Polyaire airtouch Installer Manual

airtouch.net.au

Installer Manual

airtouch

Contents

Compatible Brands

4

1. Components

5

2. Conguration

6

3. Pre-Installation

9

4. Components Installation

10

5. Recommended Commissioning Procedure

15

5.1 Parameters

16

5.1.1 Console in Group or for AC control

16

5.1.2 Total Groups in the System

16

5.1.3 Console Address

16

5.1.4 Damper RPM setting

17

5.1.5 Installer Settings Password

17

5.1.6 Reset and Save current system settings

17

5.2 Balancing

18

5.3 Sensors

20

5.3.1 Assign a sensor to a group

21

5.3.2 Pair main module and wireless sensors (ITCs)

21

Liability

Please read the instructions before installing this AirTouch Zoning Control System. Polyaire

Pty Ltd does not accept any responsibility for loss or damage that may occur as a result of

the incorrect installation of this AirTouch Control System.

5.3.3 Calibrate a Sensor

21

5.4 Grouping Zones

22

5.5 Choosing Group Temperature Control

23

5.6 Setting Minimum Ventilation

24

5.7 Spill or Bypass

24

5.8 Enabling/Disabling Service Reminder

25

5.9 Setting up AC Control

27

5.9.1 Name AC Units

27

5.9.2 AC Detail Settings

27

5.9.3

Choose AC Control Thermistor

28

5.9.4 Congure AC Fan Speed Options

29

5.9.5 Control Temperature Oset

29

5.9.6 Multiple Ducted Systems

30

5.9.7 Groups connected in each ducted system

30

5.10 Setting up Wi-Fi connection

31

5.11 Testing Damper On/O

31

5.12 Software Update

32

6. Wiring Diagrams

33

7. Downloading and Installing AirTouch 4 App

63

8. Troubleshooting

64

4

Compatible Brands

Compatible Brands

5

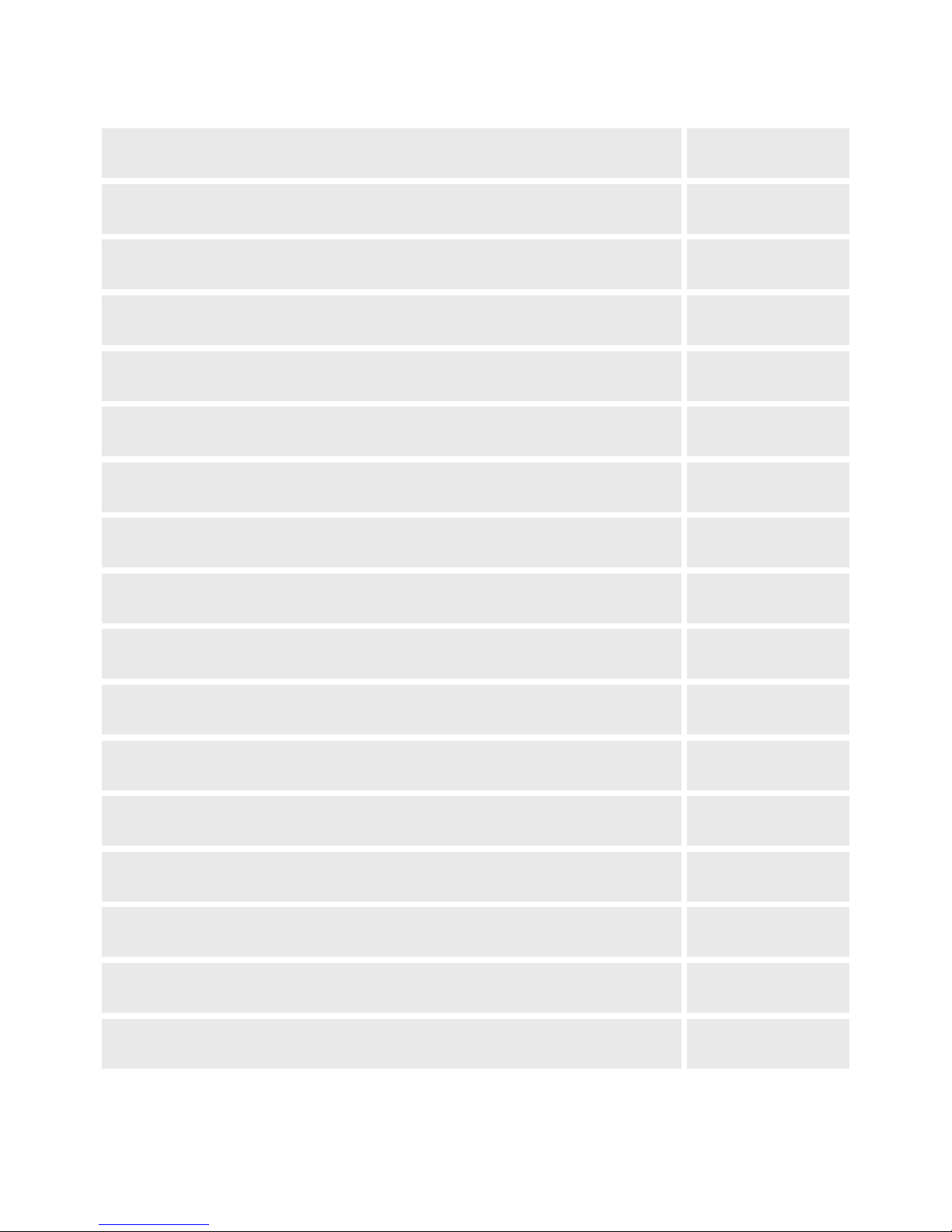

1.1 Console

Users can input control commands from the

console to turn on or o a group/zone or AC.

It is used to input all parameters. The color LCD

displays clock, zone, WiFi, AC, temperature and

other statuses.

1.2 Main Control Module and Extension Module

(optional)

Main control module (8 zones) and its optional

extension module (extra 8 zones) control the

position of motorized damper of each zone.

1.3 Motorized Damper (Bright Green)

Motorized dampers drive the blade of the

damper to adjust the air supply.

1.4 Cables

Cables with left latch or central latch plugs

connect the main control module, extension

module (if applicable), console, and

motorized dampers together.

1.5 Supply Air Sensor (optional)

Supply air sensor measures the temperature of

the supply air for auto mode recognition.

1.6 Power Supply

24VAC transformers provide power to the main

and extension modules.

1.7 AC Gateways (optional)

AC gateways are for full control of most major

brand ducted systems such as Daikin,

Panasonic, Fujitsu, Mitsubishi Electric, Mitsubishi

Heavy Industries, Toshiba, LG, Hitachi, Samsung,

Carrier, Rinnai, Midea, Braemar and Gree. Each

gateway comes with a RS485 cable for

connecting the gateway with AirTouch 4.

1. Components

Components

6

1. Components contd.

1.8 Wireless temperature sensor

Wireless sensors are used for group

temperature and On/O control. Each group

can have up to two wireless temperature

sensors. The wireless sensors send measured

room temperature or On/O command back

to main module regularly. They are driven by

button type battery and have dipswitches for

their own identication.

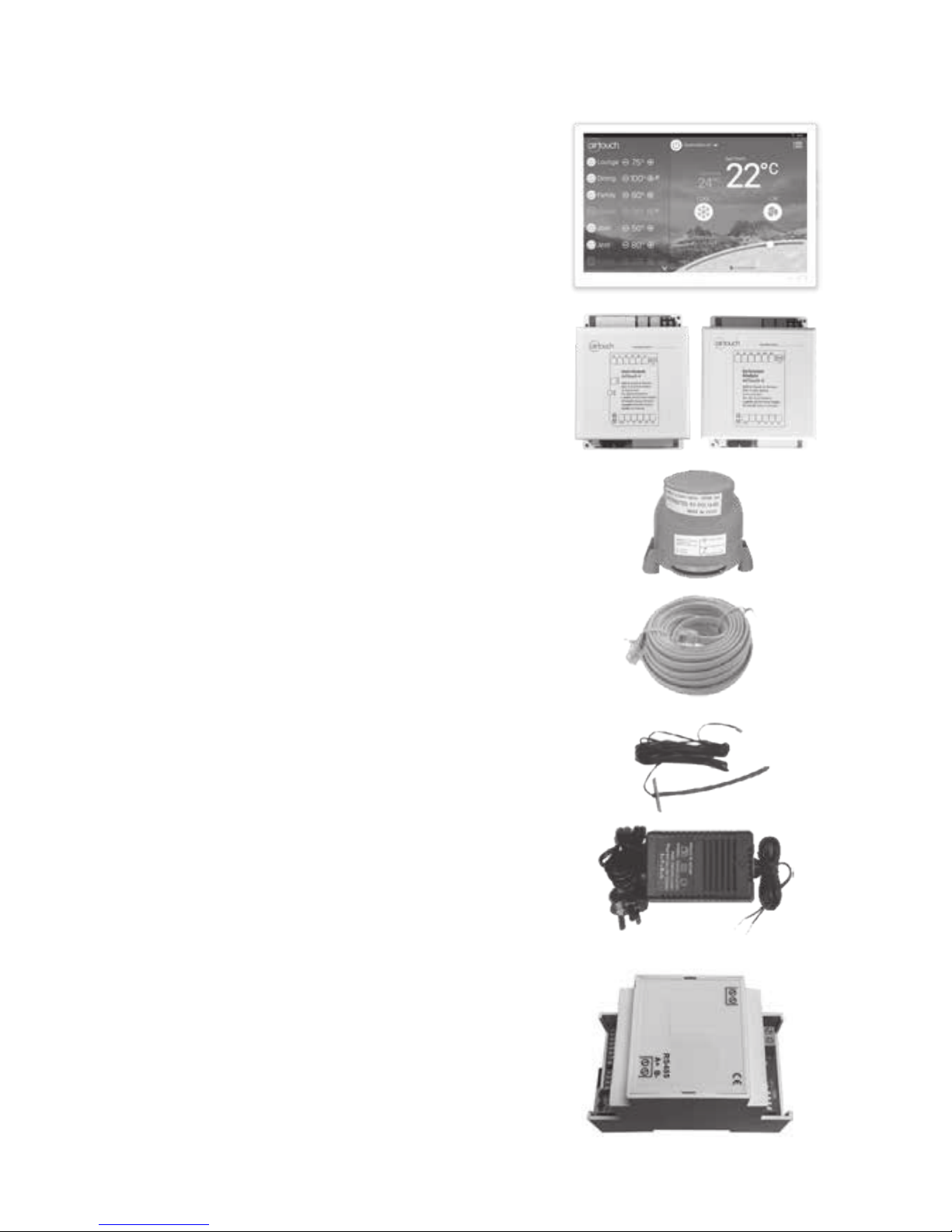

2. Conguration

AirTouch 4 System is a star architecture system that allows communications

between AirTouch 4 main control module, extension module, AC unit, WiFi router

(to connect to smart phones and internet), up to 16 zone dampers, wireless

temperature sensors and up to two consoles. Figure below shows the

connection of devices such as the WiFi router, AC indoor PCB, extension module,

two consoles, and eight dampers to the main module.

Components contd. & Configuration

Continued on next page.

Zone 4

7

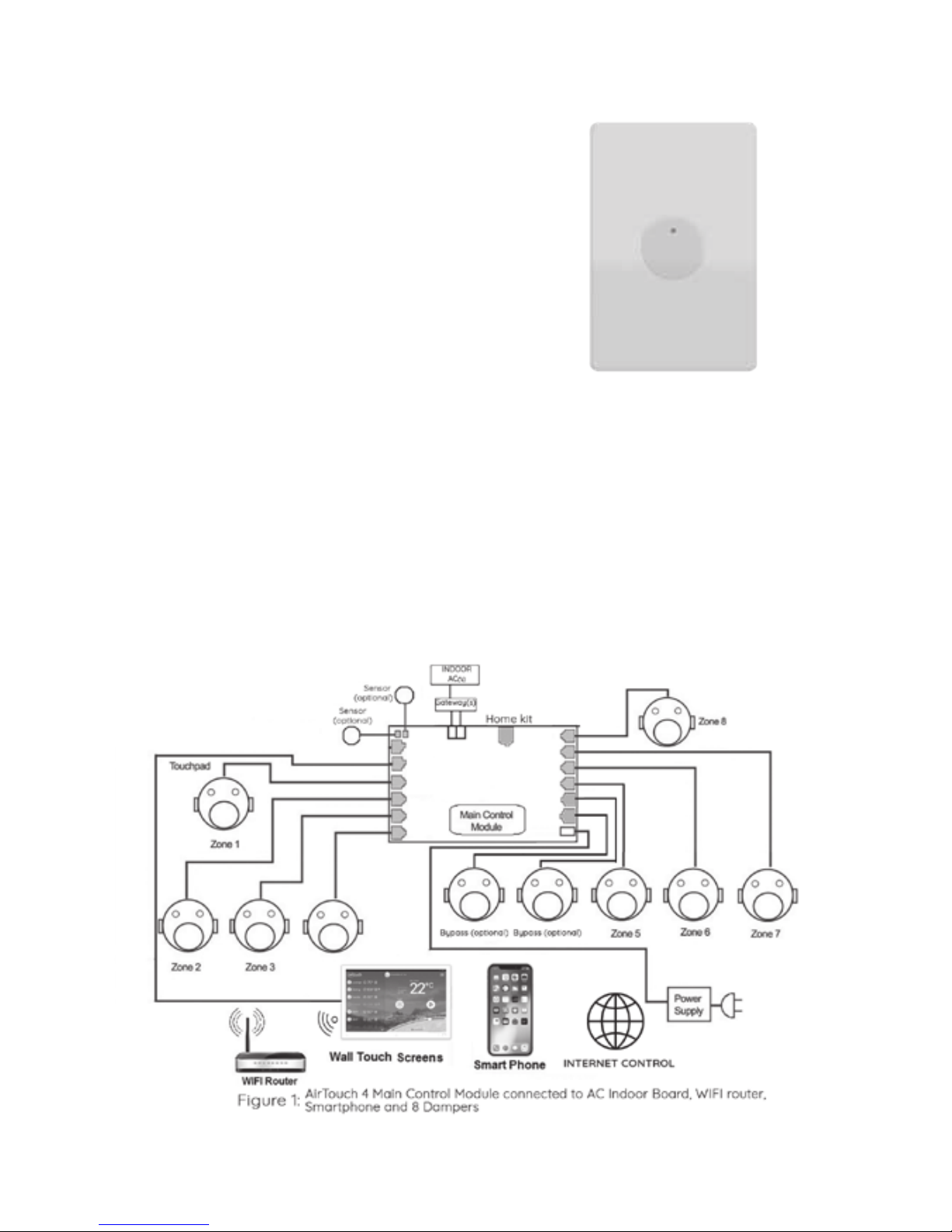

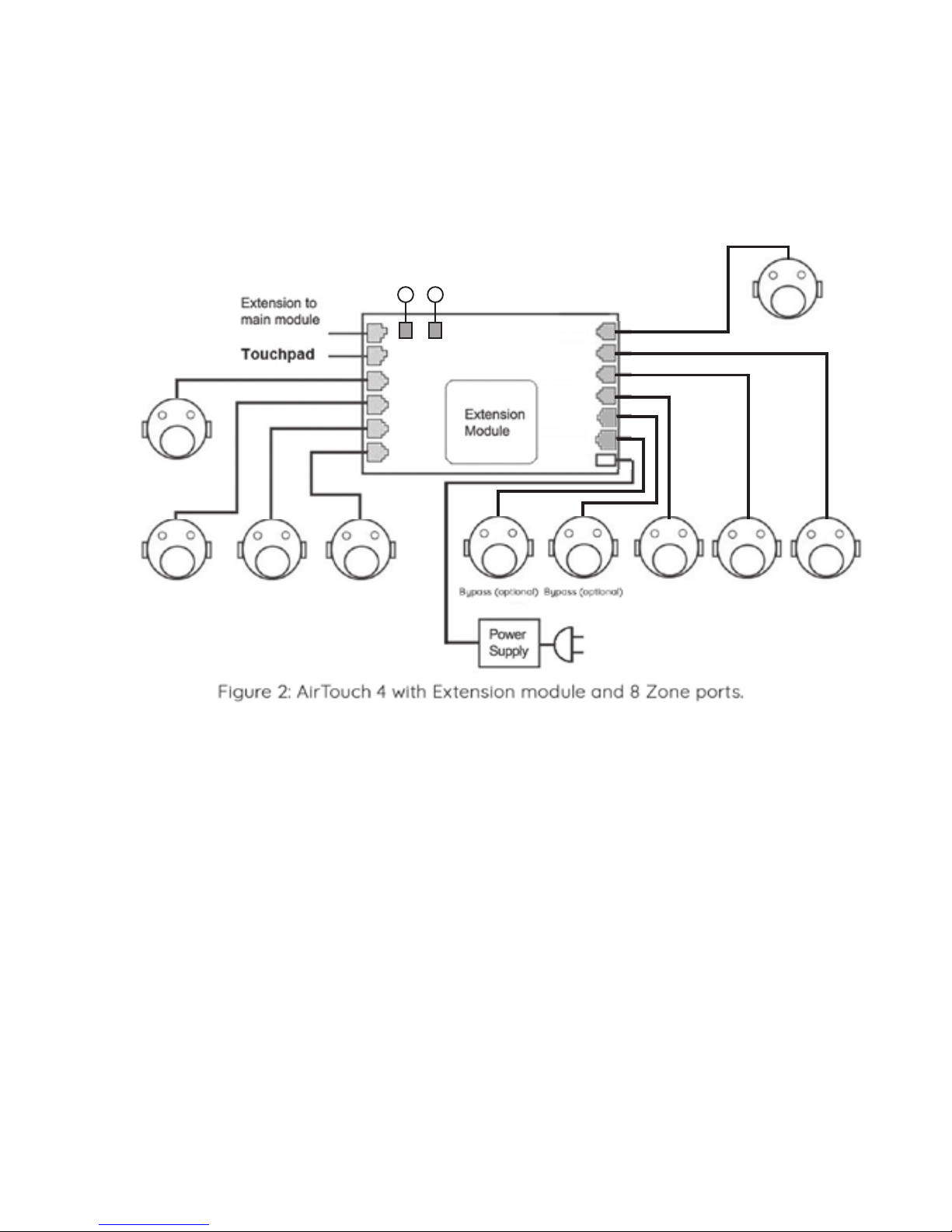

Eight motorized dampers can be connected to the main control module.

Nine dampers and above (up to 16) will need the extension module.

The wiring of the AirTouch 4 system is straightforward. A cable with central latched

plugs connects a motorized damper to the relevant output port clearly marked on

the main or extension module. Figure below shows the connection of eight

dampers to the extension module.

Configuration contd.

If there is another gateway for another AC, it will be connected to Modbus line.

Maximum four gateways can be connected for one AirTouch 4 to control four AC’s.

Please see AC wirings for details in section 6.

Main and extension modules can be in dierent locations and connected via a

cable with left latched plugs on both ends. Console is connected to the ‘T’ port on

main module.

Up to two consoles can be joined in a system. One will be connected to the main

module and the other to the extension module. One screen is set to Master (1) and

the other is set to Slave (2) .

Figure below shows the linking of the main module to the extension module,

AC unit, consoles, wireless sensors and smart phone.

Sensor

(optional)

Sensor

(optional)

Zone 9 Zone A Zone B

Zone A Zone B Zone C

Zone 9

Zone G

B3 B4

Zone FZone EZone D

8

Note:

Install the console at least 20mm away from any other wall control to avoid

potential interference.

Configuration contd.

1 Console per board

Unit

gateways

wired in

sequence

24V

24V

Touch Screen 1Home Router

Touch Screen 2

Smart Phones

Main Module

Extension Module

To Zone Dampers

Bypass 2

RS 485

Unit

Gateway

1

A B

Indoor Unit 1 Indoor Unit 2 Indoor Unit 3 Indoor Unit 4

Bypass 1

Supply Air

Sensor

(Optional)

Supply Air

Sensor

(Optional)

Supply Air

Sensor

(Optional)

Supply Air

Sensor

(Optional)

Apple

Homekit

Bypass 4

Bypass 3

To Zone Dampers

Z1

Z2

Z3

Z4

Z8

Z7

Z6

Z5

ZD

ZC

ZB

ZA

Z9

ZE

ZF

ZG

Unit

Gateway

2

Unit

Gateway

3

Unit

Gateway

4

24V

24V

Extension Module

Supply Air

Sensor

(Optional)

Supply Air

Sensor

(Optional)

Bypass 4

Bypass 3

To Zone Dampers

ZD

ZC

ZB

ZA

Z9

ZE

ZF

ZG

Unit

Gateway

2

Unit

Gateway

3

Unit

Gateway

4

24V

24V

Extension Module

Supply Air

Sensor

(Optional)

Supply Air

Sensor

(Optional)

Bypass 4

Bypass 3

To Zone Dampers

ZD

ZC

ZB

ZA

Z9

ZE

ZF

ZG

Unit

Gateway

2

Unit

Gateway

3

Unit

Gateway

4

9

3. Pre-Installation

Good planning leads to a successful zone system installation. Before installing and

commissioning a zoning system, please complete the following listed tasks:

3.1 Decide how many zones (dampers) are to be controlled in the system.

3.2 Group zones according to customer’s requirements. Each group initially has

one zone but can have up to a maximum of four zones (Example: There

could be one or more zones going into a common area such as Kitchen/

Dining or Family/Dining room). Work out the total group number (Maximum

total group number in a system is 16).

NOTE: It is important to test all cables before installation.

Testing all cables to be used before the start of the installation will save

considerable diagnostic time if the fully installed system is subsequently found

to have a problem. Cable testing is quick and easy with a Zonemaster Cable

tester available from Polyaire.

Cable Tester (Item: 657089)

Pre - Installation

10

4.1 Mount the main and/or extension

modules (if using more than 8 zones) by

screwing the boxes to a roof frame or

Polyaire Diusion Fitting (PDF).

4.2 Remove the two side covers on the

main module. All LEDs and sockets for

zone dampers are exposed.

4.3 If the extension module is used,

connect main module to extension

module at ‘E/M’ port on both modules

with a left latched cable.

4.4 Use pre-tested cable to connect ‘Z1’

port on the main module to the

motorized damper of the 1st zone.

4.5 Repeat step 6.4 to connect other

zone dampers to their relevant zone

ports on the main and extension

modules.

Components Installation

4. Components Installation

11

Components Installation

4.6 Mount the supply air sensor in the

supply air duct between the fan coil and

the rst damper and push the plug of

supply air temperature sensor into the

socket on the main module.

4.7 Connect the console to the ‘T’ port

on the main module. If two consoles

are used, connect one to T on the main

module and the other to the extension

module.

4.8 Connect the 24V AC transformer to

screw terminals on the main control

module. If extension module is used,

connect another 24 VAC transformer

to the screw terminals of the extension

module.

4.9 Connect the main module to the

AC unit using the required kit for the

respective AC unit (cables and interface

board). Follow the wiring diagram for

the respective unit provided on Page

33-62 of this manual.

12

4.10 Replace the side covers back on the main

control and extension module once nished setting

and commissioning.

4.11 Remove the cover of the ITC from the base. Install the base with screws in

proper positions where there is no direct sun, no draft and about 1.5m above

ground. Set the correct group number and identication number (Sub ID) for

each sensor. And activate the battery to start the wireless sensor. Then align the

cover with the base and click the cover to position to complete the sensor

installation.

4.12 Fit the Console to wall

The plastic casing of the console consists of two halves. The front cover

contains the PCB board along with the LCD/console. The back cover

attaches to the wall as a mounting base. During the installation process the case

will have to be opened to mount the console on the wall. Follow the steps below

to carefully install the console to the wall:

a. Slide the back base to bottom side to clear the stops on the front cover

b. Remove the base from the front cover

c. Position the back base on the wall where the cable is (about 1.5m high from

the oor). Ensure it is away from any heat or cool source and mark the cable

hole and screw holes.

Note: The correct back cover direction is marked on its surface; follow that

mark when xing the back cover.

Component Installation

Continued on next page

13

Component Installation

d. Cut the rectangular hole for the cable and x the back base to the wall by

using four screws on the marked positions.

e. Retrieve the console cable (from main control module) out of the cable hole and

plug it into the console.

f. Align the bottom edge of the back base with the bottom inside of the front cover

and the two side edges of the back base with the front cover.

Continued on next page

14

g. Gently push the front cover against the wall and make sure the back of front

cover is ash against the wall. And then push the front cover downwards with two

gures holding the top side of the front cover where there are two slots till the two

snap-ons click in.

Component Installation

15

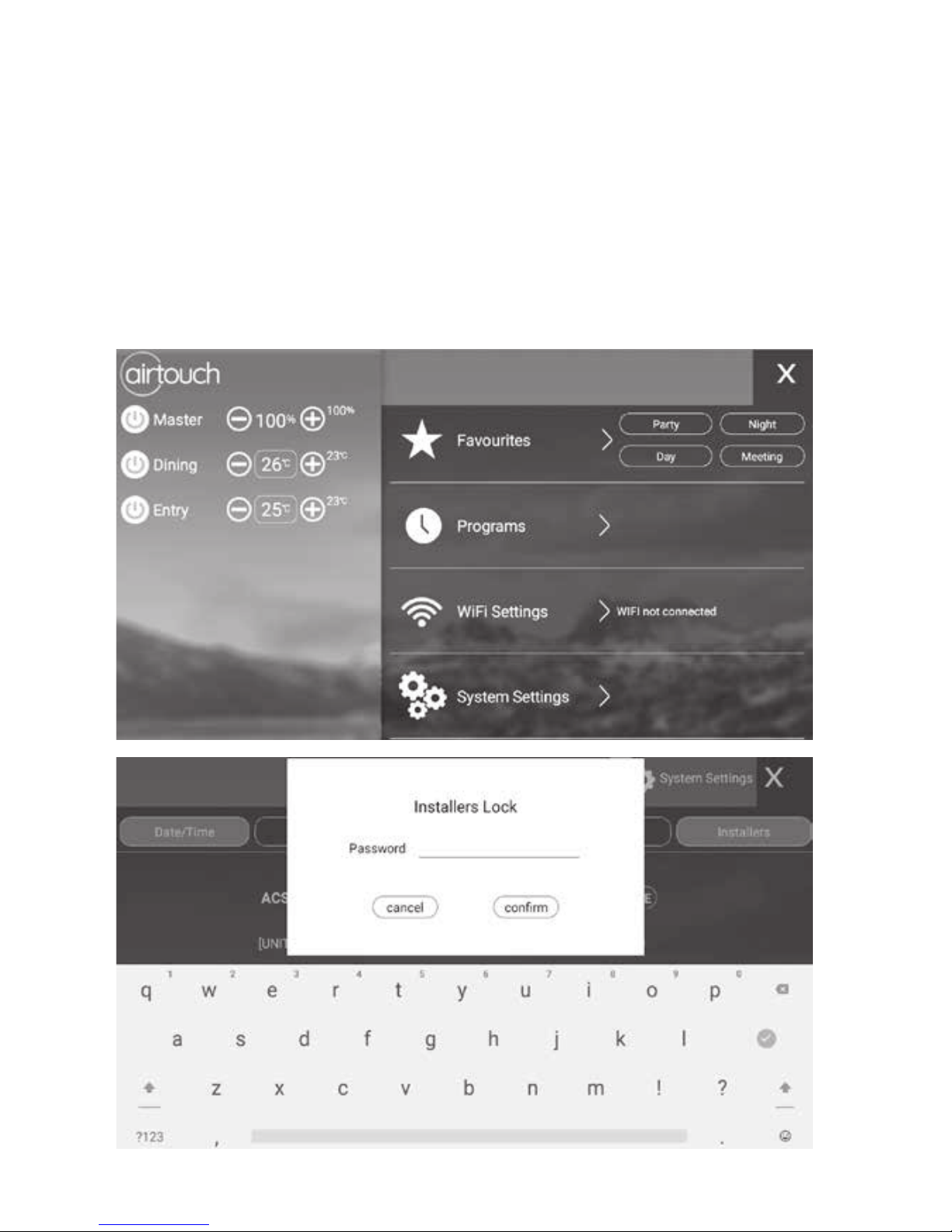

There are two sets of settings, the installer’s and user’s. In the installer’s settings,

the followings can be set: parameters, balancing, sensors, spill, grouping, service

and AC. These settings are protected by a password which has default value

Polyaire but can be changed. Touching Installer’s button in the Settings list will

bring up password input page. After inputting the correct password, installer’s

setting page will come up. In the user’s settings which are discussed in User’s

Manual, the followings can be set: owner name, date/time, group name, WiFi,

turbo group, temperature display, touch tone, child lock and temperature alert.

5. Recommended Commissioning Procedure

Recommended Commissioning Procedure

16

5.1 Parameters

5.1.2 Total Groups in the System

For the purpose of group status display and spill zone calculation, the system

needs to know the total number of groups to be installed. The factory default

number is 8.

IMPORTANT: This number must be equal to the total group number used in the

system as planned in Pre-Installation process. If this is wrong, the system may

not work properly.

5.1.1 Console in Group or for AC control

The console sensor can be used for controlling temperature in a group or an

AC unit. In this case, it should be assigned to the AC unit or the group where the

console is installed.

5.1.3 Console Address

Up to two consoles can be installed in one AirTouch 4 system. Each console is set

as Master (1) in default. If two consoles are installed in the same system, one shall

be set to Master (1) and the other is set to Slave (2). The master console will

manage WiFi communications. It’s recommended to set the console in a position

closer to the home router as the master to have a better WiFi communication

between the home router and the AirTouch 4.

NOTE: Each console must have a unique address.

Two consoles with the same address will cause communication problems

between the main control module and the consoles.

NOTE: Touch Save button to save all changes.

Parameters

17

5.1.4 Damper RPM Setting

AirTouch 4 can work with other dampers which are not made by Polyaire. But the

damper motors have to meet certain requirements:

Power supply: 24 VAC

Drive Open and Drive Close

Revolution per Minute (RPM): 0.1 to 2.5

5.1.5 Installer Settings Password

The password is used to prevent unauthorized changing of the installer settings.

To reset this password, touch the password edit eld in the ‘Parameter’ screen,

and then type in the new password and touch ‘Enter’ key to conrm the password

change.

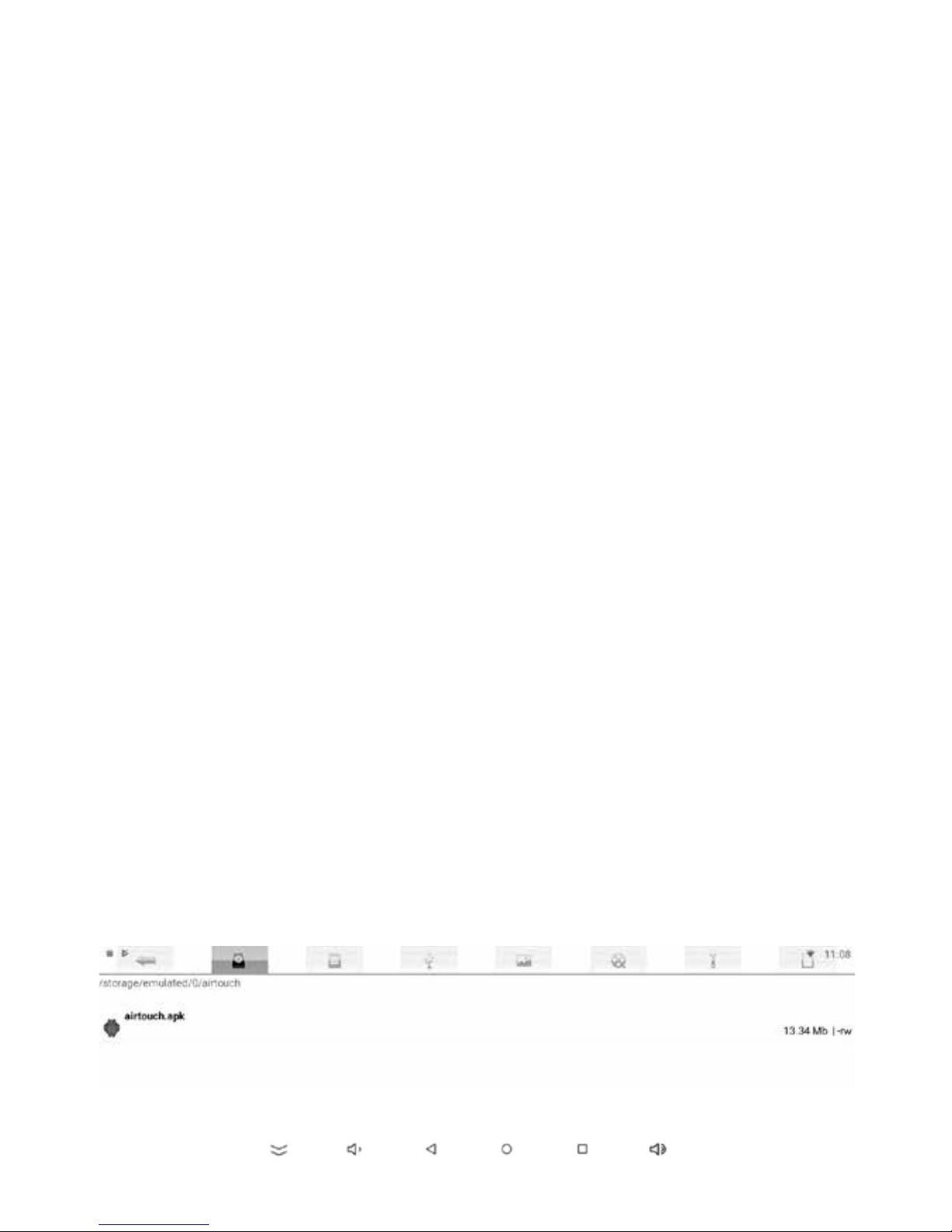

5.1.6 Reset and Save current system settings

To record all system settings, press Save Settings to File button. After the settings

have been saved successfully, it will be stored on the console in the name of

AtchV4_Setting_Id.txt. Please transfer the settings le to a micro SD card or send

it to an email address for permanent storage in case the console is unaccessible.

Use File Manager on the console to access the le under

/storage/emulated/0/airtouch.

If the main module has been replaced, the system can be recovered from this le.

After the settings le is stored under the folder /storage/emulated/0/airtouch,

press the Recover Saved Settings button to recover.

After successful recovery, the system has to be powered o for at least 30

seconds and then powered back on to use the recovered settings.

If the system needs to be reset to factory default settings in some cases, press

Reset to Factory. All group names and settings will be back to original factory

settings.

Parameters contd. & Balancing

18

5.2 Balancing

Electronic balancing feature of AirTouch 4 oers the exibility of balancing the

amount of airow to each zone electronically. Once the opening position of the

damper is set, the damper will only open to this position. The default setting for

each damper is 100% opening position and the adjustable range is between 0 and

100% with 5% increment. The balancing settings can be conducted on the touch

screen as below.

a) On ‘Installers’ screen, touch Balance menu

b) Touching the percentage value for the zone to start the balancing process.

All zones will open to its balanced position. You can input proper value and

check the airow on the y till right value reaches.

c) Repeat the process for all zones which need balancing. Then touch the Stop

button to stop the balancing process.

NOTE:

• The %OPEN value on the Zoning screen can be operated by the user for

additional air ow adjustment to the groups. The overall opening % of the

zone is calculated as %OPEN x Balance %.

19

20

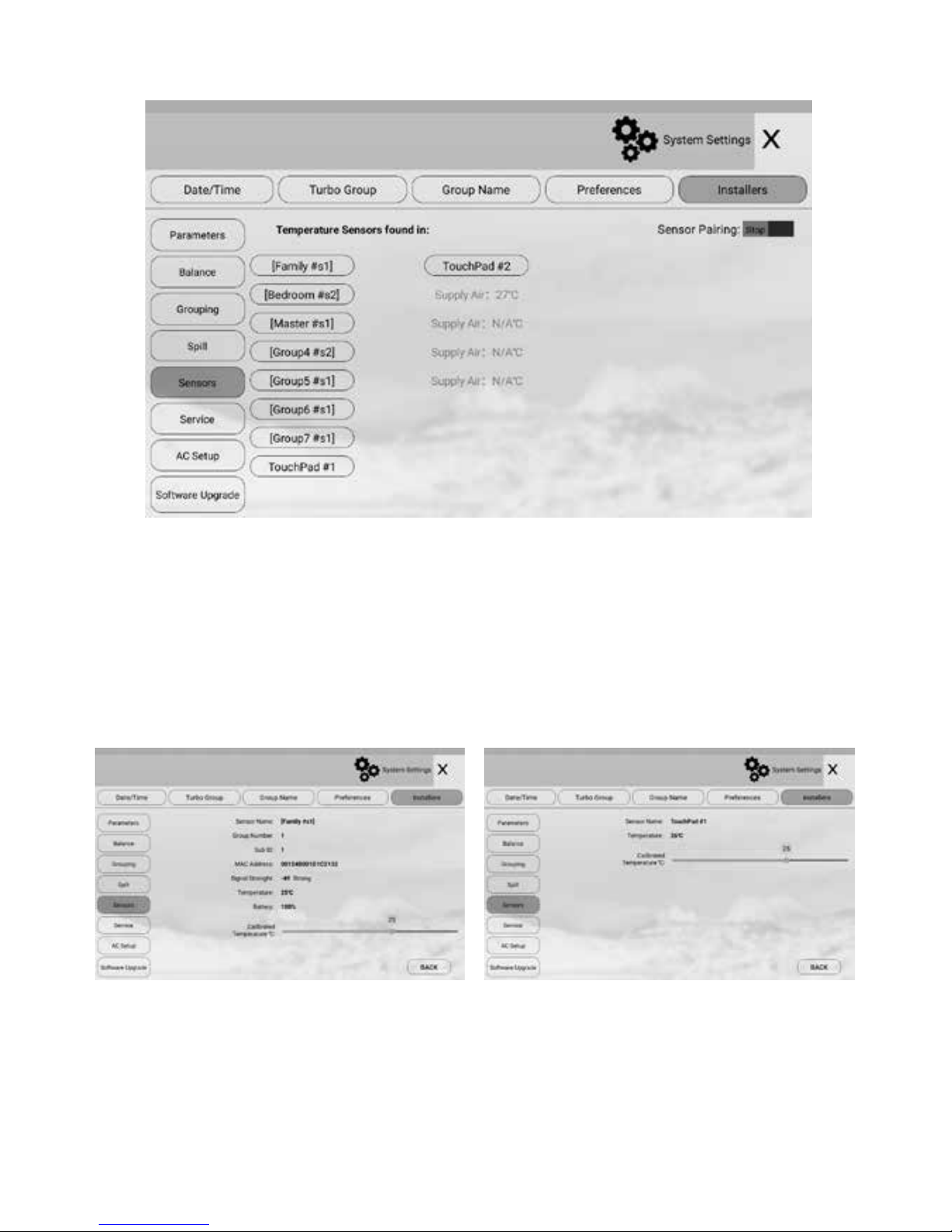

5.3 Sensors

Temperature sensors are used for measuring group temperature and control

group temperature and On/O if required. There are wireless temperatures

sensors and wired temperature sensors (on console). Each wireless sensor has

dipswitches to assign it to a particular group where it is installed and to be used

for temperature control of the group.

Balancing contd. & Sensors

Wireless Sensor Console Sensor

21

5.3.1 Assign a sensor to a group

The console sensor can be assigned to a group where it’s installed in Parameter

settings. For a wireless sensor, open the wireless sensor cover and set the dial of

the group dipswitch (with 16 digits) pointing to the group number required.

Position 0 is for group 16. If there are more than one wireless sensor for the same

group, set the group dipswitch to the same position but dierent sensor ID by

switching the Sub ID dipswitch. If the group dial switch or sub ID switch has been

changed after pairing it’s necessary to re-pair the sensor. Otherwise the change

will not be eective.

5.3.2 Pair main module and wireless sensors (ITCs)

After assigning wireless sensors to relevant groups, it’s time to pair the sensors.

The AirTouch 4 main module and wireless sensors have to be paired to enable

communications. When AirTouch 4 is rst powered up, start the pairing process

on the Sensors page in the Installer’s Settings by switching the Pair button to Start,

then push and hold the button on each of the ITCs to be used in the system to

pair. All ITCs will come up and the groups with ITCs will show set points after being

paired. Then switch the Pair button to Stop to nish the pairing process.

5.3.3 Calibrate a Sensor

If the temperature reading from the sensor is not accurate, it can be calibrated by

changing the value in the calibration box on the sensor details page. Press Save

button to save the correct value.

Sensors contd.

Loading...

Loading...