Polivac SL2000 Stingray Operations Manual & Trouble Shooting Manual

POLIVAC SL2000 STINGRAY

ULTRA HIGH SPEED POLISHER

Operations Manual & Trouble Shooting Guide

Version 6/2000 Operating instructions for a SL1600 Dominator

Please find the following correct procedure for the operation of the Polivac SL1600

Dominator or a SL2000 Stingray.

1. Ensure that the power is on, and that extension cords are not used.

2 The handle height must be adjusted to suit individual operators body proportions.

Adjust the ergo handle, to the correct height by placing the foot or hand on the

ratchet lever then positioning the handle. The correct height of the handle is

around the groin region.

3 When the handle is set at the correct height, the arms should grip the handle in a

comfortable, but loose manner (if your arms are bent at the elbows this is an

indication that you are applying too much effort to control the machine) Re-adjust

the handle.

4 Before starting the motor, you must tilt the machine back by gently pressing down

on the handle. Ensure the pad is clearly off the floor, doing this reduces the

starting torque load on the motor.

5 To start the machine, first you must depress the red safety button that is next to

the hand trigger, then grasp either of the red triggers, and the motor will engage

the pad. Do not force the trigger without first releasing the safety button as this

will damage the safety release in the trigger mechanism. Once the machine is on,

the safety button can be released.

6 Once the motor has started, engage the pad on the floor and begin walking

behind the machine.

7 Always work away from the cord and in a straight-line direction (do not try to

swing machine side to side) then complete a U-turn and continue walking straight.

8 Generally, use the left hand for steering and guiding the machine.

9 Always use ultra-high speed Polish on the floor.

10 Walk at a comfortable walking speed.

11 Never use the machine on the same spot for an extended period, as being a high

speed machine the combination of friction and heat could strip or damage the

floor unintentionally.

12 The appliance is not intended for use by young children or infirm persons without

supervision.

13 Young children should be supervised to ensure that they do not play with the

appliance.

14 If supply cord is damaged, it must be replaced by the manufacturer or it’s service

agent or a similarly qualified person to avoid a hazard.

How to Operate an SL1600

Dominator or SL2000 Stingray

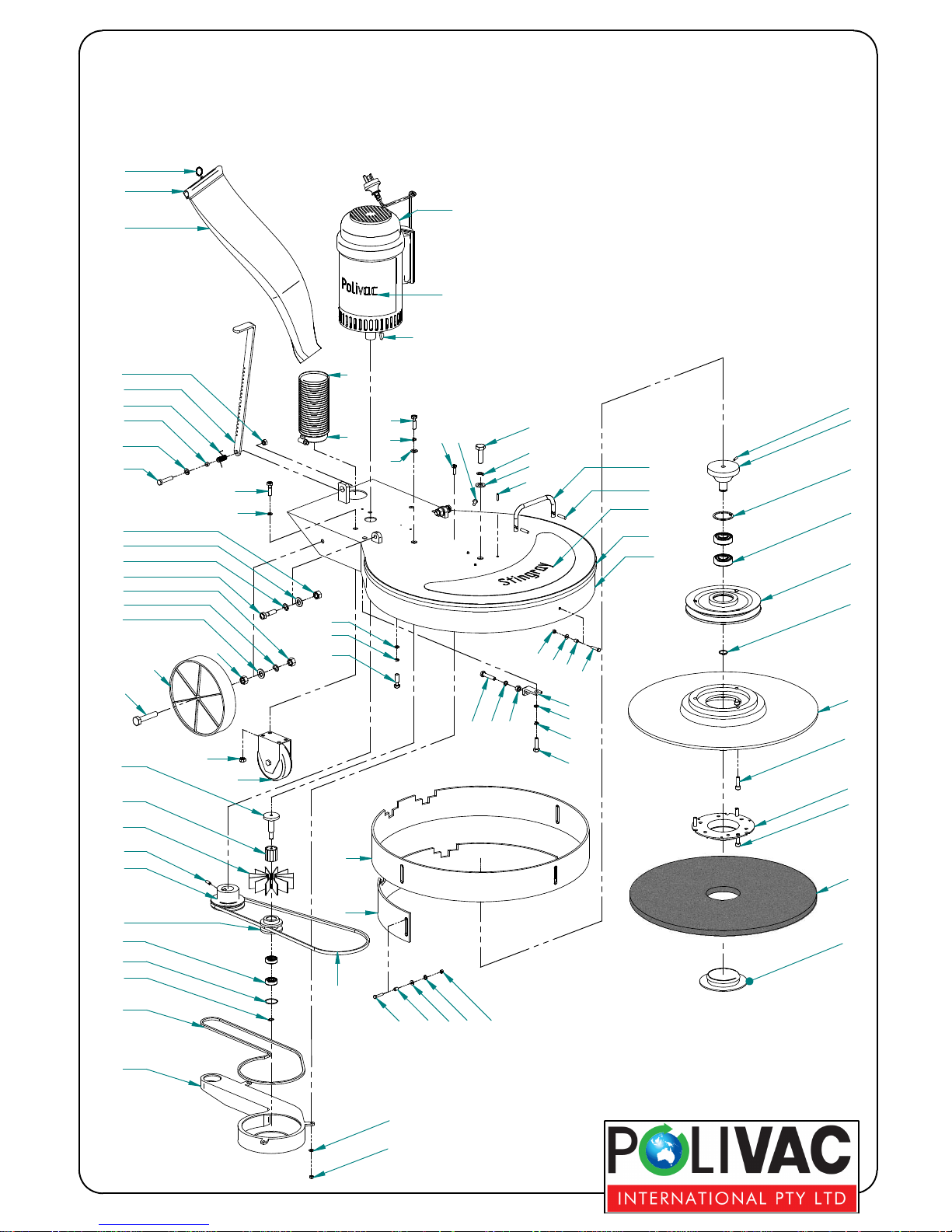

Stingray Burnisher - SL2000

Drawings by: LeanSynergicDesign.com.au

Drive & Base Assembly

41

33

35

6

4

3

5

2

60

59

21

10

20

19

22

16

15

11

17

23

36

38

39

40

67

37

57

14

55

56

54

47

48

49

46

39

38

40

25

12

31

43

42

50

45

44

9

8

7

32

53

65

13

12

14

58

1

52

31

30

51

68

69

34

24

13

25

12

70

72

71

62

61

27

28

25

13

26

63

64

29

66

61

62

28

64

18

63

35

Stingray Burnisher - SL2000

Drawings by: LeanSynergicDesign.com.au

No Code Description

1 SLB003 Body

2 SLB006 Shaft-Drive Pulley

3 VPV230 Bearing

4 SLB005 Drive Pulley

5 GAS031A Circlip

6 GAS031B Circlip

7 AAG470 Washer 1/2'' x 1'' Zinc Bright

8 GAS054 Washer Spring 1/2'' x 3/16'' x 1/8''

9 SLB034 Bolt-Drive Pulley Shaft

10 SLB018 Vac Chamber

11 SLB015 Shaft-Vac Pulley

12 GAS049 Bolt-Vac System Shaft 5/16'' x 3/4''

13 GAS045 Washer Spring 5/16'' x 1/8'' x 3/32''

14 AAG385 Washer 5/16'' x 7/8'' Zinc Bright 16G

15 VPV184 Fan Boss

16 VPV252 Fan Blades (Pkt. of 12)

17 SLB014 Pulley Vac

18 SLB016 Bearing

19 SLB050 Circlip

20 SLB017 Circlip

21 SLB012 Vac Chamber Gasket 6.4mm x 9mm

22 SLB010 Pulley-Motor

23 SLB019 Drive Belt

24 SLB004 Tension Bracket

25 AAG365 Washer Flat 5/16'' x 3/4'' Zinc

26 SK006 Bolt-Motor MNT/Tension

Drive & Base Assembly - Part List

Loading...

Loading...