Page 1

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Pololu Maestro Servo Controller

User's Guide

http://www.pololu.com/docs/0J40/all Page 1 of 73

Page 2

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.a. Micro Maestro Pinout and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.b. Mini Maestro Pinout and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.c. Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.d. Supported Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Contacting Pololu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.a. Installing Windows Drivers and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.b. Installing Linux Drivers and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.c. Using the Maestro without USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4. Using the Maestro Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.a. Status and Real-time Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.b. Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.c. Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.d. Entering a Script . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.e. Channel Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.f. Upgrading Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.f.1. Hard Bootloader Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5. Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.a. Serial Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.b. TTL Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.c. Command Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.d. Cyclic Redundancy Check (CRC) Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.e. Serial Servo Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.f. Serial Script Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.g. Daisy Chaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.h. Serial Example Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.h.1. Cross-platform C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.h.2. Windows C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.h.3. PIC18F4550 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.h.4. Bash script . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6. The Maestro Scripting Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.a. Maestro Script Language Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.b. Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.c. Example Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.d. Script Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7. Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.a. Powering the Maestro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.b. Attaching Servos and Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.c. Connecting to a Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8. Writing PC Software to Control the Maestro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9. Maestro Settings Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10. Related Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 2 of 73

Page 3

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

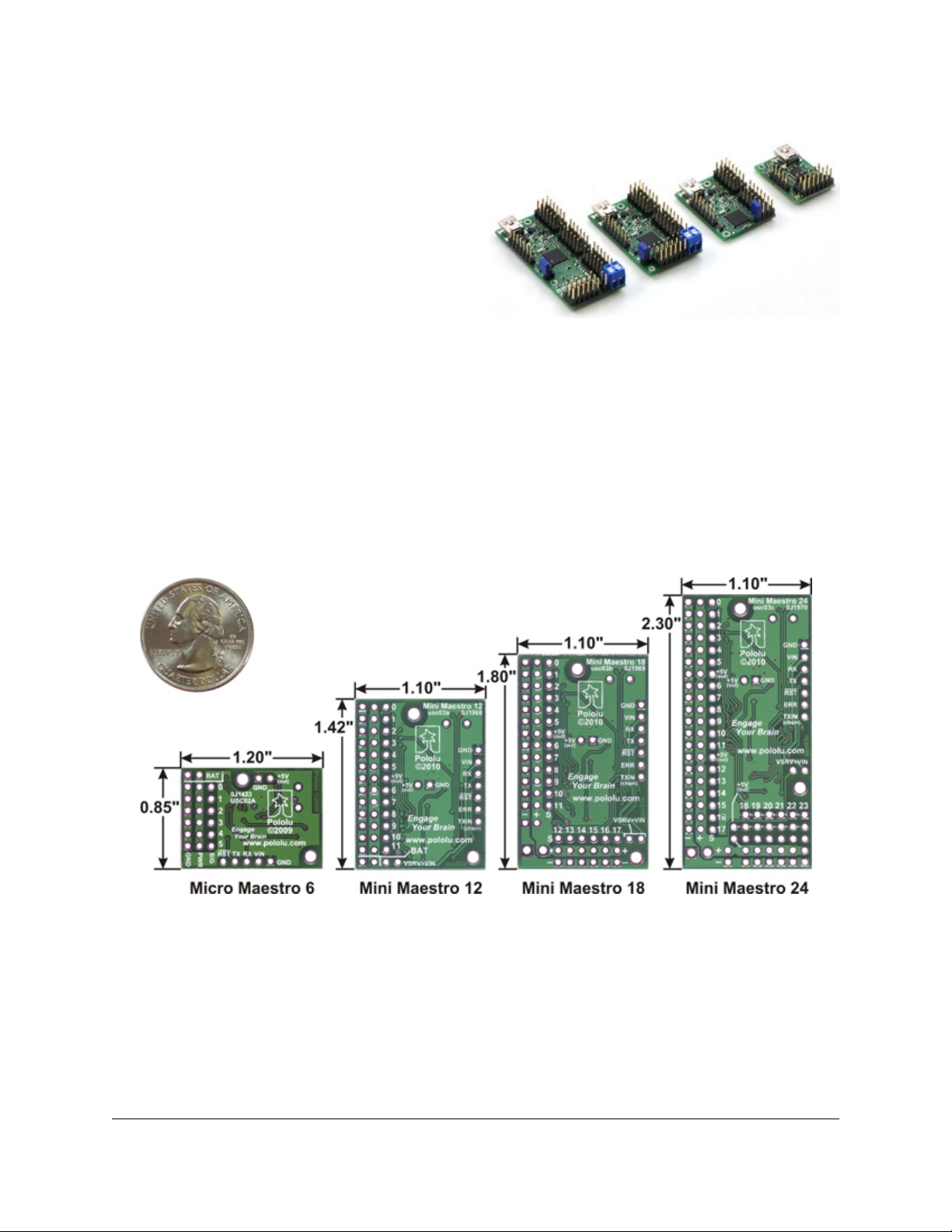

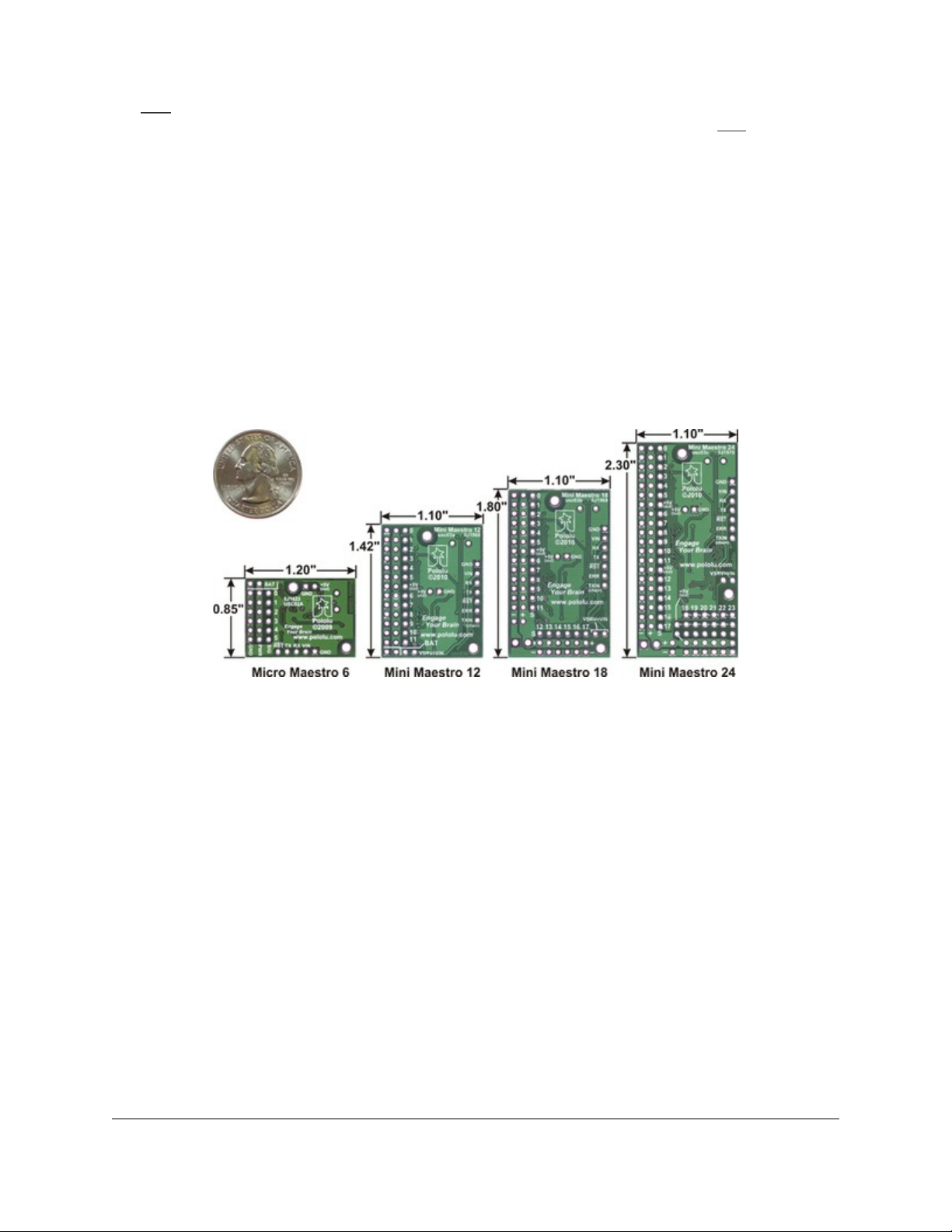

1. Overview

The Maestros are Pololu’s second-generation family of

USB servo controllers. The Maestro family consists of

four controllers, each available fully assembled or as a

partial kit:

• Micro Maestro 6 [http://www.pololu.com/product/1350]

• Mini Maestro 12 [http://www.pololu.com/product/1352]

• Mini Maestro 18 [http://www.pololu.com/product/1354]

• Mini Maestro 24 [http://www.pololu.com/product/1356]

With three control methods — USB for direct connection to a PC computer, TTL serial for use with embedded

systems, and internal scripting for self-contained, host controller-free applications — and channels that can be

configured as servo outputs for use with radio control (RC) servos [http://www.pololu.com/category/23/rc-servos] or

electronic speed controls (ESCs), digital outputs, or analog/digital inputs, the Maestro is a highly versatile servo

controller and general I/O board in a highly compact package. The extremely precise, high-resolution servo pulses

have a jitter of less than 200 ns, making the Maestro well suited for high-performance animatronics, and built-in speed

and acceleration control make it easy to achieve smooth, seamless movements without requiring the control source to

constantly compute and stream intermediate position updates to the Maestro. The Maestro features configurable pulse

rates (up to 333 Hz for Mini Maestros) and can generate a wide range of pulses to allow maximum responsiveness

and range from modern servos. Units can be daisy-chained with additional Pololu servo and motor controllers on a

single serial line.

A free configuration and control program is available for Windows and Linux (see Section 4), making it simple to

configure and test the board over USB, create sequences of servo movements for animatronics or walking robots, and

write, step through, and run scripts stored in the servo controller. The Maestro’s internal script memory allows storage

of servo positions that can be automatically played back without any computer or external microcontroller connected

(see Section 6).

The Maestros’ channels can also be used as general-purpose digital outputs and analog or digital inputs, providing

an easy way to read sensors and control peripherals directly from a PC over USB. These inputs can be used with the

scripting system to enable creation of self-contained animatronic displays that respond to external stimuli.

1. Overview Page 3 of 73

Page 4

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

A USB A to mini-B cable [http://www.pololu.com/product/130] (not included) is required to connect this device to a

computer.

1. Overview Page 4 of 73

Page 5

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Features

• Three control methods: USB, TTL (5 V) serial, and internal scripting

• 0.25μs output pulse width resolution (corresponds to approximately 0.025° for a typical servo, which is

beyond what the servo could resolve)

• Configurable pulse rate and wide pulse range (see the Maestro comparison table below)

• Individual speed and acceleration control for each channel

• Channels can be optionally configured to go to a specified position or turn off on startup or error

• Alternate channel functions allow the channels to be used as:

◦ General-purpose digital outputs (0 or 5 V)

◦ Analog or digital inputs (channels 0 – 11 can be analog inputs; channels 12+ can be digital inputs)

◦ One channel can be a PWM output with frequency from 2.93 kHz to 12 MHz and up to 10 bits of

resolution (see Section 4.a for details)

• A simple scripting language lets you program the controller to perform complex actions even after its USB

and serial connections are removed

• Free configuration and control application for Windows and

Linux makes it easy to:

◦ Configure and test your controller

◦ Create, run, and save sequences of servo movements for

animatronics and walking robots

◦ Write, step through, and run scripts stored in the servo

controller

• Two ways to write software to control the Maestro from a PC:

◦ Virtual COM port makes it easy to send serial commands

from any development environment that supports serial

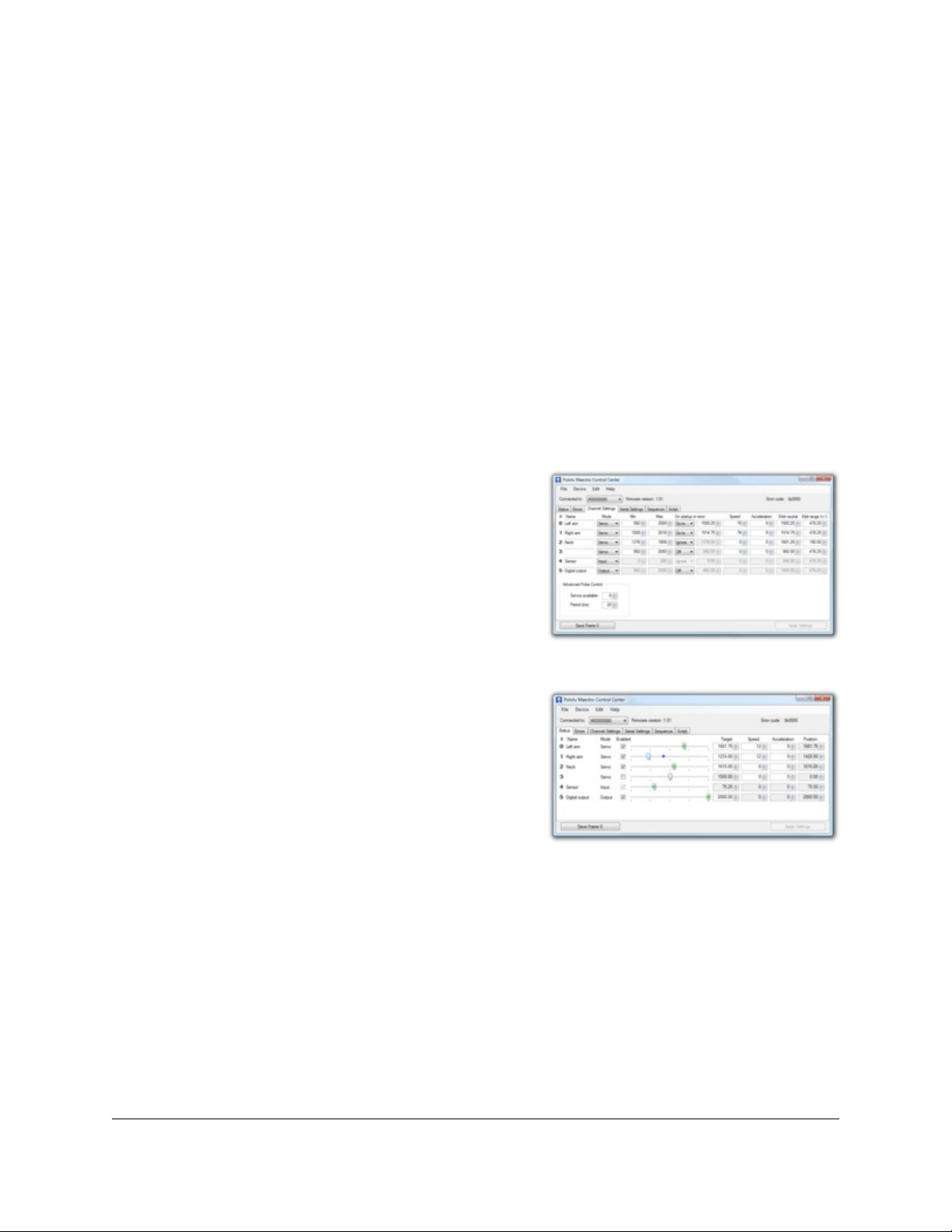

The Channel Settings tab in the Maestro

Control Center.

communication

◦ Pololu USB Software Development Kit

[http://www.pololu.com/docs/0J41] allows use of more advanced

native USB commands and includes example code in C#,

Visual Basic .NET, and Visual C++

• TTL serial features:

◦ Supports 300 – 200,000 bps in fixed-baud mode, 300 –

115,200 bps in autodetect-baud mode

◦ Simultaneously supports the Pololu protocol, which gives

The Status tab in the Maestro Control

Center.

access to advanced functionality, and the simpler Scott

Edwards MiniSSC II protocol (there is no need to configure the device for a particular protocol mode)

◦ Can be daisy-chained with other Pololu servo and motor controllers using a single serial transmit line

◦ Chain input allows reception of data from multiple Mini Maestros using a single serial receive line

without extra components (does not apply to Micro Maestros)

◦ Can function as a general-purpose USB-to-TTL serial adapter for projects controlled from a PC

• Board can be powered off of USB or a 5 – 16 V battery, and it makes the regulated 5V available to the user

• Upgradable firmware

1. Overview Page 5 of 73

Page 6

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

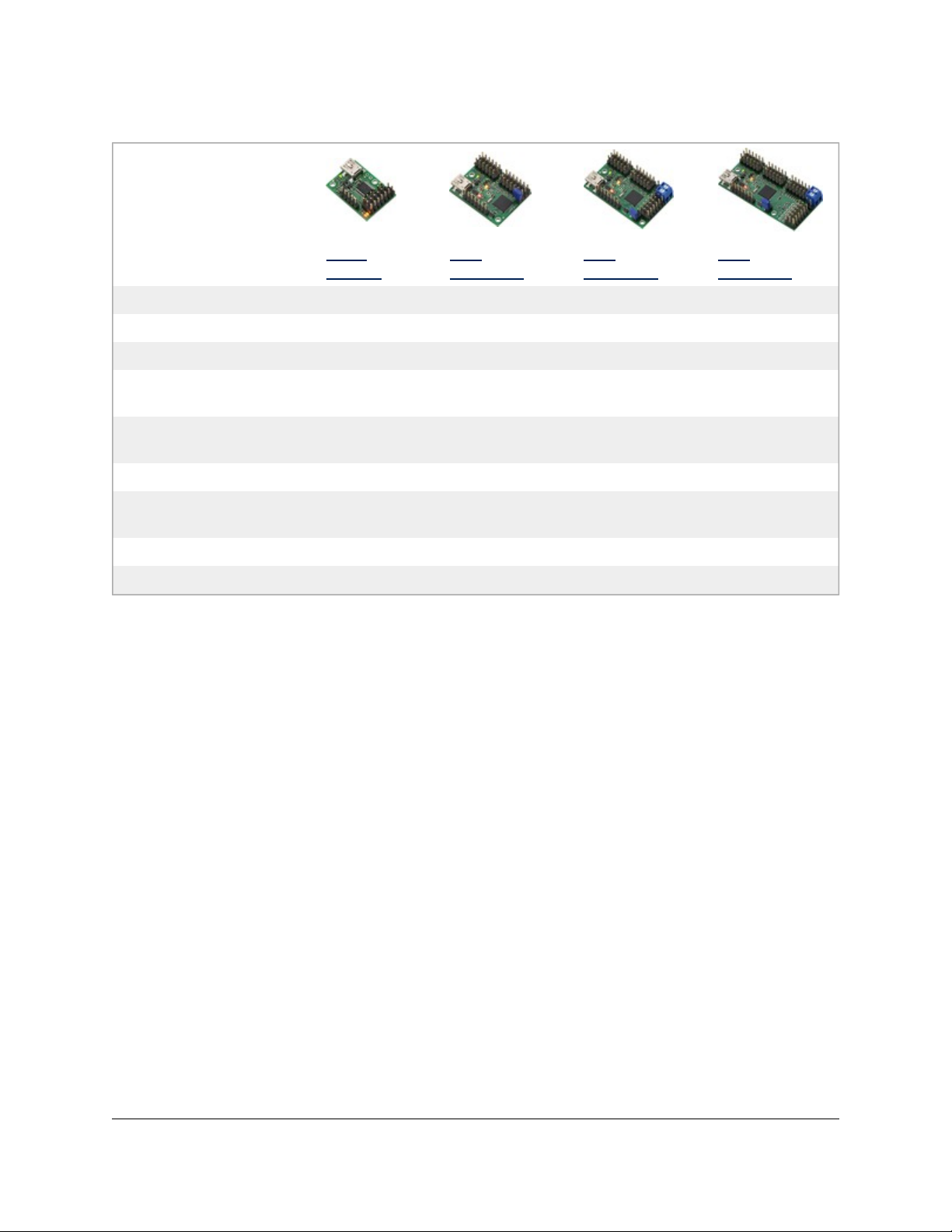

Maestro Comparison Table

Micro

Maestro

Mini

Maestro 12

Mini

Maestro 18

Mini

Maestro 24

Channels: 6 12 18 24

Analog input channels: 6 12 12 12

Digital input channels: 0 0 6 12

Width:

Length:

Weight

Configurable pulse

rate

Pulse range

Script size

1

This is the weight of the board without header pins or terminal blocks.

2

The available pulse rate and range depend on each other and factors such as baud rate and number of channels

used. See Section 9 for details.

3

The user script system is more powerful on the Mini Maestro than on the Micro Maestro. See Section 6.d for

details.

(1)

: 3.0 g 4.2 g 4.9 g 6.0 g

(2)

:

(2)

: 64–3280 μs 64–4080 μs 64–4080 μs 64–4080 μs

(3)

: 1 KB 8 KB 8 KB 8 KB

0.85"

(2.16 cm)

1.20"

(3.05 cm)

1.10" (2.79 cm) 1.10" (2.79 cm) 1.10" (2.79 cm)

1.42" (3.61 cm) 1.80" (4.57 cm) 2.30" (5.84 cm)

33–100 Hz 1–333 Hz 1–333 Hz 1–333 Hz

1. Overview Page 6 of 73

Page 7

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Application Examples

• Serial servo controller for multi-servo projects (e.g. robot

arms, animatronics, fun-house displays) based on microcontroller

boards such as the BASIC Stamp, Orangutan robot controllers

[http://www.pololu.com/category/8/robot-controllers], or Arduino

platforms

• Computer-based servo control over USB port

• Computer interface for sensors and other electronics:

◦ Read a gyro or accelerometer [http://www.pololu.com/category/

80/accelerometers-gyros-compasses] from a computer for novel user

interfaces

◦ Control a string of ShiftBrites [http://www.pololu.com/product/

1222] from a computer for mood lighting

• General I/O expansion for microcontroller projects

• Programmable, self-contained Halloween or Christmas

display controller that responds to sensors

• Self-contained servo tester

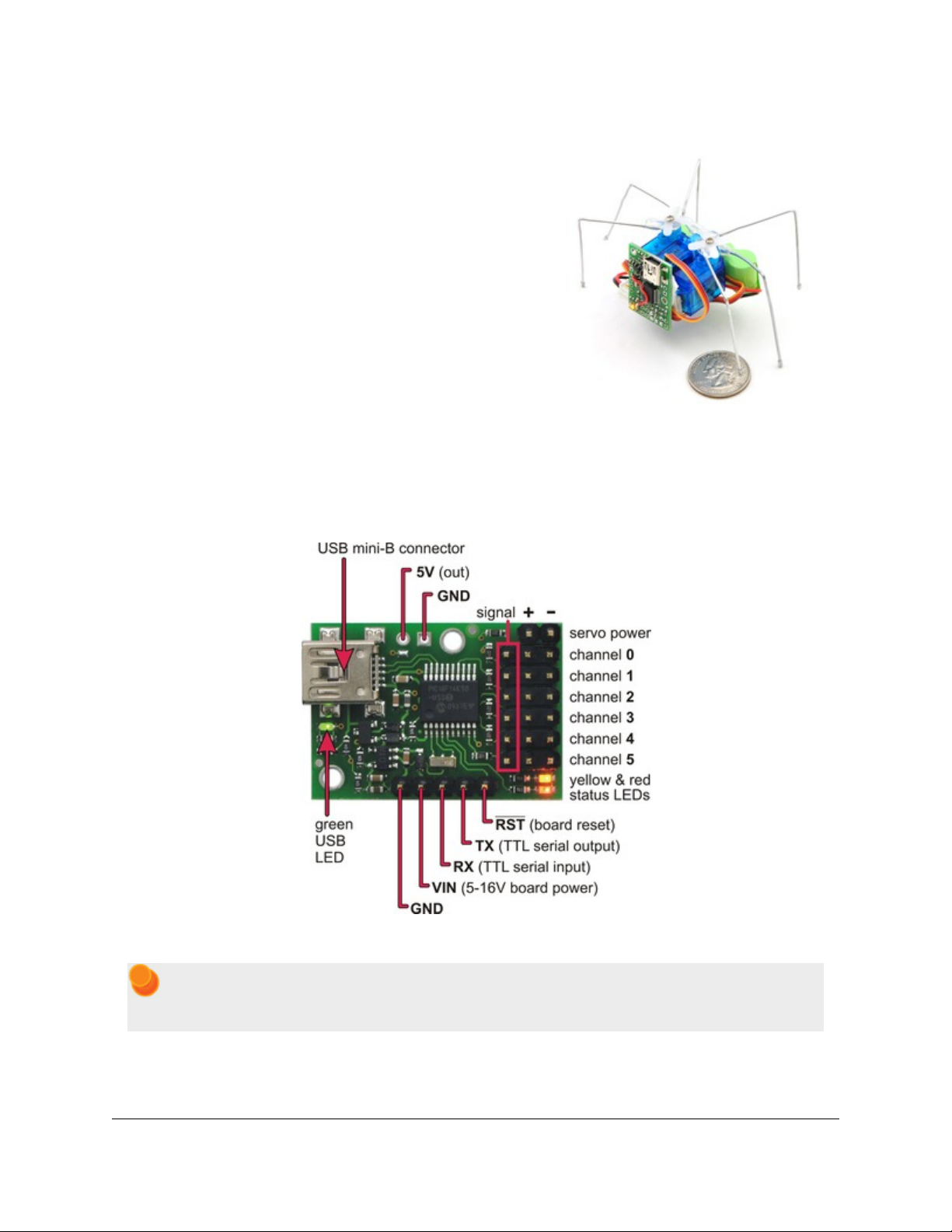

1.a. Micro Maestro Pinout and Components

Micro Maestro as the brains of a tiny

hexapod robot.

Micro Maestro 6-channel USB servo controller

(fully assembled) labeled top view.

Note: This section applies to the Micro Maestro servo controller. Please see Section 1.b for Mini

Maestro pinout and component information.

The Pololu Micro Maestro 6-channel servo controller can connect to a computer’s USB port via a USB A to mini-B

cable [http://www.pololu.com/product/130] (not included). The USB connection is used to configure the servo controller. It

1. Overview Page 7 of 73

Page 8

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

can also be used to send commands to the servo controller, get information about the servo controller’s current state,

and send and receive TTL serial bytes on the TX and RX lines.

The processor and the servos can have separate power supplies.

Processor power must come either from USB or from an external

5–16V power supply connected to the VIN and GND inputs. It is

safe to have an external power supply connected at the same time

that USB is connected; in such cases the processor will be powered

from the external supply. Note that if the external supply falls below

5 V, correct operation is not guaranteed, even if USB is also

connected.

Servo power connections are provided in the upper right corner of

the Micro Maestro board. Servo power is passed directly to the

servos without going through a regulator, so the only restrictions on

Micro Maestro power pins.

your servo power supply are that it must be within the operating

range of your servos and provide enough current for your application. Please consult the datasheets for your servos to

determine an appropriate servo power source, and note that a ballpark figure for the current draw of an average

straining servo is 1 A.

You can power the Maestro’s processor and servos from a single power

supply by connecting the positive power line to both VIN and the servo

power ports. An easy way to accomplish this on the Micro Maestro is to

solder a wire on the bottom of the board between VIN and one of the servo

power connections as shown in the picture to the right. Only one ground

connection is needed because all ground pins on the board are connected.

The 5V (out) power output allows you to power your own 5V devices from

the on-board 50mA regulator or directly from USB. The on-board regulator is

used whenever VIN is powered; in this case, since the Maestro requires

30 mA, there is about 20 mA available to power other devices.

Micro Maestro configured to use

a single power supply for both

board and servos.

The SIG lines (0, 1, 2, …) are used for sending pulses to servos, controlling

digital outputs, and measuring analog voltages. These lines are protected by 220Ω resistors. The total current limit (in

or out) for these pins is 60 mA, but when using the on-board regulator the current out is limited to 20 mA (see above.)

The RX line is used to receive non-inverted TTL (0–5 V) serial bytes, such as those from microcontroller UARTs.

These bytes can either be serial commands for the Maestro, arbitrary bytes to send back to the computer via the USB

connection, or both. For more information about the Maestro’s serial interface, see Section 5.a. Note that the Maestro

will probably be able to receive 3.3V TTL serial bytes, but it is not guaranteed to read 3.3V as high on the RX pin, so

you should boost 3.3V TTL serial signals to above 4V if you want to ensure reliable operation.

The TX line transmits non-inverted TTL (0–5 V) serial bytes. These bytes can either be responses to serial commands

sent to the Maestro, or arbitrary bytes sent from the computer via the USB connection.

The RST pin can be driven low to reset the Maestro’s microcontroller, but this should not be necessary for typical

applications. The line is internally pulled high, so it is safe to leave this pin unconnected. Driving RST low is roughly

equivalent to powering off the Maestro; it will not reset any of the configuration parameters stored in non-volatile

memory. To reset the configuration parameters, select Device > Reset to default settings… in the Maestro Control

Center.

1. Overview Page 8 of 73

Page 9

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

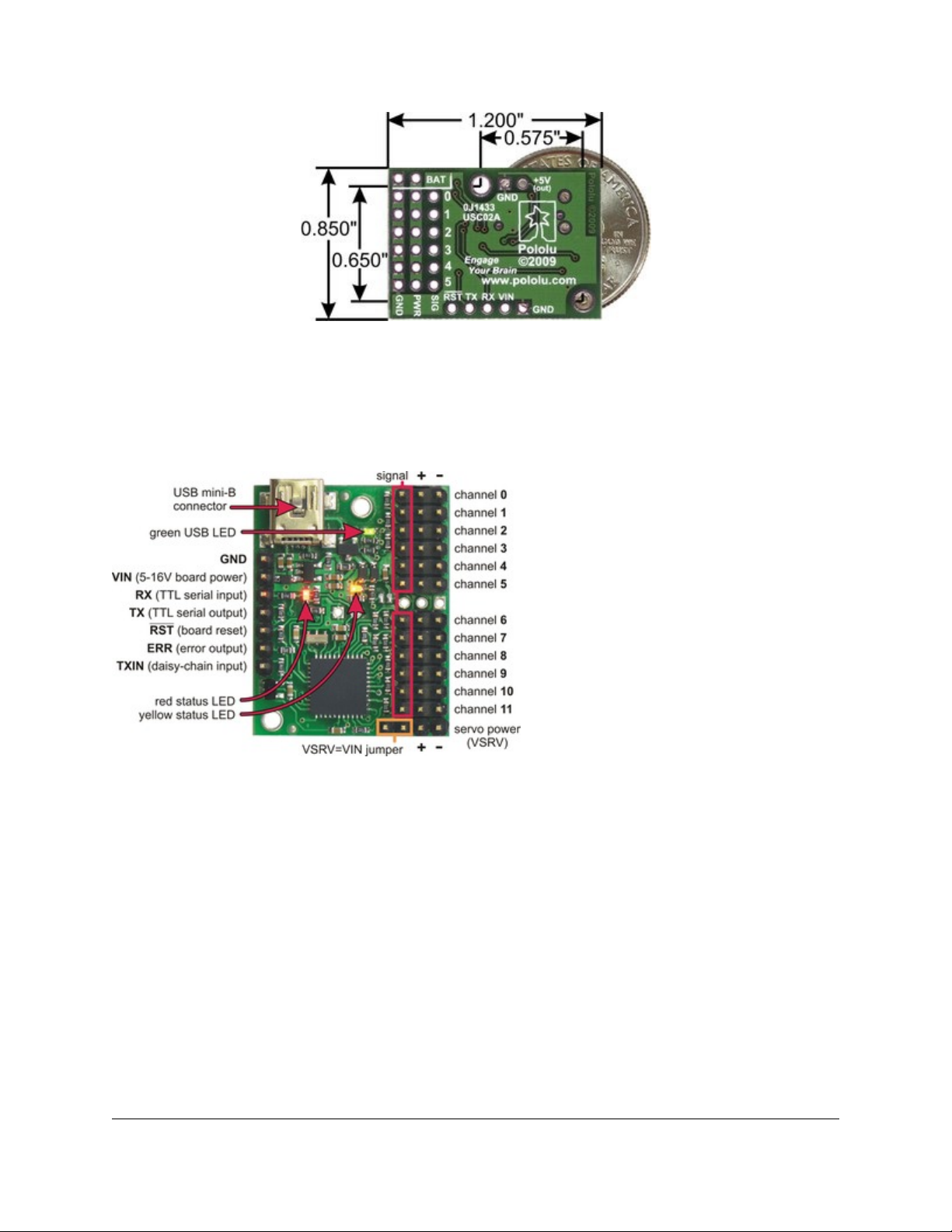

Micro Maestro 6-channel USB servo controller

bottom view with quarter for size reference.

The dimensions of the Micro Maestro PCB are 1.2″ × 0.85″. The mounting holes have a diameter of 0.086″and are

intended for #2 or M2 screws. The vertical and horizontal distances between the two mounting holes are 0.65″ and

0.575″. The Micro Maestro weighs 3.0 g (0.11 oz) without header pins.

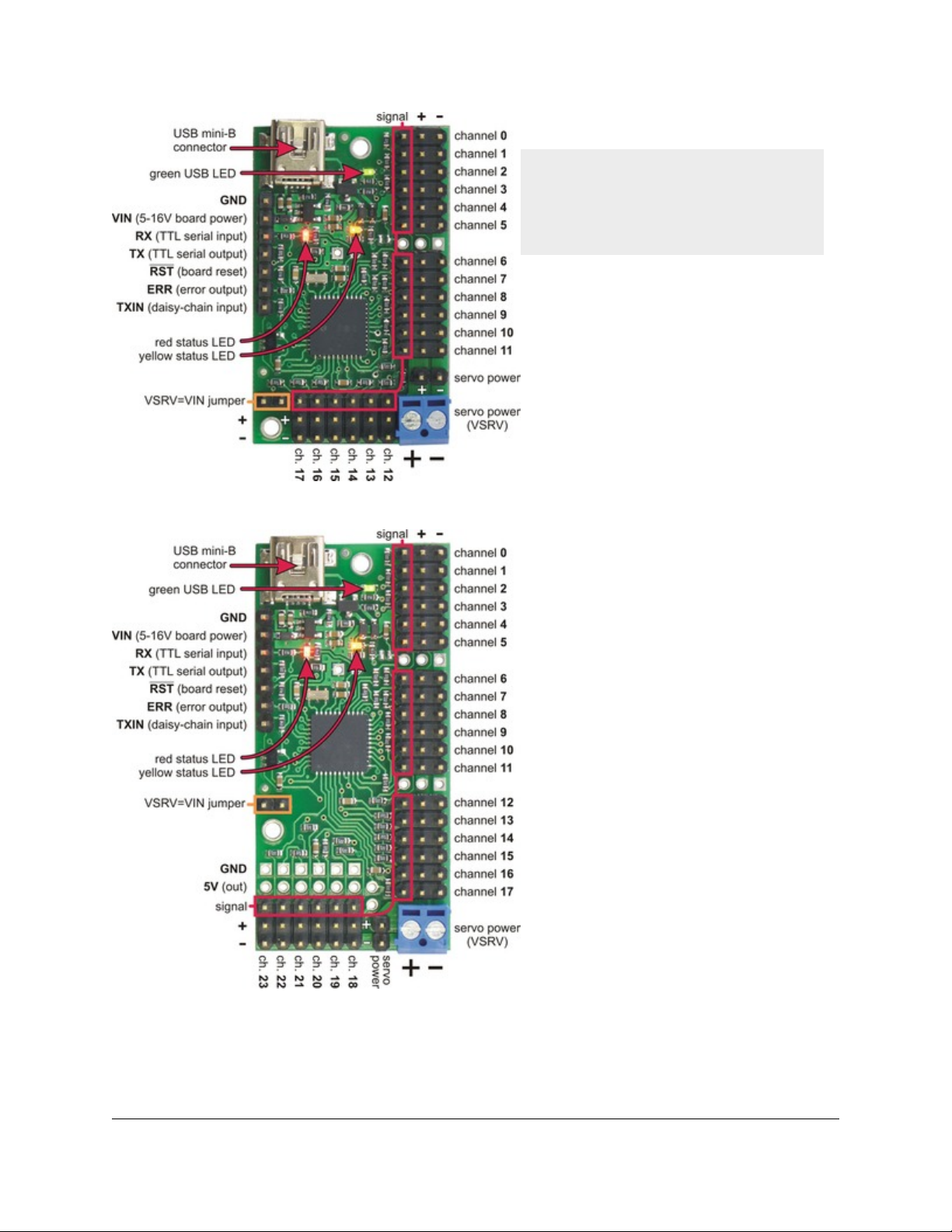

1.b. Mini Maestro Pinout and Components

Mini Maestro 12-channel USB servo controller (fully

assembled) labeled top view.

1. Overview Page 9 of 73

Page 10

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Note: This section applies to the Mini

Maestro 12, 18, and 24 servo controllers.

Please see Section 1.a for Micro Maestro

pinout and component information.

The Pololu Mini Maestro 12-,18-, and

24-channel servo controllers can connect to a

computer’s USB port via a USB A to mini-B

cable [http://www.pololu.com/product/130] (not

included). The USB connection is used to

configure the servo controller. It can also be used

to send commands to the servo controller, get

information about the servo controller’s current

state, and send and receive TTL serial bytes on

the TX and RX lines.

Mini Maestro 18-channel USB servo controller (fully

assembled) labeled top view.

Mini Maestro 24-channel USB servo controller (fully

assembled) labeled top view.

1. Overview Page 10 of 73

Page 11

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

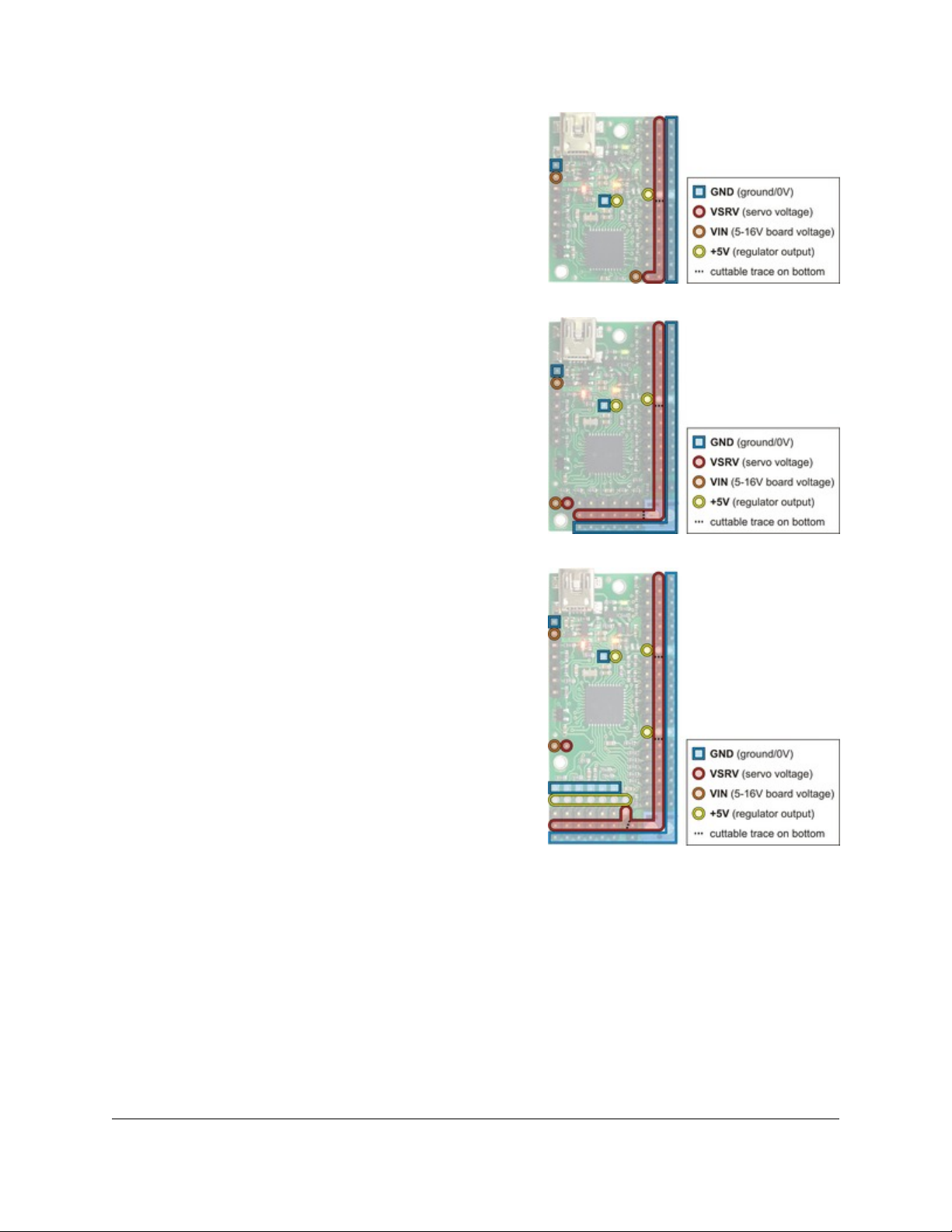

The processor and the servos can have separate power supplies.

Processor power must come either from USB or from an external

5–16V power supply connected to the VIN and GND inputs on the

left side of the board. It is safe to have an external power supply

connected at the same time that USB is connected; in that case the

processor will be powered from the external supply. Note that if the

external supply falls below 5 V, correct operation is not guaranteed,

even if USB is also connected.

Servo power connections are provided in the lower right corner of

Mini Maestro 12 power pins.

the Mini Maestro board. On the Mini Maestro 18 and 24, you can

make servo power connections via a 2-pin terminal block or a 2-pin

0.1″ header; the Mini Maestro 12 only has a 2-pin 0.1″ header for

connecting servo power. Servo power is passed directly to the

servos without going through a regulator, so the only restrictions on

your servo power supply are that it must be within the operating

range of your servos and provide enough current for your

application. Please consult the datasheets for your servos to

determine an appropriate servo power source, and note that a

ballpark figure for the current draw of an average straining servo is

1 A.

You can power the Maestro’s processor and servos from a single

Mini Maestro 18 power pins.

power supply by connecting the positive power line to both VIN and

the servo power ports (only one ground connection is needed

because all ground pins on the board are connected). The

recommended way to do this is to connect your power supply to the

dedicated servo power pins in the corner of the board and use the

included blue shorting block to connect the pins labeled

“VSRV=VIN”.

The 5V (out) power output allows you to power your own 5V

devices from the 150mA on-board regulator or directly from USB.

The on-board regulator is used whenever VIN is powered; in this

case, since the Maestro requires 50 mA, there is about 50 mA

available to power other devices.

The signal lines (0, 1, 2, …) are used for sending pulses to servos,

controlling digital outputs, and measuring voltages. The total

current limit (in or out) for these pins is 150 mA, but when using the

Mini Maestro 24 power pins.

on-board regulator the current out is limited to 50 mA (see above.)

The RX line is used to receive non-inverted TTL (0–5 V) serial bytes, such as those from microcontroller UARTs.

These bytes can either be serial commands for the Maestro, arbitrary bytes to send back to the computer via the USB

connection, or both. For more information about the Maestro’s serial interface, see Section 5.a. Note that the Maestro

will probably be able to receive 3.3V TTL serial bytes, but it is not guaranteed to read 3.3V as high on the RX pin, so

you should boost 3.3V TTL serial signals to above 4V if you want to ensure reliable operation.

The TX line transmits non-inverted TTL (0–5 V) serial bytes. These bytes are either generated by the Mini Maestro

itself (as responses to serial commands or arbitrary bytes sent from the computer via the USB connection), or they

come from the TXIN line.

1. Overview Page 11 of 73

Page 12

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

The RST pin can be driven low to reset the Maestro’s microcontroller, but this should not be necessary for typical

applications. The line is internally pulled high, so it is safe to leave this pin unconnected. Driving RST low is roughly

equivalent to powering off the Maestro; it will not reset any of the configuration parameters stored in non-volatile

memory. To reset the configuration parameters, select Device > Reset to default settings… in the Maestro Control

Center.

The ERR line is an output that is tied to the red error/user LED. It is driven high when the red LED is on, and it is a

pulled low through the red LED when the red LED is off. The red LED turns on when an error occurs, turns off when

the error flags have been cleared, and can also be controlled by the user script. Since the ERR line is never driven low,

it is safe to connect the ERR line of multiple Mini Maestros together. Please note, however, that doing this will cause

the red LEDs of all connected Mini Maestros to turn on whenever one of the Mini Maestros turns on its red LED. For

more information on the possible error conditions and response options, please see Section 4.b.

The TXIN line is a serial input line that makes it easy to chain together multiple Mini Maestros. Any serial bytes

received on this line will be buffered through an AND gate and transmitted on the TX line. See Section 5.g for more

information about daisy chaining.

Bottom view with dimensions (in inches) of Pololu Micro and Mini Maestro

servo controllers.

The dimensions of the Mini Maestro PCBs are shown in the picture above, along with the Micro Maestro for

comparison. The mounting holes have a diameter of 0.086″and are intended for #2 or M2 screws. The vertical and

horizontal distances between the two mounting holes are as follows: 1.2″ and 0.5″ for the Mini Maestro 12, 1.58″ and

0.5″ for the Mini Maestro 18, and 1.5″ and 0.5″ for the Mini Maestro 24.

1.c. Indicator LEDs

The Maestro has three indicator LEDs:

• The green USB LED indicates the USB status of the device. When the Maestro is not connected to a

computer via the USB cable, the green LED will be off. When you connect the Maestro to USB, the green

LED will start blinking slowly. The blinking continues until the Maestro receives a particular message from the

computer indicating that the Maestro’s USB drivers are installed correctly. After the Maestro gets this message,

the green LED will be on, but it will flicker briefly when there is USB activity. The control center application

constantly streams data from the Maestro, so when the control center is running and connected to the Maestro,

the green LED will flicker constantly.

• The red error/user LED usually indicates an error. The red LED turns on when an error occurs, and turns off

when the error flags have been cleared. See Section 4.b for more information about errors. The red LED can also

1. Overview Page 12 of 73

Page 13

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

be controlled by the user script; the red LED will be on if there is an error or if the script command for turning it

on was run.

• The yellow status LED indicates the control status. When the Maestro is in auto-baud detect mode (the

default) and has not yet detected the baud rate, the yellow LED will blink slowly. During this time the Maestro

does not transmit any servo pulses. Once the Maestro is ready to drive servos, the yellow LED will periodically

flash briefly. The frequency of the flashes is proportional to the servo period (the amount of time between pulses

on a single channel); with a period of 20 ms the flashing occurs approximately once per second. The number of

flashes indicates the state: a single flash indicates that none of the servos are enabled (no pulses are being sent)

and all output channels are low, while a double flash indicates that at least one of the servos is enabled or one of

the output channels is being driven high. Also, when a valid serial command is received, the yellow LED will

emit a brief, dim flash which ends when the next valid serial command is received or when the main blinking

occurs (whichever happens first). Mini Maestros with firmware version 1.00 only emit single flashes unless a

servo channel with a speed or acceleration limit is enabled. This behavior was fixed in firmware version 1.02 to

be consistent with the Micro Maestro.

When the Maestro is reset in some other way than being initially powered up, the red and/or yellow LEDs blink four

times to indicate the reset condition:

• Yellow off, red blinking: A brownout reset. This occurs when the Maestro’s 5 V line drops below about 3.0 V,

usually due to low batteries or an inadequate power supply.

• Yellow blinking, red off: The Maestro was reset by a low voltage on its RST line.

• Yellow and red blinking together: A firmware crash resulted in a “watchdog” reset. This also occurs

immediately following a firmware upgrade, as a normal part of the upgrade process.

• Yellow blinking, red steady: A firmware error resulted in a soft reset. This should never occur during normal

usage.

1.d. Supported Operating Systems

The Maestro USB drivers and configuration software work under Microsoft Windows XP, Windows Vista, Windows

7, Windows 8, and Linux.

We do not provide any software for Mac OS X, but the Maestro’s two virtual COM ports are compatible with Mac

OS X 10.7 (Lion) and later. The Maestro must be initially configured from a Windows or Linux computer, but after

that it can be controlled from a Mac.

Mac OS X compatibility: we have confirmed that the Maestro works on Mac OS X 10.7 and we can

assist with advanced technical issues, but most of our tech support staff does not use Macs, so basic

support for Mac OS X is limited.

1. Overview Page 13 of 73

Page 14

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

2. Contacting Pololu

You can check the product page of your particular Maestro model for additional information. We would be delighted

to hear from you about any of your projects and about your experience with the Maestro. You can contact us

[http://www.pololu.com/contact] directly or post on our forum [http://forum.pololu.com/]. Tell us what we did well, what we

could improve, what you would like to see in the future, or anything else you would like to say!

2. Contacting Pololu Page 14 of 73

Page 15

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

3. Getting Started

3.a. Installing Windows Drivers and Software

If you are using Windows XP, you will need to have Service Pack 3 [http://www.microsoft.com/downloads/

details.aspx?FamilyId=68C48DAD-BC34-40BE-8D85-6BB4F56F5110] installed before installing the drivers for

the Maestro. See below for details.

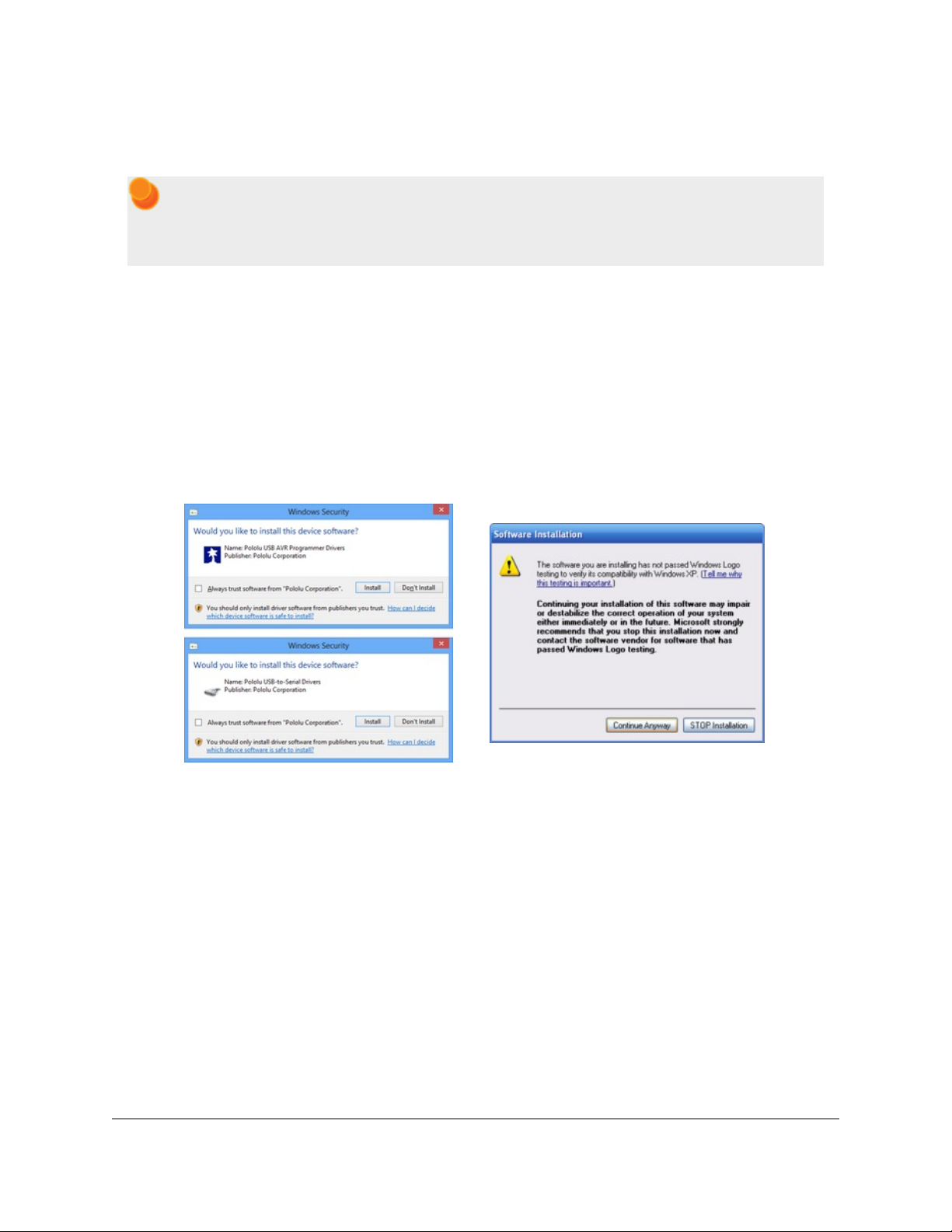

Before you connect your Maestro to a computer running Microsoft Windows, you should install its drivers:

1. Download the Maestro Servo Controller Windows Drivers and Software [http://www.pololu.com/file/

download/maestro-windows-130422.zip?file_id=0J266] (5MB zip)

2. Open the ZIP archive and run setup.exe. The installer will guide you through the steps required to install the

Maestro Control Center, the Maestro command-line utility (UscCmd), and the Maestro drivers on your computer.

If the installer fails, you may have to extract all the files to a temporary directory, right click setup.exe, and select

“Run as administrator”.

3. During the installation, Windows will ask you if you want to install the drivers. Click “Install” (Windows 7,

8, and Vista) or “Continue Anyway” (Windows XP).

4. After the installation is finished, your start menu should have a shortcut to the Maestro Control Center (in

the Pololu folder). This is a Windows application that allows you to configure, control, debug, and get real-time

feedback from the Maestro. There will also be a command-line utility called UscCmd which you can run at a

Command Prompt.

Windows 8, Windows 7, and Windows Vista users: Your computer should now automatically install the necessary

drivers when you connect a Maestro. No further action from you is required.

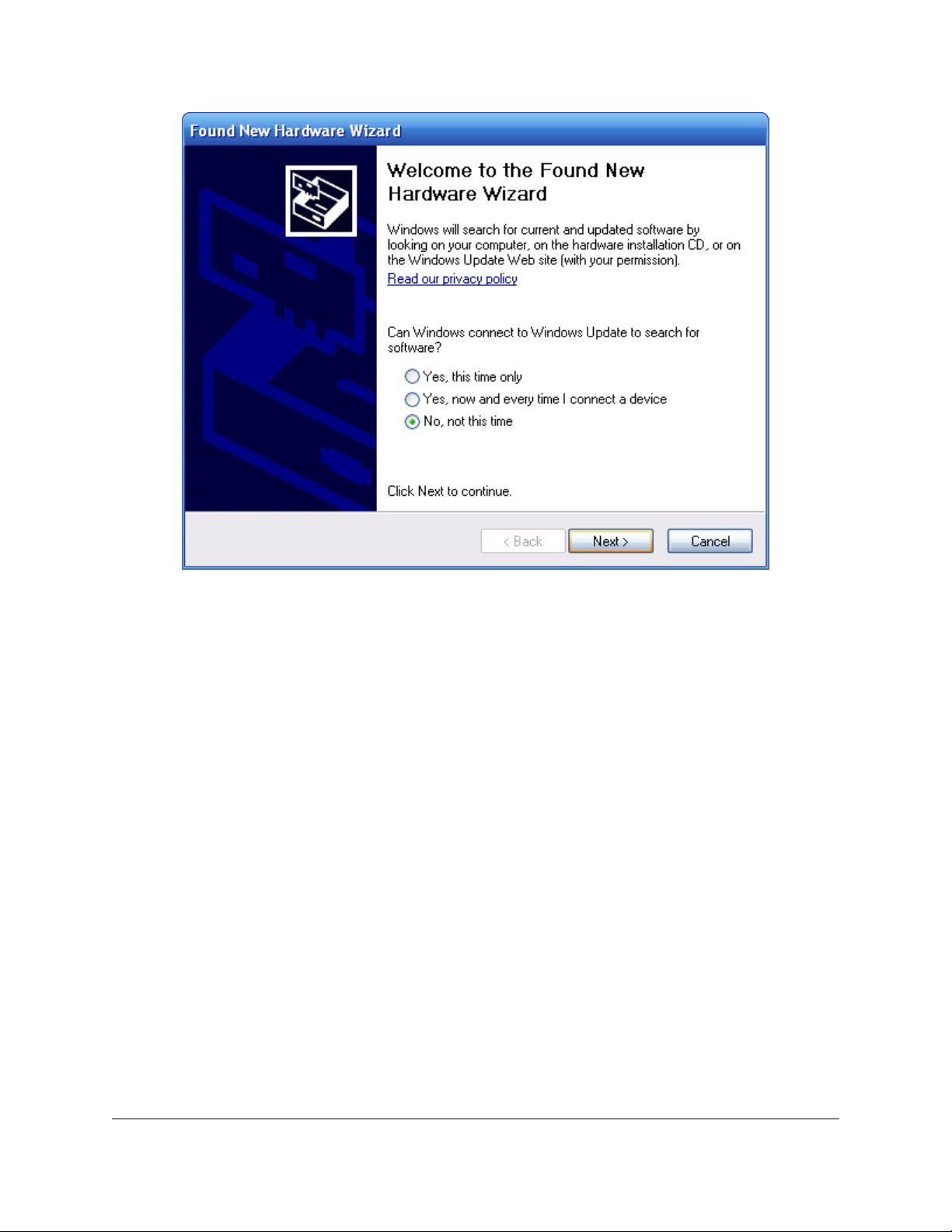

Windows XP users: Follow steps 5–9 for each new Maestro you connect to your computer.

5. Connect the device to your computer’s USB port. The Maestro shows up as three devices in one so your

XP computer will detect all three of those new devices and display the “Found New Hardware Wizard”

three times. Each time the “Found New Hardware Wizard” pops up, follow steps 6-9.

6. When the “Found New Hardware Wizard” is displayed, select “No, not this time” and click “Next”.

3. Getting Started Page 15 of 73

Page 16

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

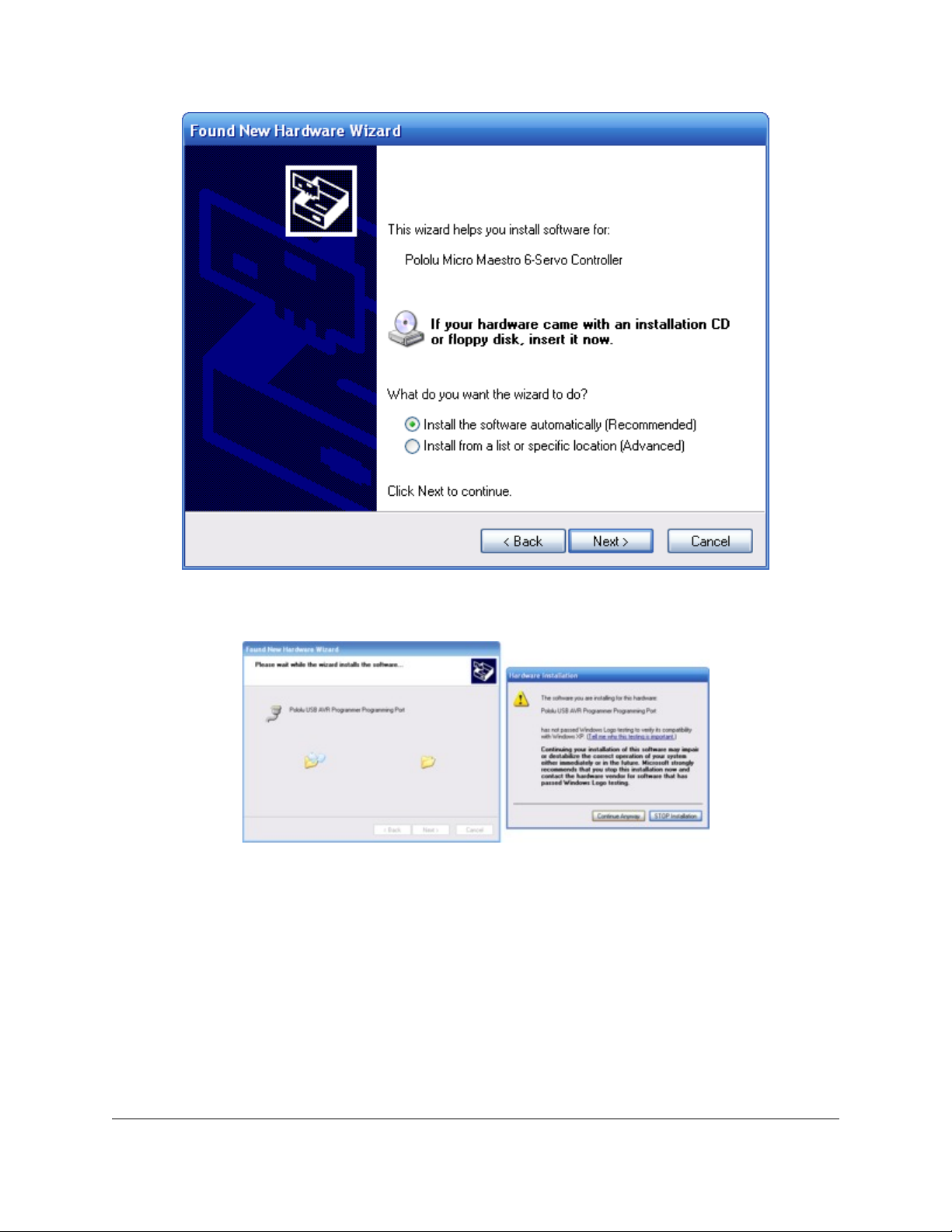

7. On the second screen of the “Found New Hardware Wizard”, select “Install the software automatically” and

click “Next”.

3. Getting Started Page 16 of 73

Page 17

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

8. Windows XP will warn you again that the driver has not been tested by Microsoft and recommend that you

stop the installation. Click “Continue Anyway”.

9. When you have finished the “Found New Hardware Wizard”, click “Finish”. After that, another wizard will

pop up. You will see a total of three wizards when plugging in the Maestro. Follow steps 6-9 for each wizard.

3. Getting Started Page 17 of 73

Page 18

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

If you use Windows XP and experience problems installing or using the serial port drivers, the cause of your problems

might be a bug in older versions of Microsoft’s usb-to-serial driver usbser.sys. Versions of this driver prior to version

5.1.2600.2930 will not work with the Maestro. You can check what version of this driver you have by looking in

the “Details” tab of the “Properties” window for usbser.sys in C:\Windows\System32\drivers. To get the fixed version

of the driver, you will need to install Service Pack 3 [http://www.microsoft.com/downloads/details.aspx?FamilyId=68C48DAD-

BC34-40BE-8D85-6BB4F56F5110]. If you do not want Service Pack 3, you can try installing Hotfix KB918365 instead, but

some users have had problems with the hotfix that were resolved by upgrading to Service Pack 3. The configuration

software will work even if the serial port drivers are not installed properly.

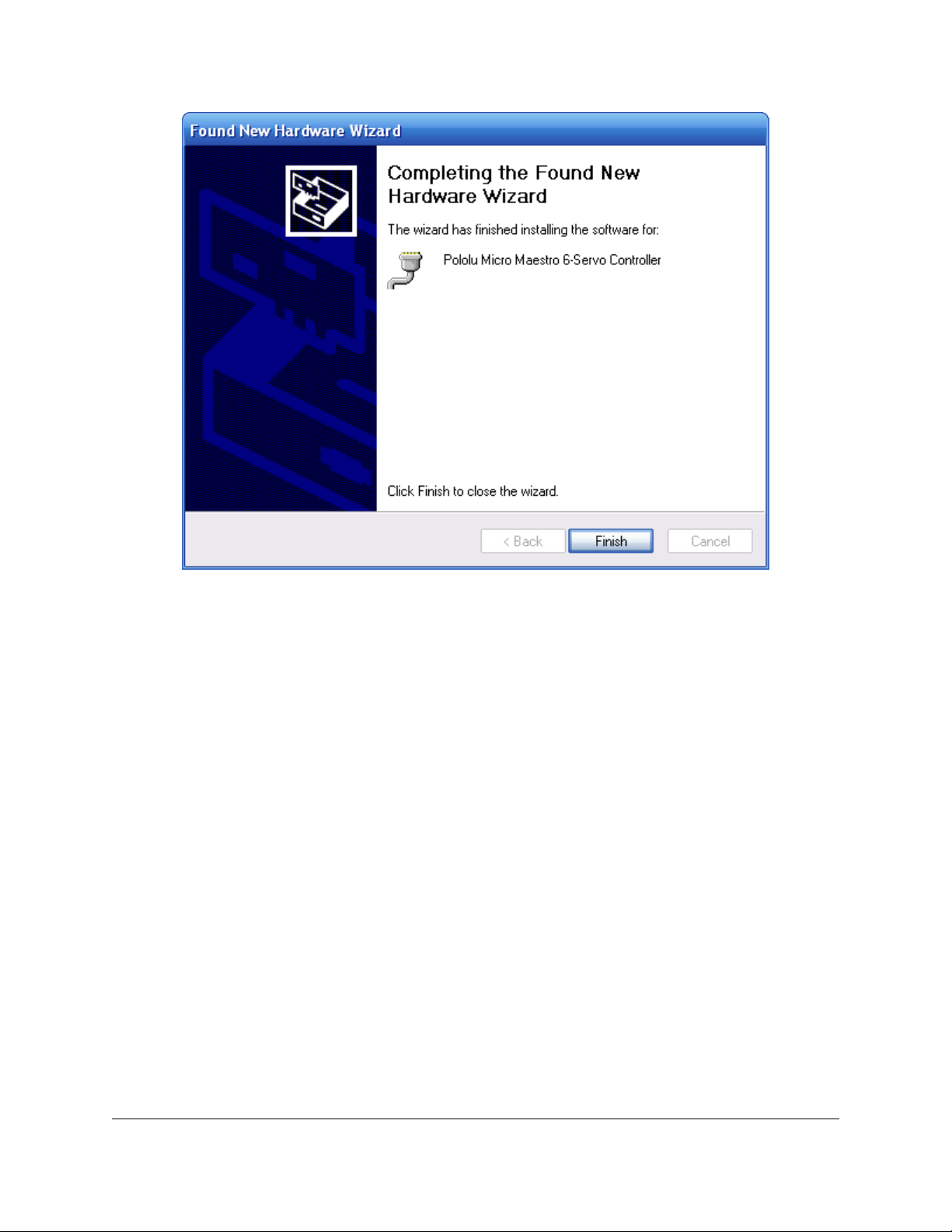

After installing the drivers, if you go to your computer’s Device Manager and expand the “Ports (COM & LPT)” list,

you should see two COM ports: the Command Port and the TTL Port. In parentheses after these names, you will see

the name of the port (e.g. “COM5” or “COM6”). If you expand the “Pololu USB Devices” list you should see an

entry for the Maestro.

3. Getting Started Page 18 of 73

Page 19

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Windows 7 device manager showing the Micro Maestro 6-channel USB servo controller.

Windows XP device manager showing the Micro Maestro 6-channel USB servo

controller.

Some software will not allow connection to higher COM port numbers. If you need to change the COM port number

assigned to your USB device, you can do so using the Device Manager. Bring up the properties dialog for the COM

port and click the “Advanced…” button in the “Port Settings” tab. From this dialog you can change the COM port

assigned to your device.

3. Getting Started Page 19 of 73

Page 20

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

3.b. Installing Linux Drivers and Software

The Maestro Control Center running in Ubuntu Linux.

You can download the Maestro Control Center and the Maestro command-line utility (UscCmd) for Linux here:

• Maestro Servo Controller Linux Software [http://www.pololu.com/file/download/maestro-

linux-100507.tar.gz?file_id=0J315] (112k gz)

Unzip the tar/gzip archive by running “tar -xzvf” followed by the name of the file. After following the instructions in

README.txt, you can run the programs by executing MaestroControlCenter and UscCmd.

You can also download the C# source code of UscCmd as part of the Pololu USB Software Development Kit

[http://www.pololu.com/docs/0J41]. Read README.txt in the SDK for more information.

The Maestro’s two virtual serial ports can be used in Linux without any special driver installation. The virtual serial

ports are managed by the cdc-acm kernel module, whose source code you can find in your kernel’s source code

drivers/usb/class/cdc-acm.c. When you connect the Maestro to the PC, the two virtual serial ports should appear

as devices with names like /dev/ttyACM0 and /dev/ttyACM1 (the number depends on how many other ACM devices

you have plugged in). The port with the lower number should be the Command Port, while the port with the higher

number should be the TTL Serial Port. You can use any terminal program (such as kermit) to send and receive bytes

on those ports.

3.c. Using the Maestro without USB

It is possible to use the Maestro as a serial servo controller without installing any USB drivers or using a PC. Without

using USB, you will not be able to change the Maestro’s settings, but you can use the default settings which are

suitable for many applications. The default settings that the Maestro ships with are described below.

Default Settings

• The serial mode is “UART, detect baud rate”; after you send the 0xAA baud rate indication byte, the Maestro

will accept TTL-level serial commands on the RX line.

• The Pololu Protocol device number is 12, the Mini SSC offset is 0, and serial timeout and CRC are disabled.

• All channels are configured as servos, with a minimum pulse with of 992 μs and a maximum pulse width of

2000 μs.

3. Getting Started Page 20 of 73

Page 21

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

• The 8-bit neutral point is 1500 μs and the 8-bit range is 476.25 μs.

• On startup or error, the servos turn off (no pulses are sent).

• On startup, there are no speed or acceleration limits, but you can set speed and acceleration limits using serial

commands.

• The servo period is 20 ms (each servo receives a pulse every 20 ms).

• The user script is empty.

3. Getting Started Page 21 of 73

Page 22

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

4. Using the Maestro Control Center

The Maestro’s USB interface provides access to all configuration options as well as support for real-time control,

feedback, and debugging. The Maestro Control Center is a graphical tool that makes it easy for you to use the USB

interface; for almost any project, you will want to start by using the control center to set up and test your Maestro.

This section explains most of the features of the Maestro and the Maestro Control Center.

4.a. Status and Real-time Control

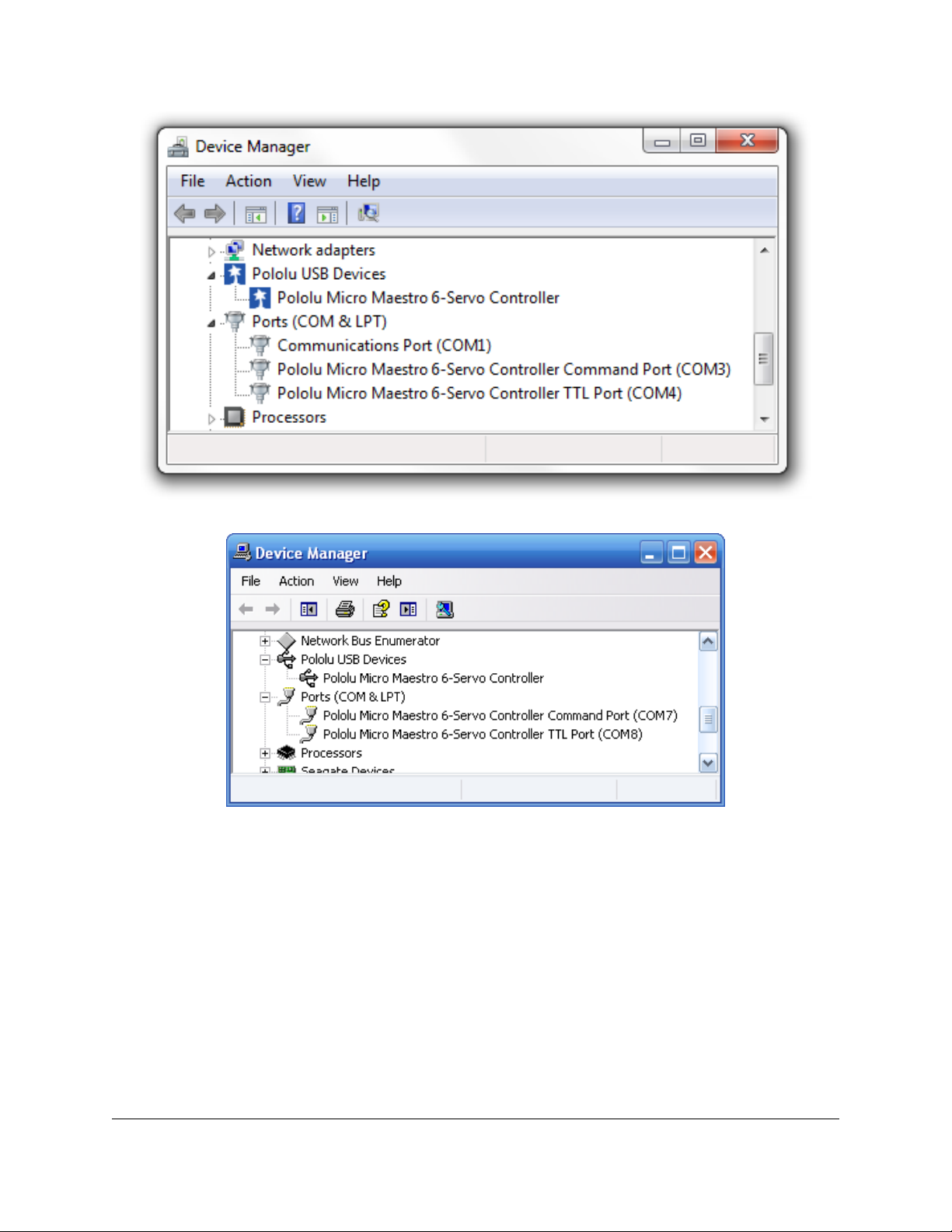

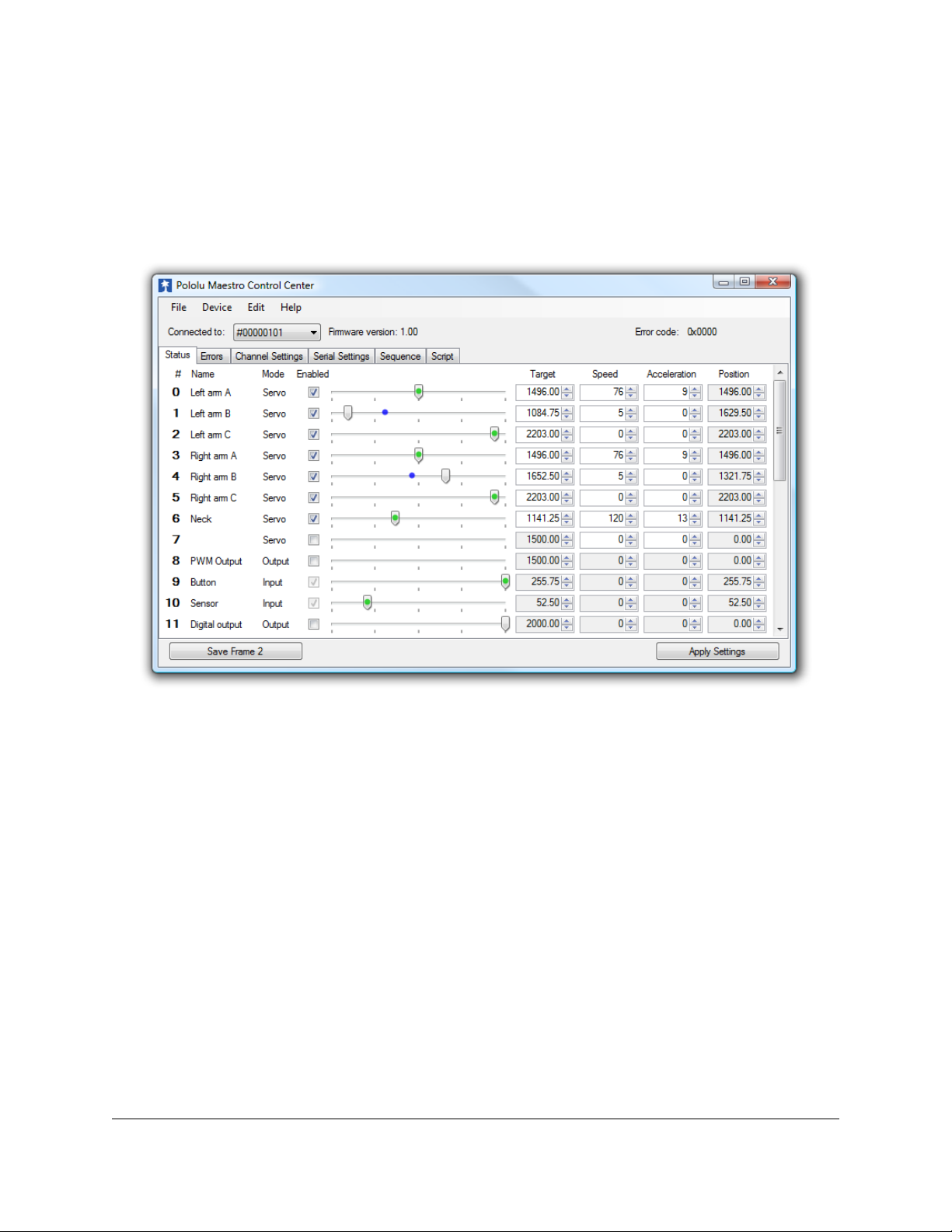

The Status tab in the Maestro Control Center.

The Status tab is used for controlling the Maestro’s outputs and for monitoring its status in real time. A separate row

of controls is displayed for each of the Maestro’s channels. In the screenshot above, there are 12 channels displayed

because the Maestro Control Center is connected to the Mini Maestro 12-channel servo controller. When the Maestro

Control Center connects to Maestro models with more or fewer channels, it displays more or fewer channels on the

screen.

For a channel configured as a servo or output, the checkbox enables the output, dragging the slider adjusts the target

setting of the channel, and the green ball indicates the channel’s current position. For example, if the channel is set

to a relatively slow speed, when the slider is moved to a new position, the green ball will slowly move until it has

reached the slider, indicating that the output has reached its target. For more precise control, a target value may also be

entered directly into the “Target” input box. The slider is automatically scaled to match the minimum and maximum

values specified in the Settings tab.

For a channel configured as input, the slider, green ball, “Target”, and “Position” display the current value of the

input. There is no control available for inputs. The inputs on channels 0–11 are analog: their values range from 0 to

255.75, representing voltages from 0 to 5 V. The inputs on channels 12–23 are digital: their values are either exactly

0 or exactly 255.75.

4. Using the Maestro Control Center Page 22 of 73

Page 23

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

The “Speed” and “Acceleration” inputs allow the speed and acceleration of individual servo channels to be adjusted

in real time. The default values are specified in the Settings tab, but it can be useful to adjust them here for fine-tuning.

All of the controls on this tab always display the current values as reported by the Maestro itself, so they are useful

for monitoring the actions caused by another program or device. For example, if a microcontroller uses the TTL serial

interface to change the speed of servo channel 2 to a value of 10, this value will be displayed immediately in the

corresponding input, even if something else was formerly entered there.

PWM Output (Mini Maestro 12, 18, and 24 only)

On the Mini Maestro 12, 18, and 24, one of the channels

may be used as a general-purpose PWM output with a

frequency from 2.93 kHz to 12 MHz and up to 10 bits of

resolution. This could be used, for example, as an input to

a motor driver or for LED brightness control. The PWM

output is on channel 8 for the Mini Maestro 12 and on

channel 12 for the Mini Maestro 18 and 24. This channel

must be configured as an output for PWM to be available.

You may use the PWM Output control at the bottom of the

Status tab to test out PWM, by checking the checkbox and

entering specific values for the on time and period, in units

of 1/48 μs. A period of 4800, for example, will generate a

frequency of 10 kHz. The resolution on these values

depends on the period as shown in the table below:

The PWM Output control in the Status tab in the

Maestro Control Center (only available on the

Mini Maestro 12, 18, and 24).

Period

range

Period

resolution

On-time

resolution

1–1024 4 1

1025–4096 16 4

4097–16384 64 16

The special periods 1024, 4096, and 16384 are not recommended, since 100% duty cycle is not available at these

values. If the on time is set equal to the period at one of the special values, the duty cycle will be 0% (a low output).

The periods 1020 (47.1 kHz), 4080 (11.7 kHz), and 16320 (2.9 kHz) provide the best possible resolution with 100%

and 0% duty cycle options, so you should use one of these periods if possible.

You will probably want to use serial commands or a script to make use of PWM in your project. See Section 5.e and

Section 6.b for more information.

4. Using the Maestro Control Center Page 23 of 73

Page 24

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

4.b. Errors

The Errors tab in the Maestro Control Center.

The Errors tab indicates problems that the Maestro has detected while running, either communications errors or errors

generated by bugs in a script.

Each error corresponds to a bit in the two-byte error register. The red LED will be on as long as any of the bits in the

error register are set to 1 (it can also be turned on by the led_on script command). The value of the error register is

displayed in the upper right corner of the main window.

When an error occurs, the corresponding bit in the error register is set to 1 and the Maestro sends all of its servos and

digital outputs to their home positions, as specified in the Settings tab (Section 4.e). Any servos or outputs that are

configured to be in the “Ignore” mode will not be changed. The error register is cleared by the “Get Errors” serial

command.

The errors and their corresponding bit numbers are listed below:

• Serial Signal Error (bit 0)

A hardware-level error that occurs when a byte’s stop bit is not detected at the expected place. This can occur if

you are communicating at a baud rate that differs from the Maestro’s baud rate.

• Serial Overrun Error (bit 1)

A hardware-level error that occurs when the UART’s internal buffer fills up. This should not occur during normal

operation.

• Serial RX buffer full (bit 2)

A firmware-level error that occurs when the firmware’s buffer for bytes received on the RX line is full and a byte

from RX has been lost as a result. This error should not occur during normal operation.

4. Using the Maestro Control Center Page 24 of 73

Page 25

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

• Serial CRC error (bit 3)

This error occurs when the Maestro is running in CRC-enabled mode and the cyclic redundancy check (CRC)

byte at the end of the command packet does not match what the Maestro has computed as that packet’s CRC

(Section 5.d). In such a case, the Maestro ignores the command packet and generates a CRC error.

• Serial protocol error (bit 4)

This error occurs when the Maestro receives an incorrectly formatted or nonsensical command packet. For

example, if the command byte does not match a known command or an unfinished command packet is

interrupted by another command packet, this error occurs.

• Serial timeout error (bit 5)

When the serial timeout is enabled, this error occurs whenever the timeout period has elapsed without the

Maestro receiving any valid serial commands. This timeout error can be used to make the servos return to their

home positions in the event that serial communication between the Maestro and its controller is disrupted.

• Script stack error (bit 6)

This error occurs when a bug in the user script has caused the stack to overflow or underflow. Any script

command that modifies the stack has the potential to cause this error. The stack depth is 32 on the Micro Maestro

and 126 on the Mini Maestros.

• Script call stack error (bit 7)

This error occurs when a bug in the user script has caused the call stack to overflow or underflow. An overflow

can occur if there are too many levels of nested subroutines, or a subroutine calls itself too many times. The

call stack depth is 10 on the Micro Maestro and 126 on the Mini Maestros. An underflow can occur when there

is a return without a corresponding subroutine call. An underflow will occur if you run a subroutine using the

“Restart Script at Subroutine” serial command and the subroutine terminates with a return command rather than

a quit command or an infinite loop.

• Script program counter error (bit 8)

This error occurs when a bug in the user script has caused the program counter (the address of the next instruction

to be executed) to go out of bounds. This can happen if your program is not terminated by a quit, return, or

infinite loop.

Performance Flags

The errors tab also shows which performance flags have been set. This feature only applies to the Mini Maestro 12,

18, and 24. The performance flags indicate that the processor missed a deadline for performing a servo control task,

and as a result the Maestro’s servo control got slowed down in some way. Performance flags should not occur during

normal operation as long as your settings are within with the limitations described in Section 9.

4. Using the Maestro Control Center Page 25 of 73

Page 26

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

4.c. Sequencer

The Sequence tab in the Maestro Control Center.

The Sequence tab allows simple motion sequences to be created and played back on the Maestro. A sequence is

simply a list of “frames” specifying the positions of each of the servos and a duration (in milliseconds) for each frame.

Sequences are stored in the registry of the computer where the sequence was created. Sequences can be copied to the

script, which is saved on the Maestro. Sequences can also be exported to another computer via a saved settings file.

To begin creating a sequence, click the New Sequence button and enter a name for the sequence. Using the controls

in the Status tab, set each of the servos to the position you would like for the first frame, then click Save Frame at

the bottom of the window. Repeat to create several frames, then switch back to the Sequence tab. You can now play

back the sequence using the “Play Sequence” button, or you can set the servos to the positions of the specific frame

by clicking the Load Frame button.

The Frame properties… button allows you to set the duration and name of a frame.

The Save Over Current Frame button overwrites the selected frame(s) with the current target values from the

Maestro.

If the Play in a loop checkbox is checked, sequence playback will loop back to the beginning of the sequence

whenever it reaches the end.

4. Using the Maestro Control Center Page 26 of 73

Page 27

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

The Sequence dropdown box along with the Rename, Delete, and New Sequence buttons allow you to create and

manage multiple sequences.

A sequence can also be used to create a script which is stored on the Maestro. There are two buttons for copying the

sequence into the script:

• Copy Sequence to Script sets the script to a looped version of the sequence. In most cases, you will also

want to check the “Run script on startup” option in the Script tab so that the script runs automatically when the

Maestro is powered up, enabling fully automatic operation without a connection to a computer.

• Copy all Sequences to Script is an advanced option that adds a set of subroutines to the end of the current

script. Each subroutine represents one of the sequences; calling the subroutine from the script will cause the

sequence to be played back a single time. These subroutines must be used together with custom script code; for

example, you could make a display in which a button connected to an input channel triggers a sequence to play

back.

Sequence Editing Tips

• You can select multiple frames by holding down the Ctrl or Shift buttons while clicking on them. This allows

you to quickly move, delete, set the duration of, cut, copy, or save over several frames at once.

• You can drag any of the tabs out of the main window in to their own windows. If you drag the Sequence tab

out of the window then you will be able to see the Status tab and the Sequence tab at the same time.

• You can cut, copy, and paste frames by selecting them and then using the Edit menu or the standard keyboard

shortcuts. Frames are stored on the clipboard as tab-separated text, so you can cut them from the frame list, paste

them in to a spreadsheet program, edit them, and then copy them back in to the frame list when you are done.

(This feature does not work in Linux.)

Keyboard Shortcuts

The following keyboard shortcuts can be used in the frame list:

• Ctrl+A: Select all frames.

• Ctrl+C: Copy selected frames.

• Ctrl+V or Shift+Insert: Paste/insert frames from clipboard.

• Ctrl+X: Cut selected frames.

• Ctrl+Up: Move selected frames up.

• Ctrl+Down: Move selected frames down.

• Del: Delete selected frames.

4. Using the Maestro Control Center Page 27 of 73

Page 28

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

4.d. Entering a Script

The Script tab in the Maestro Control Center.

The Script tab is where you enter a script to be loaded into the Maestro. For details on the Maestro scripting language,

see Section 6. Once you have entered a script and clicked the “Apply Settings” button to load the script on to the

device, there are a number of options available for testing and debugging your script on the Script tab.

Running and stepping through a script

To start a script running, click the green button labeled “Run Script”. Your script will be processed by the Maestro,

one instruction at a time, until a QUIT instruction is reached or an error occurs. In many cases it will be useful to

use a loop of some kind to cause a script to run forever. While the script is running, the red “Stop Script” button

will be available, and the small pink triangle will jump around your source code, showing you the instruction that is

currently being executed. If the script places data on the stack, it will be visible on the right side of the tab, and nested

subroutine calls are counted in a label at the top of the tab.

To examine the operation of a script in more detail, click the blue button labeled “Step Script”. This button causes the

script to execute a single instruction, then stop and wait for another command. By stepping through the script a single

instruction at a time, you can check that each part of your program does exactly what you expect it to do.

Setting the script to be run on startup

By default, the script only runs when you click the “Run Script” button. However, for many applications, you will

want the script to run automatically, so that the Maestro can be used without a permanent USB connection. Check the

“Run script on startup” option to cause the Maestro to automatically run the script whenever it is powered up. You

will still be able to use the controls on the Script tab for debugging or to stop the running script.

4. Using the Maestro Control Center Page 28 of 73

Page 29

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Examining the compiled code

Click the “View Compiled Code” button to see the actual bytes that are created by each line of your script. This is

available mostly as a tool for developers; if you are interested in the details of the bytecode used on the Maestro

(for example, if you want to write your own compiler), please contact us [http://www.pololu.com/contact]. At the end of

the compiled code is a listing of all of the subroutines, including their numbers in decimal and hex notation. These

numbers can be used with serial commands to enter the subroutines under external control.

4.e. Channel Settings

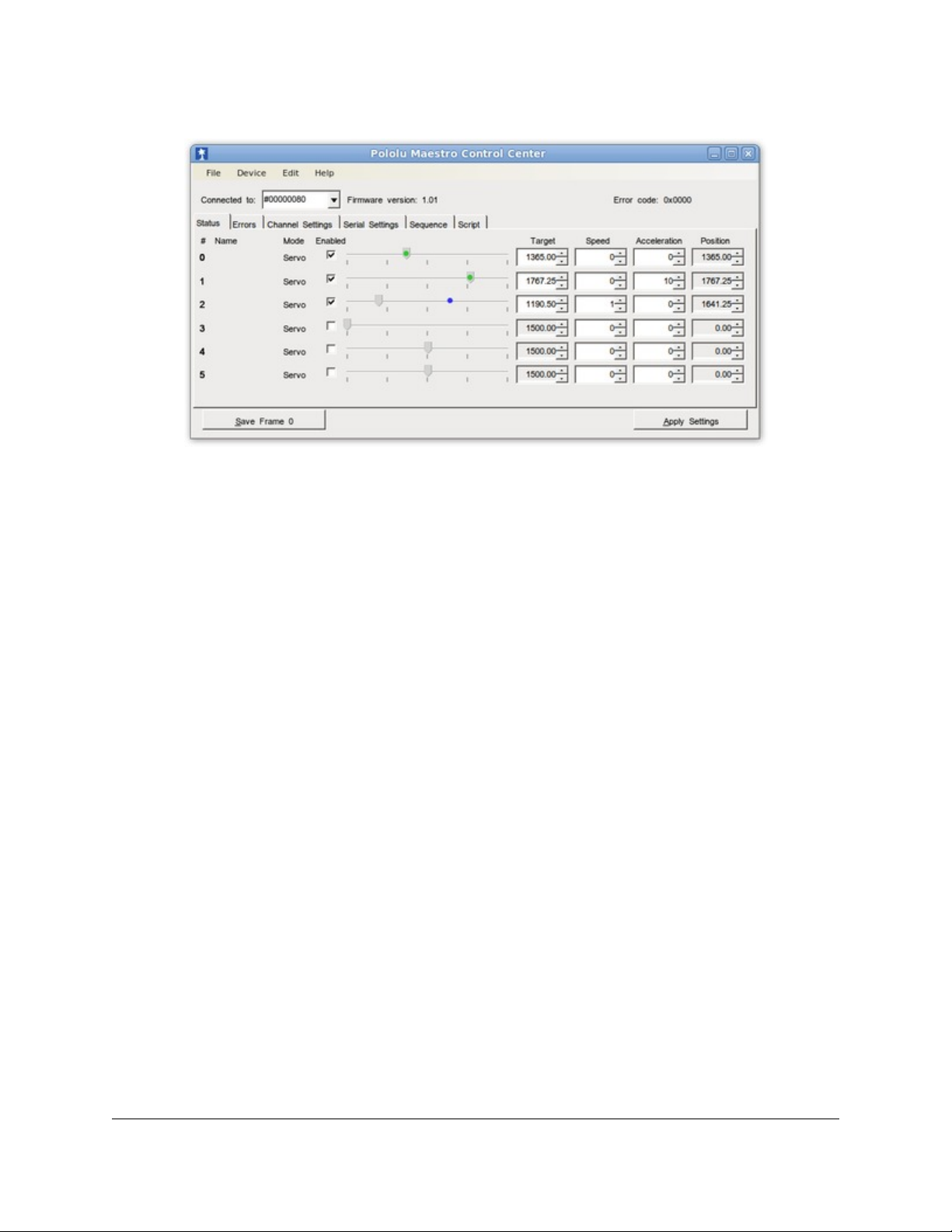

The Channel Settings tab in the Maestro Control Center.

The Channel Settings tab contains controls for many of the channel-related parameters that are stored on the Maestro,

affecting its operation immediately on start-up.

A separate row of controls is displayed for each of the Maestro’s channels:

Name. Each of the channels may be assigned a name, for your convenience. Channel names are not stored on the

device but instead in the system registry on your computer; if you want to use your Maestro on a different computer

without losing the names, save a settings file on the old computer and load it into the Maestro with the new one.

Mode. The mode of the channel is the most basic setting determining its operation. There are three options:

• Servo (the default) indicates an R/C servo PWM output.

• Input specifies that the channel should be used as an analog or digital input. The inputs on channels 0–11

are analog: they are measured continuously as a value between 0 and 1023 (VCC), at a maximum rate of about

20 kHz. The inputs on channels 12–23 are digital: their values are either exactly 0 or exactly 1023. Note that the

values displayed in the Target and Position boxes in the Status tab are one quarter of the actual input value, so

1023 is displayed as 255.75.

4. Using the Maestro Control Center Page 29 of 73

Page 30

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

• Output specifies that the channel should be used as a simple digital output. Instead of indicating a pulse

width, the position value of the channel is used to control whether the output is low (0 V) or high (VCC).

Specifically, the output is low unless the position value is greater than or equal to 1500.00 μs.

Rate specifies the pulse rate for each Servo channel. On the Micro Maestro 6, all servos must have the same pulse

rate, while on the Mini Maestro 12, 18, an 24, you can have two different rates and choose which rate to use on each

channel. The pulse rates available are controlled by the Period and Period multiplier settings described below.

Min and Max specify the allowed values for the channel’s position. For channels configured as Servo outputs, the

Min and Max settings correspond respectively to the minimum and maximum allowed pulse widths for the servo, in

units of microseconds.

On startup or error. This option specifies what value the target of the channel should have when the device starts up

(power-up or reset) or when there is an error. Note that if there is a speed or acceleration setting for the channel, the

output will smoothly transition to the specified position on an error, but not during start-up, since it has no information

about the previous position of the servo in this case.

• Off specifies that the servo should initially be off (have a value of 0), and that it should be turned off whenever

an error occurs.

• Ignore specifies that the servo should initially be off, but that its value should not change on error.

• Go to specifies a default position for the servo. The servo target will be set to this position on start-up or when

an error occurs.

Speed. This option specifies the speed of the servo in units of 0.25 μs / (10 ms). For example, with a speed of 4, the

position will change by at most 1 μs per 10 ms, or 100.00 μs/s. Mini Maestro 12, 18, and 24 only: If you use a period

other than the default 20 ms, the units of speed are different. See below for more information.

Acceleration. This option specifies the acceleration of the servo in units of (0.25 μs) / (10 ms) / (80 ms). For

example, with an acceleration of 4, the speed of the servo will change by a maximum of 1250 μs/s every second. Mini

Maestro 12, 18, and 24 only: If you use a period other than the default 20 ms, the units of acceleration are different.

See below for more information.

8-bit neutral. This option specifies the target value, in microseconds, that corresponds to 127 (neutral) for 8-bit

commands.

8-bit range. This option specifies the range of target values accesible with 8-bit commands. An 8-bit value of 0 results

in a target of neutral – range, while an 8-bit value of 254 results in a target value of neutral + range.

Advanced pulse control options are available:

Period is an advanced option that sets the period of all of the servo pulses, in milliseconds. This is the amount of time

between successive pulses on a given channel. If you are unsure about this option, leave it at the default of 20 ms.

Mini Maestro 12, 18, and 24 only: the units of speed and acceleration depend on the pulse rate. The units depend

only on Period, not on Period multiplier. Please refer to the following table for the relationship between Period and

speed/acceleration units:

4. Using the Maestro Control Center Page 30 of 73

Page 31

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Period (T) Rate Speed units Acceleration units

T = 20 ms 50 Hz (0.25 μs)/(10 ms) (0.25 μs)/(10 ms)/(80 ms)

T = 3–19 ms > 50 Hz (0.25 μs)/T (0.25 μs)/T/(8T)

T > 20 ms < 50 Hz (0.25 μs)/(T/2) (0.25 μs)/(T/2)/(4T)

Servos available is an advanced option for the Micro Maestro only specifying the number of channels that may be

used to control servos. For example, if this value is set to 4, only the channels 0–3 will be available as servo channels.

The other channels must all be set to Input or Output. The only reasons to make fewer servos available are to allow

a longer maximum pulse length or a shorter period.

Period multiplier is an advanced option for the Mini Maestro 12, 18, and 24 that allows a larger period (lower pulse

rate) on some of the channels. For example, if you select a period of 3 and a multiplier of 6, you can have some servos

run at 3 ms (333 Hz) and the others at 18 ms (55 Hz). When the multiplier is greater than 1, the pulse rate options will

be shown in each channel in the Rate column.

For the Mini Maestro 24-channel servo controller, one extra option is available:

Enable pull-ups on channels 18-20 turns on pull-up resistors for all of the channels 18-20 that are configured as

inputs. This guarantees that the input value will be high when nothing else is driving the line. When enabled, this

feature allows you to connect buttons or switches to channels 18, 19, or 20 without supplying your own external pullup resistor: simply connect the button/switch between ground and signal line.

4.f. Upgrading Firmware

Please do not attempt to upgrade your Maestro’s firmware unless you know what you are doing. Most

customers do not need to upgrade their firmware.

The firmware is the program that runs on the Maestro. The Maestro has field-upgradeable firmware that can be easily

updated with bug fixes or new features. There are four types of Maestros: the Micro Maestro 6-Channel USB Servo

Controller (usc02a), the Mini Maestro 12-Channel USB Servo Controller (usc03a), the Mini Maestro 18-Channel

USB Servo Controller (usc03b), and the Mini Maestro 24-Channel USB Servo Controller (usc03c). Each type of

Maestro has its own firmware and you cannot load the firmware for one type onto another.

Firmware Versions

• Firmware Version 1.00: This is the original version of the firmware. Currently, all Mini Maestros still ship

with this version of the firmware.

• Firmware Version 1.01 for the Micro Maestro 6-Channel USB Servo Controller: This firmware version

was released for the Micro Maestro only. It contains a bug-fix that makes “Ignore” mode servos behave correctly

at startup. All Micro Maestros shipped on or after November 19, 2009 come with this firmware version.

• Firmware Version 1.02: This firmware version was released on 2013-06-20 for all four types of Maestros.

This firmware version fixes a problem where in some cases the position of a servo with an acceleration limit

would never settle to the target value. This update also fixes some minor problems with error handling. For the

Mini Maestros, this update also fixes the yellow LED to blink the same way that it does on the Micro Maestro.

We are not yet shipping Maestros with firmware version 1.02, but it is available for download below.

4. Using the Maestro Control Center Page 31 of 73

Page 32

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Upgrade Instructions

You can determine the version of your Maestro’s firmware by running the Maestro Control Center, connecting to

a Maestro, and looking at the firmware version number which is displayed in the upper left corner next to the

“Connected to” drop-down box. If you do not already have the latest version (1.02), you can upgrade by following

the instructions below:

1. Save the settings stored on your Maestro using the “Save settings file…” option in the File menu. All of your

settings will be reset to default values during the firmware upgrade.

2. Determine which type of Maestro you have either by counting the number of channels or by looking at

the name that appears in your Device Manager. There are four types of Maestro: the Micro Maestro 6-Channel

USB Servo Controller (usc02a), the Mini Maestro 12-Channel USB Servo Controller (usc03a), the Mini Maestro

18-Channel USB Servo Controller (usc03b), and the Mini Maestro 24-Channel USB Servo Controller (usc03c).

3. Download the latest version of the firmware for your type of Maestro. It is important that you know which

type of Maestro you have so that you can download the correct version. The latest firmware versions can be

downloaded here:

◦ Firmware version 1.02 for the Micro Maestro 6-Channel USB Servo Controller (usc02a)

[http://www.pololu.com/file/download/usc02a_v1.02.pgm?file_id=0J644] (34k pgm)

◦ Firmware version 1.02 for the Mini Maestro 12-Channel USB Servo Controller (usc03a)

[http://www.pololu.com/file/download/usc03a_v1.02.pgm?file_id=0J645] (39k pgm)

◦ Firmware version 1.02 for the Mini Maestro 18-Channel USB Servo Controller (usc03b)

[http://www.pololu.com/file/download/usc03b_v1.02.pgm?file_id=0J646] (42k pgm)

◦ Firmware version 1.02 for the Mini Maestro 24-Channel USB Servo Controller (usc03c)

[http://www.pololu.com/file/download/usc03c_v1.02.pgm?file_id=0J647] (43k pgm)

4. Connect your Maestro to a Windows or Linux computer using a USB cable.

5. Run the Maestro Control Center and connect to the Maestro by selecting its serial number in the “Connected

to:” drop-down box in the upper left corner.

6. If you were not able to connect to the Maestro using the Maestro Control Center, double-check your USB

connection, make sure all other devices are disconnected from the Maestro, and try plugging it into several

different USB ports on your computer. If you are still unable to connect to it, see the instructions in Section 4.f.1

for doing a hard bootloader reset.

7. Go to the Device menu and select “Upgrade firmware…”. You will see a message asking you if you are sure

you want to proceed: click OK.

8. If you are using Windows XP and see a Found New Hardware Wizard window appear, then you should

follow steps 6–8 from Section 3.a to get the bootloader’s driver working.

9. Once the Maestro is in bootloader mode and the bootloader’s drivers are properly installed, the green LED

should be blinking in a double heart-beat pattern, and there should be an entry for the bootloader in the “Ports

(COM & LPT)” list of your computer’s Device Manager.

10. Go to the window entitled “Firmware Upgrade” that the Maestro Control Center has opened.

11. Click the “Browse…” button and select the firmware file you downloaded. Make sure that the selected file

is the right file for your type of Maestro (see steps 2 and 3).

12. Select the COM port corresponding to the bootloader. If you do not know which COM port to select, go to

the Device Manager and look in the “Ports (COM & LPT)” section.

13. Click the “Program” button. You will see a message warning you that your device’s firmware is about to be

erased and asking you if you are sure you want to proceed: click Yes.

4. Using the Maestro Control Center Page 32 of 73

Page 33

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

14. It will take a few seconds to erase the Maestro’s existing firmware and load the new firmware. Do not

disconnect the Maestro during the upgrade.

15. Once the upgrade is complete, the Firmware Upgrade window will close, the Maestro will disconnect from

your computer, and it will reappear. If there is only one Maestro plugged in to your computer, the Maestro

Control Center will connect to it. Check the firmware version number and make sure that it now indicates the

latest version of the firmware.

If you have problems during or after the firmware upgrade, then it is possible that you loaded the wrong firmware

onto your Maestro or some other problem corrupted the firmware. The solution is to retry the firmware upgrade

procedure above. Even if your Maestro is not recognized at all by your computer and you see no sign of life from

it, the instructions in step 6 and Section 4.f.1 can help you get the Maestro into bootloader mode. If you continue to

have trouble after trying multiple times, please email us [http://www.pololu.com/contact] for assistance.

4.f.1. Hard Bootloader Reset

The instructions below describe how to force the Maestro into bootloader mode by performing a hard

bootloader reset. Most customers do not need to use these instructions, but they can be used as a last resort

in case something has gone wrong.

One reason to do a hard bootloader reset is if you accidentally loaded the wrong firmware onto your Maestro. The

result of loading the wrong firmware is that your Maestro will have corrupted, unusable firmware. The Maestro will

not be recognized by your computer and it will probably not blink any of its LEDs. In this case, the normal method

for getting the Maestro into bootloader mode through the Maestro Control Center will not work, and you will have to

resort to a hard bootloader reset. After that, the Maestro will be in bootloader mode and you can restore the Maestro’s

correct firmware.

1. To perform a hard bootloader reset, first make sure the Maestro is powered off. It is best if you can just

disconnect everything from it.

2. Using a screwdriver, a small piece of wire, or some other conductive tool, short the two exposed bootloader

pads together. The pads are shown in the pictures below:

Bootloader pads for the Micro Maestro 6-Channel USB Servo

Controller.

4. Using the Maestro Control Center Page 33 of 73

Page 34

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Bootloader pads for the Mini

Maestro 12-, 18-, or 24-Channel

USB Servo Controller.

3. While the pads are shorted together, connect the Maestro to USB. Usually the easiest way to do this is to

have one end of the USB cable already plugged into the Maestro, and connect the other end to the computer after

you have shorted the pads.

This might require a few tries. Once it works, you should see the green LED double-blinking, and the Maestro’s

bootloader should be visible in your Device Manager (if you are using Windows). Then you can stop shorting together

the pads and retry the firmware upgrade procedure in Section 4.f starting at step 7.

4. Using the Maestro Control Center Page 34 of 73

Page 35

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

5. Serial Interface

5.a. Serial Settings

The Maestro has three different serial interfaces. First, it has the TX and RX lines, which allow the Maestro to send

and receive non-inverted, TTL (0 – 5 V) serial bytes (Section 5.b). Secondly, the Maestro shows up as two virtual

serial ports on a computer if it is connected via USB. One of these ports is called the Command Port and the other

is called the TTL port.

• In Windows, you can determine the COM port numbers of these ports by looking in your computer’s Device

Manager.

• In Linux, the Command Port will usually be /dev/ttyACM0 and the TTL Port will usually be /dev/ttyACM1.

These numbers may be different on your computer depending on how many serial devices are active when you

plug in the Maestro.

• In Mac OS X 10.7 (Lion) and later, the Maestro’s two virtual serial ports will have a name of the form

/dev/cu.usbmodem<number>, for example /dev/cu.usbmodem00654321. The one with the lower number is the

Command Port.

This section explains the serial interface configurations options available in the Serial Settings tab of the Maestro

Control Center.

The Serial Settings tab in the Maestro Control Center.

5. Serial Interface Page 35 of 73

Page 36

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

The Maestro can be configured to be in one of three basic serial modes:

USB Dual Port: In this mode, the Command Port can

be used to send commands to the Maestro and receive

responses from it. The baud rate you set in your

terminal program when opening the Command Port is

irrelevant. The TTL Port can be used to send bytes on

the TX line and receive bytes on the RX line. The

baud rate you set in your terminal program when

opening the TTL Port determines the baud rate used

to receive and send bytes on RX and TX. This allows

your computer to control the Maestro and

simultaneously use the RX and TX lines as a general purpose serial port that can communicate with other types of

TTL serial devices.

USB Chained: In this mode, the Command Port

is used to both transmit bytes on the TX line and

send commands to the Maestro. The Maestro’s

responses to those commands will be sent to the

Command Port but not the TX line. Bytes

received on the RX line will be sent to the

Command Port but will not be interpreted as

command bytes by the Maestro. The baud rate

you set in your terminal program when opening

the Command Port determines the baud rate used

to receive and send bytes on RX and TX. The

TTL Port is not used. This mode allows a single COM port on your computer to control multiple Maestros, or a

Maestro and other devices that have a compatible protocol.

The USB Dual Port serial mode.

The USB Chained serial mode.

UART: In this mode, the TX and RX lines can be

used to send commands to the Maestro and receive

responses from it. Any byte received on RX will be

sent to the Command Port, but bytes sent from the

Command Port will be ignored. The TTL Port is not

used. The baud rate on TX and RX can either be

automatically detected by the Maestro when a 0xAA

byte is received on RX, or it can be set to a fixed

value specified in bits per second (bps). This mode

The UART serial mode.

allows you to control the Maestro (and send bytes to

a serial program on the computer) using a microcontroller or other TTL serial device.

Other serial settings:

Enable CRC: If checked, the Maestro will require a cyclic redundancy check (CRC) byte at the end of every serial

command except the Mini SSC command (see Section 5.d).

Device Number: This is the device number (0–127) that is used to address this device in Pololu Protocol commands.

This setting is useful when using the Maestro with other devices in a daisy-chained configuration (see Section 5.g).

5. Serial Interface Page 36 of 73

Page 37

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation

Mini SSC offset: This parameter determines which servo numbers the device will respond to in the Mini SSC

protocol (see Section 5.e).

Timeout: This parameter specifies the duration before which a Serial timeout error will occur. This error can be

used as a safety measure to ensure that your servos and digital outputs go back to their default states whenever

the software sending commands to the Maestro stops working. The serial timeout error will occur whenever no

valid serial commands (or qualifying native USB commands) are received within the specified timeout period. A

timeout period of 0.00 disables the serial timeout error. The resolution of this parameter is 0.01 s and the maximum

value available is 655.35 s. The native USB commands that qualify correspond to the following methods in the Usc

class: setTarget, setSpeed, setAcceleration, setPwm, disablePWM, and clearErrors. Running the Maestro Control

Center will not prevent the serial timeout error from occurring, but setting targets in the Status tab or playing a

sequence will.

Never sleep (ignore USB suspend): By default, the Maestro’s processor will go to sleep and stop all of its operations

whenever it detects that it is only powered by USB (no VIN supply) and that the USB has entered the Suspend State.

However, this behavior can be disabled by checking the Never sleep checkbox.

5.b. TTL Serial

The Maestro’s serial receive line, RX, can receive bytes when connected to a logic-level (0 to 4.0–5 V, or “TTL”),

non-inverted serial signal. The bytes sent to the Maestro on RX can be commands to the Maestro or an arbitrary

stream of data that the Maestro passes on to a computer via the USB port, depending on which serial mode the

Maestro is in (Section 5.a). The voltage on the RX pin should not go below 0 V and should not exceed 5 V.

The Maestro provides logic-level (0 to 5 V) serial output on its serial transmit line, TX. The bytes sent by the Maestro

on TX can be responses to commands that request information or an arbitrary stream of data that the Maestro is

receiving from a computer via the USB port and passing on, depending on which Serial Mode the Maestro is in. If

you aren’t interested in receiving TTL serial bytes from the Maestro, you can leave the TX line disconnected.

The serial interface is asynchronous, meaning that the sender and receiver each independently time the serial

bits. Asynchronous TTL serial is available as hardware modules called “UARTs” on many microcontrollers.

Asynchronous serial output can also be “bit-banged” by a standard digital output line under software control.

The data format is 8 data bits, one stop bit, with no parity, which is often expressed as 8-N-1. The diagram below

depicts a typical asynchronous, non-inverted TTL serial byte:

Diagram of a non-inverted TTL serial byte.

A non-inverted TTL serial line has a default (non-active) state of high. A transmitted byte begins with a single low

“start bit”, followed by the bits of the byte, least-significant bit (LSB) first. Logical ones are transmitted as high

(VCC) and logical zeros are transmitted as low (0 V), which is why this format is referred to as “non-inverted” serial.

The byte is terminated by a “stop bit”, which is the line going high for at least one bit time. Because each byte requires

a start bit, 8 data bits, and a stop bit, each byte takes 10 bit times to transmit, so the fastest possible data rate in

5. Serial Interface Page 37 of 73

Page 38

Pololu Maestro Servo Controller User's Guide © 2001–2014 Pololu Corporation