Page 1

Atlas® Digital Amplifier

Complete Technical Reference

Performance Motion Devices, Inc.

1 Technology Park Drive

Westford, MA 01886

Revision 2.0 February, 2017

Page 2

NOTICE

This document contains proprietary and confidential information of Performance Motion Devices, Inc., and is pro-

by federal copyright law. The contents of this document may not be disclosed to third parties, translated,

tected

copied, or duplicated in any form, in whole or in part, without the express written permission of Performance

Motion Devices, Inc.

The information contained in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form, by any means, electronic or mechanical, for any purpose, without the

express written permission of PMD.

Copyright 1998–2017 by Performance Motion Devices, Inc.

Atlas, Magellan, ION, Magellan/ION, Juno, Pro-Motion, C-Motion and VB-Motion are registered trademarks of

Performance Motion Devices, Inc.

ii Atlas® Digital Amplifier Complete Technical Reference

Page 3

Warranty

PMD warrants that its products shall substantially comply with the specifications applicable at the time of sale,

provided that this warranty does not extend to any use of any PMD product in an Unauthorized Application (as

defined below). Except as specifically provided in this paragraph, each PMD product is provided “as is” and without

warranty of any type, including without limitation implied warranties of merchantability and fitness for any particular

purpose.

PMD reserves the right to modify its products, and to discontinue any product or service, without notice and advises

customers to obtain the latest version of relevant information (including without limitation product specifications)

before placing orders to verify the performance capabilities of the products being purchased. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those pertaining

to warranty, patent infringement and limitation of liability.

Unauthorized Applications

PMD products are not designed, approved or warranted for use in any application where failure of the PMD product

could result in death, personal injury or significant property or environmental damage (each, an “Unauthorized

Application”). By way of example and not limitation, a life support system, an aircraft control system and a motor

vehicle control system would all be considered “Unauthorized Applications” and use of a PMD product in such a

system would not be warranted or approved by PMD.

By using any PMD product in connection with an Unauthorized Application, the customer agrees to defend,

indemnify and hold harmless PMD, its officers, directors, employees and agents, from and against any and all claims,

losses, liabilities, damages, costs and expenses, including without limitation reasonable attorneys’ fees, (collectively,

“Damages”) arising out of or relating to such use, including without limitation any Damages arising out of the failure

of the PMD product to conform to specifications.

In order to minimize risks associated with the customer’s applications, adequate design and operating safeguards must

be provided by the customer to minimize inherent procedural hazards.

Disclaimer

PMD assumes no liability for applications assistance or customer product design. PMD does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of PMD covering or relating to any combination, machine, or process in which such

products or services might be or are used. PMD’s publication of information regarding any third party’s products or

services does not constitute PMD’s approval, warranty or endorsement thereof.

Atlas® Digital Amplifier Complete Technical Reference

iii

Page 4

Related Documents

Atlas® Digital Amplifier User’s

Description of the Atlas Digital Amplifier electrical and mechanical specifications along with a summary of

its operational features.

Magellan® Motion Control IC User’s Guide

Complete description of the Magellan Motion Control IC features and functions with detailed theory of

operations.

Magellan Motion Control Developer’s Kit User’s Manuals

How to install, configure, and operate the DK58000 series, DK55000 series, and MC58113 series Magellan

Motion Control IC Developer’s Kits.

Pro-Motion® User’s Guide

User’s guide to Pro-Motion, the easy-to-use motion system development tool and performance optimizer.

Pro-Motion is a sophisticated, easy-to-use program which allows all motion parameters to be set and/or

viewed, and allows all features to be exercised.

Manual

iv Atlas® Digital Amplifier Complete Technical Reference

Page 5

Table of Contents

1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Atlas Digital Amplifier Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Features and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Atlas Developer’s Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Functional Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Operational Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Mechanical Mounting Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3. Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Drive Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Safety and Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 DC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6 AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.7 Pin Descriptions and Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.8 Signal Interfacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.9 Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.10 Heat Sink Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.11 Atlas Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1 Functional Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2 Internal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3 Notes on Command Mnemonics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4 Commutation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.5 Current Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.6 Power Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.7 Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.8 Safety Processing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.9 Step Motor Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.10 User Memory Space & Buffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.11 Trace Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.12 Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.13 Non-Volatile (NVRAM) Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.14 Writing and Reading NVRAM Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.15 SPI Communications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5. SPI Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.1 SPI Communications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.2 Packet Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.3 Sending a Voltage or Torque Output Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.4 Sending an Amplifier Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.5 Sending a NOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.6 Sending Atlas Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Atlas® Digital Amplifier Complete Technical Reference

v

Page 6

6. Instruction Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A. Atlas Developer’s Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

A.2 Installation and Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

A.3 Atlas Carrier Card Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

A.4 L-Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

B. Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

B.1 Brushless DC Atlas with Single-Axis MC58113 Motion Control IC. . . . . . . . . 167

B.2 DC Brush & Step Motor Atlas with Multi-Axis Magellan . . . . . . . . . . . . . . . . . . 170

B.3 Step Motor Atlas Operating In Pulse & Direction Mode . . . . . . . . . . . . . . . . . . 172

B.4 DC Brush Atlas with PIC Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

B.5 Step Motor Atlas with ARM Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

B.6 Atlas Interfacing Via a Daughter Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

B.7 Multi-Motor Atlas with Single-Axis MC58113 Motion Control IC . . . . . . . . . 182

vi Atlas® Digital Amplifier Complete Technical Reference

Page 7

List of Figures

1-1 Single Axis Magellan With Atlas Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-2 Multi Axis Magellan With Atlas Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Direct Host Microprocessor With Atlas Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-4 Direct Host Microprocessor With Atlas Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-5 Atlas Force Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-6 Developer Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-1 Vertical Unit - Ultra Compact Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Horizontal Unit - Ultra Compact Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3 Vertical Unit - Compact Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-4 Horizontal Unit - Compact Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-5 Horizontal & Vertical Unit Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-6 Recommended Atlas Unit Thermal Transfer Material Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-7 Atlas Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-1 Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-2 Atlas Pinouts - Ultra Compact, Vertical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-3 Atlas Pinouts - Ultra Compact, Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-4 Atlas Pinouts - Compact, Vertical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-5 Atlas Pinouts - Compact, Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-6 Signal Interfacing ~Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-7 Signal Interfacing FaultOut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-8 Brushless DC Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-9 DC Brush Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-10 Step Motor Pulse and Direction Mode Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-11 Step Motor SPI Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-1 High Level System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-2 Internal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-3 Commutation Control Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-4 Phasing Reference Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-5 Current Loop Control Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-6 Individual Phase Control Calculation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-7 Field Oriented Control Calculation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4-8 Third Leg Floating Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-9 Power Stage Control Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4-10 Current Foldback Processing Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4-11 Pulse and Direction Signal Input Mode Control Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-12 User Memory Space and Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4-13 Example Motion Trace Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4-14 Trace Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-15 High-Level Format of a PSF (PMD Structured Data Format) Memory Space . . . . . . . . . . . . . . . . . . . 75

4-16 PSF Data Segment Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4-17 Initialization Commands Segment Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4-18 Parameter List Segment Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4-19 Format of Parameter Assignment Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4-20 Example PSF Memory Space Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4-21 SPI Communications Protocol Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4-22 Sending a Voltage or Torque Output Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5-1 SPI Communications Protocol Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5-2 Sending a Voltage or Torque Output Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5-3 Amplifier Disable Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Atlas® Digital Amplifier Complete Technical Reference

vii

Page 8

5-4 NOP Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5-5 Send Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-6 Query Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A-1 Developer Kit Components (four-axis version shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

A-2 Connecting DB9 Cable to Carrier Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

A-3 Component Placement of Vertical and Horizontal DK Carrier Cards (four-axis version shown) 158

A-4 Vertical Unit Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

A-5 Horizontal Unit Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

A-6 Vertical and Horizontal Compact to Ultra Compact Package Signal Converters . . . . . . . . . . . . . . 163

A-7 Mounting Atlas to L-bracket Plates (four-axis, vertical version shown) . . . . . . . . . . . . . . . . . . . . . . . 165

A-8 Top and Front Views of Four-Axis Horizontal Atlas DK L-bracket Vertical Plate . . . . . . . . . . . . . . . 166

A-9 Top and Front Views of One-Axis Horizontal Atlas DK L-bracket Vertical Plate . . . . . . . . . . . . . . . . 166

B-1 Brushless DC Atlas With Single-Axis Magellan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

B-2 DC Brush & Step Motor Atlas With Multi-Axis Magellan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

B-3 Step Motor Atlas Operating In Pulse & Direction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

B-4 DC Brush Atlas With PIC Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

B-5 Step Motor Atlas With ARM Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

B-6 Atlas Interfacing Via A Daughter Card #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

B-7 Atlas Interfacing Via A Daughter Card #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

B-8 Multi-motor Atlas With MC58113 Motion Control IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

viii

Atlas® Digital Amplifier Complete Technical Reference

Page 9

1.Introduction

In This Chapter

Atlas Digital Amplifier Overview

Typical Applications

Features and Functions

Atlas Developer’s Kits

1.1 Atlas Digital Amplifier Overview

Atlas Digital Amplifiers are single-axis amplifiers that provide high performance torque control of brushless DC, step

motor, and DC Brush motors. They accept digital torque commands from an external source and are used directly for

motor torque control applications, or in conjunction with higher level controllers for velocity or positioning applications.

Their very compact size and range of power output levels make them an ideal solution for single-card machine

controllers that require high performance in a small envelope.

Atlas digital amplifiers provide many advanced control features including user-programmable gain parameters,

performance trace, field oriented control, and I

voltage, and provide automatic protection from overcurrent, undervoltage, overvoltage, overtemperature, and short

circuit faults.

2

t current management. Atlas amplifiers are powered from a single supply

1

The Atlas digital amplifier family has been designed to work seamlessly with PMD’s Magellan family of motion control

ICs. Alternatively, they can be used with dedicated FPGAs, digital signal processors, or general purpose microprocessors.

Communication to/from Atlas amplifiers is via SPI (Serial Peripheral Interface) using a simple, packet-oriented

protocol. For step motors, in addition to the SPI format a dedicated pulse & direction input mode is provided.

Atlas amplifiers are packaged in plastic and metal solderable modules and are available in an ultra compact package size

with a total footprint of 1.4 inch

come in three power levels; 75 watts, 250 watts, and 500+ watts and utilize standard through-hole pins for all electrical

connections.

Atlas amplifiers are provided in both vertical and horizontal mounting configurations and have integral attachment tabs

to allow for a variety of mechanical mounting and heat sink options. The following table shows the available

configurations of the Atlas Digital Amplifiers:

Power Level

P/N

Step Motor

MD241048/02VB Low (75W) 12-48V Ultra compact Vertical Step Motor

MD241048/02HB Low (75W) 12-48V Ultra compact Horizontal Step Motor

MD241048/05VB Medium (250W) 12-48V Ultra compact Vertical Step Motor

MD241048/05HB Medium (250W) 12-48V Ultra compact Horizontal Step Motor

MD141056/25VB High (500+W) 12-56V Compact Vertical Step Motor

MD141056/25HB High (500+W) 12-56V Compact Horizontal Step Motor

(continuous) Voltage Size

2

(9.0 cm2) and a compact package size with a footprint of 2.6 inch2 (16.8 cm2). They

Mounting

Style Motor Type

Atlas® Digital Amplifier Complete Technical Reference

9

Page 10

Introduction

Brushless DC,

DC Brush, or

Step Motor

1

Brushless DC

MD231048/02VB Low (75W) 12-48V Ultra compact Vertical Brushless DC

MD231048/02HB Low (75W) 12-48V Ultra compact Horizontal Brushless DC

MD231048/05VB Medium (250W) 12-48V Ultra compact Vertical Brushless DC

MD231048/05HB Medium (250W) 12-48V Ultra compact Horizontal Brushless DC

MD131056/25VB High (500+W) 12-56V Compact Vertical Brushless DC

MD131056/25HB High (500+W) 12-56V Compact Horizontal Brushless DC

DC Brush

MD211048/02VB Low (75W) 12-48V Ultra compact Vertical DC Brush

MD211048/02HB Low (75W) 12-48V Ultra compact Horizontal DC Brush

MD211048/05VB Medium (250W) 12-48V Ultra compact Vertical DC Brush

MD211048/05HB Medium (250W) 12-48V Ultra compact Horizontal DC Brush

MD111056/25VB High (500+W) 12-56V Compact Vertical DC Brush

MD111056/25HB High (500+W) 12-56V Compact Horizontal DC Brush

Multi-Motor

MD281048/02VB Low (75W) 12-48V Ultra compact Vertical Multi-motor*

MD281048/02HB Low (75W) 12-48V Ultra compact Horizontal Multi-motor*

MD281048/05VB Medium (250W) 12-48V Ultra compact Vertical Multi-motor*

MD281048/05HB Medium (250W) 12-48V Ultra compact Horizontal Multi-motor*

MD181056/25VB High (500+W) 12-56V Compact Vertical Multi-motor*

MD181056/25HB High (500+W) 12-56V Compact Horizontal Multi-motor*

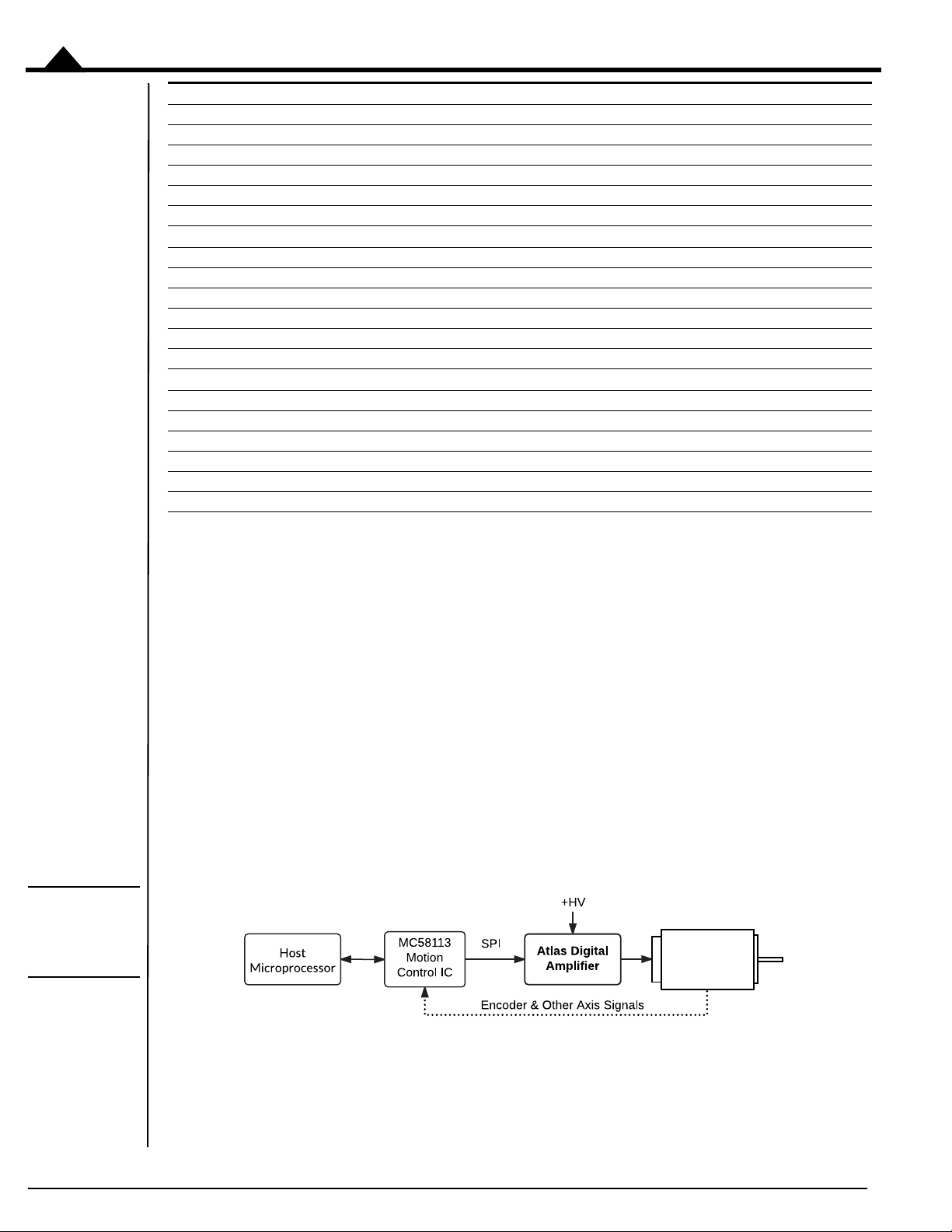

Figure 1-1:

Single Axis

Magellan With

Atlas Amplifier

*Multi-motor motor type

allows the Atlas to be configured by the user to drive either Step Motor, Brushless DC, or DC Brush motor type.

This manual provides a description of the electrical and mechanical specifications for the Atlas Digital Amplifiers,

along with a summary of its operational features. For complete documentation on all aspects of the Atlas Digital

Amplifier including a programmers command reference refer to Atlas® Digital Amplifier Complete Technical Reference.

For more information on the Magellan Motion Control IC consult the Magellan Motion Control IC User’s Guide.

1.2 Typical Applications

The following section provides overview diagrams of typical applications utilizing the Atlas amplifier products.

1.2.1 Single Axis Positioning Motion Controller

The diagram below shows a PMD MC58113 Motion Control IC sending torque commands to an Atlas Amplifier to

provide positioning control of a brushless DC, DC Brush, or Step Motor.

10 Atlas® Digital Amplifier Complete Technical Reference

Page 11

Introduction

Brushless DC,

DC Brush, or

Step Motor

Brushless DC,

DC Brush, or

Step Motor

Brushless DC,

DC Brush, or

Step Motor

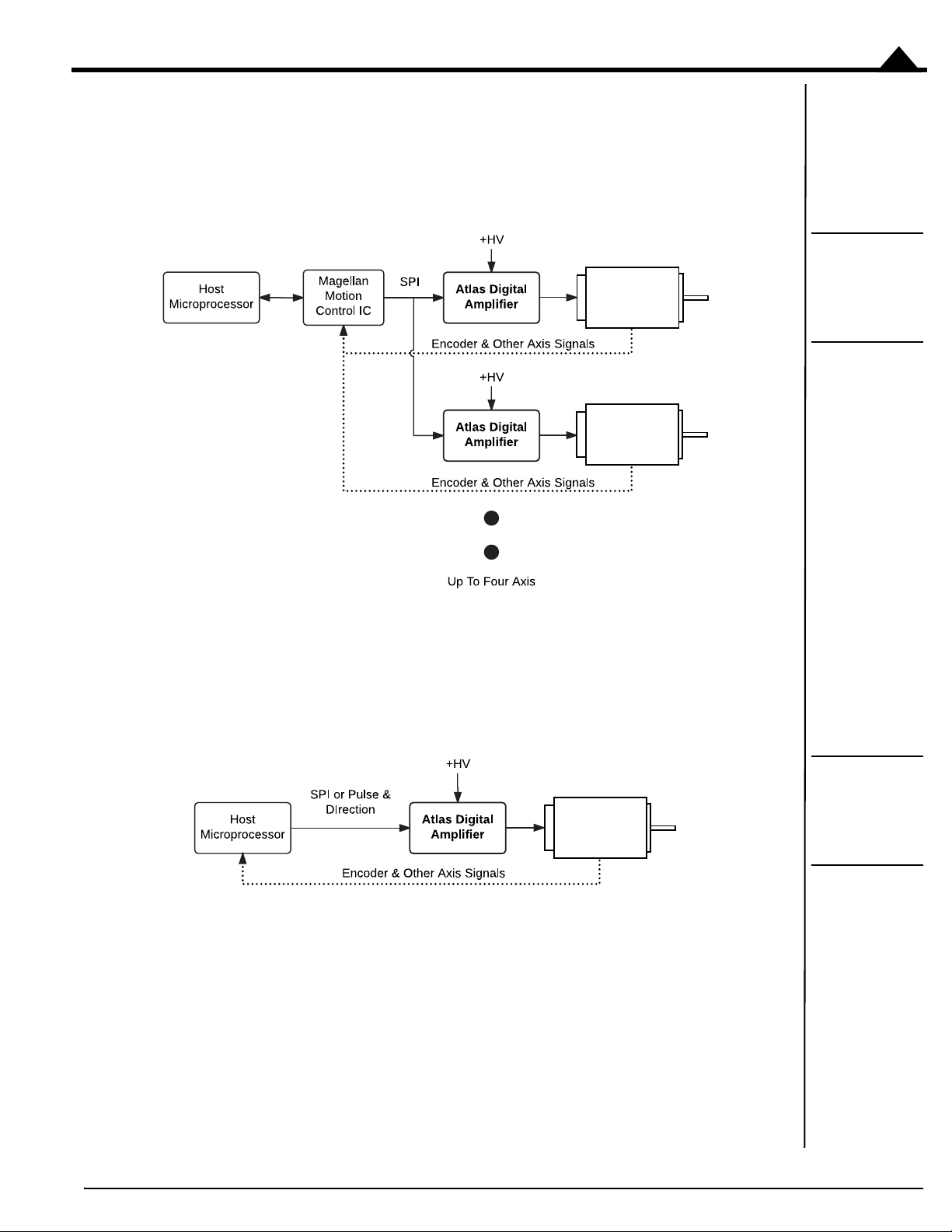

1.2.2 Multi Axis Positioning Motion Controller

The diagram below shows a PMD Magellan MC58000 series or MC55000 series multi-axis motion control IC being

used with two or more Atlas Amplifiers to provide control of brushless DC, DC Brush, or Step Motors in a

positioning application. If desired each axis can control a different motor type, so that, for example, brushless DC

motors can be used along with step motors in the same controller.

1

Figure 1-2:

Multi Axis

Magellan With

Atlas

Amplifiers

1.2.3 Microprocessor-Based Motion Controller

The diagram below shows the Atlas Amplifier being driven by a general purpose microprocessor that provides high

level path generation and servo loop closure and outputs continuous desired torque commands or desired position

increments for step motors to the Atlas Amplifier via the SPI (Serial Peripheral Interface).

1.2.4 Stand Alone Step Motor Amplifier

iagram below shows the Atlas Amplifier being directly driven by pulse & direction signals. These signals may

The d

come from a microprocessor, a control card, or any other existing motion control device that outputs pulse & direction

signals. In this mode the Atlas unit operates ‘stand-alone,’ and utilizes configuration control parameters previously

stored into the Atlas unit’s NVRAM (non-volatile) memory.

Figure 1-3:

Direct Host

Microprocessor

With Atlas

Amplifiers

Atlas® Digital Amplifier Complete Technical Reference

11

Page 12

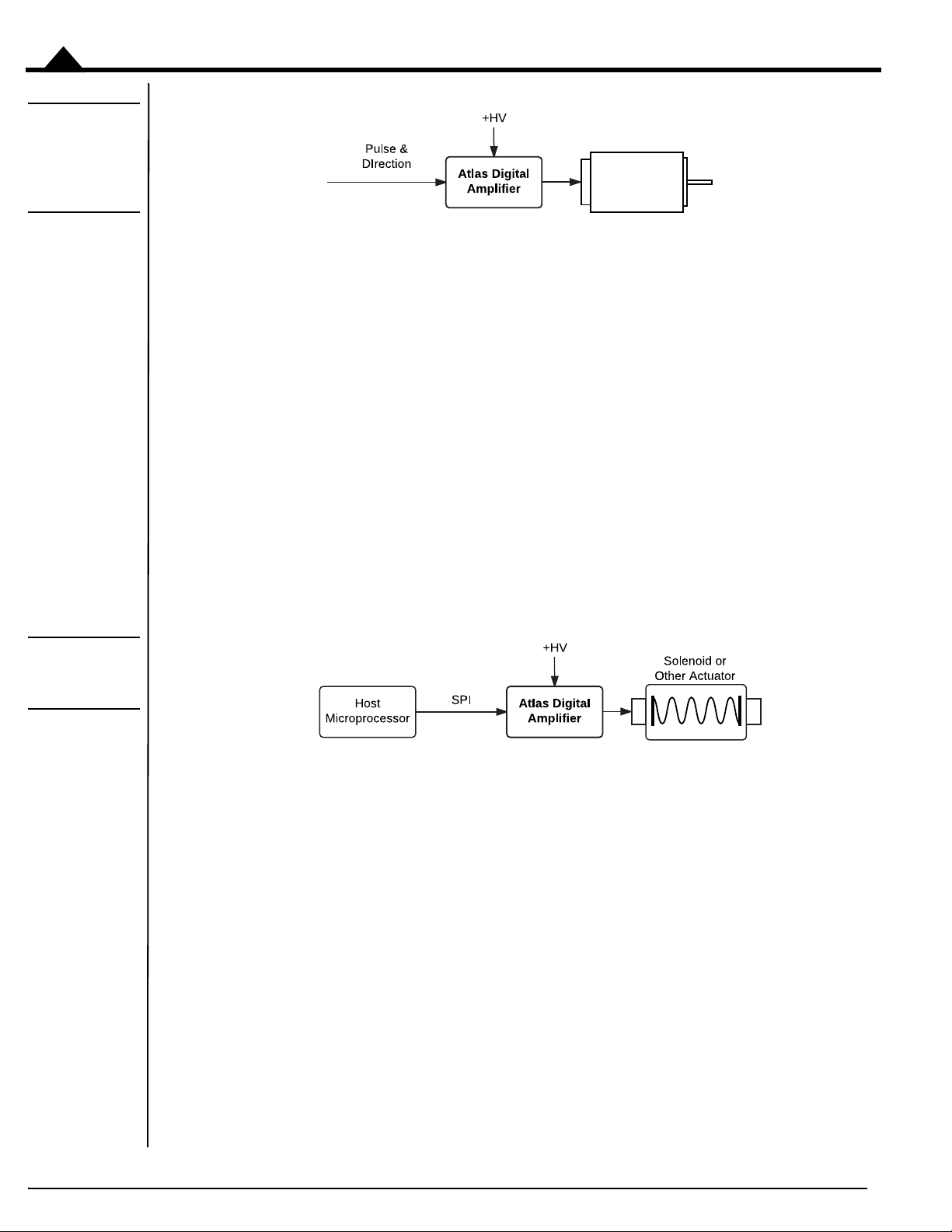

Introduction

Step Motor

1

Figure 1-4:

Direct Host

Microprocessor

With Atlas

Amplifiers

There are a few options for configuring Atlas units for stand alone operation:

• Pro-Motion can be used with the Atlas Developer’s Kit to program Atlas units

• The user can develop their own NVRAM programming system by utilizing the SPI (Serial Peripheral

Interface) Atlas command protocol. For more information refer to the Atlas® Digital Amplifier

Complete Technical Reference.

• PMD offers custom pre-configured Atlas units. For more information contact your local PMD sales

representative.

1.2.5 Force Control

The Brushless DC and DC Servo Atlas units can be used for general purpose force control applications such as remote

teleoperation, force feedback, solonoid actuation, and any other general purpose valve/actuator control where a

precisely controllable current is needed.

Figure 1-5:

Atlas Force

Control

In this application the torque command may be sent continuously by the host microprocessor or from time to time as

required by the application. In either case the Atlas provides very accurate current/torque control resulting in smooth

and precise application of force.

1.3 Features and Functions

The Atlas family of amplifiers provide an extensive list of functions, including:

• Available in Brushless DC, DC Brush, Step Motor, and multi-motor motor types

• High performance all-digital power amplifier

• Works with Magellan ICs, FPGAs or microprocessor-based controllers

• Digital SPI interface eliminates analog +/- 10V signals

• Available in 75W, 250W, and 500W+ power levels

• Rugged plastic solderable module format uses standard through-hole pins

• Total power output to 1Kilowatt

• Available in ultra compact 1.05" x 1.05" x .53" (27mm x 27mm x 13mm) size or compact 1.52" x 1.52"

x .60" (39mm x 39mm x 15mm) size

12 Atlas® Digital Amplifier Complete Technical Reference

Page 13

• Horizontal and vertical mount configurations

• Includes rugged mechanical tab mounts

• Supply voltage range of 12V up to 56V

• High current output up to 14A continuous, 25A peak

• Digital current loop with choice of standard A/B or Field Oriented Control (FOC)

• Direct signal pulse and direction input

2

•I

t current foldback limiting

Introduction

1

• Overcurrent, overvoltage, undervoltage, overtemperature, and SPI command watchdog time

protection

Single DC supply operation.

•

• Enable input and FaultOut output safety interlock signals

• SPI (Serial Peripheral Interface) up to 8 MHz

• Performance trace of up to 1,020 words and four simultaneous variables

• 1,024 word non-volatile parameter storage

• Microstepping control with up to 256 microsteps per full step

• Signal conditioning buffers and analog filters on all I/O signals

• Fully RoHS compliant and CE marked

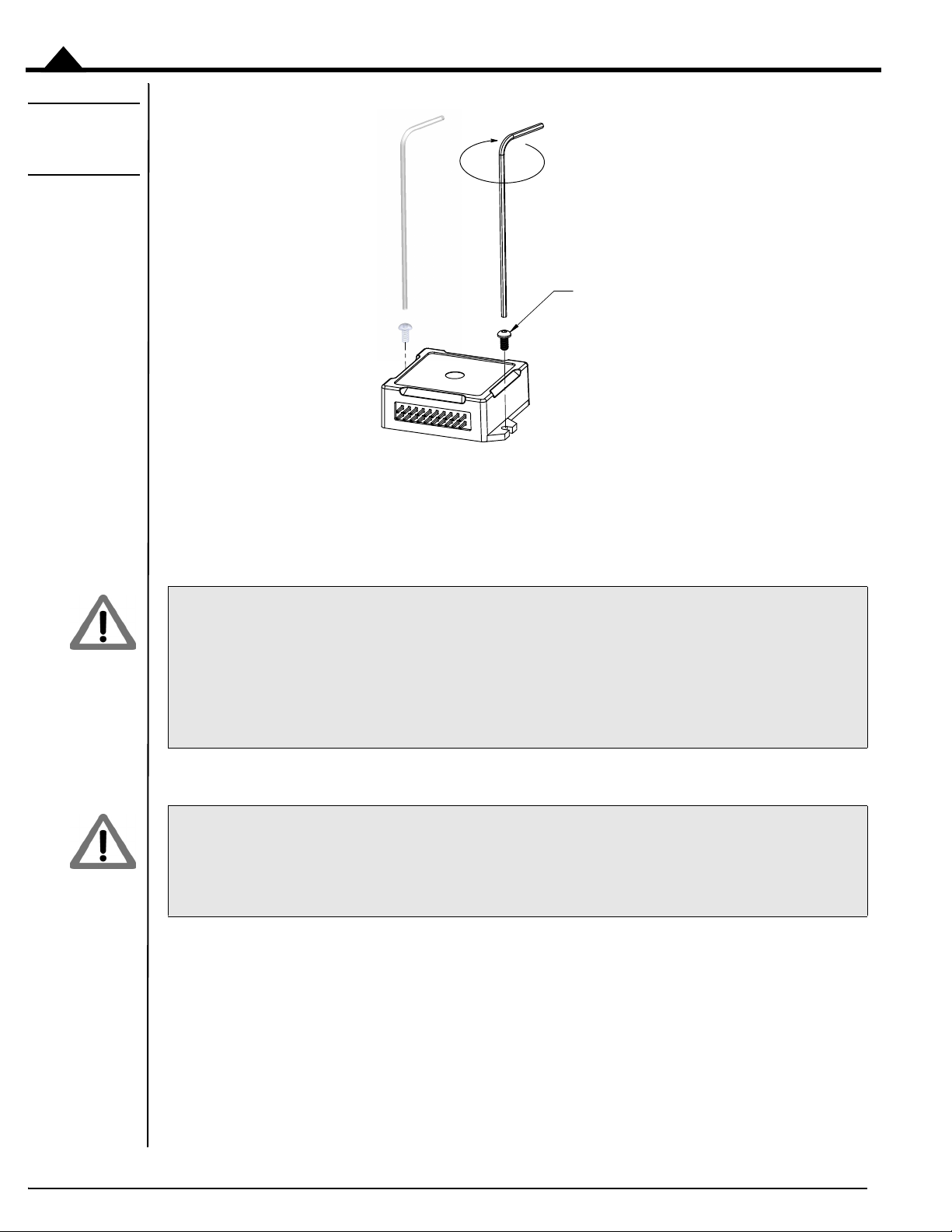

1.4 Atlas Developer’s Kit

To simplify development, an Atlas Developer’s Kit is available, shown in Figure 1-6.

out

Atlas® Digital Amplifier Complete Technical Reference 13

Page 14

Introduction

1

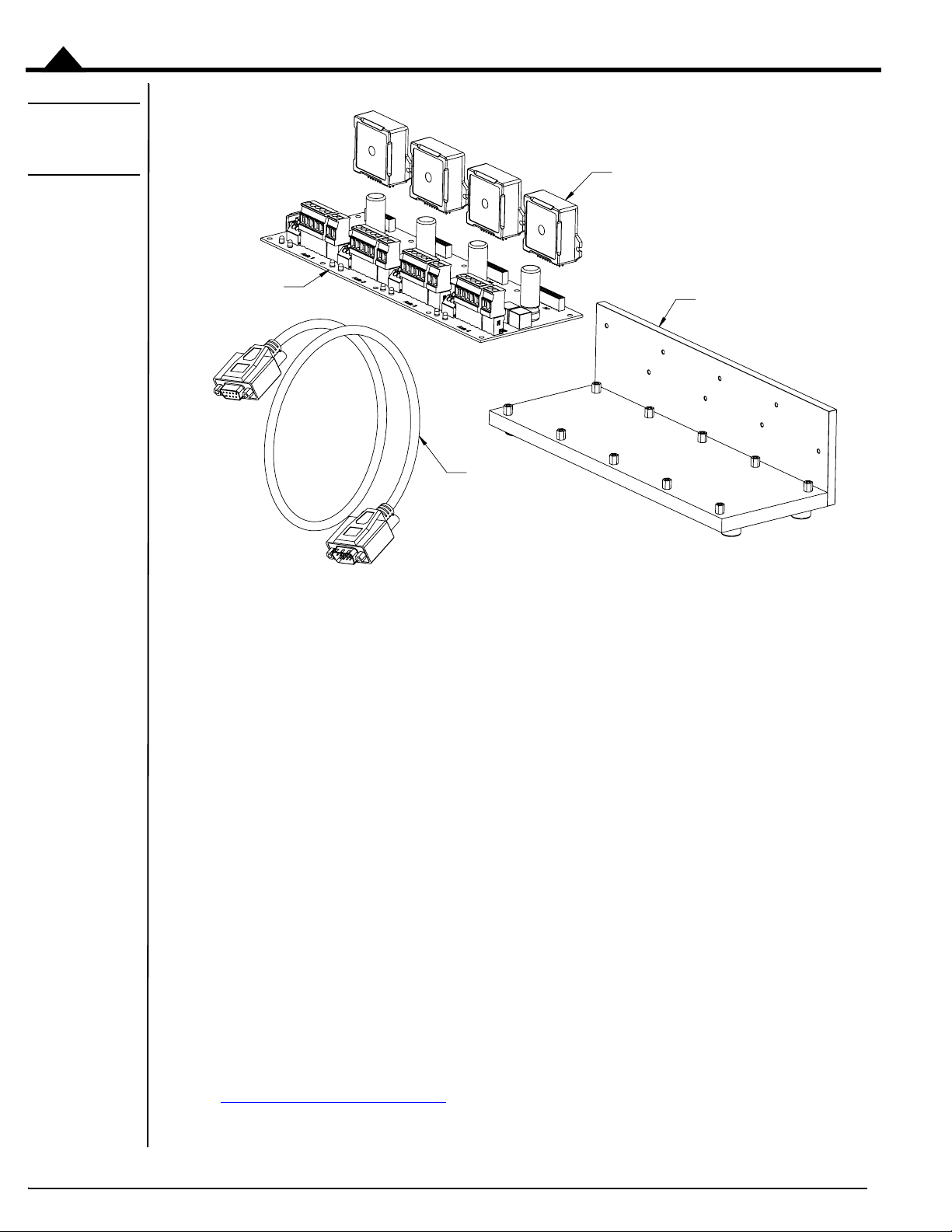

Figure 1-6:

Developer Kit

Components

The following software and hardware components are included in every Atlas Developer’s Kit:

• Pro-Motion CD and User’s Guide

• C-Motion and VB-Motion SDK CD, including PDFs of all Atlas documentation

• Atlas DK DB9 communications cable

For the following components, you will provide information that will specify how you want the DK tailored for your

exact development needs:

• Specific Atlas units to be included (motor type, power level)

• Atlas carrier card (horizontal or vertical, 1 or 4 axis version)

The carrier cards are designed for direct use with the compact Atlas format. For each ultra compact Atlas ordered a

converter card is provided that allows the ultra compact Atlas to be plugged into the compact carrier card socket

directly.

The L-bracket provides a stable mechanical base from which you can conveniently connect and operate your prototype

system motors. With the vertical plate, the Atlas units have additional heat sinking, which can be extended further by

connecting the vertical plate to your own heat sink or cold plate.

Electrical connection to the Atlas DK carrier card is made by DB9 connector, and by jack screw connectors. Designers

who plan to use the Atlas in conjunction with PMD’s Magellan Motion Control ICs can connect the Atlas DK to the

Magellan DK card, purchased separately. For more information on this product see one of the available Magellan

Motion Control IC developer’s kit user’s manuals.

Refer to Appendix A, “

Atlas DK.

Atlas Developer’s Kit” for complete information on ordering, setting up and operating the

14 Atlas® Digital Amplifier Complete Technical Reference

Page 15

2.Functional Characteristics

In This Chapter

Operational Specifications

Physical Dimensions

Mechanical Mounting Options

2.1 Operational Specifications

Operating Parameter Value

Motor types supported: Brushless DC, DC Servo, Step Motor

Communication format: SPI (Serial Peripheral Interface)

SPI clock frequency range: 2.0 MHz to 8.0 MHz

Torque command rate: up to 9.7 kHz

Current measurement resolution: 12 bits

Current loop type: P, I (proportional, integral) with Integral limit

Current loop resolution: 16 bits

Current loop rate: 19.530 kHz

Current loop modes: individual phase, field oriented control, third leg floating

Safety functions: over current detect, programmable over temperature

detect, programmable overvoltage detect, programmable

under voltage detect, programmable I

SPI command watchdog timeout

Output limiting:

Command modes: SPI voltage, SPI torque, pulse & direction signal

PWM rate: 20 kHz, 40 kHz, 80 kHz, or 120 kHz

PWM generation modes: sinusoidal, space vector modulation, standard single-phase

Pulse & direction rate: 1.0 M Pulses/sec

Microsteps per full step: up 256 per full step

Trace capture modes: one time, rolling-buffer

Trace trigger modes: internal clock, external by controller

Trace buffer size: 1,020 16-bit words

NVRAM storage size: 1,024 16-bit words

Programmable I2t energy, current, and voltage limit

2

t current foldback,

2

Atlas® Digital Amplifier Complete Technical Reference

15

Page 16

Functional Characteristics

2

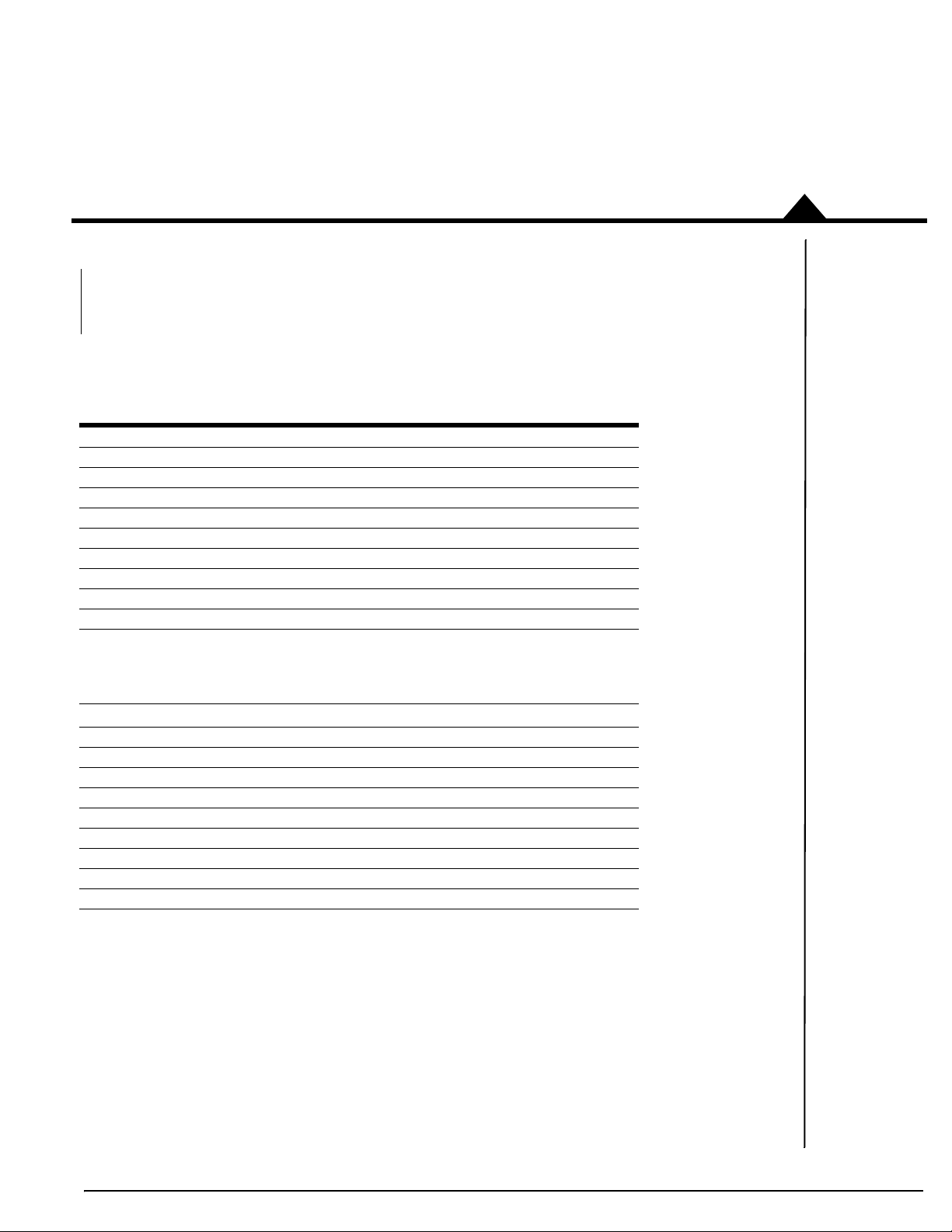

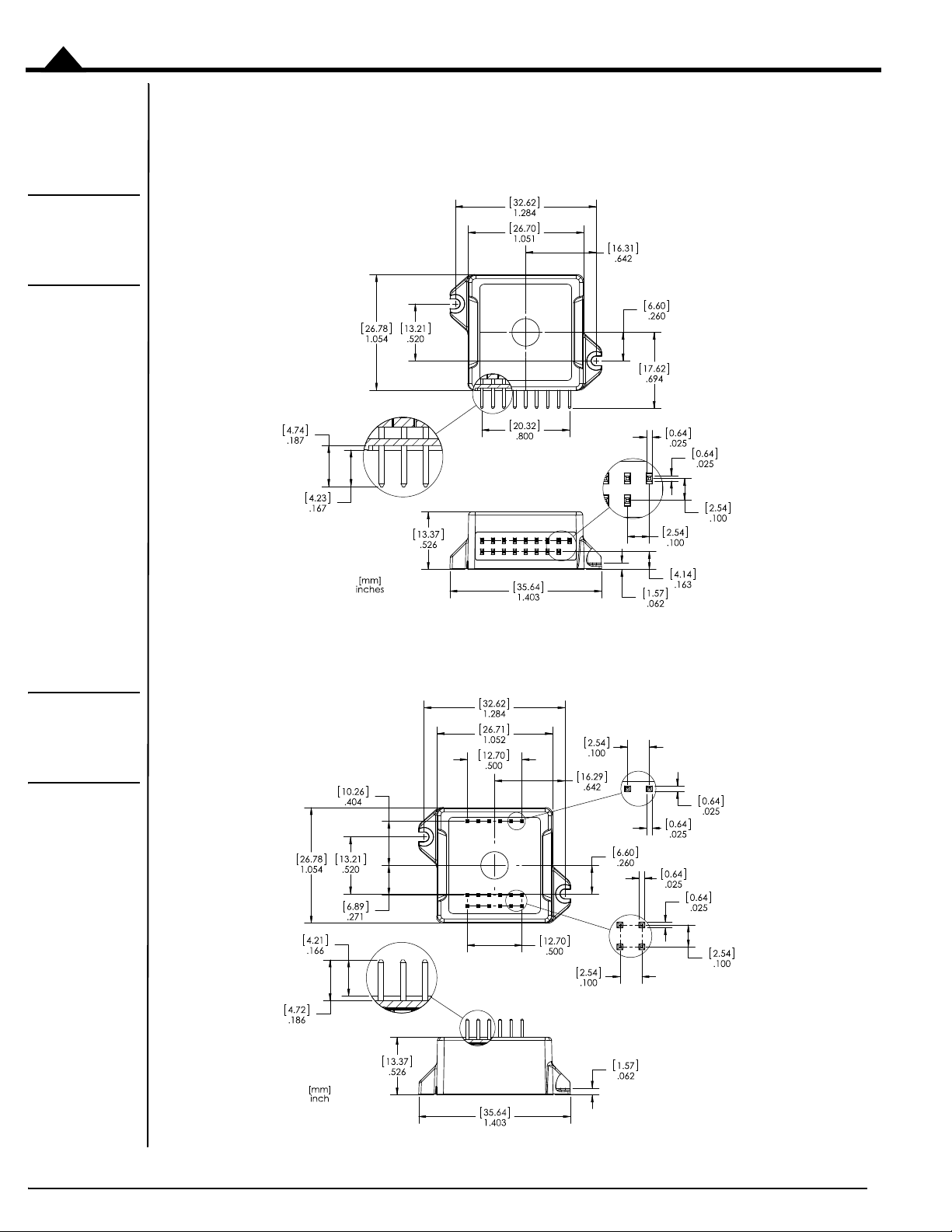

Figure 2-1:

Vertical Unit Ultra Compact

Package

2.2 Physical Dimensions

2.2.1 Vertical Unit, Ultra Compact Package

Figure 2-2:

Horizontal Unit

- Ultra Compact

Package

2.2.2 Horizontal Unit, Ultra Compact Package

16 Atlas® Digital Amplifier Complete Technical Reference

Page 17

2.2.3 Vertical Unit, Compact Package

Functional Characteristics

Figure 2-3:

Vertical Unit Compact

Package

2

2.2.4 Horizontal Unit, Compact Package

Figure 2-4:

Horizontal Unit

- Co

mpac

Package

Atlas® Digital Amplifier Complete Technical Reference 17

t

Page 18

Functional Characteristics

2

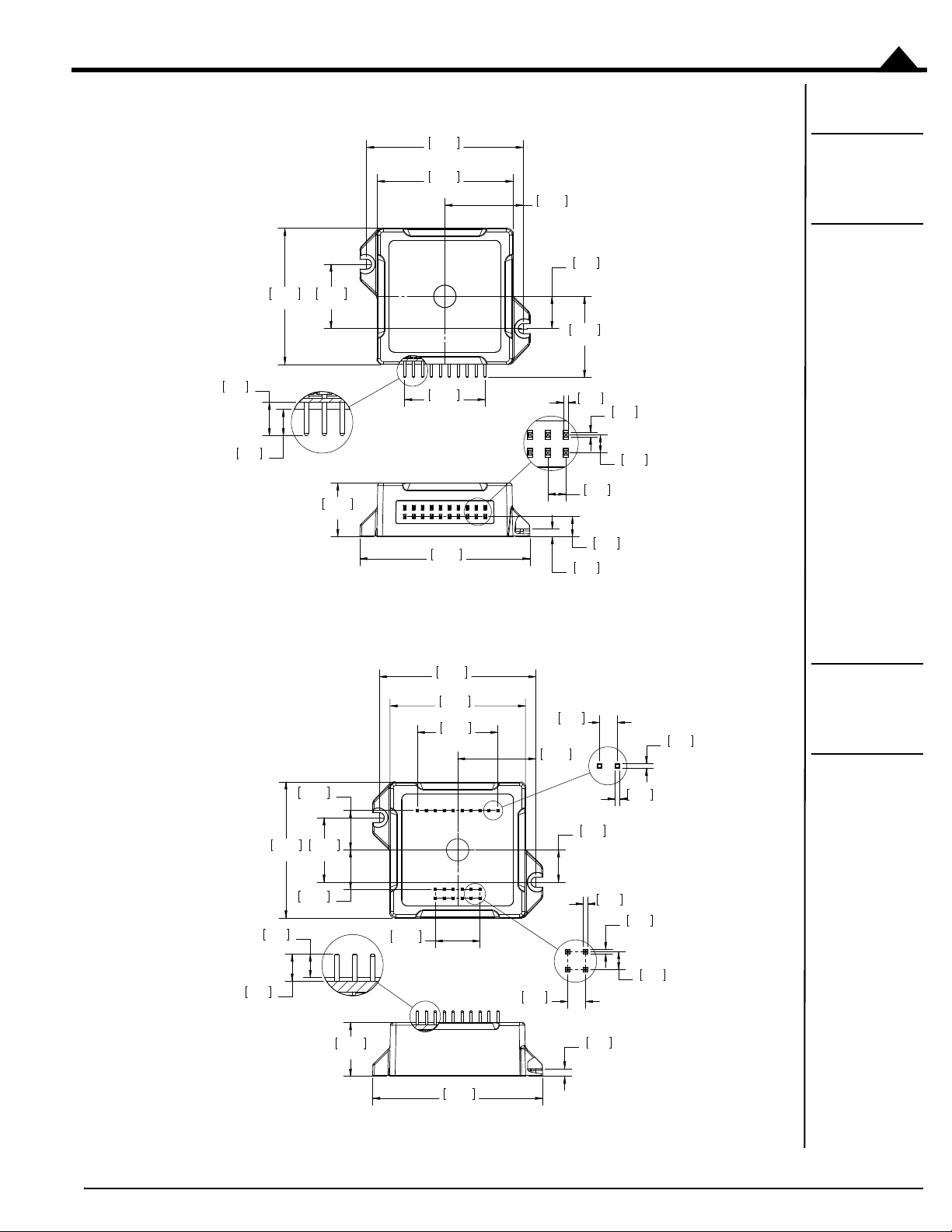

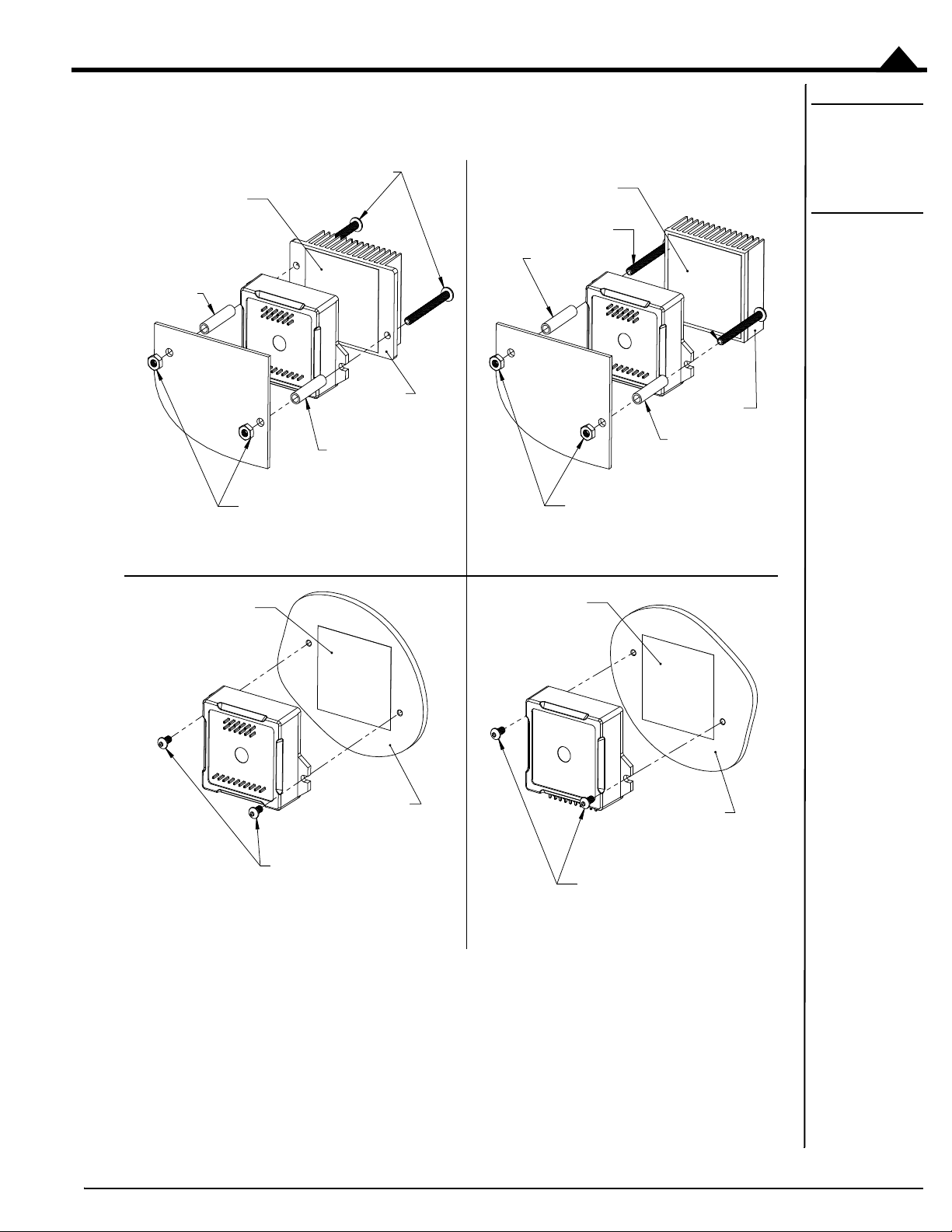

2.3 Mechanical Mounting Options

Atlas amplifiers are provided in two separate package sizes, ultra compact and compact, and in two separate mounting

configurations; vertical and horizontal. There are some very low power applications where the Atlas unit may be

mounted without mechanical attachment to the screw tabs. In such cases mechanical attachment to the PCB occurs

via the electrical solder connections.

Most applications however will utilize the Atlas unit’s integral screw tab mounts to rigidly connect the Atlas to the

PCB, to a heat sink, or to some other mechanical support. As shown in Figure 2-5 there are a number of Atlas

mounting options available when using the Atlas screw tabs. The choice of the mounting hardware depends on the

demands of the application.

The following table provides information related to the mechanical screw tab mounts:

Maximum

Recommended

Atlas Package

Ultra Compact M2.0 4.2 mm 2.2 mm

Compact M2.5 5.4 mm 2.8 mm

screw type

screw head

diameter

Maximum

screw body

diameter

18 Atlas® Digital Amplifier Complete Technical Reference

Page 19

Functional Characteristics

SCREWS (M2.0 or M2.5)

HEX NUT (M2.0 or M2.5)

STANDOFF

STANDOFF

HEAT SINK

HEAT SINK

SCREWS (M2.0 or M2.5)

HEX NUT (M2.0 or M2.5)

STANDOFF

STANDOFF

Vertical Unit, Mechanical Mount to Support/Cold Plate

SCREWS (M2.0 or M2.5)

SUPPORT/COLD

PLATE

SCREWS (M2.0 or M2.5)

Horizontal Unit, Mechanical Mount to Support/Cold Plate

Horizontal Unit, Mechanical Mount Through Heat Sink to PCB

THERMAL

TRANSFER

MATERIAL

THERMAL

TRANSFER

MATERIAL

THERMAL

TRANSFER

MATERIAL

THERMAL

TRANSFER

MATERIAL

SUPPORT/COLD

PLATE

BA

DC

Horizontal Unit, Mechanical Mount to PCB

Figure 2-5:

Horizontal &

Vertical Unit

Mounting

Options

2

2.3.1 Mounting Guidelines

Atlas amplifiers, while designed to be robust and easy to install, contain active electronics that can only function

reliably when the mechanical integrity and operating environment of the Atlas is maintained. The next three sections

Atlas® Digital Amplifier Complete Technical Reference

19

Page 20

Functional Characteristics

2

provide important recommendations and guidelines for the configuration, selection, placement, mounting method,

and installation procedure for Atlas amplifiers.

Choice of vertical or horizontal Atlas. The horizontal configuration of Atlas is recommended for applications where the

Atlas is not mechanically mated to a supporting plate and where vibration or movement-related forces may be present.

When the Atlas unit is mechanically mated to a supporting plate, either the horizontal or the vertical configuration

may be used. Figure 2-5

Attaching Atlas to a supporting plate. Some Atlas applications will utilize a supporting plate for heat removal or for

enhanced mechanical stability. For Atlas installations that may be subject to vibration or movement-related forces and

that utilize a supporting plate, special care should be taken to insure that there is no movement between the circuit

card that the Atlas is soldered or socketed to and the supporting plate which the Atlas is mechanically attached to. Such

movement could result in damage to the Atlas unit, the circuit card, or the supporting plate.

Attaching Atlas to a free-standing heatsink. Some Atlas applications will utilize a free standing heat sink, such as is shown

in Figure 2-5

recommended for use with vertical Atlas units. When mounting Atlas units with free standing heat sinks special care

should be taken where vibration or movement-related forces may be present. These forces, acting on the additional

mass of the heat sink, may impart excessive mechanical stress on the Atlas resulting in damage to the Atlas unit, the

circuit card, or the heat sink. Depending on the nature and magnitude of the forces, in these applications mounting

the Atlas to a supporting plate may be preferred.

Choice of socket or solder connection to the circuit card. For best electrical contact to the printed circuit board (PCB),

connection by soldering to the Atlas is generally recommended. This is particularly true for Atlas units that are not

mated to a supporting plate. When the Atlas unit is mounted to a supporting plate either solder or socket electrical

connections may be used, with solder connections recommended for applications benefitting from rigid connection

of the Atlas to the PCB, and sockets being recommended when greater mechanical isolation of the PCB from the

mechanical support is desired.

C and Figure 2-5D show the Atlas unit mechanically mated to a supporting plate.

A and Figure 2-5B. Free standing heat sinks are recommended with horizontal Atlas units but are not

Some of the electrical ratings of the Atlas may not be achievable when electrical connection to the Atlas is via

sockets rather than via soldering. It is the responsibility of the user to determine whether a particular motor output current and voltage rating may be achieved with a given socket.

2.3.2 Thermal Transfer Materials

Thermal transfer materials in the form of thermal tape, pads, paste, or epoxy may be used to improve thermal transfer

between the Atlas’ metal plate and an attached heat sink or supporting plate. These materials improve thermal

conductivity by filling in air gaps that form when two metallic surfaces are mated.

Figure 2-5

surface. The following guidelines may be helpful in selecting and sizing the thermal transfer material best-suited to

your application.

The capacity of thermal transfer materials to transfer heat (known as the bulk conductivity) is much lower than that

of metals such as aluminum or copper. Therefore, in general, the thinner the transfer material the better. Thickness of

the material is only precisely controllable for thermal pads and thermal tapes, with thermal pads providing the thinnest

available interfaces beginning at 5 mils (.127 mm) or even less. For use with Atlas amplifiers thermal transfer materials

that are thicker than 40 mils (1.0 mm) are not recommended regardless of the material used.

When using thermal paste or thermal epoxy glue the thickness should be carefully controlled via a silk screen or other

wet film application process. The Atlas unit itself should not be used to squeeze non-uniformly applied paste or epoxy

flat during installation. Doing so may result in damage to the Atlas.

shows a typical application of a thermal transfer material between the Atlas and a heat-removing metal

20 Atlas® Digital Amplifier Complete Technical Reference

Page 21

Functional Characteristics

1.40”

(35.6)

1.50”

(38.1)

1.00”

(25.4)

.95”

(24.1)

2

Whether using tape, pads, paste, or epoxy, as shown in Figure 2-6

, the thermal transfer material that is used as the

interface should not extend to the area under the Atlas’ tabs because this may reduce the amount of compression that

occurs in the thermal transfer area. The following table provides dimensions for the applied thermal transfer material

for the two available Atlas package sizes:

Maximum Pad

Atlas Package Size

Ultra Compact .1.00" x .95" (25.4 mm x 24.1mm)

Compact 1.40" x 1.50" (35.6 mm x 38.1

Dimensions

mm)

Figure 2-6:

Recommended

Atlas Unit

Thermal

Transfer

Material

Dimensions

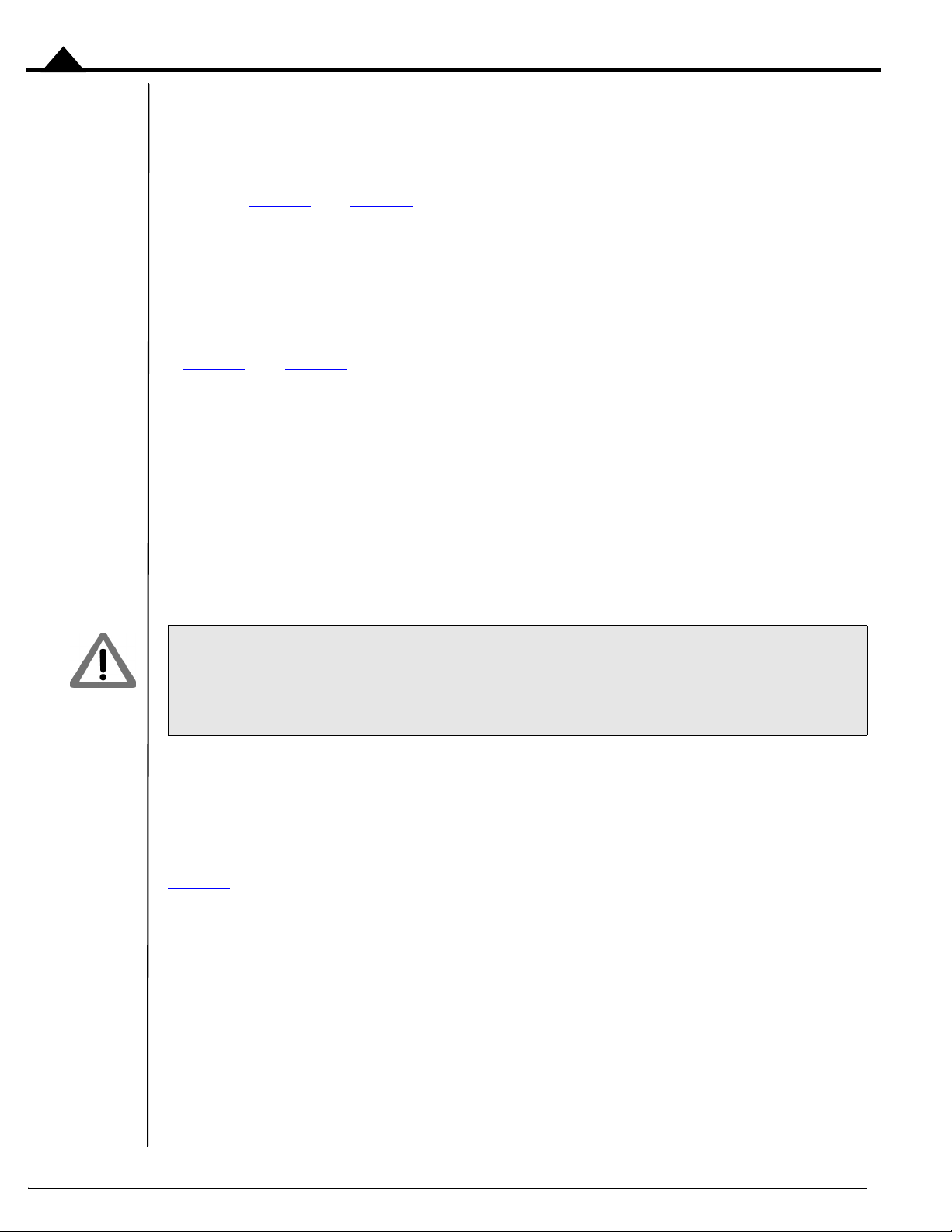

2.3.3 Atlas Installation

There are a number of precautions and procedures that should be followed to maintain the electrical and mechanical

integrity of the Atlas unit during installation.

Soldering Atlas units in place. Applications that utilize Atlas units that are not mechanically mated to a heat sink or that

are mated to a self-standing heat sink may utilize a standard soldering process without special precautions or

procedures. Applications that involve Atlas units mated to a supporting plate and that will be soldered to the PCB

should take special care to insure that the solder joints are not stressed by the supporting plate once installed. The

recommended method to achieve this is to mechanically mate the Atlas to the supporting plate before soldering the

Atlas into the PCB. If, for whatever reason, this is not possible, then special care should be taken to insure that the

Atlas is precisely aligned with the supporting plate after soldering and before mechanical attachment so that upon

mechanical attachment no stress is placed on the Atlas unit, the solder contacts, or the PCB.

Mounting surface flat and clean. Thermal performance as well as safe operation of the Atlas requires that the surface that

the Atlas is mounted to be flat and clean, free of dust, grease, or foreign objects. The recommended maximum

deviation of the mating surface flatness is 3 mils (.076 mm).

Mechanical mounting limits. Applications that will utilize a mechanical attachment to the Atlas via the Atlas’s mounting

tabs should take special care not to overstress the mechanical tabs. Regardless of the attachment method, which is most

commonly screws but may also be clips or inserts, the linear force applied to each mechanical tab should not exceed

certain values as shown in the following table and the accompanying Figure 2-7

Maximum Direct Force

Atlas Package Size

Ultra Compact 25 pounds (111 N) M2.0 x .40, 11.0oz-in (.078 N-m)

Compact 35 pounds (156 N) M2.5 x.45, 12.5oz-in (.088 N-m)

Per Tab

Screw Type, Corresponding

Maximum Rotary Torque

.

Atlas® Digital Amplifier Complete Technical Reference 21

Page 22

Functional Characteristics

11.0 Oz-in (.078 N-m) - Ultra Compact Package

12.5 OZ-in (.088N-m) - Compact Package

M2.0 or M2.5 Screw

2

Figure 2-7:

Atlas Torque

Specifications

Mechanical mounting procedure. Atlas units that are mated to a heat sink or mechanical plate should be attached by

progressively tightening both of the Atlas unit’s tabs. This means that one screw may be tightened, followed by the

other, than back to the first etc. until the desired torque at each screw has been achieved. Following this procedure is

particularly important when installing Atlas units over paste or epoxy, where the subsurface layer will undergo

compression and movement before settling to a final installed position.

To ensure that proper contact exists between the Atlas and the entire thermal transfer material substrate, and to

ensure that the Atlas unit is not damaged via mechanical overstress, the user should carefully apply equal torque

increments to each tab screw, never exceeding at any point the torque limit on either tab of 25 lbs (111 N) linear

force or 11.0 oz-in (.078 N-m) rotary torque using a M2.0 x .40 screw for the ultra compact Atlas package, and

35 lbs(156N) linear force or 12.5oz-in (.088 N-m) rotary torque using a M2.5 x .45screw for the compact Atlas

package.

.

It is the responsibility of the user to ensure that all Atlas units have been installed within the above prescribed

mechanical stress limits and following the above described procedures. Failure to observe any of the above recommended procedures and limits may result in incorrect operation or failure of the Atlas during operation.

22 Atlas® Digital Amplifier Complete Technical Reference

Page 23

3.Electrical Specifications

In This Chapter

Drive Ratings

Absolute Maximum Ratings

Environmental Ratings

Safety and Compliance

DC Characteristics

AC Characteristics

Pin Descriptions and Pinouts

Signal Interfacing

Connection Overview

Heat Sink Grounding

Atlas Conversion Factors

3.1 Drive Ratings

3.1.1 Low Power Units (P/Ns MD2x1048/02xB)

3

Specifications

Nominal supply voltage 12-48 VDC 12-48 VDC 12-48 VDC

Continuous current 1.5 ADC 1.5 Arms 1.5 Arms

Peak current (per phase) 3.8 A 3.8 A 3.8 A

Maximum continuous power 72 W 88 W 102 W

*

transformer isolated power supply, T < 40° C

A coldplate or a heatsink in an environment with sufficient airflow can be used to achieve the above drive ratings.

For temperature operation beyond the standard 0-40° C range, above-listed ratings may change. Contact your PMD

representative for additional information on Atlas extended temperature operation including higher temperature drive

ratings.

*

DC Brush

Motor

Brushless DC

Motor

Step

Motor

3.1.2 Medium Power Units (P/Ns MD2x1048/05xB)

Specifications

Nominal supply voltage 12-48 VDC 12-48 VDC 12-48 VDC

Continuous current 7.0 ADC 5 Arms 4.5 Arms

Peak current (per phase) 12.5 A 12.5 A 12.5 A

Maximum continuous power 336 W 294 W 305 W

*

DC Brush Motor Brushless DC Motor Step Motor

Atlas® Digital Amplifier Complete Technical Reference

23

Page 24

Electrical Specifications

3

*

transformer isolated power supply, T < 40° C

A coldplate or a heatsink in an environment with sufficient airflow can be used to achieve the above drive ratings.

For temperature operation beyond the standard 0-40° C range, above-listed ratings may change. Contact your PMD

representative for additional information on Atlas extended temperature operation including higher temperature drive

ratings.

3.1.3 High Power Units (P/Ns MD2x1056/25xB)

Specifications

Nominal supply voltage 12-56 VDC 12-56 VDC 12-56 VDC

Continuous current 14.0 ADC 10.0 Arms 9.0 Arms

Peak current (per phase) 25.0 A 25.0 A 25.0 A

Maximum continuous power 670 W 590 W 610 W

*

transformer isolated power supply, T < 40° C

*

DC Brush Motor Brushless DC Motor Step Motor

A coldplate or a heatsink in an environment with sufficient airflow can be used to achieve the above drive ratings.

For temperature operation beyond the standard 0-40° C range, above-listed ratings may change. Contact your PMD

representative for additional information on Atlas extended temperature operation including higher temperature drive

ratings.

3.2 Absolute Maximum Ratings

Parameter Rating

HV voltage range, low power units 0 V to +52 V

HV voltage range, medium power units 0 V to +52 V

HV voltage range, high power units 0 V to +60 V

~Enable voltage range -10 V to +24 V

SPISI, SPIClk, ~SPICS voltage range -0.5 V to 6.5 V

SPISO voltage range -0.5 V to 3.7 V

FaultOut voltage range -0.3 V to 24 V

FaultOut output current -35 uA to 50 mA

5V output current, low power units 50 mA

5V output current, medium power units 50 mA

5V output current, high power units 100 mA

All voltage values are with respect to GND unless otherwise noted.

24 Atlas® Digital Amplifier Complete Technical Reference

Page 25

3.3 Environmental Ratings

Specification Value

Operating ambient temperature 0 to 40 C

Maximum base plate temperature 75 C

Storage temperature -20 to 85 C

Reflow soldering temperature 300 C (1.5mm for 10 seconds)

Humidity 0 to 95%, non-condensing

Altitude Up to 2,000 meters without derating

Contamination Pollution Degree 2

3.4 Safety and Compliance

Specification Standard

CE LVD: EN60204-1

EMC-D: EN61000-6-1, EN61000-6-3, EN55011

Electrical safety Designed to UL508C, UL840 and EN60204-1

Hazardous materials RoHS compliant

Flammability UL94-HB

Enclosure IP20

Electrical Specifications

3

3.5 DC Characteristics

3.5.1 SPISI, SPIClk

Schmitt-trigger Input Min Max Conditions

, Positive-going input threshold voltage 1.6 V 2.0 V

V

+

V-, Negative-going input threshold voltage 0.9 V 1.2 V

VT, Hysteresis V+-V- 0.6 V 1.0 V

, input current ±1 uA Input voltage is 5.5 V or GND

I

IN

3.5.2 SPISO

Min Max Conditions

, output voltage 0 3.3 V

V

O

, Logic 1 output voltage 3.2 V IOH=-100 uA

V

OH

2.4 V I

, Logic 0 output voltage 0.1 V IOL=100 uA

V

OL

0.7 V I

I

, input current when ~SPICS is “1” 10 uA VO = 0 to 3.7 V

OZ

=-16 mA

OH

=16 mA

OL

Atlas® Digital Amplifier Complete Technical Reference 25

Page 26

Electrical Specifications

3

3.5.3 ~SPICS

, Logic 1 input voltage 2 V

V

IH

, Logic 0 input voltage 0.8 V

V

IL

, pull-up current -500 uA

I

IN

3.5.4 ~Enable

Schmitt-trigger input Min Max Conditions

V+, Positive-going input threshold voltage 1.6 V 2.0 V

V-, Negative-going input threshold voltage 0.9 V 1.2 V

VT, Hysteresis V+-V- 0.6 V 1.0 V

3.5.5 FaultOut

Output impedance with Logic 1 output 148 Kohm 152 Kohm I

, Logic 0 output voltage 0.25 V IOL=10 mA

V

OL

Min TYP Max Conditions

Min Max Conditions

=-100 uA

OH

3.5.6 5V

Min Max Conditions

Voltage tolerance, low power units -5% 5% Output current 0-50 mA

Voltage tolerance, medium power units -5% 5% Output current 0-50 mA

Voltage tolerance, high power units -5% 5% Output current 0-100 mA

Short circuit protection Not available

26 Atlas® Digital Amplifier Complete Technical Reference

Page 27

3.6 AC Characteristics

SPISI

SPISO

SPIClk

~SPICS

T1

T3

T2

T5 T6

data is valid

data

must be valid

T8

T4

T9

T7

Electrical Specifications

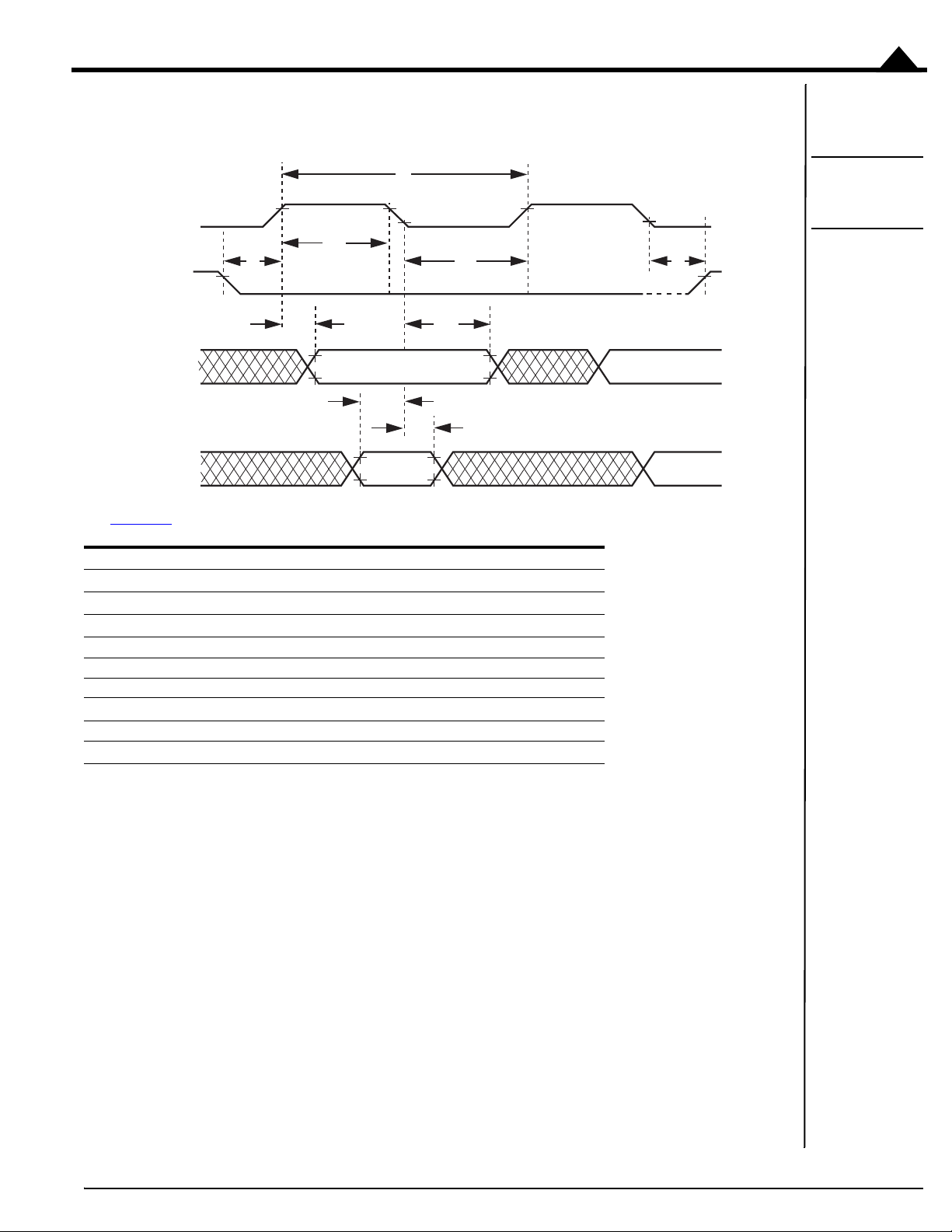

Figure 3-1:

Timing

Diagrams

3

See Figure 3-1

Timing Interval No. Min Max

, SPI clock cycle time T1 125 nsec

T

SPI

Pulse duration, SPIClk high T3 (0.5 T

Pulse duration, SPIClk low T4 (0.5 T

SPIClk high to SPISO valid delay time T5 30 nsec

SPISO date valid time after SPIClk low T6 0 nsec

SPISI setup time before SPIClk low T7 30 nsec

SPISI valid time after SPIClk low T8 (0.5 T

~SPICS low to first SPIClk high T2 400 nsec

Last SPIClk low to ~SPICS high T9 0.5 T

for timing numbers.

-10) nsec

SPI

-10) nsec

SPI

-6) nsec

SPI

SPI

3.7 Pin Descriptions and Pinouts

Atlas units regardless of package size or mounting configuration provide a common set of signals and functions

All

however the pin addresses and number of pins for various functions are different between the ultra compact Atlas

units and the compact Atlas units. In addition, the pin addresses are different between the horizontal and vertical

mounting configurations for each package size.

The following sections provide detailed pinouts for the two Atlas packages; ultra compact and compact, and the two

mounting configuration; horizontal and vertical.

All Atlas unit pins are 0.1 inch spacing and 0.025inch pin width.

Atlas® Digital Amplifier Complete Technical Reference

27

Page 28

Electrical Specifications

18

16

14 12

10

8 6

4

17

15

13 119 7 5

3

1

6 5 4321

17 15 13 11 9 7

18 16 14 12 10 8

3

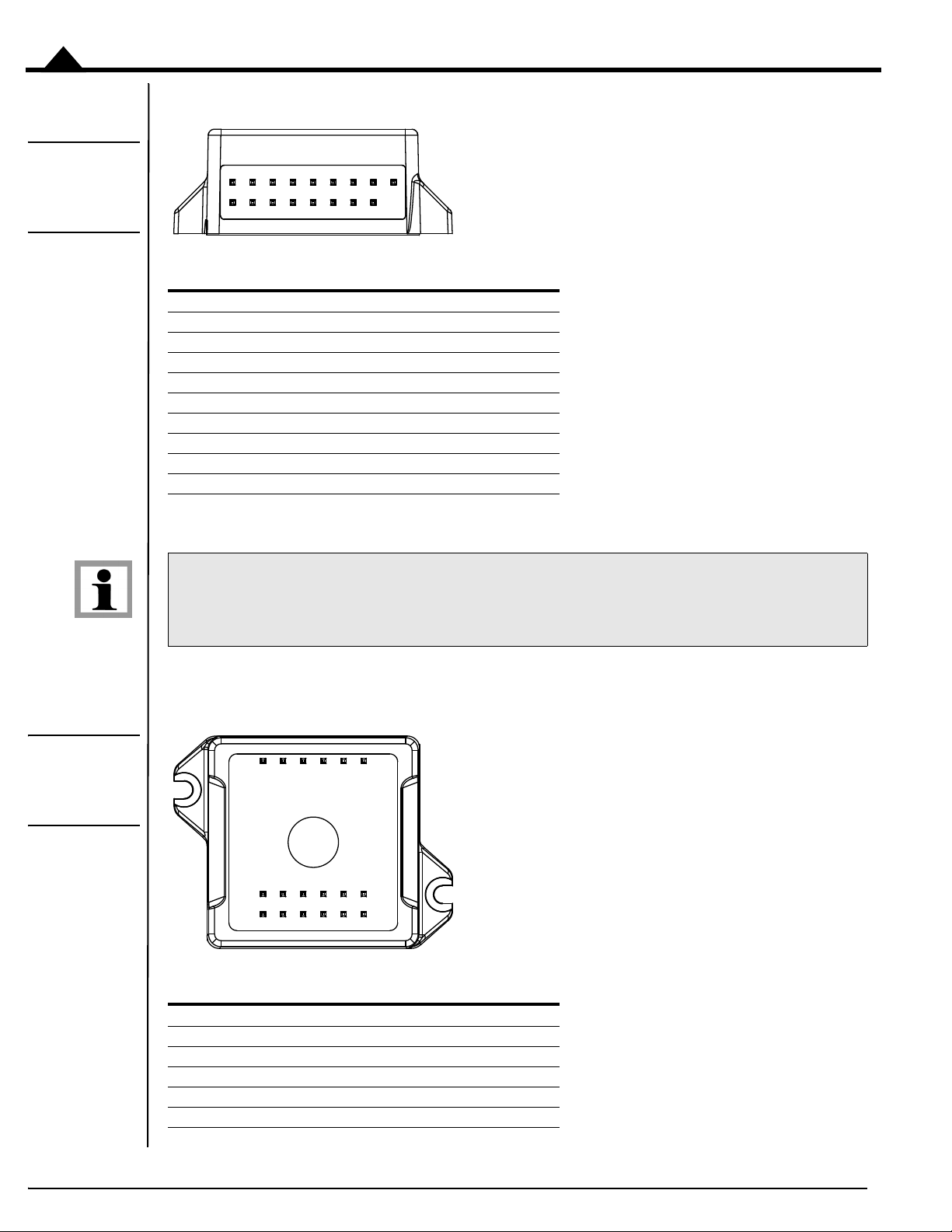

Figure 3-2:

Atlas Pinouts Ultra Compact,

Vertical

3.7.1 Atlas Pinouts - Ultra Compact, Vertical

Pin Name Pin Name

1HV 2

3Motor A 4Pwr_Gnd

5Motor C 6Motor B

7 Motor D 8 NC (No Connect)

9 NC (No Connect) 10 NC (No Connect)

11 ~Enable 12 FaultOut

13 GND 14 5V

15 SPISO 16 ~SPICS/AtRest

17 SPIClk/Pulse 18 SPISI/Direction

Figure 3-3:

Atlas Pinouts Ultra Compact,

Horizontal

The ultra compact Atlas vertical package is keyed so that it is installation direction dependent. It has no physical

pin installed at the Pin #2 location.

3.7.2 Atlas Pinouts - Ultra Compact, Horizontal

Pin Name Pin Name

1 Motor D 2 Motor C

3 Motor B 4 Motor A

5HV 6 Pwr_Gnd

7 SPISI/Direction 8 SPIClk/Pulse

9 SPISO 10 ~SPICS/AtRest

28 Atlas® Digital Amplifier Complete Technical Reference

Page 29

11 5V 12 GND

19

17 15

13 11 9 7 5 3 1

20

18

16 14

12 10 8 6

4

2

12

10 8

6

4 2

22 21 20 19

18

17 16 15 14 13

11

9

7 5

3

1

13 FaultOut 14 ~Enable

15 GND 16 NC (no connect)

17 NC (no connect) 18 NC (no connect)

3.7.3 Atlas Pinouts - Compact, Vertical

Pin Name Pin Name

1 Pwr_Gnd 2 Pwr_Gnd

3HV 4 HV

5 Motor A 6 Motor A

7 Motor B 8 Motor B

9 Motor C 10 Motor C

11 Motor D 12 Motor D

13 ~Enable 14 FaultOut

15 5V 16 GND

17 ~SPICS/AtRest 18 SPISI/Direction

19 SPIClk/Pulse 20 SPISO

Electrical Specifications

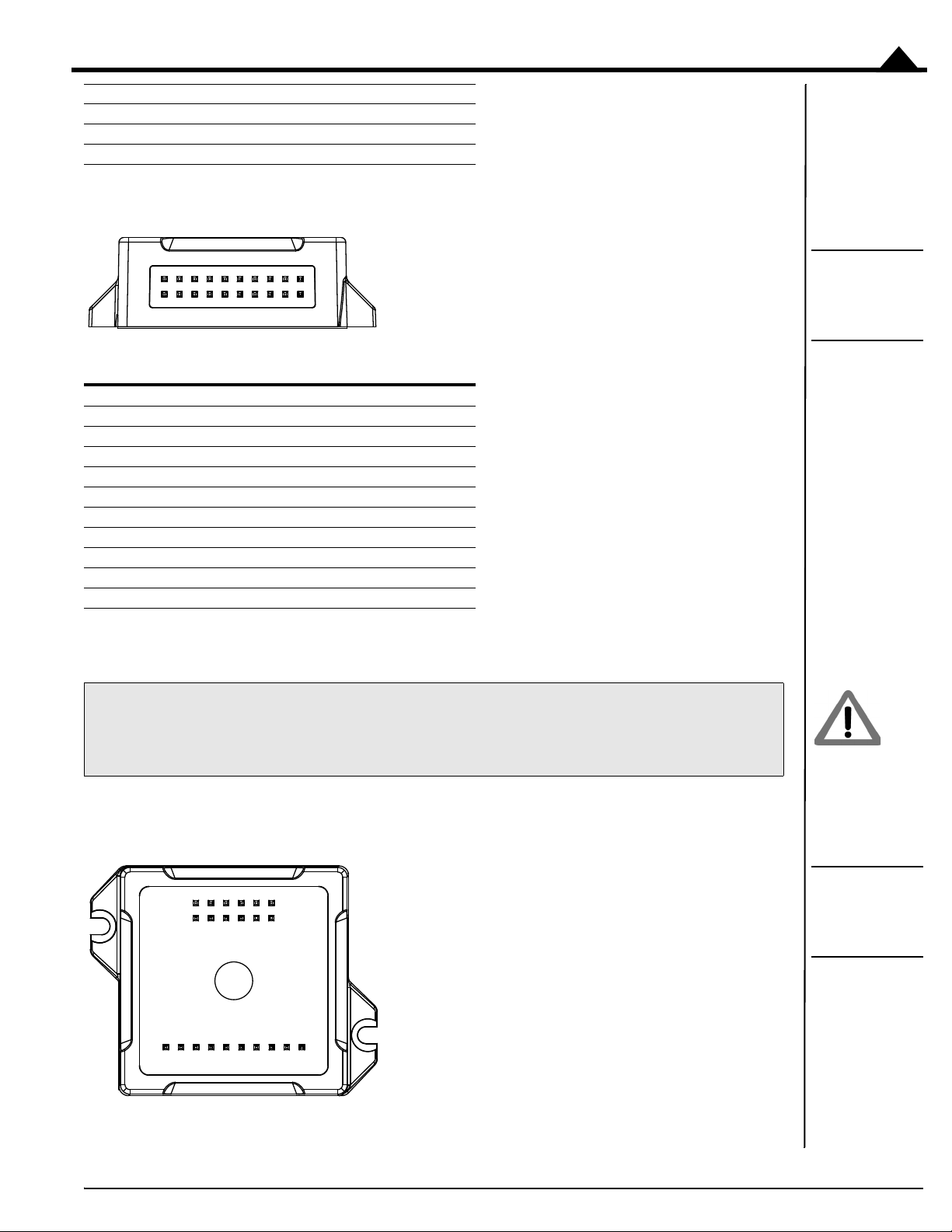

Figure 3-4:

Atlas Pinouts Compact,

Vertical

3

The compact Atlas package provides additional power output via doubling of the HV, Pwr_Gnd, and Motor output

pins. To achieve the rated unit power output be sure that both pins are connected.

The compact Atlas vertical package is not keyed and therefore care should be taken to install in the correct orientation.

3.7.4 Atlas Pinouts - Compact, Horizontal

Figure 3-5:

Atlas Pinouts Compact,

Horizontal

Atlas® Digital Amplifier Complete Technical Reference 29

Page 30

Electrical Specifications

3

Pin Name Pin Name

1 Motor D 2 Motor D

3 Motor C 4 Motor C

5 Motor B 6 Motor B

7 Motor A 8 Motor A

9HV 10 HV

11 Pwr_Gnd 12 Pwr_Gnd

13 5V 14 GND

15 ~Enable 16 FaultOut

17 GND 18 ~SPICS/AtRest

19 SPISO 20 SPISI/Direction

21 SPIClk/Pulse 22 GND

The compact Atlas package provides additional power output via doubling of the HV, Pwr_Gnd, and Motor output

pins. To achieve the rated unit power output be sure that both pins are connected.

3.7.5 Pin Descriptions

Pin Name Direction Description

HV DC power to Atlas module, referenced to Pwr_Gnd. The DC power source

Pwr_Gnd Power return for HV, Motor A, Motor B, Motor C and Motor D. For the compact

Motor A Motor output pin A. Used with Brushless DC, DC Brush, and Step Motors. For the

Motor B Motor output pin B. Used with Brushless DC, DC Brush, and Step Motors. For the

Motor C Motor output pin C. Used with Brushless DC, and Step Motors. For the compact

Motor D Motor output pin D. Used with Step Motors. For the compact Atlas package two

~Enable Input ~Enable is an active-low input. Should be tied or driven low for Atlas motor output

FaultOut Output FaultOut is high impedance when active. It provides programmable fault indication,

SPIClk/Pulse Input SPI input clock or Pulse signal.

SPISO Output SPI data master in slave out signal. It goes to high impedance when ~SPICS is high.

should be a transformer isolated power supply. For the compact Atlas package two

pins carry this signal, so care should be taken to connect both pins.

Atlas package two pins carry this signal, so care should be taken to connect both

pins. For greatest EMI protection double shielded cables on the motor winding A,

B, C, and D should be used with the inner shield connected to Pwr_Gnd and the

outer shield connected to chassis ground.

compact Atlas package two pins carry this signal, so care should be taken to connect both pins.

compact Atlas package two pins carry this signal, so care should be taken to connect both pins.

Atlas package two pins carry this signal, so care should be taken to connect both

pins.

pins carry this signal, so care should be taken to connect both pins.

to be active.

and is low when inactive.

Pulse is used when Atlas is set to pulse & direction signal mode, and causes a position change command upon a high to low transition. Selection of signal interpretation for this pin is via the SPI communications bus. The default signal interpretation

is SPIClk.

This pin is not used if Atlas is operating in pulse & direction signal mode.

30

Page 31

Electrical Specifications

Pin Name Direction Description

SPISI/Direction Input SPI data master out slave in signal or Direction signal.

Direction is used when Atlas is set to pulse & direction signal mode, and indicates

the step direction. Low means the position decreases upon a high to low transition

of the Pulse signal, and high means the position increases. Selection of signal interpretation for this pin is via the SPI communications bus. The default signal interpretation is SPISI.

~SPICS/AtRest Input ~SPICS signal or AtRest signal.

~SPICS enables SPI communication when transitioning low. The SPI block is disabled when ~SPICS is high.

AtRest is used when Atlas is set to pulse & direction signal mode, and indicates that

the step motor holding current should be used rather than the drive current.

Selection of signal interpretation for this pin is via the SPI communications bus. The

default signal interpretation is ~SPICS.

GND Ground return for ~Enable, FaultOut, SPI or pulse & direction signals and 5V.

5V 5V output used to drive external circuitry.

3

Atlas® Digital Amplifier Complete Technical Reference 31

Page 32

3

5V 5V

22k

5.6n

~Enable

10k

FaultOut

150k

5V

Q1

Figure 3-6:

Signal

Interfacing

~Enable

Electrical Specifications

3.8 Signal Interfacing

3.8.1 ~Enable

~Enable and FaultOut signals are typically used to implement a safety interlock between the Atlas module and other

portions of the system.

~Enable is an active low input that must be tied or driven low for the Atlas power output to be active. Its input buffer

is shown in Figure 3-6

thresholds. It has a pull-up to 5V to allow direct interfacing to open collector enable sources without external pull-up

resistor and a 1.3kHz R-C low-pass filter to reject noise.

. The circuit accepts signals in the range of 0-24V and has TTL compatible, Schmidt trigger

Figure 3-7:

Signal

Interfacing

FaultOut

3.8.2 FaultOut

FaultOut is asserted high when a fault occurs. The external controller can select which fault conditions drive the

FaultOut signal.

An Atlas FaultOut output circuit is shown in diagram Figure 3-7

low. It has a 150kohm pull-up resistor to 5V. Its voltage range is 0 to 24V.

. This circuit can continuously sink 50mA when pulled

32 Atlas® Digital Amplifier Complete Technical Reference

Page 33

3.9 Connection Overview

Enable FaultOut

Motor A

Motor B

Motor C

Optional Hall Sensors

Atlas

®

Digital

Amplifier

3 - Phase

Brushless

DC Motor

External

Controller

Optional

Optional Encoder Feedback

Hall & Encoder

SPI

SPICS

SPIClk

SPISI

SPISO

Pwr_Gnd

HV

3.9.1 Brushless DC Motors

Electrical Specifications

Figure 3-8:

Brushless DC

Connections

3

The following table summarizes the recommended connections when connecting Atlas amplifiers to brushless DC

motors

Optional

Type Required Connections

Connections

Power HV, Pwr_Gnd

Communication ~SPICS, SPISO, SPISI, SPIClk, GND

Motor Motor A, Motor B, Motor C

Miscellaneous ~Enable FaultOut

If Atlas is used as part of a higher level position controller, as shown in the Figure 3-8

, the Brushless DC motor

provides feedback signals to the external controller. Commonly, both Hall sensor signals and a position encoder are

used, but only one or the other is needed in a minimal configuration. In this configuration the external controller

generally consists of a PMD Magellan Motion Processor or a programmable microprocessor or DSP-type device.

Alternatively, Atlas can be operated by an external controller as a standalone device, driving the motor at commanded

voltage or torque levels and not part of a higher-level servo controller. In this configuration, the external controller

can be either a microprocessor-type device, or a logic device such as an FPGA (field programmable gate array).

Atlas functions as a power block providing amplification, current control, and safety management of the amplifier and

motor. Atlas does not directly accept Hall signals or encoder signals, so to operate with a brushless DC motor the

motor's current phase angle must be provided by the external controller through the SPI interface.

The Atlas does not support direct Hall signal inputs. To operate the Atlas with a Brushless DC motor, continuous

motor phase angle is provided by the external controller, via either Hall inputs or an encoder.

Atlas® Digital Amplifier Complete Technical Reference 33

Page 34

Electrical Specifications

Enable FaultOut

Optional Encoder Feedback

Encoder

Atlas

®

Digital

Amplifier

DC Brush

Motor

External

Controller

SPI

SPICS

SPIClk

SPISI

SPISO

Optional

Pwr_Gnd

HV

Motor A

Motor B

3

Figure 3-9:

DC Brush

Connections

3.9.2 DC Brush Motors

The following table summarizes the recommended connections when connecting Atlas amplifiers to DC Brush

motors.

Optional

Type Required Connections

Power HV, Pwr_Gnd

Communication ~SPICS, SPISO, SPISI, SPIClk, GND

Motor Motor A, Motor B

Miscellaneous ~Enable FaultOut

Connections

If Atlas is used as part of a higher level servo controller, as shown in Figure 3-9

, an encoder provides position or

velocity feedback signals to the external controller. In this configuration the external controller generally consists of a

PMD Magellan Motion Processor or a programmable microprocessor or DSP-type device.

Alternatively, Atlas can be operated by an external controller as a standalone device, driving the motor at commanded

voltage or torque levels. In this configuration the external controller can be either a microprocessor-type device, or a

logic device such as an FPGA (field programmable gate array).

34 Atlas® Digital Amplifier Complete Technical Reference

Page 35

Electrical Specifications

Enable

Pwr_Gnd

FaultOut

Optional Encoder Feedback

Encoder

Atlas

®

Digital

Amplier

2 - Phase

Step

Motor

External

Controller

Pulse

Direction

AtRest

Motor A

Motor B

Motor C

Motor D

HV

3.9.3 Step Motors in Pulse & Direction Signal Mode

The following table summarizes the recommended connections when connecting Atlas amplifiers to two-phase step

motors when using the pulse & direction signal mode. In this mode the external controller provides position

commands to Atlas via pulse and direction signals.

3

Figure 3-10:

Step Motor

Pulse and

Direction Mode

Connections

Optional

Type Required Connections

Connections

Power HV, Pwr_Gnd

Communication Pulse, Direction, GND AtRest

Motor, Phase A

Motor, Phase A

Motor, Phase B+:

Motor, Phase B-:

+

:

-

Motor A

Motor B

Motor C

Motor D

Miscellaneous ~Enable FaultOut

These connections apply to bipolar motors. If connecting to unipolar motors do not connect the center tap.

In this configuration the external controller generally consists of an off-the-shelf motion control card or module, a

programmable microprocessor or DSP-type device, or a FPGA (field programmable gate array). The external

controller provides a continuous stream of pulse and direction commands, along with (optionally) an

AtRest signal to

control the torque.

To initially set up and store its application-specific configuration parameters, Atlas is programmed using the SPI

interface and then commanded to convert to pulse & direction signal mode.

FaultOut signal input to external controller is strongly recommended when the Atlas is used in Pulse & Direction signal

mode.

Atlas® Digital Amplifier Complete Technical Reference 35

Page 36

Electrical Specifications

Enable FaultOut

Optional Encoder Feedback

Encoder

Atlas

®

Digital

Amplifier

2 - Phase

Step

Motor

External

Controller

SPI

SPICS

SPIClk

SPISI

SPISO

Optional

Motor C

Motor D

Pwr_Gnd

HV

Motor A

Motor B

3

Figure 3-11:

Step Motor

SPI Communication Connections

3.9.4 Step Motors Using SPI Communications

The following table summarizes the recommended connections when connecting Atlas amplifiers to two-phase step

motors when using the SPI communications channel. In this mode the external controller provides position

commands to Atlas via the SPI interface.

Optional Signal

Type Required Signal Connections

Connections

Power HV, Pwr_Gnd

Communication ~SPICS, SPISO, SPISI, SPIClk, GND

Motor, Phase A

Motor, Phase A

Motor, Phase B+:

Motor, Phase B

+

-

-

:

Motor A

:

Motor B

Motor C

Motor D

Miscellaneous ~Enable FaultOut

These connections apply to bipolar motors. If connecting to unipolar motors do not connect the center tap.

In this configuration the external controller generally consists of a PMD Magellan Motion Processor, a programmable

microprocessor or DSP-type device, or a FPGA (field programmable gate array). The external controller provides a

continuous stream of position commands or individual phase torque output commands to control the motor position.

3.10 Heat Sink Grounding

The heat sink may be left ungrounded or may be connected to chassis ground for best EMI protection. The heat sink

should not be connected to the Atlas Pwr_Gnd.

3.11 Atlas Conversion Factors

The following table provides electrical conversion factors for the various Atlas units. These factors convert Atlas

command values specified via the Atlas unit's digital SPI interface (referred to as counts) to physical quantities such

as amperage or volts, and vice versa. For more information on the Atlas functions related to these conversion factors

see Chapter 4,

36 Atlas® Digital Amplifier Complete Technical Reference

Operation.

Page 37

Electrical Specifications

3

Unit

All Low Power

Atlas

All Medium

Power Atlas

All High Power

Atlas Example Usage

Amps .231 mA/count .763 mA/count 1.526 mA/count To command a torque of 3.5A

to the high power Atlas a value

of 3,500mA/1.526mA/count =

2,294 counts is specified.

Volts 1.361 mV/count 1.361 mV/count 1.361 mV/count A command request to read the

Atlas unit’s DC Bus voltage gives

a value of 12,345. This corresponds to a voltage of 12,345

counts * 1.361 mV/count = 16.8

volts.

Temperature .0039°C/count

.0039°C/count

.0039°C/count A command request to read the

Atlas unit’s internal temperature

gives a value of 7,890. This corresponds to a temperature of

7,890 counts * .0039°C/count =

30.8°C.

Foldback Energy

.0059 A

2

sec/count .064 A2sec/count .256 A2sec/count

To command a foldback energy

2

sec to the high power

of 50A

Atlas a value of 50A

2

sec/.256

A2sec/count = 195 counts is

specified.

3.11.1 Atlas Settings Defaults and Limits

The following table provides default and limit values for all Atlas units.

All Low

Quantity

Power Atlas

Overtemperature

Overtemperature Limit Default: 75.0°C Default: 75.0°C Default: 75.0°C

Low Limit: 0 Low Limit: 0 Low Limit: 0

High Limit: 75.0°C High Limit: 75.0°C High Limit: 75.0°C

Overtemperature Hysteresis Default: 5.0°C Default: 5.0°C Default: 5.0°C

Low Limit: 0 Low Limit: 0 Low Limit: 0

High Limit: 25.0°C High Limit: 25.0°C High Limit: 25.0°C

Voltage

Overvoltage Limit Default: 52.0 V Default: 52.0 V Default: 60.0 V

Low Limit: 10.0 V Low Limit: 10.0 V Low Limit: 10.0 V

High Limit: 52.0 V High Limit: 52.0 V High Limit: 60.0 V

Undervoltage Limit Default: 10.0 V Default: 10.0 V Default: 10.0 V

Low Limit: 10.0 V Low Limit: 10.0 V Low Limit: 10.0 V

High Limit: 48.0 V High Limit: 48.0 V High Limit: 56.0 V

All Medium

Power Atlas

All High

Power Atlas

Atlas® Digital Amplifier Complete Technical Reference 37

Page 38

Electrical Specifications

3

Quantity

All Low

Power Atlas

All Medium

Power Atlas

All High

Power Atlas

Current Foldback

Continuous Current Limit, Default: 2.12 A Default: 7.07 A Default: 14.1 A

Brushless DC Motor Low Limit: 0.0 A Low Limit: 0.0 A Low Limit: 0.0 A

High Limit: 2.12 A High Limit: 7.07 A High Limit: 14.1 A

Continuous Current Limit, DC Default: 1.50 A Default: 7.00 A Default: 14.0 A

Brush Motor Low Limit: 0.0 A Low Limit: 0.0 A Low Limit: 0.0 A

High Limit: 1.50 A High Limit: 7.00 A High Limit: 14.0 A

Continuous Current Limit, Step Default: 2.12 A Default: 6.36 A Default: 12.7 A

Motor Low Limit: 0.0 A Low Limit: 0.0 A Low Limit: 0.0 A

High Limit: 2.12 A High Limit: 6.36 A High Limit: 12.7 A

2

2

2

2

sec

sec

sec

sec

Default:

Low Limit:

High Limit:

Default:

Low Limit:

High Limit:

Default:

Low Limit:

High Limit:

31.9 A2sec

0.0 A2sec

31.9 A2sec

32.2 A2sec

0.0 A2sec

32.2 A2sec

34.7 A2sec

0.0 A2sec

34.7 A2sec

Energy Limit, Brushless DC Default:

Motor Low Limit:

High Limit:

Energy Limit, DC Brush Motor Default:

Low Limit:

High Limit:

Energy Limit, Step Motor Default:

Low Limit:

High Limit:

2.95 A

0.0 A2sec

2.95 A2sec

3.63 A

0.0 A2sec

3.63 A

2.95 A

0.0 A2sec

2.95 A2sec

For more information on Atlas overtemperature safety functions see Section4.8.2, "

Default:

Low Limit:

High Limit:

Default:

Low Limit:

High Limit:

Default:

Low Limit:

High Limit:

127.5 A2sec

0.0 A2sec

127.5A2sec

128.7 A2sec

0.0 A2sec

128.7 A2sec

138.9 A2sec

0.0 A2sec

138.9 A2sec

Overtemperature Fault."

For more information on Atlas overvoltage and undervoltage safety functions see Section4.8.4, "Undervoltage Fault."

For more information on Atlas Current Foldback safety functions see Section4.8.9, "Current Foldback."