Page 1

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

Pololu Orangutan SVP User's

Guide

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.a. Supported Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Contacting Pololu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Module Pinout and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.a. Installing Windows Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.b. Using the Demo Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.c. Programming your Orangutan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.d. Assembling the kit version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6. AVR Pin Assignment Table Sorted by Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. AVR Pin Assignment Table Sorted by Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8. Using the USB Communication Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9. Using the TTL Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10. Motor Driver Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11. USB Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12. Upgrading Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

13. Related Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

http://www.pololu.com/docs/0J39/all Page 1 of 37

Page 2

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

1. Overview

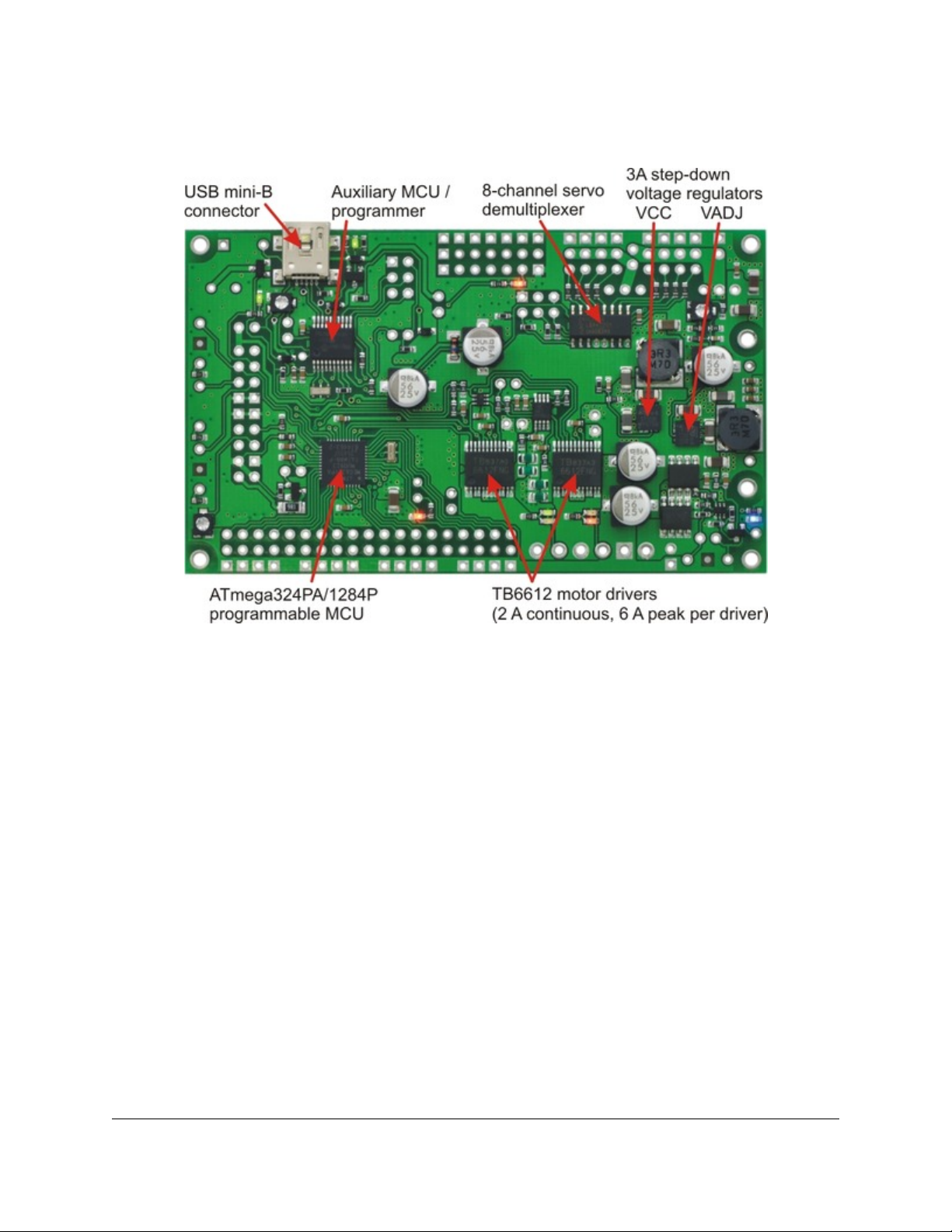

The Orangutan SVP robot controller

[http://www.pololu.com/catalog/product/1325] is a complete

control solution for small and medium-sized robots

running at 6 – 13.5 V. The module is designed around

the powerful Atmel ATmega324PA AVR

microcontroller (32 KB flash, 2 KB RAM, and 1 KB

EEPROM) or ATmega1284P (128 KB flash, 16 KB

RAM, and 4 KB EEPROM) running at 20 MHz and

features a full complement of peripheral hardware to

support robotics applications: dual motor drivers

capable of delivering 2 A continuous (6 peak) per

channel, a demultiplexer for easy control of up to eight

servos with a single hardware PWM, a removable 16×2 character LCD with backlight, a user trimmer

potentiometer, a buzzer for simple sounds and music, three user pushbuttons, and two user LEDs. The board also

provides 21 free I/O lines, of which 12 can be used as analog inputs, and two switching buck (step-down) voltage

regulators—one for the 5V bus and one adjustable from 2.5 V to 85% of VIN—each capable of supplying 3 A,

which means there’s plenty of room and power for adding sensors, servos, and other peripherals.

In addition to the user-programmable AVR microcontroller, the Orangutan SVP features an auxiliary

PIC18F14K50 MCU that supports the main processor and serves as an integrated AVR ISP programmer, which

means that no external programmer is required to use the Orangutan SVP. This auxiliary processor provides a

USB connection that allows direct communication with a PC, and its firmware lets it perform several useful

task in parallel with the main microcontroller. For example, the auxiliary processor can read two quadrature

encoders without burdening the main MCU, or those same four inputs could be used as additional analog inputs.

The ATmega324 or ATmega1284 can read data from the auxiliary MCU over SPI. A USB A to mini-B cable

[http://www.pololu.com/catalog/product/1129] is included with the Orangutan SVP.

The Orangutan SVP is compatible with freely available development software for Atmel’s AVR microcontrollers,

including Atmel Studio [http://www.atmel.com/microsite/atmel_studio6/] and the WinAVR [http://winavr.sourceforge.net/]

GCC C/C++ compiler. We provide an extensive set of software libraries [http://www.pololu.com/docs/0J20] that make

it easy to interface with all of the integrated hardware, including the auxiliary microcontroller. Using these

libraries, it takes just a few simple lines of code to write to the LCD, read button presses, drive motors, and

control servos. These libraries come with a number of sample programs that demonstrate how to use the various

components on the Orangutan SVP.

Specifications & On-Board Hardware

• Overall unit dimensions: 3.70" × 2.20"

• Input voltage: 6 – 13.5 V

• Programmable 20 MHz Atmel ATmega324PA AVR microcontroller with 32 KB flash, 2 KB SRAM, and

1 KB EEPROM (SVP-324 version)

• Programmable 20 MHz Atmel ATmega1284P AVR microcontroller with 128 KB flash, 16 KB RAM, and

4 KB EEPROM (SVP-1284 version)

• Built-in USB AVR ISP programmer (USB A to mini-B cable [http://www.pololu.com/catalog/product/1129]

included)

• 2 bidirectional motor ports (2 A continuous per channel, 6 A maximum per channel)

• 8-output demultiplexer tied to one of the AVR’s hardware PWMs for easy control of up to 8 servos

• 21 free I/O lines

1. Overview Page 2 of 37

Page 3

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

◦ 17 free I/O lines on the main MCU, of which 8 can be analog inputs

◦ 4 input lines on the auxiliary processor, which can be either 4 analog inputs or dual quadrature

encoder inputs

◦ 2 hardware UARTs

• Removable 16-character × 2-line LCD with backlight

• Primary 5V switching regulator capable of supplying 3 A

• Secondary adjustable (2.5 V – 85% of VIN) buck (step-down) voltage regulator capable of supplying 3 A

• Buzzer tied to one of the AVR’s hardware PWMs

• 3 user pushbutton switches

• 2 user LEDs

• Power (push-on/push-off) and reset pushbutton switches

• Power circuit makes it easy to add extra power buttons and provides a self-shutdown option

• Auxiliary processor (connected via SPI) provides:

◦ Battery voltage reading

◦ User trimmer potentiometer reading

◦ Integrated USB connection

◦ In-System-Programming of the main processor

◦ Ability to read two quadrature encoders

Orangutan SVP kit.

Orangutan SVP fully assembled.

For a Spanish version of this document, please see Orangutan SVP Guia de Usuario

[http://www.pololu.com/file/download/OrangutanSVPGuiaDeUsuario.pdf?file_id=0J328] (2MB pdf) (provided

by customer Jaume B.).

1.a. Supported Operating Systems

The Orangutan SVP’s USB connection works under Microsoft Windows XP, Windows Vista, Windows 7,

Windows 8, Linux, and Mac OS X 10.7 (Lion) or later. The Orangutan SVP’s USB connection can be used to

program the AVR, communicate directly with the AVR from a computer, or communicate with TTL-level serial

devices from a computer.

1. Overview Page 3 of 37

Page 4

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

In Linux, the three virtual COM ports created by the SVP should appear as devices with names like /dev/ttyACM0,

/dev/ttyACM1, and /dev/ttyACM2 (the numbers depends on how many other ACM devices you have plugged in)

and you can use any terminal program (such as kermit) to send and receive bytes on those ports.

In Mac OS X 10.7 (Lion) or later, the three virtual COM ports created by the SVP should appear as devices with

names like /dev/tty.usbmodem00022381, /dev/tty.usbmodem00022383, and /dev/tty.usbmodem00022385 and

you can use any terminal program (such as screen) to send and receive bytes on those ports. The lowest number

found in the device names is the Orangutan SVP’s serial number.

Mac OS X compatibility: we have confirmed that the Orangutan SVP’s USB connection works

on Mac OS X 10.7 (Lion) and we can assist with advanced technical issues, but most of our tech

support staff does not use Macs, so basic support for Mac OS X is limited.

Note: You may not need to use the Orangutan SVP’s USB connection. If you have an AVR

ISP programmer, then you can program the AVR on the Orangutan SVP by connecting your

programmer to the 6-pin AVR ISP header located near the SVP’s USB connector. In that case,

the operating system of your computer does not matter as long as it is compatible with your

programmer.

1. Overview Page 4 of 37

Page 5

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

2. Contacting Pololu

You can check the Orangutan SVP-324 robot controller page [http://www.pololu.com/catalog/product/1325] or

Orangutan SVP-1284 robot controller page [http://www.pololu.com/catalog/product/1327] for additional information,

including pictures, example code, and application notes. You can also find libraries for interacting with the onboard hardware and an assortment of sample code in the Pololu AVR Library [http://www.pololu.com/docs/0J20].

We would be delighted to hear from you about any of your projects and about your experience with the

Orangutan Robot controllers. You can contact us [http://www.pololu.com/contact] directly or post on our forum

[http://forum.pololu.com/]. Tell us what we did well, what we could improve, what you would like to see in the future,

or anything else you would like to say!

2. Contacting Pololu Page 5 of 37

Page 6

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

3. Schematic Diagrams

Schematic diagrams of the Orangutan SVP are available here: Orangutan SVP schematic diagram

[http://www.pololu.com/file/download/org06a02_schematic.pdf?file_id=0J265] (99k pdf)

3. Schematic Diagrams Page 6 of 37

Page 7

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

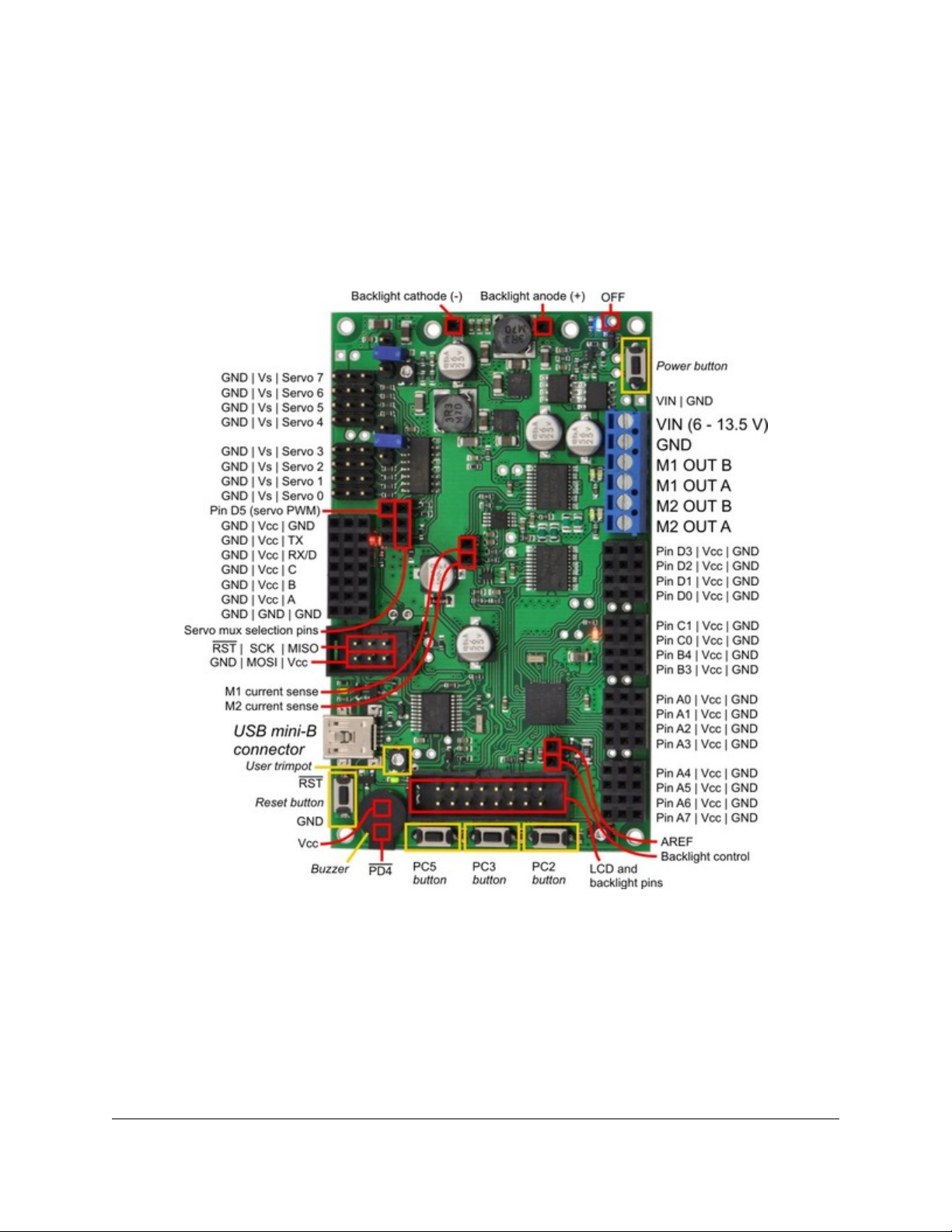

4. Module Pinout and Components

The Orangutan SVP contains a programmable AVR ATmega324PA or ATmega1284P microcontroller connected

to two motor drivers for direct control of two DC motors, a 16×2 character LCD, a buzzer, three user pushbuttons,

two user LEDs, and a demultiplexer for servo control. The AVR is also connected to an auxiliary processor (a

PIC18F14K50) that provides access to the battery voltage, a 10 kilo-ohm user trimmer potentiometer, and four

additional input lines. The auxiliary processor also serves as a programmer for the main processor, meaning that

an external programmer is not required, but you can use one if you want to. The auxiliary processor also allows

for USB communication between the AVR and a personal computer, and acts as a USB-to-serial converter.

Orangutan SVP fully assembled PCB with pins labeled.

These and the rest of the main features of the module are labeled in the picture above and in more detail

in the Orangutan SVP reference diagram [http://www.pololu.com/file/download/

orangutan_svp_reference_diagram.pdf?file_id=0J244] (82k pdf). Most of the connection points are also indicated on the

silkscreen on the back side of the PCB, as shown below. The overall unit dimensions are 3.7" × 2.2", and four

0.086" mounting holes, suitable for #2 screws, are located 0.1" from the corners of the board.

4. Module Pinout and Components Page 7 of 37

Page 8

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

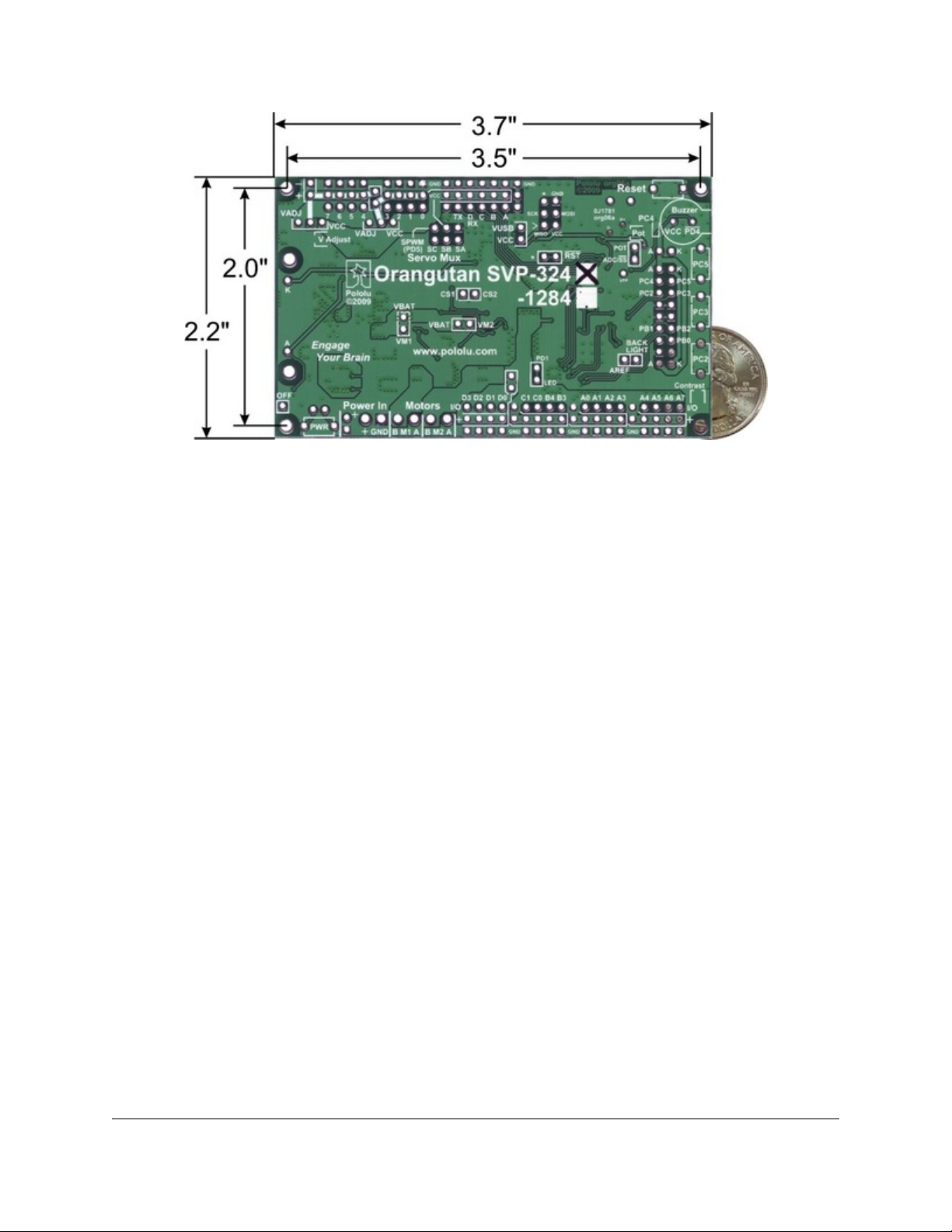

Orangutan SVP-324 with dimensions.

Power & Motor Connections

Power for the Orangutan SVP should be connected to the positive (+) and ground (GND) terminals near the words

“Power In” on the board. The input voltage (VIN) of the power supply should be 6 – 13.5 V, from which the onboard regulator generates the 5 V supply (VCC) that is used to power the logic.

The Orangutan SVP has one TB6612FNG motor driver for each motor output. Each motor driver can deliver a

continuous 2 A, and can briefly deliver up to 6 A. If you are not taking extra steps to keep the motor driver cool,

such as using a heat sink, exceeding this continuous current rating for too long will cause the motor driver to heat

up and trigger its built-in thermal shutdown.

By default, the motor drivers are powered from VBAT, which refers to the input voltage (VIN) after passing

through reverse protection and the power switch circuit. However, you can disconnect VBAT from the motor

drivers by cutting the labeled traces on the bottom of the board (VBAT-VM1 and VBAT-VM2). This allows you

to connect some other power supply to the motor drivers, such as VADJ (see below). The motor drivers have an

operating range of 4.5 – 13.5 V, so your power supply should be in that range, and should be capable of supplying

all the current that your motors might draw.

USB Power

When connected to a computer, the USB connection provides a 5 V power supply. If an external power supply is

present, the unit will run off of the external supply and not draw any power from USB. If only the USB power is

present, then by default the auxiliary processor will be powered from USB, but the AVR and the VCC power pins

on the board will not be powered. An option is available for powering the entire board from USB. See Section 11

for more information.

Motors

The motor drivers are controlled by two of the AVR’s hardware PWM outputs from eight-bit Timer2 for speed

control, along with two digital outputs for direction control. This lets you achieve variable motor speeds using

hardware PWMs rather than processor-intensive software PWMs on the motor control lines. You can control the

motors using the functions in the OrangutanMotors [http://www.pololu.com/docs/0J18/7] section of the Pololu AVR

C/C++ Library.

4. Module Pinout and Components Page 8 of 37

Page 9

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

For each motor, the Orangutan SVP has a current-sensing circuit that produces an output voltage proportional to

the current the motors are using (850 mV/A). The respective outputs of these circuits are labeled CS1 and CS2,

and they are accessible near the center of the board.

User I/O & Power Outputs

Sixteen user I/O lines can be accessed via the four 4×3 0.100" female headers along the lower edger of the board,

as shown below. Each I/O line has associated power and ground connections for easy connections to sensors: the

exterior (bottom) pin is ground, the middle pin is power, and the interior (top) pin is signal and connects directly

to an AVR I/O line.

For each four-pin bank of I/O lines, you can configure which power voltage is supplied to the power (middle)

pins. By default, the power pins are connected to VCC (5 V). You can cut a trace on the bottom of the board

to disconnect them from VCC. This will leave the power pins connected to one through-hole, which can be

connected to a different power source, such as VADJ, which is available elsewhere on the board.

The total current available on the VCC (5 V) line is 3 A, meaning you can power servos and other high-power

peripherals directly from your regulated voltage.

LCD

The Orangutan SVP is supplied with a removable 16×2 character LCD with backlight that uses the common

HD44780 parallel interface [http://www.pololu.com/file/download/DMC50448N-AAE-AD.pdf?file_id=0J71] (109k pdf). A

different LCD can be connected with an appropriate cable. The AVR has four I/O lines connected to LCD data

lines DB4 – DB7 (i.e. is configured to use the LCD in 4-bit mode) and three I/O lines connected to the three LCD

control lines RS, R/W, and E. Please note that the LCD data lines are also shared by the user pushbuttons and the

green user LED. You can print to the LCD using the functions in the OrangutanLCD [http://www.pololu.com/docs/

0J18/5] section of the Pololu AVR C/C++ Library.

The LCD’s backlight can be turned off by driving the BACKLIGHT line low. Adjustable dimming of the LCD

can be achieved by connecting the line to a free PWM output.

The AVR’s AREF pin is available next to the backlight pin.

Pushbuttons

The Orangutan SVP has five total pushbuttons: a power on/off button located on the right side of the bottom

edge of the board, a reset button located on the left side of the top edge of the board, and three user pushbuttons

located along the left edge of the board. Please note that the power button disconnects the external power supply

from the entire board, while the reset button connects directly to the AVR’s RESET pin and does not disconnect

the power supply.

The user pushbuttons, from top to bottom, are on pins PC5, PC3, and PC2. Pressing one of these buttons pulls

the associated I/O pin to ground through a resistor. You can detect button pushes using the functions in the

OrangutanPushbuttons [http://www.pololu.com/docs/0J18/9] section of the Pololu AVR C/C++ Library. The library

takes care of configuring the pins as inputs, enabling the AVR’s internal pull-up resistors, and debouncing

(accounting for the fact that pushbuttons physically bounce when pressed).

Buzzer

The Orangutan SVP comes with a buzzer controlled by pin PD4. If you alternate between driving the buzzer pin

high and low at a given frequency, the buzzer will produce sound at that frequency. You can use the functions in

the OrangutanBuzzer [http://www.pololu.com/docs/0J18/3] section of the Pololu AVR C/C++ Library to play notes in

the background (using hardware PWM) while the rest of your processor performs other tasks.

4. Module Pinout and Components Page 9 of 37

Page 10

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

Trimpot

The Orangutan SVP comes with a 10 kilo-ohm user trimmer potentiometer, located between the USB connector

and the LCD connector. The trimpot is connected to the auxiliary processor, which measures its output voltage

and reports it to the AVR.

You can disconnect the trimpot from the auxiliary processor by cutting the labeled trace between POT and

ADC/SS on the bottom side of the board. This gives you two options for that line: you can use it as a generalpurpose analog input by connecting some other output to it, or you can connect it to one of your AVR’s free I/O

lines and use it as the SPI slave-select line for the auxiliary processor, allowing you to communicate with some

other SPI peripheral.

Programming Connector

The Orangutan SVP has a 6-pin programming connector on the upper left side. This gives you the option of

using an AVR ISP in-system programmer from Atmel or a compatible programmer, such as our Pololu USB AVR

Programmer [http://www.pololu.com/catalog/product/1300] to program the AVR. This is not necessary, though, because

the Orangutan SVP’s auxiliary processor can serve as an AVR ISP programmer for the AVR.

By default, pin 5 of the Programming connector, which is labeled by an asterisk (*), is connected to the AVR’s

RESET line, which is necessary for ISP programming by an external device). However, you can disconnect those

two pins by cutting a labeled trace on the bottom of the circuit board. This gives you the option of using that line

for some other signal.

Auxiliary I/O & Power Outputs

The Orangutan SVP has five auxiliary I/O lines that are connected to the auxiliary processor. Each I/O line has

associated power and ground connections for easy connections to sensors: the exterior (top) pin is ground, the

middle pin is power (VCC), and the interior (bottom) pin is signal and connects directly to an auxiliary processor

I/O line. The TX line is the serial transmit line. It transmits TTL-level serial bytes received from the computer

on the “Pololu Orangutan SVP TTL Serial Port”. The lines A, B, C, and D/RX can be configured to do different

things. They can function as three analog inputs plus a serial receive line, as four analog inputs, or as the inputs

for two quadrature encoders. See the OrangutanSVP [http://www.pololu.com/docs/0J18/13] section of the Pololu AVR

C/C++ Library for more information.

Servo Demultiplexer

The hardware in the upper-right corner of the Orangutan SVP allows you to control up to 8 servos without

sacrificing a large number of I/O lines or processor cycles. You can control servos using the functions in the

OrangutanServos [http://www.pololu.com/docs/0J18/11] section of the Pololu USB AVR C/C++ library.

The input signal of the demultiplexer is connected to pin PD5 on the AVR. If you are not using PD5 to control

servos, you can use it as a general-purpose digital I/O line or PWM output.

The three output-selection pins of the multiplexer (SA, SB, and SC) are available in the header near the

multiplexer so they can be wired to free I/O lines on the AVR, allowing you to switch between servos. The

output-selection pins have pull-down resistors, so if you have four servos or fewer you can leave some of them

disconnected.

The eight output pins of the multiplexer are available in two 4×3 headers. These lines have current-limiting

resistors on them. Each multiplexer output line has associated power and ground connections for easy connections

to the servos: the exterior (top) pin is ground, the middle pin is power. For each bank of servos, you can configure

which power supply is connected to the power pins, using the provided headers and jumpers. You can power

the servos from VCC, VADJ (see below), or a separate power supply. The fully assembled version ships with a

4. Module Pinout and Components Page 10 of 37

Page 11

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

jumper attached to just the middle pin of each of the two servo power selection banks. In this default orientation,

the jumper supplies no power to the servo power rail.

Orangutan SVP with key integrated hardware labeled.

Adjustable Voltage (VADJ)

In addition to the 5 V regulator that supplies VCC, the Orangutan SVP comes with an adjustable voltage regulator.

Both regulators can supply a current of 3 A. The adjustable voltage regulator draws current from the external

power supply, and produces an output voltage called VADJ. The trimmer potentiometer in the upper right corner

of the board determines VADJ. If you turn the trimpot all the way counter-clockwise, VADJ goes down to about

2.5 V. If you turn it all the way clockwise, VADJ rises to 85% of VIN. The adjustable voltage regulator will be off

when the main power is switched off.

In general, it is advantageous to power servos and other high-power devices from VADJ (instead of VCC),

because if the peripherals draw too much current for the power supply to handle the AVR will not be affected.

4. Module Pinout and Components Page 11 of 37

Page 12

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

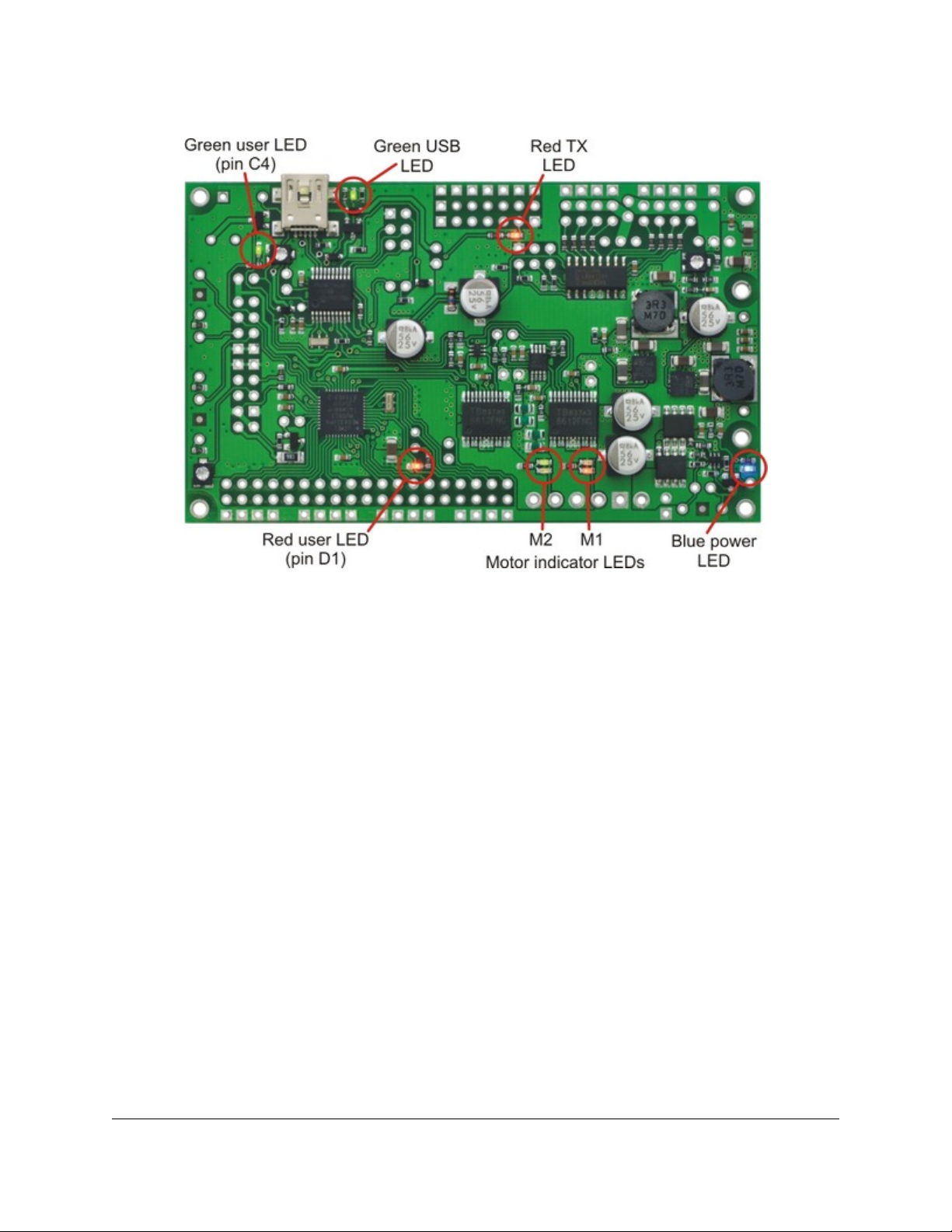

LEDs

Orangutan SVP LEDs.

The Orangutan SVP comes with 9 LEDs:

• A blue power LED is located next to the power button.

• There are four motor indicator LEDs located near the motor outputs. A green LED lit indicates that the

corresponding motor is being driven “forward” (the voltage on output B is higher than the voltage on A).

A red LED indicates that the corresponding motor is being driven in “reverse” (the voltage on output B is

lower than the voltage on output A).

• A red user LED is located near the AVR I/O banks. The LED is connected to the user I/O line PD1. It will

light if you set PD1 as a low output. Since PD1 is the serial transmit line for UART0 (TXD0), the LED will

flicker whenever serial data is being transmitted from the AVR. The LED can be disconnected from PD1 by

cutting a labeled trace (PD1-LED) on the bottom of the board.

• A green user LED is located between the trimpot and the buzzer. It will light if you set PC4 as a high

output. Note that PC4 is also used as an LCD data line, so you will see the green LED flicker when you

update the LCD.

• Another green LED is located near the USB connector. This LED is controlled by the auxiliary processor

and indicates the status of the USB connection. When the USB is disconnected, or the device is in the USB

Suspend state (because the computer went to sleep), the green LED is off. When you connect the device

to a computer via USB, the green LED will start blinking slowly. The blinking continues until it receives a

particular message from the computer indicating that the drivers are installed correctly. After the programmer

gets this message, the green LED will be on, but it will flicker briefly when there is USB activity.

• Another red LED is located near the header for the auxiliary processor’s TX line. This LED is tied to

the TX line, so it will flicker whenever the auxiliary processor is transmitting TTL-level serial bytes from

the computer. This LED will also blink when the auxiliary processor powers up to indicate bad startup

conditions. Two blinks indicates that a brown-out reset was triggered: the processor’s VDD dropped below

4. Module Pinout and Components Page 12 of 37

Page 13

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

3.0 V. If this happens to you, check your power connections and battery voltage, and make sure you are not

drawing too much power from the board.

4. Module Pinout and Components Page 13 of 37

Page 14

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

5. Getting Started

5.a. Installing Windows Drivers

If you use Windows XP, you will need to have either Service Pack 3 [http://www.microsoft.com/downloads/

details.aspx?FamilyId=68C48DAD-BC34-40BE-8D85-6BB4F56F5110] or Hotfix KB918365 installed before

installing the drivers for the Orangutan SVP. Some users who installed the hotfix have reported

problems using the programmer which were solved by upgrading to Service Pack 3, so we recommend

Service Pack 3 over the hotfix.

Before you connect your Pololu Orangutan SVP robot controller to a computer running Microsoft Windows, you

must install its drivers:

1. Download and install the Pololu AVR Development Bundle [http://www.pololu.com/file-redirect/avr-

development-bundle] (~6MB exe). This includes the drivers for the Orangutan SVP, along with the Pololu AVR

C/C++ Library and the drivers for the Pololu USB AVR Programmer. If you are not sure which of these

components you need, it is OK to install all of them. If you only need to install the drivers for the Orangutan

SVP, you can download those separately: Orangutan SVP Windows Drivers [http://www.pololu.com/file/

download/orangutan-svp-win-121115.exe?file_id=0J488] (53k exe).

2. During the installation, Windows will ask you if you want to install the drivers. Click “Install” (Windows

7, 8, and Vista) or “Continue Anyway” (Windows XP).

Windows 8, Windows 7, and Windows Vista users: After the installation is complete, your computer should

automatically install the necessary drivers when you connect an Orangutan SVP, in which case no further action

from you is required.

Windows XP users: After the installation is complete, follow steps 3-7 for each new Orangutan SVP you connect

to your computer.

3. Connect the device to your computer’s USB port. The Orangutan SVP shows up as three devices

in one so your XP computer will detect all three of those new devices and display the “Found New

Hardware Wizard” three times. Each time the “Found New Hardware Wizard” pops up, follow steps 4-7.

4. When the “Found New Hardware Wizard” is displayed, select “No, not this time” and click “Next”.

5. Getting Started Page 14 of 37

Page 15

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

5. On the second screen of the “Found New Hardware Wizard”, select “Install the software automatically”

and click “Next”.

5. Getting Started Page 15 of 37

Page 16

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

6. Windows XP will warn you again that the driver has not been tested by Microsoft and recommend that

you stop the installation. Click “Continue Anyway”.

7. When you have finished the “Found New Hardware Wizard”, click “Finish”. After that, another wizard

will pop up. You will see a total of three wizards when plugging in the Orangutan SVP. Follow steps 4-7 for

each wizard.

5. Getting Started Page 16 of 37

Page 17

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

If you use Windows XP and experience problems installing the drivers, the cause of your problems might be

a bug in older versions of Microsoft’s usb-to-serial driver usbser.sys. Versions of this driver prior to version

5.1.2600.2930 will not work with the Orangutan SVP. You can check what version of this driver you have

by looking in the “Details” tab of the “Properties” window for C:\Windows\System32\drivers\usbser.sys. To get

the fixed version of the driver, you will need to either install Service Pack 3 [http://www.microsoft.com/downloads/

details.aspx?FamilyId=68C48DAD-BC34-40BE-8D85-6BB4F56F5110] or Hotfix KB918365. Some users who installed the

hotfix have reported problems using the programmer which were solved by upgrading to Service Pack 3, so we

recommend Service Pack 3 over the hotfix.

After installing the drivers, if you go to your computer’s Device Manager and expand the “Ports (COM & LPT)”

list, you should see three COM ports: Pololu Orangutan SVP Programmer (Section 5.c), Pololu Orangutan

SVP USB Communication Port (Section 8), and the Pololu Orangutan SVP TTL Serial Port (Section 9). In

parentheses after these names, you will see the name of the port (e.g. “COM5” or “COM6”).

5. Getting Started Page 17 of 37

Page 18

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

Windows XP device manager showing the Pololu Orangutan

Windows Vista device manager showing the Pololu Orangutan SVP.

SVP.

Some software will not allow connection to higher COM port numbers. In particular, AVR Studio and Atmel

Studio can only connect to COM1 through COM9. If you need to change the COM port number assigned to one

of the COM ports, you can do so using the Device Manager. Bring up the properties dialog for the COM port and

click the “Advanced…” button in the “Port Settings” tab. From this dialog you can change the COM port assigned

to your device.

5.b. Using the Demo Program

The Demo Program

The Orangutan SVP ships with a demo program pre-loaded which demonstrates most of its features and allows

you to test that it is working correctly. After you first connect an external power supply and turn on your

Orangutan, you should see the red user LED blinking about once per second. If you have soldered a buzzer in to

your SVP (or bought the assembled version), you will also hear a beep. If you have connected an LCD, you will

see the words “Pololu Orangutan SVP”, then “Demo Program” appear, indicating that you are running the demo

program. If you see the blinking red LED but do not see any text on the LCD, you may need to adjust the contrast

potentiometer in the lower left corner of the board. When the program has started successfully, press the Middle

5. Getting Started Page 18 of 37

Page 19

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

Button button (marked PC3 on the underside of the board) to proceed to the main menu. Press the Top Button

(marked PC5) or the Bottom Button (marked PC2) to scroll forward or backward through the menu, and press

the Middle Button to make a selection or to exit one of the demos. There are nine demos accessible from the

menu:

1. Analog Inputs: This demo displays voltage readings from the Orangutan SVP’s 13 analog inputs as a

bar graph. The inputs are in this order: PA7, PA6, PA5, PA4, PA3, PA2, PA1, PA0, trimpot, A, B, C, D. You

can press the top button to enable/disable the pull-up resistors on PA0—PA7.

2. Battery Voltage: This demo displays the battery voltage in millivolts.

3. Digital Inputs: This demo displays the digital readings from some of the user-accessible digital input

lines. The pull-up resistors are enabled, so each line should read 1 if they are not connected to anything. If

you connect a wire between one of these lines and ground, you should see its reading go to zero (be careful

not to cause a short circuit).

4. LEDs: Blinks the red and green user LEDs.

5. Trimpot: Displays the position of the user trimmer potentiometer, which is located in the upper left

corner of the board, as a number between 0 and 1023. While displaying the value, this demo also blinks the

LEDs and plays a note whose frequency is a function of the current reading. It is easiest to turn the trimpot

using a 2 mm flat-head screwdriver.

6. Motors: Hold down the bottom or top buttons to run motors 1 or 2, respectively, or hold down

both buttons to run both motors simultaneously. The motors will gradually ramp up to speed; in your

own programs, you can switch them on much more suddenly. Tap the bottom or top buttons to switch

the corresponding motor to reverse (the button name becomes lowercase if pressing it will drive the

corresponding motor in reverse).

7. Music: Plays a song while scrolling a text display. This demonstrates the ability of the Orangutan to play

music in the background.

8. Timer: A simple stopwatch. Press the bottom button to start or stop the stopwatch and the top button to

reset. The stopwatch continues to count while you are exploring the other demos.

9. USB: Demonstrates the USB connection between the Orangutan SVP and a computer. Plug the

Orangutan SVP in to USB. Any bytes you send on the Pololu Orangutan SVP USB Communications Port

(Section 8) will be displayed on the screen, and echoed back to the computer so you can see them in your

terminal program. The red LED indicates the state of the DTR handshaking line, and the green LED indicates

the state of the RTS handshaking line.

The source code for the demo program is included with the Pololu AVR C/C++ Library [http://www.pololu.com/docs/

0J20] in the examples\atmega324p\svp-demo-program or examples\atmega1284p\svp-demo-program directory,

depending on whether you have the SVP-324 or SVP-1284.

5.c. Programming your Orangutan

Please see the Pololu AVR Programming Quick Start Guide [http://www.pololu.com/docs/0J51] for tutorials on how

to get started programming your Orangutan SVP’s on-board ATmega324P or ATmega1284PA microcontroller

in Windows, Linux, and Mac OS X. That guide also covers the Pololu AVR C/C++ Library

[http://www.pololu.com/docs/0J20].

5.d. Assembling the kit version

This section is a guide to the connection points where you will likely want to solder hardware on to the kit version

of the Orangutan SVP.

The Orangutan SVP kit version comes with these parts:

5. Getting Started Page 19 of 37

Page 20

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

• Six 3×4 male header blocks

• Six 3×4 female header

blocks

[http://www.pololu.com/catalog/

product/1034]

• One 3×7 male header block

• One 3×7 female header block

• Three 2-pin 3.5mm terminal

blocks

• Five blue shorting blocks

[http://www.pololu.com/catalog/

product/968]

• Two 2×3 female header

blocks

[http://www.pololu.com/catalog/

product/1023]

Hardware included with the Orangutan SVP partial kit.

• One 2×3 shrouded box

header [http://www.pololu.com/catalog/product/854]

• One 2×8 shrouded box header [http://www.pololu.com/catalog/product/898]

• One buzzer

• Five pushbuttons [http://www.pololu.com/catalog/product/1400]

• One 2×20 breakaway male header [http://www.pololu.com/catalog/product/966]

• One 1×20 breakaway male header [http://www.pololu.com/catalog/product/965]

• Five 1×2 female header blocks [http://www.pololu.com/catalog/product/1012]

• Two single-pin female headers

The labeled photo below shows possible locations for installing these parts:

5. Getting Started Page 20 of 37

Page 21

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

Orangutan SVP kit PCB showing possible locations for included buzzer,

pushbuttons, headers, and terminal blocks.

1. Power button

To turn on your the AVR, you need to connect a power button (or a jumper at location 11). The Orangutan SVP

PCB has two parallel sets of holes for the power button. You can solder a pushbutton between the wider set of

holes, and/or you can make your own connection to the narrower of holes using an included 1×2 header or direct

soldering. If the Orangutan is not easily accessible inside your robot, this allows you to install a momentary power

switch in a more convenient location.

2. Power input

There are two parallel connection points provided for the 6–13.5V power input. You can install a 3.5mm terminal

block on the large holes to accommodate large wires. You can also install a 1×2 male header on the smaller holes

and plug a battery pack [http://www.pololu.com/catalog/category/54] directly in to it.

3. Motor outputs

You can install two 3.5mm terminal blocks to accommodate your motor leads.

4. User I/O blocks

The AVR user I/O pins are divided in to four blocks. The kit comes with enough 3×4 headers so that you can

choose for each block whether to make its pins female or male. You can also mix the genders together within one

block using the other included headers.

5. Backlight and AREF header

If you want to be able to turn your LCD’s backlight off or use an external voltage reference source, you may want

to solder a 1×2 header on to this location.

6. LCD connector

The pins in the LCD connector area are arranged so that the AVR can control an LCD using the standard 4-bit

HD44780 protocol and optionally power an LCD backlight. On the assembled (non-kit) version of the Orangutan

5. Getting Started Page 21 of 37

Page 22

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

SVP, we solder a 2×8 shrouded header in to the 16 pins highlighted in the diagram. Then the 16×2 character

LCD with backlight [http://www.pololu.com/catalog/product/772] (included with the assembled version, but not the kit

version) plugs in to the lower 7 rows of the connector, as well as the A and K lines on the other side of the

board. If you have a different kind of LCD, consult its datasheet and the Orangutan SVP Reference Diagram

[http://www.pololu.com/file/download/orangutan_svp_reference_diagram.pdf?file_id=0J244] (82k pdf) to determine the correct

way to connect it.

7. User pushbuttons

The three user pushbuttons can be soldered in at this location.

8. Buzzer

The buzzer can be soldered in at this location.

9. Reset buttons.

A reset pushbutton can be soldered in at this location.

10. SPI/Programming connector

The assembled version comes with a 2×3 shrouded box header soldered in to this location (with the notch pointing

away from the USB connector). This allows you to use an external AVR ISP programmer to program the AVR if

you don’t want to use the integrated programmer for whatever reason. It also provides access to the AVR’s SPI

pins, so you could use this location to connect an SPI device to your Orangutan. A 2×3 female header is provided

for this location.

11. VCC-VUSB jumper

To power the board from USB, install a 1×2 male header at this location and use a blue shorting block to connect

VUSB to VCC. See Section 11 for more information and caveats about using this jumper.

12. Auxiliary processor I/O block

This block contains the auxiliary processor’s A, B, C, D/RX, and TX lines, as well as several connections to GND

and VCC. You can solder in either the 3×7 male or 3×7 female headers here, or mix and match genders using the

other provided headers.

13. Current sense outputs

If you want access to the analog voltage output of the current-sensing circuitry for each of the motor drivers, you

can solder a 1×2 female header here.

14. Servo demultiplexer block

To access the servo demultiplexer inputs, you can solder a 2×3 female or male header here.

15. Servo outputs

Most servo cables have female ends, so we recommend soldering 3×4 male headers in to the two servo output

blocks. However, if you want to use the demux for something other than servos, the kits has 3×4 female headers

you can use instead.

5. Getting Started Page 22 of 37

Page 23

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

16. Servo power selection

To use your servo ports, you will need to connect a power source (no power source is connected by default). You

can install two 1×3 male headers at this location and use two shorting blocks to select either VCC or VADJ for

servo power.

17. LCD backlight connection and structural support

If you choose to mount a 16×2 LCD on the Orangutan SVP as is done in the assembled version, you will want to

solder in the two single-pin female headers at this location. This prevents the LCD from tipping down on to the

board and also powers the backlight (if your LCD has one).

5. Getting Started Page 23 of 37

Page 24

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

6. AVR Pin Assignment Table Sorted by Function

Function ATmega324/1284 Pin

free analog input and digital I/O (x8) PA0 – PA7

free digital I/O (x8) PB3, PC0, PC1, PD0 – PD4, PD5**

free digital output PB4*

free PWM outputs (x2) PB3, PB4

red user LED PD1

green user LED PC4

UART0 PD0, PD1

UART1 PD2, PD3

user pushbuttons (bottom to top, x3) PC2, PC3, PC5

motor 1 (direction, speed) PC7, PD7

motor 2 (direction, speed) PC6, PD6

buzzer PD4

LCD control (RS, R/W, E) PB0, PB1, PB2

LCD data (4-bit: DB4 – DB7) PC2 – PC5

SPI auxiliary processor control lines (x3) PB5, PB6, PB7

ICSP programming lines (x3) PB5, PB6, PB7

ADC reference pin AREF

reset pushbutton RESET

*: Using PB4/SS as an input will interfere with communication to the auxiliary processor, so we recommend using

it as a digital output. See Section 3.j of the Pololu USB AVR C/C++ User’s Guide for more information.

**: PD5 is a free digital I/O unless you want to use the built-in servo pulse hardware.

6. AVR Pin Assignment Table Sorted by Function Page 24 of 37

Page 25

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

7. AVR Pin Assignment Table Sorted by Pin

Port A Pins Orangutan Function Notes/Alternate Functions

PA0 analog input and digital I/O ADC input channel 0 (ADC0)

PA1 analog input and digital I/O ADC input channel 1 (ADC1)

PA2 analog input and digital I/O ADC input channel 2 (ADC2)

PA3 analog input and digital I/O ADC input channel 3 (ADC3)

PA4 analog input and digital I/O ADC input channel 4 (ADC4)

PA5 analog input and digital I/O ADC input channel 5 (ADC5)

PA6 analog input and digital I/O ADC input channel 6 (ADC6)

PA7 analog input and digital I/O ADC input channel 7 (ADC7)

Port B Pins Orangutan Function Notes/Alternate Functions

PB1 LCD control line R/W

Divided system clock output (CLKO)

Timer/Counter 1 External Counter Input (T1)

PB2 LCD control line E

PB3 digital I/O

PB4 digital output*

PB5 auxiliary processor control line

PB6 auxiliary processor control line

PB7 auxiliary processor control line

Port C Pins Orangutan Function Notes/Alternate Functions

PC0 digital I/O I2C/TWI clock line (SCL)

PC1 digital I/O I2C/TWI input/output data line (SDA)

PC2 LCD data line DB4 user pushbutton (pressing pulls low)

PC3 LCD data line DB5 user pushbutton (pressing pulls low)

PC4 LCD data line DB6 green user LED (high turns LED on)

PC5 LCD data line DB7 user pushbutton (pressing pulls low)

External interrupt 2 (INT2)

Analog Comparator Positive Input (AIN0)

Timer0 PWM output A (OC0A)

Analog Comparator Negative Input (AIN1)

Timer0 PWM output B (OC0B)

SPI Slave Select Input (SS)

SPI Master Output/Slave Input (MOSI)

ISP programming line

SPI Master Input/Slave Output (MISO)

ISP programming line

SPI Clock (SCK)

ISP programming line

PC6 M2 direction control line

PC7 M1 direction control line

7. AVR Pin Assignment Table Sorted by Pin Page 25 of 37

Page 26

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

Port D Pins Orangutan Function Notes/Alternate Functions

PD0 digital I/O USART0 input pin (RXD0)

red user LED

PD1 digital I/O

(low turns LED on; connection

can be cut and replaced with jumper)

USART0 output pin (TXD0)

PD2 digital I/O

PD3 digital I/O

PD4 buzzer Timer1 PWM output B (OC1B)

PD5 digital I/O

PD6 M2 speed control line Timer2 PWM output B (OC2B)

PD7 M1 speed control line Timer2 PWM output A (OC2A)

Misc. Pins Orangutan Function Notes/Alternate Functions

AREF ADC reference pin

AVCC supply voltage for Port A and ADC not accessible to the user

RESET Reset input reset button (pressing resets MCU)

XTAL1 20 MHz resonator input not accessible to the user

XTAL2 20 MHz resonator input not accessible to the user

USART1 input pin (RXD1)

External interrupt 0 (INT0)

USART1 output pin (TXD1)

External interrupt 1 (INT1)

servo pulse output (SPWM)

Timer1 PWM output A (OC1A)

*: Using PB4/SS as an input will interfere with communication to the auxiliary processor, so we recommend using

it as a digital output. See Section 3.j of the Pololu USB AVR C/C++ User’s Guide for more information.

7. AVR Pin Assignment Table Sorted by Pin Page 26 of 37

Page 27

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

8. Using the USB Communication Port

The Orangutan SVP’s USB Connection provides a virtual serial port called the Pololu Orangutan SVP USB

Communication Port which allows two-way communication between a personal computer and the Orangutan

SVP’s AVR at a rate of over 20 kilobytes per second.

The bytes sent from the computer will be transmitted to the Orangutan SVP’s auxiliary processor and made

available to the AVR. Bytes sent by the AVR will be sent to the computer. In addition to this two-way data

communication, you can use the RTS and DTR handshaking lines. The state of these lines (either 0 or 1) is

controlled by the computer and can be read by the AVR. Several standard terminal programs set the DTR line to

1 when they connect to a serial port, and then set it to 0 when they disconnect. Therefore the DTR line can be

used to determine whether a terminal program is connected to the Orangutan, and make the Orangutan’s behavior

dependent on that.

On the PC side, the Orangutan SVP’s USB drivers make the USB Communication port look like a standard serial

port to the operating system, allowing you to use existing terminal programs and software designed to use serial

ports. On the AVR side, the Pololu AVR C/C++ Library provides serial communication functions for using the

port.

Communication on the PC side

To use the USB Communication Port, you must first determine what port name the operating system has assigned

it.

To determine the port name in Microsoft Windows, open the Device Manager, expand the “Ports (COM & LPT)”

list, and look for the Pololu Orangutan SVP USB Communication Port entry. The port name will be at the end

of this line in parentheses (e.g. “COM3”). In Windows, a given device will always be associated with the same

port unless you manually change its port assignment in the Device Manager (see Section 5.a).

Windows Vista device manager showing the Pololu Orangutan SVP.

To determine the port name in Linux, type ls /dev/ttyACM*. The port name will be one of the devices listed

there. If there are only three ports, then the USB Communication Port will be /dev/ttyACM1 (the programmer

will be /dev/ttyACM0 and the TTL serial port will be /dev/ttyACM2). If you see more than three ports, then you

should look at the output from dmesg when you plug in the Orangutan SVP to see which three ports are created;

8. Using the USB Communication Port Page 27 of 37

Page 28

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

the second port is the USB Communication Port. In Linux, the port name depends on how many other devices are

using the USB CDC ACM driver to create virtual serial ports at the time the Orangutan SVP is plugged in.

To determine the port name in Mac OS X, type ls /dev/tty.usb*. There should be three entries for the

Orangutan SVP, and the USB Communication Port should be the second one.

After determining the port name, you can use any serial port software to communicate on that port.

There are many free terminal programs available, including PuTTY [http://www.chiark.greenend.org.uk/~sgtatham/

putty/] (Windows or Linux), Tera Term [http://hp.vector.co.jp/authors/VA002416/teraterm.html] (Windows), and Br@y

Terminal [http://sites.google.com/site/terminalbpp/] (Windows). To use any of these terminal programs, you must

specify the port name determined above.

PuTTY is a free Windows terminal program that can send and receive bytes on a

serial port.

If you need to send and receive non-ASCII bytes, you can use the Pololu Serial Transmitter Utility for

Windows [http://www.pololu.com/docs/0J23].

Advanced users developing scripted applications may prefer the free terminal program kermit

[http://www.columbia.edu/kermit/] (Windows or Linux).

You can also write a computer program to use the serial port. The freely available Microsoft .NET framework for

Windows contains a SerialPort class that makes it easy to read and write bytes from a serial port. Here is some

example C# .NET code that uses the USB Communication Port:

// Choose the port name and baud rate.

// Port Name must be determined from the Device Manager.

// Baud rate is irrelevant for the USB Communication Port.

System.IO.Ports.SerialPort port = new System.IO.Ports.SerialPort("COM4", 115200);

// Connect to the port.

port.Open();

// Set the DTR line to 1.

port.DtrEnable = true;

// Transmit two bytes to the AVR: 0x61, 0x62

port.Write(new byte[]{0x61, 0x62}, 0, 2);

// Wait for a byte to be received on the RX line.

int response = port.ReadByte();

// Show the user what byte was received.

MessageBox.Show("Received byte: " + response);

8. Using the USB Communication Port Page 28 of 37

Page 29

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

// Set the DTR line to 0.

port.DtrEnable = false;

// Disconnect from the port so that other programs can use it.

port.Close();

Communication on the AVR side

Writing programs for the USB Communications port on the AVR side is supported by two different sections of

the Pololu AVR C/C++ Library.

The SVP-specific functions section of the library provides the rts_enabled() and dtr_enabled() functions which

return the states of those control lines. Complete documentation of the SVP-specific functions can be found

in Section 13 of the Pololu AVR Library Command Reference [http://www.pololu.com/docs/0J18]. A high level

overview can be found in Section 3.j of the Pololu AVR C/C++ Library User’s Guide [http://www.pololu.com/docs/

0J20].

The Serial Port Communication section of the library provides many functions for serial communication,

all of which will work for the USB Communications port. Complete documentation of serial communication

functions can be found in Section 10 of the Pololu AVR Library Command Reference [http://www.pololu.com/docs/

0J18]. A high level overview can be found in Section 3.h of the Pololu AVR C/C++ Library User’s Guide

[http://www.pololu.com/docs/0J20].

8. Using the USB Communication Port Page 29 of 37

Page 30

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

9. Using the TTL Serial Port

The Orangutan SVP’s USB Connection provides a serial port called the Pololu Orangutan SVP TTL Serial

Port which allows two-way communication between a personal computer and TTL-level serial devices at baud

rates between 300 bps and 115200 bps. This serial port can be used for communication between a computer and

an external serial device besides the AVR. It can also be used to debug the serial communication between the

AVR and an external serial device. If you want to communicate directly between the AVR and a computer, we

recommend using the USB Communications Port (see Section 8).

The bytes sent from the computer on this serial port will be transmitted on the TX line. Bytes received on the

D/RX line will be sent back to the computer. The bytes are sent and received eight bits at a time, non-inverted,

with no parity and one stop bit (8N1).

To use the TTL Serial Port, you must first determine what port name the operating system has assigned it.

To determine the port name in Microsoft Windows, open the Device Manager, expand the “Ports (COM & LPT)”

list, and look for the Pololu Orangutan SVP TTL Serial Port entry. The port name will be at the end of this line

in parentheses (e.g. “COM4”). In Windows, a given device will always be associated with the same port unless

you manually change its port assignment in the Device Manager (see Section 5.a).

Windows Vista device manager showing the Pololu Orangutan SVP.

To determine the port name in Linux, type ls /dev/ttyACM*. The port name will be one of the devices listed

there. If there are only three ports, then the TTL Serial Port will be /dev/ttyACM2 (the programmer will be /dev/

ttyACM0 and the USB communications port will be /dev/ttyACM1). If you see more than three ports, then you

should look at the output from dmesg when you plug in the Orangutan SVP to see which three ports are created;

the third port is the TTL Serial Port. In Linux, the port name depends on how many other devices are using the

USB CDC ACM driver to create virtual serial ports at the time the Orangutan SVP is plugged in.

To determine the port name in Mac OS X, type ls /dev/tty.usb*. There should be three entries for the

Orangutan SVP, and the TTL Serial Port should be the last one.

After determining the port name, you can use any serial port software to communicate on that port.

9. Using the TTL Serial Port Page 30 of 37

Page 31

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

There are many free terminal programs available, including PuTTY [http://www.chiark.greenend.org.uk/~sgtatham/

putty/] (Windows or Linux), Tera Term [http://hp.vector.co.jp/authors/VA002416/teraterm.html] (Windows), and Br@y

Terminal [http://sites.google.com/site/terminalbpp/] (Windows). To use any of these terminal programs, you must

specify the port name determined above, and the baud rate.

PuTTY is a free Windows terminal program that can send and receive bytes on a

serial port.

If you need to send and receive non-ASCII bytes, you can use the Pololu Serial Transmitter Utility for

Windows [http://www.pololu.com/docs/0J23].

Advanced users developing scripted applications may prefer the free terminal program kermit

[http://www.columbia.edu/kermit/] (Windows or Linux).

You can also write a computer program to use the serial port. The freely available Microsoft .NET framework for

Windows contains a SerialPort class that makes it easy to read and write bytes from a serial port. Here is some

example C# .NET code that uses the TTL Serial Port:

// Choose the port name and baud rate.

// Port name must be determined from the Device Manager.

System.IO.Ports.SerialPort port = new System.IO.Ports.SerialPort("COM4", 115200);

// Connect to the port.

port.Open();

// Transmit two bytes: 0x61, 0x62

port.Write(new byte[]{0x61, 0x62}, 0, 2);

// Wait for a byte to be received on the RX line.

int response = port.ReadByte();

// Show the user what byte was received.

MessageBox.Show("Received byte: " + response);

// Disconnect from the port so that other programs can use it.

port.Close();

9. Using the TTL Serial Port Page 31 of 37

Page 32

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

10. Motor Driver Truth Table

Input Orangutan SVP output

PD7, PD6 PC7, PC6 M1A, M2A M1B, M2B motor effect LED on

H H L H “forward”* green

H L H L “reverse”* red

L H or L L L brake low none

* Note that the concept of “forward” is arbitrary as simply flipping the motor leads results in rotation in the

opposite direction.

Motor 1 is controlled by pins PD7 (i.e. OC2A) and PC7. Motor 2 is controlled by pins PD6 (i.e. OC2B) and PC6.

Pins PD6 and PD7 are connected to the AVR’s eight-bit hardware PWM outputs, which allows you to achieve

variable motor speeds through hardware timers rather than software. This frees the CPU to perform other tasks

while motor speed is automatically maintained by the AVR timer hardware.

You can control the Orangutan SVP’s motors using the functions in the OrangutanMotors

[http://www.pololu.com/docs/0J18/7] section of the Pololu AVR C/C++ Library, or you can write your own code.

10. Motor Driver Truth Table Page 32 of 37

Page 33

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

11. USB Power

When connected to a computer, the USB connection provides a 5 V power supply. If an external power supply is

present, the unit will run off of the external supply and not draw any power from USB. If only the USB power is

present, then by default the auxiliary processor will be powered from USB, but the AVR and the VCC power pins

on the board will not be powered.

An option is available for powering the entire board from USB. To power the board from USB, install a jumper

to connect VUSB to VCC. When the board is powered this way, the voltage regulator will conduct current

backwards, resulting in a VBAT around 4.6 – 5.0 V and a VCC around 4.3 – 4.6 V. In some cases, VCC will be

low enough to trigger brown-out detection on the AVR. Therefore, if you are having trouble powering your AVR

from USB, try changing your brown-out detection fuses to be tolerant of lower voltages.

Using the VCC-VUSB jumper can also cause other problems because the Orangutan is not being USB-compliant

whenever it draws more than 100 mA from the USB. If the Orangutan draws too much power from USB, the host

may respond by disconnecting the power supply to that port. Therefore, if you are having trouble powering your

AVR from USB, you may be drawing too much power.

11. USB Power Page 33 of 37

Page 34

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

12. Upgrading Firmware

The firmware (program) that runs on the Orangutan SVP’s auxiliary processor can be upgraded with bug fixes or

new features.

Firmware Release Notes

Firmware version 1.00 is the original firmware for the SVP’s auxiliary processor, released in November 2009.

Firmware version 1.01 was released on January 15th, 2010. This version contains bug fixes related to the

quadrature encoder support that would occasionally trigger an encoder error and cause two encoder counts to be

lost.

Firmware version 1.02 was released on February 1st, 2010, to support the Orangutan SVP-1284.

Firmware version 1.03 was released on March 14th, 2012. This version adds support for AVR Studio 5 and Atmel

Studio and makes the analog readings more accurate.

Determining your firmware version in Windows

To determine the firmware version of the auxiliary processor using a Windows computer:

1. Connect the Orangutan SVP to your computer via USB.

2. Open up the Device Manager.

3. Double click on the “Pololu Orangutan SVP Programmer” entry in the “Ports (COM & LPT)” list.

4. In the Details tab, select the “Hardware Ids” property in the dropdown box.

5. The first value displayed should be something like USB\VID_1FFB&PID_0087&REV_0101&MI_00. The

number after the REV_ is your revision code. You can determine your firmware version by inserting a decimal

point after the second character of your revision code. If the revision code is “0100” then you have firmware

version 1.00. If the revision code is “0101” then you have firmware version 1.01.

Determining your firmware version in Linux

To determine the firmware version of the auxiliary processor using a Linux computer:

1. Connect the Orangutan SVP to your computer via USB.

2. Run the following command: lsusb -v -d 1ffb:0087 | grep bcdDevice. This should output a line

that has your firmware version number on it.

Upgrading firmware

To upgrade the auxiliary processor’s firmware, follow these steps:

1. Download the latest version of the firmware here:

◦ Firmware version 1.03 for the Orangutan SVP [http://www.pololu.com/file/download/

org06a_v1.03.pgm?file_id=0J540] (27k pgm) — released March 14th, 2012.

2. Connect the Orangutan SVP to your computer via USB.

3. Turn off the power to the Orangutan SVP’s AVR. The blue power LED should be off. You will have to

remove the VCC-VUSB jumper if it is present.

4. The bootloader line is shown in the picture below. Short this line to ground by connecting one end of

a wire to ground and touching the other end to the hole, being extremely careful not to touch any of the

12. Upgrading Firmware Page 34 of 37

Page 35

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

neighboring parts. Ground is available in many places on the SVP; check the Orangutan SVP Reference

Diagram [http://www.pololu.com/file/download/orangutan_svp_reference_diagram.pdf?file_id=0J244] (82k pdf) if you

are not sure where to find ground. You may have to remove the Orangutan SVP’s LCD to access the

bootloader line.

The Orangutan SVP’s bootloader line.

5. The Orangutan SVP will now disconnect itself from your computer and reappear as a new device called

“Pololu org06a Bootloader”.

◦ Windows 7, Vista and Linux: The driver for the bootloader will automatically be installed.

◦ Windows XP: When the “Found New Hardware Wizard” is displayed, follow steps 4–7 in Section

5.a to get the driver working.

6. Once the bootloader’s drivers are properly installed, the green USB LED should be blinking in a double

heart-beat pattern, and there should be an entry for the bootloader in the “Ports (COM & LPT)” list of your

computer’s Device Manager in Windows.

7. Use a terminal program (such as Br@y Terminal [http://sites.google.com/site/terminalbpp/]) to connect to the

bootloader’s virtual serial port. In Windows, you can determine the port name of the bootloader (e.g. COM5)

by looking in the Device Manager. In Linux, you can determine the port name (e.g. /dev/ttyACM0) by

running dmesg. You can use any baud rate.

8. Type the following lower-case letters in to your terminal program to send them to the bootloader:

fwbootload. After each letter is sent, the bootloader should echo back the upper-case version of that letter.

After you have finished typing this sequence, you should see “FWBOOTLOAD” as the output from the

bootloader in your terminal program.

9. Now send lower-case “s”. The bootloader will spend a few seconds erasing the current firmware, and

then it will echo back an upper-case S. Do not disconnect the device from the computer after this point until

the upgrade is complete.

10. Now send the contents of the downloaded firmware upgrade file to the bootloader. The firmware

upgrade file is a plain-text (ASCII) file, so you can open it in a text editor (such as notepad), copy the whole

thing, and then paste it in to your terminal program. Alternatively, Br@y Terminal has a “Send File” button

you can use.

11. While the file is being sent, the bootloader will echo back period characters (“….”). This process will

take about 5 seconds. When the firmware upgrade is complete, the bootloader should echo back a pipe

character (“|”).

12. You can now unplug your SVP and plug it back in to the computer and use the new firmware.

12. Upgrading Firmware Page 35 of 37

Page 36

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

If you run into problems during a firmware upgrade, please contact us [http://www.pololu.com/contact] for assistance.

12. Upgrading Firmware Page 36 of 37

Page 37

Pololu Orangutan SVP User's Guide © 2001–2012 Pololu Corporation

13. Related Resources

The following list of resources might come in handy:

• ATmega324PA documentation [http://www.atmel.com/dyn/products/product_card.asp?PN=ATmega324PA]:

ATmega324PA datasheet and additional documentation

• ATmega1284P documentation [http://www.atmel.com/dyn/products/product_card.asp?PN=ATmega1284P]:

ATmega1284P datasheet and additional documentation

• Pololu AVR Programming Quick Start Guide [http://www.pololu.com/docs/0J51]: tutorials on how to get

started programming in Windows, Linux, and Mac OS X.

• Pololu AVR Library Command Reference [http://www.pololu.com/docs/0J18]: detailed information about

every function in the library.

• Pololu AVR Library User’s Guide [http://www.pololu.com/docs/0J20]: instructions on installing and using the

library, as well as sample programs.

• Atmel Studio 6 [http://www.atmel.com/microsite/atmel_studio6/]: free development IDE from Atmel that uses

WinAVR as its compiler

• AVR Libc Home Page [http://www.nongnu.org/avr-libc/]

• Tutorial: AVR Programming on the Mac [http://bot-thoughts.blogspot.com/2008/02/avr-programming-on-

mac.html]

• WinAVR [http://winavr.sourceforge.net/]: free, open source C/C++ compiler for AVRs

Please see the resources tab of your Orangutan’s product page for even more resources.

Finally, we would like to hear your comments and questions over at the Orangutan Group [http://forum.pololu.com/

viewforum.php?f=10] on the Pololu Robotics Forum [http://forum.pololu.com/]!

13. Related Resources Page 37 of 37

Loading...

Loading...