Installing Your In-Wall

or In-Ceiling Speakers

Section 1: Introduction To Installing In-Wall or

In-Ceiling Polk Audio Speakers

Installing your new Polk Audio in-ceiling or in-wall speakers is relatively

easy to accomplish for even the most hesitant do-it-yourselfer. This

Guide will take you through the process step by step. Installing your new

olk speakers can be very rewarding, and they look and sound great too.

P

At first, many are intimidated thinking about attempting this on their

own. Thinking about cutting into your drywall should not be a barrier

to doing this yourself. Sheet rock or dry wall is by design a very forgiving

building material. We suggest that you choose walls or ceilings that are

not covered with wallpaper or have a faux finish. Since, in some cases

the need to cut into a wall to install the cabling is necessary, and that

hole will need to be patched and painted, matching the patterns on

some wall papers, and harmonizing a faux finish can be difficult.

But if you consider yourself to be a wiz at wallpaper and/or paint

repair, go for it!

Here is a quick “personal test” to see if you’re up for doing this yourself:

e you familiar the following tools:

Ar

• Stud finder

• Tape measure

• Utility Knife

• Power drill and driver

• Sheet rock saw

• Putty knife

• Wire fish tape

• Wire stripers

• Full frequency 50 nanosecond vector scope and are confident about

troubleshooting any frequency scatter between 5 and 2.35 gig?

afety and Code Review

S

• Use material and speaker cabling that conforms to your community

and state building codes–your retailer or home center service

personal will know if these are unique and which material to use.

• Use caution when standing on a ladder.

• Always use eye protection.

When in a crawl space, attic or unfinished basement be sure

•

o light the space safely.

t

Take your time.

•

• When drilling into walls or ceilings shut of power to that area

of the house.

• When drilling through a fire block or any fire barrier, after installing

the wire, be sure to fill the hole with a comparable fire retardant

material (available in small quantities at any home improvement

center in a convenient aerosol can).

• When cutting or stripping wires, or using sharp blades–slow down,

make sure you have enough light, and always cut or slice in a motion

away from your body.

If you at least have a working knowledge of these basic tools

then see below to gain confidence.

Have you ever run cabling for any of the following:

• Telephones

• Computer network

• Printer cable

• Track lighting

• Automatic sprinklers

Outdoor or indoor lighting

•

Cable or satellite television

•

• A security system

And do you feel comfortable with any of the following:

• Repairing a hole in sheetrock or drywall

• Installing “on wall” shelving

own molding

Installing baseboar

•

ds or cr

If you answered yes to any of these and are familiar with the tools

listed, we’re confident that you are capable of installing Polk speakers.

DIY CI Tutorial

2

hotos and description of the Tools

P

Sheet rock saw

Fish tape to help install wire into existing walls

Stiff Putty blade

Tape measure, utility knife and wire stripper

y powered hand held drill and driver

Batter

(shown with magnetic driver extension)

DIY CI Tutorial

3

Section 2: Polk Audio In-Wall and In-Ceiling

Speaker Installation Guide

Materials and Preparation

Before cutting into your walls to install your new Polk Audio speakers,

gather up all the tools and materials needed to complete the project.

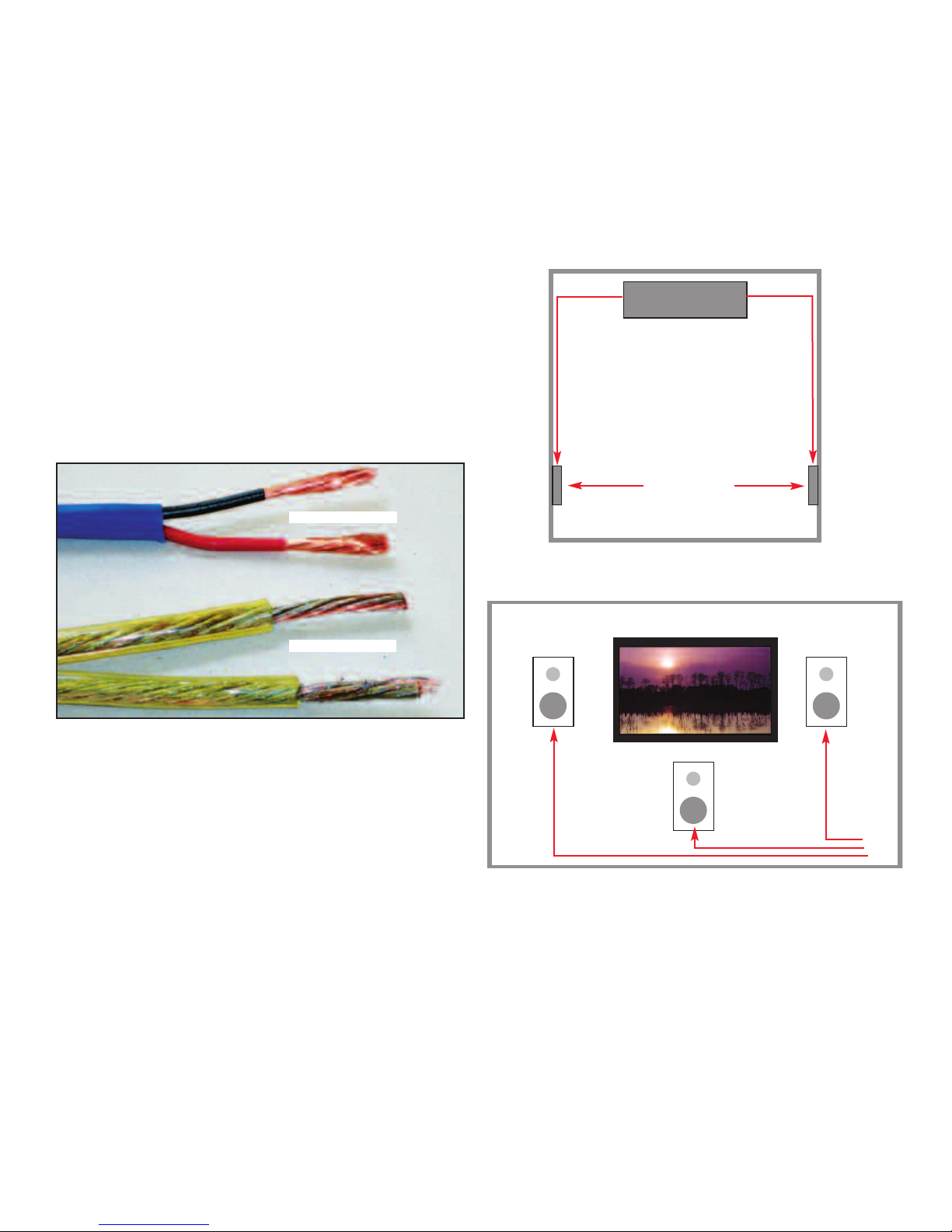

Speaker cable: the audio signals are going to run on the cables you

install. Here are some things to know and options to think through:

1. Cable vs. wire: A cable utilizes more than one conductor, a wire uses

just one conductor-even if the wire is “stranded” or has several bare

wires together-in all basic speaker applications you will need a

minimum of 2 conductors, thus the term cable is used here instead

of “wire”.

Planning Where to Run the Cable

The planning process starts with some basic layout decisions and the

ype of application chosen. Here are three basic types of systems:

t

Scenario 1

Home Theater: In this example the three front speakers (front left,

front center, and front right) are traditional free-standing speakers

hile the rear surround speakers are in-wall (or in-ceiling) speakers.

w

This situation will require running cables to the rear locations from

the surround receiver.

Floor plan view:

2) Be certain that you have enough speaker cable–it is always a good

idea to cut each run of cable 3' to 6' longer than needed. The length

of your cable run will determine the gauge of wire needed. The term

“gauge” refers to the size of the cross section of the wire, (the lower

the gauge number, the larger the wire is in diameter).

The following is a good general guide for wire sizing:

a. Runs under 100' (33m) use 14 or 16 gauge cable.

b. Runs over 100' use 12 gauge cable.

16 gauge speaker cable

12 gauge speaker cable

3) Your audio retailer can recommend the brand and type of cable that

will work best for your application. Some things your retailer will

need to know to make an appr

opriate recommendation:

Television Display

and component

entertainment cabinet

Surround speakers

Scenario 2

Wall-mounted flat-screen TV with in-wall speakers in the front:

a. Overall length of the cable run

b. The room application (is this for your home theater

or for background music in your bathroom?)

c. The local building codes

ecommend utilizing a stranded cable that is manufactur

e r

W

4)

specifically for speakers which wraps the conductors in one jacket

and are commonly called 16/2:

16/2 = meaning that the conductor size is 16 gauge with 2 conductors.

5) Plan where you plan to run the cable. If you want to run cable under

a carpet or on a wall then we recommend “flat” style cable. If you are

going to run the cable entirely inside of walls or through attics or

crawl spaces, “round” cable will do and will save you some money.

Any of your choices will work and but final leg of you cable route

will need to be run in the wall.

ed

In this case the cabling would be run from the surround

eceiver to the speakers.

r

DIY CI Tutorial

4

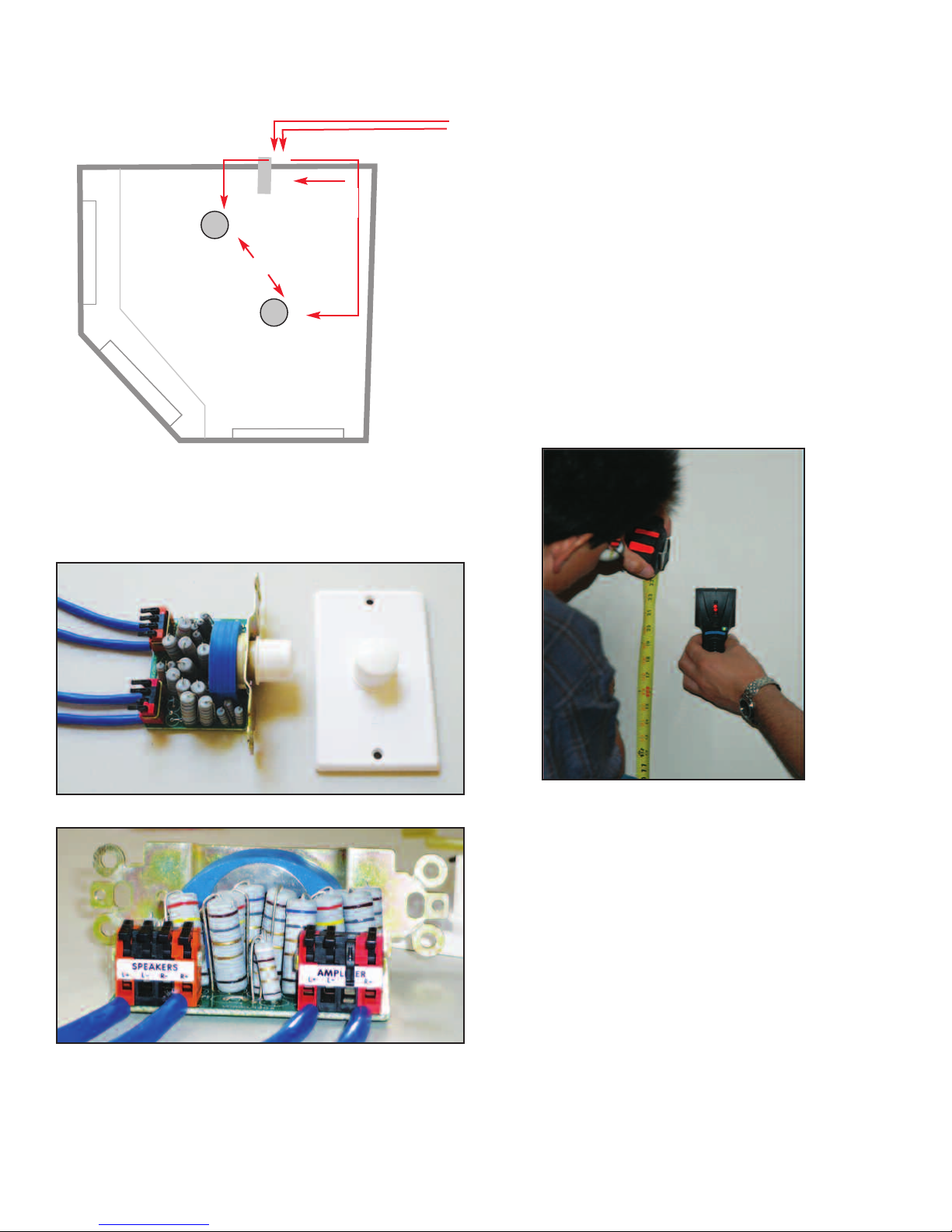

cenario 3

S

The speakers will be installed in the ceiling for music in the kitchen utilizing a volume control on the wall to adjust the volume to the speakers.

From amplifier to

Volume control

Volume

control

Speakers

In this room there are three cable runs, the first is two sets of speaker

cables that run from the amplifier or receiver to the volume control on

the wall, then another run of speaker cables to each speaker.

lanning Your Cable Routes

P

NOTE: In a stereo installation the cable length to each speaker within

a room should be about the same to avoid volume or time shifts from

channel to channel. In home theater installations the cable lengths for

Front Left, Center and Right channels should be about the same. The

cable lengths to the rear speakers will in most cases be longer than

those to the front three speakers and that’s OK.

Whenever possible take advantage of attic and crawl spaces as it

is much easier to run cables through them than walls.

Section 3:Checking For Obstacles Before Installation

Speaker placement research: Once you have a good idea about

where you want to install your new Polk speakers, we suggest you

check out the space just to make sure there is enough room for the

speakers. When your home was built the contractors ran gas piping,

air ducts, drain and water pipes, electrical, phone and data cables.

Also check that the placement of the speakers will be symmetrical

once you have established where the joists and studs are:

Note the location of all studs using your stud sensor.

Volume control with face plate:

Rear view of a typical volume control:

Use a stud finder to locate structural members inside

the walls and ceiling.

input fr

om amplifier

DIY CI Tutorial

5

hen:

T

Drill a small 1/2" hole in the sheet rock then using a stiff wire

or bent coat hanger “feel” for any obstructions.

Be sure to check the locations for all the speakers, if you discover that

one location won’t work and you have to go to an alternate location that

may affect where you want to place the others.

nce you have determined the locations for your Polk speakers

O

ape the supplied templates to the wall or ceiling.

t

Drill a small exploratory hole

The use a pencil and trace the edge of the template:

Bend a stiff wire at a right angle

Use the wire to “feel” for wires, pipes and obstructions in the wall

If you feel an obstruction, wire or pipe with the wire probe, choose

another speaker location. Some obstr

uctions could include electrical

wiring, drain, hot, and cold water piping. If you feel no obstr

now you can cut the opening for the speaker.

uctions,

DIY CI Tutorial

6

Section 4: Installing Polk Speakers: Cutting Drywall

and Running Speaker Cables

This section covers cutting into the walls and installing the cables.

upplies

S

Now is the time to gather your supplies:

) Speakers

1

) Speaker cable

2

3) Cleaning material

4) Tools

5) Wall plates

6) Connectors

Cutting Sheet Rock

Cutting sheetrock is a deal-breaker for some people and you may

be one of them. At this point you may make the decision to bring in a

professional to pull the cable and install the speakers. Polk Audio can

recommend a professional installation company, call (800) 377-7655

during normal east coast business hours. But cutting sheetrock is not

that difficult, and in the long run you’ll enjoy your built-in speakers

even mor

e knowing that you installed them yourself.

ome obstructions could include electrical wiring, drain, hot,

S

nd cold water piping:

a

Don’t cut these things. Bad things will happen.

120 Volt AC “Romex”

drain pipe

Note: There are many “Roto” type power tools on the market and you

may be tempted to use them to impress your audience – but they are no

faster than hand saws and increase dust by a factor of 10! Hand saws

also have the advantage of giving you more “feel” making it less likely

that you’ll saw through a water pipe.

Sheetrock saws have a pointed tip that make it easy to punch

into the sheetrock to start the cut.

Hot and cold

water pipe

Installing the speaker cables:

A few rules, some general guidelines and a couple of tips will help this

process go smoothly.

The Universal Building Code or UBC, and most all local codes have some

restrictions on how large of a hole you drill in structural members, for

the vast majority of installations this will not be an issue because of the

small holes - you only have to pull a cable or two.

Here are the guidelines:

When working with studs: studs support your roof and partition off the

various rooms in the home. Standard stud sizing is as follows:

2 x 4 measures 1 1/2" by 3 1/2"

2 x 6 measures 1 1/2" by 5 1/2"

2 x 8 measures 1 1/2" by 7 1/2"

DIY CI Tutorial

7

tandard cross section of a modern 2 x 4

S

Codes usually recognize walls in two categories:

“load bearing” and “non-load bearing”.

In load bearing walls be sure to

keep your drilled holes to less then

40% the width of the stud

unning speaker cable with alternating current or AC lines:

R

The national code restricts the use of common holes for both. Also

for performance reasons try to separate your speaker cabling from the

C lines with as much distance as practical:

A

National Electric

Code does not allow

low voltage cable to

be installed in the

same holes or boxes

as AC.

speaker cables

WRONG!

Studs in load bearing walls have these restrictions:

Holes must be LESS then 40% the width of the stud

Notches must NOT exceed 25% the width of the stud

When unsure if the wall you’re planning on using is a load bearing

wall or not then just treat it as if it were “Load Bearing”.

speaker cables

AC wiring

The above photos show the wr

ong way to run your speaker

cables and the photo to the right show the correct way.

DIY CI Tutorial

8

When running speaker cables separate them from AC wiring and when

rossing the AC wires cross them at 90 degrees:

c

speaker cables

AC wiring

RIGHT

When bending the speaker cables use a gentle or gradual arch:

Wrong

Correct

speaker cables

AC wiring

DIY CI Tutorial

9

Wrong

And when using tie wraps or staples be careful to not “over tighten”

or “over fasten” the cables: These cables so mashed and attached to

these studs that they now rate as part of the structural mass helping

hold the house up!

ips to running cable in existing walls

T

Vertical runs: In a 2 story home where you want to run

cabling between floors to some ceiling speakers:

ceiling

joist

proposed cable run

Much

Better

Leave a bit of room, these cables are not going anywhere, and we have

not damaged the integrity of the conductors–Elvis is pleased that his

music is not distor

ted.

Using your stud finder determine which way the joists or structural

members above your ceiling run. Then notch out a small section

of the drywall on the wall and ceiling as shown:

top

plate

ceiling

joist

View from inside the ceiling space

DIY CI Tutorial

10

arefully drill through the top plate as shown to create a cable channel:

C

ceiling

joist

p

top

late

wall

stud

hread the pull tape from the top notch through the wall to the opening,

T

ttach the speaker wire and pull (gently) up through the wall.

a

wall

stud

ceiling

joist

When attaching speaker cabling to the pull or fish tap–overlap the cable

through the “paper-clip” on the end of the fish tape. Start with the fishtape end and cover the whole connection with at least two layers of

electrical tape as shown:

top

plate

wall

stud

Thread the cable through the top plate (use the fish-tape if needed).

Fish the tape fr

om your speaker opening back thr

ough the wall/ceiling

notch,attach the cable and pull over to the speaker opening.

DIY CI Tutorial

11

orizontal runs

H

Running speaker cabling across a room may seem difficult–one good

idea is to utilize the base board molding.

First use a utility knife and score the top edge of the base molding to

separate the paint on the dry wall and the paint on the molding then

using a stiff putty blade gently pry the molding outward as shown:

When you find a fire-block in between the studs it is possible to drill

through using the speaker hole to get your drill into the wall:

DIY CI Tutorial

12

he image below is a photo of a cross section of a typical wall:

T

The idea here is to utilize the space behind the base molding

for our horizontal cable runs, if needed notch the studs:

wall stud

base

molding

sheet rock

or dry wall

carpet & pad

sub floor

Section 5: Speaker Installation and Hook Up

By now you have the speaker cables in the walls and the holes

cut for your new Polk speakers.

tart by dry-fitting your speakers into the openings. The speaker should

S

slide into the hole with approximately 1/8" wiggle room–this leaves

enough space to “straighten” the speaker to the walls and ceiling.

In most cases walls are not exactly “true” or squared to each other.

Now you can install the cable:

Replace the molding, and touch up with paint, now you

are ready to install your new Polk speakers!

otating cam

r

clamps

Our speakers utilize a

unique “r

otating cam”

that presses the front

baffle casing to the wall

and allows for easy

installation fr

fr

ont side of the speaker.

Phillips head scr

accessed from the

front of the speaker

baffle

plate

DIY CI Tutorial

om the

ew,

13

or additional acoustic performance install some insulation into the wall

F

avity (be sure to place the same amount behind each speaker).

c

Strip your speaker cables back about 3/4", and insert the pair into

the input on the back of the speaker: (note* Reminder-for an easier

installation if you leave a generous cable lead to work with).

ow install the speaker into the wall and tighten up the dog-clamps

N

ith your screwdriver. Be careful not to over tighten the speaker–the

w

ry wall or sheet rock could dimple, or break.

d

his is most likely to

T

happen if you are using a power driver. Set your power driver’s

torque setting to “1” to help avoid over-tightening screws.

View of rotating cam after installation from inside the wall.

DIY CI Tutorial

14

inally install the grill:

F

Terminate the speaker cable to the binding post inserts

and install like this:

For a professional look we recommend terminating the cables near the

receiver or amplifier with a wall plate, this allows a very clean finish,

without any gaps or holes in the wall. Your friends will think a professional did the install! The simple install goes like this:

Install a single gang retrofit box: These are available at all home centers,

cost about $3.00 and are installed just like your speakers:

DIY CI Tutorial

15

atching and restoring the wall

P

As we talked about above, sheet rock is a very forgiving building

material. We suggest using a wall repair patch witch is a small section

f wire or nylon mesh, some drywall joint tape and joint compound.

o

Here are the steps:

1. Clean the wall and ceiling area, remove any loose debris.

2. Remove the backing of the patch and apply to cover holes,

press the self-adhering mesh against the surface.

Be sure to overlap the remaining wall and ceiling by

at least 2 1/4" in each direction.

Now just connect to the amplifier. Congratulations, you’re done!

3. Apply joint compound (commonly referred to as “drywall mud”)

over patch. Spread evenly with a broad knife. Fill all depressions

and joints. Cover an area 2" to 4" past the edges of the patch

and tape.

4. Feather edges out to match the existing surfaces.

Allow material to dry.

5. Sand area lightly to smooth and match the finish.

6. Repeat steps 3 & 4 if necessary to achieve desired finish,

cleaning and sanding as you go.

7. Paint.

8 Refreshments, cold beer, and invite your good buddy Jack Daniels

over to hear your system rock.

DIY CI Tutorial

16

Loading...

Loading...