Page 1

2007 - 2008 IQ SNOWMOBILE

SERVICE MANUAL

FOREWORD

This service manual is designed prim arily for use by ce rtified Polaris Mas ter Service Dealer technicians in a properly

equipped shop and should be kept available for reference. All references to left and right side of the vehicle are from

the operator's perspective when seated in a normal riding position.

Some procedures outlined in this manual require a sound knowledge of mechanical theory, tool use, and shop

procedures in order to perform the work safely and correctly . T echnicians should read the text and be familiar with service

procedures before starting the work. Certa in procedur es require the use o f special tools. Use o nly the proper to ols as

specified.

Comments or suggestions about this manual may be d irected to: Service Publications Dept. @ Polaris Sales Inc. 2100

Hwy 55 Medina Minnesota 55340.

2007 - 2008 IQ Snowmobile Service Manual PN 9921044

© Copyright 2007 Polaris Sales Inc. All information contained within this publica tio n is based on th e late st prod uct informa tion at the time of publication. Due to constant

improvements in the design and quality of production componen ts, some minor discrep ancies may result between the actua l vehicle and the informatio n presented in this

publication. Depictions and/or procedures in this publication are intend ed for reference use only. No liability can be accept ed for omissions or inaccuracies. An y reprinting

or reuse of the depictions and/or procedures contained within, whether whole or in part, is expressly prohibited. Printed in U.S.A.

Page 2

UNDERSTANDING MANUAL SAFETY LABELS AND DIRECTIONS

Throughout this manual, important information is brought to your attention by the following symbols:

WARNING

SAFETY ALERT WARNING indicates a potential hazard that may result in severe injury or death to the operator,

bystander or person(s) inspecting or servicing the vehicle.

CAUTION

SAFETY ALERT CAUTION indicates a potential hazard that may result in minor personal injury or damage to the vehicle.

CAUTION

CAUTION indicates special precautions that must be taken to avoid vehicle damage or property damage.

NOTE:

NOTE provides key information by clarifying instructions.

IMPORTANT:

IMPORTANT provides key reminders during disassembly, assembly and inspection of components.

= In. / mm.

MEASUREMENT provides a key for a determined measurement specification.

= T

TORQUE provides a key for a required torque value.

TRADEMARKS

POLARIS ACKNOWLEDGES THE FOLLOWING PRODUCTS MENTIONED IN THIS MANUAL:

Loctite, Registered Trademark of the Loctite Corporation

Nyogel, Trademark of Wm. F. Nye Co.

Fluke, Registered Trademark of John Fluke Mfg. Co.

Mity-Vac, Registered Trademark of Neward Enterprises, Inc.

Torx, Registered Trademark of Textron

M-10, Registered Trademark of FAST Inc.

WD-40, Registered Trademark of WD-40 Company

Rapid Reaction Driven Clutch, Registered Trademark of Team Industries Inc.

VM and TM Carburetors, Registered Trademarks of Mikuni Amer ica n Corp or ation

Fox and Fox PS-5 Registered Trademark of Fox Racin g Shox, Inc.

Ryde FX and Air 2.0, Registered Trademark of Arvin Meritor, Inc.

Walker Evans Air Shock, Registered Trademark of Walker Evans Racing, Inc.

Page 3

2007 - 2008 IQ Snowmobile

Service Manual Chapters

Model Specifications........................... ....1

General Information............................ ....2

Maintenance....................................... ....3

Fuel Systems...................................... ....4

Engine Systems.................................. ....5

Final Drive and Brake Systems.......... ....6

PVT System........................................ ....7

Suspension and Steering.................... ....8

Shocks................................................ ....9

Chassis............................................... ....10

Electrical Systems.............................. ....11

Wiring Schematics.............................. ....12

Page 4

Model Specifications

CHAPTER 1

Model Specifications

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

2007 600 HO IQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2

2007 600 HO SWITCHBACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4

2007 600 HO RMK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6

2007 600 HO IQ CFI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.8

2007 600 HO SWITCHBACK CFI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.10

2007 600 HO IQ LX CFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.12

2007 600 HO IQ TOURING CFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.14

2007 700 HO IQ DRAGON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.16

2007 700 HO RMK DRAGON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.18

2008 IQ SHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.20

2008 600 RMK 144 / 600 RMK SHIFT 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.22

2008 600 DRAGON IQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.24

2008 600 SWITCHBACK / 600 DRAGON SWITCHBACK. . . . . . . . . . . . . . . . . . . . . . .1.26

2008 600 IQ LX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.28

2008 600 IQ TOURING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.30

2008 600 RMK 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.32

2008 700 IQ / 700 DRAGON IQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.34

2008 700 SWITCHBACK / 700 DRAGON SWITCHBACK. . . . . . . . . . . . . . . . . . . . . . .1.36

2008 700 RMK 155 / 700 DRAGON RMK 155 / 163 . . . . . . . . . . . . . . . . . . . . . . . . . . .1.38

2008 800 DRAGON RMK 155 / 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.40

1

1.1

Page 5

Model Specifications

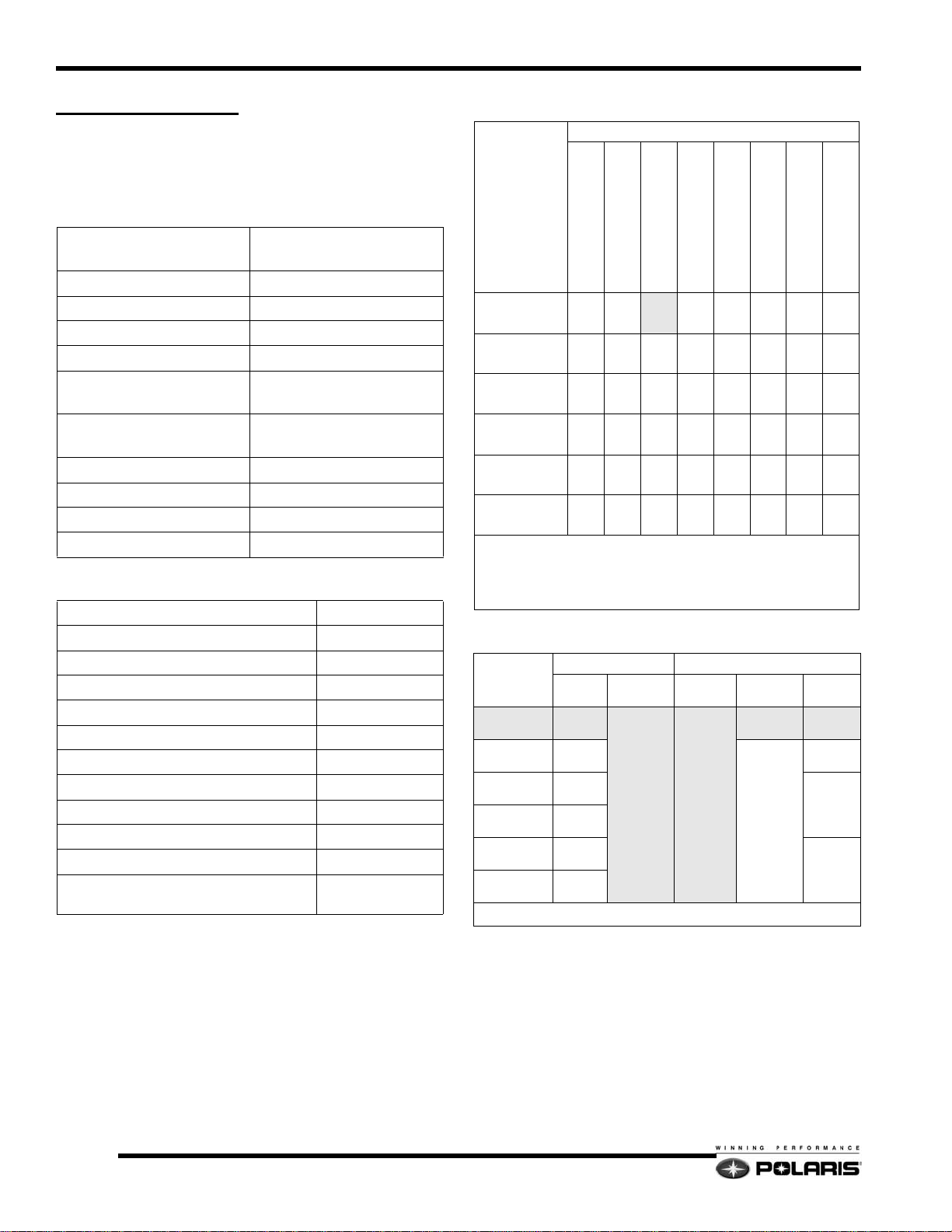

SPECIFICATIONS

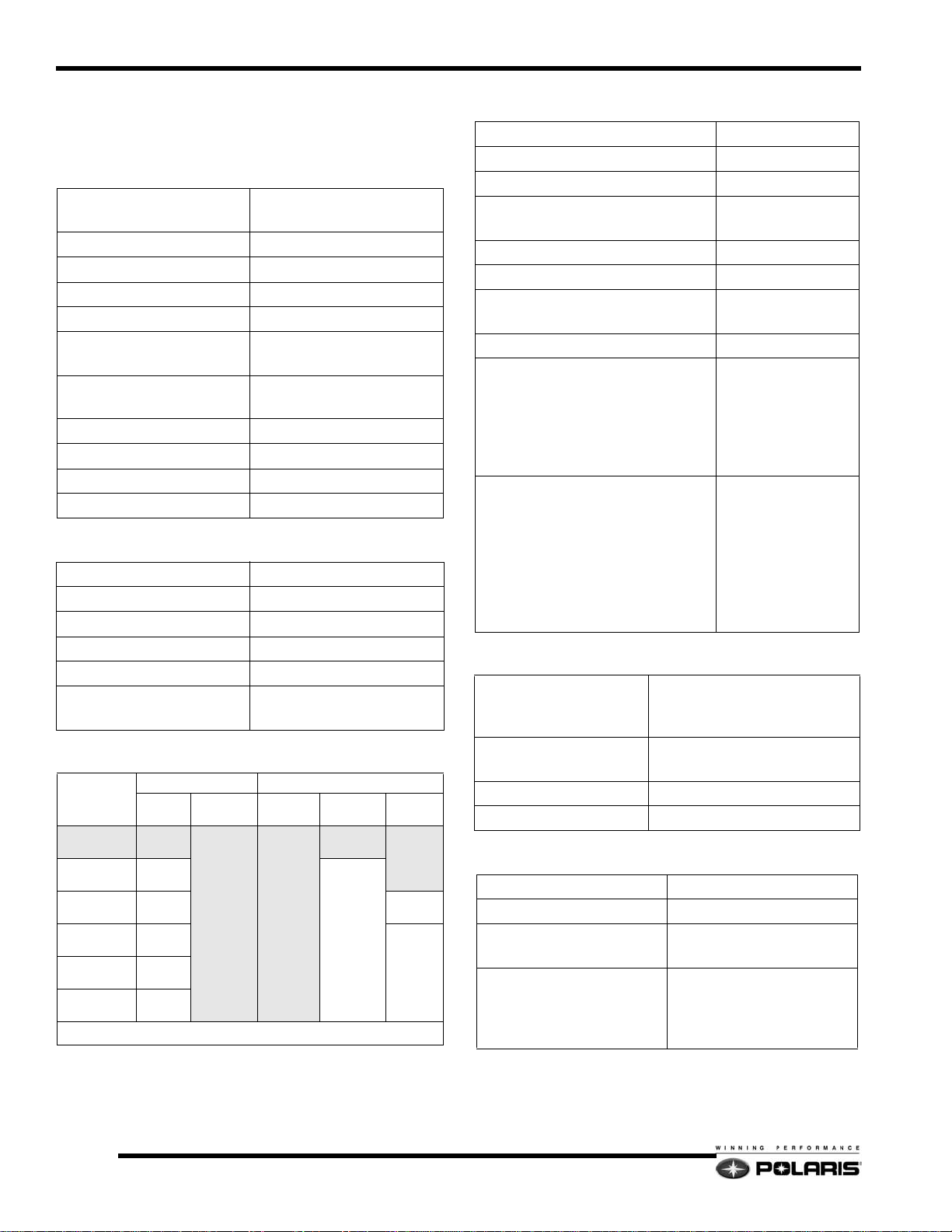

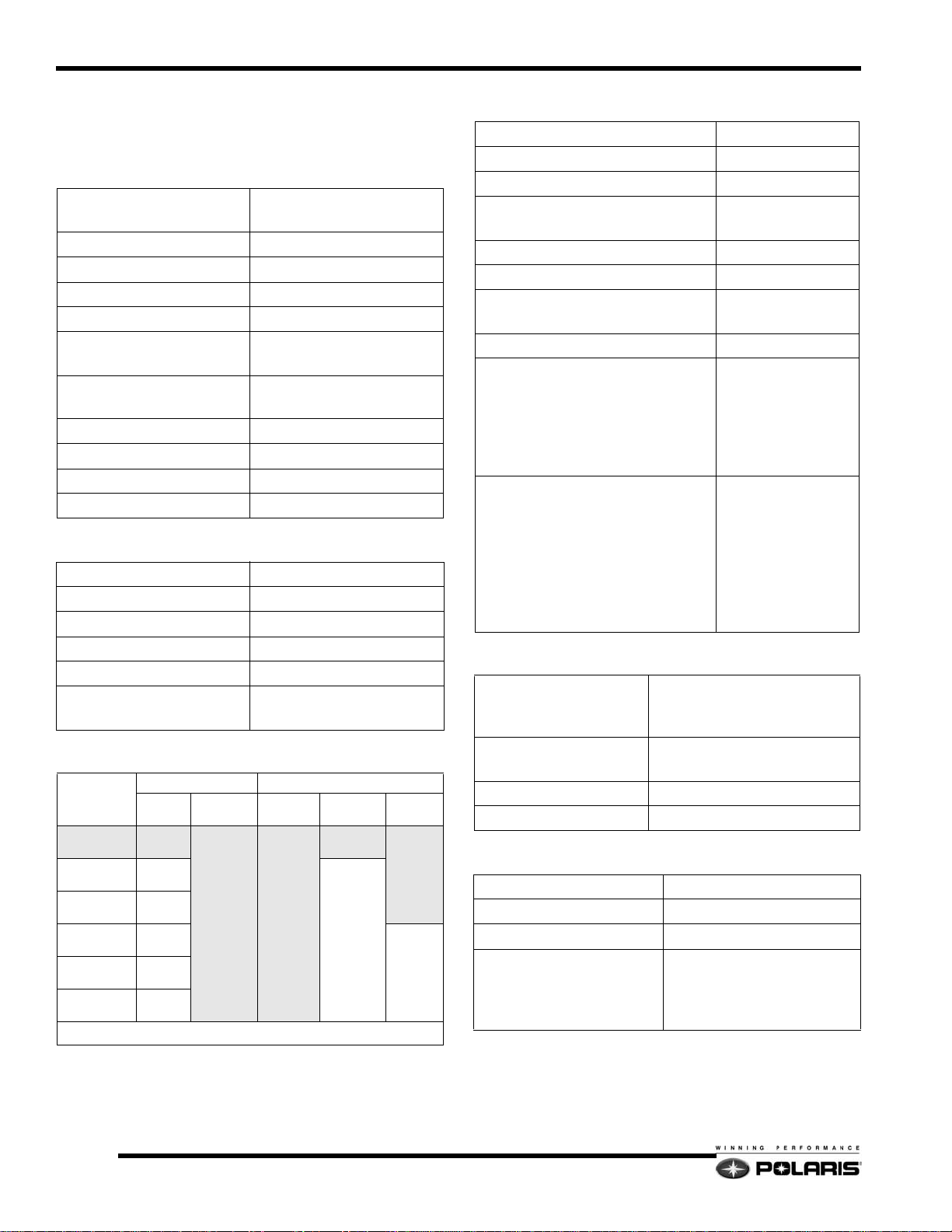

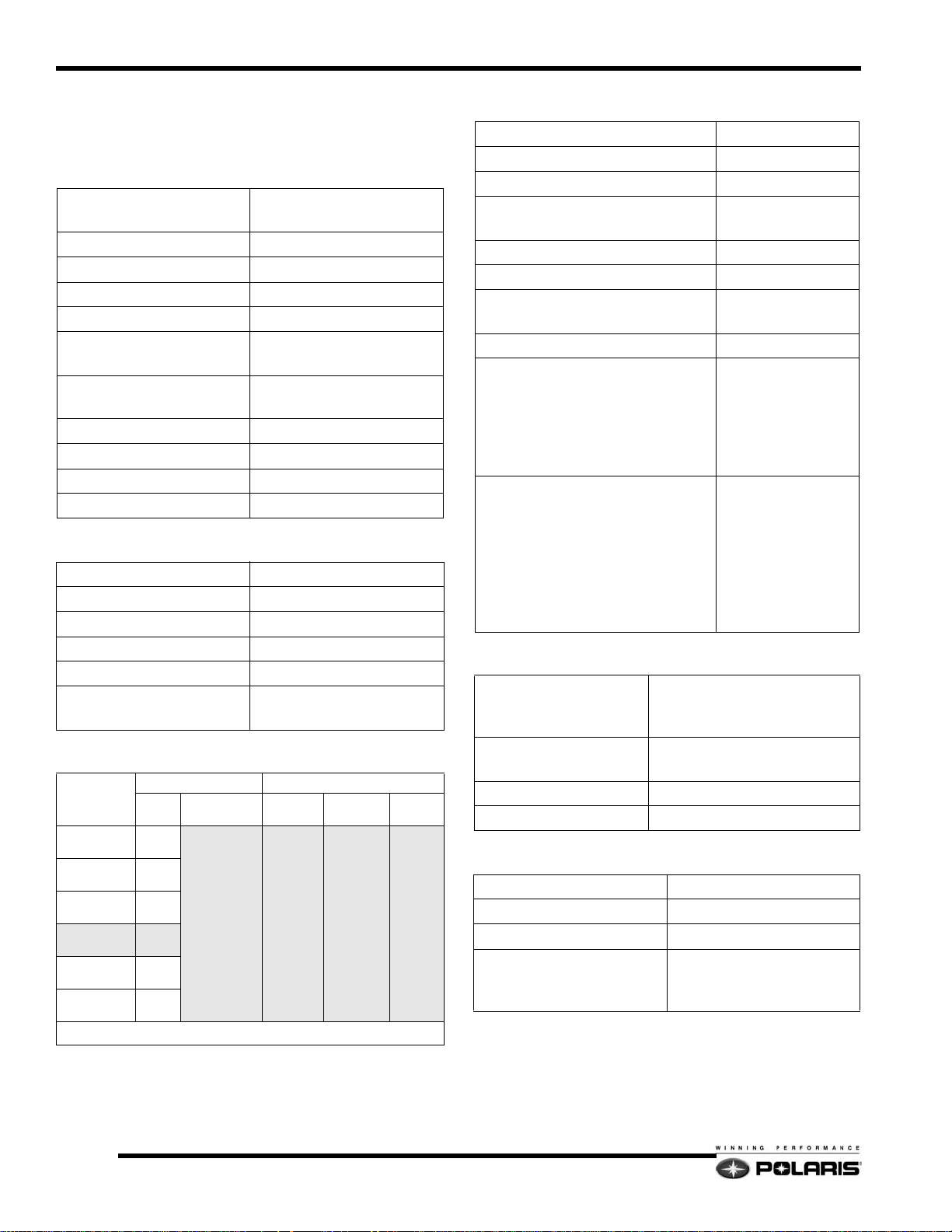

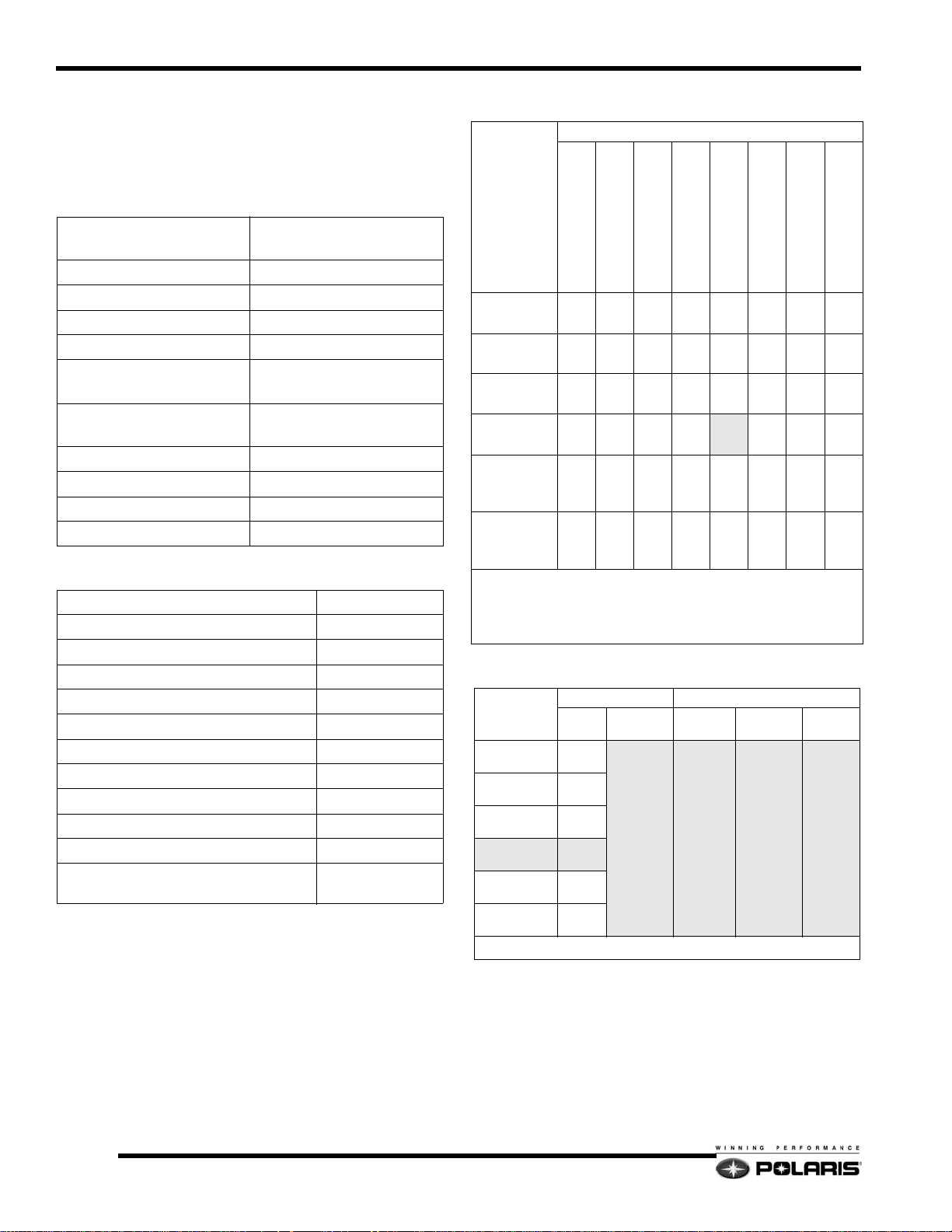

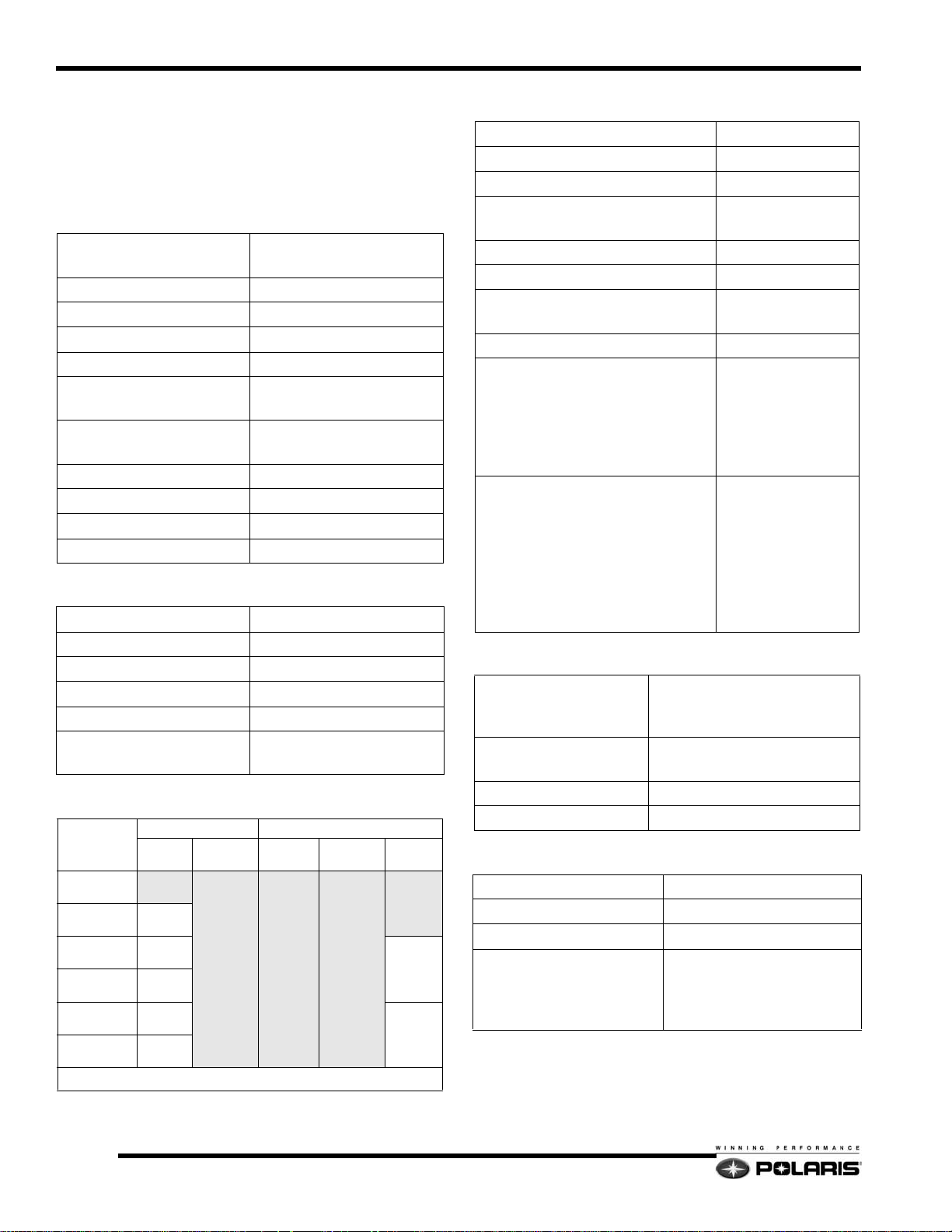

2007 600 HO IQ

Model Number: S07PP6FS (A) (B)

Engine

Engine Type

Model Number S3273-6044-PF6F

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8100

Idle RPM 1500

Engagement RPM ±200 3800

Exhaust Valve Spring Pink

Carburetor Settings

Type

Main Jet

Pilot Jet

Jet Needle/Clip position

Needle Jet

Throttle Gap (Under Cutaway) (in/mm)

Cutaway

Valve Seat

Starter Jet

Pilot Air Jet

Fuel screw (Turns Out)

Recommended Fuel Octane (R+M/2)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

Mikuni TM38

420

50

9DGN6-57 / 2

P-8

0.08 / 2.1

1.5 Notch

1.5

145

.6

1.25

91

(Non-Oxygenated)

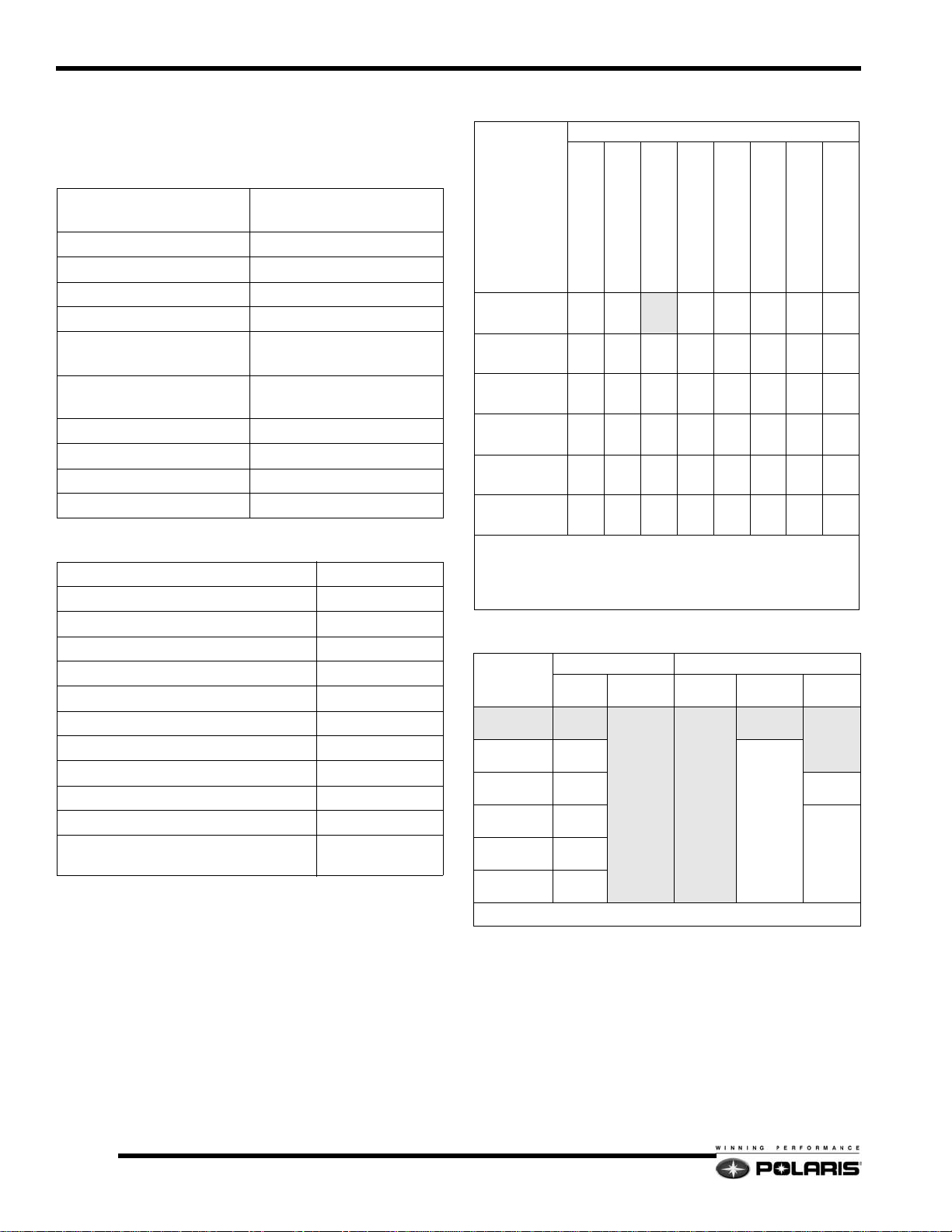

Carburetor Jetting

Ambient Temperature

Altitude

Meters (feet)

< -25°F/<-35°C

0°F to +20°F/-18°C to -7°C

+15°F to +35°F/-9°C to +2°C

+30°F to +50°F/-1°C to +10°C

+45°F to +65°F/+7°C to +18°C

#1

#1

#1

#1

#1

#1

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3700

(10000-12000)

-15°F to +5°F/-26°C to -15°C

-30°F to -10°F/-34°C to -23°C

440#3430#3420#2400#2390#2380#2370#2360

410#3400#3390#2370#2360#2350#2340#1330

370#3360#2350#2340#2330#2320#1310#1300

340#3320#2310#2300#2280#2280#1270#1260

310#2300#2290#2280#1270#1260#1250#1240

290#2280#2270#1250#1240#1230#1220#1210

When using non oxygenated fuel with a RON greater than 93,

decrease the main jet number in the above chart by 10 and raise the

E-clip one position. If the chart recommends clip #1, install washer

on top when using RON 93.

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42.36

LW ER

56/42 - .36

LW ER

Drive Clutch Bolt Torque: 50 lb.ft. (68Nm)

Gearing

23:39-76

22:39-76

22:40-76

20:41-76

>+60°F/>+16°C

1.2

Page 6

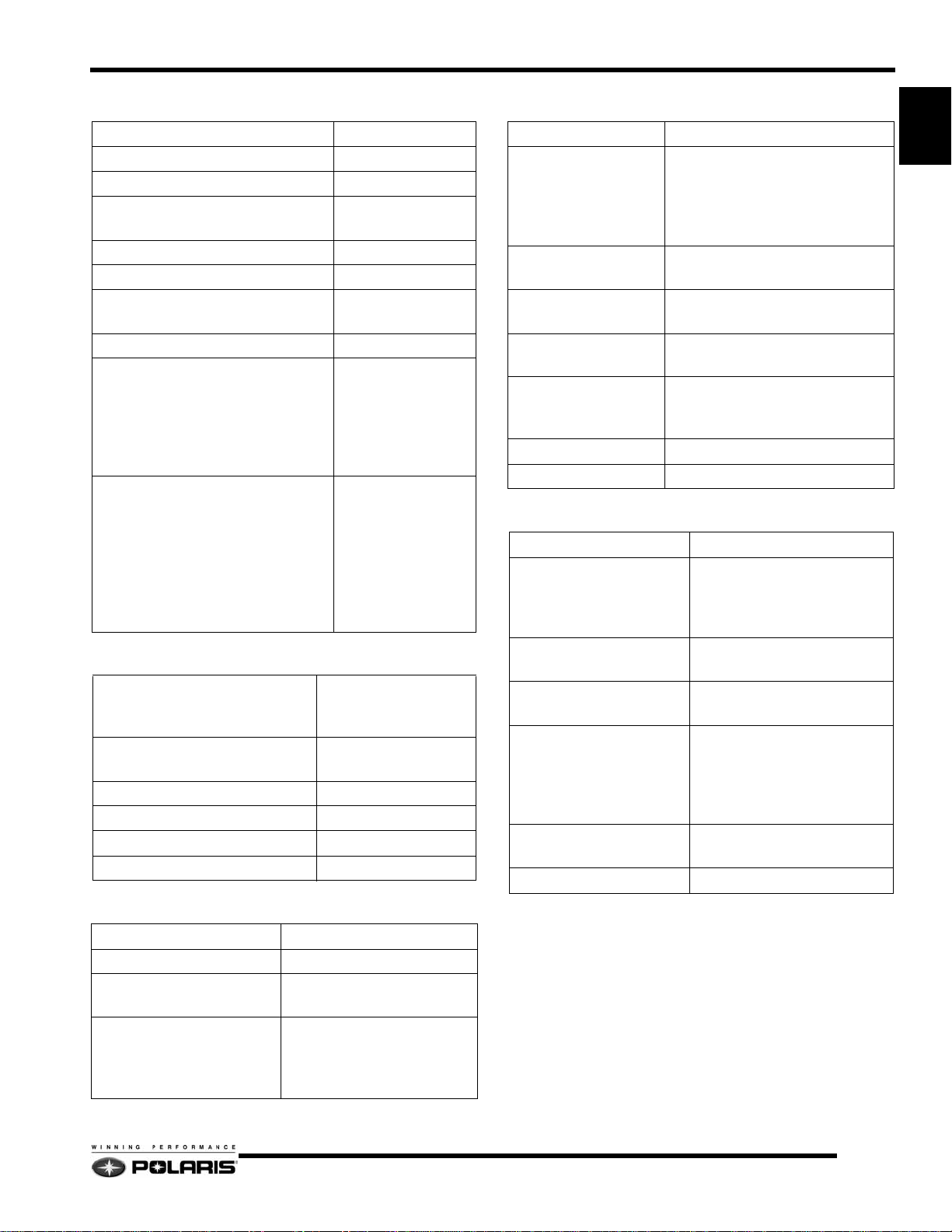

Model Specifications

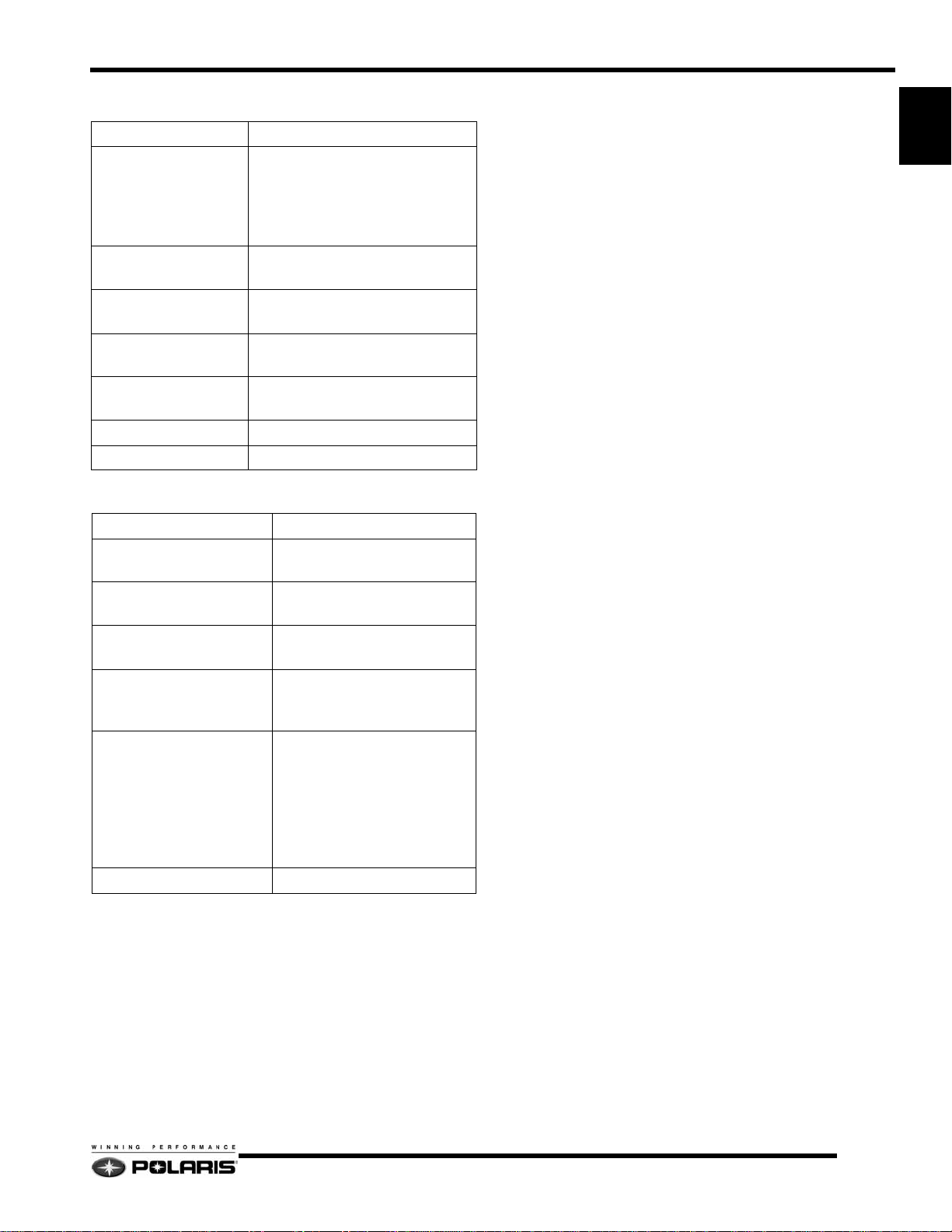

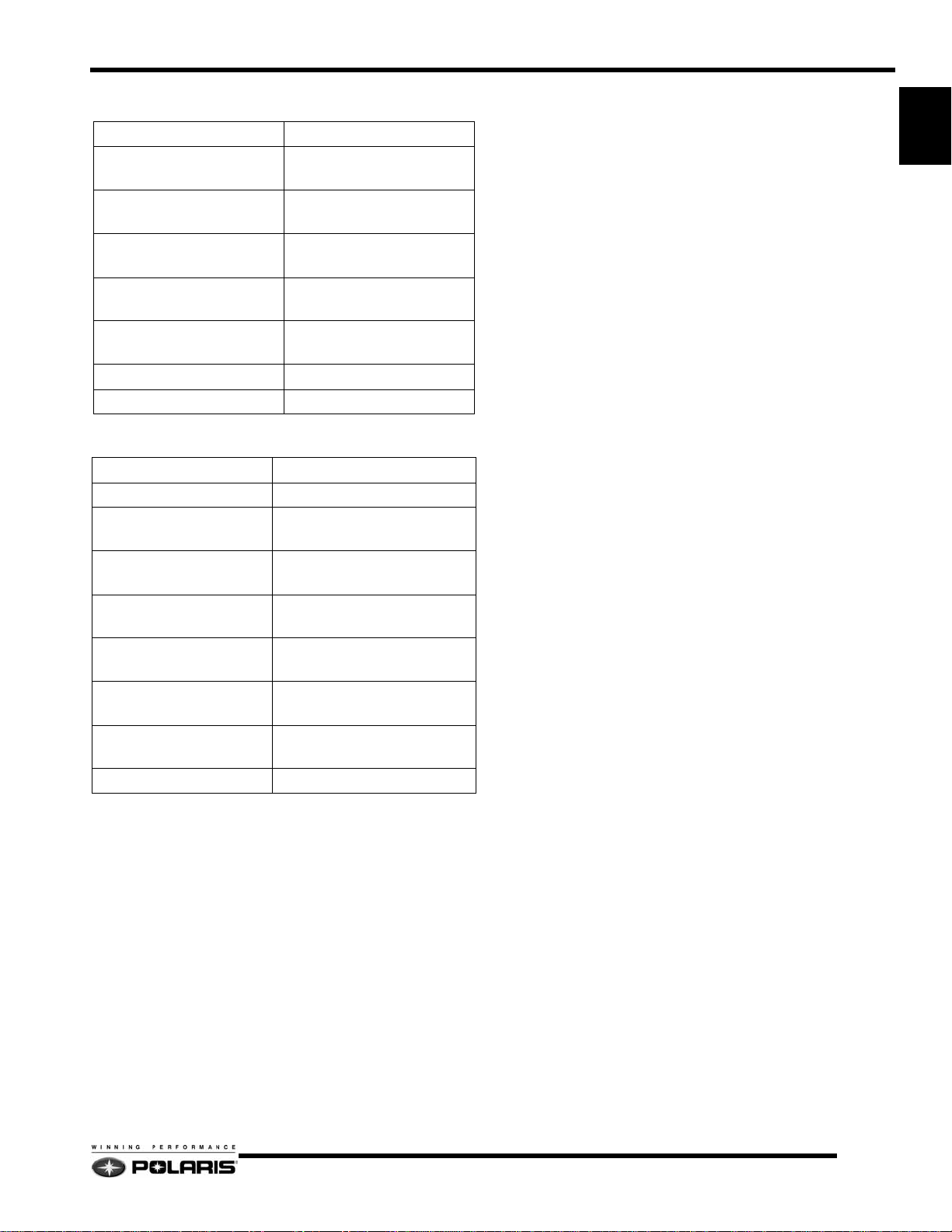

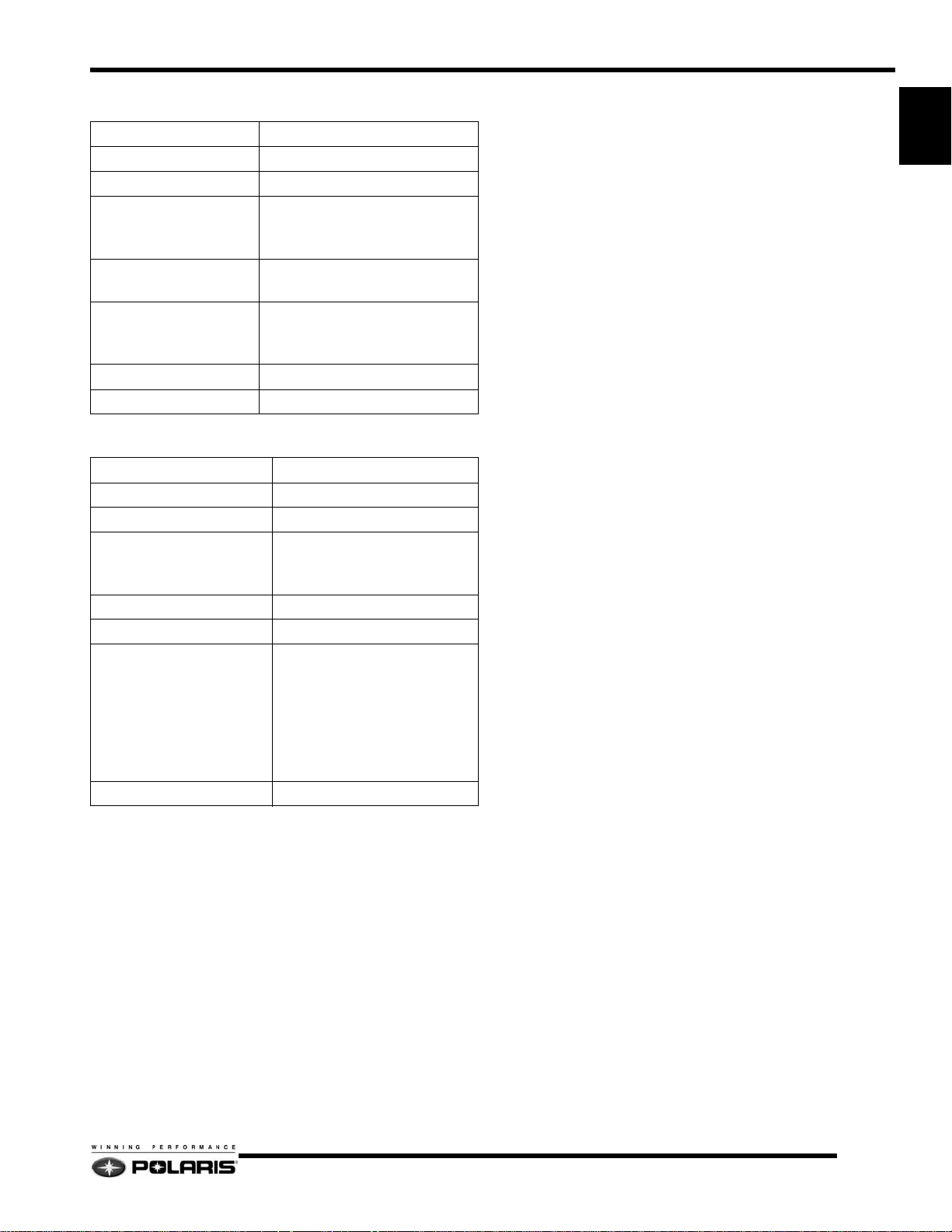

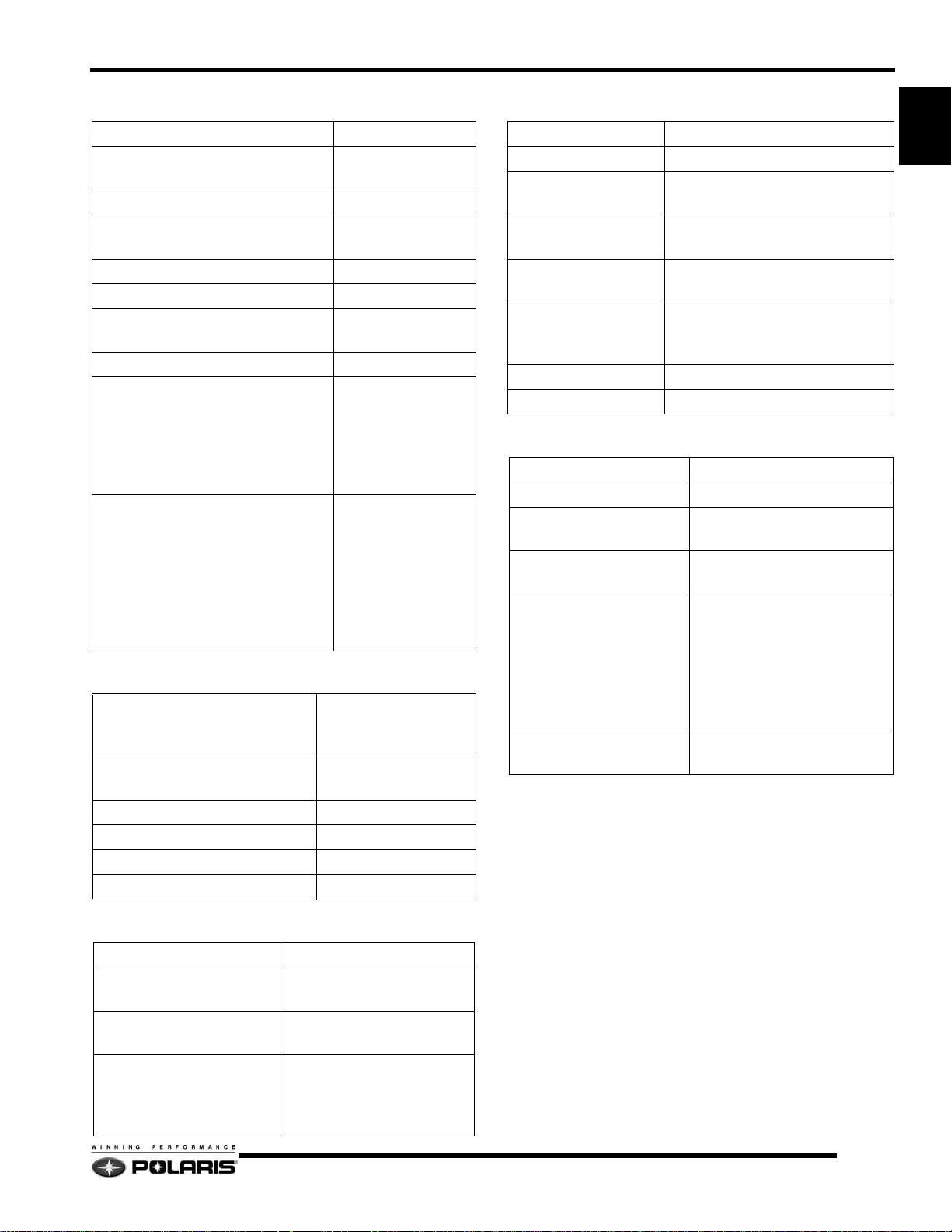

General

Width (in/cm) 48 / 121.9

Length (in/cm) 115 / 292.1

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

Fuel (Gallons / Liters) 10.8 / 40.9

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug Champion RN57YCC

CDI Marking 4011033

Flywheel Marking 4010677

Track

475 / 215.7

6.3 / 6

3211080

1.438 / 3.65

28_

46.625 / 118.4

11.5 / 29.2

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

13.5 - 14.5 Vdc

280

26_ @3500 RPM

(TPS Un-plugged)

Front Suspension

Suspension Type IQ 42.5

Ryde FX HPG w/IFP (STD.)

(Rebuidlable)

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Suspension Setup

Width

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Suspension Type IQ 121

Front Track Shock (FTS)

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Torsion Spring Diameter

Tail Angle

Rear Travel Inches (cm) 13.9 (35.3)

Fox Compression Adj. Remote

Resevoir HPG (OPT.)

(Rebuidable)

100 (17.5)

10.55 (26.8)

10 (25.4)

41.16 (104.54)

Rear Suspension

Ryde FX HPG w/IFP (STD.)

(Rebuildable)

Fox HPG w/IFP (OPT.)

(Rebuildable)

130 - 270 (23 - 47)

7.97 (20.2)

Fox PS5 w/IFP (STD.)

(Rebuildable)

Fox Compression Adjustable

Remote Resevoir HPG (OPT.)

(Rebuildable)

.374

80_

1

Width - Inches (cm) 15 (38)

Length - Inches (cm) 121 (307)

Lug Height - Inches (cm)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

shaft

7/8

1.0 / (2.5)

1.25 (3.175) - Option

″ - 1-1/8″(2.2 - 2.9cm)

1.3

Page 7

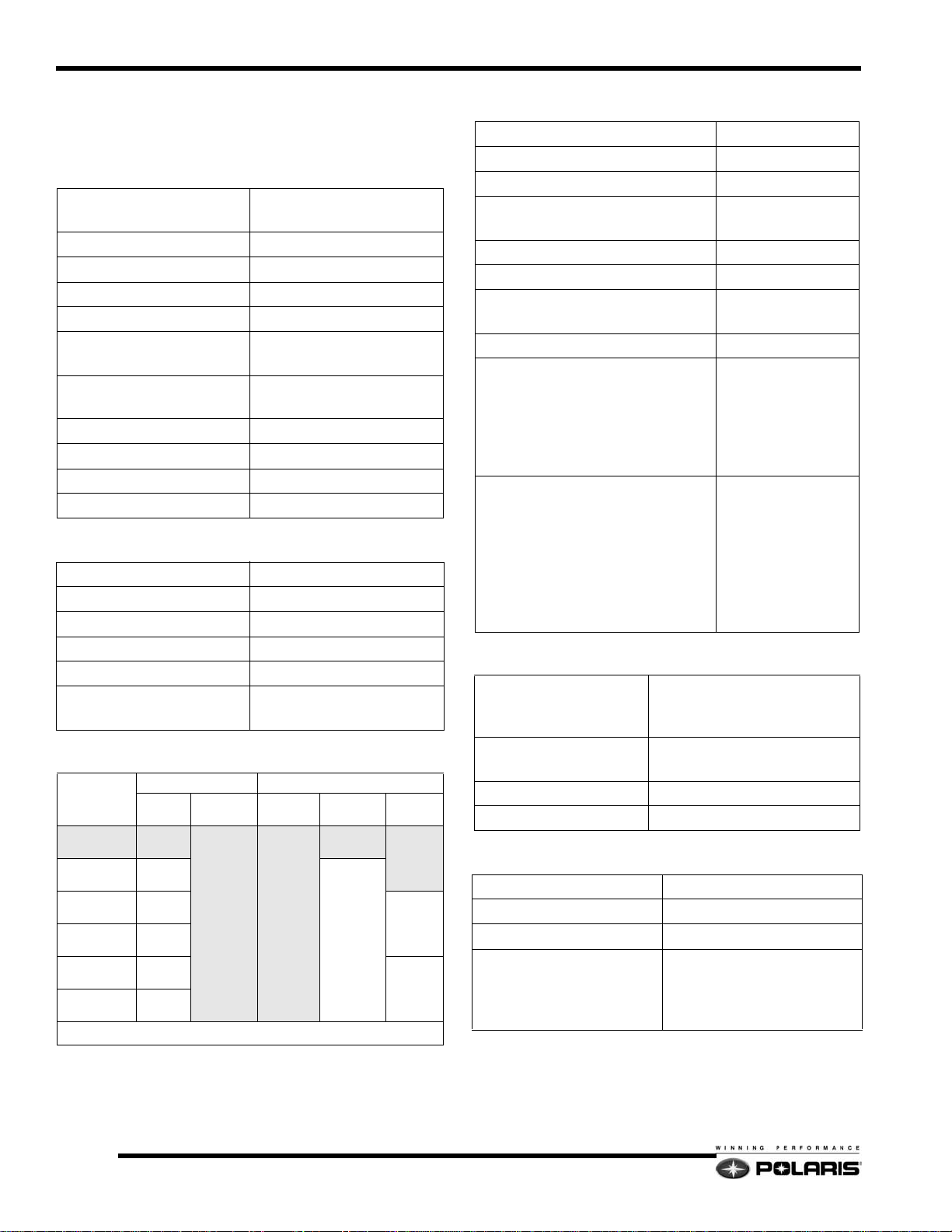

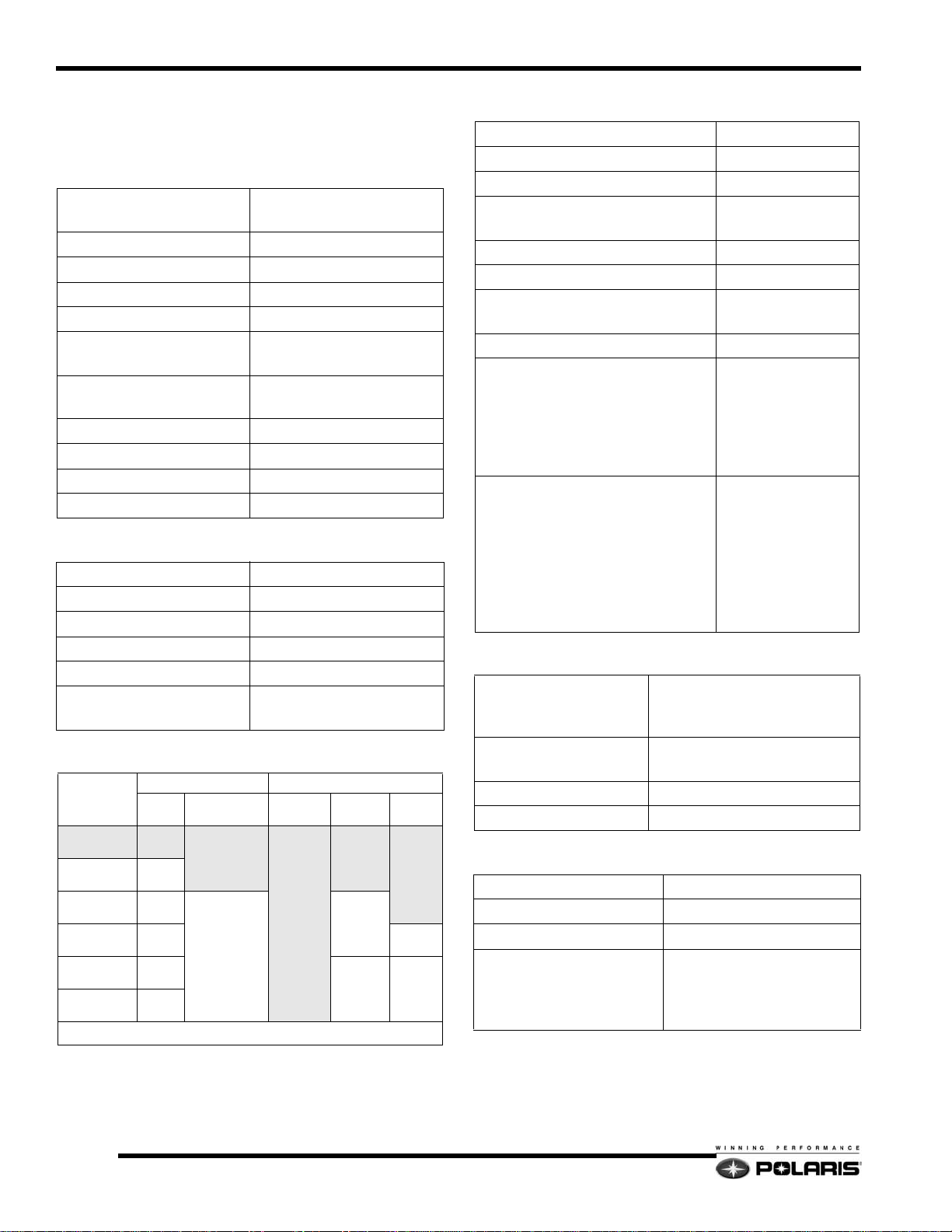

Model Specifications

2007 600 HO Switchback

Model Number: S07PS6FS (A)

Engine

Engine Type

Model Number S3273-6044-PF6F

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8100

Idle RPM 1500

Engagement RPM ±200 3800

Exhaust Valve Spring Pink

Carburetor Settings

Type

Main Jet

Pilot Jet

Jet Needle/Clip position

Needle Jet

Throttle Gap (Under Cutaway) (in/mm)

Cutaway

Valve Seat

Starter Jet

Pilot Air Jet

Fuel screw (Turns Out)

Recommended Fuel Octane (R+M/2)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

Mikuni TM38

420

50

9DGN6-57 / 2

P-8

0.08 / 2.1

1.5 Notch

1.5

145

.6

1.25

91

(Non-Oxygenated)

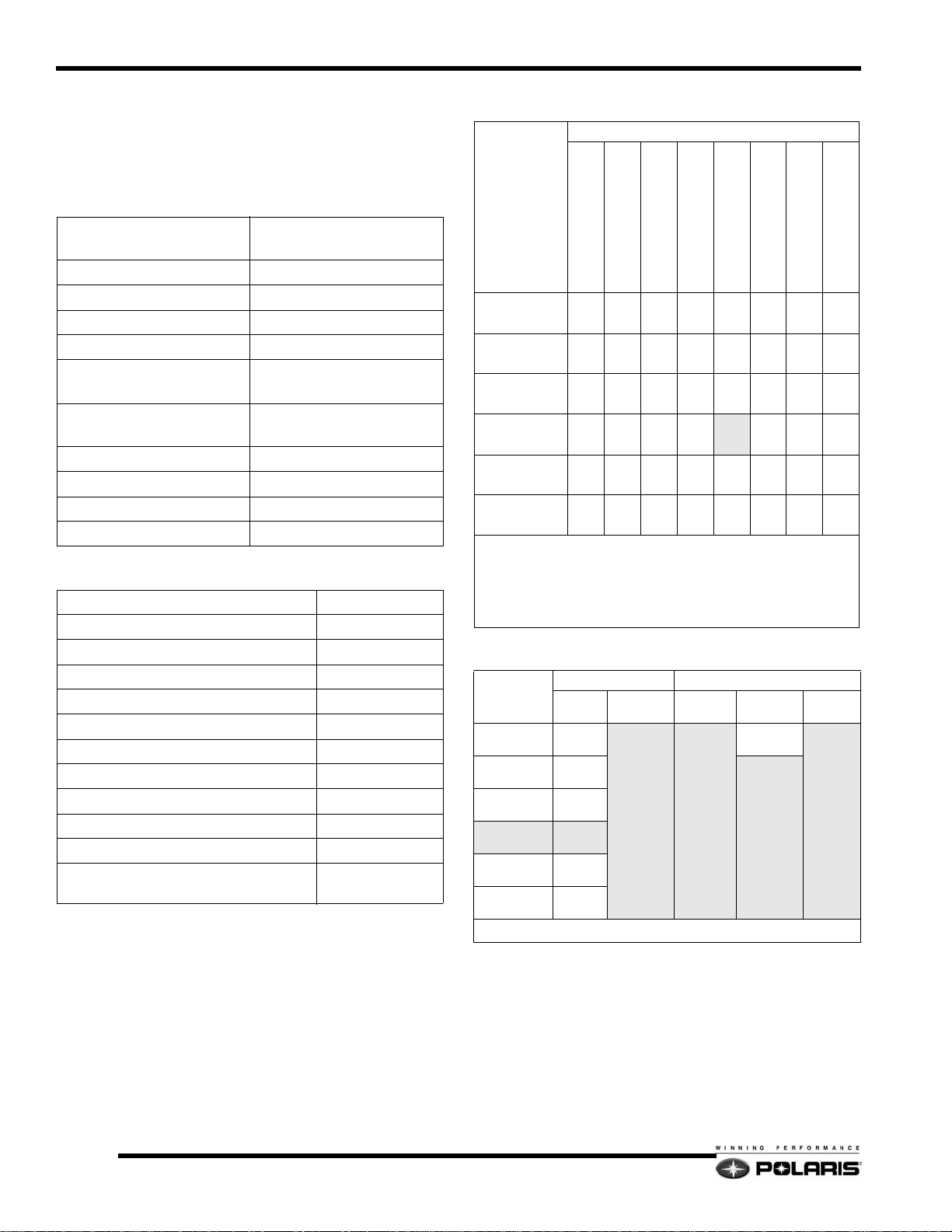

Carburetor Jetting

Ambient Temperature

Altitude

Meters (feet)

< -25°F/<-35°C

0°F to +20°F/-18°C to -7°C

+15°F to +35°F/-9°C to +2°C

+30°F to +50°F/-1°C to +10°C

+45°F to +65°F/+7°C to +18°C

#1

#1

#1

#1

#1

#1

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3700

(10000-12000)

-15°F to +5°F/-26°C to -15°C

-30°F to -10°F/-34°C to -23°C

440#3430#3420#2400#2390#2380#2370#2360

410#3400#3390#2370#2360#2350#2340#1330

370#3360#2350#2340#2330#2320#1310#1300

340#3320#2310#2300#2280#2280#1270#1260

310#2300#2290#2280#1270#1260#1250#1240

290#2280#2270#1250#1240#1230#1220#1210

When using non oxygenated fuel with a RON greater than 93,

decrease the main jet number in the above chart by 10 and raise the

E-clip one position. If the chart recommends clip #1, install washer

on top when using RON 93.

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58 22:40-76

10-56

10-54

10-AL

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42-.36

LW ER

56/42 - .36

LW ER

Drive Clutch Bolt Torque: 50 lb.ft. (68Nm)

Gearing

22:39-76

20:41-76

>+60°F/>+16°C

1.4

Page 8

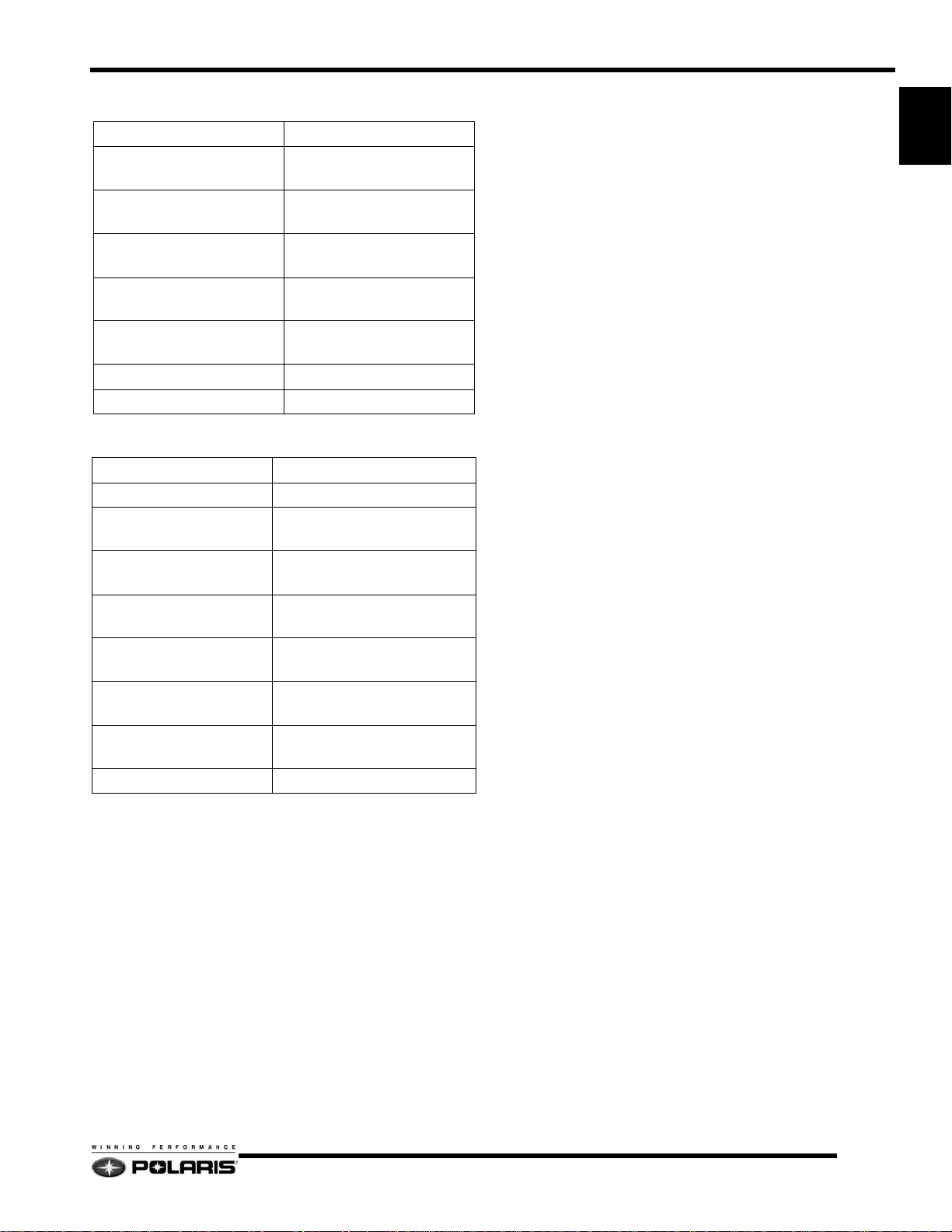

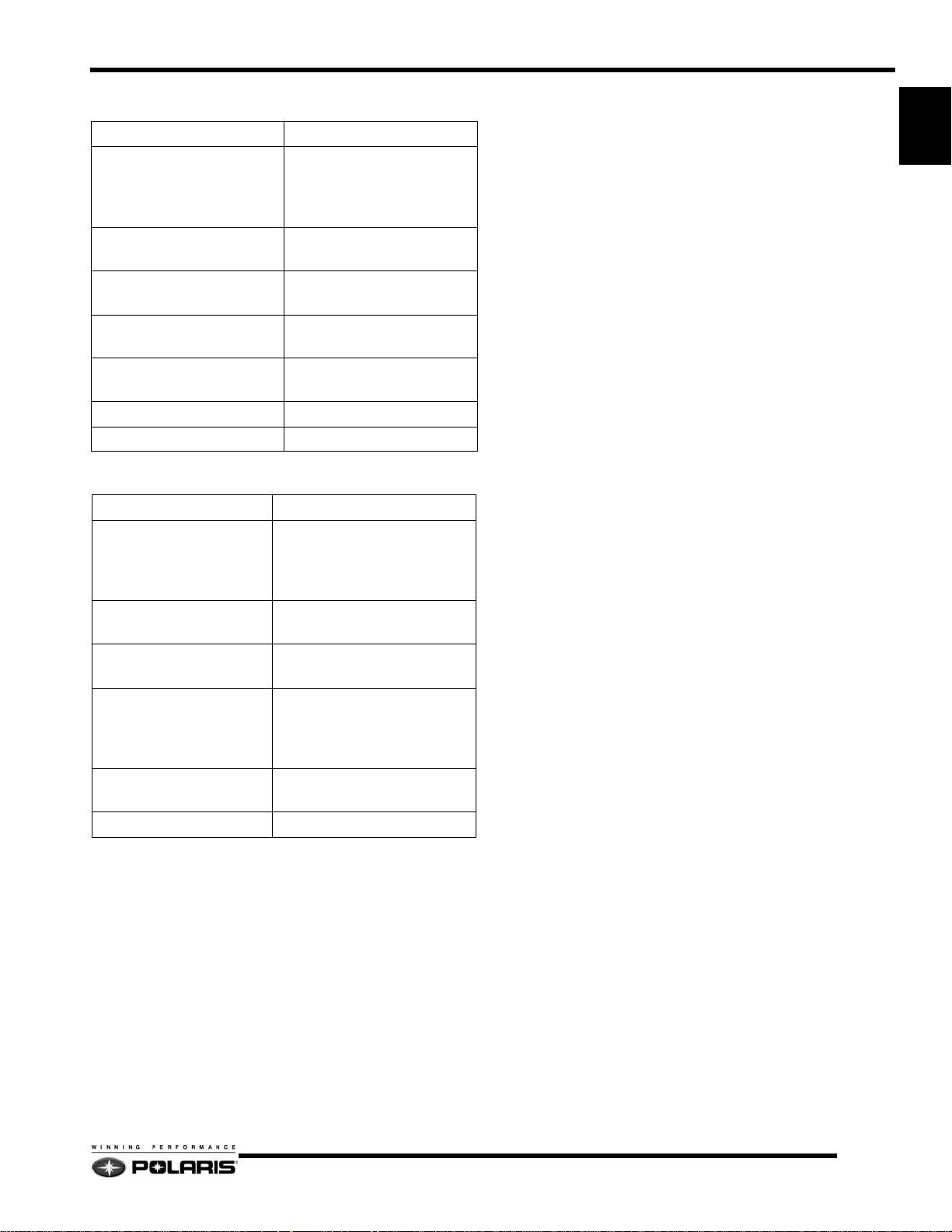

Model Specifications

General

Width (in/cm) 48 / 121.9

Length (in/cm) 125 / 317.5

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

Fuel (Gallons / Liters) 10.8 / 40.9

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug Champion RN57YCC

CDI Marking 4011033

Flywheel Marking 4010677

Track

483 / 219.3

6.3 / 6

3211080

1.438 / 3.65

28_

46.625 / 118.4

11.5 / 29.2

8.373

22

39

76

Polaris Synthetic

11 / 325.3

Perc

13.5 - 14.5 Vdc

280

26_ @3500 RPM

(TPS Un-plugged)

Front Suspension

Suspension Type IQ 42.5

Fox HPG w/IFP (STD.)

(Rebuidlable)

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Suspension Type IQ 144

Front Track Shock (FTS)

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Torsion Springs

Rear Travel Inches (cm) 13.9 (35.3)

Fox Compression Adj. Remote

Resevoir HPG (OPT.)

(Rebuidable)

100 (17.5)

10.55 (26.8)

10 (25.4)

42.5 (108)

Rear Suspension

Fox HPG w/IFP

(Rebuildable)

170 (30)

7.25 (18.4)

Fox Compression Adjustable

Remote Resevoir HPG

(Rebuildable)

.359 Square / 77_ (Stock)

.347 / 77_ / (Soft)

- PN 7041627 - 067

- PN 7041628 - 067

.375 / 77_ / (Firm)

- PN 7041942 - 067

- PN 7041943 - 067

1

Width - Inches (cm) 15 (38)

Length - Inches (cm) 144 (366)

Lug Height - Inches (cm)

Track tension sag in /cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

shaft

1.25 (3.175) (STD.)

1.50 (3.8) (OPT.)

3/8

″- 1/2″ (1 - 1.3cm)

1.5

Page 9

Model Specifications

2007 600 HO RMK

Model Number:

144 = S07PK6FS / S07PK6FE

155 = S07PM6FS (A)

Engine

Engine Type

Model Number S3273-6044-PF6F

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8100

Idle RPM 1500

Engagement RPM ±200 3800

Exhaust Valve Spring Pink

Carburetor Settings

Type

Main Jet

Pilot Jet

Jet Needle/Clip position

Needle Jet

Throttle Gap (Under Cutaway) (in/mm)

Cutaway

Valve Seat

Starter Jet

Pilot Air Jet

Fuel screw (Turns Out)

Recommended Fuel Octane (R+M/2)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

Mikuni TM38

280

50

9DGN6-57 / 1

P-8

0.13 / 3.2

2.5

1.5

145

.6

1

91

(Non-Oxygenated)

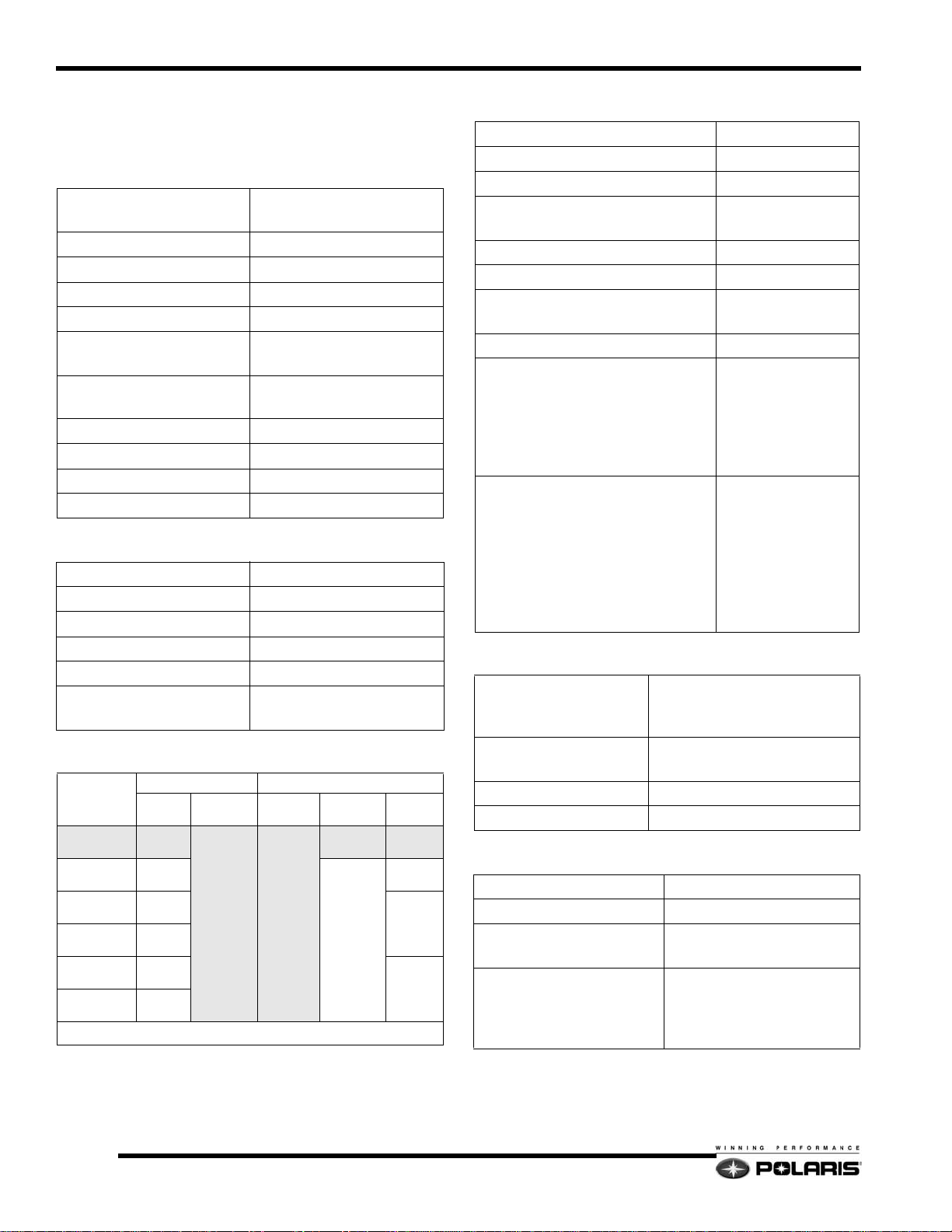

Carburetor Jetting

Ambient Temperature

Altitude

Meters (feet)

< -25°F/<-35°C

0°F to +20°F/-18°C to -7°C

+15°F to +35°F/-9°C to +2°C

+30°F to +50°F/-1°C to +10°C

+45°F to +65°F/+7°C to +18°C

#1

#1

#1

#1

#1

**

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3700

(10000-12000)

-15°F to +5°F/-26°C to -15°C

-30°F to -10°F/-34°C to -23°C

440#3430#3420#2400#2390#2380#2370#2360

410#3400#3390#2370#2360#2350#2340#1330

370#3360#2350#2340#2330#2320#1310#1300

340#3320#2310#2300#2280#1280#1270#1260

310#2300#2290#2280#1270#1260#1250#1240

290#2280#2270#1250#1240**230**220**210

** = Clip in # 1 position with washer placed on top of clip. When

using non-oxygenated fuel with a RON greater than 93, decrease the

main jet number in the above chart by 10 and raise the E-clip one

position. If the chart recommends **, do nothing with the clip when

using RON 93.

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42-.36

LW ER

56/42 - .36

LW ER

Drive Clutch Bolt Torque: 50 lb.ft. (68Nm)

Gearing

19:41-76

>+60°F/>+16°C

1.6

Page 10

Model Specifications

General

Width (in/cm) 46.5 / 118.1

Length (in/cm)

Height (in/cm) 49 / 124.5

Estimated Dry Weight

(lb/kg)

Fuel (Gallons / Liters) 12 / 45.4

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug Champion RN57YCC

CDI Marking 4011033

Flywheel Marking 4010677

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm)

Lug Height - Inches (cm) 2.0(5) or 2.4(6.1)

Track tension sag in /cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

shaft

144 = 125 / 318

155 = 130 / 330.2

144 = 472 / 214.3

155 = 478 / 217

6.3 / 6

3211115

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

8.373

Polaris Synthetic

11 / 325.3

Perc

13.5 - 14.5 Vdc

280

26_ @3500 RPM

(TPS Un-plugged)

144 (325)

155 (393.7)

3/8

″- 1/2″ (1 - 1.3cm)

19

41

76

Front Suspension

Suspension Type IQ RMK Adjustable

Ryde FX Compression Adjustable

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

WE Air Oil Volume 95cc

WE Air Nitrogen

Charge

Stock

Optional

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.17 ± 0.31 (55 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ 144 / 155

Front Track Shock (FTS)

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

WE Air Oil Volume 70cc

WE Air Nitrogen Charge

Stock

Optional

Torsion Springs

Rear Travel Inches (cm)

Walker Evans Air (OPT.)

39(99.1) / 40(101.6) / 41(104.1)

.359 Square / 77_ (Stock)

.347 / 77_ / (Soft)

- PN 7041627 - 067

- PN 7041628 - 067

.375 / 77_ / (Firm)

- PN 7041942 - 067

- PN 7041943 - 067

(STD.)

(Rebuidable)

100 (17.5)

10.35 (26.3)

215 psi

220 - 225 psi

9 (22.9)

Ryde FX (STD.)

Walker Evans Air (OPT.)

190 (33)

7.4 (18.8)

Ryde FX (STD.)

Walker Evans Air (OPT.)

(Rebuildable)

215 psi

210 - 220 psi

144 = 14.5(36.8)

155 = 15.5(39.4)

1

1.7

Page 11

Model Specifications

2007 600 HO IQ CFI

Model Number: S07PP6HS (A) (B)

Engine

Engine Type

Model Number S3206-6044-PF6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42.36

LW ER

56/42 - .36

LW ER

23:39-76

22:39-76

22:40-76

20:41-76

Gearing

General

Width (in/cm) 48 / 121.9

Length (in/cm) 115 / 292.1

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

485 / 220.2

Fuel (Gallons / Liters) 11.7 / 44.3

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

6.3 / 6

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211080

1.438 / 3.65

28_

46.625 / 118.4

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 121 (307)

Lug Height - Inches (cm)

1.0 (5) (STD.)

1.25 (3.175) (OPT.)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.8

Page 12

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Ryde FX HPG w/IFP (STD.)

(Rebuidlable)

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Suspension Type IQ 121

Front Track Shock (FTS)

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Torsion Spring Diameter

T ail Angle

Rear Travel Inches (cm) 13.9 (35.3)

Fox Compression Adj. Remote

Resevoir HPG (OPT.)

(Rebuidable)

100 (17.5)

10.55 (26.8)

10 (25.4)

42.5 (108)

Rear Suspension

Ryde FX HPG w/IFP (STD.)

(Rebuildable)

Fox HPG w/IFP (OPT.)

(Rebuildable)

130 - 270 (2.3 - 4.8)

7.97 (20.2)

Fox PS5 w/IFP (STD.)

(Rebuildable)

Fox Compression Adjustable

Remote Resevoir HPG (OPT.)

(Rebuildable)

.374

80_

1

1.9

Page 13

Model Specifications

2007 600 HO Switchback CFI

Model Number: S07PS6HS (A) (B)

Engine

Engine Type

Model Number S3206-6044-PF6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58 22:40-76

10-56

10-54

10-AL

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42.36

LW ER

56/42 - .36

LW ER

22:39-76

20:41-76

Gearing

General

Width (in/cm) 48 / 121.9

Length (in/cm) 125 / 317.5

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

485 / 220.2

Fuel (Gallons / Liters) 11.7 / 44.3

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

6.3 / 6

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211080

1.438 / 3.65

28_

46.625 / 118.4

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

22

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 144 (366)

Lug Height - Inches (cm)

1.25 (3.175) (STD.)

1.50 (3.8) (OPT.)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

3/8

″- 1/2″ (1 - 1.3cm)

shaft

1.10

Page 14

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Fox HPG w/IFP (STD.)

(Rebuidlable)

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Suspension Type IQ 144

Front Track Shock (FTS)

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Torsion Springs

Rear Travel Inches (cm) 13.9 (35.3)

Fox Compression Adj. Remote

Resevoir HPG (OPT.)

(Rebuidable)

100 (17.5)

10.55 (26.8)

10 (25.4)

42.5 (108)

Rear Suspension

Fox HPG w/IFP

(Rebuildable)

170 (29.75)

7.25 (18.4)

Fox Compression Adjustable

Remote Resevoir HPG

(Rebuildable)

.359 Square / 77_ (Stock)

.347 / 77_ / (Soft)

- PN 7041627 - 067

- PN 7041628 - 067

.375 / 77_ / (Firm)

- PN 7041942 - 067

- PN 7041943 - 067

1

1.11

Page 15

Model Specifications

2007 600 HO IQ LX CFI

Model Number: S07PD6HS / S07PD6HE

Engine

Engine Type

Model Number S3206-6044-PF6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42.36

LW ER

56/42 - .36

LW ER

22:39-76

22:40-76

20:41-76

Gearing

General

Width (in/cm) 48 / 121.9

Length (in/cm) 115 / 292.1

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

505 / 229.3

Fuel (Gallons / Liters) 11.7 / 44.3

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

6.3 / 6

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211080

1.438 / 3.65

28_

46.625 / 118.4

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

22

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 128 (325)

Lug Height - Inches (cm) 1 (2.5)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.12

Page 16

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type Fast M-10 128

Front Track Shock (FTS) Ryde FX Gas Bag

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Lower Outer Spring Rate

lbs/in (N/mm)

Lower Inner Spring Rate

lbs/in (N/mm)

Upper Spring Rate

lbs/in (N/mm)

Rear Travel Inches (cm) 13 (33)

Ryde FX Gas Ba g

Compression Adjustable

120 (21)

9.95 (25.3)

9.92 (25.2)

42.5 (108)

180 (31)

8.5 (21.6)

Fox HPG w/IFP

(Rebuildable)

715 (125)

425 (74.4)

273 (48)

1

1.13

Page 17

Model Specifications

2007 600 HO IQ Touring CFI

Model Number: S07PT6HS / S07PT6HE

Engine

Engine Type

Model Number S3206-6044-PF6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42.36

LW ER

56/42 - .36

LW ER

22:43-78

21:44-78

Gearing

General

Width (in/cm) 48 / 121.9

Length (in/cm) 129 / 327.7

Height (in/cm) 53 / 134.6

Estimated Dry Weight

(lb/kg)

574 / 260.6

Fuel (Gallons / Liters) 11.7 / 44.3

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

6.3 / 6

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211080

1.438 / 3.65

28_

46.625 / 118.4

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

22

43

78

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 136 (345)

Lug Height - Inches (cm) 1 (2.5)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

3/4

″ - 1.0″(1.9 - 2.5cm)

shaft

1.14

Page 18

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type Fast M-10 136

Front Track Shock (FTS) Ryde FX Gas Bag

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Lower Outer Spring Rate

lbs/in (N/mm)

Lower Inner Spring Rate

lbs/in (N/mm)

Upper Spring Rate

lbs/in (N/mm)

Rear Travel Inches (cm) 14 (35.6)

Ryde FX Gas Ba g

Compression Adjustable

120 (21)

9.95 (25.3)

10 (25.4)

42.5 (108)

220 (38.5)

8.5 (21.6)

Fox HPG w/IFP

(Rebuildable)

715 (125)

425 (74.4)

273 (48)

1

1.15

Page 19

Model Specifications

2007 700 HO IQ Dragon

Model Number: S07PC7JS / S07PC7JE

Engine

Engine Type

Model Number S3305-7044-PF7J

Displacement / # Cylinders 700cc / 2

Bore (inches/mm) 3.19 / 81

Stroke (inches/mm) 2.68 / 68

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

VES Spring Color Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-64

10-62

10-62

10-60 22:39-76

10-58

10-56

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch Spring

DK BLU/WHT

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.0044 - .0059 / .112 - .151

.017 - .026 / .44 - .650

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

66/44-.46

LW ER

64/42-.36

LW ER

56/42 -

.36

LW ER

Gearing

23:39-76

20:41-76

General

Width (in/cm) 48 / 121.9

Length (in/cm) 115 / 292.1

Height (in/cm) 47 / 119.4

Estimated Dry Weight

(lb/kg)

476 / 216.1

Fuel (Gallons / Liters) 10.8 / 40.9

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

6.3 / 6

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211115

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 121 (307)

Lug Height - Inches (cm) 1.25 (3.2)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.16

Page 20

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Walker Evans w/IFP

Shocks

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ 121

Front Track Shock (FTS)

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS)

Torsion Spring

T ail Angle

Rear Travel Inches (cm) 13 (33)

Remote Resevoir

Compression Adjustable

(Rebuildable)

100 (17.5)

10.30 (28.4)

10.55 (26.8)

42.5 (108)

Walker Evans w/IFP

Remote Resevoir

Compression Adjustable

(Rebuildable)

130 - 270 (23 - 47)

7.97 (20.2)

Walker Evans w/IFP

Remote Resevoir

Compression Adjustable

(Rebuildable)

.347”

80_

1

1.17

Page 21

Model Specifications

2007 700 HO RMK Dragon

Model Number: S07PL7JS / S07PL7JE

Engine

Engine Type

Model Number S3322-7044-PF7J

Displacement / # Cylinders 700cc / 2

Bore (inches/mm) 3.19 / 81

Stroke (inches/mm) 2.68 / 68

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

VES Spring Color Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

10-66

10-64

10-62

10-60

10-58

10-56

Clutch Spring

BLK / GRN

(120 / 340)

(7042083)

Weight

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Liberty Liquid-Cooled /

Case Reed Induction

.0042 - .006 / .109 - .163

Upper: .010 - .018 / .25 - .45

Lower: .014 - .020 / .35 - .50

91 Non-Oxygenated

Clutch

Spring

BLACK

(155 / 222)

Driven

Helix

56/42 .36

LWT ER

Gearing

20:41-76

General

Width (in/cm) 46.5 / 118.1

Length (in/cm) 130 / 330.2

Height (in/cm) 49 / 124.5

Estimated Dry Weight

(lb/kg)

478 / 217

Fuel (Gallons / Liters) 12 / 45.4

Oil (Quarts / Liters) 3.4 / 3.2

Cooling System Capacity

(Quarts / Liters)

6.3 / 6

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211115

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

20

41

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 155 (393.7)

Lug Height - Inches (cm) 2.4 (6.1)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

3/8

″- 1/2″ (1 - 1.3cm)

40cm ahead of rear idler shaft

1.18

Page 22

Front Suspension

Model Specifications

Suspension Type IQ RMK

Shocks Walker Evans Air

Oil Volume 95cc

Nitrogen Charge

Stock

Optional

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width

Camber Inches (cm) 2.17 ± 0.31 (55 ± 0.79)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ RMK 155

Front Track Shock (FTS) Walker Evans Air

Oil Volume 70cc

FTS Nitrogen Charge

Stock

Optional

Rear Track Shock (RTS) Walker Evans w/IFP

RTS Nitrogen Charge 200 psi

Torsion Springs

Rear Travel Inches (cm) 15.5 (39.4)

39(99.1) / 40(101.6) / 41(104.1)

.359 Square / 77_ (Stock)

.347 / 77_ / (Soft)

- PN 7041627 - 067

- PN 7041628 - 067

.375 / 77_ / (Firm)

- PN 7041942 - 067

- PN 7041943 - 067

215 psi

220 - 225 psi

9 (22.9)

38.67 (98.2)

215 psi

210 - 220 psi

1

1.19

Page 23

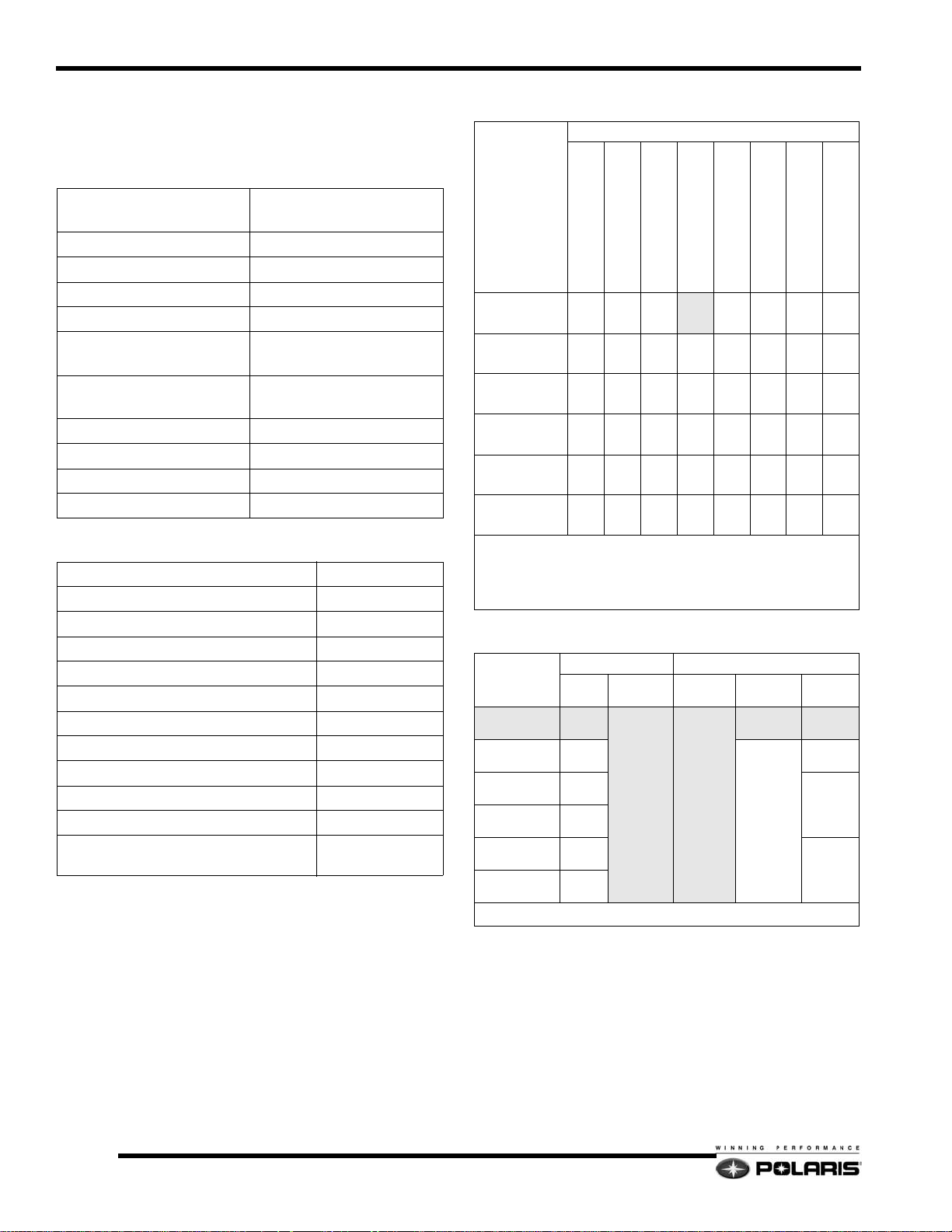

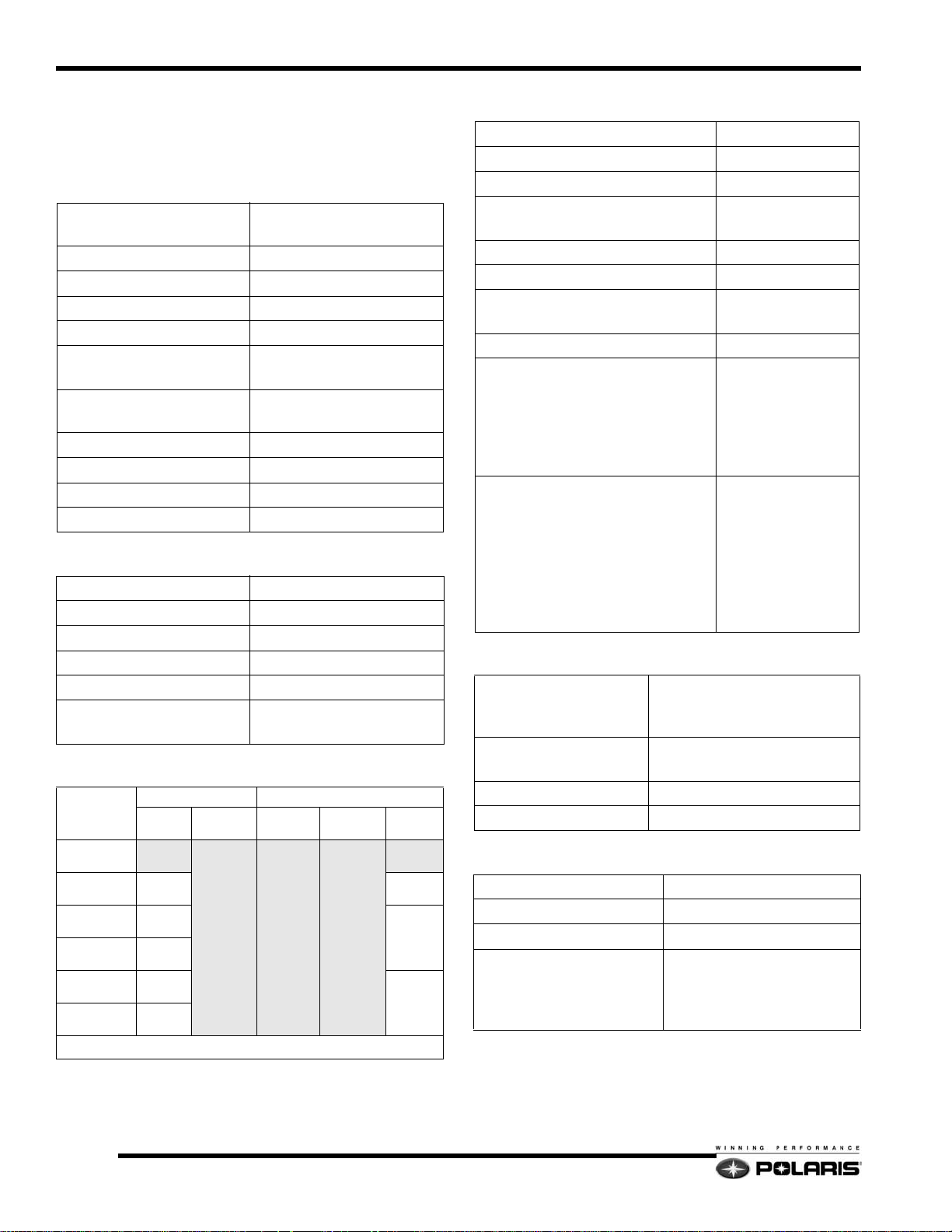

Model Specifications

2008 IQ Shift

Model Number: S08PB6FS / S08PB6FE

Engine

Engine Type

Model Number S3466-6044-PU6F

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8100

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Pink

Carburetor Settings

Type

Main Jet

Pilot Jet

Jet Needle/Clip position

Needle Jet

Throttle Gap (Under Cutaway) (in/mm)

Cutaway

Valve Seat

Starter Jet

Pilot Air Jet

Fuel screw (Turns Out)

Recommended Fuel Octane (R+M/2)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .0356 - .508

Mikuni TM38

400

45

9DGN6-57 / 3

P-8

.082 / 2.1

2.0

1.5

145

1.0

1.0

91

(Non-Oxygenated)

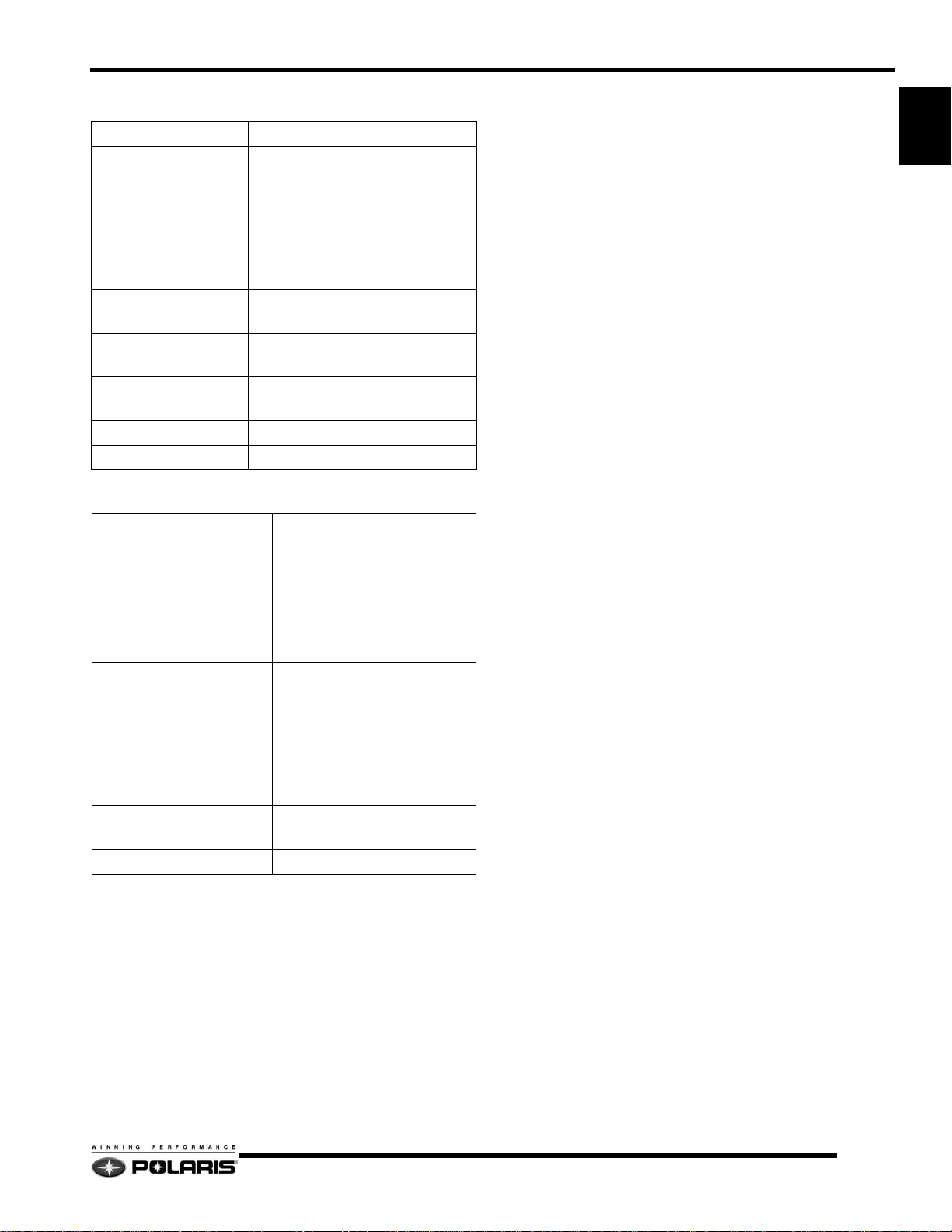

Carburetor Jetting

Ambient Temperature

Altitude

Meters (feet)

< -25°F/<-35°C

0°F to +20°F/-18°C to -7°C

+15°F to +35°F/-9°C to +2°C

+30°F to +50°F/-1°C to +10°C

+45°F to +65°F/+7°C to +18°C

#1

#1

#1

#1

#1

#1

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10,000)

3000-3700

(10,000-12,000)

-15°F to +5°F/-26°C to -15°C

-30°F to -10°F/-34°C to -23°C

440#3430#3420#3400#3390#3380#2370#2360

410#3400#3390#3370#3360#2350#2340#1330

370#3360#2350#2340#2330#2320#1310#1300

340#3320#2310#2300#2280#2280#1270#1260

310#2300#2290#2280#1270#1260#1250#1240

290#2280#2270#1250#1240#1230#1220#1210

When using non oxygenated fuel with a RON greater than 93,

decrease the main jet number in the above chart by 10 and raise the

E-clip one position. If the chart recommends clip #1, install washer

on top when using RON 93.

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10,000)

3000-3600

(10,000-12,000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

64/42.36

LW ER

56/42 - .36

LW ER

Drive Clutch Bolt Torque: 50 lb.ft. (68Nm)

Gearing

23:39-76

22:39-76

22:40-76

20:41-76

>+60°F/>+16°C

1.20

Page 24

Model Specifications

General

Width (in/cm) 48.5 / 123.2

Length (in/cm) 115 / 292.1

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

Fuel (Gallons / Liters) 11.7 / 44.3

Oil (Quarts / Liters) 3 / 2.8

Cooling System Capacity

(Quarts / Liters)

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug Champion RN57YCC

CDI Marking 4011033

Flywheel Marking 4010677

466 / 211.6

8.5 / 8

3211122

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

13.5 - 14.5 Vdc

280

26_ @3500 RPM

(TPS Un-plugged)

Front Suspension

Suspension Type IQ 42.5

Shocks Ryde FX MPV

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width (cm)

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ 121

Front Track Shock (FTS) Ryde FX MPV

FTS Spring Rate

lbs/in (N/mm)

Rear Track Shock (RTS) Ryde FX MPV

.347 Square / 80_ (Stock)

- PN 7043070 - 067

- PN 7043071 - 067

.347 Square / 77_ (Soft)

Torsion Springs

Rear Travel Inches (cm) 13.9 (35.3)

- PN 7043240 - 067

- PN 7043241 - 067

.359 Square / 12.5# (Firm)

- PN 7043079 - 067

- PN 7043080 - 067

100 (17.5)

10.5 (26.67)

10 (25.4)

42.5 (108)

41.16 (104.5)

170 (29.75)

1

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 121 (307)

Lug Height - Inches (cm) .91 / (2 .3)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

shaft

7/8

″ - 1-1/8″(2.2 - 2.9cm)

1.21

Page 25

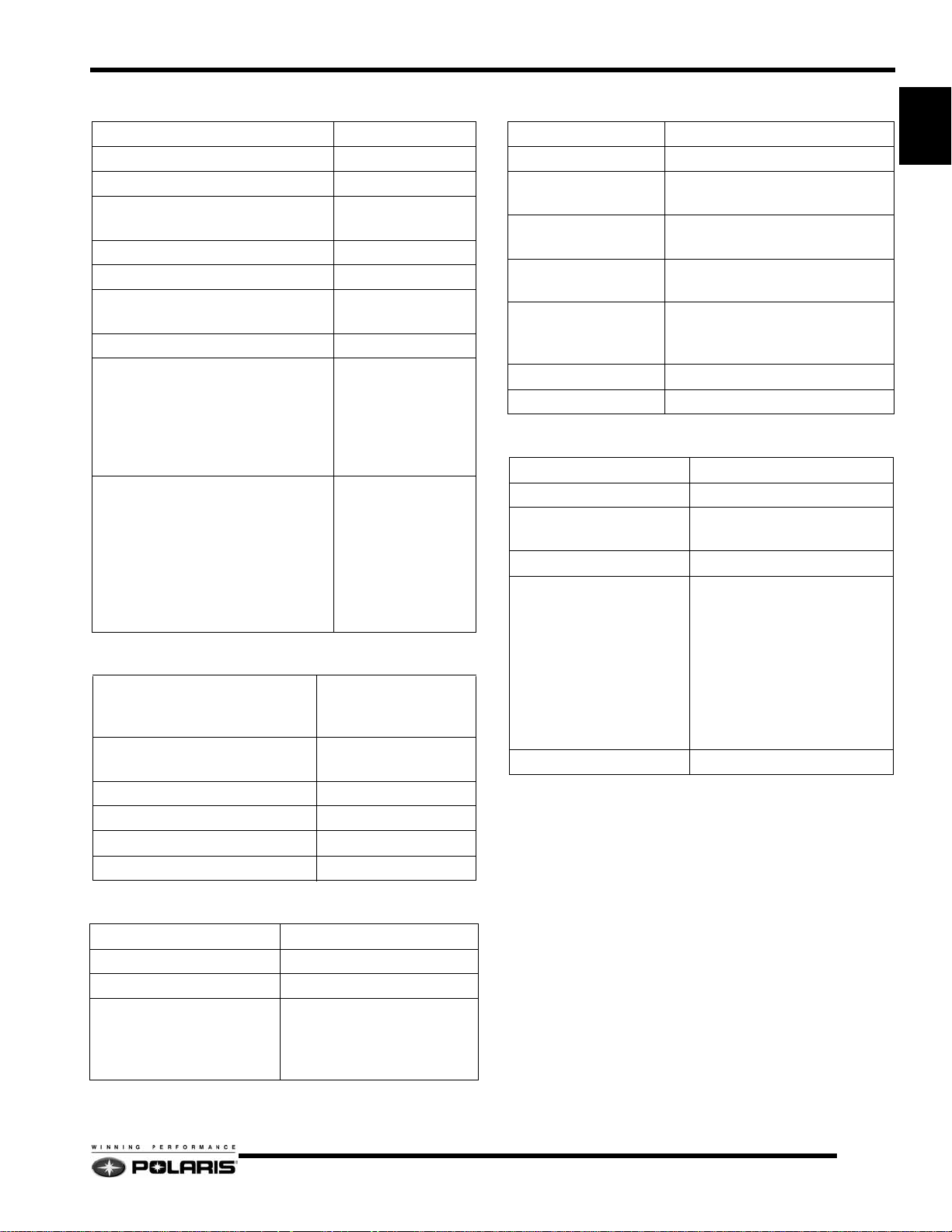

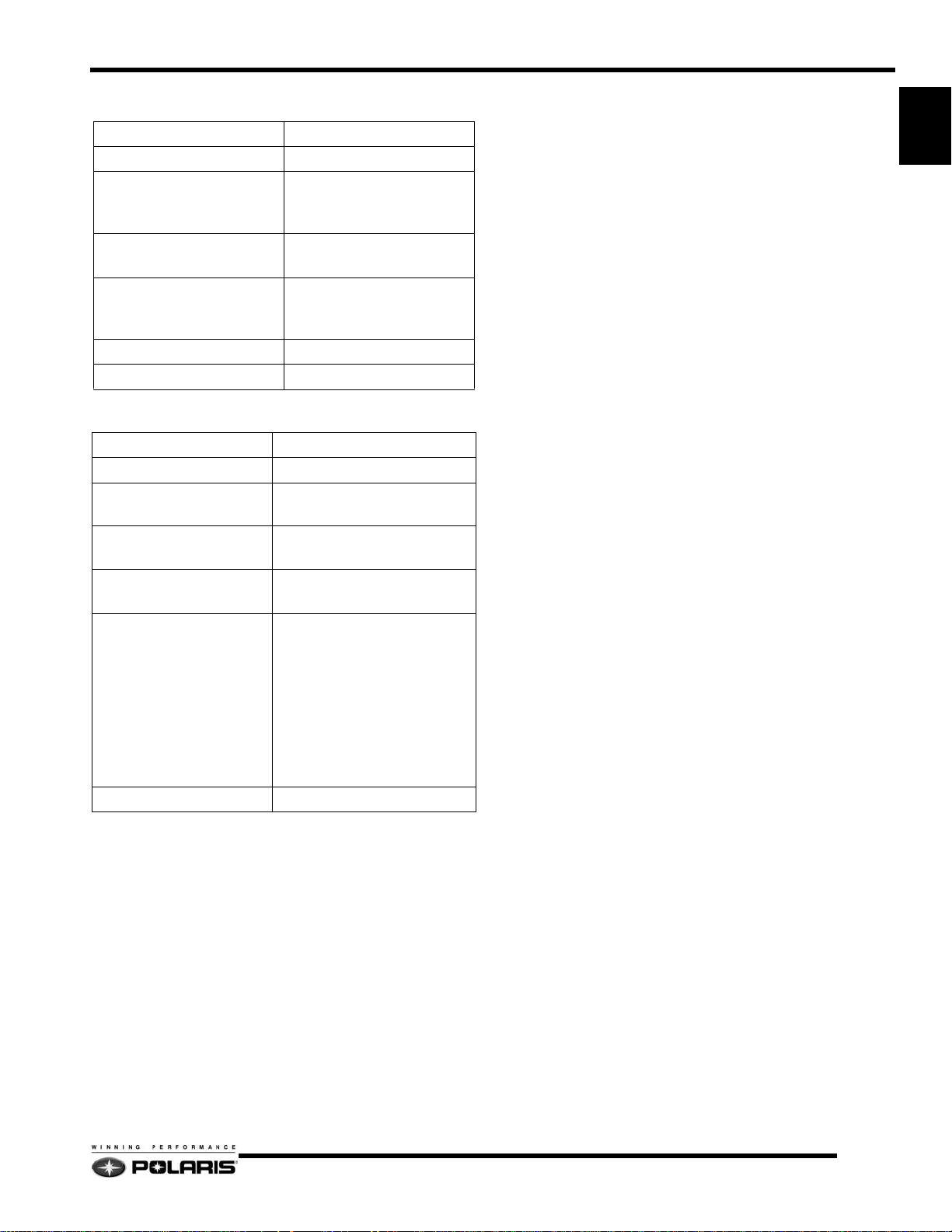

Model Specifications

2008 600 RMK 144 / 600 RMK Shift 155

Model Number:

600 RMK 144: S08PK6FS / S08PK6FE

600 RMK Shift 155: S08PM6FS

Engine

Engine Type

Model Number S3467-6044-PU6F

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8100

Idle RPM 1500

Engagement RPM ±200 3800

Exhaust Valve Spring Pink

Carburetor Settings

Type

Main Jet

Pilot Jet (Pj)

Jet Needle/Clip position

Needle Jet

Throttle Gap (Under Cutaway) (in/mm)

Cutaway

Valve Seat

Starter Jet

Pilot Air Jet

Fuel screw (Turns Out)

Recommended Fuel Octane (R+M/2)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .0356 - .508

Mikuni TM38

280

50

9DGN6-57 / 2

P-8

.125 / 3.2

2.5

1.5

145

.9

.5

91

(Non-Oxygenated)

Carburetor Jetting

Ambient Temperature

Altitude

Meters

(feet)

< -25°F/<-35°C

0°F to +20°F/-18°C to -7°C

270

55Pj

#2

240

55Pj

#1

+15°F to +35°F/-9°C to +2°C

+30°F to +50°F/-1°C to +10°C

+45°F to +65°F/+7°C to +18°C

#1

#1

#1

#1

260

250

240

55Pj

55Pj

55Pj

#1

#1

#1

230

220

210

55Pj

55Pj

55Pj

#1

#1

#1

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10,000)

3000-3700

(10,000-12,000)

-15°F to +5°F/-26°C to -15°C

-30°F to -10°F/-34°C to -23°C

440#3430#3420#2400#2390#2380#2370#2360

410#3400#3390#2370#2360#2350#2340#2330

370#3360#2350#2340#2330#2320#2310#1300

340#3320#2310#2300#2280#2280#1270#1260

310

300

290

280

55Pj

55Pj

55Pj

55Pj

#2

#2

#2

#2

290

280

270

250

55Pj

55Pj

55Pj

55Pj

#2

#2

#2

#1

When using non oxygenated fuel with a RON greater than 93,

decrease the main jet number in the above chart by 10 and raise the

E-clip one position. If the chart recommends clip #1, install washer on

top when using RON 93.

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10,000)

3000-3600

(10,000-12,000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-62

10-60

10-58

10-56

10-54

10-AL

Clutch

Spring

140 / 330

(7043342)

Clutch

Spring

BLACK

(155 / 222)

Driven

Helix

56/42 - .36

LW ER

Drive Clutch Bolt Torque: 50 lb.ft. (68Nm)

Gearing

19:41-76

>+60°F/>+16°C

1.22

Page 26

Model Specifications

General

Width (in/cm) 46.5 / 115.6

Length (in/cm)

Height (in/cm) 48 / 121.9

Estimated Dry Weight

(lb/kg)

Fuel (Gallons / Liters) 11.5 / 43.5

Oil (Quarts / Liters) 3 / 2.8

Cooling System Capacity

(Quarts / Liters)

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug Champion RN57YCC

CDI Marking 4011033

Flywheel Marking 4010677

124 / 315 (144)

129 / 327.7 (155)

472 / 214.3 (144)

478 / 216.8 (155)

144 = 6.25 / 6

155 = 6.5 / 6.1

3211115

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

8.373

19

41

76

Polaris Synthetic

11 / 325.3

Perc

13.5 - 14.5 Vdc

280

26_ @3500 RPM

(TPS Un-plugged)

Front Suspension

Suspension Type IQ RMK

Shocks Ryde FX

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width

Camber Inches (cm) 2.17 ± 0.31 (55 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Suspension Type IQ RMK 144 / 155

Front Track Shock (FTS) Ryde FX

FTS Spring Rate

lbs/in (N/mm)

Rear Track Shock (RTS)

Torsion Springs

Rear Travel Inches (cm)

39 - 40 - 41 (99.1 - 101.6 - 104.1)

Rear Suspension

.359 Square / 77_ (Stock)

.347 / 77_ / (Soft)

- PN 7041627 - 067

- PN 7041628 - 067

.375 / 77_ / (Firm)

- PN 7041942 - 067

- PN 7041943 - 067

100 (17.5)

10.35 (26.2)

9 (22.9)

38.67 (98.2)

190 (33)

Ryde AFX

Compression Adjustable

14.5 (36.8) (144)

15.5 (39.4) (155)

1

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm)

Lug Height - Inches (cm)

Track tension sag in /cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

shaft

144 (365.7)

155 (393.7)

2.0 (5.08) (144)

2.4 (6) (155)

3/8

″- 1/2″ (1 - 1.3cm)

1.23

Page 27

Model Specifications

2008 600 Dragon IQ

Model Number:

S08PP6HS / S08PP6HE

Engine

Engine Type

Model Number S3468-6044-PU6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-64

10-62 22:39-76

10-60

10-58

10-56

10-AL

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

56/42 - .36

LW-ER

23:39-76

22:40-76

20:41-76

Gearing

General

Width (in/cm) 48 / 121.9

Length (in/cm) 115 / 292.1

Height (in/cm) 48.5 / 123.2

Estimated Dry Weight

(lb/kg)

476 / 216.1

Fuel (Gallons / Liters) 11.7 / 44.3

Oil qts/l 3/2.8

Cooling System Capacity

(Quarts / Liters)

8.5 / 8

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211122

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 121 (307.3)

Lug Height - Inches (cm) 1.25 (3.175)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.24

Page 28

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Shocks Ryde FX Air 2.0

Air 2.0 Nitrogen Pressure

36mm Cylinder

47mm Cylinder

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ 121

Front Track Shock (FTS) Ryde FX HPG w/IFP

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length (inches / cm)

Rear Track Shock (RTS)

Torsion Springs

Rear Travel Inches (cm) 13.9 (35.3)

Ryde FX Compression

Adjustable w/Remote Res.

.347 Square / 80_ (Soft)

- PN 7043070 - 067

- PN 7043071 - 067

.347 Square / 77_ (Softest)

- PN 7043240 - 067

- PN 7043241 - 067

.359 Square / 12.5# (Stock)

- PN 7043079 - 067

- PN 7043080 - 067

145 psi

60 psi

10 (25.4)

42.5 (108)

41.16 (104.5)

130 - 270 (23 - 47)

7.97

1

1.25

Page 29

Model Specifications

2008 600 Switchback 600 Dragon Switchback

Model Number:

Base = S08PR6HS / S08PR6HE

Dragon = S08PS6HS / S08PS6HE

Engine

Engine Type

Model Number S3468-6044-PU6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-64

10-62

10-60

10-58

10-56

10-AL

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

56/42 - .36

LW-ER

22:39-76

22:40-76

20:41-76

Gearing

General

Width (in/cm) 48 / 121.9

Length (in/cm) 120 / 308.4

Height (in/cm) 48.5 / 123.2

Estimated Dry Weight

(lb/kg)

490 (222.5)

494 (224.3) Dragon

Fuel (Gallons / Liters) 11.7 / 44.3

Oil qts/l 3/2.8

Cooling System Capacity

(Quarts / Liters)

9.0 / 8.5

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211122

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 136 (345.4)

Lug Height - Inches (cm) 1.25 (3.175)

Track tension sag in /cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.26

Page 30

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Shocks

Base

Dragon

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Air 2.0 Nitrogen Pressure

36mm Cylinder

47mm Cylinder

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ 136 Coupled

Front Track Shock (FTS) Ryde HPG w/IFP

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length (inches / cm)

Ryde FX HPG w/IFP

Ryde FX Air 2.0

100 (17.5)

10.55 (26.8)

145 psi

60 psi

10 (25.4)

42.5 (108)

41.16 (104.5)

130 - 270 (23 - 47)

7.97

1

Rear Track Shock (RTS)

Base

Dragon

Adjustable w/Remote Res.

.347 Square / 80_ (Soft)

- PN 7043070 - 067

- PN 7043071 - 067

.347 Square / 77_ (Softest)

Torsion Springs

Rear Travel Inches (cm) 14 (35.5)

- PN 7043240 - 067

- PN 7043241 - 067

.359 Square / 12.5# (Stock)

- PN 7043079 - 067

- PN 7043080 - 067

Fox PS5

Ryde FX Compression

1.27

Page 31

Model Specifications

2008 600 IQ LX

Model Number: S08PD6HS

Engine

Engine Type

Model Number S3468-6044-PU6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-64

10-62

10-60

10-58

10-56

10-54

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

56/42 - .36

LW-ER

Gearing

22:39-76

22:40-76

20:41-76

General

Width (in/cm) 48 / 121.9

Length (in/cm) 115 / 292.1

Height (in/cm) 48.5 / 129.5

Estimated Dry Weight

(lb/kg)

475 / 218.2

Fuel (Gallons / Liters) 11.7 / 44.3

Oil qts/l 3/2.8

Cooling System Capacity

(Quarts / Liters)

8.5 / 8

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211122

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

23

39

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 128 (325)

Lug Height - Inches (cm) 1 (2.54)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.28

Page 32

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Shocks Ryde FX MPV

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type Fast M-10 128

Front Track Shock (FTS) Ryde FX MPV

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length Inches (cm)

Rear Track Shock (RTS) Fox Zero Pro

Lower Outer Spring Rate

lbs/in (N/mm)

Lower Inner Spring Rate

lbs/in (N/mm)

Upper Spring Rate

lbs/in (N/mm)

Rear Travel Inches (cm) 13 (33)

120 (21)

9.95 (25.3)

10 (25.4)

42.5 (108)

41.16 (104.5)

160 (28)

8 (20.3)

715 (125)

425 (74.4)

273 (48)

1

1.29

Page 33

Model Specifications

2008 600 IQ Touring

Model Number: S08PT6HS / S08PT6HE

Engine

Engine Type

Model Number S3468-6044-PU6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings

ALTITUDE

meters

(feet)

0-600

(0-2000)

600-1200

(2000-4000)

1200-1800

(4000-6000)

1800-2400

(6000-8000)

2400-3000

(8000-10000)

3000-3600

(10000-12000)

DRIVE CLUTCH DRIVEN CLUTCH

Shift

Weight

10-64

10-62

10-60

10-58

10-56

10-54

Drive Clutch Bolt Torque: 80 lb.ft. (108Nm)

Clutch

Spring

BLK / GRN

(120 / 340)

(7042083)

Liberty Liquid-Cooled /

Case Reed Induction

.004 - .006 / .105 - .159

.014 - .020 / .356 - .508

91 Non-Oxygenated

Clutch

Spring

RED/BLK

(140 / 240)

(7043058)

Driven

Helix

56/42 - .36

LW-ER

Gearing

22:43 - 78

21:44 - 78

General

Width (in/cm) 48 / 121.9

Length (in/cm) 129 / 327.7

Height (in/cm) 53 / 134.6

Estimated Dry Weight

(lb/kg)

574 / 260.6

Fuel (Gallons / Liters) 11.7 / 44.3

Oil qts/l 3/2.8

Cooling System Capacity

(Quarts / Liters)

TBD

Brake Fluid DOT 4

Drive Belt

Part Number

Width (inches / cm)

Side Angle

Circumference (inches / cm)

Center Distance (inches / cm)

3211122

1.460 / 3.7

26_

46.77 / 118.8

11.5 / 29.2

Chaincase

Center Distance (inches)

Top Gear (Stock)

Bottom Gear (Stock)

Chain (Stock)

Gear Lube

Capacity (oz / ml)

Reverse System

8.373

23

37

76

Polaris Synthetic

11 / 325.3

Perc

Electrical

Alternator Output

Operating Voltage

Watts @ 13.5 Vdc (Total)

Ignition Timing

Coolant Temp = 120_F (49_C)

13.5 - 14.5 Vdc

400

18_ @1700 RPM

Spark Plug Gap in.(mm) .027 (.70)

Spark Plug C hampion RN57YCC

Track

Width - Inches (cm) 15 (38)

Length - Inches (cm) 136 (345.4)

Lug Height - Inches (cm) 1 (2.54)

Track tension sag in/cm with

10 lbs/4.54kg placed 16 in/

40cm ahead of rear idler

7/8

″ - 1-1/8″(2.2 - 2.9cm)

shaft

1.30

Page 34

Front Suspension

Model Specifications

Suspension Type IQ 42.5

Shocks Ryde FX MPV

IFS Spring Rate

lbs/in (N/mm)

Spring Installed Length

Inches (cm)

Front Vertical Travel

Inches (cm)

Ski Center Distance

Inches (cm)

Setup Width

Camber Inches (cm) 2.25 ± 0.31 (57 ± 7.9)

Toe Out Inches (cm) 0 - 0.12 (0 - 0.31)

Rear Suspension

Suspension Type IQ 136 Comfort

Front Track Shock (FTS) Ryde FX MPV

FTS Spring Rate

lbs/in (N/mm)

FTS Spring Installed

Length (inches / cm)

Rear Track Shock (RTS) Ryde FX MPV

.405 / 16# (Stock)

- PN 7043347 - 067

Torsion Springs

Rear Travel Inches (cm) 14 (35.6)

- PN 7043346 - 067

.421 / 18# (Firm)

- PN 7043369 - 067

- PN 7043368 - 067

140 (24.5)

9.95 (25.3)

10 (25.4)

42.5 (108)

41.16 (104.5)

275 (48)

8.74 (21)

1

1.31

Page 35

Model Specifications

2008 600 RMK 155

Model Number: S08PM6HS / S08PM6HE

Engine

Engine Type

Model Number S3468-6044-PU6H

Displacement / # Cylinders 599cc / 2

Bore (inches/mm) 3.04 / 77.25

Stroke (inches/mm) 2.52 / 64

Piston to Cylinder Clearance

(inches/mm)

Installed Ring Gap

(inches / mm)

Operating RPM ±200 8250

Idle RPM 1700

Engagement RPM ±200 3800

Exhaust Valve Spring Purple

Fuel Delivery

Type Cleanfire Direct Injection

Throttle Body Marking 1203213

Throttle Body Bore 46mm

TPS Voltage @ Idle 0.95 +/- 0.01 Vdc

Fuel Pressure - PSI (bar) 58 (4.0)

Recommended Fuel Octane

(R+M/2)

Clutch Settings