Page 1

2019

Owner’s MAnual

TI

MBERSLED® ST 93 RIPPER

Page 2

IMPORTANT NOTICE TO OWNERS

Read, understand, and follow all of the instructions and

safety precautions in this manual and on all product labels.

Failure to follow the safety precautions could result in

serious injury or death.

WARNING

Read, understand, and follow all of the instructions and

safety precautions in this manual and on all product labels.

Failure to follow the safety precautions could result in

serious injury or death.

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects or other reproductive harm.

For videos and more information about a safe

riding experience with your Polaris vehicle, scan

this QR code with your smartphone.

Page 3

2019 Owner’s Manual

ST 93 RIPPER

Page 4

POLARIS® and Timbersled® are trademarks of POLARIS Industries Inc.

Copyright 2018 Polaris Industries Inc. All information contained within this

publication is based on the latest product information at the time of

publication. Due to constant improvements in the design and quality of

production components, some minor discrepancies may result between the

actual vehicle and the information presented in this publication. Depictions

and/or procedures in this publication are intended for reference use only. No

liability can be accepted for omissions or inaccuracies. Any reprinting or

reuse of the depictions and/or procedures contained within, whether whole or

in part, is expressly prohibited.

Loctite® is a registered trademark of Henkel AG & Co.

EK® is a copyright trademark of Enuma Chain Mfg. Co., Ltd.

The original instructions for this vehicle are in English. Other languages are

provided as translations of the original instructions.

Printed in U.S.A.

2019 Timbersled Owner’s Manual

9928777

Page 5

WELCOME

Thank you for purchasing a POLARIS vehicle, and welcome to our world-wide

family of POLARIS enthusiasts. Be sure to visit us online at www.polaris.com for

the latest news, new product introductions, upcoming events, career

opportunities and more.

Here at POLARIS we proudly produce an exciting line of utility and recreational

products. We believe POLARIS sets a standard of excellence for all utility and

recreational vehicles manufactured in the world today. Many years of experience

have gone into the engineering, design, and development of your POLARIS

vehicle, making it the finest machine we’ve ever produced.

• Snowmobiles

• All-terrain vehicles (ATVs)

• Low emission vehicles (LEVs)

• RANGER® utility vehicles

• BRUTUS® work vehicles

• SLINGSHOT® three wheel motorcycles

• RZR® sport vehicles

• GEM® vehicles

• INDIAN® motorcycles

• POLARIS POWER® generators

• POLARIS DEFENSE® combat vehicles

• Timbersled® Snow Bikes

For safe and enjoyable operation of your vehicle, be sure to follow the

instructions and recommendations in this owner’s manual. Your manual contains

instructions for minor maintenance, but information about major repairs is

outlined in the POLARIS Service Manual and can be performed by a factory

certified Master Service Dealer® (MSD) technician.

Your POLARIS dealer knows your vehicle best and is interested in your total

satisfaction. Your POLARIS dealership can perform all of your service needs

during, and after, the warranty period.

3

Page 6

WELCOME

The following signal words and symbols appear throughout this manual. Your

safety is involved when these words and symbols are used. Become familiar

with their meanings before reading the manual.

WARNING

WARNING indicates a hazardous situation that, if not avoided, may result in

death to the operator, bystanders or person(s) inspecting or servicing the

vehicle.

CAUTION

SAFETY ALERT CAUTION indicates a potential hazard that may result in minor

personal injury or damage to the vehicle.

CAUTION

CAUTION indicates special precautions that must be taken to avoid vehicle

damage or property damage.

NOTICE

NOTICE provides key information by clarifying instructions.

IMPORTANT

IMPORTANT provides key reminders during disassembly, assembly, and

inspection of components.

4

Page 7

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . 7

Safety . . . . . . . . . . . . . . . . . . . . . . . 9

Features . . . . . . . . . . . . . . . . . . . . . 23

Pre-Ride Inspection . . . . . . . . . . . . . . . 25

Operation . . . . . . . . . . . . . . . . . . . . 29

Maintenance . . . . . . . . . . . . . . . . . . 33

Installation. . . . . . . . . . . . . . . . . . . . 43

Specifications . . . . . . . . . . . . . . . . . . 67

Warranty . . . . . . . . . . . . . . . . . . . . 73

Maintenance Log . . . . . . . . . . . . . . . . 77

5

Page 8

6

Page 9

INTRODUCTION

INTRODUCTION

IMPORTANT NOTES FOR OWNERS AND DRIVERS

After reading this manual, store it with the snow bike for convenient reference. It

should remain with the vehicle when it is sold.

Some of the illustrations and photos used in this manual are general

representations. Your model may differ.

Follow the maintenance program outlined in this manual. Preventive

maintenance ensures that critical components of the snow bike are inspected at

specific mileage intervals. This service can be performed by your authorized

Timbersled dealer.

You and your dealer must complete the registration form included with your

vehicle and forward it to us. This form should be completed at the dealership

upon purchase, and is necessary to ensure warranty coverage.

Protect and preserve your right to ride by joining your local trail riding clubs.

When teaching inexperienced operators to ride, set up a predetermined course

for practice. Make sure they know how to drive and control the vehicle before

allowing them to make longer trips. Teach them proper riding courtesy, and

enroll them in driver’s training and safety courses sponsored by local or state

organizations.

PRESERVATION OF THE ENVIRONMENT

Timbersled is committed to supporting an environmental education campaign.

We encourage state and provincial governments across the snowbelt to adopt

rigorous safety training programs that encourage protection of our environment,

including wildlife and vegetation.

Clubs and other organizations are working together to protect our environment.

Please support their efforts and operate your snow bike with consideration for

the protection and preservation of our environment.

INSTALLATION

See your local Timbersled dealer for installation instructions and accessory

attachments.

7

Page 10

INTRODUCTION

VEHICLE IDENTIFICATION NUMBERS

Record your Timbersled’s serial number in the spaces provided.

NOTICE

If installing an aftermarket tunnel wrap, do not cover the tunnel serial number

with the wrap. If the tunnel wrap doesn’t provide an opening for the label,

Serial Number

q

remove the section of wrap where the label is located.

SERIAL NUMBER:

8

Page 11

SAFETY

SAFETY

OPERATOR SAFETY

Follow the recommended maintenance program on page 33 to ensure that all

critical components on the snow bike are thoroughly inspected at specific

intervals outlined in the Periodic Maintenance Chart. Your dealer can perform

this service.

WARNING

Driving a snow bike requires your full attention. DO NOT drink alcohol or use

drugs or medications before or while driving or riding as a passenger. They will

Snow bikes are capable of traveling at high speeds. Use extra caution to

ensure operator safety. Make sure your snow bike is in excellent operating

condition at all times. Always check major and vital safety components before

All Timbersled snow bikes are designed and tested to provide safe operation

when used as directed. Failure of critical machine components may result from

operation with any modifications, especially those that increase speed or

power. DO NOT MODIFY YOUR MACHINE. The snow bike may become

aerodynamically unstable at speeds higher than those for which it is designed.

Loss of control may occur at higher speeds. Modifications may also create a

HOST BIKE

The Timbersled Snow Bike system is designed to be attached to a variety of

host bikes. Read and understand your host bike’s operation manual and follow

all safety and maintenance information. Failure to do so could result in serious

injury or death.

reduce your alertness and slow your reaction time.

every ride.

safety hazard and lead to bodily injury.

STAY CLEAR OF TRACK

Your snow bike is propelled by a revolving track that must be partially exposed

for proper operation.

WARNING

Serious injuries may result if hands, feet, or clothing become entangled in the

track. Be alert when riding, and remain properly seated to stay clear of the

track. Never hold the snow bike up or stand behind it while warming up the

track. A loose track or flying debris could cause serious injury or death. We

recommend having your dealer perform all track service and alignment

procedures.

9

Page 12

SAFETY

RIDING POSITION

Operating a Timbersled requires skill and balance for proper control. Rider

positions may vary with experience and the features available on some models,

but under many conditions the proper position is to be seated with both hands

on the handlebar grips for proper throttle, brake, and steering control. See your

host bike’s owners manual for proper riding position.

WARNING

Improper riding position may reduce control and could result in serious injury or

death. Always ride in a position that allows for control of your vehicle.

RIDER CAPACITY

This Timbersled is designed for a single rider only. Never carry a passenger on

this vehicle.

RIDING APPAREL

HELMET

Wearing a helmet can prevent a severe head injury. Whenever riding a

Timbersled vehicle, always wear a helmet that meets or exceeds established

safety standards.

Approved helmets in the USA and Canada bear a U.S. Department of

Transportation (DOT) label.

Approved helmets in Europe, Asia and Oceania bear the ECE 22.05 label. The

ECE mark consists of a circle surrounding the letter E, followed by the

distinguishing number of the country which has granted approval. The approval

number and serial number will also be displayed on the label.

EYE PROTECTION

Do not depend on eyeglasses or sunglasses for eye protection. Whenever riding

a Timbersled vehicle, always wear shatterproof goggles or use a shatterproof

helmet face shield. Timbersled recommends wearing approved Personal

Protective Equipment (PPE) bearing markings such as VESC 8, V-8, Z87.1, or

CE. Make sure protective eye wear is kept clean.

CLOTHING

Be prepared, be warm and be comfortable when riding. Be aware of the weather

forecast, especially the windchill, and dress accordingly. See page 21.

WARNING

Avoid wearing loose clothing or long scarves, which can become entangled in

moving parts and cause serious injury. Always wear an approved helmet and

10

eye protection.

Page 13

SAFETY

SURVIVAL PREPARATION

For your safety, always ride in a group. Always tell someone where you're going

and how long you expect to be gone. If it isn't possible to ride with others, and

you must travel into remote areas, always carry survival equipment that's

appropriate to the conditions you may encounter. Such equipment may include,

but is not limited to: extra clothing, a sleeping bag, a flashlight, food and water, a

signaling mirror, a means of building a fire, and a two-way radio or cellular

telephone.

Always carry the owner’s manual on your snow bike. For added protection,

purchase and carry the following items on your snow bike as well:

• Extra Set of Spark Plugs

• Tow Rope

• Extra Oil

• Fuel Deicer

• Winter Survival Kit

• Spare Drive Chain

• Spare Chain Case Chain (if equipped)

• Trail Map

• First Aid Kit

• Tool Kit

EXCESSIVE SPEED

WARNING

High speed driving, especially at night, could result in serious injury or death.

Always reduce speed when driving at night or in inclement weather.

Always observe all state and local laws governing snow bike operation and

speed limits. Always be alert and pay attention to the trail ahead. If your speed is

40 MPH (64 km/h), your snow bike is traveling about 60 feet (18 m) per second.

If you look back for only two seconds, your snow bike will travel about 120 feet

(36 m). If your speed is 60 MPH (96 km/h), your snow bike will travel about 180

feet (55 m) in two seconds.

Traveling at night requires extra caution. If your host bike is equipped with a

headlight, check headlight and taillight to ensure proper operation, and don’t

over-drive your headlight beam. Always be able to bring your snow bike to a

stop in the distance illuminated by the headlight.

11

Page 14

SAFETY

DRIVER AWARENESS

Slow down when traveling near poles, posts, or other obstacles. Be especially

alert if you're snow biking after dark. Always be on the alert for wire fences.

Single strands are especially dangerous, since there may be a great distance

between posts. Guy wires on utility poles are also difficult to distinguish.

Make sure the way is clear before crossing railroads and other roads and

highways. The noise of your snow bike will drown out the sound of approaching

vehicles. Look ahead, behind, and to both sides before turning or crossing

railroad tracks or highways. Steep embankments may also hide your view.

Always leave yourself a way out.

Variances in snow depth and/or water currents may result in uneven ice

thickness. You may drown if you break through the ice. Never travel on frozen

bodies of water unless you have first verified that the ice is sufficiently thick to

support the weight and moving force of the snow bike, you and your cargo,

together with any other vehicles in your party. Always check with local authorities

and residents to confirm ice conditions and thickness over your entire route.

Operators assume all risk associated with ice conditions on frozen bodies of

water.

When teaching inexperienced operators to ride, set up a predetermined course

for practice. Make sure they know how to drive and control the snow bike before

allowing them to make longer trips. Teach them proper snow bike courtesy, and

enroll them in driver's training and safety courses.

DISABLED OPERATORS

Safe operation of this rider-active vehicle requires good judgement and physical

skills. Operators with cognitive or physical disabilities have an increased risk of

loss of control, which could result in serious injury or death.

12

Page 15

SAFETY

MOUNTAINOUS TERRAIN RIDING

Mountainous terrain operation, even for experienced riders, can present

conditions and situations that could result in serious injury or death. Please

review all of the information about riding in mountainous terrain on the following

pages of this manual.

WARNING

An avalanche can occur at any time, in any conditions and on any slope.

The avalanche information provided in this manual should be considered basic

information and is not intended to replace your participation in an avalanche

safety training course. After reviewing the avalanche information in this manual,

be sure to participate in an avalanche safety training course before riding in

mountainous terrain. The training course will provide more information as well as

the opportunity to practice riding and using proper search and recovery

techniques.

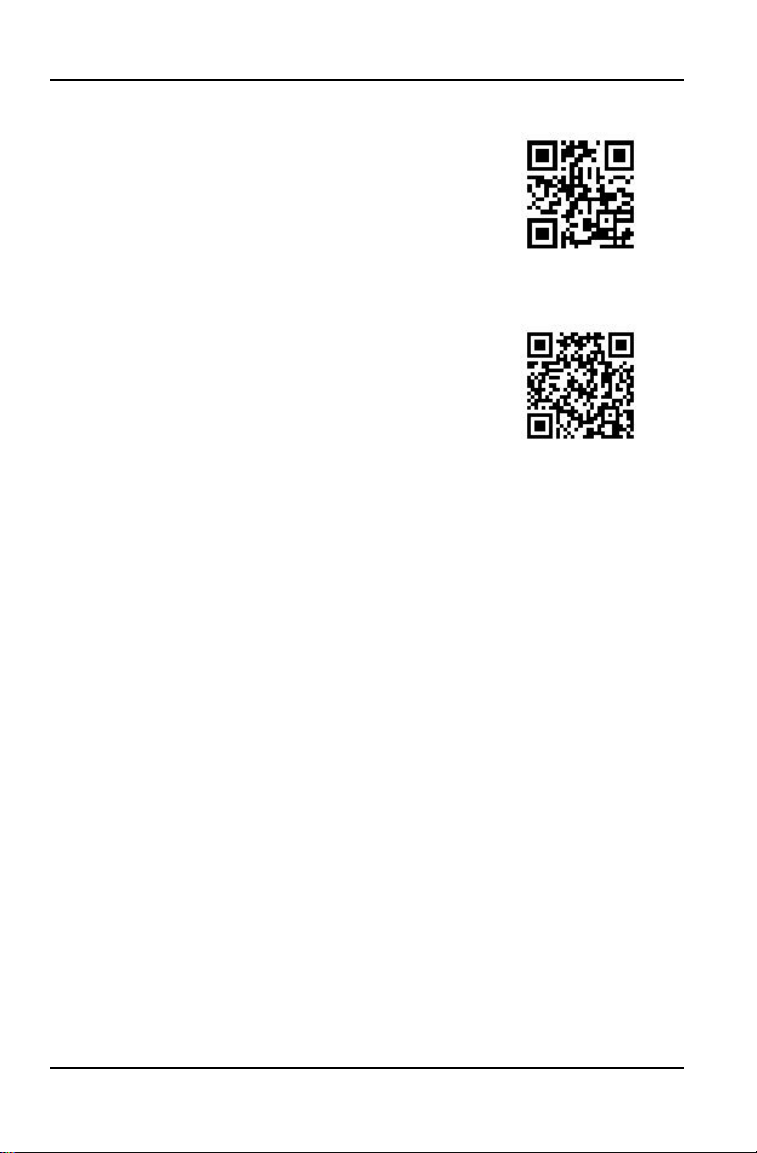

For more information, education, training courses, and links to international

resources, visit www.avalanche.org or scan the QR code with your smartphone

or other device.

GET THE SAFETY GEAR

In addition to carrying a spare belt, spark plugs and tools on each snow bike,

each person in your riding group should wear the recommended snow bike

riding apparel and carry (on their person) the following survival items when

riding in mountainous terrain:

• A digital avalanche beacon with new “fresh” alkaline batteries

• An avalanche probe

• A compact shovel and hand saw

• A backpack (preferably an avalanche air bag backpack)

• Emergency provisions, including the following items:

– Small first aid kit

– Extra pair of gloves

– Extra dry socks

– Tow rope, map, compass/GPS

– Lighter or waterproof matches

– Signal mirror and whistle

– Bottled water

– High calorie snack food

– Compact emergency blanket

– Cell phone

– Radio

13

Page 16

SAFETY

GET TO KNOW YOUR SAFETY GEAR

Following the safety gear and apparel recommendations will increase your

chances of survival if you encounter an avalanche or become stranded in the

backcountry, but even experienced and properly-equipped snow bikers, hikers

and skiers perish in avalanches or succumb to hypothermia. Using a beacon or

probe for the first time during an avalanche recovery operation, or not knowing

how to deploy your avalanche air bag backpack during a slide, should be

considered UNACCEPTABLE to you and all members of your riding group. It’s

critical that you and all members of your riding group know how to use the safety

gear.

While you may know how to use your gear, you may have to rely on your

riding group to find you in an avalanche. Make sure they know how to use

their gear.

• Dress in layers. Multiple layers of clothing provide the best barrier to cold and

wind. Layers can be removed, but if you start out without enough layers, they

cannot be added later. Avoid cotton materials, which will freeze if they get wet.

• Wear highly visible gear.

• Try on all gear and equipment to make sure it fits and doesn’t interfere with

your riding capabilities. Place all survival aids in your backpack and wear the

backpack at all times. Non-essential items can be stored on the snow bike in

an accessory bag.

• Read and follow the manufacturer’s user and maintenance instructions for all

gear. If you have questions about how your gear works, contact the

manufacturer for more information.

• Practice using your beacons, shovels and probes with your riding group in

real-world conditions wearing all of your gear. Have someone hide an active

“transmitting” beacon by throwing it (not walking it) into a snowbank and

timing your group’s search for it.

• Test deploying your gear. If you own an avalanche air bag backpack, check

with the manufacturer’s test deployment guidelines and bottle weight

replacement specifications. Most air bag backpack manufacturers

recommend testing the pack once a year so you know it works and feel

comfortable with the bag and deployment time.

• Make sure your probe and shovel are in good condition and that you know

how to assemble them.

14

Page 17

SAFETY

GET THE PICTURE

Slopes steeper than 30º are more prone to avalanches, but any slope should be

considered avalanche terrain, even small slopes with trees. Low-angle slopes

are also avalanche terrain if they have steeper slopes above them.

NOTE

The 30º slope graphic is for illustration purposes only. The risk of an avalanche

is always present in mountainous terrain, regardless of slope angle.

Always look for the following warning signs of unstable snow. If you see or hear

any of these signs, riding on or below any slope is dangerous and should be

avoided:

• Recent avalanches

• A “whumpfing” sound under a

snowpack

• Cracks across the top of a

snowpack

• A recent heavy snowfall

• Blowing snow

• Rain

• Rapid warming

GET OUT OF HARM’S WAY

• Before riding, always tell a responsible person (i.e. at the lodge or gas station)

where your group is going.

• Never ride alone. Always ride in a small, manageable group. Riding in a large

group makes it more difficult to track riders or find missing members.

• Go “one at a time”. Only one snow bike at a time should cross, ascend or

highmark a slope. Other riders should watch from a safe location until the

previous rider exits the slope.

• Never park at the base of a slope or at the bottom of a gully or valley. When

parking to take a break or watch other riders, park at the sides of the slope

with the front of your snow bike pointed away from the slope.

15

Page 18

SAFETY

GET THE FORECAST

Make a riding plan based on the current avalanche

and weather forecast. It is important to remember that

overnight weather conditions may have created

unsafe riding terrain that was considered safe the day

before. Visit www.avalanche.org or scan the QR code.

Follow the page links to locate current avalanche

reports and conditions for your area of operation.

GET AVALANCHE SAFETY TRAINING

Timbersled recommends you and all members of your

riding group participate in an avalanche safety

course. Visit www.avalanche.org/education or scan

the QR code for education and training resources.

AVALANCHE AWARENESS

Avalanches are a matter of timing. A steep slope can be safe one day, but

unsafe the next day due to changing weather and wind conditions.

• Always review the user instructions provided with your safety equipment and

follow the recommendations for maintenance, testing and use. Always test

your safety equipment to ensure it works properly before riding in

mountainous terrain.

• Always store your survival gear in your backpack and wear the backpack. Do

not store your survival gear on the snowmobile.

• Always research current avalanche conditions in your area of operation

before riding. Check with local law enforcement, resort or lodging personnel,

gas station attendants and other riders to learn about current conditions and

any advisories in the area.

• Read and understand the avalanche danger scale. Pay attention to any

danger level warnings issued for your area of operation.

• Always remain alert while riding in mountainous terrain. Be aware of

snowpack conditions above you as you ride. Avalanches can occur at any

time regardless of current condition reports.

16

Page 19

SAFETY

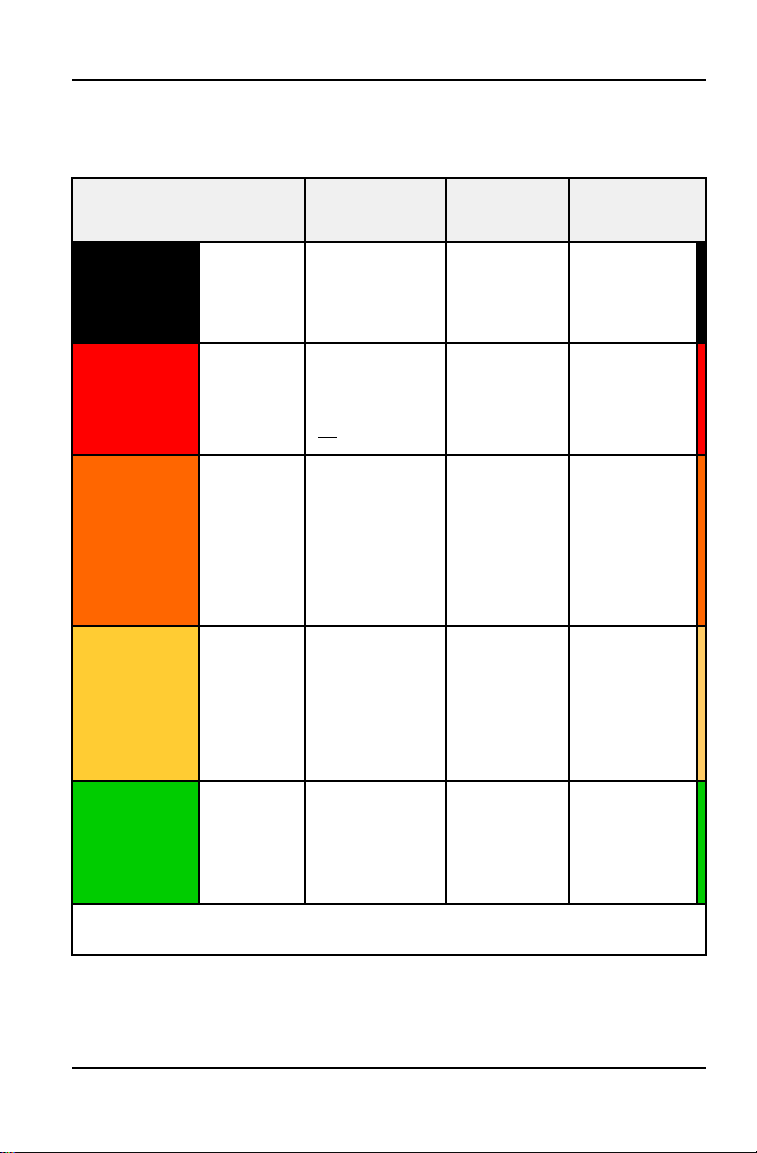

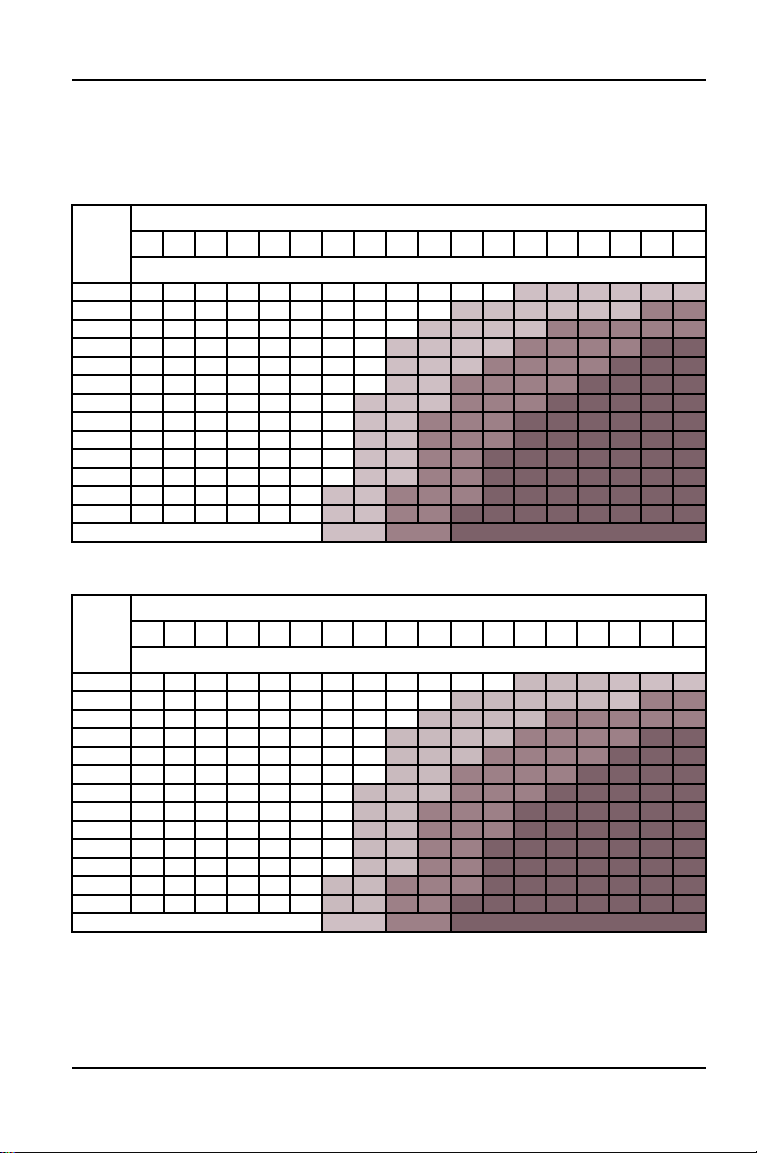

North American Public Avalanche Danger Scale

Avalanche danger is determined by the likelihood, size and distribution of

avalanches.

DANGER LEVEL TRAVEL ADVICE LIKELIHOOD

OF

AVALANCHES

AVALANCHE

SIZE AND

DISTRIBUTION

5

Extreme

4

High

3

Considerable

2

Moderate

1

Low

Avoid all avalanche

terrain.

Very dangerous

avalanche

conditions. Travel

in avalanche terrain

not recommended.

Dangerous

avalanche

conditions. Careful

snowpack

evaluation,

cautious route-

finding and

conservative

decision-making

essential.

Heightened

avalanche

conditions on

specific terrain

features. Evaluate

snow and terrain

carefully; identify

features of

concern.

Generally safe

avalanche

conditions. Watch

for unstable snow

on isolated terrain

features.

Natural and

human-triggered

avalanches

certain.

Natural

avalanches

likely; human-

triggered

avalanches very

likely.

Natural

avalanches

possible;

human-triggered

avalanches

likely.

Natural

avalanches

unlikely; human-

triggered

avalanches

possible.

Natural and

human-triggered

avalanches

unlikely.

Large to very

large avalanches

in many areas.

Large

avalanches in

many areas; or

very large

avalanches in

specific areas.

Small

avalanches in

many areas; or

large avalanches

in specific areas;

or very large

avalanches in

isolated areas.

Small

avalanches in

specific areas; or

large avalanches

in isolated areas.

Small

avalanches in

isolated areas or

extreme terrain.

Safe backcountry travel requires training and experience. You control your own risk by

choosing where, when and how you travel.

17

Page 20

SAFETY

ICE AND SNOW BUILD-UP

WARNING

Ice and snow build-up may interfere with the steering and braking of your snow

bike, resulting in serious injury or death. Keep the snow bike free of snow and

Before driving, manually turn the ski to the left and right to be sure ice and snow

are not interfering with full left and right steering. If difficulty is encountered,

remove ice and snow build-up that may be obstructing the steering.

ice.

DRIVING ON SLIPPERY SURFACES

WARNING

Never attempt an abrupt change of direction when operating on slippery

surfaces. Proceed slowly and use extra caution. Driving on ice or hard-packed

snow reduces steering and braking control, which may result in loss of control

and serious injury or death. Slow down and use extra caution when operating

on slippery surfaces.

INADEQUATE SNOW CONDITIONS

Driving in too little snow will result in excessive wear and damage to the front ski

and skags. The ST 93 Ripper is designed to be ridden in inadequate snow

conditions or no snow when the front ski is removed and front host bike wheel is

installed.

OPERATING IN DEEP SNOW

If the snow bike becomes stuck in snow, clear the track and tunnel area of snow,

then step down the snow in front of the snow bike so that when the throttle is

opened, the snow bike will be able to climb up and over the snow.

DRIVING DOWNHILL

When riding downhill, shift your weight to the rear of the snow bike and reduce

your speed to a minimum. Apply just enough throttle to keep the engine from

stalling, allowing the engine's compression to help slow the snow bike and keep

it from rolling freely downhill.

WARNING

When driving on long downhill stretches, pump the brakes. Riding the brakes

may cause the brake system to overheat, which may result in brake failure.

Excessive or repetitive use of the brakes for high speed stops will also cause

an overheated brake system. This condition may lead to a sudden loss of

brakes and/or fire and may result in serious injury or death.

18

Page 21

SAFETY

DRIVING IN HILLY TERRAIN

WARNING

Climbing a hill or crossing the face of a slope may result in loss of balance and

rollover, causing serious injury or death. Use caution and good judgement

Use extra caution when operating in hilly terrain. If climbing a hill is unavoidable,

keep your weight low and forward. If you must cross the face of a slope, keep

your weight on the uphill side of the snow bike to maintain proper balance and

avoid possible roll-over.

Slow down when reaching the crest of a hill. Be prepared to react to obstacles,

sharp drops or other people or vehicles that may be on the other side of the hill.

If you're unable to continue up a hill, turn the snow bike downhill before it loses

momentum. If this isn't possible, spin the track just enough to dig in to prevent it

from rolling back down the hill. Stop the engine and set the parking brake (if

equipped). Keeping away from the downhill side of the snow bike, pull the rear of

the snow bike around and point the front end and skis downhill. Remount the

snow bike, restart the engine, release the parking brake (if equipped), and

descend the hill carefully.

when driving in hilly terrain.

COLD WEATHER DRIVE-AWAY

Whenever your snow bike has been parked for a length of time, especially

overnight, always make sure the ski and track are loosened from ice and snow

before attempting to drive. Apply the throttle with enough authority to put the

snow bike into motion, but always operate within safety limits.

CAUTION

Reference host bike’s owner’s manual to insure bike is adequately prepared

for cold temperature conditions.

19

Page 22

SAFETY

MANEUVERABILITY

While much control and maneuverability is achieved through the steering

system and ski, maximum control is achieved by the shifting of your body

weight. Maneuverability will change for lighter operators.

DRIVING RESPONSIBLY

Every snow bike handles differently, and even the most docile conditions may

become dangerous if operators drive improperly. If you're new to snow biking,

acquaint yourself with the snow bike and with what it will and won't do under

various conditions. Even seasoned drivers should spend some time getting the

feel for a snow bike before attempting ambitious maneuvers.

• A snow bike depends on the rider's body position for proper balance in

executing turns, traversing hills, etc. Always start on a smooth, level area to

begin building your operating experience.

• Before allowing someone else to use your snow bike, know the extent of their

operating skills. Check to see if they've taken a safety course and have an

operator's certificate. For their protection, as well as yours, make sure they

take a safety course. Everyone can benefit from the course.

• Don't “jump” your snow bike over large drifts or similar terrain. Jumping may

injure your back because of spinal compression that could occur when the

snow bike impacts the ground. The seat and suspension of your snow bike

have been designed to provide protection under normal riding conditions.

Your snow bike is not intended for this kind of use.

• Be courteous to oncoming traffic by dimming your headlights (if equipped)

and reducing your speed.

• When traveling in a group of snow bikes, don't tailgate (follow too closely).

Leave enough distance between snow bikes to provide ample stopping room

and to provide protection from flying snow and debris. Allow even more

distance when driving on slippery surfaces or when driving in darkness or

other low visibility conditions. Be aware of any traffic around your vehicle.

Drive defensively to avoid accidents.

• If equipped, remove the key from the ignition when you leave the snow bike

unattended.

20

Page 23

SAFETY

WINDCHILL/TEMPERATURE CHARTS

The following information is provided to help you determine when temperatures

become dangerous for riding.

WINDCHILL CHART (°F)

Wind

Speed

in MPH

Calm 40 35 30 25 20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35 -40 -45

40 35 30 25 20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35 -40 -45

5 36 31 25 19 13 7 1 -5 -11 -16 -22 -28 -34 -40 -46 -52 -57 -63

10 34 27 21 15 9 3 -4 -10 -16 -22 -28 -35 -41 -47 -53 -59 -66 -72

15 32 25 19 13 6 0 -7 -13 -19 -26 -32 -39 -45 -51 -58 -64 -71 -77

20 30 24 17 11 4 -2 -9 -15 -22 -29 -35 -42 -48 -55 -61 -68 -74 -81

25 29 23 16 9 3 -4 -11 -17 -24 -31 -37 -44 -51 -58

30 28 22 15 8 1 -5 -12 -19 -26 -33 -39 -46 -53 -60 -67 -73 -80 -87

35 28 21 14 7 0 -7 -14 -21 -27 -34 -41 -48 -55 -62 -69 -76 -82 -89

40 27 20 13 6 -1 -8 -15 -22 -29 -36 -43 -50 -57 -64 -71 -78 -84 -91

45 26 19 12 5 -2 -9 -16 -23 -30 -37 -44 -51 -58 -65 -72 -79 -86 -93

50 26 19 12 4 -3 -10 -17 -24 -31 -38 -45 -52 -60 -67 -74 -81 -88 -95

55 25 18 11 4 -3 -11 -18 -25 -32 -39 -46 -54 -61 -68 -75 -82 -89 -97

60 25 17 10 3 -4 -11 -19 -26 -33 -40 -48 -55 -62 -69 -76

Frostbite in >> 30 min. 10 min. 5 min.

WINDCHILL CHART (°C)

Wind

Speed

in Km/h

5 2 -1 -4 -7 -10 -13 -16 -19 -22 -25 -28 -31 -34 -37 -40 -43 -46

Calm 5 2 -1 -4 -7 -10 -13 -16 -19 -22 -25 -28 -31 -34 -37 -40 -43 -46

8 3 0 -4 -7 -11 -14 -18 -22 -25 -29 -32 -36 -39 -43 -46 -50 -53 -57

16 2 -2 -6 -10 -13 -17 -21 -24 -28 -32 -36 -39 -43 -47 -50 -54 -58 -62

24 1 -3 -7 -11 -15 -19 -22 -26 -30 -34 -38 -42 -45 -49 -53 -57 -61 -65

32 0 -4 -8 -12 -16 -20 -24 -28 -32 -36 -39 -43 -47 -51 -55 -59 -63 -67

40 -1 -5 -9 -13 -17 -21 -25 -29 -33

48 -1 -5 -9 -13 -18 -22 -26 -30 -34 -38 -42 -46 -50 -54 -58 -62 -66 -70

56 -2 -6 -10 -14 -18 -22 -26 -31 -35 -39 -43 -47 -51 -55 -59 -64 -68 -72

64 -2 -6 -10 -15 -19 -23 -27 -31 -35 -40 -44 -48 -52 -56 -61 -65 -69 -73

72 -2 -7 -11 -15 -19 -23 -28 -32 -36 -40 -45 -49 -53 -57 -61 -66 -70 -74

80 -3 -7 -11 -15 -20 -24 -28 -33 -37 -41 -45 -50 -54 -58 -62 -67 -71 -75

88 -3 -7 -12 -16 -20 -24 -29 -33 -37 -42 -46 -50 -55 -59 -63 -67 -72 -76

96 -3 -8 -12 -16 -21 -25 -29 -34 -38 -42

Frostbite in >> 30 min. 10 min. 5 min.

Actual Thermometer Reading (°F)

Equivalent Temperature (°F)

-64 -71 -78 -84

-84 -91 -98

Actual Thermometer Reading (°C)

Equivalent Temperature (°C)

-37 -41 -45 -49 -53 -57 -61 -65 -69

-47 -51 -55 -60 -64 -68 -73 -77

21

Page 24

SAFETY

SAFETY LABELS AND LOCATIONS

Safety and warning labels have been placed on the vehicle for the operator's

protection. Make sure the operator understands the information on all labels. If

any label becomes illegible or comes off, contact your POLARIS dealer for a

replacement. Replacement safety labels are provided by POLARIS at no

charge. The part number is printed on the label.

The safety labels are located on the tunnel/cowling of your snow bike.

PROPER USE WARNING

WARNING

Prior to operation, read and understand Timbersled and OEM motorcycle

owner’s manuals and all warnings.

• ALWAYS wear a DOT approved helmet, eye protection, and protective

clothing while operating this vehicle.

• Never carry a passenger.

• Before starting engine, check throttle and brake for proper operation.

• Reduce speed and use extreme caution when operating in unfamiliar terrain.

• Ensure that sprocket and track shrouds are in place and secure. Do not

operate with shrouds removed.

Failure to follow these instructions could result in severe injury or death. If

owners manual is missing contact Timbersled for a replacement.

TOWING WARNING

WARNING

NEVER pull or tow any person or object behind this Timbersled. Objects towed

can easily collide with the rear of the track or other objects, resulting in severe

injury or death.

NEVER sit on track tunnel. ALWAYS stay clear of track. Entanglement with track

can cause severe injury or death.

22

Page 25

FEATURES

COMPONENT LOCATIONS

Cowling

q

Track

w

Brake System

e

Drive Chain

r

Shock

t

y

u

i

o

a

FEATURES

Rail

Track Tensioning Block

Ski

Spindle

Ski Skags

TOOLS

Timbersled recommends carrying a few tools to work on the snow bike kit when

in the backcountry. These tools will take the entire snow bike kit apart.

• Wrenches: 8 mm, 10 mm, 13 mm, 14 mm, 15 mm, 16 mm, adjustable wrench.

• Torques: T25, T27, T30, T40

• Hex Keys: 4 mm, and 5 mm.

• Other Tools: flat blade screwdriver, pliers

23

Page 26

24

Page 27

PRE-RIDE INSPECTION

PRE-RIDE INSPECTION

PRE-RIDE CHECKLIST

Inspect all items on the checklist for proper operation or condition before each

use of the snow bike. Procedures are outlined in the referenced sections.

ITEM SEE SECTION

Steering System page 27

Injection Oil Level See Host Bike’s Owners Manual

Ignition Switch See Host Bike’s Owners Manual

Headlight/Taillight/Brakelight See Host Bike’s Owners Manual

Suspension Mounting Bolts page 36

Skags (Wear Bars) page 40

Ski Saddle and Spindle Bolts page 40

Track Alignment/Condition page 38

25

Page 28

PRE-RIDE INSPECTION

PRE-RIDE SUSPENSION INSPECTION

Loose nuts and bolts can reduce your snow bike's reliability and cause needless

repairs and down time. Before beginning any ride, a visual inspection will

uncover potential problems. Check the following items on a weekly basis or

before any long trip.

ITEM SEE SECTION

Check suspension mounting bolts for

tightness.

-

Check rear idler wheel bolt for

tightness.

Check rear idler adjusting bolt

locknuts for tightness.

Check torque arm limiter strap

condition.

Check track tension. page 41

Check ski runner/skag condition. page 40

Check ski spindle bolts for tightness.

page 38

-

-

-

BEFORE STARTING THE ENGINE

Before starting the engine, reference your host bike’s owner’s manual for engine

starting process and safety warnings.

WARNING

Operating the vehicle with worn, damaged, or malfunctioning components

could result in serious injury or death. Never start the engine without checking

all vehicle components to be sure of proper operation.

26

Page 29

PRE-RIDE INSPECTION

READ AND UNDERSTAND YOUR OWNER'S MANUAL

Read your Timbersled owner's manual, as well as your host bike’s owner’s

manual, completely and refer to it often. The manual is your guide to safe and

enjoyable experience.

STEERING SYSTEM

WARNING

Ice and snow build-up may interfere with the steering of your snow bike,

resulting in serious injury or death. Keep the vehicle free of snow and ice.

Before driving, manually turn the ski to the left and right to be sure ice and snow

are not interfering with full left and right steering. If difficulty is encountered,

remove ice and snow build-up that may be obstructing the steering linkage or

front ski and skags.

Ensure fork clamps, spindle and ski bolts, and front axle bolt are torqued

properly.

BRAKES

Always check the following items for proper operation before starting the engine.

BRAKE LEVER TRAVEL

Squeeze the brake lever. It should move no closer to the handgrip than 1/2 inch

(1.3 cm). A smaller distance indicates low brake fluid level or air in the hydraulic

system. Your dealer can assist.

LEVER FEEL

If the brake lever feels “spongy” when squeezed, check the brake fluid level and

condition.

WARNING

Continued use of “spongy” brakes may cause a complete loss of brakes, which

could result in serious injury or death. Always have the brakes serviced at the

To gain 100% braking performance, Timbersled recommends performing 20–

50 stop cycles of the Timbersled Brake System before first ride. Brake cycles

should be performed at a slow controlled speed in a flat, open environment.

Starting the snowbike and engaging it into gear, allow the track to spin 3–5 full

rotations. Apply moderate pressure to the brake until the track is completely

stopped and is no longer spinning. Repeat as necessary.

first sign of sponginess.

NOTICE

27

Page 30

28

Page 31

OPERATION

BREAK-IN PERIOD

SNOW BIKE SYSTEM BREAK-IN

Break-in Function Engine Run

Time

Chain: Drive and Chain Case 3 hours Lubricate

Description

OPERATION

Chain (Drive and Chain Case)

Deflection

Brake Line Connections 3 hours Check for leaks

Track Tension 3 hours Check Tension

Swing Arm Bolt 3 hours Re-Torque

Strut Rod Bolts 3 hours Re-Torque

Front Axle 3 hours Re-Torque

Ski Bolt 3 hours Re-Torque

Drive with extra caution during the break-in period. Perform regular checks on

fluid levels, lines, and all other important areas of the snow bike.

3 hours

Check Tension

TRACK WARM-UP

WARNING

A loose track or flying debris could cause serious injury or death. Stand clear of

the front of the snow bike and the moving track. Never hold the snow bike off

the ground or stand behind it while warming up the track. Do not use excessive

throttle during warm-up or when the track is free-hanging. Use a stable rear

support.

29

Page 32

OPERATION

WARNING

Use of traction products such as studs, ice growsers, etc. will increase the

possibility of track damage and/or failure. This could cause loss of control,

resulting in serious injury or death. Always inspect for track damage before

Follow these steps to ensure proper warm-up of the engine, drive train and

track.

1. Use an appropriate stand to securely support the rear of the snow bike at the

rear bumper. The track should be about 4 inches (10 cm) off the ground.

2. Start the engine and allow it to warm up two to three minutes.

3. Engage the throttle abruptly and allow the track to rotate several revolutions.

It will take longer to warm up the track sufficiently during colder outdoor

4. Release the throttle, apply the brakes, shut off the engine and lower the

snow bike to the ground.

5. Grasp the ski by the front loop and move it from side to side to loosen snow

and ice.

operating the snow bike.

TIP

temperatures.

30

Page 33

OPERATION

FUEL STORAGE

WARNING

Gasoline is highly flammable and explosive under certain conditions.

• Always exercise extreme caution whenever handling gasoline.

• Always follow the safety procedures outlined in your host bike’s owner’s

manual.

• Always refuel outdoors or in a well-ventilated area.

• Always turn off the engine before refueling.

• Do not overfill the tank. Do not fill the tank neck.

• Do not smoke or allow open flames or sparks in or near the area where

refueling is performed or where gasoline is stored.

• If gasoline spills on your skin or clothing, immediately wash it off with soap

and water and change clothing.

• Never start the engine or let it run in an enclosed area. Engine exhaust

fumes are poisonous and can cause loss of consciousness or death in a

short time.

FUEL RECOMMENDATION

See host bike owner’s manual for fuel recommendation.

NOTICE

Operating with obstructed fuel systems will result in serious engine damage.

Perform maintenance as recommended. Prolonged exposure to petroleum

based products may damage paint. Always protect painted surfaces when

handling fuel.

DAILY STORAGE

At the end of each ride, park the vehicle on a level surface and support it at the

rear with an appropriate track stand. The track should be suspended

approximately 4 inches (10 cm) off the ground.

Remove the key (if applicable) and cover the vehicle.

31

Page 34

32

Page 35

MAINTENANCE

MAINTENANCE

HOST BIKE MAINTENANCE

For host bike maintenance procedures and recommendations, refer to your host

bike’s owner’s manual. The maintenance information found in the manual only

applies to the Timbersled Snow Bike system.

TIMBERSLED RECOMMENDED MAINTENANCE

PROGRAM

Always follow recommended regular maintenance and perform service checks

as outlined in this manual. Record maintenance and service in the Maintenance

Log.

The recommended maintenance schedule on your vehicle calls for service and

maintenance inspections at 150 miles (240 km), 500 miles (800 km) and 1000

miles (1600 km). These inspections should be performed by a qualified service

technician. For continued optimum performance and component life, continue

maintenance checks at 1000 mile (1600 km) intervals.

All necessary replacement parts and labor incurred, with the exception of

authorized warranty repairs, become the responsibility of the registered owner.

If, during the course of the warranty period, part failures occur as a result of

owner neglect in performing recommended regular maintenance, the cost of

repairs are the responsibility of the owner.

Personal safety is critical when attempting to service or make adjustments to

your vehicle. If you're not familiar with safe service or adjustment procedures

and the use of tools, or if you don't feel comfortable performing these tasks

yourself, your authorized Timbersled dealer can provide any needed service.

NOTICE

Hot components can cause damage to plastic. Always make sure the exhaust

system and engine have cooled before tipping the vehicle on its side for

service or inspection.

NOTE

Timbersled recommends changing the oil in your host bike more frequently

that stated in the host bike’s owners manual.

33

Page 36

MAINTENANCE

PERIODIC MAINTENANCE INTERVAL TABLE

The following chart is a guide based on average riding conditions. You may need

to increase frequency based on riding conditions. When inspection reveals the

need for replacement parts, always use genuine Timbersled parts, available

from your Timbersled dealer.

I - INSPECT (CLEAN, ADJUST, TIGHTEN, LUBRICATE, REPLACE IF NECESSARY)

C - CLEAN, R - REPLACE, L - LUBRICATE

FREQUENCY

ITEM

150 MI.

(240 KM)

BRAKES

500 MI.

(800 KM)

1000 MI.

(1600 KM)

2000 MI.

(3200 KM)

PRE-

SEASON

Hose Routing

Hose Condition

Fluid Leaks

Brake Pads

Brake Disc

Brake System

Brake Fluid

Air Box/Air Intake

Suspension Mounting

Bolts

Steering Fasteners

Rear Suspension

Fasteners

Ski Saddle/Spindle Bolts

Drive Chain Tensioner

I I I I I

I I I I I

I I I I I

I I I I I

I I I I I

I I

I I

FUEL MANAGEMENT

I I I I I

CHASSIS

I I I I I

I I I I I

I I I I I

I I I I I

I I I I I

Rear Wheel Idler Bolt

34

I I I I I

Page 37

MAINTENANCE

I - INSPECT (CLEAN, ADJUST, TIGHTEN, LUBRICATE, REPLACE IF NECESSARY)

C - CLEAN, R - REPLACE, L - LUBRICATE

FREQUENCY

ITEM

150 MI.

(240 KM)

500 MI.

(800 KM)

1000 MI.

(1600 KM)

2000 MI.

(3200 KM)

PRE-

SEASON

Idler Bolt Jam Nut

Track Alignment

Track Tension

Fork Clamp Bolts

Swing Arm Bolts

Strut Rod Bolt

Front Axle Bolt

I I I I

I I I I I

I I I I I

I I I I

I I I

I I I I

I I I I

LUBRICATION

CHAIN LUBRICATION

Lubricate the chains every 8 to 10 hours of operation. We have found that the

use of Maxima Chain Wax for O- ring chains works best. It is recommended to

lift the track off the ground. Start the bike and put it into first gear and let the

clutch out allowing the drive system to spin. Slowly spray lube directly onto the

chain rollers and O-rings, soaking the chain. This will allow good penetration into

the moving chain parts.

EXHAUST SYSTEM

For exhaust system inspection procedures, see your host bike’s owner’s

manual.

CAUTION

Hot exhaust system parts can cause burns. Allow adequate time for the

exhaust system to cool. Never perform this procedure with the engine running.

35

Page 38

MAINTENANCE

SUSPENSION

SUSPENSION MAINTENANCE

The following procedure should be performed regularly to properly maintain the

suspension of your snow bike.

1. Adjust the track only if it starts to skip on the drivers. This sometimes

happens with new tracks after they have been run. Proper track tension

should be 1/2 to 3/4” free hang from the top of track clip to the bottom of the

track at its lowest hanging point. Adjust equally on both sides for the track to

run true.

BRAKES

HYDRAULIC BRAKE INSPECTION

Inspect the brake lever reserve before each use of the snow bike. See page 27.

Brake pads must be replaced when the brake pad material becomes thinner

than 1/16 inch (1.5 mm). A kit is available for replacing brake pads. Your

Timbersled dealer can assist.

WARNING

Brake failure during operation can result in serious injury or death. Properly

functioning brakes are vital to your safety. Be sure the brake pads do not drag

on the disc and that brake lever travel is not excessive. Always replace brake

pads when the brake pad material becomes thinner than 1/16 inch (1.5 mm).

36

Page 39

MAINTENANCE

BRAKE COMPONENTS

Brake Caliper

q

Brake Disc

w

Brake Line

e

EXCESSIVE LEVER TRAVEL

Hydraulic brakes are self-adjusting, but if excessive brake pad clearance

develops, bring the snow bike to an authorized Timbersled dealer for inspection

and adjustment.

37

Page 40

MAINTENANCE

BRAKE FLUID

The brake fluid level can be seen through a plastic sight glass in the brake

reservoir. If the fluid is sufficient, the sight glass will be black. If the sight glass is

any color other than black, add brake fluid.

Replace brake fluid at least every two years with DOT 4 high temperature brake

fluid, or an equivalent product.

WARNING

After opening a bottle of brake fluid, always discard any unused portion. Never

store or use a partial bottle. Brake fluid is hygroscopic, meaning it rapidly

absorbs moisture from the air. The moisture causes the boiling temperature of

the brake fluid to drop, which can lead to early brake fade and the possibility of

Keep the master cylinder cover free of dirt and debris. The vent slits allow for

diaphragm movement, and if they become plugged, movement of brake fluid

below the diaphragm may be restricted, altering brake function.

Brake fluid will damage labels, paint and some plastics. Always wipe up spills

accident or serious injury.

WARNING

NOTICE

immediately.

TRACK INSPECTION

1. Using a hoist, safely lift and support the rear of the snow bike off the ground.

2. Rotate the track by hand to check for damage.

3. Carefully examine the track along the entire length of each rod. Bend the

track to check for breakage.

4. Replace the track if any rod damage is found.

WARNING

Broken track rods can cause a rotating track to come off the snow bike, which

could cause serious injury or death. Never operate with a damaged track.

38

Never rotate a damaged track under power.

Page 41

MAINTENANCE

SKI MAINTENANCE

Timbersled recommends periodically inspecting your ski for damage.

• Check the ski bolt to make sure it is tight. Torque to specification.

TORQUE

50 Nm (37 ft. lbs)

WARNING

Failure to torque fasteners as directed will adversely affect the steering system

• Inspect for cuts or peeled up plastic that will cause the ski to handle poorly.

• Inspect for bent, broken, or worn-out ski skags.

• Inspect the ski saddle for bends that may make the ski crooked.

• Inspect the ski rubber to make sure it is not smashed or worn out.

Timbersled highly recommended that you DO NOT tie your bike against the

front of the ski. This can permanently bend the plastic ski causing your bike to

and may lead to severe injury or death.

NOTE

handle poorly.

39

Page 42

MAINTENANCE

SKI SKAGS

WARNING

Worn skis and/or skags will adversely affect handling. Loss of vehicle control

may result, causing serious injury or death. See your dealer's studding chart

Check skags before each use of the snow bike to ensure positive steering

characteristics. Skags must be replaced when worn to half their original

diameter.

Carbide skags must be replaced if any abnormal wear or chipping is found.

SKAG REPLACEMENT

1. Raise and support the front of the snow bike so the ski is approximately 6

inches (15.2 cm) from the ground.

2. Remove the attaching nuts and pry the skag downward.

3. Remove the front end of the skag.

4. Remove the rear end of the skag.

5. Reverse the steps to install a skag.

for recommended skags.

TIP

SPINDLE MAINTENANCE

The spindle does not require any maintenance. It is designed to bend if it comes

in contact with a rock or stump during operation. Timbersled recommends

thoroughly inspecting the assembly for bends or cracks before you ride.

FALL TUNE-UP

For maximum performance, your Timbersled dealer can perform a fall service

tune-up. Their experienced and trained service technicians will keep your snow

bike in peak operating condition.

40

Page 43

MAINTENANCE

EXTENDED STORAGE

Off-season or extended storage of your snow bike requires preventive measures

to aid against deterioration and to prolong the useful life of many components.

CLEANING AND PRESERVATION

Proper storage starts with cleaning, washing, and waxing the cowling, side

panels, chassis, and plastic parts. Wipe down remaining surfaces with a damp

cloth. Clean and touch up with paint any rusted or previously painted surfaces.

Be sure that corrosive salt and acids are removed from surfaces before

beginning preservation with waxes and rust inhibitors (grease, oil or paint).

The snow bike should be stored in a dry garage or shed, out of direct sunlight,

and covered with a fabric snow bike cover. Plastic tarp may cause condensation

to form and damage snow bike components.

TRACK AND SUSPENSION

Moderate track tension should be maintained during summer storage. The snow

bike should be supported off the ground to allow the track to hang freely.

TRANSPORTING THE SNOW BIKE

Whenever the snow bike is transported:

1. Be sure the fuel cap and oil cap are installed correctly.

2. Tie the snow bike to the transporting unit securely using suitable straps.

3. Remove the ignition key (if equipped) to prevent loss.

NOTE

Use of a cover is recommended when transporting your vehicle on an open

trailer.

41

Page 44

42

Page 45

INSTALLATION

INSTALLATION

APPLICATION

The Timbersled Model No. J19RTAXXXA is designed specifically for the bike

models listed below:

• Yamaha

• Honda

• Kawasaki

BEFORE YOU BEGIN

Read these instructions and check to be sure all parts and tools are accounted

for. Please retain these installation instructions for future reference and parts

ordering information.

KIT CONTENTS

The ST 93 Ripper Install Kit includes: Qty.- 1, Install kit for your specific model.

ST 93 Ripper sold separately.

®

— TTR110, 2008 to current

®

— CRF110F, 2013 to current

®

— KLX110, 2003 to current; KLX110L, 2010 to current

REF QTY PART DESCRIPTION PART NUMBER

1* 1 Honda Install Kit 2882729

2* 1 Yamaha Install Kit 2882730

43

Page 46

INSTALLATION

REF QTY PART DESCRIPTION PART NUMBER

3* 1 Kawasaki Install Kit 2882731

4 1 ST 93 Ripper Install Kit

instructions

Items marked (*) are specific to your make and model of bike. Only items

specific to your make and model of bike are included in the Install Kit. See Install

Kit drawings and parts lists for items specific to each Install Kit.

9927988

INSTALL KIT: 2882729

This install kit is specific to the Honda models listed in the application section:

REF QTY PART DESCRIPTION PART NUMBER

1 1 RDCR, Ripper - Honda, LH 5141218

2 1 RDCR, Ripper - Honda, RH 5141219

3 1 Drive Sprocket - Honda 1333882

4 1 Bearing-Ball 3514549

5 1 Asm, Backer Plate - Honda 1333883

6 1 Chain, 420 - Ripper 3222273

44

Page 47

INSTALLATION

REF QTY PART DESCRIPTION PART NUMBER

7 3 Washer-Split 7557064

8 1 Screw - M6X65 7520727

9 2 Screw - M6X75 7520729

10 5

11 2 Screw - M8X75 7519948

12 1 Plate, Fork Tube, Clamp 5264330

13 2 Clamp, Fork Tube, Top 5454078

14 1 Reducer-Spindle - Honda, RH 5141389

15 1 Reducer-Spindle - Honda, LH 5141390

16 2 Nut, Locking - M8, 7547332

17 1 Screw - 7/16X6.5 7520726

18 1 Nut, Locking - 7/16 7542525

19 1 Screw - M10X50 7518971

20 1 Nut, Locking - M10 7547423

21 1 Strut, Fixed - Ripper 5141221

Cable Tie, Nylon 7081504

45

Page 48

INSTALLATION

INSTALL KIT: 2882730

This install kit is specific to the Yamaha models listed in the application section:

REF QTY PART DESCRIPTION PART NUMBER

1 1 Spacer, Ripper - Yamaha 5141220

2 1 Drive Sprocket - Yamaha 1333888

3 1 Chain, 420 - Ripper 3222273

4 1 Bearing-Ball 3514549

5 1 Asm, Backer Plate - Yamaha 1333889

6 1 Washer - Split 7557064

7 2 Screw - M6X65 7520727

8 1 Screw - M6X75 7520729

9 5

10 2 Screw - M8X75 7519948

11 1 Plate-Fork Tube Clamp 5264330

12 2 Clamp-Fork Tube Top 5454078

46

Cable Tie, Nylon 7081504

Page 49

INSTALLATION

REF QTY PART DESCRIPTION PART NUMBER

13 1 Reducer, Spindle - Yamaha, LH 5141394

14 1 Reducer, Spindle - Yamaha, RH 5141393

15 2 Nut, Locking - M8 7547332

16 1 Screw - 7/16X6.5 7520726

17 1 Nu t- 7/16 Nylon 7542525

18 1 Screw - M10X50 7518971

19 1 Nut, Locking - M10 7547423

20 1 Strut, Fixed - Ripper 260mm 5141221

47

Page 50

INSTALLATION

INSTALL KIT: 2882731

This install kit is specific to the Kawasaki models listed in the application section:

REF QTY PART DESCRIPTION PART NUMBER

1 1 Chain, 420 - Ripper 3222273

2 1 Drive Sprocket, - Kawasaki 1333885

3 1 Bearing-Ball 3514549

4 1 Asm, Backer Plate - Kawasaki 1333886

5 1 Washer, Split 7557064

6 2 Screw - M6X55 7520728

7 1 Screw - M6X65 7520727

8 5

9 2 Screw - M8X75 7519948

10 1 Plate, Fork Tube Clamp 5264330

11 2 Clamp, Fork Tube Top 5454078

12 2 Reducer, Spindle - Kawasaki 5141392

48

Cable Tie, Nylon 7081504

Page 51

INSTALLATION

REF QTY PART DESCRIPTION PART NUMBER

13 2 Nut, Locking - M8 7547332

14 1 Screw - 7/16X6.5 7520726

15 1 Nut, Locking - 7/16 7542525

16 1 Screw - M10X50 7518971

17 1 Nut, Locking - M10 7547423

18 1 Strut, Fixed - Ripper 5141388

TOOLS REQUIRED

• Safety Glasses

• Screwdriver, Standard

• Pliers, Slip Joint

• Pliers, Side Cutting

• Hex Key Set, Metric

• Socket Set, Metric

IMPORTANT

Your is exclusively designed for your vehicle. Please read the installation

instructions thoroughly before beginning. Installation is easier if the vehicle is

clean and free of debris. For your safety, and to ensure a satisfactory

installation, perform all installation steps correctly in the sequence shown.

ASSEMBLY TIME

2–4 Hours

49

Page 52

INSTALLATION

INSTALLATION INSTRUCTIONS

MOTORCYCLE DISASSEMBLY:

NOTE

The disassembly process listed is universal for all bikes using the ST 93 Ripper

kit. This process may vary slightly between makes and models. Refer to your

host bike’s owner’s manual for specific references and disassembly

1. Place bike on a stand or suitable support where both wheels are off the

ground. Secure properly to prevent bike from tipping when wheels are

removed.(An adjustable stand is helpful for reassembly.)

2. Remove the seat and side panels.

3. Remove chain by disconnecting master link.

4. Remove the rear brake lever from frame and let hang (this includes the

spring).

5. Remove upper rear shock bolt or pin.

Keep upper shock bolt for later use as this item will be reinstalled.

procedures.

NOTE

6. Remove the rear swing arm bolt (this will drop the entire swing arm assembly

off the bike) and remove the shock, tire, brake, and swing arm assembly from

the bike as a complete unit.

NOTE

It is recommended to cable tie all bushings, spacers, etc. to their

corresponding parts at all pivoting points to prevent losing any parts during

7. Remove the front brake lever and cable retainer bolts from the bikes front

forks. (On some models use the provided cable tie to secure start button).

8. Loosen the front axle bolt and remove the front wheel.

storage.

NOTE

Keep front axle bolt for later use, this item will be reinstalled.

9. Remove the front drive sprocket and sprocket cover.

50

Page 53

INSTALLATION

10. Check to ensure all previous steps are complete. You are now ready to start

the assembly portion of the process.

REAR RIPPER ASSEMBLY

Left Side Right side

Spacer

Spec.

Honda 0.80 mm

Kawasaki N/A N/A N/A N/A

Yamaha N/A N/A 15 mm

*Left and Right as positioned sitting on the bike

1. Locate rear track assembly

location on the bike. Some fit kits will require spacers

of the frame, located between the Ripper frame mount brackets and the

bike’s swing-arm bolt bracket location. See table at the beginning of this

section for specific bike model spacers.

q

Part # Spacer

5141218

Spec.

6.87 mm

Part #

5141219

5141220

and position it up to the rear swing arm bolt

on one or either side

t

NOTE

Kawasaki KLX models do not require any spacers. Honda CRF models require

left and right swing arm bolt spacers/reducers. Yamaha TTR models require a

single spacer positioned on the right side of the bike.

51

Page 54

INSTALLATION

2. Slide provided 7/16” x 6-1/2” swing arm bolt r in from the left hand side of

the bike and tighten lock nut

to listed torque specification.

y

TORQUE

54 Nm (40 Ft. Lbs)

3. Bolt the lower portion of the strut rod

provided M 10 x 40mm bolt

strut rod has been bolted in place.

4. See note below before continuing.

. DO NOT TIGHTEN until after upper portion of

w

to the kit assembly q using the

e

NOTE

KAWASAKI MODELS ONLY skip Step 4 and complete Steps 5 and 6. For

Bolt upper portion of the strut rod

the bike’s upper shock mount bolt or pin. For bikes using a bolt, torque to the

bike manufacturer’s specifications. Once you have the upper portion of the

strut rod in place, torque the lower portion of the strut rod to the specification

listed below.

Honda and Yamaha models continue with Step 4.

into the bike’s upper shock bracket using

e

TORQUE

60 Nm (44 Ft. Lbs)

For Honda and Yamaha models continue to the Brake Line Assembly and

Routing section.

52

Page 55

INSTALLATION

5. See note below before continuing.

NOTE

This step includes the upper strut rod installation and brake line routing for

Kawasaki models only.

Once you’ve completed Step 3 and before you fasten the upper strut rod bolt,

move the strut rod

and master cylinder over top of the rear right sub-frame tubing B of the bike

and under the gas tank

the strut rod

e

up to provide enough clearance, feed the brake line

e

as seen in the image below. Now move the top of

down back into place lining up the mounting holes.

C

A

NOTE

Some Kawasaki models can use secondary bolt hole in the strut rod for lower

Bolt in place using the original upper strut rod bolt or pin and torque to the

bike manufacturer’s specifications. Once you have the upper portion of the

strut rod in place, torque the lower portion of the strut rod to the specification

listed below.

ride height.

TORQUE

60 Nm (44 Ft. Lbs)

53

Page 56

INSTALLATION

6. Keeping all of the slack out of the brake line, fasten the brake line to the top

and the bottom of the strut rod with provided cable ties in the locations

indicated in the image below.

WARNING

When routing brake lines it is critical that you keep all brake lines away from

any surfaces, such as engine or exhaust, that can become hot while operating

the vehicle. Failure to comply will adversely affect the vehicles brake system

and may lead to severe injury or death.

F

54

Page 57

INSTALLATION

7. Run the brake line A forward under the bottom of the gas tank along the

main frame of the bike towards the bike’s front neck-tube. Make sure there is

a minimum of one inch of clearance between the brake line and the lower

head set turning stop posts

Place another cable tie

throttle cable keeper bracket

to the master cylinder mounted on the right handle bar. Adjust the pitch of the

brake lever, ensuring it is easily reached and easy to pull. Tighten the brake

lever perch hand tight being careful to not strip the mounting perch threads. If

needed, you can loop any remaining slack in the brake line in between the

right fork tube upper and the neck-tube of the bike frame as seen in the photo

below. (Honda model shown for reference)

to prevent the brake line from being pinched.

B

around the brake line fastening it to the bike’s

F

. The remaining brake line can free hang up

C

WARNING

When routing brake lines, make sure there is a minimum of one inch of

clearance between the brake line

to prevent the brake line from being pinched. Failure to comply will

B

adversely affect the vehicles brake system and may lead to severe injury or

For Kawasaki models, once you have completed Step 7 continue to the Drive

Chain and Sprocket Assembly section.

and the lower head set turning stop posts

A

death.

55

Page 58

INSTALLATION

BRAKE LINE ASSEMBLY AND ROUTING

WARNING

When routing brake lines it is critical that you keep all brake lines away from

any surfaces, such as engine or exhaust, that can become hot while operating

the vehicle. Failure to comply will adversely affect the vehicles brake system

• Yamaha Models

Refer to images of Honda model for routing references.

– For the Yamaha TTR models, run the brake line forward either on top of the

strut rod or located parallel against the left hand side of the strut rod. Secure

the brake line to the strut rod with a cable tie located at the top of the strut rod

and one at the bottom of the strut rod in a similar fashion to the photo for the

Honda model. From here feed the brake line and master cylinder to the right

side of the bike feeding the brake line between the bike’s upper sub-frame

column and the wiring harness brackets on the frame. This will help hold the

brake line against the bikes frame and as far away from the exhaust system

as possible. From here route the brake line forward towards the front of the

bike underneath the bikes fuel tank. Place another cable tie near the front of

the bike securing the brake line to the bikes lower horizontal frame tube.

and may lead to severe injury or death.

NOTE

56

Page 59

INSTALLATION

WARNING

When routing brake lines, make sure there is a minimum of one inch of

clearance between the brake line

to prevent the brake line from being pinched. Failure to comply will

B

adversely affect the vehicles brake system and may lead to severe injury or

and the lower head set turning stop posts

A

death.

57

Page 60

INSTALLATION

• Honda Models

– Remove the two rear gas tank bolts

bike. Lift up on the rear of the gas tank giving yourself enough room to feed

the brake line and master cylinder over top of the rear right sub-frame tubing

of the bike and under the gas tank as indicated in the image below

the brake line forward under the bottom of the gas tank along the main frame

of the bike. Keeping all of the slack out of the brake line fasten the brake line

to the top and the bottom of the strut rod with cable ties as shown

Reinstall the two rear gas tank bolts

bike manufacturers specification. Next, torque the front tank bolt to

manufacturers specifications. See image below for brake line routing

reference

R

:

and loosen the front tank bolt on the

A

R

.

previously removed and torque to

A

F

Feed

– Near the front of the bike where the brake line is approaching the front neck

tube of the bike, cable tie the brake line to the front gas tank frame mount

and another cable tie to the bikes frame-mounted wire harness on the bike’s

neck tube. See photo below for cable tie locations

line can free hang up to the master cylinder mounted on the right handle bar.

58

. The remaining brake

F

Page 61

INSTALLATION

Adjust the pitch of the brake lever, ensuring it is easily reached and easy to

pull. Tighten the brake lever perch hand tight being careful to not strip the

mounting perch threads. See image below:

WARNING

When routing brake lines, make sure there is a minimum of one inch of

clearance between the brake line

to prevent the brake line from being pinched. Failure to comply will

B

adversely affect the vehicles brake system and may lead to severe injury or

and the lower head set turning stop posts

A

death.

59

Page 62

INSTALLATION

DRIVE CHAIN AND SPROCKET ASSEMBLY

1. Install provided sprocket w and bearing carrier housing e onto transmission

output shaft. Make sure to use Blue Loctite

head screws

before installing sprocket.

. HONDA ONLY: Place provided spacer q onto output shaft

y

NOTE

Reference you host bikes owner’s manual or manufacturers specifications for

proper torque specifications.

®

243 on the provided 3 button

2. Tighten sprocket backer plate e to the engine case and torque to bike

manufacturers specifications before chain

set.

3. Route chain

4. Complete the assembly of the chain with the master link provided. Be sure to

install the master link with the opening of the link facing rearward in relation

to the chain direction.

5. Set the proper chain tension by loosening chain slider nut and bolt. Slide the

chain slider up or down until 1/2”-5/8” of vertical deflection is met in the upper

chord of the drive chain. Torque chain slider nut to specification below when

proper tension is achieved.

60

around both sprockets.

u

is installed and chain tension is

u

Page 63

INSTALLATION

TORQUE

25 Nm (18 Ft. Lbs)

NOTE

Chain will stretch within the first 5hrs. You will want to check for proper chain

tension. Chain slider is not intended to roll and can be rotated as needed to

keep proper chain tension on usable surface of slider.

FRONT SKI AND SPINDLE ASSEMBLY

Left Side Right side

RDCR

Spec.

Honda 18.03 mm

Kawasaki 17.35 mm

Yamaha 14.91 mm

*Left and Right as positioned sitting on the bike

1. Locate the front ski

, spindle e, ski rubber w, and provided hardware.

q

Part # RDCR

5141390

5141392

5141394

Spec.

25.4 mm

17.35 mm

20.49 mm

Part #

5141389

5141392

5141393

61

Page 64

INSTALLATION

2. Place the Ski Rubber w on top of the center of the ski q with the indicated

“Front” of the Ski Rubber towards the front tip of the Ski.

3. Place the lower portion of the Spindle e on top of the Ski Rubber w in the

ski saddle to where the Fork Clamp support bracket would be positioned

behind the front forks of the bike. Line up the bottom bolt hole and insert the

M 10 x 155 mm bolt

r

.

Apply nut t to bolt and torque to specification listed below.

TORQUE

45 Nm (33 Ft. Lbs)

62

Page 65

INSTALLATION

WARNING

Failure to torque fasteners as directed will adversely affect the steering system

and may lead to severe injury or death.

4. Insert front spindle reducers

manufacturer. Your individual bike model fit kit will come with the appropriate

spindle reducers/spacers, see the table at beginning of this section for

spindle reducer placement for your specific bike model.

5. Use existing front axle bolt B to attach the front spindle e to the forks A.

into spindle e. These will change per bike

y

For now, just snug the front axle bolt, do not tighten until after step 6.

63

Page 66

INSTALLATION

6. Using the composite fork clamp a (fork clamp halves are identical), place

one half of the fork clamp in front of the fork tubes

portions sitting around the face of the lower fork tube. Take the other half and

mate it around the back side of the fork tubes between the fork tubes and the

spindle backer plate. Take the Fork Clamp washer plate

the face of the front fork clamp lining up the bolt holes of the washer plate

with the clamp.

Using Qty.–2, M8 x 75mm bolts i supplied with your kit, insert bolt through

the washer plate, both halves of the fork clamp, and through the spindle

backer plate. Apply the supplied M8 locking nuts

specification listed below.

with the concave

A

and place it over

s

and torque to

o

TORQUE

20 Nm (15 Ft. Lbs)

7. Tighten front axle bolt

B

.

IMPORTANT

Refer to manufacturers specifications for proper torque setting.

8. Check to ensure all previous steps are complete then move on to the rear

cowling assembly section.

64

Page 67

INSTALLATION

REAR COWLING ASSEMBLY

1. Install the rear cowling q with the provided, Qty.– 4, nylon rivet fasteners.w.

2. Slide cowling q forward under bikes rear fender making sure the front left

chain guard portion of the cowling is positioned behind the Drive Sprocket

Plate.

65

Page 68

INSTALLATION

3. Start with the front left side mounting hole A. Insert nylon rivet fastener w.

Repeat process for the front right side mounting hole

fastener securely.

NOTE

The rear cowling is pliable, the easiest process for lining up the rear fastener

mounting holes of the skid frame with the cowling holes is to pull out on the

bottom most part of the cowling in the middle of the molding. This will pull the

rear hole in the cowling forward allowing you to line up the holes to insert the

nylon rivet fastener.

, inserting nylon rivet

B

4. Repeat this process for both left

5. Check to ensure all tools are accounted for and all steps have been

completed in the proper order.

then right D rear mounting holes.

C

66

Page 69

SPECIFICATIONS

SPECIFICATIONS

ST 93 RIPPER

DIMENSIONS

Estimated Dry Weight - Front (lbs./kg.) 13 lbs (6 kg)

Estimated Dry Weight - Rear (lbs./kg.) 55 lbs (25 kg)

Overall Length - pivot to bumper (in./cm.) 97 in (246 cm)

ENGINE AND DRIVETRAIN

Disc Brake Type Hydraulic Disk

Drive Shaft Sprocket 26 tooth - splined

Engine Sprocket 13 tooth - splined

Drive Chain 420

Chain Slider Round Composite Slider

SUSPENSION

Rear Suspension 8 inches - Ripper Suspension

Front Track Shock RydeFX

Rear Travel - Fixed Fit Kit (in./cm.) 43.8 in (111 cm)

Ski Type Ripper Balance Ski

Skag Type Center Ripper Balance Tri Skagg

Skag Type Outer Ripper Balance Tri Skagg