PMD MC1401A, MC1401A-P, MC1101A, MC1101A-P, MC1201A Datasheet

...

Available in 1, 2, or 4 axes configurations

32-bit position, velocity, acceleration and jerk

Choice of S-curve, trapezoidal, or contoured

Electronic gearing

1.0 megacount/sec quadrature incremental encoder

Choice of PWM or DAC motor output signals

with pre-load

Programmable host interrupts

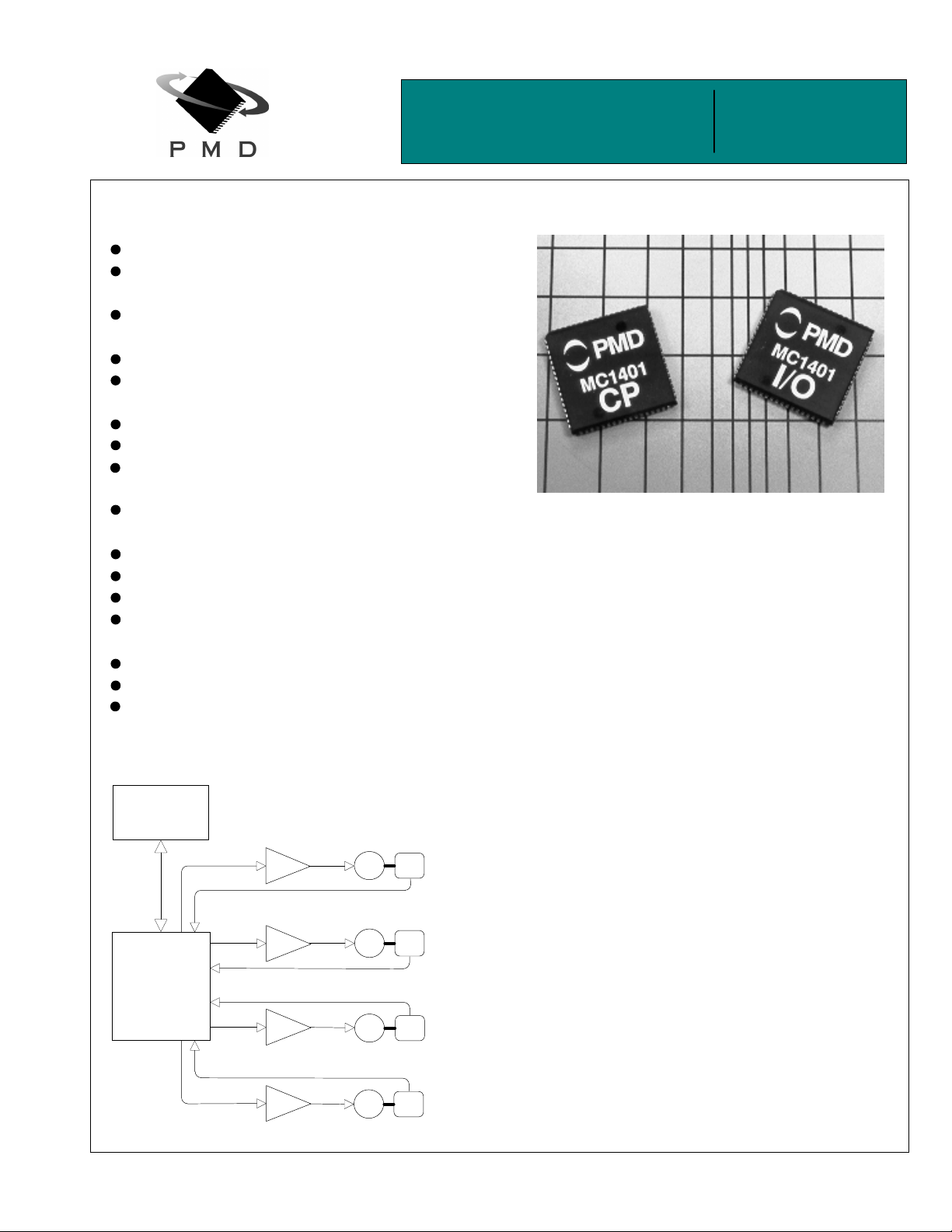

Host

Processor

MC1401A

(I/O & CP)

Axis 1

Axis 2

Axis 3

Axis 4

$GYDQFHG0XOWL$[LV0RWLRQ

Features

Provides trajectory generation and servo loop

closure

registers

Two directional travel-limit switches per axis

velocity profile modes

Programmable loop rate to 100 micro sec

Choice of either PID or PI with velocity feedforward

servo control loops

with index position capture

Parallel encoder and resolver input support

High speed home-signal position capture

"On the fly" control of profile and filter parameters

Programmable torque limit

Easy to use packet-oriented host protocol

&RQWURO&KLSVHW

General Descripti on

The MC1401A is a 2-IC general purpose motion contr ol chipset

available in one, two, or four axis configurations. It provides

trajectory generation and clo sed-loop digital servo control for a

large variety of servo motors. It uses incremental or absolute

encoder positi on feedback signals, and a DAC or P WM

compatible ou tput drive. Axe s can be progra m m ed either

independently or in synchrony to allow advanced multi-axis

motion such as ci rcular and contin uous-path profiles.

0&$0&$3

0&$0&$3

0&$0&$3

Typical Configuration

Amp

Amp

Amp

Amp

The MC1401A is functionally similar to other members of

PMD's 1st generation chipset family, provid i ng software an d

architectural compatibility with these chipsets. All of these

products support advanced features such as S-curve profile

generation, bi-directional motion-travel limit switches, and

separate hom e and index positio n capture signals.

The chipset is controlled by a host processor which interfaces

with the chipset vi a an 8-bit, bi-directional port. Communications

E

M

M

E

(MC1401A,

MC1201A only)

E

M

(MC1401A only)

E

M

(MC1401A only)

to/from the chi pset consist of pack et-oriented messages. A ho st

interrupt line is provided so that the chipset can signal the host

when special condi tions occur such as enc o der index pulse

received.

Each axis interfaces to either a quadrature encoder with an

optional index pulse, or a parallel-word device such as an

absolute enco der or resolver . For motor a m pl if i er output, PWM

signals are provided, as well as DAC-compatible signals with up

to 16 bits of resolution.

The chipset is packaged in 2 68-pin PLCC pa ck ages. Both

chips utilize CMOS technology and are powered by 5 volts.

Doc. Rev. 6.14, Nov , 1997

Performance Motion Dev ices, In c. 12 Waltham St. Le xington, M A 02421 te l: 781. 674.98 60 fax: 781.674.9 861 www.pmdcorp.com

Table of Contents

Product Family Overview.......................................Page 3

Introduction ............................................................ Page 3

Family Summary..................................................... Page 3

Electrical Characteristics....................................... Page 4

Absolute Maximum Ratings..................................Page 4

Operating Ratings................................................. Page 4

DC Electrical Characteristics................................ Page 5

AC Electrical Characteristics................................Page 5

I/O Timing Diagrams............................................. Page 7

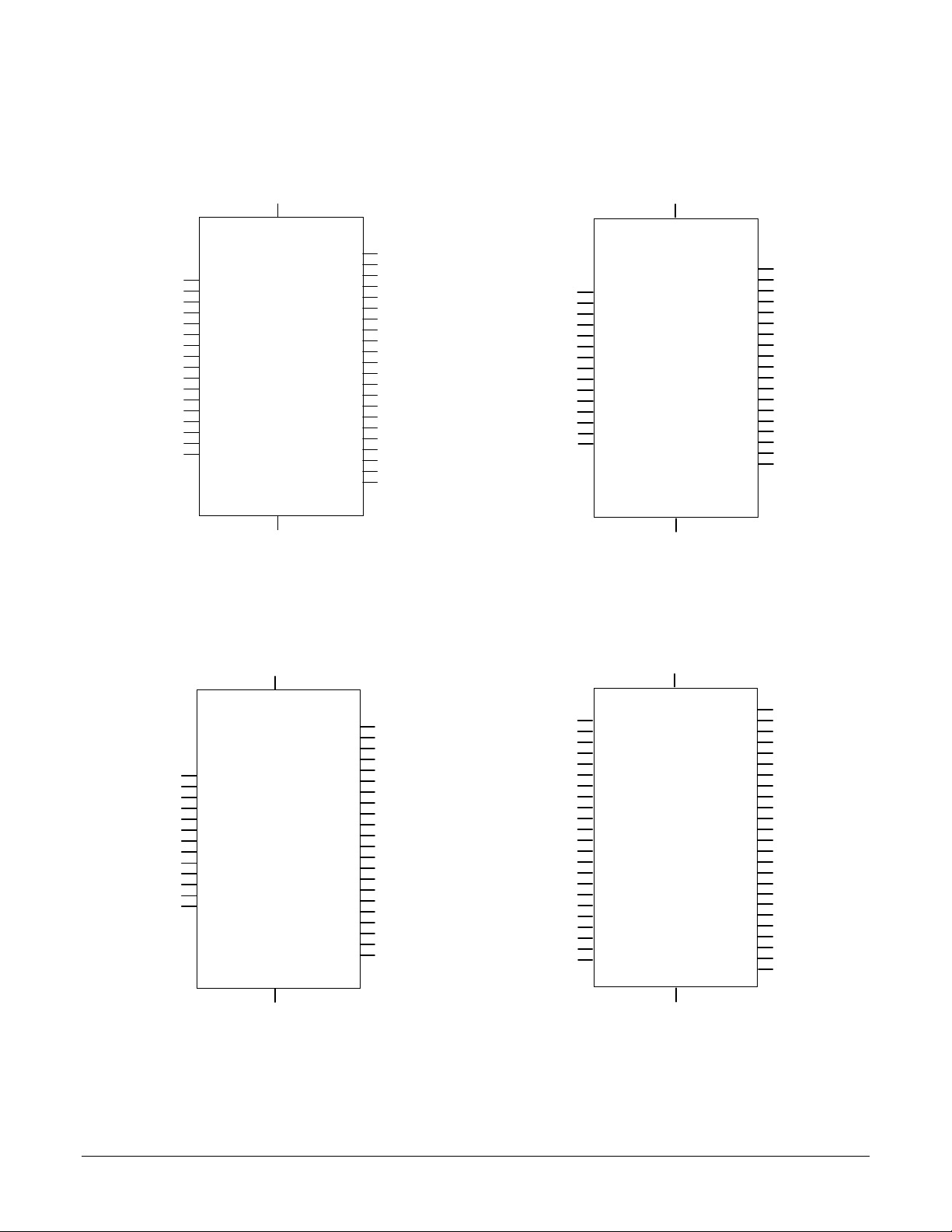

Pinouts....................................................................Page 13

MC1401A. MC1201A............................................ Page 13

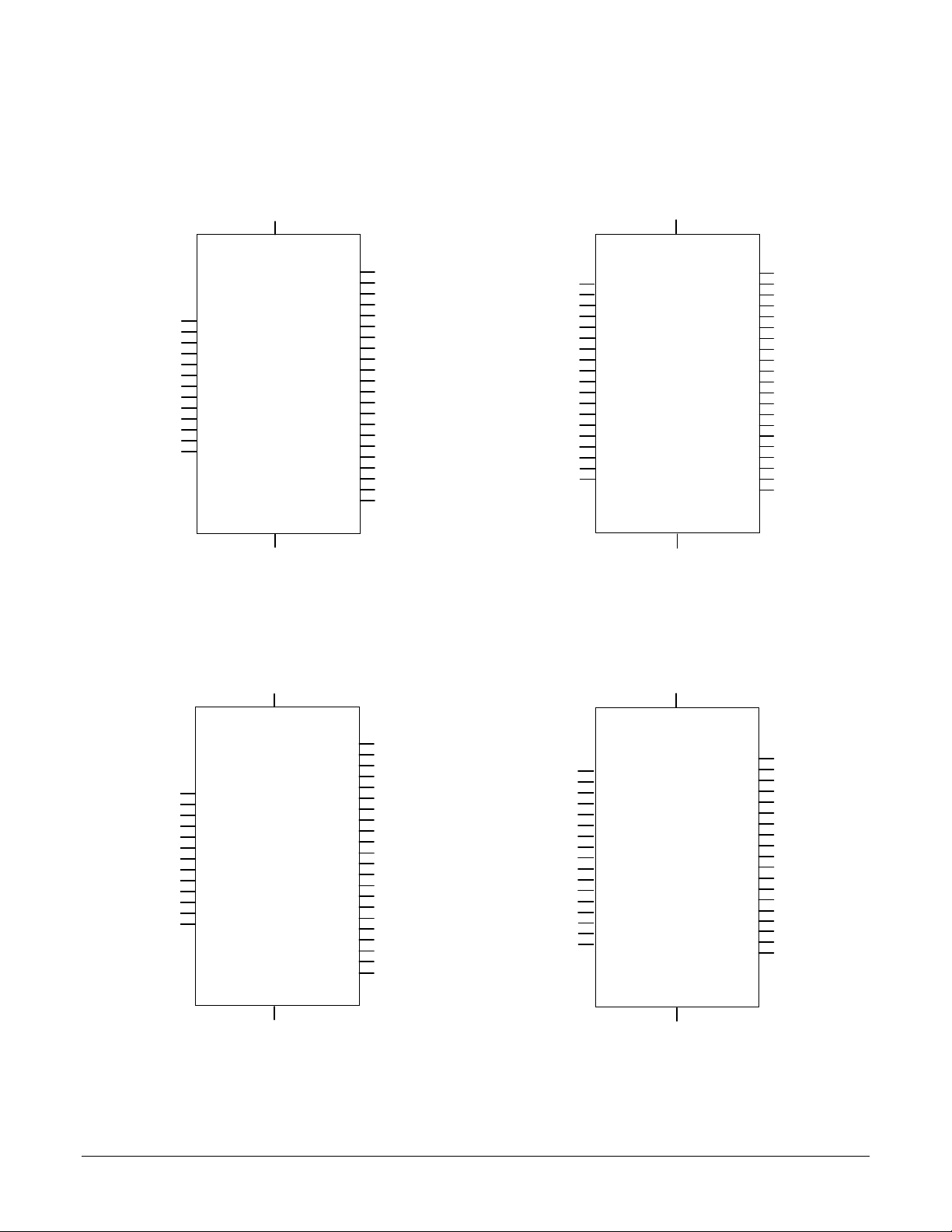

MC1101A, MC1401A-P........................................ Page 14

MC1201A-P, MC1101A-P.....................................Page 15

Pin Descriptions.................................................... Page 16

Theory of Operations............................................. Page 20

Trajectory Profile Generation................................ Page 21

S-curve Point to Point....................................... Page 22

Trapezoidal Point to Point.................................Page 23

Velocity Contouring...........................................Page 23

Electronic Gear.................................................Page 24

Trajectory Control................................................. Page 24

Halting The Trajectory......................................Page 24

Motion Complete Status...................................Page 25

Digital Servo Filtering ........................................... Page 25

Motor Limit........................................................Page 26

Motor Bias........................................................ Page 26

Parameter Loading & Updating............................Page 26

Manual Update.................................................Page 27

Breakpoints....................................................... Page 27

External Breakpoints and Homing.................... Page 28

Disabling Automatic Profile Update..................Page 28

Travel Limit Switches............................................ Page 28

Motion Error Detection and Recovery.................. Page 29

Recovering From a Motion Error......................Page 29

Axis Timing........................................................... Page 29

Host Communications .......................................... Page 30

Electrical Interface............................................ Page 30

Packet Format..................................................Page 30

Packet Checksum.............................................Page 31

Illegal Commands .............................................Page 31

Command Errors...............................................Page 31

Axis Addressing....................................................Page 31

Axis Status............................................................Page 32

Status Word ......................................................Page 32

Miscellaneous Mode Status Word.....................Page 32

Host Interrupts.......................................................Page 32

Encoder Position Feedback..................................Page 34

Incremental Encoder Input................................Page 34

Encoder Filtering...............................................Page 34

High Speed Position Capture............................Page 34

Parallel-Word Device Input................................ Page 34

Parallel-Word Device Interfacing.......................Page 35

Motor Outputs.......................................................Page 35

Motor Output Control.........................................Page 35

PWM Output......................................................Page 36

12-Bit DAC Output.............................................Page 36

16-Bit DAC Output.............................................Page 36

Host Commands .....................................................Page 38

Command Summary.............................................Page 38

Command Reference............................................Page 40

Axis Control.......................................................Page 40

Profile Generation.............................................Page 41

Digital Filter.......................................................Page 45

Parameter Update............................................. Page 47

Interrupt Processing..........................................Page 50

Status/Mode......................................................Page 51

Encoder.............................................................Page 52

Motor.................................................................Page 52

Miscellaneous ...................................................Page 54

Application Notes ...................................................Page 58

Interfacing to ISA bus............................................Page 58

Parallel-Word Device Interface .............................Page 60

PWM Motor Interface............................................Page 62

16-Bit Parallel DAC Motor interface......................Page 64

16-Bit Serial DAC Motor Interface.........................Page 66

Performance Motion Devices, Inc. does not assume any responsibility for use of any circuitry described in this manual, nor does it make

any guarantee as to the accuracy of this manual. Performance Motion Devices, Inc. reserves the right to change the circuitry described in

this manual, or the manual itself, at any time.

The components described in this manual are not authorized for use in life-support systems without the express written permission of

Performance Motion Devices, Inc.

2

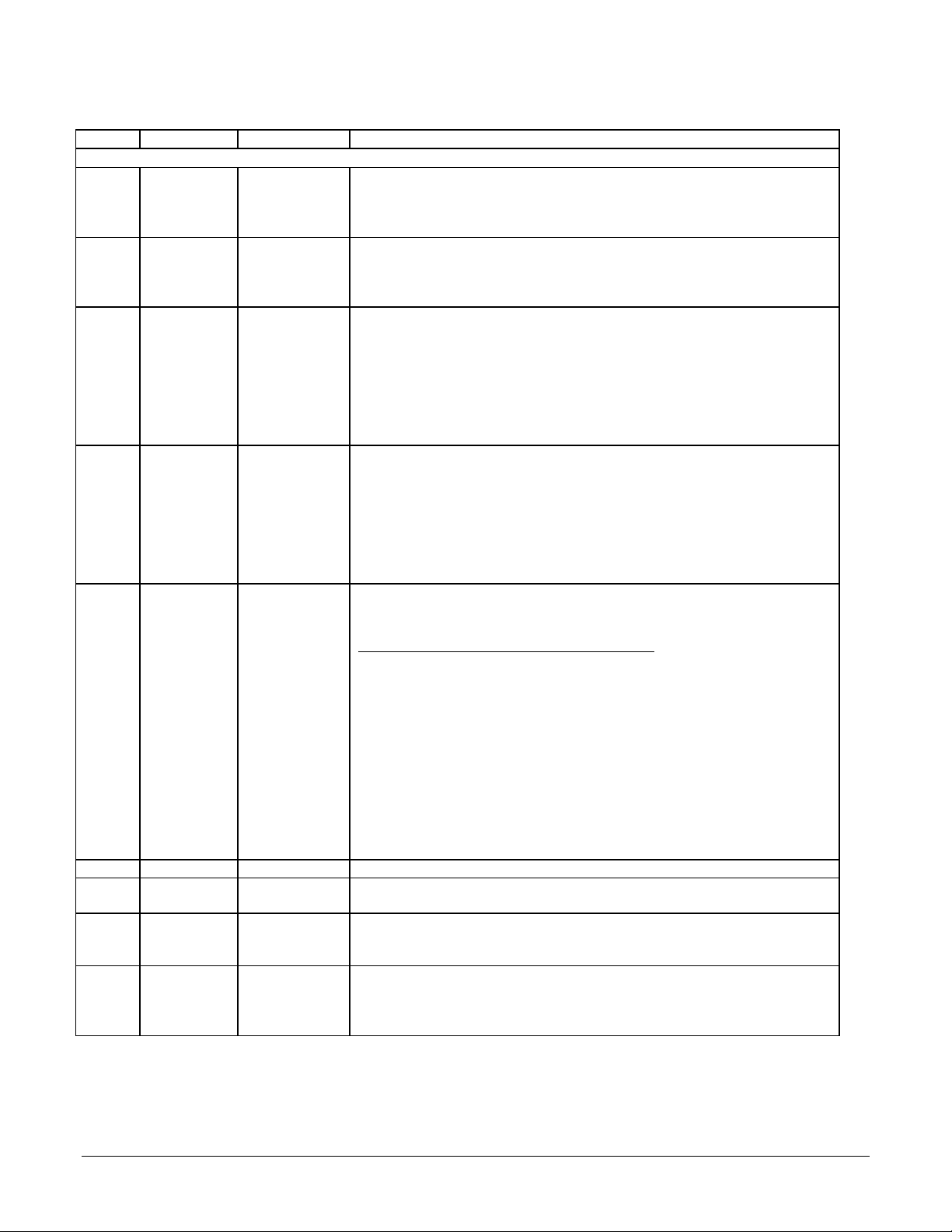

Product Family Overview

MC1401 series MC1231 series MC1241 series MC1451 series

# of axes 4, 2, or 1 2 or 1 2 or 1 4, 2, or 1

Motors Supported DC Servo Brushless Servo Stepper Stepper

Encoder Format Incremental (no dash version)

and Parallel ('-P' version)

Output Format DC servo Sinusoidally

S-curve profiling Yes Yes Yes Yes

Electronic gearing Yes Yes Yes Yes

On-the-fly changes Yes Yes Yes Yes

Limit switches Yes Yes Yes Yes

PID & feedforward Yes Yes - -

PWM output Yes Yes Yes -

DAC-compatible output Yes Yes Yes -

Pulse & direction output ---Yes

Index & Home signal Yes Yes Yes Yes (-E version)

Chipset p/n's MC1401A, MC1401A-P (4 axes)

MC1201A, MC1201A-P (2 axes)

MC1101A, MC1101A-P (1 axis)

Developer's Kit p/n's: DK1401A, DK1401A-P DK1231A DK1241A DK1451A

Incremental Incremental Incremental (-E version)

Microstepping Pulse and Direction

commutated

MC1231A (2 axes)

MC1131A (1 axis)

MC1241A (2 axes)

MC1141A (1 axis)

MC1451A, MC1451A-E (4 axes)

MC1251A, MC1251A-E (2 axes)

MC1151A, MC1151A-E (1 axis)

Introduction

This manual describes the operational characteristics of the MC1401A,

MC1201A, MC1101A, MC1401A-P, MC1201A-P, and MC1101A-P

Motion Processors. These devices are members of PMD's 1st

generation motion processor family, which consists of 16 separate

products organized into four groups.

Each of these devices are complete chip-based motion controllers.

They provide trajectory generation and related motion control functions.

Depending on the type of motor controlled they provide servo loop

closure, on-board commutation for brushless motors, and high speed

pulse and direction outputs. Together these products provide a

software-compatible family of dedicated motion processor chips which

can handle a large variety of system configurations.

Each of these chips utilize a similar architecture, consisting of a highspeed DSP (Digital Signal Processor) computation unit , along with an

ASIC (Application Specific Integrated Circuit). The computation unit

contains special on-board hardware such as a multiply instruction that

makes it well suited for the task of motion control.

Along with a similar hardware architecture these chips also share most

software commands, so that software written for one chipset may be reused with another, even though the type of motor may be different.

This manual describes the operation of the MC1401A, MC1201A,

MC1101A, MC1401A-P, MC1201A-P, and MC1101A-P chipsets. For

technical details on other members of PMD's first ge neration

motion processors see the corresponding product manual.

Family Summary

MC1401 series (MC1401A, MC1201A, MC1101A, MC1401A-P,

MC1201A-P, MC1101A-P)

encoder signals (standard version) or parallel word encoder signals

(-P version) and output a motor command in either PWM or DACcompatible format. These chipsets come in 1, 2 or 4 axis versions

and can be used with DC brushed motors, or brushless motors using

external commutation.

MC1231 series (MC1231A, MC1131A) -

incremental quadrature encoder signals and output sinusoidally

commutated motor signals appropriate for driving brushless motors.

They are available in one or two axis versions. Depending on the

motor type they output two or three phased signals per axis in either

PWM or DAC-compatible format.

MC1241 series (MC1241A, MC1141A)

internal microstepping generation for stepping motors. They are

available in a one or a two-axis version. Two phased signals are

output per axis in either PWM or DAC-compatible format. An

incremental encoder signal can be input to confirm motor position.

MC1451 series (MC1451A, MC1251A, MC1151A, MC1451A-E,

MC1251A-E, MC1151A-E) -

pulse and direction signal output appropriate for driving step motorbased systems. They are available in a one, two, or four-axis version

and are also available with quadrature encoder input.

Each of these chipsets has an associated Chipset Developer's

Kit available for it. For more information contact your PMD

representative.

- These chipsets take in incremental

These chipsets take in

- These chipsets provide

These chipsets provide very high speed

3

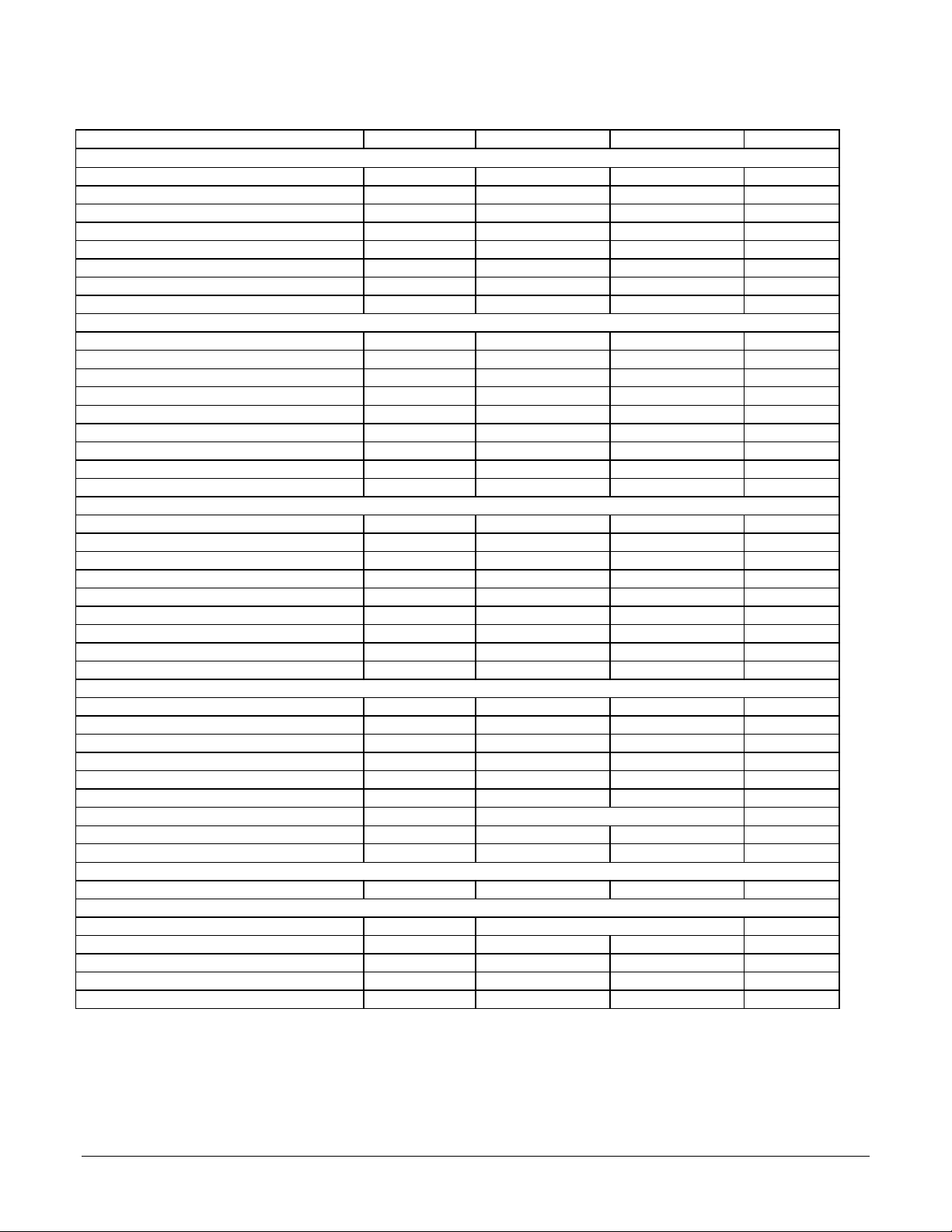

Electrical Characteristics

Overview

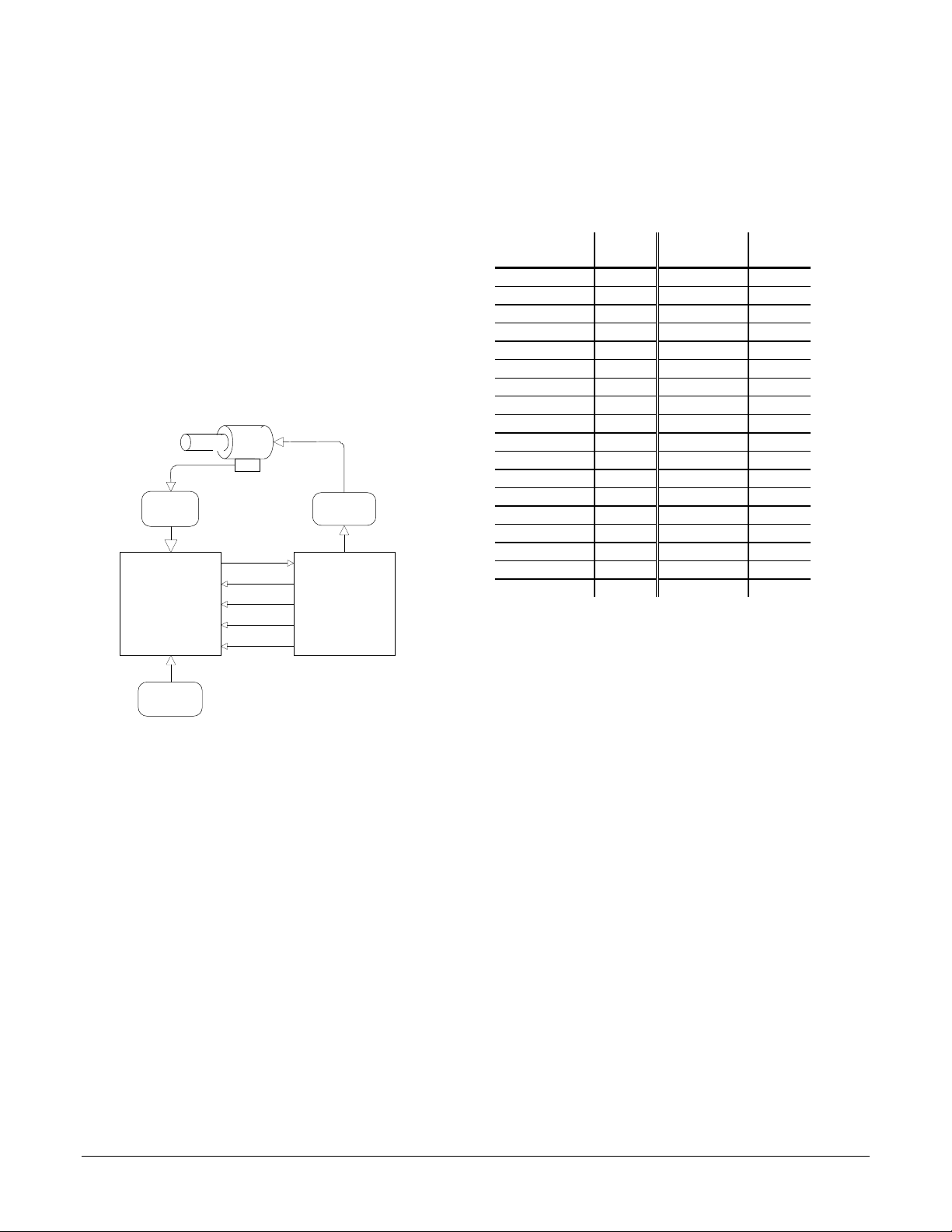

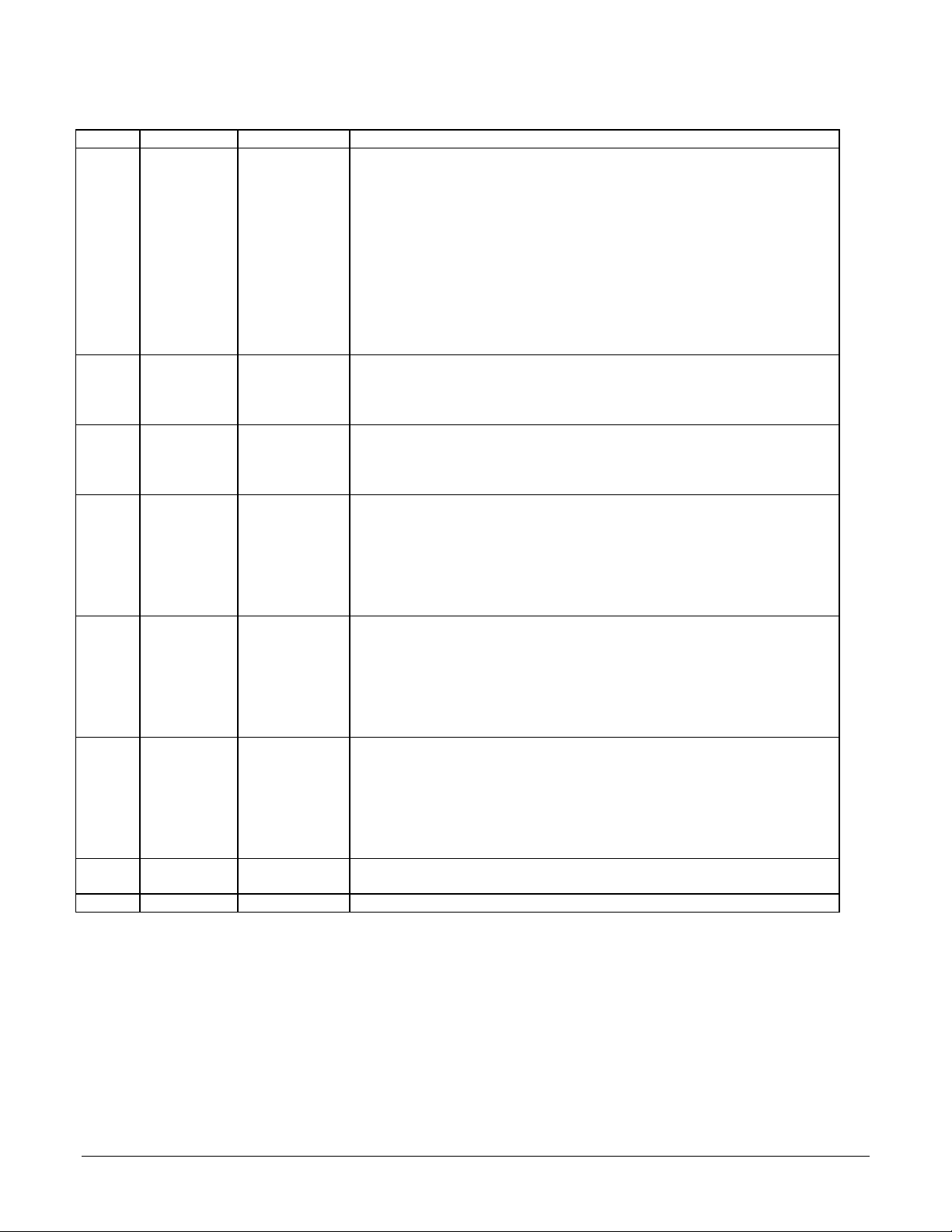

Interconnections between the two chips consist of a data bus and

various control and synchronization signals. The following table

summarizes the signals that must be interconnected for the chipset to

function properly. For each listed signal the I/O chip pin on the left side

of the table is directly connected to the pin to the right.

The MC1401A-consists of two 68 pin PLCC's both fabricated in CMOS.

The Peripheral Input/Output IC (I/O chip) is responsible for interfacing

to the host processor and to the position input encoders. The Command

Processor IC (CP chip) is responsible for all host command, profile and

servo computations, as well as for outputting the PWM and DAC

signals.

The following figure shows a typical system block diagram, along with

the pin connections between the I/O chip and the CP chip.

Motor

(4 axis)

Encoder

(1-4 axis)

I/O

Host

Processor

Data4-11

I/OAddr0-3

I/OWrite

I/OCntrl0-3

ClkOut

Amplifier

(1-4 axis)

CP

I/O Chip Signal

Name

I/O Chip

Pin

CP Chip

Signal Name

CP Chip

Pin

CPData4 18 Data4 50

CPData5 5 Data5 49

CPData6 6 Data6 46

CPData7 7 Data7 43

CPData8 8 Data8 40

CPData9 17 Data8 39

CPData10 3 Data10 36

CPData11 1 Data11 35

CPAddr0 68 I/OAddr0 28

CPAddr1 27 I/OAddr1 9

CPAddr2 29 I/OAddr2 6

CPAddr3 12 I/OAddr3 5

CPCntr0 20 I/OCntr0 16

CPCntr1 36 I/OCntr1 18

CPCntr2 22 I/OCntr2 68

CPCntr3 63 I/OCntr3 67

CPWrite 2 I/OWrite 15

CPClk 46 ClkOut 19

For a complete description of all pins see the 'Pin Descriptions'

section of this manual.

Unless specifically noted otherwise, the term 'MC1401A' refers to

the MC1401A, MC1201A, MC1101A, MC1401A-P, MC1201A-P, and

MC1101A-P Motion Processors.

The CP and I/O chips function together as one integrated motion

processor. The major components connected to the chip set are the

Encoder (4, 2, or 1 axes), the motor amplifier (4, 2, or 1 axes), and the

host processor.

For the standard MC1401A parts (non '-P' parts), the encoder signals

are input to the I/O chip in quadrature format. For the '-P' parts the

encoder information is input directly into the CP chip, via an 8 bit data

bus and various control signals.

The chipset's motor output signals are connected to the motor amplifier.

Two types of output are provided; PWM (pulse width modulation), and

DAC-compatible signals used with an external DAC (digital to analog

converter).

The host processor is interfaced via an 8-bit bi-directional bus and

various control signals. Host communication is coordinated by a

ready/busy signal, which indicates when communication is allowed.

Absolute Maximum Ratings

Unless otherwise stated, all electrical specifications are for both

the I/O and CP chips.

Storage Temperature, Ts.....................-55 deg. C to +150 deg. C

Supply Voltage, Vcc.............................-0.3 V to +7.0 V

Power Dissipation, Pd..........................650 mW (I/O and CP

combined)

Operating Ratings

Operating Temperature, Ta .................0 deg. C to +70 deg. C*

Nominal Clock Frequency, Fclk...........25.0 Mhz

Supply Voltage, Vcc.............................4.75 V to 5.25 V

* Industrial and Military operating ranges also available. Contact your

PMD representative for more information.

4

DC Electrical Characteristics

(Vcc and Ta per operating ratings, Fclk = 25.0 Mhz)

Symbol Parameter Min. Max. Units Conditions

Vcc Supply Voltage 4.75 5.25 V

Idd Supply Current 100 mA open outputs

Input Voltages

Vih Logic 1 input voltage 2.0 Vcc + 0.3 V

Vil Logic 0 input voltage -0.3 0.8 V

Vihclk Logic 1 voltage for clock pin

(ClkIn)

Vihreset Logic 1 voltage for reset pin

(reset)

Output Voltages

Voh Logic 1 Output Voltage 2.4 V @CP Io = 300 uA

Vol Logic 0 Output Voltage 0.33 V @CP Io = 2 mA

Iout Tri-State output leakage current -20 20 uA 0 < Vout < Vcc

Iin Input current -50 50 uA 0 < Vi < Vcc

Iinclk Input current ClkIn -20 20 uA 0 < Vi < Vcc

3.0 Vcc+0.3 V

4.0 Vcc+0.3 V

AC Electrical Characteristics

(see reference timing diagrams)

(Vcc and Ta per operating ratings; Fclk = 25.0 Mhz)

(~ character indicates active low signal)

@I/O Io = 4 mA

@I/O Io = 4 mA

Timing Interval T# Min. Max. Units

Encoder and Index Pulse Timing

Motor-Phase Pulse Width T1 1.6 uS

Dwell Time Per State T2 0.8 uS

Index Pulse Setup and Hold

(relative to Quad A and Quad B low)

Reset Timing

Stable Power to Reset 0.25 Sec

Reset Low Pulse Width 1.0 uS

Clock Timing

Clock Frequency (Fclk) 6.7 25.6 Mhz

Clock Pulse Width T4 19.5 75 (note 2) nS

Clock Period T5 39 149 (note 2) nS

T3 0 uS

5

Timing Interval T# Min. Max. Units

Command Byte Write Timing

~HostSlct Hold Time T6 15 2000 (note 3) nS

~HostSlct Setup Time T7 10 nS

HostCmd Setup Time T8 10 nS

Host Cmd Hold Time T9 25 nS

HostRdy Delay Time T13 70 nS

~HostWrite Pulse Width T14 50 nS

Write Data Setup Time T15 35 nS

Write Data Hold Time T16 30 nS

Data Word Read Timing

~HostSlct Hold Time T6 15 2000 (note 3) nS

~HostSlct Setup Time T7 (read only) - 20 nS

HostCmd Setup Time T8 (read only) - 20 nS

HostCmd Hold Time T9 25 nS

Read Data Access Time T10 50 nS

Read Data Hold Time T11 10 nS

~HostRead high to HI-Z Time T12 50 nS

HostRdy Delay Time T13 70 nS

Read Recovery Time T17 60 nS

Data Word Write Timing

~HostSlct Hold Time T6 15 2000 (note 3) nS

~HostSlct Setup Time T7 10 nS

HostCmd Setup Time T8 10 nS

HostCmd Hold Time T9 25 nS

HostRdy Delay Time T13 70 nS

~HostWrite Pulse Width T14 50 nS

Write Data Setup Time T15 35 nS

Write Data Hold Time T16 30 nS

Write Recovery Time T18 60 nS

DAC Interface Timing

I/OAddr Stable to ~I/OWrite setup time T19 35 nS

~I/OWrite Pulse Width T20 56 95 nS

Data Hold Time After ~I/OWrite T21 17 nS

ClkOut Low to I/OAddr stable T22 10 40 nS

ClkOut Low to ~I/OWrite Low T23 75 92 nS

ClkOut Low to Data Valid T24 92 nS

ClkOut Cycle Time T25 160 typical (note 4) nS

I/OAddr Stable to DACSlct High T26 66 nS

~I/OWrite Low to DACSlct High T27 44.5 nS

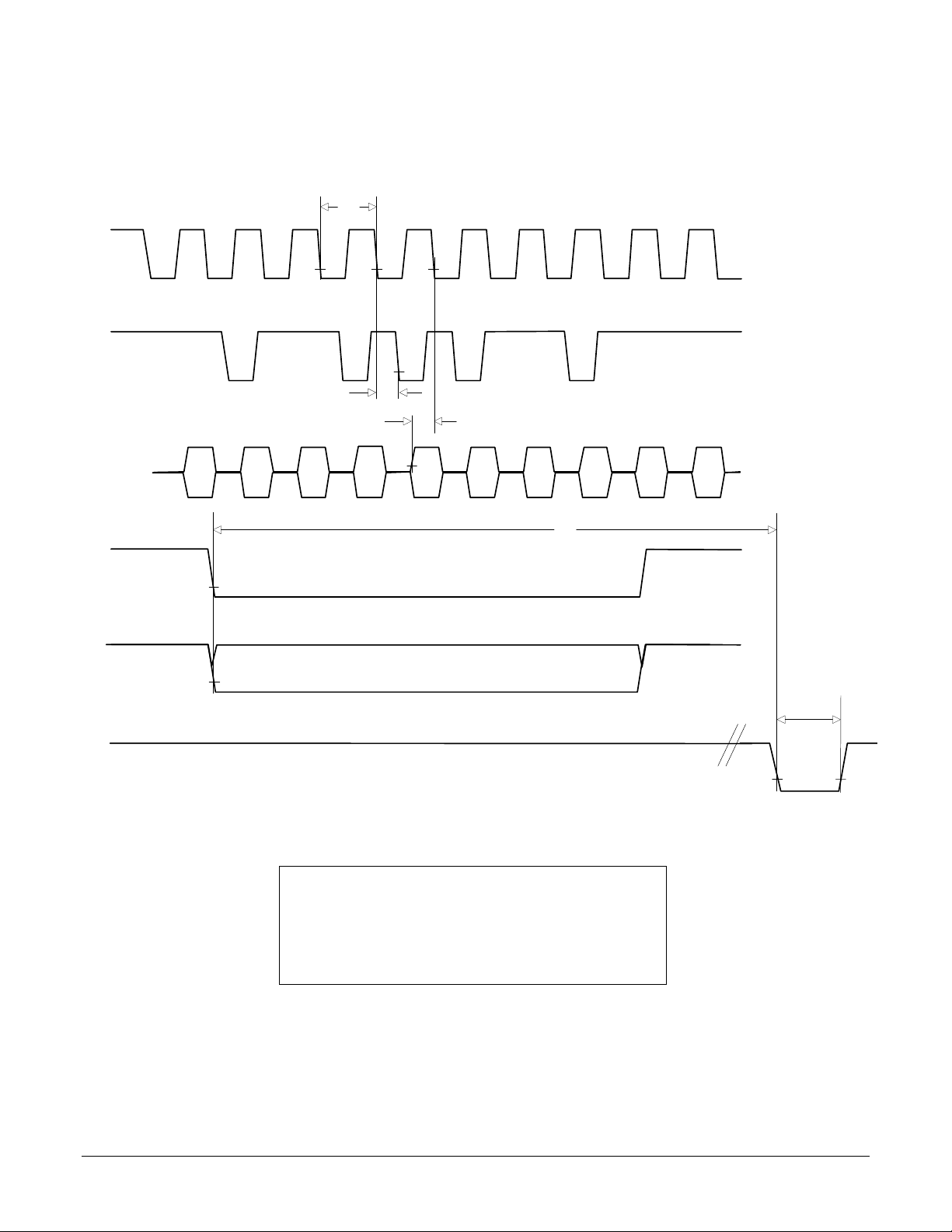

PWM Output Timing

PWM Output Frequency 24.5 Khz

Parallel-Word Enc oder Timing (-P versi ons only)

ClkOut Period T28 160 typical (note 4) nS

I/OCtrnl0 Delay Time T29 35 47 nS

Data Setup Time to ClkOut T30 40 nS

I/OAddr Stable to DACSlct High T31 22.0 27.0 uSec

Convert Pulse Width T32 320 nSec

note 1 ~HostSlct and HostCmd may optionally be de-asserted if setup and hold times are met.

note 2 Chip-set performance figures and timing information valid at Fclk = 25.0 only. For timing information & performance parameters at Fclk <

25.0 Mhz, call PMD.

note 3 Two micro seconds maximum to release interface before chip set responds to command

note 4 ClkOut from CP is 1/4 frequency of ClkIn (CP chip).

6

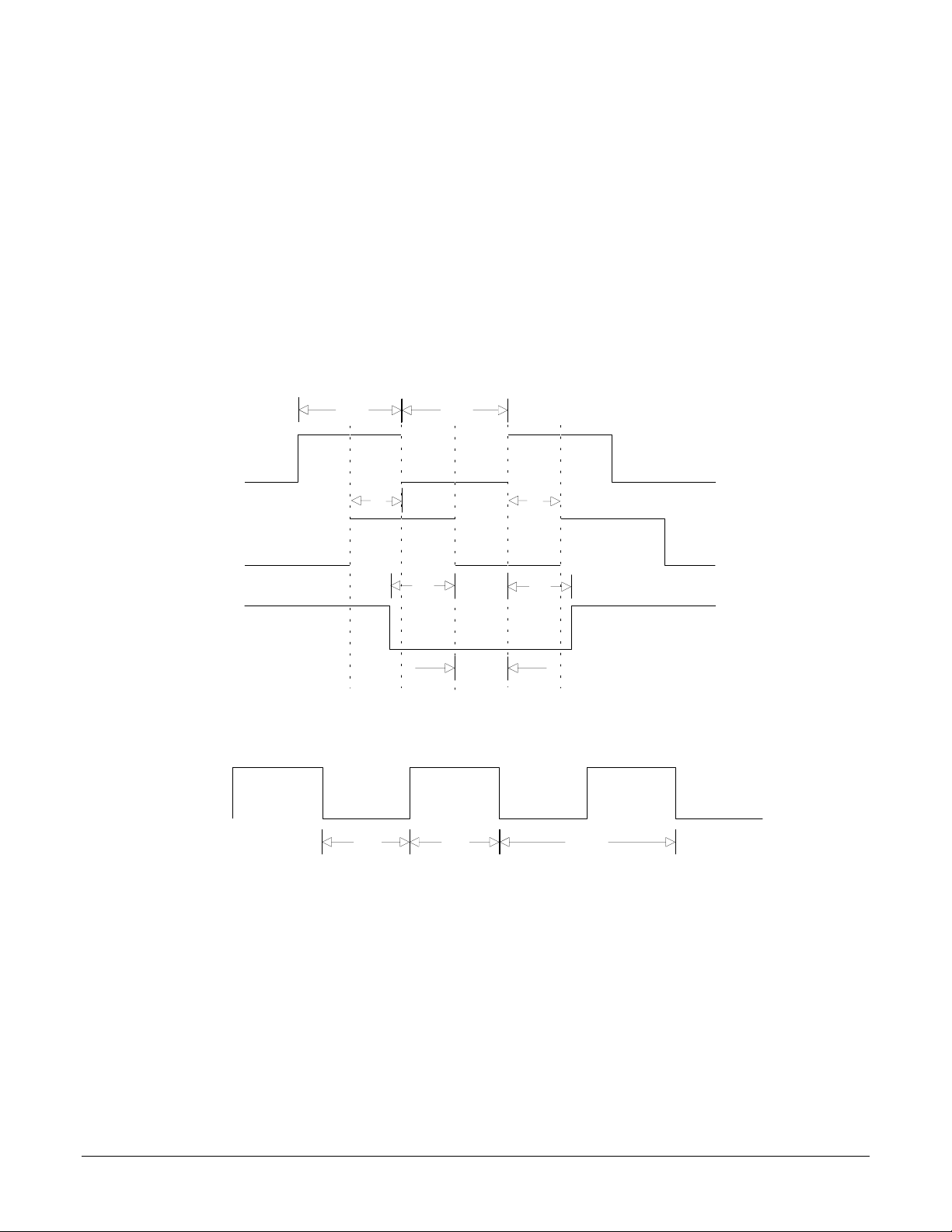

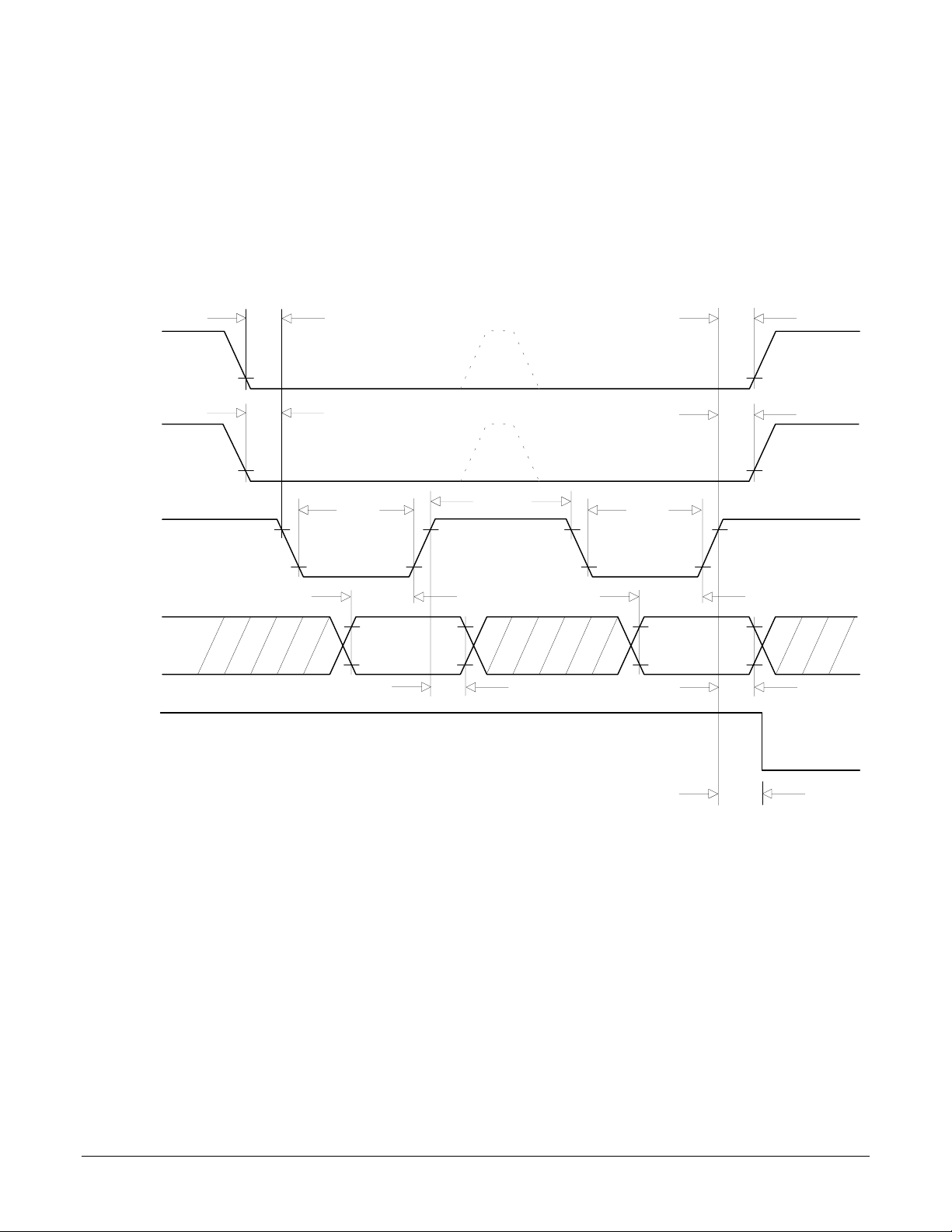

I/O Timing Diagrams

The following diagrams show the MC1401A electrical interface timing. T#' values are listed in the above timing chart.

Quadrature Encoder Input Timing

Quad A

Quad B

~Index

ClkIn

T1

T1

T2 T2

T3

Clock Timing

T3

T4 T4 T5

Index = ~A * ~B * ~IND

7

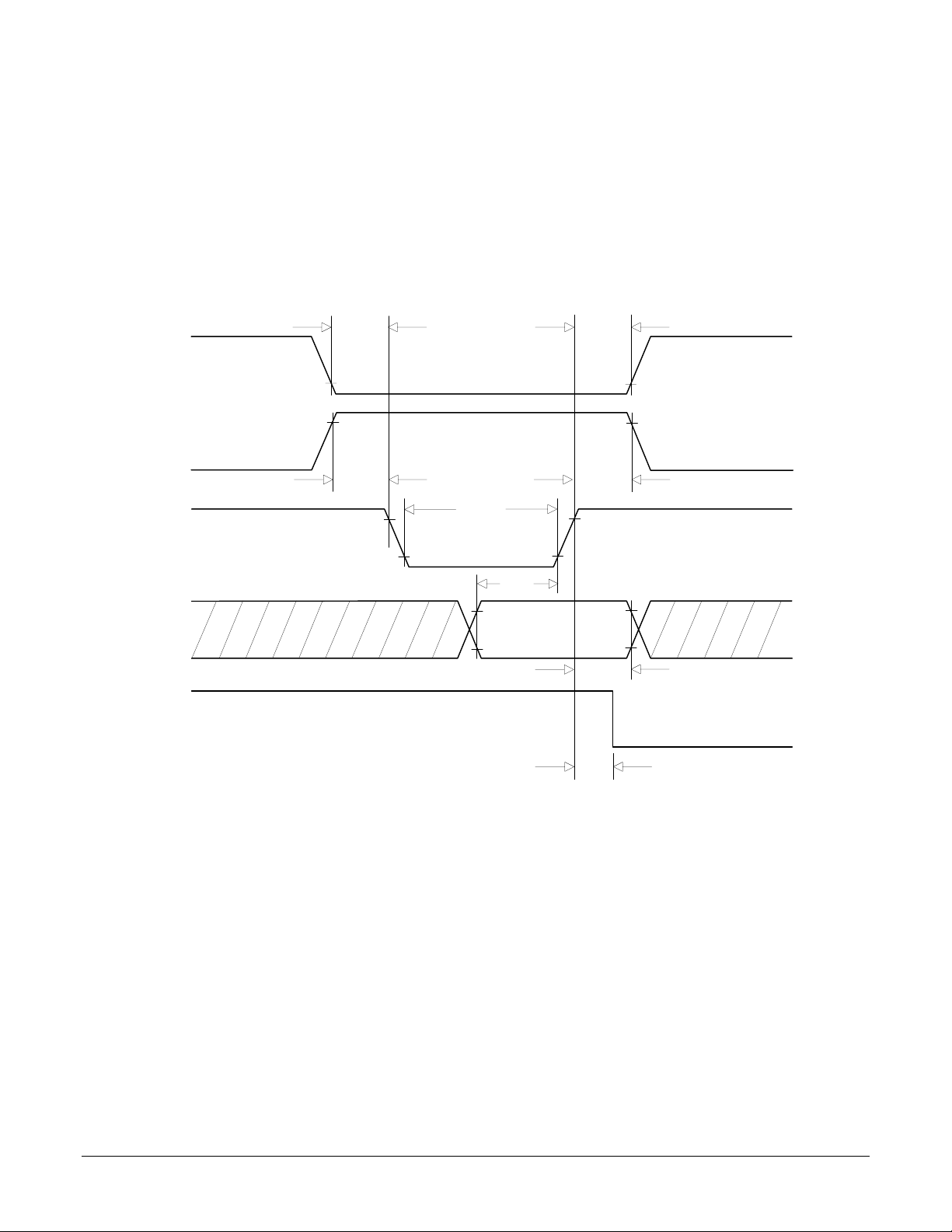

Command Byte Write TIming

~HostSlct

HostCmd

~HostWrite

HostData0-7

HostRdy

T7

T8

T6

T9

T14

T15

T16

T13

8

Data Word Read TImi ng

~HostSlct

HostCmd

~HostRead

HostData0-7

HostRdy

T7

T6

Note 1

T8

Note 1

T9

T17

T12

High-Z High-Z High-Z

High

Byte

T10

T11

Low

Byte

T13

9

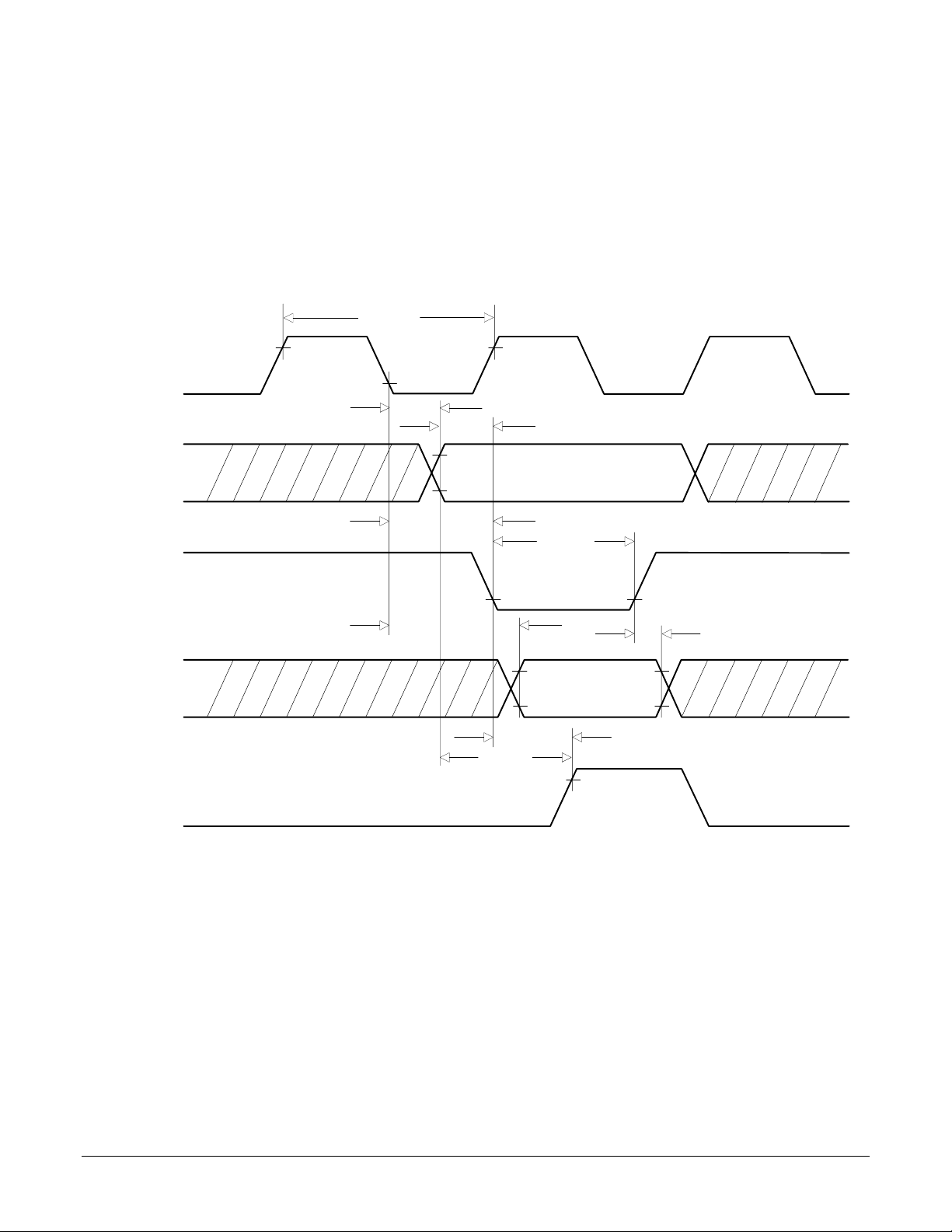

Data Word Write TIming

~HostSlct

HostCmd

~HostWrite

HostData0-7

HostRdy

T7

T8

T14

T15

High

Byte

T16

T18

Note 1

Note 1

T6

T9

T14

T15

Low

Byte

T16

10

T13

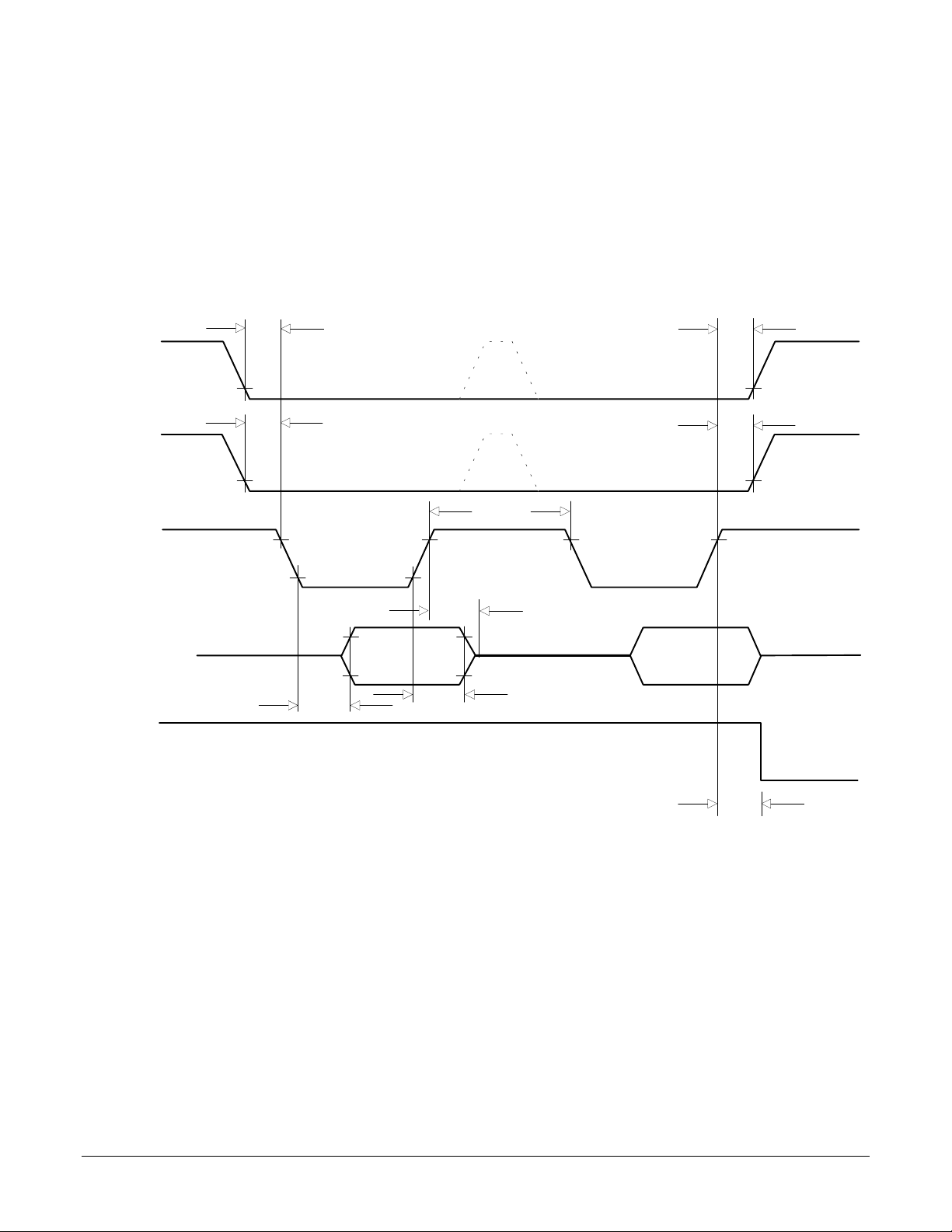

ClkOut

I/OAddr

~I/OWrite

DAC Interface Timing

T25

T22

T19

T23

T20

Data 0-11,

DACAddr0,1

DACSlct

T24

T21

T27

T26

11

ClkOut

Parallel Word Device Read Timing

T28

I/OCntrl0

Data0-11,

DACLow0-3

PosSlct

Dac16Addr0, 1

Convert

12345

T29

T30

T31

T32

6

One data read shown. Axis address read sequence is 1, 2, 4, 3

Legend

1 - Instruct i on Fetch

2 - Instruct i on Fetch

3 - Read the data value

4 - Instruct i on Fetch

5 - Instruct i on Fetch

12

6 - Convert strobe

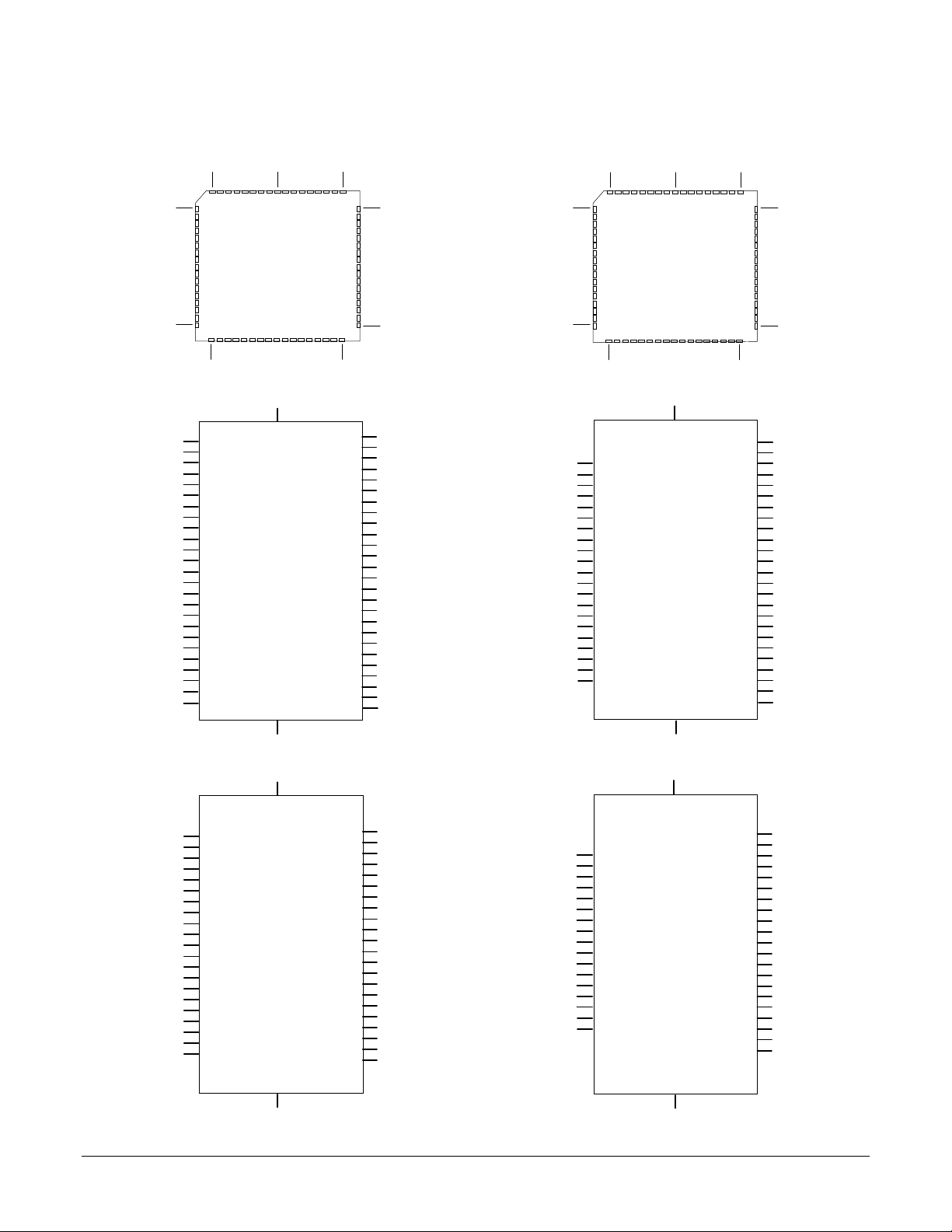

Pinouts

9

10

(Top view)

26

27 43

4, 21, 25, 38, 55

28

QuadA1

42

QuadB1

24

Index1

13

Home1

26

QuadA2

30

QuadB2

9

Index2

23

Home2

40

QuadA3

35

QuadB3

19

Index3

11

Home3

39

QuadA4

34

QuadB4

16

Index4

10

Home4

33

DACSlct

46

CPClk

52

I/OClkIn

45

I/OClkOut

29

CPAddr2

12

CPAddr3

2

CPWrite

20

CPCntrl0

36

CPCntrl1

1

I/O

VCC

I/O

GND

61

CPCntrl2

CPCntrl3

HostCmd

HostRdy

HostRead

HostWrite

HostSlct

HostIntrpt

HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

CPAddr0

CPAddr1

60

44

MC1401A Pinouts

22

63

41

37

51

47

48

44

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

68

27

9

10

1

61

60

CP

(Top view)

26

27 43

4, 22, 33

56

55

54

53

30

29

24

19

17

16

18

68

67

64

63

62

61

8

7

2

1

PWMMag1

PWMSign1

PWMMag2

PWMSign2

PWMMag3

PWMSign3

PWMMag4

PWMSign4

DAC16Addr0

DAC16Addr1

ClkIn

ClkOut

Reset

I/OCntrl0

I/OCntrl1

I/OCntrl2

I/OCntrl3

DACLow0

DACLow1

DACLow2

DACLow3

VCC

CP

GND

Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

I/OWrite

PosLimit1

PosLimit2

PosLimit3

PosLimit4

NegLimit1

NegLimit2

NegLimit3

NegLimit4

44

60

59

58

57

50

49

46

43

40

39

36

35

28

9

6

5

15

52

45

42

38

51

44

41

37

14, 15, 32, 49, 54, 66

4, 21, 25, 38, 55

VCC

QuadA1

28

QuadB1

42

Index1

24

Home1

13

QuadA2

26

QuadB2

30

Index2

9

Home2

23

DACSlct

33

CPClk

46

I/OClkIn

52

I/OClkOut

45

CPAddr2

29

CPAddr3

12

CPWrite

2

CPCntrl0

20

CPCntrl1

36

CPCntrl2

22

CPCntrl3

63

CPAddr0

68

CPAddr1

27

I/O

GND

14, 15, 32, 49, 54, 66

HostCmd

HostRdy

HostRead

HostWrite

HostSlct

HostIntrpt

HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

MC1201A Pinouts

41

37

51

47

48

44

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

PWMMag1

8

PWMSign1

56

PWMMag2

7

PWMSign2

55

DAC16Addr0

30

DAC16Addr1

29

ClkIn

24

ClkOut

19

Reset

17

I/OCntrl0

16

I/OCntrl1

18

I/OCntrl2

68

I/OCntrl3

67

DACLow0

64

DACLow1

63

DACLow2

62

DACLow3

61

3, 34

4, 22, 33

VCC

CP

GND

3, 34

Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

I/OWrite

PosLimit1

PosLimit2

NegLimit1

NegLimit2

60

59

58

57

50

49

46

43

40

39

36

35

28

9

6

5

15

52

45

51

44

13

4, 21, 25, 38, 55

MC1101A Pinouts

4, 22, 33

VCC

HostCmd

HostRdy

28

QuadA1

42

QuadB1

24

Index1

13

Home1

33

DACSlct

46

CPClk

52

I/OClkIn

45

I/OClkOut

29

CPAddr2

12

CPAddr3

2

CPWrite

20

CPCntrl0

36

CPCntrl1

22

CPCntrl2

63

CPCntrl3

68

CPAddr0

27

CPAddr1

I/O

GND

14, 15, 32, 49, 54, 66

HostRead

HostWrite

HostSlct

HostIntrpt

HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

41

37

51

47

48

44

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

8

56

30

29

24

19

17

16

18

68

67

64

63

62

61

PWMMag1

PWMSign1

DAC16Addr0

DAC16Addr1

ClkIn

ClkOut

Reset

I/OCntrl0

I/OCntrl1

I/OCntrl2

I/OCntrl3

DACLow0

DACLow1

DACLow2

DACLow3

VCC

CP

GND

3, 34

Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

I/OWrite

PosLimit1

NegLimit1

60

59

58

57

50

49

46

43

40

39

36

35

28

9

6

5

15

52

51

MC1401A-P Pinouts

4, 21, 25, 38, 55

4, 22, 33

VCC

8

HostCmd

HostRdy

HostRead

HostWrite

DACSlct

33

CPClk

46

I/OClkIn

52

I/OClkOut

45

CPAddr2

29

CPAddr3

12

CPWrite

2

CPCntrl0

20

CPCntrl1

36

CPCntrl2

22

CPCntrl3

63

CPAddr0

68

CPAddr1

27

I/O

GND

14, 15, 32, 49, 54, 66

HostSlct

HostIntrpt

HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

41

37

51

47

48

44

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

56

55

54

53

30

29

31

32

24

19

17

16

18

68

67

64

63

62

61

7

2

1

PWMMag1

PWMSign1

PWMMag2

PWMSign2

PWMMag3

PWMSign3

PWMMag4

PWMSign4

DAC16Addr0

DAC16Addr1

PosSlct

Convert

ClkIn

ClkOut

Reset

I/OCntrl0

I/OCntrl1

I/OCntrl2

I/OCntrl3

DACLow0

DACLow1

DACLow2

DACLow3

VCC

CP

GND

3, 34

Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

I/OWrite

PosLimit1

PosLimit2

PosLimit3

PosLimit4

NegLimit1

NegLimit2

NegLimit3

NegLimit4

60

59

58

57

50

49

46

43

40

39

36

35

28

9

6

5

15

52

45

42

38

51

44

41

37

14

4, 21, 25, 38, 55

MC1201A-P Pinouts

4, 22, 33

VCC

HostCmd

HostRdy

HostRead

HostWrite

DACSlct

33

CPClk

46

I/OClkIn

52

I/OClkOut

45

CPAddr2

29

CPAddr3

12

CPWrite

2

CPCntrl0

20

CPCntrl1

36

CPCntrl2

22

CPCntrl3

63

CPAddr0

68

CPAddr1

27

I/O

GND

14, 15, 32, 49, 54, 66

HostSlct

HostIntrpt

HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

41

37

51

47

48

44

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

56

55

30

29

31

32

24

19

17

16

18

68

67

64

63

62

61

8

7

PWMMag1

PWMSign1

PWMMag2

PWMSign2

DAC16Addr0

DAC16Addr1

PosSlct

Convert

ClkIn

ClkOut

Reset

I/OCntrl0

I/OCntrl1

I/OCntrl2

I/OCntrl3

DACLow0

DACLow1

DACLow2

DACLow3

VCC

CP

GND

3, 3 4

Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

I/OWri te

PosLimit1

PosLimit2

NegLimit1

NegLimit2

60

59

58

57

50

49

46

43

40

39

36

35

28

9

6

5

15

52

45

51

44

MC1101A-P Pinouts

4, 21, 25, 38, 55

4, 22, 33

VCC

HostCmd

HostRdy

HostRead

HostWrite

DACSlct

33

CPClk

46

I/OClkIn

52

I/OClkOut

45

CPAddr2

29

CPAddr3

12

CPWrite

2

CPCntrl0

20

CPCntrl1

36

CPCntrl2

22

CPCntrl3

63

CPAddr0

68

CPAddr1

27

I/O

GND

14, 15, 32, 49, 54, 66

HostSlct

HostIntrpt

HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

41

37

51

47

48

44

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

8

56

30

29

31

32

24

19

17

16

18

68

67

64

63

62

61

PWMMag1

PWMSign1

DAC16Addr0

DAC16Addr1

PosSlct

Convert

ClkIn

ClkOut

Reset

I/OCntrl0

I/OCntrl1

I/OCntrl2

I/OCntrl3

DACLow0

DACLow1

DACLow2

DACLow3

VCC

CP

GND

3, 34

Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

I/OWrite

PosLimit1

NegLimit 1

60

59

58

57

50

49

46

43

40

39

36

35

28

9

6

5

15

52

51

15

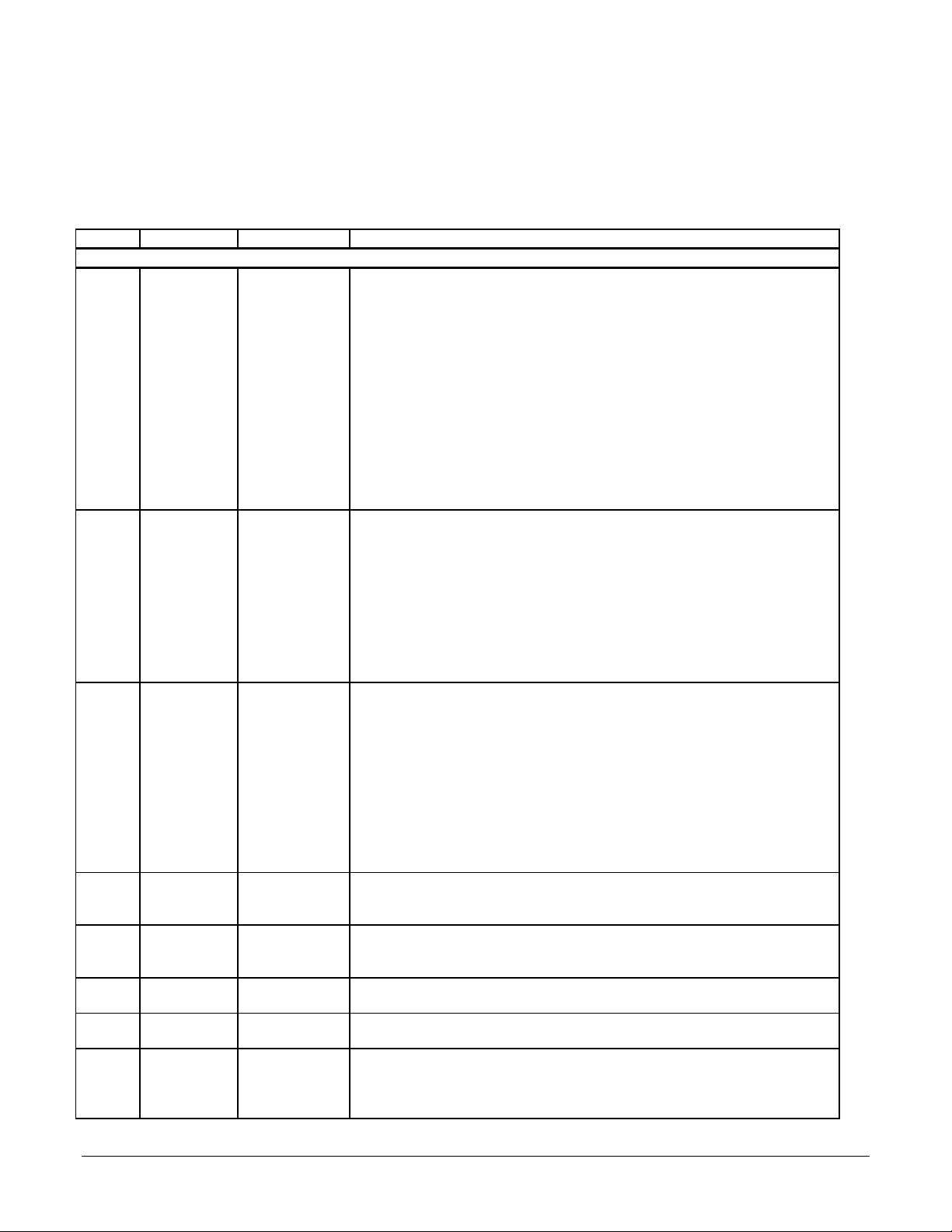

Pin Descriptions

The following tables provide pin descriptions for the MC1401A and MC1401A-P series chipsets.

IC Pin Name Pin # Description/Functionality

I/O Chip Pinouts

I/O QuadA1

QuadB1

QuadA2

QuadB2

QuadA3

QuadB3

QuadA4

QuadB4

I/O ~Index1

~Index2

~Index3

~Index4

28

42

26

30

40

35

39

34

24

9

19

16

Quadrature A, B channels for axis 1 - 4 (input). Each of these 4 pairs of quadrature (A, B)

signals provide the position feedback for an incremental encoder. When the encoder is

moving in the positive, or forward direction, the A signal leads the B signal by 90 degs. The

quadrature signals must stay in the same state for .8 uSec to register a valid encoder state,

resulting in a maximum theoretical encoder state capture rate of 1.2 Mcounts/sec. Actual

maximum rate will vary depending on signal noise. Typical maximum is 1.0 Mcounts/sec.

NOTE: Many encoders require a pull-up resistor on each of these signals to establish a

proper high signal (check the encoder electrical specifications)

NOTE: For MC1401A all 8 pins are valid. For MC1201A pins for axes 1 & 2 only are valid.

For MC1101A pins for axis 1 only are valid. Invalid axis pins can be left unconnected.

NOTE: Not valid for -P parts.

Index encoder signals for axis 1-4 (input). Each of these 4 signals indicate the index flag

state from the encoder. A valid index pulse is recognized by the chip set when the index flag

transitions low, followed by the corresponding A and B channels of the encoder transitioning

low. The index pulse is recognized at the later of the A or B transitions. If not used this signal

must be tied high.

NOTE: For MC1401A all 4 pins are valid. For MC1201A pins for axes 1 & 2 only are valid.

For MC1101A pin for axis 1 only is valid. Invalid axis pins can be left unconnected.

NOTE: Not valid for -P parts.

I/O ~Home1

~Home2

~Home3

~Home4

I/O DACSlct 33 DAC Select (output). This signal is asserted high to select any of the available DAC output

I/O CPClk 46 I/O chip clock (input). This signal is connected directly to the ClkOut pin (CP chip) and

I/O I/OClkIn 52 Phase shifted clock (input). This signal is connected to I/OClkOut (I/O chip), and inputs a

I/O I/OClkOut 45 Phase shifted clock (output). This signal is connected to I/OClkIn (I/O chip), and outputs a

I/O CPAddr0

CPAddr1

CPAddr2

CPAddr3

13

23

11

10

68

27

29

12

Home signals for axis 1-4 (input). Each of these signals provide a general purpose input to

the hardware position capture mechanism. A valid home signal is recognized by the chipset

when the home flag transitions low. These signals have a similar function as the ~Index

signals, but are not gated by the A and B encoder channels. For valid axis pins, If not used,

this signal must be tied high. See below for valid pin definitions for the MC1401A, MC1201A,

and MC1101A.

NOTE: For MC1401A all 4 pins are valid. For MC1201A pins for axes 1 & 2 only are valid.

For MC1101A pin for axis 1 only is valid. Invalid axis pins can be left unconnected.

NOTE: Not valid for -P parts.

channels. For details on DAC decoding see description of DACAddr0-1 and DAC16Addr0-3

signals.

provides the clock signal for the I/O chip. The frequency of this signal is 1/4 the user-provided

ClkIn (CP chip) frequency.

phase shifted clock signal.

phase shifted clock signal.

I/O chip to CP chip communication address (input). These 4 signals are connected to the

corresponding I/OAddr0-3 pins (CP chip), and together provide addressing signals to

facilitate CP to I/O chip communication.

16

IC Pin Name Pin # Description/Functionality

I/O ~CPWrite 2 I/O chip to CP chip communication write (input). This signal is connected to the ~I/OWrite pin

(CP chip) and provides a write strobe to facilitate CP to I/O chip communication.

I/O CPCntrl0

CPCntrl1

CPCntrl2

CPCntrl3

I/O HostCmd 41 Host Port Command (input). This signal is asserted high to write a host command to the chip

I/O HostRdy 37 Host Port Ready/Busy (output). This signal is used to synchronize communication between

I/O ~HostRead 51 Host Port Read data (input). Used to indicate that a data word is being read from the chip set

I/O ~HostWrite 47 Host Port Write data (input). Used to indicate that a data word or command is being written to

I/O ~HostSlct 48 Host Port Select (input). Used to select the host port for reading or writing operations (low

I/O ~HostIntrpt 44 Host Interrupt (output). A low assertion on this pin indicates that a host interrupt condition

I/O HostData0

HostData1

HostData2

HostData3

HostData4

HostData5

HostData6

HostData7

I/O CPData4

CPData5

CPData6

CPData7

CPData8

CPData9

CPData10

CPData11

I/O Vcc 4, 21, 25, 38, 55 I/O chip supply voltage pin. All of these pins must be connected to the supply voltage. Supply

I/O GND 14, 15, 32, 49, 54,66I/O chip ground pin. All of these pins must be connected to the power supply return.

20

36

22

63

50

61

53

65

67

62

64

60

18

5

6

7

8

17

3

1

I/O chip to CP chip communication control (mixed). These 4 signals are connected to the

corresponding I/OCntrl0-3 pins (CP chip), and provide control signals to facilitate CP to I/O

chip communication.

set. It is asserted low to read or write a host data word to the chipset

the DSP and the host. HostRdy will go low (indicating host port busy) at the end of a host

command write or after the second byte of a data write or read. HostRdy will go high

(indicating host port ready) when the command or data word has been processed and the

chip set is ready for more I/O operations. All host port communications must be made with

HostRdy high (indicating ready).

Typical busy to ready cycle is 100.0 uSec.

(low asserts read).

the chip set (low asserts write).

assertion selects port). ~HostSlct must remain inactive (high) when the host port is not in use.

exists that may require special host action.

Host Port Data 0-7 (bi-directional, tri-stated). These signals form the 8 bit host data port used

during communication to/from the chip set. This port is controlled by ~HostSlct, ~HostWrite,

~HostRead and HostCmd.

I/O chip to CP chip data port (bi-directional). These 8 bits are connected to the corresponding

Data4-11 pins on the CP chip, and facilitate communication to/from the I/O and CP chips..

voltage = 4.75 to 5.25 V

17

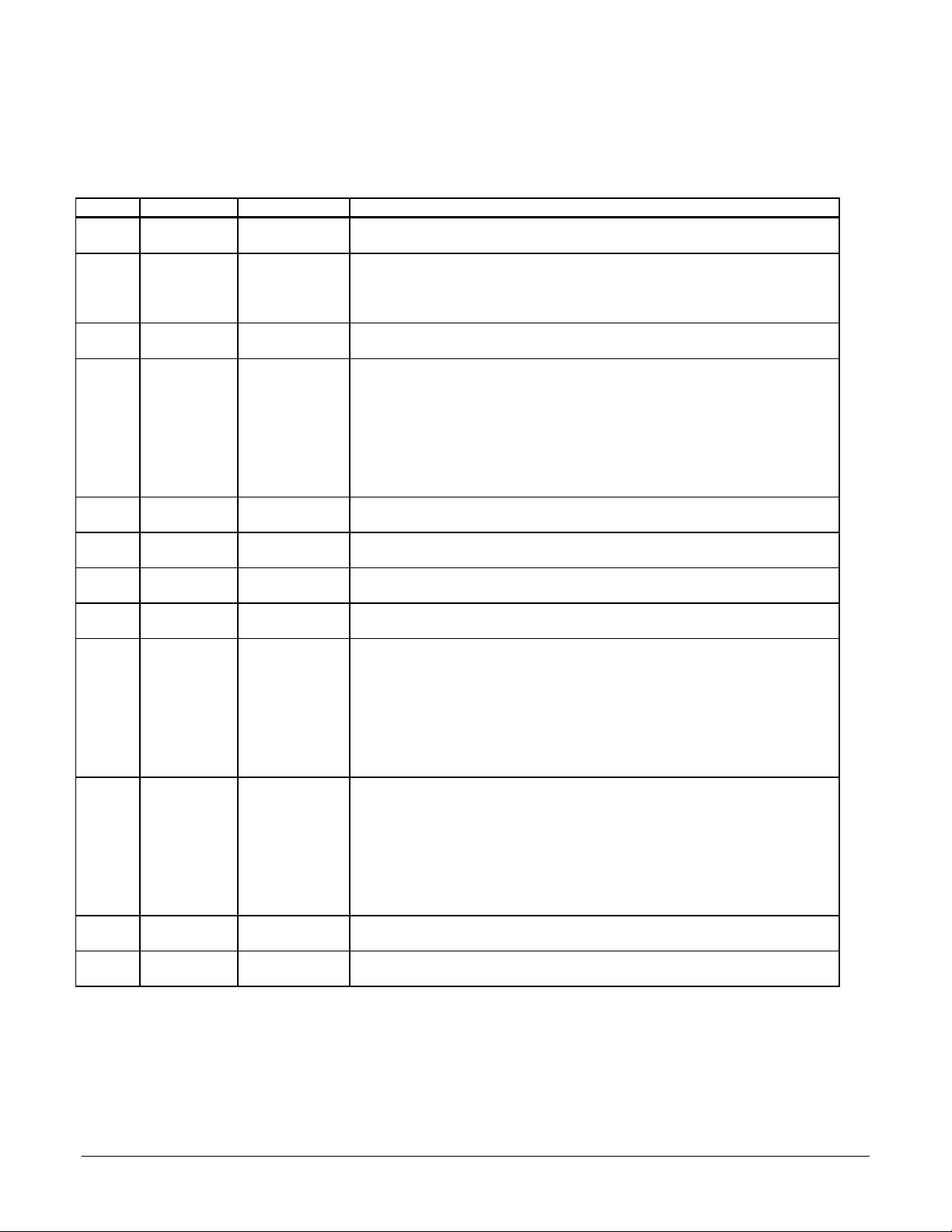

IC Pin Name Pin # Description/Functionality

CP Chip Pinouts

CP PWMMag1

PWMMag2

PWMMag3

PWMMag4

CP PWMSign1

PWMSign2

PWMSign3

PWMSign4

CP PosLimit1

PosLimit2

PosLimit3

PosLimit4

CP NegLimit1

NegLimit2

NegLimit3

NegLimit4

CP DAC16Addr0

DAC16Addr13029

8

7

2

1

56

55

54

53

52

45

42

38

51

44

41

37

PWM motor output magnitude signals (output). When the chip set is in PWM output mode

these pins provide the Pulse Width Modulated magnitude signal to the motor amplifier. Each

PWM signal output directly corresponds to the axis # being driven.

PWM motor output sign signals for axis 1-4 (output). When the chip set is in PWM output

mode these pins provide the Pulse Width Modulated sign signal to the motor amplifier for

each axis.

Positive limit switch input for axis 1-4. These signals provide directional limit inputs for the

positive-side travel limit of the axis. Upon powerup these signals default to "active high"

interpretation, but the interpretation can be set explicitly using the SET_LMT_SENSE

command. If not used these signals should be tied low for the default interpretation, or tied

high if the interpretation is reversed.

NOTE: For MC1401A all 4 pins are valid. For MC1201A pins for axes 1 & 2 only are valid.

For MC1101A pin for axis 1 only is valid. Invalid axis pins can be left un connected.

Negative limit switch input for axis 1-4. These signals provide directional limit inputs for the

negative-side travel limit of the axis. Upon powerup these signals default to "active high"

interpretation, but the interpretation can be set explicitly using the SET_LMT_SENSE

command. If not used these signals should be tied low for the default interpretation, or tied

high if the interpretation is reversed.

NOTE: For MC1401A all 4 pins are valid. For MC1201A pins for axes 1 & 2 only are valid.

For MC1101A pin for axis 1 only is valid. Invalid axis pins can be left un connected.

Axis Address used during 16-bit DAC motor command output and parallel-word encoder input

(output). When used to encode the motor DAC address or the parallel word encoder address

these signals are encoded as follows:

Dac16Addr1 Dac16Addr0 Addressed Encoder

Low Low Axis 1

Low High Axis 2

High Low Axis 3

High High Axis 4

To read a parallel position word from an external device, the chipset loads DAC16Addr0-1

with the axis # and PosSlct is asserted low.

To write a valid DAC motor command value DACSlct (I/O chip) and I/OAddr0-3 (CP chip)

must be high, and I/OWrite (CP chip) must be low. The 16 bit DAC data word is organized as

follows: High twelve bits are in Data0-11 (CP chip), and low 4 bits are in DACLow0-3 (CP

chip).

CP ClkIn 24 Clock In (input). This pin provides the chip set master clock (Fclk = 25.0 Mhz)

CP ClkOut 19 Clock Out (output). This pin provides a clock output which is 1/4 the ClkIn frequency. This pin

is connected to CPClk (I/O chip).

CP ~Reset 17 Master chip set reset (input). When brought low, this pin resets the chip set to its initial

condition. Reset should occur no less than 250 mSec after stable power has been provided

to the chip set.

CP I/OCntrl0

I/OCntrl1

I/OCntrl2

I/OCntrl3

16

18

68

67

I/O chip to CP chip communication control (mixed). These signals provide various inter-chip

control signals and are connected to the corresponding CPCntrl0-3 pins on the I/O chip.

18

IC Pin Name Pin # Description/Functionality

CP Data0

Data1

Data2

Data3

Data4

Data5

Data6

Data7

Data8

Data9

Data10

Data11

CP DACLow0

DACLow1

DACLow2

DACLow3

CP I/OAddr0

I/OAddr1

I/OAddr2

I/OAddr3

CP PosSlct 31 Parallel-word position-input device select (output). This pin selects the parallel word device(s)

60

59

58

57

50

49

46

43

40

39

36

35

64

63

62

61

28

9

6

5

Multi-purpose Data0-11. (Bi-directional). These pins have 3 functions:

1) Pins Data4-11 (8 bits total) are connected to the corresponding CPData4-11 pins on the

I/O chip, and are used to communicate between the CP and I/O chips

2) Pins Data0-11 hold the high 12 bits of the DAC output value when the output mode is set

to 16-bit DAC.

3) Pins Data0-11 input the high 12 bits of the parallel-word position data (-P version chipsets

only).

DACLow0-3 (output). These pins hold the lowest 4 bits of the 16 bit DAC output word when

DAC16 motor output mode is selected. In addition they input the low 4 bits of the parallel

word (-P version chip set only).

Multi-purpose Address0-3 (output). These pins are connected to the corresponding CPAddr0-

3 pins on the I/O chip. They have 2 functions; They provide addressing signals to facilitate

communication between the I/O chip and CP chip, and they are used during DAC data

decoding.

for reading.

To read a parallel position word from an external device, the chipset loads DAC16Addr0-1

with the axis # and PosSlct is asserted low.

Note: Only valid for -P parts.

CP Convert 32 Parallel-word conversion start signal (output). This pin provides a signal which momentarily

strobes low at the end of the parallel word read sequence.

This signal is useful for starting A/D converters or for synchronizing external latch hardware

associated with the parallel-word read circuitry

Note: Only valid for -P parts.

CP I/OWrite 15 Multi-purpose write (output). This pin is connected to CPWrite on the I/O chip. It has 2

functions:

1) It provides a control signal to the I/O chip to facilitate communication between the I/O chip

and CP chip.

2) It is used during DAC data decoding.

CP Vcc 4, 22, 33 CP chip supply voltage pin. All of these pins must be connected to the supply voltage. Supply

voltage = 4.75 to 5,.25 V

CP GND 3, 34 CP chip ground pin. All of these pins must be connected to the power supply return.

19

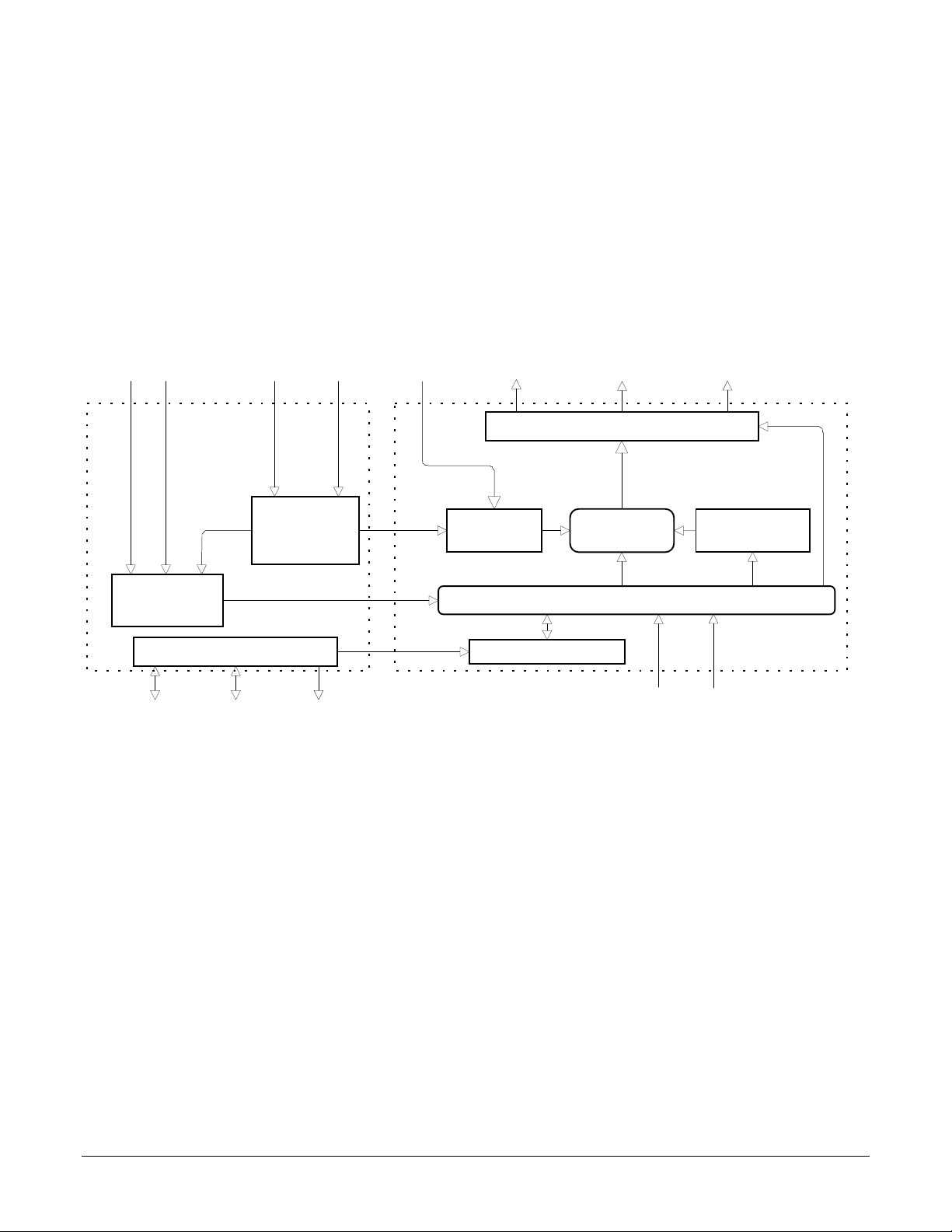

Theory of Operations

Incremental Encoder

Index B A

Home

1/a

1/a

I/O Chip

Internal Block Diagram

1/a 1/a

Parallel I nput

(-P chipset only)

8 data

2 Control

PWM sign,

mag

1/phase 2

Motor Output

DAC address

DAC data

16

DAC, PWM signal generator (1-4 channels)

CP Chip

Quadrature

decoder

counter (1-4)

Position capture

register (1-4)

Host I/O controller

185

host interr uptDataControl

The above figure shows an internal block diagram for the MC1401A

and MC1401A-P series motion processors.

Each servo axis inputs the actual location of the axis using either

incremental encoder signals or signals from a parallel-word input device

such as an absolute encoder or resolver. If incremental signals are

used then the incoming A, and B quadrature data stream is digitally

filtered, and then passed on to a high speed up/down counter. Using

the parallel-word interface a direct binary-encoded position of up to 16

bits is read by the chipset. Regardless of the encoder input method this

position information is then used to maintain a 32-bit actual axis

position counter.

If incremental feedback is used, then the chipset also supports the

ability to capture the instantaneous position of each axis using an

external trigger signal. The captured value may then later be retrieved

by the host processor.

Position

register (1-4)

Host command

generation and digital servo loop closure. In this mode the motor output

value is controlled by the servo filter. Open loop mode, which is used

for direct motor-control operations only, does not use the output of the

servo filter, and allows the motor output value to be controlled directly

by the host processor.

When closed loop mode operations are used the actual axis position is

combined with the target position generated by the trajectory profile

generator to calculate a position error, which is passed through a PID

filter. The resultant value is then output by the chipset to an external

amplifier using either PWM or DAC signals.

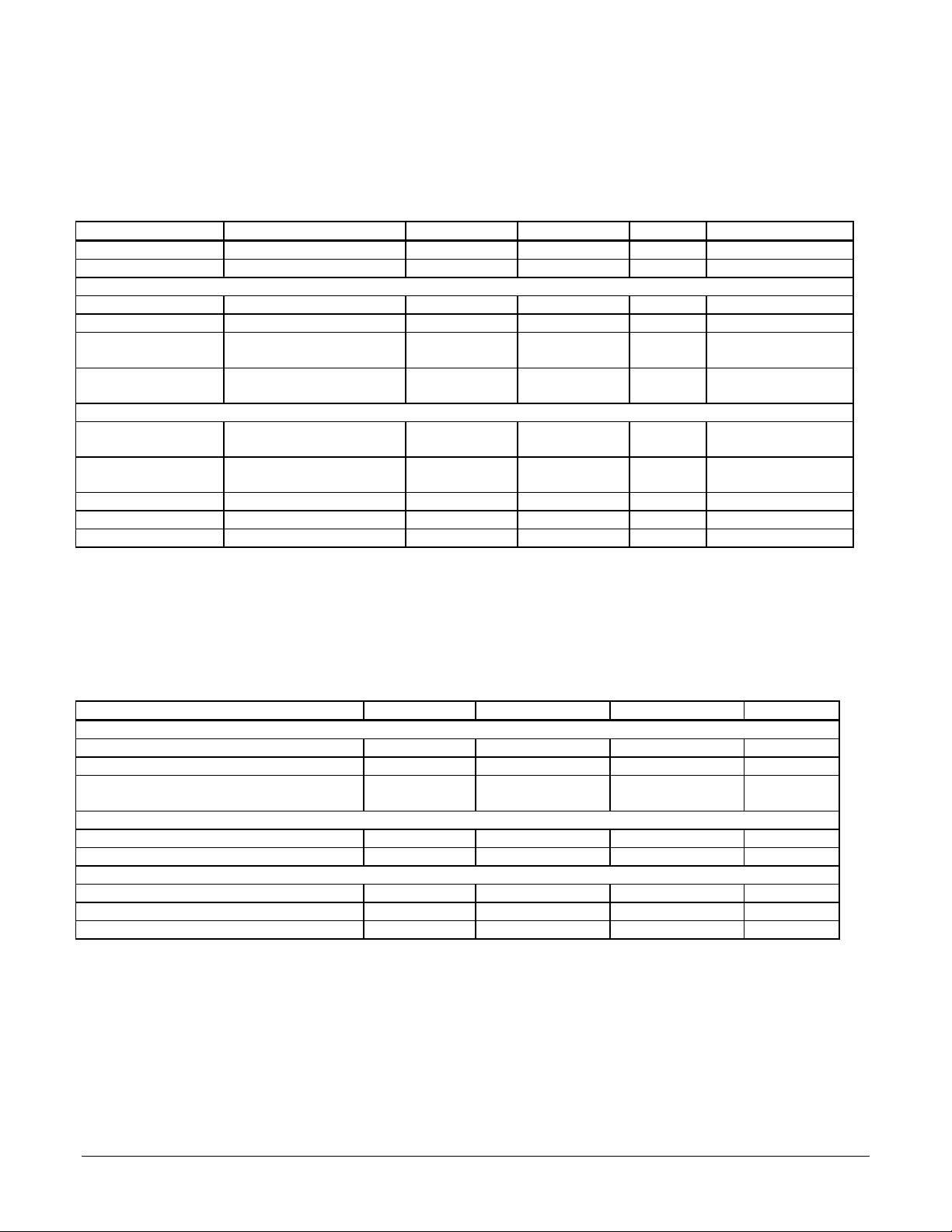

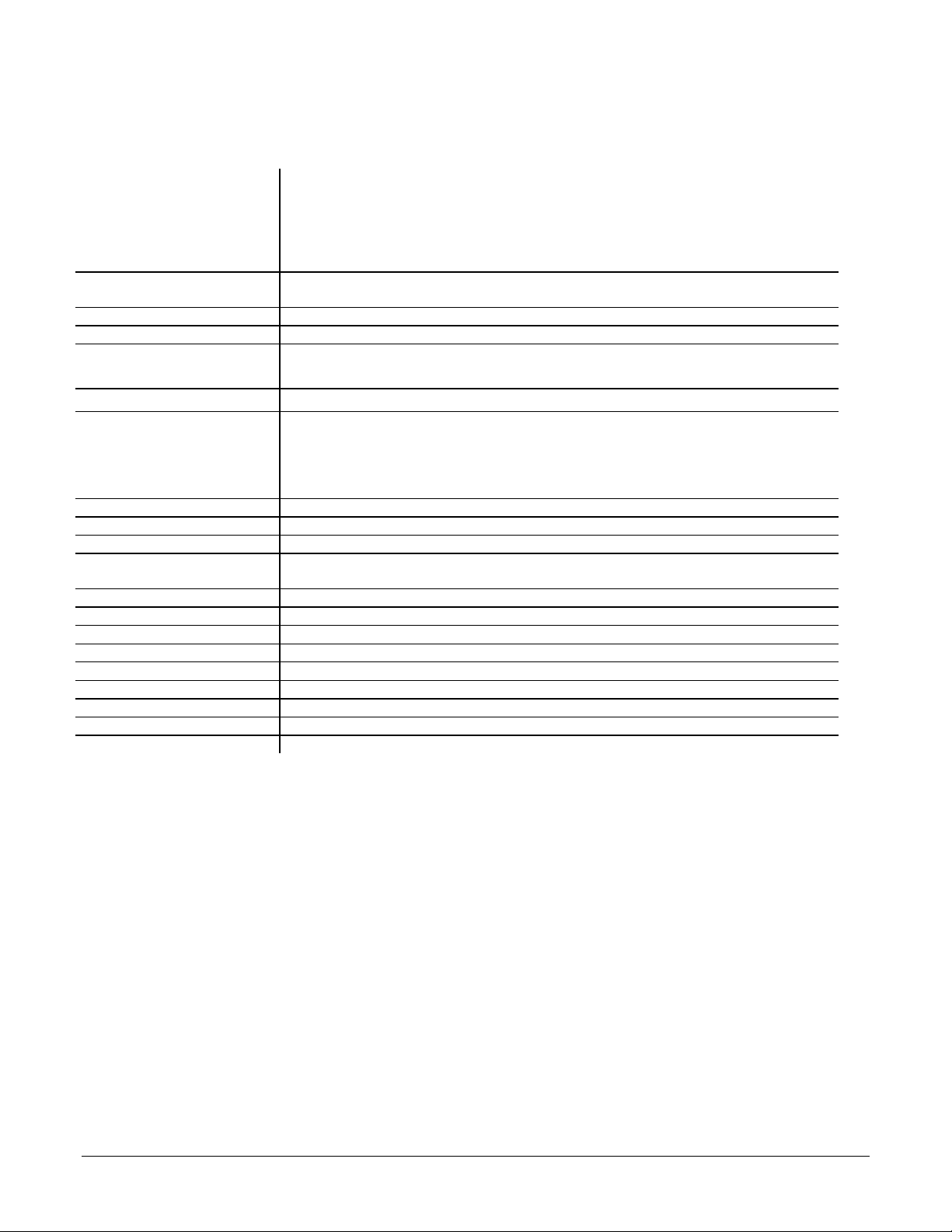

The following table summarizes the operational parameters of the

MC1401-series chipsets.

Digital Servo

filtering (1-4)

System Registers (1-4)

1/a

PosLimit

NegLimit

Trajectory profile

generator (1-4)

1/a

The chipset can be operated in two modes. Closed loop mode, which is

the normal operating mode of the chipset, performs trajectory

20

MC1401-series Chipset Operational Parameters

Available configurations: 4 axes with incremental quadrature encoder input (MC1401A)

2 axes with incremental quadrature input (MC1201A)

1 axis with incremental quadrature input (MC1101A)

4 axes with parallel word encoder input (MC1401A-P)

2 axes with parallel word encoder input (MC1201A-P)

1 axes with parallel word encoder input (MC1101A-P)

Operating modes: Closed loop (motor command is driven from output of servo filter)

Open loop (motor command is driven from user-programmed register)

Position range: -1,073,741,824 to 1,073,741,823 counts

Velocity range: -16,384 to 16,383 counts/sample with a resolution of 1/65,536 counts/sample

Acceleration range:

Jerk range:

Trajectory profile generator modes: S-curve (host commands final position, max velocity, max acceleration, and jerk)

Electronic gear ratio range: 32768:1 to 1:32768 (negative and positive direction)

Filter modes: PID+Vff (standard PID loop plus velocity feedforward plus bias offset)

Filter parameter resolution: 16 bits

Motor output modes: PWM (10 bits resolution @ 24.5 Khz)

Max incremental. encoder rate: Incremental: 1.0 Mcounts/sec Parallel-word: 80.0 Mcounts/sec

Parallel encoder word size: 16 bits (read in 2 byte reads) (-P version parts only)

Parallel encoder read rate: 10 kHz (reads all axes every 100 uSec)

Servo loop rate range: standard, -P parts: 100* uSec minimum, 3,276 mSec max.

Max servo loop rate: standard, -P parts: 100* uSec per enabled axis.

# of limit switches per axis 2 (one for each direction of travel)

# of position capture triggers: 2 (index, home signal)

Capture trigger latency: 160 nSec

# of host commands: 94

S-curve profile: - 1/2 to + 1/2 counts/sample2 with a resolution of 1/65,536 counts/sample

All others: -16,384 to 16,383 counts/sample2 with a resolution of 1/65,536 counts/sample

-1/2 to +1/2 counts/sample3, with a resolution of 1/4,294,967,296 counts/sample

Trapezoidal (host commands final position, max velocity and acceleration)

Velocity contouring (host commands max. velocity, acceleration)

Electronic Gear (Encoder position of one axis is used as position command for another axis). A total of 2

electronic gears are supported (2 encoders and 1 output each). Not available in MC1101A

DAC 16 bits

2.

2

3

* Exact servo loop time is 101.12 uSec, 100 uSec is an approximation

Trajectory Profile Generation

The trajectory profile generator performs calculations to determine the

target position, velocity and acceleration at each servo loop. These

calculations are performed taking into account the current profile mode,

as well as the current profile parameters set by the host. Four trajectory

profile modes are supported:

- S-curve point to point

- Trapezoidal point to point

- Velocity contouring

- Electronic Gear

The commands to select these profile modes are

SET_PRFL_S_CRV (to select the s-curve mode), SET_PRFL_TRAP

(to select the trapezoidal mode) SET_PRFL_VEL (to select the

velocity contouring mode) and SET_PRFL_GEAR (to select the

electronic gear mode).

Throughout this manual various command mnemonics will be

shown to clarify chipset usage or provide specific examples. See

the Host Communications section for a description of host

command nomenclature.

21

Loading...

Loading...