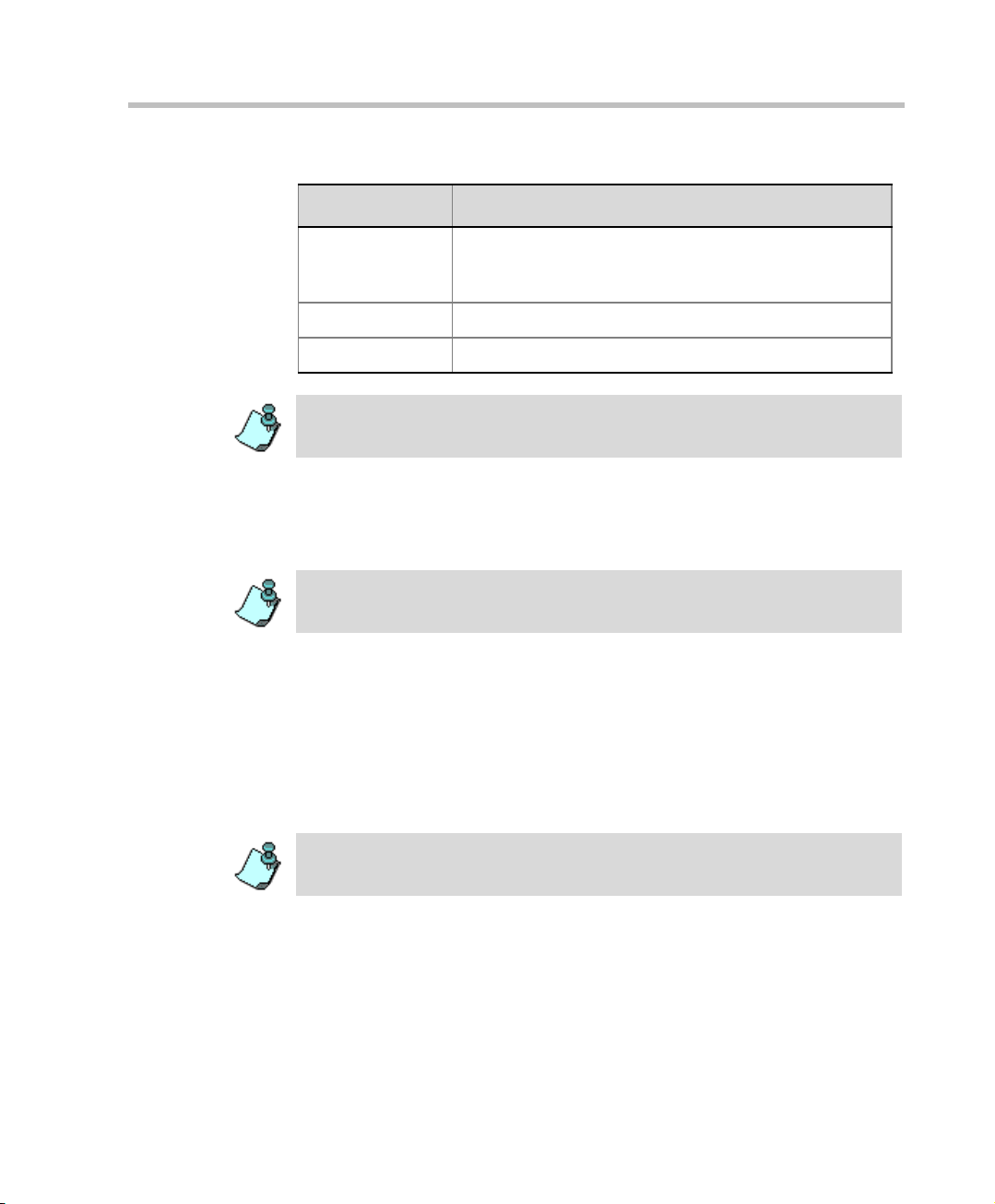

Table 2-1: IP Configurati on Options

Option Description

IP Address The system displays the currently defined IP address.

Enter the IP address allocated to the MCU by the

network administrator.

Subnet Mask Enter the Subnet Mask of the MCU.

Default Gateway Enter the IP Address of the default gateway/router.

Make sure no blank spaces occur at the end of each line.

3. Save the changes in the LAN.cfg file.

4. Use the Microsoft Unplug or Eject Hardware procedure prior to

removing the Flash disk.

Failure to stop the hardware properly can result in a corrupt Compact Flash disk.

When the disk fails, a replacement is required.

5. Remove the Compact Flash disk from the reader.

6. Insert the Compact Flash disk into the Compact Flash slot of the MGC+

Control Module.

7. Press the Reset button on the MGC+ unit.

The Options menu appears.

8. Press 1, to Change the MGC+ IP Settings.

If no monitor is connected, the automatic default time-out (15 seconds) selects

option 1.

The Flash Memory LED must be active and flash.

2-15

Page 28

Chapter 2 - Hardware Installation

9. Press the Eject button.

Once the message “1 File(s) copied” is displayed on screen, the

Flash Memory LED no longer flashes.

Do not press the Eject button while the Flash Memory LED is flashing.

10. Remove the Compact Flash disk from the Compact Flash slot on the

MGC+ Control Module and press the Reset button on the MGC+.

11. Connect the MCU to your site’s networ k.

12. Install the MGC Manager and start this application. For more

information, see Chapter 3, “Starting the MGC Manager Application”

on page 3-4.

13. In the MGC Manager, define a new MCU using the IP address you have

entered in the LAN.CFG file. For more information, see Chapter 3,

“Defining the MCU” on page 3-5.

Using a Cross-over Hub Cable and a Laptop to Connect to the MCU Locally

2-16

1. Connect a cross-over hub cable between the laptop LAN connection to

the LAN connection of the control unit on the rear panel of the MCU.

2. On the laptop Start menu, click Control Panel ->Network Connection>Local Area Connection.

3. In the Local Ar ea Con necti on - General di alog bo x

button

.

4. In the Local Area Connection Properties dialog box, click Use the

following IP address, and define the address of the laptop as part of the

same network segment as the MCU. For example, 129.254.4.7.

5. Click OK.

6. Install the MGC Manager and start this application. For more

information, see Chapter 3, “Starting the MGC Manager Application”

on page 3-4.

7. Define the MCU using the default IP address (129.254.4.8). For more

information, see Chapter 3, “Defining the MCU” on page 3-5.

, click the Properties

Page 29

MGC+50/MGC+100 Getting Started Guide

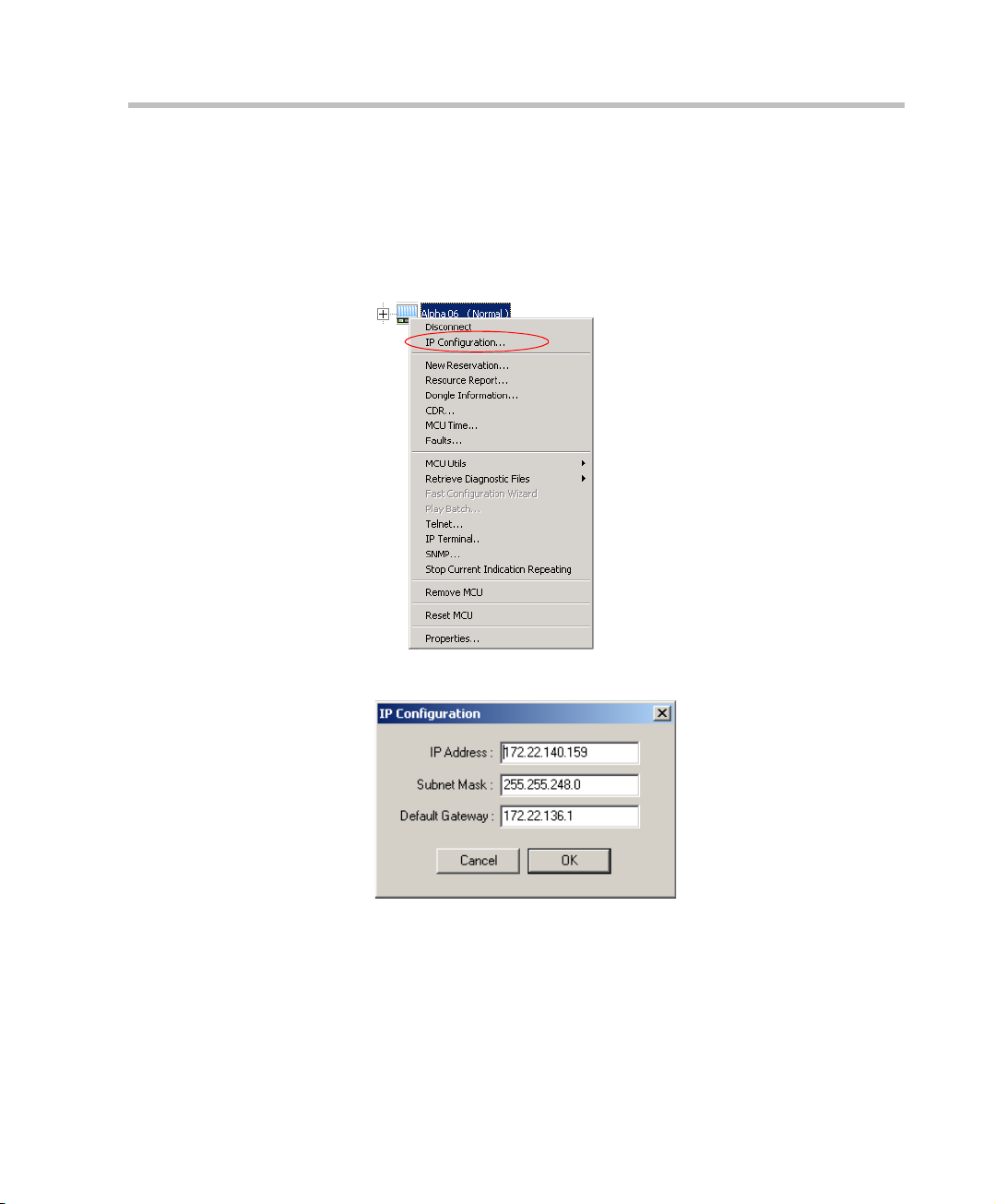

8. In the MCUs list, double-click the MCU icon to connect to it.

9. Modify the IP address of the MCU unit as allocated by the network

administrator. This is the IP address with which the MCU is identified on

the LAN and not its definition in the MGC Manager application:

a. Right-click th e MCU icon, and then click IP Configuration.

The IP Configuration dialog box opens.

b. The following parameters may be modified:

c. Click OK.

10. Press the Reset button on the MGC+ unit.

11. Disconnect the MCU from the local network that you have created.

12. Connect the MCU to your site’s network.

2-17

Page 30

Chapter 2 - Hardware Installation

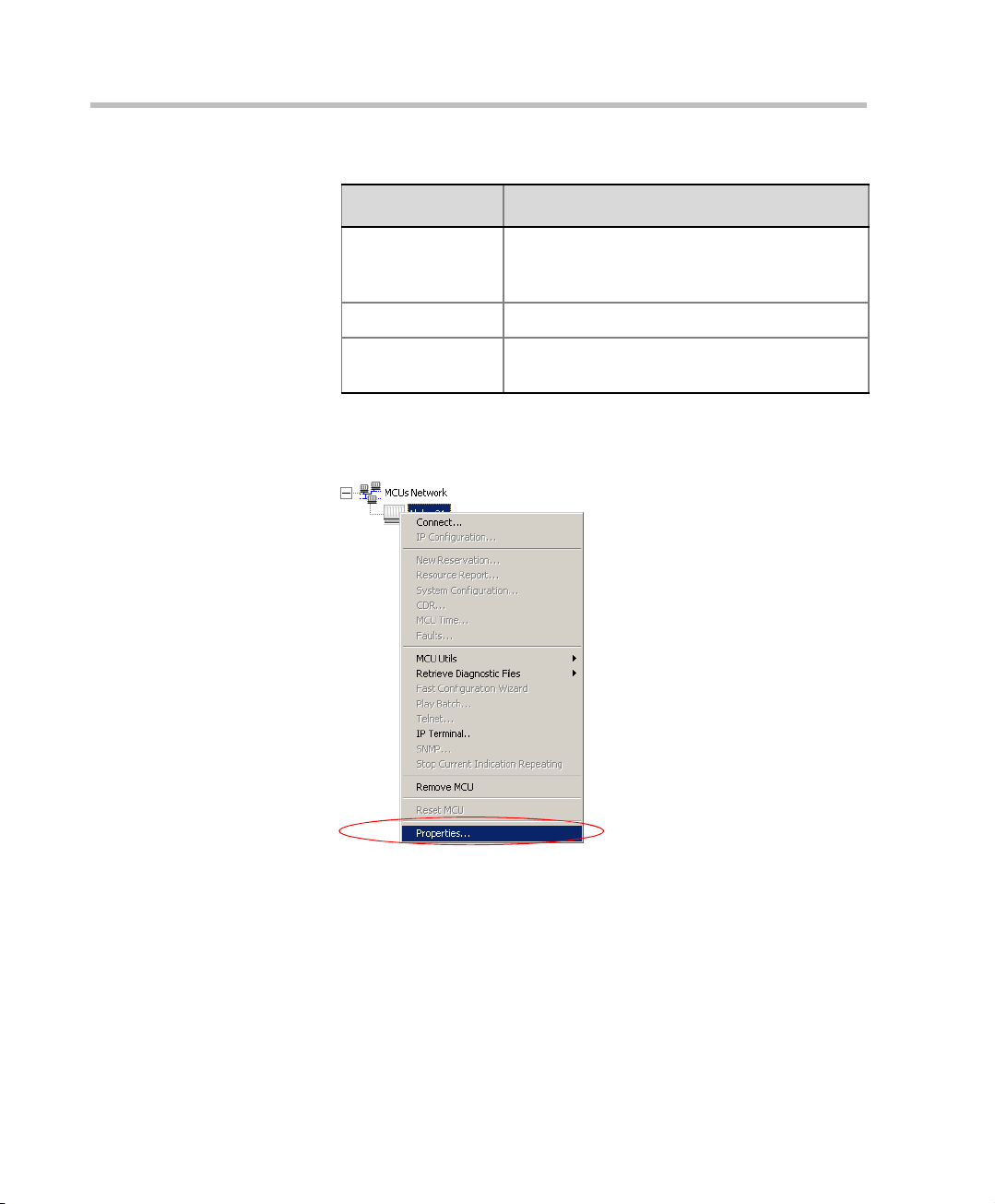

13. In the MGC Manager application, modify the MCU definition:

a. Right-click the MCU icon, and then click Properties.

Table 2-2: IP Configuration Options

Option Description

IP Address The system displays the currently defined IP

address. Enter the IP address allocated to the

MCU by the network administrator.

Subnet Mask Enter the Subnet Mask of the MCU.

Default Gateway Enter the IP Address of the default gateway/

router.

2-18

Page 31

MGC+50/MGC+100 Getting Started Guide

The MCU Properties dialog box opens.

The current MCU name.

To modify, type a new

name

MCU IP address. Enter

the IP address of the MCU

as allocated by the

network administrator

b. Enter the IP address of the MCU as you have defined in the IP

Configuration.

c. Click OK.

14. Connect to the MCU.

Using a Keyboard and Monitor Attached to the MGC+ unit

1. Access the Main Control Module rear I/O panel and connect the

keyboard and the monitor to the appropriate ports.

2-19

Page 32

Chapter 2 - Hardware Installation

2. Press the Reset button on the MCU.

The comma nd line is displayed on the monitor.

3. Type C:\>dir mcu\cfg and press Enter.

4. Type C:\>\mcu\cfg>edit lan.cfg and press Enter.

The Edit screen opens displaying the IP configuration parameters.

5. Move the cursor to the appropriate line and enter the new IP Addr ess, as

supplied by the network administrator.

If required, modify the Subnet Mask and the Default Gateway values.

6. Save the new IP configuration and exit the DOS editor.

7. Press the Reset button on the MCU.

8. Connect the MCU to your local network.

9. Install the MGC Manager application and start this applicat ion. For more

information, see Chapter 3, “Installing the MGC Manager” on page 3-2.

10. Define a new MCU using the address entered via the monitor and

keyboard. For more information, see Chapter 3, “Defining the MCU” on

page 3-5.

The new MCU is added to the MCUs list.

2-20

Another method to connect to the MCU and modify its IP configuration is via a

telephone line with a modem or directly via a serial connection. For details, see

the MGC+ Administrator’s Guide, Appendix C, “PPP Setup”.

Page 33

MGC+ Sof tware Installation and Configuration

The MGC+50/MGC+100 requires basic configuration before you can start

running conferences. You are required to configure the ReadiManager IAM

and MGC+ Control Unit (CU) blades on the MGC+.

Initial ReadiManager IAM Configuration

For entering system config uration settings an d deployi ng the ReadiM anager

IAM to your Network refer to the Polycom ReadiManager IAM Getting

Started Guide, Chapters 1 and 2.

3

3-1

Page 34

MGC+50/MGC+100 Getting Started Guide

Installing the MGC Manager

To configure the MGC+ unit to your environment, setup conferences and

Initial IP

Configuration

Installing the

MGC Manager

Start ing the MGC

Manager

control the MGC+ uni t yo u must install the MGC Manager softwar e o n a PC.

A single MGC Manager-enabled PC can manage multiple MCUs.

During the installation, default Reservat ion templates are installed.The MGC

unit is shipped with a Default IVR Service and Default Entry Queue Service.

For information about restoring these services when upgrading MCU

software, refer to the MGC Administrator’s Guide, Chapter 5.

To install the MGC Manager software:

1. Insert the software CD into the CD drive.

2. On the Start menu, click Run.

The Run dialog box opens.

Defining an MCU

Connecting

to an MCU

Configuring the

Network Services

3. Type D:\SETUP (where D is the name of the CD drive), and then click

OK.

The installation wizard starts and the Software License Agreement

window opens.

4. Click Yes to accept to the terms of the agreement or No to exit the

installation.

If you clicked Yes, the Welcome window opens.

5. Click Next.

3-2

Page 35

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

The User Information screen opens.

6. Enter your name and the name of your company in the appropriate

boxes. For a standard installation, enter Polycom in the Serial box.

7. Click Next.

8. Follow the on-screen instructions to complete the installation process.

At the end of the installation procedure, the Setup Complete window

opens.

9. Click Finish.

The MGC Manager software is now installed on your computer.

3-3

Page 36

MGC+50/MGC+100 Getting Started Guide

Starting the MGC Manager Application

The MGC Manager application is designed to set up and m onitor multipoint

Initial IP

Configuration

Installing the

MGC Manager

Start ing the MGC

Manager

Defining an MCU

Connecting

to an MCU

video conferences, and to perform system configuration activities for the

MGC+ Multipoint Control Units (MCUs) to which it connects.

To start the MGC Manager application:

• On the Start - Programs menu, select MGC Manager ver 9.0, and then

click MGC Manager ver 9.0.

The MGC Manager main window opens

Configuring the

Network Services

3-4

Main Menu

Toolbars

Status pane

Browser

Monitor pane

Page 37

Defining the MCU

T o manage and control the M GC+ unit i t must be added t o the MCUs network

Initial IP

Configuration

Installing the

MGC Manager

Starti ng the MGC

Manager

list in the MGC Manager application.

The MGC unit has to be installed and its IP address properly

configured before defining its connection parameters in the MGC

Manager application. For details, see Chapter 2, “First Entry MGC+

Control Unit (CU) IP Configuration” on page 2-18.

To define an MCU Connection:

1. In the Browser pane, right-click the MCUs Network icon, and then click

New MCU.

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

Defining an MCU

Connecting

to an MCU

Configuring the

Network Services

The Add MCU dialog box opens.

2. In the Name box, e nter the name of the MCU. Specify a name that clearly

identifies the MCU.

3. In the IP Address box, enter the IP Address of the MCU.

The IP address should be identical to the one configured during the Initial IP

Configuration.

3-5

Page 38

MGC+50/MGC+100 Getting Started Guide

4. Click OK.

The Add MCU dialog box closes.

A new icon with the specified MCU name appears in the Browser pane

listed below the MCUs Network icon.

3-6

Page 39

Connecting to an MCU

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

Initial IP

Configuration

Installing the

MGC Manager

Start ing the MGC

Manager

Defining an MCU

Connecting

to an MCU

Configuring the

Network Services

Once the MCU connection parameters are defined, the MGC Manager can

connected to it. The MGC Manager reports the status of each MCU

connection.

To connect the operator workstation to an MCU:

1. In the Browser pane, dou ble-click the MCUs Network icon, or expand t he

MCUs Network icon.

A list of MCUs appears below the MCUs Network icon.

2. Double-clic k the MCU icon.

Alternatively, right click the MCU icon to which you want to connect,

and then click Connect.

The Logon dialog box opens.

3. Enter your Login Name and Password, and then click OK.

Note that each MCU is initially configured with a default operat or whose

Login and Password are both POLYCOM. Additional operators can be

defined. For more details, see the MGC Administrator’s Guide,

Chapter 6.

3-7

Page 40

MGC+50/MGC+100 Getting Started Guide

Configuring the Network Services

The Network Services include the parameters of the networks connected to

Initial IP

Configuration

the MCU. If no Network Services have been configured, depending on your

system configuration, the appropriate Network Service must be configured.

This section describes the configuration of both IP and ISDN networks.

Installing the

MGC Manager

Starti ng the MGC

Manager

Defining an MCU

Connecting

to an MCU

Configuring the

Network Services

For information about defi ning T1 -CAS, MPI, N FAS ISDN, Leased lines

ISDN and additional ISDN and IP Network Services, or modifying

existing Network Services, refer to the MGC Administrator’s Guide,

Chapter 3.

ISDN Network Service

The Net-2/4/8 card installed in the MCU interfaces between the MGC unit

and the ISDN switch. The ISDN Network Service is used to define the

properties of the switch and the ISDN lines running from the switch to the

ISDN card. Each group of ISDN lines having the same characteristics and

originating from the same ISDN switch, will be assigned to the same ISDN

Network Service.

IP Network Service

The IP Network Service defines the properties of the IP netwo rk connected t o

the IP+ cards (installed in the MCU). Several of the network compon ents are

used by both H.323 and SIP endpoints to connect to the conference, and the

same IP+ card is used for H.323 and SIP connections. One IP Network

Service, therefore, can be defined for both H.323 and SIP environments as

well as an H.323-only or a SIP-only Network Service.

Defining the Network Services

The first time you connect to the MGC+ unit from the MGC Manager, the

system automatically detects that no Network Service is defined in your

system and automatically displays the Network Configuration Wizard to let

you configure the IP and ISDN Network Services.

If the system detect an ISDN only connection to the MCU, only the ISDN

Configuration dialog b ox opens. If an IP-onl y connect ion is de tected, on ly the

IP Configuration dialog box opens.

3-8

You can always access the Fast Configuration Wizard by right-clicking the MCU

icon.

Page 41

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

To define the Network Service:

1. In the Network Conf iguration Wizard window, click either IP or ISDN.

The the configuration process can start in any order.

If you have selected IP, the IP Configuration dialog box opens.

3-9

Page 42

MGC+50/MGC+100 Getting Started Guide

2. Define the following parameters:

To route Meet Me H.323 dial-in participants to their conferences using a IP

Network Service prefix as part o f the dia ling strin g, some gatekeep ers require th e

configuration of an IP Network Service prefix prior to its definition in the

gatekeeper. With Polycom PathNavigator, the IP Network Service prefix

automatically registers with the gatekeeper and does not require prior definition.

Table 3-1: IP Configuration Parameters

Field Description

IP Service

Name

Obtain IP

Address

automatically

(DHCP)

All Spans

Configuration

Enter a name using up to 20 characters, or use the

default name (IP Default Service).

Select this check box to use a DHCP server for

automatic assignment and tracking of IP addresses to

the conference devices.

Do not select this check box if you need to:

• Establish a static IP address, for example, when

working with a firewall and you need to translate an

internal IP address, that must be static, with an

external one.

• When dialing in directly to the card, using the card’s

IP address.

Select this check box to indicate that a LAN span is

connected to the IP+ card in the MCU and to define the

properties of this card.

3-10

Page 43

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

Table 3-1: IP Configuration Parameters (Continued)

Field Description

Cards

Configuration

Click this button to automatically detect the IP address

and Alias (if known) of the IP+ cards installed on the

MCU.

The IP+ card type and its slot number, IP address and

alias are listed. When the Obtain IP Address

automatically (DHCP) check box is selected, the IP

address of the card appears as 0.0.0.0.

To configure a specific IP+ card:

Highlighting and then double clicking on any card.

Enter or change the IP address, and add the card’s

Alias if required and click OK.

Subnet Mask Enter the subnet mask of the MCU’s IP+ card. If the

DHCP is used, the subnet mask is automatically

retrieved from the DHCP server and cannot be

modified. For more det a ils, see the M GC Adm inist rators

Guide, Chapter 3, “Defining an IP Network Service”.

3-11

Page 44

MGC+50/MGC+100 Getting Started Guide

Table 3-1: IP Configuration Parameters (Continued)

Field Description

Default Router Enter the IP address of the default router. If a DHCP is

DNS Select this check box to indicate that a DNS server is

used, the IP address of the default router is

automatically retrieved from the DHCP server and

cannot be modified.

used in the network. Then select:

• Specify - Select this option to enter the IP address

of the DNS server.

• Auto - select this option to automatically detect the

primary DNS IP address, provided the DNS Server

is defined in the DHCP and if the DHCP -obtain IP

Address automatically check box was selected.

DNS Server IP

Address

Local Domain

Name

H.323 Select this option to allow H.323 participants to connect

Gatekeeper If a gatekeeper is used, select the Gatekeeper check

Gatekeeper IP

Address or

Name

If Specify was selected, enter the IP address of the

primary D NS server to be used.

Enter the domain name where the MCU is installed.

The name of the domain includes the host part of URL

or URI (the part of the host’s address that appears after

the at sign (@), or in a URL the part following the www.

prefix), for example, polycom.com.

This field is used both for SIP proxy registration

purposes and DNS resolution and therefore it is

required if you are using DNS servers in this service.

to the MCU using this service.

box to define its properties.

Enter either the gatekeeper’s host name (if the DNS

server is us ed), or IP address.

3-12

Page 45

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

Table 3-1: IP Configuration Parameters (Continued)

Field Description

Prefix Enter a number to be used by H.323 participants to dial

to the MCU as part of the dial-in string.

789 to use the default Entry Queues and Meeting

Enter

Rooms shipped with the MGC+ unit without modifying

their properties.

When PathNavigator is used, this prefix automatically

registers with the gatekeeper. When another

gatekeeper is used, this prefix must also be defined in

the gatekeeper.

SIP Select this check box to indicate that SIP participants

can connect to the MCU using this service. Then select:

• Specify - to manually define the SIP server.

• Auto - to automatically detect the SIP server’s IP

address if a DHCP or if a DNS Server is defined.

SIP Server IP

Address or

Name

Domain Name

or IP Address

If SIP-Specify is selected, and a DHCP is not used,

enter either the IP address of the preferred SIP server

or its host name (if a DNS server is used).

Conferences and En try Q ueues can be regist ered i n the

proxy in the format user@host. for example,

EQ1@polycom.com, where EQ1is the user part and

polycom.com is the host part.

When dialing to a conference or Entry Queue, the SIP

server expects to receive the host either as domain

name or as an IP address.

The domain name is used for identifying the SIP server

in the appropriate domain according to the host part in

the dialed string. For example, when the call to

EQ1@polycom.com reaches the outbound proxy, this

proxy looks for the SIP server in the polycom.com

domain to which it will forward the call.

When this call arriv es at the SIP ser ver in poly com.c om,

the server looks for the registered user (EQ1) and

forwards the call to this Entry Queue or conference.

3-13

Page 46

MGC+50/MGC+100 Getting Started Guide

3. Click OK.

If your system supports only IP networks, a confirmation message is

displayed.

4. Click OK.

If you are defining only th e IP Networ k Service, th e Netwo rk Con figurati on dial og

box closes and the new IP Network Service appears in the IP Network Services

list.

If you are defining both IP and ISDN Network Services, the Network

Configuration Wizard dialog box is displayed.

To configure an ISDN Network Service:

5. Click the ISDN button.

The ISDN Configuration dialog box opens.

3-14

6. In the ISDN Service Name box, enter a name or use the default name

(ISDN Default Service) .

Page 47

Chapter 3 - MGC+ Softwa r e I ns tallation and Configuration

7. Click PRI Configuration to define any ISDN span.

The ISDN Cards configuration window appears.

ISDN (Net) cards present on the MCU are automatically listed together

with their slot numbe r.

a. Select any PRI span by selecting the relevant check box.

b. Click OK when complete.

8. In the Line Type list, select either T1 (usually in the U.S., T1 has 23 B

channels + 1 D channel), or E1 (usuall y in Euro pe, E1 has 30 B channels

+ 1 D channel).

9. In the Switch Type list, select the brand and revision level of equipment

installed in the telephone company’s central office.

10. In the Dial-In Numbers Range boxes, enter the phone numbers to be used

for dial-in connection s as allocated to th e MCU by your service pr ovider.

Enter the first and last numbers in the range of phone numbers.

11. Click OK.

A confirmation message is displayed.

12. Click OK.

For advanced settings, see the MGC Administrator’s Guide, C hap ter 3.

3-15

Page 48

MGC+50/MGC+100 Getting Started Guide

The Network Services definition is complete, and the Network Configuration

dialog box closes. The new Network Services appear in the IP Network

Services and the ISDN Network Services lists.

3-16

The following icons are used to indicate the IP Network Service type:

Table 3-2: IP Network Service Icons

Icon Description

The Network Service supports both SIP and H.323

connections.

The Network Service supports only H.323

connections.

The Network Service su ppo rt s on ly SIP c on nec tio ns .

By default, the new Network Services are set as the system default. When

defining additional Network Services for IP or ISDN connections these

defaults can be changed. For more details, see the MGC Administrator’s

Guide, Chapter 3.

Page 49

About Conferences

Different conference types are available according to their initiation modes:

reservationless conferences and scheduled conferences.

On-Demand (Reservation-le ss) Conferencing

Reservation-less conferencing enables participants to immediately start and

connect to an On Going Conference from their endpoint, with no advanced

scheduling. The MGC Manager offers two methods for Reservation-less

conferencing:

• Ad Hoc Conferencing

• Meeting Rooms

Ad Hoc Conferencing

In Ad Hoc conferencing, participants connect to an Ad Hoc-enabled Entry

Queue. An Entry Queue is a special routing lobby to which one or several

dial-in numbers are assigned. The participants are prompted for the

destination conference Numeric ID. If no conference with a matching

Numeric ID is running, but the participant is authorized to create a

conference, the system creates a new On Going Conference. The new

conference is created according to the conference parameters defined in a

Profile assigned to the Entry Queue. All other participants connect directly

to the newly created conference. With this method, only the conference

Profile is created once and is used repeatedly to create numerous

conferences.

This conferencing method is often used to globally enable all employees in

an organization to star t On Going Conf erences from thei r endpoints, wit hout

having to define the conference parameters for each employee and for each

conference.

When authentication with external database applicat ion is configured for the

Entry Queue and for the conference, the MCU verifies with the external

4

4-1

Page 50

MGC+50/MGC+100 Getting Started Guide

database application whether a conferen ce with a speci fic Numeric ID may be

started. This is the method used with Windows Messenger and Office

Communicator to initiate multipoint Video or Audio conferences.

For more information about Ad Hoc conferencing, see the MGC Manager

User’s Guide, Volume II, Chapter 3.

Meeting Rooms

Meeting Rooms are conferences created once, with no starting date or time,

no reserved resources and it can be activated as many times as required. The

Meeting Room remains in passive mode until the first parti ci pant conne cts t o

it and activates the conference. To start the conference you simply let the

participants know the start date and time, dial -in numb er and the Numeri c ID

of the conference. No prior booking is required. The conference returns to

passive mode once the conference ends and remains in the MCU memory

until the next activ ati on . In thi s mode, a Meeting Room is usually defined for

each of the employees in your organization. This may require tedious work

when your organization i ncludes many empl oyees, and i t also loads the MC U

memory with all the saved Meeting Rooms.

Scheduled Conferences

You can define a conference to start at a certain date and time or to start

immediately. Scheduled conferences run once and are then deleted from the

MCU memory. For scheduled conferences, the MCU reserves resources for

the conference participants, provided the participant endpoints are defined

during the conference definition. You can define conferences without

defining their participants and let participants connect to the conference as

long as there are resources available.

4-2

Page 51

Video Conference Attributes

There are four general types of video conferences:

• Video Switching - A conference in which all participants use the same

video and audio formats. Whenever a participant starts to speak, the

participant appears on all endpoints in full screen display as the

conference is a voice activated video switching conference.

• Transcoding (requires Video card) - A conference in which participants

use different video, audio and data formats, while maintaining the

highest video and audio capability each participant can achieve with his

or her codec. Like video switching, the current speaker is displayed on

all endpoints in full screen.

• Continuous Presence (requires Video card) - A conference in which

several participants can be viewed simultaneously. In this type of

conference, the highest video , audio and dat a qua lity for each partici pant

depends on the parti cipants endpoint capabilities.

In a traditional Continuous Presence conference, each participant uses a

different video port on the V ideo card. This method enabl es such features

as full Transcoding per participant, Personal Layouts (individualized

Continuous Presence layouts per par ticipan t) and main tenance of overall

video and audio quality for the conf erence—even when par ticip ants with

lower capabilities connect. However, this method limits the number of

Continuous Presence participants to the number of ports on the Video

card, which is six.

• Conference On Port (requires Video card) - A conferencing method

suitable for large Continuous Presence conferences or when several

Continuous Presence conferences are running on the MCU.

In Conference On Port, all conference participants use a single video

port. This method allows for more than six participants to join a

Continuous Presence conference and allows for up to six Continuous

Presence conferences to be run on the MCU.

In a Conference on Port conference, a video layout can be selected for

the conference, but all the participants, including the speaker, view the

same layout and the same participants. The Personal layout selection is

not available in Conference on Port and the video quality is determined

by the highest common video parameters and by the video line rate.

Chapter 4 - About Conferenc e s

4-3

Page 52

MGC+50/MGC+100 Getting Started Guide

Entry Queue

An Entry Queue is a special rout ing lo bby that is used f or rout ing part icip ants

to their target conference. One or several dial-in numbers are assigned to the

Entry Queue, and they are used by callers to all conferences. Once callers are

connected to the Entry Queue, they are routed and connected to the target

conferences if they provide the appropriate conference IDs and passwords

(optional). Both Video and Audio Only conferences can be accessed from an

Entry Queue. For information about de fini ng an Entr y Queue, see Chap ter 6,

“Defining a New Audio Only Entry Queue” on page 6-1 or see Chapter 7,

“Defining a New Video Entry Queue” on page 7-1.

4-4

Page 53

Basic Operations

This chapter describes how to start, monitor and manage On Going

Conferences.

Reservation Templates

A Reservation template includes the conference parameters, such as the

conference media (audio, video ), video session, line rate, v ideo p rotocol an d

other video parameters, IVR Service and more. The reservation can include

the conference participant parameters.

Default Reservation Templates

There are five default Reservation templates installed with the MGC

Manager:

• Video-Switch: Video Switching at 384 Kbps

• SW CP: Software Continuous Presence (IP) at 384 Kbps

• Default-Audio: Audio Only with default IVR Service

• Default_Video: Continuous Presence Conference at 384 Kbps

• Default_COP: Conference On Port at 384 Kbps

5

In order to run a Default_Video or Default_COP conference, the Video+ card

and MCU Version 5.6 or later must be installed in your system.

Using the default Reservation templates, you can schedule a conference to

start immediately (On Going Conference), or to start automatically at a

predefined date and time (Reservation).

5-1

Page 54

MGC+50/MGC+100 Getting Started Guide

Starting a Conference

You can start an On Going Conference from one of the default Reservation

templates provided with the system or you can define a new On Going

Conference. For more details about defining new conferences, see MGC

Manager User’s Guide, Chapter 4, “Defining a new Audio Only Conference”

or MGC Manager User’s Guide, Chapter 4, “Defining a New Video

Conference”.

To start an On Going Conference from a default Reservation template:

1. Connect to an MCU. For more details,see “Connecting to an MCU” on

page 3-11.

2. The Default folder in the Reservations Database window opens

automatically when you open the MGC Manager. Otherwise, access this

window by clicking Reservations in AccordDB from the Window

menu.

5-2

The Reservations Database window opens.

If the Reservations in Database window did not appear automatically and is not

included in the Window menu options, reopen this window using the login

procedure described in MGC Manager User’s Guide, Volume I, Chapter 3 “MGC

Manager Basics”.

You can move the Reservations in Database window by dragging the

blue title bar. You can also resize the window by clicking an edge and

dragging it.

3. In the Reservations in Database window, expand the Default folder to

display the list of default Reservation templates.

Page 55

Chapter 5 - Basic Operations

4. Right-click the icon of the Reservations in Database template and click

Start Immediately . If more than one MCU is connected , select the name

of the MCU to run the conference from the pop-up list.

If the MGC Manager application is connected to several MCUs, select the MCU

name as well as the reservation template.

The conference begins and appears in the list of On Going Conferences.

If no participants were defined in the Reservation template, the

conference starts but contains no participants.

5-3

Page 56

MGC+50/MGC+100 Getting Started Guide

Viewing the Conference Dial-in Properties

The dial-in numbers and passwords n eeded to enter a conferenc e, including IP

Network Prefixes and Numeric IDs appear in the MGC Manager Status pane.

To view the list of On Going Conferences and their dial-in numbers:

• Expand the MCU tree, and then click the On Going Conferences icon.

The list of On Going Conferences with their Numeric IDs and dial-in

numbers are displayed in the Status pane.

In some configurations, the ISDN/PSTN number is truncated by the PBX, and

you must add the appropriate prefix to the dial-in number that is displayed in

the Status pane.

5-4

Page 57

Chapter 5 - Basic Operations

Connecting to a Conference/Ent ry Queue

Defined dial-in participants can connect to any conference by dialing the

conference dialing string (ISDN, H.323 or SIP). The MCU identifies their

CLI or IP address (as d efine d i n t he p arti ci pan t pr ope rti es) an d r o ut es t hem to

the appropriate conference. Dial-out participants must be defined in the

conference.

Undefined participants can connect directly to conferences defined as Meet

Me per Conference or Meetin g R oom by di ali ng it s di al -in str i ng. If r eq ui re d,

the participants enter the conference password before joining the conference.

Undefined participants can also connect to a single-dial Entry Queue to

access conferences. The dialing methods are the same as for the conference.

Once participants connect to the Entry Queue, they are routed to their

conference according to the conference numeric ID or password that they

enter.

In the default templates, just the Audio Only template is defined with Entry

Queue Access. To create a new video conference with Entry Queue Access,

see Chapter 7, “Creating an On Going Video Conference” on page 7-6.

Dialing-in to a Conference/Entry Queue

Undefined dial-in participants can access the conference using the following

methods:

ISDN/PSTN Participants

Audio Only and ISDN Video participants dial the conference/Entry Queue

ISDN dial-in number, as assigned to the conference by the operator or

automatically by the MCU. The dial-in number can be viewed in the MGC

Manager Status pane.

H.323 Participants

When a gatekeeper is present, H.323 participants dial: the [IP Network

Service Prefix] and [conference/Entry Queue Numeric ID or name] for

example, if the Network Service prefix is 925 and the Conference Numeric

ID is 1222, participants will dial 9251222. If participants dial only the

Network Service Prefix, or if the wrong numeric ID is dialed, participants will

be automatically routed to the default Entry Queue if one is defined. For more

information about the IP Ne twork Service Prefix, see Chapter 3.

5-5

Page 58

MGC+50/MGC+100 Getting Started Guide

For example, if the IP Network Service prefix is 27, the conference Numeric

ID is 1478 and the conference name is ‘MARKETING’, the participant can

dial 271478 or 27MARKETING. IF the Entry Queue name is EQ1 and its

numeric ID is 3000, the participant can dial 273000 or 27EQ1 to access the

MR. IF only 27 is dial ed, partici pants are be routed t o the defaul t Entry Queue

(if one is defined).

When no gatekeeper is present, H.323 participants dial the IP address of the

MCU’s IP card, followed by # # and th e conference/E ntry Queue Numeric ID.

For example, if the IP card address is 172.22.190.162, participants will enter

172.22.190.162##1478 to access the confere nce, or 172.22.190. 162##300 0 to

access the Entry Queue.

If no Entry Queue /conference numeric ID or if the wrong numeric ID is

entered, participants are be routed to the default Entry Queue (if one is

defined). If no default entry queue is defined in the system, the call is

disconnected.

SIP participants

When a new conference reservation or Entry Queue is defined the conference

or Entry Queue registers with the SIP proxy.

SIP participants dial the conference/Entry Queue URI using the format:

Conference or Entry Queue name@domain name.

For example, MRO1@polycom.com, or EQ1@polycom.com.

Usually for SIP conferencin g, an Ad Hoc Entry Queue is used. In this

scenario, the first participant dials the Entry Queue and creates a new

conference, while the other conference participants dial directly to the

conference using the conference name or Numeric ID.

When dialing from a Microsoft Windows Messenger endpoint that does not

have DTMF capabilities, the first participant (who creates the new con ference

in Ad Hoc Conferencing) enters the Entry Queue name foll owed by the tar g et

conference name and the numeric ID in the format:

EQ Name (Target Conference Name)(Target Conference Numeric ID).

For example, EQ1(sales)(12345). In this example, the Entry Queue name is

EQ1, and a new On Going Conference by the name sales with the Numeric

ID 12345 will be created on the MCU.

5-6

You do not need to add the domain name to the conference name, as it is

automatically added by Microsoft Windows Messenger when the request is sent

to the SIP server.

Page 59

Monitoring On Going Conferences

You can monitor conferences and perform various operations while

conferences are running.

Monitoring involves viewing the status of On Going Conferences and the

status of their participants.

Three levels of monitoring are available with the MGC Manager:

• General Monitoring - You can monitor the general status of all the On

Going Conferences and their participants in the MGC Manager mai n

window.

• Conference Level Monitoring - You can view additional information

regarding the conference using the Conference - Properties option.

• Participant Level Moni toring - You can view detailed information on the

participant's status using the Participant - Properties option.

When an operator is available to attend participants, you can view the

status of participants in the Participants Queue window. For more

information about the Participants Queue, see the MGC Manager User’s

Guide, Volume I, Chapter 8.

Operations can be performed at the conference level or at the participant

level. For example, you can terminate a conference before its scheduled

ending or you can extend its duration. You can also disconnect an individual

participant while the conference is in progress, or temporarily mute

transmission to and from a site so that the other par ticipants c an hold a privat e

discussion. You can also connect dial-out participants during the conference

and add a new participant while the conference is in session.

Chapter 5 - Basic Operations

General Monitoring

Monitoring a conference enables you to keep track of its participants and its

progress. When monitoring a conference, you can check whether all its

participants are correctly connected and whether errors and faults have

occurred.

The MGC Manager allows you to monitor several On Going Conferences

simultaneously . The On Goi ng Conference information is easily avail able and

clearly represented.

5-7

Page 60

MGC+50/MGC+100 Getting Started Guide

Monitoring a Conference

When you click a conference icon, the conference appears in the Status pane.

However, to get more details regarding the conference and participants

statuses or to monitor several conferences simultaneously, it is advised to

monitor the conferences in the Monitor pane.

Automatic Monitoring of conferences is available. For details, see the MGC

Manager User’s Guide, Volume I, Chapter 5.

You can display the list of On Going Conferences in the Status pane so you

can view their dial-in numbers and Numeric IDs while monitoring the

conferences with their participants in the Monitor pane.

Displaying the conference and participants statuses in the Monitor pane:

1. Expand the MCU tree.

2. Expand the On Going Conferences tree.

3. In the On Going Conferences list, right-click the conference to monitor,

and then click Monitor to view all the conference participants in the

Monitor pane.

5-8

Alternatively, on the conference right-click menu, click Monitor Filter

to view only participants of the selected filtering status.

Page 61

Chapter 5 - Basic Operations

The Participant Monitoring Filter dialog box opens.

4. Select the appropriate check boxes that indicate the statuses to monitor.

The following statuses may be selected:

Table 5-1: Participant Statuses to be Monitored

Filtering Option Description

Faulty participant Participants who have problems connecting to the

conference.

Participants

Requesting

Assistance

Asked question Participants who wanted to ask questions, were

Noisy Line Participants who the MCU detected as having noisy

Participants who have requested the operator’s

assistance and have yet to be assisted by the

operator.

added to the Question-and-Answer Queue and are

now waiting for their turn to ask a question.

lines.

5-9

Page 62

MGC+50/MGC+100 Getting Started Guide

The conference and participant details appear in the Monitor pane.

The Status and Monitor panes take the form of a table. Each row

represents a conference or a participant. Each column represents a

parameter that is being monitored. The Conference Name, Status,

Phone#, Connection Type, Retries Left, Channel# and Bonding fields

also appear in the Status pane.

5-10

You can modify the order of columns in the Monitor and Status panes by moving

the column heading(s) to the desired location in the table header.

The data in the Monitor and Status tables can be sorted according to a selected

column. Clicking on a column heading sorts the table data in descending order.

Clicking on the same column heading a second time sorts the data in ascending

order.

Additional information about monitoring parti ci pants and con ferences i s

described in the MGC Manager User’s Guide, Volume I, Chapter 5.

Listing Participants in the Browser and Status Panes

You can view the list of participants currently connected to the conference in

the Browser, Status and Monitor panes.

To view the list of participants in the

Browser pane:

1. Expand the On Going Conferences or Reservations tree.

Page 63

Chapter 5 - Basic Operations

2. Expand the On Going Conference or Reservation to list its participants.

The participants are listed below the conference or Reservation.

Different icons are used to indicate the participant roles and their

connection status. For details, see the MGC Manager User’s Guide,

Volume I, Chapter 5.

To list the participants in the

Status pane:

1. Expand the On Going Conferences or Reservations tree.

2. Double-click the icon of the On Going Conference or Reservation whose

participants you want to list.

The participants are l isted in the Status pane.

To list the participants in the

Status pane:

1. Expand the On Going Confer ences or Reservations tree to display the list

of On Going Conferences or Reservations.

2. Double-click the icon of the On Going Conference or Reservation whose

participants you want to list.

The participants are l isted in the Status pane.

5-11

Page 64

MGC+50/MGC+100 Getting Started Guide

Participant Level Monitoring

In addition to the data that appears in the Status and the Monitor panes, you