Polar Furnace G2-PLUS, G2, G3 Owner's Manual

Heater Setup

Owner’s Manual for G2, G2-Plus & G3

G-Class

Outdoor Wood Furnace

1

Wood Moisture Requirements

See Section 8.2 of this Manual

1

Polar Furnace Mfg. Inc. | 9086 RD31 NW | Sperling | MB | R0G 2M0 | www.polarfurnace.com

The G-Class indoor/outdoor hydronic heater by Polar Furnace is listed by Intertek to the applicable portions of the following

standard: ASTM E 2618-10 and/or EPA Method 28 WHH or EPA Method 28 WHH-15 and ASTM E2515-2011. The

G-Class G2-Plus indoor/outdoor hydronic heater by Polar Furnace is also listed by Intertek to the applicable portions of the

following standard: CSA B415.1-10. The G-Class indoor/outdoor hydronic heater by Polar Furnace is listed by CSA group

to the applicable portions of the following standards: UL 2523 Standard for Solid Fuel-Fired Hydronic Heating Appliances,

Water Heaters and Boilers and CAN/CSA-B366.1-11 Solid-Fuel-Fired Central Heating Appliance. The G-Class is CSA and

UL certified for indoor or outdoor installation. Indoor installations must satisfy CSA CAN/CSA-B365 installation code for

solid fuel burning appliances as well as any other applicable standards or regulations. The G-Class includes one 2-foot stainless

steel insulated chimney section. Use only stainless steel solid fuel chimneys specified by Polar Furnace to extend the chimney.

To obtain a French translation of this manual, please contact your dealer or visit www.polarfurnace.com.

(Pour obtenir une traduction française de ce manuel, s’il vous plaît contacter votre revendeur ou visitez www.polarfurnace.com.)

Specifications

8-Hour Output Rating Btu/hr 66 897 108 982 142 533

8-Hour Average Efficiency

Manufacturer’s Rated Heat

Output Capacity

Output Range Btu/hr 0 to 160 000 0 to 180 000 0 to 200 000

Annual Efficiency Rating

1

Specifications subject to change without notice

*This heater is U.S. ENVIRONMENTAL PROTECTION AGENCY certified to comply with 2015 particulate emission

standards. Not approved for sale after May 15, 2020. Under specific test conditions, this heater has been shown to deliver heat

at rates shown for the respective model above.

**This heater is U.S. ENVIRONMENTAL PROTECTION AGENCY Certified to comply with 2020 particulate emission

standards using cord fuel. Under specific test conditions, this heater has been shown to deliver heat at rates shown for the

respective model above.

Performance is a product of the combustion rate, combustion efficiency and heat exchange efficiency of a single fuel load. Results

may vary because of many additional factors including wood species, wood quality, wood quantity and moisture content of the

wood used. Efficiencies are determined under the same test conditions using higher heating value, lower heating value and

annual fuel utilization efficiency (AFUE). This wood heater has a manufacturer-set minimum low burn rate that must not be

altered. It is against federal regulations to alter this setting or otherwise operate this wood heater in a manner inconsistent with

operating instructions in this manual.

1

U of M G2* G2-Plus** G3*

lower/higher

heating value (%)

Btu/hr 160 000 180 000 200 000

lower/higher

heating value (%)

76.5/71.2 87.2/81 80.5/74.8

71.6/66.5 78.7/73.1 77.9/72.3

DO NOT OVERFIRE THIS HEATER. Attempts to achieve heat output rates that exceed heater design specifications can

result in permanent damage to the heater. Any person(s) operating a hydronic heater must comply with all applicable laws,

including but not limited to local ordinances. Improper use or failure to maintain the hydronic heater may cause nuisance

conditions. The person(s) operating a hydronic heater is/are responsible for operation in a manner that does not create a

nuisance condition. Meeting the setback distance and stack height recommendations from the manufacturer and requirements

in applicable State and local regulations may not always be adequate to prevent nuisance conditions in some areas due to

terrain or other factors. Operating and maintaining an outdoor furnace may not be suitable to every individuals’ abilities or

lifestyles. Be sure to review the Owner’s Manual for the appliance with your dealer prior to purchasing or operating this heater.

IMPORTANT: Read and fully understand this manual prior to installing and/or operating

a Polar Furnace heater. This wood heater needs periodic inspection and repair for proper

operation. It is against federal regulations to operate this wood heater in a manner

inconsistent with operating instructions in this manual.

2

Owner’s manual for Polar Furnace models: G-2 & G-3

POLAR FURNACE G-CLASS HEATER WARRANTY (v. 15-1)

The longevity of your G-Class heater will depend on how well the heater is maintained and if the wood

burned in the unit meets the wood moisture requirements specified in the owner’s manual. With proper

operation, proper maintenance and proper wood quality your new furnace will last a long time. Be sure

to understand and follow the operational and maintenance instructions included in the owner’s manual.

Polar Furnace Mfg. Inc. (The Company) warrants the water jacket and fire chamber of the heater identified herein

to be free from leaks during normal use for a period of 4 (four) years from the date of original purchase to the original

purchaser of this heater. From year 1 (one) through year 4 (four) The Company will cover the cost of repairing any

leaks in the fire chamber and water jacket onsite or at our factories including materials, parts, travel, shipping and labor.

Electric and electronic components as well as high temperature refractory and the heater housing are limited to

a 12 month 100% replacement warranty including parts, shipping, travel and labor. Only the manufacturer at

the address on this certificate will determine, in its sole and absolute discretion, all warranty issues. Any repair

work claimed under warranty must be approved in writing by The Company prior to any repairs being started.

If repair is not feasible for any reason as judged by The Company, our obligations under this warranty are limited

to providing a replacement heater per the following schedule. For the 15 year warranty period the following prorated replacement charge will apply.

Schedule of Charges for Replacement of the Complete Heater.

From 1 through 2 years Company’s then current list price less 100%

From 3 through 4 years Company’s then current list price less 100%

From 5 through 6 years Company’s then current list price less 60%

From 7 through 10 years Company’s then current list price less 25%

From 11 through to 15 years Company’s then current list price less 10%

All replacement heaters are FOB our factory unless otherwise specified in this warranty.

The warranty period on any replacement heater is from the date of the sale of the original heater.

General Conditions of this Warranty.

The warranty registration form, delivery checklist, and customer acceptance must be completely filled in and

signed by the customer and dealer and submitted to The Company for this warranty to be valid. The warranty

contained herein shall be voided if the heater is not installed, operated and maintained as instructed in the owner

manual. Using wood that does not meet the wood moisture requirements detailed in the owner’s manual voids

this warranty. The heater must never be pressurized; pressurizing the heater voids this warranty. The boiler

protection valve must be maintained as described in the owner’s manual and failure to properly maintain the

boiler protection valve voids this warranty. A properly qualified tradesperson/s should supervise or perform all

installations. If the chimney needs be extended an appropriately certified and approved insulated chimney system

must be used. The insulated chimney is not covered under this warranty. This warranty is void if the chimney

3

installation does not meet all of the installation requirements detailed in the owner’s manual. Your dealer may

charge you for a service call to do warranty work. Parts will be replaced on an even exchange basis. Polar Furnace

heaters are not intended to be the only source of heat. A backup system should be in place to prevent resultant

damage due to a lack of heat. This warranty is limited to defective parts repair and/or replacement only and

excludes any incidental and consequential damages. Door seals, door insulation, light bulbs, fire tending tools,

heat shields, Strong Wall liner, hearth plates and any other wear items are not covered under this warranty.

High temperature refractory materials are warranted for 1 year under this warranty. In use, small cracks can

occur in high temperature refractory and will not affect the performance of the heater. Damage caused by abuse,

accidents, improper use, improper installation, excess creosote buildup, overheating, freezing, corrosion, negligence,

accidents in transit, and pressurization are not covered under this warranty. Damage resulting from modifications

or alterations will not be covered under this warranty. If the serial number on the equipment is defaced, altered or

removed this warranty is void. Damage caused by burning flammable materials (such as petroleum products) or

any other material besides properly prepared wood will void this warranty. Only nontoxic antifreeze that meets

and/or is approved per all applicable regulations and standards may be used. The Company will not be responsible

for any environmental damages or charges resulting from use of toxic and or unapproved types of antifreeze.

Antifreeze will breakdown over a period of time and therefore should be tested annually to ensure adequate freeze

protection. Always dispose of antifreeze per federal, state, provincial, local or any applicable laws and regulations.

Loss of antifreeze under any situation and condition is not covered under this warranty. The Company is not

responsible for replacement of water, water treatment, antifreeze, removal, disposal, costs of transportation, or

shipping charges unless otherwise specified in this warranty. Warranty does not cover any plumbing components,

boiler piping, valves, controls or any other component or system external to the boiler package. WARNING,

The Company will not warranty the inside of the fire box due to ash corrosion. Rotation of ashes and/or removal

of ashes from the fire chamber must be performed as per the operator manual instructions. WARNING, The

Company will not warranty the water jacket due to corrosion from corrosive or improperly treated water. An

appropriate water treatment must be added and maintained and receipt retained for proof of use to establish

any warranty claims. We will not be liable to any contingency beyond our control including war, strikes, floods,

government restrictions or short supply of material. We will not be liable for any labor cost, except above schedule.

This warranty replaces and supersedes any and all other warranties, expressed or implied, directly and or indirectly

whether at law, common law, equity and/or statute and constitutes the only warranty of The Company and the

only liability of The Company. This warranty constitutes the entire agreement between the parties with respect

to the subject matter and supersedes all prior agreements, negotiations, discussions, undertakings, representations,

warranties and understandings, whether written or verbal. This Warranty is governed by, and is to be construed and

interpreted in accordance with the laws of Manitoba and the federal laws of Canada applicable in Manitoba. The

purchaser and The Company each irrevocably agree to submit to the jurisdiction of the courts of Manitoba. The

Company’s limitation of liability pursuant to any warranty shall be equivalent in all respects to the sum of $1.00.

Polar Furnace Mfg. Inc.

Box 159. Sperling, Manitoba. R0G 2M0

PH: 1-204-626-3485 FAX: 1-204-626-3326

NOTICE: To activate this warranty, the white copy of the warranty activation form (page 5) as well as a copy

of the original bill of sale (invoice) must be mailed to the Polar Furnace address above within thirty (30) days of

furnace delivery to end user.

4

Owner’s manual for Polar Furnace models: G-2 & G-3

POLAR FURNACE MFG. INC.

WARRANTY (v.15-1) ACTIVATION1 FORM—DOWN DRAFT HEATER

WARRANTY REGISTRATION FORM

Customer’s Name:____________________________ Dealership Name: ___________________________

Address:____________________________________ Address: __________________________________

City, State/Prov. Code:_________________________ City, State/Prov. Code:_______________________

Phone: (____)________________________________

Serial No.___________________________________ Date of Purchase: ____________/_______/_______

DELIVERY CHECKLIST

_____ Review owner’s manual.

_____ Identify safety hazards & demonstrate proper

operation.

_____ Review warranty and service requirements.

_____ Explain requirement that properly seasoned wood

_____ Explain required maintenance schedule.

_____ Review and explain Boiler Protection Valve

Maintenance (Manual Section 14.4)

must be used. (review manual section 8.2)

_____ No warranties are validated unless this form and

registration are completed and returned.

CUSTOMER ACCEPTANCE

I have inspected the Polar Furnace heater with the customer and reviewed all items on the delivery checklist.

I have thoroughly instructed the customer on the equipment identified herein and thoroughly reviewed the

operator’s manual. The customer has accepted responsibility for the operation and maintenance of the product

identified herein.

Date: ________________________________ Dealer’s Rep. Signature: ___________________________

The dealer rep. and I have inspected my new Polar Furnace heater and reviewed all items on the delivery checklist.

The dealer rep. has reviewed the operator’s manual with me and has thoroughly instructed me on the equipment

herein. I assume full responsibility for the operation and maintenance of the product identified herein.

Date: ________________________________ Owner’s Signature: ______________________________

A nominal fee may be charged for service calls. All sales are final. Heater approved for use with well-seasoned

wood only. Suitability of use is the customer’s decision. The customer is responsible for ensuring conformance to

local bylaws and regulations. A backup heating system is strongly recommended.

White—Polar Furnace copy Yellow—Dealer copy Pink—Customer copy

1

To activate this warranty, the white copy of this warranty registration form as well as a copy of the original bill of sale (invoice) must be mailed to

Polar Furnace Mfg. Inc., Box 159, Sperling MB, R0G 2M0 within 30 days of delivery of furnace to end user.

5

Table of Contents

A. Warranty Details 3

B. Warranty Activation Form 5

C. Table of Contents 7

1. Introduction 8

2. Warnings & Cautions 9

3. Responsible Ownership 11

4. Heater Components 12

5. Safety 13

6. Heater Setup 14

7. Heater Controls 21

8. Operating the Heater 24

9. Maintaining the Heater 30

10. Water Testing & Treatment 36

11. Heater Model Specifications 37

12. Electrical Diagrams 38

13. G-Class Parts 39

14. Plumbing 45

For service and support on your Polar Furnace contact your local dealer

7

1

Introduction

The Polar Furnace G-Class Heaters are wood-fired,

downdraft, hydronic heaters. The downdraft burning

design allows for controlled combustion of wood

which results in far lower smoke and particulate

emissions and higher efficiency when compared to

other designs.

1.1 !! NOTICE !!

The Warranty Activation form is located on page 5.

This form must be thoroughly completed and the

white copy returned to Polar Furnace Mfg. Inc. to

ensure product support and warranty activation.

G-Class heaters are tested and approved by CSA

INTERNATIONAL to

CSA/CSA-366.1-M91 and UL2523

G-Class heaters are tested to EPA test Method 28

WHH and are EPA Phase II qualified.

1.2 Product Feature Variation

Our commitment is to provide you with the best

possible wood burning technology. As part of this

commitment, we make improvements to our products

on a regular basis as we strive to make them even

better. Although a concerted effort is made to keep

this manual as up-to-date regarding any changes to

our products, there may be noticeable differences. If

clarification of any part of this manual is needed, don’t

hesitate to contact your local Polar Furnace dealer or

contact Polar Furnace directly.

1.3 Save These Instructions!

Keep this manual for as long as you own the

Polar Furnace heater. Read and understand these

instructions before installing or operating this heater.

8

Owner’s manual for Polar Furnace models: G-2 & G-3

Warnings & Cautions

2.1 !!WARNING!!

A person operating a hydronic heater must comply

with all applicable laws or other requirements such

as state or provincial laws or regulations and local

ordinances.

2

The manufacturer does not recommend burning

treated or contaminated wood (i.e. railroad ties or

pressure treated lumber).

2.2 !!WARNING!!

All installations and operations must follow the

applicable federal, provincial, state, and local codes

for wiring, plumbing, chimney installation, chimney

extension (if required) and firing of this unit. When

the relevant local codes differ from this manual, the

local codes take precedence.

2.3 !!WARNING!!

Strictly maintain the following clearances around the

heater to any combustibles including fuel storage.

Front—24”, Right—6”, Left—1”, Rear—6”, Top—2”,

Flue—6”.

2.4 !!WARNING!!

This heater is designed to burn natural wood only.

Higher efficiencies and lower emissions generally

result when burning air-dried seasoned hardwoods

as compared to softwoods or to green or freshly

cut hardwoods. DO NOT BURN: unclean wood,

unseasoned wood, garbage, tires, lawn clippings,

leaves, brush trimmings or general yard waste,

materials containing asbestos, materials containing

lead, mercury or other heavy toxic metals, materials

containing plastic, waste petroleum products, paints

and paint thinners, asphalt products, chemicals, coal,

glossy or colored paper, construction and demolition

debris, plywood, particleboard, salt water driftwood

and other salt water saturated materials, manure, or

animal carcasses. Burning these materials may lead

to the release of toxic fumes or render the heater

ineffective and cause smoke. Burning these materials

can cause irreparable damage to your heater which is

not covered under warranty.

2.5 !!WARNING!!

Burn wood only! Dry seasoned wood is preferable.

2.6 !!WARNING!!

All Polar Furnace heaters operate at atmospheric

pressure. DO NOT, in any way, obstruct, block or plug

the overflow/fill pipe located on top of the heater. DO

NOT install a pressure relief valve. This boiler should

not be connected to an existing heating system unless

a water to water or water to air heat exchanger is used.

2.7 !!WARNING!!

Use of a rain cap with an approved spark arrestor is

required.

2.8 !!WARNING!!

Most Polar Furnace heaters are installed outdoors. All

fire clearances on page 15 should be observed. Always

keep area around and in front of fire door cleared from

combustible materials. DO NOT store fuel within

clearances listed on label.

2.9 !!WARNING!!

Polar Furnace heaters are CSA certified for outdoors

and indoors. When used indoors, special care must

be taken to ensure the installation conforms to

local installation requirements. Plan for makeup

air, ventilation of smoke when opening door,

chimney clearances and heights, and clearances from

combustibles. Consult local professionals. Field

installations must satisfy CSA CAN/CSA-B365

installation code for solid fuel burning appliances as

well as any other applicable standards or regulations.

If extended chimney height is needed, use an insulated

chimney system.

2.10 !!WARNING!!

Installation should be completed by appropriately

qualified personnel.

For service and support on your Polar Furnace contact your local dealer

9

SECTION 2: WARNINGS & CAUTIONS

2.11 !!WARNING!!

Never let small children play near or tamper with the

heater. Only responsible adults should operate the

heater. Outer surfaces may be hot during operation.

Ensure children do not touch heater.

2.12 !!WARNING!!

Always open the load door slowly while standing well

back and behind the door. Open the outer door and

wait one minute before opening inner doors. Do not

look directly into the fire chamber until at least 60

seconds after opening the load door. Failure to do so

may result in serious injury from flashbacks.

2.13 !!WARNING!!

Keep fuel door tightly closed during operation.

2.14 !!WARNING!!

In case of a runaway fire, disconnect the heater from

the electrical supply and ensure all doors are closed.

Check to ensure the air supply gates are not stuck

open. Check aquastat settings. Add water to ensure

that the heater is not low on water.

2.16 !!WARNING!!

Be concerned about ground water and insulate

the distribution pipes to avoid excessive wood

consumption.

2.17 !!WARNING!!

The secondary combustion chamber, heat exchanger

and areas above and below the heat exchanger should

be cleaned regularly to remove accumulated creosote

and ash.

2.18 !!WARNING!!

Cleaning the firebox, flue pipes, chimney, heat

exchanger and fan is especially important at the end

of the heating season to minimize corrosion. All

accumulated ash MUST be removed.

2.19 !!WARNING!!

Care should be taken to avoid potential smoke

problems. Downdraft heaters can smoke if not

operated as per recommendations or without properly

prepared wood. Be a responsible neighbor and use

properly seasoned firewood. Use a chimney extension

if required.

2.15 !!WARNING!!

DO NOT operate heater unless the water level gauge

shows that the water jacket is in the “Full” range.

2.20 !!Alert: Monitoring Smoke and Carbon Monoxide!!

During the combustion process, the presence of smoke is a strong indicator that the fuel is not being

consumed efficiently. Smoke is created when the combustion air supply to the fuel load is inadequate to

burn all the gases and particulate being released as the wood is consumed. This is why it is important to

establish the correct draft with the furnace/chimney system. One of the byproducts of poor combustion

is carbon monoxide, a colourless, odourless, and tasteless gas that is toxic when inhaled and which can

be fatal depending on concentration levels and exposure time. Note that although carbon monoxide is

produced during poor combustion that might also create smoke (as described above), high levels of carbon

monoxide may be produced in the absence of smoke. For example, this could take place when a wood fire

has been reduced to the coal state and the draft starts to reduce as less heat is available to keep the chimney

warm. Some level of carbon monoxide is being generated in all stages of the combustion process regardless

of the fuel.

Continued on next page....

10

Owner’s manual for Polar Furnace models: G-2 & G-3

Owner’s manual for Polar Furnace models: G-2 & G-3

Several precautions must be taken to minimize the risk of carbon monoxide poisoning especially when the

G-Class is installed in a building:

• First, run the furnace in the most efficient manner possible to reduce the production of carbon monoxide.

Use well seasoned, dry wood and establish the correct operating draft as laid out in these operating instructions

to help limit CO emissions.

• Second, Building Pressure—if the combustion air for an appliance (i.e., the wood furnace) comes from

within the same building in which the appliance is located, there will be a tendency for the internal building

pressure to become negative. Adequate mechanical ventilation must be supplied to the building to neutralize

the building pressure, otherwise there is a risk of reversing the flow of exhaust flue products back into the

building. These flue products may not only come from the wood furnace but also from other combustion

appliances in the building.

• Thirdly, Smoke Alarms and Carbon Monoxide Detectors—Smoke alarms and carbon monoxide detectors

are not only important tools for protecting the inhabitants of a building, but they are mandated in many

jurisdictions. Although these items should be located on every level of a building there are two locations

that are of prime importance. The first is in the sleeping areas of the building, and the second is in the

location where the combustion process is taking place. Check with local codes for details on alarm/detector

requirements. Carefully follow installation instructions included with the purchase of your Smoke Alarm and

Carbon Monoxide Detector(s).

Responsible Ownership

3.1 Safety First!

• Be safety conscious.

• Clear ground around heater.

• Use non-combustible cement blocks, patio blocks

or cement base under heater.

• Install the rain cap on the chimney. Use an

approved spark arrestor.

• Use a good quality pipe for hot water distribution.

• ALWAYS HIRE APPROPRIATELY QUALIFIED

INSTALLERS!

3

3.2 Minimize Smoke Emissions.

Burn Wisely.

• Be considerate of your neighbours when operating

your furnace. If you use your furnace in the summer

months, ensure that your chimney exhaust is not

adversely affecting any neighbours with open

windows.

• Consider prevailing wind direction when choosing

a site location for the heater.

• Water can be piped a long distance with minimal

heat loss. This is a good option to avoid smoke

related problems.

• Don’t burn garbage. Burn only well-seasoned

firewood.

11

4

Heater Components

Diagram 4.1–Heater Components

Item # Description

1 Heat Exchanger Access Cover

2 Chimney Hookup

3 Waterjacket Temperature Gauge (On some models, check inside Main Outer Door)

4 Furnace ON/OFF Switch, Work Light ON/OFF Switch

5 Water Level Sight Gauge

6 Heat Exchanger Cleaning Actuator Lever (Easy Sweep)

7 Heat Exchanger Bottom Cleanout

8 Rear Bottom Access Panel—Plumbing Hookup, Air Damper Setting

9 Work Light (inside outer door)

10 Rear Top Access Panel—Suction Fan Access, Electrical Access

11 Overflow/Fill Pipe

12 Lifting Hook

13 Main Outer Door

14 Loading Door

15 Ignition Door

16 Front Bottom Cleanout Door

12

Owner’s manual for Polar Furnace models: G-2 & G-3

Owner’s manual for Polar Furnace models: G-2 & G-3

5.1 !! WARNING !!

Maintain minimum distances between heater and

combustibles. (Refer to section 6.6)

5.2 !! WARNING!!

Develop and implement a clearly formulated plan of

what to do in the event of a chimney fire.

5.3 !! WARNING!!

Keep area around heater clear of combustibles.

5.4 Flashbacks

5.4.1 !! CAUTION !!

ALWAYS KEEP BODY AND FACE WELL

AWAY FROM LOAD DOOR, ACCESS

DOORS AND CLEANOUT DOORS WHILE

OPENING THEM. FAILURE TO DO SO CAN

RESULT IN SERIOUS BODILY INJURY FROM

FLASHBACKS.

When opening any access panels on the heater there

is danger of flashbacks. It is important to understand

what causes flashbacks before operating the heater.

Read the following explanations carefully and be sure

to understand what flashbacks are before attempting

to operate the heater.

Safety

5

5.5 The Combustion Fans Have

Just Shut Off

Once the heater reaches the point where the water

temperature is high enough, the controller shuts off

the combustion fans. When the fans stop blowing,

actuators also close off the air supply openings. This

stops any new air and oxygen from getting into the

fire chamber. At this point the fire chamber is still

extremely hot. The heat in the fire chamber continues

to bake the wood which continues to break down into

combustible smoke and gases. Without oxygen, these

combustible, hot gases do not burn off but accumulate

in the fire chamber. When a door is opened, fresh air

and oxygen mix with the hot combustible gases which

then ignite and explode. Always keep face and body

well away when opening the load door, ignition door,

bottom and side cleanout doors.

5.6 Hot Surfaces

Some surfaces on the boiler get hot. Always wear

protective leather gloves when working on or

around the heater, when loading the heater or when

performing maintenance on the heater.

5.4.2 Cause of Flashbacks

The root cause of flashbacks is the accumulation of

oxygen-starved hot gases inside the fire chamber.

These gases cannot combust without oxygen. Opening

the load door allows fresh air and oxygen to mix with

the hot gases causing them to ignite and explode.

5.4.3 Conditions Causing Flashbacks

There are some combustion conditions that greatly

increase the risk of flashbacks. It is important to

understand these conditions. It is important to note

that flashbacks can occur whenever any of the front

heater doors are opened and are not limited to the

conditions described below.

5.7 Smoke Inhalation / Eye

Irritation

Burning wood produces smoke. Avoid inhaling smoke.

Whenever there is smoke, wait until it has cleared

before proceeding to load the heater or performing

maintenance work.

5.8 !! DANGER !!

NEVER PRESSURIZE THIS HEATER! NEVER

block or obstruct the overflow/vent pipe located on the

roof of the heater (item #11 on page 12). Pressurizing

this heater could result in very serious injury and

damage to the heater and property!!

13

6

Heater Setup

6.1 !! NOTICE !!

All installation work must be completed by

appropriately qualified personnel and must conform

to all applicable standards, regulations and local codes

(e.g. CAN/CSA-B365 Installation Code for Solid

Fuel Burning Appliances).

6.2 Heater Delivery

Wash the heater immediately following delivery to

remove salt and dirt from shipping. Inspect the heater

for shipping damage. If damaged, make note of it on

carrier shipping paperwork.

6.3 Unpacking

Several items are shipped with each furnace. These

components are located inside the main fire chamber

and the rear bottom access panel. They include:

• Owner’s Manual.

• Distribution pipe finishing duct (diagram 14.2 of

manual).

• Anti-Condensation Valve (diagram 14.5 of the

manual).

• Stack Temperature Gauge (diagram 6.1 of the

manual).

6.4 Indoor Installation

Polar Furnaces are CSA & UL certified for both

indoor and outdoor installation. However, care

must be taken whenever a heater is near or inside a

building. When installed indoors, proper air supply is

required for combustion and ventilation. Continuous

air supply is mandatory. Installation must conform to

all applicable codes and standards. Consult a heating

professional.

• Ash shovel (diagram 8.5 of manual).

• Small ash tool (diagram 8.5 of manual).

• Small ash scoop (diagram 8.5 of manual).

• Poker (diagram 8.5 of manual)

• Flue brush (handle and brush may ship separated

from each other and may need to be assembled)

(diagram 8.5 of manual).

• Initial boiler treatment kit.

• Anti-evaporation cap (diagram 6.2 of manual).

• Insulated chimney pipe extension (total of at least

2’ of extension. Either 1pc x 2’ or 2pcs x 1’).

• Chimney rain cap.

6.5 Electrical Requirements

Electrical Rating: 120V AC, 6 amps, 60Hz.

Installation must meet federal, provincial and local

codes and must be completed by qualified personnel

only. Wire must be rated and approved for direct burial

if is to be included in the same trench as the water

lines. Heater power connection box is located inside

the rear access panel. Minimum supply conductor

ampacity is 15 amps. Maximum over current device is

15 amps. Use copper conductors only.

6.6 Heater Fire Clearances

All G-Class Heaters are CSA and UL approved to the

following fire clearances. No combustibles should be

stored within these measurements.

Front 24”

Back 6”

Left Side 1”

Right Side 6”

Top 2”

Chimney 6”

14

Owner’s manual for Polar Furnace models: G-2 & G-3

SECTION 6: HEATER SETUP

Consult with your insurance company to ensure

that the boiler to building clearances are acceptable.

Failure to do so may void insurance. The manufacturer

assumes no liability in the event of damages to

personnel or buildings.

6.7 Chimney Requirements

The chimney is a very important component in the

successful operation of the G-Class heater. A good

chimney provides a continuous, dependable draft to

ensure proper operation of the heater. If your furnace

is installed indoors, a continuous draft is especially

important to pull the exhaust gases out of the

building. The entire chimney exhaust system must be

designed to prevent possible soot build up, insufficient

draft, and condensation. Chimneys are very prone

to draft and creosote related problems when they

have diameters that are too large, are insufficiently

insulated, or when they have dents and bends.

Incorrect chimney installation will void the warranty.

The heater must be connected to a factory-built

chimney that must be designed for solid fuel

appliances, must be 6” in diameter, and must be UL103 or ULC-S629 listed. Chimneys that do not meet

these requirements MUST NOT be used for any part

of the chimney system. Never use black stove pipe

or uninsulated double wall chimney pipe for any part

of the chimney system. The chimney connection on

the G-Class heater will work best with the Security

Chimney ASHT+ 6” chimney system. Other chimney

systems can be used, but strictly follow the chimney

installation instructions for making a connection.

If a short piece of stove pipe is used to make the

connection, the stove pipe must be as short as

possible and must be insulated using suitable blanket

insulation. A dripless adaptor must be used at the

connection between the boiler and the factory-built

chimney. The top of the chimney must be at least 3

feet above the top of the roof penetration level and at

least 2 feet above any portion of the roof within a 10

foot diameter measured horizontally.

Always follow the chimney manufacturer’s installation

instructions when installing and supporting a chimney.

All chimneys and connections must conform to

all applicable standards and local codes. No other

appliance should be connected to the chimney unless

allowed by the local code authority. Consult your local

inspector for chimney requirements and install the

heater in accordance with all applicable codes.

6.7.1 Chimney Draft

When measuring draft, ensure that there is a fire in

the fire chamber, the fan has been on for at least 10

minutes and the water temperature in the boiler is

above 160˚F. This ensures the chimney is at proper

operating temperature. Breech draft is the draft near

the connection point to the furnace and should be

measured within 6” from the top roof panel of the

heater. Minimum breech draft is .02” water column.

Maximum breech draft is .14” water column. Strong

winds blowing across the top of a chimney (especially

a chimney which has a strong natural draft) can cause

the G-Class heater to continue firing when the fan has

switched off. This can cause the furnace to overheat.

If there is excessively high draft or an irregular draft, a

draft regulator must be used.

6.7.2 Draft Regulator

Whenever the breech draft exceeds .12” water column,

a draft regulator must be installed. The diameter of

the draft regulator used must be equal to or larger than

that of the chimney connector and should be installed

as close as possible to the boiler. If one draft regulator

is not sufficient to bring the draft below .10” water

column, a second draft regulator may be required.

After installing a draft regulator, the draft must always

be measured on the boiler side of the draft regulator.

The draft regulator adjustment should be made with

a vacuum gauge if possible. If the damper is adjusted

during warm weather, an adjustment may be required

during cold weather.

6.7.3 Off Cycle Draft

A slight but measurable draft during the off cycle is

required. The draft must persist for at least 30 minutes

after the fan has switched off. A draft during the off

cycle moves a very small amount of fresh air through

the heater which evacuates moisture laden air from

15

SECTION 6: HEATER SETUP

the primary fire chamber. In some conditions a reverse

draft or back draft may occur during the off cycle. This

may be the case if the boiler is installed near a very

tall building or near a high hill or if the chimney is

improperly installed and/or terminates on the side of a

building. A back draft must be remedied and stopped.

If a back draft is suspected or detected, consult with

your dealer or local HVAC professional to determine a

possible solution. Lack of a draft and/or back drafting

during the off cycle is one possible cause of water

condensating and accumulating inside the primary air

delivery channels during the off cycle.

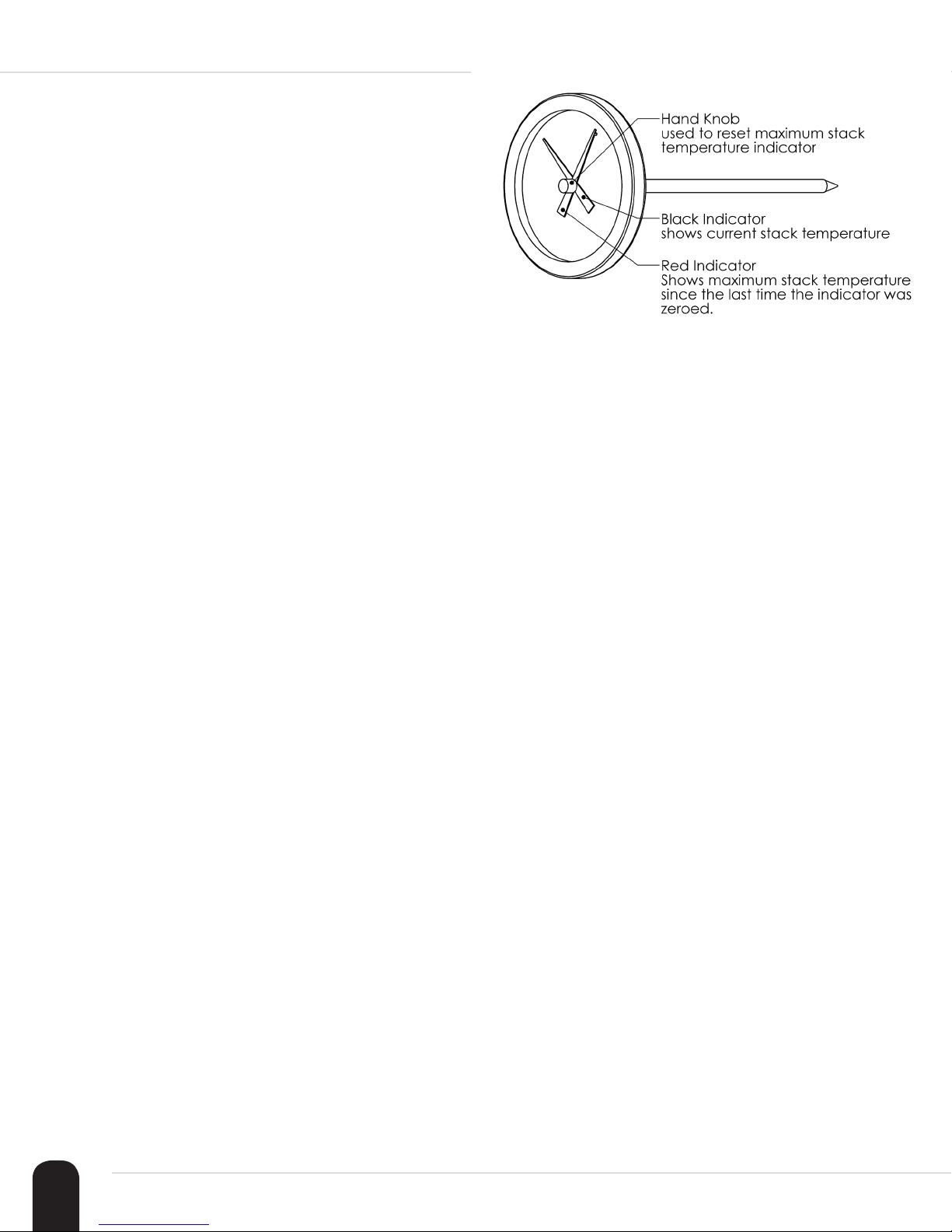

Diagram 6.1–Stack

Temperature Gauge

6.8 Stack Temperature

Stack temperature is an important factor in the proper

functioning of a chimney. e chimney’s maximum

stack temperature must never exceed 400˚F. If the

chimney temperature exceeds 400˚F, consult with your

local dealer or with the factory on how to decrease the

maximum stack temperature. e stack temperature

must always increase to over 275˚F during every burn

cycle. If the stack temperature fails to exceed 275˚F

during each burn cycle, consult with your local dealer

or with the factory to increase the stack temperature.

6.8.1 Stack Temperature Gauge

A stack temperature gauge is shipped with each

G-Class furnace. This gauge must be installed in

the chimney within 4” from the point at which the

chimney penetrates the rear roof panel. The gauge is

installed by sliding it into a small hole drilled through

the chimney wall. The stack temperature gauge has a

red temperature indicator which shows the maximum

temperature measured since the last time the max

temperature dial was turned counterclockwise until it

contacted the black current temperature indicator.

Notice: Always turn the hand knob

very carefully. Only turn the hand knob

counterclockwise until the red maximum

temperature indicator gently touches the

black current temperature indicator.

Additionally, if there are any known issues with the

water supply we strongly recommend testing the

water to verify that the boiler treatment we supply

will provide adequate treatment. Such known issues

include:

• high chloride levels (salty taste).

• high iron levels (metallic taste, looks reddish).

• a lot of scaling in the toilet, on shower heat, or in

your teapot.

• needing to replace your domestic hot water heater

every 2 or 3 years.

• have corrosion on your water taps.

6.9 Water Quality & Treatment

Ensure the water that will be used to fill the water

jacket meets at least the following minimum criteria:

• does not have an odor

• is not discolored

• does not discolor after sitting in a container for a

number of days.

16

Owner’s manual for Polar Furnace models: G-2 & G-3

Wood Boiler Solutions (phone: 920-324-2007) are

water treatment professionals and they offer water

testing service for a reasonable fee. Simply browse to

their website (woodboilersolutions.com) and order a

water testing service kit to initiate this service. Wood

Boiler Solutions will test your water and make a

determination if your water supply is suitable for use

or not.

SECTION 6: HEATER SETUP

Once the water source is determined to be suitable,

begin filling the water jacket. After adding water for

about 5 minutes add the water treatment supplied

with your heater. Add the treatment by pouring it into

the overflow/fill pipe (diagram 4.1, item #11). Refer to

section 10 for more information regarding the water

treatment kit supplied with your heater.

6.10 Filling the Water Jacket

6.10.1 !! WARNING !!

Do NOT start a fire in the heater before filling the

heater water jacket with water. Starting a fire in

the heater without first filling the water jacket can

damage or destroy the heater.

6.10.2 !! DANGER!!

Do NOT pressurize this heater since it is designed

with an open system type water jacket. Pressurizing

the heater could result in damage to the heater,

damage to property, and could cause severe bodily

injury and even death.

6.11 Using the Water Level Sight

Tube

The water level sight tube is located on the side of the

heater. To check the water level in the heater turn the

valve handle into the vertical position. The sight tube

will fill with water showing the level of the water in

the water jacket. If the level is in the red, “ADD” zone,

add water until the level reaches the green, “FULL”

zone. After using the water level sight tube, always

turn the handle back into the horizontal position to

drain water from the sight tube. Output Settings (V.2)

6.12 Anti-Evaporation Fill Pipe

Cap

An anti-evaporation cap ships with each heater

(diagram 6.2-Anti-Evaporation Cap). This cap

reduces the amount of evaporant escaping the water

jacket and helps maintain the water level over long

periods of time. The cap is installed into the overflow/

fill pipe. To install, slide the stem into the overflow

pipe. To locate the overflow/fill pipe, refer to diagram

4.1, item #11.

6.10.3 !! WARNING !!

This heater is a hydronic heater. This means that it

operates by heating water that is inside its water jacket.

This water jacket must be filled with water or a water/

glycol mixture before operating the heater. Filling the

water jacket can be achieved by adding water through

the overflow pipe on top of the heater or by hooking

the water supply hose to the drain/fill valve located

inside the rear access panel. Alternately, the water

jacket can be filled by adding water into any part of

the hot water distribution piping. Fill the heater until

the water level is in the green “FULL” zone (See

Section 6.11).

Note: Check the water level daily during the first few

weeks after the heater is installed and used.

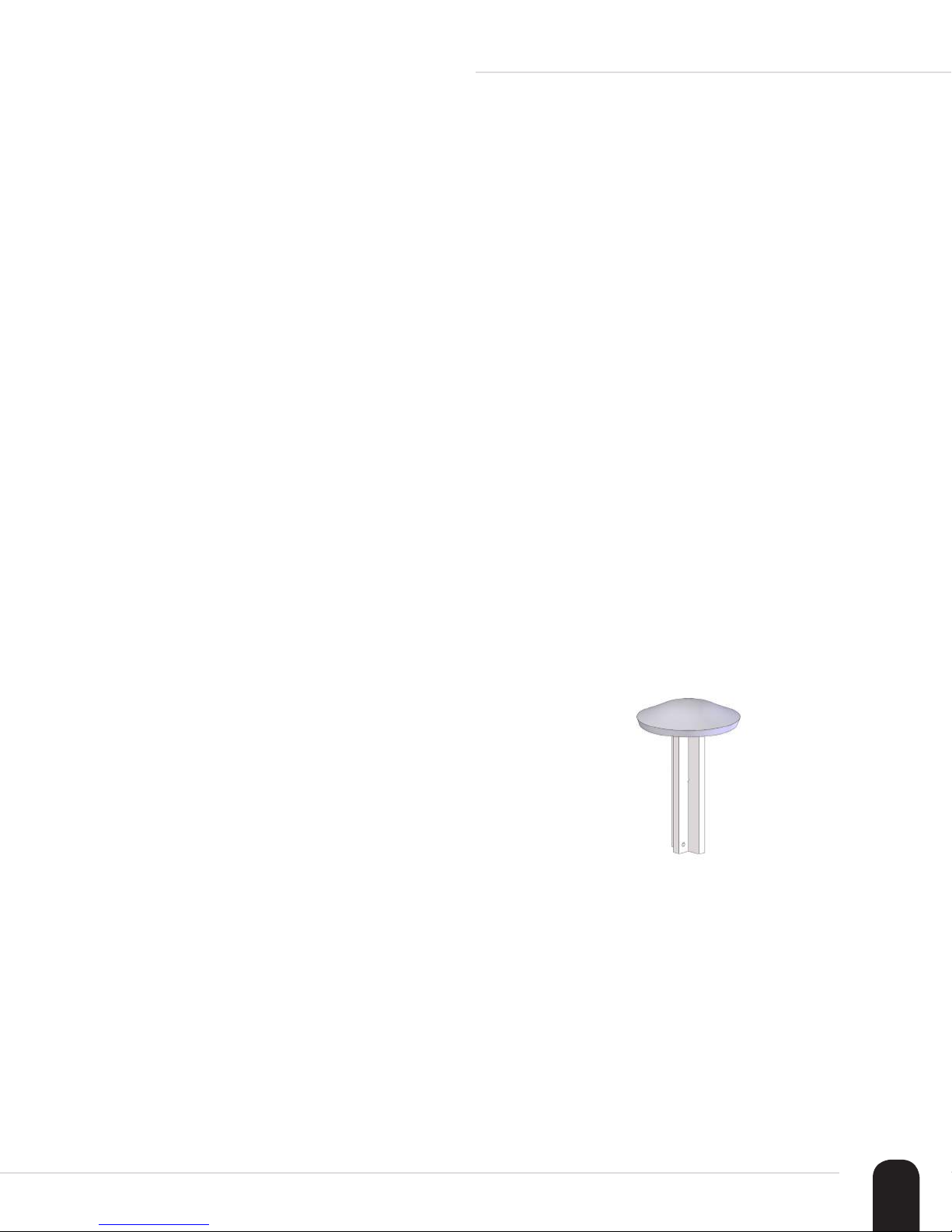

Diagram 6.2–Anti-

Evaporation Cap

17

Loading...

Loading...