PM-LUFT GOLD 1, GOLD 2, GOLD 3 Commissioning, Operation, And Maintenance

1

GOLD 1-3 SK-GB -708

Right to make modifications without prior notice

:

:: :

Commissioning, operation,

and maintenance: GOLD 1-3

1. INTRODUCTION ............................................................ 1

2. ELECTRICAL CONNECTION ........................................ 4

3. CONNECTION OF EXTERNAL FUNCTIONS ............... 5

4. WIRING DIAGRAM POWER CARD .............................. 6

5. WIRING DIAGRAM CONTROL CARD .......................... 7

6. STARTING-UP ............................................................... 8

7. ADJUSTMENTS ............................................................. 9

8. FUNCTIONS ................................................................. 13

9. ADJUSTMENT PROTOCOLE...................................... 18

10. ALARM .........................................................................19

11. MAINTENANCE ............................................................ 21

TELEPHONE NUMBERS PM-LUFT ............................22

INDEX

1. INTRODUCTION

1.1 GENERAL

GOLD is a complete air handling unit, with built-in control

system, developed and manufactured by PM-LUFT AB.

The unit contains supply and exhaust air fans, rotary heat

exchanger Turbo, supply and exhaust air filters F85/EU7

and control system.

These instructions are for the commissioning, operation,

and maintenance of the unit. It is important that they are

read by all personnel involved before the unit is put into

service. Please see separate instructions for installation

WARNING!

Inspection hatches located on the pressure side behind

the fan must not be opened while the fan is operating. The

hatch can open suddenly and cause personal injury.

2

GOLD 1-3 SK-GB-708

Right to make modifications without prior notice

1.2 SPECIFICATION

When contacting PM-LUFT, please use manufacture

number, program version (see 7.3), and description as

given below:

Silencer GODA-1-aaa

Size 025, 031, 040

Round, Size 016-040

Silencer GODB-1-aaa

Size 010, 012, 016, 020

Outdoor Air Hood

(Incl. ceiling vent assembly) GOHA-1-a

Exhaust Air Hood GOHB-1-a

(Incl. ceiling vent assembly)

Size 1, 2, 3

Combi Hood GOHC-1-a

(Incl. ceiling vent assembly)

Outer Wall Hood GOHE-1-a

Outer Wall Grille GOHF-1-a

Size 1, 2, 3

Smoke Function Box GOQA-1-01

Incl. Control Unit ABAV

Smoke Detector VS 1130 GOQA-1-02

Damper Adjuster SQ B 21.1 GOQA-1-03

EXTRA ACCESSORIES

Stand GOLZ-1-a-02

Size 1, 2, 3

Motion Detector GOLZ-1-03

Extension Cable GOLZ-1-05-a

Type 5 m with bayonet coupling

to manoeuvre display, 4 pole =1

5 m with bayonet coupling

to battery, 7 pole =2

Transformer 12 VDC GOLZ-1-06

For supply to motion detector

Set of Hinges GOLZ-1-a-07

Delivered unassembled

Cannot be used with the GOLZ stand

Size 1, 2, 3

Replacement Material

Filter F85/EU7, 1 pc. GOLZ-1-a-01

Size 1, 2, 3

Air Handling System GOLD-a-b-cc

Type

Size 1 =2

2, 3 =3

Size 1, 2, 3

Display Language SWE - ENG =01

SWE - FIN =02

POL - ENG =03

TJECK - TY =04

FRA - ENG =05

EST - ENG =06

COMPLEMENTS

Damper and motor GOSA-1-aaa-b

Tightness Class 4

Round size 016, 020, 025, 031, 040

Damper motor with spring return =1

On/Off =2

Adjustment Damper (Round) GOSB-1-aaa

Size 010, 012, 016, 020, 025, 031, 040

Water Heat Radiator GOLA-1-a

Incl. 2-way valve, adjuster, anti-freeze protection,

and connection cable with bayonet coupling.

Size 1, 2, 3

Anti-freeze sensor GOLZ-1-04

Electric Heat Radiator GOLE-1-a-b

Incl. integrated thyristor and connection

cable with bayonet coupling.

Size 1, 2, 3

Voltage 400V =1

230V =2

Water Cooling Radiator GOKx-1-a-b-c-d

Cooling Agent Water =A

Evaporative =C

Size 1, 2, 3

Duct Connection Ø 250 = 1

Dimension Ø 315 = 2

Ø 400 = 3

Ø 500 = 4

No. of Tube Rows 4, 6

Connection Side Right =1

Left =2

3

GOLD 1-3 SK-GB -708

Right to make modifications without prior notice

:

:: :

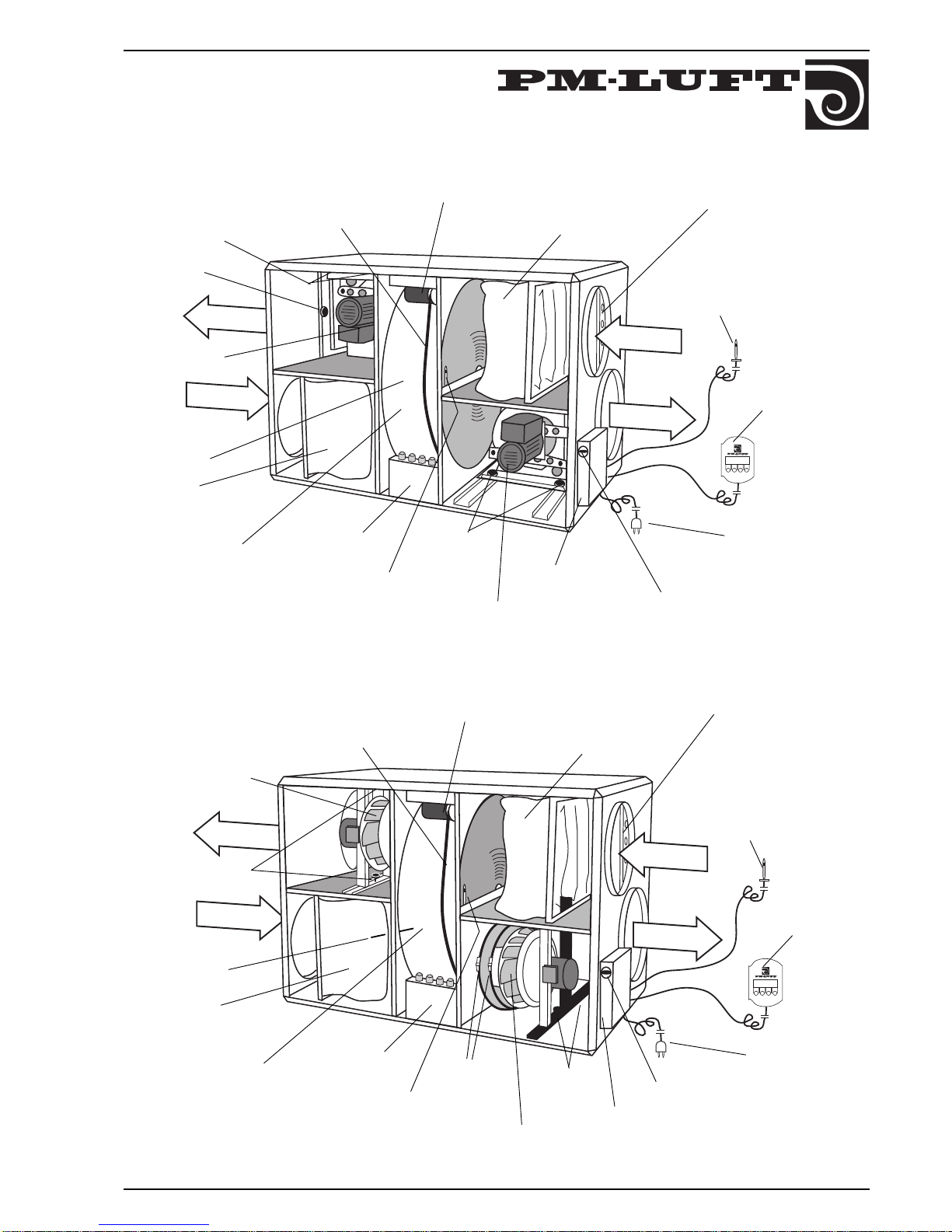

Drive belt

heat exchanger

Locking knob

flex. conn.

Drive motor

heat exchanger

Supply air filter

Heat exchanger

Exhaust air filter

Plug contact

Throttle damper

Exhaust air fan

OUTDOOR

EXHAUST

SUPPLY

Locking

knobs fan

Supply air fan

Exhaust air

sensor

EXTRACT

Power card

Control enclosure

with control card

Main-/safetyswitch

Locking

knobs fan

:

:: :

Drive Motor, Heat

Exchanger

Supply Air Filter

Heat Exchanger

Exhaust Air Filter

Throttle Damper

Exhaust Air

Sensor

Main/Safety Breaker

Clamp Belt

Outdoor Air

Sensor

SUPPLY

Supply Air Fan

Drive Belt, Heat

Exchanger

EXHAUST

Electric Plug

(Size 2)

Locking

Knobs, Fan

Assembly

Control Box

with Controller

Card

Power Card

EXTRACT

OUTDOOR

GOLD size 1

GOLD 2 and 3

Outdoor air

sensor

Locking Knobs,

Fan Assembly

Exhaust Air Fan

Supply air sensor

(to be placed in

supply air duct)

Display

Supply air sensor

(to be placed in

supply air duct)

Display

4

GOLD 1-3 SK-GB-708

Right to make modifications without prior notice

2. ELECTRICAL CONNECTION

2.1 Power

Units in sizes 1 and 2 are connected with factory installed

electrical plug, otherwise permanently connected to

single phase 230V, 50Hz, 10A.

For size 3 permanent connection applies, 2 x 230 V + N,

50 Hz, 2 x 10 A.

2.2 Safety

Lockable isolator switch is located on the control enclosure.

2.3 Display

The display is connected to the unit via contact on the

factory mounted cable on the display.

2.4 Supply air sensor

The sensor is fixed into the supply air duct at a distance

of at least 5 x the duct diameter from the unit or possible

reheater. Shall always be mounted after coil.

2.5 Reheater

2.5.1 Electrical heater

Power supply shall be carried out through working switch

directly from distribution box.

Unit size 1 2,0 kW, 2-phase 400 v + earth, 5,0 A.

Unit size 2 3,6 kW, 2-phase 400 V + earth, 9,0 A.

Unit size 3 6,0 kW, 3-phase 400 V + earth, 8,7 A.

Control signal to the built-in thyristor is connected to the

unit via a quick coupling on the factory mounted cable on

the electrical heater.

Alarm from the overheating protection is transferred to

the unit and shown on the display.

Possible reset of alarm is done on the battery and the

display.

At stopped unit cooling is carried out when necessary.

2.5.2 Watercoil

The control signal to the valve + actuator is connected to

the unit via a quick coupling on the pre-connected cable

to the actuator.

5

GOLD 1-3 SK-GB -708

Right to make modifications without prior notice

3. CONNECTION OF EXTERNAL FUNCTIONS

3.1 General

Cables from external functions are connected to

connection boxes on the control card.

Knockout openings for screw caps are located in the

control enclosure.

Functions:

External stop of unit (external disconnection)

External Fire/Smoke (external disconnection)

External alteration High/Low speed

(external connection/disconnection)

Set value shifting (external 0 – 10 VDC)

Flow indication FL/alt. stepless controlling of

cooling unit (output 0 – 10 VDC)

Flow indication TL (output 0 – 10 VDC)

Summary alarm A (free making contact)

Summary alarm B (free making contact)

Controlling of cooling unit on/off (free

making contact

Unit in operation (free making contact)

3.2 External stop

If the connection between connections 1–2 is broken the

unit is unconditionally stopped. "Stop" is shown in the

display. The unit is started when the connection closes.

Clamp is factory mounted.

3.3 External Fire/Smoke

If the connection between connections 3–4 is cut the unit

is unconditionally stopped and the alarm text "External

Fire alarm released" is shown in the display. Alarm light

and summary alarm relay A-alarm are activated. The error

must be repaired and the alarm reset on the display

before starting. Clamp is factory mounted.

3.4 External alteration Low/high speed

On connection 5–6 device for alteration between low and

high speed can be connected. It might be presence

sensor, overtime timer, overtime pushbutton, air quality

sensor, hygrostat or other potential free contact function.

Use the display to choose if high speed is required with

closed or broken contact. Delay of resetting to low speed

after contact alteration is programmed with the display,

0.00–3.59 in hours and minutes.

The internal high speed of the time switch is placed

above external contact function. If for instance presence

sensor is used the internal time switch shall be programmed to low speed all the time.

3.5 External set value displacement

Connections 7(-) and 8(+) is input for 0–10 VDC for

displacement of set value. Upon regulation of supply/

exhaust air, the set value for supply/exhaust air

temperature is displaced. Upon regulation of ERS, the

difference between EA/SA is displaced.

The function is activated in the display. The influence is

+/- 5°C according to 8.4.

3.6 Flow indication Supply–Exhaust air

On connections 9(+) and 10(-) there is a output voltage of

0 –10 VDC which is proportional to measured supply air

flow. Connections 11(+) and 12(-) contains 0 – 10 VDC for

exhaust air flow.

3.7 Summary alarm outputs

Connections 13–14 summary alarm B free making

contact (10 A), closed at alarm.

Connections 15–16 summary alarm A free making

contact (10 A), closed at alarm.

3.8 Cooling unit

3.8.1 On/off control

Connections 17–18 free making contact (10 A) for ON/

OFF controlling of possible cooling. The function is

activated in the display.

When need for cooling the contact closes. A neutral zone

of 2°C is programmed. When the need for cooling stops

a restart time of 10 minutes starts, which must end

before the contact can close again. This time delay is to

prevent the unit from starting and stopping too often.

3.8.2 Stepless control

Controlling can also be carried out stepless, depending of

the need of cooling via 10 VDC. Connections 11(+) and

12(-), which normally are for indication of exhaust air

flow, is then used. Due to this, indication of exhaust air

flow can not be obtained.

When using the valve adjuster, 24V supply must be

taken from an external source.

3.9 Operation indication

Connection 19–20 free making contact(10 A). The

contact is closed when the unit is in operation (low/high

speed). The contact is broken when unit is stopped,

regardless to if it has been stopped manually, via clock or

alarm.

3.10 UTG 230 V

Connections L, , N marked with UTG 230 V is a

connection with 230 VAC supply, which is cut off with the

main switch.

The socket lays on the supply fuse and therefore the

maximum load is depending on how hard the unit is

driven.

The outlet is recommended for use for control voltage or

for damper motors.

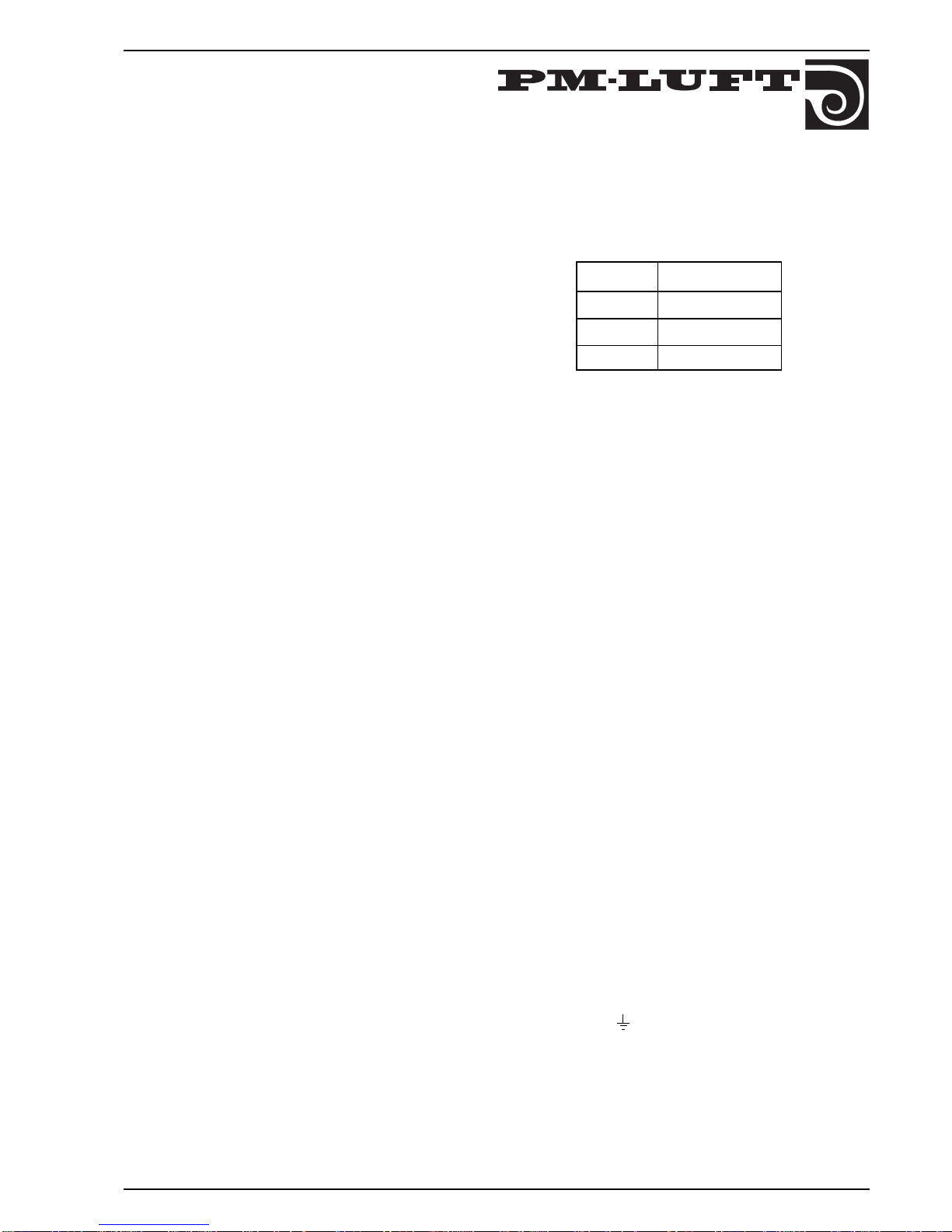

Size 0–10 VDC

1 0–320 l/s

2 0–500 l/s

3 0–900 l/s

6

GOLD 1-3 SK-GB-708

Right to make modifications without prior notice

1

5432

1

32

1

4

32

1

2

PRESSURE

SENSOR

SA–FLÄKT

PRESSURE

SENSOR

EA–FLÄKT

*GOLD* POWER CARD

3

4

1

2

3

4

SUPPLY AND

CONTROLLING

SUPPLY AIR FAN

5

6

7

1

2

3

4

5

6

7

SUPPLY AND

CONTROL FROM

CONTROL CARD

OUTDOOR AIR SENSOR

EXHAUST AIR

FAN SUPPLY

AND CONTROL

HEAT EXCH

MOTOR

EXHAUST AIR SENSOR

+

-

Black

Brown

Black

Yell/Green

Blue

Brown

Yell/Grey

Blue

Brown

White

Green

Yellow

White

Brown

Blue

Brown

Black

Yell/Green

Blue

Brown

White

Yellow

Green

1

2

Black

Yell/Green

Blue

Brown

White

Yellow

Green

GOLD POWER

+

-

+

-

+

-

GOLD-PRESSURE

FUSE

1 A

folio

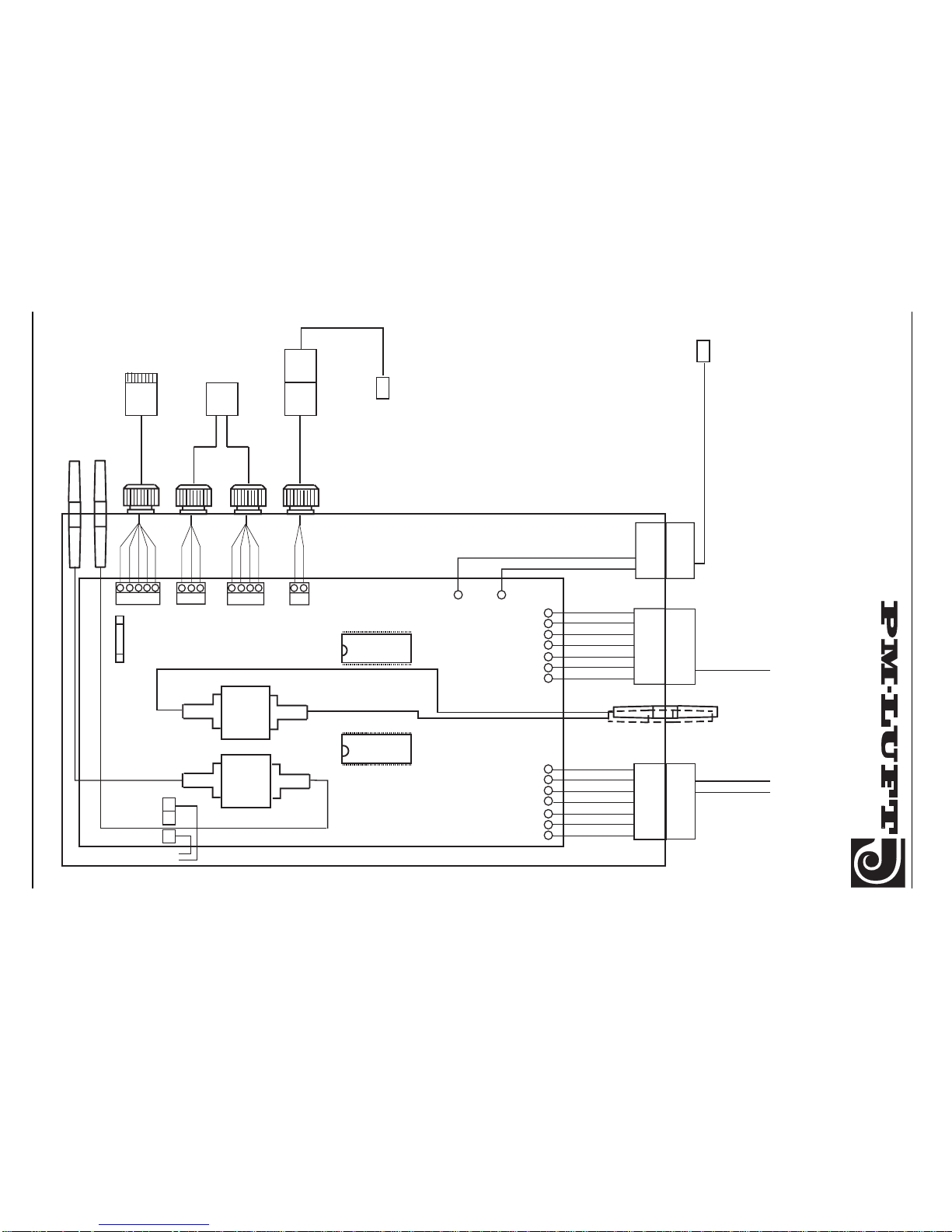

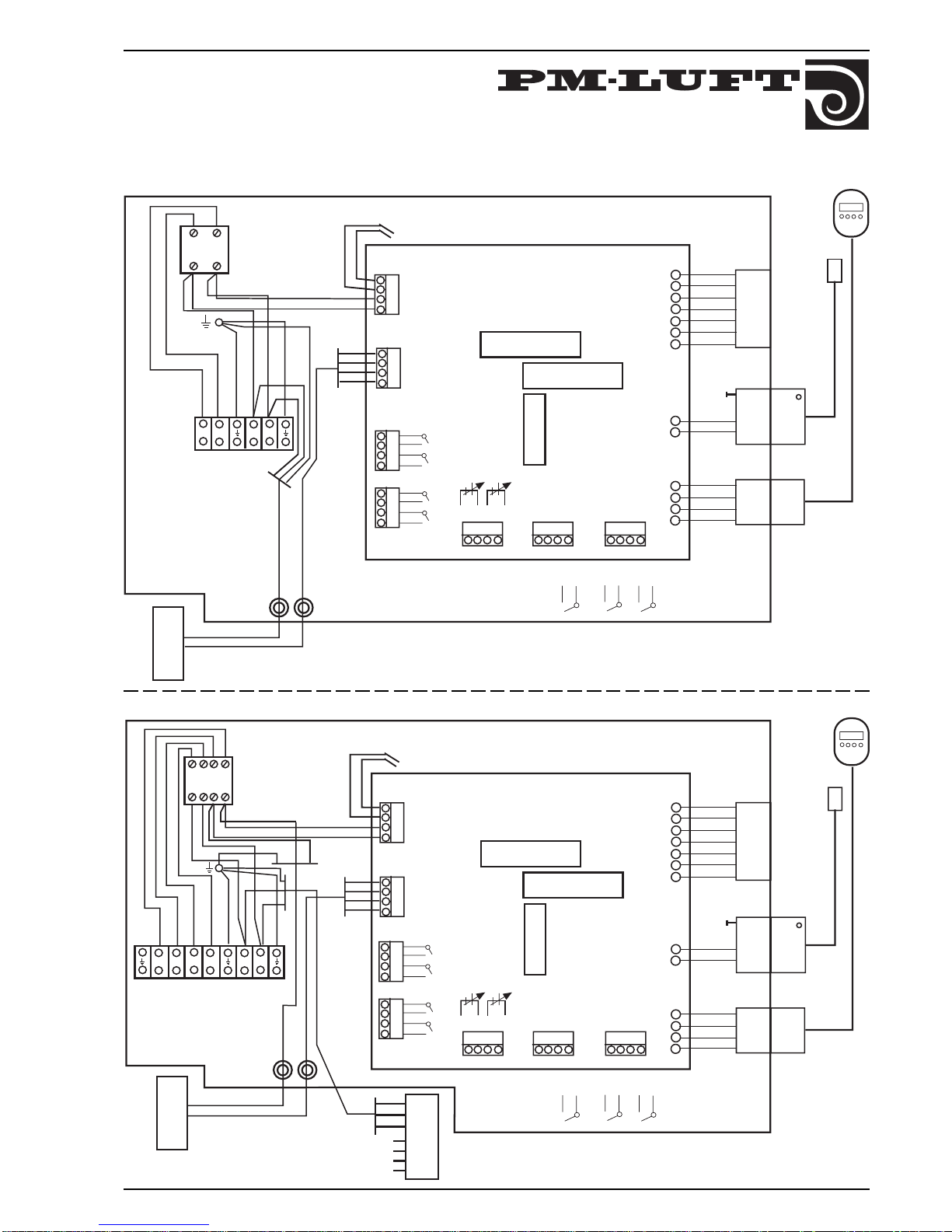

4. WIRING DIAGRAM POWER CARD

7

GOLD 1-3 SK-GB -708

Right to make modifications without prior notice

Size 1 and 2

Size 3

5. WIRING DIAGRAM CONTROL CARD

*GOLD* CONTROL CARD

CONNECTION

POSSIBLE

HEATER

SUPPLY AIR

SENSOR

-

+

-

+

DC-OUTPUT

FL TL

HIGH

LOW

FIRE

INPUT

STOP

UNIT

DISPLAY

COMMUNICATION

DISPLAY

ALARM

OUTP. A

ALARM

OUTP. B

-

+

SUPPLY AND COMMUNICATION POWER CARD

MAIN

SWITCH

N

Black

Red

Blue

Brown

White

Yellow

Green

1

7

6

5

4

3

2

Blue

Brown 4

3

Pin

2

1

Green

Yellow 2

1

White

Brown 4

3

1112 910 78563412

24

21

22

23

20

17

18

19

16

13

14

15

L

27 28

UNIT IN

OPER.

COOL.

UNIT

230 V

INPUT

GOLD-CPU

GOLD-PROG

GOLD-CONTROL

QUICK COUPLING

Brown

Blue

Yell/Green

Blue

Brown

Yellow

Green

Blue

Brown

Brown

White

24

21

22

23

20

17

18

19

16

13

14

15

L1

27 28

2 x 230 V INPUT

L2N1 N2

Brown

Yell/G

Blue

Supply

SA fan

Black

Blue

Blue

Brown

Brown

Yellow

Green

Blue

Blue

Brown

Blue

Brown

White

Brown

Blue

Yell/Green

Yell/Green

-

+

-

+

-

+

1

7

6

5

4

3

2

4

3

2

1

2

1

4

3

GOLD-CPU

GOLD-PROG

GOLD-CONTROL

1112 910 78563412

Yell/Green

Yell/Green

*GOLD* CONTROL CARD

DC-OUTPUT

FL TL

DC-IN

SET VALUE

DISPL.

HIGH

LOW

FIRE

INPUT

STOP

UNIT

MAIN

SWITCH

Black

Red

Blue

Brown

White

Yellow

Green

Blue

Brown

Pin

Green

Yellow

White

Brown

ALARM

OUTP. A

ALARM

OUTP. B

SUPPLY AND COMMUNICATION POWER CARD

UNIT IN

OPER.

COOL.

UNIT

QUICK COUPLING

CONNECTION

POSSIBLE

HEATER

SUPPLY AIR

SENSOR

DISPLAY

COMMUNICATION

DISPLAY

Folio

Black

Black

Brown

Blue

Yell/Green

Folio

Black

Black

Brown

DC-IN

SET VALUE

DISPL.

28

25

26

27

28

25

26

27

Loading...

Loading...