Polaris INDY TRAIL RMK, INDY 500 RMK, INDY 700 SKS, INDY 700 EURO SKS, 700 EDGE RMK Service Manual

...Page 1

PN 9917366

Printed in U.S.A.

2002 DEEP SNOW

SERVICE MANUAL

2002 DEEP SNOW SERVICE MANUAL

INDY TRAIL RMK

INDY 500 RMK

INDY 500 SKS EURO

600 EDGE RMK

INDY 700 SKS / (EURO SKS)

700 EDGE RMK

800 EDGE RMK

PART NUMBER 9917366

Cover 12/23/02 11:54 AM Page 1

Page 2

DEEP SNOW

SERVICE MANUAL

Foreword

This manual is designed primarily for useby Polaris snowmobile service technicians in a properly equipped

shop. Persons using this manual should have a sound knowledge of mechanical theory, tool use, and shop

proceduresinordertoperformtheworksafely andcorrectly. Thetechnicianshouldreadthetext and be familiarwith service procedures before starting the work. Certain procedures requirethe use of specialtools. Use

onlythe proper tools,as specified. Cleanlinessof parts andtoolsaswell as the workareais of primaryimportance.

Allreferences toleft andright side of thevehicle are from the operator’s perspective when seatedin a normal

riding position.

This manual includes procedures for maintenanceoperations, component identification and unit repair,along

with service specifications for the Polaris Indy (500 Euro) / 700SKS , TrailRMK, 500 RMK, 600 EDGERMK,

700 EDGE RMK, 800 EDGE RMK snowmobiles. A table of contents is placed at the beginning of each

chapter,andan alphabetic index is provided at the endofthemanualforlocationof specificpagenumbersand

service information. Keep this manual available for reference in the shop area.

At the time of publication all information contained in this manual was technically correct. However, all

materials and specifications are subject to change without notice.

Comments or suggestions about this manual may be directed to: Polaris Sales Inc., Service Publications

Department, 2100 Hwy 55 Medina, Minnesota 55340.

Deep Snow Snowmobile Service Manual (PN 9917366)

Copyright 2001 Polaris Sales Inc. Printed in U.S.A.

Page 3

UNDERSTANDING SAFETY LABELS AND INSTRUCTIONS

Throughout these instructions, important information is brought to your attention by the following symbols:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER

Failure to follow DANGER instructionswill result in severeinjuryordeathtothe operator,bystander or person

inspecting or servicing the snowmobile.

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the operator, bystander or

person inspecting or servicing the snowmobile.

CAUTION:

ACAUTION indicatesspecial precautions thatmust be takento avoid personal injury,orsnowmobile orproperty damage.

NOTE:

A NOTE provides key information to clarify instructions.

Trademarks

Polaris acknowledges the following products mentioned in this manual:

FLEXLOC, Registered Trademark of SPS Technologies

Loctite, Registered Trademark of the Loctite Corporation

STA-BIL, Registered Trademark of Gold Eagle

FOX, Registered Trademark of Fox Shox

Nyogel, Trademark of Wm. F. Nye Co.

Fluke, Registered Trademark of John Fluke Mfg. Co.

Mity Vac, Registered Trademark of Neward Enterprises, Inc.

Ammco, Registered Trademark of Ammco Tools, Inc.

Torx, Registered Trademark of Textron

Hilliard, Trademark of the Hilliard Corporation

Page 4

GENERAL

MAINTENANCE

ENGINE

CARBURETION

DRIVE/DRIVEN CLUTCHES

SUSPENSIONS

BODY AND STEERING

BRAKES AND FINAL DRIVE

ELECTRICAL

WIRING DIAGRAMS

Page 5

Page 6

CHAPTER 1

GENERAL INFORMATION

Publication Part Numbers / Service Manuals 1.1.............

Model Number Identification 1.2...........................

Vehicle Identification Number (VIN) 1.3.....................

Standard Bolt Torque Specifications 1.4....................

Decimal Equivalents 1.5..................................

Tap Drill Size Charts 1.6..................................

Units of Measure Chart 1.7...............................

Recommended Shop Supplies 1.8.........................

Glossary of Terms 1.9 - 1.11....................................

General Precautions 1.12..................................

Notes Page 1.13..........................................

Indy 500 SKS Euro Specifications 1.14 - 1.15......................

Indy 500 RMK Specifications 1.16 - 1.17..........................

Indy Trail RMK Specifications 1.18 - 1.19..........................

600 EDGE RMK Specifications 1.20 -- 1.21.........................

Indy 700 SKS (Euro) Specifications 1.22 -- 1.23.....................

700 EDGE RMK Specifications 1.24 -- 1.25.........................

800 EDGE RMK Specifications 1.26 -- 1.27.........................

Page 7

Page 8

GENERAL INFORMATION

1.1

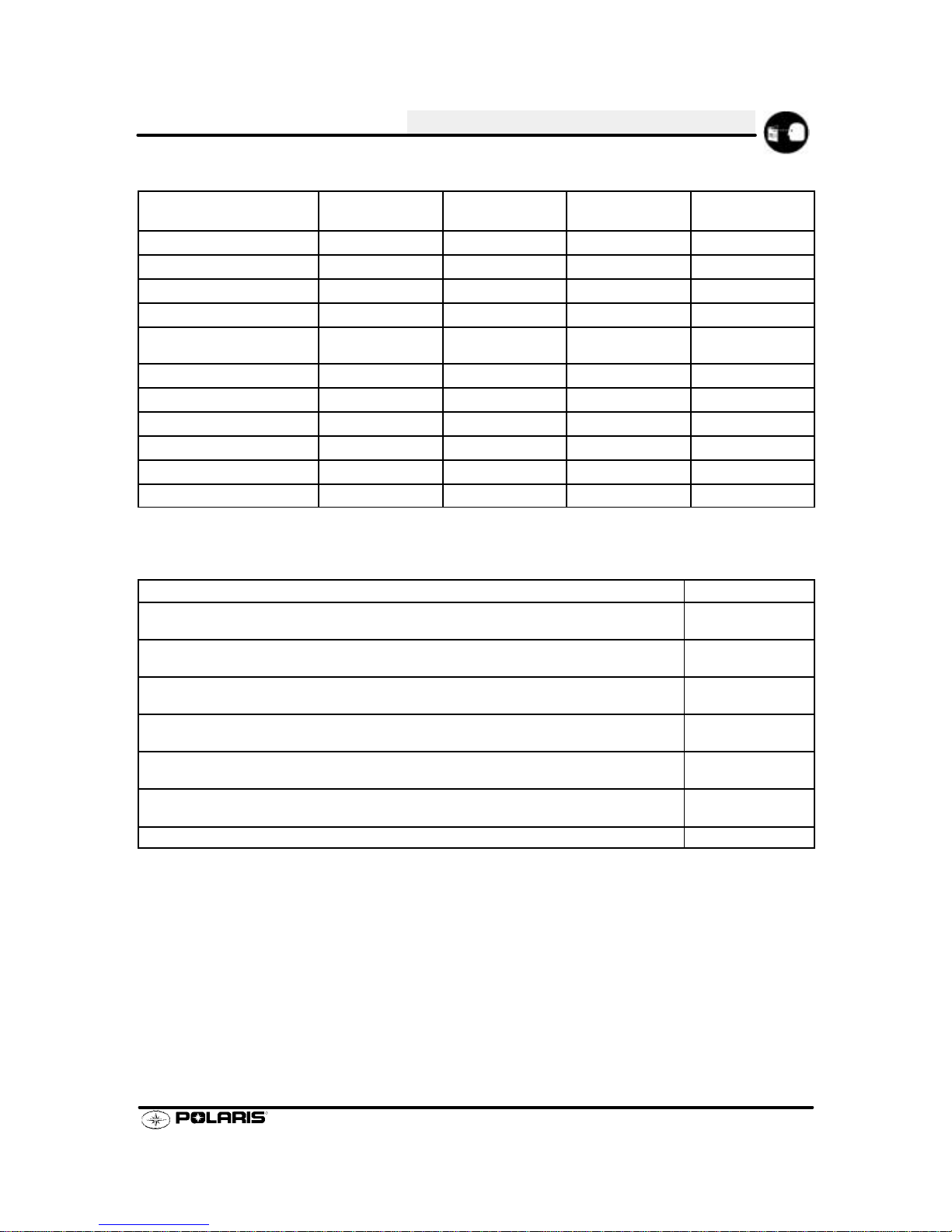

2002 Publication Numbers

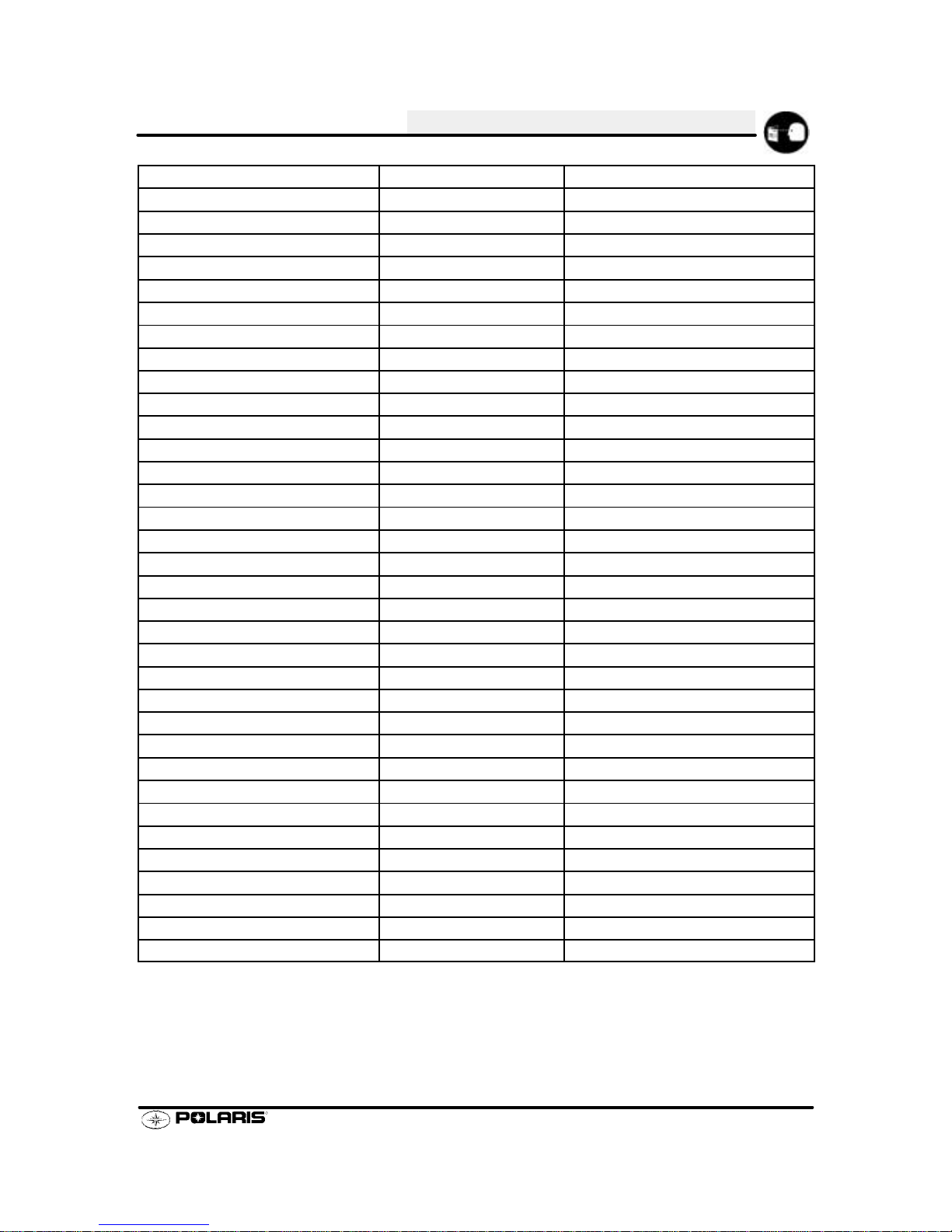

Model Model No. Owner’s Manual

Supplement

Parts

Manual

Parts

Microfiche

Indy Trail RMK S02SR5BS 9916935 9916936 9916937

Indy 500 RMK S02SR5AS 9916932 9916933 9916934

Indy 500 SKS Euro S02SS5AE 9916941 9916942 9916943

Indy 600 EDGE RMK S02NJ6ES 9916944 9916945 9916946

Indy 700 SKS (Euro) S02SS7CS

(S02SS5AE)

9916938 9916939 9916940

700 EDGE RMK - 136² S02NJ7CSA 9917055 9917056 9917057

700 EDGE RMK - 144² S02NK7CS 9916953 9916954 9916955

700 EDGE RMK -- 151” S02NL7CS 9917061 9917062 9917063

800 EDGE RMK - 144² S02NK8CS 9917058 9917059 9917060

800 EDGE RMK - 151² S02NL8CS 9916950 9916952 9916953

800 EDGE RMK - 156² S02NM8CS 9917064 9917065 9917066

2000 Snowmobile Owner’s Manual (All) - PN 9916649

Snowmobile Assembly Manual - PN 9916508

2002 Service Manuals

120 XC SP 9917361

Trail Sport

Super Sport, Indy 500, 340 Delux

9917362

Two-Up / Touring

Wide Trak LX, 340 Touring, Sport Touring, Trail Touring, 500 Classic Touring, 600 Classic Touring

9917364

Trail Luxury

500Classic, 550 Classic, 600 Classic, 700 Classic

9917363

Deep Snow

TrailRMK, 500 RMK, 500 SKS Euro, 700 SKS, Trail RMK, 600/700/800 EDGE RMK

9917366

Performance

500 XC, 500/600/700/800 XC SP, 800 XCR

9917367

High Performance

440 XCF SP, 440 XC SP, 500/600/700/800 XC SP ,600/700/800 RMK, 800 XCR

9917365

Wallcharts 9917369

Page 9

GENERAL INFORMATION

1.2

MODEL NUMBER IDENTIFICATION

YEAR DESIGNATION ENGINE DESIGNATION

MODEL / CHASSIS DESIGNATION

2002 MODEL DESIGNATION

S02 SD 5 BS

S=Snow

U= European Model

S= North AmericanModel

MODEL LINE (4TH DIGIT) MODEL TYPE (5TH

DIGIT)

S=Gen II A= Feature Option

L= Lite B= Basic

N= EDGE C= Feature Option

W=Mini Indy D= Deluxe

E= Feature Option M--10

F= Feature Option

J= 136 RMK (Edge)

K= 144 RMK (Edge)

L= 151 RMK (Edge)

M= 156 RMK (Edge)

P= Performance

R= RMK (Gen II)

S= SKS

T= Touring

U= Utility

X= Racer

2002

ENGINE DESIGNATION

NUMBERS

1A - 121 F/C OHV 4 cycle Fuji

3A - 340 F/C Piston Port Fuji

4A - 440 F/C Cylinder Reed Fuji

4B - 488 L/C Piston Port Fuji

4C - 440VES L/C Case Reed (domestic)

4D -- 440 F/C Piston Port

4E - 488 F/C Piston Port Fuji

5A - 497 L/C Case Reed 2 Cyl (domestic)

5B - 544 F/C Cylinder Reed

5C - 500 VES L/C Case Reed 2 Cylinder (domestic)

6D - 600/700 L/C Case Reed 2 Cylinder(domestic)

6E - 600/440 VES L/C Case Reed 2 Cylinder (domestic)

7A - 700 L/C Case Reed 2 Cylinder (domestic)

7C -- 700 VES L/C Case Reed 2 Cyl (domestic)

8A - 800 VES L/C Case Reed 3 Cylinder Fuji

8B - 800 L/C Case Reed 2 Cylinder (domestic)

8C -- 800 VES L/C Case Reed 2 Cyl (domestic)

MODEL NO.

V.I.N. NO.

MFD. DATE:

THIS VEHICLE CONFORMSTO ALL APPLICABLE

U.S. FEDERAL AND STATEREQUIREMENTS AND

CANADA MOTORVEHICLE SAFETY STANDARDS

IN EFFECT ON THE DATE OF MANUFACTURE.

MADE IN U.S.A.

7072133

Mfd. by Polaris Industries Inc.. in Roseau, M N under one or

more of the following patents:

U.S. Patents

3,605,511 3,613,810 5,050,559

3,580,647 3,867,991 5,048,503

3,483,766 4,793,950 5,056,482

3,533,662 5,038,881 5,099,813

3,545,821 5,172,675 5,074,271

3,605,510 5,090,386 5,191,531

3,525,412 5,050,564 3,613,811

PATENT NOTICE

Patented Canada

882,491/71

883,694/71

864,394/71

Canadian Rd.

34,573/71

34,572/71

1,227,823/87

TUNNEL DECAL

These numbers should be referred to in any correspondenceregardingwarranty, service or replacement parts.

The machinemodelandserialnumber identification decalislocatedon the right frontside ofthetunnel. The serial number is

permanentlystamped into the tunnel. The model number is embossed on the decal.

Whenever corresponding about an engine it is important that the engine model and serial numbers be called out. Laser

engraved model and serial numbers are located on the crankcase (intake side).

Page 10

GENERAL INFORMATION

1.3

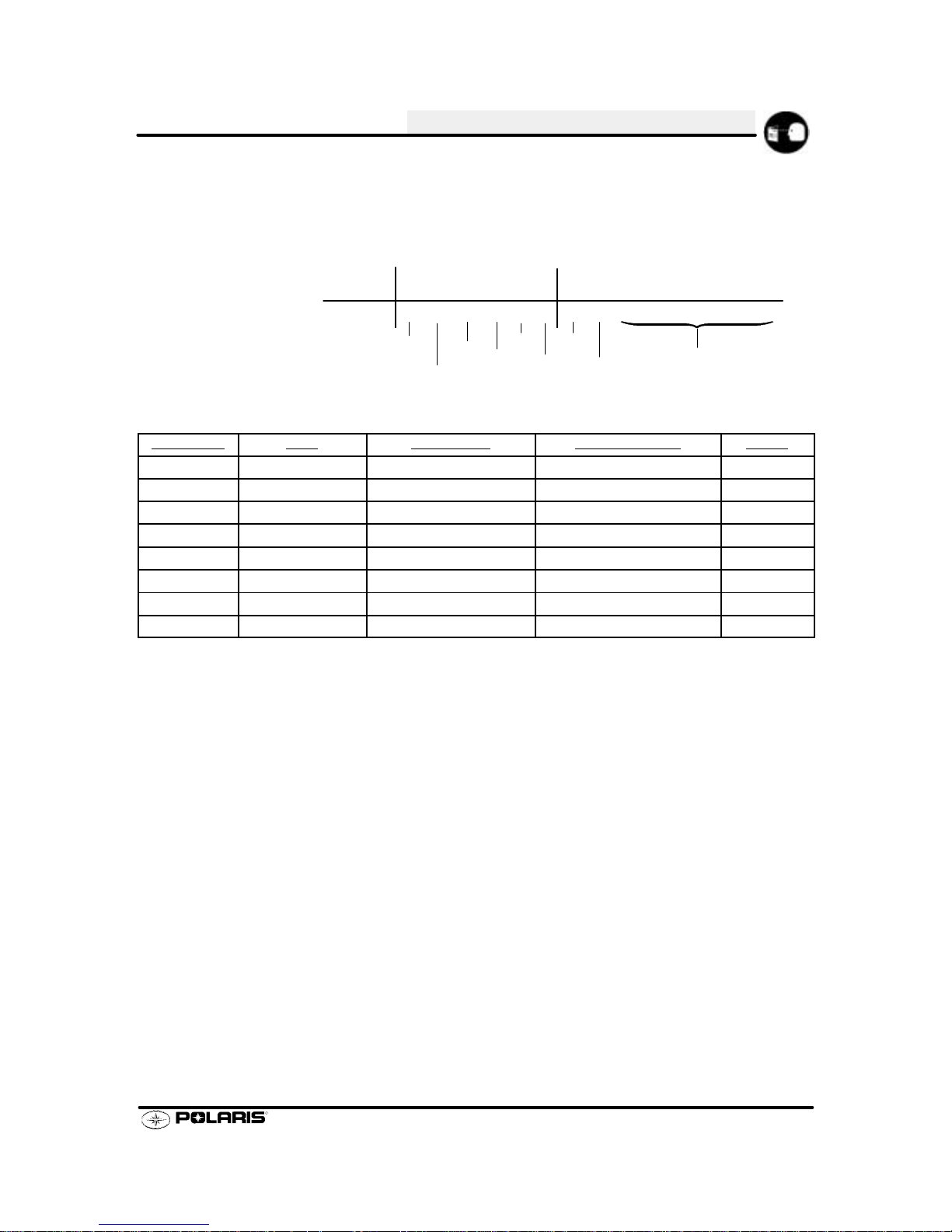

Vehicle Identification Number

Current snowmobiles havea 17 digit VehicleIdentification Number(VIN). TheVIN is organizedas follows: Digits

1-3: WorldManufacturerIdentifier. For Polaris, this is4XA. Digits 4-9: VehicleDescriptor Section. Digits 10-17:

Vehicle Indicator Section. Digits 4-8 of the VIN identify the body style, type, engine type, and series. The VIN

and the model number must be used with any correspondence regarding service or repair.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

4XA SB

5BS022000000

Vehicle Descriptor

Vehicle Identifier

Type

Engine

Size

Engine

Modifier

Model

Year

Manufacturing.

Location Code

Individual Serial No.

Body Style

Series

World Mfg. ID

Example of

Current

VIN Number

Check

Digit

Vehicle Identification Number / Model Number Key

Body Style Type Engine Size Engine Modifier Series

L=Lite B=Base Model 1=100-199 cc A=Fan S=Domestic

N=Edge D=Deluxe 2=200-299 cc B=Liquid Twin U=Europe

S=Gen II P=Performance 3=300-399 cc C=Case Reed Twin

W=Mini R=RMK 4=400-499 cc D=Liquid Triple

S=SKS 5=500-599 cc E=Case Reed Triple

T=Touring 6=600-699 cc

U=Utility 7=700-799 cc

X=Racer 8=800-899 cc

Year / Letter Identification

The tenth digit of a 17 digit VIN is the model year of the vehicle. Example: W = 1998; X =1999 etc. Refer to the

listing below.

1 = 2001

2 = 2002

3 = 2003

Page 11

GENERAL INFORMATION

1.4

Standard Torque Specifications

Thefollowingtorquespecificationsaretobeusedasageneralguidelinewhentorquevalueisnotspecified. There

are exceptions in the steering, suspension, and engine areas. Always consult the torque chart and

the specific

manual section for torque values of fasteners.

Bolt Size Threads/In Grade 2 Grade 5 Grade 8

(MM/Thread)

Torque in. lbs. (Nm)

#10 - 24 27 (3.1) 43 (5) 60 (6.9).............. ................ ...............

#10 - 32 31 (3.6) 49 (5.6) 68 (7.8).............. ................ ..............

To rque ft. lbs. (Nm)*

1/4 - 20 5 (7) 8 (11) 12 (16).............. .................. ................

1/4 - 28 6 (8) 10 (14) 14 (19).............. .................. ..............

5/16 - 18 11 (15) 17(23) 25 (35).............. ................ ..............

5/16 - 24 12 (16) 19 (26) 29 (40).............. ................ ..............

3/8 - 16 20 (27) 30 (40) 45 (62).............. ................ ..............

3/8 - 24 23 (32) 35 (48) 50 (69).............. ................ ..............

7/16 - 14 30 (40) 50 (69) 70 (97).............. ................ ..............

7/16 - 20 35 (48) 55 (76) 80 (110).............. ................ ..............

1/2 - 13 50 (69) 75 (104) 110 (152).............. ................ .............

1/2 - 20 55 (76) 90 (124) 120 (166).............. ................ .............

*To convert ft. lbs. to Nm multiply foot pounds by 1.356.

*To convert Nm to ft. lbs. multply Nm by .7376.

Page 12

GENERAL INFORMATION

1.5

1/64 .0156.........................

1/32 .0312 1 mm = .0394²................... ................

3/64 .0469.........................

1/16 .0625..............

5/64 .0781 2 mm = .0787²......................... ................

3/32 .0938...................

7/64 .1094 3 mm = .1181²....................... ................

1/8 . .1250. .......

9/64 .1406.........................

5/32 .1563 4 mm = .1575²................... ................

11/64 .1719........................

3/16 .1875 5 mm = .1969².............. ................

13/64 .2031........................

7/32 .2188...................

15/64 .2344 6 mm = .2362²........................ ................

1/4 .25..........

17/64 .2656 7 mm = .2756²........................ ................

9/32 .2813...................

19/64 .2969........................

5/16 .3125 8 mm = .3150².............. ................

21/64 .3281........................

11/32 .3438 9 mm = .3543².................. ................

23/64 .3594........................

3/8 .375..........

25/64 .3906 10 mm = .3937²........................ ................

13/32 .4063..................

27/64 .4219 11 mm = .4331²........................ ................

7/16 .4375..............

29/64 .4531........................

15/32 .4688 12 mm = .4724².................. ................

31/64 .4844........................

1/2 .5 13 mm = .5118.......... ...................

33/64 .5156........................

17/32 .5313..................

35/64 .5469 14 mm = .5512²........................ ................

9/16 .5625..............

37/64 .5781 15 mm = .5906²........................ ................

19/32 .5938..................

39/64 .6094........................

5/8 .625 16mm = .6299².......... .................

41/64 .6406........................

21/32 .6563 17 mm = .6693².................. ................

43/64 .6719.......................

11/16 .6875.............

45/64 .7031 18 mm = .7087²........................ ................

23/32 .7188..................

47/64 .7344 19 mm = .7480²........................ ................

3/4 .75..........

49/64 .7656........................

25/32 .7813 20 mm = .7874².................. ................

51/64 .7969........................

13/16 .8125 21 mm = .8268²............. ................

53/64 .8281........................

27/32 .8438..................

55/64 .8594 22 mm = .8661²........................ ................

7/8 .875..........

57/64 .8906 23 mm = .9055²........................ ................

29/32 .9063..................

59/64 .9219.......................

15/16 .9375 24 mm = .9449²............. ................

61/64 .9531........................

31/32 .9688 25 mm = .9843.................. ................

63/64 .9844........................

Page 13

GENERAL INFORMATION

1.6

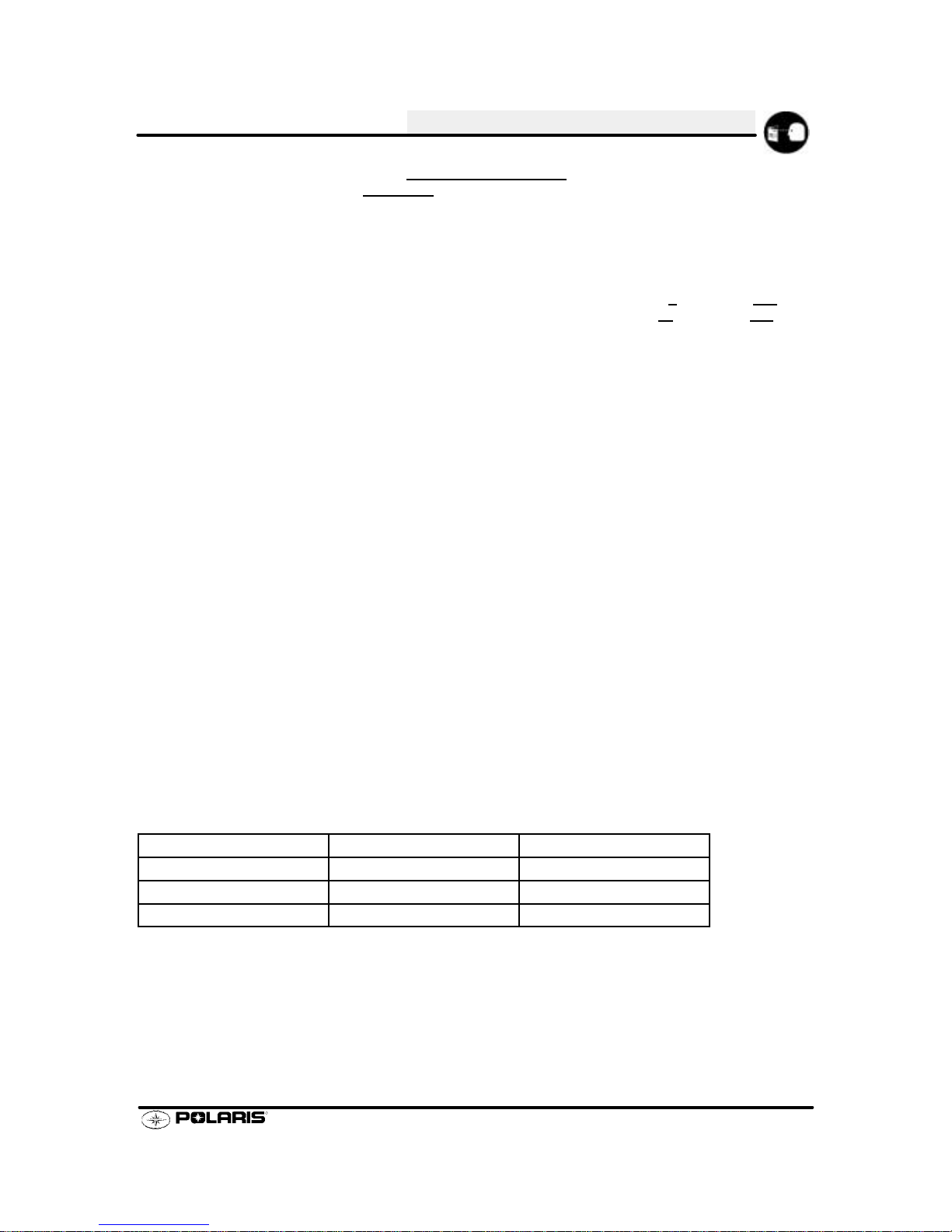

SAE Tap Drill Sizes

Thread Size Drill Size Thread Size Drill Size

#0-80 3/64

#1-64 53

#1-72 53

#2-56 51

#2-64 50

#3-48 5/64

#3-56 45

#4-40 43

#4-48 42

#5-40 38

#5-44 37

#6-32 36

#6-40 33

#8-32 29

#8-36 29

#10-24 24

#10-32 21

#12-24 17

#12-28 4.6mm

1/4-20 7

1/4-28 3

5/16-18 F

5/16-24 I

3/8-16 O

3/8-24 Q

7/16-14 U

7/16-20 25/64

1/2-13 27/64

1/2-20 29/64

9/16-12 31/64

9/16-18 33/64

5/8-11 17/32

5/8-18 37/64

3/4-10 21/32

3/4-16 11/16

7/8-9 49/64

7/8-14 13/16

1-8 7/8

1-12 59/64

1 1/8-7 63/64

1 1/8-12 1 3/64

11/4-7 17/64

1 1/4-12 1 11/64

11/2-6 111/32

1 1/2-12 1 27/64

13/4-5 19/16

1 3/4-12 1 43/64

2-4 1/2 1 25/32

2-12 1 59/64

2 1/4-4 1/2 2 1/32

21/2-4 21/4

23/4-4 21/2

3-4 2 3/4

Metric Tap Drill Sizes

Tap Size Drill Size Decimal Equivalent Nearest Fraction

3x.50

3x.60

4x.70

4x.75

5x.80

5x.90

6 x 1.00

7 x 1.00

8 x 1.00

8 x 1.25

9 x 1.00

9 x 1.25

10 x 1.25

10 x 1.50

11 x 1.50

12 x 1.50

12 x 1.75

#39

3/32

#30

1/8

#19

#20

#9

16/64

J

17/64

5/16

5/16

11/32

R

3/8

13/32

13/32

0.0995

0.0937

0.1285

0.125

0.166

0.161

0.196

0.234

0.277

0.265

0.3125

0.3125

0.3437

0.339

0.375

0.406

0.406

3/32

3/32

1/8

1/8

11/64

5/32

13/64

15/64

9/32

17/64

5/16

5/16

11/32

11/32

3/8

13/32

13/32

Page 14

GENERAL INFORMATION

1.7

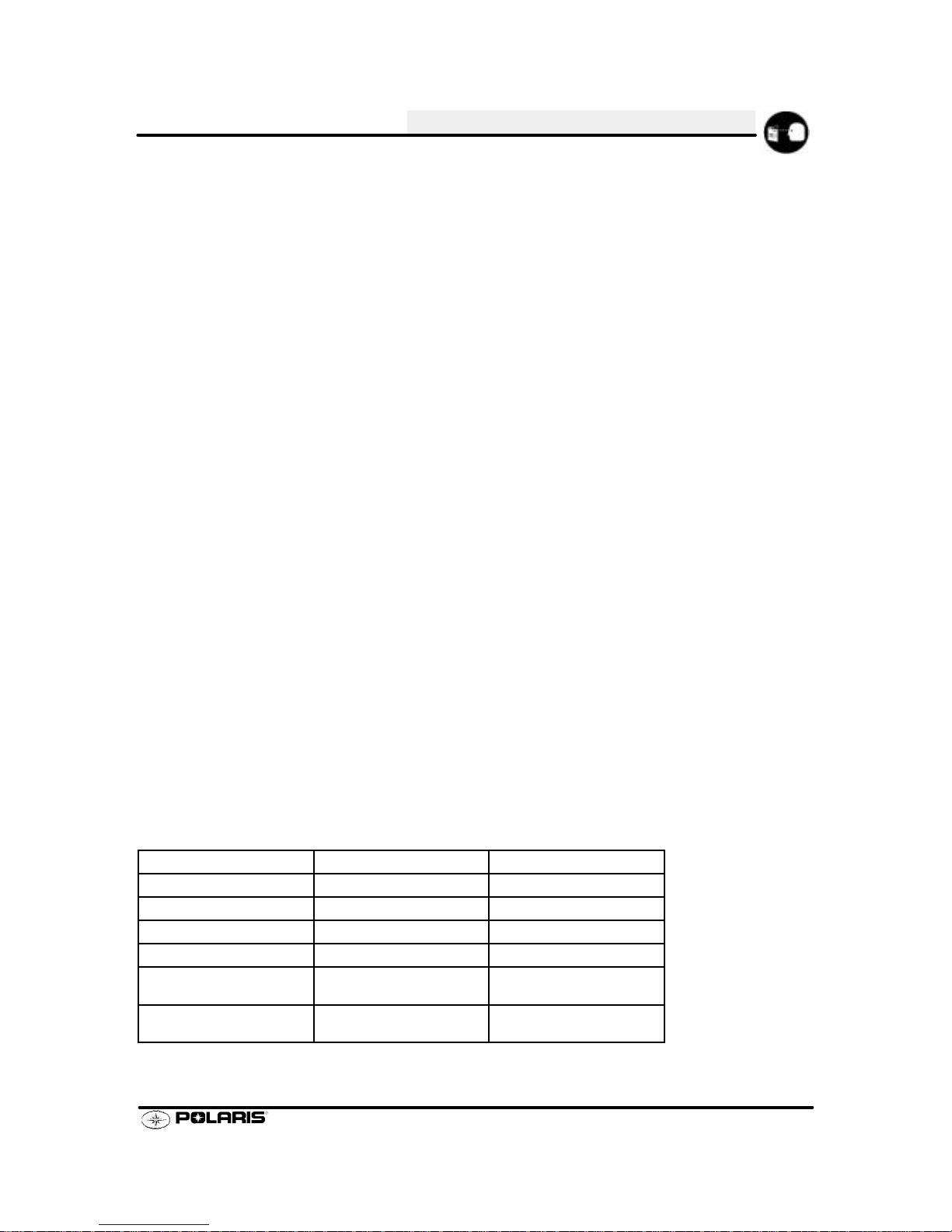

Unit of Measure Multiplied by Converts to

ft. lbs. x12 =in.lbs.

in. lbs. x .0833 = ft. lbs.

ft. lbs. x 1.356 =Nm

in. lbs. x.0115 =kg-m

Nm x .7376 = ft. lbs.

kg-m x 7.233 = ft. lbs.

kg-m x86.796 =in.lbs.

kg-m x10 =Nm

in. x25.4 =mm

mm x .03937 =in.

in. x2.54 =cm

mile (mi.) x1.6 =km

km x .6214 = mile (mi.)

Ounces (oz) x28.35 = Grams (g)

Grams (g) x 0.035 = Ounces (oz)

cc x .03381 = Fluid Ounces (oz)

lb. x.454 =kg

kg x 2.2046 =lb.

Cubic inches (cu in) x16.387 = Cubic centimeters (cc)

Cubic centimeters (cc) x 0.061 = Cubic inches (cu in)

Imperial pints (Imp pt) x 0.568 = Liters (l)

Liters (l) x1.76 = Imperial pints (Imp pt)

Imperial quarts (Imp qt) x 1.137 = Liters (l)

Liters (l) x0.88 = Imperial quarts (Imp qt)

Imperial quarts (Imp qt) x 1.201 =USquarts(USqt)

US quarts (US qt) x 0.833 = Imperial quarts (Imp qt)

US quarts (US qt) x 0.946 = Liters (l)

Liters (l) x 1.057 =USquarts(USqt)

US gallons (US gal) x 3.785 =Liters (l)

Liters (l) x 0.264 = US gallons (US gal)

Pounds - force per square inch (psi) x 6.895 = Kilopascals (kPa)

Kilopascals (kPa) x 0.145 = Pounds - force per square inch (psi)

Kilopascals (kPa) x0.01 = Kilograms - force per square cm

Kilograms - force per square cm x98.1 = Kilopascals (kPa)

°Cto°F: 9 (°C + 40) ¸ 5--40=°F

°Fto°C: 5 (°F+40)¸ 9--40=°C

Page 15

GENERAL INFORMATION

1.8

Description Part Number

Chaincase Lubricant - Quart 2871280.......................

Chaincase Lubricant - Gallon 2870464......................

Chaincase Lubricant - 2.5 Gallon 2872281...................

Fuel System Deicer (Isopropyl) 2870505.....................

Loctite Primer T - 6 Oz. Aerosol 2870585....................

Loctite RC 680 - 10cc Retaining Compound 2870584..........

Loctite/Chisel -- Gasket Remover - 18 Oz. 2870601...........

Metal Polish - 8 Oz. 2870632...............................

DOT 3 Brake Fluid 2870990...............................

Fogging Oil 2870791......................................

Nyogelt Grease 2871329.................................

Fox Shock Oil 2870995....................................

Premium All Season Grease (14 oz) 2871423................

Premium All Season Grease (3 oz) 2871322.................

Premium 60/40 Anti-Freeze/Coolant 2871323................

Premium Carbon Clean Fuel System Additive 2871326........

Polaris Battery Tender 2871076............................

Carbon Clean Fuel System Additive 2871326.................

T-9 Metal Protectant 2871064..............................

Crankcase Sealant 3 Bond 1215 2871557...................

Page 16

GENERAL INFORMATION

1.9

ACS: Alternator control switch.

ACV: Alternating current voltage.

Air Gap Spark Test: Agoodcheckfor ignition voltage and general ignition system condition. Spark shouldarc 3/8” (1

cm) minimum from end of high tension lead to ground. Several testers are available commercially.

Alternator: Electrical generator producing alternating current voltage.

Bore: Diameter of cylinder.

BTDC: Before Top Dead Center.

Bump Steer: When skis toe in and toe out through suspension travel.

CDI: Capacitor Discharge Ignition. Ignition system which stores voltage generated by the stator plate exciter coil in a

capacitor or condenser (in CDI box). At thepropermomentavoltagegeneratedbythestatorplatepulsercoilclosesan

electronicswitch (thyristor) intheCDI boxandallows the voltage in the capacitor to discharge into the primary windings

of the ignition coil.

Center Cylinder: On three cylinder engines, the cylinder between Mag and PTO ends.

Center Distance: Distance between center of crankshaft and center of driven clutch shaft.

Chain Pitch: Distance between chain link pins (No. 35 = 3/8” or 1 cm). Polaris measures chain length in number of

pitches.

Clutch Buttons: Plastic bushings which transmit rotation of the clutch to the movable sheave in thedrive anddriven

clutch.

ClutchOffset: Driveanddrivenclutches are offsetsothat drive beltwillstay nearlystraightasit movesalongthe clutch

face as the engine torques back.

Clutch Weights: Threelevers in the drive clutchwhich relative to their weight,profileandengineRPMcausethedrive

clutch to close.

Coil: Awindingofwirearoundanironcorewhichhas the ability to generate an electricalcurrent whenamagneticfield

passes through it.

Combustion Chamber: Space between cylinder head and piston dome at TDC.

Compression: Reduction in volume or squeezing of a gas.

Condenser/Capacitor: A storage reservoir for electricity, used in both E.T. and CDI systems.

Crankshaft Run-Out: Run-out or “bend” of crankshaft measured with a dial indicator while crankshaft is supported

between centers on V blocks or resting in lower half of crankcase. Measure at various points especially at PTO.

Maximum allowable run-out is .006” (.02 cm).

DCV: Direct current voltage.

Detonation: The spontaneous ignition of the unburned fuel/air mixture after normal spark ignition. Piston looks

“hammered”through,rough appearance around hole. Possible causes: 1)leanfuel/air mixture; 2) low octane fuel; 3)

over-advanced ignition timing; 4)compression ratio too high for the fuel octane.

Dial Bore Gauge: A cylinder measuring instrument which uses a dial indicator. Good for showing taper and

out-of-round in the cylinder bore.

Displacement: The volume of the cylinder displaced by

the piston as it travelsfromBDC to TDC. The formula is:

Effective Compression Ratio: Compression ratio measured from after the piston closes the exhaust port.

Electrical Open: Open circuit. An electrical circuit whichisn’t complete. (i.e.poor connections or brokenwire at hi-lo

beam switch resulting in loss of headlights.

Electrical Short: Short circuit. An electrical circuit which is completed before the current reaches the intended

component. (i.e. a bare wire touching the snowmobile chassis under the seat resulting in loss of taillights and brake

lights).

End Seals: Rubber seals at each end of the crankshaft.

Engagement RPM: Engine RPM at which the drive clutch engages to make contact with the drive belt.

Flat Head Bolt: To be used where finished surfaces require a flush fastening unit. Countersunk.

Foot Pound: Ft. lb. A force of one pound at the end of a lever one foot in length, applied in a rotational direction.

g: Gram. Unit of weight in the metric system.

Head V o lume: Cylinder head capacity in cc, head removed from engine with spark plug installed.

4

Bore x Stroke x 3.1416

2

= Displacement in

CCs

Page 17

GENERAL INFORMATION

1.10

Heat Exchanger: A device used to transfer heat. They dissipate engine heat to the atmosphere.

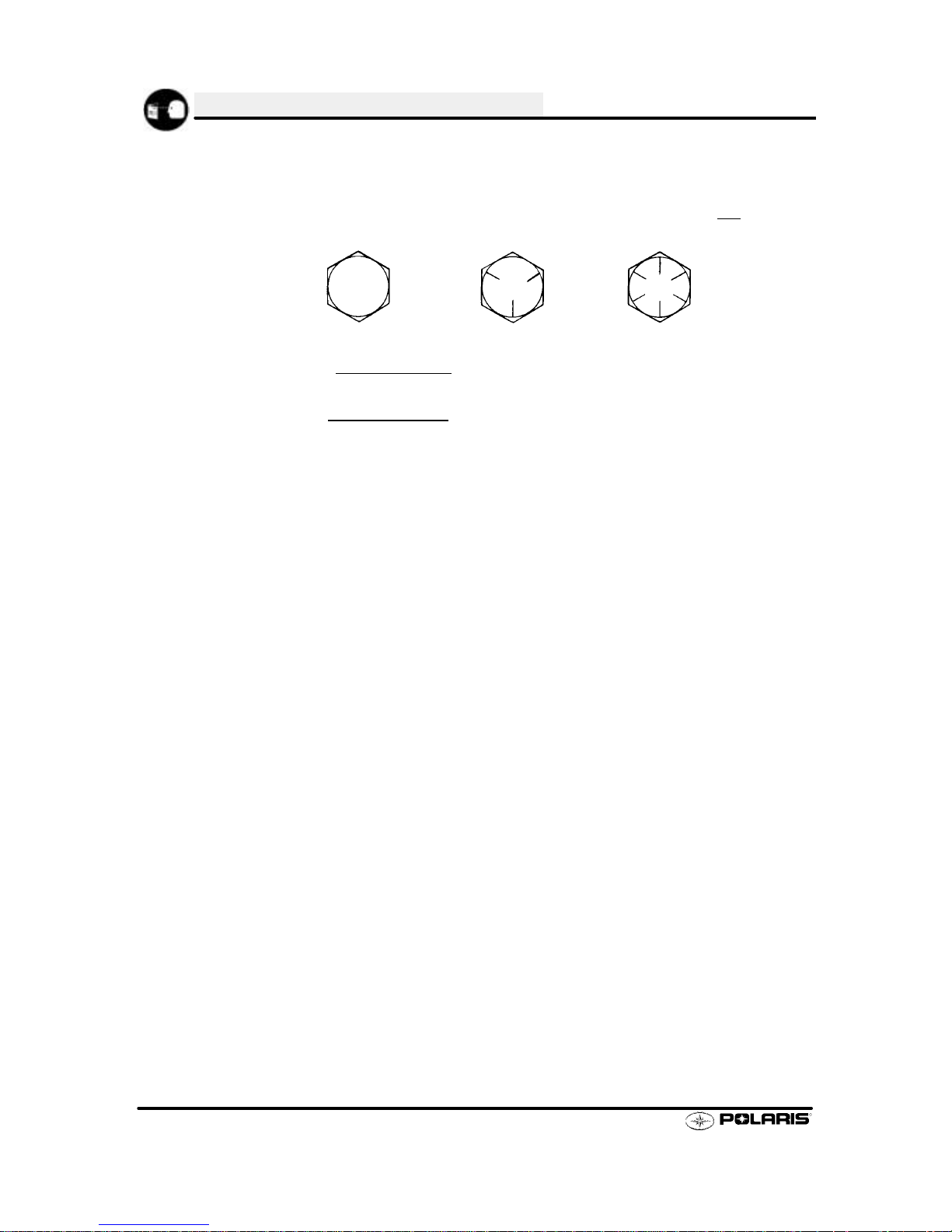

HexHead Bolt: Standardtypeofwrench-appliedhexagonhead,characterized by clean, sharp corners trimmed

to close tolerances. Recommended for general commercial applications.

Hi-Fax: Trademark of Himont Advanced Materials. The special slide material which fits onto the bottom of the

suspension rails.

High Side: Sled pushes or tips up toward outside of turn.

High TensionWire: Theheavy insulated wire which carries the high secondaryvoltagefromthecoil tothesparkplug.

Hole Shot: A term used when machine starts a race from a dead stop.

Holed Piston: Piston in which a hole has formed on the dome. Possible causes: 1) detonation; 2) pre-ignition.

IgnitionCoil: A typeoftransformerwhichincreasesvoltage in the primary windings (approx. 200V) to a higher voltage

in the secondary windings (approx. 14KV -32KV) through inductions. Secondary voltage is high enough toarc the air

gap at the spark plug.

IgnitionGenerating Coil: Excitercoilorprimary charge coil. Statorplatecoilwhichgeneratesprimary ignitionvoltage.

CDI system uses one ignition generating coil.

Inch Pound: In. lb. 12 in. lbs. = 1 ft. lb.

Kg/cm2: Kilograms per square centimeter. Metric equivalent of PSI.

Keystone Ring: A piston ring with bevel on upper surface.

Kilogram/meter: A force of one kilogram at the end of a lever one meter in length, applied in a rotational direction.

Metric equivalent of ft. lbs.

LRing: A wide face piston ring with an ”L” shaped cross section. Leg of ”L” goes up when installing on piston.

Labyrinth Seal: A pressure typecenter seal identified by series of grooves and lands. Polarisengines us this type of

seal to separate the cylinders in the crankcase halves.

Left Side: Always referred to based on normal operating position of the driver.

Lighting Coil: Generates voltage for lights, battery charging, etc by electromagnetic induction.

Loose: When the rear of the vehicle slides outward in a turn. The track does not grab sufficiently.

mm: Millimeter. Unit of length in the metric system. 1mm = .040”.

Mag End: Flywheel side of engine.

Magnetic Induction: As a conductor (coil) is moved through a magnetic field, a voltage will be generated in the

windings. This is how mechanical energy in our engines is converted to electrical energy in the lighting coil, ignition

generating coils and trigger coil.

Ohm: The measurement of electrical resistance opposing current flow.

Oval Head Screw: Fully specified as ”oval countersunk”, this head is identical to the standard flat head, but

possesses a rounded upper surface for attractiveness of design.

PTO End: Power Take Off drive (clutch side).

Pan Head Screw: Provides a low, large diameter head, but with characteristically high outer edges along the

outeredgeof the headwheredrivingaction is mosteffective. Slightly differentheadcontourwhensupplied with Phillips

Recess. See dotted line.

Piston Clearance: Total distance between piston and cylinder wall.

PistonErosion: Pistondomemelts. Usuallyoccursat theexhaustportarea. Possible causes: 1) leanfuel/airmixture;

2) improper spark plug heat range; 3) Poor fuel.

Pre-Ignition: A problem in combustion where the fuel/air mixture is ignited beforenormal spark ignition. Piston looks

melted at area of damage. Possible causes: 1)incorrect spark plug heatrange; 2) spark plug notproperly torqued; 3)

“glowing” piece of head gasket, metal burr or carbon in the combustion chamber; 4) lean fuel/air mixture; 5) Incorrect

ignition timing.

Primary Circuit: Thiscircuitisresponsibleforthe voltagebuildupinthe primarywindingsofthe coil. Inthe CDIsystem

thepartsinclude the exciter coil,the trigger coil, the wiresfromstatorplatetoCDIboxandtothelowresistanceprimary

windings in the ignition coil.

Primary Clutch: Drive clutch on engine.

Primary Compression: Pressure built up in the crankcase of a two stroke engine.

Page 18

GENERAL INFORMATION

1.1 1

psi.: Pounds per square inch.

Pushing: Whenthe front of the vehicle does not steeras much as the driverdesires. The skis donot grab sufficiently.

R&R: Remove and replace.

RFI: RadioFrequencyInterference. Caused by high voltage from the ignition system. Therearespecialplugcapsand

spark plugs to help eliminate this problem. Mandated in Canada.

RPM: Revolutions Per Minute.

Resistance: Inthe mechanicalsense,frictionor load. Intheelectricalsense,ohms. Bothresultinenergy conversionto

heat.

Right Side: Always referred to based on normal operating position of the driver.

Round Head Screw:The familiar head most universally used for general application. Good slot depth, ample

underhead bearing surface and finished appearance are characteristic of this head.

Running Time: Ignition timing at specified RPM.

Secondary Circuit: Thiscircuitconsists ofthelargesecondarycoilwindings,hightensionwire andgroundthroughthe

spark plug air gap.

Secondary Clutch: Driven clutch on chaincase or jackshaft.

SeizedPiston: Gallingof the sidesofapiston. Usually there is atransferofaluminumfromthe piston onto the cylinder

wall. Possible causes: 1) improper lubrication; 2) excessive temperatures; 3) insufficient piston clearance; 4)stuck

piston rings.

Self Steer: Pulling the machine to the inside of the track.

Spark Plug Reach: Length of threaded portion of spark plug. Polaris uses 3/4” (2 cm) reach plugs.

Static Timing: Ignition timing when engine is at zero RPM.

Stator Plate: The plate mounted under the flywheel supporting the primary ignition components and lighting coils.

Stroke: Themaximum movement of the piston from bottom deadcentertotop deadcenter. Itischaracterizedby180°

of crankshaft rotation.

Surge Tank: The fill tank in the liquid cooling system.

TDC: Top Dead Center. Piston’s most outward travel from crankshaft.

Transfer: The movement of fuel/air from the crankcase to the combustion chamber in a two stroke engine.

Trigger Coil: Pulser coil. Generates the voltage for triggering (closing) the thyristor and timing the spark in CDI

systems. Small coil mounted at the top of the stator plate next to the ignition generating coil, or on the outside of the

flywheel.

V Regulator: Voltage regulator. Maintains maximum lighting coil output at approx. 14.5 ACV as engine RPM

increases.

Venturi: Anareaofairconstriction. Aventuriisusedincarburetors tospeedupair flowwhichlowerspressureinventuri

tobelowatmosphericpressure,causingfuelto be pushedthroughjets,etc.,andintotheventuri to be mixed with air and

form a combustible air/fuel mixture.

Volt: The unit of measure for electrical pressure of electromotive force. Measured by a voltmeter in parallel with the

circuit.

Watt: Unit of electrical power. Watts = amperes x volts.

Page 19

GENERAL INFORMATION

1.12

In order to perform service work efficiently and toprevent costly errors, the technician should read the text in this

manual, thoroughly familiarizing him/herself with procedures before beginning. Photographs and illustrations

havebeenincluded with the text as an aid. Notes,cautions and warningshave also been included forclarification

of text and safety concerns. However, a knowledge of mechanical theory, tool use and shop procedures is

necessary to perform the service work safely and satisfactorily. Use only genuine Polaris service parts.

Cleanlinessofpartsandtoolsaswellastheworkareaisof primaryimportance. Dirtandforeignmatter will act

asanabrasiveandcausedamagetoprecisionparts. Cleanthesnowmobile before beginning service. Cleannew

parts before installing.

Watch for sharp edges which can cause personal injury, particularly in the area of the tunnel. Protect hands

with gloves when working with sharp components.

If difficulty is encountered in removingor installing acomponent, look tosee if acausefor thedifficulty canbe

found. If it is necessary to tap the part into place, use a soft face hammer and tap lightly.

Some of the fasteners in the snowmobile were installed with locking agents. Use of impact drivers or

wrenches will help avoid damage to fasteners.

Alwaysfollowtorquespecifications as outlined throughout thismanual. Incorrect torquing may leadtoserious

machine damage or, as in the case of steering components, can result in injury or death for the rider(s).

If a torquing sequence isindicated for nuts, bolts or screws, start all fasteners in their holes and handtighten.

Then, following the method and sequence indicated in this manual, tighten evenly to the specified torque value.

When removing nuts, bolts or screws from a part with several fasteners, loosen them all about 1/4 turn before

removing them.

If the condition ofany gasket or O-Ring is inquestion, replaceit witha new one. Besure the matingsurfaces

around the gasket are clean and smooth in order to avoid leaks.

Some procedures will require removal of retaining rings or clips. Because removal weakens and deforms

theseparts, they should always bereplacedwithnewparts. Wheninstallingnewretainingringsandclipsusecare

not to expand or compress them beyond what is required for installation.

Because removal damages seals, replace any oil or grease seals removed with new parts.

Polaris recommends the use of Polaris lubricants and greases, which have beenspecially formulated for the

top performance and best protection of our machines. In some applications, such as the engine, warranty

coverage may become void if other brands are substituted.

Grease should be cleaned from parts and fresh grease applied before reassembly of components.

Deteriorating grease loses lubricity and may contain abrasive foreign matter.

Whenever removing or reinstalling batteries, care should be taken to avoid the possibility of explosion

resulting in serious burns. Always disconnect the negative (black) cable first and reconnect it last. Battery

electrolyte contains sulphuric acid and is poisonous! Serious burns can result from contact with the skin, eyes or

clothing. ANTIDOTE: External - Flush with water. Internal - Drink large quantities or water or milk. Follow with

milkofmagnesia,beatenegg,orvegetableoil. Call physician immediately. Eyes - Flushwithwaterfor 15minutes

and get prompt medical attention.

Page 20

GENERAL INFORMATION

1.13

Notes

Page 21

GENERAL INFORMATION

1.14

MODEL: INDY 500 SKS EUROPEAN..........

MODEL NUMBER: E02SS5AE.

ENGINE MODEL: S2209--5044PL5A..

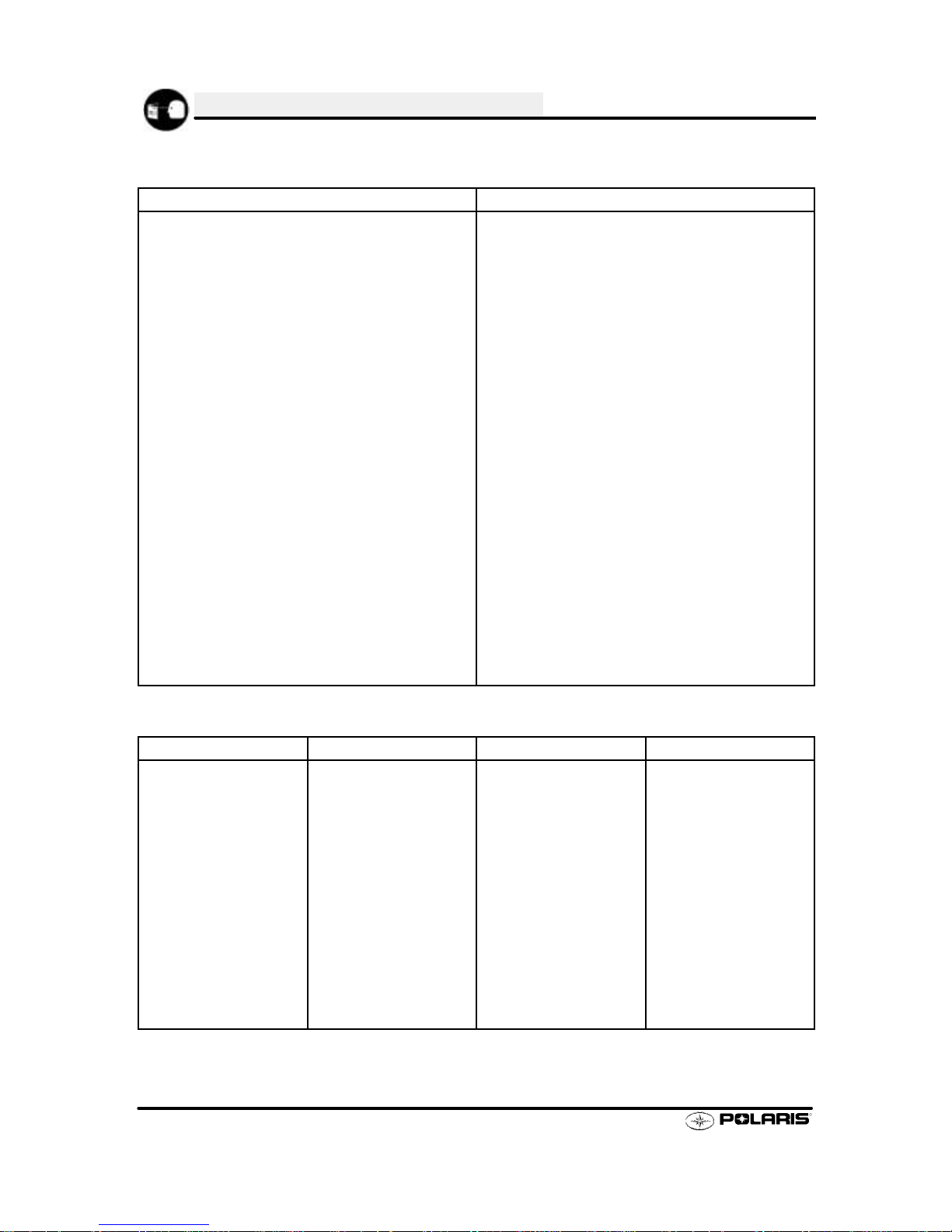

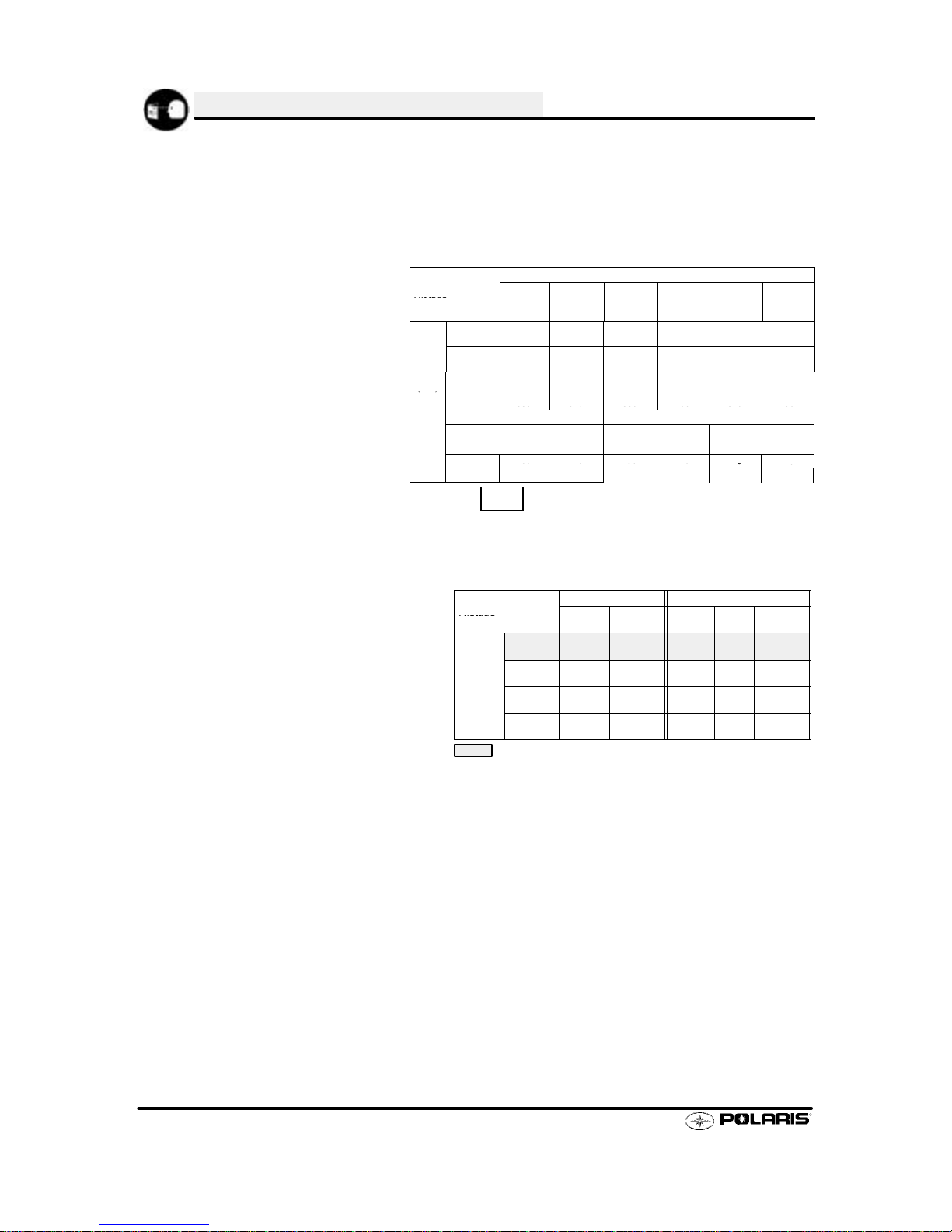

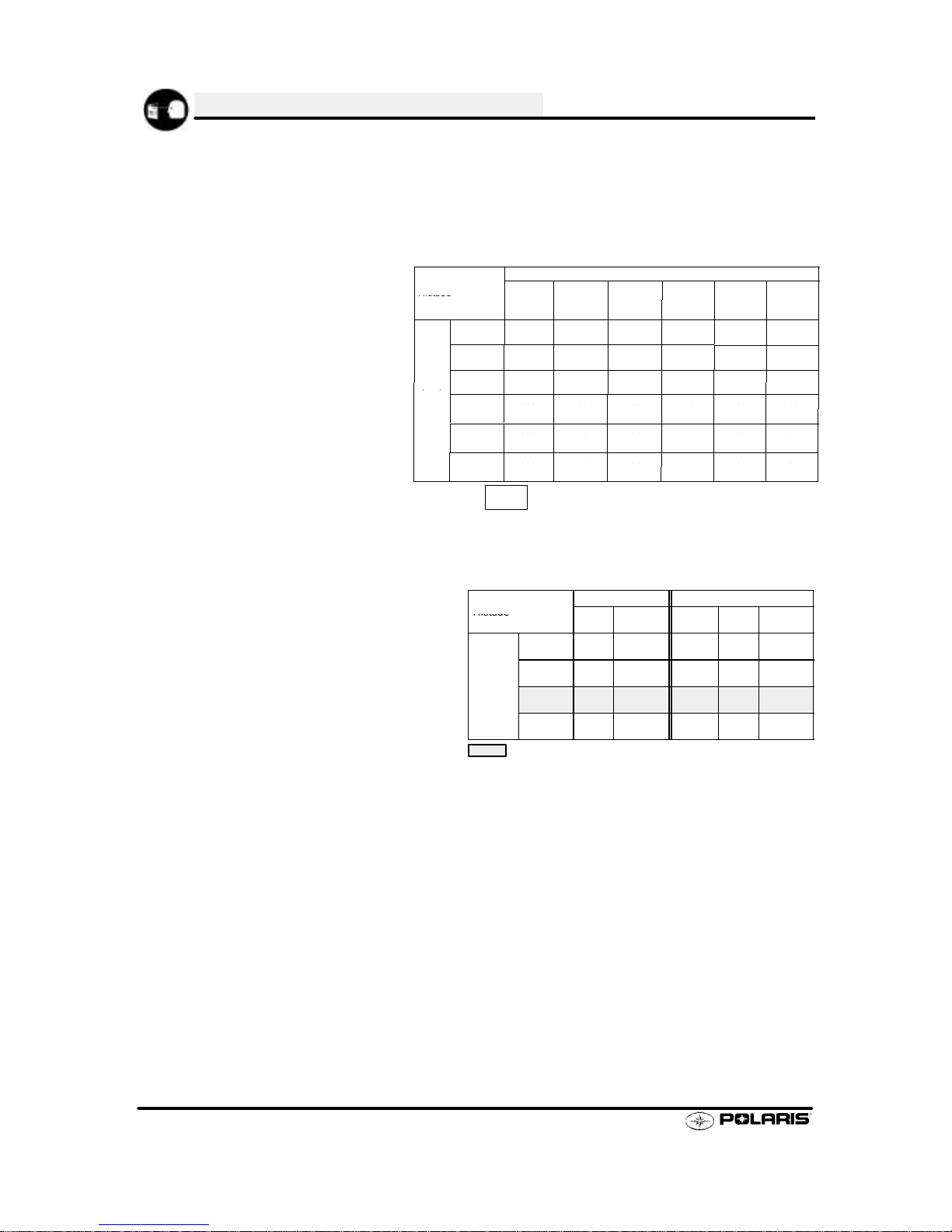

JETTING CHART

AMBIENT TEMPERATURE

Altitude

Below -30°F

Below -34°C

-30

_ to --10_F

-34_to -23_C

-- 1 0

_to +10_F

-23_ to --12_C

+10

_to +30_F

-12_to --1_C

+30

_to +50_F

-1_to +10_C

Above +50

_F

Above +10_C

Altitud

e

Below34

C

-

34t

o-23C

-

23t

o--12C

-

12t

o--1

C

-

1to+10CAbove+10

C

0--600

(0--2000)

390

#3

380

#3

360

#3

350

#3

330

#3

320

#3

600--1200

(2000--4000)

370

#3

360

#3

340

#3

330

#3

310

#3

300

#2

Meters

1200--1800

350

330

320

300

290

280

Meter

s

(Feet)

1200180

0

(4000--6000)

350

#3

330

#3

320

#3

300

#3

290

#2

280

#2

(

)

1800--2400

330

310

300

290

370

250

(6000--8000)

330

#3

3

0

#3

300

#3

9

0

#2

3

0

#2

5

0

#2

2400--3000

300

290

280

260

250

230

(8000--10000)

300

#3

9

0

#3

8

0

#2

6

0

#2

5

0

#2

3

0

#1

3000--3700

280

270

250

240

220

210

(10000--12000)

8

0

#3

0

#2

5

0

#2

0

#2

0

#2

0

#2

XXX

#X

- # refers to the clip position from top of jet needle.

CLUTCH CHART

DRIVE DRIVEN

Altitude

Shift Clutch Clutch Driven

Chaincase

Altitud

e

Shift

Weight

Clutc

h

Spring

Clutc

h

Spring

Drive

n

Helix

Chaincase

Gearing

Meters

0-900

1

-

D

rk Bl

R

2

18-41-68P

Meter

s

(Feet)

0-900

(0-3000)

1

0-5

6

Bushed

DarkBlue/

White

Silver

R32

#2

1

8-4

1-68P

HYVO

900-1800

1-L

lm

n

R

2

18-41-68P

900-180

0

(3000-6000)

1

0-A

L

Bushed

Almond/

Round

Silver

R32

#2

1

8-4

1-68P

HYVO

1800-2700

1

lm

n

R

2

18-41-68P

180

0-270

0

(6000-9000)

1

0

Bushed

Almond/

Round

Silver

R32

#2

1

8-4

1-68P

HYVO

2700-3700

10M

5

Almond

/R3

2

18-41-68P

270

0-370

0

(9000-12000)

10M

5

Bushed

Almond/

Round

Silver

R32

#2

1

8-4

1-68P

HYVO

- Production Setting

ENGINE

Type Liquid Cooled Case Reed Twin.......................

Displacement 500cc Fuel Pump Manuf. N/A............... .....

Bore 2.776²² (70.5mm) Fuel Pump Mark N/A....................... .......

Stroke 2.520²² (64mm) Oil Pump Manuf. Mikuni..................... .......

Piston / Cylinder Clearance 0.0045² - 0.0063² (0.11 - 0.16mm) Oil Pump Mark 2540051... ........

Service Limit N/A Cylinder Head Mark 3021048................ ....

Piston Marking 3021038..............

Piston Ring Marking N/A.........

Piston Ring End Gap 0.012² -0.018² (.30 - .46mm)........

Head ccs (Uninstalled) 27.5±.50cc.......

Head ccs (Installed) 25cc.........

Operating RPM±200 8000 RPM.........

Idle RPM±200 1500 RPM..............

Engagement RPM±300 4200 RPM......

Cylinder Head Torque 20-24 ft.lbs. (28-33Nm)........

Cylinder Base Nut Torque 30-34 ft.lbs. (41-47 Nm)....

Crankcase Torque (8mm) 20-24ft.lbs. (28-33 Nm).....

Crankcase Torque (10mm) N/A...

Flywheel Torque 90ft.lbs. (124 Nm).............

CARBURETION

Type TM 38 Mikuni................

Main Jet 370............

Pilot Jet 45.............

Jet Needle 9FH4--57/3...........

Needle Jet P-6...........

Cutaway 1.5............

Fuel Mixture Screw 2 Turns...

Valve Seat 1.5...........

Fuel Octane (R+M/2) 87 Non-Oxygenat

ed

.

89 Oxygenated

ThrottleGap

Under Cutaway 0.098² (2.5mm)......

Starter Jet 155...........

Pilot Air Jet 1.0..........

CLUTCH

Type P 85................

Belt 3211074.................

Belt Width (Projected) 1.438².

Side Angle (Overall) 28°..

Outside Circumference 47.625²

Center Distance 12.00²......

Shift Weights 10-56 Bushed........

Primary Spring Dark Blue / White.......

Secondary Spring Silver....

Driven Helix R32 #2.........

Page 22

GENERAL INFORMATION

1.15

MODEL: INDY 500 SKS EUROPEAN..........

MODEL NUMBER: E02SS5AE.

ENGINE MODEL: S2209--5044PL5A..

ELECTRICAL CAPACITIES

Flywheel I.D. 4010523 Fuel Tank 11.8 gallons (44.7 liters)...... ..........

CDI Marking 4010584 Oil Tank 3 quarts (2.8 liters)....... ............

Alternator Output 280 Watts Coolant 5 quarts (4.7 liters)... ............

Ignition Timing 12° BTDC@22500 RPM Chaincase Oil 11 fl. oz. (325cc)..... .......

0.0327² BTDC

0.8294mm BTDC

Spark Plug / Gap Champion RN2C / 0.028² (0.7mm)...

Voltage Regulator LR7..

Electric Start Option.......

LR7= Full wave voltage regulator

Magneto Pulses 6....

SUSPENSION / CHASSIS CHAINCASE

Body Style Gen II Sprockets / Chain 18-41, 68P HYVO........ ...

Front Suspension Indy XC 10 Reverse Option.. ............

Front Shocks Indy Select Brake Pads Type 81, Large...... .........

IFS Spring Rate 100#/in. Chaincase Center Dist.7.05² (17.91cm)....

Front Spring Preload 3/4² Thread Adjust Driveshaft Sprockets 2 Drivers Wide.

Front Vertical Travel 9.6² (24.4cm) Brake Type Polaris HPB.........

Rear Suspension XTRA-10 EURO...

Rear Axle Travel 9.5² (24.1cc)...

Front Track Shock Nitrogen Cell..

Spring Rate 190#/in. variable........

Rear Track Shock Indy Select..

Rear Springs .405² (sq.) / 77°......

Track Type 15²x136²x1.25² (38.1x345.44x3.175cm)........

Track Tension 3/8² -1/2² (1-1.3 cm) slack with 10# (4.54kg) weight 16² (40.64cm) ahead of rear idler......

shaft.

Overall Snowmobile Length 116² (295cm).................

Overall Snowmobile Height 45² (114cm).................

Maximum Snowmobile Width 43.5² (110.5cm)...............

OPTIONAL REAR TORSION SPRINGS

(STD)

.405²(Sq.) Diameter x 77°

L.H. 7041655--067

R.H 7041655--067

Page 23

GENERAL INFORMATION

1.16

MODEL: INDY 500 RMK..........

MODEL NUMBER: S02SR5AS.

ENGINE MODEL: S2186--5044PL5A..

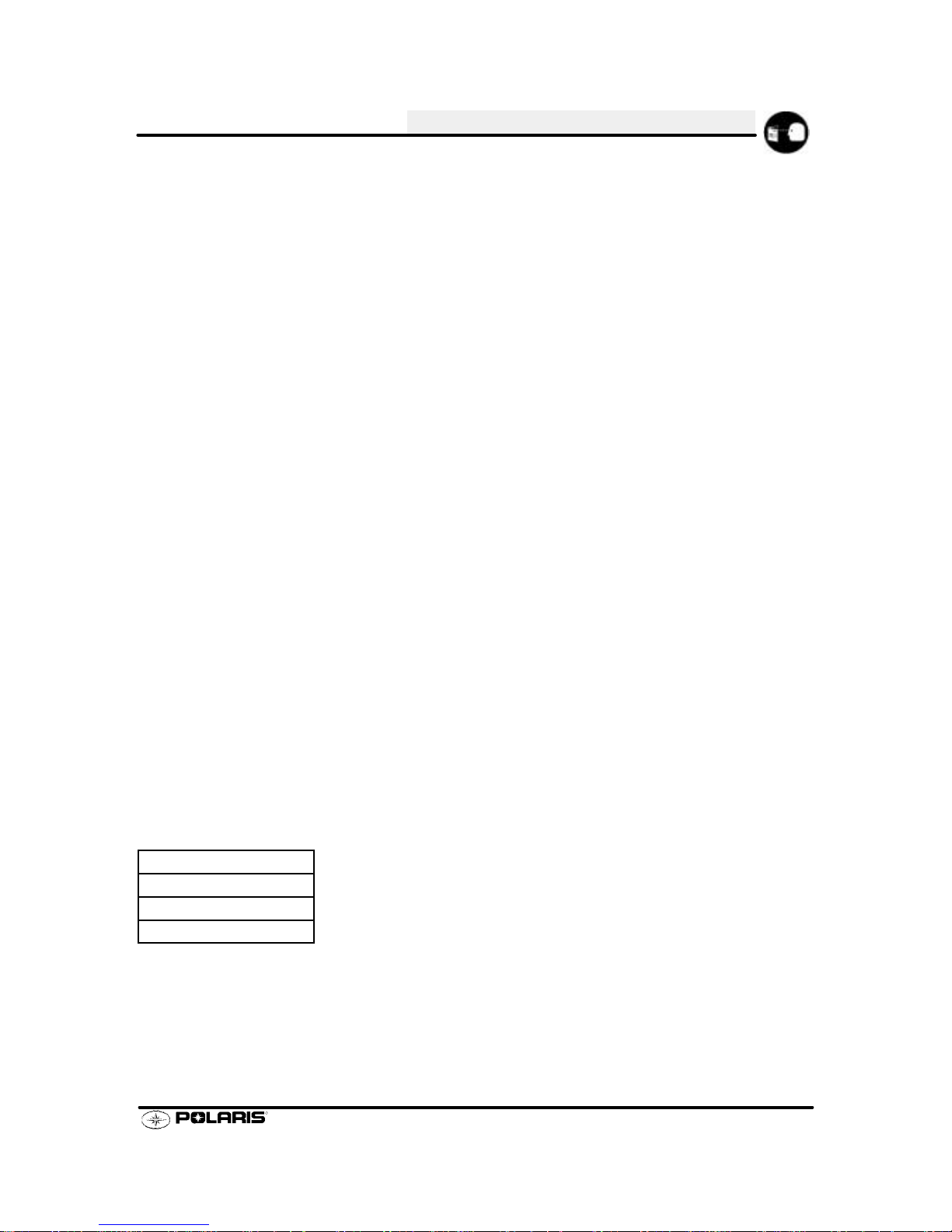

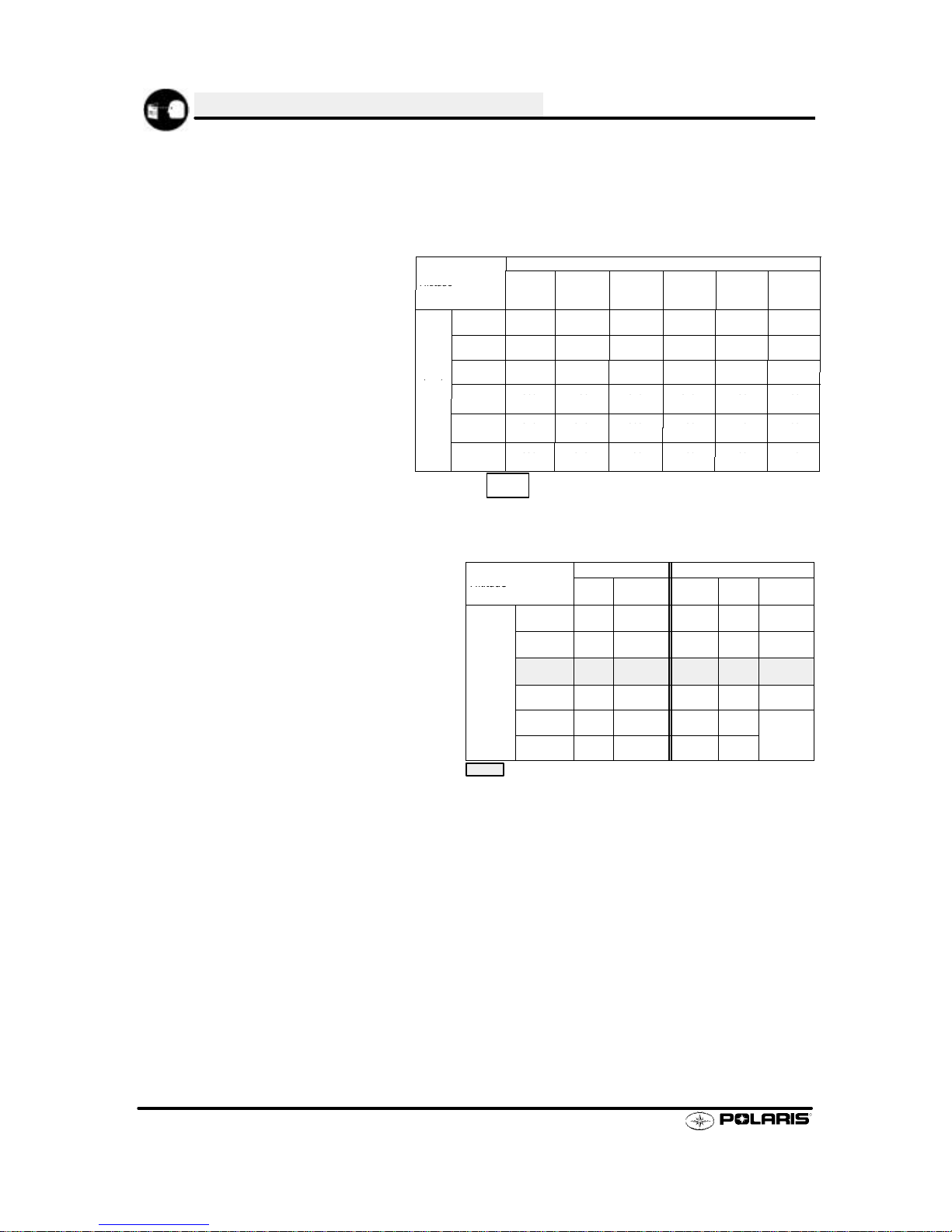

JETTING CHART

AMBIENT TEMPERATURE

Altitude

Below -30°F

Below -34°C

-30

_ to --10_F

-34_to -23_C

-- 1 0

_to +10_F

-23_ to --12_C

+10

_to +30_F

-12_to --1_C

+30

_to +50_F

-1_to +10_C

Above +50

_F

Above +10_C

Altitud

e

Below34

C

-

34t

o-23C

-

23t

o--12C

-

12t

o--1

C

-

1to+10CAbove+10

C

0--600

(0--2000)

440

#3

420

#3

410

#3

390

#3

380

#3

370

#3

600--1200

(2000--4000)

390

#3

380

#3

370

#3

350

#3

340

#2

320

#2

Meters

1200--1800

350

330

320

310

300

290

Meter

s

(Feet)

1200180

0

(4000--6000)

350

#2

330

#2

320

#2

310

#2

300

#2

290

#2

(

)

1800--2400

300

290

280

270

260

250

(6000--8000)

300

#2

9

0

#2

8

0

#2

0

#2

6

0

#2

5

0

#2

2400--3000

280

270

260

250

240

230

(8000--10000)

8

0

#2

0

#2

6

0

#2

5

0

#2

0

#2

3

0

#2

3000--3700

260

250

240

230

220

210

(10000--12000)

6

0

#2

5

0

#2

0

#2

3

0

#2

0

#2

0

#2

XXX

#X

- # refers to the clip position from top of jet needle.

CLUTCH CHART

DRIVE DRIVEN

Altitude

Shift Clutch Clutch Driven

Chaincase

Altitud

e

Shift

Weight

Clutc

h

Spring

Clutc

h

Spring

Drive

n

Helix

Chaincase

Gearing

Meters

0-900

10-

56Almond

S

ilver/R-32

18-41-68P

Meter

s

(Feet)

0-900

(0-3000)

1

0-5

6

Bushed

Almon

d

Round

Silver/

Blue

R-3

2

#3

1

8-4

1-68P

HYVO

900-1800

10-ALAlmon

d

S

ilver/R-32

18-41-68P

900-180

0

(3000-6000)

1

0-A

L

Bushed

Almon

d

Round

Silver/

Blue

R-3

2

#3

1

8-4

1-68P

HYVO

1800-2700

1

0

Almond

S

ilver/R-32

18-41-68P

180

0-270

0

(6000-9000)

1

0

Bushed

Almon

d

Round

Silver/

Blue

R-3

2

#3

1

8-4

1-68P

HYVO

2700-3700

1

M

lm

n

ilv

r

R-

2

18-41-68P

270

0-370

0

(9000-12000)

10M

Bushed

Almon

d

Round

Silver/

Blue

R-3

2

#3

1

8-4

1-68P

HYVO

- Production Setting

ENGINE

Type Liquid Cooled Case Reed Twin.......................

Displacement 500cc Fuel Pump Manuf. Walbro............... .....

Bore 2.776² (70.5mm) Fuel Pump Mark FPA-3....................... .......

Stroke 2.520² (64mm) Oil Pump Manuf. Mikuni..................... .......

Piston / Cylinder Clearance 0.0045² -0.0063² (0.11 - 0.16mm) Oil Pump Mark 2540051... ........

Service Limit 0.0063” (0.16mm) Cylinder Head Mark 3021048................ ....

Piston Marking N/A..............

Piston Ring Marking N/A.........

Piston Ring End Gap 0.012² -0.018² (0.30 - 0.46mm)........

Head ccs (Uninstalled) 27.5±0.5cc.......

Head ccs (Installed) 25.0cc.........

Operating RPM±200 8000 RPM.........

Idle RPM±200 1500 RPM..............

Engagement RPM±300 4500 RPM......

Cylinder Head Torque 20-24 ft.lbs. (28-33Nm)........

Cylinder Base Nut Torque 30-34 ft.lbs. (41-47 Nm)....

Crankcase Torque (8mm) 20-24ft.lbs. (28-33 Nm).....

Crankcase Torque (10mm) N/A...

Flywheel Torque 90ft.lbs. (124 Nm).............

CARBURETION

Type TM38 Mikuni................

Main Jet 270............

Pilot Jet 45.............

Jet Needle 9FH4-57-2...........

Needle Jet P-6...........

Cutaway 1.5 Notched............

Fuel Screw 0.5 Turns..........

Valve Seat 1.5 Viton...........

Fuel Octane (R+M/2) 87 Non-Oxygenated.

89 Oxygenated

ThrottleGap

Under Cutaway 0.130² (3.3mm)......

Starter Jet 155...........

Pilot Air Jet 0.7 Long..........

CLUTCH

Type P-85................

Belt 3211074.................

Belt Width (Projected) 1.438² (36.52mm).

Side Angle (Overall) 28°..

Outside Circumference 47.625² (121cm)

Center Distance 12.00²......

Shift Weights 10 Bushed........

Primary Spring Almond Round.......

Secondary Spring Silver / Blue....

Driven Helix R-32 #3.........

Page 24

GENERAL INFORMATION

1.17

MODEL: INDY 500 RMK..........

MODEL NUMBER: S02SR5AS.

ENGINE MODEL: S2186--5044PL5A..

ELECTRICAL CAPACITIES

Flywheel I.D. Kokusan 4060223 Fuel Tank 11.8 gallons (44.7 liters)...... ..........

CDI Marking 4010259 Oil Tank 3 quarts (2.8 liters)....... ............

Alternator Output 280 Watts Coolant 5 quarts (4.7 liters)... ............

Ignition Timing 22° BTDC@3000RPM±1.5° Chaincase Oil 9 fl. oz.(266cc)..... .......

0.1139² BTDC (±0.0175²)

2.8927mm BTDC (±0.48mm)

Spark Plug / Gap Champion RN2C / 0.025² (0.64mm)...

Voltage Regulator LR7..

Electric Start Option.......

LR7= Full wave voltage regulator

Magneto Pulses 6....

SUSPENSION / CHASSIS CHAINCASE

Body Style Gen II Sprockets / Chain 18-41, 68P HYVO........ ...

Front Suspension Indy X-10 38² CRC Reverse Option.. ............

Front Shocks Nitrogen Cell Brake Pads Type 81, Large...... .........

IFS Spring Rate 100#/in. Chaincase Center Dist.7.05² (17.91cm)....

Front Spring Preload 1/8² Thread Adjust Driveshaft Sprockets 2 Drivers Wide.

Front Vertical Travel 8.05 in.(21cm) Brake Type Polaris HPB.........

Rear Suspension XTRA-Lite 136²...

Rear Axle Travel 12² (30.5cm)...

Front Track Shock Nitrogen Cell..

Spring Rate 200#/in. variable........

Rear Track Shock Indy Select..

Rear Springs .347² (sq.) / 77°......

Track Type 15²x136²x1.5² (38.1x345.44x3.81cm)........

Track Tension 3/8² -1/2² (1-1.3 cm) slack with 10# (4.54kg) weight 16² (40.64cm) ahead of rear idler......

shaft.

Overall Snowmobile Length 116² (295cm).................

Overall Snowmobile Height 45² (114cm).................

Maximum Snowmobile Width 43.5² (110.4cm)...............

OPTIONAL REAR TORSION SPRINGS

(STD) FIRM

.347²(Sq.) Diameter x 77° .375” (Sq.) Diameter x 77____

L.H. 7041627--067 L.H. 7041631--067

R.H 7041628--067 R.H. 7041632--067

Page 25

GENERAL INFORMATION

1.18

MODEL: INDY TRAIL RMK..........

MODEL NUMBER: S02SR5BS.

ENGINE MODEL: EC55PM024..

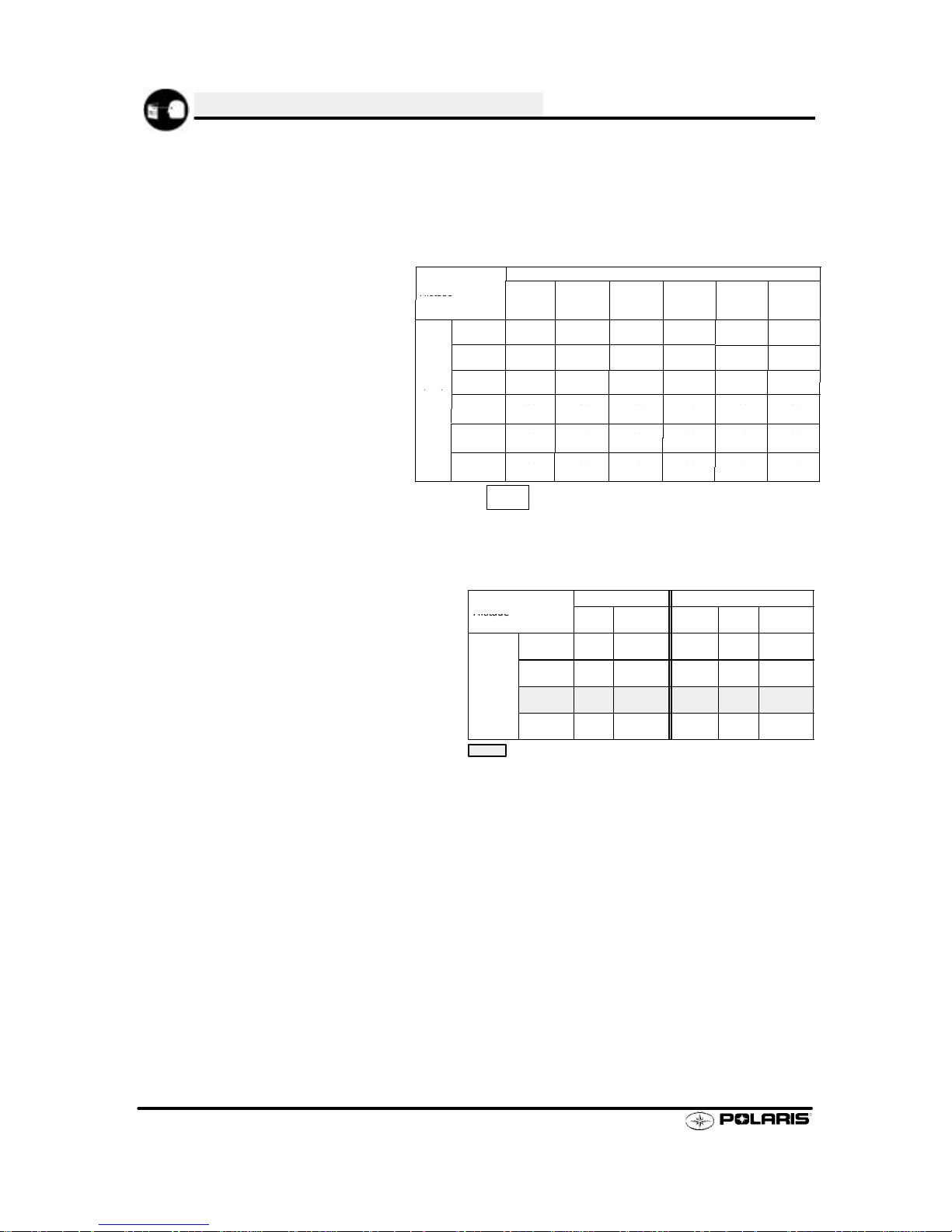

JETTING CHART

AMBIENT TEMPERATURE

Altitude

Below -30°F

Below -34°C

-30

_ to --10_F

-34_to -23_C

-- 1 0

_to +10_F

-23_ to --12_C

+10

_to +30_F

-12_to --1_C

+30

_to +50_F

-1_to +10_C

Above +50

_F

Above +10_C

Altitud

e

Below34

C

-

34t

o-23C

-

23t

o--12C

-

12t

o--1

C

-

1to+10CAbove+10

C

0--600

(0--2000)

300

#3

290

#3

280

#3

270

#3

260

#3

250

#3

600--1200

(2000--4000)

300

#3

290

#3

280

#3

270

#3

260

#3

250

#3

Meters

1200--1800

300

290

280

270

260

250

Meter

s

(Feet)

1200180

0

(4000--6000)

300

#3

290

#3

280

#3

270

#3

260

#3

250

#3

(

)

1800--2400

300

290

280

270

260

250

(6000--8000)

300

#3

9

0

#3

8

0

#3

0

#3

6

0

#3

5

0

#3

2400--3000

300

290

280

270

260

250

(8000--10000)

300

#3

9

0

#3

8

0

#3

0

#3

6

0

#3

5

0

#3

3000--3700

300

290

280

270

260

250

(10000--12000)

300

#3

9

0

#3

8

0

#3

0

#3

6

0

#3

5

0

#3

XXX

#X

- # refers to the clip position from top of jet needle.

CLUTCH CHART

DRIVE DRIVEN

Altitude

Shift Clutch Clutch Driven

Chaincase

Altitud

e

Shift

Weight

Clutc

h

Spring

Clutc

h

Spring

Drive

n

Helix

Chaincase

Gearing

Meters

0-900

10-62 Dark Bl

ue/

S

ilver/R-32

18-41-68P

Meter

s

(Feet)

0-900

(0-3000)

1

0-6

2

Bushed

DarkBlue/

White

Silver/

Blue

R-3

2

#2

1

8-4

1-68P

HYVO

900-1800

10-

5

8Da

rk Bl

ue/

S

ilver/R-32

18-41-68P

900-180

0

(3000-6000)

1

0-5

8

Bushed

DarkBlue/

White

Silver/

Blue

R-3

2

#2

1

8-4

1-68P

HYVO

1800-2700

10-

5

6Da

rk Bl

ue/

S

ilver/R-32

18-41-68P

180

0-270

0

(6000-9000)

1

0-5

6

Bushed

DarkBlue/

White

Silver/

Blue

R-3

2

#2

1

8-4

1-68P

HYVO

2700-3700

1-4 D

rk Bl

ilv

r

R-

2

18-41-68H

270

0-370

0

(9000-12000)

1

0-5

4

Bushed

DarkBlue/

White

Silver/

Blue

R-3

2

#2

1

8-4

1-68H

YVO

- Production Setting

ENGINE

Type Fan Cooled Reed Assist Twin.......................

Displacement 544cc Fuel Pump Manuf. T aiyo............... .....

Bore 2.874² (73mm) FuelPump Mark FJP-3-100....................... .......

Stroke 2.559² (65mm) Oil Pump Manuf. Mikuni..................... .......

Piston / Cylinder Clearance 0.0035² -0.0049² (0.09 - 0.125mm) Oil Pump Mark 55MB... ........

Service Limit 0.0078² (0.20mm) Cylinder Head Mark EC55PM................ ....

Piston Marking 5MB..............

Piston Ring Marking N.........

Piston Ring End Gap 0.016² -0.022² (0.40 - 0.55mm)........

Head ccs (Uninstalled) 33.8±0.4cc.......

Head ccs (Installed) 27.7cc.........

Operating RPM±200 6800 RPM.........

Idle RPM±200 1600 RPM..............

Engagement RPM±300 3800 RPM......

Cylinder Head Torque 18-19.5 ft.lbs. (25-27 Nm)........

Cylinder Base Nut Torque 24-28 ft.lbs. (33-39 Nm)....

Crankcase Torque (8mm) 16.6-18ft.lbs. (23-35 Nm).....

Crankcase Torque (10mm) N/A...

Flywheel T orque 60-65 ft.lbs. (83-90Nm).............

CARBURETION

Type VM34SS Mikuni................

w/ACCS

Main Jet 270............

Pilot Jet 35.............

Jet Needle 6DEH11-3...........

Needle Jet Q-0 (480)...........

Cutaway 3.0............

Air Screw 1.5 Turns...........

Valve Seat 1.5 Viton...........

Fuel Octane (R+M/2) 87 Non-Oxygenated.

Throttle Gap 89 Oxygenated

Under Cutaway .218² (5.54mm)......

CLUTCH

Type P-85................

Belt 3211070.................

Belt Width (Projected) 1.375² (34.93).

Side Angle (Overall) 28°..

Outside Circumference 47.250² (120cm)

Center Distance 12.00²......

Shift Weights 10-56 Bushed........

Primary Spring Dark Blue / White.......

Secondary Spring Silver / Blue....

Driven Helix R-32 #2.........

Page 26

GENERAL INFORMATION

1.19

MODEL: INDY TRAIL RMK..........

MODEL NUMBER: S02SR5BS.

ENGINE MODEL: EC55PM024..

ELECTRICAL CAPACITIES

Flywheel I.D. Mitsubishi Fuel Tank 11.8 gallons (44.7 liters)...... ..........

CDI Marking 17620111 Oil Tank 3 quarts (2.8 liters)....... ............

Alternator Output 240 Watts Coolant N/A... ............

Ignition Timing 27° BTDC@3500RPM±1.5° Chaincase Oil 9 fl. oz.(266cc)..... .......

0.175² BTDC (±0.157² -0.195²)

4.45mm BTDC (±3.97 - 4.93mm)

Spark Plug / Gap NGK BR9ES / 0.028² (0.7mm)...

Voltage Regulator LR7..

Electric Start Option.......

LR7= Full wave voltage regulator

Magneto Pulses 6....

SUSPENSION / CHASSIS CHAINCASE

Body Style Gen II Sprockets / Chain 18-41, 68P HYVO........ ...

Front Suspension Indy XTRA 38² Reverse Option.. ............

Front Shocks Nitrogen Cell Brake Pads Type 81, Small...... .........

IFS Spring Rate 80#/in. Chaincase Center Dist.7.05² (17.9cm)....

Front Spring Preload 5/16² Thread Adjust Driveshaft Sprockets 2 Drivers.

Front Vertical Travel 8.25² (21cm) Brake Type Polaris HPB.........

Rear Suspension XTRA-Lite 136²...

Rear Axle Travel 12² (30.5cm)...

Front Track Shock Nitrogen Cell..

Spring Rate 181#/in.........

Rear Track Shock Indy Select..

Rear Springs .347² (sq.) / 77°......

Track Type 15²x136²x.1.25² (38.1x345.44x3.175cm)........

Track Tension 3/8² -1/2² (1-1.3 cm) slack with 10# (4.54kg) weight 16² (40.64cm) ahead of rear idler......

shaft.

Overall Snowmobile Length 116² (295cm).................

Overall Snowmobile Height 45² (114cm).................

Maximum Snowmobile Width 43.5² (110.5cm)...............

OPTIONAL REAR TORSION SPRINGS

SOFT MEDIUM(STD) FIRM

.347²(Sq.) Diameter x 77° .375”(Sq.) Diameter x 77°

L.H . L.H. 7041627--067 L.H. 7041631--067

R.H. R.H. 7041628--067 R.H. 7041632--067

Page 27

GENERAL INFORMATION

1.20

MODEL: 600 EDGE RMK..........

MODEL NUMBER: S02NJ6ES.

ENGINE MODEL: S2187--6044PL6E..

JETTING CHART

AMBIENT TEMPERATURE

Altitude

Below -30°F

Below -34°C

-30

_ to --10_F

-34_to -23_C

-- 1 0

_to +10_F

-23_ to --12_C

+10

_to +30_F

-12_to --1_C

+30

_to +50_F

-1_to +10_C

Above +50

_F

Above +10_C

Altitud

e

Below34

C

-

34t

o-23C

-

23t

o--12C

-

12t

o--1

C

-

1to+10CAbove+10

C

0--600

(0--2000)

450

#4

430

#4

420

#3

400

#3

380

#3

370

#3

600--1200

(2000--4000)

410

#4

390

#3

380

#3

360

#3

340

#3

330

#2

Meters

1200--1800

380

360

350

330

320

300

Meter

s

(Feet)

1200180

0

(4000--6000)

380

#3

360

#3

350

#3

330

#3

320

#2

300

#2

(

)

1800--2400

360

430

320

310

290

280

(6000--8000)

360

#3

430

#3

320

#3

310

#2

290

#2

280

#2

2400--3000

340

320

300

290

270

260

(8000--10000)

3

0

#3

3

0

#3

300

#2

9

0

#2

0

#2

6

0

#2

3000--3700

330

310

290

280

260

240

(10000--12000)

330

#2

3

0

#2

9

0

#2

8

0

#2

6

0

#2

0

#2

XXX

#X

- # refers to the clip position from top of jet needle.

CLUTCH CHART

DRIVE DRIVEN

Altitude

Shift Clutch Clutch Driven

Chaincase

Altitud

e

Shift

Weight

Clutc

h

Spring

Clutc

h

Spring

Drive

n

Helix

Chaincase

Gearing

Meters

0-900

10-

6

0Bla

ck/

S

ilver/R-32

19-39 72P

Meter

s

(Feet)

0-900

(0-3000)

1

0-6

0

Bushed

Black

/

Green

Silver/

Blue

R-3

2

#3

1

9-3972P

HYVO

900-1500

10-

5

8Bla

ck/

S

ilver/R-32

19-39 72P

900-150

0

(3000-6000)

1

0-5

8

Bushed

Black

/

Green

Silver/

Blue

R-3

2

#3

1

9-3972P

HYVO

1500-2100

1

-

Bl

k

ilv

r

R-

2

19-39 72P

150

0-210

0

(6000-9000)

1

0-5

6

Bushed

Black

/

Green

Silver/

Blue

R-3

2

#3

1

9-3972P

HYVO

2100-2700

(7000-9000)

10 54

Bushed

Black/

Green

Silver /

Blue

R-32

#3

19-39 72P

HYVO

2700-3350

(9000-11000)

10AL

Bushed

Black/

Green

Silver /

Blue

R-32#319-39 72P

HYVO

3350--4000

(11000-13000)

10

Bushed

Black/

Green

Silver /

Blue

R-32

#3

19-39 72P

HYVO

- Production Setting

ENGINE

Type Liquid Cooled Case Reed w/TPS.......................

Displacement 593cc Fuel Pump Manuf. Walbro............... .....

Bore 2.9930² 3.041² (77.25mm) Fuel Pump Mark N/A....................... .......

Stroke 2.520 (64mm) Oil Pump Manuf. Mikuni..................... .......

Piston / Cylinder Clearance 0.0044² -0.0058² (0.11 - 0.15mm) Oil Pump Mark 2540097... ........

Service Limit .0059” (0.15mm) Cylinder Head Mark 3022057................ ....

Piston Marking 3021088..............

Piston Ring Marking N/A.........

Piston Ring End Gap 0.012² -0.018² (0.30 - 0.46mm)........

Head ccs (Uninstalled) 36.0cc.......

Head ccs (Installed) 29.0cc.........

Operating RPM±200 8000 RPM.........

Idle RPM±200 1500 RPM..............

Engagement RPM±300 N/A RPM......

Cylinder Head Torque 18-22 ft.lbs. (25-30Nm)........

Cylinder Base Nut Torque 30-34 ft.lbs. (41-47 Nm)....

Crankcase Torque (8mm) 20-24ft.lbs. (28-33 Nm).....

Crankcase Torque (10mm) 26-30ft.lbs. (36-41 Nm)...

CARBURETION

Type TM 38 w/TPS Mikuni................

Main Jet 310............

Pilot Jet 45.............

Jet Needle 9DGI1--60--2...........

Needle Jet P-8 (825)...........

Cutaway 1.5 Notched............

Fuel Screw 2.0 Turns..........

Valve Seat 1.5...........

Fuel Octane (R+M/2) Key Switch Adj..

Premium 91

Regular 87 Non-Oxy.

ThrottleGap

Under Cutaway 0.102² (2.6mm)......

Starter Jet 140...........

Pilot Air Jet N/A..........

Exhaust Spring Green/White

Low Elevation Exhaust

Valve Spring Pink.........

CLUTCH

Type P-85................

Belt 3211080.................

Belt Width (Projected) 1.438² (36.53mm).

Side Angle (Overall) 28°..

Outside Circumference 48.375² (122.87cm)

Center Distance 11.5²......

Shift Weights 10-56 Bushed........

Primary Spring Black/Green.......

Secondary Spring Silver / Blue....

Driven Helix R-32#3.........

Page 28

GENERAL INFORMATION

1.21

MODEL: 600 EDGE RMK..........

MODEL NUMBER: S02NJ6ES.

ENGINE MODEL: S2187--6044PL6E..

ELECTRICAL CAPACITIES

Flywheel I.D. 4010629 Fuel Tank 11.8 gallons (44.7 liters)...... ..........

CDI Marking 4010554 Oil Tank 3.25 quarts (3.07 liters)....... ............

Alternator Output 280 Watts Coolant 4.3 quarts (4.07 liters)... ............

Ignition Timing 24_@3500RPM±500° Chaincase Oil 11 fl. oz.(325cc)..... .......

With TPS Unplugged.

.1350² BTDC

3.43mm BTDC

Spark Plug / Gap Champion RN57YCC / 0.025² (0.64mm)...

Voltage Regulator T1..

Electric Start Option.......

Magneto Pulses 6....

SUSPENSION / CHASSIS CHAINCASE

Body Style EDGE RMK Sprockets / Chain 19-39 72P HYVO........ ...

Front Suspension EDGE RMK Reverse Option.. ............

Front Shocks Nitrex Brake Pads Type 81, Large...... .........

IFS Spring Rate 100#/in. Chaincase Center Dist.7.92² (20.12cm)....

Front Spring Preload 3/4² Thread Adjust Driveshaft Sprockets 2 Drivers Wide, XHS.

Front Vertical Travel 7.2² -7.6² (18.3 - 19.3cm) Brake Type Polaris HPB Liquid Cooled.........

Rear Suspension EDGE RMK...

Rear Axle Travel 13.8² (35cm)...

Front Track Shock Nitrex..

Spring Rate 170#/in.........

Rear Track Shock Indy Select..

Rear Springs .375² (sq.) / 77°......

Track Type 15²x136²x1.75² (38.1x345.44x4.45cm)........

Track Tension 3/8² -1/2² (1-1.3 cm) slack with 10# (4.54kg) weight 16² (40.64cm) ahead of rear idler......

shaft.

Overall Snowmobile Length 102.5² (306cm).................

Overall Snowmobile Height 47.5² (120.7cm).................

Maximum Snowmobile Width 47.25² (120cm)...............

OPTIONAL REAR TORSION SPRINGS

SOFT (STD) FIRM

-- .347²²²²(Sq.) Diameter x 77°°°° .359²²²²(Sq.) Diameter x 77°

°°

°

N/A L.H.(136” ) 7041627--067 L.H.(136”) 7041629--067

N/A R.H.(136”) 7041628--067 R.H.(136”) 7041630--067

.347²²²²(Sq.) Diameter x 47°°°° .359²²²²(Sq.) Diameter x 47°°°° .375²²²²(Sq.) Diameter x 47°

°°

°

L.H.(144”/151”)

7042081--067

L.H.(144”/151”)

7042068--067

L.H.(144”/151”)

7042079--067

R.H.(144”/151”)

7042082--067

R.H.(144”/151”)

7042069--067

R.H.(144”/151”)

7042080--067

Page 29

GENERAL INFORMATION

1.22

MODEL: INDY 700 SKS / (EUROPEAN MODEL)..........

MODEL NUMBER: S02SS7CS / (E02SS7CE

).

ENGINE MODEL: S2189--7070PL7C..

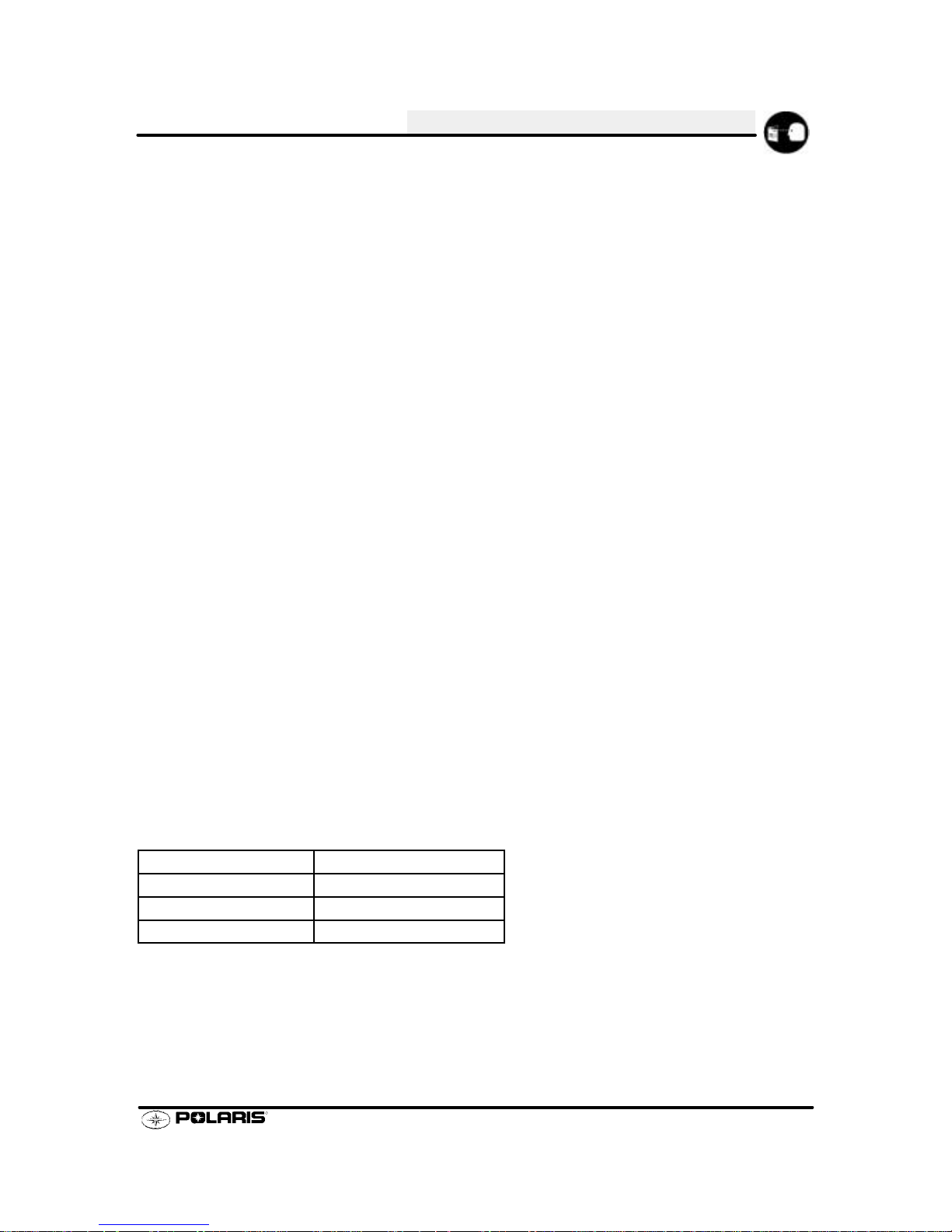

JETTING CHART

AMBIENT TEMPERATURE

Altitude

Below -30°F

Below -34°C

-30

_ to --10_F

-34_to -23_C

-- 1 0

_to +10_F

-23_ to --12_C

+10

_to +30_F

-12_to --1_C

+30

_to +50_F

-1_to +10_C

Above +50

_F

Above +10_C

Altitud

e

Below34

C

-

34t

o-23C

-

23t

o--12C-12t

o--1

C

-

1to+10CAbove+10

C

0--600

(0--2000)

450

#3

440

#3

420

#3

400

#3

390

#2

370

#2

600--1200

(2000--4000)

430

#3

410

#3

390

#3

380

#3

360

#2

340

#2

Meters

1200--1800

400

390

370

350

340

320

Meter

s

(Feet)

1200180

0

(4000--6000)

400

#3

390

#3

370

#3

350

#2

340

#2

320

#1

(

)

1800--2400

380

360

340

330

310

290

(6000--8000)

380

#3

360

#3

3

0

#2

330

#2

3

0

#1

9

0

#1

2400--3000

350

340

320

300

290

270

(8000--10000)

350

#3

3

0

#2

3

0

#2

300

#1

9

0

#1

0

#1

3000--3700

330

310

290

280

260

240

(10000--12000)

330

#2

3

0

#2

9

0

#1

8

0

#1

6

0

#1

0

#1

XXX

#X

- # refers to the clip position from top of jet needle.

CLUTCH CHART

DRIVE DRIVEN

Altitude

Shift Clutch Clutch Driven

Chaincase

Chaincase

Altitud

e

Shift

Weight

Clutc

h

Spring

Clutc

h

Spring

Drive

n

Helix

Chaincase

Gearing

Gearing

European

Meters

0-900

1

-

Bl

k

ilv

r

R

23-40-70P

23-40-70P

Meter

s

(Feet)

0-900

(0-3000)

1

0-5

8

Bushed

Black

/

Green

Silver/

Blue

R

8

#2

2

3-4

0-70P

HYVO

234070P

HYVO

900-1800

1

-

Bl

k

ilv

r

R

23-40-70P

23-40-70P

900-180

0

(3000-6000)

1

0-5

6

Bushed

Black

/

Green

Silver/

Blue

R

8

#2

2

3-4

0-70P

HYVO

234070P

HYVO

1800-2700

10-54 Bl

a

ck/

S

ilver/R

8

21-41-70P

21-41-70P

180

0-270

0

(6000-9000)

1

0-5

4

Bushed

Black

/

Green

Silver/

Blue

R

8

#2

2

1-4

1-70P

HYVO

214170P

HYVO

2700-3700

10-AL Bl

a

ck/

S

ilver/R

8

21-41-70P

21-41-70P

270

0-370

0

(9000-12000)

1

0-A

L

Bushed

Black

/

Green

Silver/

Blue

R

8

#2

2

1-4

1-70P

HYVO

214170P

HYVO

- Production Setting

ENGINE

Type Liquid Cooled Case Reed Twin.......................

Displacement 701cc Fuel Pump Manuf. Walbro............... .....

Bore 3.1889² (81mm) Fuel Pump Mark FPA-4....................... .......

Stroke 2.6772² (68mm) Oil Pump Manuf. Mikuni..................... .......

Piston / Cylinder Clearance 0.0044² -0.0058² (0.11 - 0.15mm) Oil Pump Mark 03A... ........

Service Limit 0.0060” Cylinder Head Mark 3021022................ ....

Piston Marking 3021041..............

Piston Ring Marking N/A.........

Piston Ring End Gap 0.014² -0.020² (.36 - .51mm)........

Head ccs (Uninstalled) 37.5±.50cc.......

Head ccs (Installed) 33.5cc.........

Operating RPM±200 8250 RPM.........

Idle RPM±200 1500 RPM..............

Engagement RPM±300 4000 RPM......

Cylinder Head Torque 18-22 ft.lbs. (25-30Nm)........

Cylinder Base Nut Torque 30-34 ft.lbs. (41-47 Nm)....

Crankcase Torque (8mm) 20-24ft.lbs. (28-33 Nm).....

Crankcase Torque (10mm) 26-30ft.lbs. (36-42 Nm)...

Flywheel Torque 90ft.lbs. (124 Nm).............

CARBURETION

Type TM40 Mikuni................

Main Jet 420............

Pilot Jet 38.............

Jet Needle 9DFH10--57 / 3...........

Needle Jet P--8...........

Cutaway 1.5............

Air Screw N/A...........

Valve Seat 1.8...........

Fuel Octane (R+M/2) 87 Non-Oxygenated.

89 Oxygenated

ThrottleGap

Under Cutaway (2.0mm)......

Starter Jet 145...........

Pilot Air Jet 1.1Long..........

Exhaust Valve Spring Green/Yellow.

CLUTCH

Type P-85................

Belt 3211065.................

Belt Width (Projected) 1.438² (3.63cm).

Side Angle (Overall) 28°..

Outside Circumference 48.375² (122.87cm)

Center Distance 12.50²......

Shift Weights 10-58 Bushed........

Primary Spring Black/Green.......

Secondary Spring Silver / Blue....

Driven Helix R8 #2.........

Page 30

GENERAL INFORMATION

1.23

MODEL: INDY 700 SKS / (EUROPEAN MODEL)..........

MODEL NUMBER: S02SS7CS / (E02SS7CE

).

ENGINE MODEL: S2189--7070PL7C..

ELECTRICAL CAPACITIES

Flywheel I.D. 4010523 Fuel Tank 11.8 gallons (44.7 liters)...... ..........

CDI Marking 4010587 Oil Tank 3 quarts (2.8 liters)....... ............

Alternator Output 280 Watts Coolant 5.5/ 6

quarts (5.2 / 5.7 liters)... ............

Ignition Timing 18° @3000RPM±500 Chaincase Oil 9 / 11

fl. oz.(266 / 325cc)..... .......

0.0815² BTDC

2.075mm BTDC

Spark Plug / Gap Champion RN57YCC / 0.025² (0.64mm)...

Voltage Regulator LR7..

Electric Start Option.......

LR7= Full wave voltage regulator

Magneto Pulses 6....

SUSPENSION / CHASSIS CHAINCASE

Body Style Gen II Sprockets / Chain 23-40-70P HYVO........ ...

Front Suspension Indy XC 10 Reverse Option.. ............

Front Shocks Indy Select Brake Pads Type 81, Large...... .........

IFS Spring Rate 100#/in. Chaincase Center Dist.7.05² (17.91cm)....

Front Spring Preload 3/4² Thread Adjust Driveshaft Sprockets 2 Drivers Wide.

Front Vertical Travel 9.6² (24.4cm) Brake Type Polaris HPB, Liquid Cooled.........

Rear Suspension XTRA-10 136², (XTRA 10 European)...

Rear Axle Travel 9.5 in.(24.1cm)...

Front Track Shock Nitrogen Cell..

Spring Rate 200#/in. variable........

Rear Track Shock Indy Select..

Rear Springs .359² (sq.) / 77°......

Track Type 15²x136²x1.25² (38.1x345.44x3.175cm)........

Track Tension 3/8² -1/2² (1-1.3 cm) slack with 10# (4.54kg) weight 16² (40.64cm) ahead of rear idler......

shaft.

Overall Snowmobile Length 116² (295cm).................

Overall Snowmobile Height 45² (114cm).................

Maximum Snowmobile Width 48² (122cm)...............

OPTIONAL REAR TORSION SPRINGS (700 SKS)

SOFT MEDIUM(STD) FIRM

.347”(Sq.) Diameter x 77____ .359²(Sq.) Diameter x 77_ .405”(Sq.) Diameter x 77_

L.H. 7041627--067 L.H. 7041629--067 L.H. 7041655--067

R.H. 7041628--067 R.H. 7041630--067 R.H. 7041656--067

Page 31

GENERAL INFORMATION

1.24

MODEL: 700 EDGE RMK 136”, 144”, 151”..........

MODEL NUMBER: S02NJ7CS, S02NK7CSA, S02NK7CS, S02NL7CS.

ENGINE MODEL: S2190--7070PL7C..

JETTING CHART

AMBIENT TEMPERATURE

Altitude

Below -30°F

Below -34°C

-30_ to - -10_F

-34_to -23_C

-- 1 0 _to +10_F

-23_ to - -12_C

+10_to +30_F

-12_to - -1_C

+30_to +50_F

-1_to +10_C

Above +50_F

Above +10_C

Altitud

e

Below34

C

-

34t

o-23C

-

23t

o--12C

-

12t

o--1

C

-

1to+10CAbove+10

C

0--600

(0--2000)

490

#4

480

#4

460

#3

440

#3

420

#3

400

#3

600--1200

(2000--4000)

470

#4

450

#3

430

#3

410

#3

390

#3

380

#2

Meters

1200--1800

440

420

400

380

370

350

Meter

s

(Feet)

1200180

0

(4000--6000)

440

#3

420#3400#3380

#3

370#2350

#2

(

)

1800--2400

410

390

370

350

340

320

(6000--8000)

0#3390

#3

3

0

#3

350

#2

3

0

#2

3

0

#2

2400--3000

380

360

340

320

310

290

(8000--10000)

380#3360

#3

3

0#23

0#23

0

#2

9

0

#2

3000--3700

350

330

320

300

280

260

(10000--12000)

350

#3

330#23

0#2300

#2

8

0#26

0

#2

XXX

#X

- # refers to the clip position from top of jet needle.

CLUTCH CHART

DRIVE DRIVEN

Altitude

Shift Clutch Clutch Driven

Chaincase

Chaincase

Altitud

e

Shift

Weight

Clutc

h

Spring

Clutc

h

Spring

Drive

n

Helix

Gearing

(136”)

Gearing

(144”,151”)

0-900

10--62 Bl

a

ck/

S

ilver/R-

8

21--41 74P

19-39 72P

0-900

(0-3000)

1

0--6

2

Bushed

Black

/

Green

Silver/

Blue

R-8#32

1--4174P

HYVO

193972P

HYVO

900-1500

1

--

Bl

k

ilv

r

R-

21--41 74P

19-39 72P

900-150

0

(3000-5000)

1

0--6

0

Bushed

Black

/

Green

Silver/

Blue

R-8#32

1--4174P

HYVO

193972P

HYVO

1500-2100

10-

5

8Bla

ck/

S

ilver/R-

8

21--41 74P

19-39 72P

Meters

150

0-210

0

(5000-7000)

1

0-5

8

Bushed

Black

/

Green

Silver/

Blue

R-8

#3

2

1--4174P

HYVO

193972P

HYVO

Meter

s

(Feet)

2100-2700

1

-