PMI Piranha GTI User Manual

07GTIInstructions 7/5/06 9:59 AM Page 1

The Piranha®GTI is capable of high rates of fire and an agitating hopper such as an

®

Extreme Rage

WARNING: READ OPERATOR’S MANUAL BEFORE USE. EVERY PERSON WITHIN RANGE OF AN AREA WHERE A PAINTBALL

MARKER IS IN USE MUST WEAR PROTECTIVE GOGGLES AND HEADGEAR SPECIFICALLY DESIGNED FOR PAINTBALL.

WARNING: ALWAYS COCK MARKER BEFORE ATTACHING AIR SOURCE. MARKER CAN DISCHARGE IF AIR SOURCE IS ATTACHED

BEFORE MARKER IS COCKED. THE MARKER CONTAINS COMPRESSED GAS OR AIR WHEN PRESSURIZED. NEVER DISASSEMBLE MARKER UNTIL REMOVING ALL GAS OR AIR FROM THE SYSTEM. RULES FOR SAFE HANDLING OF COMPRESSED GAS OR AIR MUST BE FOLLOWED AT ALL TIMES.

WARNING: WHEN COCKING THE PRESSURIZED MARKER, DO NOT RELEASE THE COCKING KNOB UNTIL AFTER THE COCKING MECHANISM

HAS LOCKED BACK INTO THE COCKED POSTITION; RELEASING THE COCKING KNOB DURING COCKING CAN CAUSE THE MARKER TO SHOOT.

Overdrive™is recommended for better performance.

INSTRUCTIONS FOR USE

PMI High Per

OPERATING THE PIRANHA®GTI: 1. Attach threaded barrel

firmly to marker. 2. At this time, do not attach air source or loader and do

not load paintballs into marker. 3. Insert barrel plug firmly into barrel.

4. Pull the cocking knob straight back from the rear of the marker until the

cocking mechanism locks back in the cocked position. Always cock marker

before airing it up. During cocking the flush cocking rod will recoil or “spring

back” into the marker once released and will only move slightly during

marker operation. 5. Slide safety “of

pressure. You should hear the hammer and bolt assembly slide forward.

7. Cock the marker. 8. Before attaching the air source, read and understand

the section in the manual on “Compressed Gas/Air.” Follow safety rules for

handling compressed gas/air. If any leak occurs in the marker, refer to troubleshooting guide or to a qualified airsmith. Use only cylinders for compressed gas or air that comply with all applicable laws and regulations,

including but not limited to those of the U.S. Depar

OSHA, Compressed Gas Association, and/or American Society for Testing and

Materials. 9. With goggles on, test for function after attaching air source:

Squeeze the trigger. The marker should shoot air and the cocking knob

should cycle slightly after each trigger squeeze, repeat several times. Flush

cocking rods will bobble some, but they will not come out all the way.

10. Slide safety forward (semi version). Paintballs may then be loaded.

formance Barrel

f,” 6. Squeeze the trigger with an even

tment of T

ranspor

Dual Ball Detents

tation,

Gas Thru Grip

Cocking Rod

Safety Slide

Velocity

Adjustment

Screw

Sear Release

Bottom Line

Adapter

WARNING: BEFORE DISASSEMBLY, STORAGE, OR TRANSPORT OF THE MARKER, REMOVE AIR SOURCE FIRST, THEN REMOVE ALL

PAINTBALLS FROM THE MARKER, BARREL, AND LOADER. REMOVE ALL GAS OR AIR FROM THE MARKER. INSERT BARREL PLUG AND

SLIDE THE MECHANICAL SAFETY FORWARD SO THE SAFETY IS ENGAGED AND THE RED DOT IS NOT LIT. THE SAFETY IS A SMALL

MECHANICAL SLIDE ON THE LEFT SIDE OF THE MARKER ABOVE THE TRIGGER. WHEN THE SAFETY IS “OFF,” A RED DOT IS VISIBLE ON

THE MARKER. THE TRIGGER CAN STILL BE PULLED IF THE SAFETY IS “ON,” BUT THE MARKER WILL NOT FIRE OR DE-COCK. E-FORCE

MODEL: THE ON/OFF BUTTON ON THE LEFT SIDE OF THE FRAME SHOULD BE USED AS SAFETY.

07GTIInstructions 7/5/06 9:59 AM Page 2

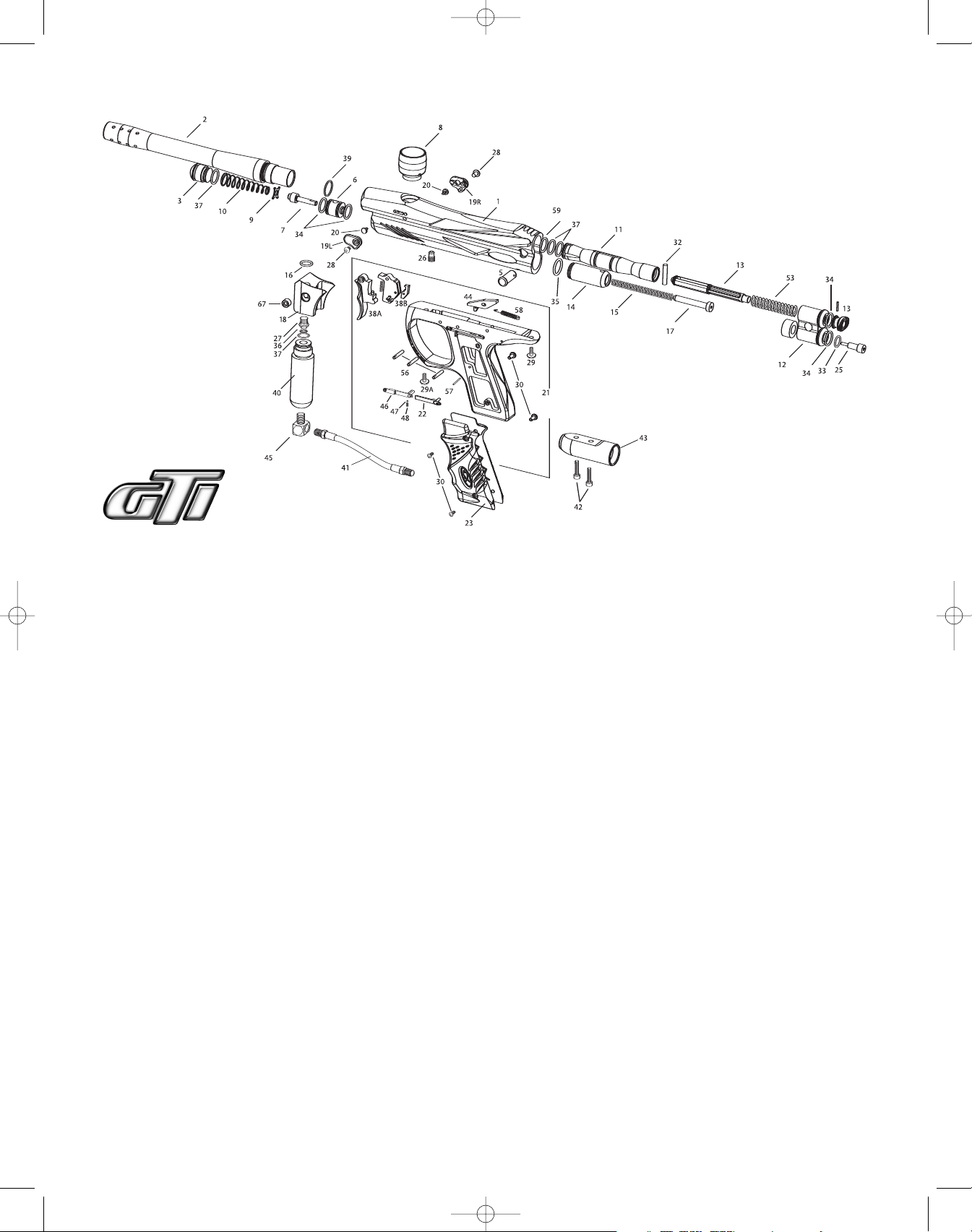

1A. Milled Receiver Body - Matte Black 73100

1B. Milled Receiver Body - Matte Blue 73101

1C. Milled Receiver Body - Matte Gunmetal 73102

2. 9” Barrel 73120

End Cap GTI 73123

3.

5. Field Strip Pin

Assembly 10038

6. Valve Body 10027

7. Red Valve Cup Seal Assembly 10140

Black Valve Cup Seal Assembly 10127

7.

8A. Removable Low Rise - Matte Black 73110

w Rise - Matte Blue 73111

vable Lo

Remo

8B.

8C. Removable Low Rise - Matte Gunmetal 73112

9. Valve Guide 10520

10. Valve Spring 71597

11. Molded Flush Cocking Bolt 73124

12. Molded Flush Cocking Rear Block Assembly 73127

Molded Flush Cocking Rod 73126

13.

14.

Hammer

Assembly

10024

15. Blue Hammer Spring 10351

16.

ASA O-ring

10257

17. Spring Guide 10301

18A. Vertical ASA Adapter - Matte Black 73105

18B. Vertical ASA Adapter - Matte Blue 73106

18C. Vertical ASA Adapter - Matte Gunmetal 73107

19L. Ball Detent Cap Left 73129

19R. Ball Detent Cap Right 73130

Ball Detent 10160

20.

21. Polymer Frame Assembly ‘07 73140

Sear Release Slide

22.

73144

23. Wrap Around Grip 73145

25. Velocity Screw 10026

26.

alve Set Screw

V

10513

27. ASA Screw 71580

28. Ball Detent Screw 10180

29. Rear Trigger Frame Screw 10682

29A. Front Trigger Frame Screw 71583

Grip Screws 10782

30.

32. Bolt Pin 10291

33. Velocity Screw O-Ring 10460

34. Valve/Rear Block O-Rings 10260

Blue Hammer O-Ring 10129

35.

36. Screen Filter 71667

Bolt O-Rings

37.

41010

37. Gas Thru Grip O-Ring 41010

37. ASA Slug O-Ring 41010

38A. Trigger 73141

38B. Trigger Pawl Assembly 73142

39. Barrel O-Ring 10161

Gas-Thru Foregrip 73121

40.

6.25" SS hose

41.

47011

42. Bottom line SS screw 42016

Straight Bottomline

43.

Adapter

73122

44. Sear 10721

45. 90° Elbows 47000

46. Safety Slide 73143

47. Safety Ball 10730

48. Safety Spring 10750

53. Flush Spring 10203

Trigger Spring 73146

55.

56. Sear/Trigger Pin 10766

rigger/Spring Pin

T

57.

10767

58. Sear Spring 10753

59. Front Bolt O-Ring 57738

67.

1/8th”

NPT

Plug

47006

Loading...

Loading...