Page 1

-1-

PROSPECTOR TRACK MOUNT KIT

1

6

6

RANGER 1000 / RANGER XP 1000

P/N 2889069

Application

RANGER 1000 / RANGER XP 1000 MODELS -- MY21 AND NEWER

Before you begin, read these instructions and check to be sure all parts and tools are

accounted for. Please retain these installation instructions for future reference and parts

ordering information.

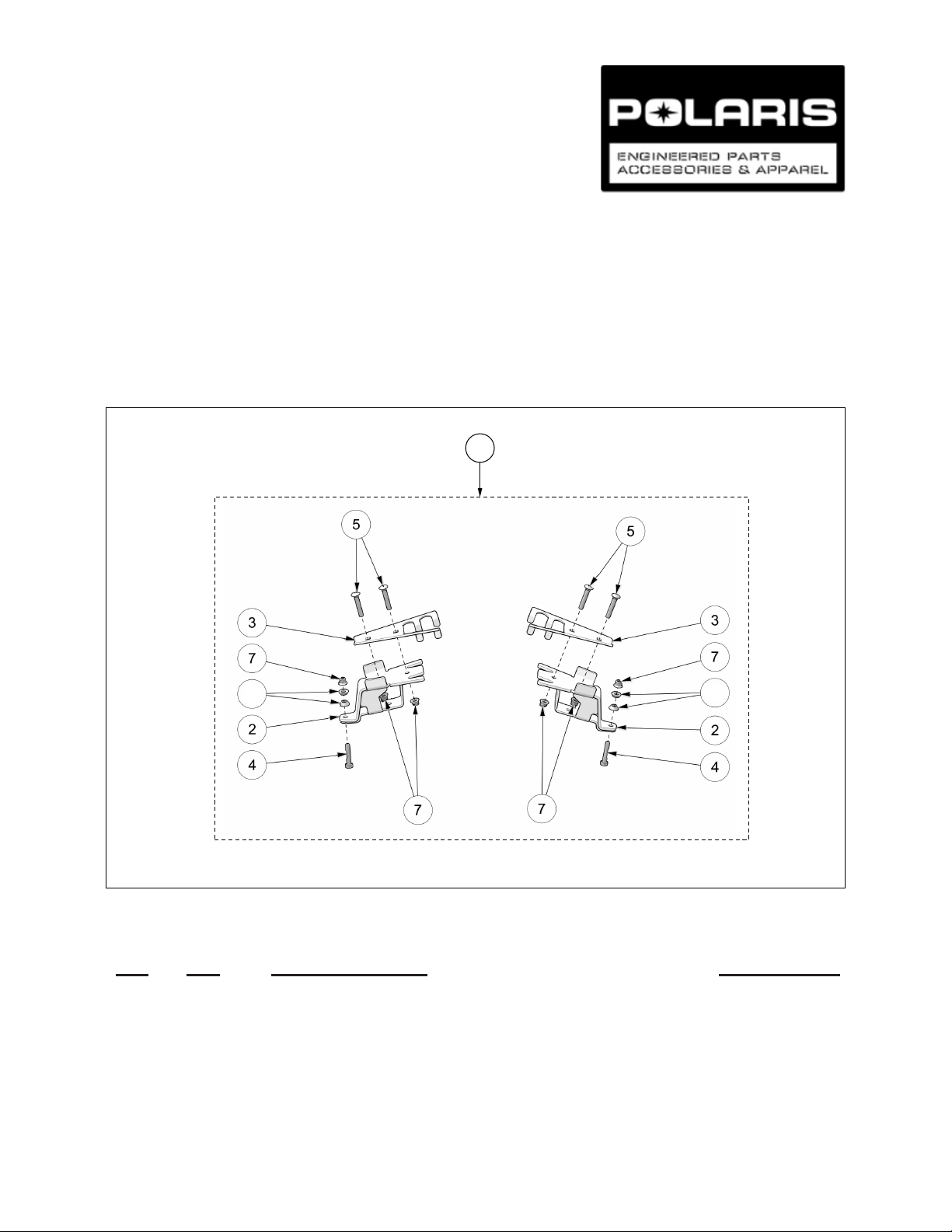

FRONT ANCHOR BRACKET:

Figure 1

Kit Contents:

Ref Qty Part Description Part Number

1 1 Front Bracket Kit 2208848

2 1 Front Anchor Bracket 3 1 Front Bracket Cover 4 2 Hex Bolt - HCS, M10-1.5X55, 10.9, ZP, DIN931 5 4 Carriage Bolt - CB, M10-1.5X60, 8.8, ZP, DIN603 6 4 Taper Sleeve 7 6 Nylon Nut - FNN, M10-1.5, 8, ZP, DIN6926 -

5000-05-9140-MAN

Page 2

-2-

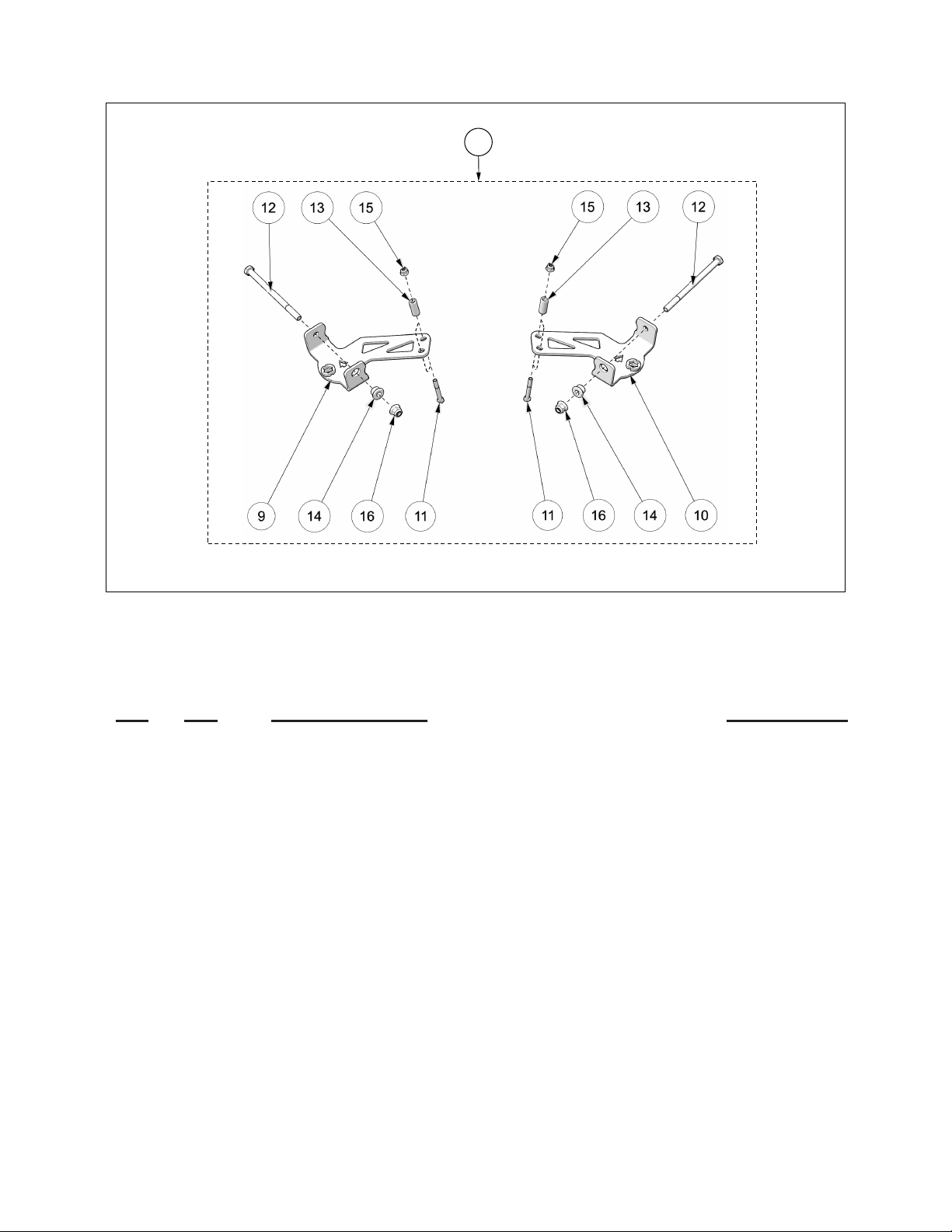

REAR ANCHOR BRACKET:

8

Figure 2

Kit Contents:

Ref Qty Part Description Part Number

8 1 Rear Bracket Kit 2208849

9 1 Rear Left Anchor Bracket 10 1 Rear Right Anchor Bracket 11 2 Hex Bolt - HCS, M8-1.25X60,10.9,ZP,DIN931 12 2 Hex Bolt - HCS, M12-1.75x190, 8.8, ZP, DIN931 13 2 Bushing 1-1/2 0.410IDX0.625ODx1.50L YZN 14 2 Taper bushing 15 2 Nylon Nut - FNN, M8-1.25,8,ZP,DIN6926 16 2 Nylon Nut - FNN, M12-1.75, 8, ZP, DIN6926 -

Page 3

-3-

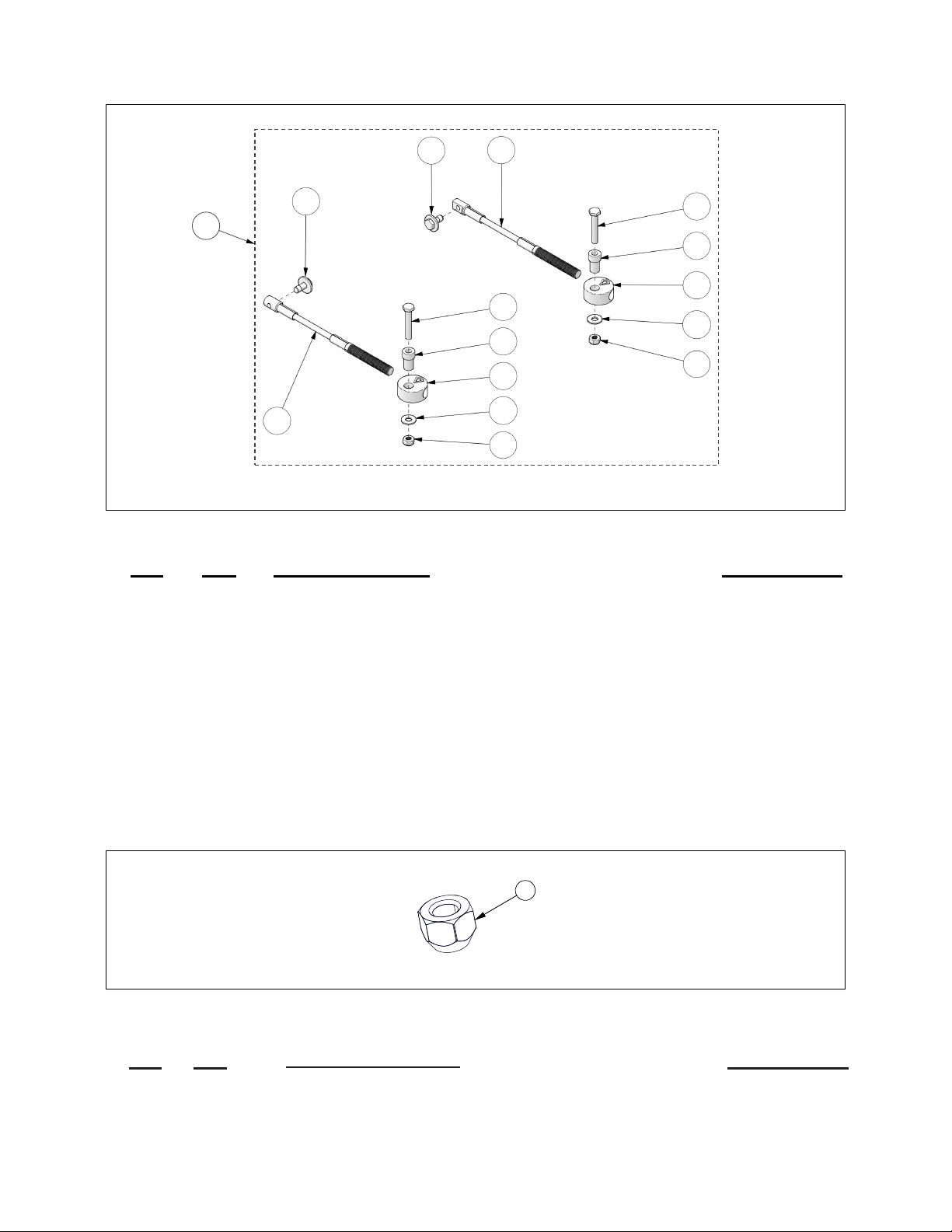

STEERING LIMITER ASSEMBLY:

17

18

18

19

19

20

19

20

21

21

22

22

23

23

24

24

Figure 3

Kit Contents:

WHEEL LUG NUT:

Kit Contents:

Ref Qty Part Description Part Number

17 1

18 2

19 2

20 2

21 2

22 2

23 2

24 2

Figure 4

Steering Limiter Cable Assembly

Steering Limiter Mounting Disk

Steering Limiter Cable

Hex Bolt - HCS, M10-1.5X60, 8.8, ZP, DIN931

Hex Bolt - HCSW, M10-1.5X25, 8.8, ZP, TL, DIN933

Step Spacer

Washer - W, 7/16X1.0X0.072, 8, ZP, USS

Nylon Nut - NN, M10-1.5, ZP, 8, DIN982

2205456

-

-

-

-

-

-

-

Ref Qty

25 16

Part Demscription

Wheel Lug Nut-LN, M12-1.5X14, 8, ZP

Part Number

2205458

Page 4

-4-

Tools Required:

Lift Table or Floor Jack Torque Wrench 2 Jack Stands

Ratchet Metric Socket Set Metric Wrench Set

APPROXIMATE ASSEMBLY TIME: 60 minutes

IMPORTANT: Please read carefully each part of this document as well as the User Manual prior to

assembling, installing and using the track systems.

INSTALLATION INSTRUCTIONS:

CAUTION: Before beginning the installation, make sure you received all the components

included in the parts lists of the preceding pages.

1. For installation purposes, directional

arrows have been cut out of the main

components in the anchor bracket

kits. These arrows indicate the front of

the vehicle relative to the component.

Figure 5.

Figure 5

PREPARATION:

WARNING: Never place parts of your body under the vehicle unless it is securely supported by

appropriate stands. Severe injuries could occur if the vehicle collapses or moves. Do not use a

lifting device as a secure stand.

1. Stop the vehicle on a flat and level

surface (or on a suitable lifting device),

shift the transmission into Park and

turn off engine.

2. Identify and position each unit of

the track system near the position

indicated on the sticker affixed on the

frame. Figure 6.

Figure 6

Page 5

-5-

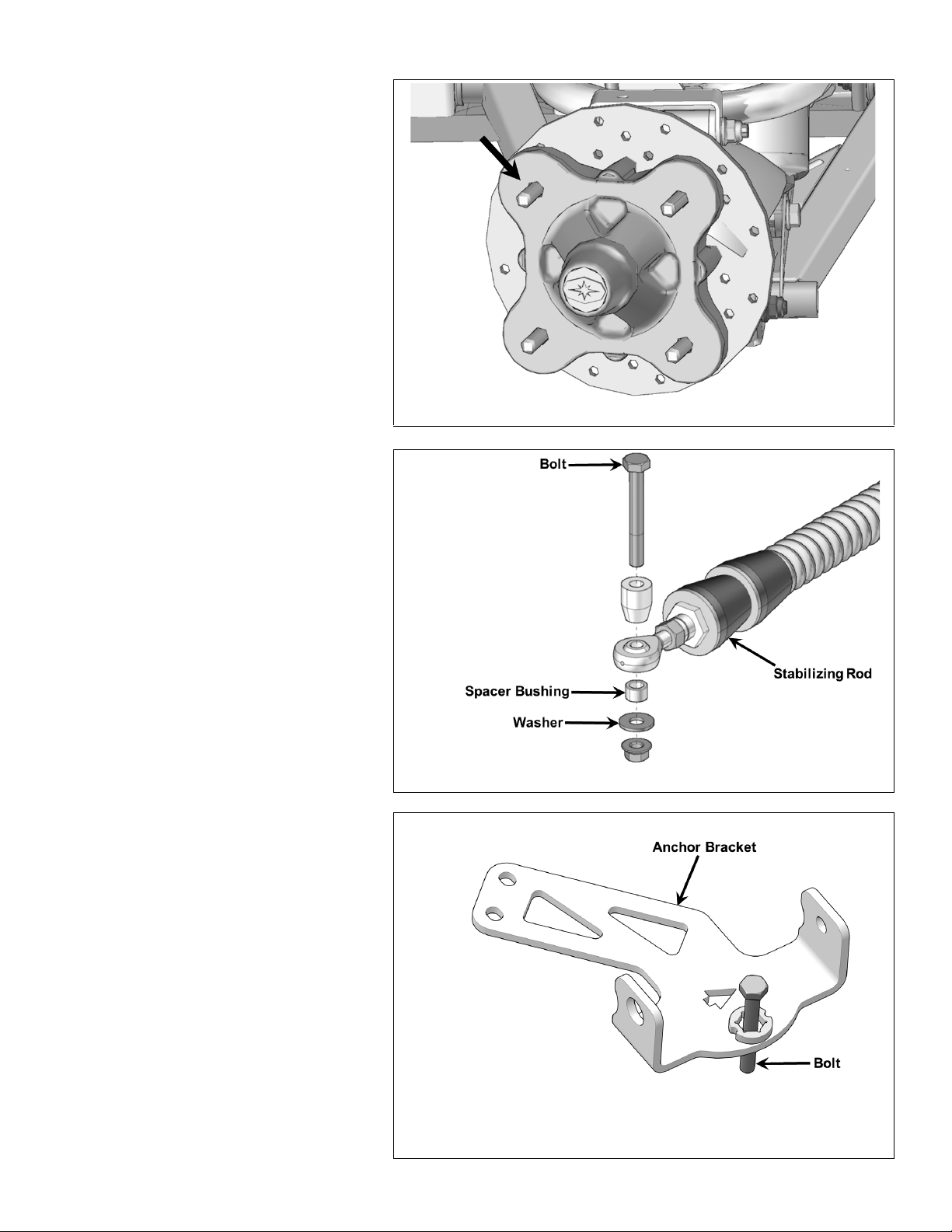

REAR TRACK SYSTEMS:

1. Using a lifting device, raise the rear

of the vehicle and install appropriate

stands. Ensure that the vehicle is

immobilized and safe to work on.

2. Remove the rear wheels to begin

Track Mount installation. Make sure

that wheel studs and wheel hubs are

free of dirt. Figure 7.

3. Remove bolt, washer and spacer

bushings from the rear stabilizing

rod end. Figure 8.

Figure 7

Figure 8

4. Insert the bolt in the rear anchor

bracket as shown in Figure 9.

NOTE: It is not possible to insert

this bolt once the bracket is attached

to the suspension arm.

Figure 9

Page 6

-6-

5. Remove bolt securing the lower

suspension arm to the wheel hub.

A new M12-1.75x190 mm bolt

provided in the installation kit

will be used to assemble the anchor

bracket, lower suspension arm and

wheel hub. Figure 10.

6. Position anchor bracket under

lower rear suspension arm.

See Figure 11 or Figure 12.

NOTE: Lower rear suspension arms

come in

depending on the vehicle

installation differs slightly for each

version.

straight or arched versions

. The bracket

Figure 10

,

Figure 11

Figure 12

Page 7

-7-

7. Align anchor bracket holes with

suspension arm holes. Install flange

bushing in bracket and suspension arm.

Slide the new M12x190 mm assembly

bolt through anchor bracket, suspension

arm, wheel hub, and flange bushing.

Thread nut on bolt but do not tighten

immediately.

See Figure 13 or Figure 14 depending

on version of suspension arm installed.

Figure 13

8. Position spacer bushing between

anchor bracket and lower suspension

arm. Align bushing with one of two holes

at the back of anchor bracket and

existing hole in suspension arm. See

Figure 15 or Figure 16.

NOTE: Bracket hole used is different

depending on version of suspension

arm installed. Straight version uses hole

nearer front of vehicle. Arched version

uses hole nearer rear of vehicle.

Figure 14

Figure 15

Page 8

-8-

8. Secure back of anchor bracket to

suspension arm with M8x60 mm bolt and

nut. Torque M12 bolt to 63 ft. lbs. (85

Nm) and M8 bolt to 18 ft. lbs. (25 Nm).

See Figure 17 or Figure 18 depending

on version of suspension arm installed.

Figure 16

Figure 17

Figure 18

Page 9

-9-

9. Secure the undercarriage to the rear hub

using the nuts (ref. #25) provided in this

mount kit. See Figure 22.

NOTE: If needed, take rubber

protector off of hub

NOTE: Ensure that the cotter pin of

the axle nut does not interfere with the

undercarriage hub.

NOTE: Torque lug nuts to 85 ft. lbs.

(115 Nm) at this time.

10. Attach the stabilizing rod to the anchor

bracket, using the long spacer bushing,

short spacer bushing,

flat washer and nut. Torque

to 52 ft. lbs. (70 Nm). Figure 23.

.

Figure 22

NOTE: Ensure that parts are

assembled in the correct order.

11. Inspect the rear track systems and

ensure that all mounting bolts were

correctly tightened during installation.

Lower the vehicle to the ground and

proceed to install the front track

systems.

Figure 23

Page 10

-10-

FRONT TRACK SYSTEMS:

1. Using a lifting device, raise the front

of the vehicle and install appropriate

stands. Ensure that the vehicle is

immobilized and safe to work on.

2. Remove front wheels to begin

Track Mount installation. Make sure

that wheel studs and wheel hubs are

free of dirt. Figure 24.

3. If applicable, remove the CV joint

protectors from the A-arms.

4. Remove and discard the bolt,

bushings, washer and nut that are

assembled on the front stabilizing

rod end. Figure 25.

Figure 24

NOTE: Lower front suspension arms

come in straight or arched versions,

depending on the vehicle

installation differs slightly for each

version. Figure 26.

. The bracket

Figure 25

Figure 26

Page 11

-11-

6. Position the bottom part of the

anchor bracket underneath the

lower suspension arm. Position

the bracket cover over the

suspension arm. Align holes

in cover with holes in bottom part.

See Figure 27 or Figure 28,

depending on version of

suspension arm installed.

Figure 27

7. Insert the M10x60 mm carriage bolts

through the bracket cover and secure

the two parts together with the nuts

provided.

See Figure 29 or Figure 30,

depending on version of

suspension arm installed.

Figure 28

Figure 29

Page 12

-12-

8. Torque assembly to 37 ft. lbs. (50 Nm).

See Figure 31 or Figure 32.

Figure 30

Figure 31

Figure 32

Page 13

-13-

9. Secure the undercarriage to the front hub

using the nuts (ref. #25) provided in this

mount kit. Figure 33.

NOTE: If needed, take rubber

protector off of hub

NOTE: Ensure that the cotter pin of

the axle nut does not interfere with the

undercarriage hub.

NOTE: Torque lug nuts to 85 ft. lbs.

(115 Nm) at this time.

.

STEERING LIMITER INSTALLATION:

10. Insert Step spacers in the Steering limiter

assemblies to get left and right steering

limiters. Figure 34.

Figure 33

NOTE: Apply grease to Step spacers

and Mounting disks before assembling

the components.

11. Attach the stabilizing rod to the

anchor bracket, using the two taper

spacers, bolt and nut. Torque to 52 ft.

lbs. (70 Nm). Figure 35.

Figure 34

Figure 35

Page 14

-14-

12. Use bolt, washer and nut to secure

Steering limiter assembly under center of

anchor bracket. Tighten nut to 37 ft. lbs.

(50 Nm). Figure 36.

NOTE:

top of assembly.

NOTE:

aluminium Mounting disk points toward

the front of the vehicle. Figure 37.

Bolt must be inserted through

Make sure the arrow on top of

Figure 36

Figure 37

Page 15

-15-

STEERING LIMITER ADJUSTMENT:

CAUTION: The angle of attack must absolutely be set before beginning steering limiter

adjustment on front track systems. Refer to the User Manual for angle of attack settings.

13. Turn the vehicle’s steering wheel to its

maximum point of travel on the left hand

side. While maintaining pressure on the

steering wheel, turn threaded rod to

adjust length of cable so that the center

of the hole at the end of the cable is

located ½ to ¾ inch [13 to 19 mm] short

of the center of the support plate

mounting hole. Figure 38.

Figure 38

14. Reverse steering wheel a little to be able

to bolt support plate and cable together.

Tighten provided bolt to 24 ft. lbs. (35

Nm). Figure 39.

Repeat steps to adjust right side.

Figure 39

COMPLETION:

1. Verify the suspension settings. If the shock absorbers are adjustable, they should be adjusted to the firmest

level to allow for maximum clearance between the track systems and the vehicle fenders.

2. Verify for possible contact between the undercarriage and the lower fender. If there is contact, the fender

should be modified (cut) to avoid damage to the vehicle’s components and premature wear on rubber track.

3. Lower the vehicle to the ground.

ADJUSTMENTS:

CAUTION: The track systems are designed to provide the best performance in terms of traction

and floatability. Adjustments such as alignment, track tension, and angle of attack are necessary

and mandatory for optimal performance of the systems. For more information on these

adjustments, refer to the USER MANUAL provided with the installation kit specific to the vehicle.

P/N 9939878 Rev 01 09/20

Loading...

Loading...