Page 1

LEAK/POINT

PNEUMERCAT OR

Liquid Level Control Systems

LEVEL ALARM

CONSOLE

OPERATION MANUAL

MODEL LC2000

© COPYRIGHT 2017 PNEUMERCATOR CO., INC.

1785 EXPRESSWAY DRIVE NORTH

HAUPPAUGE, NY 11788

http://www.pneumercator.com

LC2000 Operation Manual - 2017-07-08.docx July 8, 2017

DRAWING NO. 20068 RE V. N/C

TEL: (631) 293-8450

FAX: (631) 293-8533

Page 2

Page 3

OPERATION MANUAL LC2000

Section 1 SYSTEM OVERVIEW ................................................................................................. x

1.1 Front Panel Description ............................................................................................... 4

1.2 Display ......................................................................................................................... 6

1.3 Pushbutton Layout ...................................................................................................... 6

1.4 Edit Enable/Save Button ............................................................................................. 7

Section 2 OPERATION ............................................................................................................... x

2.1 View Mode ................................................................................................................... 8

2.2 Program Mode ............................................................................................................. 8

Section 3 LOGS/REPORTS ........................................................................................................ x

3.1 Alarm Log .................................................................................................................. 11

3.2 Event Log .................................................................................................................. 12

Section 4 PRINTER OPERATION............................................................................................... x

4.1 Paper Replacement ................................................................................................... 13

4.2 Ribbon Replacement ................................................................................................. 13

Appendixes .................................................................................................................................... x

A Alarm Conditions And Code Table ............................................................................ 14

TABLE OF CONTENTS

Page

Page 4

OPERATION MANUAL LC2000

WARNING

This product is wired to sensors installed in hazardous, explosive environments.

Initial application of AC power to this system should occur only after complete

verification of safe, proper installation by authorized Pneumercator-certified

service personnel. Failure to do so may result in serious injury and/or property

loss.

This manual is intended to be used for instruction on operation and basic sensor programming of the

LC2000 using it’s front panel controls, display and optional printer. Much more extensive

programming is available using the TMSComm communications software provided on CD ROM.

SECTION 1 – SYSTEM OVERVIEW

1.0 GENERAL

The LC2000 series Leak and Point Level Alarm Console offers essentially all of the sensor-related

features of the TMS series Tank Management Systems, and will interface to all of the same sensor

model types, including discriminating and non-discriminating electronic or mechanical secondary

containment leak sensors as well as single and multi-point level float sensors. All sensor inputs can

be programmed for either alarm or relay control applications, including time delay, conditional logic

and latching functions for pump/valve controls. Optional printer and numerous communications

options are also supported.

1.1 FRONT PANEL DESCRIPTION

The front panel of the LC2000 is available in four different configurations as listed below:

LC2000-1... Console without display or printer

LC2000-2... Console with display, no printer

LC2000-3... Console with display and internal printer

LC2000-4... Console with display and internal printer w/autowinder

This manual describes operational procedures pertaining to -2, -3, and -4 consoles. The LC2000-1

"Black Box" Remote Acquisition Unit is described in a separate Pneumercator document for operating

the LC2000 using TMS Communicator.

As illustrated in Figure 1-1 below, the LC2000 front panel consists of an array of green, yellow and

red LED indicators for sensor status, power LED, audible alarm annunciator, ultra-bright summary

alarm LED strobe (optional), membrane pushbutton controls, security lock, and optional printer with

or without autowinder.

LC2000 Operation Manual.docx July 8, 2017

PAGE 4

Page 5

OPERATION MANUAL LC2000

PNEUMERCATOR

Liquid Level Control Sy stems

PAPER

FEED

PRINT

LC 2000

PRODNORM WATER

1

FAULT

2

3

4

5

6

7

8

SENSOR NO/NC TLUAFTLUAFNO/NCSENSOR

RESET

PROGRAM

LEAK/POINT LEVEL CONSOLE

WATERNORM PROD

9

10

11

12

13

14

15

16

PGM

TEST

SENSOR

SELECT

Figure 1-1 – Front Panel View

PROGRAM

SELECT

ON/OFF

DWG NO. 20078 REV. N/C

LC2000 Operation Manual.docx July 8, 2017

PAGE 5

Page 6

OPERATION MANUAL LC2000

1.2 DISPLAY

The front panel display consists of an array of 4, 8, 12 or 16 groups of ultra-high intensity green,

yellow and red LED indicators for sensor state and basic configuration status, green power LED and

optional ultra-bright summary alarm LED strobe. Operating in the normal or VIEW mode, sensor LEDs

indicate NORMAL and ALARM conditions for non-discriminating sensors or NORMAL, PRODUCT

and WATER alarm conditions for discriminating sensors. Sensor and wiring FAULT conditions are

also indicated for sensors having Pneumercator’s exclusive supervised wiring feature. The optional

summary alarm flashing strobe is activated for any new alarm condition and can be programmed to

de-activate on front panel RESET, or persist until the alarm condition is removed. See figure 1-2

below.

LC 2000

PRODNORM WATER

1

2

3

4

5

6

7

8

SENSOR NO/NC

1.3 PUSHBUTTON LAYOUT

LEAK/POINT LEVEL CONSOLE

WATERNORM PROD

9

FAULT

PROGRAM

10

11

12

13

14

15

16

NO/NCSENSOR

TLUAFTLUAF

Figure 1-2 - LC2000 LED Layout

DWG NO. 20079 REV. N/C

RESET

SENSOR

SELECT

LC2000 Operation Manual.docx July 8, 2017

PGM

PROGRAM

SELECT

TEST

ON/OFF

Figure 1-3 – Pushbutton Layout

PAGE 6

DWG NO. 20076 REV. N/C

Page 7

OPERATION MANUAL LC2000

D

N

GSENSOR

1.4 EDIT ENABLE/SAVE BUTTON

ISCRIMINATI

(OPEN = DISABLED)

SENSOR # 1 4

DISCRIMINATINGSENSOR ENABLES

SENSORNO .

1234

ENABLES

8

5678910

12

11 121314

16

15 16

ENABLED

DISABLED

OPEN= DISABLED

EDIT

ENABLE / SAVE

BUTTON

PUSH UP AND

RELEASE

Figure 1-4 – Edit Enable/Save Button

DWG NO. 20077 REV. A

LC2000 Operation Manual.docx July 8, 2017

PAGE 7

Page 8

OPERATION MANUAL LC2000

SECTION 2 – OPERATION

2.0 OVERVIEW

The LC2000 has two operational modes, VIEW(normal) and PROGRAM, offering the following

functions;

VIEW Mode:

Display of current sensor statuses and audible annunciation of alarm conditions

Front panel acknowledgement of alarm conditions

Testing of front panel display and audible alarm

Viewing of basic sensor programming information

Printing of current sensor status report and Alarm/Event logs (if equipped with optional printer)

Initialization of logs and system configuration programming

PROGRAM Mode:

Viewing/Programming of basic sensor configuration (Note: More extensive programming must

be performed using the supplied TMSComm software)

Printing of sensor-only or complete system configuration reports

2.1 VIEW MODE

Pushbutton Operation:

RESET acknowledges the front panel horn, changes blinking new alarm LEDs to steady “on”

and turns off strobe if so programmed. All programmed relay FP acknowledges are also

activated.

TEST turns on all LEDs, strobe and double beeps horn.

PGM (recall) displays basic sensor programming.

Combined TEST and RESET enters PROGRAM mode. (See Section 2.2)

PRINT generates a CURRENT SENSOR STATUS Report.

Press and hold PRINT for 1 second to generate an Alarm and Event Log Report.

PAPER FEED advances printer paper.

Initialize all LC2000 logs – Press and hold EDIT ENABLE/SAVE pushbutton for at least 10

seconds while in VIEW mode. LC2000 will beep 3 times to confirm operation.

Initialize LC2000 configuration – Press and hold EDIT ENABLE/SAVE and RESET

pushbuttons for at least 10 seconds while in VIEW mode. LC2000 will beep 3 times to confirm

operation. WARNING! This operation will clear all user-programmed configuration data

and set factory defaults.

LED Operation:

1. During start-up, all LEDs blink while loading configuration, followed by a display, LED strobe

and beeper check.

2. During VIEW mode, green = NORMAL, red = ALARM or PRODUCT ALARM, yellow = WATER

ALARM and red and yellow = FAULT. Alarms and faults blink until acknowledged.

3. During PGM recall mode, LEDs indicate basic sensor programming. Refer to table PROGRAM

Mode LED Indicators for details.

LC2000 Operation Manual.docx July 8, 2017

PAGE 8

Page 9

OPERATION MANUAL LC2000

(

)

A

2.2 PROGRAM MODE

1. Enter PROGRAM mode by first pressing and holding TEST to enter DISPLAY CHECK mode,

followed by RESET (while still holding TEST). After two seconds the LC2000 will beep twice,

indicating transition to PROGRAM mode. The display will now show basic sensor

programming information as indicated by the orange lettering on the front panel.

2. Initial entry into PROGRAM mode: First SENSOR ENABLE LED blinks 3 times, then goes to

programmed state, i.e. ON for enabled, OFF for disabled.

3. Press TEST/ON-OFF to enable/disable selected item(EDIT ENABLE/SAVE button must be

pressed once after entering PROGRAM mode). If selected item is SENSOR ENABLE and

item is set to DISABLE, then all associated LEDs are turned off. See PROGRAM Mode LED

Indicators table below for programming selections.

4. Press PGM/PROGRAM SELECT until the “beep” to advance to the right to the next program

item. If the selected sensor is DISABLED, pressing PGM/PROGRAM SELECT until the “beep”

will not advance to the right, and instead, the SENSOR ENABLE LED will blink 3 times, then

retain its current state, which would be OFF.

5. Press and immediately release PGM/PROGRAM SELECT (w/o beep) to recall the currently

selected LED item. Associated LED will blink 3 times and return to currently programmed

state.

6. DISCRIMINATING SENSOR mode is selected via dip switches on the back of the display

board. See FRONT PANEL SENSOR PROGRAMMING table below. IMPORTANT! Dip

switch programming of DISCRIMINATING SENSOR enables will not take affect until an EDIT

SAVE operation is performed. Also, programming DISCRIMINATING SENSOR enables via

dip switches must be enabled in the LC2000 configuration file (Factory Default).

7. Edits are saved by pressing EDIT ENABLE/SAVE button.

8. PRINT generates a SENSOR CONFIGURATION Report.

9. Press and hold PRINT for 1 second to generate a complete configuration report.

PROGRAM Mode LED Indicators

SENSOR

ENABLE

OFF - DISABLED OFF - NC OFF - DISABLED

ON (2 Fast Blinks)

LARM INPUT

ON (3 Slow Blinks)

RELAY CONTROL

NORMALLY

OPEN/CLOSED

NO/NC

ON - NO ON - ENABLED

FAULT DETECT

ENABLE

LC2000 Operation Manual.docx July 8, 2017

PAGE 9

Page 10

OPERATION MANUAL LC2000

(

)

Front Panel Sensor Programming

SENSOR

MODEL

All Float Switches

w/o Fault Detection

All Float Switches

w/ Fault Detection

ES825-100F NO ENABLED OPEN

ES825-200F NO ENABLED CLOSED

HS100 Series NC DISABLED CLOSED

NORMALLY

OPEN/CLOSED

NO/NC

As Built DISABLED OPEN

As Built ENABLED OPEN

FAULT

DETECT

ENABLE

DISCRIMINATION

ENABLE

Dip Switch Programming(S1)

S1-1 S1-2 S1-3 S1-4

OPEN -

CLOSED FACTORY

ENABLE

Strobe Acknowledge

DISABLE Front Panel

Strobe Acknowledge

Front Panel

ENABLE

Communications

Security

DISABLE

Communications

Security

-

FACTORY

LC2000 Operation Manual.docx July 8, 2017

PAGE 10

Page 11

OPERATION MANUAL LC2000

SECTION 3 – LOGS

The LC2000 can log the occurrence of various alarm and system error conditions. These logs are

stored in battery-backed memory for retrieval using TMSComm, and additionally can be manually or

automatically printed with optional printer installed.

3.1 ALARM LOG

This log captures the occurrence of alarm conditions based on sensor and non-hazardous contact

closure inputs programmed as alarm inputs. Inputs programmed for non-alarm functions will not be

captured. The alarm log will maintain the 24 most recent alarm occurrences. All ALARM log data is

available via the TMSComm communications software or optional printer. See Section 2.1 VIEW

Mode for instructions on printing an alarm log report. NOTE: If optional printer is included, factory

default is automatic printout on ALARM condition. The console can be programmed to disable

automatic printouts, i.e. manual or demand printouts only, using TMSComm.

The following is a description of ALARM log data;

Date: Month and Day of alarm occurrence

Time: Hour and Minutes of alarm occurrence (24 hour format)

Alarm Name: Assigned sensor or contact closure name

Device ID: Sensor Input #1–16 or Contact Closure Input #1-10.

Alarm ID: Identifies alarm type SENSOR or CONTACT CLOSURE

Alarm Detail: Additional alarm information when applicable

ALARM, CLOSED, OPEN, OIL, WATER

LC2000 Operation Manual.docx July 8, 2017

PAGE 11

Page 12

OPERATION MANUAL LC2000

3.2 EVENT LOG

This log captures the occurrence of system hardware and configuration-related problems. More

serious problems are identified as FATAL ERROR or ERROR conditions, while others are identified

as WARNING conditions. The EVENT log will maintain the 8 most recent system problem

occurrences. All EVENT log data is available via the TMSComm communications software or optional

printer. See Section 2.1 VIEW Mode for instructions on printing an EVENT log report. NOTE: If

optional printer is included, factory default is automatic printout on EVENT condition. The console

can be programmed to disable automatic printouts, i.e. manual or demand printouts only, using

TMSComm.

The following is a description of EVENT log data;

Date: Month and Day of alarm occurrence

Time: Hour and Minutes of alarm occurrence (24 hour format)

Fatal Error, Error or Warning #: Two-digit error or warning identification code. See Appendix A,

Device ID: Sensor Input #1–16 or Contact Closure Input #1-10, if applicable

Event ID: See Appendix A

Detail See Appendix A

LC2000 Operation Manual.docx July 8, 2017

PAGE 12

Page 13

OPERATION MANUAL LC2000

SECTION 4 PRINTER OPERATION

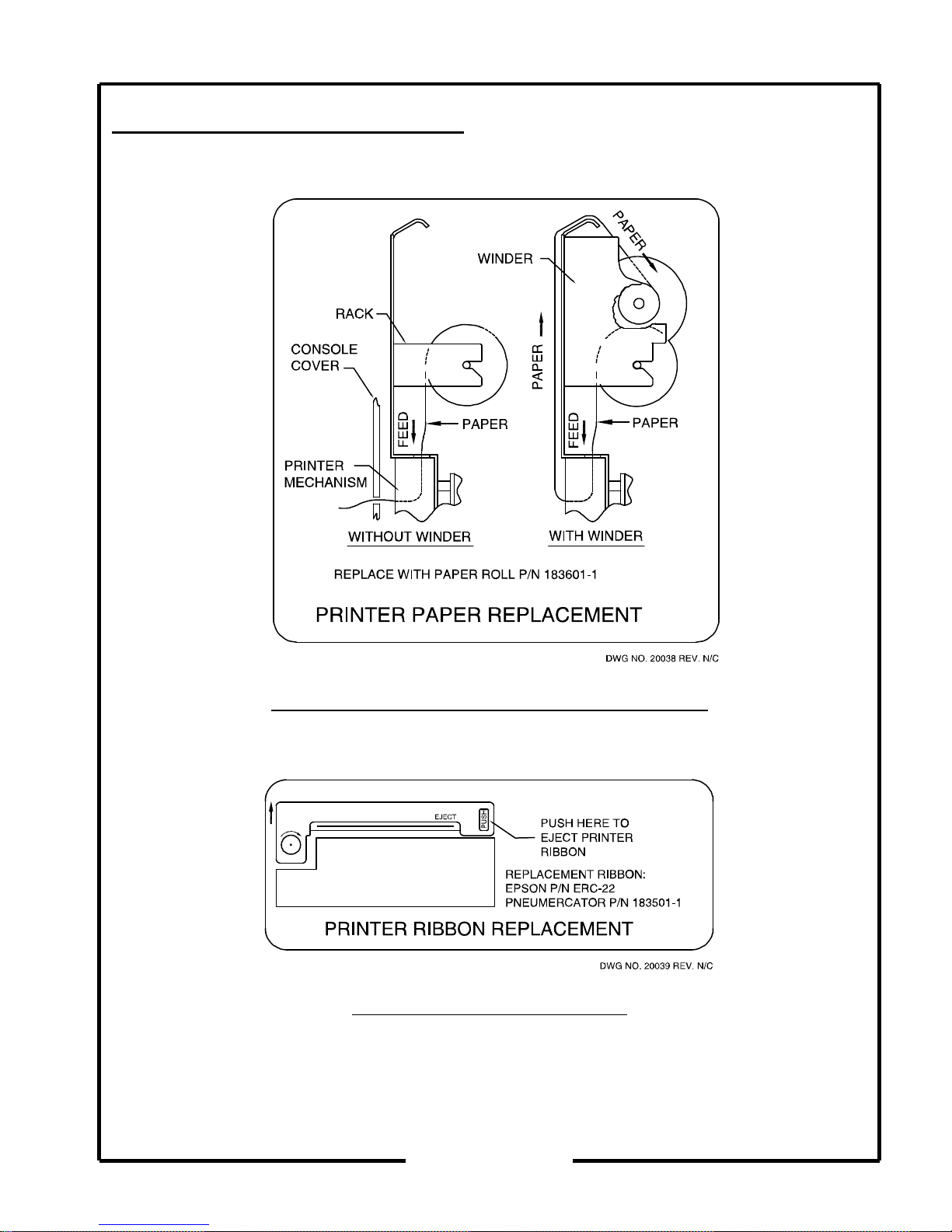

4.1 PRINTER PAPER REPLACEMENT

P

A

P

E

R

WINDER

RACK

CONSOLE

COVER

PAPER

PRINTER

MECHANISM

WITHOUT WINDER

REPLACE WITH PAPER ROLL P/N 183601- 1

PRINTER PAPER REPLACEMENT

H

Figure 4-1 – Printer Paper Replacement (No Winder)

4.2 RIBBON REPLACEMENT

FEED

EJECT

PAPER

FEED

WITH WINDER

PUSH

PUSH HERE TO

EJECT PRINTER

RIBBON

REPLACEMENT RIBBON:

EPSON P/N ERC-22

PNEUMERCATOR P/N 183501-1

PAPER

DWG NO. 20038 REV. N/C

LC2000 Operation Manual.docx July 8, 2017

PRINTER RIBBON REPLACEMENT

DWG NO. 20039 REV. N/C

Figure 4-2 - Ribbon Replacement

PAGE 13

Page 14

OPERATION MANUAL LC2000

APPENDIX A EVENT CONDITIONS AND CODE TABLE

Warning Conditions Codes: Detail:

Modem Initialization Warning 01 Attempt to initialize modem with no response.

Modem Command Warning 02 Contact Factory.

Modem Timeout Warning 03 One minute transmission time-out during program down

loading or no response within 10 minutes.

Modem Carrier Warning 04 No host data line for modem or line (disconnected).

Modem Communication Warning 05 Receive background noise from modem that is

meaningless to LC2000.

Modem No dial tone Warning 06 No dial tone present. Check line connection.

Header Configuration Warning 09 Configuration data checksum error. Check specific

configuration data group for corrupted data.

Relay cc Configuration Warning 11 “ “ “

Relay Sensor Configuration Warning 12 “ “ “

Relay Status Configuration Warning 13 “ “ “

cc Configuration Warning 15 “ “ “

Sensor Configuration Warning 16 “ “ “

Modem Configuration Warning 19 “ “ “

Dial out Configuration Warning 20 “ “ “

Power Failure Warning 21 LC2000 acknowledges a (2) minute or greater Power

Outage.

Error Conditions: Codes: Detail:

Boot Prom Checksum error 01 Boot Memory Checksum Error – This is a fatal error

indicating corruption of start-up firmware. Contact

Product Support.

Flash Prom Checksum error 02 Flash Memory Checksum Error – This is an error

indicating corruption of application firmware. Re-Flash

or Contact Product Support.

Flash Prom Write error 03 Unable to write to flash memory during flash upload.

Contact Product Support

Flash Prom Erase error 04 Unable to erase flash memory prior to flash upload.

Contact Product Support

Serial Prom Error 05 Communications error encountered while reading

configuration memory. Check that all boards and cables

are properly seated.

Fault detecting sensors

Sensor Short Circuit error 20 Shorted field wiring or sensor -Fault detecting sensors

only.

Sensor Open Circuit error 21 Open field wiring or sensor -Fault detecting sensors

only.

Sensor Fault error 22 Open/Shorted field wiring or sensor – ES825-200F

sensors only

LC2000 Operation Manual.docx July 8, 2017

PAGE 14

Page 15

OPERATION MANUAL LC2000

LC2000 Operation Manual.docx July 8, 2017

PAGE 15

Page 16

PNEUMERCATOR LC SERIES

LIMITED WARRANTY

LC Series

Pneumercator, here and after referred to as PCO, warrants its LC Series family of products to be free of defects in

material and workmanship for a period of Twelve (12) months from date of installation or Fifteen (15) months from

date of invoice, whichever comes first.

During the warranty period on the LC Series, PCO, or factory third party independent representatives will repair or

replace the product at the location where it is installed at no additional cost to the customer.

Packages must be inspected upon receipt for damage, missing parts, and/or manuals. PCO must be contacted by

telephone immediately with a description of damaged or missing parts so replacements can be sent. Written details

must be sent within thirty (30) days.

Pneumercator will not be responsible for shipping charges incurred by the customer.

Warranty repair coverage invoices will be paid if all the following conditions are met:

PCO has acknowledged and authorized warranty work to be done by issuing a Warranty Repair Number.

Start-up Service technician has been trained by PCO

Warranty start-up form has been submitted to PCO

Technician fills out and submits a PCO “Service Report”

Parts (if any) used are returned to PCO with a proper WRGA (Warranty Return Goods Authorization)

Returned parts are found to be defective.

Repair time will be paid according to PCO document “Standard Warranty Labor Charge Schedule”

If the Warranty Registration/Start up Check List has been completed and returned on file with the factory and the

product is installed in accordance with the specific PCO Installation Product Manual, PCO will activate and meet

warranty criteria as described above. Warranty criteria shall be voided if any product has been subjected to misuse,

negligence, damage from acts of nature (lightning, wind, rain, etc.) or is in violation of the products design intent,

disregard to warnings, instructions, modified or repaired by unauthorized personnel or improperly installed. Given

that the third party independent contractor has installed the equipment in accordance with the specific product

instruction manual, and followed all precautions, PCO will fulfill the terms stated in our warranty obligation.

Under no circumstances does the warranty provide a remedy in excess of the equipment. No other expressed or

implied warranty is given by PCO. PCO shall not be liable for consequential damages or any expenses incurred by

the user.

Distributed by:

PNEUMERCAT OR

Liquid Level Control Systems

1785 Expressway Drive North

Hauppauge NY 11788

(631) 293-8450 Fax (631) 293-8533

Loading...

Loading...