Point Four Systems MBD075, MBD300, MBD100, MBD600, MBD900 User Manual

...

Oxygenation and Water Management Specialists - Making your water better!

MICROBUBBLE OXYGEN DIFFUSERS

USER MANUAL

MAKING YOUR WATER BETTER!

WWW.POINTFOUR.COM

103 - 16 Fawcett Road

Coquitlam BC V3K 6X9

CANADA

Toll Free: 1 800 267 9936

Phone: 1 604 759 2114

Fax: 1 604 759 2115

Email: sales@pointfour.com

1

INSTRUCTIONS FOR USE

Safety Precautions and Good Practice

It is essential that distributors ensure users of the Point Four diffusers are

informed both verbally and in writing about the safe and correct use of diffusers.

WARNING: THE DIFFUSER MUST ONLY BE OPERATED WHEN SUBMERGED.

When the diffuser is under pressure substantial potential energy is stored in it. Should

the porous ceramic fail due to over pressure it may burst with possible injury to anyone

close by if the diffuser is not submerged.

WARNING: USING OXYGEN

Oil, grease and other hydrocarbons when combined with oxygen, become highly

combustible and should never be used on any part of the oxygen cylinder, valve,

regulator, diffuser fitting or other equipment used with oxygen. If using O2, supply lines,

regulators, flowmeters etc. must be CLEAN FOR OXYGEN SERVICE

Use of pressure regulators and flow meters. Wherever possible use a pre-set

pressure regulator, pre-set to 50 psig (345 kPa), in conjunction with a flowmeter. A

flowmeter is highly recommended in almost all cases. Use only rotameter type

flowmeters (floating ball in a tube).

Do not use an adjustable regulator with bourdon gauge flow indicator. Because of

back pressure (25 to 35 psig) in the supply line to the diffusers, the indicated flow will

be wrong and very misleading, and may even result in over pressuring of the diffuser.

Use Pressure Relief Valve in the gas supply line if an adjustable regulator is

used. It is strongly recommended that a pressure relief valve be installed just after

the pressure regulator to protect the flow meter and diffuser/s from over

pressurization- use 55 or 60 psig rated pressure relief valve.

Water in diffuser. If the diffuser is left submerged with no pressure applied to it water

will seep through the porous ceramic and enter the air plenum. To prevent this from

happening, turn on the oxygen and apply a slight pressure to the diffuser as the tank

begins to fill with water. Once the diffuser is pressurized, the oxygen can be turned

off. If water does enter the air plenum, it will be forced out by the oxygen but it will

take several minutes for an even bubble pattern to form.

• DO NOT allow diffusers to become contaminated with oil.

• AVOID physical shock.

2

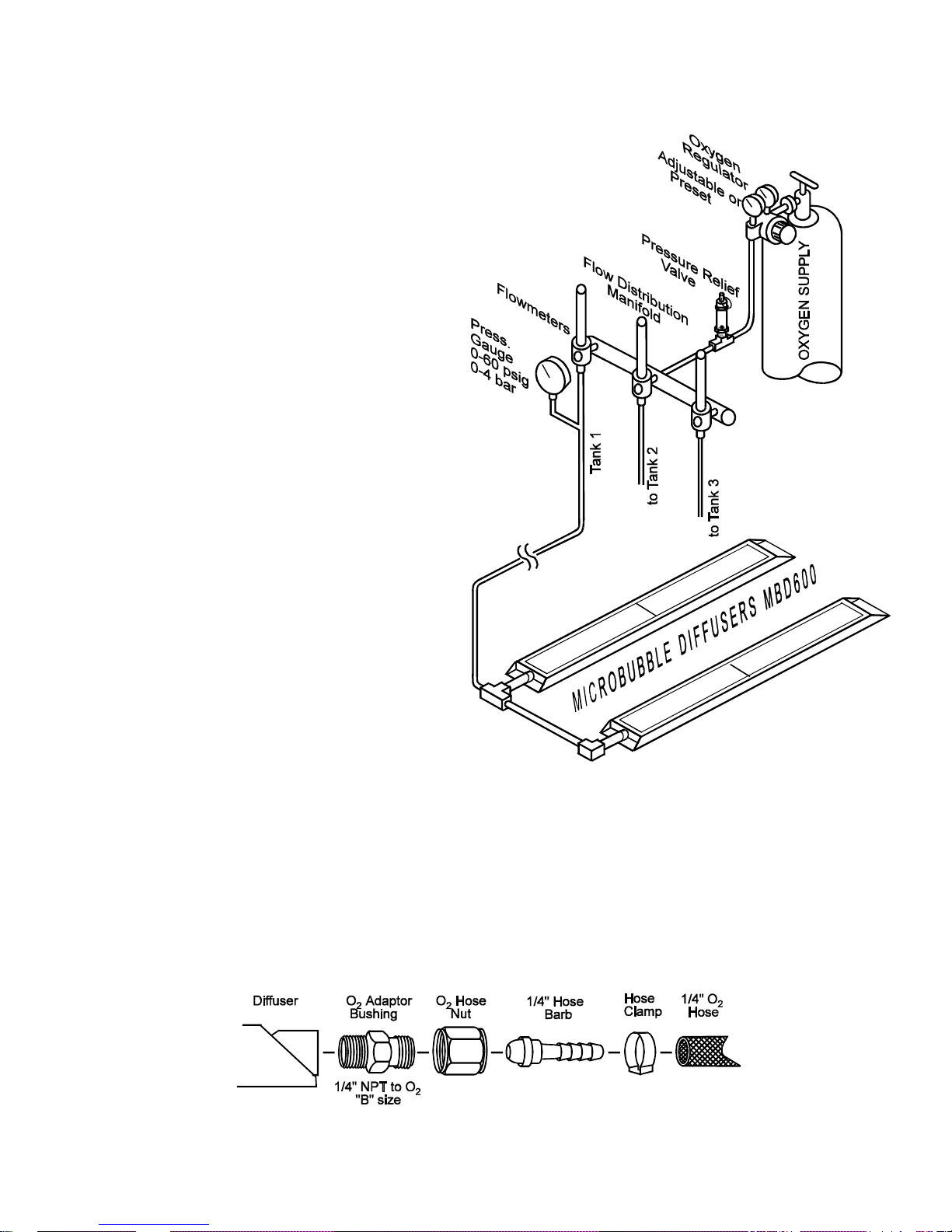

INSTALLATION

To avoid bubble coalescence, place the

diffuser horizontally and do not obstruct

the surface with protective screens. The

deeper the diffuser is placed in the water

the more effective it will be. Secure

diffuser to a flat surface using "Velcro"

strips, silicone or screws. Do not over

tighten. Use ¼" (6 mm) ID hose and brass

or plastic fittings. Use Teflon tape on

threaded pipe joints. Any number of

diffusers can be connected to a common

supply line. For flow distribution manifolds

and fittings consult your supplier. Supply

pressure must not exceed 50 psi (3.5 bar).

Use a preset pressure regulator (set to 50

psi) and back pressure compensated

flowmeter with needle valve to control flow

Alternatively, but not recommended, if an

adjustable pressure regulator is used to

control now, then this MUST BE USED in

conjunction with a 50 psi pressure relief

valve.

OPERATION

Ensure that the supply pressure at the

diffuser cannot exceed 50 psi (3.5 bar).

Pressurize the diffuser only when

submerged. Turn the gas on and control

flow via the needle valve on flowmeter. If an adjustable pressure regulator is being used

to control flow, ensure that the regulator is in the "Off" position i.e adjustment knob fully

screwed out (anti-clockwise) before turning on the gas supply. Slowly increase pressure

to the desired level, usually 20 to 30 psi (1.5 to 2 bar), by turning adjustment knob

clockwise. There will be a small delay before the diffuser responds to flow adjustments,

especially if the diffuser's air plenum has filled with water.

Brass inlet fittings for MBD600 and MBD300 diffusers

Loading...

Loading...