Pollardwater PSUPERDECHLORPRO Installation Manual

Item Code: PSUPERDECHLORPRO

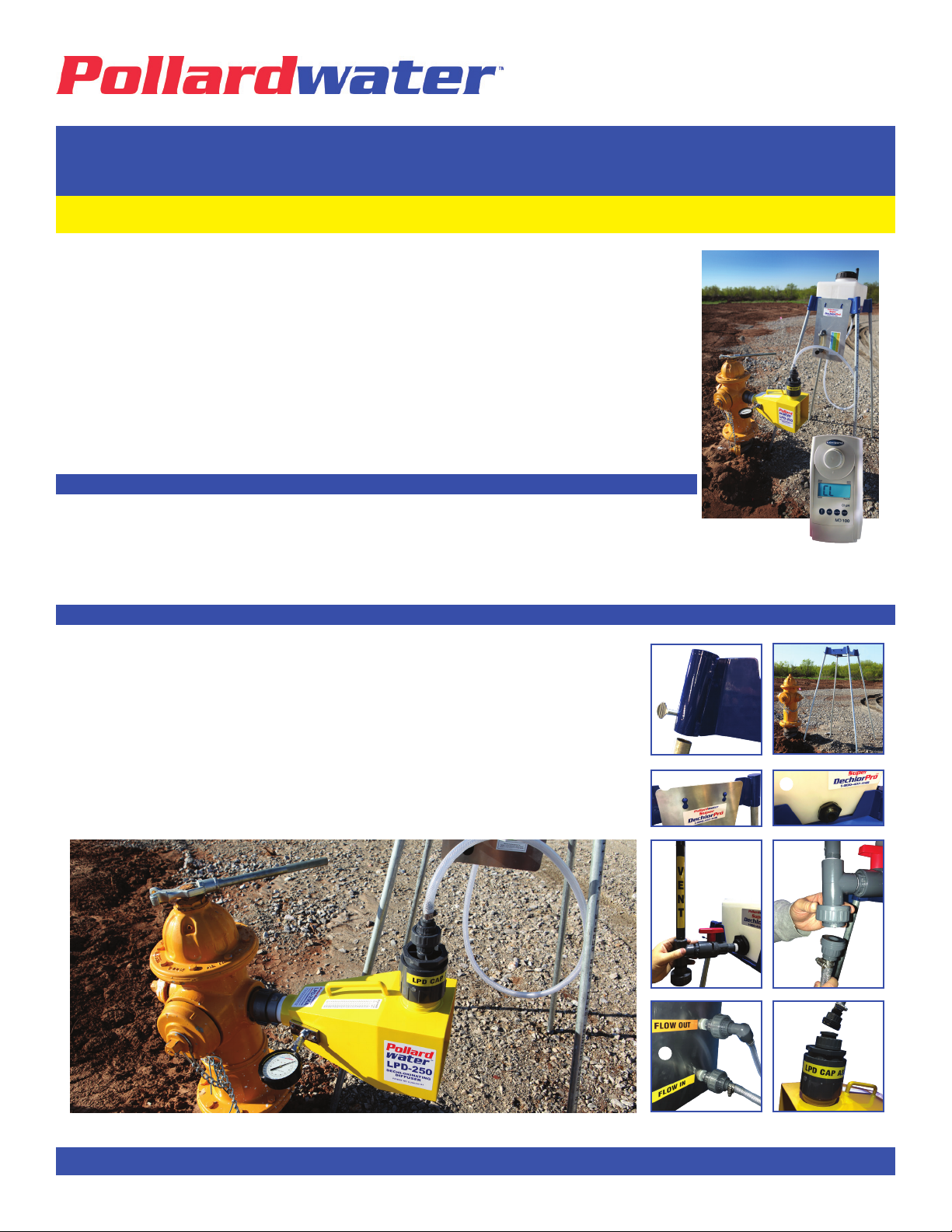

SUPER DECHLORPRO™ DECHLORINATING SYSTEM

Always wear Personal Protective Equipment like Safety Glasses, Gloves, and Work Boots.

SUPER DECHLORPRO™ OVERVIEW

The Super DechlorPro™ dechlorinating system is for high chlorine concentration projects

using a gravity fed dechlorination chemical in a discharged ow through the LPD-250

Dechlorinating Diffuser to minimize site disturbance and maximize efcient use of eld

chemical treatment.

The recommended dechlorination chemical is Captor® Calcium Thiosulfate, but other

liquid dechlorinating agents may be used (other chemical agents may require a different ow

meter assembly). Captor

depleting properties and is an economical and safe chemical to handle.

ON SITE CONSIDERATIONS

• Level ground for system stability and proper gravity ow

• Discharge location is lower in elevation to assure maximum gravity feed

• Pre-test chlorine level of discharge and periodically test during process to ensure dechlorination

• Make certain all safety procedures and job site safety precautions have been addressed

®

is commonly used due to it’s non-hazardous and non-oxygen

Cl2 Colorimeters

(order separately)

QUICK SET UP GUIDE

1. Remove Legs from Storage Tube.

2. Insert Legs in to Tank Cradle and secure Thumb Screws.

3. Set Cradle Assembly near Hydrant and make level.

4. Hang aluminum Flow Panel onto Cradle Pins.

5. Open Chemical Tank and remove LPD Cap and Hoses, set aside for now.

6. Place Tank on Cradle with Outlet facing away from Flow Panel.

7. Use Pipe Thread Tape (provided) and install Tank Valve / Vent in Tank Outlet.

8. Install Hose from Tank Valve / Vent to Back Panel Flow-In connection.

9. Install Hose with 90º elbow to Back Panel Flow-Out connection.

10. Install Cap Assembly on to LPD-250 (order separately) and connect Hose.

800-437-1146 • Fax 516-746-0852 • www.pollardwater.com • info@pollardwater.com

SUPER DECHLORPRO™ OPERATING INSTRUCTIONS

DETERMINE SCOPE OF DECHLORINATION PROJECT

1. Determine the Total Volume of water to be dechlorinated in gallons.

Volume in Gallons = 3.14* x (radius of pipe in feet squared)* x Length of Pipeline in feet x 7.48

For Example: 5000 Feet of 8” Ductile Iron Pipe

3.14 x (.333 x .333) x 5000 x 7.48 = 13,023 Gallons to be Dechlorinated

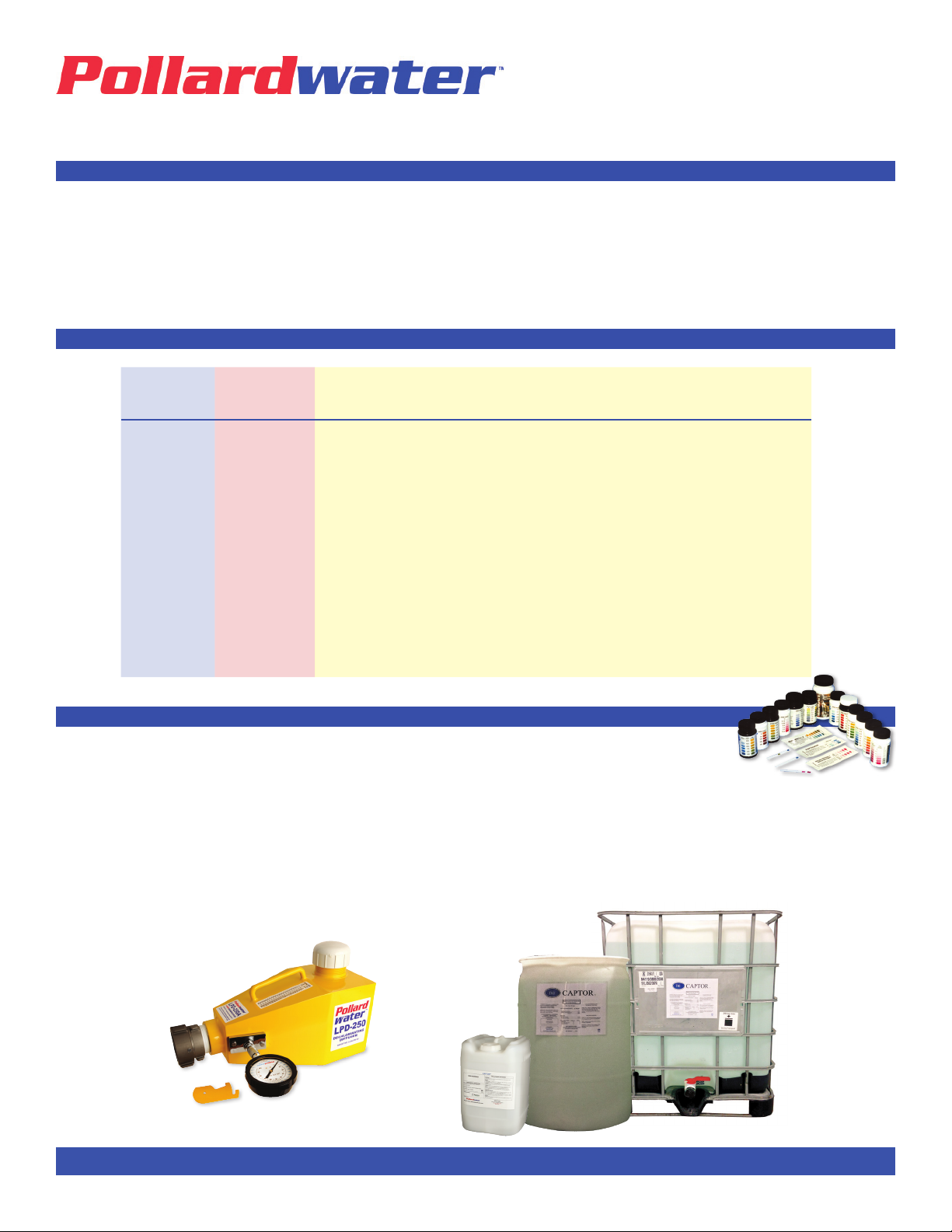

VOLUME OF WATER IN A PIPELINE CHART

Nominal Gallons Gallons Per Pipeline Length

Pipe Size Per Foot 100 200 300 400 500 1000

4 0.65 65 130 196 261 326 652

6 1.47 147 294 440 587 734 1,468

8 2.61 261 522 783 1,044 1,305 2,610

10 4.08 408 816 1,223 1,631 2,039 4,078

12 5.87 587 1,174 1,762 2,349 2,936 5,872

14 7.99 799 1,598 2,398 3,197 3,996 7,992

16 10.44 1,044 2,088 3,132 4,176 5,219 10,439

18 13.21 1,321 2,642 3,963 5,285 6,606 13,212

20 16.31 1,631 3,262 4,893 6,524 8,155 16,311

24 23.49 2,349 4,697 7,046 9,395 11,744 23,487

*rounded up

DETERMINE AMOUNT OF CHLORINE TO BE DECHLORINATED

2. Determine the Parts Per Million (ppm) of Chlorine (Cl2) to be Dechlorinated.

• For super chlorinated water Test Strips are most commonly used.

• Always test the water before dechlorination as Cl2 levels may have changed.

• NOTE: In cases of new watermain installations, most State, County or Municipal agencies require chlorination up

to a specied concentration (ppm). This chlorinated water, over a period of specied time, disinfects and kills any

active and harmful bacteria. The Cl2 levels may be lower than the starting point depending on how much Cl2 was

used up in the disinfection process.

Cl2 Test Strips

(order separately)

800-437-1146 • Fax 516-746-0852 • www.pollardwater.com • info@pollardwater.com

Loading...

Loading...