Page 1

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Custom Laser Cutting Guide

1. Steps for Ordering Laser-Cut Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Pricing for Laser Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Materials for Laser Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Capabilities and Limitations of Custom Laser Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. Instructions for Laser Cutting File Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6. Examples of Custom Laser-Cut Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.a. Laser Cutting Example: Robot Chassis Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.b. Laser Cutting Example: Architectural Ornament Created from a Photograph . . . . . . . . . . . . . . . 22

6.c. Laser Cutting Example: Giant 3-D Pterosaur Puzzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.d. Laser Cutting Example: Servo-Driven Sumo Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.e. Laser Cutting Example: Pentominoes Puzzle With Engraved Solutions . . . . . . . . . . . . . . . . . . 26

6.f. Laser Cutting Example: Calculator Robot Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.g. Laser Cutting Example: Acrylic Cat Logo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

http://www.pololu.com/docs/0J24/all Page 1 of 29

Page 2

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

1. Steps for Ordering Laser-Cut Parts

Once you have a design for a custom part, getting it laser cut is simple. Upon receiving your design, we typically ship

within five business days, and we can ship as quickly as the same day. Here are the steps involved in making a custom

part:

1. You prepare CAD or other drawing files of your custom part. (See Section 5 for information on preparing

your files.)

2. You send us your designs via our quote request form [http://www.pololu.com/laserquote/new].

3. We email you a quote within 1-2 business days (faster for expedited parts).

4. You confirm a PDF proof and order the parts through our website. See our ordering information page

[http://www.pololu.com/ordering] for information on payment methods and shipping options.

5. We cut the parts and send them to you!

1. Steps for Ordering Laser-Cut Parts Page 2 of 29

Page 3

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

2. Pricing for Laser Cutting

The cost of a laser-cut part is determined by how long the parts take to cut on the machine, the amount of labor

involved (unloading and verifying parts), and the amount of risk involved in cutting a part (multiple medium-sized

pieces are less risky to cut than a single large piece that takes hours to cut).

Here are some factors that affect the price of laser-cut parts:

• Laser cutting cost: The laser cutting charge is based on the time it takes to cut the parts, which depends on

the material type and thickness. For example, cutting 1/8" acrylic starts at roughly $0.15 per inch. Please see the

list of materials on our quote request form [http://www.pololu.com/laserquote/new] to see the cost per inch for cutting

your material. There is a $3 minimum charge per unique part and a $1 minimum per additional copy of each

part. We do lower these minimums for simple parts or for large quantities.

• Laser engraving cost: Raster engraving and vector engraving start at $1.00 per square inch. Raster engraving

larger areas starts at $60 per square foot. Long, continuous vector engraving lines cost roughly $0.10 per inch.

We do provide discounts off of these rates on a case-by-case basis.

• Material costs: We stock various plastics (acrylic, ABS, Mylar, PETG, and styrene), which we sell by the

square foot. You may also mail us your own material or have a supplier ship it to us directly. Here are some

prices for plastic we stock; we provide discounts if you require larger quantities:

◦ 3 mm ABS: starts at $4/sq. ft.

◦ 3 mm birch plywood: starts at $5/sq. ft.

◦ 3 mm acrylic: starts at $5/sq. ft.

◦ 6 mm acrylic: starts at $10/sq. ft.

• Minimum order: There is a $25 minimum order per material type (the minimum includes charges for labor

and materials). We do lower this minimum if your design is simple or if your quantities are large.

• Shipping: We can add shipping costs or charge to FedEx shipping accounts.

• Optional charges:

◦ Expediting services: Rushing an order costs 20% – 50% more (on top of the standard-turn price) per

expedited day, depending on what your standard turn time is. The standard turn time for most parts is 3-5

business days.

◦ File creation: $60 per hour with a $15 minimum

◦ Handling fee: Large or delicate parts that require custom packaging will incur a handling charge, which

can range from $10 – $50.

• Exceptions: We do make exceptions to our minimums and pricing depending on the parts. If your parts are

particularly simple to handle and cut, we will provide more competitive pricing. On the other hand, we are less

likely to discount our rates if your parts are more difficult or risky to cut, such as:

◦ Single large or complex parts that take a long time to cut

◦ Parts that involve a lot of careful or tedious handling (such as very small parts or fragile parts), which

are more time consuming to verify and unload from our machines.

◦ Parts that have many small, sharp, acute angles and small details (such as the frills in a dress), which

tend to melt back into the scrap plastic and become difficult to remove from the sheet.

◦ Parts that have many disjointed cuts (such as an array of small holes or a lace pattern), which take longer

to cut since the laser cutting head has to stop and move from cut to cut more often than when it cuts along

a continuous path.

2. Pricing for Laser Cutting Page 3 of 29

Page 4

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Expediting costs for laser cutting

The standard turn time for most parts is 3-5 business days assuming you do not need many hundreds or thousands of

parts. If you need the parts more quickly, we generally charge 20% – 50% more per expedited day depending on the

standard turn time (the percentage is such that the minimum turn will cost double the standard turn price). Here are

examples for cutting a minimum order of parts with a standard 3-day turn and standard 5-day turn:

Sample prices for expedited service on a 3-day standard-turn order:

Turn time Price

3 business days $25 base price for standard turn time

2 bus. days $33.25, added 33% ($8.25) to base price

1 bus. days $41.50, added 66%

Same-day service$50, added 100% (double the price of standard turn)

Sample prices for expedited service on a 5-day standard-turn order:

Turn time Price

5 business days $25 base price for standard turn time

4 bus. days $30, added 20% ($5) to base price

3 bus. days $35, added 40%

2 bus. days $40, added 60%

1 bus. day $45, added 80%

Same-day service$50, added 100% (double the price of standard turn)

To place an expedited order, fill out the quote request form [http://www.pololu.com/laserquote/new], indicating that you

would like your order to be expedited. After receiving your quote, you will be given a list of expedited options for the

order.

File creation costs for laser cutting

If you are not able to provide a vector-format file of your parts for laser cutting (DXF, DWG, CDR, AI, SVG, or PDF

file), we might be able to draw your part on the computer for you for $60 per hour with a $15 minimum.

To request a quote that includes file creation, please submit a standard file type in the quote request form that

communicates exactly the part you need. The file can be any file type that we can read, such as a text file with a

written description, a scan of a hand sketch (JPG, GIF, BMP, PDF), a mock-up in Word, Paint, or Excel, etc. For more

information, please see Section 5.

2. Pricing for Laser Cutting Page 4 of 29

Page 5

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

3. Materials for Laser Cutting

We can laser cut plastics, woods, rubbers, foams, papers, and thin metals as long as they do not contain chlorine.

Depending on the material, there is usually no limit to the thinnest sheet we can cut, and the thickest sheet we can cut

is typically 1" (24 mm). We stock some woods and various plastics including acrylic, ABS, Mylar, Delrin®, PETG,

and styrene, and you are welcome to mail us material or have suppliers ship us material directly. A complete list of

materials is available on the quote request form [http://www.pololu.com/laserquote/new].

Materials we can laser cut

We can cut the following materials. If you do not see your material listed, we would be happy to try cutting it as long

as it does not contain chlorine (please submit a quote request and provide details about your material in the special

instructions section of the quote request form).

• Plastics:

◦ ABS (acrylonitrile butadiene styrene)

◦ Acrylic (also known as Plexiglas, Lucite, PMMA)

◦ Delrin (POM, acetal) – for a supplier, try McMaster-Carr [http://www.mcmaster.com/].

◦ High density polyethylene (HDPE) – melts badly

◦ Kapton tape (Polyimide)

◦ Mylar (polyester)

◦ Nylon – melts badly

◦ PETG (polyethylene terephthalate glycol)

◦ Polyethylene (PE) – melts badly

◦ Polypropylene (PP) – melts somewhat

◦ Styrene

◦ Two-tone acrylic – top color different than core material, usually for custom instrumentation panels,

signs, and plaques.

• Thin metals:

◦ Stainless steel (up to 0.060")

◦ Spring steel (up to 0.060")

• Foam:

◦ Depron foam – often used for RC planes.

◦ EPM

◦ Gator foam – foam core gets burned and eaten away compared to the top and bottom hard shell.

• Other:

◦ Cloths (leather, suede, felt, hemp, cotton)

◦ Magnetic sheets

◦ Papers

◦ Rubbers (only if they do not contain chlorine) – for a supplier, try McMaster-Carr

[http://www.mcmaster.com/]

◦ Teflon (PTFE, Polytetrafluoroethylene) – for a supplier, try McMaster-Carr [http://www.mcmaster.com/].

3. Materials for Laser Cutting Page 5 of 29

Page 6

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

◦ Woods (MDF, balsa, birch, poplar, red oak, cherry, holly, etc.) – we stock 3 mm birch plywood; for other

types of wood, try Midwest Products [http://www.midwestproducts.com/].

Materials we cannot laser cut

We do not or cannot cut the following materials:

• Most metals – We cannot cut most metals. The two exceptions are thin sheets of stainless or spring steel (up

to 0.060" thick). We also stock an acrylic-based, dual-tone plastic with a faux-metal finish on one side. If you

need thicker metal parts, you might consider a water jet cutting service.

• Polycarbonate (PC, Lexan) – we stopped cutting Lexan due to the fumes.

• Any material containing chlorine

• PVC (Cintra) – contains chlorine

• Vinyl – contains chlorine

• Glass – we can engrave glass, but we cannot cut it.

• Fiberglass

• Printed circuit board (FR4 and other material types)

• Carbon fiber

• High-density polyethylene (HDPE) thicker than 1/16" – We are unable to cut HDPE thicker than 1/16", and

HDPE of any thickness melts badly when laser cut.

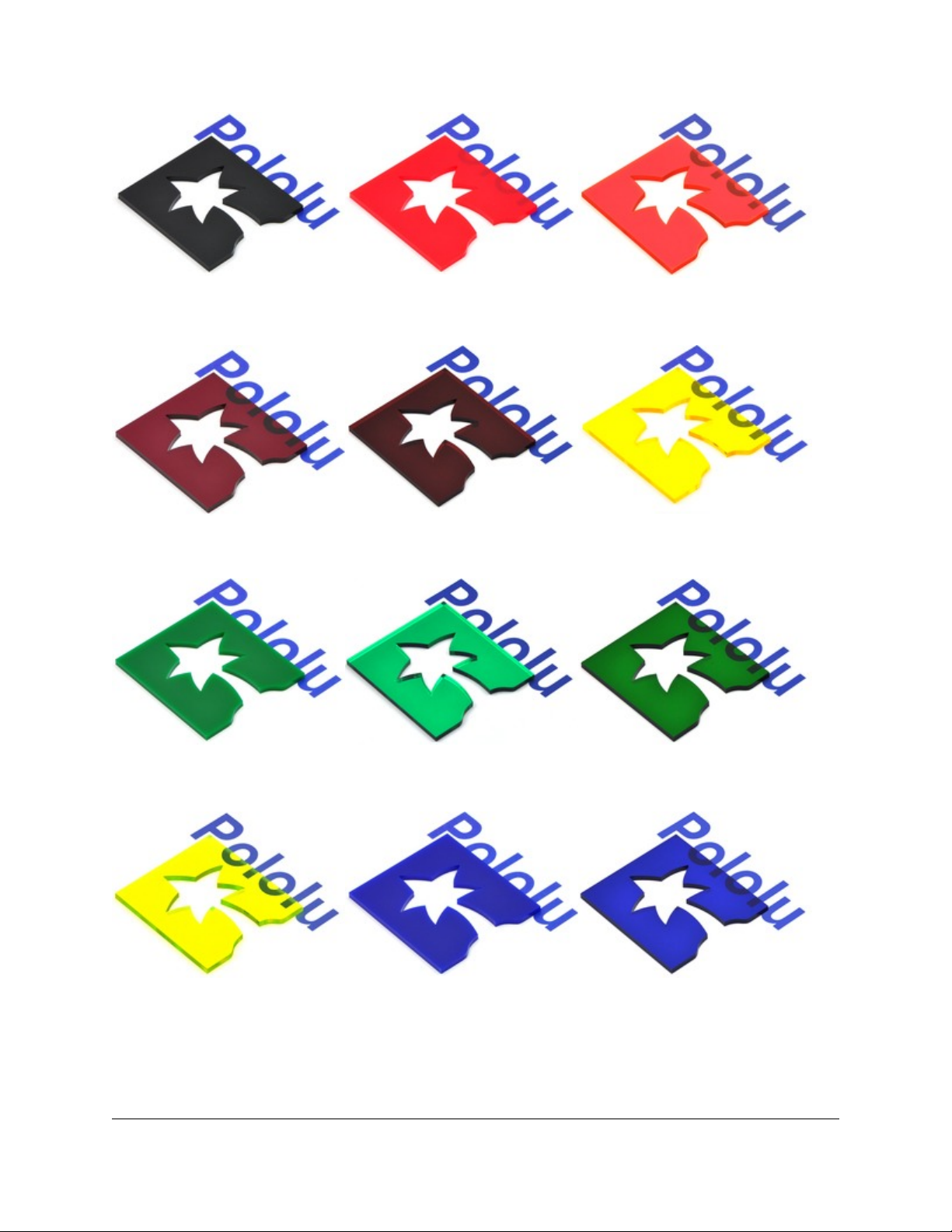

Pictures of some acrylic colors we stock

Below are pictures of most of the 1/8" acrylic colors we stock. Your monitor will probably not show the colors exactly,

but the pictures should give you some idea of what the colors are like. We do stock other colors and materials: see the

quote request form [http://www.pololu.com/laserquote/new] for a complete list.

Gold mirrored acrylic.

Yellow mirrored acrylic.

Clear “silver” mirrored acrylic.

3. Materials for Laser Cutting Page 6 of 29

Page 7

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Opaque black acrylic #2025.

Transparent red acrylic #2423.

Translucent red acrylic (#2283

or similar).

Red mirrored acrylic.

Transparent fluorescent red

acrylic #2085.

Transparent yellow acrylic

(#2208 or similar).

Translucent green acrylic

(#2108 or similar).

Transparent fluorescent green

acrylic #2154.

Green mirrored acrylic. Transparent green acrylic

Translucent dark-blue acrylic

(#2114 or similar).

Transparent blue acrylic #2424.

#2092.

3. Materials for Laser Cutting Page 7 of 29

Page 8

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

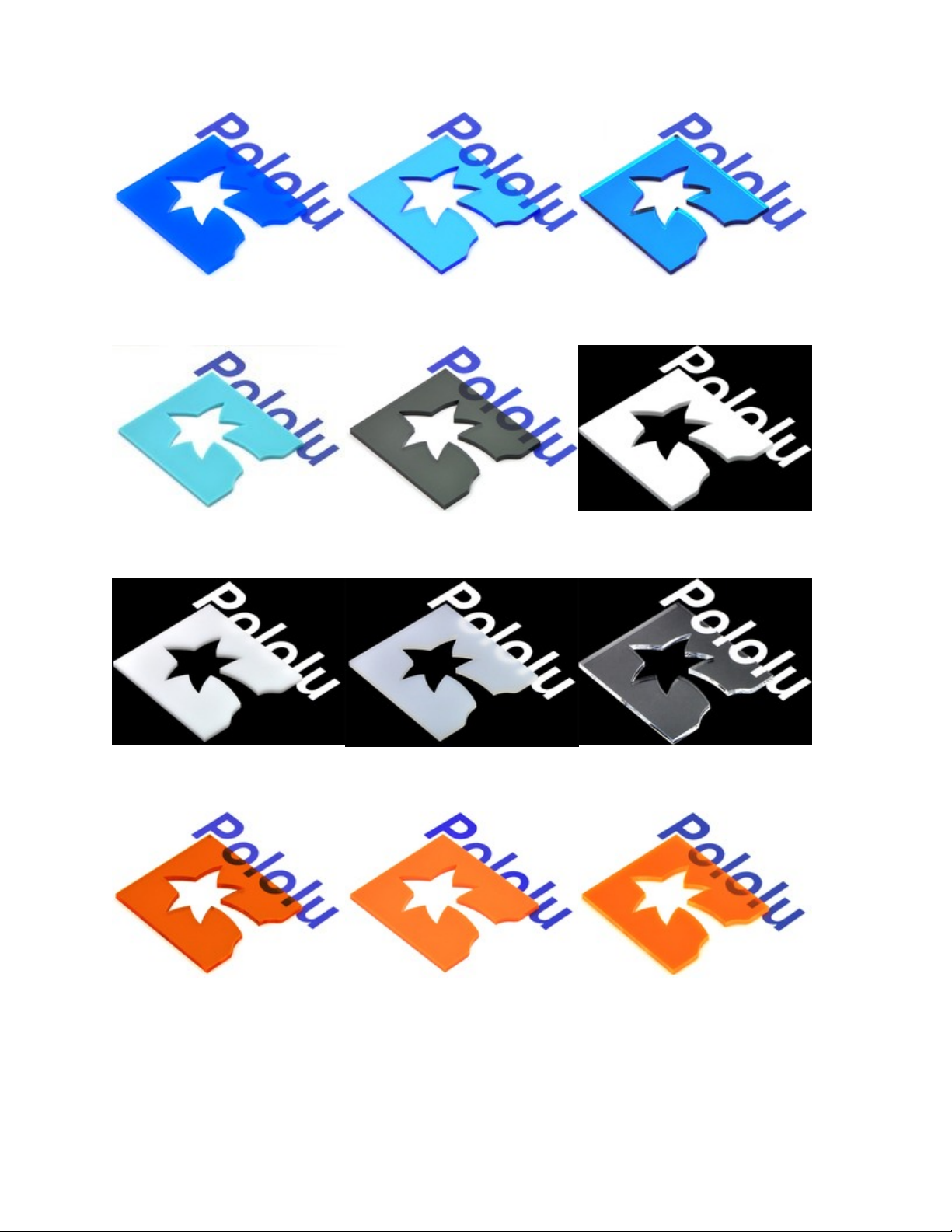

Translucent blue acrylic #2051.

Translucent turquoise acrylic

#2308.

Transparent light-blue acrylic

#2069.

Transparent gray acrylic (#2064,

#2074, or similar).

Sapphire blue mirrored acrylic.

Opaque white acrylic #3015.

Translucent white or “sign

white” acrylic #7328.

Transparent amber acrylic

#2422.

Very translucent white acrylic

#2447.

Translucent orange acrylic

#2119.

Transparent clear acrylic.

Transparent fluorescent orange

acrylic #2086.

3. Materials for Laser Cutting Page 8 of 29

Page 9

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

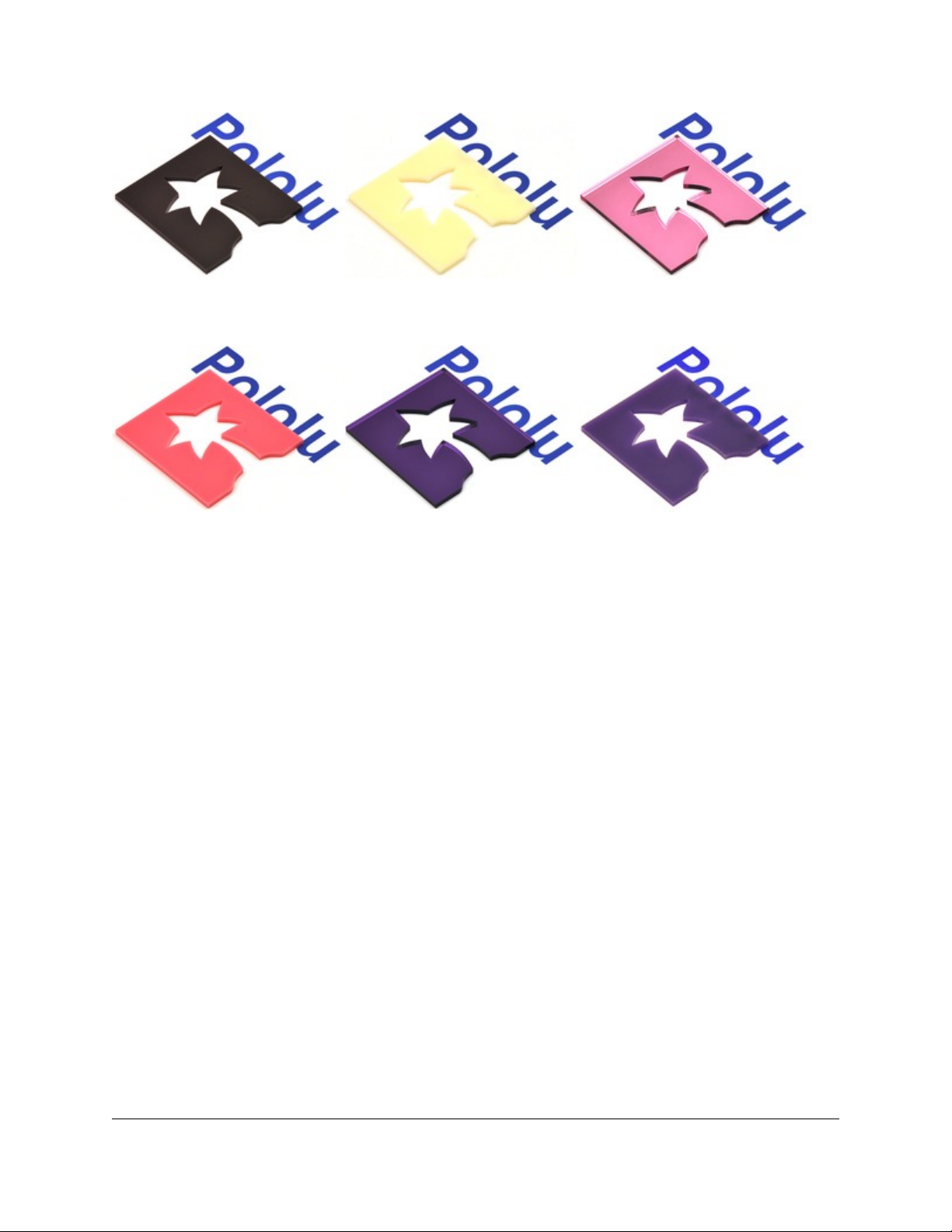

Translucent brown acrylic

#2418.

Translucent pink acrylic #3119. Purple mirrored acrylic. Translucent violet acrylic #2287.

Translucent ivory acrylic #2146. Pink mirrored acrylic.

Two-tone acrylic stocked: We also stock two-tone acrylic with either a black top and white core, or a brushedaluminum top and black core (in both 1/8" and 1/16" thicknesses). You can have other laser-safe two-tone materials

shipped to us from suppliers such as Johnson Plastics [http://www.johnsonplastics.com/].

Special-order acrylic colors available:

• Translucent acrylic in orange, yellow, purple, turquoise, and ivory

• Transparent acrylic in orange, dark blue, and green

• Transparent neon or fluorescent acrylic in red/pink, orange, green, and blue

• Mirrored acrylic in red, yellow, green, blue, purple, and bronze

General information about some plastics

We mainly laser cut the following plastics, for which we have provided some additional information:

Acrylic (PMMA, Plexiglas)

Acrylic, also known as PMMA, is a type of plastic with a variety of brand name manufacturers, including Plexiglas,

Lucite, Acrylite, and Optix. We stock different brands depending on what our suppliers carry. We can cut up to 1"

acrylic. The thicknesses in inches of acrylic is nominal; the actual thicknesses are in millimeters and vary by + or –

10% within the same sheet.

Acrylic is the cheapest plastic to laser cut. It is attractive (it has a glossy surface), comes in a variety of thicknesses

and colors, and the edges of laser-cut acrylic have a “laser-polished” look. Acrylic is somewhat brittle (you have to

be careful not to crack if you want to drill holes after laser cutting; it is better to have us laser-cut all screw holes

and mounting holes). Acrylic parts will crack or chip (especially at sharp corners) if you drop them on a hard surface.

Acrylic usually comes with a paper masking on both sides.

3. Materials for Laser Cutting Page 9 of 29

Page 10

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Acrylic is manufactured in two main ways: via casting or extrusion. Extruded acrylic has a lower melting point than

cast acrylic, so extruded acrylic tends to have a shinier, polished finish when cut. We mainly stock extruded acrylic for

this reason. However, we do stock some cast acrylic since cast acrylic is better for engraving (the engraved portions

of cast acrylic become a milky-white, sand-blasted version of the original color).

Acrylic comes in a variety of thicknesses. It is available in transparent, translucent, and opaque colors, including

neons, fluorescents, and mirrored colors. If we do not stock the thickness or color you need, we can special-order

it for you from our suppliers, or you may have it shipped to us from a supplier such as United States Plastics

[http://www.usplastics.com], or McMaster-Carr [http://www.mcmaster.com/].

Two-tone acrylic (with a thin, top layer that is a different color than the core material) is available for parts that

require high-contrast engraving such as instrumentation panels, signs, and plaques. We stock a few basic colors

(including one with a faux-metal, brushed-aluminum finish on one side); you can get other colors at Johnson Plastics

[http://www.johnsonplastics.com/].

Acrylic is transparent to infrared light (IR), so it is not appropriate for blocking IR (e.g. shielding around IR sensors).

You can glue acrylic together using special acrylic glues such as Weld-On. Please contact your local hardware store

and ask for glues used for acrylic or Plexiglas.

Our customers have made the following types of parts with acrylic:

• robot parts and chassis

• computer case parts

• computer fan grills

• custom jewelry and charms

• custom stencils

• luthier templates and tools

• instrument inlays

• instrument-making tools

• enclosures for electronics

• custom ornaments

• trophies

• custom awards

• custom gifts

• custom trinkets

• custom model railroad parts

• other scale model parts

• custom art pieces

• custom sign lettering and logos

ABS (acrylonitrile butadiene styrene)

ABS comes in black or white, with one side smooth, and the other side textured. The texture is called a “hair cell

texture” and is similar to the texture on the sides of older refrigerators. We have cut up to 1/4" ABS. We can probably

3. Materials for Laser Cutting Page 10 of 29

Page 11

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

cut thicker ABS, but we have not tried. The thickness in inches of ABS is nominal; the actual thicknesses are in

millimeters and vary by + or – 10% within the same sheet.

ABS does not come masked. If you would like us to mask it during cutting, please request this in the special

instructions section of our quote request form. ABS is opaque to infrared light (IR), so it can be used for IR-sensing

applications.

ABS is easy to machine and is not brittle (it will bend quite a bit before it cracks). ABS parts will not crack or break

easily, even if you drop them. Legos, many computer peripherals, and graphing calculator cases are made from ABS.

ABS is less rigid than acrylic, and is somewhat soft. You can glue ABS parts together using sticky, black, ABS glue

available at hardware stores. With ABS, you can design parts that snap together by making tabs with small “hooks”

or “feet” that fit into slots that are slightly smaller than the feet (so they stay hooked in to the slots).

Laser-cut ABS parts tend to smell, so you might have to air them out for a few days and wipe dust and residue from

the edges. Do not attempt to clean ABS parts in your dishwasher (the parts become discolored).

Other customers have made laser-cut encoders, sturdy robot chassis, instrumentation panels, gears, and sprockets

using ABS.

PETG (polyethylene terephthalate glycol)

We only stock PETG in clear. We have cut up to 3/16" PETG; we can probably cut thicker PETG, but we have not

tried. The thickness in inches of PETG is nominal; the actual thicknesses are in millimeters and vary by + or − 10%

within the same sheet.

PETG usually comes with a thin, plastic, film masking on both sides. It is not brittle (it will bend quite a bit before it

cracks), and PETG parts will not crack or break easily, even if you drop them. PETG is less rigid than acrylic, and is

somewhat soft.

Laser-cut PETG parts tend to smell, so you might have to air them out for a few days and wipe off any dust and

residue with warm water.

Other customers have laser cut PETG to make very thin grids/nets for scientific experiments and guards for pinball

machines to protect the pinball parts from the impact of the pinballs.

Delrin (POM, acetal)

Delrin is a very tough, slippery material that resists warping and deforming well. You cannot glue anything to Delrin.

It is more expensive than acrylic, ABS, or PETG. Gears are often made from Delrin. We do not stock Delrin, but

you can order it from McMaster-Carr [http://www.mcmaster.com/] or another supplier and have it drop-shipped to us

directly. Please be sure the material is shipped FLAT (not rolled).

How to supply your own material for laser cutting

If you plan to supply your own material, please mention this in the special instructions section in our quote request

form, and also specify the sheet size of the material you plan to supply. Material sheets must be no larger than

35.5" x 50". If you are raster engraving parts, or if you can only supply a CDR, AI, SVG, or PDF file (not a CAD

file set up for laser cutting), your material must be no larger than 24" x 36". Please send the material to our address as

shown on our contact page.

If you are sending the material yourself, please include a note that has your full name, day-time phone number, quote

number, and email address that you check regularly. The material must be very flat (not bowed, warped, or rolled;

otherwise the laser cannot focus properly).

3. Materials for Laser Cutting Page 11 of 29

Page 12

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

If a material supplier is shipping to us directly, please be sure they include your full name and quote number in the

attention line in the address. If possible, the shipping receipt, label, invoice, or packing list should also include your

day-time phone number. Please instruct the supplier to select the flattest material and ship it flat, not rolled, folded, or

bent.

It is always good to supply extra material just in case something goes wrong with the cutting, and for testing and

calibration purposes, especially if you are sending material we have not cut before. If you would like us to ship excess

material back to you, please let us know in the special instructions section of our quote request form.

3. Materials for Laser Cutting Page 12 of 29

Page 13

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

4. Capabilities and Limitations of Custom Laser Cutting

With our custom laser cutting service, you can create custom, two-dimensional plastic parts suitable for a variety of

projects. We can laser cut almost anything you can draw, including sharp angles, smooth curves, small screw holes,

and complex lace designs, and we can also laser engrave text, logos, and photos onto your parts.

We can…

• Cut up to 1/2" acrylic or wood comfortably, and up to 1" acrylic or wood under special circumstances.

• Cut very thin materials including 0.003" mylar sheets

• Cut stainless steel and spring steel up to 0.060"

• Cut, raster engrave, and vector engrave parts up to 47.5" x 47.5"

• Cut holes as small as the laser beam widths, around 0.01"

• Use a variety of file types including DXF, DWG, CDR, AI, PDF, and SVG.

• Draw parts for you based on a sketch

• Cut just one part or thousands of parts, and anything in between (we do provide price breaks)

Materials

We mainly laser cut custom plastic parts, but we can also make custom wood, rubber, and foam parts, as well as thin

custom metal parts. We stock acrylic, ABS, Delrin®, Mylar, PETG, and styrene in various colors and thicknesses. You

may also send us your own material. Please see our Materials for Laser Cutting section [http://www.pololu.com/docs/

0J24/3] for a complete list of materials we can cut.

We cannot cut glass, polycarbonate (Lexan), carbon fiber, thicker metals, or any material containing chlorine,

including PVC and vinyl. Please see materials we cannot laser cut [http://www.pololu.com/docs/0J24/3#cannot_cut] for a

comprehensive list. If you need a metallic look, we do stock two-tone acrylic-based sheets with a thin, faux-metal top

layer, and you could also consider cutting up to 0.060" stainless or spring steel pieces and adhering them to thicker

backing made of plastic or wood.

Two-dimensional parts

We can only laser cut two-dimensional parts, but you can create three-dimensional designs from flat pieces with tabs

and slots and some glue, brackets, and screws, as shown in these examples:

Calculator Robot Pterosaur Puzzle Sumo Robot

4. Capabilities and Limitations of Custom Laser Cutting Page 13 of 29

Page 14

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

You might try Weld-On acrylic adhesives for gluing acrylic/Plexiglas parts. Hardware stores usually carry thick, black

glue for gluing ABS parts. You must take care when drilling holes in acrylic, which is brittle and tends to crack (it is

better to have us laser-cut small screw holes). ABS, PETG, styrene, and wood are easier to machine by hand.

Laser engraving

We can do two types of laser engraving (also called laser etching): vector

engraving and raster engraving. Engraving depths can range from barely

scratching the surface to almost going through the material; we cannot control

the depths very precisely, but we will try our best to achieve what you need.

In general, laser engraving is suitable for marking material (not for making

deep grooves for mechanical purposes).

• Vector engraving is for etching lines that are the width of the laser beam

(around 0.01"); it is just like laser cutting, but the laser does not cut all the

way through the material. Vector engraving is limited to line art. The blue

pentominoes puzzle piece [http://www.pololu.com/docs/0J24/6.e] example uses

vector engraving to show the puzzle solutions on the pieces.

• Raster engraving is slower and more costly than vector engraving, and is

used for engraving bitmaps (JPG or GIF files of logos, photos, etc.), text,

and filled-in areas of your vector drawing file. Raster engraving is more

flexible; you can engrave thin lines as well as recessed areas. The laser blasts away material one pixel at a time,

similar to the printing process used by inkjet printers. We usually raster engrave at 400 dpi, but we can use lower

resolutions and can also use 600 dpi and 1200 dpi settings.

A pentomino piece, showing

engraved solution.

Issues to consider

• The laser cuts at a slight taper (1-2 degrees) since the

laser beam is shaped like a cone (it gets focused from a

larger spot to a small point). The tapering causes one

side of a laser-cut part (the side facing up during laser

cutting) to be slightly smaller than the other side. The

taper is almost unnoticeable in 1/8" material; the thicker

the material, the more noticeable the taper. When using

laser-cut parts such as wheels or gears, you might need

to position the parts in an alternating pattern so that the

tapers “cancel out”.

• The kerf (the thickness of the laser beam) is about

0.010". Please see our file preparation instructions to

learn how to adjust for the kerf.

• Small circles (usually for screw holes) will not be

perfectly circular. Also, the holes will be conical due to

the slight taper of the laser cut as described above. If

you need the holes to be more circular and cylindrical,

we suggest that you have us laser-cut small starter holes,

which you clean up with a drill.

• Plastic thickness can vary by + or – 10%, so you

cannot count on the thickness to be exact when

designing your parts. If you are designing interlocking

parts with slots and tabs and you are trying to create a

tight fit, keep in mind that you can only control the

dimension being cut by the machine (not the material thickness). You will have to decide whether to design the

The kerf of our laser beams varies from roughly

0.007" to 0.01" which causes hole and part sizes

to vary.

4. Capabilities and Limitations of Custom Laser Cutting Page 14 of 29

Page 15

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

part so that the dimensions you control are slightly too big or too small (so that to achieve a tight fit, you might

have to either sand some parts, or use glue or add some shims).

• The edges of some materials including wood, paper, felt, and cloth, will get charred from the laser. The degree

of charring depends on the material. The back side might show more charring or some scorching (the laser

bounces off of the metal grill on which the material sits and hits the back of the material, leaving scorch marks).

You can mask the material to decrease the charring and scorching on the material surface, but the edges will still

be charred. Most plastics that we cut, including acrylic, PETG, and ABS, do not char.

• Sharp, thin pieces, especially those that taper to a needle-sharp point, might warp from the laser’s heat, or

crack when taken out of the scrap. This is true especially if the width of a piece is the same or less than the

material thickness.

• If you have parts that taper to a thin, sharp point, note that once the two converging lines are closer than

0.01" apart, the laser beam (which is roughly 0.01" in diameter) will eat away any material left between the

two lines. The material at the end of the tip will become paper-thin and brittle and will probably break off in

an unpredictable spot. We would suggest that you round off any acute, sharp corners where the two converging

lines are no less than 0.018" apart.

• The material sits on a metal grid during cutting. When the laser cuts through the material, it hits the metal

grill and bounces back and hits the bottom of the material, causing a small dent or mark. The backs of the parts

will usually have small dents along the cut edges of the part wherever the laser, metal grid, and material meet.

• Many plastics including acrylic and PETG come with a protective masking on both sides. Other plastics, such

as ABS and styrene, do not have any protective masking. The masking helps to decrease denting on the back side

described above, and protects the material surface from any flames or residues that are created during cutting.

If you would like us to mask your material, please request this in the special instructions section of our quote

request form.

To order custom laser cut parts, see information in Section 5 about file setup or proceed to the quote request

form [http://www.pololu.com/laserquote/new].

4. Capabilities and Limitations of Custom Laser Cutting Page 15 of 29

Page 16

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

5. Instructions for Laser Cutting File Setup

We will be adding more tutorials, instructions, and tips

for setting up your laser-cut parts. In the meantime,

please read the following information before sending

us a file for a quote [http://www.pololu.com/laserquote/

new]:

Accepted file types for laser cutting

We use CorelDRAW X6 to draw and laser-cut parts.

We can also use files from a variety of other programs

as long as you can export or save as one of the

following vector-format file types:

• DXF compatible with AutoCAD version 2011 or earlier

• DWG compatible with AutoCAD version 2011 or earlier

• CDR (CorelDRAW)

• AI (Adobe Illustrator)

• EPS (Adobe Illustrator)

• SVG

• PDF

• The file can contain any type of curve or line

Other file types

We might be able to use other vector drawing file formats not listed above; you are welcomed to send a different

file type via the quote request form (if we cannot open it, we will let you know). If in doubt, please send a DXF file

compatible with AutoCAD version 2004 or earlier (most programs let you “Save as” or “Export” to this file type and

have a “Set up” or “Advanced” option to set the AutoCAD version compatibility). If you need us to create a file for

you, please see the topic below about setting up a sketch or mock-up.

Laser cutting file set up instructions

If you would like to create a laser cutting file for your parts using a program such as CorelDRAW, Adobe Illustrator,

TurboCAD, AutoCAD, or Open Office Draw, please set up your files as follows:

• Cut lines – Draw thin, blue lines where you

want the laser to cut; the laser will cut down

the center of your lines. In CorelDRAW, the

lines should be “Hairlines”. In TurboCAD, the

line thickness should be 0. In other programs,

be sure the cut lines are 0.003 inches wide or

less.

• Size reference – Include and label a oneinch square size reference in your file.

• Standard layout areas are listed below. The

parts shown below were laid out in a

11.75" x 23.75" area. Be sure to leave at least 0.05" between adjacent parts in your layout (for materials thicker

than 1/4", adjacent parts should be no closer together than the material thickness). If you need a different layout

5. Instructions for Laser Cutting File Setup Page 16 of 29

Page 17

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

area, we can use any sheet size up to 48" x 48" sheet, in which case the layout must have at least a 1/4" border

all the way around.

◦ 11.75" x 11.75"

◦ 11.75" x 23.75"

◦ 23.75" x 23.75"

◦ 23.75" x 35.25"

◦ 23.75" x 47.75"

• Laying out your own parts – If you would like to lay out your own parts, please include the layout in a

different area in your file (away from the single copies of each unique piece) and label it as your layout. (If you

have many small, unique pieces in your layout, you do not have to separately include a single copy of each part

and state how many of each you need; the layout by itself will suffice.)

• The largest layout area is 47.5" x 47.5".

• CAD files – If you are drawing your parts in CAD, be sure the file is purely two-dimensional.

• Send only one file for each material – The file should include one copy of each unique part with indications

of how many of each you need, and the material from which they should be cut. This information can either be

text in the file, or explained in the special instructions section of the quote request form. Please make sure to

leave enough space around every part so that we can easily select them by dragging a rectangle around them.

• Multiple files – If you must send more than one file for a single design, you may submit them together. Please

clearly explain what you would like us to do with each file in the special instructions section of the quote request

form.

• Choose a unique name for your file – something like “paul_robot_arm.dxf” is much better than

“laser_cut_part.dxf”.

• Line sharing – When setting up a layout that includes line sharing (two parts right next to each other so that

they share a single cut line), please be sure to delete any redundant copies of lines. If you have lines stacked on

top of each other, though you might not be able to see them in your file, the laser cutter will see the paths and

end up cutting twice along the same line, degrading the final part (and possibly causing melting or warping).

• Saving cutouts – If you need the cutouts that fall out from your main parts, please specify this in your file or

in the special instructions field in the quote request form.

• Sharp corners – If you have any sharp corners, you might consider rounding them (called “adding a radius”

to a corner, or “adding a fillet”) so your parts will be less likely to crack around the corners. We can certainly cut

your parts with sharp corners if you prefer.

• Adjust for kerf – You may want to adjust for the kerf (the thickness of the laser beam), which is about 0.01".

(The laser centers itself on the lines you draw and takes off about 0.005" of material from either side of the lines.)

For example, if you would like the hole in your part to have a diameter of roughly 1.0", you should draw a hole

with a diameter of 0.99". If you would like a circular part with a diameter of about 3.0", draw a circle with a

3.01" diameter. (These numbers are approximate and can vary depending on the material and its thickness.) In

CAD programs, this can be achieved using an offset of 0.005".

• Small details should be no smaller than material thickness. For example, if you are cutting a spider web

pattern from 1.5 mm acrylic, the thin pieces of plastic that make up the web must be no thinner than 1.5 mm

wide in your drawings. Note that the laser beam thickness will cause the final piece to have webs that are slightly

less than 1.5 mm wide. We can attempt to cut thinner pieces than this general rule of thumb allows, but the part

will likely warp and be very fragile.

• Text should be converted from a font to line art (often called “breaking apart text to lines or polylines” in

CAD, or “converting text to curves” in other drawing programs). Otherwise, if we do not have the font you are

using, our programs will substitute your font with a different one.

5. Instructions for Laser Cutting File Setup Page 17 of 29

Page 18

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Laser engraving file set up instructions

We can do two types of laser engraving (also called laser etching): vector engraving and raster engraving. Please note

the following when setting up your files for engraving:

• Vector engraved lines should be indicated with

different RGB colors (each color indicating a

different engraving depth) as shown in this file of a

pentominoes puzzle set with vector-engraved

solutions shown in red. Please group all items of the

same color and indicate the approximate engraving

depths that you would like for each color.

• Raster-engraved areas in your file should not

have an thin, black outline around it (otherwise the

laser will cut along that outline). The depth of the

engraving is specified by the gray-scale color of the

pixel (black gets engraved the deepest, gray is

engraved to medium depth, and white is left unengraved). Please specify the depth of the black (deepest) portions of your image and color everything else with

the appropriate grays (50% black will get engraved about half as deep as the black portion). We can rasterengrave parts that are up to 23.5" x 35.5".

• Engraving depths – We can vary the laser speed and power to change the raster engraving and vector

engraving depths. If you just want your engraving to be clearly visible, we recommend that you allow us to select

the appropriate engraving depth (usually very shallow, just scratching the surface of the plastic enough to leave

an attractive, clearly visible engraving). If you must have particular depths, please let us know the rough depth

you would like (for example, "vector engrave red lines to be about 1/16" deep, green lines just enough to be

clearly visible, and raster engrave black areas to be about 1/64" deep). We will try our best to achieve the depths

you specify by playing with the laser speed and power, but note we cannot guarantee any particular accuracy

with engraving depths. Raster and vector engraving are best for making cosmetic markings and are not suitable

for making mechanical grooves and features with precise depths.

• Front or back engraving – We can engrave clear and transparent plastic from the front or back of the material.

When engraving from the back, we will be sure to set up your file correctly (mirror image) so that any text and

all images look correct when viewed from the front. Mirrored acrylic is typically engraved from the back (the

matte gray side) so that when you look at the piece from the front, mirrored side, you can see the engraved areas

that have been etched away in the mirror substrate.

• Text for engraving should be converted from a font to line art (often called “breaking apart text to lines or

polylines” in CAD, or “converting text to curves” in other drawing programs). Be sure to fill the line-art text

black and remove any thin, black outlines that would otherwise get cut.

• Protective masking – We typically remove the paper masking on acrylic when engraving (to avoid gooing up

the engraving with the glues in the masking, and to make peeling the masking easier for you), and we re-mask the

material during cutting (to protect the plastic from residues that are created during cutting). You might consider

requesting that we engrave with the masking left on if you plan to paint the engraved areas a different color (so

that the masking will serve as a mask during painting). If you need a high-contrast engraving, you might consider

using two-tone acrylic (top thin layer is a different color than the core).

• Files with cutting, raster engraving, and vector engraving – We can laser cut, vector engrave, and raster

engrave a part all as a single job. All images, lines, text, etc. to be raster engraved or vector engraved should be

a part of the same file as the cutting file (see the above section about laser cutting file set up for details). You do

not need to split the cutting and engraving among different files.

5. Instructions for Laser Cutting File Setup Page 18 of 29

Page 19

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Programs for drawing laser-cut parts

We use CorelDRAW® Graphics Suite X6 to draw and cut parts. We can also open files from a variety of other

programs (please see our accepted file types above). If you need a program to draw your parts in vector-format, here

are a few free trials or completely free programs to try:

• Open Office Draw: This free vector-graphics drawing software is part of a free office suite, OpenOffice.org

[http://www.openoffice.org/]. You will have to download the entire suite of programs to use Open Office Draw. Please

save files in PDF format.

• Inkscape: This free vector-graphics drawing software is available at www.inkscape.org

[http//www.inkscape.org/]. Please be sure to include a 1" square size reference in your SVG file generated from

Inkscape, as sometimes there are scaling issues when opening SVG files in the software we use.

• CorelDRAW trial version: You can download a free trial of this vector-graphics drawing software (with

capabilities similar to Adobe Illustrator) at www.corel.com [http://www.corel.com/]. Please save your files in CDR

format (default).

• TurboCAD professional trial version: You can download a free trial of this CAD software at

www.turbocad.com [http://www.turbocad.com/]. Please save your file as a DXF (compatible with AutoCAD

version 2004 or earlier). You can access this option in TurboCAD in the “Save As” window under a “Setup”

button or tab. Please see accepted file types above to learn about certain restrictions on the file for larger parts.

Setting up a sketch or mock-up (if we are drawing your parts for you)

To laser cut parts, we will need one of the accepted file types listed above. If you would like us to draw your parts

on the computer for you, you will need to prepare a mock-up file of your parts or a file with a written description

communicating the parts you need. The file can be any file type that we can read, such as a text file with a written

description, a scan of a hand sketch (JPG, GIF, BMP, PDF), a mock-up in Word, Paint, or Excel, etc.

To request a quote that includes file creation, please submit your file in the quote request form and mention that you

need us to draw your parts in the special instructions field. File creation costs are listed at our laser cutting pricing

page.

Please follow these guidelines when

preparing your mock-up file:

• Written descriptions should include

all sizes of parts, quantities required,

and material types and colors for each

part. For example:

5. Instructions for Laser Cutting File Setup Page 19 of 29

Page 20

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

QuantityMaterial Description

2

8

10

1/8" clear

acrylic

1/16"

black

ABS

1/16"

white

Delrin

• If you are drawing a sketch by hand, please scan your drawing and send the resulting JPG, GIF, BMP, or PDF

file. Kinko’s, Office Max, Office Depot, or any copy shop should be able to make a scan for you.

• Mock-ups and scans should include all relevant dimensions (be sure to indicate the units of measure you are

using). Please try as much as possible to make your drawings close to scale.

• When showing the location of a hole, please specify the distances from the hole’s center to the nearby edges

of the part.

• Include the quantity required for each part.

• Include the material type, thickness, color, and supplier for each part. You can see the materials we stock at

our materials page. If you will be supplying the material, please specify the sheet size you will be sending.

• If you need to send more than one file, please zip the files.

Circle diameter 3"

5" x 5" square with four 1/8"-diamter mounting holes in the corners (center of mounting holes

should be 1/2" away from the corners of the square)

Circle diameter 10" with 1/4" center hole, will supply the Delrin in 12" x 12" sheets, will ship a

few extra sheets just in case, material will be coming from McMaster-Carr

To order custom laser cut parts, proceed to the quote request form [http://www.pololu.com/laserquote/new].

5. Instructions for Laser Cutting File Setup Page 20 of 29

Page 21

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

6. Examples of Custom Laser-Cut Parts

We can cut almost any two-dimensional part that you can draw. We have made many types of custom laser-cut parts,

including:

• custom jewelry and charms

• custom robot parts

• custom stencils

• encoder wheels

• custom computer case parts

• custom computer fan grills

• custom instrumentation panels

• luthier templates and tools

• instrument inlays

• instrument-making tools

• custom enclosures

Browse the following sections to see some examples of laser cutting projects.

• custom sign lettering and logos

• custom ornaments

• custom trophies

• custom awards

• custom gifts

• custom trinkets

• custom gaskets

• custom art pieces

• custom radio control airplane parts from Depron

foam or balsa wood

• custom model railroad parts

• other scale model parts

6.a. Laser Cutting Example: Robot Chassis Parts

6. Examples of Custom Laser-Cut Parts Page 21 of 29

Page 22

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

This custom laser-cut chassis is designed to work with

a pair of GM7 Gearmotors

[http://www.pololu.com/product/183] and our laser-cut

wheels [http://www.pololu.com/product/360]. The cutting

work consists of two 3.0" x 2.4" acrylic plates that

sandwich the two gearmotors. Cross-shaped cutouts on

both plates accommodate plastic tabs on the

gearmotors to lock them into place securely. The

bottom plate has a large hole for press-fitting a plastic

ball caster, and the top plate has a rectangular hole for

holding a battery pack. Various small holes for holding

the plates together and attaching a printed circuit board

are included.

The drawings for the two plates are shown below, followed by a cost breakdown.

Pricing

FOUR sets of 1/8" yellow acrylic parts for the minimum order: $25.00

6.b. Laser Cutting Example: Architectural Ornament Created from a Photograph

Our custom laser-cutting service is not just for robot enthusiasts; it can be for anybody with a creative project

requiring custom parts! This custom ornament was laser cut from red oak and was designed to be used as an applique

for a door. The customer provided us a photograph of a similar pattern, which we referenced to draw this design on the

computer to create a file suitable for laser cutting. The decoration was cut from 1/4" red oak and is 5.5" in diameter.

6. Examples of Custom Laser-Cut Parts Page 22 of 29

Page 23

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Once we have laser cutting file, we can easily re-use the same file to cut a smaller or larger version of the part — we

could cut the same design to be as wide as 35".

The intricate design, geometric nature, and small size

of the piece would make it difficult to cut by hand but

is no problem for the laser cutter. In fact, the laser

cutter can cut any scroll saw pattern and produces

beautiful fretwork from various woods and plastics. As

you can see in the pictures, the laser cutting process

chars the cutting edges in wood, which can be

attractive in many applications. To remove charring

you can sand and polish the edges to restore the natural

wood color.

The intricacy of this ornament and the relatively thick

material (1/4") makes for a higher cutting cost per

piece, but if you were to order multiple units, you

could take advantage of discounted cutting rates for

longer jobs.

Close-up of the ornament.

If you want to design a similar decoration, you can use our laser cutting service to create your own custom appliques

to adorn your study, mantle, front door, or even your entire home to create a unique, attractive living environment.

Pricing

- One-time laser cutting file creation fee (since customer could only provide a photograph): $35.00

- ONE of this custom architectural ornament shipped to you for: $30.95

- TWO of this ornament shipped to you for: $39.95

6.c. Laser Cutting Example: Giant 3-D Pterosaur Puzzle

Continuing with our non-robot examples, we made this custom laser-cut pterosaur puzzle as an example of how you

can use two-dimensional pieces to build a three-dimensional part — in this case, the skeleton of a flying dinosaur!

6. Examples of Custom Laser-Cut Parts Page 23 of 29

Page 24

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

As you can see from the picture to the right, the

assembled pterosaur has a whopping 4-foot wingspan.

It is comprised of 21 two-dimensional pieces laser cut

from 1/8" acrylic. Each piece of the puzzle has slots for

connecting to other pieces; all the parts fit snugly so

the pterosaur stays intact. Mounting holes in the head

and spine are available for hanging the completed 3-D

dinosaur puzzle from the ceiling.

The size and quantity of parts for this dinosaur puzzle

makes it a longer cutting job, but we offer discounted

rates for such jobs to help keep your costs down.

This puzzle design was based on a small, wooden

dinosaur puzzle available at many hobby shops; below

is the drawing we created to cut some of the parts for

our puzzle. If you would like to design a similar dinosaur puzzle as a unique gift or a fun decoration for your living

room, you can use our laser cutting service to create your own giant 3-D dinosaur puzzle, or anything else you can

think of – if you can draw it, we can cut it!

Pricing

CAD drawing for the dinosaur puzzle.

Cutting cost: $68.00

Material cost for 5 sq. ft. of 1/8" transparent gray acrylic $20.00

This custom 3-D petrosaur puzzle shipped for: $88.00

6. Examples of Custom Laser-Cut Parts Page 24 of 29

Page 25

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

6.d. Laser Cutting Example: Servo-Driven Sumo Robot

This custom sumo robot chassis is propelled by two radio-control hobby servos modified for continuous rotation.

The five laser-cut components consist of top and bottom panels, two identical side panels that hold the servos, and a

front shovel panel (see drawing below). The top, bottom, and side panels are attached by bolts and standoffs, and the

interlocking front panel is held in place with nylon cable ties. All the pieces were cut from 1/8" acrylic, and the top

and bottom panels are about 3.25" x 2.25".

This particular design was initially built with a BEAM circuit controlling the servos, but you could also control such

a robot with a microcontroller-based robot controller [http://www.pololu.com/category/8/robot-controllers].

If you want to design a similar robot, you can use our laser cutting service to build your own custom sumo robot for

less cost than most pre-made kits. For a tougher version of the robot that can take more abuse, you could also have

us cut the components out of ABS. The cutting cost would be about 60% more, and you wouldn’t have as many color

choices, but your robot would be almost indestructible!

Pricing

CAD drawing for the laser-cut sumo robot.

TWO SETS of these custom sumo robot parts $25

6. Examples of Custom Laser-Cut Parts Page 25 of 29

Page 26

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

6.e. Laser Cutting Example: Pentominoes Puzzle With Engraved Solutions

Laser cutting is a perfect process for making your own custom brain teasers

and puzzles that involve tessellations (mosaics or tilings that cover a plane

without gaps). For this example, we made a pentominoes puzzle out of

transparent blue acrylic. Pentominoes are polyominoes with five squares; the

pieces that fall down in the original Tetris game are tetrominoes, or

polyominoes with four squares. There is only one domino.

The pentominoes puzzle consists of all twelve possible pentominoes. These

twelve pieces can be assembled into a 6 square x 10 square rectangle in

thousands of different ways, yet it is surprisingly difficult to find even a

single solution! There are many other games you can play with a set of

pentominoes – just do a search for “pentominoes” [http://www.google.com/

search?hl=en&ie=UTF-8&oe=UTF-8&q=pentominoes].

A pentomino piece, showing

engraved solution.

One of the properties of pentominoes is that each pentomino can be made,

three times bigger, out of nine of the other pentominoes. We added a novel touch to our pentominoes set by engraving

the nine-piece solutions into each piece.

An engraving is just a cut that does not go all the way through. In the drawing below, all of the black lines are cut all

the way through, but the red lines are cut with five times less power (a process called vector engraving). A picture can

also be engraved (using a different process called raster engraving), so you could customize a pentominoes set with a

company logo or a personal message.

Of course, we can laser cut any 2-D puzzle you can draw. You can extend the pentominoes idea and make hexominoes

or even higher order polyominoes, you can make custom tangrams, or you can prototype the next great puzzle that

everyone will want to solve!

6. Examples of Custom Laser-Cut Parts Page 26 of 29

Page 27

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

CAD drawing for the laser-cut pentominoes puzzle.

In this case, it is helpful for you to lay out your own

parts.

One-time laser cutting file creation fee (since customer could only provide a photograph): $35.00

ONE of this custom architectural ornament shipped to you for: $25.00

TWO of this ornament for: $34.00

6.f. Laser Cutting Example: Calculator Robot Chassis

Norland Research [http://www.smallrobot.com/] manufactures a robot based on a graphing calculator, which has a

chassis that is a good example of what can be made with a laser cutter. The dimensions of this chassis are designed

to fit a Texas Instruments graphing calculator on the top level and the electronics, batteries, and servos on the bottom

level. A similar design could be used for any basic robot.

This custom, two-level chassis is propelled by two radio-control

hobby servos modified for continuous rotation. The chassis uses

our plastic ball caster [http://www.pololu.com/product/174] as a third

contact point. There are eleven laser-cut parts, with eight

different shapes; all parts are made of 1/8" acrylic (plexiglass),

except for a 1/4" spacer also made of acrylic. The pieces

interlock tightly enough that the chassis (barely) holds together

on its own; in this particular design, the parts are glued together.

A similar design could instead use a few screws or bolts should

the possibility of disassembly be desirable. The design has since

been changed to an ABS chassis that uses a “snap together”

design with tabs with small feet that snap into a smaller slot.

(This would not be possible using acrylic since acrylic is brittle.)

6. Examples of Custom Laser-Cut Parts Page 27 of 29

Page 28

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Pricing

CAD drawing of the calculator robot chassis.

One set (minimum order applies): $25.00

Two sets (discounted cutting rate for longer cutting time): $35.00

6.g. Laser Cutting Example: Acrylic Cat Logo

This custom laser-cut logo for Anna started as a pencil sketch on a cocktail napkin. To laser-cut any design, we need a

vector-format drawing file. We can draw the part on the computer for you, or you can draw it yourself using a vector

drawing or CAD program (CorelDRAW, Adobe Illustrator, TurboCAD, etc.).

The smaller cat is around 2.3" x 3" and was cut from 1/8" transparent gray acrylic; the larger cat was created from the

same file but enlarged to 9" x 11.5", and it was cut from 1/4" black acrylic. Vector-format drawings can be resized to

the size you need (unlike bitmaps, you do not get “jagged edges” when you resize vector drawings), and we can cut

parts up to 49.5" x 35", so this kitty could be made as large as 35" x 45"!

6. Examples of Custom Laser-Cut Parts Page 28 of 29

Page 29

Custom Laser Cutting Guide © 2001–2014 Pololu Corporation

Laser cutting is a great way to make unique, personal gifts, or even works of art. If you have a creative design but it

is only on paper, we can help you take your idea from sketch to fabrication.

Pricing

Scanned sketch used to create the logo.

ONE piece out of 1/4" black acrylic: $31.00

One-time laser cutting file creation fee (since customer could only provide a sketch): $38.00

6. Examples of Custom Laser-Cut Parts Page 29 of 29

Loading...

Loading...