Page 1

2017-2021 RANGER 500 / 570

Service Manual

FOREWORD

The information printed within this publication includes the latest product information at time of print. The most recent

version of this Service Manual is available in electronic format at www.polarisdealers.com.

This Service Manual is designed primarily for use by certified Polaris Master Service Dealer®technicians in a properly

equipped shop and should be kept available for reference. All references to left and right side of the vehicle are from

the operator's perspective when seated in a normal riding position.

Some procedures outlined in this manual require a sound knowledge of mechanical theory, tool use, and shop

procedures in order to perform the work safely and correctly. Technicians should read the text and be familiar with the

service procedures before starting any repair. Certain procedures require the use of special tools. Use only the proper

tools as specified. If you have any doubt as to your ability to perform any of the procedures outlined in this Service

Manual, contact an authorized dealer for service.

We value your input and appreciate any assistance you can provide in helping make these publications more useful.

Please provide any feedback you may have regarding this manual. Authorized dealers can submit feedback using 'Ask

Polaris'. Click on 'Ask Polaris', and then click on 'Service Manual / Service Literature Question'.

Consumers, please provide your feedback in writing to: Polaris Industries Inc. ATTN: Service Publications Department,

2100 Hwy 55, Medina, MN 55340.

Publication Printed January 2021 (PN 9850043 R01)

© Copyright 2021 Polaris Inc. All information contained within this publication is based on the latest product information at the time of publication. Due to constant

improvements in the design and quality of production components, some minor discrepancies may result between the actual vehicle and the information presented in this

publication. Depictions and/or procedures in this publication are intended for reference use only. No liability can be accepted for omissions or inaccuracies. Any reprinting

or reuse of the depictions and/or procedures contained within, whether whole or in part, is expressly prohibited. Printed in U.S.A.

Page 2

SAFETY WARNINGS

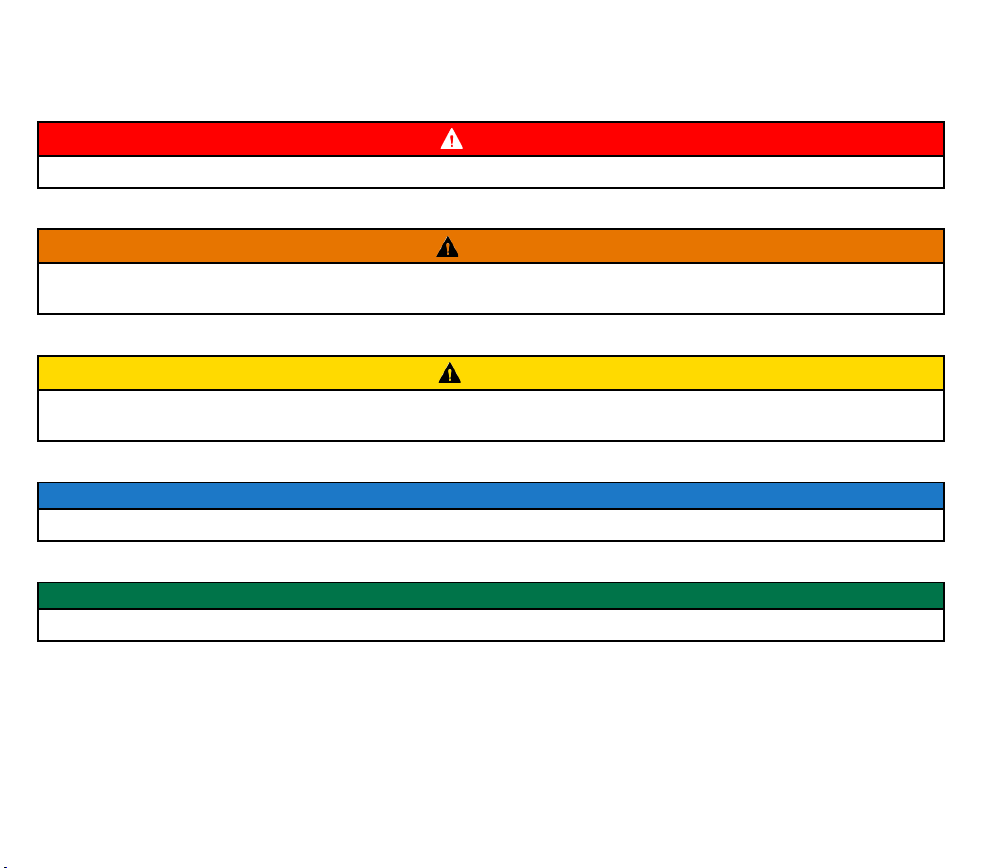

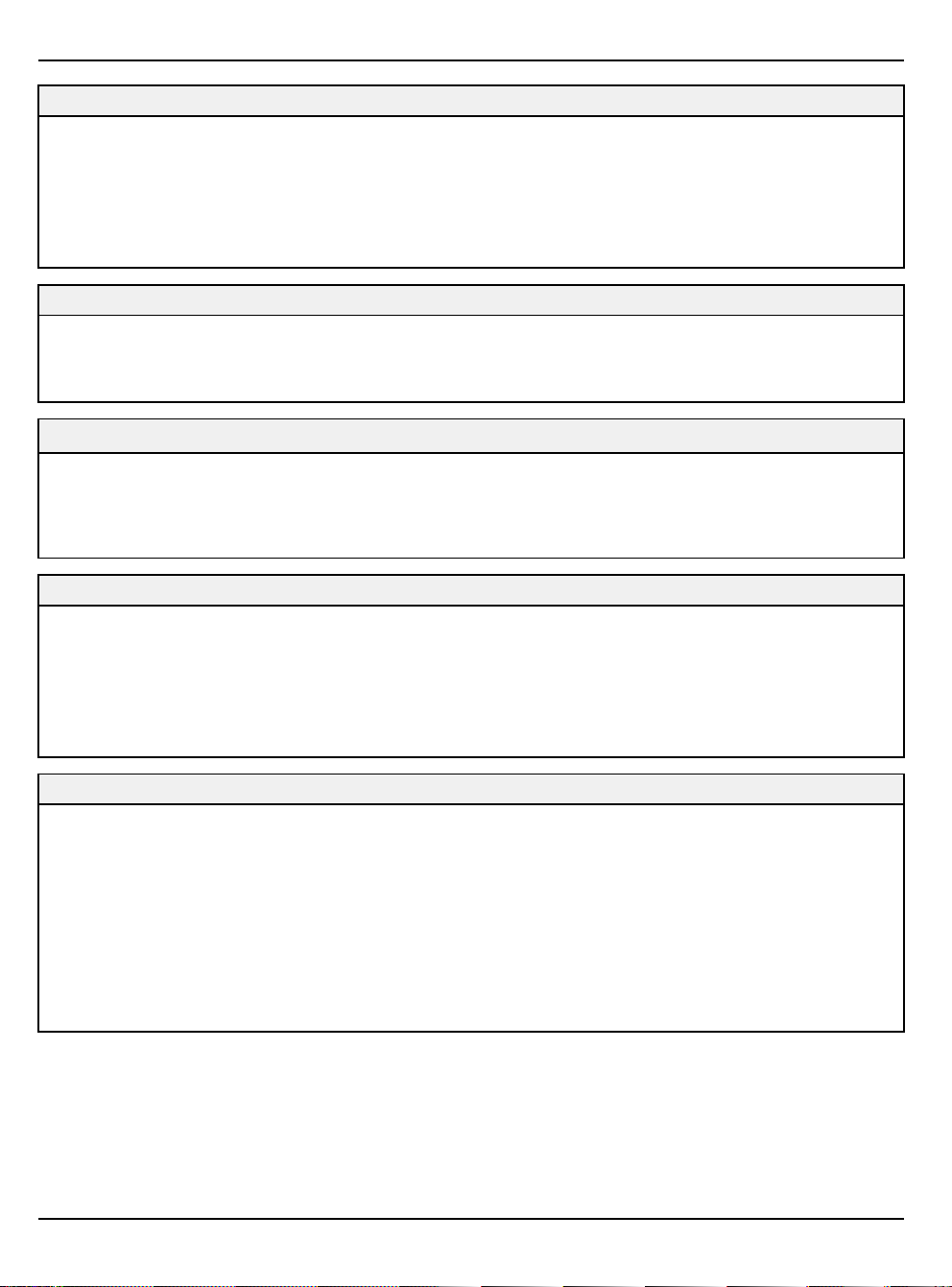

The following signal words and symbols appear throughout this manual and on the vehicle. Your safety is involved

when these words and symbols are used. Become familiar with their meanings before reading the manual.

DANGER

DANGER indicates a hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING

SAFETY ALERT WARNING indicates a hazardous situation which, if not avoided, COULD result in death or serious

SAFETY ALERT CAUTION indicates a hazardous situation which, if not avoided, COULD result in minor to moderate

NOTICE provides key information by clarifying instructions.

IMPORTANT provides key reminders during disassembly, assembly and inspection of components.

injury.

CAUTION

injury.

NOTICE

IMPORTANT

Page 3

TRADEMARKS

POLARIS ACKNOWLEDGES THE FOLLOWING PRODUCTS MENTIONED IN THIS MANUAL:

Loctite, Registered Trademark of the Loctite Corporation

Nyogel, Trademark of Wm. F. Nye Co.

Fluke, Registered Trademark of John Fluke Mfg. Co.

Mity-Vac, Registered Trademark of Neward Enterprises, Inc.

Torx, Registered Trademark of Textron

Hilliard, Trademark of the Hilliard Corporation

Warn, Trademark of Warn Industries

FOX, Registered Trademark of FOX RACING SHOX

RydeFX, Registered Trademark of ArvinMeritor

Some Polaris factory publications can be downloaded from www.polarisindustries.com, purchased from

www.purepolaris.com or by contacting the nearest Polaris dealer.

Page 4

REVISION INDEX

REV DATE

R01 01/13/2021

CHANGES

Initial release

Page 5

FEEDBACK FORM

A feedback form has been created for the technician or consumer to provide Polaris

with an overall satisfaction rating for this service manual, provide comments on your

experience or upload pictures/video. This feedback form is viewable on a mobile

device by scanning the QR code or by clicking

electronically.

HERE if viewing this document

Page 6

Page 7

2017-2021 RANGER 500 / 570

Service Manual

Chapter Summary

CHAPTER 1 : GENERAL INFORMATION

CHAPTER 2 : MAINTENANCE

CHAPTER 3 : ENGINE / COOLING SYSTEM

CHAPTER 4 : ENGINE ELECTRICAL

CHAPTER 5 : FUEL SYSTEM

CHAPTER 6 : PVT SYSTEM

CHAPTER 7 : TRANSMISSION

CHAPTER 8 : FINAL DRIVE

CHAPTER 9 : STEERING / SUSPENSION

CHAPTER 10 : BRAKE SYSTEM

CHAPTER 11 : BODY / FRAME

CHAPTER 12 : ELECTRICAL

Page 8

Page 9

GENERAL INFORMATION

CHAPTER 1

GENERAL INFORMATION

VEHICLE INFORMATION. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. 1.4

MODEL NUMBER DESIGNATION (2015 +) ... . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . ... . .. . . . . . 1.4

VEHICLE IDENTIFICATION NUMBER (VIN) DESIGNATION (2015+) . . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. 1.4

VIN / ENGINE NUMBER LOCATION ... . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . . .. . . 1.4

REFERENCE INFORMATION . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . 1.5

REPLACEMENT KEYS . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . 1.5

PUBLICATION PART NUMBERS .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . . 1.6

SPECIAL TOOLS . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. 1.8

MASTER SPECIAL TOOLS TABLE . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. 1.9

MASTER TORQUE TABLE . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .1.17

CLUTCHING CHART . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .1.19

GENERAL SPECIFICATIONS ... . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . .1.20

2017-2018 RANGER 500 . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . . .. . .. . . .. . .. .1.20

2017-2018 RANGER 570 4X4. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . ..1.22

2017-2018 RANGER 570 4X4 (INTL.) . . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .1.24

2017-2018 RANGER 570 4X4 TRACTOR (INTL.). .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . ..1.26

2017-2018 RANGER 570 CREW ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . ... . .. . .. . . .. . .1.28

2019 RANGER 500. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ..1.30

2019 RANGER 570 4X4 . . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. .1.32

2019 RANGER 570 4X4 (INTL.).. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . . .. . .. . . ..1.34

2019 RANGER 570 4X4 TRACTOR (INTL.) . . . . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . ... . .. . . . .1.36

2019 RANGER 570 CREW... . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . . .. . .. . . . . . .. . .. . . .. . .. .1.38

2020 RANGER 500. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ..1.40

2020 RANGER 570 4X4 . . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. .1.42

2020 RANGER 570 CREW... . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . . .. . .. . . . . . .. . .. . . .. . .. .1.44

2021 RANGER 500. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ..1.46

2021 RANGER 570 4X4 . . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. .1.48

2021 RANGER 570 CREW... . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . . .. . .. . . . . . .. . .. . . .. . .. .1.50

MISC. SPECIFICATIONS AND CHARTS . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . .. . .. . .. . . .. . ..1.52

CONVERSION TABLE.. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .1.52

SAE TAP / DRILL SIZES . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .1.53

METRIC TAP / DRILL SIZES.. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . ..1.54

DECIMAL EQUIVALENTS ... . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. .1.55

GENERAL DIAGNOSTICS. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . .1.57

GENERAL DIAGNOSTICS INFORMATION OVERVIEW .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . ..1.57

GUIDED SYMPTOM DIAGNOSTIC . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. .1.57

GUIDED SYMPTOM REFERENCES. . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . .1.58

ENGINE AND DRIVABILITY DIAGNOSTIC PROCEDURES .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ..1.59

ENGINE CRANKS BUT DOES NOT START . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .1.62

NO CRANK NO START OR SLOW CRANK . . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . .1.64

OVER HEATING. . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . .1.65

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.1

Page 10

GENERAL INFORMATION

WARNING LIGHTS . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .1.66

ENGINE TROUBLESHOOTING.. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . ..1.67

COOLING TROUBLESHOOTING . . . .. . . . . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . .. . .. . . . . . .. . .1.69

DIGITALWRENCH .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . ..1.70

DIGITALWRENCH® SOFTWARE OVERVIEW . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. .1.70

SPECIAL TOOLS . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .1.70

GUIDED DIAGNOSTICS.. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . ..1.70

DIGITALWRENCH® SOFTWARE INSTALLATION AND UPDATES .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .1.71

DIGITALWRENCH® COMMUNICATION ERRORS. .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. .1.72

DIGITALWRENCH® - DIAGNOSTIC CONNECTOR . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . ..1.72

DIGITALWRENCH® SERIAL NUMBER LOCATION . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . ..1.72

DIGITALWRENCH® FEATURE MAP . . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .1.73

ENGINE CONTROLLER REPROGRAMMING (REFLASH) ... . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . ..1.74

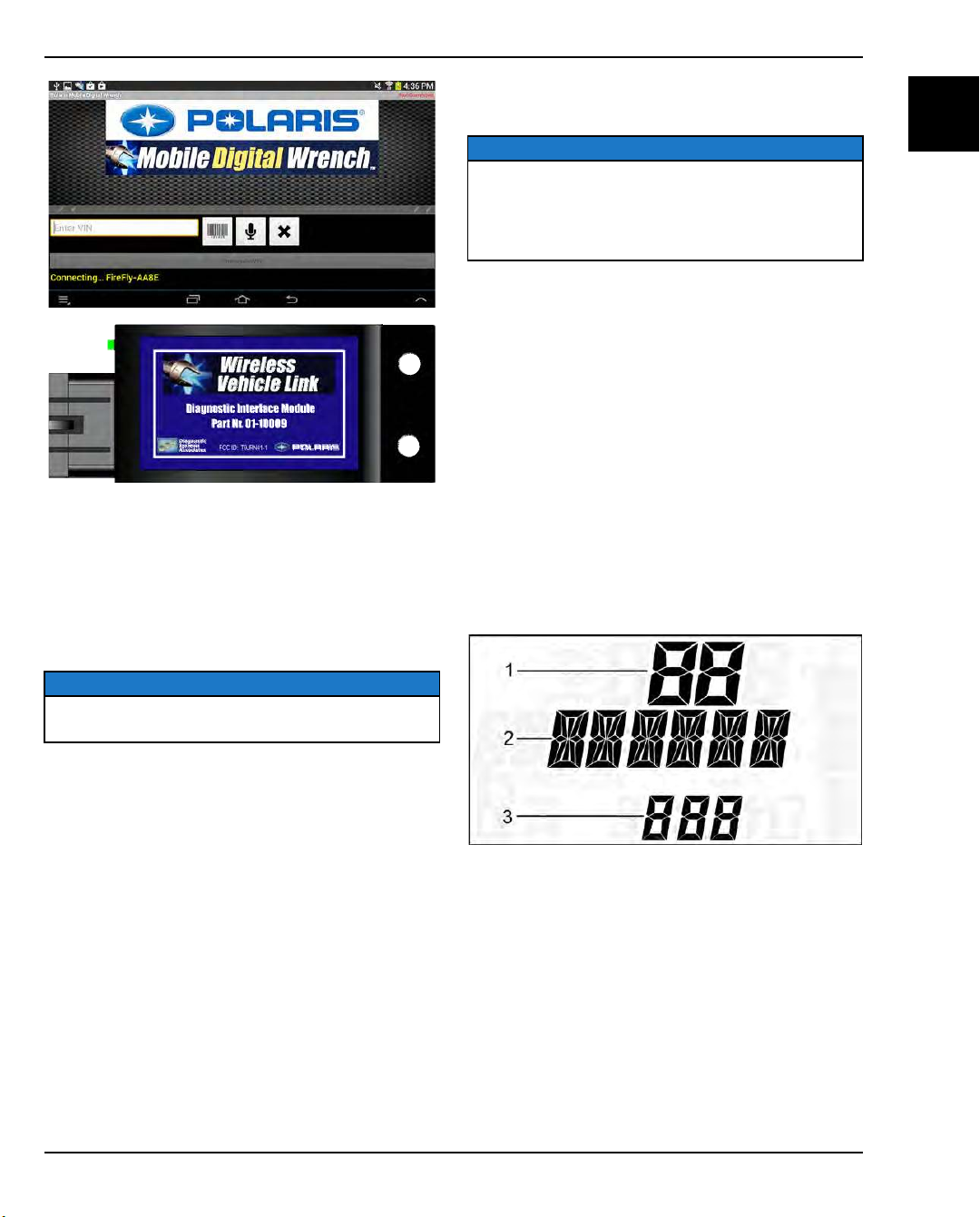

POLARIS MOBILE DIGITAL WRENCH® (PMDW) ... . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . ..1.74

ENGINE ELECTRICAL DIAGNOSTICS .. .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .1.75

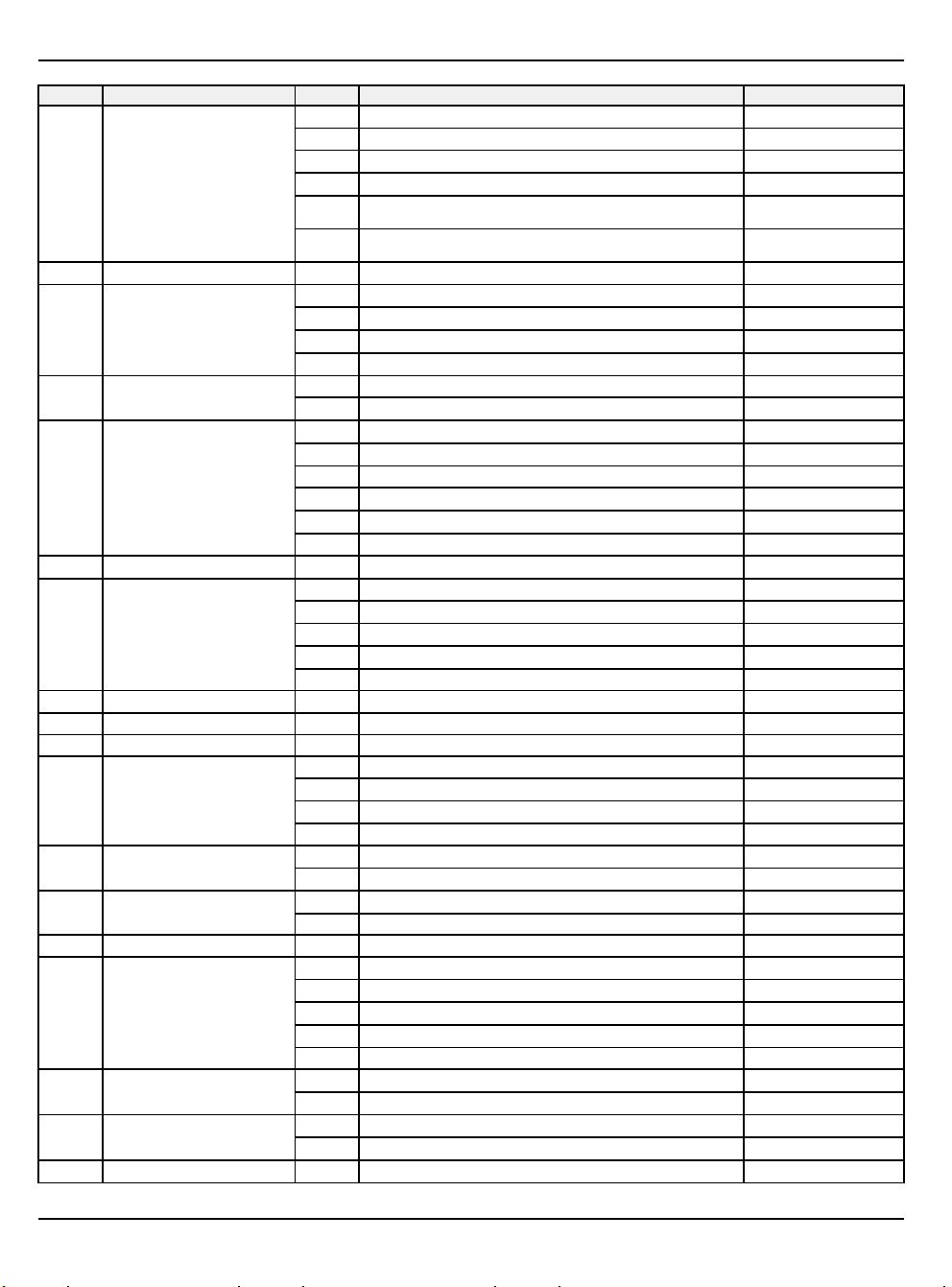

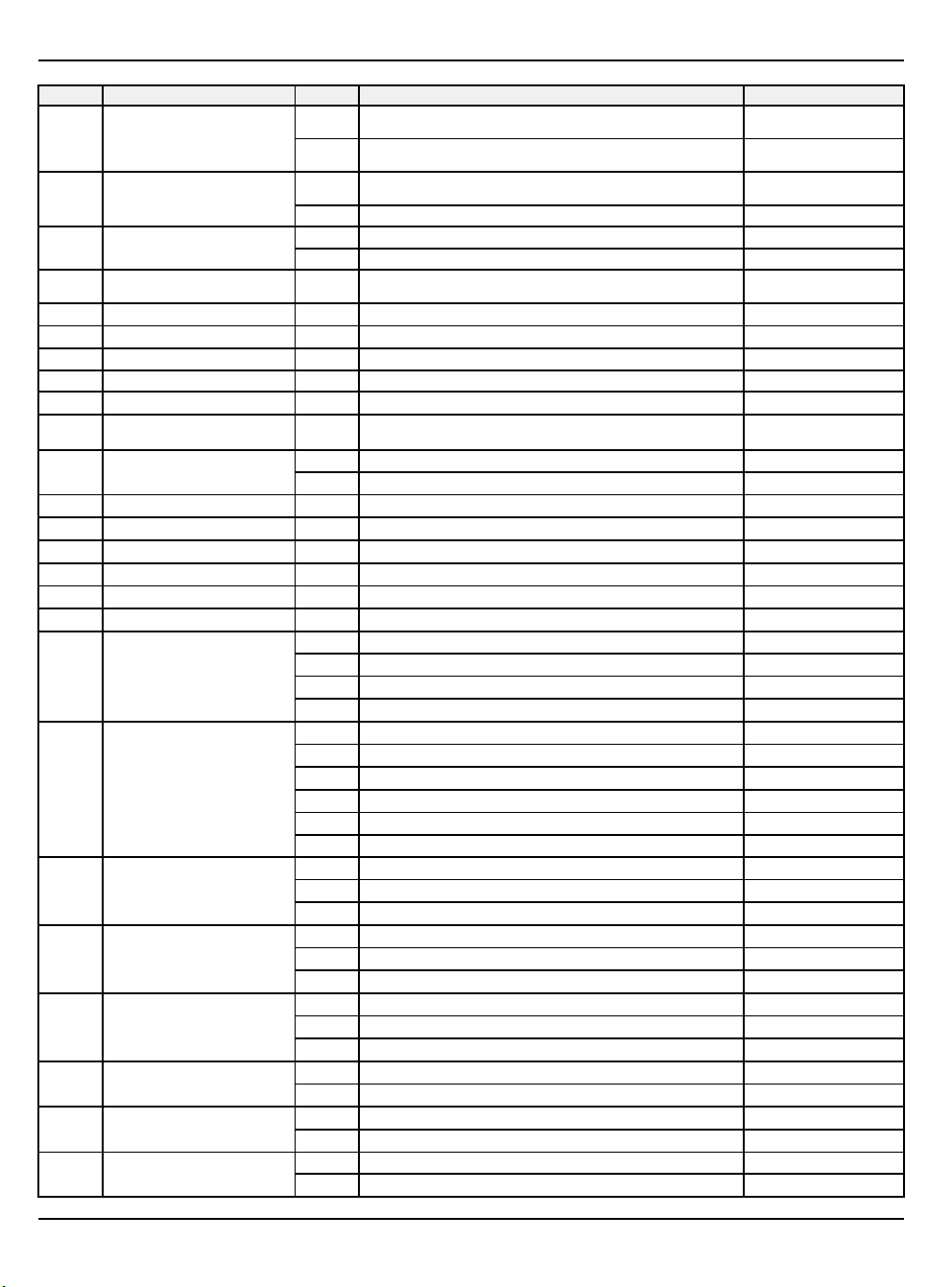

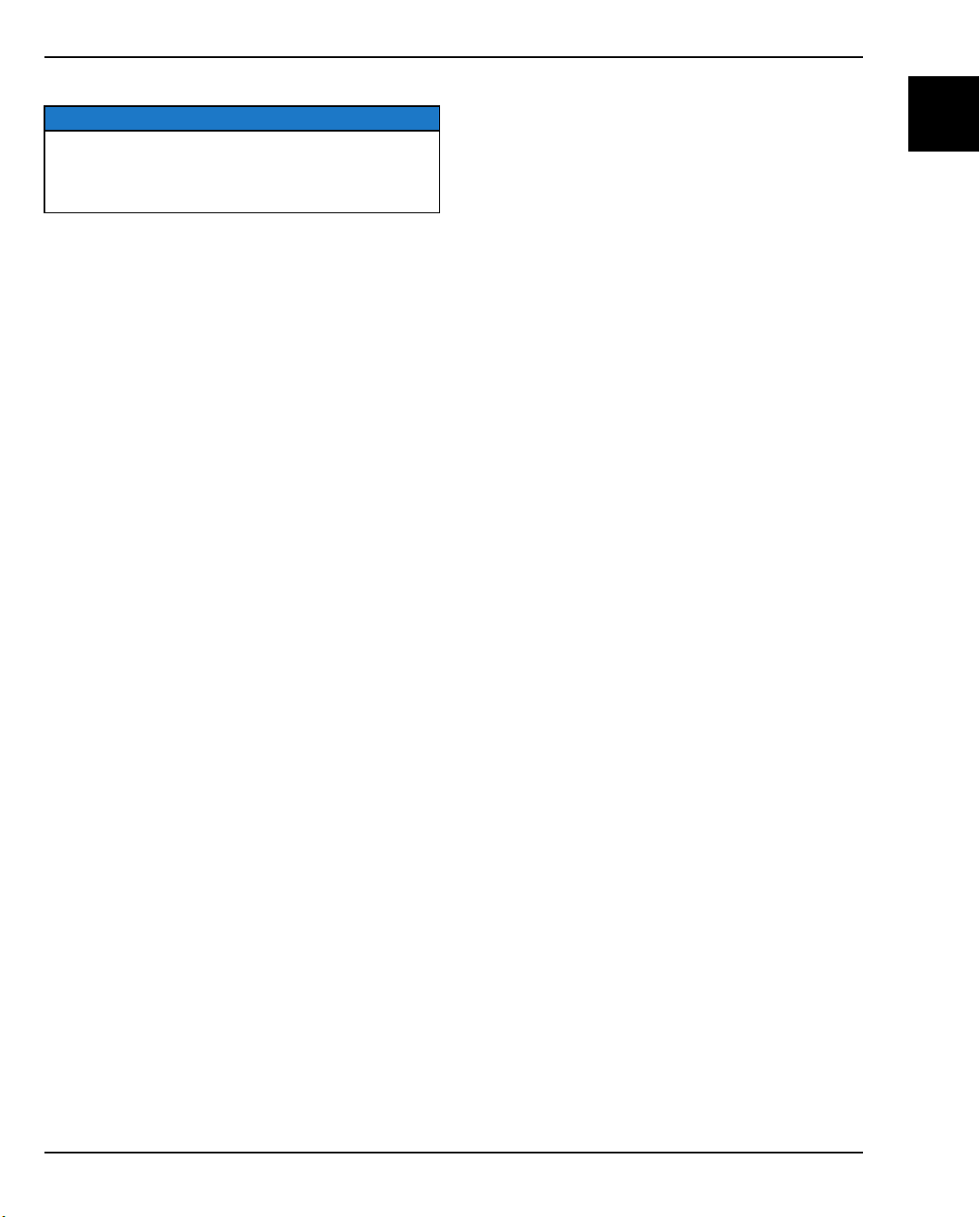

DIAGNOSTIC TROUBLE CODES OVERVIEW .... . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . .1.75

MASTER TROUBLE CODE LIST.. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .1.76

CYLINDER MISFIRE DETECTION... . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . ..1.87

FLUID LEAKS ... . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . ..1.88

FLUID INSPECTION.. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .1.88

FUEL SYSTEM DIAGNOSTICS. .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. .1.89

FUEL SYSTEM TROUBLESHOOTING. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. .1.89

PVT SYSTEM DIAGNOSTICS . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . . .. . .. . . .. . .. .1.91

PVT SYSTEM TROUBLESHOOTING . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. .1.91

PVT SYSTEM OVERHEATING / DIAGNOSIS .. .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . . . . .1.93

TRANSMISSION DIAGNOSTICS . . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . .1.94

HARD SHIFTING . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ..1.94

TRANSMISSION ISOLATION . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . .1.94

FINAL DRIVE DIAGNOSTICS... . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .1.95

ALL WHEEL DRIVE (AWD) CONCERNS . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .1.95

DRIVESHAFT (HALF SHAFT) DIAGNOSTICS . . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . ... . ..1.95

BRAKE SYSTEM DIAGNOSTICS. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. .1.96

BRAKE NOISE TROUBLESHOOTING ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . .. . . .. . ... . .. . ..1.96

BRAKE VIBRATION ... . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . ..1.96

CALIPER OVERHEATS (BRAKES DRAG) . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . . .. . .. . .1.97

POOR BRAKE PERFORMANCE... . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . .1.97

BRAKES LOCK.. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .1.97

STEERING / SUSPENSION DIAGNOSTICS . . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . ... . ..1.98

EPS TROUBLESHOOTING (POWER STEERING NON-FUNCTIONAL WITH MIL ON) .. . . .. . .. . . .. . .. .1.98

EPS TROUBLESHOOTING (POWER STEERING NON-FUNCTIONAL WITH MIL OFF) . . .. . . .. . .. . . .. .1.99

EPS TROUBLESHOOTING (USING DIGITAL WRENCH®) . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... 1.100

SHOCK ANALYSIS . . . .. . . . . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. 1.101

ELECTRICAL DIAGNOSTICS. . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . . . . . .. . .. . . .. . .. . . .. . .. 1.102

ELECTRICAL SERVICE NOTES. . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . . . . . .. . .. . . .. 1.102

DIGITAL MULTI-METER (DMM) NOTES .... . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . 1.102

STATIC AND DYNAMIC TESTING .... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . . .. . .. . .. . 1.102

CONNECTOR PROBING GUIDELINES. . . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . . . . . .. . .. . . .. . . . . . .. 1.103

TESTING CONTINUITY / RESISTANCE . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . 1.104

1.2

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 11

GENERAL INFORMATION

TESTING FOR A SHORT TO GROUND . . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . 1.104

TESTING FOR A SHORT TO VOLTAGE .... . .. . . . . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . 1.105

TESTING FOR INTERMITTENT CONDITIONS. . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . . 1.106

TESTING CURRENT FLOW (AMPERAGE) . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . . 1.106

CURRENT DRAW - KEY OFF. .. . .. . . .. . .. . . .. . .. . ... . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . . 1.107

TESTING VOLTAGE DROP. .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ... . 1.107

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.3

Page 12

GENERAL INFORMATION

VEHICLE INFORMATION

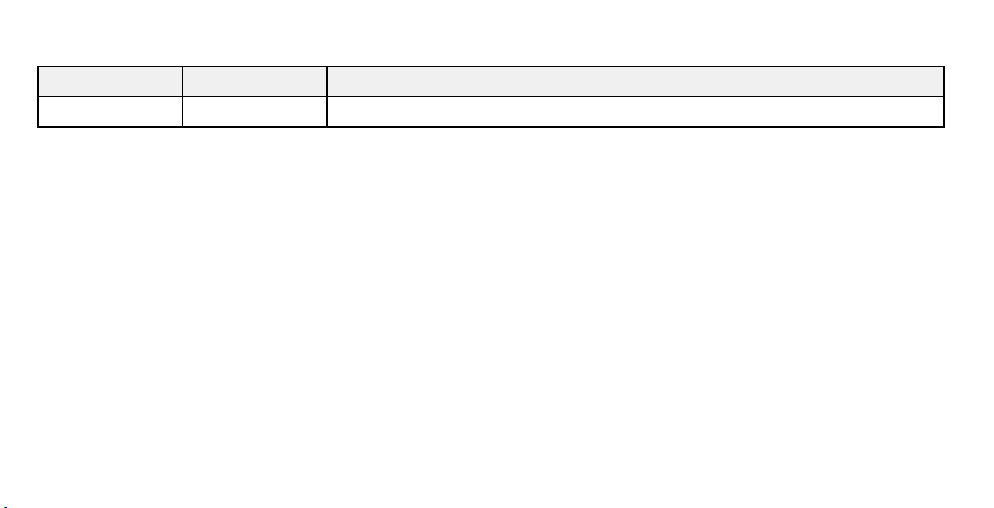

MODEL NUMBER DESIGNATION (2015 +)

Example: R15RUE57AC

GROUP MODEL YEAR MAKE / CHASSIS CODE ENGINE CODE REGION OPTION

1st 2nd 3rd 4th* 5th* 6th* 7th* 8th* 9th 10th**

R 1

5

R U E

5

* = digits that would transfer to 17 digit VIN and are used in digits 4-8 respectively

** = 10th digit will be used on color/featured versions of models (not including the base)

First 3 digits and 10th digit are used in model number only. They are not used with the 17 digit VIN.

Digits 1 through 8 determine Digital Wrench calibration.

VEHICLE IDENTIFICATION NUMBER (VIN) DESIGNATION (2015+)

Example: 4XARUE573FG000000

VEHICLE DESCRIPTORS VEHICLE IDENTIFIERS

7

A C

WORLD MFG. ID

CHASSIS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

4 X A R U E 5 7 3 F G 0 0 0 0 0 0

* Model Year: A = 2010; B = 2011; C = 2012; D = 2013; E = 2014; F = 2015; G = 2016; H = 2017; J = 2018; K = 2019, L = 2020,

M = 2021

CHASSIS

DRIVELINE

MODIFIER

ENGINE SIZE

CHECK DIGIT

MODEL YEAR *

ENGINE MODIFIER

MFG. LOCATION

INDIVIDUAL SERIAL NO.

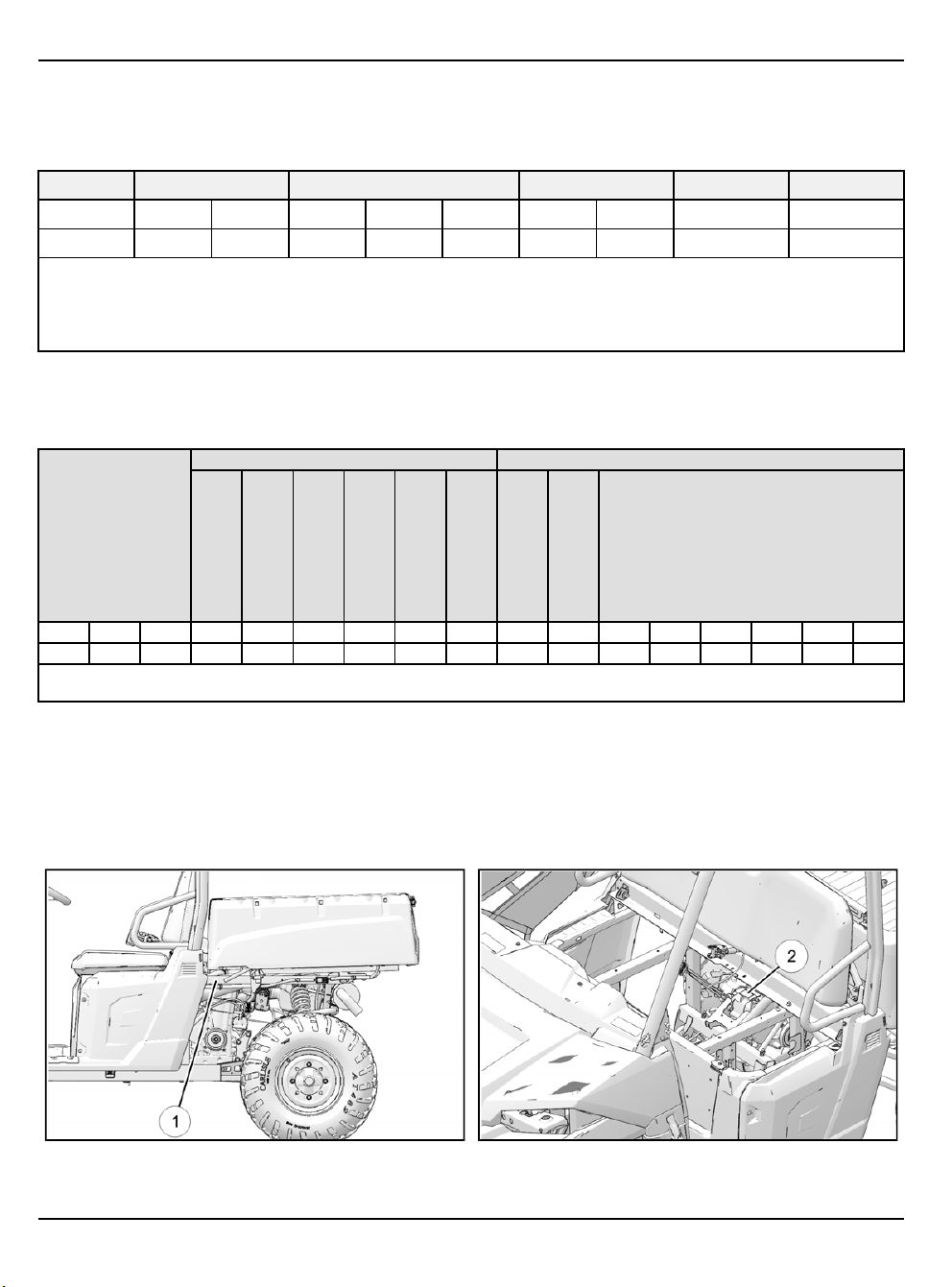

VIN / ENGINE NUMBER LOCATION

Whenever corresponding about a Polaris RANGER utility vehicle, be sure to refer to the Vehicle Identification Number

(VIN) and the engine model and serial number.

The VIN

The engine model and serial number

can be found stamped on the upper frame rail on the rear LH side of the vehicle below the cargo box.

q

can be found on a decal applied to the engine’s magneto cover.

w

1.4

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 13

GENERAL INFORMATION

REFERENCE INFORMATION

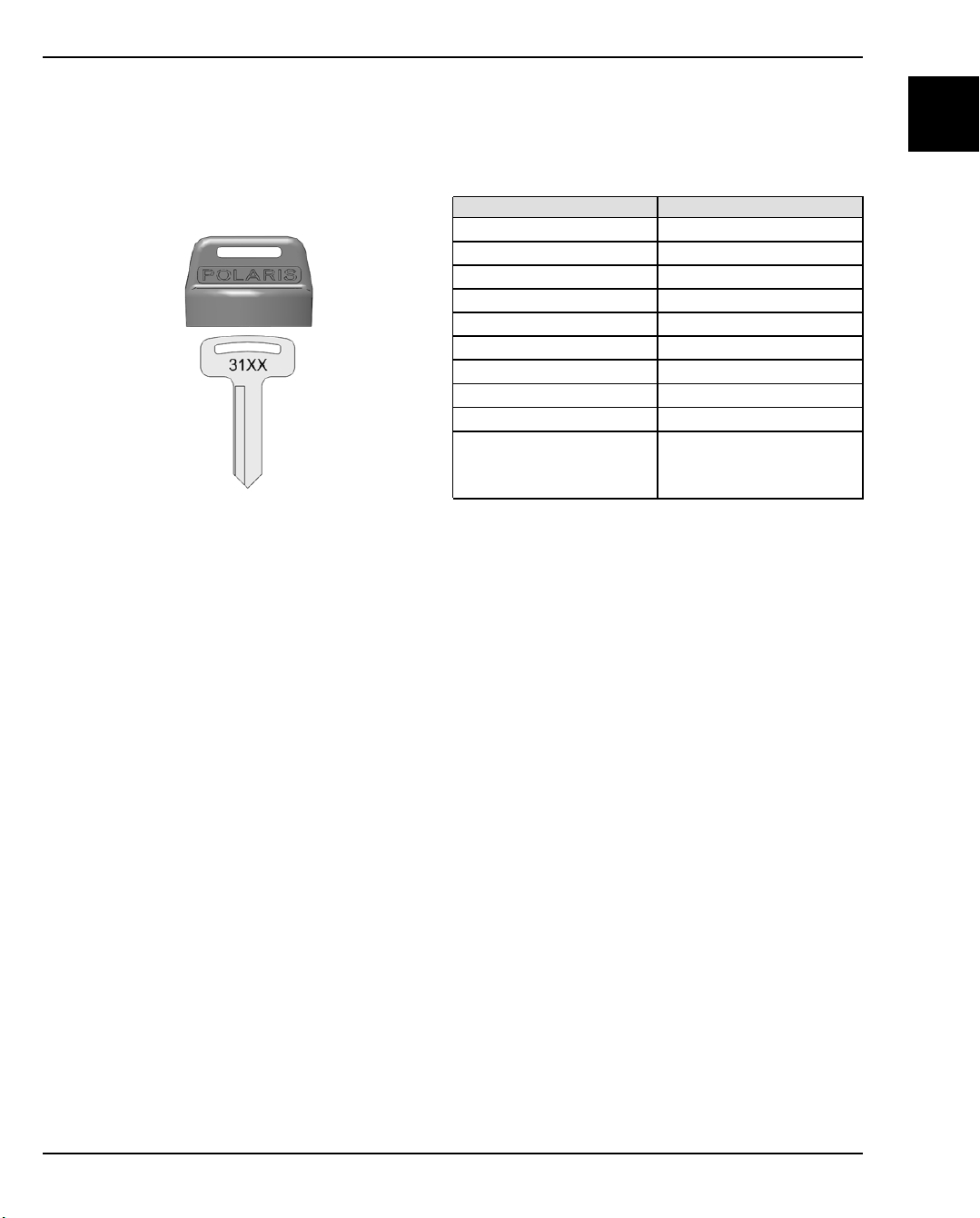

REPLACEMENT KEYS

Replacement keys can be made from the original key. To identify which series the key is, take the first two digits on the

original key and refer to the chart to the right for the proper part number.

(i.e. In this example, the first two digits are 31 which would use key blank PN 4110141.)

SERIES# PART NUMBER

20 4010278

21 4010278

22 4010321

23 4010321

27 4010321

28 4010321

31 4110141

32 4110148

67 4010278

68 4010278

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.5

Page 14

GENERAL INFORMATION

PUBLICATION PART NUMBERS

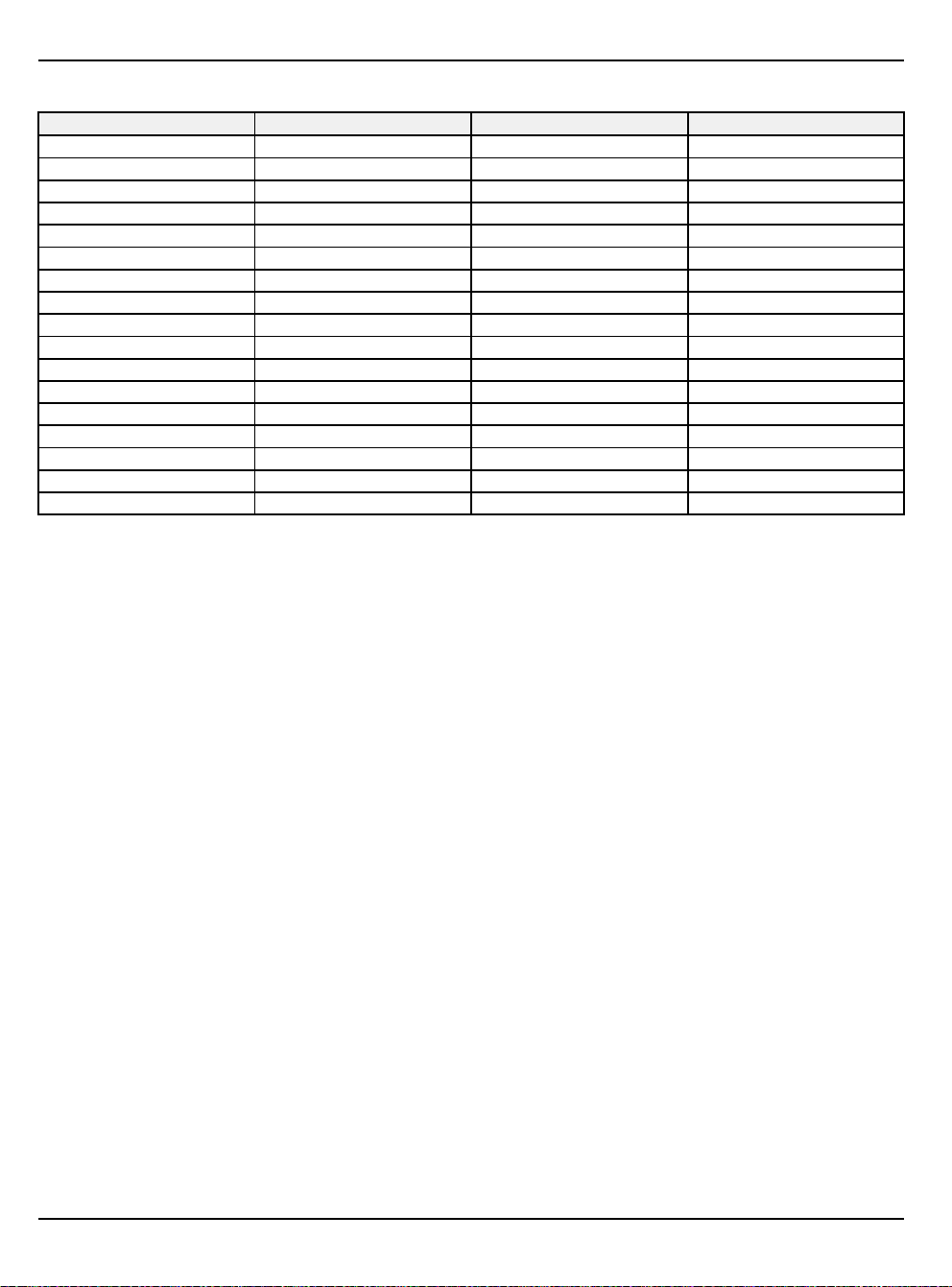

MODEL MODEL NUMBER OWNER’S MANUAL

2017 RANGER 500 2x4 R17RM250A1

2017 RANGER 500

2017 RANGER 570 / EPS

2017 RANGER 570 HD R17RMH57A4

2017 RANGER 570 CREW R17RNA57A1

2017 RANGER 570 CREW EPS

2017 RANGER 570 (Intl.)

2017 RANGER 570 EPS (Intl.)

2017 RANGER 570 Tractor (Intl.)

2017 RANGER 570 EPS Tractor (Intl.)

2018 RANGER 500 2x4 R18RM250B1

2018 RANGER 500

2018 RANGER 570 / EPS

2018 RANGER 570 HD (Intl.)

2018 RANGER 570 CREW R18RNA57B1

2018 RANGER 570 CREW EPS

2018 RANGER 570 (Intl.)

2018 RANGER 570 EPS (Intl.)

2018 RANGER 570 Tractor (Intl.)

2018 RANGER 570 EPS Tractor (Intl.)

2019 RANGER 500 2x4 R19RM250B1

2019 RANGER 500

2019 RANGER 570 / EPS

R17RMA50A1

R17RMA50A4

R17RMA57A1

R17RMA57A9

R17RME57AK

R17RNA57A9

R17RNE57AM

R17RNE57NM

R17RMA57F1

R17RMA57N1

R17RME57F1

R17RMS57F1

R17RMT57C1

R17RMT57E1

R17RMS57C1

R17RMS57CK

R17RMS57E1

R17RMS57EK

R18RMA50B1

R18RMA50B4

R18RMA57B1

R18RMA57B9

R18RME57BV

R18RME57N4

R18RNA57B9

R18RNE57BV

R18RNE57NV

R18RMA57F1

R18RMA57L1

R18RMS57F1

R18RMT57C1

R18RMT57E1

R18RMS57EV

R18RMS57C1

R18RMS57CV

R18RMS57E1

R19RMA50B1

R19RMA50B4

R19RMA57B1

R19RMA57B9

R19RME57BX

9927885

9927170

9927385

9927386

9928588

9928587

9928409

9928410

9928852

1.6

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 15

MODEL MODEL NUMBER OWNER’S MANUAL

2019 RANGER 570 HD (Intl.)

2019 RANGER 570 CREW R19RNA57B1

2019 RANGER 570 CREW EPS

2019 RANGER 570 (Intl.)

2019 RANGER 570 EPS (Intl.)

2019 RANGER 570 Tractor (Intl.)

2019 RANGER 570 EPS Tractor (Intl.)

2020 RANGER 500

2020 RANGER 570 / EPS

2020 RANGER 570 HD (Intl.)

2020 RANGER 570 CREW

2020 RANGER 570 CREW EPS R20M4E57BH

2020 RANGER 570 (Intl.)

2021 RANGER 500

2021 RANGER 570 / EPS

2021 RANGER 570 HD (Intl.) R21MAE57D7

2021 RANGER 570 CREW

2021 RANGER 570 CREW EPS R21M4E57BX

2021 RANGER 570 (Intl.)

2021 RANGER 570 EPS (Intl.)

2021 RANGER 570 EPS Tractor (Intl.)

R19RME57D7

R19RNA57B9

R19RNE57BX

R19RMA57F1

R19RMA57L7

R19RMS57F1

R19RMS57E1

R19RMS57C1

R20MAA50B1

R20MAA50B7

R20MAA50J7

R20MAA57B1

R20MAA57B9

R20MAE57BH

R20MAE57D7

R20M4A57B1

R20M4A57B9

R20M4A57L1

R20MAA57K1

R21MAA50B1

R21MAA50B7

R21MAA50J7

R21MAA57B1

R21MAA57B9

R21MAE57BX

R21M4A57B1

R21M4A57B9

R21MAA57F1

R21MAA57F9

R21MAS57F1

R21MAS57F9

R21MAS57C1

R21MAS57C9

R21MAS57CK

GENERAL INFORMATION

1

9929233

9929235

9931336

9931254

9931411

9931412

When ordering service parts be sure to use the correct parts manual.

Polaris factory publications can be found at www.polaris.com or purchased from www.purepolaris.com.

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

NOTICE

1.7

Page 16

GENERAL INFORMATION

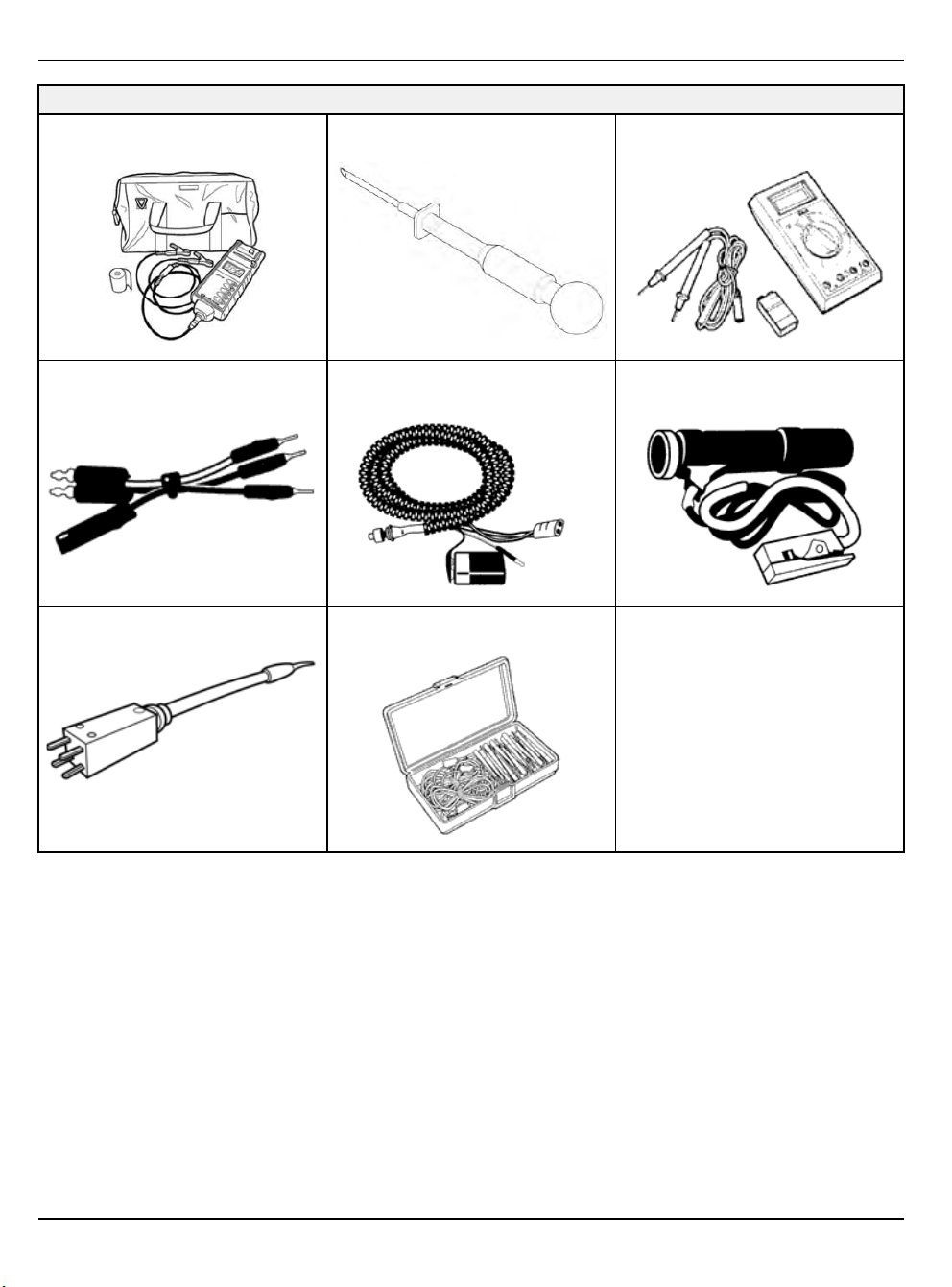

SPECIAL TOOLS

Special tools may be required while servicing this vehicle. Some of the tools listed or depicted are mandatory, while

other tools may be substituted with a similar tool, if available. Polaris recommends the use of Polaris Special Tools

when servicing any Polaris product. Dealers may order special tools through the Polaris official tool supplier.

Bosch Automotive Service Solutions 1-800-345-2233 or https://polaris.service-solutions.com

1.8

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 17

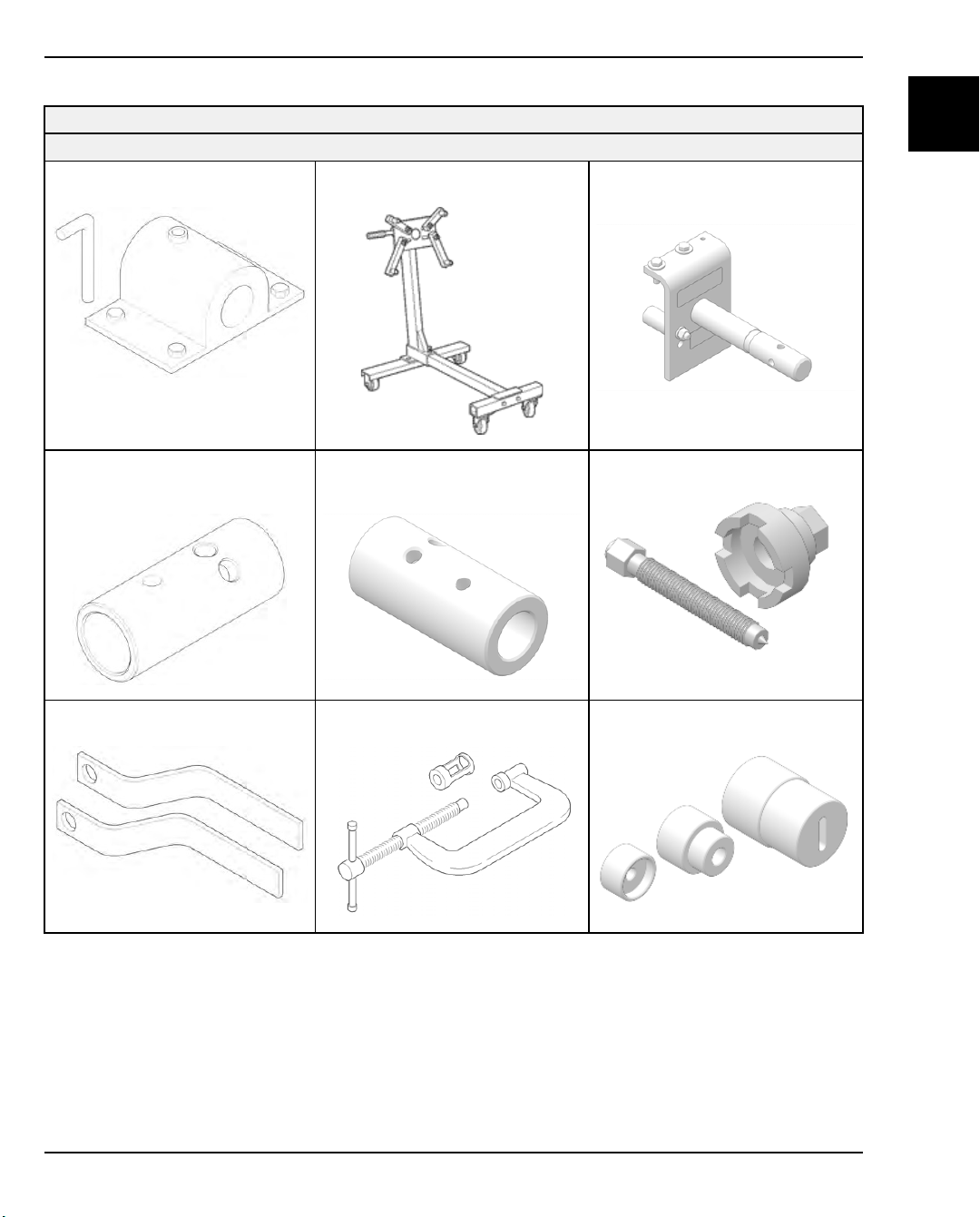

MASTER SPECIAL TOOLS TABLE

ENGINE / COOLING SYSTEM

GENERAL

Bench Mount Engine Stand Adapter

PW-47053

Rolling Engine Stand

PU-50624

GENERAL INFORMATION

1

Engine Stand Adapter

(Mounts To The Engine)

PU-50824-A

Engine Stand Sleeve Adapter

(Use With 2” Bore Stand)

PU-50625

Stator Cover Removal Handles

PA-49317

Engine Stand Sleeve Adapter

(Use With 2.375” Bore Stand)

PW-47054

Valve Spring Compressor

PV-1253

Flywheel Puller

PA-49316

Water Pump Seal Installation Tool

PU-50869

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.9

Page 18

GENERAL INFORMATION

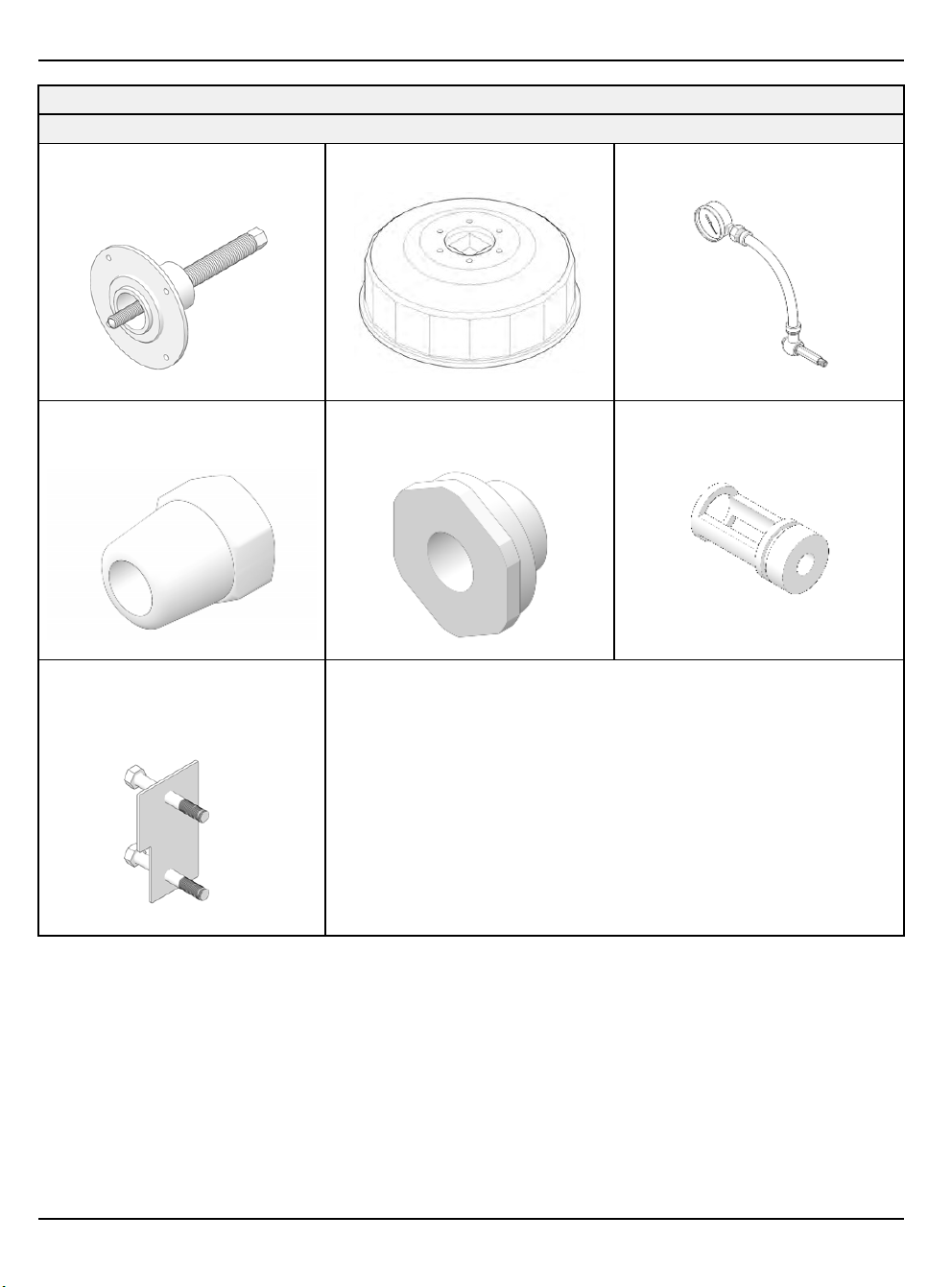

ENGINE / COOLING SYSTEM

GENERAL

Crankshaft Removal / Installation

Tool Kit

PU-50784

Oil Filter Wrench

PU-50105

Oil Pressure Gauge

PV-43531

Oil Pressure Gauge Adapter (2017

and earlier models)

PU-50569

570 ONLY

Cylinder Holding &

Camshaft Timing Plate

PU-50563

Oil Pressure Gauge Adapter (2018

and later models)

PU-52502

Valve Spring Compressor Adapter

PV-43513-A

1.10

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 19

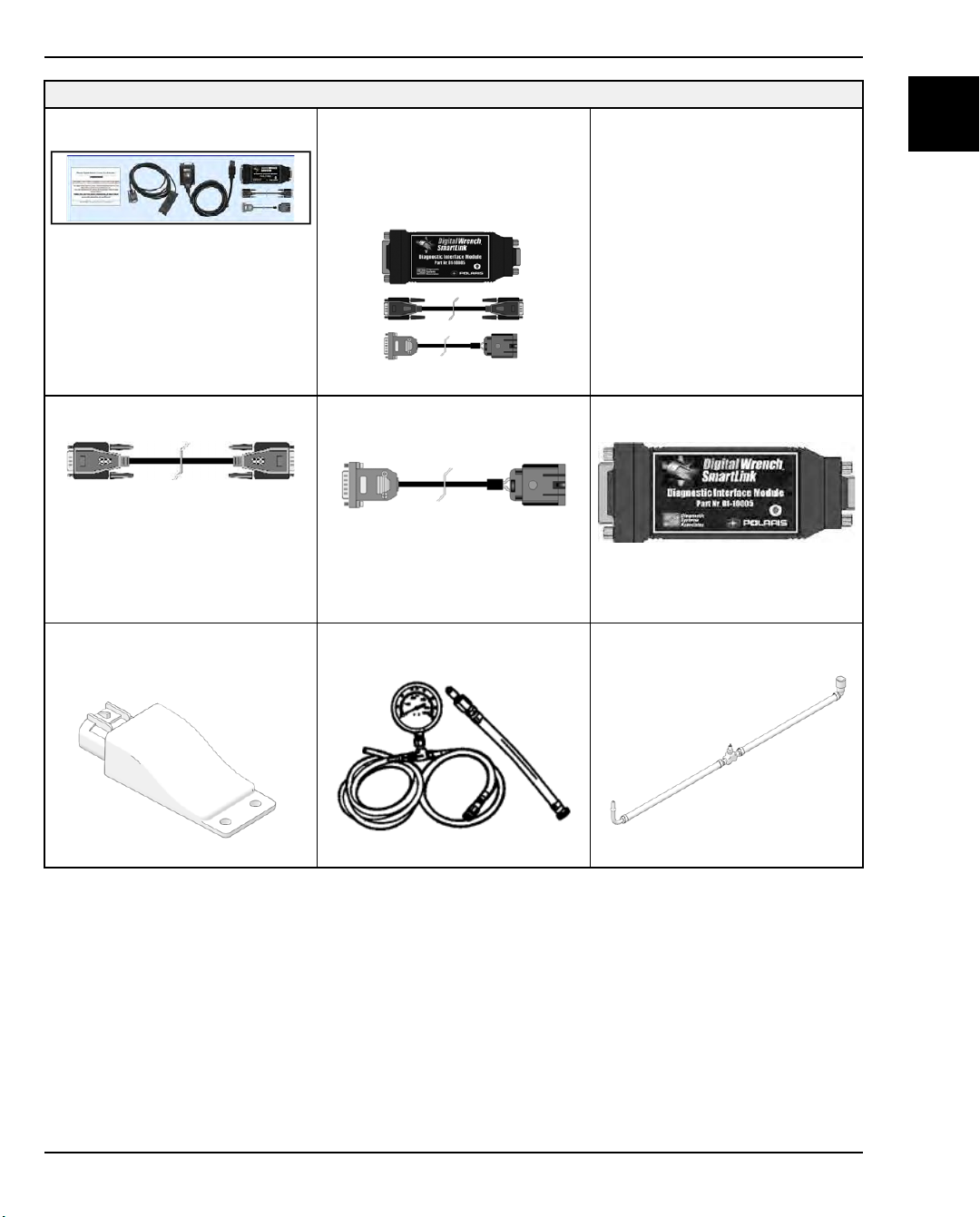

FUEL SYSTEM

Digital Wrench Kit

PU-47063-C

Digital Wrench Smart

Link Module Kit

PU-47471

(Includes: PU-47470, PU-47469,

PU-47468)

GENERAL INFORMATION

*Serial Number Registration Card

PU-48731-A

1

*Digital Wrench® PC Interface Cable

PU-47470

Digital Wrench® Wireless

Vehicle Link

PU-51435

*Digital Wrench® Vehicle

Interface Cable

PU-47469

Fuel Pressure Gauge Kit

PU-43506-A

*Digital Wrench® SmartLink Module

PU-47468

Fuel Pressure Gauge Adapter

PV-48656

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.11

Page 20

GENERAL INFORMATION

FUEL SYSTEM

Fuel Pressure Gauge Adapter

PS-48762

Laptop or Desktop Computer USB/

Serial Adaptor: Saelig RS-232

Commercially Available (refer to

diagnostic software user manual or

HELP section for minimum

requirements)

Fluke 77 Digital Multi-Meter

(Fluke 77: PV-43568)

Throttle Position Sensor Tester Kit

2201519-A

(Includes: 547927, PU-47466)

1.12

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 21

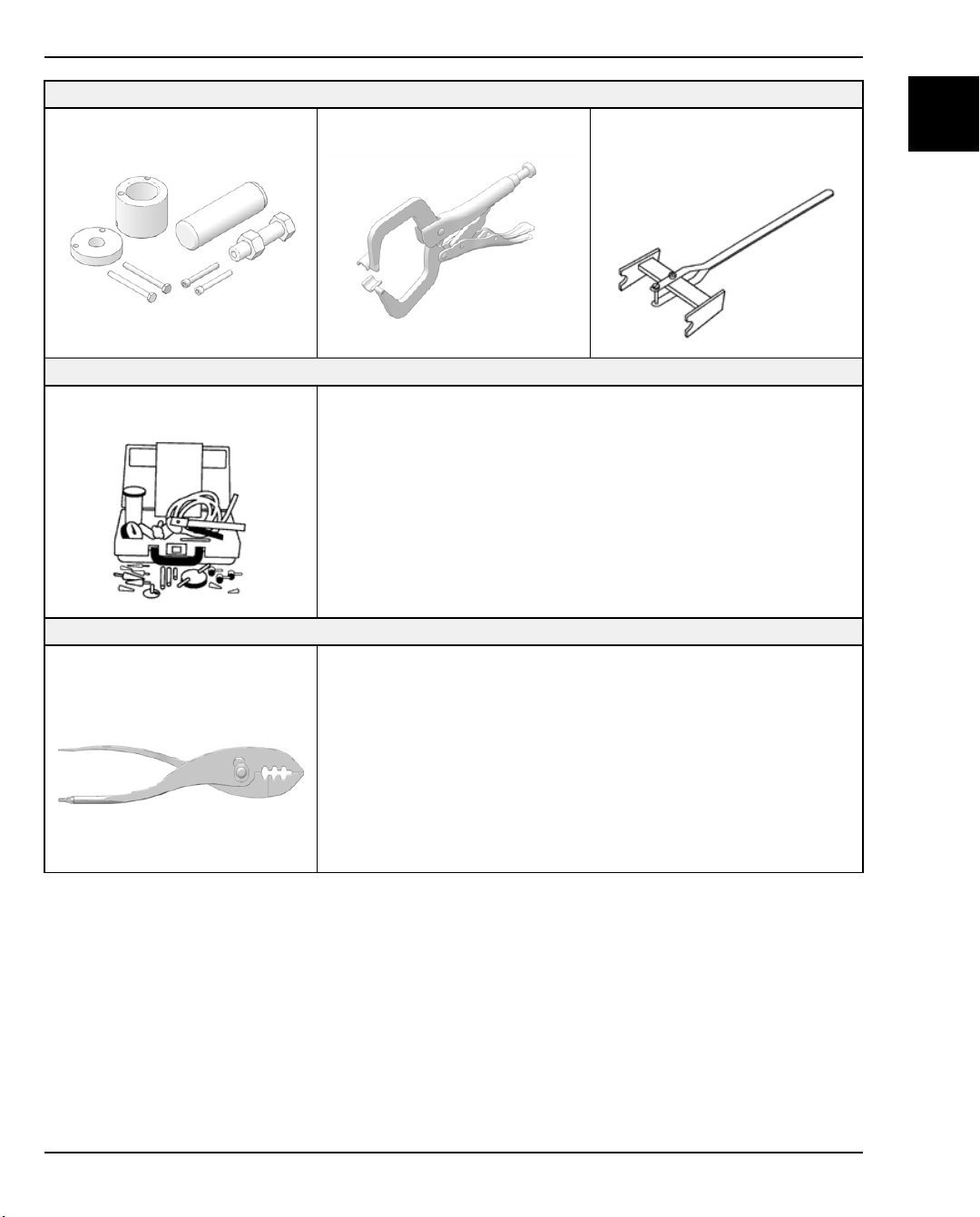

PVT SYSTEM

Clutch Bushing Replacement

Tool Kit

2871226

Drive Clutch Puller - Short

PA-48595

GENERAL INFORMATION

Drive Clutch Holding Tool

9314177-A

1

Drive Clutch Spider Removal

and Install Tool

2870341

Universal Clutch Compressor Tool

PU-50518-A

Piston Pin Puller

2870386

Standard Clutch Alignment Tool

2870654

Roller Pin Tool

2870910-A

Clutch Center Distance Tool

PU-50658-A

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.13

Page 22

GENERAL INFORMATION

TRANSMISSION

Bearing Seal Driver (50 mm)

2871282

Backlash Setting Tool

2871695 (Part of 2871702 Kit)

Rear Driveshaft Seal Guide

2871699 (Part of 2871702 Kit)

Rear Output Seal Driver

2871698 (Part of 2871702 Kit)

FINAL DRIVE

1 3/4” Straight Wrench

2870772

Roller Pin Removal Tool

2872608

Snorkel Tool

PA-50231

ADC Gearcase Piston

Installation Tool

PA-48542

Transmission Nut Socket

PU-50566

CV Boot Clamp Pliers

8700226 or PU-48951

1.14

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 23

STEERING / SUSPENSION

Ball Joint Removal / Installation Tool

2870871

BRAKES

Mity Vac® Pressure Test Tool

2870975

Strut Compression Tools

2871573, 2871574

GENERAL INFORMATION

Shock Absorber Spring

Compression Tool

2870623

1

BODY / FRAME

Multi-Function Pliers

2876389

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.15

Page 24

GENERAL INFORMATION

ELECTRICAL

Battery Conductance Analyzer

PU-50296

Battery Hydrometer

PU-50338

Fluke® 77 Digital Multimeter

PV-43568

Hall Sensor Probe Harness

2460761

Relay Bypass

PU-49466

Static Timing Light Harness

2871745

Connector Test Kit

PV-43526

Timing Light

2870630

1.16

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 25

GENERAL INFORMATION

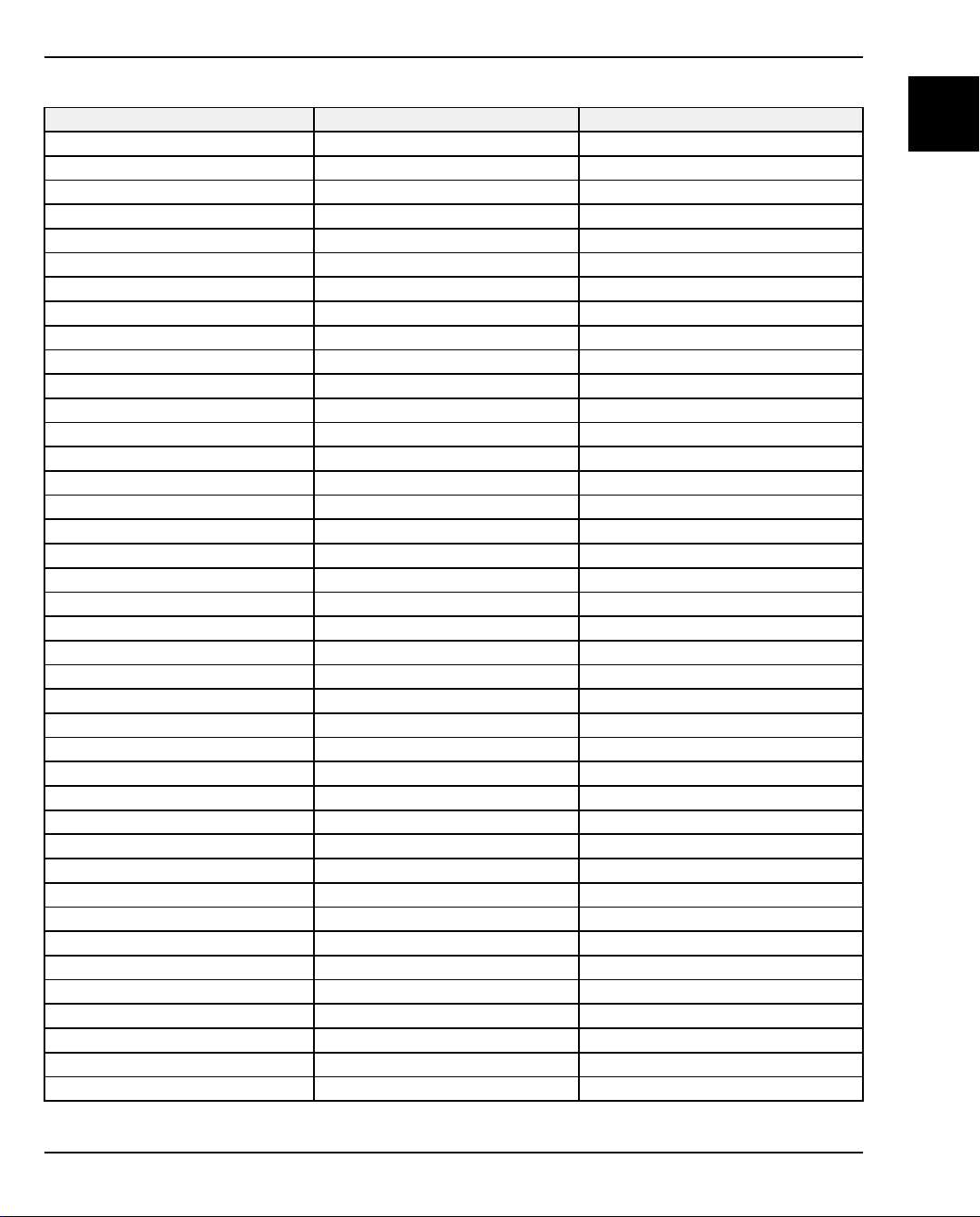

MASTER TORQUE TABLE

ITEM

Ball Joint Nut

Ball Joint Retaining Plate

Screws

Bearing Carrier Fasteners 40 ft-lbs (54 Nm)

Body Screws (T-40) 8 ft-lbs (11 Nm)

Brake Disc Mounting Bolts

(front)

Brake Disc Mounting Bolts

(rear)

Brake Bleed Screws

Brake Caliper Mounting Bolts 46 ft-lbs (62 Nm)

Brake Line Banjo Bolts 15 ft-lbs (20 Nm)

Brake Line Flare Fittings 14 ft-lbs (19 Nm)

Brake Switch

Cam Chain Tensioner RGR

500

Cam Chain Tensioner RGR

570

Cam Chain Guide Fasteners

Camshaft Carrier Bolts

Camshaft Sprocket BoltsRGR

500

Camshaft Sprocket BoltsRGR

570

Chassis Ground Fastener

Control Arm Fasteners

(front and rear)

Coolant Bleed Screw

Coolant Temperature Sensor 17 ft-lbs (23 Nm)

CPS Retaining Bolt 9 ft-lbs (12 Nm)

Crankcase Bolts

Crankshaft Bearing Retainer

(PTO)

Cylinder Head Bolts - Black

TORQUE

30 ft-lbs (41 Nm)

8 ft-lbs (11 Nm)

18 ft-lbs (25 Nm)

27 ft-lbs (36 Nm)

47 in-lbs (5 Nm)

15 ft-lbs (20 Nm)

37 ft-lbs (50 Nm)

30 ft-lbs (40 Nm)

9 ft-lbs (12 Nm)

8 ft-lbs (10 Nm)

45 ft-lbs (60 Nm)

14 ft-lbs (19 Nm)

54 in-lbs (6 Nm)

40 ft-lbs (54 Nm)

72 in-lbs (8 Nm)

22 ft-lbs (30 Nm)

8 ft-lbs (11 Nm)

Torque in sequence for

all steps

Step 1: 21 ft-lbs (28

N·m)

Step 2: 26 ft-lbs (35

N·m)

Step 3: Additional 135°

Torque the Outer M6

Head Bolts 89 ± 9 in-lbs

(10 ± 1 Nm)

ITEM

Cylinder Head Bolts - Silver

Differential Cover Screws

Drive Clutch Retaining Bolt 45 ft-lbs (61 Nm)

Driven Clutch Retaining Bolt 38 ft-lb (52 Nm)

Drive Clutch Cover Plate

Drive Clutch Spring Retaining

Driven Clutch Retaining Bolt 38 ft-lbs (51 Nm)

Exhaust Head Pipe Bolts 18 ft-lbs (25 Nm)

Frame Bolts (front to rear)

Front Gearcase Cover Plate

Screw

Drive Clutch Spider 290 ft-lbs (393 Nm)

Ring Bolts

ETC Fasteners

ECU Mounting Screws 10 in-lbs (1 Nm)

Engine Oil Plug 12 ft-lbs (16 Nm)

Engine Oil Gallery Plug 14 ft-lbs (18 Nm)

Engine Mount (front) 40 ft-lbs (54 Nm)

Engine/Transmission

Mounting Bolts (570)

Flywheel Nut 133 ft-lbs (180 Nm)

CREW

Front Bumper / Fender

Screws

Screws

*see procedure for sequence

TORQUE

Apply light coat of

engine oil to bolt

threads and under bolt

head

Torque in sequence for

all steps

Step 1: 18 ft-lbs (25

N·m)

Step 2: 30 ft-lbs (41

N·m)

Step 3: Loosen all

fasteners until they are

unseated

Step 4: 15 ft-lbs (20

N·m)

Step 5: 26 ft-lbs (35

N·m)

Step 6: Additional 180°

Step 7: Additional 180°

Torque the Outer M6

Head Bolts 89 ± 9 in-lbs

(10 ± 1 Nm)

22 ft-lbs (30 Nm)

8 ft-lbs (10 Nm)

12 ft-lbs (16 Nm)

7 ft-lbs (10 N·m)

In Sequence:

55 ft-lb (75 Nm)

40 ft-lbs (54 Nm)

5 ft-lbs (7 Nm)

11 ft-lbs (15 Nm)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.17

Page 26

GENERAL INFORMATION

ITEM

Front Gearcase Drain/Fill

Plugs

Front Gearcase Mounting

Bolts

Fuel Pump PFA Nut 70 ft-lbs (90 Nm)

Fuel Rail Mounting Screws 7 ft-lbs (10 Nm)

Fuel Tank Mounting Screw 17 ft-lbs (23 Nm)

Hub Castle Nut (front) 90 ft-lbs (122 Nm)

Hub Castle Nut (rear) 110 ft-lbs (150 Nm)

IAC Mount Screw

Master Cylinder Mount Bolts 17 ft-lbs (23 Nm)

Oil Pump Cover Bolt 9 ft-lbs (12 Nm)

Power Steering Bracket to

Frame Nuts

Power Steering Unit to Mount

Bracket

Prop Shaft Support Bearing

Fasteners

Prop Shaft Support Bearing

Set Screws

PVT Inner Cover Screws

(Phillips)

PVT Inner Cover Screws

(Hex)

PVT Outer Cover Screws

Seat Belt Mounting Fasteners 40 ft-lbs (54 Nm)

Shift Cable Bracket Bolts

Shock Mounting Fasteners

(rear)

Skid Plate Fasteners

Spark Plug

Spark Plug

Speed Sensor Screw 10 ft-lbs (14 Nm)

Stabilizer Bar Linkage (rear) 17 ft-lbs (23 Nm)

Stabilizer Bar Mounting

Bracket Bolts (rear)

Starter Mounting Bolts 8 ft-lbs (10 Nm)

Starter Power Wire Nut

Starter One-Way Clutch Bolts 9 ft-lbs (12 Nm)

Stator Cover Screws

Stator Mounting Bolts 9 ft-lbs (12 Nm)

Stator Wire Retainer

TORQUE

10 ft-lbs (14 Nm)

33 ft-lbs (56 Nm)

18 in-lbs (2 Nm)

15 ft-lbs (20 Nm)

30 ft-lbs (41 Nm)

36 ft-lbs (49 Nm)

35 in-lbs (4 Nm)

50 in-lbs (5 Nm)

12 ft-lbs (16 Nm)

50 in-lbs (5 Nm)

37 ft-lbs (50 Nm)

40 ft-lbs (54 Nm)

8 ft-lbs (11 Nm)

15ft-lbs (20 Nm)

Do Not Apply Anti-Seize

9ft-lbs (12 Nm)

Do Not Apply Anti-Seize

17 ft-lbs (23 Nm)

54 in-lbs (6 Nm)

9 ft-lbs (12 Nm)

6 ft-lbs (9 Nm)

ITEM

Steering Rack Mounting Bolts 16 ft-lbs (22 Nm)

Steering Shaft to EPS Unit 20 ft-lbs (27 Nm)

Steering Shaft to Steering

Rack

Steering Wheel Nut 65 ft-lbs (88 Nm)

Strut Casting Pinch Bolt 17 ft-lbs (23 Nm)

Strut Mounting Nut (top) 15 ft-lbs (21 Nm)

Thermostat Cover Bolts

Throttle Pedal Mounting Nuts 8 ft-lbs (11 Nm)

Tie Rod End to Knuckle

Tie Rod Jamb Nuts

TMAP Retaining Bolt 24 in-lbs (3 Nm)

TPS Mounting Screws 18 in-lbs (2 Nm)

Transmission Bell Crank Nut

Transmission Case Screws

Transmission Drain / Fill

Plugs

Transmission Isolator Bolt

(rear)

Transmission Rear Mount

Bracket Fasteners

Transmission Joint Bracket

Bolts

Transmission Park Flange

Screws

Transmission Sector Gear

Cover

Transmission Shift Fork

Screws

Transmission Snorkel Bearing

Retaining Plate Screws

Transmission Snorkel Tube

Locking Screw

TRS Retaining Nuts 7 ft-lbs (10 Nm)

TORQUE

46–51 ft-lbs (62-69 Nm)

8 ft-lbs (10 Nm)

40 ft-lbs (54 Nm)

14 ft-lbs (19 Nm)

15 ft-lbs (20 Nm)

18 ft-lbs (24 Nm)

14 ft-lbs (19 Nm)

40 ft-lbs (54 Nm)

17 ft-lbs (23 Nm)

ft-lbs ( Nm)

8 ft-lbs (11 Nm)

11 ft-lbs (15 Nm)

10 ft-lbs (14 Nm)

8 ft-lbs (11 Nm)

8 ft-lbs (11 Nm)

TPS Mounting Screws 18 in-lbs (2 Nm)

Valve Cover Bolts

Water Pump Impeller

Water Pump Cover Bolts

Wheel Lug Nuts (Steel

Wheels)

Wheel Lug Nuts (Aluminum

Wheels)

8 ft-lbs (10 Nm)

Finger Tight

*LH threads

9 ft-lbs (12 Nm)

(Apply Loctite® 204™ to

bolt threads)

36 ft-lbs (49 Nm)

30 ft-lbs + 90º (41 Nm + 90º)

1.18

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 27

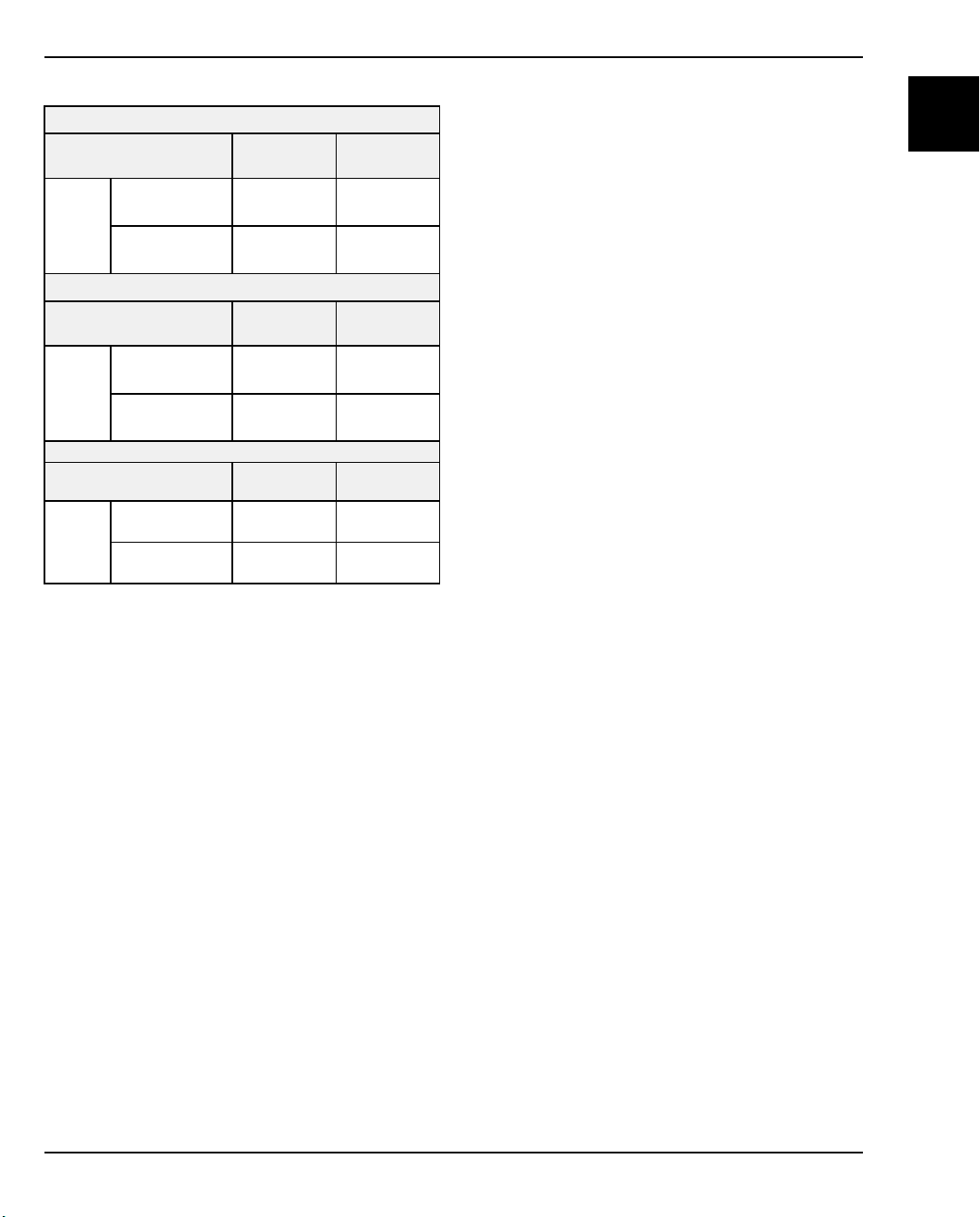

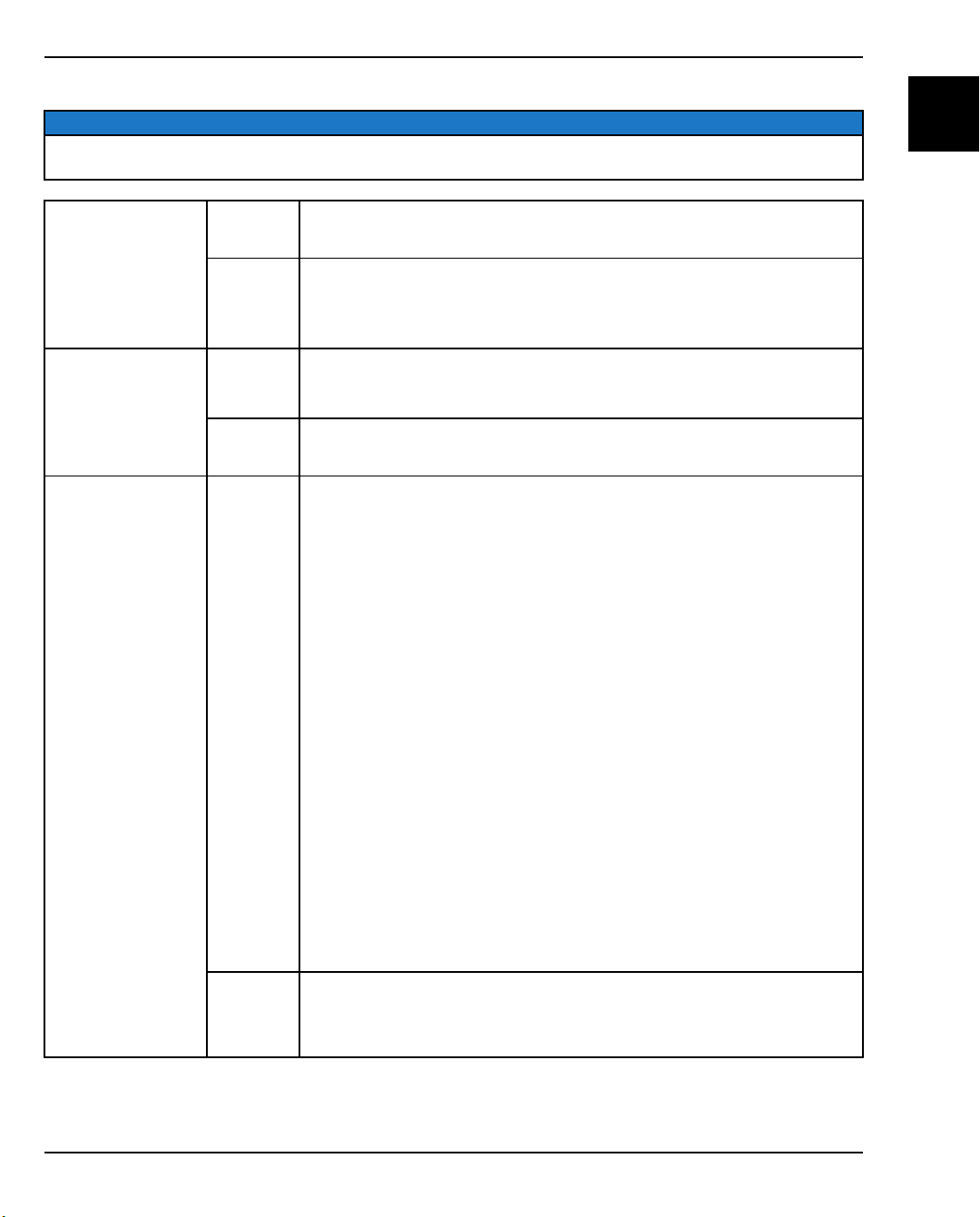

CLUTCHING CHART

RANGER 500

ALTITUDE

0-1800

Meters

(Feet)

RANGER 570

ALTITUDE

Meters

(Feet)

RANGER CREW 570

ALTITUDE

Meters

(Feet)

(0-6000)

1800-3700

(6000 - 12000)

0-1800

(0-6000)

1800-3700

(6000 - 12000)

0-1800

(0-6000)

1800-3700

(6000 - 12000)

SHIFT

WEIGHT

25–52G

(5632409)

25-48

(5633217)

SHIFT

WEIGHT

25–52G

(5632409)

25-48

(5633217)

SHIFT

WEIGHT

25-52G

(5632409)

25-48

(5633217)

GENERAL INFORMATION

1

DRIVE

SPRING

Black

(7043594)

Black

(7043594)

DRIVE

SPRING

Black

(7043594)

Black

(7043594)

DRIVE

SPRING

Black

(7043594)

Black

(7043594)

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.19

Page 28

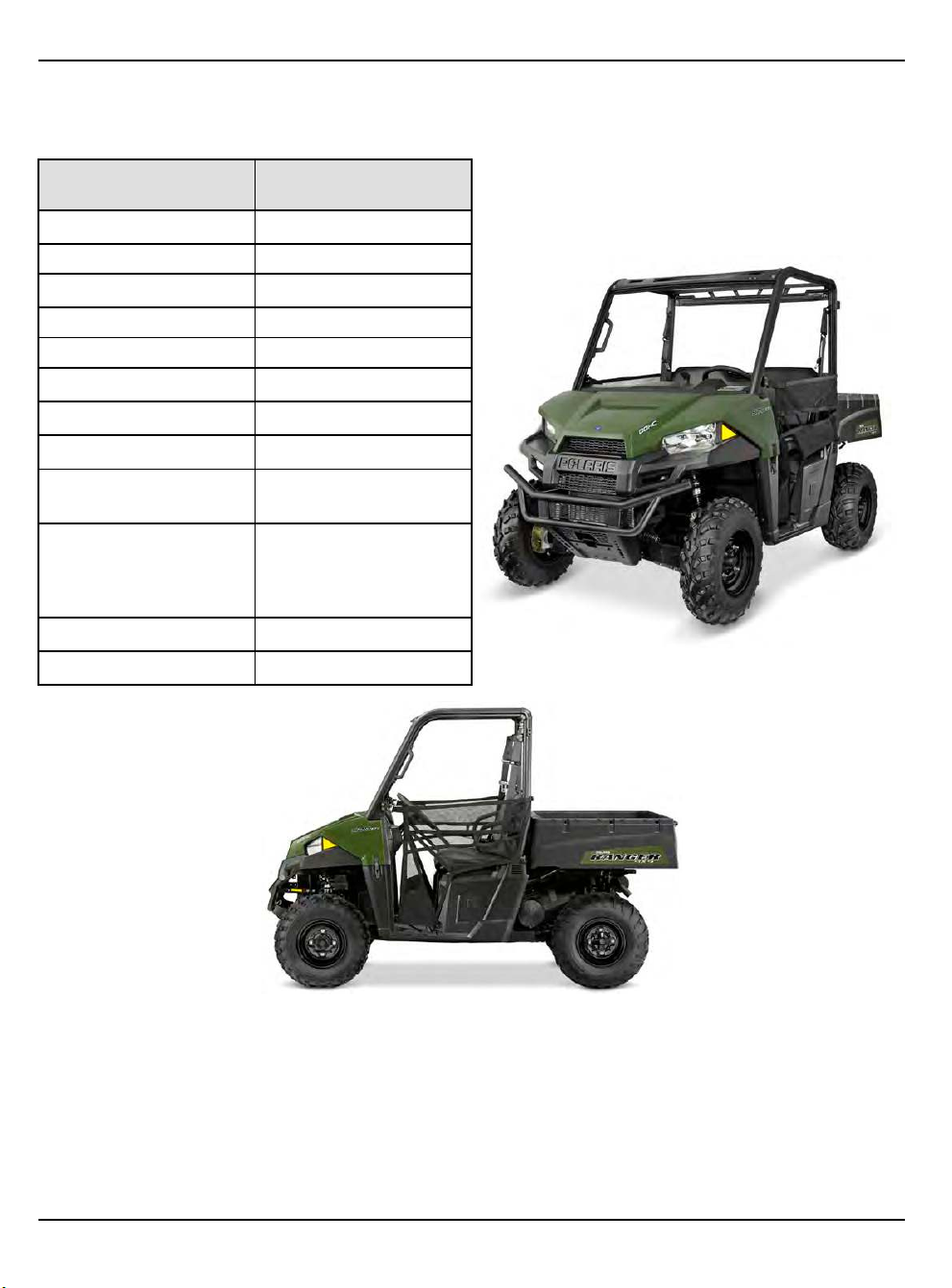

GENERAL INFORMATION

GENERAL SPECIFICATIONS

2017-2018 RANGER 500

MODEL NUMBER:

2017 2x4: R17RM250A1

2017 4x4: R17RMA50A4

2018 2x4: R18RM250B1

2018 4x4: R18RMA50B1

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

Dry Weight 1080 lbs. / 490 kg

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.20

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 29

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 93 mm x 73.6 mm

Compression Ratio

Engine Idle Speed

Engine Max Speed 7000 RPM

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2.0 qts. (1.9 l)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 W

Ignition Timing ECU Controlled

Spark Plug / Gap Autolite 5923 / 0.030” - 0.037”

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

DRIVETRAIN

Transmission Type

Shift Type

Single overhead cam, 2 valve

4 stroke single cylinder.

500cc

10:1

1250 ±200 RPM

0.006 ± 0.002" (0.152 ± 0.051

mm)

0.010 ± 0.002" (0.254 ± 0.051

mm)

tank)

(minimum)

50W quartz/halogen

(0.85 +/- 0.08 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

DRIVETRAIN

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 9″ (20.3 cm)

Rear Suspension Independent (IRS), Dual A-

Rear Travel 10″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 8 / Steel

Rear Wheel Size / Type 12 x 9 / Steel

Front Tire Model / Size AT489 / 24 x 8 - 12

Rear Tire Model / Size AT489 / 24 x 9 - 12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

arm, Anti-Sway Bar

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.21

Page 30

GENERAL INFORMATION

2017-2018 RANGER 570 4X4

MODEL NUMBER:

2017: R17RMA57A1/A9, R17RME57AK

2018: R18RMA57B1/B9

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

1075 lbs. (488 kg) (570)

1100 lbs. (499 kg) (570

Dry Weight

EPS)

1140 lbs. (517 kg) (570

w/park

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.22

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 31

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005-0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.9 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

(3.20 − 6.35 mm)

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.23

Page 32

GENERAL INFORMATION

2017-2018 RANGER 570 4X4 (INTL.)

MODEL NUMBER:

2017: R17RMA57N1, R17RMT57C1, R17RME57F1, R17RMS57F1

2018: R18RMS57F1

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

1075 lbs. (488 kg) (570)

1100 lbs. (499 kg) (570

Dry Weight

EPS)

1140 lbs. (517 kg) (570

w/park)

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.24

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 33

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005-0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.9 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.25

Page 34

GENERAL INFORMATION

2017-2018 RANGER 570 4X4 TRACTOR

(INTL.)

MODEL NUMBER:

2017: R17RMT57C1, R17RMS57C1, R17RMS57CK

2018: R18RMS57C1, R18RMS57CV, R18RMT57C1

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

1075 lbs. (488 kg) (570)

1100 lbs. (499 kg) (570

Dry Weight

EPS)

1140 lbs. (517 kg) (570

w/park)

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.26

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 35

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005-0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.9 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.27

Page 36

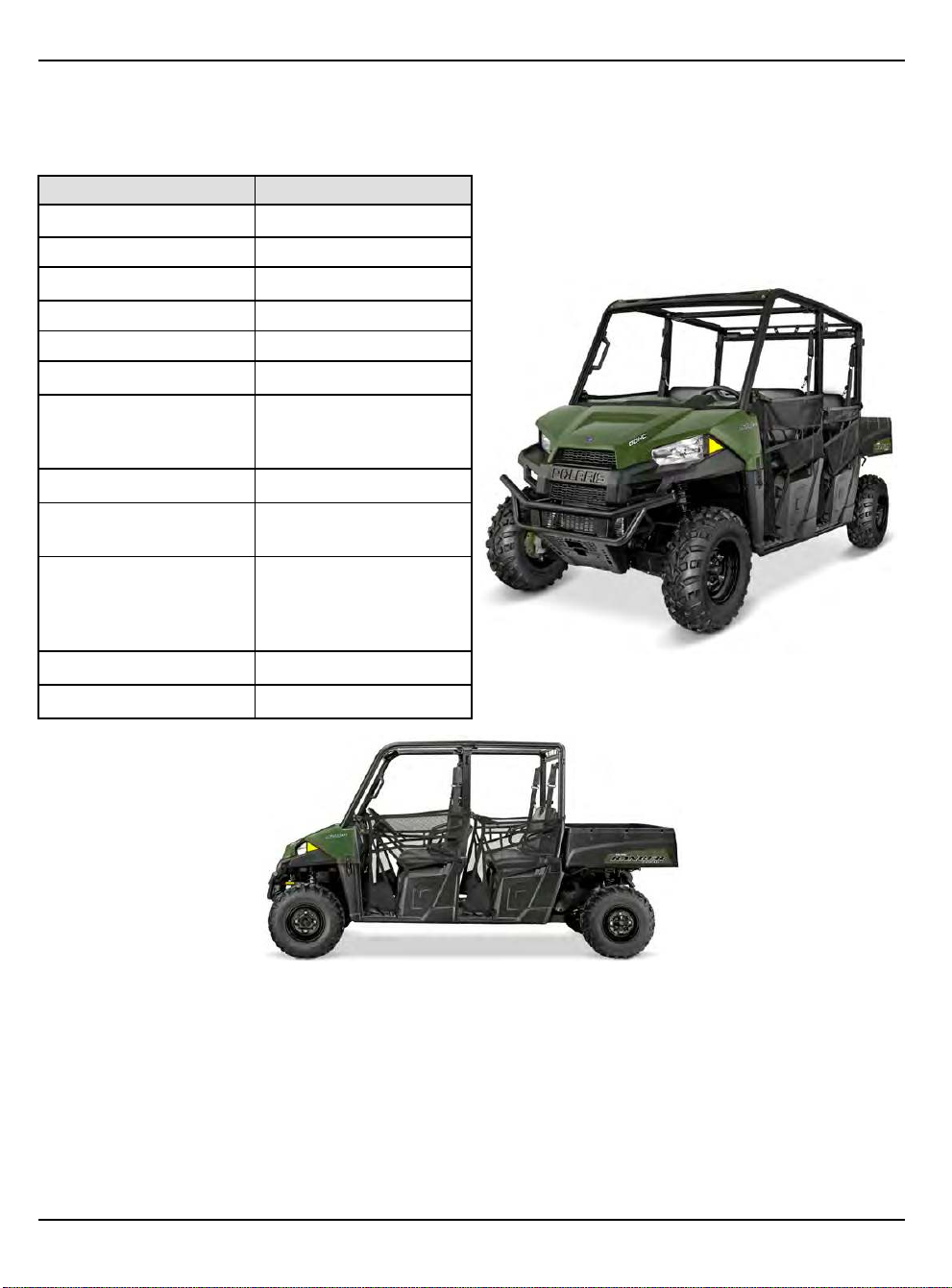

GENERAL INFORMATION

2017-2018 RANGER 570 CREW

MODEL NUMBER:

2017: R17RNA57A1

EPS: R17RNE57AM, R17RNE57NM, R17RNA57A9

2018: R18RNA57B1

R18RNA57B9

EPS: R18RNE57BV

R18RNE57NV

CATEGORY DIMENSION / CAPACITY

Length

Width 60″ / 152.4 cm

Height

Wheel Base 105″ / 266.7 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius 237″ / 602 cm

Dry Weight 1323 lbs. / 600 kg

Cargo Box Capacity 500 lbs. / 227 kg

140″ / 355.6 cm

73″ / 185 cm

1352 lbs. / 613 kg (W /

EPS)

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

Vehicle Payload 1250 lbs. / 567 kg

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4 kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.28

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 37

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Number of Cylinders

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Lubrication

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 170 Oz (5 L)

FUEL SYSTEM

Type Bosch M17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Lamp 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Instrumentation Multifunction Instrument

Relays EFI / Chassis / Fan / Fuel

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

1

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005–0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

Pressurized Dry Sump

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.8 mm)

Hr / 12 Volt

Cluster

Pump / Headlight / EPS (EPS

model only)

ELECTRICAL

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (23 cm)

Spring Adjustment Cam Adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure Front: 10 psi

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission — Park Lock

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

8.97 oz. (265 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

Rear: 14 psi

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.29

Page 38

GENERAL INFORMATION

2019 RANGER 500

MODEL NUMBER:

2x4: R19RMA50B1

4x4: R19RMA50B4

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

Dry Weight 1080 lbs. / 490 kg

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.30

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 39

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 93 mm x 73.6 mm

Compression Ratio

Engine Idle Speed

Engine Max Speed 7000 RPM

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2.0 qts. (1.9 l)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 W

Ignition Timing ECU Controlled

Spark Plug / Gap Autolite 5923 / 0.030” - 0.037”

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

DRIVETRAIN

Transmission Type

Shift Type

Single overhead cam, 2 valve

4 stroke single cylinder.

500cc

10:1

1250 ±200 RPM

0.006 ± 0.002" (0.152 ± 0.051

mm)

0.010 ± 0.002" (0.254 ± 0.051

mm)

tank)

(minimum)

50W quartz/halogen

(0.85 +/- 0.08 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

DRIVETRAIN

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 9″ (20.3 cm)

Rear Suspension Independent (IRS), Dual A-

Rear Travel 10″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 8 / Steel

Rear Wheel Size / Type 12 x 9 / Steel

Front Tire Model / Size AT489 / 24 x 8 - 12

Rear Tire Model / Size AT489 / 24 x 9 - 12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

arm, Anti-Sway Bar

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.31

Page 40

GENERAL INFORMATION

2019 RANGER 570 4X4

MODEL NUMBER:

R19RCA57A1, R19RCA57A4, R19RCA57B1, R19RCA57B4

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

1075 lbs. (488 kg) (570)

1100 lbs. (499 kg) (570

Dry Weight

EPS)

1140 lbs. (517 kg) (570

w/park)

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.32

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 41

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005-0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.9 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

(3.20 − 6.35 mm)

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.33

Page 42

GENERAL INFORMATION

2019 RANGER 570 4X4 (INTL.)

MODEL NUMBER:

R19RMA57F1

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

1075 lbs. (488 kg) (570)

1100 lbs. (499 kg) (570

Dry Weight

EPS)

1140 lbs. (517 kg) (570

w/park

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.34

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 43

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005-0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.9 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.35

Page 44

GENERAL INFORMATION

2019 RANGER 570 4X4 TRACTOR (INTL.)

MODEL NUMBER:

R19RMS57C1

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

1075 lbs. (488 kg) (570)

1100 lbs. (499 kg) (570

Dry Weight

EPS)

1140 lbs. (517 kg) (570

w/park

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.36

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 45

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Light 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Relays EFI / Chassis / Fan / Fuel

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005-0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.9 mm)

Hr / 12 Volt

Pump / Headlight / EPS (EPS

model only)

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (22.9 cm)

Spring Adjustment Cam adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission - Park Lock

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

6.7–7.6 oz. (200–225 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

Front: 10 psi (69 kPa)

Rear: 10 psi (69 kPa)

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.37

Page 46

GENERAL INFORMATION

2019 RANGER 570 CREW

MODEL NUMBER:

R19RNA57B1

EPS: R19RNE57BX

R19RNA57B9

CATEGORY DIMENSION / CAPACITY

Length

Width 60″ / 152.4 cm

Height

140″ / 355.6 cm

73″ / 185 cm

Wheel Base

105″ / 266.7 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius 237″ / 602 cm

Dry Weight 1323 lbs. / 600 kg

1352 lbs. / 613 kg (W /

EPS)

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

Vehicle Payload 1250 lbs. / 567 kg

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4 kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.38

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 47

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Number of Cylinders

Bore & Stroke 99 x 73.6 mm

Compression Ratio

Compression Pressure

Engine Idle Speed

Engine Max Speed

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Lubrication

Oil Requirements PS4 synthetic

Oil Capacity 2 qts. (1.9 L)

Coolant Capacity 170 Oz (5 L)

FUEL SYSTEM

Type Bosch M17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL

Alternator Max Output 560 W @ 3000 RPM

Headlights 2 single beam

Taillights / Brake Lights 10 LED 0.28 Watt / 3.1 Watt

Indicator Lamp 1.0 Watt

Ignition Timing ECU Controlled

Spark Plug / Gap NGK MR7F / 0.0276 −

Battery / Amp Hr Yuasa Conventional 14 Amp

DC Outlet Standard 12 Volt

Instrumentation Multifunction Instrument

Relays EFI / Chassis / Fan / Fuel

Domestic Single Cyl., Liquid

Cooled, 4–Stroke, DOHC

567cc

1

10:1

80-120 psi (compression

release)

1200 +/- 100 RPM

7750 RPM

0.005–0.007″ (0.125–0.175

mm)

0.008 ± 0.002″ (0.152–0.254

mm)

Pressurized Dry Sump

tank)

(minimum)

50W quartz/halogen

0.0315″

(0.7 – 0.8 mm)

Hr / 12 Volt

Cluster

Pump / Headlight / EPS (EPS

model only)

ELECTRICAL

Circuit Breaker Fan Motor: 20 Amp

Fuses Brake Light: 5 Amp

DRIVETRAIN

Transmission Type

Shift Type

Front Gearcase Lubricant

Requirement

Transmission Lubricant

Requirement

STEERING / SUSPENSION

Toe Out 1/8 − 1/4″ (3.20 − 6.35 mm)

Front Suspension Strut / A-arm

Front Travel 8″ (20.3 cm)

Rear Suspension Independent (IRS)

Rear Travel 9″ (23 cm)

Spring Adjustment Cam Adjustment (rear)

WHEELS / BRAKES

Front Wheel Size / Type 12 x 6 / Steel

Rear Wheel Size / Type 12 x 8 / Steel

Front Tire Model / Size AT489 / 25 x 8 R12

Rear Tire Model / Size AT489 / 25 x 11 R12

Tire Air Pressure Front: 10 psi

Brake System 4 Wheel Hydraulic Disc

Brake Fluid DOT 4

Parking Brake Transmission — Park Lock

EFI: 20 Amp

Fuel Pump: 10 Amp

EPS (EPS model only): 20

Amp

Accessory: 20 Amp

Drive: 10 Amp

Lights: 20 Amp

Polaris Automatic PVT

In Line Shift - P/ H / L / N / R

Demand Drive

8.97 oz. (265 ml)

Full Synthetic AGL

33.8 oz. (1000 ml)

Rear: 14 psi

1

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

1.39

Page 48

GENERAL INFORMATION

2020 RANGER 500

MODEL NUMBER:

2x4: R20RMAA50B1

CATEGORY

Length

DIMENSION /

CAPACITY

110″ / 279.4 cm

Width 58″ / 147.3 cm

Height

73″ / 185 cm

Wheel Base 73″ / 185 cm

Ground Clearance 10″ / 25.4 cm

Turning Radius

150″ / 381 cm

Dry Weight 1080 lbs. / 490 kg

Cargo Box Capacity 500 lbs. / 227 kg

Cargo Box Dimensions

(inside dimensions)

L- 42″ x W-32″ x H-11.5″

(107 x 81 x 29 cm)

1000 lbs. / 454 kg

Vehicle Payload

(Includes weight of

riders, cargo and

accessories)

Towing Capacity 1500 lbs. / 680.4kg

Hitch Tongue Capacity 150 lbs. / 68 kg

1.40

9850043 R01 - 2017-2021 RANGER 500 / 570 Service Manual

© Copyright Polaris Inc.

Page 49

GENERAL INFORMATION

MODEL SPECIFICATIONS

ENGINE

Platform

Engine Displacement

Bore & Stroke 93 mm x 73.6 mm

Compression Ratio

Engine Idle Speed

Engine Max Speed 7000 RPM

Valve Clearance (Intake)

Valve Clearance (Exhaust)

Oil Requirements PS4 synthetic

Oil Capacity 2.0 qts. (1.9 l)

Coolant Capacity 120 Oz (3.5 L)

FUEL SYSTEM

Type Bosch ME17 EFI

Fuel Delivery Electronic Fuel Pump (in-

Fuel Pressure 58 ± 2 PSI (400 ± 14 kPa)

Fuel Capacity / Requirement 8.8 gal. (33.3 L) 87 Octane

ELECTRICAL