Polaris Sportsman 400, Sportsman 500, Sportsman 500 H.O., SPORTSMAN 500 DUSE Service Manual

Page 1

CHAPTER INDEX

CHAPTER 1 GENERAL

CHAPTER 2 MAINTENANCE

CHAPTER 3 ENGINE

CHAPTER 4 FUEL SYSTEM/CARBURETION

CHAPTER 5 BODY / SUSPENSION

CHAPTER 6 PVT SYSTEM

CHAPTER 7 FINAL DRIVE

CHAPTER 8 TRANSMISSION

CHAPTER 9 BRAKES

CHAPTER 10 ELECTRICAL

Page 2

CHAPTER 1

GENERAL INFORMA

Model Identification 1.1...........................

Serial Number Location 1.1.......................

Replacement Keys 1.2............................

Model Color Identification 1.3-1.7......................

Machine Dimensions 1.8-1.10..........................

Specifications - Sportsman 400 1.11-1.12.................

Specifications - Sportsman 500 DUSE 1.13-1.14..........

Specifications - Sportsman 500 H.O. 1.15-1.16............

Publication Numbers 1.17..........................

Paint Codes 1.17.................................

Standard Torque Specifications 1.18................

Torque Conversion Table 1.19-1.20......................

Decimal Equivalent Chart 1.21......................

Conversion Table 1.22.............................

Tap Drill Charts 1.23...............................

Glossary of Terms 1.24-1.25............................

TION

1

Page 3

GENERAL INFORMATION

MODEL IDENTIFICATION

The machine model number must be used with any correspondence regarding warranty or service.

Machine Model Number Identification

A01CH50AA

Emissions &

Year Designation

Basic Chassis

Designation Engine Designation

Model Option

ENGINE DESIGNATION NUMBERS

42 EH42PLE05 Single, L/C, SOHC 4 Stroke, Electric Start............

50 EH50PLE09/13 Single, L/C, SOHC 4 Stroke, Electric Start..........

VIN IDENTIFICATION

World Mfg. ID

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

4XACH

Body Style

Vehicle Descriptor

50A*1P0 00000

Engine

Powertrain

Emissions

Check Digit

Model

Year

Plant No.

Vehicle Identifier

Individual Serial No.

* This could be either

a number or a letter

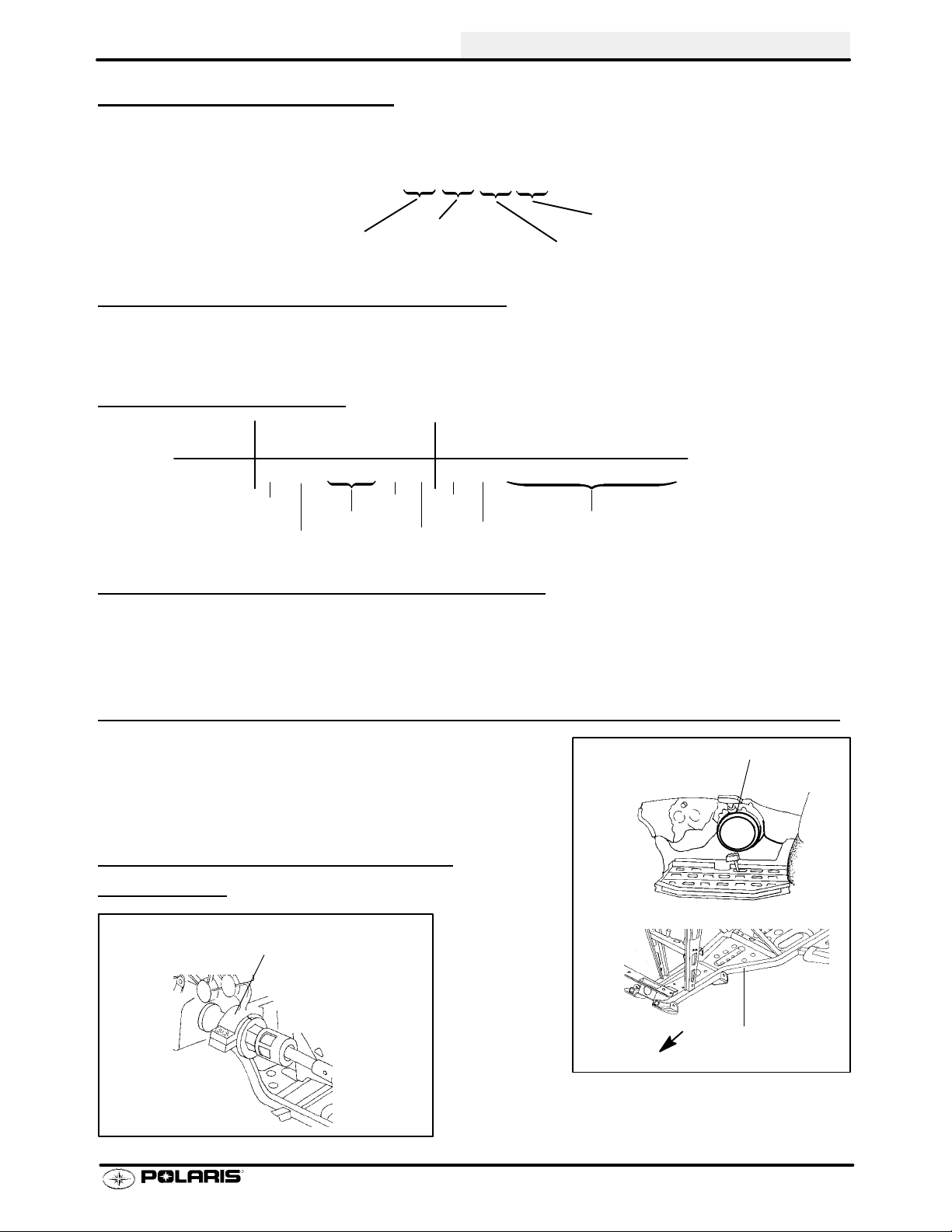

ENGINE SERIAL NUMBER LOCATION

Whenever corresponding about an engine, be sure to refer to the engine model number and serial number. This

information can be found on the sticker applied to the recoil housing on the right side of engine.(A) Anadditional

number is stamped on the center top of crankcase beneath the cylinder coolant elbow.

MACHINE MODEL NUMBER AND SERIAL NUMBER LOCATION

Themachinemodelnumber andserialnumberare

important for vehicle identification. The machine

serial number is stamped on the lower left side of

the frame tube.(B)

A

TRANSMISSION I.D. NUMBER

LOCA

The transmission I.D. number is located

on top of the transmission snorkel, right

side of machine.

TION

Front

B

1.1

Page 4

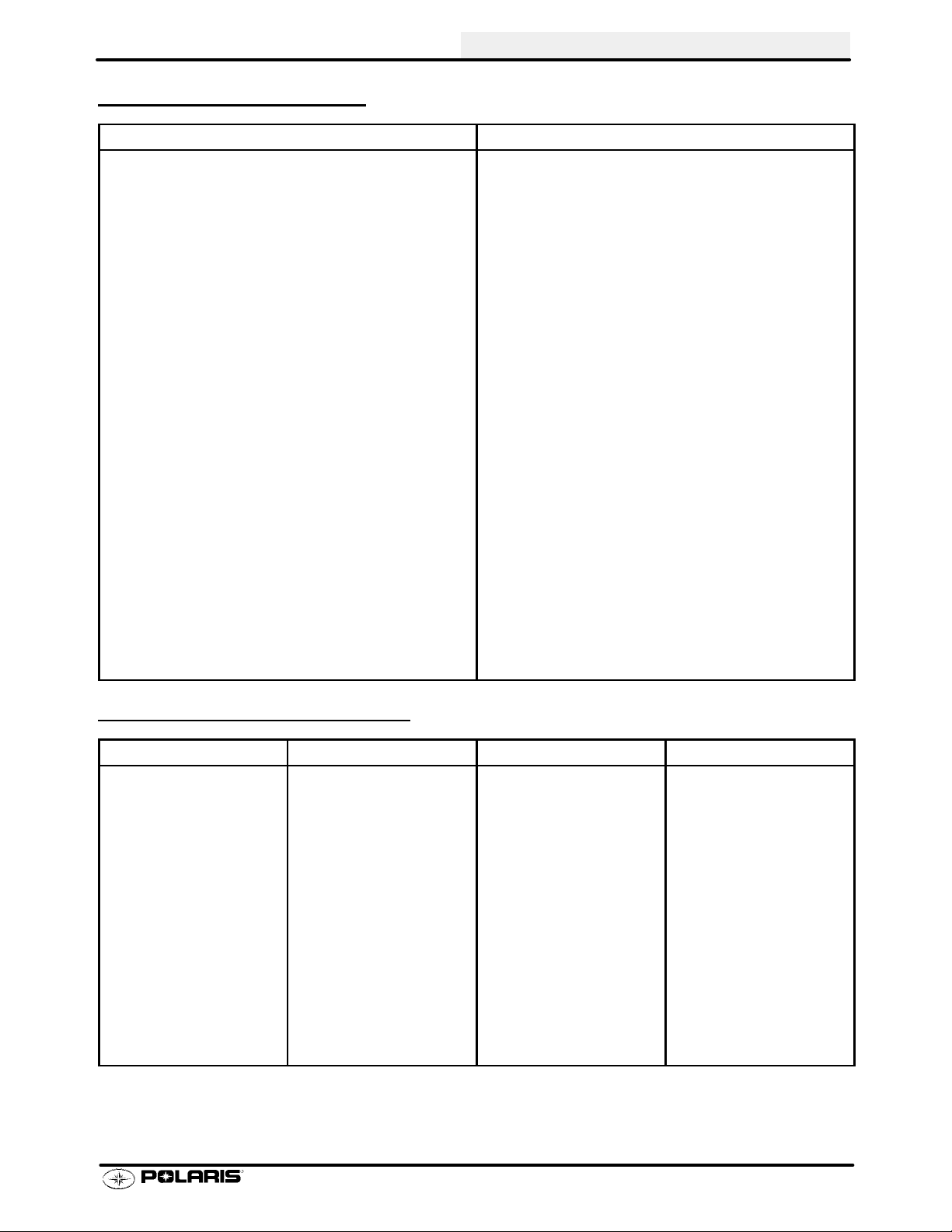

GENERAL INFORMATION

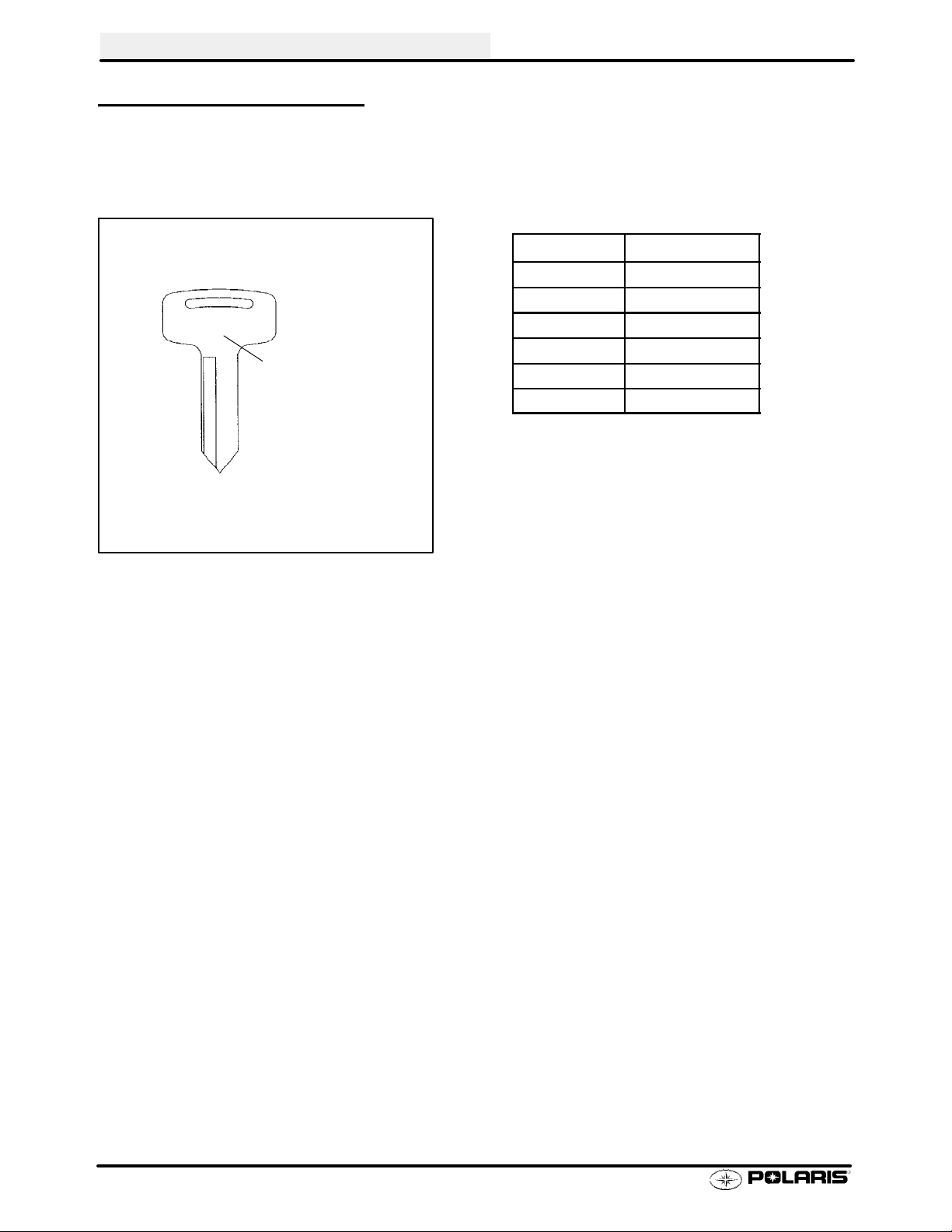

REPLACEMENT KEYS

Replacement keys can be made from the original

key. To identify which series the key is, take the

first two digits on the original key and refer to the

chart to the right for the proper part number.

31XX

Key Series

Number

Series # Part Number

31 41 10141

32 41 10148

67 4010278

68 4010278

27 4010321

28 4010321

1.2

Page 5

MODEL COLOR IDENTIFICA TION

GENERAL INFORMATION

SPORTSMAN 400 -

A01CH42AA

SPORTSMAN 400 - A01CH42AB

1.3

Page 6

GENERAL INFORMATION

MODEL COLOR IDENTIFICA TION

SPORTSMAN 400 - A01CH42AC

1.4

Page 7

MODEL COLOR IDENTIFICA TION

GENERAL INFORMATION

SPORTSMAN 500 H.O. -

A01CH50AA

SPORTSMAN 500 H.O. - A01CH50AB

1.5

Page 8

GENERAL INFORMATION

MODEL COLOR IDENTIFICA TION

SPORTSMAN 500 DUSE - A01CH50AD

SPORTSMAN 500 H.O. -

A01CH50AE

1.6

Page 9

MODEL COLOR IDENTIFICA TION

SPORTSMAN 500 H.O. DUSE - A01CH50AF

GENERAL INFORMATION

SPORTSMAN 500 H.O. RSE - A01CH50AJ

1.7

Page 10

GENERAL INFORMATION

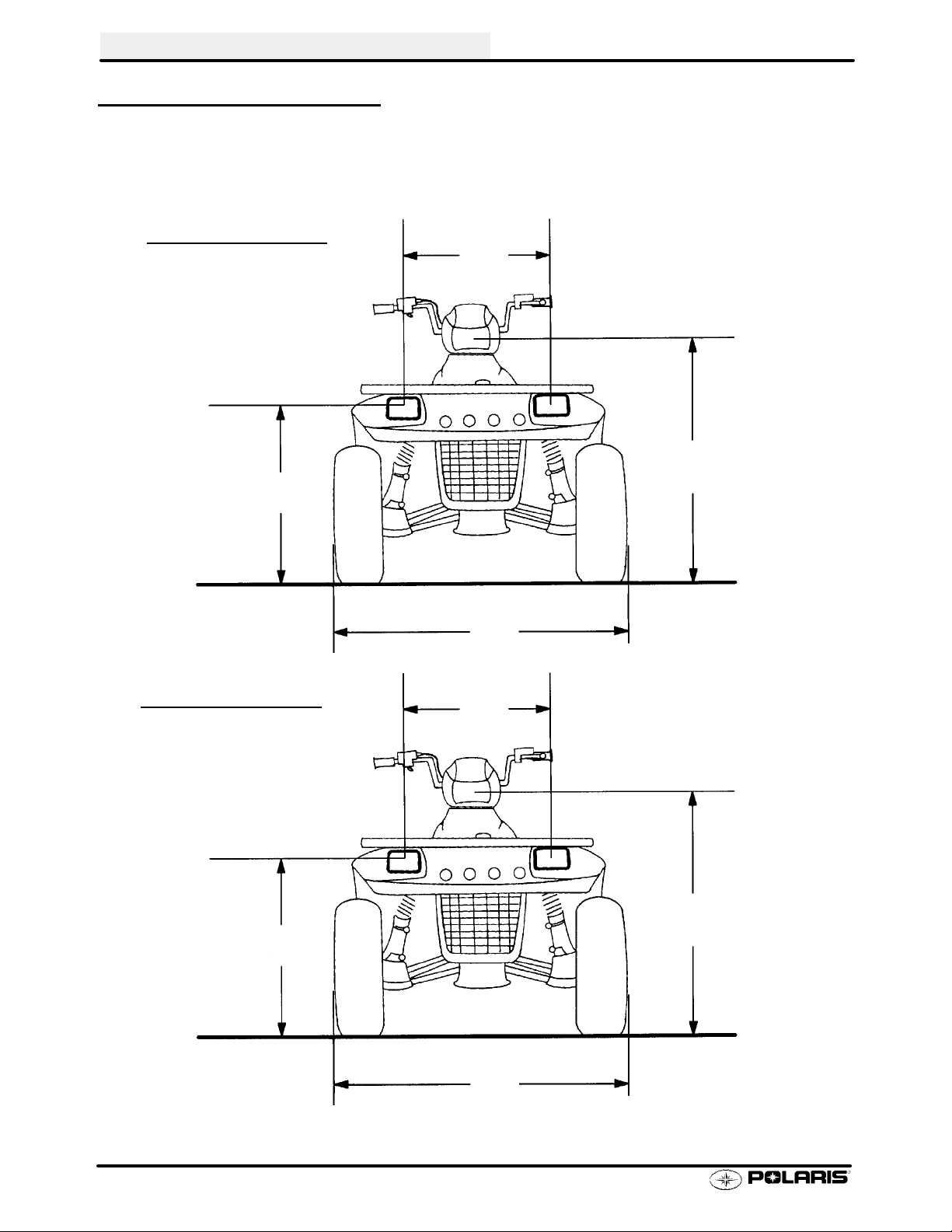

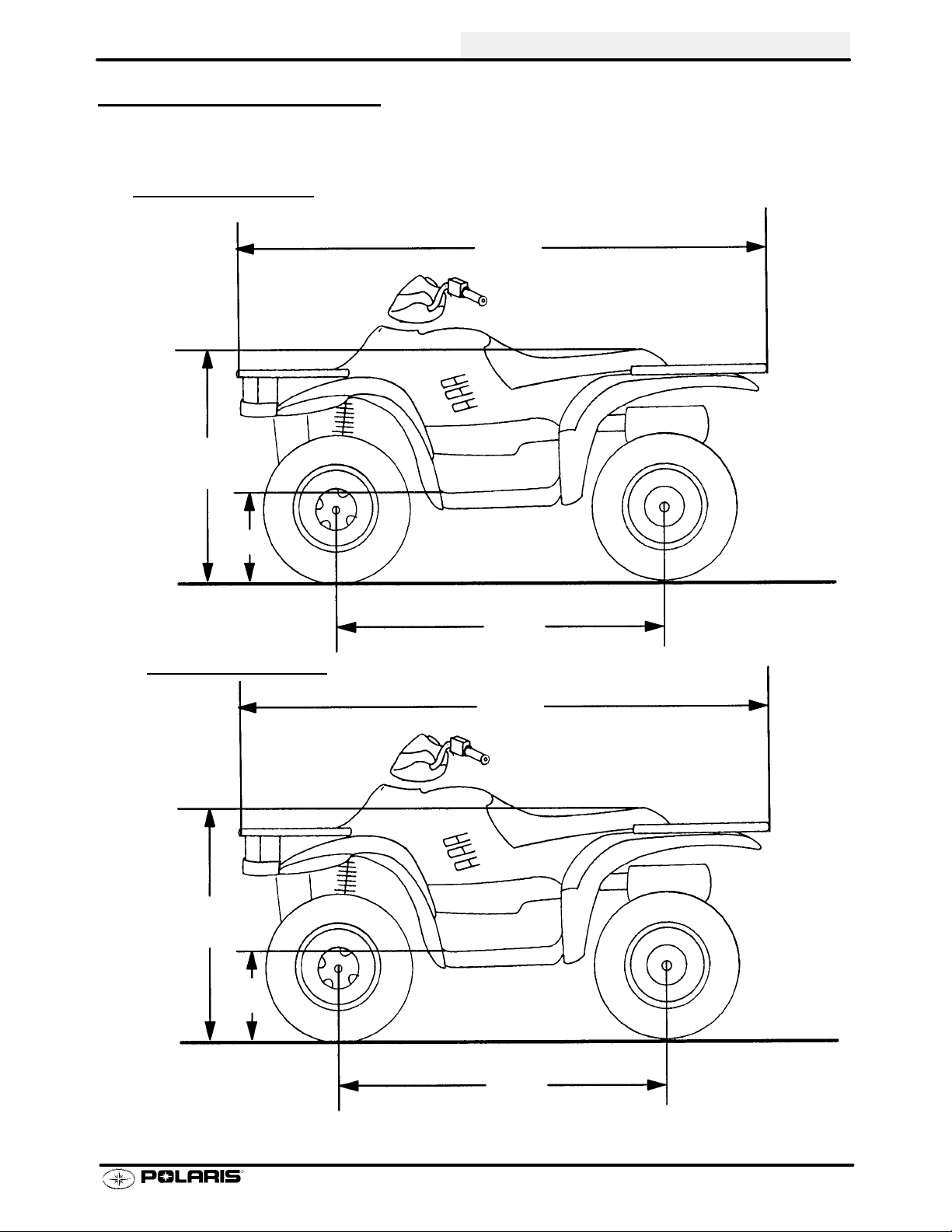

MACHINE DIMENSIONS

SPORTSMAN

30 in

76.2 cm

400

22 in

55.8 cm

41 in

104.1 cm

45 in

114.3 cm

SPORTSMAN 500

32 in

81.2 cm

22 in

55.8 cm

42 in

106.6 cm

46 in

116.8 cm

1.8

Page 11

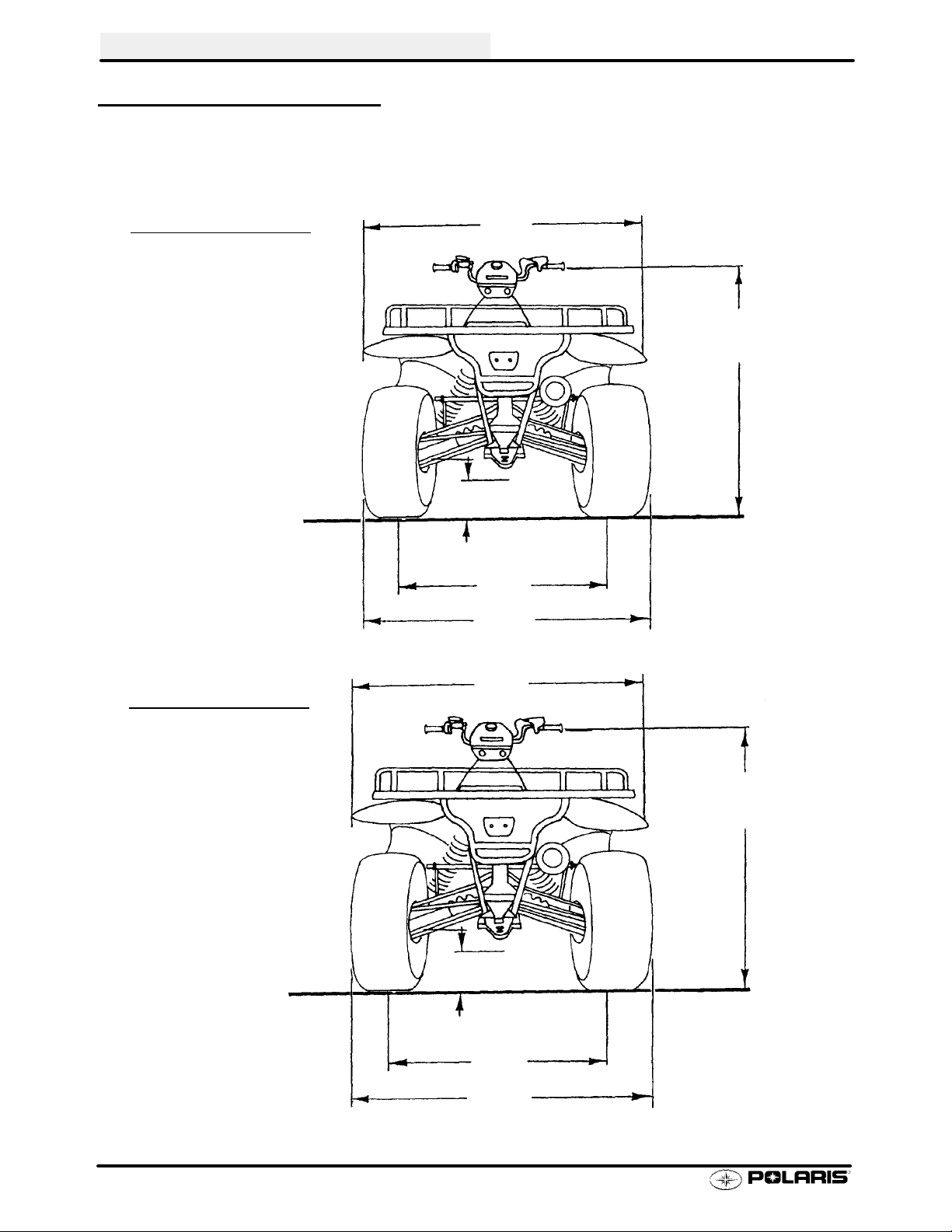

MACHINE DIMENSIONS

SPORTSMAN 400

35 in

89 cm

GENERAL INFORMATION

81 in

205.7 cm

13.5 in

34.29 cm

SPORTSMAN

34 in

86.3 cm

51 in

129.5 cm

500

81 in

205.7 cm

15 in

38.1 cm

50.5 in

128.2 cm

1.9

Page 12

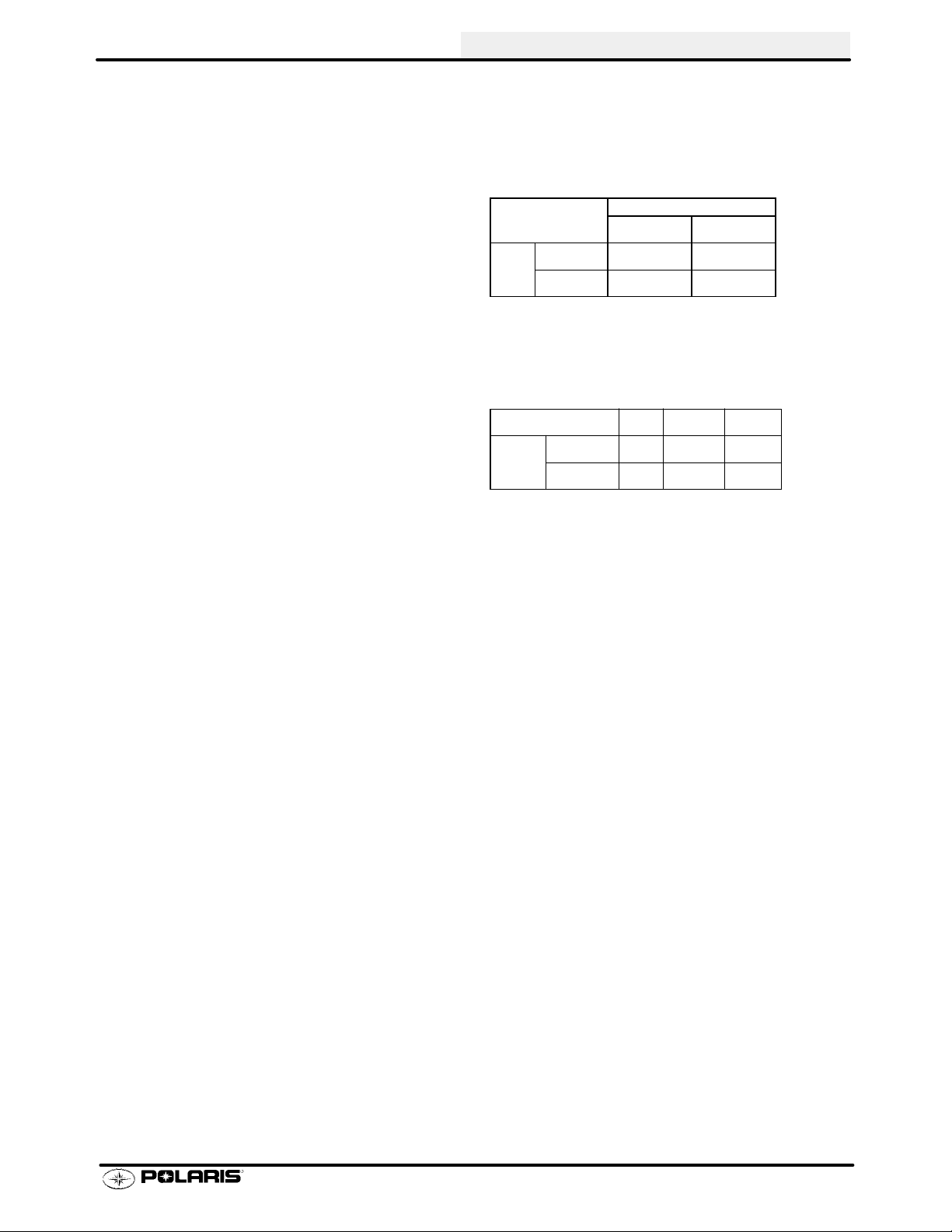

GENERAL INFORMATION

MACHINE DIMENSIONS

SPORTSMAN 400

45 in

114.3 cm

46 in

116.8 cm

9.25 in

23.5 cm

38 in

96.5 cm

47 in

119.4 cm

SPORTSMAN

500

45 in

114.3 cm

48 in

121.9 cm

10 in

25.4 cm

37 in

93.9 cm

47 in

119.3 cm

1.10

Page 13

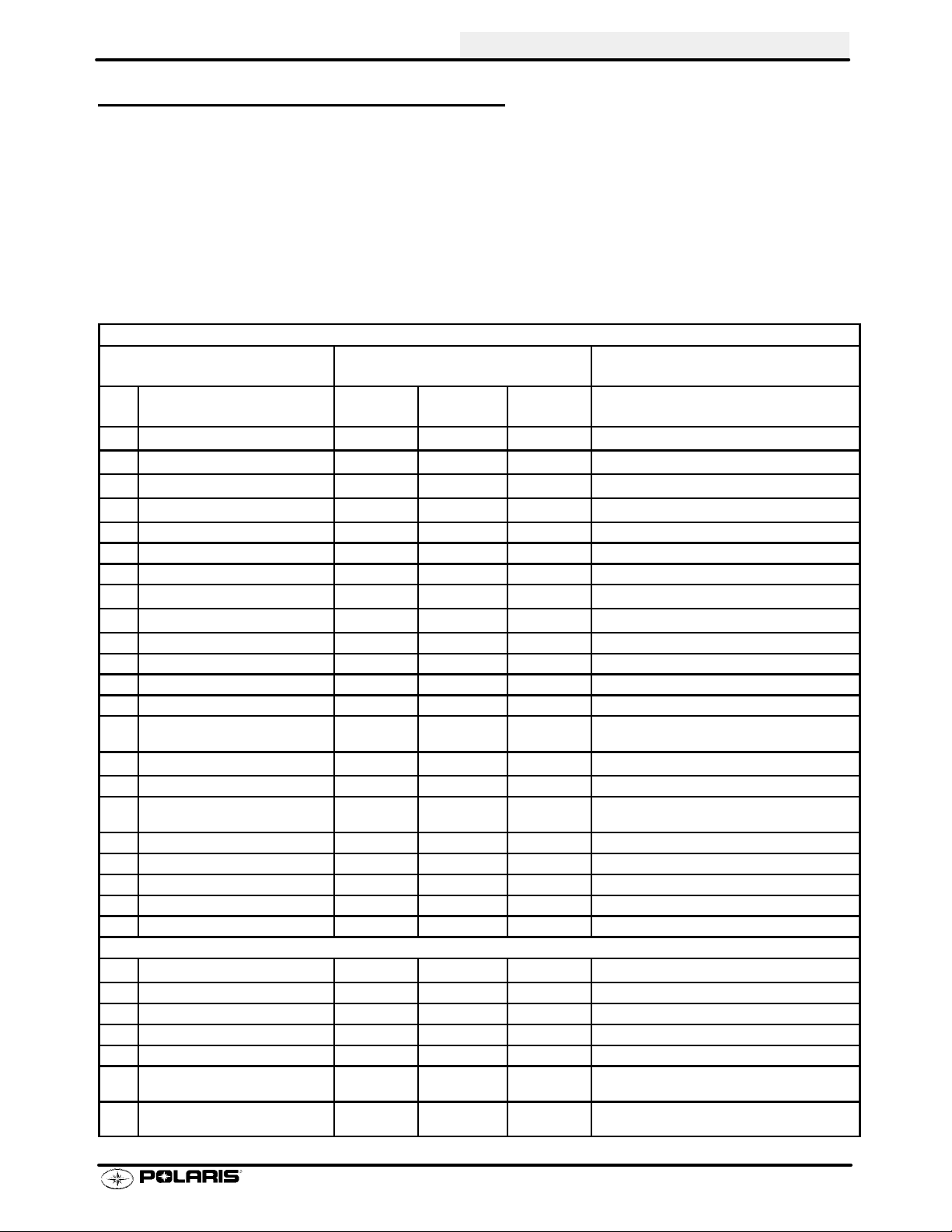

MODEL: SPORTSMAN 400..........

Altitud

e

Below40

F

+40Fandabov

e

Meter

s

0-180

0

(Feet

)

Above1800

Altitud

e

Meter

s

0-180

0

(Feet

)

180

0-370

0

MODEL NUMBER: A01CH42AA/AB/AC.

ENGINE MODEL: EH42PLE05..

CARBURETION

Type BST 34 Mikuni................

Main Jet 167.5............

Pilot Jet 40.............

Jet Needle JF-3...........

Needle Jet Q-0 (829)...........

Throttle Valve #100........

Pilot Screw 2 3/4 Turns Out..........

Pilot Air Jet 160..........

Valve Seat 1.5...........

Float Height 13.0mm (.51I)±1mm.........

Fuel Octane (R+M/2) 87 Non-Oxygenated or.

89 Oxygenated

CLUTCH

Type PVT....................

Belt 321 1069.....................

Belt Width (Projected) 1.188I (30.18mm).....

Side Angle (Overall) 26°......

Outside Circumference 40.86 ±.12I....

Center Distance 10±.12I (254.5mm)..........

Clutch Offset 0.5I (12.7mm)............

Secondary Spring Black........

Driven Helix 44-36°.............

Spring Position (Helix) 2....

Spring Position (Sheave) 2..

GENERAL INFORMATION

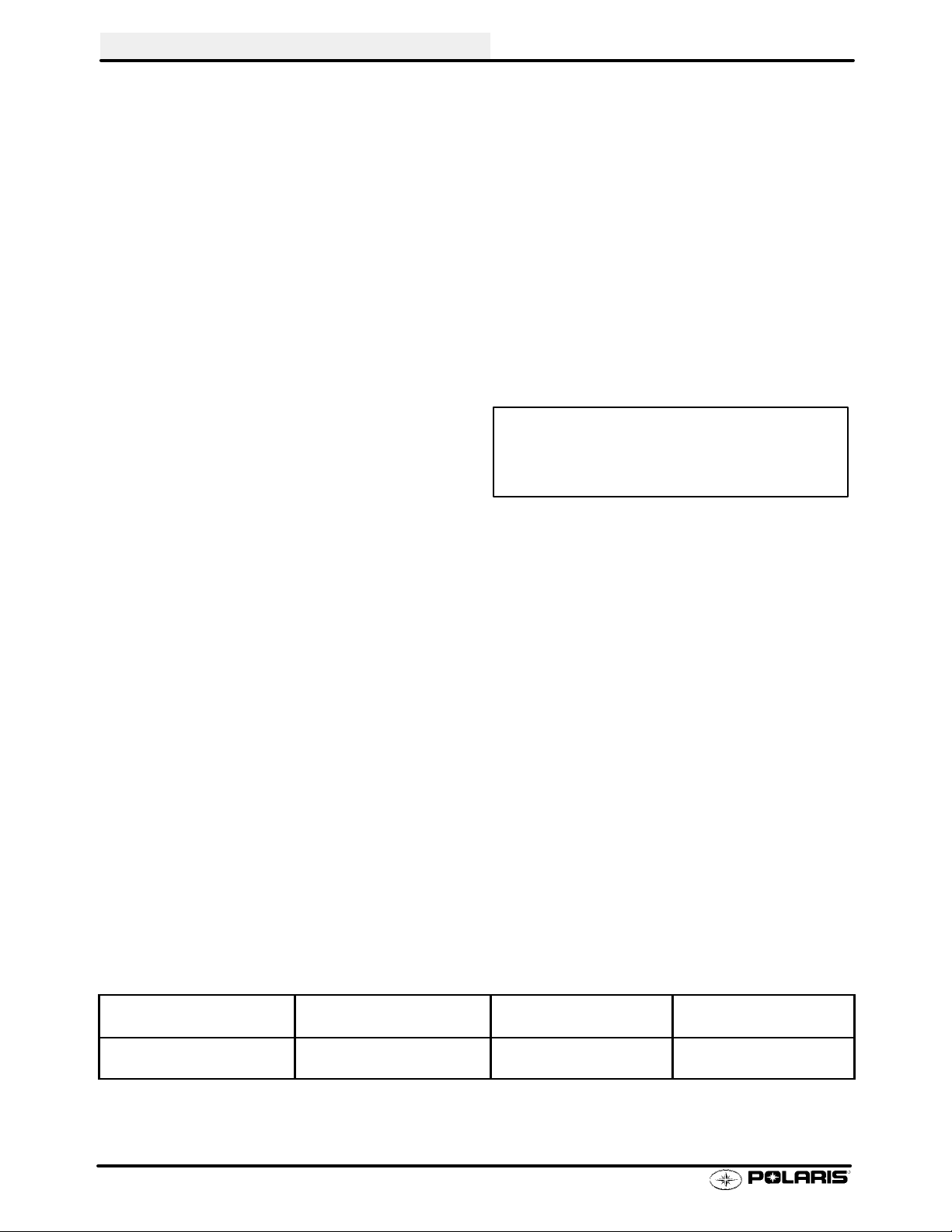

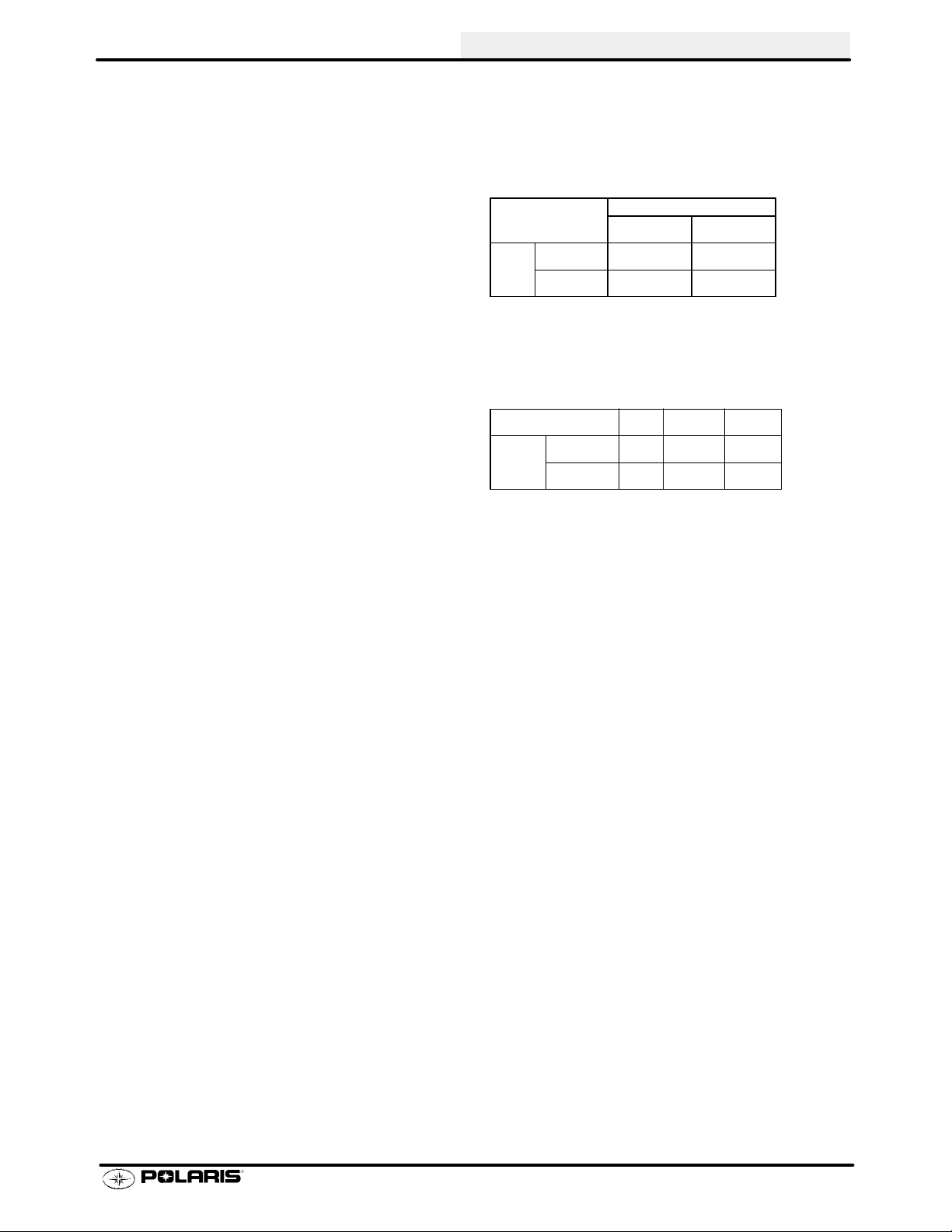

JETTING CHART

Altitude

Meters

(Feet)

CLUTCH CHART

Meters

(Feet)

0-1800

(0-6000)

Above 1800

Above (6000)

0-1800

(0-6000)

1800-3700

(6000-12000)

AMBIENT TEMPERATURE

Below 40°F

Below +5°C

175 167.5

165 160

Shift

Weight Spring Helix

10BH Blue/Green 2+2

10WH Blue/Green 2+2

+40_F andabove

+5_C andabove

Clutch

Driven

ENGINE

Type 4 Cycle, Single Cyl........................

Displacement 425 cc...............

Bore 3.461I (87.9mm).......................

Stroke 2.756I (70mm).....................

Valve Clearance In/Ex 0.006/0.006I@ TDC on compression.......

CompressionRatio 9.2/1 Full Stroke..........

Cooling Liquid....................

Lubrication Type Dry Sump............

Operating RPM±200 6300 RPM.........

Idle RPM±200 (lights off) 1200 RPM.....

Compression Pressure (Std) ±15%.......

1.11

Page 14

GENERAL INFORMATION

MODEL: SPORTSMAN 400............

MODEL NUMBER: A01CH42AA/AB/AC...

ENGINE MODEL: EH42PLE05....

ELECTRICAL FLUID Capacity Type

Flywheel I.D. FF95 Fuel Tank 5.25 gals. (19.9L)...... ..........

CDI Marking CU2565 Injector Oil N / A....... .......... .........

Alternator Output 200 Watts Coolant 2.25 qts. (2.1L) PP6*... ............

Ignition Timing 30° BTDC@5000RPM±2° Transmission 32 oz. PPS*..... ....... .......

Spark Plug / Gap NGK BKR5E / 0.036I (0.9mm) Gearcase Oil (Front) 4 oz. (120ml) 80-90 GL5... . .

Lights: Head Halogen 60/60 watts Gearcase Oil (Center) N / A......

Tail 8.26 watts Gearcase Oil (Rear) N / A........ .

Brake 26.9 watts Engine Counter Bal. N / A...... . .........

Voltage Regulator LR39 Engine Oil 2 qts. (1.9L) PP4*.. .......... ..

Electric Start Standard Brake (Hand) Dot 3....... .......

Brake (Foot) Dot 3........

Front Hubs (AWD) 2.5 oz. (75ml) PDD*...

Shift Selector Box 1 oz. (30ml) PP4*... ..

Lubricant Key

*PP6 Polaris Premium 60/40 Antifreeze/Coolant

*PPS Polaris Premium Synthetic Gear Case Oil

*PP4 Polaris 0W/40 Synthetic Engine Lubricant

*PDD Premium Demand Drive Hub Fluid

SUSPENSION / CHASSIS DRIVE TRAIN

Body Style Gen IV Chain Type Shaft Drive........ .........

Front Suspension MacPherson Strut Gear Reduction-Low 6.69/1.. .

Tow Capacity 850 lbs. (385.6kg) Gear Reduction-Rev 5.17/1...... .

Turning Radius 65I (165.1cm) Gear Reduction-High 3.34/1.....

Toe Out 1/8I-1/4I (3-6.35mm) Front Drive Ratio 2/1........... ....

Ground Clearance 11I (27.94cm) Center Drive Ratio N / A.. ...

Front Vertical Travel 6.7I (17.02cm) Final Drive Ratio 3.16/1....

Rear Suspension Progressive Rate Independent Brake (Hand) Single Lever, Hyd. Disc... .......

Rear Travel 9.5I (24.13cm) Brake ( Auxiliary Foot) Hydraulic........

Rear Shock 2I Twin Tube........

Shock Adjustment Cam..

TIRES

Tire Size - Front 25 x 8 - 12....

Tire Size - Rear 25 x 11 - 10....

Tire Size - Center N / A..

Tire Pressure - F/R 5/5 lbs.

Total Width 46I (116.84cm)........

Total Length 81I (205.74cm).......

Total Height 47I (119.38cm)........

Wheel Base 50.50I (128.27cm).......

Weight - Dry 697 lbs. (316.4kg).......

LOAD CAPACITY

Front Rack (Std) 90 lbs......

Rear Rack (Std) 180 lbs.......

Tongue Weight 30 lbs.....

Tow Hitch Std...........

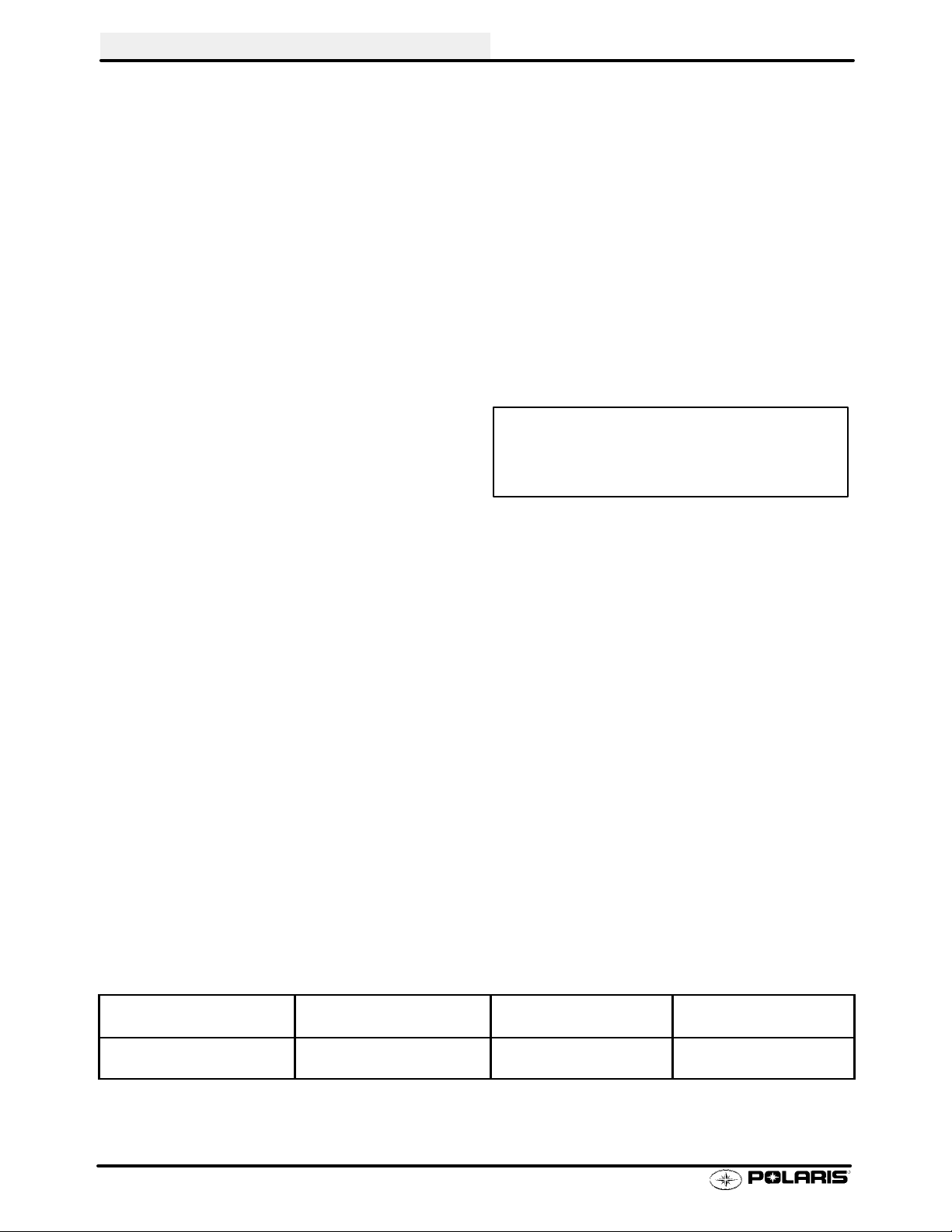

OPTIONAL SUSPENSION SPRINGS

SOFT STANDARD FIRM

Rear Compression Spring

Front Strut Spring 7041238-067

N/A 7041453-067

Option 61 lb/in.

1.12

Standard 100 lb/in.

7041375-067

Standard 64/113 lb/in.

7041519-067

Option 140 lb/in.

7041450-067

Option 101 lb/in.

Page 15

MODEL: SPORTSMAN 500DUSE..........

Altitud

e

Below40

F

+40Fandabov

e

Meter

s

0-180

0

(Feet

)

Above1800

Altitud

e

Meter

s

0-180

0

(Feet

)

180

0-370

0

MODEL NUMBER: A01CH50AD.

ENGINE MODEL: EH50PLE09..

CARBURETION

Type BST 34 Mikuni................

Main Jet 162.5............

Pilot Jet 40.............

Jet Needle 4HB41-3...........

Needle Jet Q-0 (513)...........

Throttle Valve #100........

Pilot Screw 2 5/8 Turns Out..........

Pilot Air Jet 160..........

Valve Seat 1.5...........

Float Height 13.0mm (.51I)±1mm.........

Fuel Octane (R+M/2) 87 Non-Oxygenated or.

89 Oxygenated

CLUTCH

Type PVT....................

Belt 321 1069.....................

Belt Width (Projected) 1.188I (30.18mm).....

Side Angle (Overall) 26°......

Outside Circumference 40.86 ±.12I....

Center Distance 10±.12I (254.5mm)..........

Clutch Offset 0.5I (12.7mm)............

Secondary Spring White/Green........

Driven Helix Compound (EBS).............

Spring Position (Helix) N/A....

Spring Position (Sheave) N/A..

GENERAL INFORMATION

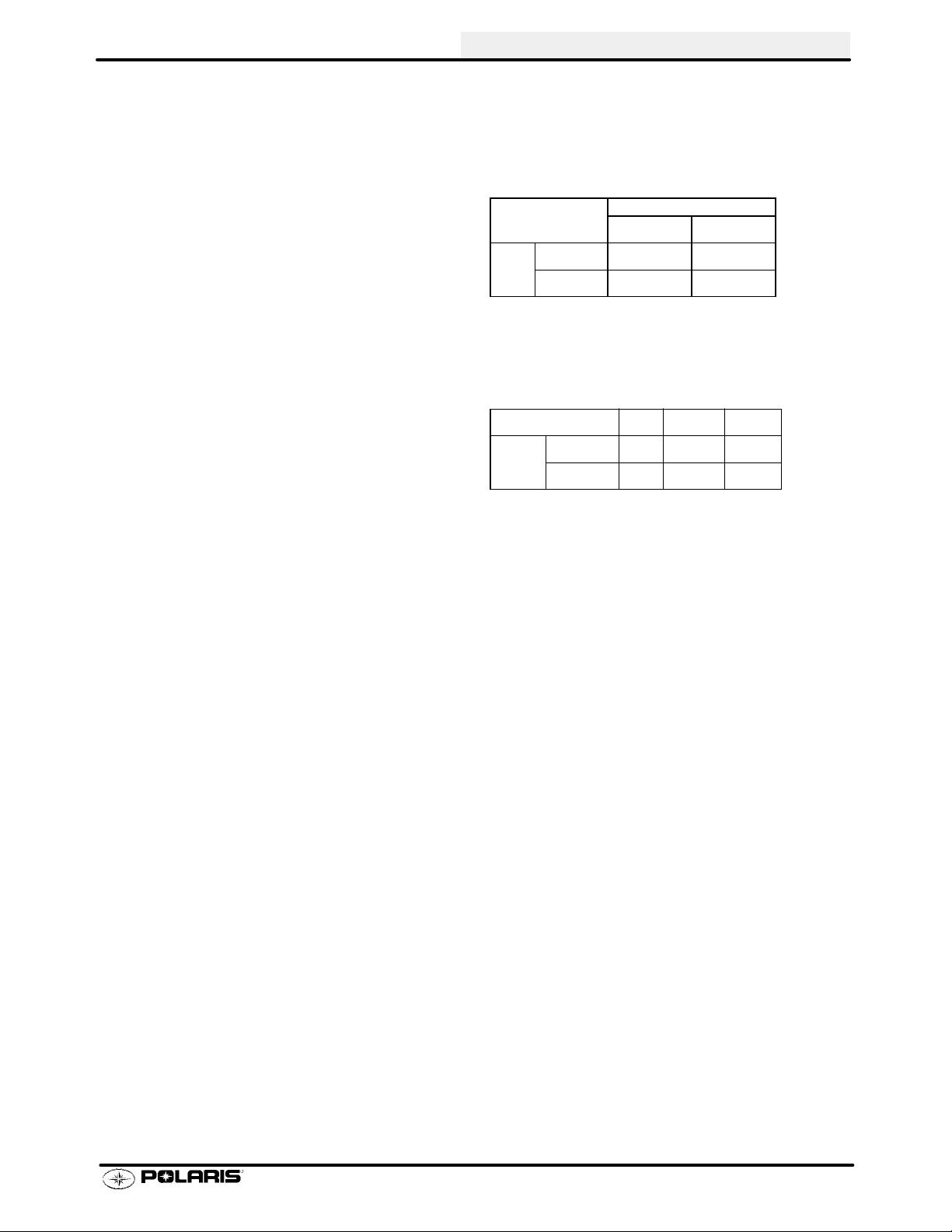

JETTING CHART

Altitude

Meters

(Feet)

0-1800

(0-6000)

Above 1800

Above (6000)

CLUTCH CHART

Meters

(Feet)

*EBS require no helix/spring adjustment

0-1800

(0-6000)

1800-3700

(6000-12000)

AMBIENT TEMPERATURE

Below 40°F

Below +5°C

170 162.5

160 155

Shift

Weight Spring Helix*

10MH Blue/Green EBS

10WH Blue/Green EBS

+40_F and above

+5_C and above

Clutch

Driven

ENGINE

Type 4 Cycle, Single Cyl........................

Displacement 499 cc...............

Bore 3.6248I (92mm).......................

Stroke 2.955I (75mm).....................

Valve Clearance In/Ex 0.006/0.006I@ TDC on compression.......

Compression Ratio 10/2 Full Stroke..........

Cooling Liquid....................

Lubrication Type Dry Sump............

Operating RPM±200 6000 RPM.........

Idle RPM±200 (lights off) 1200 RPM.....

Compression Pressure (Std) ±15%.......

1.13

Page 16

GENERAL INFORMATION

MODEL: SPORTSMAN 500 DUSE............

MODEL NUMBER: A01CH50AD...

ENGINE MODEL: EH50PLE09....

ELECTRICAL FLUID Capacity Type

Flywheel I.D. FF97 Fuel Tank 5.25 gals. (19.9L)...... ..........

CDI Marking CU2570 Injector Oil N / A....... .......... .........

Alternator Output 250 Watts Coolant 2.25 qts. (2.1L) PP6*... ............

Ignition Timing 30° BTDC@5000RPM±2° Transmission 32 oz. PPS*..... ....... .......

Spark Plug / Gap NGK BKR5E / 0.036I (0.9mm) Gearcase Oil (Front) 4 oz. (120ml) 80-90 GL5... . .

Lights: Head Halogen 60/60 watts Gearcase Oil (Center) N / A......

Tail 8.26 watts Gearcase Oil (Rear) N / A........ .

Brake 26.9 watts Engine Counter Bal. N / A...... . .........

Voltage Regulator LR39 Engine Oil 2 qts. (1.9L) PP4*.. .......... ..

Electric Start Standard Brake (Hand) Dot 3....... .......

Brake (Foot) Dot 3........

Front Hubs (AWD) 2.5 oz. (75ml) PDD*...

Shift Selector Box 1 oz. (30ml) PP4*... ..

Lubricant Key

*PP6 Polaris Premium 60/40 Antifreeze/Coolant

*PPS Polaris Premium Synthetic Gear Case Oil

*PP4 Polaris 0W/40 Synthetic Engine Lubricant

*PDD Premium Demand Drive Hub Fluid

SUSPENSION / CHASSIS DRIVE TRAIN

Body Style Gen IV Chain Type Shaft Drive........ .........

Front Suspension MacPherson Strut Gear Reduction-Low 6.69/1.. .

Tow Capacity 1225 lbs. (555.6kg) Gear Reduction-Rev 5.17/1...... .

Turning Radius 65I (165.1cm) Gear Reduction-High 3.34/1.....

Toe Out 1/8I-1/4I (3-6.35mm) Front Drive Ratio 2/1........... ....

Ground Clearance 11I (27.94cm) Center Drive Ratio N / A.. ...

Front Vertical Travel 6.7I (17.02cm) Final Drive Ratio 3.16/1....

Rear Suspension Progressive Rate Independent Brake (Hand) Single Lever, Hyd. Disc... .......

Rear Travel 9.5I (24.13cm) Brake ( Auxiliary Foot) Hydraulic........

Rear Shock 2I Twin Tube........

Shock Adjustment Cam..

TIRES

Tire Size - Front 25 x 8 - 12....

Tire Size - Rear 25 x 11 - 10....

Tire Size - Center N / A..

Tire Pressure - F/R 5/5 lbs.

Total Width 46I (116.84cm)........

Total Length 81I (205.74cm).......

Total Height 47I (119.38cm)........

Wheel Base 50.50I (128.27cm).......

Weight - Dry 697 lbs. (316.4kg).......

LOAD CAPACITY

Front Rack (Std) 90 lbs......

Rear Rack (Std) 180 lbs.......

Tongue Weight 35 lbs.....

Tow Hitch Std...........

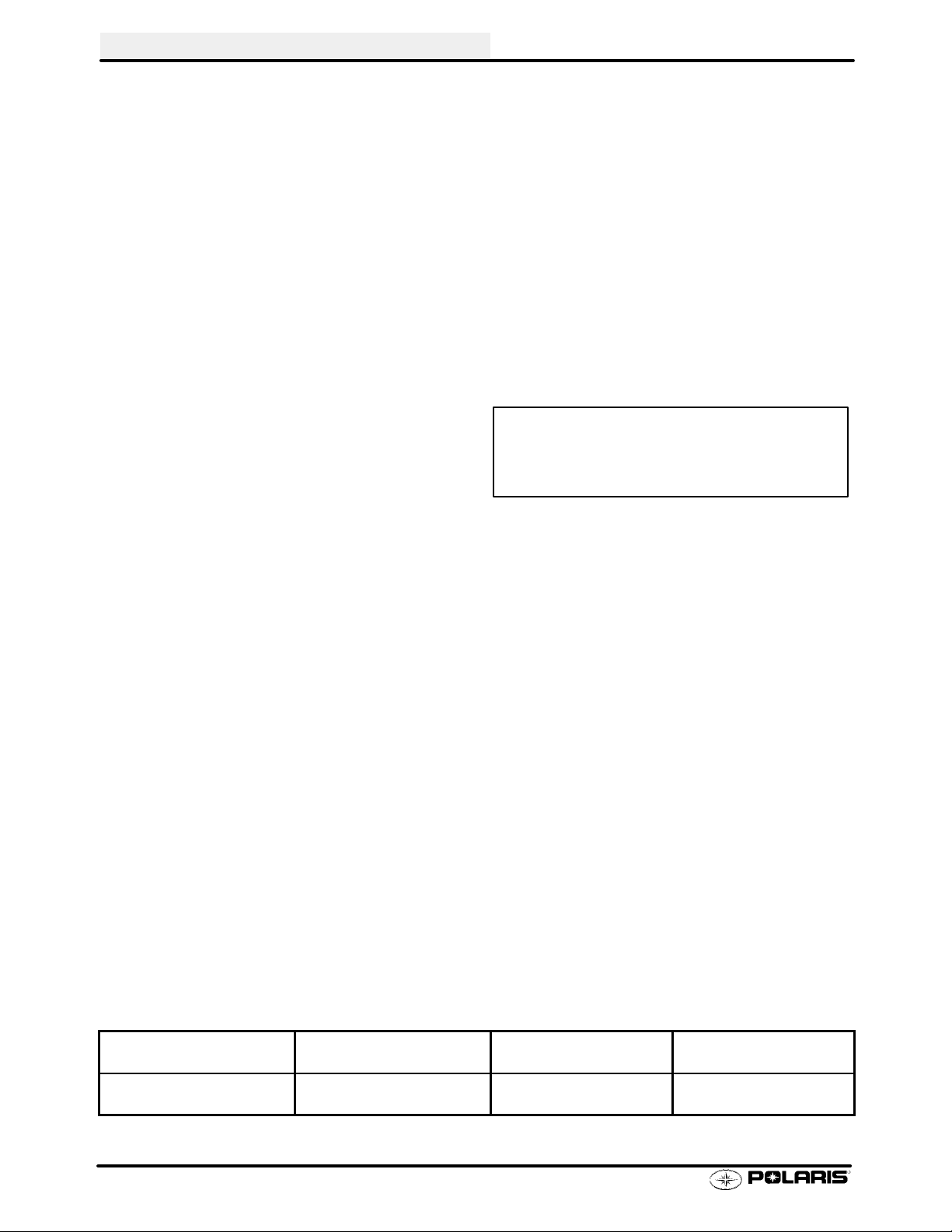

OPTIONAL SUSPENSION SPRINGS

SOFT STANDARD FIRM

Rear Compression Spring

Front Strut Spring 7041238-067

N/A 7041453-067

Option 61 lb/in.

1.14

Standard 100 lb/in.

7041375-067

Standard 64/113 lb/in.

7041519-067

Option 140 lb/in.

7041450-067

Option 101 lb/in.

Page 17

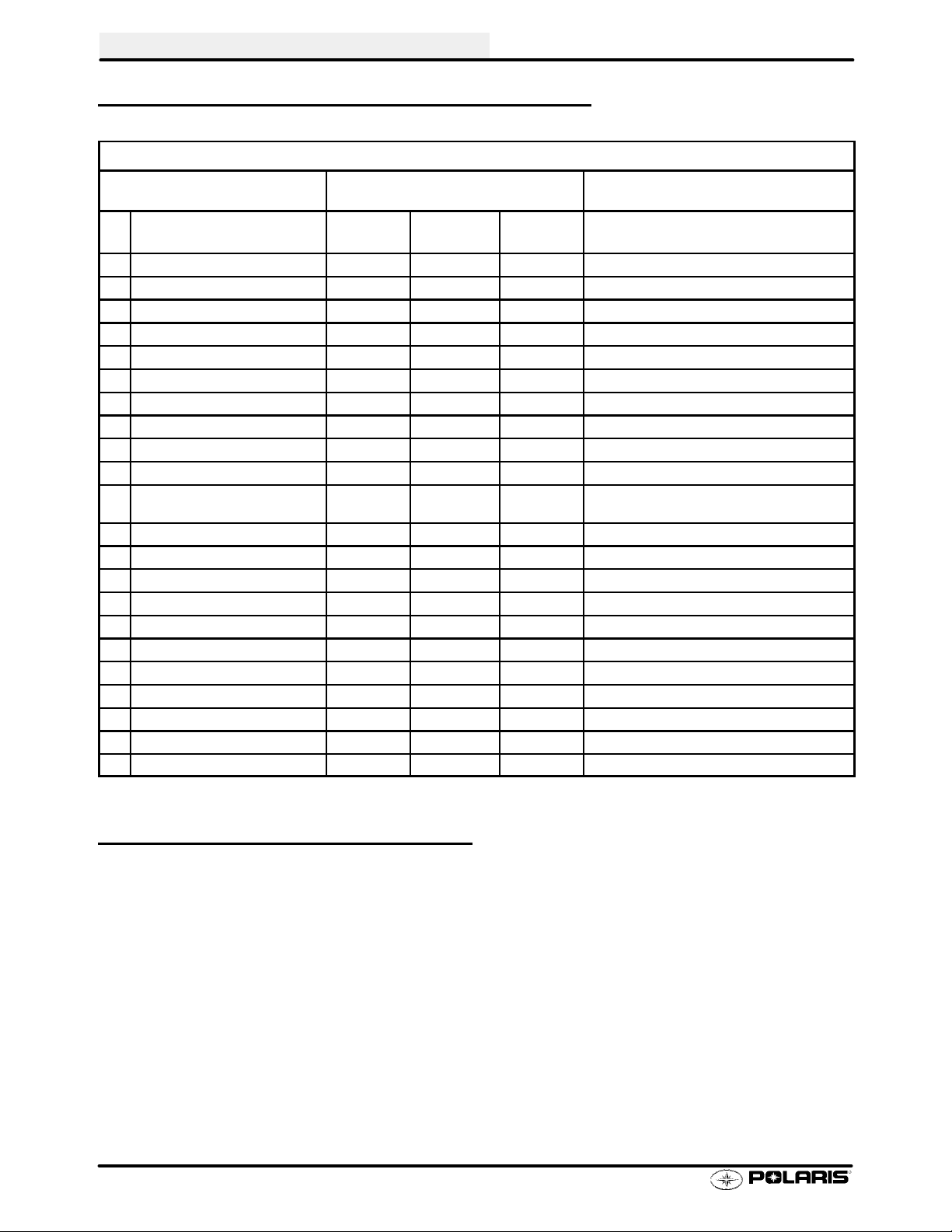

MODEL: SPORTSMAN 500 H.O...........

Altitud

e

Below40

F

+40Fandabov

e

Meter

s

0-180

0

(Feet

)

Above1800

Altitud

e

Meter

s

0-180

0

(Feet

)

180

0-370

0

MODEL NUMBER: A01CH50AA/AB/AE/AF/AJ.

ENGINE MODEL: EH50PLE13..

CARBURETION

Type BST 40 Mikuni................

Main Jet 152.5............

Pilot Jet 40.............

Jet Needle KE-3 (683)...........

Needle Jet X-6...........

Throttle Valve #120........

Pilot Screw 2 1/2 Turns Out..........

Pilot Air Jet 1.3..........

Valve Seat 1.5...........

Float Height 14.7mm (.58I)±1mm.........

Fuel Octane (R+M/2) 87 Non-Oxygenated or.

89 Oxygenated

CLUTCH

Type PVT....................

Belt 321 1069.....................

Belt Width (Projected) 1.188I (30.18mm).....

Side Angle (Overall) 26°......

Outside Circumference 40.86 ±.12I....

Center Distance 10±.12I (254.5mm)..........

Clutch Offset 0.5I (12.7mm)............

Secondary Spring White/Yellow........

Driven Helix Compound (EBS).............

Spring Position (Helix) N/A....

Spring Position (Sheave) N/A..

GENERAL INFORMATION

JETTING CHART

Altitude

Meters

(Feet)

0-1800

(0-6000)

Above 1800

Above (6000)

CLUTCH CHART

Meters

(Feet)

*EBS require no helix/spring adjustment

0-1800

(0-6000)

1800-3700

(6000-12000)

AMBIENT TEMPERATURE

Below 40°F

Below +5°C

157.5 152.5

150 145

Shift

Weight Spring Helix*

10WH Blue/Green EBS

10RH Blue/Green EBS

+40_F and above

+5_C and above

Clutch

Driven

ENGINE

Type 4 Cycle, Single Cyl........................

Displacement 499 cc...............

Bore 3.6248I (92mm).......................

Stroke 2.955I (75mm).....................

Valve Clearance In/Ex 0.006/0.006I@ TDC on compression.......

Compression Ratio 10/2 Full Stroke..........

Cooling Liquid....................

Lubrication Type Dry Sump............

Operating RPM±200 6500 RPM.........

Idle RPM±200 (lights off) 1200 RPM.....

Compression Pressure (Std) ±15%.......

1.15

Page 18

GENERAL INFORMATION

MODEL: SPORTSMAN 500 H.O.............

MODEL NUMBER: A01CH50AA/AB/AE/AF/AJ...

ENGINE MODEL: EH50PLE13....

ELECTRICAL FLUID Capacity Type

Flywheel I.D. FF97 Fuel Tank 5.25 gals. (19.9L)...... ..........

CDI Marking CU2570 Injector Oil N / A....... .......... .........

Alternator Output 250 Watts Coolant 2.25 qts. (2.1L) PP6*... ............

Ignition Timing 30° BTDC@5000RPM±2° Transmission 32 oz. PPS*..... ....... .......

Spark Plug / Gap NGK BKR5E / 0.036I (0.9mm) Gearcase Oil (Front) 4 oz. (120ml) 80-90 GL5... . .

Lights: Head Halogen 60/60 watts Gearcase Oil (Center) N / A......

Tail 8.26 watts Gearcase Oil (Rear) N / A........ .

Brake 26.9 watts Engine Counter Bal. N / A...... . .........

Voltage Regulator LR39 Engine Oil 2 qts. (1.9L) PP4*.. .......... ..

Electric Start Standard Brake (Hand) Dot 3....... .......

Brake (Foot) Dot 3........

Front Hubs (AWD) 2.5 oz. (75ml) PDD*...

Shift Selector Box 1 oz. (30ml) PP4*... ..

Lubricant Key

*PP6 Polaris Premium 60/40 Antifreeze/Coolant

*PPS Polaris Premium Synthetic Gear Case Oil

*PP4 Polaris 0W/40 Synthetic Engine Lubricant

*PDD Premium Demand Drive Hub Fluid

SUSPENSION / CHASSIS DRIVE TRAIN

Body Style Gen IV Chain Type Shaft Drive........ .........

Front Suspension MacPherson Strut Gear Reduction-Low 6.69/1.. .

Tow Capacity 1225 lbs. (555.6kg) Gear Reduction-Rev 5.17/1...... .

Turning Radius 65I (165.1cm) Gear Reduction-High 3.34/1.....

Toe Out 1/8I-1/4I (3-6.35mm) Front Drive Ratio 2/1........... ....

Ground Clearance 11I (27.94cm) Center Drive Ratio N / A.. ...

Front Vertical Travel 6.7I (17.02cm) Final Drive Ratio 3.16/1....

Rear Suspension Progressive Rate Independent Brake (Hand) Single Lever, Hyd. Disc... .......

Rear Travel 9.5I (24.13cm) Brake ( Auxiliary Foot) Hydraulic........

Rear Shock 2I Twin Tube........

Shock Adjustment Cam..

TIRES

Tire Size - Front 25 x 8 - 12....

Tire Size - Rear 25 x 11 - 10....

Tire Size - Center N / A..

Tire Pressure - F/R 5/5 lbs.

Total Width 46I (116.84cm)........

Total Length 81I (205.74cm) (AA/AB/AE).......

85I (215.9cm) (AF/AJ)...................

Total Height 47I (119.38cm)........

Wheel Base 50.50I (128.27cm).......

Weight - Dry 697 lbs. (316.4kg) (AA/AB/AE).......

750 lbs. (340kg) (AF/AJ)...................

LOAD CAPACITY

Front Rack (Std) 90 lbs......

Rear Rack (Std) 180 lbs.......

Tongue Weight 35 lbs.....

Tow Hitch Std...........

OPTIONAL SUSPENSION SPRINGS

SOFT STANDARD FIRM

Rear Compression Spring

Front Strut Spring 7041238-067

N/A 7041453-067

Option 61 lb/in.

1.16

Standard 100 lb/in.

7041375-067

Standard 64/113 lb/in.

7041519-067

Option 140 lb/in.

7041450-067

Option 101 lb/in.

Page 19

PUBLICATION NUMBERS

GENERAL INFORMATION

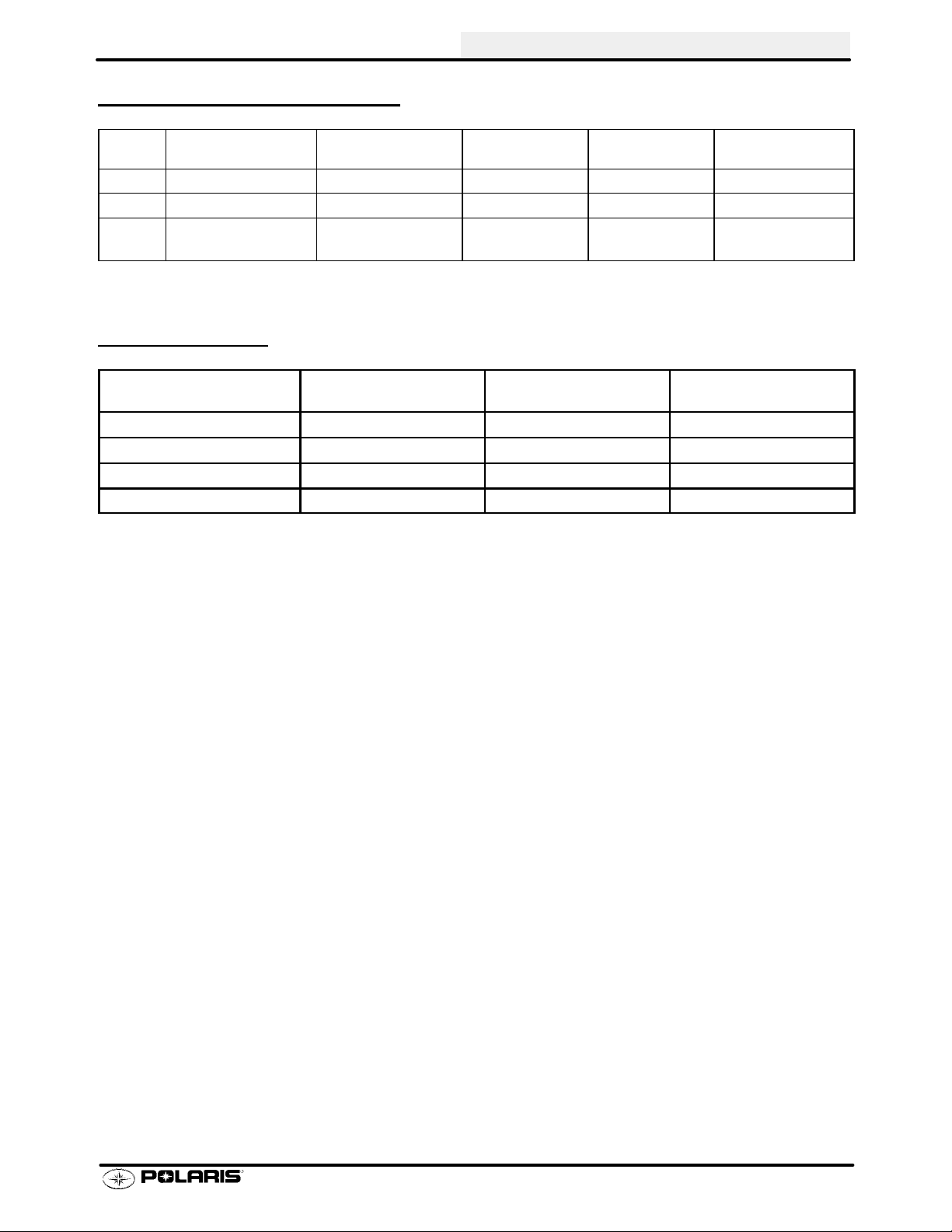

Year Model Model No. Owner’s Manual

PN

2001 Sportsman 400 A01CH42AA/AB/AC 9915754 9916443 9916444

2001 Sportsman 500 DUSE A01CH50AD 9915754 9916002 9916003

2001 Sportsman 500 H.O. A01CH50AA/AB/AE/

AF/AJ

When ordering service parts be sure to use the correct parts manual.

9915754 9916446 9916447

Parts

Manual PN

Micro Fiche PN

PAINT CODES

PAINTED PART COLOR

DESCRIPTION

(400) Springs/Rims Black 9440 P-067

(500) Springs/Rims Black 9440 P-067

(500) Opt. B Springs Black 9440 P-067

(500) Opt. B Rims Brushed Aluminum N/A P-117

FRAME COLOR - (All) P067 Medium Gloss Black 9440 / 8520147.

Order direct from Midwest Industrial Coatings (952-942-1840). Mix as directed.

DITZLER

NUMBER

POLARIS

NUMBER

Parts

1.17

Page 20

GENERAL INFORMATION

STANDARD TORQUE SPECIFICATIONS

The following torque specifications are to be used as a general guideline. There are exceptions in the steering,

suspension, and engine areas. Always consult the exploded views in each manual section for torque values of

fasteners before using standard torque.

Bolt Size Threads/In Grade 2 Grade 5 Grade 8

T orque in. lbs. (Nm)

#10 - 24 27 (3.1) 43 (5.0) 60 (6.9).............. ................ ..............

#10 - 32 31 (3.6) 49 (5.6) 68 (7.8).............. ................ ..............

T o rque ft. lbs. (Nm)*

1/4 - 20 5 (7) 8(11) 12 (16).............. .................. ................

1/4 - 28 6 (8) 10(14) 14 (19).............. .................. ..............

5/16 - 18 11 (15) 17 (23) 25 (35).............. ................ ..............

5/16 - 24 12 (16) 19 (26) 29 (40).............. ................ ..............

3/8 - 16 20 (27) 30 (40) 45 (62).............. ................ ..............

3/8 - 24 23 (32) 35 (48) 50 (69).............. ................ ..............

7/16 - 14 30 (40) 50 (69) 70 (97).............. ................ ..............

7/16 - 20 35 (48) 55 (76) 80 (110).............. ................ ..............

1/2 - 13 50 (69) 75 (104) 110 (152).............. ................ .............

1/2 - 20 55 (76) 90 (124) 120 (166).............. ................ .............

Metric

6 x 1.0 72-78 In. lbs.

8 x 1.25 14-18 ft. lbs.

10 x 1.25 26-30 ft. lbs.

*To convert ft. lbs. to Nm multiply foot pounds by .1.382

*To convert Nm to ft. lbs. multiply Nm by .7376.

SPECIFIC TORQUE VALUES OF FASTENERS

Refer to exploded views in the appropriate section.

1.18

Page 21

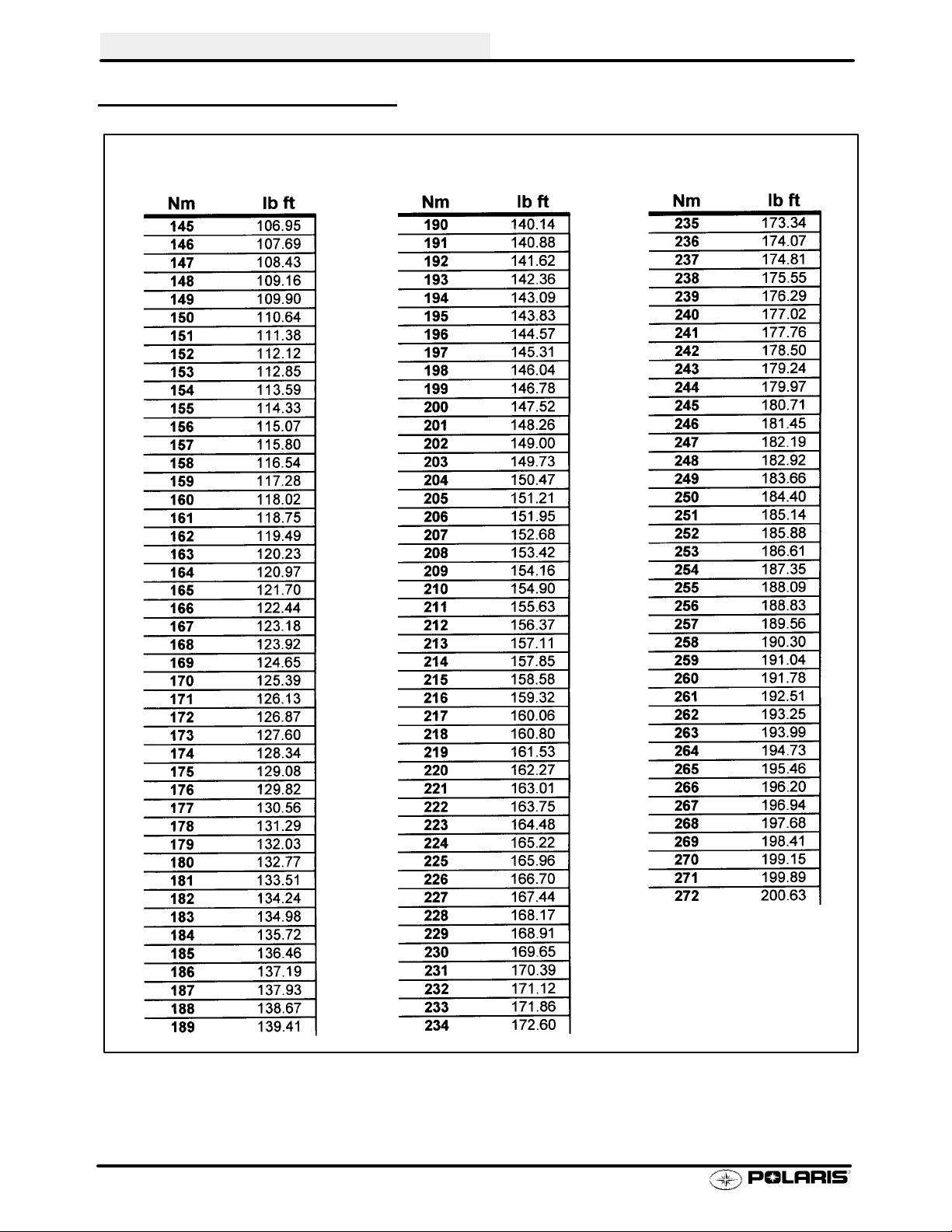

TORQUE CONVERSIONS

Newton Meter to Pound Foot and Pound Inch

GENERAL INFORMATION

1.19

Page 22

GENERAL INFORMATION

TORQUE CONVERSIONS

Newton Meter to Pound Foot and Pound Inch

1.20

Page 23

DECIMAL EQUIVALENTS

1/64 .0156.........................

1/32 .0312 1 mm = .0394″................... ................

3/64 .0469.........................

1/16 .0625..............

5/64 .0781 2 mm = .0787″......................... ................

3/32 .0938...................

7/64 .1094 3 mm = .1181″....................... ................

1/8 . 1250. .......

9/64 .1406.........................

5/32 .1563 4 mm = .1575″................... ................

11/64 .1719........................

3/16 .1875 5 mm = .1969″.............. ................

13/64 .2031........................

7/32 .2188...................

15/64 .2344 6 mm = .2362″........................ ................

1/4 .25..........

17/64 .2656 7 mm = .2756″........................ ................

9/32 .2813...................

19/64 .2969........................

5/16 .3125 8 mm = .3150″.............. ................

21/64 .3281........................

11/32 .3438 9 mm = .3543″.................. ................

23/64 .3594........................

3/8 .375..........

25/64 .3906 10 mm = .3937″........................ ................

13/32 .4063..................

27/64 .4219 1 1mm = .4331″........................ ................

7/16 .4375..............

29/64 .4531........................

15/32 .4688 12 mm = .4724″.................. ................

31/64 .4844........................

1/2 .5 13 mm = .5118.......... ...................

33/64 .5156........................

17/32 .5313..................

35/64 .5469 14 mm = .5512″........................ ................

9/16 .5625..............

37/64 .5781 15 mm = .5906″........................ ................

19/32 .5938..................

39/64 .6094........................

5/8 .625 16 mm = .6299″.......... .................

41/64 .6406........................

21/32 .6563 17 mm = .6693″.................. ................

43/64 .6719.......................

/16 .6875.............

1 1

45/64 .7031 18 mm = .7087″........................ ................

23/32 .7188..................

47/64 .7344 19 mm = .7480″........................ ................

3/4 .75..........

49/64 .7656........................

25/32 .7813 20 mm = .7874″.................. ................

51/64 .7969........................

13/16 .8125 21 mm = .8268″............. ................

53/64 .8281........................

27/32 .8438..................

55/64 .8594 22 mm = .8661″........................ ................

7/8 .875..........

57/64 .8906 23 mm = .9055″........................ ................

29/32 .9063..................

59/64 .9219.......................

15/16 .9375 24 mm = .9449″............. ................

61/64 .9531........................

31/32 .9688 25 mm = .9843.................. ................

63/64 .9844........................

11.0............

GENERAL INFORMATION

1.21

Page 24

GENERAL INFORMATION

CONVERSION TABLE

Unit of Measure Multiplied by Converts to

ft. lbs. x12 =in.lbs.

in. lbs. x .0833 = ft. lbs.

ft. lbs. x 1.356 =Nm

in. lbs. x .0115 =kg-m

Nm x .7376 = ft.lbs.

kg-m x 7.233 = ft. lbs.

kg-m x 86.796 =in.lbs.

kg-m x10 =Nm

in. x 25.4 =mm

mm x .03937 =in.

in. x2.54 =cm

mile (mi.) x1.6 =km

km x .6214 = mile (mi.)

Ounces (oz) x 28.35 = Grams (g)

Fluid Ounces (fl. oz.) x 29.57 = Cubic Centimeters (cc)

Cubic Centimeters (cc) x .03381 = Fluid Ounces (fl. oz.)

Grams (g) x 0.035 = Ounces (oz)

lb. x .454 =kg

kg x 2.2046 =lb.

Cubic inches (cu in) x 16.387 = Cubic centimeters (cc)

Cubic centimeters (cc) x 0.061 = Cubic inches (cu in)

Imperial pints (Imp pt) x 0.568 = Liters (l)

Liters (l) x1.76 = Imperial pints (Imp pt)

Imperial quarts (Imp qt) x 1.137 = Liters (l)

Liters (l) x0.88 = Imperial quarts (Imp qt)

Imperial quarts (Imp qt) x 1.201 = US quarts (US qt)

US quarts (US qt) x 0.833 = Imperial quarts (Imp qt)

US quarts (US qt) x 0.946 = Liters (l)

Liters (l) x 1.057 = US quarts (US qt)

US gallons (US gal) x 3.785 =Liters (l)

Liters (l) x 0.264 = US gallons (US gal)

Pounds - force per square inch (psi) x 6.895 = Kilopascals (kPa)

Kilopascals (kPa) x 0.145 = Pounds - force per square inch (psi)

Kilopascals (kPa) x0.01 = Kilograms - force per square cm

Kilograms - force per square cm x 98.1 = Kilopascals (kPa)

π (3.14) xR2x H (height) = Cylinder Volume

°Cto°F: 9 (°C + 40) ÷ 5-40=°F

°Fto°C: 5 (°F + 40) ÷ 9-40=°C

1.22

Page 25

GENERAL INFORMATION

SAE TAP DRILL SIZES

Thread Size Drill Size Thread Size Drill Size

#0-80 3/64

#1-64 53

#1-72 53

#2-56 51

#2-64 50

#3-48 5/64

#3-56 45

#4-40 43

#4-48 42

#5-40 38

#5-44 37

#6-32 36

#6-40 33

#8-32 29

#8-36 29

#10-24 24

#10-32 21

#12-24 17

#12-28 4.6mm

1/4-20 7

1/4-28 3

5/16-18 F

5/16-24 I

3/8-16 O

3/8-24 Q

7/16-14 U

7/16-20 25/64

1/2-13 27/64

1/2-20 29/64

9/16-12 31/64

9/16-18 33/64

5/8-11 17/32

5/8-18 37/64

3/4-10 21/32

3/4-16 11/16

7/8-9 49/64

7/8-14 13/16

1-8 7/8

1-12 59/64

1 1/8-7 63/64

1 1/8-12 1 3/64

11/4-7 17/64

1 1/4-12 1 11/64

11/2-6 111/32

1 1/2-12 1 27/64

13/4-5 19/16

1 3/4-12 1 43/64

2-4 1/2 1 25/32

2-12 1 59/64

2 1/4-4 1/2 2 1/32

21/2-4 21/4

23/4-4 21/2

3-4 2 3/4

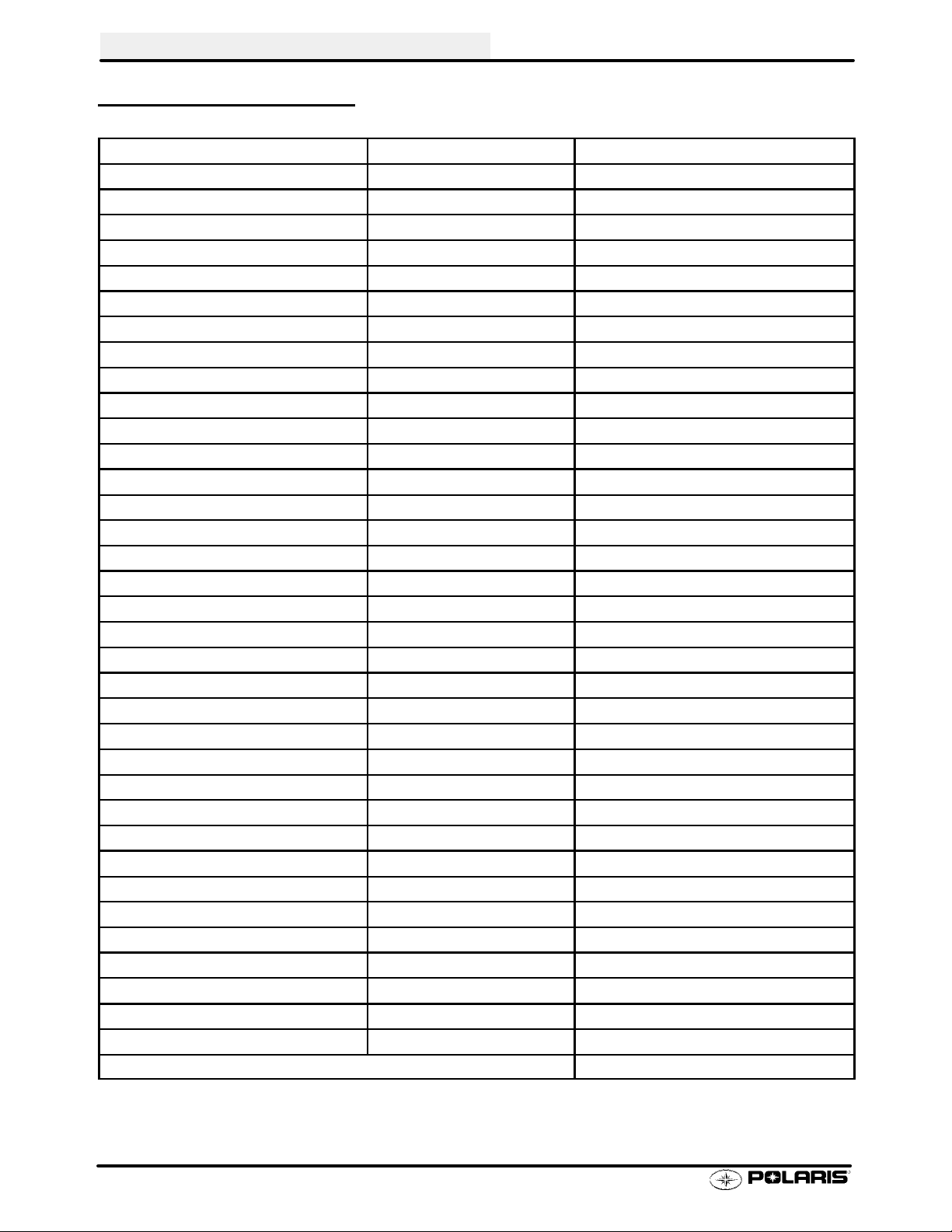

METRIC TAP DRILL SIZES

Tap Size Drill Size Decimal Equivalent Nearest Fraction

3x.50

3x.60

4x.70

4x.75

5x.80

5x.90

6 x 1.00

7 x 1.00

8 x 1.00

8 x 1.25

9 x 1.00

9 x 1.25

10 x 1.25

10 x 1.50

11 x 1.50

12 x 1.50

12 x 1.75

#39

3/32

#30

1/8

#19

#20

#9

16/64

J

17/64

5/16

5/16

11/32

R

3/8

13/32

13/32

0.0995

0.0937

0.1285

0.125

0.166

0.161

0.196

0.234

0.277

0.265

0.3125

0.3125

0.3437

0.339

0.375

0.406

0.406

3/32

3/32

1/8

1/8

11/64

5/32

13/64

15/64

9/32

17/64

5/16

5/16

11/32

11/32

3/8

13/32

13/32

1.23

Page 26

GENERAL INFORMATION

GLOSSARY OF TERMS

ABDC: After bottom dead center.

ACV: Alternating current voltage.

Alternator: Electrical generator producing voltage alternating current.

ATDC: After top dead center.

BBDC: Before bottom dead center.

BDC: Bottom dead center.

BTDC: Before top dead center.

CC: Cubic centimeters.

Center Distance: Distance between center of crankshaft and center of driven clutch shaft.

Chain Pitch: Distance between chain link pins (No. 35 = 3/8″ or 1 cm). Polaris measures chain length in number of

pitches.

CI: Cubic inches.

Clutch Buttons: Plastic bushings which transmit rotation of the clutch to the movable sheave in the drive and driven

clutch.

ClutchOffset: Driveand drivenclutchesareoffsetsothat drive beltwillstaynearlystraightasit movesalongtheclutch

face.

Clutch Weights: Three levers in the drive clutchwhich relative totheir weight, profile andengine RPM causethe drive

clutch to close.

Condenser/Capacitor: A storage reservoir for DC voltage.

Crankshaft Run-Out: Run-out or “bend” of crankshaft measured with a dial indicator while crankshaft is supported

between centers on V blocks or resting in crankcase. Measure at various points especially at PTO.

DCV: Direct current voltage.

Dial Bore Gauge: A cylinder measuring instrument which uses a dial indicator. Good for showing taper and

out-of-round in the cylinder bore.

Electrical Open: Open circuit. An electrical circuit which isn’t complete.

Electrical Short: Short circuit. An electrical circuit which is completed before the current reaches the intended load.

(i.e. a bare wire touching the chassis).

End Seals: Rubber seals at each end of the crankshaft.

Engagement RPM: Engine RPM at which the drive clutch engages to make contact with the drive belt.

ft.: Foot/feet.

Foot Pound: Ft. lb. A force of one pound at the end of a lever one foot in length, applied in a rotational direction.

g: Gram. Unit of weight in the metric system.

gal.: Gallon.

HP: Horsepower.

ID: Inside diameter.

in.: Inch/inches.

Inch Pound: In. lb. 12 in. lbs. = 1 ft. lb.

kg/cm2: Kilograms per square centimeter.

kg-m: Kilogram meters.

Kilogram/meter: A force of one kilogram at the end of a lever one meter in length, applied in a rotational direction.

lorltr: Liter.

lbs/in2: Pounds per square inch.

Left Side: Always referred to based on normal operating position of the driver.

1.24

Page 27

GENERAL INFORMATION

GLOSSARY OF TERMS

m: Meter/meters.

Mag: Magneto.

Magnetic Induction: As a conductor (coil) is moved through a magnetic field, a voltage will be generated in the

windings. Mechanical energy is converted to electrical energy in the stator.

mi.: Mile/miles.

mm: Millimeter. Unit of length in the metric system. 1mm = approximately .040″.

Nm: Newton meters.

OD: Outside diameter.

Ohm: The unit of electrical resistance opposing current flow.

oz.: Ounce/ounces.

Piston Clearance: Total distance between piston and cylinder wall.

psi.: Pounds per square inch.

PTO: Power take off.

PVT: Polaris Variable Transmission (Drive Clutch System)

qt.: Quart/quarts.

RPM: Revolutions per minute.

Regulator: Voltage regulator. Regulates battery charging system output at approx. 14.5 DCV as engine RPM

increases.

Reservoir Tank: The fill tank in the liquid cooling system.

Resistance: Inthemechanicalsense,frictionor load. Inthe electricalsense, ohms. Bothresultinenergy conversionto

heat.

Right Side: Always referred to based on normal operating position of the driver.

RPM: Revolutions per minute.

Secondary Clutch: Driven clutch on chaincase or jackshaft.

SeizedPiston: Galling ofthesidesofa piston. Usually thereis atransferof aluminumfromthepistononto thecylinder

wall. Possible causes: 1) improper lubrication; 2) excessive temperatures; 3) insufficient piston clearance; 4) stuck

piston rings.

Stator Plate: Theplate mounted under the flywheel supporting the battery charging coils.

TDC: Top dead center. Piston’s most outward travel from crankshaft.

Volt: Theunit of measure for electrical pressure of electromotive force. Measured by a voltmeter in parallel with the

circuit.

Watt: Unit of electrical power. Watts = amperes x volts.

WOT: Wide open throttle.

1.25

Page 28

CHAPTER 2

MAINTENANCE

Periodic Maintenance Chart 2.1-2.2....................

Pre-Ride Inspection 2.2...........................

Recommended Lubricants and Capacities 2.3.......

Lubricant and Maintenance Product Numbers 2.4....

Lubrication Charts 2.5-2.8............................

Front Gearcase Lubrication 2.9...................

Transmission Lubrication 2.10......................

Transmission LInkage Adjustment 2.11-2.12..............

Carburetor Adjustments 2.13-2.15.......................

Fuel System 2.16-2.17.................................

Compression Test 2.18............................

Battery Maintenance 2.19..........................

Electrical 2.20....................................

Coolant System Maintenance 2.21-2.22..................

Air Filter Service 2.23..............................

Air Box Sediment Tube Service 2.24.................

Breather Filter 2.24................................

Recoil Housing 2.25...............................

Oil Change/Filter 2.26-2.27.............................

Valve Clearance 2.28-2.29..............................

Steering and Toe Alignment 2.30-2.32....................

Front Hub Maintenance 2.33.......................

Exhaust System Maintenance 2.34..................

Brake System Service 2.35-2.36.........................

Suspension Service 2.37...........................

Controls 2.38.....................................

Wheel Removal/Installation 2.39....................

Tire Inspection 2.40...............................

2

Page 29

MAINTENANCE

PERIODIC MAINTENANCE CHART

Inspection, adjustment and lubrication intervals of important components is listed in the following chart.

Maintenance intervals are based upon average riding conditions and a vehicle speed of approximately 10 mph.

Inspect, clean, lubricate, adjust or replace parts as necessary. NOTE: Inspection may reveal the need for replacement parts. Always use genuine Polaris parts.

HCAUTION: Due to the nature of these adjustments, it is recommended that service be performed by an

authorized Polaris dealer.

"Vehicles subjected to severe use (operation in wet or dusty areas, low speed heavy load operation, prolonged

idle) should be inspected and serviced more frequently. For engine oil, short trip cold weather riding also constitutes severe use. Pay specialattention to oil level. Arise in oil level in coldweather can indicate moisturecollecting in the oil tank. Change oil immediately if oil level begins to rise.

E Emission Control System Service (California).

PERIODIC MAINTENANCE - ENGINE

Frequency

(Whichever comes first)

Item Hours Calendar Miles

(Km)

Engine Oil - Level/Change 100 hrs 6 months 1000 (1600) Check Level Daily; Break In service at 1 month

E"

Oil Filter 100 hrs 6 months 1000 (1600) Replace with oil change

E

Air Filter - Foam Pre-Cleaner Daily Daily Inspect-Clean & oil more often in dirty conditions.

E"

Air Filter - Main Element Weekly Weekly Inspect - Replace if necessary

E"

" Air Box Sediment Tube - Daily Drain deposits whenever visible

" Engine Breather Filter 20 hrs Monthly 200 (320) Inspect and replace if necessary

" Oil Tank Vent Hose 100 hrs 12 months 1000 (1600) Inspect hose routing /hose condition

Valve Clearance 100 hrs 12 months 1000 (1600) Inspect/Adjust

EH

Idle Speed As required As required Adjust

E

H Throttle Cable / ETC Switch 50 hrs 6 months 500 (800) Inspect -Adjust, Lubricate, Replace if necessary

Choke (Enricher) Cable 50 hrs 6 months 500 (800) Inspect -Adjust, Lubricate, Replace if necessary

Carburetor Float Bowl 50 hrs 6 months 500 (800) Drain bowl periodically and prior to storage

Carburetor Air Intake Ducts/Flange 50 hrs 6 months 500 (800) Inspect all ducts for proper sealing/air leaks

Fuel System 100 hrs 12 months 1000 (1600) Check for leaks at tank cap, lines, fuel valve, filter,

EH

Fuel Filter 100 hrs 12 months 1000 (1600) Replace filter annually

EH

Coolant/Level Inspection Daily Daily Replace engine coolant every 2 years

Coolant Strength / Pressure Test

System

Radiator 100 hrs 12 months 1000 (1600) Inspect / Clean external surface

CoolingSystemHoses 100 hrs 12 months 1000 (1600) Inspect

Engine Mounts 100 hrs 12 months 1000 (1600) Inspect

Drain Recoil Housing Weekly Weekly More often if operating in wet environment

Exhaust Muffler / Pipe 100 hrs 12 months 1000 (1600)

100 hrs 6 months 1000 (1600) Inspect strength seasonally; Pressure test sys-

pump & carburetor. Replace lines every 2 years.

tem annually

ELECTRICAL

Spark Plug 100 hrs 12 months 1000 (1600) Inspect - Replace if necessary

E

Wiring 100 hrs 12 months 1000 (1600) Inspect for abrasion, routing, security

Ignition Timing 100 hrs 12 months 1000 (1600) Inspect

Battery 20 hrs Monthly 200 (320) Check terminals; Clean; Check fluid level

Headlight Aim As required As required Adjust if Necessary

Headlamp Inspection Daily Daily Check operation daily; Apply Nyogelt Grease

Tail Lamp Inspection Daily Daily Check Operation Daily; Apply Nyogelt Grease

to connector when lamp is replaced

to socket when lamp is replaced

Remarks

2.1

Page 30

MAINTENANCE

PERIODIC MAINTENANCE CHART, CONT.

CHASSIS

Frequency

(Whichever comes first)

Item Hours Calendar Miles

(Km)

" General Lubrication 50 hrs 3 months 500 (800) Lubricate All Fittings, Pivots, Cables, Etc.

" Front Hubs/Fluid Check 50 hrs 6 months 500 (800) Check monthly

" Front Hubs/Fluid Change 100 hrs 12 months 1000 (1600) Check monthly

" Front Gearcase Lubricant 100 hrs 12 months 1000 (1600) Inspect Monthly; Change Annually

Drive Belt 50 hrs 6 months 500 (800) Inspect - Adjust, Replace if Necessary

Clutches (Drive And Driven) 100 hrs 12 months 1000 (1600) Inspect, Clean

" Transmission Oil Level 25 hrs Monthly 250 (400) Inspect Monthly; Change Annually

Shift Linkage 50 hrs 6 months 500 (800) Inspect,Lubricate, Adjust

Shift Selector Box 200hrs 24 months 2000 (3200) Change Lubricant Every Two Years

H Steering 50 hrs 6 months 500 (800) Inspect Daily, Lubricate

H Toe Adjustment As required As required Periodic Inspection, Adjust When Parts are Re-

placed

" Front Suspension 50 hrs 6 months 500 (800) Inspect - Lubricate

" Rear Suspension 50 hrs 6 months 500 (800) Inspect - Lubricate

Tires Pre-ride Pre-ride Inspect Daily, Pre-Ride Inspection Item

H Brake Fluid 200 hrs 24 months 2000 (3200) Change Every Two Years

" Brake Fluid Level Pre-ride Pre-ride Inspect Daily, Pre-Ride Inspection Item

" Brake Lever Travel Pre-ride Pre-ride Inspect Daily, Pre-Ride Inspection Item

H Brake Pad Wear 10 hrs Monthly 100 (160) Inspect Periodically

Auxiliary Brake Adjustment As required As required Inspect Deflection Daily; Adjust

Brake System Pre-ride Pre-ride Pre-Ride Inspection Item

Wheels Pre-ride Pre-ride Pre-Ride Inspection Item

Frame Nuts, Bolts, Fasteners Pre-ride Pre-ride Pre-Ride Inspection Item

Remarks

PRE-RIDE / DAILY INSPECTION

Perform the following pre-ride inspection daily, and when servicing the vehicle at each scheduled maintenance.

S Tires - check condition and pressures

S Fuel and oil tanks - fill both tanks to their proper level; Do not overfill oil tank

S All brakes - check operation and adjustment (includes auxiliary brake)

S Throttle - check for free operation and closing

S Headlight/Taillight/Brakelight - check operation of all indicator lights and switches

S Engine stop switch - check for proper function

S Wheels - check for tightness of wheel nuts and axle nuts; check to be sure axle nuts are se-

cured by cotte r pins

S Air cleaner element - check for dirt; clean or replace

S Steering - check for free operation noting any unusual looseness in any area

S Loose parts - visually inspect vehicle for any damaged or loose nuts, bolts or fasteners

S Engine coolant - check for proper level at the recovery bottle

2.2

Page 31

MAINTENANCE

RECOMMENDED LUBRICANTS - QUICK REFERENCE

LUBRICANTS AND MAINTENANCE PRODUCT PART NUMBERS ARE LISTED ON PAGE 2.4. REFER

TO SPECIFICATIONS CHAPTER 1 FOR CAPACITY INFORMA

Item

Engine Oil Polaris Premium 4

Synthetic, 0W/40

Transmission Polaris Synthetic Gear

Case Lubricant

Front Gear Case Premium Front Gearcase

Fluid or GL5 80-90 Gear

Lube

Gear Shift Selector

Box

Coolant Level Polaris Premium 60/40

Front Hubs Premium Demand Drive

Brake Fluid Polaris DOT 3 Brake Fluid Fill to indicated level inside reservoir. 2.35

Polaris 0W/40 Synthetic

Engine Lubricant or

10W Motor Oil

Pre-mixed Antifreeze/

Coolant or a 50/50 mixture

high quality antifreeze/

coolant and distilled water

Hub Fluid

Type Notes See

Add to proper level on dipstick. 2.26-2.27

Refer to procedures outlined later in this

chapter.

Refer to procedures outlined later in this

chapter.

Oil in selector box should be at the center

line of the shift selector plungers. Do not

overfill or the selector may hydro-lock.

Fill reservoir tank to full line. Add if necessary. If reservoir was empty or extremely

low, allow engine and cooling system to

cool completely and check level in radiator. Fill to top of filler neck.

Fill hub at 4:00 or 8:00 position until fluid

trickles out. Do not force fluid into hub.

TION.

Pages

2.10

2.9

8.4

2.22

2.33

COLD WEATHER KITS FOR 4 CYCLE ATVS

Oil Tank Cover -- PN 287187

Engine Heater -- PN 2871507

Oil Tank Heater -- PN 2871873

2.3

Page 32

MAINTENANCE

POLARIS PREMIUM LUBRICANT AND MAINTENANCE PRODUCT PART

Part No. Description

2870791 Fogging Oil

2871281 Engine Oil (Quart) Premium 4 Synthetic 0-W40 (4-Cycle)

2871567 Engine Oil (16 Gallon) Premium 4 Synthetic 0-W40 (4-Cycle)

2871477 Premium Synthetic Gearcase Lubricant (1 Gal.)

2871478 Premium Synthetic Gearcase Lubricant (12 oz.. bottle)

2870465 Oil Pump for Gearcase Oil

2871653 Premium Front Gearcase Fluid (12 oz..)

2871322 Premium All Season Grease (3 oz.. cartridge)

2871423 Premium All Season Grease (14 oz.. cartridge)

2871460 Starter Drive Grease

2871515 Premium U-Joint Lube (3 oz..)

2871551 Premium U-Joint Lube (14 oz..)

2871312 Grease Gun Kit

1350046 CV Joint Grease Pack (30g)

1350047 CV Joint Grease Pack 50g

2871329 Dielectric Grease (Nyogelt)

2871654 Premium Demand Drive Hub Fluid (12 oz..)

2871323 60/40 Coolant Gallon

2871534 60/40 Coolant Quart

2870585 Loctitet Primer N, Aerosol, 25g

2871949 Loctitet Threadlock 242 (50ml.)

2871950 Loctitet Threadlock 242 (6ml.)

2871951 Loctitet Threadlock 262 (50ml.)

2871952 Loctitet Threadlock 262 (6ml.)

2871953 Loctitet Threadlock 271 (6ml.)

2871954 Loctitet Threadlock 271 (36ml.)

2870584 Loctitet RC 680-Retaining Compound (10ml. )

2870587 Loctitet 518 Gasket Eliminator / Flange Sealant (50ml.)

2871326 Premium Carbon Clean 12 oz..

2870652 Fuel Stabilizer 16 oz..

2871957 Black RTV Silicone Sealer (3 oz.. tube)

2871958 Black RTV Silicone Sealer (11oz.. cartridge)

8560054 Marine Grade Silicone Sealer (14 oz.. cartridge)

2870990 DOT3 Brake Fluid

2872113 Disc Brake Quiet, Aerosol, (9 oz..)

2871557 Crankcase Sealant, 3-Bond 1215

NUMBERS

Engine Lubricant

Gearcase / Transmission Lubricants

Grease / Specialized Lubricants

Coolant

Additives / Sealants / Thread Locking Agents / Misc.

2.4

Page 33

LUBRICATION

MAINTENANCE

Ill.

Item Lube Rec. Method Frequency*

#

1 Engine Oil Polaris 0W/40

Synthetic

2 Transmission Polaris Synthet-

ic Gear Case

Lubricant

3 Brake Fluid Polaris DOT 3

Brake Fluid

Add oil to proper level. Change after 1st month, 6 months or 100

hours thereafter; Change more often (25-50

hours) in extremely dirty conditions, or s hort

trip cold weather operation.

Add lube to FULL level on dipstick.

Fill master cylinder reservoirto indicated level inside reservoir. See

page 2.36.

Change annually ©

As required. Change fluid every 2 years.

* More often under severe use, such as operated in water or under severe loads.

Transmission Dipstick

Dipstick

Full

Filter

1. Engine Oil and Filter

2. Transmission

OperatingRange

Master Cylinder

Reservoir

3. Brake Fluid (Left hand Master Cylinder)

2.5

Page 34

MAINTENANCE

LUBRICATION, CONT.

5. Front Drive

Axle

U-Joint

Ill.

#

4 Demand 4 Hubs -

All Wheel Drive

ATVs

5 FrontDriveAxle“U”

Joints

6 Ball Joint Polaris All Season

7 FrontA-Arm Pivot

Shaft

8 Tie Rod Ends Polaris All Season

9 Steering Post Bush-

ings

Item Lube Rec. Method Frequency*

Polaris Demand

Drive Hub Fluid or

ATF Type F

Polaris U-Joint

Grease¢

Grease¢

Polaris All Season

Grease¢

Grease¢

All Season

Grease¢

9. Steering Post

Bushings

Upper

8. Tie Rod End

Lower

4. Demand 4 Hubs

4 or 8 O’clock position-

(end view)

7. Front A-Arm

Pivot Shaft

6. Ball Joint

Remove filler hole screw in hubs. Rotatewheels to

4 or 8 O’clock position. If lubricant is not visible add

until it flows from filler hole. Reinstall screw.

Locate grease fitting and grease with grease gun. Semi-annually

Locate grease fitting on back side of struts and

grease with grease gun.

Locate grease fitting on pivot shaft and grease with

grease gun.

Lift boot. Clean away dirt and grease. Apply fresh

grease by hand and reassemble.

Locate fittings on upper and lower steering post and

grease with grease gun.

Semi-annually

¡

¡

Semi-annually

¡

Semi-annually

¡

Semi-annually

¡

Semi-annually

¡

* More often under severe use, such as operated in water or under severe loads.

¡ Semi-annually or 50 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

© Annually or 100 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

¢ Grease conforming to NLGI No. 2, such as Polaris Premium All Season Grease, Conoco Superlube M or

Mobilegrease Special

2.6

Page 35

LUBRICATION, CONT.

10. Front Gear Case Fill Plug

MAINTENANCE

Fill Plug

Ill.

#

10 FrontGearcase Oil GL5 80-90 Weight

11 U-Joints - Front Prop Shaft Premium U-Joint

12 PropshaftYoke PremiumU-Joint

Item Lube Rec. Method Frequency*

Gear Lube

Grease

Grease

11. Front Prop Shaft

U-Joint

Add to bottom of fill plug

threads. See page 2.10

Locate Fittingsand Grease Semi-annually¡

Locate fittings and grease - 3

pumps maximum

12. Propshaft Yoke

(3 pumps max.)

Change annually©

Annually©

* More often under severe use, such as operated in water or under severe loads.

¡ Semi-annually or 50 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

© Annually or 100 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

¢ Grease conforming to NLGI No. 2, such as Polaris Premium All Season Grease, Conoco Superlube M or

Mobilegrease Special

2.7

Page 36

MAINTENANCE

LUBRICATION, CONT.

13. Upper Control

Arm

15. Rear Wheel Hub Bearing Carrier

14. Lower Control

Arm

14. Lower Control

Arm

16. Rear AntiRoll Bar

Ill.

#

13 Upper Control Arms Polaris All Season

14 Lower Control Arms Polaris All Season

15 Rear Wheel Hub Bearing Carrier Polaris All Season

16 Rear Anti-Roll Bar Polaris All Season

Item Lube Rec. Method Frequency*

Locate fittings and grease Semi-annuall y ¡

Grease¢

Locate fittings and grease Semi-annuall y ¡

Grease¢

Locate fittings and grease Semi-annuall y ¡

Grease¢

Locate fittings and grease Semi-annuall y ¡

Grease¢

* More often under severe use, such as operated in water or under severe loads.

¡ Semi-annually or 50 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

© Annually or 100 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

¢ Grease conforming to NLGI No. 2, such as Polaris Premium All Season Grease, Conoco Superlube M or

Mobilegrease Special

2.8

Page 37

MAINTENANCE

FRONT GEARCASE LUBRICATION

The gearcase lubricant level should be checked and changed in accordance with the maintenance schedule.

S Be sure vehicle is level before proceeding.

S Check vent hose to be sure it is routed properly and unobstructed.

S The correct gearcase lubricant to use is Polaris Premium GL5 80-90 Gear Lube, or an equivalent lubricant

with a GL5 rating.

FRONT GEARCASE SPECIFICATIONS

Specified Lubricant:

Polaris Front Gearcase Lube PN 2871653

...Or API GL5 80-90 Gearlube

Capacity: 4.0 Oz. (120ml.)...........

Drain Plug / Fill Plug Torque:

14 ft. lbs. (19.4 Nm)

To check the level:

1. The front gearcase lubricant level cannot be

checked with a dipstick or by visual reference.

The gearcase must be drained and re-filled with

theproperamount oflubricant. Refertoprocedure

below.

To change lubricant:

1. Remove gearcase drain plug located on the bottom

and drain oil. Catch and discard used oil properly.

2. Clean and reinstall drain plug using a new sealing

washer.

3. Remove fill plug.

4. Add proper amount of lubricant.

5. Install fill plug.

6. Check for leaks.

Make sure vent is unobstructed

Fill plug

Drain plug

2.9

Page 38

MAINTENANCE

TRANSMISSION LUBRICATION

The transmission lubricant level should be checked and changed in accordance with the maintenance schedule.

S Be sure vehicle is level before proceeding.

S Check vent hose to be sure it is routed properly and unobstructed.

TRANSMISSION SPECIFICATIONS

Specified Lubricant:

Polaris Premium Synthetic Gearcase Lubricant

PN 2871477 (Gallon) PN 2871478 (12 oz..)

Capacity: At change: Approx. 20 oz.....

Drain Plug:

14 ft. lbs. (19.4 Nm)

To check the level:

1. Remove dipstick and wipe clean.

2. Reinstall dipstick completely, remove and check the

level. Add the proper lubricant as required to bring

level into operating range as shown.

To change lubricant:

1. Remove skid plate (if necessary).

2. Place a drain pan beneath the transmission oil drain

plug area.

3. Remove the drain plug and wipe the magnetic end

clean to remove accumulated metallic filings.

4. After the oil has drained completely, install a new

sealing washer and install the drain plug. Torque to

14 ft. lbs. (19 Nm).

5. Addtheproperlubricant through thedipstick holeun-

til the oil level is between the upper and lower limits.

Do not overfill.

6. Check for leaks.

7. Reinstall skid plate if removed in step 1.

Full

Dipstick

Operating

Range

2.10

Page 39

MAINTENANCE

TRANSMISSION GEARSHIFT LINKAGE ADJUSTMENT, PRELIMINARY

S If shifting problems are encountered, the transmis-

sion linkage can be adjusted.

S Tighten shift linkage rod end jam nuts properly after

adjustment. Youshould be able to rotate the linkage

rod between 1/8 and 1/4 turn after both jam nuts are

tight.

S The transmission shift linkage should be periodically

inspected for wear and parts replaced as required to

remove excess play from shift linkage.

S Refer to Transmission chapter for more information.

INSPECTION

SHIFT LINKAGE ADJUSTMENT

Linkage rod adjustment is necessary when symptoms include:

S No All Wheel Drive light

Linkage rod will rotate

1/8 -1/4 turn if rod ends

are tightened properly.

Correctly Tightened

Jam Nut

Parallel

Incorrectly Tightened

Jam Nut

S Noise on deceleration

S Inability to engage a gear

S Excessive gear clash (noise)

S Shift selectors moving out of desired range

NOTE: When adjusting linkage, always adjust both linkage rods. The adjustment of one rod can prevent proper

adjustment of the other rod. Remove necessarycomponents togain access to shift linkagerodends (i.e. exhaust

heat shield, exhaust pipe, etc.).

1. Inspect shift linkage tie rod ends, clevis pins, and

pivot bushings and replace if worn or damaged.

Lubricate the tie rod ends with a light aerosol

lubricant or grease.

2. Loosen all rod end adjuster jam nuts see Ill. 1.

3. Note orientation of tie rod end studs with stud up or

down. Remove both rod end studs from

transmission bell cranks.

4. Be sure idle speed is adjusted properly.

NOTE: It is important to disconnect both rod ends from

the transmission bell cranks. If one linkage rod is incorrectly adjusted, it can affect the adjustment of the other

rod.

Low Range

Jam Nut

NOTE: Rod end orientation, rod ends are

both down.

Ill. 1

Gear Selector

Slides

Jam

Nut

2.11

Page 40

MAINTENANCE

SHIFT LINKAGE ADJUSTMENT, CONT.

5. Place gear selector in neutral. Make sure the

transmission bell cranks are engaged in the neutral

position detents.

6. Besure the shift linkagerod endsare firmly attached

to the gear selector slides. Adjust the low range

(inside) rod so the rod end is centered on the

transmission bell crank. Installthelock nut to the rod

end and torque to 35 in. lbs.

Adjust to align linkage rod end studs

with holes in bellcrank(s).

35 in. lbs.

35 in. lbs.

7. Rotate the linkage rod clockwise until resistance is

felt. Mark the rod so revolutions can be easily

counted. See Ill. 3 at right.

8. Rotate the linkage rod counterclockwise until the

same resistance is felt, counting the revolutions as

the rod is turned.

9. Turn the rod clockwise again one half of the

revolutions counted in Step 9.

10. Tighten the rod end jam nuts securely while holding

the rod end. The jam nuts must be tightened with

both front and rear rod ends parallel to each other. If

jamnutsare properly tightened, the rodshouldrotate

freely 1/4 turn without binding.

1 1. Repeat steps 7-10 for the High/Reverse rod.

Ill. 2

Place

mark

on rod

Ill. 3

S Rotate rod both directions to

find points where resistance

is felt.

S Center the rod between the

points.

S Hold rod end parallel to

mounting surface and

tighten jam nut.

Parallel

2.12

Page 41

THROTTLE OPERATION

Check for smooth throttle opening and closing in all handlebar positions. Throttle lever operation should be

smooth and lever must return freely without binding.

1. Place the gear selector in neutral.

2. Set parking brake.

3. Start the engine and let it idle.

4. Turnhandlebarsfrom full right to full left. If idle speed

increases at any point in the turning range, inspect

throttle cable routing and condition.

5. Replace the throttle cable if worn, kinked, or damaged.

To remove the ETC cover:

1. Useamedium flat bladescrewdriverandinsertblade

into the pocket of the cover starting on the #1

position.

2. Twistscrewdriver slightly while lifting on the cover to

release snap.

3. Repeat procedure at the other five locations as

shown. NOTE: Do not attempt toremovecoveruntil

all latch points are released.

MAINTENANCE

3

6

2

1

565

4

CHOKE (ENRICHER) ADJUSTMENT

With the choke control pushed in, the choke plunger must

be seated on the fuel passage way in the carburetor. If the

plunger is not seated on the fuel passage way inside the

carburetor (notenough cablefreeplay),theenginewillflood

or run too rich, causing plug fouling and poor performance.

If cable slack is excessive, the choke fuel passage will not

open far enough, which may cause cold starting difficulty.

Also, the half-choke position used for intermittent applications will not function properly.

1. Locatethe boot behind the chokeknoband pull it back.

Loosenthe friction nut1 turnor untilchokeslidesfreely.

Re-install boot.

2. Push the choke knob in to the full off position.

3. Slide boots off in-line cable adjuster and loosen

adjustment locknut.

4. Turn adjuster until the choke knob pulls out over 1/4″.

5. Push on the choke knob lightly while turning the

adjuster the opposite way.

6. Turn the adjuster until the knob contacts the boot.

Boot

Adjuster

Sleeve

Locknut

Boot

7. Tighten adjuster nut.

8. Slide boots back over cable adjuster sleeve until they

touch at the middle point of the adjuster.

9. Pull back the choke knob boot and tighten the friction

nut until the choke will maintain a set position.

Re-install boot.

2.13

Page 42

MAINTENANCE

PILOT SCREW ADJUSTMENT

Pilot Screw (Idle Mixture) Adjustment Notes

Donot tightenthepilot screwforcefully against the seat or thescrew and/or seat willbe permanently damaged.

Start engine and warm it up to operating temperature (about 10 minutes). This is a very important step.

1. Turn pilot screw in (clockwise) until lightly seated.

Turn screw out the specified number of turns.

Pilot Screw Adjustment:

2.0 Turns

2. Connect an accurate tachometer that will read in

increments of + or -- 50 RPM such as the PET

2100DX (P/N 8712100DX) or the PET 2500 (P/N

8712500).

3. Set idle speed to 1200 RPM. Always check throttle

cable freeplay after adjusting idle speed and adjust if

necessary.

4. Slowly turn mixture screw clockwise using the pilot

screw wrench until RPM begins to decrease by 50

RPM or greater.

5. Slowly turn mixture screw counterclockwise until idle

speedincreases tomaximum RPM. Continueturning

counterclockwise until idle RPM begins to drop.

6. Center the pilot screw between the points in step 5

and 6.

7. Re adjust idle speed if not within specification.

IDLE SPEED ADJUSTMENT

FRONT

(Engine)

Pilot Screw

1. Start engine and warm it up thoroughly.

2. Adjustidlespeedby turning theidle adjustmentscrew

in(clockwise) toincreaseorout (counterclockwise)to

decrease RPM. (Refer to Ill. at right).

NOTE: Adjusting the idle speed affects throttle cable

freeplay and electronic throttle control (ETC) adjustment.

Always check throttle cable freeplay after adjusting idle

speed and adjust if necessary .

Idle Speed:

1200 +/-- 200 RPM

2.14

CV Carburetor

Idle Screw

Page 43

THROTTLE CABLE / ELECTRONIC THROTTLE

MAINTENANCE

CONTROL (ETC SWITCH)

1. Slide boot off throttle cable adjuster and jam nut.

2. Place shift selector in neutral and set parking brake.

3. Start engine and set idle to specified RPM, thenshut

off engine.

NOTE: Be sure the engine is at operating temperature.

See Idle Speed Adjustment.

4. Loosen lock nut on in-line cable adjuster (Ill. 1).

5. Turnadjuster until 1/16″ to 1/8″ freeplay is achieved

at thumb lever. (Ill. 2). While making adjustment,

quickly actuate the thumb lever several times.

6. Tightenlock nutsecurelyand slideboot completely in

place to ensure a water-tight seal.

7. Turn handlebars from left to right through the entire

turning range. If idle speed increases, check for

proper cable routing. If cable is routed properly and

in good condition, repeat adjustment procedure.

ADJUSTMENT

Ill. 1

Boot

Adjuster

Sleeve

Locknut

Boot

Ill. 2

Direction

of travel

1/16″ -1/8″

Freeplay

2.15

Page 44

MAINTENANCE

FUEL SYSTEM

WARNING

Gasoline is extremely flammable and explosive under certain conditions.

Always stop the engine and refuel outdoors or in a well ventilated area.

Do not smoke or allow open flames or sparks in or near the area where refueling is performed or where

gasoline is stored.

Do not overfill the tank. Do not fill the tank neck.

If you get gasoline in your eyes or if you swallow gasoline, see your doctor immediately.

Ifyouspillgasolineonyourskin orclothing,immediatelywash itoff withsoapandwaterand changeclothing.

Neverstarttheengine orlet it run inan enclosedarea. Gasolinepowered engineexhaustfumesarepoison-

ous and can cause loss of consciousness and death in a short time.

Never drain the float bowl when the engine is hot. Severe burns may result.

FUEL LINES

1. Check fuel lines for signs of wear, deterioration,

damage or leakage. Replace if necessary.

2. Besure fuellines areroutedproperlyand secured with

cableties. CAUTION: Make sure lines are not kinked

or pinched.

3. Replace all fuel lines every two years.

VENT LINES

1. Check fuel tank, oil tank, carburetor, battery and

transmission ventlines for signsof wear,deterioration,

damage or leakage. Replace every two years.

2. Be sure vent lines are routed properly and secured

with cable ties. CAUTION: Make sure lines are not

kinked or pinched.

FUEL FILTER

The fuel filter should be replaced in accordance with the

Periodic Maintenance Chart or whenever sediment is visible in the filter.

1. Shut off fuel supply at fuel valve.

2. Remove line clamps at both ends of the filter.

3. Remove fuel lines from filter.

4. Install new filter and clamps onto fuel lines with arrow

pointed in direction of fuel flow.

5. Install clamps on fuel line.

6. Turn fuel valve ON.

7. Start engine and inspect for leaks.

8. Reinstall fuel tank.

Arrow Indicates Direction

of Flow

To Carburetor

2.16

Page 45

CARBURETOR DRAINING

The carburetor float bowl should be drained periodicallyto

remove moisture or sediment from the bowl, or before extended periods of storage.

NOTE: The bowl drain screw is located on the bottom left

side of the float bowl.

MAINTENANCE

1. Turn fuel valve to the off position.

2. Place a clean container beneath the bowl drain spigot

or bowl drain hose.

3. Turn drain screw out two turns and allow fuel in the

float bowl and fuel line to drain completely.

4. Inspect the drained fuel for water or sediment.

5. Tighten drain screw.

6. Turn fuel valve to “on”.

7. Start machine and check for leaks.

NOTE: If there is a tube attached, it must be replaced as

this will effect engine performance.

Drain tube

attached

here

Drain Screw

RES

OFF

ON

2.17

Page 46

MAINTENANCE

COMPRESSION TEST

NOTE: 4-Stroke engines are equipped with anautomatic decompressor. Compression readings will vary in pro-

portion tocrankingspeedduringthetest. Averagecompression (measured) isabout50-90 psiduringa compression test.

Smoothidle generallyindicatesgood compression. Lowenginecompressionis rarely afactorinrunningcondition

problems above idle speed. Abnormally high compression can be caused by a decompressor malfunction, or

worn or damaged exhaust cam lobes. Inspect camshaft and automatic decompression mechanism if compression is abnormally high.

Acylinder leakagetestis the bestindicationofengine conditiononmodels with automatic decompression. Follow

manufacturer’s instructionstoperform acylinderleakagetest. (Never use highpressureleakagetesteras crankshaft seals may dislodge and leak).

Cylinder Compression

Standard 50-90 PSI

Cylinder Leakage

Service Limit 10 %

(Inspect for cause if leakage exceeds 10%)

ENGINE MOUNTS

Inspect rubber engine mounts (A) for cracks or damage.

FASTENER TORQUE - ENGINE

Check engine fasteners and ensure they are tight.

A

A

A

2.18

Page 47

BATTERY MAINTENANCE

WARNING

Battery electrolyte is poisonous. It contains sulfuric acid. Serious

burns can result from contact with skin, eyes or clothing. Antidote:

External: Flush with water.

Internal: Drink large quantities of water or milk. Follow with milk

of magnesia, beaten egg, or vegetable oil. Call physician immediately.

Eyes: Flush with water for 15 minutes and get prompt medical

attention.

Batteries produce explosive gases. Keep sparks, flame, cigarettes, etc. away. Ventilate when charging or using in an enclosed

space. Always shield eyes when working near batteries. KEEP

OUT OF REACH OF CHILDREN.

The battery is located under the left rear fender.

MAINTENANCE

Inspect the battery fluid level. Whenthebattery fluid nears

thelowerlevel, thebattery should beremovedanddistilled

water should be added to the upper level line. Toremove

the battery:

1. Disconnect holder strap and remove cover.

2. Disconnect battery negative (-) (black) cable first,

followed by the positive (+) (red) cable.

CAUTION

Whenever removing or reinstalling the battery,disconnect

the negative (black) cable first and reinstall the negative

cable last!

3. Disconnect the vent hose.

4. Remove the battery.

5. Remove the filler caps and add distilled water only as needed to bring each cell to the proper level. Do not

overfill the battery. Fully recharge after refilling.

To refill use only distilled water. Tap water contains minerals which are harmful to a battery.

Do not allow cleaning solution or tap water to enter the battery. It will shorten the life of the battery.

6. Reinstall the battery caps.

7. Cleanbattery cables and terminals with a stiff wire brush. Corrosion can be removed using a solution of one

cup water and one tablespoon baking soda. Rinse well with clean water and dry thoroughly.

8. Reinstall battery, attaching positive (+) (red) cable first and then the negative (-) (black) cable.

9. Reattach vent hose making sure it is properly routed and not kinked or pinched.

10. Coat terminals and bolt threads with Nyogelt grease.

1 1. Reinstall battery cover and holder strap.

Maintain

between upper

and lower level

marks

NOTE: New Battery:

of batterys’ full potential.

Battery must befullychargedbeforeuse orbattery lifewillbe significantly reduced 10-30%

2.19

Page 48

MAINTENANCE

SPARK PLUG

1. Removesparkplughightensionlead. Cleanplug area

so no dirt and debris can fall into engine when plug is

removed.

2. Remove spark plug.

3. Inspect electrodes for wear and carbon buildup. Look

for a sharp outer edge with no rounding or erosion of

the electrodes.

4. Clean with electrical contact cleaner or a glass bead

spark plug cleaner only. CAUTION: A wire brush or

coated abrasive should not be used.

5. Measure gap with a wire gauge. Refer to

specifications for proper spark plug type and gap.

Adjust gap if necessary by bending the side electrode

carefully.

6. If necessary, replace spark plug with proper type.

CAUTION: Severe engine damage may occur if the

incorrect spark plug is used.

7. Apply a small amount of anti-seize compound to the

spark plug threads.

8. Install spark plug and torque to 14 ft. lbs.

IGNITION TIMING

Recommended Spark Plug:

Refer to Specifications

Spark Plug Torque: 14 Ft. Lbs.

(19 Nm)

Spark Plug Gap

.024 - .028″ (.6 - .7 mm)

Refer to Electrical chapter for ignition timing procedure.

Engine-To-Frame Ground

Inspect engine-to-frame ground cable connection. Be

sure it is clean and tight.

2.20

Page 49

MAINTENANCE

LIQUID COOLING SYSTEM OVERVIEW

Theenginecoolantleveliscontrolledormaintainedbyt her ecoverysystem. Therecoverysystemcomponents

are t he recover y bott le, r adiat or filler neck , radiat or pres sur e cap and connecting hose.

Ascoolantoperatingt emper at ur eincreases,t heexpanding(heated)excessc oolantisfor cedoutoftheradiator

pastt he pressurecapandint o ther ec over y bottle. As enginecoolant temperatur e decreases thec ont rac t ing

(cooled) coolant is drawn bac k up from the tank past the press ure cap and into the radiator.

S Somecoolantleveldroponnewmachinesisnormalasthesystemispurgingitselfoft rappedair. Observe

coolant levels often during the break-in period.

S Overheating of engine could occur if air is not fully purged from system.

S Polaris Premium 60/40 is already premixed and ready to use. Do not dilute with water.

COOLANT STRENGTH / TYPE

Test the strength of the coolant using an antifreeze

hydrometer.

S A 50/50 or 60/40 mixture of antifreeze and distilled wa-

ter will provide the optimum cooling, corrosion protection, and antifreeze protection.

S Do not use tap water, straight antifreeze, or straightwa-

ter in the system. Tap water contains minerals and impurities which build up in the system.

S Straight water or antifreeze may cause the system to

freeze, corrode, or overheat.

Polaris 60/40 Anti-Freeze / Coolant

PN 2871323

COOLING SYSTEM HOSES

1. Inspectall hosesfor cracks, deterioration,abrasionor

leaks. Replace if necessary.

2. Check tightness of all hose clamps.

CAUTION:Do not over-tighten hose clampsat radiator,or

radiator fitting may distort, causing a restriction to coolant

flow. Radiator hose clamp torque is 36 inch lbs.

RADIATOR

1. Check radiator air passages for restrictions or

damage.

2. Carefully straighten any bent radiator fins.

3. Remove any obstructions with compressed air or low

pressure water.

Antifreeze Hydrometer

COOLING SYSTEM PRESSURE TEST

Refer to page 3.6 for pressure test procedure.

2.21

Page 50

MAINTENANCE

COOLANT LEVEL INSPECTION

Therecoverybott le,located onthelef tside ofthe mac hine,

mustbemaintainedbetweentheminimumandmaximum

levels indic at ed on the recovery bott le.

With the engineat operatingtemperature, the coolantlevel

should be bet ween the upper and lower marks on t he

coolant reservoir. If not:

1. Remove reservoir cap. Inner splash cap vent hole

must be clear and open.

2. Fill reservoir to upper mark with Polaris Premium

60/40 Anti Freeze / Coolant or 50/50 or 60/40 mixture

of antifreeze and distilled water as required for freeze

protection in your area.

3. Reinstall cap.

NOTE: If overheating is evident, allow system to cool

completely and check coolant level in the radiator and inspect for signs of trapped air in system.

Recovery

Bottle

Accessible

Under Side

Panel

RADIATOR COOLANT LEVEL INSPECTION

NOTE: This procedure is only required if the cooling sys-

tem has been drained for maintenance and/or repair.

However, if the recovery bottle has run dry,or if overheating is evident, the level in the radiator should be inspected

and coolant added if necessary.

WARNING Never remove the pressure cap when

the engine is warm or hot. Escaping steam can cause severe burns. The engine must be cool before removingthe

pressure cap.

NOTE: Useof a non-standard pressure cap will not allow

the recovery system to function properly.

To access the radiator pressure cap:

Remove the four screws securing front rack. Turnhandle

bars full left or right to provide more clearance. Remove

front cover by placing your fingers under the front of the

cover and pulling upward.

Front

Cover

Rack

2.22

Page 51

AIRFILTERPRE-FILTERSERVICE

MAINTENANCE

Itis recommended thattheair filter andprefilterbereplaced

annually. When riding in extremely dusty conditions replacement will be required more often.

The pre filter should be cleaned before each ride, using the

following procedure.