Page 1

Page

1

User Manual 500 & 700 Single

500/502 & 700/702 Dual

Warning: Before installing your Polaris

Automatic Gate operator (som etim e s also

referred to as the “Product”), read this entire

Installation Manual for information about Product

safety matters and proper use of the Product.

Only use the Product for the purpose of

operating a driveway gate.

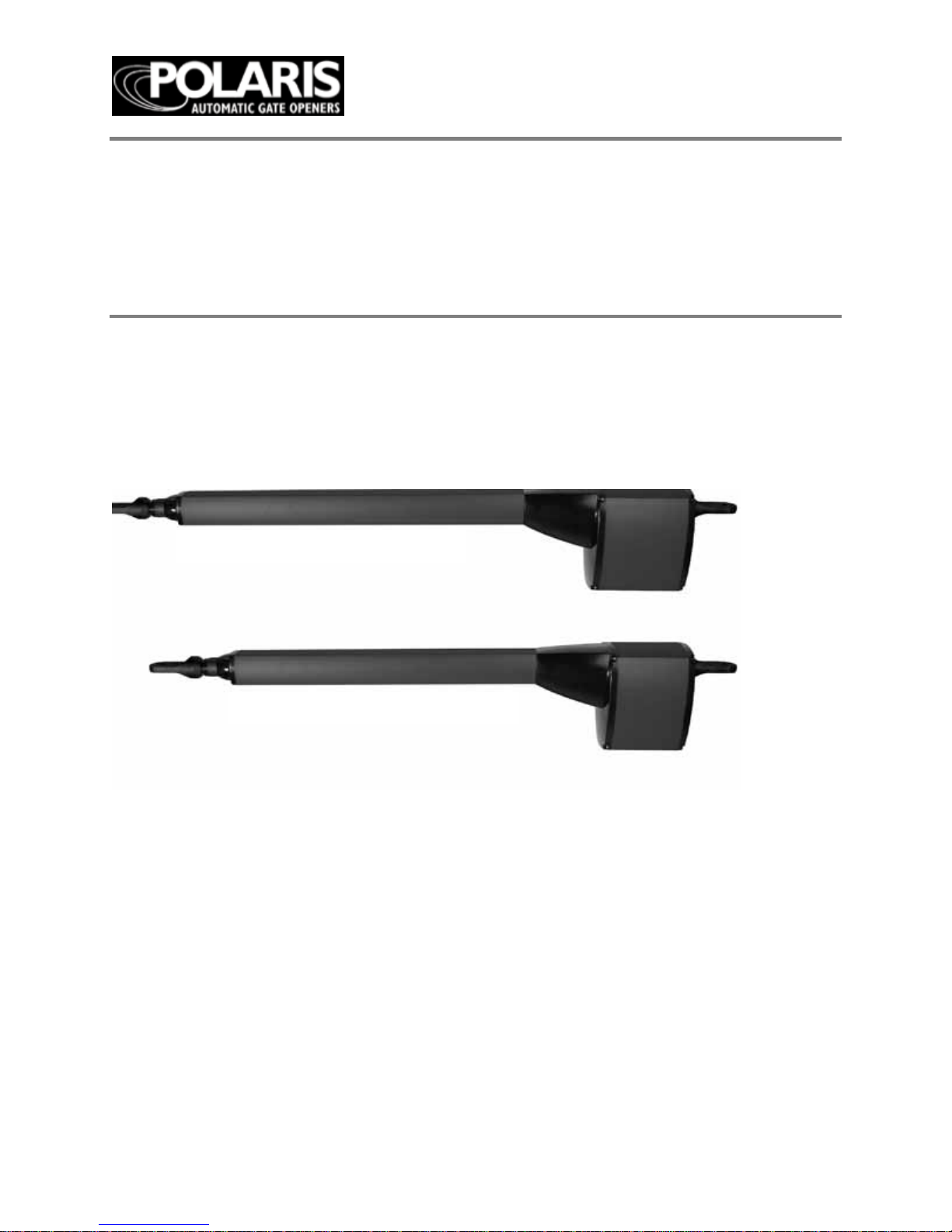

Polaris 700/702

Polaris 500/502

Page 2

Page

2

Document revision: 1.1

Table of Contents

Gate Operator Class Categories ........................................................................... 4

Warnings and Precautions .................................................................................... 5

Installing The Polaris Operator(s)

................................

................................

......... 8

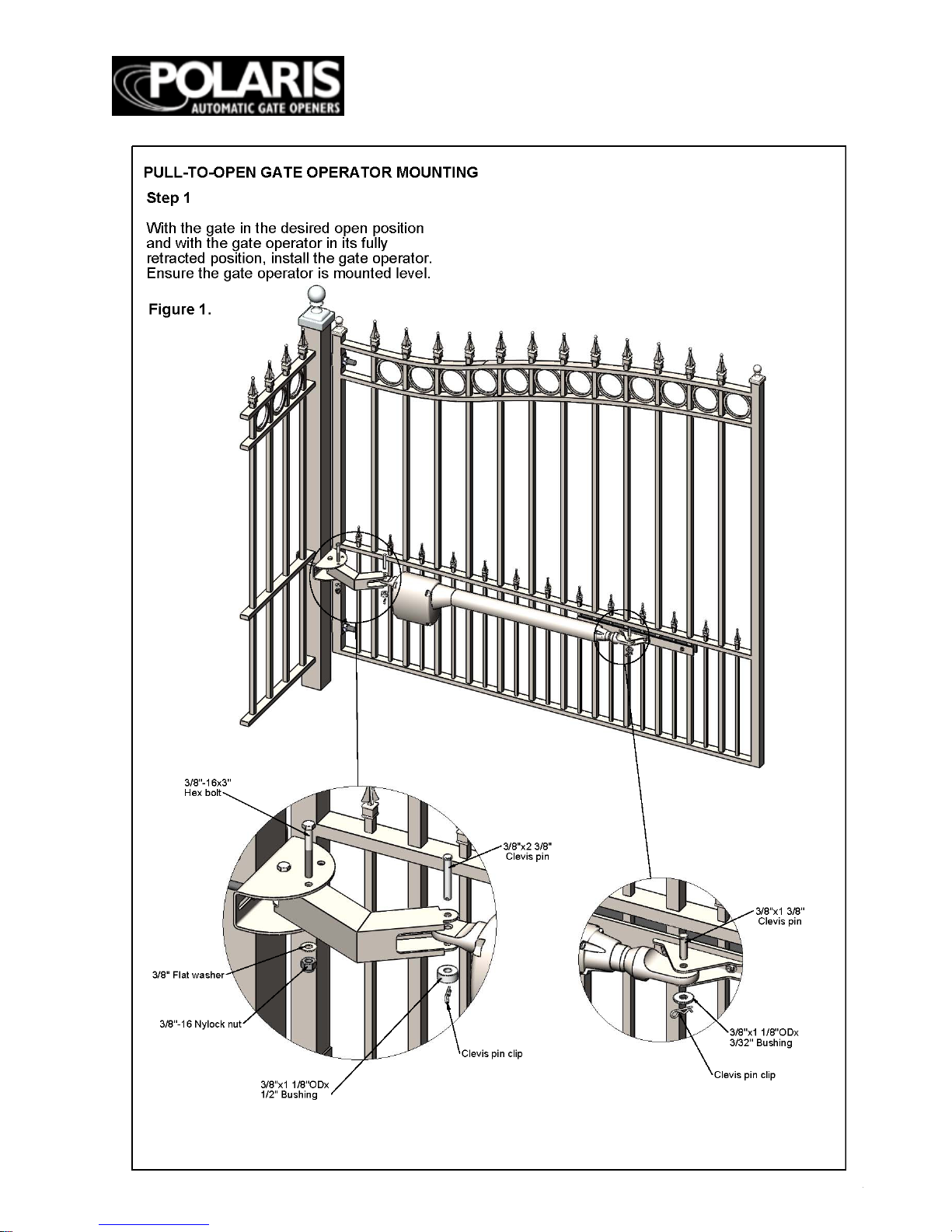

Pull-to-Open Gate Operat or Mounting

................................

................................

... 9

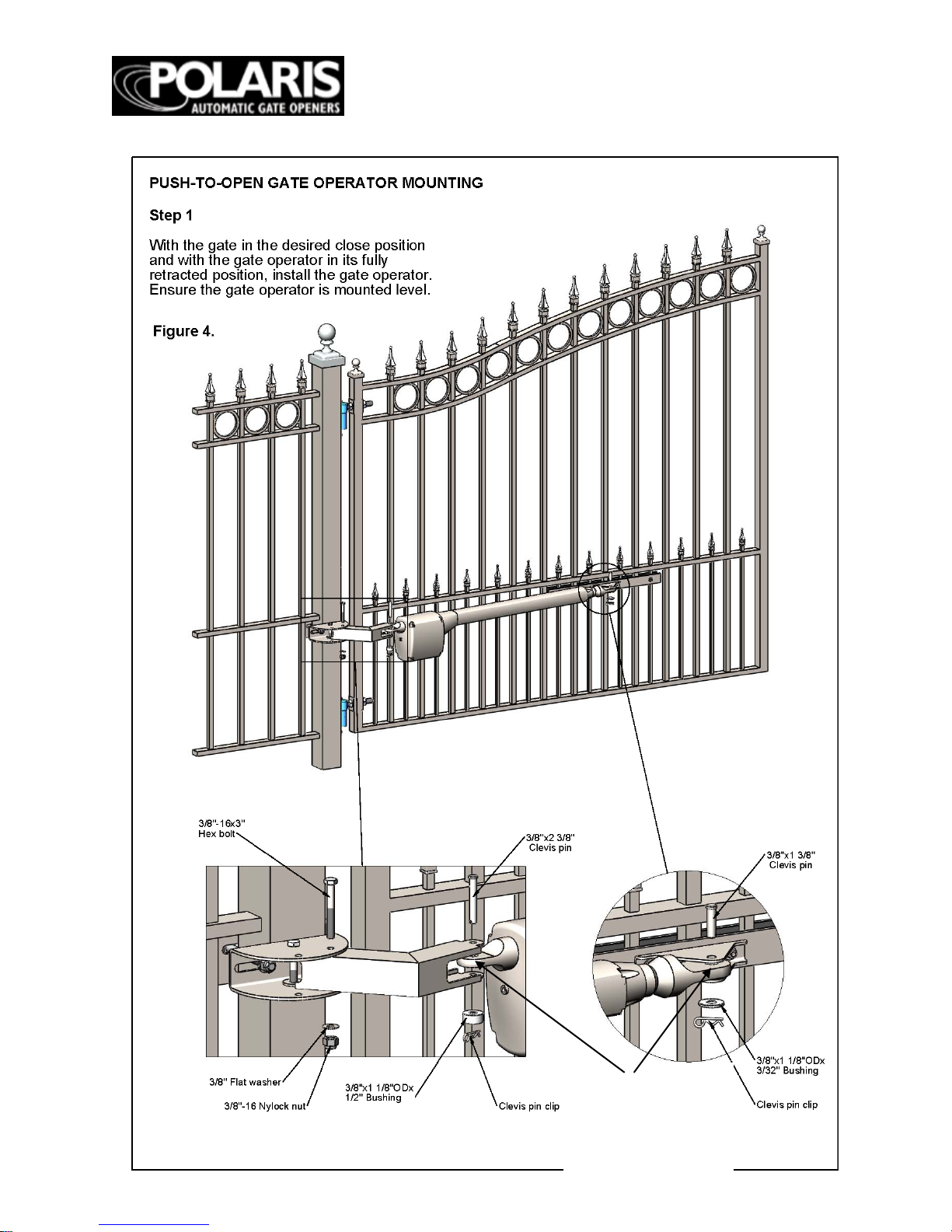

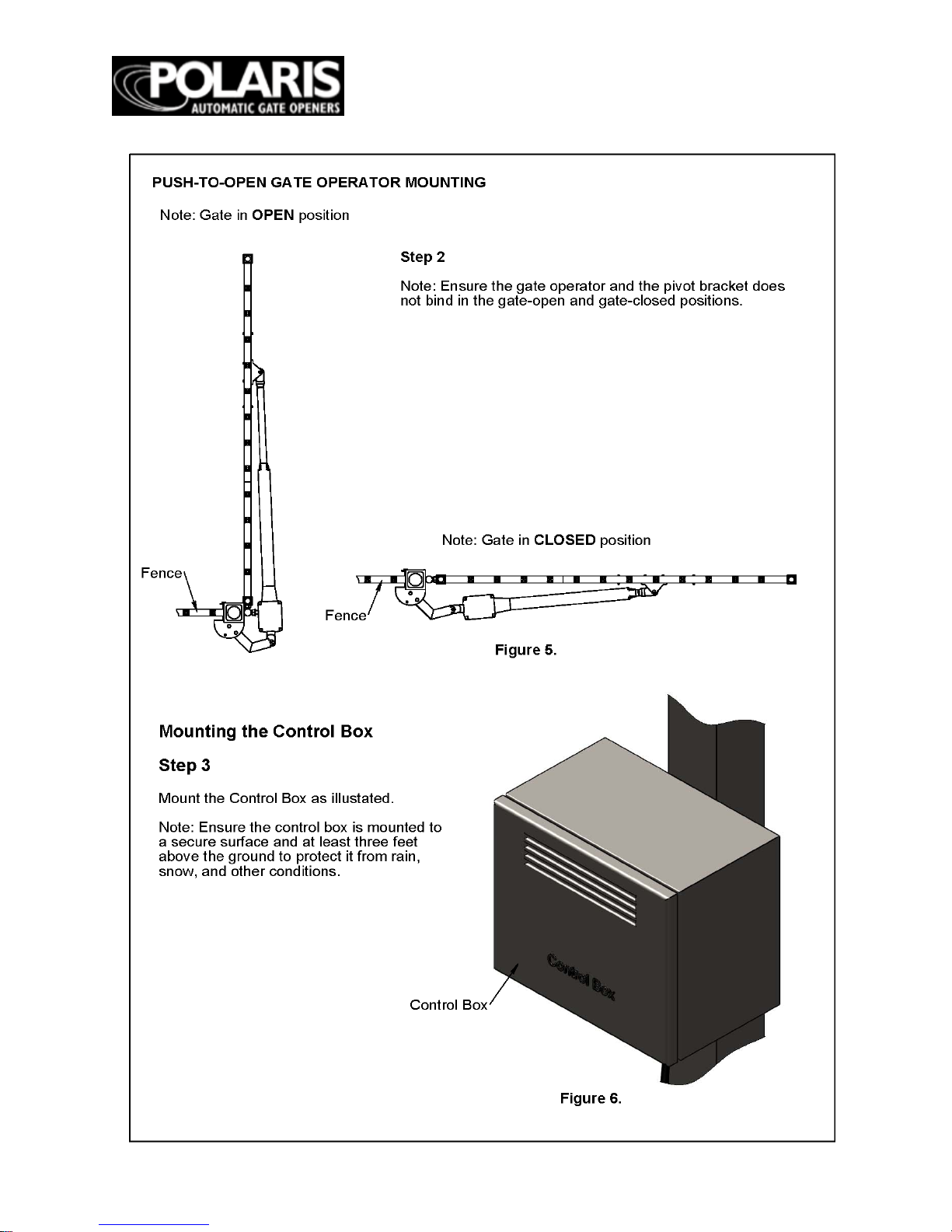

Push-to-O pen Gate Operator Mounting............................................................... 11

Post Mount Brackets

................................

................................

...........................

13

Circuit Board Diagram

................................

................................

.........................

16

Board Layout Des c ription ...................................................................................

16

Di p Sw i tc h e s ........................................................................................................

17

Wiring Operator

................................................................................................... 18

Pull-to-Open L im it S e tting ................................................................................... 22

Push-to-Op e n Li m i t Se ttin g ................................................................................. 24

Primary/Secondary Gate Movement .................................................................... 26

Obstruction Sensitivity Set Up

................................

................................

............ 27

Auto Close Timer ................................................................................................. 28

Transmitter/Receiver ................................................................

...........................

29

Accessory Hook Up Diagram .............................................................................. 30

Exit Wand Hook Up Diagram ............................................................................... 33

Photo Eyes Hook Up Diagram ............................................................................. 34

Emergency Disconnect .......................................................................................

36

Technical Specifications ..................................................................................... 37

Parts List and Illustrations .................................................................................. 38

Troubleshooting/Maintenance .............................................................................

40

List of Accessories .............................................................................................. 42

Warranty .............................................................................................................. 43

Polaris Automatic Gate Operators

8617 Paseo Alameda NE

Albuquerque, NM 87113

Phone: 877-313-8902

Fax: 800-830-3952

Email: ask@polarisgate.com

Web: ww w.p olarisgate.com

Page 3

Page

3

WARNING OF RISKS, PURCHASER’S RESPONSIBILITIES, AND ASSUMPTION OF

CE RT A IN R ISK S :

The directio ns for installation and use of the Product must be followed carefully. It is

imp ossible to eliminate all risks inherently associated with use of the Product. The

effectiveness of the Polaris Automati c Gate Operator depend s on pro

per installation and

the manner of use or application, all of which are beyond the control of Polaris Professional

Products or the seller. All such risks are assumed by the purchaser, and by the purchaser’s

installation and use of the Product.

The Polaris Automatic Gate Operator is for use on driveway gates only. The Product meets

or exceeds the requirements of UL 325, the standard that regulates gate operator safety, as

established and m ade effective March 14, 2003, by Underw riters Laboratories, Inc.

Page 4

Page

4

Gate Op erato r Class C ategories

Ga te o pe ra to r CLA S S C AT EGOR I E S *

The Polaris Autom ati c Gate Operator is intended for use with vehicular swing gates. The

operator can be used in Class I and Class II applications.

Residential V ehicular G ate Opener–Class I: A vehi cular gate opener (or system) intended

for use in a home of one-to-four single family dwelling, or a garage or parking area

associated therewith.

Light Commercial/General Access Vehicular Gate Opener Class II: A vehicular gate

opener (or system) intended for use in a commercial location or building such as a

multifamily housing unit (five or less single family units), hotel, garages, retail store or

other building servicin g the general public.

Industrial/Limited Access Vehicular Gate Opener–Class III:

A vehicular ga te opener (or system) intended for use in an industrial location or building

such as a factory or loading dock area or other locations not intended to service the general

public.

Restricted Access Vehicular Gate Opener–C l a ss IV: A

vehicular g ate opener (or system) intended for use in a guarded industrial location or

building such as an airport security area or other restricted access locations not servicing

the general public, in which unauthori zed access is prevented via supervision by security

personnel.

*Categories establi shed by Underw ri ters Laboratories for vehicle gate operators

Polaris is a high end residential gate operator. Also suited for light commercial

applications. Not advised for continuous duty.

GATE OPERATOR CLASS CATEGORIES

FOR YOUR RECORDS

Please record the serial numb er

(found on the control box cover)

and purchase information below.

Keep this with your proof of purchase

(receipts) in case your product is lost, stolen

or requires service.

Serial number: _______________________

Purchase date: ____________________

Retailer/store name: __________________

Custom er Servi ce

8:00am to 5:00pm, MST, Monday – Friday

Polaris Gate Operators

8617 Paseo Alameda NE

Albuquerque, NM 87113

Phone: 877-313-8902 Fax: 800-830-3952

Email: techsupport@polarisgate.com

Page 5

Page

5

Warn ings an d Precau tion s

General Safety Information

The Pola ris A uto ma tic Gat e Oper ator is des ign ed to

pro vide for sa fe opera tio n. One of th e most imp ort ant

safet y feat ure s of the gate oper ator is obs tru ct ion

sen sing. Wh e n there is an obst ruc tio n that pre vent s

the gate from opening or closing, the gate will

imm ed iately re ver s e directio n and re turn to the f ull y

open or clo s e d pos ition. W hile in t he proce ss o f

return ing to th e fully op en or clo sed posit io n, if the

gate senses an additional obstruction the gate will

sto p imm e d iat e ly a nd so u nd an a larm. At th is point

the gate operator will need to be reset by turning the

power switch on the control box OFF for a minimum

of ten seco nds.

The Polaris gate operator includes an adjustment for

setting the sensitivity of the obstruction performance.

Refer to page 27 fo

r O bstruction Se nsitiv ity Set Up

details.

Vehicular gates are large heavy objects. Polaris

Automatic gate operators provide a convenient way

to open and clo se the ga tes. S ince th e gate syste m an d

its com pon ent s exert a high le vel of forc e to open and

close the gat e, they can be da nge rou s, cau sin g sever e

injur ies or dea th to you and ot her s.

Your saf et y and the safe ty of othe rs dep end on th e

insta ller of this sys te m to read, und er sta nd, and

follow the information and instructions in this

manual.

The P ola r is Automatic Gate Operator is designed to

comply with UL 325, the safety standard covering

automatic gate opening systems. UL 325 requires that

gate opening systems have provisions for, or be

supplied with, at least one independent primary and

one independent secondary means of protection

again st ent rap me nt. The pr imar y me ans of

entr a p me nt pr o te c tion in th e Po la r is A uto m a tic

Gat e Op er at or is Typ e A, an in her en t m ean s of

entra pm ent pr ote ction. The sec on dar y mean s of

entr a p me nt pr o te c tion in th e Po la r is A uto m a tic Gate

Operator is Type B1, the provision for the connection

of a photo cell or othe r non con tac t senso r

The gate op era tor’ s bui lt-in means of entrapment

prote ct ion (T ype A) ma y not be sens itive e nou gh to

prevent bodily injury in some circumstances.

Secondary means of entrapment protection (Type

B1), su ch as a photo cell are su gge ste d for enh anc ed

safety.

Safety overview check list:

WARNING

– To reduc e the ris k of inj ury or death:

• S AVE T HESE INSTRUCT IONS

•

U se this oper ator on ly with s win g gate s.

• RE AD AND FOL LOW ALL INSTR UCT IONS.

• Ne ver let ch ildre n op erat e or play with ga te

controls.

• Keep the remote control away from children.

• Always keep people and objects away from the

gate.

• NO O NE SHO ULD CROS S T HE PATH OF

THE MOVING GATE.

• The e ntr anc e is for vehic les

only. Pedestrians

mu st use a separate ent ran ce.

• Remember that the Polaris Automatic Gate

Operator must only be installed on gate

systems meeting the requirements of the

application.

• Ensur e t ha t you are usin g the c or rect ga t e

operator f or t he typ e

a nd size

of gate, it s

frequenc y of us e a nd the class rating.

• Ensure that the gate and gate operator

installation comply with applicable

local codes.

• Cont act local fire and law enforcement to

arrange emergency access procedures.

• Keep people, animals, and property away

from the gate area. Do not let children

play in or near the gate area.

• Use caution with moving parts to avoid

injuring fingers or hands.

• Consider installing contact sensors, or

non-contact sensors to provide

additional safety and protection against

entrapment.

• Never activate the gate operator until you

ensure that the area is clear of people,

pets, or other obstructions.

• Watch the gate until it stops.

• Controls must be far enough from the

gate so that the user is prevented from

coming in contact with the gate while

operating the controls.

Page 6

Page

6

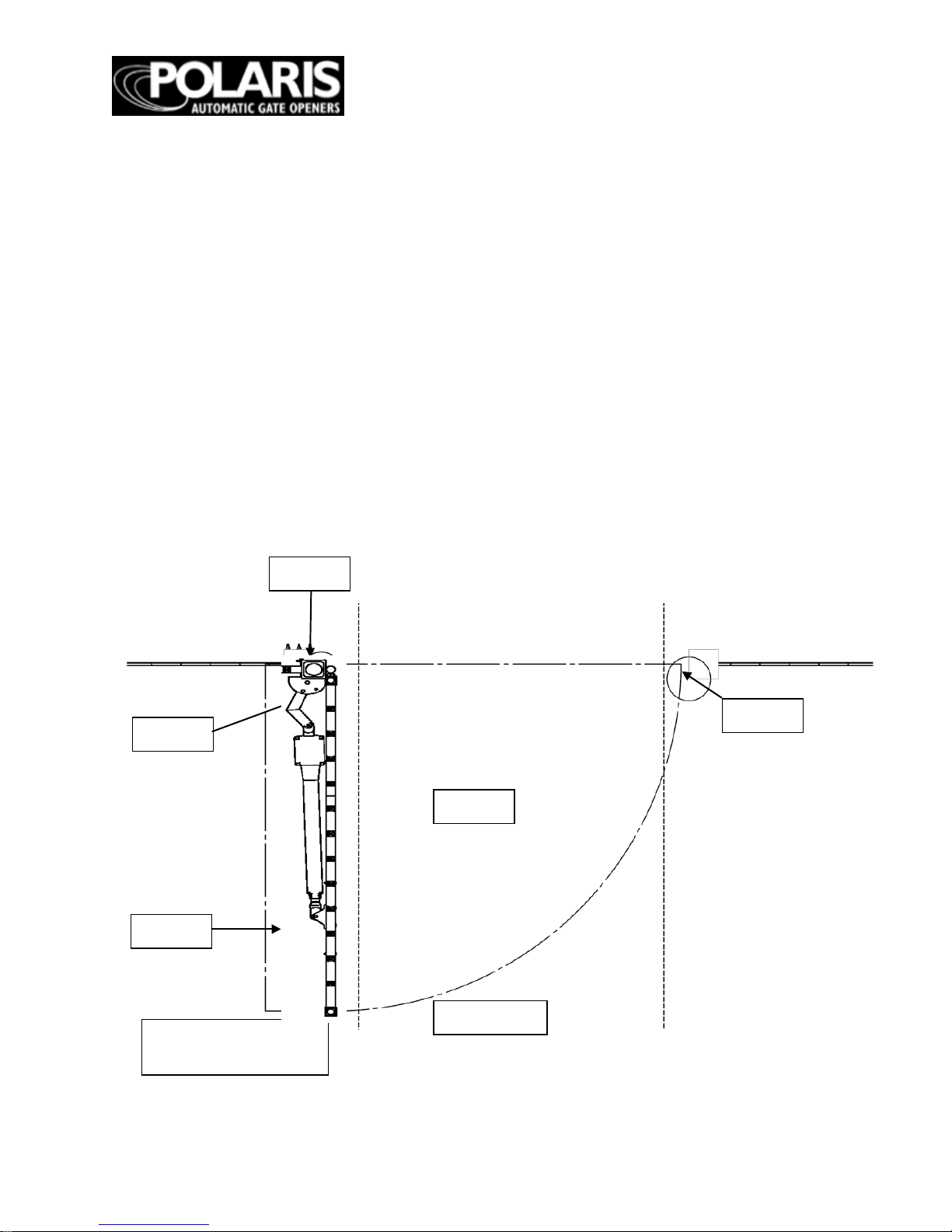

Protection against Entrapment

Important! Study

the figure below

and keep safety foremost at all

times.

Entrapm ent areas for a proper pull-to-open installation

Entrapm ent A rea 1

Hing ed edge of the gate and the fence post

Entrapm ent A rea 2

Between the gate and the gate post

Entrapm ent A rea 3

The p ath o f th e g ate

Entrapm ent A rea 4

The space betw een the gate in the open position and

any object such as a wall, fence, tree, etc.

Entrapm ent A rea 5

Pin

ch points between the operator and gate or post

Area 2

Area 1

Area 3

Area 4

Area 5

Gate in open

position

Driveway

Page 7

Page

7

Entrapment Alarm

(UL 325; 30.1)

In com pliance with UL 325 the Polaris

Automatic Gate Operator is designed to

stop and reverse direction within two

seconds of sensing an obstruction. In

additio n, th e P ola ri s A u tom a ti c G ate

Operator activates an audible alarm if the

unit incurs an obstruction

twice while

opening or closing. This alarm sounds for

five minutes, or until the operator receives

a renewed, intended input from a

hardwired control such as the Push Button

Con tr ol . At tha t poi n t th e g ate re tu rn s to a

fully open or fully closed position.

Turning

the power switch on the control box OFF

for ten seconds and back ON also

deactivates the alarm.

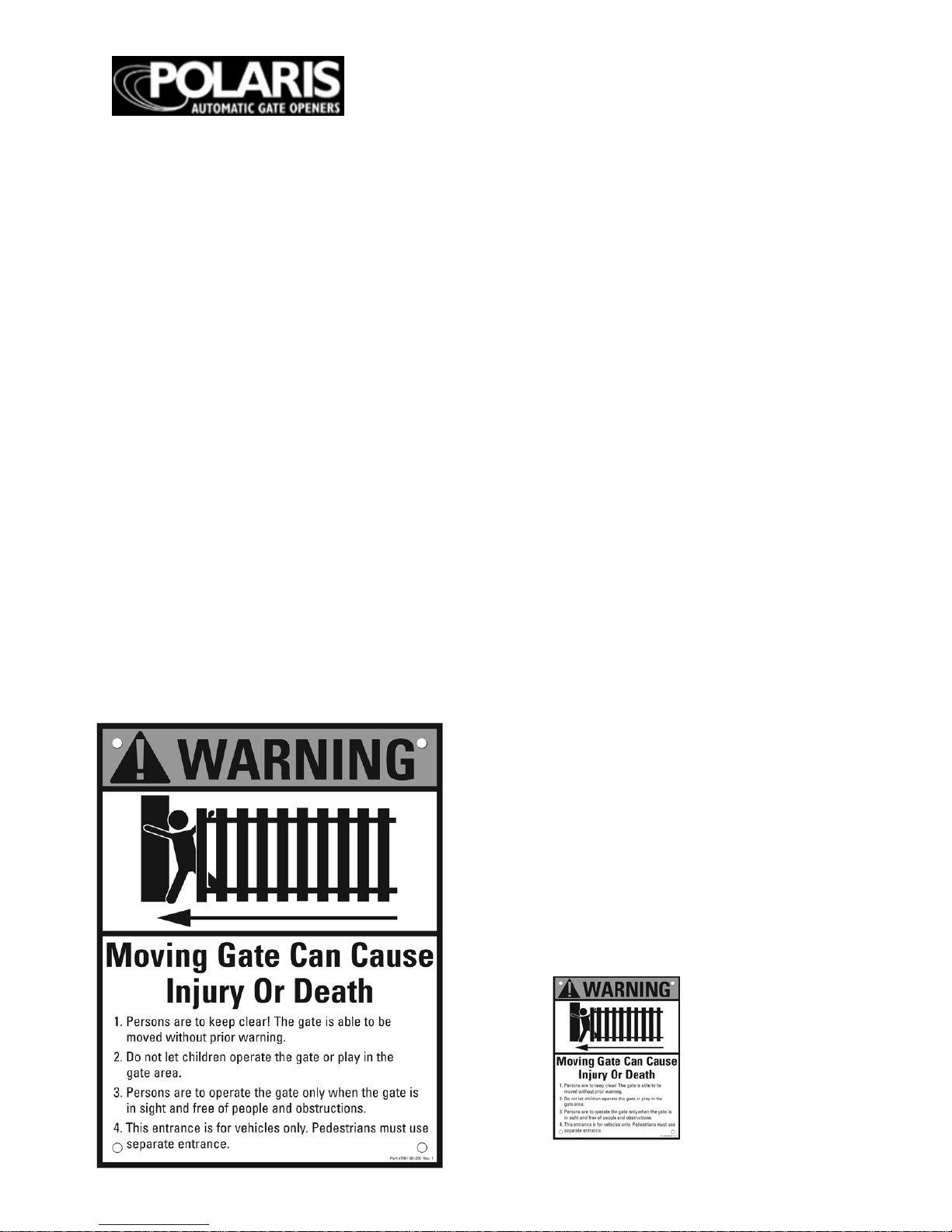

Warning Signs and Labels

Required Safety Precautions for Gates

Warning signs alert people of automatic

gate operation. They are required when

insta lling the Po la ris Automatic Gate

Operator. If pedestrian s will be in the area,

install a walkthrough gate for their use.

Warning Signs

The warning signs must be installed on

both s i d es o f th e g a te.

These warning signs and decals must be

used. If any

were missing wh en the

gate operator was

purchased,

immediately contact Polaris Automatic

Gate Op erators for replacemen ts.

Figure 2

Warning signs (two enclosed) to be

installed on each side of the gate

(three to fi v e fe et a b ov e th e b otto m

of the g ate )

Figure 3

Install warning decals,

one on each side of gate

operator

Page 8

Page

8

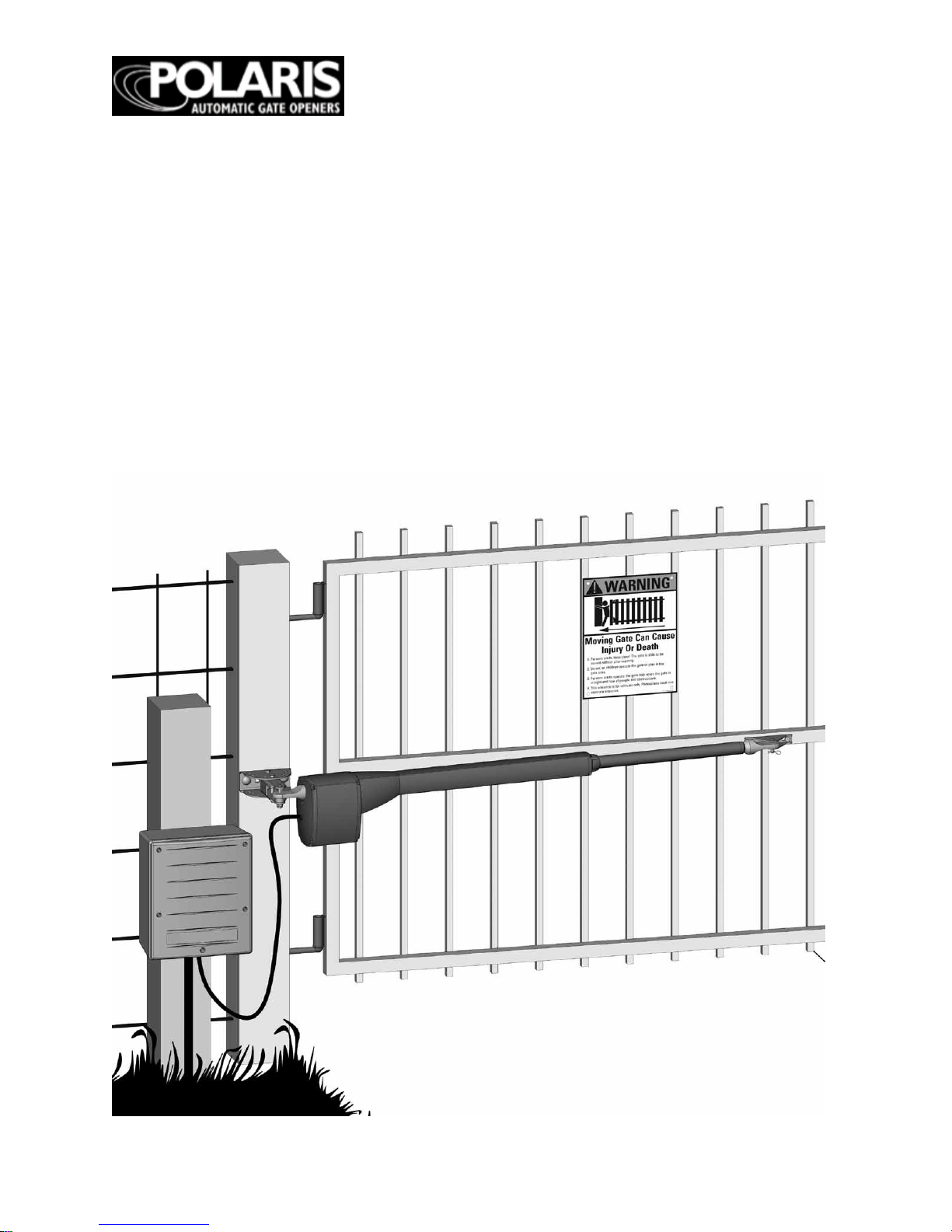

INST A LL ING TH E PO L AR IS 500 & 700 S W ING OPER AT O R

WARNINGS---------------------

1. Read and follow all instructions.

2. NEVER let children

operate the gate or play with the controls.

3. Keep people and objects away from the gate and its immediate areas, both open and closed.

4. After the limit adjustments are made, all auto reversing controls including the current

sensing circuit built into

the Polaris must be checked. They must be working and set to proper

sensitivity. Failure to adjust and retest the gate system increases the chance of injury or

death.

5. T e st th e sy ste m M ONT H L Y. Ch e ck to ma k e su r e that a ll a uto -reversi ng d evices includin g

the current sensing circuit are working and set to the proper sensitivity.

6.Verify that the emergency (manual ) release pin connected to the gate leaf can be easily

removed. This check should only be made with the battery disconnected to prevent the gate

from moving during the test.

7. Thi s is a VEH IL CL E GAT E ONLY. Ped estri an s must use a sepa rate e ntra nc e.

8. NEVER install any control device on the outside of the Polaris cabinet or in such a way that

someone can reach through the gate to activate it.

9. SAV E THE S E IN S TRUC T I ONS!

CAUTIONS-----------------------

1. NEVER operate the gate unless you can see it.

2. Do not enter the gate area while the gate is in motion.

3. Do not allow children near the gate and do not allow anyone to ride on the gate.

4. Do not attempt to drive through the gate opening while the gate is in motion.

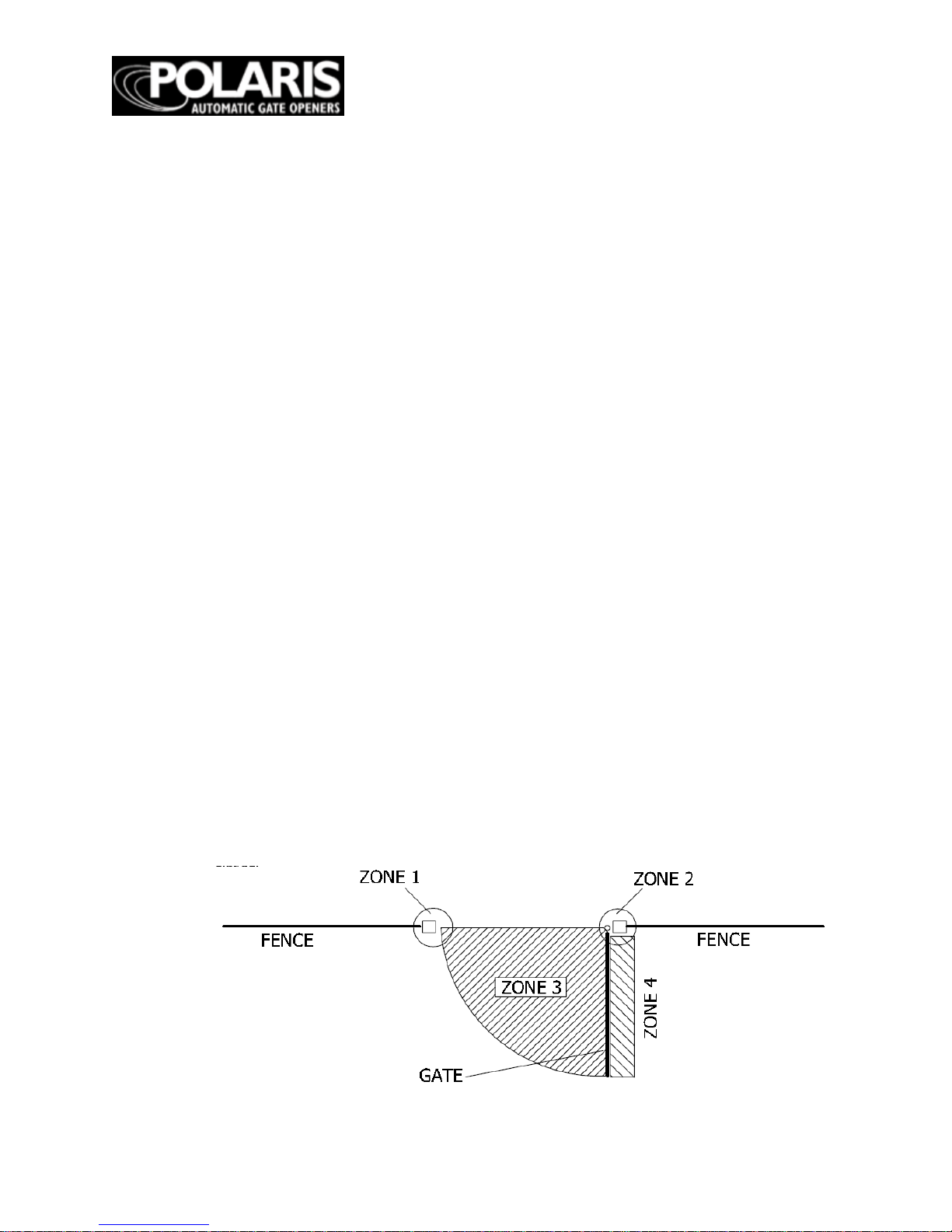

ENTRAPMENT ZONES---------------------

Zone 1- Leading edge of the gate and catch-post

Zone 2

- Area between g ate and hinge post.

Zone 3- The gate path or "arc of the swing"

Zone 4- The area between the gate in its' open position and any obstruction like a fence,

building, landscaping feature, etc...

Zone 5- Not shown below but similar to zone 1- the point where tw o biparting gate leafs meet

when cl osed.

Page 9

Page

9

Page 10

Page

10

Page 11

Page

11

Bushings to be set

betw ee n b otto m

side of actuator

rod ends and

mounting bracket

Page 12

Page

12

Page 13

Page

13

Amazing Gates Post Mount Brackets Pull and Push

Arm

with Amazing Gates 3 1/2" Pos ts

With the purch ase of a Polaris Opener System, you will receive the Amazing Gates Universal

Pull brackets and gate attach brack et(s).

The Am azin g Gates post attachment arm does not require drilling of the post to be installed.

You simply se t it in to the p osi tion and bolt it tight. The correct angle is preset.

3 1/2" Post Push to Open

3 1/2" Post Pull to Open

“AGA recommends using self

tapping screws on flat plates as

indicated after final setup is

compl ete. This will help to secure

the univ ersal bracket from

shifting”

“AGA recommends using self

tapping screws on flat plates as

indicated after final setup is

compl ete. This will help to secure

the univ ersal bracket from

shifting”

Page 14

Page

14

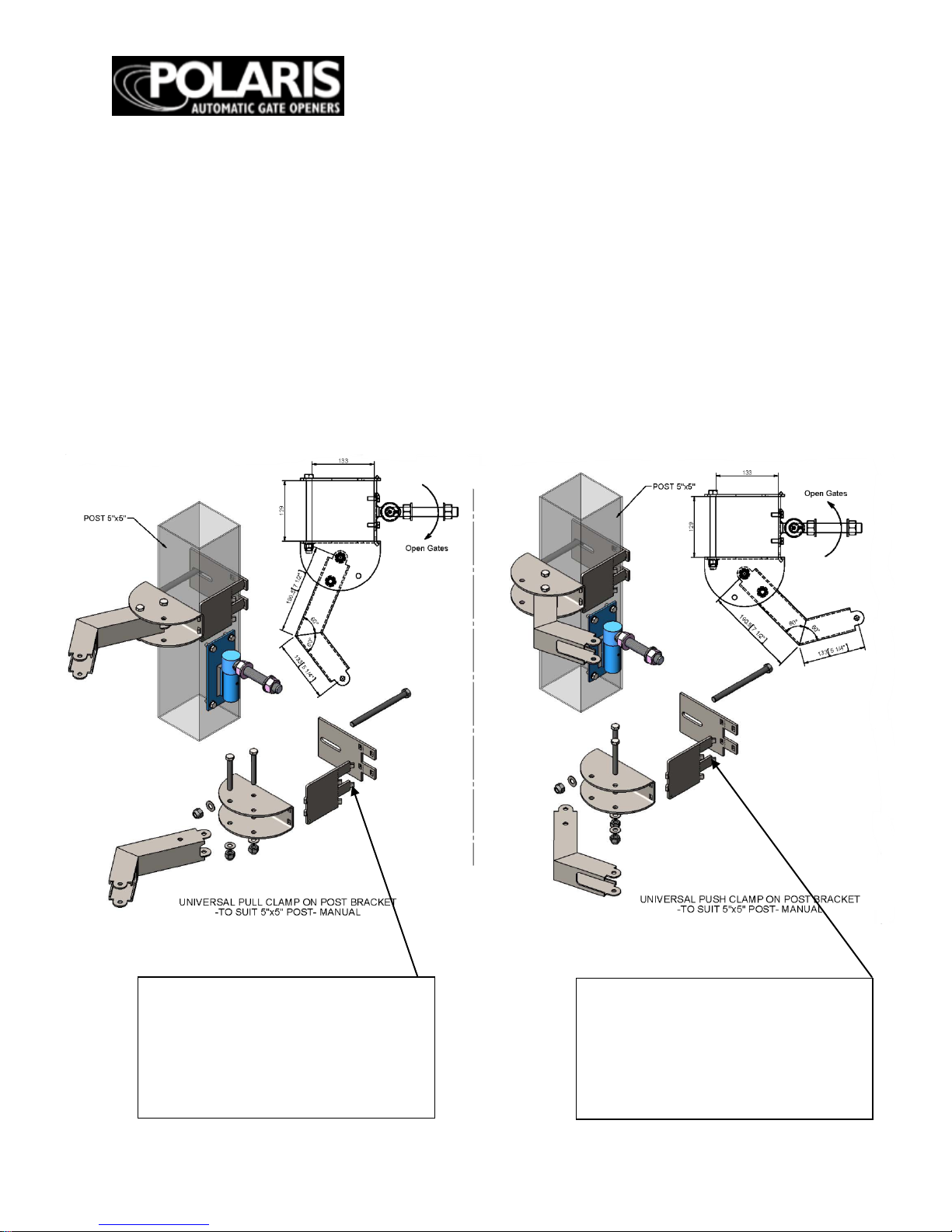

Amazing Gates Post Mount Brackets Pull and Push Arm

w i th Am a z i n g G ate s 5

" Po st s

With the purchase of a

Polaris Opener System, you will receive the Amazing Gates Universal

Pull brackets and gate attach brack et(s).

The Am azin g Gates post attachment arm does not require drilling of the post to be installed.

You simply se t it in to the p os i ti o n an d bo l t it ti gh t. The correct angle is preset.

5" Post Pull to Open

5" Post Push to Open

“AGA recommends using self

tapping screws on flat plates as

indicated after final setup is

compl ete. This will help to secure

the univ ersal bracket from

shifting”

“AGA recommends using self

tapping screws on flat plates as

indicated after final setup is

compl ete. This will help to secure

the univ ersal bracket from

shifting”

Page 15

Page

15

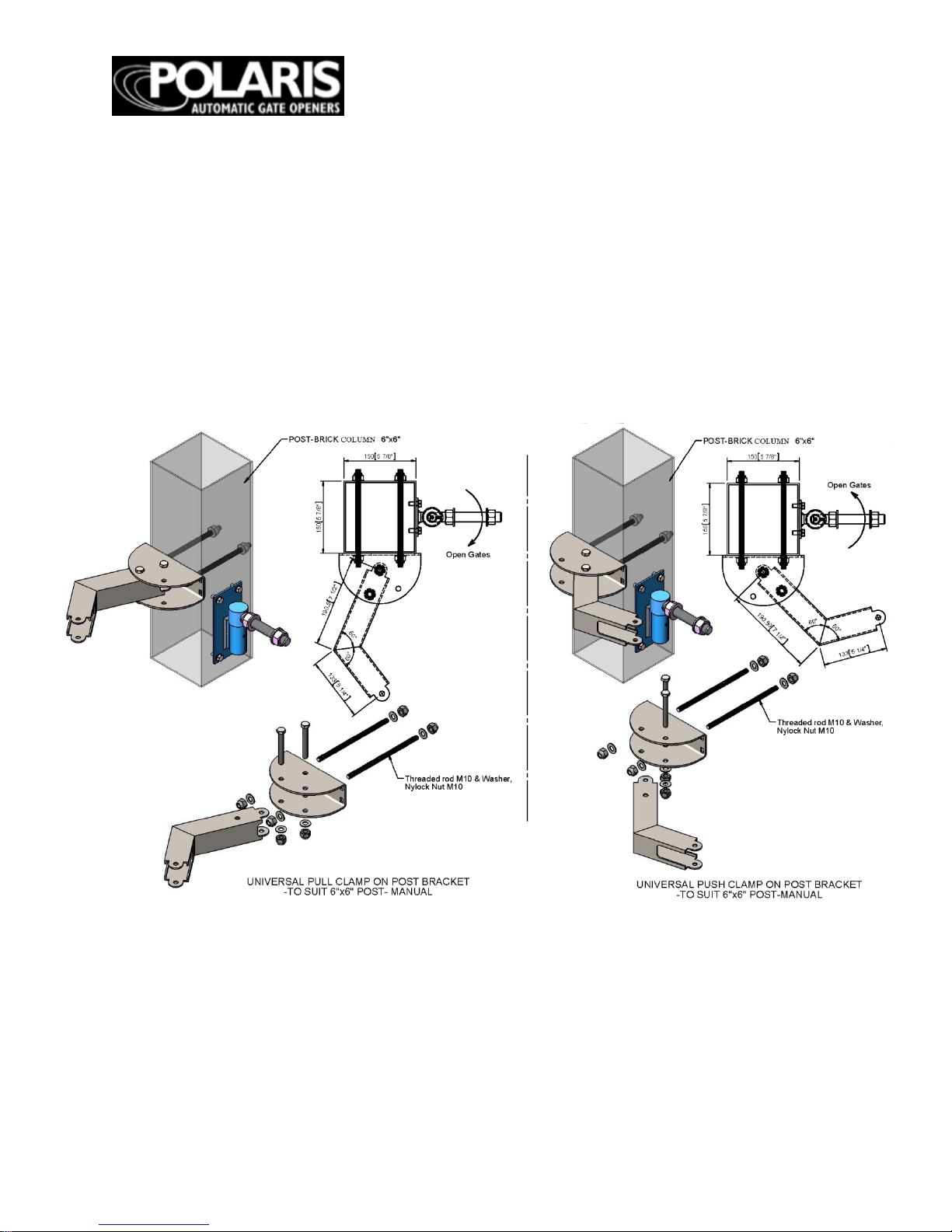

Amazing Gates Post Mount Brackets Pull/Push Arm

with

customers existing Posts other than Am azi ng Ga tes.

With the purch ase of a Polaris Opener System, you will receive the Amazing Gates Universal

Pull and Push brack ets and gate attach bracket(s). These brackets can be used with your

exiting posts or any non-Amazing Gates posts, to include column mounting. Though the

Am azing Gates bracket system can be used on any post/column setup, the diagram shown

below must be followed concerning geometry of pivot point and hinge point.

Page 16

Page

16

Board Layout Description

LED’s

1. 18 VAC Power

2. 24V Converter

3. Gate Operator Retracting

4. Gate Operator Extending

5. Obstruction

6. Auto Cl o se

7. Battery OK

8. Battery Charging

9. S tatu s

10. Safety Loop

11. Shadow Loop

12. Exit Loop

13. Radio Receiv er

Potentiometers

14. Stall Force Adjustm ent

15. A u to Cl o se A d ju stmen ts

Buttons

16. Cycle

– used as an input device

17. S e t Lim it

18. Learn Code

19. Power Save

Fuses

20. 15 amp Fuse

21. 4 amp Fuse

Connectors

22. Buzzer Conn ection

23. RF Board Connection

Page 17

Page

17

DIP S W ITC HES

* - Defau l t fa cto ry se tti n g

Block 1, D IP Switc h 1

– A uto C lose

ON

– Auto close feature enabled

OFF* – Au to c lo se f ea tu re d isa b le

Block 2, D IP Switc h 2 – Pull-to-O pen or Pu sh-toOpen fo r P rimary G a te Operator

ON – Prima r y gate ope rat or set up for push -to-open

operation

OFF* – P r ima ry gat e opera tor s et up for pull-to-open

operation

Block 2, D IP Switc h 3

– Pull-to-Open or Pus h-toOpen fo r Secondar y Ga t e Oper at or

ON –

S econ d ary ga te oper ator se t up for

push-toopen operation

OFF* – S e con d ary gate op era tor set up for pul l

-toopen operation

NOTE : On ly ac t ive if B lo ck 2, DIP S w itc h 1 is s et in

the ON position

Block 2, D IP

Swit c h 4

– T iming of D ua l Gates

ON – One gate is delayed when opening or closing

OFF* – G ates open and close simultaneously

NOTE : On ly ac t ive if B lo ck 2, DIP S w itc h 1 is s et in

the ON position

ON – Exte nde d soft star t/ stop ope r ation en ab led

OFF* – Normal soft sta rt / s to p operation

Block 1, D IP Switc h 4 – Time of Sof t Star t/S t op

ON – Ma x. exten ded t ime of sof t start/ stop op era tio n

OFF* – Ext end ed time of soft star t/st op oper at ion

NOTE : On ly ac t ive if B lo ck 1, DIP 3 is s et to O N

Block 2, D IP Switc h 1 – Single or Du al Gat e

ON – Dual gate applications

OFF* – S in g le ga t e ap p lica t ion s

Block 1, D IP Switc h 2 – Aud ib le Mo t io n Ala r m

ON – Audible motion alarm enabled

OFF* – Au d ib le m ot io n ala r m d isa b led

Block 1, D IP Switc h 3 – Extended Soft Start/Stop

NO T E : To ad ju st au to clo se t ime ref er to f igu r e 17.

Block 2

Block 1

NOTE : A l l DIP

Switches are

shown in the factory

Block 2, D IP Switc h 5 – Sequencing of

Dua l G a t e

Opening and Closing

ON – Secon d ary ga te oper ator op en s

firs t an d c lo se s

second (2 s e cond delay)

OFF* – P rimary gate operator opens

firs t an d c lo se s

second (2 s e cond delay)

NOTE : On ly ac t ive if B lo ck 2, DIP 4 is

in the ON po s itio n

Block 2, D IP Switc h 6 – D ual Gate

Po sit io n Limit

Settings

ON – Set lim it se tt in g for sec o nd ar y

gate operator

OFF* – S e t lim it s e tt in g for prim ar y

gate operator

NOTE : On ly ac t ive if B lo ck 2, DIP

Sw itc h 1 is se t in th e

ON position

Block 2, D IP Switc h 7 – Off - Not Used

Block 2, D IP Switc h 8 – Off - Not Used

Page 18

Page

18

WIRING OPERATOR

NOT E: Be fore po wer ing, gate ope rat or mu st be

connected to the control box

– damage may occur if

gate op era tor is conne ct ed dir ectly to a bat tery or

other power so urce.

Step 1

Ensure the contr ol bo x power s witc h is in the OFF

positio n. T he con tro l box powe r switc h is loca ted on

the bottom of the control box.

NOT E: Us e only 16 gau ge dua l cond uct or, mu ltistranded, direct buria l wire f or AC p ower hookup.

Follow local electrical codes.

Step 2

If usin g AC power t o char ge the b attery, c onnect w ir e

to the control box as shown in fig. 19.

If chargin g bat tery w ith a solar pa ne l(s), refe r to

Accessor y Hoo k

-Up D iagr am fi g. 32 on page 28.

Con ne ct wir e s f rom primary opera to r (and seco ndary

operator if in stallin g on a dua l gate) to the contr o l box

as shown in fi g. 19. Wir e shou ld be bur ied in

ac cor d anc e wit h

local codes.

WARN ING: DO NOT CONN ECT BOT H

TRANS FORM ER AND SO LAR PAN EL. THIS

SYSTEM IS DESIGNED TO RUN ON ONL Y ONE

POWER SOUR C E. C ONNE CTING BOT H POWER

SOURCES

CAN RESULT IN D AMAGE T O CIRCU IT B OARD

AND WILL VOID WAR RANT Y.

Figure 19

Page 19

Page

19

Circui t Board

Step 5

Connect the battery terminal

wi re s to the ba tter y.

Step 6

Plug in transform er. Turn control

box power switch to the ON position.

Step 3

The transformer provided is for dry

location use only. If used in an outside

outlet, the transformer must be enclosed

or covered for weather protection. Attach

AC power wire to the transformer.

NOTE: DO NOT PLUG TRANSFORMER

INTO AC POWER UNTIL ALL WIRING IS

COMPLETED.

Step 4

Install the battery by placing the battery

into the control box. The control box can

accommodate one or two batteries.

Warning:

Do not attempt to splice operator

wires for the purpose of extending your wiring

conn

ections. Doing so can void your warranty.

Contact technical supp ort for recommended

procedure. 1-877-313-8902.

Batte

Second

Battery

(not included)

Figure 22

Black (-)

Red (+) term i n al

WAR N ING : Please make sure

the batteries are fully charged

before connecting and poweri ng

up the new circuit board.

Undercharged batteries m ay

damage the circuit board and

void your warranty.

Page 20

Page

20

WIR IN G THE OPERATO R

LED Descriptions

Prop er wirin g and pe rfor ma n ce can be verif ied b y

chec kin g the opera tio n of the LED’ s loc ated on th e

cir cu it b oa rd.

LED #1: 18VAC OK

Lit wh e n A C po wer is be in g s up plie d t o the c ir c u it

board.

LED #2: +24V OK

Lit whe n 24V con vert er is acti vat ed.

LED #3: IN

There are two “IN” LED’s. One near the Opener 1

terminals and one near the Opener 2 terminals.

On e LED wi ll lig h t wh e n a sing le ga te op e r ator is

retracting. Both LED’s will light when dual gate

operators are retracting.

LED #4: OUT

The re a re t w o “O U T” LED’s. One n ear the Open er 1

terminals and one near the Opener 2 terminals. One

LED

w ill li gh t w hen a sin

gle gate op erat or is

extending. Both LE D’ s wi ll lig ht w h en dua l ga te

operators are extending.

LED #5

: OBSTR

Lit wh e n an o b str uc tio n is sen s ed.

LED #6: TIMER ON

Blinks when auto close feature is enabled and gate is

in op en po sit io n. L it wh en gat e ar m c yc le limit e r is

automatically activated.

LED #7: BATT OK

Lit whe n batter y is OK or “char ged. ”

LED #8: CHARG IN G

Lit when battery is being charged.

LED #9: STATUS

Blin ks to in d ica t e th at the s ys te m is fun ct io n in g

properly. Also used to indicate a user input during

installation.

LED #10: SAFETY LOO P

Lit when the safety loop contact is made.

LED #11: SHADOW LO OP

Lit when shadow loop contact is made.

LED #12: EX IT LO O P

Lit wh e n an e xit lo o p co nt a ct is m a de.

LED #13: RADIO REC VR

Lit wh i le tr a ns m itt er bu t to n is pu sh ed.

Power Sa ve Mo de (Recomm end ed for Solar

Applications)

Polaris Automatic Gate Operators come equipped

with a Po wer S av e f eat ur e. Th e de f au lt mo d e is for a ll

LED’ s to be opera tio na l as descr ibed. If it is desir ed

to con s erve power to maximize battery lif e

Reco mm en ded for th e follow in g step s can be take n.

Pre s s and hold th e P WR S AVE bu tton fo r thre e

seconds. An audible beep will sound confirming the

change to the power save mode. This will disable

sever a l LED’s wh en not a ctivate d fo r five min ute s. In

Po we r Sa ve m od e, th e L ED ’ s wil l op era te a s

descr ib ed upo n an inpu t. Whe n the gate sits idle for

five m in ute s, t he LED ’s w il l t urn off t o conserve

power.

Wh en tr ou b le sh oo t in g th e in sta lla t io n it is

recommended to disable the Power Save feature. The

feature can be disabled by pressing and holding the

PW R SAVE but t on for three secon ds. T w o a udible

beeps will sound confirming the change to normal

mode op era tio n.

Page 21

Page

21

WIRING THE OPERATOR

Page 22

Page

22

PULL-TO-OPEN LIMIT SETTING

(Open gate to inside of property)

Single Gate Installations

Step 1

Make sure the gate is in the fully open position.

Ensure power switch is in the ON position.

Step 2

Verify Block 2, DIP Switch #1 is in OFF position.

Press the cycle button on circuit board and the

gate will begin to close. Stop the gate using the

cycle button when the desired limit has been

reached.

Step 3

Press and hold the “SET LIMIT” button until one

audible beep is heard to acquire the closed limit

setting. The STATUS light will turn on

immediately upon pressing the SET LIMIT

button. The STATUS light will turn off and an

audible beep will verify the closed limit is now

set.

Step 4

Press cycle button on circuit board to return the

gate to the fully open position.

Step 5

Again, using the cycle button close the gate to

verify it meets the desired location. If the gate did

NOT reach the desired closed limit, proceed to

step 6.

Step 6

CLEARING THE CLOSED LIMIT SETTING:

a) Return the gate to the fully open position.

b) Press and hold the SET LIMIT button until two

audible beeps are heard.

c) Two audible beeps will verify the closed limit

setting is now cleared.

Repeat steps 1 – 5 to program the gates “closed

lim it setting”.

WA R N ING: Do not use hand held

transmitters to program primary

and secondary limits. Only the

cycle button should be used until

final set up is complete to avoid

damage to actuators and voiding

warranty.

***Dip switch number 6 dictates which

gate i s b e ing affe cte d b y th e set limit

button, whether setting or clearing the

limit. If dip switch 6 is in the up position,

it will set or clear the limit for the

secondary operator. If it’s in the down

position it will set or clear the limit for

the prim ary operator.***

Page 23

Page

23

PULL-TO-OPEN LIMIT SETTING

Dual Gate Installations

Step 1

Make sure both gates are in the fully open

position.

Ensure power switch is in the ON position.

Step 2

Verify Block 2, DIP Switch #1 is in ON position.

Press the cycle button on the circuit board and the

gates will begin to close. Stop the gates using the

cycle button when the desired limit for the

primary gate has been reached.

Step 3

Veri fy Bl o ck 2, DIP Switch #6 is in the OFF

position. Press and hold the “SET LIMIT” button

until one audible beep is heard to acquire the closed

lim it setting (fig. 28).The STATUS light will turn on

immediately upon pressing the SET LIMIT button.

The STATUS light will turn off and an audible beep

will verify the closed limit is now set.

Step 4

Press the cycle button on circuit board to return

the gates to the fully open position.

Step 5 (setting secondary gate)

Set Block 2, DIP switch #6 to the ON position.

Again, press t

he cycle button. The gates will

begin to close. The primary gate should stop at the

closed limit position that was programmed in the

previous steps. The secondary gate will continue

to close until you press the cycle button on the

circuit board.

Step 6

Press and hold the “SET LIMIT” button until one

audible beep is heard to acquire the closed limit

setting (fig. 28). The STATU S light will turn on

immediately upon pressing the SET LIMIT

button. The STATUS light will turn off and an

audible beep will verify the closed limi t is now

set.

Step 7

Press the cycle button on circuit board to open

both gates. Then once again press the button to

close the gates and verify the closed limits are set

properly. If the gates did not reach the desired

closed limits, proceed to Step 8.

Step 8

CLEARING THE CLOSED LIMIT SETTINGS:

a) Return the gates to the fully open position.

b) Set Block 2, DIP switch #6 to the OFF position.

c) Press and hold the SET LIMIT button until two

audible beeps are heard. Two audible beeps will

verify the closed limit setting is now cleared.

d) Set Block 2, DIP switch #6 to the ON position.

e) Press and hold the SET LIMIT button until two

audible beeps are heard. Two audible beeps will

verify the closed limit setting is now cleared.

Repeat steps 1 – 7 to program the gates “closed

limit setting”.

Page 24

Page

24

PUSH-TO-OPEN LI M I T S ETT IN G

(Open Gate to Outside)

Single Gate Installations

St e p 1

Make sure the gate is in the fully closed position.

Ensure pow

er switch is in the ON position.

St e p 2

Verify Block 2, DIP Switch #1 is in OFF position

and Block 2, DIP switch 2 is in the ON position.

Press the cycle button on circuit board and the

gate will begin to open. Stop the gate using the

cycle button when

the desired limit has been

reached.

St e p 3

Press and hold the “SET LIMIT” button until one

audible beep is heard to acquire the open limit

setting. The STATUS light will turn on

immediately upon pressing the SET LIMIT

button. The STATUS light will turn off and an

audible beep will verify the open limit is n o w s e t.

St e p 4

Press cycle button on circuit board to return the

gate to the fully closed position.

St e p 5

Again, using the cycle button open the gate to

verify it meets the desired location. If the gate did

NOT reach the desired open limit, proceed to step

6.

St e p 6

CLEARING THE OPEN LIMIT SETTING:

a) Return the gate to the fully closed position.

b) Press and hold the SET LIMIT button until two

audible beeps are heard.

c) Two audible beeps will verify the open limit

setting is now clea

red.

Repeat steps 1 – 5 to program the gates

“open limit setting”.

WA R N ING: Do not use hand held

transmitters to program primary

and secondary limits. Only the

cycle button should be used until

final set up is complete to avoid

damage to actuators and voiding

warranty.

***Dip swi tch num ber 6 dictates which

gate is being a ffecte d b y th e set limit

button, whether setting or clearing the

limit. If dip switch 6 is in the up position,

it will set or clear the limit for the

secondary operator. If it’s in the down

position it will set or clear the limit for

the prim ary operator.***

Page 25

Page

25

Dual Gate Installations

Step 1

Make sure both gates are in the fully closed

position.

Verify Block 2, DIP Switch #1,2 & 3 are in the

ON position,

Step 2

Ensure power switch is in the ON position. Press

the cycle button on the circuit boar

d and the gates

will begin to open. Stop the gates using the cycle

button when the desired limit for the primary gate

has been reached.

Step 3

Press and hold the “SET LIMIT” button until you

hear one beep to acquire the open limit setting

(fig. 29). The STATUS light will turn on

immediately upon pressing the SET LIMIT

button. The STATUS light will turn off and an

audible beep will verify the open limit is now set.

Step 4

Press cycle button on circuit board to return the

gates to the fully closed position.

Step 5

Again, press the cycle button on circuit board.

The gates will begin to open. The primary gate

should stop at the open limit position that was

programmed in the previous steps. The secondary

gate will continue to open until you press the

cycle button.

Step 6 (setting secondary gate)

Set Block 2, DIP switch #6 to the ON position.

Press and hold the “SET LIMIT” button until you

hear one beep to acquire the open limit setting

(fig. 29). The STATUS light will turn on

immediately upon pressing the SET LIMIT

button. The STATUS light will turn off and an

audible beep will verify the open limit is now set.

Step 7

Press the cycle button on circuit board to close

both gates. Then once again press the button to

open the gates and verify the open limits are set

properly. If the gates did not reach the desired

open limits, proceed to step 8.

Step 8

CLEARING THE OPEN LIMIT SETTINGS:

a) Return the gates to the fully closed position.

b) Set Block 2, DIP switch #6 to the OFF

position.

Fig.29

c) Press and hold the SET LIMIT button

until two audible beeps are heard. Two

audible beeps will verify the open limit

setting is now cleared.

d) Set Block 2, DIP switch #6 to the ON

position.

e) Press and hold the SET LIMIT

button for until two audible beeps are

heard. Two audible beeps will verify the

open limit setting is now cleared.

Repeat steps 1 – 7 to program the gates

“open limit setting”.

Page 26

Page

26

PRIMARY/SECONDARY GATE

MOVEMENT

For dual gate installations the timing of the

gates opening and closing can be adjusted. To

set a dual gate installation for both gates to

open and close simultaneously, set the DIP

switch es a s follo w s.

Blo c k 2, DI P 1 – O N p osi ti on

Blo c k 2, DI P 4 – O FF position

If it is desired to have one gate open and close

prior to the other, this can be accomplished by

adjus ti n g th e D IP swi tch setting s.

Blo c k 2, DI P 1 – O N p osi ti on

Blo c k 2, DI P 4 – O N p osi ti on

Now d etermine which ga te is desired to open

first and close second. Another DIP swi tch

adjus tment is req u i re d to se t th i s.

For primary g ate operator (wired to operator 1

terminal s) to open first and close second:

Blo c k 2, DI P 5 – O FF position

For secondary gate operator (wired to operator

2 terminals) to open first and close second:

Blo c k 2, DI P 5 – O N p osi ti on

The delay in opening and closing is always set

for two seconds.

PRIMARY/SECONDARY GATE

MOVEMENT

Control Box Cover

Once you have programmed your

remote/keyp ad, you ca n then install the cover

of the control box. Use five #10 x 3/4” screws to

secure the cover to the control box.

Page 27

Page

27

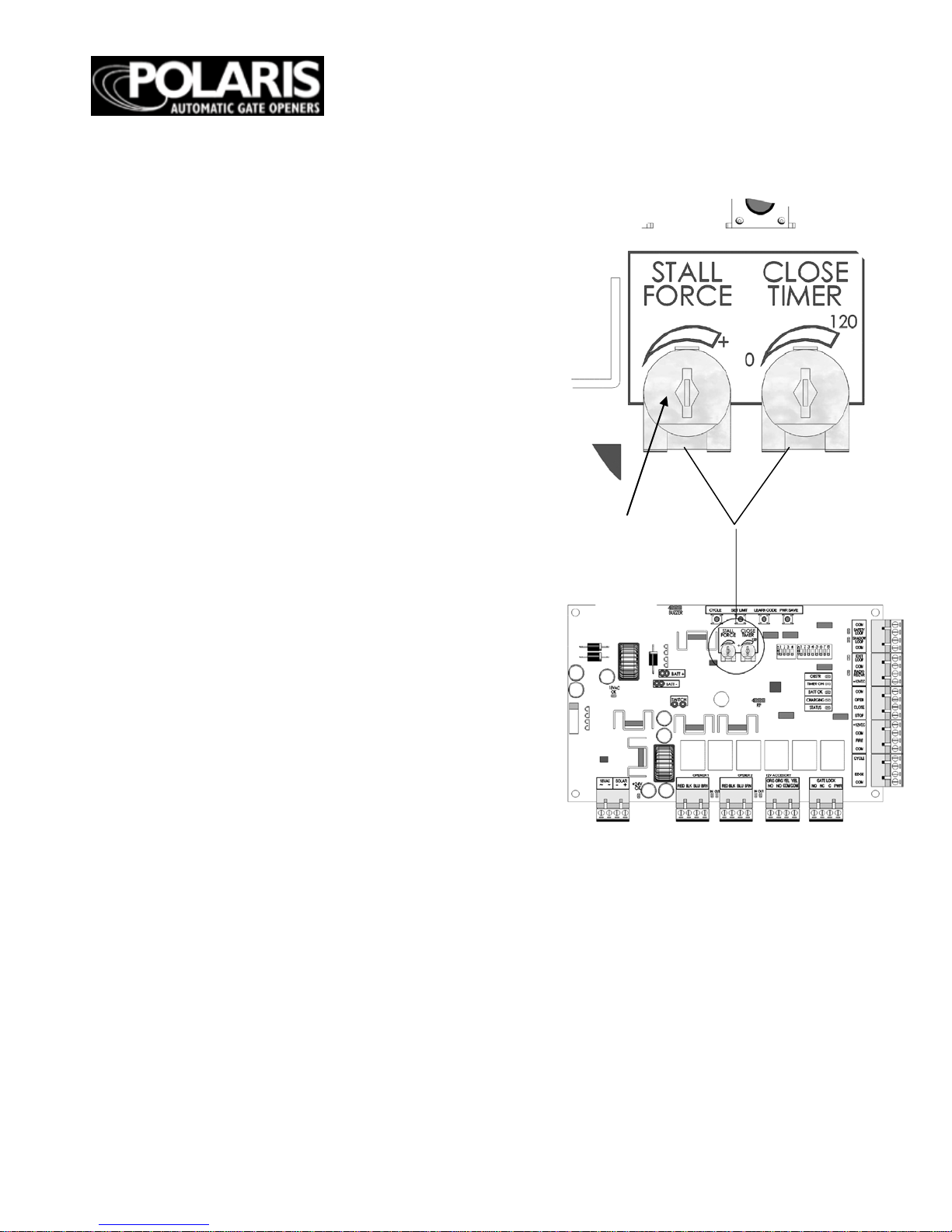

OBSTR UC TION S EN SITI VITY SE T UP

* Note: Cycle is an open/close input.

Exit is a open only input.

IMPOR TA N T : For safety reasons the

obstruction setting or stall force on the Polaris

Autom atic Gate Operator control boa rd comes

from th e fac tor y s et a t minimum , (turned all

the way counter

-clockwise). In many gate

installations, this setting will need to be

adjusted to overcome the w eight and size of the

gates.

The S TA L L FOR CE po ten ti om e ter on th e

circuit board controls the obstruction

sensitivity (or the amount of force the operator

wil l ap p l y to an o bs tru ction ) be fo re it

automatically stops and reverses direction of

the gate. Adjust the sensitivity beginning at the

factory d efa u l t co u n ter -clockwise position.

Continu e to incrementally increase the force

until the gate can open and close without

obstructing under its own weight.

NO TE: Th e stal l fo rc e may need to be

increased in cold weather du e to increased

resistance from gate hinges.

NO TE: Th e O BS T R L ED w il l lig h t to in di ca te

an obstruction is sensed.

NOTE : Th e Stall Force dial in Figure 31

should ideally be at the 10 o’ clock position

inste ad o f th e 12 o’ clock position pictured.

Figure 31

Obstruction

Potentiometer

Page 28

Page

28

Auto Close T im er

The amount of time betw een opening the gate

and automatically closing the gate can be

adjusted between 0 seconds and 120 seconds.

The adjustment is made by

turning the

CLOSE TIMER potentiometer. The default

position of the potentiometer is zero seconds.

Timer wi ll

activ ate after gates have comp leted one full

cycle. To increase the dela y time, turn the

potentiometer

clockwise.

NOTE: Only active if Block 1, DIP switch 1 is

in the ON position.

PO LA R IS STRONG L Y

RECOMMENDS THE USE OF A

SAFETY DEVICE SUCH AS:

PHOTO BEAMS OR SAFETY

LOOP WHEN AUTO CLOSE

TIME R IS ACT IV AT ED !

Page 29

Page

29

TRANSMITTER/RECEIVER

NO TE: Al l Pol ar i s Au to mati c G a te O pe ra to r

transmitters use a standard code set at the

factory. It is recommended that this code is re-set

for safety and security before programm i ng

receiver.

Step 1

Remov e the battery access cover on the

transmitter. When the cover is off, you will see

the battery and the DIP switches.

Step 2

The DIP switch block contains 10 small switches.

Using a small screwdriver or pen, move any

switch or combination of the switches to either the

open or closed position.

NOTE: Do not set the switches to all open or all

closed.

Step 3

Locate the LEARN COD

E button on the circuit

board in the control box.

Step 4

Press and hold the LEARN CODE button for at

least three seconds, but no more than five

seconds. Upon release, the CHARGING LED will

light, the STATUS LED will stop blinking, and an

audible beep will occur verifying the circuit board

is in the learn code mode.

Step 5

Press and hold the transmitter button until the

CHARGING LE D t urn s off, th e STATUS light

blinks, and an audible beep occurs. Release the

transmitter button. The transmitter code is now set.

Step 6

Replace the battery access cover on the transmitter.

Step 7

Verify the transmitter is operational by pressing

the transmitter button. The

RADIO R ECEIVER

LED

will light and the gate will move if the setting is

correct.

If the gate does not move, repeat the process

starting with step 4.

NOTE: The control box circuit board can learn

and hold up to 10 different codes.

NOTE: To clear all codes, press and hold the

LEARN CODE button for 10 seconds. Two audible

beeps verify LEARN C ODE has been cleared.

Figure 25

DIP S wi tch es

Transmitter

Figure 26

Page 30

Page

30

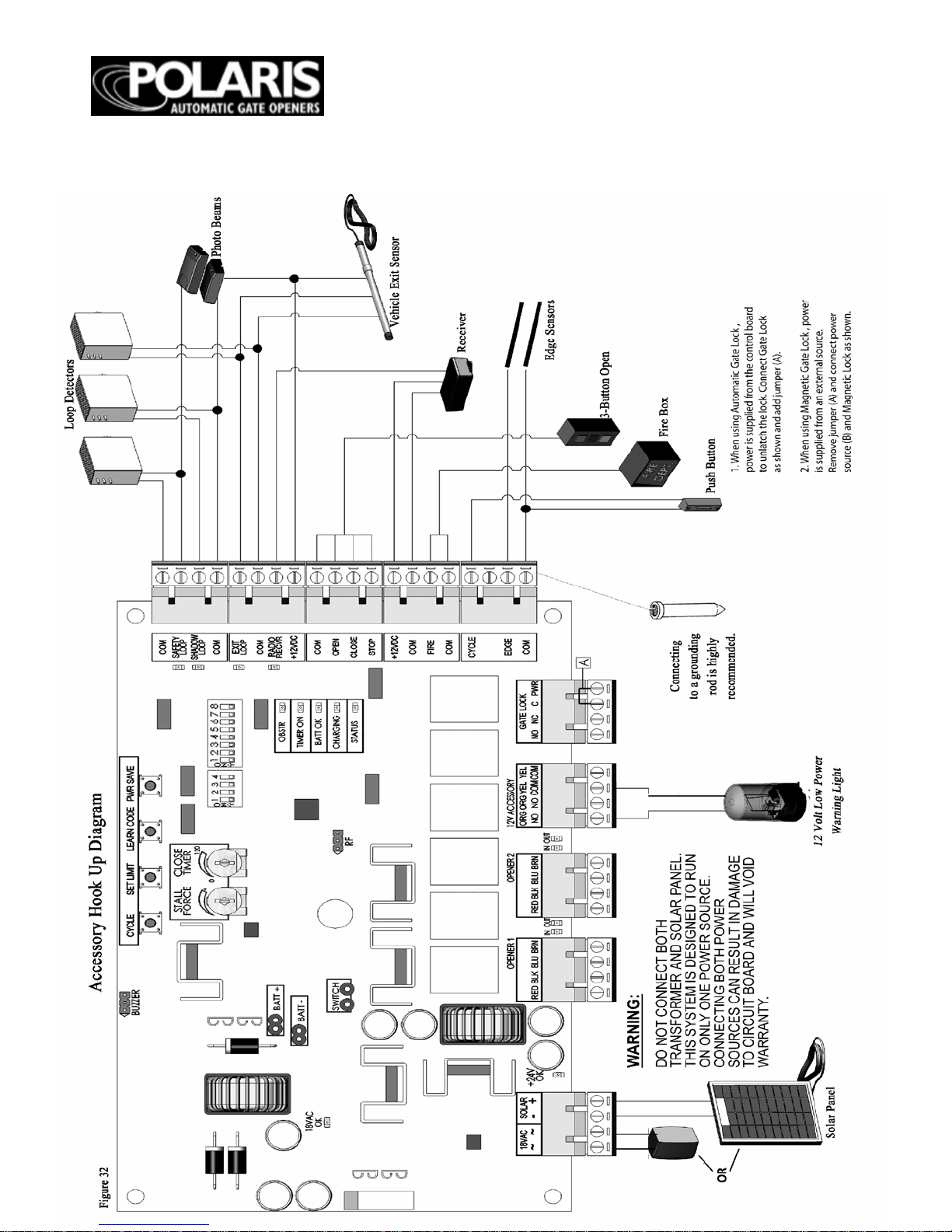

* Note: Some ac c e s s orie s ma y re quire a dditional w ire a nd/or ha rdwa re a nd is to be s upplie d by the

installer.

Page 31

Page

31

ACCESSORY HOOK UP DIAGRAM

Telephone Entry System

Fire Access Control

Keyswitch Control

Solenoid Lock- #1 see page 30.

Accessory Con nection s Strip

Magnetic Lo ck- #2 see page 30

Please refer to Magnetic

Lock instruction manual for

connection instructions.

Connections differ for 12v or

24v connection.

Page 32

Page

32

ACCESSORY HOOK UP DIAGRAM

Wired K eyp ad

Photo Eye Beams

Victory PB-1200 Photo Eye Beams

External R adio Receiver

Page 33

Page

33

EXIT WAND HOOK UP DIAGRAM

Page 34

Page

34

PHOTO EYE

HOOK UP DIA GRAM

NIR Photo Eye

The NIR photo-eye has two parts: the EMITTER and the REFLECTOR. The

EMITT E R has 5 screw terminal s labeled by color. Attach the terminals in the emitter

to thos e o n th e gate operator circuit board as shown below. Use a direct-burial type of

control wire like "sprinkler wire" and posi tion the emitter on the hinge-side of th e

*Use these instructions in combination with the NIR

instr u cti o n s th at c o m e wi th th e p h oto e ye s. *

NIR Photo

Brown

Gray

White

Black

Blue

*Blac k wire no t used *

Page 35

Page

35

PHOTO EYE HOOK UP DIAGR A M

The IRB 4X photo-eye has two parts: the TRA N S M IT TE R an d th e REC E IVE R. T h e

TRANSMITTER has 2 screw terminals labeled plus and minus. The RECEIVER has 5

terminal s, DO NOT u se terminal #4. To connect the units to the gate operator circuit

board, see the drawin g below. Use a direct-burial type of control wire like "sprinkler

IRB 4X Photo Eye

*Use these instructions in

combination with the IRB 4X

instr u cti o n s th at c o m e wi th th e

Page 36

Page

36

EMERGENCY

DISCONNECT

CAUTION

: The gate will move

freely and uncontrolled when the

gate operator is remov ed from the

gate. ONLY d isconn ect the gate

operator when the con trol box

power switch is OFF an d the gate

is NO T m ovin g .

Page 37

Page

37

TECHN ICA L SP EC IF ICATIONS

Mechanical Specificati ons

Motor: 24 VDC

Shipping Weight:

POLAR IS 500: 6

5 lbs

POLARIS 500/502: 88 lbs

POLAR IS 700: 65

lbs

POLARIS 700/702: 90 lbs

Travel Speed:

16 seconds for 90° (opening

under normal conditions and normal load)

Electrical Specifications

Voltage Ratings:

Powered by a 24 v VDC motor

18 VAC transformer: 18.0 to 22.0 VAC

12 V Battery: 12.0 to 13.5 VDC 7.2Ah

Charging Circuit: 12.0 to 14.8 VDC

Transm itter/R eceiver Frequ ency: 433MHz

Transmitter Range: Up to 1 00 feet (90

meters) *varies greatly dep ending on gate

surroundings

POLARIS 500/502

Capacity

12 feet/200 pounds

Stroke Length

19 inches

Minimum Gate Length

60 inches

POLARIS 700/702

Capacity

14 feet/300 pounds

Stroke Length

24 inches

Minimum Gate Length

72 inches

44.6 inches retracted

68.6 inches extended

39.6 inches retracted

58.6 inches extended

Page 38

Page

38

PARTS LIST AND ILLUSTRATIONS

Page 39

Page

39

PARTS LIST AND ILLUSTRATIONS

Secondary Gate Operator

40 ft. cable

Polaris 502

Polaris 702

Circui t Board

Cabinet Dimensions:

14.5h x 12.5w x 6.5d

Transformer

Battery

Page 40

Page

40

TROUBLE SHOOTIN G

The gate(s) stops or reverses before reaching

the desired position.

1. Verif y the gate fr am e is not encou nte rin g an

obstruction and the gate hinges are not binding.

2. If th e OBS T R L ED is lit , th e sta ll fo rc e m ay b e set

too s en sit iv e. Incr e a se th e sta l l for c e by

turning the STALL FORCE potentiometer clockwise

1/8 turn. O perat e th e gate a ga in to s e e if the prob lem

stil l ex ist s. If th e p ro b lem s ti ll e xist s in cr e a se th e stall

force a gain and re try. If the proble m sti ll exists pro ce e

to step 3.

CA UT IO N: Increa sing the sta ll fo rc e reduc es

obstruction pr o tec tio n.

3. Re s et the op erat or by tur ning t he po w er off for

five sec ond s. Turn th e powe r bac k on and pre ss the

CYCLE bu tto n and allo w the ope rat ors to fully

retract.Try operating the gate again to see if the

prob lem sti ll exists. If the gate sto ps befo re rea ch ing

the desir ed p ositio n , clear and re def ine t he limit

sett in gs as de sc r ib ed e ar lier in th e ma n ua l.

4. Che ck for an y loose or in corr ec t conn ectio ns.

5. If steps 1–4 did no t solve the pr ob lem plea se

call technical support at 1-877-313-8902.

The gate will not operate using the handheld

transmitter.

1. Pr e s s tr ansmit t e r butt on to ve rify L E D on

tran s m itt er il lu minates. If not, replace 9V battery.

2. Obse rve "rad io rec ei ver led" on the co ntr o l

board an d verif y it turns on wh en tra nsm itt er

butto n is pres sed. If so,the tra nsm itt er is workin g

corre ctly refer to troubleshooting section “The

Gate

Wi ll Not Opera te.” If the LED does not illuminate,

proceed to step 3.

3. Ref er to page 22 of manual “Transmitter/Receiver”

and relearn the transmitter code. If the problem still

exists proceed to s t e p 4.

4. Verif y RF Board C on nec tio n.

If con n e ctio n s ar e cor re ct, please call technical

support.

The G a te Will Not Cl o se Au tomaticall y

1. M a ke s ure dip switc h 1, bloc k 1 is in t he on

position.

2. Adjust timer to preferred close time.

3. G ate m u st co mp le te on e f ull c yc le be for e t ime r is

activated.

The ga te (s) w il l n ot o p er a te.

1. Verif y pow er switc h is on.

2. V erif y t he ST ATU S L ED is bl in kin g

approximately once per second. If not, check

battery connections and both 4A and 15A fuses.

3. Verify SAFETY LOOP LED, SHAD O W

LOOP LED and EXIT LOOP LED are not on. If

any of the se are on, try disco nn ec tin g the

corresponding device.

4. If using an AC po wer sou r ce, ver ify the 18V AC

LED is on.

5. Verif y the 12V ba tter y volta ge. If belo w 12.3 V,

then replace or recharge the battery.

6. Clear and redefine limits as described earlier in

the manual.

7. Try the CY CL E butto n on the con tro l board.

8. Verify all connections especially the actuators.

9. Verify FIR E BOX, PHOT O BEAMS, or EXIT

WAND (if insta lled) is not pr eve nting ga te

movement.

The gate(s) are operating slowly.

1. This is usually due to low power. Check voltage

on batterie s. If voltage is belo w 12.3 V , a l low time

for b at t er ie s to ch arge b efore o pera t ing gates. (if

this is a so lar app lic a tio n and t here has bee n a lack

of sunligh t, yo u will nee d to char ge batt eries with

a trickle cha r ger befor e op era ting your ga te( s).)

The status light is flashing rapidly.

1. Th is is a lso m o st lik e ly du e to a po we r pro b le m.

Chec k batt ery vo ltage a nd char ge bat ter ies if

necessary.

2. Af t er b atteries ar e f ully charge d, pow e r dow n

syste m for 5 seco nds and tu rn bac k to on positio n.

There are no remaining inputs for 12vdc for my

accessories.

1. You ma y creat e a pigtai l conne ctio n and

con ne c t mor e th an on e a cce ss ory to a 12 vdc inp ut

connector.

Can I a d jus t th e actuator manua lly to fi t my

gate?

1. No. T he act u ato r mu s t be in st a lled in th e fully

retra cted po sitio n and co nne ct ed to the gate att ach

bracket at that p oint. P lease refer to page 1 0 for a

pull-to-open app licat ion or pa ge 12 for a pu sh-toopen application.

Page 41

Page

41

TROUBLE SHOO

TING

MAINTENANCE

Th e 1 5 amp f u s e i s bl ow n.

1. Che ck w irin g from ac tuator ar ms to circuit

board for lo o se or cut conn ect ion s.

2. V erif y t hat a ll w irin g is cor r ec t acc or d in g to

page 18.

3. Chec k for any over he atin g or singed w ir ing.

4. Call technical s upport at 1-877-313-8902 before

attem ptin g to rep lace fu se so as to preve nt an y

further da m age

.

Th e 4 amp f u s e i s bl o wn.

1. Che ck wiring f rom tr a nsfor mer to circ uit board.

2. Chec k for any loos e or incorr ec t conn ectio n s.

3. Che ck ba tt e ry connection s f or any c orros io n or

loo s e wir e s.

4. After re plac ing fus e, ver ify that 18 vac ligh t is

illu min a t ed . (th is is no t val id o n a sola r p ow e red

system.)

5. Ca ll te ch nic a l su pp or t if fuse b lo w s aga in .

How do I reset the limits on my gate(s)?

1. Make sur e you star t with bo th arms in the fully

retracte d posit ion.

2. Cle a r t he limits on both a rms by pressing the se t

lim it bu tt on a nd ho ld ing it in un t il it b eep s t wic e.

Set d ip sw it c h 6 in th e op po sit e po sit ion a nd pre ss

set limit a ga in u nt i l it be eps t wic e . Yo u ha ve n o w

cleared th e limits for bot h op er a to rs.

3. Dip switc h num b er 6 dictate s which ga te is

being af fec ted by the se t limit but ton, whet her

sett in g or cle ar in g th e lim it. If dip sw it c h 6 is in

the up po s itio n, it will s et o r cle ar t he limit for t he

secon da ry ope rat or. If it’s in the dow n posit ion it

will set o r clear t he limit for t he primar y oper ato r.

4. Once limits have been cleared, cycle the gates

to (clo s e- p ull to open) o r (open- push to open)

and stop th e gates u sing th e cycle bu tton w hen a

gate gets to the desired closed/open position. Once

this oc cur s s et the l im it f or th a t ga te by pr e ss ing

the s et limit b utt o n un ti l it be ep s on ce. (m ak e su re

dip s wit c h 6 is set a pp ro pr ia t ely ) C yc le th e gates

back to the open/ closed position.

5. With the gat es in the ope n/c lose d po sition,

cycle gates to close/open once again. This time

stop the ga te s when the othe r gate get s to the

des ir ed s to p lo ca tio n. On ce th a t is ac co mp l ish e d,

set th e limit f o r th at gate by setting the dip switch

6 cor re ct ly an d pr e ss in g th e set limit b ut t on un t il it

beeps once.

Preventive Maintenance

• Using a clean, dry cloth, wipe the gate

operator shaft, and then apply a silicone

spray. The silicone spray will reduce friction

in extreme temperature ranges and help the

gate operator operate smoothly. This should

be repeated every 4–6 weeks. If needed, spray

a small amount of silicone lubricant into tiny

pinhole found on shaft of actuator with

actuator in extended position.

• Check the gate hinges to make sure gate is

swinging smoothly and freely. Grease hinges

if needed.

• Check batteries occasionally for corrosion

and clean leads if necessary. Check voltage

occasionally.

• In some cold weather climates it is

recommen ded to purchase battery heaters to

ensure that your batteries maintain a charge

throughout cold weather months. In this case,

battery heaters need to be unplugged during

spring, summer and fall months to prevent

overheating.

• For optimal performance, it’s recommended

that new batteries be installed annually.

Customer Service

8:00am to 5:00pm, Mountain Time

Monday – Friday

Polaris Gate Operators

8617 Paseo Alameda NE

Albuquerque, NM 87113

Phone: 877-313-8902

Fax: 800-830-3952

emai l : techsuppo r t@ a m azingga tes.c om

Page 42

Page

42

LIST OF ACCESSORIES

Solar Powered Battery Charger (20-Watt: RSP2 0 ) The solar panel charges

the 12 volt battery when AC power is not available.

One-Bu tto n T ra n sm i tte r. T he transmitter works as an input device allowing

the user to open or close the gate from a remote location. It has a range up to

100 fe et.

Two-Bu tto n T ra n smitte r. The two -button transmitter provides the capability

to remotely opera te two separate devices such as two gates, or a gate and a

garage door opener. It has a range up to 1

00 feet.

Mini-transmitter. The mini-tran smi tter fi ts o n a k eychain and allows the user

to open or close the gate from a remote location. It has a range up to 100 fee t.

Keypad. The keypad allows for entry by authorized guests informed of the

pre-set code. Entering the correct code causes the gate to open or close. T h e

access code can be easily modified.

Pin Lock. The pin lock replaces the clevis pin when mounting the gate

operator to the brackets. It helps to prevent theft of the gate operator from the

gate, while allowing quick release of the operator.

In-Ground Vehicle Sensor . The vehicle sensor is buried near the gate and

senses a veh i cl e that pa sses w i thin its 12-foot range. Once detected, the gate

opens automatically.

Solenoid Gate Lock. The automatic gate lock provides an additional level of

security for the property. W hen the gate swings shut, the gate lock closes,

securing the gate in the closed position. The gate lock is powered from the

control box of the gate operator. The locking mechanism is a mechanical latch.

Magnetic Gate Lock. The automatic gate lock provides an additional level of

security for the property. When the gate swings shut, the gate lock closes,

securing the gate in the closed position. The gate lock is powered from an

external AC pow er source. The lockin g mechanism i s magnetic.

Page 43

Page

43

WARRANTY

You may obt ain additional copies of this manual from our web

site at www.polarisgate.co m, or contact Polaris Gate Operators

at: 8617 Paseo Alameda NE Albuquerqu e NM 87113,

877-313-8902.

Two Year Limi ted W arranty

Limited Warranty Coverage

If your Polaris Gate Operator (sometimes also referred to as

the “Product”) does not work properly because of a defect in

materials or workman ship, Polaris Gate Operators will, for the

length of the period indicated below, which starts with the date

of the original purchase by the first non-consumer purchaser

(the “Limited Warranty period”), at its option either (a) repair

your Product with new or refurbished parts, or (b) replace it

with a new or a refurbished Product. The decision to repair or

replace will be made by Polaris Gate Operators.

Parts Labor Labor

Two (2) Years Two (2) Years

During the “Labor” Limited Warranty period there will be no

charge for labor. (Note: labor appl ies only to the repair of the

Product at an Authorized Repair Center. It does not apply to

removal or installation of the Product any purchaser’s

premises). During the “Parts” Limited Warranty period, there

will be no charge for parts.

You must ship your Polaris Gate Operator to Polaris Gate

Operators during the applicable Limited Warranty period. This

Limited Warrant y excludes both parts and labor for batter ies,

antennas, and cosmetic parts (such as the Product housing).

This Limited Warrant y only applies to Product s purchased in

the United States. This Limited Warranty is extended onl

y to

the original non-consumer pu rchaser (“you” o r “your”) o f a

new Product that was not sold “as is”.

Limited Warranty Service

For assistance in the continental U.S.A. in obtaining the

benefit of the Limited Warranty please carefully follow these

steps:

1) Complete carefull y all troubleshoot ing procedures in the

Maintenance and Troubleshooting Guide in this Manual.

2) If you ar e

still unable to sol ve the problem, contact Polaris

Gate technical support at techsupport@amaz inggates.com.

Please have the mod el and serial number of the Product

available to give to the customer service representative. The

custo me r ser vic e rep re sen t ati ve will provide further assistance

or authorize repair or replacement, as app ropriate.

3) If repair or replacement is appropriate you will be given a

return authorization number (RMA# ). This RMA# must be

visible on all documents and packages returned to Polaris Gate

Operators.

4) Carefully pack the de fective Product o r Product part in a

sturdy shipping carton, include (i) a letter detailing the

complaint, (ii) a daytime phon e number where you can be

reached, (iii) your name and address for any return, (iv) your

sales receipt/proof of purchase, and ( v) the RMA# o n all

correspondence and th e shipping carton.

5) Prepay the freight and insure the d efective Product or

Product part against shipping damage. Note that defective

Products or Product parts shipped freight collect will not

be accepted.

6) Ship the carton to: Polaris Gate Operators, 8617 Paseo

Alameda NE, Albuquerque, NM 87113.

IF REPAIR OR REPLACEMENT IS NEEDED

DURIN G THE LIMITED WARRAN TY PERIOD,

YOU WILL BE REQUIRED TO FURNISH A SALES

RECEIPT/PROOF OF PURCHASE INDICATING

DATE OF PURC HAS E, AMOU NT PAID AND

PLACE OF PURCHASE. YOU WILL BE

CHARGED FOR THE REPAIR OF ANY PR ODU C T

OR PRODUCT PART RECEIVED WITHOUT

SUCH PROOF OF PURCHASE OR FOR REPAIRS

REQUESTED AFTER THE APPLICABLE

LIMITED WAR RANTY PER IOD.

Limited Warranty Limitations and Exclusions

This Limited Warranty ONLY COVERS failures due to

de f ects in materials or workmanship, and DOES NOT

COVER no rmal wear and tear or cosmetic damage. The

Limited Warranty ALSO DOES NOT COVE R dama ges

which occurred in shipment, or failures which are caused

by products not supplied by Polaris Gate Operators, or

failures which result fro m accidents, misuse, abuse,

neglect, mishandling, misapplication, mod ifications or

alterations, faulty installation, connection to an improper

po wer sou rc e, s et-up ad justments, mis-adjustment of

controls, improper maintenanc e, power line surges,

damage from acts of God such as lightning, wind, fire,

flood or insects, introduction of sand, humidity or liquids,

commercial or rental use or service by anyone other than

an Authorized Repair Center.

THERE ARE NO EXPRESS WARRANTIES

EXCEP T AS STATED UNDER “LIMITED

WARR AN TY CO VERAGE ”. POLAR IS GATE

OPERATORS IS NOT LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES RESULTING

FR OM T HE U S E OF T H E PR ODUCT, O R

ARISING OUT OF ANY BREACH OF THIS

LIMITED WAR RANTY. (As examples, this e xcludes

damages for lost time, lost calls or messages, cost of

having someone remove or re-install an installed Product

or Product part, travel to and from an Authorized Repair

Center, etc. The example s listed are not an exhaustive or

exclusive list, but are for illustration only). ALL

EXPRE SS AND IMPL IED W ARRAN TIE S,

INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO THE

PERIOD OF T HE LIMITE D WARR AN TY.

Some States do not allo w the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Some States do not allo w limitations on how long an

implied warranty lasts, so the abo ve limitation may not

apply to you.

This warranty gives you specific legal rights, and you

may also ha ve other rights which vary from St ate to State.

PARTS AND SE RVICE S WH ICH ARE N OT

EXPRESSLY COVERED BY THIS LIMITED

WARRANTY ARE YOUR RESPONSIBILITY

.

Loading...

Loading...