PNEUMERCATOR

Liquid Level Control Systems

Quick Start-up Guide

For Factory Preprogrammed

TMS2000 & TMS3000 Systems

© COPYRIGHT 2017 PNEUMERCATOR CO., INC.

1785 EXPRESSWAY DRIVE NORTH

HAUPPAUGE, NY 11788

TMS Quick Start-up Guide.docx www.pneumercator.com November 21, 2017

DRAWING NO . 20001 REV. A

Pneumercator Co., Inc.

1785 Expressway Drive North

Hauppauge NY 11788

Phone (631) 293-8450

Fax (631) 293-8533

Tech Support (800) 209-7858

Quick Start-up Guide TMS Series

Note: Separate manuals are available for System Operation and Installation.

Page

Introduction

Start-up of preprogrammed systems .................................................................................................. 6

Probe Worksheet ................................................................................................................................ 7

Programming Float Height Offsets using TMS Communicator ........................................................... 8

Programming Float Height Offsets using TMS Front Panel .............................................................. 10

TMS Front Panel Navigation Chart ................................................................................................... 12

TMS Wiring Diagrams ....................................................................................................................... 15

Programming for RA100/RA200 Remote Annunciator ..................................................................... 24

Figures:

1. MP45xS Label ............................................................................................................................... 6

2. MP46xS Label ............................................................................................................................... 6

3. TMSComm Direct Connect Site Default Settings .......................................................................... 8

4. TMSComm Probe Configuration ................................................................................................... 9

5. TMS Front Panel Keys Layout .................................................................................................... 10

6. TMS Edit Enable Button .............................................................................................................. 11

7. TMS Front Panel Navigation Chart ............................................................................................. 12

8. TMS AC Power Wiring ................................................................................................................ 15

9. TMS Probe Wiring ....................................................................................................................... 16

10. TMS2000 Sensor Wiring ............................................................................................................. 17

11. TMS3000 Sensor Wiring ............................................................................................................. 18

12. TMS Series to RA200KR Wiring ................................................................................................. 20

13. TMS Series to RA100R Wiring .................................................................................................... 22

TABLE OF CONTENTS

Quick Start-up Guide TMS Series

Introduction

This guide is intended for use as a field help guide for factory-trained technicians when

performing a start-up on the Pneumercator TMS Series tank gauging system. You can use this

guide for both the TMS2000 and TMS3000 consoles. The first part of this guide shows what is

needed to perform a start-up on a FACTORY PREPROGRAMMED TMS Series console. The

second part has the basic wiring needed for the TMS2000 & TMS3000 systems. For detailed

installation instructions please refer to the appropriate TMS Installation Manual. For systems NOT

factory preprogrammed, please refer to the standard TMS Operations Manual for programming

instructions. Please make sure that the Warranty Start-up paperwork is completely filled out by a

factory authorized technician and returned to Pneumercator in a timely fashion to qualify the

system for warranty consideration.

For information on becoming a factory authorized service/start-up technician, please contact

Pneumercator below, or e-mail at training@pneumercator.com. Your local Pneumercator sales

representatives may also be of assistance.

This guide is for reference purposes only. Complete installation guidelines are contained in

the TMS2000 & TMS3000 Installation manuals.

For more information, please contact:

Pneumercator Co.

1785 Expressway Drive North

Hauppauge, NY 11788

(631) 293-8450

Fax (631) 293-8533

Toll Free (800) 209-7858

www.pneumercator.com

TMS Quick Start-up Guide.docx November 21, 2017

Quick Start-up Guide TMS Series

Start-up of Preprogrammed systems

This section is for the start-up of systems that have been preprogrammed at the factory with

information supplied by the customer/distributor.

IT IS THE RESPONSIBILITY OF THE START-UP TECHNICIAN TO VERIFY THE

INFORMATION PROGRAMMED INTO THE TMS SYSTEM MATCHES THE SITE

REQUIREMENTS. IF ANY INFORMATION IS NOT CORRECT, THEY SHOULD CORRECT THE

PROGRAMMING PER THE OPERATIONS MANUAL OR CONTACT THE FACTORY FOR

PROGRAMMING ASSISTANCE.

All systems are supplied with factory configuration sheets showing what was programmed into

the TMS system. Please review these sheets prior to continuing.

1. Verify the list of equipment matches what is found on the packing list.

2. Record probe serial number(s), model number(s), calibration factor(s) (Probe C.F.), and length(s)

on the worksheet on the next page. This information must match the factory programming printout

provided with the console to avoid reprogramming the console.

PNEUMERCA TOR

PNEUMERCA TOR

Liquid Level Control Systems

Liquid Level Control Systems

PNEUMERCATOR

SERIAL No.

SERIAL No.

MP

MODEL

MODEL

PROBE C.F.

PROBE C.F.

LENGTH

LENGTH

MP

100

100

F1234TM-1

F1234TM-1

450S

450S

9.128

9.128

Liquid Level Control Systems

SERIAL NUMBER:

R1234-2

BASE P/N:

MP463SA-460-21

PROBE CAL . FAC TOR:

9.104

EFFECT IVE L ENGTH:

446"

Figure 1 – MP45xS Label Figure 2 – MP46xS Label

3. Confirm the TMS system (includes probes, sensors, and any other wires terminating within the

TMS) has been installed in accordance with the corresponding Installation Manual. This includes

but is not limited to the following:

a. Confirm TMS system is on a separate circuit breaker. (See Figure 8)

b. Confirm there are two (2) 12 AWG wires connected to the IS ground terminals going

to the main circuit panel ground buss bar. (See Figure 8)

c. Verify the intrinsically safe wiring is properly separated from all other wiring as per

Article 504 in the National Electric Code.

d. Verify the probes and sensor cabling is properly terminated. (See Figures 9-11)

4. Power up TMS.

5. Observe and record any alarms or errors. Power Fail, Warning 21 is expected on power-up.

6. Stick tanks for product level & water level and record on the worksheet on the next page.

Note: Stick readings should be taken in the same opening the TMS probe is installed for greater

accuracy. The Product Float must be floating in the product in order to calibrate the TMS.

7. Record the Product and Water level readings (inches or millimeters) displayed on the TMS on the

worksheet on the next page. To access the product level readings on the TMS, hold the MODE

button until the TMS beeps. Repeat until the level unit LED (IN/mm) is lit. Hold the MODE button

until the TMS beeps to access the water level. A “w” (w) will be displayed to the left of the reading.

8. For multi-tank systems, hit the TANK SELECT button and repeat steps 8 & 9 for each tank.

9. Calculate float height offsets using the worksheet on the following page.

Note: If programming via the front panel buttons is desired, skip to Page 10.

TMS Quick Start-up Guide.docx

Page 6 of 24 November 21, 2017

Quick Start-up Guide TMS Series

Probe Worksheet

Ex: F1 Probe 1 Probe 2 Probe 3 Probe 4 Probe 5 Probe 6

Probe Information

Serial #

Model #

C.F.

Length

R1234-1

MP450S

9.128

100”

Product Level Information

Stick

TMS

Prod HO

42.5”

43.7”

-1.2”

Water Level Information

Stick

TMS

H2O HO*

0.0”

1.7”

-1.5”

Ex: F2 Probe 7 Probe 8 Probe 9 Probe 10 Probe 11 Probe 12

Probe Information

Serial #

Model #

C.F.

Length

R1234-2

MP463SA

9.104

446”

Product Level Information

Stick

TMS

Prod HO

242.5”

224.7”

+17.8”

Water Level Information

Stick

TMS

H2O HO*

0.0”

5.5”

-5.0”

*Note: The final water level should be set to at least 0.2” for MP45xS or 0.5” for MP46xS to allow for

thermal expansion and/or contraction of the system. The MP46xS Series probes should be allowed

to settle for a couple of days before performing the float offset adjustments. If this is not feasible,

adjust the final water level to 1.0” to allow for probe straightening/settling. If the TMS has a negative

water level calculation, the Water alarm will immediately activate.

The expected value for the offset should not exceed the combination of the float height with the

distance between the bottom of the probe and the tank floor. If the calculated value exceeds

expectations, check the floats are not stuck at the top of the tank. Also confirm the TMS has been

properly configured.

TMS Quick Start-up Guide.docx

Page 7 of 24 November 21, 2017

Quick Start-up Guide TMS Series

Programming Float Height Offsets using TMS Communicator

1) Install TMSComm on your computer.

a. Insert TMSComm CD-ROM and follow on-screen instructions.

2) Start TMSComm by clicking on Pneumercator in the Start menu under Programs or All

Programs and then clicking TMSComm.

3) Sign into the TMSComm Administrator account.

a. Click on the Options menu and click on the Security tab.

b. Click the Login… button and enter the User Name and Password.

User Name: ADMIN Password: ROBUST

Note: the password for TMSComm before version 94 is JONESTOWN.

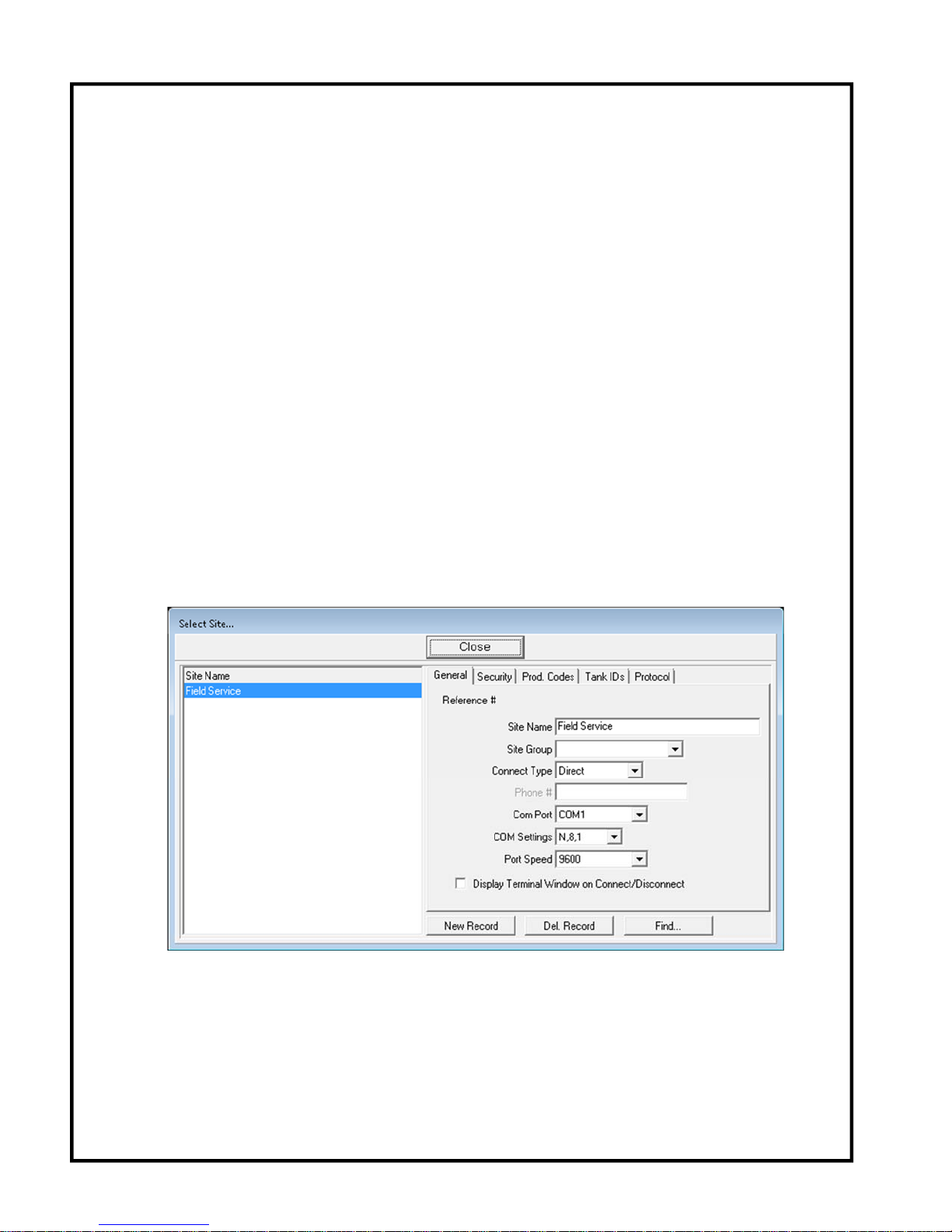

4) Create a Site to connect to.

a. Click on the Sites menu and click Select Sites.

b. Click the New Record button.

Note: If you already have a site configured, simply select the site by clicking on its name

and clicking the Close button. Proceed with Step 5.

c. Enter a Site Name.

d. Verify the settings below Site Name match Figure 3, the default values for the TMS.

Note: COM Port must be set according to your computers hardware settings.

e. Click the Close button.

Figure 3 – TMSComm Direct Connect Site Default Settings

TMS Quick Start-up Guide.docx

Page 8 of 24

November 21, 2017

Quick Start-up Guide TMS Series

5) Connect to the Site by clicking Connect in the Sites menu.

6) Read the configuration from the TMS.

a. Click on the Configurations menu.

b. Click on the File menu in the Configurations window and choose Read Configuration From

Connected Device.

7) Click on the Tanks tab and select the desired Tank Channel.

8) Click on the Probe button.

9) Verify the Probe Information (Calibration Factor, Type, and Length) from the worksheet on Page

2 matches the data shown in TMSComm. If this is correct, proceed to the next step. If this is not

correct, make the appropriate changes, close the Probe window, and proceed to Step 13. Return

to Step 7 to begin the calibration process.

10) Enter the Height Float Offset (HO) information from the worksheet on Page 7 as shown in

Figure 4 for both the Product and Water floats.

11) Click the close button.

12) If there is more than one tank enabled, click on the next enabled tank tab and return to Step 8.

13) Click on the File menu and select the Write configuration to Connected Device option.

Figure 4 - TMSComm Probe Configuration Window

TMS Quick Start-up Guide.docx

Page 9 of 24

November 21, 2017

Quick Start-up Guide TMS Series

Programming Float Height Offsets using TMS Front Panel

Refer to the Figure 5 below for the relative locations of the buttons. Note that each button has three

labels depending upon your display status. Without entering programming mode, the main labels

printed on the buttons are used. Once in programming mode, a nonflashing display represents

Review Mode where a flashing display represents Edit Mode. Note that this represents the latest front

panel button configuration available. Earlier systems maintained the same labeling system but had

physically different buttons.

REVIEW

EDIT

MODE

STEP GROUP SELECT

TANK

SELECT

TEST

EDIT

DWG NO. 20043 REV. N/C

Figure 5 - TMS Front Panel Keys Layout (TMS3000 colors shown)

1) Enter programming Mode by pressing and holding the TEST button and then pressing the

MODE button at the same time until Log (Log) appears. Release both buttons.

2) Press the EDIT (TEST) button repeatedly until Config (Config) appears flashing.

3) Press the ► (MODE) button one time. Header (Header) appears.

4) Press the EDIT (TEST) button repeatedly until Probe (Probe) appears flashing.

5) Press the ► (MODE) button one time. The value for Probe CF for Tank Channel 1 is displayed.

6) Press the GROUP SELECT (TANK SELECT) button until the desired Tank Channel number is

displayed over the TANK ID label on the display.

7) Press and hold the STEP (MODE) button until it beeps ONE TIME and immediately release the

button. Repeat this twice more and Prod HO (Prod HO) will appear briefly then the current value

for the Product Float Height Offset will appear. Note that this number will start with a + (+) or a (-) sign indicating a positive or negative number.

TMS Quick Start-up Guide.docx

Page 10 of 24 November 21, 2017

Quick Start-up Guide TMS Series

8) Press the EDIT ENABLE/THEFT ALARM ACKNOWLEDGE button on the inside of the front door

up one time. This will NOT cause the display to change but will authorize you to make

programming changes to the TMS for the duration of the programming session.

PUSH UP AND

RELEASE

EDIT EN ABLE/

THEFT ALARM

ACKNOW LEDGE

EDIT ENABLE/

THEFT ALARM

ACKNOWLEDGE

DWG NO. 20045 RE V. N/C

Figure 6 - Edit Enable Button

9) Press the EDIT (TEST) button one time and the first digit (cursor) will start flashing. This digit

indicates a positive or negative number. Use the ▼ (GROUP SELECT) and/or ▲ (TEST) buttons

to change the value of what’s flashing. Use the ► (MODE) button to move the cursor to the right.

Once the last digit is flashing the correct value, enter by pressing the ► (MODE) button. It will

stop flashing and show you the current value for the Product Float Height Offset.

10) Press and hold the STEP (MODE) button until it beeps ONE TIME and immediately release the

button. h2o HO (H

O HO) will appear briefly then the current value for the Water Float Height

2

Offset will appear. Note that this number will start with a + (+) or a - (-) sign indicating a positive

or negative number.

11) Press the EDIT (TEST) button one time and the first digit (cursor) will start flashing. This digit

indicates a positive or negative number. Use the ▼ (GROUP SELECT) and/or ▲ (TEST) buttons

to change the value of what’s flashing. Use the ► (MODE) button to move the cursor to the right.

Once the last digit is flashing the correct value, enter by pressing the ► (MODE) button. It will

stop flashing and show you the current value for the Water Float Height Offset.

12) If there is more than one tank enabled, go to Step 6 to calibrate the next tank.

13) Press and hold the STEP (MODE) button until it beeps TWO TIMES and immediately release the

button. Return (Return) appears.

14) Press the EDIT (TEST) button two times. Probe (Probe) will appear flashing on the display.

15) Press the GROUP SELECT (TANK SELECT) button until Return (Return) appears flashing.

16) Press the ► (MODE) button one time. Config (Config) appears.

17) Press the EDIT (TEST) button until Return (Return) appears flashing.

18) Press the ► (MODE) button one time. The system returns to normal operating mode.

TMS Quick Start-up Guide.docx

Page 11 of 24 November 21, 2017

Quick Start-up Guide TMS Series

TMS Front Panel Navigation Chart

Figure 7A - TMS Front Panel Navigation Chart - Legend

TMS Quick Start-up Guide.docx

Page 12 of 24 November 21, 2017

Quick Start-up Guide TMS Series

Figure 7B - TMS Front Panel Navigation Chart - All menus except Configuration

TMS Quick Start-up Guide.docx

Page 13 of 24 November 21, 2017

Quick Start-up Guide TMS Series

Figure 7C - TMS Front Panel Navigation Chart - Configuration menu only

TMS Quick Start-up Guide.docx

Page 14 of 24 November 21, 2017

Quick Start-up Guide TMS Series

TMS Quick Start-up Guide.docx

Page 15 of 24 November 21, 2017

TMS Wiring Diagrams

Figure 8 - TMS AC Power Wiring

PNEUMERCATOR

Liquid Level Control Systems

Bulletin 172 Rev. A (01/19/07)

Page 1 of 1

IMPORTANT! LC2000 AND TMS SERIES GROUND WIRING INSTRUCTIONS

NOTE:

ALL GROUNDS MUST BE TERMINATED AT THE GND BUSS BAR IN THE SAME SERVICE PANEL AS LC2000

AND/OR T MS POWE R. A G ROUNDING ROD, CO LDWAT E R PIPE OR OTHER CONNECTION SHOULD

NOT BE

USED.

BREAKER 6

BREAK ER 5

BREAK ER 4BREAK ER 3

BREAKER 2

BREAK ER 1

GND BUSS BAR

NEUTRAL

BUSS BAR

LINE 2 BUSS

BAR

LINE 1 BUSS

BAR

PARTIAL VIEW OF A TYPICAL

SERVICE PANEL

NEUT

GND

ISGND

ISGND

HOT

PARTIAL VIEW OF

LC2000/TMS CONSOLE

Quick Start-up Guide TMS Series

TMS Quick Start-up Guide.docx

Page 16 of 24 November 21, 2017

Figure 9 - TMS Probe Wiring

Page 1 of 1

IMPORTANT! PROBE WIRING INSTRUCTIONS - MODELS TMS2000/TMS3000/TMS4000

PNEUMERCATOR

Liquid Level Control Systems

NON-INTRIN SICALLY SAFE WIRI NG

INTRINSICALLY SAFE WIRING

HAZARDOUS AREA

CLASS 1, GROUP S C,D

NON-HAZARDOUS AREA

CONDUIT AND VAPOR SEAL FITTING

(SIZE AND LOCATION TO BE

DETERMINED BY QU ALIFIED INST ALLER)

REDUCER FITTING

(IF NEEDED)

JUNCTION BOX

(PROVIDED BY

INSTALLER)

1/2" NPT OR EQ UIV. CABLE GRIP

REQ'D ONLY ON MP45xS MODEL S

(JUNCTION BOX MOUNTS DIRECTL Y

TO PROBE ON MP46xS MODELS)

WIRE SPLICE SEAL CONNECTOR (BY PCO *)

FOLLOW SUPPLIE D WIRE SPLICE INSTRUCTIONS

BULLETIN 179; KIT P/N 10585-2 (FOR MP46xS)

BULLETIN 181; KIT P/N 10585-2L (FOR MP45xS)

FIELD WIRING CABLE (BY CUSTOMER)

EXAMPLE: BELDEN 8441, AVAILABLE

FROM PCO * AS CW1-0500 (500' SPOOL)

TMS CONSOLE

TYPICAL

TANK

W/ PROBE

G

R

N

RED

B

L

K

FIELD CABLE

Note for all probe models:

Conductor colors may vary

depending on cable manufacturer.

The field cable shield wire must

be connected to the PROBE

SHIELD TERMINAL in the console

I.S. compartment and should be cut

back and left unterminated at the

probe junction box.

W

H

T

B

L

K

GND

STUD

TO

TO

TO

TMS2000 PROBE INPUT WIRING TMS3000/TMS4000 PROBE INPUT WIRING

+V

+V

SIG

GND

SHD

GND

+V

2

1

SHD

BLK

RED

C

H

A

N

N

E

L

1

S

E

N

S

O

R

S

P

R

O

B

E

PROBE 2

SHIELD

GND

+V

SHIELD

GND

+V

SHD

BLK

RED

PROBE 1

TYPICAL WIRING FOR TMS CONSOLES

* "PCO" REFERS TO P NEUMERCATOR COMPANY.

FROM

PROBE

TO CONSOLE

(AS SHOWN ABOVE)

3/4" NPT (TMS2000)

1" NPT (TMS3000/TMS4000)

OR EQUIVALENT

CONDUIT FITTING

WIRING MUST BE DONE IN WATERTIGHT RATED BOX/HOUSING

PROBE MODELS

COVERED BY THIS BUL LETIN

MP461SC

MP461S[A], [V]

MP462S[A], [V]

MP463S[A], [V]

MP450S

MP451S

MP452S

Refer to TMS installation manual for

WARNINGS and CAUTIONS before

proceeding. FAILURE TO COMPLY

MAY RESULT IN PER SONAL INJURY,

PROPERTY LOSS AND EQUIPMENT

DAMAGE.

WARNING

MP45xS

RED

B

L

K

R

E

D

BL

K

TO

TO

MP46xS

Bulletin 199 Rev. B (03/25/16)

!

Page 1 of 1

IMPORTANT! PROBE WIRING INSTRUCTIONS - MODELS TMS2000/TMS3000/TMS4000

PNEUMERCATOR

Liquid Level Control Systems

NON-INTRIN SICALLY SAFE WIRI NG

INTRINSICALLY SAFE WIRING

HAZARDOUS AREA

CLASS 1, GROUP S C,D

NON-HAZARDOUS AREA

CONDUIT AND VAPOR SEAL FITTING

(SIZE AND LOCATION TO BE

DETERMINED BY QU ALIFIED INST ALLER)

REDUCER FITTING

(IF NEEDED)

JUNCTION BOX

(PROVIDED BY

INSTALLER)

1/2" NPT OR EQ UIV. CABLE GRIP

REQ'D ONLY ON MP45xS MODEL S

(JUNCTION BOX MOUNTS DIRECTL Y

TO PROBE ON MP46xS MODELS)

WIRE SPLICE SEAL CONNECTOR (BY PCO *)

FOLLOW SUPPLIE D WIRE SPLICE INSTRUCTIONS

BULLETIN 179; KIT P/N 10585-2 (FOR MP46xS)

BULLETIN 181; KIT P/N 10585-2L (FOR MP45xS)

FIELD WIRING CABLE (BY CUSTOMER)

EXAMPLE: BELDEN 8441, AVAILABLE

FROM PCO * AS CW1-0500 (500' SPOOL)

TMS CONSOLE

TYPICAL

TANK

W/ PROBE

G

R

N

RED

B

L

K

FIELD CABLE

Note for all probe models:

Conductor colors may vary

depending on cable manufacturer.

The field cable shield wire must

be connected to the PROBE

SHIELD TERMINAL in the console

I.S. compartment and should be cut

back and left unterminated at the

probe junction box.

W

H

T

B

L

K

GND

STUD

TO

TO

TO

TMS2000 PROBE INPUT WIRING TMS3000/TMS4000 PROBE INPUT WIRING

+V

+V

SIG

GND

SHD

GND

+V

2

1

SHD

BLK

RED

C

H

A

N

N

E

L

1

S

E

N

S

O

R

S

P

R

O

B

E

PROBE 2

SHIELD

GND

+V

SHIELD

GND

+V

SHD

BLK

RED

PROBE 1

TYPICAL WIRING FOR TMS CONSOLES

* "PCO" REFERS TO P NEUMERCATOR COMPANY.

FROM

PROBE

TO CONSOLE

(AS SHOWN ABOVE)

3/4" NPT (TMS2000)

1" NPT (TMS3000/TMS4000)

OR EQUIVALENT

CONDUIT FITTING

WIRING MUST BE DONE IN WATERTIGHT RATED BOX/HOUSING

PROBE MODELS

COVERED BY THIS BUL LETIN

MP461SC

MP461S[A], [V]

MP462S[A], [V]

MP463S[A], [V]

MP450S

MP451S

MP452S

Refer to TMS installation manual for

WARNINGS and CAUTIONS before

proceeding. FAILURE TO COMPLY

MAY RESULT IN PER SONAL INJURY,

PROPERTY LOSS AND EQUIPMENT

DAMAGE.

WARNING

MP45xS

RED

B

L

K

R

E

D

BL

K

TO

TO

MP46xS

Bulletin 199 Rev. B (03/25/16)

!

Quick Start-up Guide TMS Series

IMPORTANT! TMS2000 SENSOR WIRING INSTRUCTIONS

IDENTIFY THE TYPE OF SENSOR(S) TO BE INSTALLED. WIRING MUST BE TERMINATED ON THE

TERMINALS INDICATED BELOW TO ENSURE CORRECT OPERATION.

2-WIRE SENSORS

NOTE: "S" = SIGNAL AND IS CONSECUTIVELY NUMBERED "S1"

THROUGH "S8" ON THE TMS2000 CIRCUIT BOARD

+V

W

R

N

G

S

I

I

+V

S

RED

BLK

GRN

BLK

3-WIRE SENSORS

HS100-ND

LS600

NOTE : CONDUCTOR COLOR PAIR PER

SW ITC H POIN T. REFER TO THE TAG

ATTACHED TO THE SENSO R.

M

O

LS600 LD / LS610

RSU801

D

E

L

RSU800

(NON-DISCRIMINATING)

NOTE: "S" = SIGNAL AND IS CONSECUTIVELY NUMBERED "S1"

THROUGH "S8" ON THE TMS2000 CIRCUIT BOARD

+V

S

RED

WHT OR GRN

BLK

+V

W

R

S

I

I

+V

S

RED

BLK

WHT OR GRN

N

G

+V

S

GRN

RED

*

+V

S

BLK

ES825-100 SERIES

ES825-200 SERIES

HS100D

RSU800

(DISCRIMINATING)

* RED IS COMMON GROUND WIRE

M

O

D

E

L

Bulletin 173 Rev. A (11/01/07)

TMS Quick Start-up Guide.docx

Questions? Contact Technical Support at (800) 209-7858

PNEUMERCATOR

Liquid Level Control Systems

Figure 10 - TMS2000 Sensor Wiring

Page 17 of 24 November 21, 2017

Page 1 of 1

Quick Start-up Guide TMS Series

IMPORTANT! TMS3000/TMS4000 SENSOR WIRING INSTRUCTIONS

IDENTIFY THE TYPE OF SENSOR(S) TO BE INSTALLED. WIRING MUST BE TERMINATED ON THE

TERMINALS INDICATED BELOW TO ENSURE CORRECT OPERATION.

SEE PAGE 2 FOR TMS3000 SENSOR NUMBERING SEQUENCE

2-WIRE SENSORS

MODEL

HS100D

FIELD CABLE C ONDUCTOR COLORS SHO WN.

(NON-DISCRIMINATING)

HS100ND

LS600

FIELD CABLE C ONDUCTOR COLORS SHO WN.

NOTE: LS600 SUPPLIED WITH

CONDUCTOR CO LOR PAIR PER

SWITCH POINT. REFER TO THE

TAG ATTACHED TO THE SENSOR.

LS600LD / LS610

RSU800

FIELD CABLE C ONDUCTOR COLORS SHO WN.

(NON-DISCRIMINATING)

RSU801

4-PROBE/8-SENSOR

CARD WIRING

3-WIRE SENSORS

BLK

RED

16-SENSOR

CARD WIRING

GND

SIG

+V

RED

BLK

+V

SIG

4-PROBE/8-SENSOR

CARD WIRING

MODEL

ES825-100 SERIES

ES825-200 SERIES

"W" = WHITE; "G" = GREEN

BLK

W OR G

RED

BLK

HS100D

FIELD CABLE CO NDUCTOR COLORS SHOWN.

(DISCRIMINATING)

"W" = WHITE; "G" = GREEN

RED

W OR G

RED

RSU800

(DISCRIMINATING)

* RED IS COMMON GROUND WIRE

GRN

BLK

NOTE THE REVERSE ORDERING OF SENSOR INPUT NAMES

Questions? Contact Technical Support at (800) 209-7858

16-SENSOR

CARD WIRING

GND

SIG

+V

GND

SIG

+V

+V

SIG

GND

*

GND

SIG

+V

+V

SIG

GND

RED

W OR G

BLK

RED

BLK

W OR G

GRN

RED

BLK

+V

SIG

+V

SIG

+V

SIG

+V

SIG

*

+V

SIG

Bulletin 174 Rev. B (12/07/15)

Figure 11A - TMS3000 Sensor Wiring

TMS Quick Start-up Guide.docx

PNEUMERCATOR

Liquid Level Control Systems

Page 1 of 2

Page 18 of 24 November 21, 2017

Quick Start-up Guide TMS Series

(3)

4-PROBE/

8-SENSOR

CARDS

(2)

4-PROBE/

8-SENSOR

CARDS

(1)

16-SENSOR

CARD

G

PROBE

C

SENSOR 1

H

1

SENSOR 2

PROBE

C

SENSOR 1

H

2

SENSOR 2

PROBE

C

SENSOR 1

H

3

SENSOR 2

PROBE

C

SENSOR 1

H

4

SENSOR 2

SENSOR 1

SENSOR 2

SENSOR 3

SENSOR 4

SENSOR 5

SENSOR 6

SENSOR 7

SENSOR 8

SENSOR 9

SENSOR 10

SENSOR 11

SENSOR 12

SENSOR 13

SENSOR 14

SENSOR 15

SENSOR 16

M

B

I

R

E

C

H

1

C

H

2

C

H

3

C

H

4

C

H

1

C

H

2

C

H

3

C

H

4

G

N

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

G

1

P

U

O

R

U

N

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

G

N

I

3

P

U

O

R

17

18

19

20

21

22

23

24

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

R

E

B

M

U

N

PROBE

C

SENSOR 1

H

1

SENSOR 2

PROBE

C

SENSOR 1

H

2

SENSOR 2

PROBE

C

SENSOR 1

H

3

SENSOR 2

PROBE

C

SENSOR 1

H

4

SENSOR 2

PROBE

C

SENSOR 1

H

1

SENSOR 2

PROBE

C

SENSOR 1

H

2

SENSOR 2

PROBE

C

SENSOR 1

H

3

SENSOR 2

PROBE

C

SENSOR 1

H

4

SENSOR 2

G

2

P

U

O

R

10

11

12

13

14

15

16

10

11

12

13

14

15

16

U

N

9

9

M

G

N

I

R

E

B

SENSOR 1

SENSOR 2

SENSOR 3

(1)

4-PROBE/

8-SENSOR

CARD

(2)

16-SENSOR

CARDS

Bulletin 174 Rev. B (12/07/15)

TMS Quick Start-up Guide.docx

SENSOR 4

SENSOR 5

SENSOR 6

SENSOR 7

SENSOR 8

SENSOR 9

SENSOR 10

SENSOR 11

SENSOR 12

SENSOR 13

SENSOR 14

SENSOR 15

SENSOR 16

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

9

C

H

1

C

H

2

C

H

3

C

H

4

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

SENSOR 1

SENSOR 2

SENSOR 3

SENSOR 4

SENSOR 5

SENSOR 6

SENSOR 7

SENSOR 8

SENSOR 9

SENSOR 10

SENSOR 11

SENSOR 12

SENSOR 13

SENSOR 14

SENSOR 15

SENSOR 16

Figure 11B - TMS3000 Sensor Wiring

Page 19 of 24 November 21, 2017

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

PROBE

SENSOR 1

SENSOR 2

1

2

3

4

5

6

7

8

Page 2 of 2

Quick Start-up Guide TMS Series

TMS Quick Start-up Guide.docx

Page 20 of 24 November 21, 2017

Figure 12A - TMS Series to RA200KR Wiring

Quick Start-up Guide TMS Series

TMS Quick Start-up Guide.docx

Page 21 of 24 November 21, 2017

Figure 12B - TMS Series to RA200KR Wiring

WIRING DRAWING - RA200* TO LC2000 & TMS SERIES

50214 Rev. G (07/18/12) Page 2 of 2

FROM RS2 SWITCH

(SEE PAGE 1)

FROM RA200

AUDIBLE/VISUAL

ANNUNCIATOR

(SEE PAGE 1)

BLK JUMPER

CC

CC

CC

CC

CC

CC

CC

10

9

7

8

5

6

3

4

4

3

NO

NO

6

5

NO

NO

8

7

NO

NO

9

NO

10

NO

CC

I

N

P

U

T

S

O

U

T

P

U

T

S

BLK JUMPER

O

U

T

P

U

T

S

I

N

P

U

T

S

BUILT-IN RELAY I/Os

OR

4X4 RELAY I/O CARD

OR

8X8 RELAY I/O CARD

O

U

T

P

U

T

S

I

N

P

U

T

S

SIG

3

SIG

4

SIG

RELAY 6

COM

NC

RELAY 4

NC

RELAY 3

SIG

56

COM

NO

COM

RELAY 5

COM

NO

NC

NO

NC

NO

BLK JUMPER

SIG

SIG

2 1

COM

NC

NO

COM

NC

RELAY 2

RELAY 1

NO

LC2000/TMS2000

WIRING TERMINATION EXAMPLES SHOWN FOR REFERENCE

(SEE NOTES)

O

U

T

P

U

T

S

I

N

P

U

T

S

O

U

T

P

U

T

S

I

N

P

U

T

S

FROM RA200

AUDIBLE/VISUAL

ANNUNCIATOR

(SEE PAGE 1)

BLK JUMPER

4X4 RELAY I/O CARD

OR

8X8 RELAY I/O CARD

FROM RS2 SWITCH

(SEE PAGE 1)

BLK JUMPER

CC

CC1

1

3

2

4

RELAY 1RELAY 2RELAY4 RELAY 3

CC2

CC3

CC4

NO

NO

NC

NC

COM

COM

NO

NC

NO

COM

COM

NC

1

CC

2

CC

3

CC

4

CC

5

CC

6

CC

7

CC

8

NO

1

NO

2

NO

NO

4

3

NO

NO

6

5

NO

NO

8

7

TMS3000

WIRING TERMINATION EXAMPLES SHOWN FOR REFERENCE

(SEE NOTES)

NOTES:

1.

WIRING MAY BE TERMINATED ON ANY TMS RELAY INPUT/OUTPU T .

HOWEVER, IF REQUESTED WITH ORDER, WIRING MUST BE

TERMINATED ON THE SPECIFIED PRE-PROGRAMMED INPUTS/OUTPUTS.

REMINDER : PROGRAMMING STARTS WI TH THE BUILT-IN MAIN BOARD

RELAYS FOR LC2000 AND TMS2000.

2.

DO NOT MODI FY LC2000/TMS ENCLOSUR E . USE DESIGNAT ED CONDUIT

KNOCKOUTS/OPENINGS AS SHOWN IN THE TMS INSTALLATION MANUAL.

3. TOP CONDUIT HO LE ELIMINATED ON RS2 AS SHOWN O N PAGE 1.

HOWEVER, EXISTING STOCK WITH TOP CONDUIT HOLE MAY STILL BE

SUPPLIED. IF AVAILABLE BUT NOT USED, THE TOP CONDUIT HOLE MUST

BE PLUGGED WITH AN APPROPRIATE FITTING AND WATERTIGHT IF

LOCATED OUTDOORS.

SEE NOTE 1

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

"W" = WHITE; "G" = GREEN

STROBE

HORN

RED

TEST (N.O.)

COND.

COLOR

W OR G

RED

W OR G

3 COND.

CABLE

BLACK

BLACK HORN/ST ROBE COMMON

RESET (N.O.)

SWITCH COMMON

FUNCTION

* "RA200" CAN ALSO BE WRITTEN AS "RA200-1"

"W" = WHITE

"G" = GREEN

Questio ns? Contact Tech nical Suppo rt at (800) 209-7858

W OR G (RESET; N.O.)

BLK (COM)

RED (TEST; N.O .)

BLK (COM)

W OR G (STROBE)

RED (HORN)

W OR G (RESET; N.O.)

BLK (COM)

RED (TEST; N.O .)

BLK (COM)

W OR G (STROBE)

RED (HORN)

CC

NO

1

2

1

NO

NO

NO

2

4

3

W OR G (STROBE)

RED (TEST; N.O .)

BLK (COM)

BLK (COM)

W OR G

(RESET; N.O.)

RED (HORN)

BLK (COM)

W OR G (STROBE)

RED (HORN)

RED (TEST; N.O .)

BLK (COM)

W OR G

(RESET; N.O.)

RED (TEST; N.O .)

BLK (COM)

W OR G

(RESET; N.O.)

RED (HORN)

W OR G (STROBE)

BLK (COM)

I

N

P

U

T

S

O

U

T

P

U

T

S

TMS1000

(4X4 AND 8X8 RELAY CARDS ARE NOT SUPPORTED)

RED (TEST; N.O .)

BLK (COM)

BLK JUMPER

BLK (COM)

W OR G (STROBE)

RED (HORN)

"W" = WHITE

"G" = GREEN

FROM RA200 AUDIBLE/VISUAL

ANNUNCIATOR (SEE PAGE 1)

FROM RS2 SWIT CH

(SEE PAGE 1)

BUILT-IN RELAY I/Os

CC

W OR G (RESET; N.O.)

Quick Start-up Guide TMS Series

TMS Quick Start-up Guide.docx

Page 22 of 24 November 21, 2017

Figure 13A - TMS Series to RA100R Wiring

Page 1 of 2

50256 Rev. E (07/18/12)

WIRING DRAWING - RA100 TO LC2000 & TMS SERIES

W

H

T

(

S

T

R

OB

E

)

B

L

K

R

E

D

(

H

O

R

N

)

W

H

T

W

H

T

B

L

K

B

L

K

(

C

O

M

)

WIRE NUTS

COVER

(BACK VIEW)

1/2" NPT

(TYP.)

JUNCTION BOX ( BY CUSTOMER)

MUST BE WATERTIGHT IF

LOCATED OUTDOORS

(SHOWN ENLARGED F OR CLARITY)

DO NOT USE THE TMS POWER AS THE SOURCE FOR POWERING THE

RA100.

THIS SYSTEM IS NOT INTRINSICALLY SAFE OR EXPLOSION PROOF.

DO NOT INSTALL INS IDE THE HAZARDOUS AREA.

WARNING

!

1

2

3

1 = RED (TEST)

2 = BLACK (COM)

3 = WHT OR GRN (RESET)

SEE NOTE 3

ON PAGE 2

TEST

RESET

RS2

REMOTE SWITCH

COVER

TO CONTACT

CLOSURE INPUTS

TO RELAY

OUTPUTS

TO LC2000/TMS

(SEE PAGE 2)

3-CONDUCTOR 22 AWG CABLE

BELDEN 8443 OR EQUIVALENT

R

E

D

* INSTALL SO THAT THE DRIP HOLES ARE LOCATED ON

THE BOTTOM (SEE OUTLINE DRAWING 10506). IF

NOT SUPPLIED, DRAWING MAY BE DOWNLO ADED

FROM www.pneumerc ator.com

* RA100 REMO TE AUDIBLE/ VISUAL

ANNUNCIATOR

COVER

(FRONT VIE W)

123412341234432

BELL

HI/LO

HORN

SIREN

WOOP

SLOW

TONE

CODE 3

HORN

CODE 3

TIME

MARCH

1

REMOTE AUDIBLE/V ISUAL ANNUNCIATOR

TONE OPTIONS/SW1 SWI TCH POSITIONS

SER. NO.

RA100-115VAC

MODEL NO.

Liquid Level Control Systems

PNEUMERCATOR

NL

AUD

L

STB

N

PNEUMERCA

Liquid Level C ontrol Sys tems

L NO.

115VAC

SER.

TO

REMOTE AUDIB L CIAT OR

1234

RED

BLK

WHT

WHT

BLK

(H)

WHT

(N)

115 VAC

POWER

PNEUMERCATOR

Liquid Level Control Systems

Questions? Co ntact Technical Support at (800) 209-7858

FUNCTION

HORN/STROBE CO MMON

RESET (N.O.)

SWITCH COMMO N

TEST (N.O.)

W OR G

3 COND.

CABLE

COND.

COLOR

BLACK

W OR G

BLACK

RED

RED

STROBE

HORN

"W" = WHITE; "G" = GREEN

Quick Start-up Guide TMS Series

TMS Quick Start-up Guide.docx

Page 23 of 24 November 21, 2017

Figure 13B - TMS Series to RA100R Wiring

Page 2 of 2

50256 Rev. E (07/18/12)

WIRING DRAWING - RA100 TO LC2000 & TMS SERIES

Questions? Co ntact Technical Support at (800) 209-7858

FUNCTION

HORN/STROBE CO MMON

RESET (N.O.)

SWITCH COMMO N

TEST (N.O.)

W OR G

3 COND.

CABLE

COND.

COLOR

BLACK

W OR G

BLACK

RED

RED

STROBE

HORN

"W" = WHITE; "G" = GREEN

FROM RS2 SWITCH

(SEE PAGE 1)

FROM RA100

AUDIBLE/VISUAL

ANNUNCIATOR

(SEE PAGE 1)

BLK JUMPER

CC

CC

CC

CC

CC

CC

CC

10

9

7

8

5

6

3

4

4

3

NO

NO

6

5

NO

NO

8

7

NO

NO

9

NO

10

NO

CC

I

N

P

U

T

S

O

U

T

P

U

T

S

BLK JUMPER

O

U

T

P

U

T

S

I

N

P

U

T

S

BUILT-IN RELAY I/Os

OR

4X4 RELAY I/O CARD

OR

8X8 RELAY I/O CARD

O

U

T

P

U

T

S

I

N

P

U

T

S

SIG

3

SIG

4

SIG

RELAY 6

COM

NC

RELAY 4

NC

RELAY 3

SIG

56

COM

NO

COM

RELAY 5

COM

NO

NC

NO

NC

NO

BLK JUMPER

SIG

SIG

2 1

COM

NC

NO

COM

NC

RELAY 2

RELAY 1

NO

LC2000/TMS2000

WIRING TERMINATION EXAMPLES SHOWN FOR REFERENCE

(SEE NOTES)

O

U

T

P

U

T

S

I

N

P

U

T

S

O

U

T

P

U

T

S

I

N

P

U

T

S

FROM RA100

AUDIBLE/VISUAL

ANNUNCIATOR

(SEE PAGE 1)

BLK JUMPER

4X4 RELAY I/O CARD

OR

8X8 RELAY I/O CARD

FROM RS2 SWITCH

(SEE PAGE 1)

BLK JUMPER

CC

CC1

1

3

2

4

RELAY 1RELAY 2RELAY4 RELAY 3

CC2

CC3

CC4

NO

NO

NC

NC

COM

COM

NO

NC

NO

COM

COM

NC

1

CC

2

CC

3

CC

4

CC

5

CC

6

CC

7

CC

8

NO

1

NO

2

NO

NO

4

3

NO

NO

6

5

NO

NO

8

7

TMS3000

WIRING TERM INATION EXAMPLES SHOW N FOR REFERENCE

(SEE NOTES)

NOTES:

1.

WIRING MAY BE TERMINATED ON ANY TMS RELAY INPUT/OUTPU T.

HOWEVER, IF RE QUESTED WITH ORDER, W IRING MUST BE

TERMINATED ON THE SPECIFIED PRE-PROGRAMMED INPUTS/OUTPUTS.

REMINDER : PROGRAMMING STARTS WITH THE BUILT-IN MAIN BOARD

RELAYS FOR LC2000 AND TMS2000.

2.

DO NOT MODIF Y LC2000/TMS ENCLOSUR E . USE DESIGNATED CONDUIT

KNOCKOUTS/OPENINGS AS SHOWN IN THE TMS INSTALLATION MANUAL.

3. TOP CONDUIT HOLE ELIMINATED ON RS2 AS SHOWN ON PAGE 1.

HOWEVER, EXIST ING STOCK WITH TOP CONDUIT HOLE MAY STILL BE

SUPPLIED. IF AVAILABLE BUT NOT USED, THE TOP CONDUIT HOLE MUST

BE PLUGGED WITH AN APPROPRIATE FITTING AND WATERTIGHT IF

LOCATED OUTDOORS.

SEE NOTE 1

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

"W" = WHITE

"G" = GREEN

W OR G (RESET; N.O. )

BLK (COM)

RED (TEST; N.O .)

BLK (COM)

W OR G (STROBE)

RED (HORN)

W OR G (RESET; N.O.)

BLK (COM)

RED (TEST; N.O .)

BLK (COM)

W OR G (STROBE)

RED (HORN)

CC

NO

1

2

1

NO

2

NO

NO

4

3

W OR G (STROBE)

RED (TEST; N.O .)

BLK (COM)

BLK (COM)

W OR G

(RESET; N.O.)

RED (HORN)

BLK (COM)

W OR G (STROBE)

RED (HORN)

RED (TEST; N.O .)

BLK (COM)

W OR G

(RESET; N.O.)

RED (TEST; N.O .)

BLK (COM)

W OR G

(RESET; N.O.)

RED (HORN)

W OR G (STROBE)

BLK (COM)

I

N

P

U

T

S

O

U

T

P

U

T

S

TMS1000

(4X4 AND 8X8 RELAY CARDS ARE NOT SUPPORTED)

RED (TEST; N.O .)

BLK (COM)

BLK JUMPER

BLK (COM)

W OR G (STROBE)

RED (HORN)

"W" = WHITE

"G" = GREEN

FROM RA100 AUDIBLE/VISUAL

ANNUNCIATOR (SEE PAGE 1)

FROM RS2 SWIT CH

(SEE PAGE 1)

BUILT-IN RELAY I/Os

CC

W OR G (RESET; N.O.)

Quick Start-up Guide TMS Series

r

r

RA100R/RA200KR Remote Alarm Programming

Note: For wiring, refer to: Figure 12 for RA200KR.

Figure 13 for RA100R

The following wiring scenario is being provided as a guideline only. The advantage to wiring

the CC Inputs as illustrated is to use the Reset switch in combination with the Test switch. The relays

can be wired in any combination. This is the way your system will be preprogrammed if supplied with

an RA100/RA200 alarm.

Programming:

1. Sets the tank conditions that must occur to activate the relays. Factory default conditions shown

below activate for SP1 (Above 95% volume) and SP2 (Above 90% volume).

Front Panel TMS Communicator

Config Rely Tank Configuration Relays Tank Triggers

Relays Relays

Leak Trig no.no.no Leak Trigger None - None - None

SP1 Trig 01.02.no Set Point #1 Trigger Relay #1 - Relay #2 - None

SP2 Trig 01.02.no Set Point #2 Trigger Relay #1 - Relay #2 - None

SP3 Trig no.no.no Set Point #3 Trigger None - None - None

H2O Trig no.no.no Water Trigger None - None – None

2. Chooses the CC Inputs (wired to RS2) that the relays will react to.

Front Panel TMS Communicator

Config Rely cc Configuration Relays Non-Hazardous Contact Closure Inputs

cc Trig Relays CC Trigger Relay Selects

1 02.no.no #1 Relay #2 – None – None

2 01.02.no #2 Relay #1 – Relay #2 – None

3. Controls the behavior of a relay.

Front Panel

Relay Normally FP Ack Delay Latch En

1 Off No None No

2 Off Yes None No

Relay Normal Contact State Allow Front Panel Acknowledgements Delayed Shutoff Latch Enable

#1 Off

#2 Off

Configuration Relays Relay Mode

4. Controls the behavior of a Contact Closure Input. Note: Only settings used for supporting the RS2 are

listed below. Do not change the factory default values for other unlisted settings.

CC Input cc Enable Normally

1 Ack Open

2 Relay Open

CC Input Contact Closure Enable Normally

#1 Acknowledge Open

TMS Quick Start-up Guide.docx

#2 Relay Open

Configuration Contact Closure Inputs Non-Hazardous Contact Closure Inputs

Config Rely Mode

TMS Communicato

None

None

Front Panel

Config cc Input

TMS Communicato

Page 24 of 24 November 21, 2017

Contact Closure 1 Reset

Contact Closure 2 Test

Relay 1 Strobe

Relay 2 Horn

Loading...

Loading...