THOR 100 - 200

USE AND MAINTENANCE MANUAL

PI 470

INTRODUCTION

Congratulation for purchasing a Polini engine. By purchasing it

you have become one of a large family of satisfied Polini products owners. Thor product has been designed to perform as competitively as possible. Read this use and maintenance manual

carefully throughout before flying with your new engine. This

manual contains important information that will help you to

achieve the best satisfactions with the use of the Thor 100 engine. To ensure care-free and satisfying usage you must get to

know your new engine thoroughly and set it up correctly before

you start using it.

INDEX

1- GENERAL ADVICES

2- FUEL

3- ENGINE STARTING

4- RUNNING IN

5- ENGINE SWITCING OFF

6- CARBURETION CHECK

7- CLEANING

8- CARRIAGE

9- ORDINARY SERVICING

10- HOW TO BEHAVE IN FLIGHT

11- ENGINE FITTING ON THE FRAME

12- SERVICING TABLE

1- GENERAL ADVICES

Polini Motori and the distributor decline any and all responsibility

whatsoever - either direct or indirect - for the use of the engine,

above all in the case the engine is modified or manumitted by

third parties. Polini Motori doesn’t assume responsibility for

damages caused by little servicing or wrong assembly, excluding

the pieces from the warranty. Any technical modification may be

introduced by the buyer, who assumes all the responsibilities for

possible damages; spare parts for any modification are not under

warranty. We advice you that any engine modification made by

the buyer or the removal of original parts may make the engine

dangerous to be used!

The user is invited to respect and follow what written in the use

and maintenance manual for his own and third parties safety.

When you use this engine you are making a very dangerous

action, so you may have the maximum care before, during and

after flying, in order to avoid serious accidents. We invite you to

be careful to prevent accidents or damages and to keep always in

mind that:

- the engine can’t solve all the flight problems, so it is important

to avoid dangerous maneuverings. One of the most common

errors is to fly over zones where it is not allowed to land; you

have always to take into consideration the possibility of engine

failure or the need to make an emergency landing. It is forbid-

den to fly over built-up areas, urban centers, to drop things or

liquids when flying.

- the lack of engine power can disturb the flight stability: the

engine could stop suddenly and you may be obliged to make an

emergency landing on a safety area.

Before using it, for your own and third parties safety, it is necessary to be sure that the weather conditions are good, or anyway

adequate for a safety flight, in order not to compromise the good

engine work. Rain or unfavorable weather conditions, besides

being dangerous, could also damage the engine, prejudicing its

normal working. It is not allowed to use the paramotor when

raining or with strong wind. Only fly if the wind speed, its direction and the conditions grant a safety flight. It is important to

check the weather forecasting for the hours close to the flight

and to know the taking off and landing areas. Because of the

risks inherent to the paramotor use, and the flight,

Polini doesn’t give any warranty against accidents,

breakings, injuries or death. To fly with a paramotor

always needs great attention. Be aware that you fly at

your risk. Before every use check the good condition of

your paramotor. This engine is not covered by any

responsibility insurance. By using it you automatically

assume all the risks inherent the paramotor sport or

the personal responsibility towards damages to

yourself or to third parties, accidents, injuries or death.

We invite you to carefully read the instructions contained in this manual since they are helpful for a better

knowledge of the products and the use itself and useful

to prevent and contain the risks.

WARRANTY

All the Polini engines are manufactured with high quality materials which grant a product without defects, under the conditions

that the buyer purchase the products from a Polini authorized

dealer.

VALIDITY OF THE WARRANTY

The warranty is valid for a period of 12 months from the date of

purchase. It is necessary to activate the warranty by filling the

form out and keeping the payment slip or the invoice.

COVERAGE

The present warranty covers the engine damages caused by

defective parts, in shape or materials, for projects not in conformity with the use indicated, wrong assembly by the manufacturer. The warranty includes spare parts only. Delivery costs

are charged to the user.

The warranty doesn’t cover damaged caused by:

- Engine modifications not approved by Polini;

- Wear and tear of the parts;

- Carelessness, lack of servicing, accidents, installations or wrong

maintenance;

- Accidental falls or engine fall or of its components;

ENGLISH

TECHNICAL LIST THOR 100

Polini Engine 2 stroke monocylinder

Cooling Forced air

Bore for stroke 52 x 52

Displacement 110 cm

3

Power 20,5 HP at 8900 R.P.M.

Cylinder Aluminum with Gilnisil coating

Compression ratio 12,5:1

Piston Two chromium plated rings mm 1

Intake Reed valve in the crankcase

Carburetor Walbro / Polini PWK

Air filter Air box

Ignition Electronic and with battery charger possible

Battery charger prearrangement Output power 80 W at 5500 RPM

Spark plug hood 5k Ω resistance

Fuel type Lead free petrol with 2% synthetic oil

Gear reduction unit Helical teeth in oil bath with 3,43 reduction ratio

Starting Pull start with self winding cable

Clutch Centrifugal in oil bath

Muffler Expansion with oval silencer

Engine weight 13,8 Kg

Propeller rotation Clockwise

TECHNICAL LIST THOR 200

Polini Engine 2 stroke monocylinder

Cooling Forced air

Bore for stroke 64 x 60

Displacement 193 cm

3

Power 29 HP at 7400 R.P.M.

Cylinder Aluminum with Gilnisil coating

Compression ratio 11,4:1

Piston Two chromium plated rings mm 1

Intake Reed valve in the crankcase

Carburetor Polini PWK Ø 28 / Walbro

Air filter Air box

Ignition Electronic and with battery charger possible

Battery charger prearrangement Output power 80 W at 5500 RPM

Spark plug hood 5k Ω resistance

Fuel type Lead free petrol with 2% synthetic oil

Gear reduction unit Helical teeth in oil bath with 2,8 reduction ratio

Clutch Centrifugal in oil bath

Muffler Expansion with oval silencer

Engine weight 17,5 Kg (18,5 with electric starter)

Propeller rotation Clockwise

- Engine improper use or misusage;

- Assembly of parts or components not specified for the engine

use;

- Engine overheating or stop after long usage, beyond the term

indicated by Polini;

- Missing or irregular engine servicing as suggested by Polini, use

of improper petrol or oils, presence of dirty parts or foreign

bodies in the engine, even sucked;

- Engine overwork because overloaded;

- Engine or parts deterioration because of improperly storage;

- Faulty engine assembly, including the use of not original Polini

parts or coming from third parties;

- Damages to the engine caused by foreign bodies;

- Servicing operated by person outside Polini or by not authori

zed people;

- Competition use of the engine.

Final user obligations

Claims shall be done by delivering the engine to a Polini authorized dealer. The user shall provide the original document that proves the purchasing or the warranty ticket authenticated by Polini

or by its distributor. To keep the validity of the warranty the user

shall carry out recurrent servicing according to the use and maintenance manual.

Limited liability

Pursuant to this warranty, Polini’s obligations are limited to the

defective parts reparation or, at its discretion, to change one or

more parts, necessary to remedy every malfunctioning caused by

defective materials or labor covered by the warranty. Polini or

the distributor can’t be held responsible for problems or damages

to persons/things/animals during the engine life. We remind

you that this product is not certificated and it is only

dedicated to experimental aircraft and that it can break or

suddenly stop working. No warranty or compensation are foreseen for damages caused to:

- persons/animals/things during the engine use

- persons/animals/things caused by a collide with the propeller

or with parts detached from the engine

- frame, parts and/or propeller caused by the collide with parts

coming out from the engine

- costs for rescue, shipping, phone or rent after the collide,

problems or loss of time, or other indirect damages.

DANGER! This not-certified engine can suddenly stop working. The engine stop can require emergency landings causing

injuries or death. The aircraft thrusts by this engine should fly in

open spaces only or during the daylight. The buyer assumes all

the risks for the use and he knows that by using it the engine can

suddenly stop working. This product is not covered by products

and public liability. Who flies with a paramotor or only

switches it on assumes all the risks inherent to the

paragliding sport and all the responsibilities for damages to things or persons or death caused by the use of

this product.

2- FUEL

Thor 100/200 is a 2-stroke engine that needs oil/petrol mixture.

Only use good lead-free petrol purchased by a petrol station with

98 octane. Add good 2% synthetic oil to the petrol. It is possible

to use a 1,5% oil mixture with the following oils:

MOTUL 800 - CASTROL 242 - BARDAL KXT - ELF 976 - ELF 909.

WARNING: The nature of the carbon deposits on the cylinder

head, spark plug and exhaust port give important information

about the fuel mixture burning in your engine. Remember that

mixes that contain too much oil do not extend the engine’s life.

ATTENTION: petrol is extremely inflammable and explosive. Carry out these operations in a well ventilate place and with

the engine switched off. Refrain from smoking and avoid all

naked flames or sparks where petrol is being drained or where

re-fuelling is being performed.

3- ENGINE STARTING

Start the engine only when all is in good conditions and perfectly

working. Furthermore check that all the nuts are well tightened.

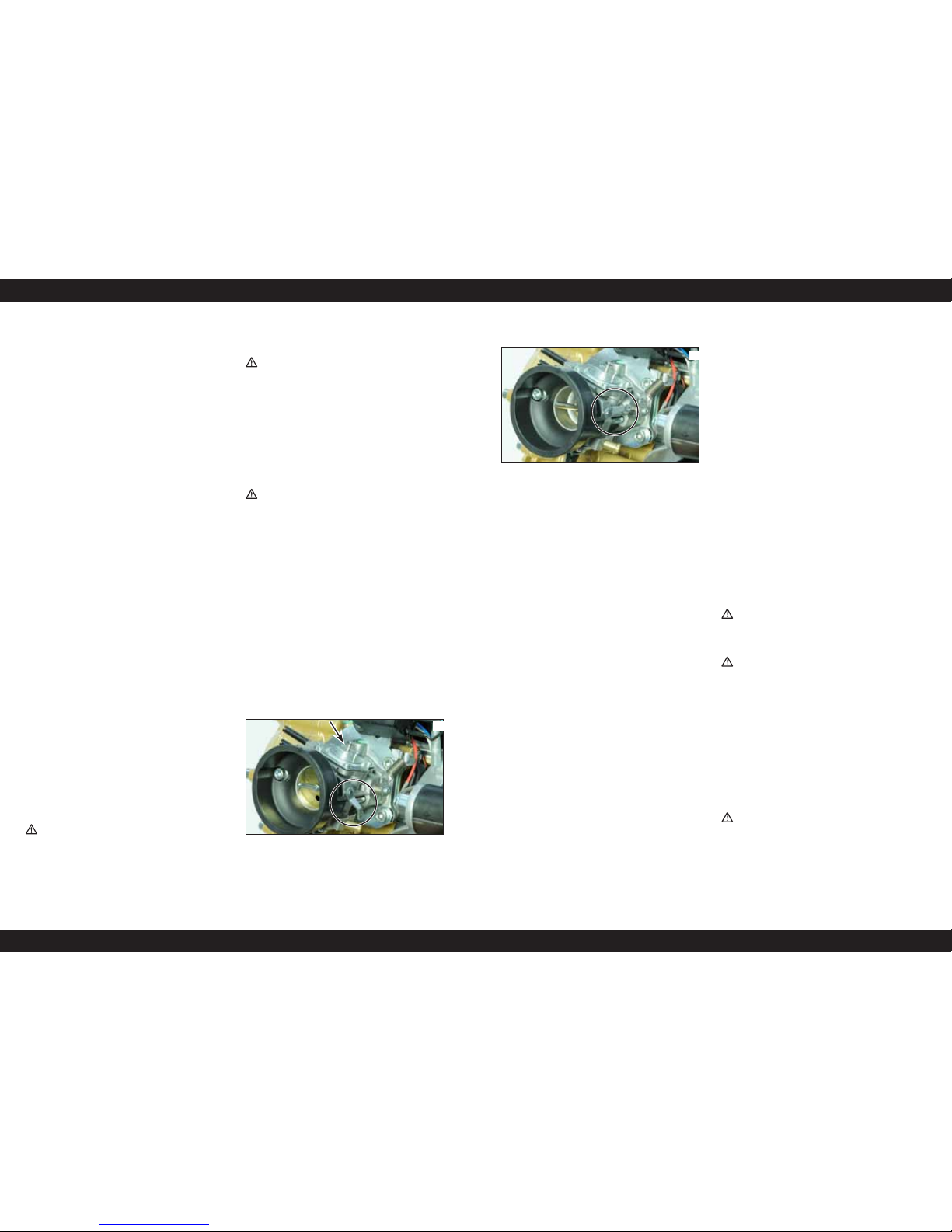

3.1 WALBRO CARBURATOR (THOR 100-200)

First cold starting: fill in the fuel system using the pump provided

(carefully follow the instructions provided by the frame’s manufacturer to find out it and use it in the correct way). To make this

operation easier push softly with a finger the diaphragm through

the hole indicated by the arrow in photo 1. Fill it in till the petrol

reaches the carburettor. At that moment immediately stop; if you

go on acting on the pump the petrol will leak causing the engine

flooding.

01

WALBRO WG8 CARBURETOR (THOR 100 engine only):

Move the starter level to the off position (photo 1); now hand the

starter and start pulling the rope till it grows hard. Pull with

strength without accelerating till the engine seems to start working (do not repeat this operation more than 3 times otherwise

the engine may flood). Now move the starter lever to the on

position (photo 2) and act on the starting rope without accelerating. If the engine doesn’t work with the first two attempts, try

again accelerating gently.

02

3.2 24/28 PWK CARBURETOR

Fill in the fuel system till the petrol reaches the carburetor hole

and then pump up three times (using the pump provided- Code

316.0016) to fill out the bowl. To start the engine pull upwards

the black level placed in the upper side of the carburettor.

Work the starter without accelerating till the engine start. Once it

works switch it off, disconnect the starter and start the engine

again slightly accelerating. For your safety only start the engine

after your harness has been COMPLETELY fixed!

3.3 THOR 200 ENGINE STARTING WITH ELECTRIC

STARTER

According to the carburettor model (Pwk or Walbro WB37) refer

to section 3.1 and 3.2 to fill in the fuel system. For the model

with electric starter the Polini throttle system has 3 buttons on the

bottom part of the throttle device. To start both the engines push

the black buttons together and slightly accelerate. For your safety

only proceed with this operation after your harness has been

COMPLETELY fixed!

ATTENTION: keep the switch in your hand during all the stages

and be ready to work it in case of any anomaly. If necessary

keep it pressed till the engine has completely stopped.

Once the engine starts we suggest testing the right functioning of

the kill switch button. After having checked it, start the engine

again without accelerating and without using the starter. Now

start the engine and leave it idle until it warms up to normal

temperature.

4- RUNNING IN

Run your engine in as instructed below to ensure that the engine

and transmission bed in correctly and to ensure continuous reliability in future. Once the engine starts, leave it idle until it warms

up to normal temperature. We suggest running the engine 15

minutes at medium-low engine power output gently accelerating

and with different intensity. Now we suggest checking the correct

idling calibration.

During the first flights or for the first 20 litres of petrol we suggest not keeping the engine at the maximum rpm for too much

time, considering that the 2-stroke engine doesn’t stand to the

constant rpm even if of medium power. We suggest varying the

engine rpm. Check the carburetion after the first landing (section

6). Repeat the running in every time you change one of the following parts: piston, rings, cylinder, crankshaft or main bearings.

5- ENGINE SWITCING OFF

Switch the engine off by pressing the button till the complete stop

(see the frame manufacturer’s instructions to find the button

position)

6- CARBURETION CHECK

For a complete carburetion check switch the engine off after

having worked it for some minutes under load. Remove the

spark plug; unscrew it by using the proper key and verify that

the porcelain colour is light-brown. On the contrary, ask to an

authorized dealer for the calibration.

7- CLEANING

Clean the engine when it is switched off and cold to avoid burns.

Clean the engine with a soft cloth soaked with neutral cleansing

and non-aggressive.

WARNING: Do not use acids that may damage the engine.

8-CARRIAGE

ATTENTION: Carry the engine only when cold. Follow the

frame manufacturer’s instructions for its carriage. Be careful of

the petrol during the carriage; its leaking may cause a fire.

8.1 CARRIAGE OF THE ENGINE WITH PWK

CARBURETOR

PWK carburetor has a breather pipe studied to carry the engine

when lying. To empty the carburettor unscrew half turn the breather brass nut (highlighted in photo 3 with an arrow) and wait till

the fuel enters the tank. Close the brass connection again. Now

the carburettor is empty and you can lay the engine ready to be

carry.

ATTENTION: never unscrew more than half a turn the bre-

ather nut to avoid damaging the OR seal. Never close too hard.

03

9- ORDINARY SERVICING

ATTENTION: THE SERVICING OPERATIONS MUST BE DONE

BY QUALIFIED PEOPLE ONLY. IF THE INSTRUCTIONS MENTIONED

BELOW WILL RESULT NOT CLEAR, WE SUGGEST ASKING FOR

SPECIALISTS BY POLINI MOTORI RETAILERS OR WHOLESALERS.

FOLLOW CAREFULLY WHAT DESCRIBED BELOW.

Maintenances and servicing necessary for the best set up of your

engine should be done regularly, or on all occasions before you

start flying. All the tasks and adjustments described below can be

done easily by following the instructions given in this manual.

Refer to your POLINI MOTORI dealer for scheduled services and

repairs, and insist that only original spare parts are used to

replace worn or broken components. Refer to the servicing tables

in sections 12 below for the frequency with which the various servicing operations must be performed.

9.1- REMOVE AND CLEAN THE AIR FILTER

Dirty air filter is one of the most common causes of poor engine

performance.

Clean the filter periodically or change it. Remove the filter loosening the clamps, unscrew the 4 screws using a cross screwdriver,

remove the filter cover and then the filter. Wash the filtering

material with water and mild soap,

After rinsing and wringing the filter, moisten it with oil for filters.

Clean filter box inside using a cloth and check the presence of

foreign bodies. Now reassemble all the parts being careful to

place correctly the 4 bars that maintain the filter in its position

and screw the 4 screws again. Wash the filter for maximum 2-3

times, then replace it.

WARNING. If the filter becomes clogged with fine dust as

well as normal dirt, replace it with a new one.

WARNING. Dirty air filters choke the engine and cause poor

performance. Torn or broken filters can allow dirt to enter the

engine and cause rapid deterioration of the piston rings, piston

and barrel.

9.2- CHECKING OF THE GEAR OIL LEVEL

Operate when the engine is cold. Maintain the engine in vertical

position and remove the oil level screw on the transmission

crankcase. (photo 4). Check that the oil level reaches the lower

edge of the level hole. If there is too much oil, let it flow out

from the level hole until it stops flowing and collect the oil in a

suitable container. If there is not enough oil, top up as required

through the breather hole located at the top. After checking it,

tighten the screws. Use ELF Moto Gear Oil 10 W 40 ANTI Clutch

Slippage or Shell advance gear SAE 10 W 40 API GL-3

04

OIL LEVEL

A

9.3 GEAR OIL REPLACEMENT

Change the oil when the engine is cold. Unscrew the screw on the

lower side of the clutch/gear group. Collect the oil flowing out in

a suitable container. Wait till the oil has completely flown out

and, if necessary, tilt the engine to the side to make this operation easier. Tighten the screws. Unscrew the breather pipe in the

top side of the crankcase and fill it out with:

(FOR THOR 100 ENGINE) 25cc of ELF MOTO GEAR OIL 10 W 40

ANTI CLUTCH SLIPPAGE. Place the connection/breather again.

(FOR THOR 200 ENGINE) 100cc of ELF MOTO GEAR OIL 10 W 40

ANTI CLUTCH SLIPPAGE. Place the connection/breather again.

Another option is: Shell Advance Gear SAE 10 W 40 API GL-3

WARNING: Do not throw spent oil into the environment. Dispose

of it correctly through authorised collection points.

9.4-STARTER ROPE REPLACEMENT

Remove the starter from the engine unscrewing the 4 screws

(Photo 5).

Remove the handle rope. Be careful since the central wheel will

turn till the complete spring discharge: keep it and discharge it

slowly to avoid damages or possible injuries. Remove the central

screw and its cover (photo 5.1).

Attention! Under the cover there are two teeth for the starter

jaw (check their condition and if worn replace them); under them

2 small callipers. Be very careful not to lose these small parts.

Prepare the new rope and tie a knot at the top. Remove the plastic wheel and the old rope.

05

5.1

Thread the new rope in its hole (photo 6), wind the rope on the

wheel (according to the entrance sense of the rope on the wheel)

(Photo 7). Now insert the plastic wheel in its housing again, the

spring, the teeth for the starter jaw and screw the cover again.

Now go on by charging the return spring: take the head of the

rope leaving 5-7 cm coming out the hole with “u” shape on the

wheel side. Turn the wheel three times in anti clock wise sense till

it stops in front of the exit hole on the aluminium case. Keeping

the plastic wheel stopped make the rope go through the case

hole. Insert the handle and the washer and tie a single knot as

shown in photo 8.

Reassemble the starter in the engine and screw the 4 M5 screws

with strength (see the tightening torque values table).

06

07

08

9.5- WALBRO WG8 AND WB37 CARBURETOR

DIAPHRAGM CHANGING

Remove the filter unscrewing the clamp by using a cross screwdriver. After removing the accelerator cable from the carburettor,

the supplementary spring, the carburettor pipe and the diffusion

pipe unscrew the two socket head screws and remove the carburettor from the engine. Now place the parts on a flat plane.

Remove the upper cover by unscrewing the 4 screws , remove the

diaphragm and the gasket, check that the inside part is clean and

reassemble by using the new diaphragm and the new gasket

(photo 09).

09

ATTENTION: The carburettor is made of many small and

fragile parts. Be very careful during all the phases with particular

attention to the idling and its springs; they both must not be touched.

Remove the lower cover by unscrewing the 4 screws (Photo 10),

remove the diaphragm and the gasket, check that the inside part

is clean in particular the metallic filter provided on the Walbro

WG8 model only (Photo 11) and assemble it again using the new

diaphragm and the new gasket. Reassemble the carburettor following the instructions in the opposite way, being very careful to

place the gaskets in the right places.

10

11

10- HOW TO BEHAVE IN FLIGHT

Maximum acceleration is recommended only to take off (full

power) or when really necessary!

In order to avoid a poor mixture from acceleration/ascension to

level flight conditions, loosen the engine till a descending phase

and then gradually accelerate again till achieving a level flight

or a glide angle or a rise angle wished. In this way you will be

sure to maintain firm and efficient the carburation, avoiding to

be over rpm with a minimum valve/throttle opening.

Two stroke engines do not stand constant range for a long time

too much. Take care of your engine by varying now and then the

rpm range. In this way the engine will have constant performance and a good elasticity improving its working during the time.

10.1 TEMPERATURE THERESHOLDS

Your 100/200 Thor engine, according to the pilot weight and

wind size, must have a flight temperature between 230° and

250° under sparkplug (these measures have been taken with

Polini thermocouple tool – 928.830.002). This parameters may

vary according to different factors: environment temperature,

working height, wet, quality of the fuel used, anyway this temperature has not to exceed 265°/280 for short period.

Furthermore it is important to say that carbon deposits caused by

a richer mixture may limit during the time the exceeding loss of

heat, favouring high temperatures that can compromise the reliability of the engine. For these reasons we remind you to follow

very carefully the section concerning the servicing.

11- ENGINE FITTING ON THE FRAME

The engine is supplied in a packaging and it is screwed on a cage

to protect it during its carriage. Unscrew the 4 M8 screws that fix

it and extract the engine. KEEP THE PACKAGING AND ITS CAGE

FOR POSSIBLE REPARATIONS UNDER WARRANTY. WARRANTY IS

NOT ACCEPTED IF THE ENGINE IS NOT SHIPPED IN THE ORIGINAL

PACKAGING. The engine must be fixed on the frame using the 4

clamps with the silent-block and positioning some spacers (on

the Thor 100 only) if the frame doesn’t have the necessary space

to fit the manual starter. Refer to the drawing for the engine

fixing measures.

ATTENTION: The engine must be positioned as indicated in

the picture. To assure a perfect lubrication, do not rotate it.

Because of the overall dimensions during the carriage the filter is

180° rotated. Do not unscrew the clamp to rotate it to reach the

original position. The filter has a hole at the top to be used to

avoid its rotation when using. Place the clamp or a small cable

(they are not provided with the engine) fixing them in a proper

zone of the frame.

ATTENTION: the filter may rotate if you do not fix it and it

could collide with the propeller, breaking it. This may be very

dangerous for your safety.

11.1 FUEL SYSTEM

Prearrange the frame with a proper tank and its pump to make

the fuel reach the carburettor. Connect the fuel pipe to the manifold on the carburettor, fix it using a clamp and verify that there

is not air coming in.

11.2 ACCELERATOR

Fix the carburettor by using the proper accelerator support (not

supplied). After assembling the accelerator, check that its travel is

enough to reach the carburettor throttle valve opening and check

that recovery is good in order to avoid the engine staying accelerated. Check the presence and the right supplementary spring

installation (photo 12) provided with the Thor 100 with Walbro

carburettor only. Connect the electrical wires of the throttle, one

on the mass wire of the coil and the other on the + of the coil

(female connector)

12

11.3 SPARK PLUG

Remove the spark plug and check that the gap between the

spark plug electrodes is 0,9mm. Fit the spark plug hood inside

the conveyor cap being careful to fit it completely. Now engage

on the spark plug and enter the small rubber inside the hole in

the plastic conveyor (photo 13). Spark plug type: NGK BR10EG

13

11.4 PROPELLER

Use propellers by Polini Motori, both for Thor 100 and 200 . The

use of a not proper propeller may compromise the engine working.

11.5 HOW TO CONNECT THE VOLTAGE REGULATOR

(OPTIONAL)

Connect the voltage regulator to the connector. Connect the red

cable (E) to the positive pole on a lead battery (photo 14).

WARNING. Use lead batteries only. The usage of other kind

of batteries could provoke explosions or bursts.

Connect the negative pole of the battery to earth on the engine.

During its working the voltage regulator, if connected in the right

way, will give a 14,5 Vdc voltage on the battery.

14

OPTIONAL

A

B

E

C

D

12- SERVICING TABLE

At every use Check the bolts and screws tightening

Check the silent-block conditions

After the first 10 hours Change the gear oil level

Check carburation

Check the spark plug electrode distance

Every 25 hours Replace the spark plug

Clean the air filter

Replace the muffler springs

Every 50 hours Change the gear oil

Replace the silencer deadening material

Every 100 hours or every year Replace the air filter

Replace the starter rope

Replace the diaphragm and clean it

Replace the silent-block

Replace the fuel system pipes

Replace the reed valves

Every 100 hours Check the piston and piston rings

Replace the pin and rollers cage

Decarbonise and clean the decompression hole

Disassemble the reduction gear and check the clutch and bell wear

Every 200 hours Replace the piston and piston rings

Replace the reed valve

Every 400 hours Replace all the bearings and seals

Replace the crankshaft

100 200

TIGHTENING TORQUE VALUE FOR ENGINE BOLTS AND

SCREWS

M N.m Kgf.m Lbf.ft

Locking

compound

•

HEAD NUTS THOR 100 7 14 1,4 10,3

•

HEAD NUTS THOR 200 6 14 1,4 10,3

•

HEAD NUTS THOR 200 8 22 2,2 16,2

•

CRANKSHAFT NUT - CLUTCH SIDE 12 60 6 44,4

• •

CRANKSHAFT NUT - IGNITION SIDE 10 40 4 29,5

• •

PROPELLER CENTRAL SCREW 10 40 4 29,5 LOCTITE 243

• •

SPARK PLUG 20 2 14,8

•

COUNTERSHFAT THOR 200 12 60 6 44

•

CLUTCH NUT THOR 200 20 80 8 59

• •

CRANKCASE SCREWS 6 8 0,8 5,9

• •

CARBURATOR LOCKING SCREWS 6 8 0,8 5,9

• •

INTAKE MANIFOLD LOCKING SCREWS 6 8 0,8 5,9

• •

MUFFLER STUDS NUTS 6 10 1 7,4 LOCTITE 270

• •

SILENCER LOCKING SCREWS 8 15 1,5 11,1 LOCTITE 243

• •

MUFFLER LOCKING SCREWS 8 15 1,5 11,1 LOCTITE 243

STANDARD TIGHTENING TORQUE VALUES N.m Kgf.m Lbf.ft

5mm Bolts and nuts 6 0,6 4,44

6mm Bolts and nuts 10 1 7,40

8mm Bolts and nuts 25 2,5 18,50

10mm Bolts and nuts 45 4,5 33,30

12mm Bolts and nuts 55 5,5 40,70

13- PROBLEMS DIAGNOSTIC REASON REMEDY

The engine doesn't start Out of petrol Add petrol

Petrol doesn't reach the carburetor Check the fuel system circuit

Old or wrong petrol Empty the tank and the fuel system circuit and replace the petrol.

Flooded engine

Remove the spark plug, start the engine, dry or replace the

spark plug.

Defective spark plug Replace it

Blackened spark plug or wet Clean and dry the spark plug or replace it

Earthened switching off cable Check the wiring

Spark plug hood Check it

Carburetor has problems Clean and check it; eventually replace the diaphragm

No spark Check the ignition, coil and wiring

The engine doesn't idle Dirty carburetor Calibrate the carburetor

Out-of-adjustment screws Clean and check it; eventually replace the diaphragm

Defective spark plug Replace it

The engine doesn't reach the maximum rpm

Wrong carburetion Calibrate the carburetor

The carburetor has problems Clean and check it; eventually replace the diaphragm

The reed valve has problems Replace the reeds or the whole reed valve

Dirty air filter Clean or replace it

Dirty exhaust system Clean or replace the deadening material

Engine revved up when idling Out-of-adjustment screws Calibrate the carburetor

Air through the gaskets Replace the gaskets and seals

Loading...

Loading...