Page 1

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

Pololu TReX Jr User's Guide

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Contacting Pololu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.a. Motor and Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.b. Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.c. Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.d. LED Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.e. Automatic Calibration for Your RC/Analog Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. RC/Analog in Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.a. Channel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.b. Channel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.c. General RC Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.d. General Analog Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.e. Safe-Start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. The Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.a. Serial Communication Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.b. Serial Command Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.c. Serial Command List and Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.d. Configuration Parameter List and Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.e. Cyclic Redundancy Check (CRC) Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.f. CRC-Generation Algorithm in C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.g. Resetting the Serial Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6. Updating the TReX Jr’s Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Page 1 of 23

Page 2

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

1. Overview

The TReX Jr Dual-Motor Controller [http://www.pololu.com/catalog/product/767] is a versatile DC motor controller

designed to seamlessly blend autonomous and human control of small- and medium-sized robots. The TReX can

control two bidirectional and one unidirectional motor via three independent control interfaces: radio control (RC)

servo pulses, analog voltage, and asynchronous serial (RS-232 or TTL). It uses five input channels to receive the RC

or analog control signals. When operating in RC or analog mode, the five channels function as follows:

• Channel 1: motor 1 speed and direction or, if in mix mode, turn left/right

• Channel 2: motor 2 speed and direction or, if in mix mode, go forward/reverse

• Channel 3: auxiliary (unidirectional) motor speed

• Channel 4: can be used to enable “flipped mode”, which allows invertible robots to be controlled as normal

when they are inverted

• Channel 5: determines whether the motors are controlled by the channel inputs or the serial interface; this

channel allows you to switch between autonomous and human control at will

The serial interface can switch instantly with one of the other two interfaces, allowing mixed autonomous and

remote control. For example, a robot could be configured to run autonomously most of the time, but a human

operator could override the autonomous function if the robot gets stuck or into a dangerous situation. If the serial

mode is selected as the primary interface, high-resolution measurements of all five channel input signals (be they

RC pulses or analog voltages) are made available to the autonomous robot controller, allowing for complex and

unlimited mixing of operator control and sensor input. For example, the TReX would be a great motor controller for

a line-following robot whose overall speed is controlled by an RC throttle, or an RC car with sensors that

autonomously dodges obstacles in its path as you drive it around.

1. Overview Page 2 of 23

Page 3

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

2. Contacting Pololu

You can check the TReX Jr motor controller page [http://www.pololu.com/catalog/product/767] for additional

information. We would be delighted to hear from you about any of your projects and about your experience with the

TReX motor controller. You can contact us [http://www.pololu.com/contact] directly or post on our

forum [http://forum.pololu.com/]. Tell us what we did well, what we could improve, what you would like to see in the

future, or anything else you would like to say!

2. Contacting Pololu Page 3 of 23

Page 4

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

3. Getting Started

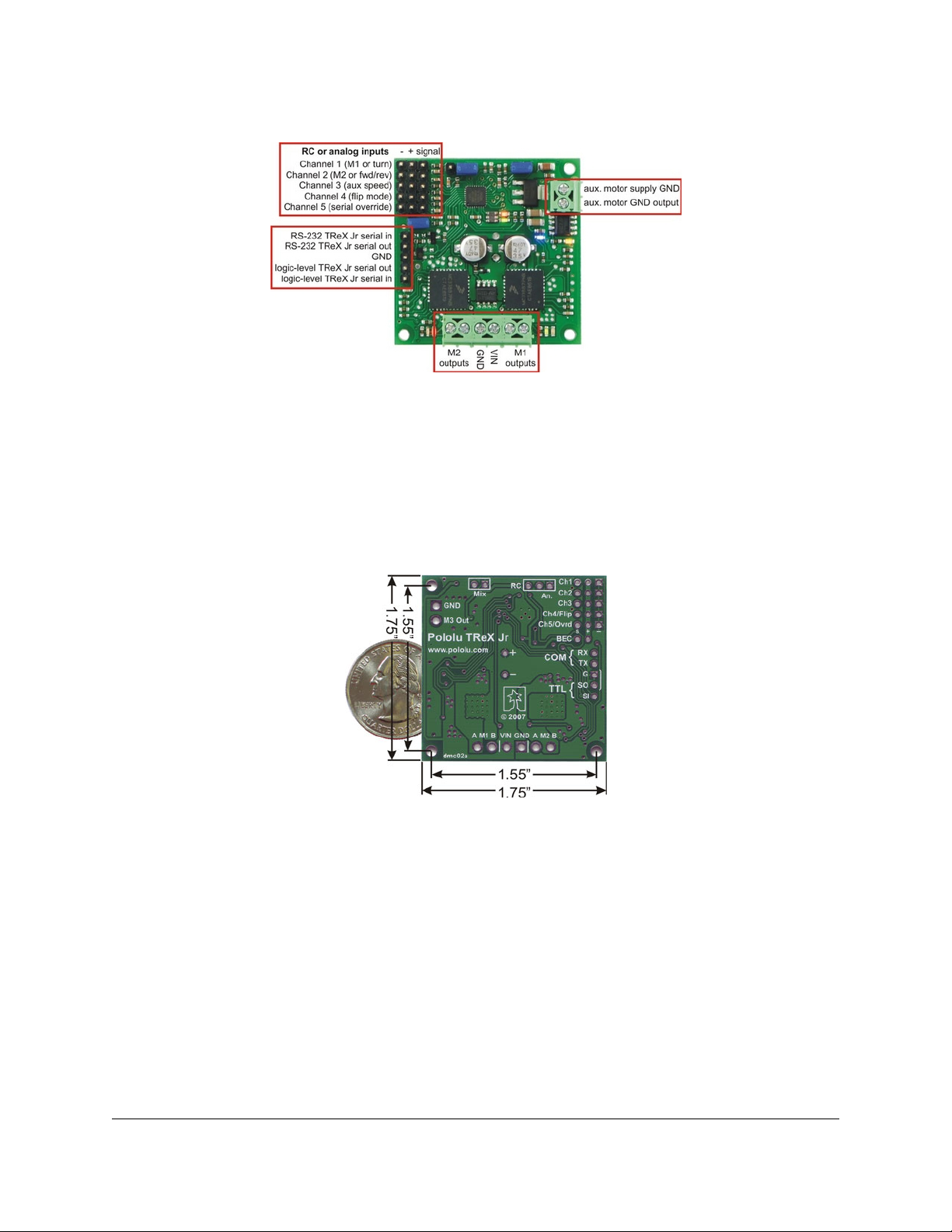

TReX Jr input/output connection points

Getting started with your TReX Jr can be as simple as connecting power, your motors, and your RC or analog

control signals (see Section 3.a and Section 3.b). Configure your jumpers for RC or analog mode (see Section 3.c)

and you’re good to go. While it’s running, the TReX Jr will communicate with you via its LEDs (see Section 3.d).

Once you have all your connections in place, we recommend your first step be to calibrate your TReX Jr for your

particular RC or analog controller (see Section 3.e).

Pololu TReX Jr Dual Motor Controller bottom view with dimensions

3.a. Motor and Power Connections

The TReX Jr receives its power through the VIN/GND connector terminals. VIN should be between 5 and 24 V and

your power source must be able to supply the current your motors will be drawing. The TReX Jr can supply peaks of

5 A and up to a continuous 2.5 A to each of its two bidirectional motors. Performance will depend the on actual

system and its ability to dissipate heat. The TReX Jr is designed to help heat flow along the board away from the

MC33887 motor driver chips, but addition of a heat sink and good air flow will further improve performance. The

TReX Jr can supply up to 10 A (continuous) to the auxiliary motor.

3. Getting Started Page 4 of 23

Page 5

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

Note: The TReX Jr uses a linear voltage regulator to obtain its logic voltage (5-V Vcc). If you supply a

VIN of 24 V, your Vcc line will be limited to a maximum of 50 mA because of the regulator’s 1-W power

dissipation rating. This limitation might prevent your TReX Jr from being able to safely power an RC

receiver when VIN is so much higher than Vcc.

There are several different ways to connect motors to your TReX Jr:

Option 1:

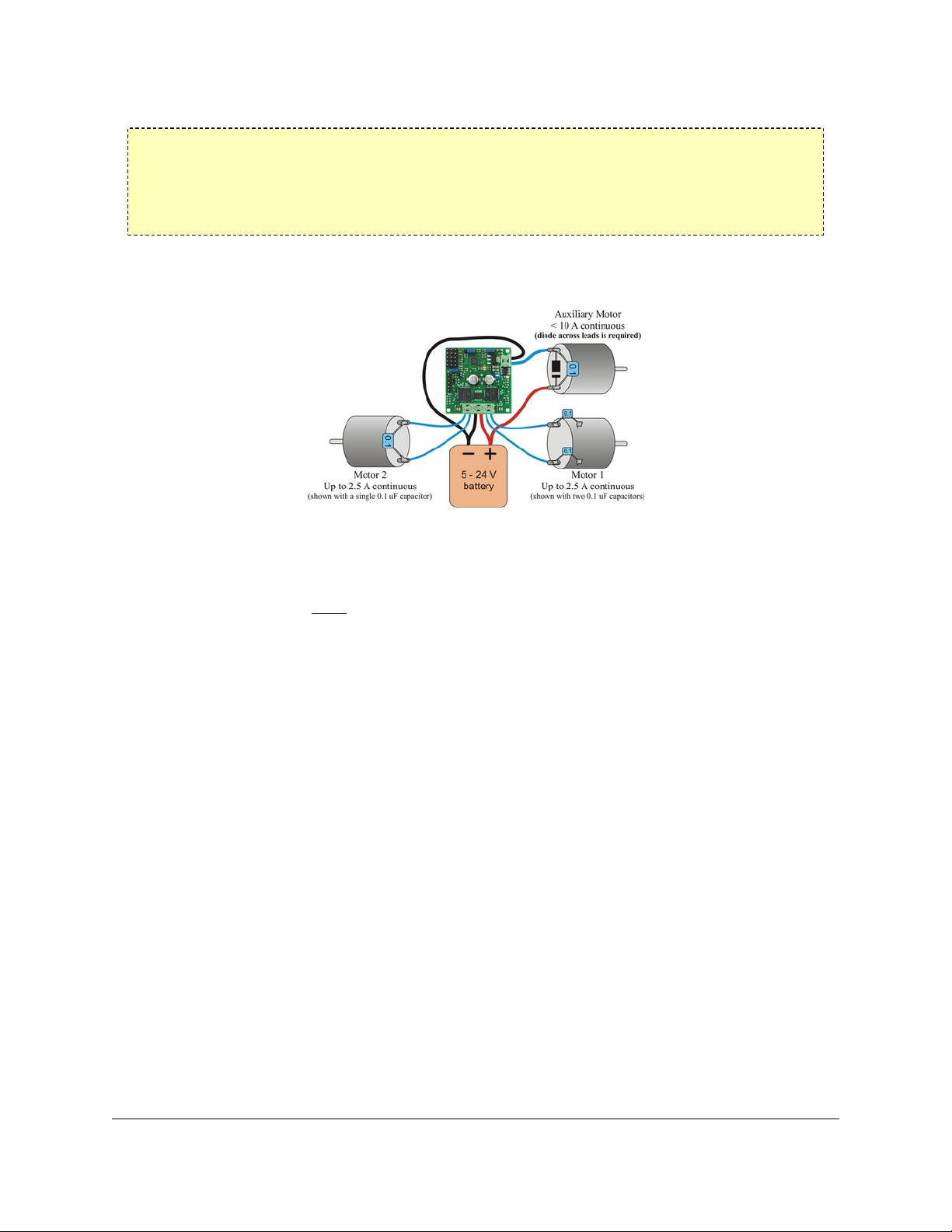

TReX Jr motor connections (single battery)

The figure above demonstrates how to connect two bidirectional motors and a unidirectional auxiliary motor to your

TReX Jr, all powered by the same battery. Note that the auxiliary motor is driven by permanently connecting one

lead to power while the board PWMs the other lead between high impedance and ground. You must connect your

battery’s ground directly to the upper port of the auxiliary motor’s connection block if you plan to use the auxiliary

motor. Otherwise, the auxiliary motor could attempt to pull too much current through the TReX Jr itself, thereby

damaging the unit.

The auxiliary motor’s other lead connects to the lower port of its connection block. You will need to connect a diode

across the auxiliary motor’s terminals as shown below. Failing to do so will adversely affect the performance of

your TReX Jr and could result in permanent damage to the device. Take great care to ensure you do not solder the

diode in backwards! You should not solder a diode to your bidirectional motors.

You may find it beneficial to solder 0.1uF capacitors across all of your motors’ terminals. This will decrease the

noise put out by your motors and can improve performance of your TReX Jr. You can further decrease the noise put

out by your motors by keeping their leads as short as possible and twisting them around each other in a helix.

Option 2:

3. Getting Started Page 5 of 23

Page 6

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

TReX Jr motor connections (separate battery for the auxiliary motor)

It is possible to power the auxiliary motor with a second, separate 0 – 24 V battery, as shown above. To do so,

connect that battery’s ground to the upper of the two auxiliary motor connection block ports. Connect one of your

auxiliary motor’s leads to the lower connection block port and connect the other of your motor’s leads directly to the

battery’s positive side. You will still need to solder a diode across your auxiliary motor’s terminals.

Option 3:

TReX Jr joint-motor connection

Lastly, you can use both motor 1 and 2 outputs to control a single, more powerful (up to 5 A continuous)

bidirectional motor by connecting it as shown above. One of the motor’s terminals connects to both of motor 1’s

outputs while the other of the motor’s terminals connects to both of motor 2’s outputs. In order to use your TReX Jr

in this way, you must use the serial interface to set the TReX Jr to “joint motor mode”. In this mode, the single

bidirectional motor is considered “motor 1”. The motor speed/direction indicator LEDs will not work in this mode,

nor will current sensing or channel mixing. Although it is not shown in the figure above, you can additionally

control an auxiliary motor while running in “joint motor mode”.

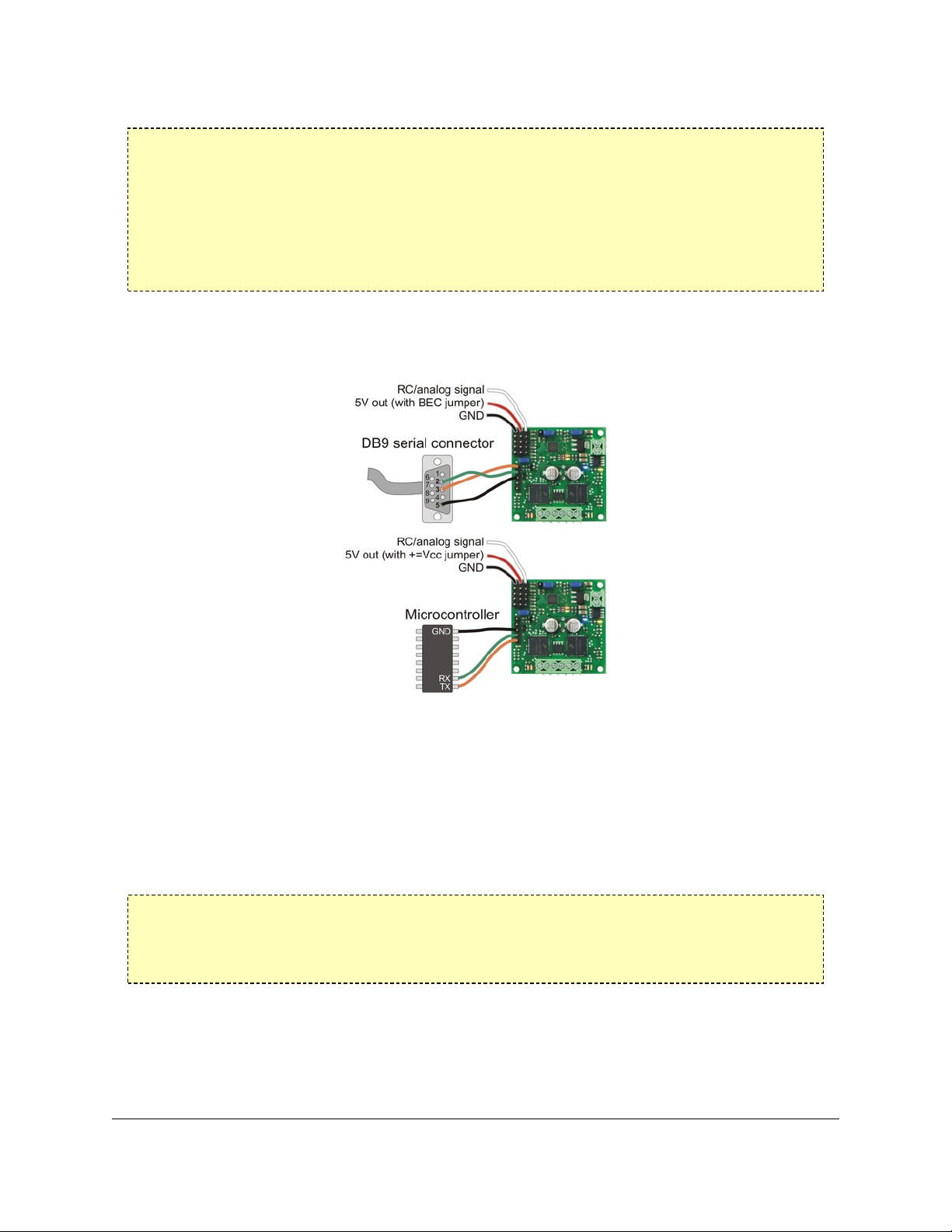

3.b. Signal Connections

RC/analog signals should connect to the interior of the three channel columns; this connection is represented by the

white wire in the figure below.

The middle column is connected to the TReX Jr’s regulated power (Vcc) through the Battery Elimination Circuit

(BEC) jumper and will provide 5 V to your RC receiver or analog controller when this jumper in place. This

connection is represented by the red wire in the figure below. If you want to power your RC receiver or analog

controller from a source other than the TReX Jr, make sure you remove the BEC jumper.

3. Getting Started Page 6 of 23

Page 7

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

Warning: This middle Vcc column is tied to the output of a linear voltage regulator, so its current output

is limited by thermal dissipation. The regulator will only be able to safely supply a maximum of 100 mA

when VIN is 12 V and 50 mA when VIN is 24 V (it has a 1-W power dissipation rating). This is typically

sufficient for powering an analog joystick or RC receiver, but it is insufficient for powering servos. If you

want to connect servos to some of your RC receiver channels, you must power your RC receiver

separately and disconnect the BEC jumper. Attempting to use the TReX Jr’s regulated Vcc line to power

servos can permanently damage the TReX Jr.

The exterior column is ground and is represented by the black wire in the figure below. Your input source and the

TReX Jr must share a common ground, even if you are powering your input source from something other than the

TReX Jr. You only need to make a single ground connection.

TReX Jr RC/serial input signal connections

In addition to RC/analog connections, you can connect the TReX Jr to either an RS-232 (COM) or logic-level (TTL)

serial port. Note that you should not simultaneously have both RS-232 and TTL connected. The figure above depicts

the two possible serial connections. The serial pins are labeled from the perspective of the TReX Jr, meaning you

should connect the TReX Jr’s TX or SO line to your target’s receive line (the green wire in the figure above); your

TReX Jr’s RX or SI line should connect to your target’s transmit line (the orange wire in the figure above). On a

DB9 connector, pin 2 is your computer’s receive line and pin 3 is your computer’s transmit line.

Warning: It is very important that you do not connect your TReX Jr’s TTL pins (SO and SI) to an

RS-232 port. RS-232 serial communication signals range from -12 to +12 V, which is well outside the 0 –

5 V expected on those lines. Only the COM pins (TX and RX) are designed to handle RS-232 voltages.

3.c. Jumper Settings

The TReX Jr comes with four blue shorting blocks as shown in the picture below. These jumpers let you affect some

aspects of its behavior without serial configuration commands. Note that we recommend you always power off your

3. Getting Started Page 7 of 23

Page 8

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

TReX Jr before changing jumpers (other than the mix jumper, which can be changed at an time). This is not strictly

necessary, but it is the safest practice.

TReX Jr jumpers

• Channel-Mix (a.k.a. Single-Stick) Jumper: When this jumper is in place, the TReX Jr operates in singlestick mode. Channel 1 is treated as turn left/right while channel 2 is treated as forward/reverse. When this

jumper is off, channel 1 directly controls motor 1 and channel 2 directly controls motor 2. This jumper may be

added or removed on the fly.

• Battery Elimination Circuit (BEC) Jumper: When this jumper is in place, the middle column of channel

input pins is connected to Vcc (5 V). You can use this jumper to power your RC receiver or analog controller

through your TReX Jr. If your RC receiver is powered via another source, you must leave this jumper off.

Warning: The Vcc column is tied to the output of a linear voltage regulator, so its current output is

limited by thermal dissipation. The regulator will only be able to safely supply a maximum of 100 mA

when VIN is 12 V and 50 mA when VIN is 24 V (it has a 1-W power dissipation rating). This is typically

sufficient for powering an analog joystick or RC receiver, but it is insufficient for powering servos. If you

want to connect servos to some of your RC receiver channels, you must power your RC receiver

separately and disconnect the BEC jumper. Attempting to use the TReX Jr’s regulated Vcc line to power

servos can permanently damage the TReX Jr.

• Mode-Select Jumper: This jumper specifies the interface that is in control of the TReX Jr. When it shorts

the right two pins (as shown in the jumper image above), the TReX Jr is in RC mode, which means the TReX

Jr is expecting RC pulse inputs on its five input channels and that these RC signals will determine the motor

outputs. When the jumper shorts the left two mode pins, the TReX Jr is in analog mode; the TReX Jr measures

the analog voltages on the five input channels and sets the motor outputs accordingly. When there is no jumper

on the three mode pins, the TReX Jr is in serial mode and the serial interface controls the motors. The control

interface is determined by the location of the mode jumper when the TReX Jr is first powered up. Changing the

location of the mode jumper while the TReX Jr is running will have no effect.

• Learning-Mode/Firmware Upgrade Jumper: The TReX Jr can automatically calibrate itself for your RC

or analog controller by learning the neutral and extreme values for each channel you use. It also has the ability

3. Getting Started Page 8 of 23

Page 9

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

to upgrade its firmware. When placed across the SO and G pins, this jumper puts the TReX Jr into learning/

firmware-upgrade mode via the “secret handshake” (see Section 3.e). The TReX Jr ships with this jumper in

place since we recommend your first step be to calibrate for your controller. This jumper should be removed

before you begin normal operation.

Warning: You should never add this jumper while the board is powered! Disconnect power from the

board, add this jumper, and then reconnect power.

3.d. LED Feedback

This section explains the meanings of the various illumination patterns of the TReX Jr’s LEDs. The TReX Jr has

eight colored LEDs as shown below:

TReX Jr LEDs

• Power LED (1): The blue power LED is located on the right side of the board. When it is brightly

illuminated, the TReX Jr is receiving power and is running. Note that the power LED can occasionally glow

dimly when the TReX Jr is unpowered if it is connected serially to a powered device.

• Motor LEDs (5): Motors 1 and 2 each have two indicator LEDs—one red, one green—tied directly to the

motor outputs. These LEDs are located along the lower edge of the board flanking the motor/power connection

block. For a given motor, the color of the illuminated LED indicates its direction and the intensity indicates its

speed. Our convention is to consider the direction indicated by the green LED “forward” and the direction

indicated by the red LED “reverse”. The auxiliary motor output is directly tied to the yellow LED on the right

side of the board near the auxiliary motor port; the intensity of this LED indicates the auxiliary motor speed.

• Status LEDs (2): The TReX Jr has two status LEDs—one red and one green—located near the middle of

the board. These LEDs are used to communicate a great deal of information to the user. The illumination

patterns mean different things depending on the TReX Jr’s state.

◦ On TReX Jr Startup:

▪ Status LEDs flash rapidly five times: When the TReX Jr starts up, it signals which channels it has

learned by flashing its status LEDs five times. A green flash indicates the corresponding channel has

been learned; a red flash indicates the corresponding channel has not been learned. For example, a

flash sequence of “red, red, green, red, green” means only channels 3 and 5 have been learned. If the

TReX Jr is in analog mode, it signals which analog channels have been learned; if it is in RC mode, it

signals which RC channels have been learned; if it is in serial mode, the learned-channel signals are

3. Getting Started Page 9 of 23

Page 10

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

for the mode selected by the “channel input source” parameter (this parameter’s default value is RC

mode).

▪ Red and green LEDs blink in unison around once per second: The TReX Jr is waiting to see if it

should enter learning mode. This happens when the TReX Jr is in RC or analog mode, the mix

jumper is in place, and the serial out (SO) pin is grounded. This last condition can arise if the TReX

Jr is connected serially to an unpowered microcontroller. Ungrounding the SO pin will cause the

TReX Jr to startup as normal; removing the mix jumper will put the TReX Jr into learning-mode, at

which point it will either start trying to learn the channels or will wait for a valid signal on the input

lines. If it waits, it will flash the red and green LEDs in unison four times faster while waiting.

▪ Red and green LEDs alternate around once per second: The TReX Jr is waiting to see if it should

enter firmware-upgrade mode. This happens when the TReX Jr is in serial mode (i.e. there is no

mode jumper in place), the mix jumper is in place, and the serial out (SO) pin is grounded. This last

condition can arise if the TReX Jr is connected serially to an unpowered microcontroller.

Ungrounding the SO pin will cause the TReX Jr to startup as normal; removing the mix jumper will

put the TReX Jr into firmware-upgrade mode, which will cause the red and green LEDs to start

alternating four times faster.

◦ While Running Normally:

▪ Red LED on solid, green LED might flicker: The red LED solidly on indicates that serial is in

control of the motors (i.e. serial override is active or the TReX Jr is in serial mode). While serial is in

control of the motors, the green LED acts as a serial-packet-received indicator. It lights when a

command byte is received and stays lit until the last byte of the command packet is received. The

flicker rate of the green LED will depend on the baud rate you’re using and the rate at which you’re

sending serial commands to the TReX Jr.

▪ Green LED on solid, red LED might flicker: The green LED solidly on indicates that the channel

inputs are in control of the motors (i.e. the TReX Jr is in RC or analog mode and serial override is not

active). While the channel inputs are in control of the motors, the red LED acts as a serial-packetreceived indicator. It lights when a command byte is received and stays lit until the last byte of the

command packet is received. The flicker rate of the red LED will depend on the baud rate you’re

using and the rate at which you’re sending serial commands to the TReX Jr.

▪ Green LED is rapidly flashing, red LED might flicker: The TReX Jr will not let the channel inputs

start controlling the motors until safe-start conditions are first met (see Section 4.e). Specifically, it is

waiting for a valid signal on all required channels, for the motor signals to request no motor

movement, and for the serial override signal to not be requesting serial override mode. This state

occurs when the TReX Jr first starts running in RC or analog mode, and can be retriggered if an RC

signal is ever lost on a required channel. This state will never occur if the TReX Jr is in serial mode.

While in this state, the red LED acts as a serial-packet-received indicator as described in the bullet

point above.

◦ While in Learning Mode (see Section 3.e):

▪ Red and green LEDs blinking rapidly in unison: The TReX Jr is in RC mode and it is waiting for a

valid RC signal on at least one channel before it begins learning the channel calibration values.

▪ Red LED on solid, green LED off: This is the first stage of the learning sequence in which the

TReX Jr is attempting to learn the neutral values of each channel. This phase should last around two

seconds. Do not touch the RC/analog sticks while the red LED is on or you could cause learning to

fail.

▪ Status LEDs flash rapidly five times: When the TReX Jr is through learning the neutral values, it

will flash the status LEDs five times to indicate which channels had neutrals successfully learned and

which channels failed neutral learning. A green flash indicates success for the corresponding channel;

a red flash indicates failure. If all five channels fail to learn neutral values, the learning process stops,

3. Getting Started Page 10 of 23

Page 11

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

otherwise it continues to the next phase, which is learning the values of the extremes. Once this last

learning phase is complete, the status LEDs will again flash five times to indicate whether the

corresponding channel was successfully learned. This final five-flash sequence will repeat until the

TReX Jr is reset.

▪ Red and green LEDs both on solid: This is the second and final stage of the learning sequence in

which the TReX Jr is attempting to learn the maximum and minimum values for each channel. This

phase lasts around ten seconds, during which time you should move the control sticks to their

extremes. Make sure to hold each channel at each extreme for at least 0.5 seconds.

◦ While in Firmware-Upgrade Mode (see Section 6):

▪ Red and green LEDs alternate around once per second: The TReX Jr is waiting to see if it should

enter firmware-upgrade mode. This happens when the TReX Jr is in serial mode (i.e. there is no

mode jumper in place), the mix jumper is in place, and the serial out (SO) pin is grounded. This last

condition can arise if the TReX Jr is connected serially to an unpowered microcontroller.

Ungrounding the SO pin will cause the TReX Jr to startup as normal; removing the mix jumper will

put the TReX Jr into firmware-upgrade mode, which will cause the red and green LEDs to start

alternating four times faster.

▪ Red and green LEDs alternate around four times per second: The TReX Jr is in firmware-upgrade

mode and is waiting for the short between the serial out (SO) pin and ground to be removed.

▪ Green LED flashes briefly once per second: The TReX Jr is in firmware-upgrade mode and is

waiting for the correct initial serial input sequence. The TReX Jr enters this state when the short

between the serial out (SO) pin and ground is removed after the mix jumper has been removed.

▪ Red LED flashes: There was a faulty input to the bootloader that has caused the bootloader to

revert to waiting for the correct initial serial input sequence. Note: once the firmware upload is

complete, the TReX Jr will reboot and the red LED may flash as part of the startup sequence. This is

not an indication of a firmware-update error. See the firmware-update section for further details.

▪ Green LED rapidly flashes: Everything is proceeding as expected during the firmware upgrade

process. Each successfully uploaded data packet causes the green LED to flash.

3.e. Automatic Calibration for Your RC/Analog Controller

The TReX Jr has the ability to automatically calibrate itself for your particular RC or analog controller. We strongly

recommend you use this feature to calibrate your TReX Jr as it can result in a substantial increase in performance.

You only need to perform the calibration once, but you should recalibrate if you ever change controllers. The TReX

Jr can simultaneously store a set of analog calibration values and a set of RC calibration values; the calibration

values used depends on the mode of operation (or on the value of the “channel input source” parameter if the TReX

Jr is running in serial mode).

The TReX Jr calibrates itself by first learning the neutral values of all the channels and then learning the extremes.

You can enter learning mode via the secret handshake:

1. Power off your TReX Jr.

2. Connect your RC receiver or analog controller to your TReX Jr’s channel inputs.

3. Turn on your RC transmitter/analog controller. Set the sticks to the positions you would like to consider

“neutral” and, if desired, zero your trim settings.

4. Attach the channel-mix jumper.

5. Attach the learning-mode jumper (i.e. short the serial out pin, SO, to ground, G). You must never attach

this jumper while the board is powered!

3. Getting Started Page 11 of 23

Page 12

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

6. Place the mode jumper to select for either RC or analog (whichever type of controller you’re trying to

calibrate for).

7. Restore power to your TReX Jr. You should see the red and green status LEDs blinking in unison around

once per second.

8. Remove the channel-mix jumper. If you now see the red and green status LEDs blinking together around

four times per second, the TReX Jr is unable to detect a valid RC pulse signal on any of its input channels. If

instead you see the red LED turn on solid, you are now in learning mode, which proceeds in the following four

phases:

Learning mode phase 1: learning neutrals

While the red LED is on solid, the TReX Jr is attempting to learn the neutral values of all five channels. Do NOT

move the control sticks at all while the red LED is on. It should only take around two seconds for this first phase,

though it could be much shorter if the TReX Jr encounters problems learning the neutrals for all five channels. If any

RC pulse errors occur during the learning process or if the channel variance is too large, the TReX Jr will not learn

the channel.

Learning mode phase 2: neutral learning report

Once phase one is through, the TReX Jr will flash its status LEDs five times to indicate neutral-learning success or

failure for each channel. A green flash means that the neutral value was successfully learned for the corresponding

channel. A red flash means there was a problem and that channel will not be learned. For example, a flash pattern of

“red, red, green, red, green” means that neutrals were learned successfully for channels 3 and 5; channels 1, 2, and 4

will not be learned. If all five flashes are red, the learning process terminates here.

Learning mode phase 3: learning the extremes

This phase begins when both the red and green status LEDs light simultaneously and lasts approximately ten

seconds. During this time, the TReX Jr is attempting to determine the maximum and minimum values for each of the

five channels. You should try to hold each channel at each of its two extremes for at least half a second. Move the

control sticks around slowly and steadily. If you jerk them around very rapidly the TReX Jr may reject the channel

inputs as unreliable. If any RC pulse errors occur or if the channel variance isn’t large enough, the TReX Jr will not

learn the channel.

Learning mode phase 4: final learning report

This phase is identical to phase 2, except here the green flashes represent channels that were fully learned. The

flashing pattern will repeat until the TReX Jr is reset. Now every time the TReX Jr starts up, it will quickly flash the

LEDs in this pattern to indicate which channels are calibrated and which are not.

Note: Once learning is complete, you should remove the learning-mode jumper and reset your TReX Jr.

3. Getting Started Page 12 of 23

Page 13

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

4. RC/Analog in Detail

This section provides a detailed overview of the RC and analog modes of operation. It explains how the TReX Jr

processes its channel inputs and how those inputs influence the TReX Jr when its in RC or analog mode.

4.a. Channel Functions

The five input channels along the left side of the TReX Jr accept either radio-controlled (RC) servo pulses or analog

voltages, depending on the position of the mode-selection jumper (or on the value of the “channel input source”

parameter if the TReX Jr is in serial mode). When not in serial mode, the TReX Jr acts on the five channels as

follows:

• Channel 1: If mix jumper is in place, turn left/right at the specified speed; if mix jumper is off, set motor 1

direction and speed.

• Channel 2: If mix jumper is in place, go forward/reverse at the specified speed; if mix jumper is off, set

motor 2 direction and speed.

• Channel 3: Set auxiliary motor speed (aux. motor is unidirectional).

• Channel 4: Enable/disable flipped mode. Flipped mode causes the TReX Jr to treat motor 1 as motor 2 (and

vice versa), and to swap its notions of forward and reverse for each motor. The result is that a differential-drive

robot will behave as normal when inverted if flipped mode is enabled. This channel acts like a switch that gets

flipped when the channel value falls below a certain threshold. If your controller is not calibrated, this channel

may not function as intended.

• Channel 5: Enable/disable serial override. Serial override gives serial control of the motors for as long as

channel 5 enables it. When serial override is first enabled, each motor is set based on its most recently received

motor command, even if that command occurred while serial override was disabled. Channels 1, 2, and 3 will

not affect the motors while serial override is active (unless your serial control source is reading the values of

those channels and issuing its commands based in part on them). This channel acts like a switch that gets

flipped when the channel value falls below a certain threshold. If your controller is not calibrated, this channel

may not function as intended.

4.b. Channel Calibration

As was covered in Section 3.e, you can automatically calibrate your TReX Jr for your RC or analog controller. If

this doesn’t prove sufficient for your needs, you can manually calibrate your TReX Jr for your controller by

specifying the minimum, neutral, maximum, and deadband values for each channel. The TReX Jr can

simultaneously store both a set of RC and a set of analog calibration parameters. The calibration parameters are in

the units of the raw channel values: 0.4 us for RC, 4.89 mV for analog. In general, these parameters affect how the

TReX Jr interprets the channel input values.

Perhaps most noticeably, these parameters help determine how the channel inputs affect the motors. Motor speed is

scaled linearly (or parabolically, if the channel is set as parabolic using the “parabolic channels” configuration

parameter) from 0 at a channel input of neutral+deadband to max speed at a channel input of maximum. In the

other direction, motor speed goes from 0 at neutral-deadband to max speed at minimum. Motor speed is 0 for

channel inputs between neutral-deadband and neutral+deadband, and motor speed is at a maximum for channel

inputs greater than maximum or less than minimum. Motor direction is determined by the side of neutral the

channel input is on, and notions of forward and reverse can be switched on a channel by channel basis using the

“reversed channels” configuration parameter.

4.c. General RC Information

When the channel inputs are RC servo pulses, the update rate of the channel values is determined by the pulse-train

frequency of your RC receiver. Typically this is 50 Hz (each channel updates every 20 ms). The TReX Jr can handle

channel pulse-train frequencies of 10 Hz to 125 Hz.

4. RC/Analog in Detail Page 13 of 23

Page 14

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

The TReX Jr measures the width of RC servo pulses with 12-bit resolution and an accuracy of 1 us. The raw channel

value is provided as a 12-bit number in units of 0.4 us, so a raw channel value of 2500 can be physically interpreted

as a pulse width of 2500×0.4 =1500 us. Servo pulse widths typically range from 1 ms to 2 ms, with a neutral value

of 1.5 ms. This would correspond to raw channel values of 2500, 5000, and 3750, respectively. The TReX Jr can

handle pulse widths as short as 0.5 ms (raw channel value 1250) and as long as 2.5 ms (raw channel value 6250). If

a channel reading is considered to be an error, the raw channel value will be 0xFFFF (65535 in decimal). Errors

result from pulse widths outside the acceptable range and from pulse trains with frequencies outside of the

acceptable range. If a signal ceases on a channel, that channels value will stop updating until approximately 150 ms

elapse, at which point the channel’s raw value will become 0xFFFF. It will remain as such until valid signals are

once again detected on the line.

As a safety feature, you can designate channels as required using the “required channels” configuration parameter.

If a required channel goes for more than 500 ms without receiving a valid RC servo pulse and the TReX Jr is in RC

mode, the TReX Jr will enter safe-start mode (see Section 4.e). By default, the TReX Jr only requires channel one.

If you are not using all five channels, you can optionally ignore unused channels via the “ignored channels”

configuration parameter. Ignored channels are treated as fixed at their neutral values (no matter what signals their

lines receive).

4.d. General Analog Information

When the channel inputs are analog voltages, the update rate of the channel values is approximately 50 Hz (each

channel updates every 20 ms or so). Each channel’s value is the result of a 16-sample average of analog-to-digital

conversions.

The TReX Jr measures analog voltages with 10-bit resolution. The raw channel value is provided as a number

ranging from 0 to 1023, where 0 corresponds 0 V and 1023 corresponds to 5 V. Your channel source can be as

simple as the output of a potentiometer whose inputs are the channel’s associated power (make sure the BEC jumper

is in place) and ground connections.

Unlike with RC signals, the TReX Jr has no way of telling if a channel is receiving a valid analog signal. A

disconnected channel will still produce a result when run through the analog-to-digital converter. This poses two

potential problems:

1. If your analog signal source gets disconnected from your TReX Jr, the TReX Jr could drive the motors in

unexpected and potentially dangerous ways. Because of this, please be very careful when operating the TReX

Jr in analog mode.

2. Unused channels can impact behavior of the TReX Jr in undesirable ways. You may not plan on using the

flip or override channels, but leaving them disconnected could result in their floating to a value that would

enable flipped mode or serial override. One solution to this problem is to use the “ignored channels”

configuration parameter to set unused analog channels as ignored. The TReX Jr considers ignored channels to

be fixed at their neutral positions. An alternate, purely hardware-based solution would be to short any unused

motor channels to a used one and to tie any unused “enable” channels (4 or 5) to Vcc (the 5-volt line). By

shorting unused motor channels to a used one, you should be able to get past the safe-start portion of the

TReX’s start-up routine.

4.e. Safe-Start Mode

When the TReX Jr starts up in either RC or analog mode, it first enters safe-start mode. In this mode, the three

motors are shut down and are unaffected by the channel inputs. The TReX Jr lets you know its in this mode by

rapidly flashing its green status LED. To exit this mode, the following conditions must all be simultaneously met:

4. RC/Analog in Detail Page 14 of 23

Page 15

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

1. All required channels must have a valid signal. This only applies when the TReX Jr is in RC mode since

it’s not possible to have an invalid analog signal. Required channels are determined by the “required channels”

configuration parameter. Only channel one is required by default.

2. All motor channels must be close to their neutral values (i.e. they must not be instructing the motors to

move very quickly). Channel 5 must be disabling serial override. The TReX Jr will not allow you to start with

serial controlling the motors if you’re in RC or analog mode.

If you have floating channels while running in analog mode, it may be impossible for you to satisfy the safe-start

conditions. Bullet point #2 in the analog section (Section 4.d) provides several ways to fix this problem.

Once you have satisfied the safe-start conditions, the green status LED should stop flashing and turn solidly on. This

indicates that the channel inputs are now in control of the motors.

4. RC/Analog in Detail Page 15 of 23

Page 16

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

5. The Serial Interface

You can use the serial interface for four general purposes: querying the TReX Jr for information (any mode), setting

its configuration parameters (serial mode only), sending it motor commands (any mode), and upgrading its firmware

(must be in firmware-upgrade mode). Firmware upgrading is addressed in Section 6.

Serial motor commands are accepted in any mode, but they will only immediately affect the motors if the TReX Jr is

in serial mode or channel 5 has serial override active. When the TReX Jr is in RC or analog mode and serial override

is not active, the most recently received serial motor command for each motor is buffered. These buffered motor

commands take effect if serial override becomes active.

Note that when you are using the serial interface, it is crucial that you do not transmit to the TReX Jr while it is

transmitting to you. Because of the way the RS-232 circuit is tied to the logic-level serial lines, the TReX Jr can

sometimes get its transmissions echoed back to itself. It deals with this by ignoring its receive line while it is

transmitting, so anything you send it during this time will be lost. As a consequence, the TReX Jr will never transmit

anything over the serial line without your first explicitly asking it to. The high-level protocol for sending commands

that cause the TReX Jr to transmit data back to you should be as follows:

1. Transmit command packet that causes the TReX Jr to send data back to you

2. Wait for all the expected data to be received or for a reasonable timeout period

3. Transmit your next command packet

Motor commands are strictly one-way; the TReX Jr will not send data back in response to these. All other

commands result in two-way data transfer.

An additional consequence of the RS-232 circuit is everything you send to the TReX Jr using the RS-232

connection will be echoed back to you as you’re transmitting it (RS-232 transmit and receive lines are physically

tied together by a resistor). If you are connecting your TReX Jr to a COM port, you can either disable your receiver

while you transmit or you can simply discard the echoed bytes you know to expect. The command packet echo will

always arrive before any data the TReX Jr sends to you. Note that you will receive no echo if you use the logic level

(TTL) serial lines to communicate with the TReX Jr.

5.a. Serial Communication Settings

Unlike our other Pololu serial controllers, the TReX Jr does not support automatic baud detection. Instead, you can

configure the TReX Jr to run at one of 11 common baud rates ranging from 1200 to 115,200 bits per second. The

TReX Jr ships with a default baud rate of 19,200 bps.

The TReX Jr allows you to optionally select one of three different kinds of error detection to help you ensure the

integrity of your communications: even parity, odd parity, or 7-bit cyclic redundancy checking (CRC-7). Cyclic

redundancy checking is explained in more detail in Section 5.e. The default setting is no error detection.

Lastly, you can specify whether serial communication with the TReX Jr will use one or two stop bits. The default

setting is one stop bit.

These serial settings are controlled by a single “serial-settings” configuration parameter (see Section 5.d for more

information).

5.b. Serial Command Protocols

The TReX Jr serial command protocol is fairly straightforward. Communication is achieved by sending command

packets consisting of a single command byte followed by any data bytes that command requires. Command bytes

always have their most significant bits set (i.e. range from 128 – 255) while data bytes always have their most

5. The Serial Interface Page 16 of 23

Page 17

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

significant bits cleared (i.e. range from 0 – 127). This means that each data byte can only transmit seven bits of

information.

One significant improvement over other Pololu serial controllers is the TReX Jr’s ability to gracefully handle serial

errors (such as bad commands, incorrectly formatted commands, or even hardware-level serial errors). The TReX Jr

has a configuration parameter that, if set, will shut down the motors if a serial error occurs, but the TReX itself will

continue running and accepting commands. This is a safety precaution taken in case the serial error occurred during

a command that was intended to stop the motors.

The TReX Jr will respond to two sub-protocols:

Compact Protocol:

This is the simpler and more compact of the two protocols; it is the protocol you should use if your TReX Jr is the

only device connected to your serial line. The TReX Jr Compact protocol command packet is simply:

command byte (with MSB set), any necessary data bytes

For example, if we want to set the auxiliary motor (command 0xF0) to full speed (127) using the Compact protocol,

we would send the following byte sequence:

in hex: 0xF0, 0x7F

in decimal: 240, 127

Pololu Protocol:

This protocol is compatible with the serial protocol used by our other serial motor and servo controllers. As such,

you can daisy-chain a TReX Jr on a single serial line along with our other serial controllers (including additional

TReX Jrs) and, using this protocol, send commands specifically to the desired TReX Jr without confusing the other

devices on the line.

The Pololu protocol is to transmit 128 (0x80 in hex) as the first (command) byte, followed by a device-number data

byte. The default device number for the TReX Jr is 7, but this is a configuration parameter you can change. Any

Pololu device on the line whose device number matches the specified device number will accept the command that

follows; all other Pololu devices will ignore the command. The remaining bytes in the command packet are the same

as the Compact protocol command packet you would send, with one key difference: the Compact protocol command

byte is now a data byte for the command 128 and hence must have its most significant bit cleared. Therefore, the

command packet is:

0x80, device # byte, command byte with MSB cleared, any necessary data bytes

For example, if we want to set the auxiliary motor (command 0xF0) to full speed (127) for a TReX with device

number 7, we would send the following byte sequence:

in hex: 0x80, 0x07, 0x70, 0x7F

in decimal: 128, 7, 112, 127

Note that 0x70 is the command 0xF0 with its most significant bit cleared.

The TReX Jr will respond to both the Pololu and Compact protocols on the fly; you do not need to use a jumper or

configuration parameter to identify which protocol you will be using.

5. The Serial Interface Page 17 of 23

Page 18

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

5.c. Serial Command List and Documentation

The TReX Jr command documentation [http://www.pololu.com/file/download/TReXJr_Commands_v1.0.pdf?file_id=0J12]

(100k pdf) contains a list of all the serial commands the TReX Jr recognizes along with detailed documentation.

5.d. Configuration Parameter List and Documentation

The TReX Jr parameter documentation [http://www.pololu.com/file/download/TReXJr_Parameters_v1.0.pdf?file_id=0J13]

(124k pdf) contains a list of all the TReX Jr’s configuration parameters along with detailed documentation.

5.e. Cyclic Redundancy Check (CRC) Error Detection

For certain applications, verifying the integrity of the data you’re sending and receiving can be very important.

Because of this, the TReX Jr has optional 7-bit cyclic redundancy checking, which is similar to a standard checksum

but somewhat more robust as it can detect duplicated and out-of-order bytes.

When bit 6 of the serial settings parameter is cleared and bit 5 is set, cyclic redundancy checking is enabled. In CRC

mode, the TReX Jr expects an extra byte to be tacked onto the end of every command packet. The lower seven bits

of this byte must be the 7-bit CRC for that packet, or else the TReX Jr will set its CRC Error bit in the UART Error

Byte and ignore the command. The TReX Jr will also transmit an additional byte every time it returns data; the

lower seven bits of this byte will be the 7-bit CRC for the packet of data the TReX Jr is sending you.

A detailed account of how cyclic redundancy checking works is beyond the scope of this document, but you can find

a wealth of information using Wikipedia [http://en.wikipedia.org/wiki/Cyclic_redundancy_check]. The quick version is that

a CRC computation is basically a carryless long division of a CRC “polynomial” into your message, where all you

care about is the remainder. The TReX Jr uses CRC-7, which means it uses an 8-bit polynomial (whose MSB must

always be 1) and, as a result, produces a 7-bit remainder. This remainder is the lower 7 bits of the CRC byte you

tack onto the end of your command packets.

The CRC-7 algorithm is as follows:

1. Express your 8-bit CRC-7 polynomial (TReX Jr default is 0x89) and message in binary.

2. Add 7 zeroes to the end of your message.

3. Write your CRC-7 polynomial underneath the message so that the MSB of your polynomial is directly

below the MSB of your message.

4. If the MSB of your CRC-7 is aligned under a 1, XOR the CRC-7 with the message to get a new message; if

the MSB of your CRC-7 is aligned under a 0, do nothing.

5. Shift your CRC-7 right one bit. If all 8 bits of your CRC-7 polynomial still line up underneath message bits,

go back to step 4.

6. What’s left of your message is now your CRC-7 result (transmit these seven bits as your CRC byte when

talking to the TReX Jr with CRC enabled).

If you’ve never encountered CRCs before, this probably sounds a lot more complicated than it really is. Allow me to

demonstrate a sample CRC-7 calculation so you can see how this actually works. Our CRC-7 polynomial will be

0x89 (the default TReX CRC-7 polynomial) and our message will be a two-byte sequence: 0x86, 0x1F (the

command packet to get raw channel input values for all five channels).

Steps 1 & 2 (write as binary, add 7 zeroes to the end of the message):

CRC-7 Polynomial = [1 0 0 0 1 0 0 1]

message = [1 0 0 0 0 1 1 0] [0 0 0 1 1 1 1 1] 0 0 0 0 0 0 0

Steps 3, 4, & 5:

_______________________________________________

5. The Serial Interface Page 18 of 23

Page 19

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

1 0 0 0 1 0 0 1 ) 1 0 0 0 0 1 1 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0 0

XOR 1 0 0 0 1 0 0 1 | | | | | | | | | | | | | | |

--------------- | | | | | | | | | | | | | | |

0 0 0 1 1 1 1 0 0 0 1 | | | | | | | | | | |

shift ----> 1 0 0 0 1 0 0 1 | | | | | | | | | | |

_______________ | | | | | | | | | | |

1 1 1 1 0 0 0 1 | | | | | | | | | |

1 0 0 0 1 0 0 1 | | | | | | | | | |

_______________ | | | | | | | | | |

1 1 1 1 0 0 0 1 | | | | | | | | |

1 0 0 0 1 0 0 1 | | | | | | | | |

_______________ | | | | | | | | |

1 1 1 1 0 0 0 1 | | | | | | | |

1 0 0 0 1 0 0 1 | | | | | | | |

_______________ | | | | | | | |

1 1 1 1 0 0 0 1 | | | | | | |

1 0 0 0 1 0 0 1 | | | | | | |

_______________ | | | | | | |

1 1 1 1 0 0 0 0 | | | | | |

1 0 0 0 1 0 0 1 | | | | | |

_______________ | | | | | |

1 1 1 1 0 0 1 0 | | | | |

1 0 0 0 1 0 0 1 | | | | |

_______________ | | | | |

1 1 1 1 0 1 1 0 | | | |

1 0 0 0 1 0 0 1 | | | |

_______________ | | | |

1 1 1 1 1 1 1 0 | | |

1 0 0 0 1 0 0 1 | | |

_______________ | | |

1 1 1 0 1 1 1 0 | |

1 0 0 0 1 0 0 1 | |

_______________ | |

1 1 0 0 1 1 1 0 |

1 0 0 0 1 0 0 1 |

_______________ |

1 0 0 0 1 1 1 0

1 0 0 0 1 0 0 1

_______________

0 0 0 0 1 1 1 = 0x07

So the full command packet we would send to retrieve the raw channel inputs for all five channels with CRC

enabled is: 0x86, 0x1F, 0x07

There are some tricks you can use in your programs to make the CRC calculation much more efficient from a speed

perspective. You can find an example of this Section 5.f.

5.f. CRC-Generation Algorithm in C

The CRC algorithm is typically defined as a bit-wise operation, however it is possible to rewrite the algorithm to

work at the byte level if we do some calculations ahead of time. We can store CRC computations for all 256

possible byte values when our program first runs, and then retrieve those values as needed when generating a CRC

for a given message. This requires we set aside 256 bytes of RAM/EEPROM/flash, but it makes the CRC

calculation for an arbitrary message much faster than if we work through the message bit by bit.

The following sample code stores a CRC lookup table in RAM using the function GenerateCRCTable(), which

only needs to be called once (probably somewhere during the initialization phase of your program). You could

easily change this function to store the lookup table to EEPROM or flash. To process a message, initialize your CRC

variable to zero and use the CRCAdd() function to “add” each message byte to your CRC, as is done in the

getCRC() function.

unsigned char CRCPoly = 0x89; // the value of our CRC-7 polynomial

unsigned char CRCTable[256];

void GenerateCRCTable()

{

int i, j;

5. The Serial Interface Page 19 of 23

Page 20

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

// generate a table value for all 256 possible byte values

for (i = 0; i < 256; i++)

{

CRCTable[i] = (i & 0x80) ? i ^ CRCPoly : i;

for (j = 1; j < 8; j++)

{

CRCTable[i] <<= 1;

if (CRCTable[i] & 0x80)

}

}

}

// adds a message byte to the current CRC-7 to get a the new CRC-7

unsigned char CRCAdd(unsigned char CRC, unsigned char message_byte)

{

return CRCTable[(CRC << 1) ^ message_byte];

}

// returns the CRC-7 for a message of "length" bytes

unsigned char getCRC(unsigned char message[], int length)

{

int i;

unsigned char CRC = 0;

for (i = 0; i < length; i++)

CRC = CRCAdd(CRC, message[i]);

return CRC;

}

CRCTable[i] ^= CRCPoly;

5.g. Resetting the Serial Communication Parameters

It is possible to reset the TReX Jr to its default serial settings using the following jumper sequence:

1. Power off your TReX Jr.

2. Attach the channel-mix jumper.

3. Attach the learning-mode/firmware-update jumper (i.e. short SO (Serial Out ) pin to G (Ground)).

4. Remove the mode-selection jumper (i.e. set the TReX Jr for Serial Mode).

5. Restore power to your TReX Jr. You should see the red and green status LEDs alternating around once per

second.

6. Remove the channel-mix jumper. You should now see the red and green status LEDs alternating around

four times per second.

7. Power off your TReX Jr.

When you next power up your TReX Jr, its serial settings will be back to their default values: 19.2 kbps baud, 1

stop bit, no error detection

5. The Serial Interface Page 20 of 23

Page 21

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

6. Updating the TReX Jr's Firmware

Current Firmware Versions

• Our most recently released firmware update for the TReX Jr motor controller is

trexjrv1_2.trx [http://www.pololu.com/file/download/trexjrv1_2.trx?file_id=0J238] (161k trx) (version 1.2). This version

fixes a bug that prevented baud rates of 38.4 and 28.8 kbps from working in versions 1.0 and 1.1. All other

supported baud rates work properly in firmware versions 1.0 and 1.1, so if your TReX Jr does not have version

1.2 firmware and you do not need communicate serially at 38,400 or 28,800 bps, you do not need to update

your firmware to 1.2. Version 1.2 also adds a new configuration parameter that lets you optionally delay the

TReX Jr’s serial responses by 1ms so that slower microcontrollers, such as the Basic Stamp, won’t miss the

first byte of the TReX Jr’s response. Previously, if you wanted such a delay, you needed to use firmware

version 1.1; if you didn’t want this delay, you needed to use firmware version 1.0. Please note that you should

upgrade your TReX Configurator [http://www.pololu.com/file/download/

TReXConfiguratorInstaller_090923.zip?file_id=0J236] (294k zip) to version 090923 or later prior to updating your

firmware to version 1.2. If you have an older version of the TReX Configurator installed, you should manually

uninstall it first using the Add/Remove Programs control panel.

• The firmware that comes preloaded on every TReX Jr motor controller is

trexjrv1_0.trx [http://www.pololu.com/file/download/trexjrv1_0.trx?file_id=0J91] (137k trx).

• We have released an alternate firmware version: trexjrv1_1.trx [http://www.pololu.com/file/download/

trexjrv1_1.trx?file_id=0J92] (138k trx). Please note that this alternate version is not considered an upgrade over

the original version 1.0. Rather, version 1.1 exists to improve serial communication with controllers that require

a delay between transmitting and receiving, such as the Basic Stamp. Firmware version 1.1 inserts a 1 ms delay

between the last byte of a received command packet and the first byte of the TReX Jr’s transmitted response,

which should give your controller enough time to switch from serial-out mode to serial-in mode. Without this

delay, some slower controllers will miss the first byte of the TReX Jr’s response, especially if you are

communicating at higher baud rates. If your controller can simultaneously transmit and receive, or if it does not

take much time to switch between serial-out and serial-in mode, you should use firmware version 1.0 as this

will increase the rate at which you can communicate with and control your TReX Jr.

Updating Firmware

To update the firmware, you need to put your TReX Jr into firmware-update mode and then send the new binary

firmware file, which you can do using the TReX Configurator program [http://www.pololu.com/file/download/

TReXConfiguratorInstaller_090923.zip?file_id=0J236] (294k zip) or a terminal program. We recommend you read through

the following procedure before performing the update.

1. Turn off power to your TReX Jr.

2. Put the TReX Jr into Serial Mode by removing the Mode jumper.

3. Ground the TTL Serial Out (SO) pin by attaching the Learning-Mode/Firmware-Upgrade jumper.

4. Attach the Mix jumper.

5. Restore power to the TReX Jr; the status LEDs should alternately flash red and green.

6. Remove the Mix jumper; the status LEDs should alternate faster.

7. Remove the Learning-Mode/Firmware-Upgrade jumper; the green status LED should now briefly flash

every second.

8. Reconnect your TReX Jr’s serial cable to establish a connection between your TReX Jr and your computer.

6. Updating the TReX Jr's Firmware Page 21 of 23

Page 22

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

Option 1: using the TReX Configurator program Run the TReX Configurator program [http://www.pololu.com/file/download/

TReXConfiguratorInstaller_090923.zip?file_id=0J236] (294k zip) and click on the “Upgrade Firmware” button, which is

circled in the screen capture below.

This will bring up the Firmware Upgrade dialog, as shown below.

Select the COM port your TReX Jr is connected to and enter the firmware update file’s path. Click the Program

button to initiate the firmware update. If all goes correctly, you will be prompted to confirm that you want to erase

6. Updating the TReX Jr's Firmware Page 22 of 23

Page 23

Pololu TReX Jr User's Guide © 2001–2009 Pololu Corporation

your current firmware and you will then see a progress bar showing you the status of the upload. If no errors occur,

you will see a success message when the update is finished.

Option 2: using a terminal program

If you would rather use a terminal program, you will need one that is capable of transferring binary files, such as

Tera Term Pro. Connect to the serial port that your TReX Jr is on at 115.2 kbsp with 8-bit characters, no parity, and

one stop bit. No flow control is necessary. If you have completed the 8 steps above (so that the green status LED is

flashing once per second), you are ready to upload the new firmware file. First, transmit the character ’s’. This will

erase the current firmware. Next, transfer the firmware update file (.trx) to the TReX Jr as a binary file. If

everything works correctly you should see a ’*’ appear and the TReX Jr’s red status LED will flash five times as it

starts up before staying solidly on.

6. Updating the TReX Jr's Firmware Page 23 of 23

Loading...

Loading...