Page 1

Precision Measurement Engineering, Inc. • www.Turner Designs.com

USB Cyclops-7 Logger User’s Manual

(Interchangeable and Fixed Sensors)

2018

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

1

Page 2

(INTENTIONALLY BLANK)

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

2

Page 3

Warranty

1-YEAR LIMITED WARRANTY

Precision Measurement Engineering, Inc. warrant that the Logger shall be free of

defects in workmanship and materials, under normal use, for a period of one year

from the date of shipment. This warranty is made only to the original purchaser. In the

event a Logger covered by this warranty fails to operate according to our published

specifications, then return it freight pre-paid to Precision Measurement Engineering or

an authorized Service Provider. Precision Measurement Engineering (PME) will

repair the unit at no charge to the customer and bear the cost of return shipment to

customer. Carefully pack all components, as the customer is responsible for any

freight damage.

This warranty does not apply to services or consumable / expendable items (such as

batteries, fuses and ropes) required for general maintenance. The Cyclops-7

sensor, manufactured by Turner Designs, is warranted only to the limit of the

warranties provided by their original manufacturer.

PME makes no warranty, either expressed or implied, that the sensors will be

operable after they are exposed to adverse environmental conditions, such as biofouling, oil fouling, freezing temperatures or others.

This warranty is void if, in our opinion, the Logger has been damaged by accident,

mishandled, altered, or repaired by the customer, where such treatment has affected

its performance or reliability. In the event of such treatment by the customer, costs for

repairs plus two-way freight costs (no COD shipments will be accepted) will be borne

by the customer. In such cases, an estimate will be submitted for approval before

repair work is started. Items found to be defective should be returned to PME

carefully packed, as the customer will be responsible for freight damage.

Incidental or consequential damages or costs incurred as a result of the product

malfunction are not the responsibility of PME.

For all warranty or non-warranty returns please obtain, complete, and submit a RMA

to PME. This RMA form may be obtained at

http://www.pme.com/HTML%20Docs/RMAform.html

After submission of this form, then PME will respond with a RMA number. Please

place this number on all shipments and related communications.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

3

Page 4

Safety Information

BURSTING HAZARD

Should water enter the Cyclops-7 Logger and come into contact with the enclosed

batteries, then the batteries may generate gas causing the internal pressure to

increase. This gas will likely exit via the same location where the water entered, but

not necessarily. The Cyclops-7 Logger is designed to release internal pressure as

the end cap is unscrewed, prior to the disengagement of the end cap threads. If

internal pressure is suspected, then treat the Cyclops-7 Logger with extreme caution.

Revision History

Date Revision Description

2015FEB24 Copied from RS232 C7 manual

2015APR16 Added Android device instructions

2015APR28 Updated wording

2015MAY08

2015MAY25 Released for distribution to customer

2015JUN25 Added evaluation of calibration result

2015NOV09 Added Notes section

2016MAR03 Modified autorange description

2017AUG03 Clarified battery orientation, added warnings

2018MAY02 Added information on silicon spray

Inserted pictures in Chapter 3

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

4

Page 5

CONTENTS

Chapter 1 Quick Start

1.1 Calibrate and Go

1.2 A Few Details

Chapter 2 Software

2.1 Overview and Software Installation

2.2 Cyc7Control

2.3 Cyc7Plot

2.4 Cyc7Concatenate

Chapter 3 Cyclops-7 Logger

3.1 Overview

3.2 Opening and Closing the Logger

3.3 Electrical Connections and Controls

3.4 Battery Replacement

3.5 Interchangeable Sensor Installation

3.6 Notes

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

5

Page 6

Chapter 1: Quick Start

1.1 Calibrate and Go

PME produces two types of loggers, a logger with the sensor permanently installed

and a logger with a connector that you will use to plug in your own sensor. Even if

the sensor is already installed, the logger/sensor are provided to you in an uncalibrated state. The logger itself is set to measure temperature and concentration

once every 10 minutes and record 1 file of measurements daily. However, you must

calibrate the sensor before the system can be used. At one measurement every 10

minutes the Cyclops-7 Logger will operate for roughly a half year before the internal

battery is expended.

At the end of the deployment period you need only to open the logger and connect it

to a host device via USB. The Cyclops-7 Logger will appear as a ‘thumb drive’. Your

temperature and sensor measurements, together with a time stamp indicating the

time the measurement was made, are recorded in text files in the folder having the

serial number of your Cyclops-7 Logger. These files can be copied onto any

Windows or Mac host computer.

This Manual and other software is supplied in files on the Cyclops-7 Logger:

Cyc7Control allows you to see the state of the logger as well as set the recording

interval.

Cyc7Plot allows you to see plots of the recorded measurements.

C7Concatenate gathers all the daily files into one CAT.txt file.

When not connected to USB, your Cyclops-7 Logger will record measurements if the

Recording Control Switch is in the Record position. If you wish to stop recording,

switch the Recording Control Switch to the Halt position.

You may switch the Recording Control Switch at any time.

Follow these steps to start the deployment, logging Cyclops-7 output and

Temperature once each 10 minutes:

1) Install your sensor onto the logger if required as described in Chapter 3.

2) Calibrate the sensor/logger as described in Chapter 2, Cyc7Control program.

3) Open the Cyclops-7 Logger (if not already open from calibration) as described in

Chapter 3.

4) Switch the Recording Control Switch to the Record position. The LED will flash

green 5 times. The Cyclops-7 Logger will now record a measurement of time,

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

6

Page 7

battery voltage, temperature, and sensor output every 10 minutes (or at some

other interval you may have set using Cyc7Control).

5) Inspect the o-ring seal for debris.

6) Close the Cyclops-7 Logger by screwing the white housing back onto the black

end cap.

7) Deploy the Cyclops-7 Logger.

Follow these steps to end the deployment

1) Recover the Cyclops-7 Logger

2) Clean and dry all accessible surfaces.

3) Open the Cyclops-7 as described in Chapter 3.

4) Connect to a Windows host computer via USB. The Cyclops-7 Logger will appear

as a ‘thumb drive’.

5) Copy the folder having the same serial number as the Cyclops-7 Logger (example

7377-191770) to the host computer.

6) (Suggested, but optional) Delete the measurement folder, but NOT Cyc7Control

or the other .jar programs or manual.

7) (Optionally) run the Cyc7Plot program to see a plot of measurements.

8) (Optionally) Run the C7Concatenate program to gather together all the daily files

of measurements into one CAT.txt file.

9) If no more recording is desired, switch the Recording Control Switch to Halt,

otherwise leave it set to Record to begin recording after USB disconnection.

10) Disconnect the Cyclops-7 Logger from the USB connection.

11) Inspect the o-ring seal for debris.

12) Close the Cyclops-7 Logger by screwing the white housing back onto the black

end cap.

Remove the batteries if storing the Cyclops-7 Logger for extended periods.

1.2 A Few Details

The previous section gives instructions for sampling at 10-minute intervals. However

there are a few additional details that will enhance use of the Cyclops-7 Logger.

Sensor guard – The sensor guard is the long tube having slots in the end that covers

the Turner C7 sensor. This guard not only protects the sensor but also establishes a

consistent field of view for the sensor. The guard must be used when the sensor is

calibrated and also when it is used for measurements in the field.

Sampling rate – The Cyclops-7 Logger records measurements at equal time

intervals. The default time interval is 10 minutes. However, it is also possible to

instruct the Cyclops-7 Logger to record at different intervals. This is accomplished by

connecting a Windows computer to the logger and using the Cyc7Control program

supplied for this purpose. Recording intervals must be 1 or more minutes and must

be less than or equal to 60 minutes. Intervals outside this range will be rejected by

Cyc7Control. (Contact PME for other recording intervals.)

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

7

Page 8

Please refer to Chapter 2 for instructions on operating the Cyc7Control program.

Time – All Cyclops-7 Logger times are UTC (formerly known as Greenwich mean

time (GMT)). The Cyclops-7 Logger internal clock will drift in the < 10 ppm range

(<about 30 secnds/month) so you should plan to connect it occasionally to a host

having an internet connection. The Cyc7Control program will automatically set time

based on an internet time server.

Please refer to Chapter 2 for instructions on operating the Cyc7Control program.

File Information – The Cyclops-7 Logger software creates 1 file daily on the

Cyclops-7 Logger’s internal SD card.. The number of measurements in each file will

depend upon the sample interval. Files are named by the time of the first

measurement within the file based on the logger’s internal clock and expressed in

YYYY-MM-DD HHMMSSZ.txt format. For example a file having the first

measurement on September 9, 2014 at 17:39:00 UTC will be named

2014-09-09 173900Z.txt

Files can be uploaded from the Cyclops-7 Logger by connecting the Logger to a host

computer and by using the host computer to copy/past the files from Logger to some

host computer storage.

Each measurement within files has a time stamp. The time stamp format is Unix

Epoch 1970, the number of seconds that have passed since the first moment of

1970. This may be inconvenient in some cases. If so, the C7Concatenate software

not only concatenates all the measurement files but also adds more readable

statements of the time stamp.

Please refer to Chapter 2 for instructions on operating the C7Concatenate program.

The Cyclops-7 Logger requires time and battery energy to work through the file

directory on SD card to allocate new file space. A few hundred files on SD is not a

problem, but as the number of files grows large into the thousands the Logger may

suffer decreased battery life or other performance problems. Please, at the earliest

convenient time, copy recorded files to a host computer and delete them from the

Logger. Also, do not use the Logger to store files unrelated to Logger operation.

Cleaning the Sensor – The sensor may be cleaned by unscrewing the black sensor

guard and gently wiping the optical face.

Battery Life – The Cyclops-7 Logger consumes battery power mostly from the

Cyclops-7 sensor, but also slightly from simply keeping track of time, writing files,

sleeping, and other activities. The Cyclops-7 Logger will record approximately

30,000 total samples and will operate for up to a year (depending on sample interval)

when powered by the battery pack (2 X alkaline ‘C’ cells) supplied by PME.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

8

Page 9

Keep a general record of Cyclops-7 Logger number of samples. It is not possible to

accurately determine the charge state of the battery pack from measurements of its

terminal voltage. If you have a general idea of the number of samples already

obtained on a battery, then you can make a guess as to how many more samples

remain. Err on the side of caution.

The 2 X ‘C’ battery pack holds the batteries very tightly. The holder itself is glued to

the aluminum chassis. Take care when changing batteries that the glue joint is not

broken. Always use the paper tube supplied with the Cyclops-7 to contain the

batteries. Use only new batteries as replacements.

Coin Cell Battery Life – The Cyclops-7 Logger uses a coin cell for backup of the

clock when the power is switched off. This coin cell will supply roughly 2 years of

clock operation, but this is only required if the main power is off. Should the coin cell

discharge it must be replaced. Coin cells are not user-replaceable.

O-Ring and Seal – When the cover is screwed on, it passes along the o-ring located

in the end cap several revolutions. Keep this o-ring lightly lubricated with silicone

grease or oil compatible with buna-N o-ring material.

When the Cyclops-7 Logger is opened after deployment, a small number of water

drops are deposited on the inner surface of the o-ring. When the pressure housing is

screwed back on, these drops become trapped inside the Cyclops-7 Logger. Be sure

to carefully dry the o-ring and adjacent surfaces (especially underneath) prior to

closing the Cyclops-7. Re-lube the o-ring at this time. Remove any debris from the

drying process.

Closing the Logger – The logger is much more difficult to open than to close. Screw

the white logger housing onto the black cap until the housing touches the cap. No

further tightening is necessary.

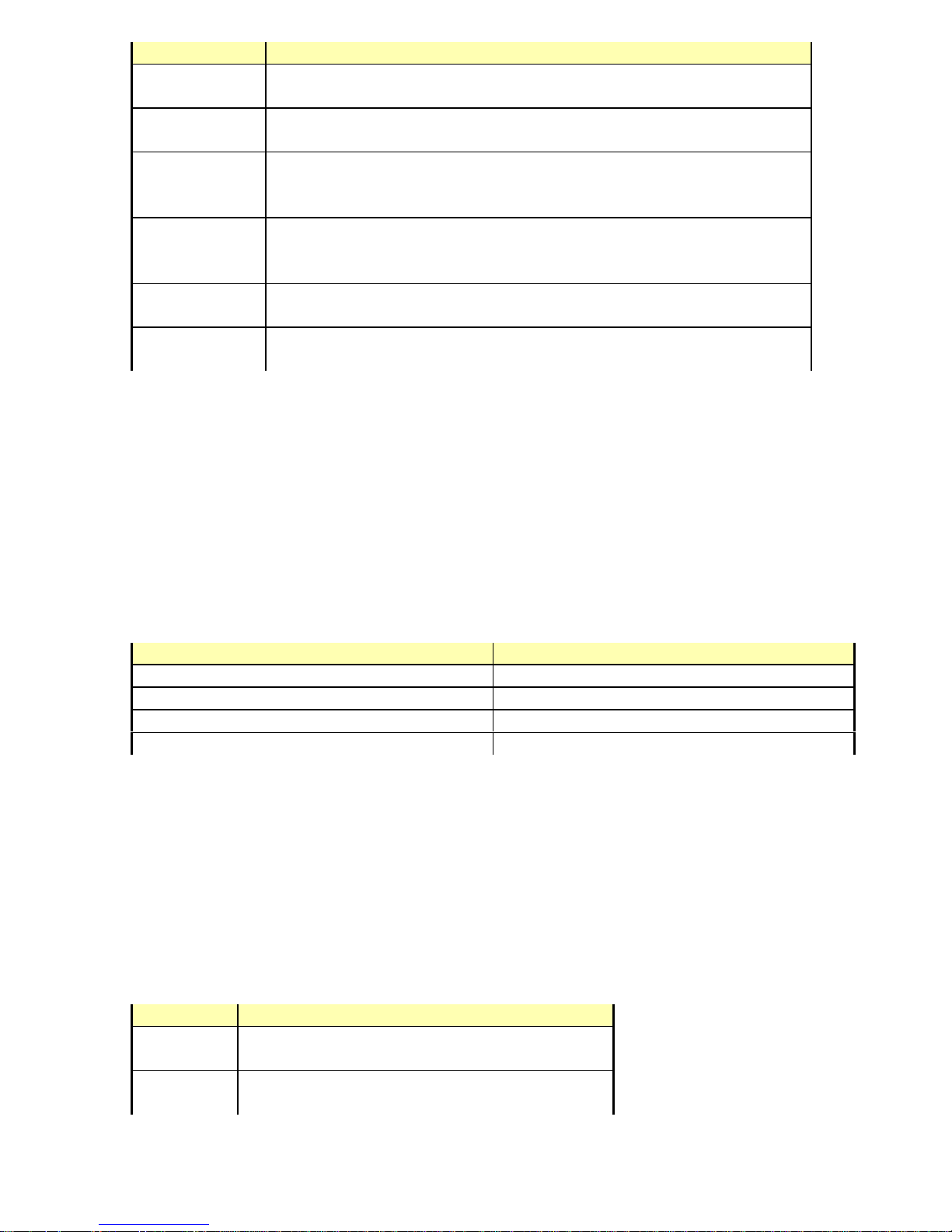

LED Indications – The Cyclops-7 Logger performs various tests as it begins logging

operations. If any test fails the software flashes the LED light and re-conducts the

test. In general if a test fails once it will continue to fail and the LED light will

continue to flash. The following table gives the number of flashes and the reason

these flashes appear.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

9

Page 10

LED Reason

1 Green

Flash

1 Green

Flash

5 Green

Flashes

Normal. Presented immediately after new batteries are

installed. Indicates that the CPU has started its program.

Occurs at the time of sampling for sample intervals of 1 minute

or less.

Normal. Indicates that miniDOT is beginning to record

measurements. This indication appears in response to

switching the Recording Control Switch to Record.

5 Red

Flashes

Normal. Indicates the miniDOT is ending recording of

measurements. This indication appears in response to

switching the Recording Control Switch to Halt.

Continuously

Green

Continuously

Flashing Red

Normal. Indicates the miniDOT is connected to a host device

via USB.

SD card write error. Try removing/reinstalling batteries.

Contact PME.

AutoRanging – The Cyclops-7 sensor has three output ranges: 1X, 10X and 100X.

The best of these ranges is automatically selected by the logger based on the voltage

measured of the sensor. The logger software remembers the best range and, at

each sample time, first measures sensor output voltage using this range. Software

then reviews this voltage to determine if the range was appropriate. In most cases

the range will be appropriate and the measurement is recorded. However sometimes

software determines that a different range would yield a better measurement. In this

case software selects a new “best range” and re-measures the sensor output voltage

using this range. This new best range becomes the range selected at the next

sample time. The best range is determined as follows:

Sensor Voltage (Gain = 1) Best Range

0.00 to 0.04 100X

0.04 to 0.4 10X

0.4 and higher 1X

Should the first voltage measurement be unacceptably close to the sensor maximum

output voltage (an over-range condition) the first voltage is re-measured using range

of 1X and the best range calculated. This range becomes the best range and

software proceeds as above.

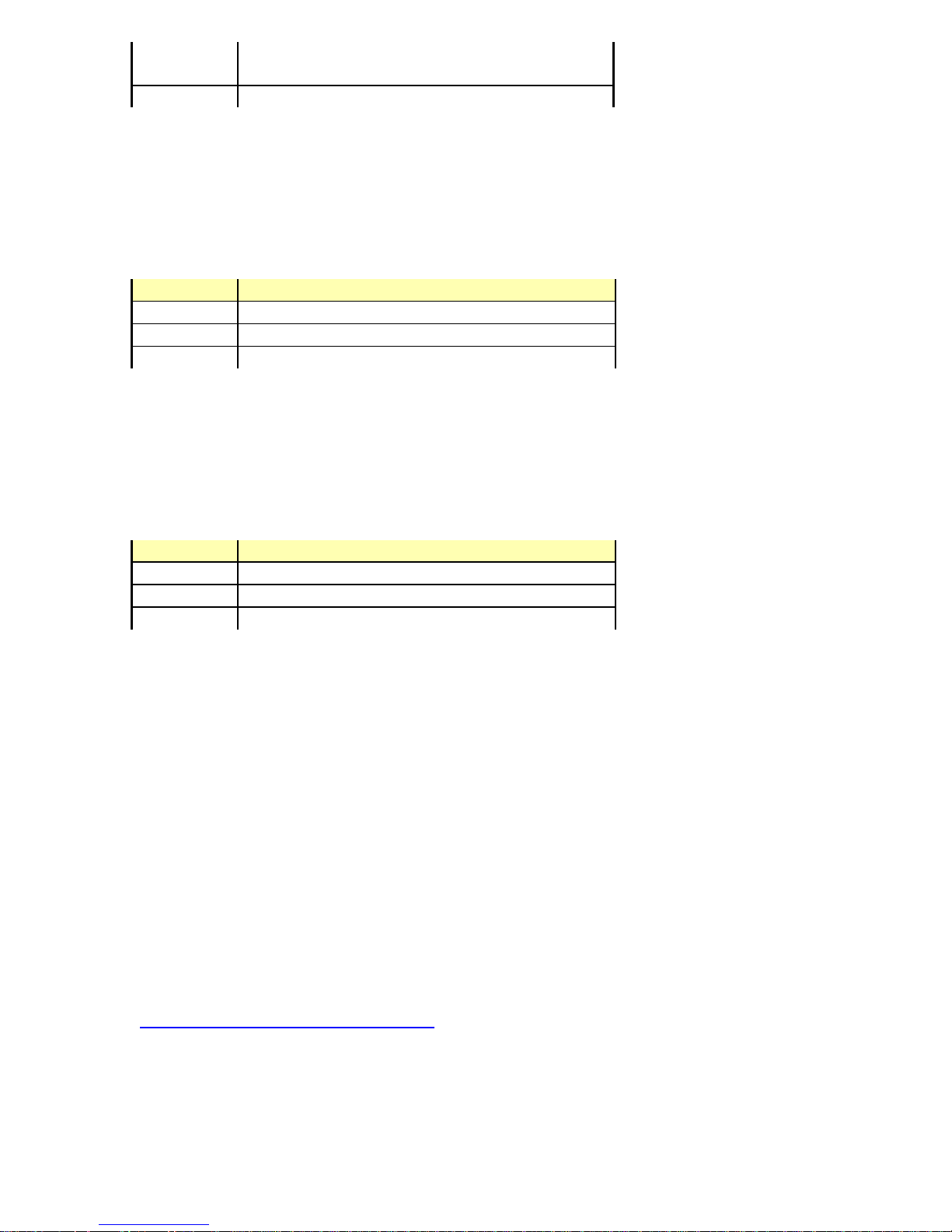

Calculation of Engineering Units – Engineering units are calculated from voltage

measurements of the sensor and from information gained during calibration (see

Chapter 4). The result of calibration is the following information:

Name Definition

Vz1 Voltage output of sensor in zero solution on

range 1X

Vz10 Voltage output of sensor in zero solution on

range 10X

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

10

Page 11

Vz100 Voltage output of sensor in zero solution on

range 100X

S Sensitivity of sensor

Vz1, Vz10, and Vz100 are measured with the sensor in a solution of zero

concentration. S is determined from the voltage output of the sensor using the “best

range”, described above, with the sensor in a reference solution of known

concentration. The user must enter the concentration value of this solution, given the

name C. The sensor voltage is measured in this solution and given the name Vs.

The following table shows how S is determined.

Range S

1X S = C / (Vs – Vz1)

10X S = 10.0 * C / (Vs – Vz10)

100X S = 100 * C / (Vs – Vz100)

Note that since only one calibration concentration is actually measured, there is only

one S determined. However this S is used to compute engineering units from the

other ranges should these be implemented by the logger during the measurement of

samples.

Engineering units are computed as shown in the following table:

Range EU

1X EU = S * (Vs – Vz1)

10X EU = S * (Vs– Vz10) / 10.0

100X EU = S * (Vs– Vz100) / 100.0

Engineering units computed using the same range that was used to determine S will

be more accurate than engineering units computed using other ranges since the

sensor may not exactly implement ranges. For example the 100X range may

actually be implemented by circuitry as 100.1X but the calculations would use 100X.

Closing and Opening – Close and open Cyclops-7 Logger like you would a

flashlight: open by unscrewing the white cylinder from the black end cap. Close by

screwing the white cylinder on. When closing, do not tighten the white cylinder. Just

screw it on until it makes contact with the black end cap. See Chapter 3 for more

instructions.

Storage When Not in Use – Remove the batteries.

Java – miniDOT programs depend on Java and require Java 1.7 or higher. Update

Java at

https://java.com/en/download/index.jsp

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

11

Page 12

Upload Files to an Android device – It is possible to transfer your measurement

files from your logger to an android device. This operation has 3 prerequisites.

1. An Android device equipped with USB On-The-Go (OTG). OTG is a feature on

most modern Android devices that allows them to act as a USB host. OTG was

introduced with Android version 3.1 and should be a useable feature on most

devices. It is still possible that your device doesn't support OTG. Please test your

device with a logger prior to attempting to upload while in the field.

2. A USB OTG cable. This is essentially an adapter with a micro USB connector on

one end that connects to your Android device and a standard A type USB plug on

the other. The cable supplied with the logger connects to this end.

3. A "File Explorer" app downloaded on your Android device. These types of apps

assist with being able to view and move files from device to device. "ES File

Explorer" is a free app available on the Google app store and is recommended for

use with the logger.

If the 3 requirements are met, then connect the logger to your device. You should

see the logger green connection light come on and your device display a message

about "preparing USB storage". When "USB storage ready" is shown, use your "file

explorer" program to move your data from the logger onto you device.

Again, it is highly recommended that you try this operation at your work station prior

to depending upon this in the field.

Currently the associated logger programs, Control, Plot, and Concatenate, are not

supported by Android devices.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

12

Page 13

Chapter 2: Software

2.1 Overview and Software Installation

The miniDOT arrives with these files:

Cyc7Control.jar allows you to see the state of the logger as well as set the

recording interval.

Cyc7Plot.jar allows you to see plots of the recorded measurements.

C7Concatenate.jar gathers all the daily files into one CAT.txt file.

Manual.pdf this manual.

These files are located on the root directory of the Cyclops-7 Logger.

PME suggests you leave these programs where they are on the Logger, but you may

copy them to any folder on your computer’s hard drive.

Cyc7Control, Cyc7Plot, and C7Concatenate are Java language programs that require

the host computer to have the Java Runtime Engine V1.7 (JRE) or later installed.

This engine is commonly required for internet applications and will likely already be

installed on the host computer. You can test this by running Cyc7Plot. If this

program displays its graphical user interface then the JRE is installed. If not then the

JRE can be downloaded via internet from

http://www.java.com/en/download/windows_xpi.jsp

At this time Cyclops-7 Logger software is supported on Windows operating systems,

but may also operate on Macintosh and perhaps Linux.

2.1 Cyc7Control

The Cyc7Control program provides these services:

It enables time setting (based on internet timeserver clock).

It enables sample interval setting.

It enables calibration of the sensor.

Turner C7 sensors, are not factory calibrated. Calibration must be physically

performed by the customer. Calibration consists of an experiment where the sensor

is exposed to two solutions, the first having 0 concentration of the sensed material

(chl-a, rhodamine… whatever the C7 sensor senses) and a second solution having a

known concentration created by the customer. Cyc7Control software records sensor

output in each solution and creates a linear fit to these two points. After calibration

the Cyclops 7 Logger will measure sensor output and record it in engineering units

using this linear fit.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

13

Page 14

Begin program operation by clicking on Cyc7Control.jar. Software presents the

screen shown below:

The Cyclops-7 Logger must be connected to USB at this time. When correctly

connected the Logger will display a constant green light.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

14

Page 15

Click the Connect button. The software will contact the logger. If the connection is

successful the button will turn green and display “Connected”. The Serial Number

and other parameters will be filled in from information take from the Logger.

If the host computer is connected to the internet, the current difference between an

internet time server’s time and the Logger internal clock will be displayed. And, if

more than a week has passed since time was last set, the Logger clock will be set

and check mark icon will appear. If the host computer is not connected to the internet

no time services will occur.

The current Logger sample interval will be displayed next to the Set Sample Interval

button. If this interval is acceptable the interval need not be set.

To set the interval, enter a interval not less than 1 minute and not greater than 60

minutes. Click the Set Sample Interval button. Shorter and faster intervals are

available. Contact PME.

Turner C7 sensors are optical devices that operate by sending colored light into the

water and observing how much light returns. The field of view available to these

sensors is quite important in establishing their response. PME’s Cyclops 7 Logger is

supplied with a sensor cover that not only protects the sensor from damage but also

establishes the field of view. This cover has slots near where it covers the sensor so

that exterior water can enter and be sensed.

The sensor cover must be in position when the sensor is calibrated and must be in

the same position when the sensor is used.

A small amount of light can exit through the sensor cover slots, be reflected by the

container holding the calibration solution, and return. Calibrate the sensor in black

containers.

Exterior light such as room lighting or sunlight can enter through the slots and cause

a very small measurement effect. Attempt to calibrate in the same lighting as the

system will experience in field use.

Be sure that there are no bubbles trapped in the cover or stuck on the sensor.

Calibration proceeds by dipping the system in one solution and then the next. Take

care not to transport one solution to the next. Mix two 0 solutions and two solutions

of the sensed material. Label one each as the “calibration” and one each as the

“wash” When moving the sensor back and forth first dip the sensor in the wash then

into the calibration. The most noticeable effect is when the 0 solution is contaminated

prior to calibration. If the 0 solution is contaminated and is actually 1, and if this is not

noticed and the value 0 is entered into Cyc7Control, then later in a truly 0 solution the

Cyclops 7 Logger will be indicated as a concentration of –1. A negative

concentration can not exist and so the sensor is suspected of poor measurement

when the problem is that it was poorly calibrated.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

15

Page 16

Cyc7Control requires that the host computer be connected to the Cyclops 7 Logger at

the time the calibration is performed. The logger must be open at this time. Take

care that no calibrating solutions splash onto logger circuits.

When calibration is completed, use the sensor to log measurements in each

calibration solution. Do this right away using the same solutions that were used for

calibration. The values 0 and the known concentration should be recorded by the

logger. This gives a check on the results of calibration.

Cyclops-7 Loggers support various Turner Cyclops-7 sensors. The sensor type is

shown on a small tag inside the logger.

Sensors are calibrated in response to the Calibrate button, after both the Unit of

Measure and the Calibration Value are entered.

Enter the unit of measure that is appropriate for the Cyclops 7 sensor mounted on the

logger.

Enter the calibration value for the solution.

Click on the Calibrate button. The adjacent scroll bar shows how far the program has

progress through the calibration procedure.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

16

Page 17

A dialog window appears instructing you to place the sensor in the zero solution.

This will most likely simply be clear water contained in a bucket. Whatever the

solution, the sensor after calibration will report 0 when returned to this solution. Click

OK when the sensor is suitably positioned. If this solution is NOT 0 and the sensor is

later placed into a solution that IS 0 the sensor will report a negative concentration!

Negative concentration values can also result if the reflected light in a later solution is

less.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

17

Page 18

At this time the software reads information from the sensor, selecting all three ranges

of the sensor sensitivity.

When this is completed a Zeroing of sensor completed dialog appears. Click OK.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

18

Page 19

A “Please place sensor in calibration standard of <Calibration Value> (<Unit of

Measure>)” dialog appears. In the screen shot above the value of 400 (ppb) is

displayed. This information is taken from the Unit of Measure and Calibration Value

text boxes and will be whatever is entered in the boxes.

Place the sensor in the calibration solution. Whatever the solution, the sensor after

calibration will report the calibration value (400 ppb in the above example) when

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

19

Page 20

returned to this solution. The same considerations about solution accuracy and

reflected light apply in a similar way to those a zeroing.

Click OK. At this time the software reads information from the sensor, selecting the

best sensitivity range.

When this is completed a “Calibration completed” dialog window appears along with

the actual calibration results.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

20

Page 21

Notice that calibration information is displayed in the bottom window. Also, this

information is automatically transmitted to the Cyclops-7 Logger. The Logger is now

calibrated.

Click OK. At this time the calibration is saved on the Cyclops-7 Logger SD card.

Note that the calibration has been installed in the sensor and the sensor is calibrated

no matter if the results are saved on disk or not.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

21

Page 22

A dialog window appears indicating the location where the calibration has been

saved. You may later use the host computer’s file copy/paste to move this file to

some host computer location. You may choose to leave the file on Logger SD or

delete it.

You may read the saved file later using a text file editor. The file will be similar to this

file except that “test” will be replaced with the unit of measure selected for calibration.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

22

Page 23

================================================

Turner Cyclops 7 Logger Calibration

Date: Oct 17, 2014 14:54:13

S/N: 18 Battery: 3.103 (V)

Unit of Measure: test

================================================

Gain = 1, Sensor Output in Zero Solution, Vz1: 0.015335 (Volts)

Gain = 10, Sensor Output in Zero Solution, Vz10: 0.018888 (Volts)

Gain = 100, Sensor Output in Zero Solution, Vz100: 0.066867 (Volts)

Gain = 1, Sensor Output in 100.0(test) Solution: 1.22355 (Volts)

Gain = 1 Sensor Sensitivity (Measured at Gain = 1): 82.76672612076494 (test/Volt)

A note about judging your calibration result: The table below presents typical values

that result from calibration.

Sensor Solution Vz1

(Volt)

Rhodamine (1) 0 to

Vz10

(Volt)

Vz100

(Volt)

Sensitivity

(Unit)

0 to 0.075 5 to 0.150 200 ppb/Volt

0.035

Phycocanin (2) 0 to

0 to 0.075 5 to 0.150 8000 ppb/Volt

0.035

PTSA (3) 0 to

0 to 0.200 0 to 0.500 130 ppb/Volt

0.035

Optical

Brighteners

CDOM (3) 0 to

(3) 0 to

0.035

0 to 0.200 0 to 0.500 3000 ppb/Volt

0 to 0.200 0 to 0.500 1000 ppb/Volt

0.035

Crude Oil (3) 0 to

0 to 0.200 0 to 0.500 540 ppb/Volt

0.035

Turbidity (4) 0 to

0.035

Fluorescein (5) 0 to

0.035

Phycoerythrin (6) 0 to

0 to 0.075 0.005 to

600 NTU/Volt

0.150

0 to 0.075 0.005 to

100 ppb/Volt

0.150

0 to 0.075 0 to 0.500 150 ppb/Volt

0.035

in vivo

Chlorophyll

(7) 0 to

0.035

0 to 0.075 0.005 to

0.200

100 ug/l

(1) Rhodamine dye diluted in deionized water.

(2) Specific species pigment diluted in deionized water

(3) PTSA (1, 3, 6, 8 - Pyrenetetrasulfonic Acid Tetrasodium Salt) calibration standard

(4) Amco Clear Turbidity Standard Solutions

(5) Fluorescein dye diluted in artificial sea water.

(6) Phycoerythrin pigment diluted in Deionized water

(7) algal monoculture consisting of the species Skeletonena costatum.

Unit

Sensor calibrations should always show Vz1..Vz100 in the ranges given. The

sensitivity can vary but variations larger than +/- 20% should be suspect.

Also note that sensors can only produce as much as 5 Volts at their lowest sensitivity.

Therefore your reference solutions have a maximum concentration that can be

sensed. For example Rhodamine typical sensitivity is 200 ppb/Volt so only a

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

23

Page 24

maximum of 1000 ppb can be sensed. The “Sensor Output in xxx Solution” will

always be less than 5.0 Volts since this is all the sensor can produce but should be

less than 4.0 Volts.

A note about Turner solid state secondary standards: These standards are not

supplied with any calibration value, so they are not at first useful for calibration.

However, once the sensor is calibrated the solid state secondary standard can be

placed onto the sensor and adjusted so that the sensed value is some arbitrary value.

Please refer to Turner’s documentation concerning the Solid Secondary Standard

that is supplied with the standard or via the internet:

http://www.turnerdesigns.com/t2/doc/instructions/998-6800.pdf

Install the standard as described. The logger’s sensor guard must be unscrewed and

removed for this procedure.

Operationally, adjustment of a standard is not well implemented in the logger

software. Step 2 of the Use of the Solid Secondary Standard for in vivo Chlorophyll

Applications on page 1 of this document assumes that the sensor output can be

viewed in real time. However this output can only be logged by the Cyclops-7

Logger. A short recording of the measurement must be made, and then the record

reviewed, to determine the sensed value. The process must be repeated by trials to

adjust the standard as described in the document.

A note on chlorophyll calibration: Please review the Turner Designs document titled

“In Vivo Chlorophyll: Concepts & Concerns”. PME sometimes provides this

document together with this Manual or it can be found at Turner’s Application Notes

http://www.turnerdesigns.com/customer-care/fluorometer-application-notes/chlorophyll-fluorometer-applicationnotes

2.2 Cyc7Plot

The Cyc7Plot program provides the service of plotting Cyclops-7 Logger files.

Begin program operation by clicking on C7Plot.jar. Software presents the screen

shown below.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

24

Page 25

C7Plot plots the files recorded by the Cyclops-7 Logger. The software reads all

Logger files in a folder, except the CAT.txt file.

Notice that the software has automatically suggested the Cyclops-7 Logger SD card

as the Data Folder. You may accept this or click Select DATA Folder to find some

other source for the plot.

DATA folders MUST NOT contain any other files besides files written by the Cyclops7 Logger. This folder can be on the SD card from the Cyclops-7 or it can be from a

copy of this on your computer’s hard drive.

A few thousand measurements can be plotted directly from Cyclops-7 Logger SD.

However it is best to copy large measurement sets to the host computer and select

them there since file access to the Logger is slow.

Press ‘Plot’ to begin measurement processing. The software reads all Cyclops-7

Logger data files in the Data presents a plot of the measurements similar to the plot

shown below.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

25

Page 26

You may zoom this plot by drawing a square from upper left to lower right (click and

hold left mouse button) that defines the zoom region. To zoom completely out,

attempt to draw a square from lower right to upper left. The mouse will scroll the

image if the CTRL key is held down. Right click on the plot for options such as copy

and print.

The software may be run multiple times at the same time (select Data Folder, press

Process, select new Data Folder, press Process...). In this case it produces multiple

plots. Presently the plots are presented exactly on top of each other and so when a

new plot appears it is not obvious that the old plot is still there. It is. Just move the

new plot to see it. Closing any plot closes all.

End C7Plot by closing any window.

The software can be re-run at any time. If an already processed DATA Folder is

selected the software simply reads the measurement files again.

Special note: plotting of sample sets of more than 200K samples may consume all

memory available to the host computer’s Java. C7Plot will present a partial plot and

freeze in this case. A simple solution is to separate the files into multiple folders and

plot each folder individually.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

26

Page 27

2.3 Cyc7Concatenate

The Cyc7Concatenate program provides these services:

It gathers together all Cyclops-7 Logger files in the DATA folder in time sequence.

It translates the Logger time stamp into two additional formats.

It writes all times and measurements into a single CAT.txt file in the DATA Folder.

Begin program operation by clicking on Cyc7Concatenate.jar. Software presents the

screen shown below.

Cyc7Concatenate concatenates the files recorded by the Cyclops-7 Logger. The

software reads all Logger files in a folder, except the CAT.txt file. Software

translates Logger time stamps into two additional formats, and saves the result in a

CAT.txt file in the DATA Folder.

Notice that the software has automatically suggested the Cyclops-7 Logger SD card

as the Data Folder. You may accept this or click Select DATA Folder to find some

other source for the plot.

DATA folders MUST NOT contain any other files besides files written by the Cyclops7 Logger. This folder can be on the SD card from the Cyclops-7 or it can be from a

copy of this on your computer’s hard drive.

A few thousand measurements can be concatenated directly from Cyclops-7 Logger

SD. However it is best to copy large measurement sets to the host computer and

select them there since file access to the Logger is slow.

Press ‘Concatenate’ to begin measurement processing. The software reads all

Cyclops-7 Logger data files in the DATA Folder. These are written to the same

folder. Software presents a dialog window when the process is completed.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

27

Page 28

Click OK. The Cyc7Concatenate software can be re-run at any time.

End Cyc7Concatenate operation by closing the window.

The CAT.txt file will resemble the following:

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

28

Page 29

Chapter 3: Cyclops-7 Logger

3.1 Overview

All of the Cyclops-7 Logger measurements pass from the sensors onto the SD card it

contains. Files are transferred to a host computer via USB connection where the

Cyclops-7 Logger appears as a “thumb drive”. Measurements may be plotted by

Cyc7Plot and files concatenated by Cyc7Concatenate. The Cyclops-7 Logger itself is

controlled and calibrated by Cyc7Control. Customers are required to open the logger

each time measurements are transferred to the host computer. This chapter

describes the logger internal features.

3.2 Opening and Closing the Logger

The logger circuitry is contained in a waterproof housing that must be opened. The

housing is opened by unscrewing the white pressure housing from the black end cap.

Turn the pressure housing counter clockwise relative to black end cap. Close by

reversing this procedure after being sure that the o-ring is free from debris. Lube oring occasionally with grease intended for buna-n o-ring material.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

29

Page 30

The logger is much more difficult to open than to close. Screw the white logger

housing onto the black cap until the housing touches the cap. No further tightening is

necessary.

Please attempt to handle the Cyc7Logger only by the aluminum chassis, without

touching the circuit card.

When closing the Cyclops-7 Logger inspect the o-ring and interior of the white

cylinder for debris, lube the o-ring, and screw the white cylinder onto the black end

cap until the cylinder just touches the end cap. Do not Tighten! The Cyclops-7

Logger tends to get a little tighter during deployment.

If you can not open the Cyclops-7 Logger by yourself, find another person with strong

hands. This person should grip the black end cap while you turn the white cylinder.

3.3 Electrical Connections and Controls

Removal of the cover reveals the logger connections and controls, shown below.

The LED Light is a LED that can display either red or green light. This is used to

indicate different features described in Chapter 1 in this manual.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

30

Page 31

The Logger Control Switch controls the logger mode:

Record – When the switch is in this position the logger is recording

measurements.

Halt – When the switch is in this position the logger is not recording and is

sleeping at low power.

The USB Connection allows communication between the logger and an external

host computer. When connected, the logger is in halt mode regardless of the Logger

Control Switch position. When disconnected the logger mode is controlled by the

switch position. The switch position may be changed while the USB is connected.

The Main Batteries (2 X “C” at right of picture above) provide main power to the

Cyclops-7 Logger. Note the positive (+) terminal.

Caution: Improper replacement of the batteries will damage the Cyclops-7

Logger.

3.4 Battery Replacement

Carefully remove both “C” cells, noting the direction of the (+) terminals. Take care

not to break the glue connection between the holder and the aluminum chassis.

These both are oriented towards the Logger circuit. Insert new ‘C’ cells into the

paper tube and re-install the pair into the battery holder. When replacing batteries use

only fresh batteries. Don’t mix battery types. If one battery differs in type or charge

level from the other and the Cyclops-7 Logger runs them to full discharge, then one

battery may leak.

Please be aware that the warranty will become void if the batteries are installed

backwards.

3.5 Interchangeable Sensor Installation

PME provides two types of Cyclops-7 loggers. One type has the sensor permanently

mounted by PME. This section describes the other type where the sensor is plugged

to the logger. The other features described throughout this document are the same

for both types of loggers.

Arrange the parts as shown in the picture below

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

31

Page 32

The small circular black clip shown to the right of the C7 sensor will be found installed

on the logger connector. This can be removed by unscrewing it from the connector,

and then gently prying open the ‘C’ clip center piece.

Screw one side of the clip fully on to the sensor. Screw the opposite side fully onto

the connector as shown in the picture below.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

32

Page 33

Be sure both are fully screwed on. If either is not, the clip will hold the sensor in a

position where it may not make full contact with the connector.

Spray silicone lubricant on the male pins of the sensor. Wipe off any excessive

lubricant.

NOTE: A light coat of silicone spray should be used on the rubber of the male pins of

the bulkhead to aid in sealing. The manufacturer recommends 3M Silicone Lubricant

Spray. DO NOT use silicone lubricant containing acetone or WD-40, it will destroy the

connectors.

The recommended spray can be purchased here:

https://www.mscdirect.com/product/details/33010091?item=33010091

Plug the senor fully into the connector as shown in the picture below.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

33

Page 34

The clip faces will mate. Note that if the clip is not fully screwed onto the connector it

will still appear as shown in the picture above, but the sensor may not be making

complete reliable contact with the logger.

Snap the remaining clip part onto the clip to secure the sensor to clip connection.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

34

Page 35

Slide the sensor support (middle-right in first picture) over the sensor. Note this part

has an internal o-ring that comes against the sensor. This is not a water-proof seal.

It’s purpose is to firmly secure the sensor within the support. Next screw the sensor

guard (middle left in first picture) onto the sensor support. The completed assembly

is shown in the picture below.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

35

Page 36

When exchanging the sensor, reverse the process steps given above.

The sensor connector is itself threaded into the logger end cap. This connector is

tightened, but since the logger end cap is plastic there is a limit to how tightened this

connector can be made. If the connector unscrews water can enter the logger and

cause permanent damage. Be observant when installing sensors. When installed,

the sensor should not be able to be rotated. Take care not to unscrew the sensor

and watch the sensor when unscrewing the sensor support since the o-ring will apply

a sight loosing rotation to the sensor. Should the sensor/connector become loose

discontinue use of the logger and contact PME.

3.6 Notes

This section collects general notes concerning the instrument.

Do not use harsh solvents on any of the logger plastic parts. In particular do not use

acetone on the sensor guard. This part is constructed of ABS plastic and will

dissolve if exposed to acetone.

Precision Measurement Engineering, Inc.

(760) 727-0300

www.Turner Designs.com

36

Loading...

Loading...