Page 1

In-wall

loudspeaker

User-Guide

Serial No

Builder

wafer1-iw

™

wafer2-iw

™

Page 2

Product Support

For product support, accessories or servicing advice, please contact a

PMC authorised distributor. See www.pmc-speakers.com.

Guarantee Certificate

Please take a few moments to complete the warranty card at the back of this booklet

or register at www.pmcloudspeaker.com/guarantee. It records the purchase and

provides you, the customer, an opportunity to make suggestions and provide feedback

directly to PMC.

Company Details

PMC LIMITED

43-45 CRAWLEY GREEN ROAD LUTON LU2 0AA UK

T +44 00 (0)870 4441044 F +44 00 (0)870 4441045

email sales@promonitor.co.uk web www.pmc-speakers.com

PMC USA LLC

17932 SKY PARK CIRCLE DR., SUITE A IRVINE, CA 92614

T 949-861-3350 F 949-861-3352

email sales@pmc-speakers.us web www.pmc-speakers.com

' 2006 PMC. All rights reserved.

This document should not be construed as a commitment on the part of PMC.

The information it contains is subject to change without notice. PMC assumes no responsibility for errors that may appear within this document.

CE Conformity PMC passive loudspeakers conform to CE Directive LVD 73/23/EEC and EMC 89/336/EEC

Page 3

Contents

Introduction

The ATLTMApproach

Our Attention to Detail

General Guidelines

Unpacking

wafer-iw

TM

installation examples

wafer-iwTMcontrol - High frequency adjustment

wafer-iwTMControl - TT T echnology

TM

UsingTT T echnology

TM

StealthBaffle

TM

& H-Line ATL

TM

Wall/Ceiling installation of the wafer-iw

TM

wafer-iw

TM

in-ceiling Installation (cont.)

wafer-iw

TM

in-ceiling Installation examples

wafer-iw

TM

in-ceiling Installation examples (cont.)

Connections

Service

Specification Table

Specification diagrams

Suggested Associate Loudspeakers

Inspection Certificate

GUARANTEE CERTIFICATE - Part 1

GUARANTEE CERTIFICATE - Part 2

Help us improve

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

Loudspeaker User-Guide

Page 4

wafer-iw

™

Loudspeaker User-Guide

4

Introduction

The wafer™series of in & on-wall loudspeakers are a true breakthrough and encompass

PMC s award-winning professional monitoring heritage in a slim and elegant design,

ideally suited to match modern d cor and lifestyles.

PMC products are to be found in every demanding environment, from broadcast and

major film scoring to CD and DVD mastering. No other manufacturer can rival the

accumulated technical knowledge and high level of engineering excellence PMC has

developed over many years at the peak of professional monitoring. This expertise has

been encapsulated in the development and production of the PMC consumer range.

The wafer

™

series is ideal for stereo or all channels of a surround system. The wafer™has

been engineered with an identical tonal balance and similar dispersion characteristics

to all PMC models, thereby any combination will afford seamless integration and a

perfect audio picture. The professionally proven TLE1 active subwoofer can also

partner any of the range to provide the ultimate in low frequency power and

musicality.

See page 22 of this user guide & www.pmc-speakers.com

Closing the loop between the studio and the home

Page 5

The DB1+ ATL

TM

The ATL

TM

Approach

PMC ATL“(Advanced Transmission Line) enclosures have taken loudspeaker design to

the highest level. A PMC transmission line design utilises sophisticated cabinet

construction, proprietary drive units and patented absorption materials and

techniques. The benefits are enormous compared to the relatively simple sealed and

ported models currently available elsewhere.

The main driver is placed at one end of a long tunnel (the transmission line), which is

heavily damped with absorbent acoustic material. This material is specified to absorb

the upper bass and higher frequencies that radiate from the rear of the main driver.

The lowest frequencies, which remain in phase, then emerge from the large vent at

the end of the line, which essentially acts as a second driver. One advantage to this

approach is that the air pressure loading the main driver is maintained, thus controlling

the driver over a wide frequency range, which in turn significantly reduces distortion.

A spin-off from the lack of distortion is that the upper bass and midrange is not masked

by harmonic distortion residing in the very low frequencies. The result is PMC’s

characteristic transparent midrange and fast, attacking bass notes, all with

outstanding clarity. A further advantage of the transmission line approach is a cabinet

that produces a higher SPL and lower bass extension than a ported or sealed design of

a similar size, even if identical drivers were used. Moreover, as the loading on the main

driver is maintained at all volumes, the frequency response also remains consistent

regardless of listening level. Neither casual late night listening nor prolonged monitoring

sessions have to be conducted at high volumes to achieve maximum bass response,

a characteristic that is especially suited for both the home user and recording

professional alike.

wafer-iw

™

Loudspeaker User-Guide

5

Page 6

wafer-iw

™

Loudspeaker User-Guide

6

Our Attention to Detail

All PMC loudspeakers are hand-built in the U.K. using individual components that are

matched to our reference model; this includes the structural integrity of every cabinet

and the testing and recording of each component. This guarantees it will be within our

strict tolerances and ensures your purchase sounds identical to the original design.

Each completed loudspeaker then undergoes a set of objective and subjective

measurements - frequency response sweeps ensure that the design meets our

exacting performance criteria, and then listening tests are conducted against the

reference model using a wide variety of material, from a benchmark BBC speech test

to classical music, pop and rock.

Page 7

wafer-iw

™

Loudspeaker User-Guide

7

General Usage Guidelines

Read these instructions and keep them in a safe place for further reference.

Heed all electrical safety warnings, including any on the loudspeakers

themselves.

Do not use the loudspeakers near water.

Clean only with a dry, lint-free, cloth.

Do not install near any heat sources such as radiators, ovens or other

equipment that produce excessive heat.

High volume audio signals, however short their duration, have the potential to

cause hearing damage. Use care when setting the system volume level to

ensure playback sound pressure levels remain within comfortable limits.

Refer all servicing to qualified service personnel. Servicing is required when the

apparatus has been damaged in any way or exhibits a distinct or sudden

change of operation or performance.

The wafer

™

series is not magnetically shielded, please ensure that they are

positioned at least 1 metre/3 feet away from items that could be damaged by

stray magnetic fields. Conventional glass tube (CRT) televisions and computer

monitors together with media such as floppy discs, cassettes and videotapes

are particularly susceptible.

PMC has made efforts to provide accurate installation information and good

quality fixings, PMC Ltd / PMC USA LLC cannot be held responsible or liable for

injuries or property damage - direct, indirect or consequential - arising out of

use or inability to use this product safely and properly.

9

8

765

4

3

2

1

Page 8

wafer-iw

™

Loudspeaker User-Guide

8

Unpacking

Please retain your packaging for future use as all PMC cartons are durable,

reusable and can be employed to safely transport your loudspeakers should

they be relocated.

Much of the packing is constructed from recyclable materials, so if you are to

dispose of it please do so in an environmentally friendly manner.

Check list

1 x Printed card positioning template.

1 x Perforated grille. (paintable)

1 x Grille removing hook

1 x Paint/dust mask (Within the grille - remove before operation)

1 x Cabinet including 8 concealed spring lugs and integrated

paintable bezel/frame

Page 9

wafer-iw

™

Loudspeaker User-Guide

9

wafer

™

series installation examples

Mixing and matching any of

the wafer

™

series and PMC s

consumer range creates a

supreme and unbeatable

surround system.

See page 22

wafer1

TM

stereo

wafer1

TM

stereo with 42" plasma

wafer1

TM

Left, Centre, Right

with 42" plasma

wafer1

TM

series installation examples

Optional TLE1 sub

wafer2

TM

stereo wafer2

TM

stereo with 42" plasma wafer2

TM

Left, Right, wafer1

TM

Centre,

with 42" plasma

wafer2

TM

Left, Centre, Right,

with 42" plasma

wafer 2

TM

series installation examples

Optional TLE1 sub

Side view showing waferTMbehind screen

Installation example with

non-perforated projection screen

Installation example with perforated

projection screen

wafer

TM

series installation examples with projection screens

Optional TLE1 sub

Page 10

wafer-iw

™

Loudspeaker User-Guide

10

wafer-iw

™

control

- High frequency adjustment

Fine adjustment for perfect definition.

The wafer-iw

“

sports a three position tweeter level control to ensure a perfect tonal

integration into even the most difficult environment.

FLAT

The FLAT setting is perfect for the majority of installations.

HF-

Rooms with very little soft furnishings, like kitchens, can emphasise the high frequency,

so a reduction may be desirable by moving the switch to the HF- position.

HF+

Conversely a very heavily furnished absorbent room or if the wafer-iw“is placed

behind a perforated projector screen may need a small high frequency boost to

improve definition. Set to the HF+ position.

control

HF +

HF -

FLAT

VERTICAL

BEAM-UP

HORIZONTAL

Select from the

3 switch positions

These are not hard and fast rules, as every

listening environment has its own distinct

acoustic. For the best results listen to the same

recording on each of the HF settings and

adjusting accordingly.

Page 11

wafer-iw

™

Loudspeaker User-Guide

11

wafer-iw™Control - TT Technology

™

Perfect response in either horizontal or vertical placement.

The wafer-iw

“

has a number of innovative features that will further enhance the quality

of sound so it can be sited where it is convenient and most pleasing to the eye.

The first of these is TT Technology

“

. This feature has two distinct benefits; firstly, either

tweeter can be switched to ensure a perfect response in either horizontal or vertical

placement.

control

Shading denotes

functioning drivers

Page 12

wafer-iw

™

Loudspeaker User-Guide

12

control

HF +

HF -

FLAT

VERTICAL

BEAM-UP

HORIZONTAL

Switch in the 'Beam-Up' position

Hi Zone

Lo Zone

Mid Zone

no need for beam up setting

Lo Zone

PMC s TT Technology™also allows for steerable image techniques which utilises

both tweeters to tilt the direction of the sound - a perfect solution if the wafer-iw

“

is placed much higher or lower than the listening position. It can also come into

play in some large environments when ceiling mounted. This mode should be tried

if the prime listening position is in no way directly below the wafer

™

but some 20

feet further forward or behind. Experimentation is best in this circumstance,

as room acoustics will play a large role in the result (see diagram below).

NB This mode will only function when the cabinet is in the correct horizontal

position with the wafer-iw

“

controls set as per the diagram above.

Using TT Technology

™

to ensure high performance when

placement is less than ideal.

6 metres

6 metres

6+ metres 6+ metres

Page 13

wafer-iw

™

Loudspeaker User-Guide

13

H-Line ATL

™

The ultra-shallow H-LineTM interior of each

cabinet is divided to create a long chamber,

which is in turn lined with special acoustic

materials. The result is an expansive, dynamic

soundstage, with the type of deep bass one

would only expect from a speaker many

times the size.

StealthBaffle

™

Standard in-wall and on-wall designs are

compromised by the large surface area of

their front baffle that surrounds the drive units.

This detrimental effect is best compared with

cupping your hands around your mouth whilst

speaking. PMC s acoustic specialists have

developed a unique, structured, absorbent

surface that prevents these unwanted

characteristic sound waves being reflected.

The drive units behave as though in free space

and concentrate pure, untainted audio

directly into the listening space.

StealthBaffle

™

Page 14

14

wafer-iw

™

Loudspeaker User-Guide

Safety instructions

Instructions detailed in this manual assumes the installer has the required skill and

knowledge of the tools, local building and fire regulations and is aware of the

environment within which the speakers will be installed. If in doubt, consult a

qualified professional.

Before attempting to make the wall cut-out by using the enclosed template, ensure

your actions do not detrimentally affect the structural integrity of the building nor disrupt

any hidden services or other installations. E.g. power, pipe work, air conditioning, signal

cable etc.

This wafer

™

may contain nuts.

Before embarking on the installation ensure the kit is complete.

Check list

1 x Printed card positioning template.

1 x Perforated grille. (paintable)

1 x Grille removing hook

1 x Paint/dust mask (Within the grille - remove before operation)

1 x Cabinet including 8 concealed spring lugs and integrated paintable bezel/frame

Ensure correct orientation for optimum performance. (See pages 12,16 &17)

Produce the wall cut-out using the supplied template. (See Safety instructions

before taking action)

Check inside the cavity for obstructions that will impede the spring lugs on the

sides of the cabinet.

Tighten up the spring lug bolts that correspond with the spring lugs intended for

use until they appear fully from rebate in the sides of the cabinet. It is ideal if all 8

can be utilised, but if there is obstructions e.g. studwork etc. The recommended

minimum is 4.

4

3

2

1

Wall/Ceiling installation of the wafer-iw

™

Page 15

wafer-iw

™

Loudspeaker User-Guide

15

Note the wall thickness, and tighten the spring lug bolts so the spring lugs move

close to the position they will remain once the cabinet is secured. This will avoid

aching arms and swearing.

Ensure the unused spring lugs are returned to their rest position and do not

protrude from the cabinet rebate. Failure to do so may result in rattling.

Connect loudspeaker cables (See connections, page No.18)

Install the cabinet through the prepared hole ensuring the cable are safely inside

the cavity. The spring lugs should click into place and temporarily secure the

cabinet from falling out from the opening.

Tighten the appropriate number of spring lug bolts required until the bezel/frame

and cabinet are fully secure.

Make any adjustments to the wafer

™

control switches - Vertical, Horizontal,

HF+, HF- etc

Remove the Dust/paint mask if painting is complete and there is no risk from dust.

Gently press the grille into place.

Removal of the wafer-iw

TM

from the wall

To remove the wafer-iw“from the wall/ceiling. Remove the grille starting from one

edge using the grille removing hook. Slacken all 8 spring lug bolts; this will retract

the lugs into the rebate freeing the cabinet. Do this operation gently.

PMC has made efforts to provide accurate installation information and good quality fixings, PMC Ltd / PMC USA LLC

cannot be held responsible or liable for injuries or property damage - direct, indirect or consequential arising out of use or inability to use this product safely and properly.

12

11

10

9

8

7

6

5

Wall/Ceiling installation of the wafer-iwTM(Cont.)

Page 16

wafer-iw

™

Loudspeaker User-Guide

16

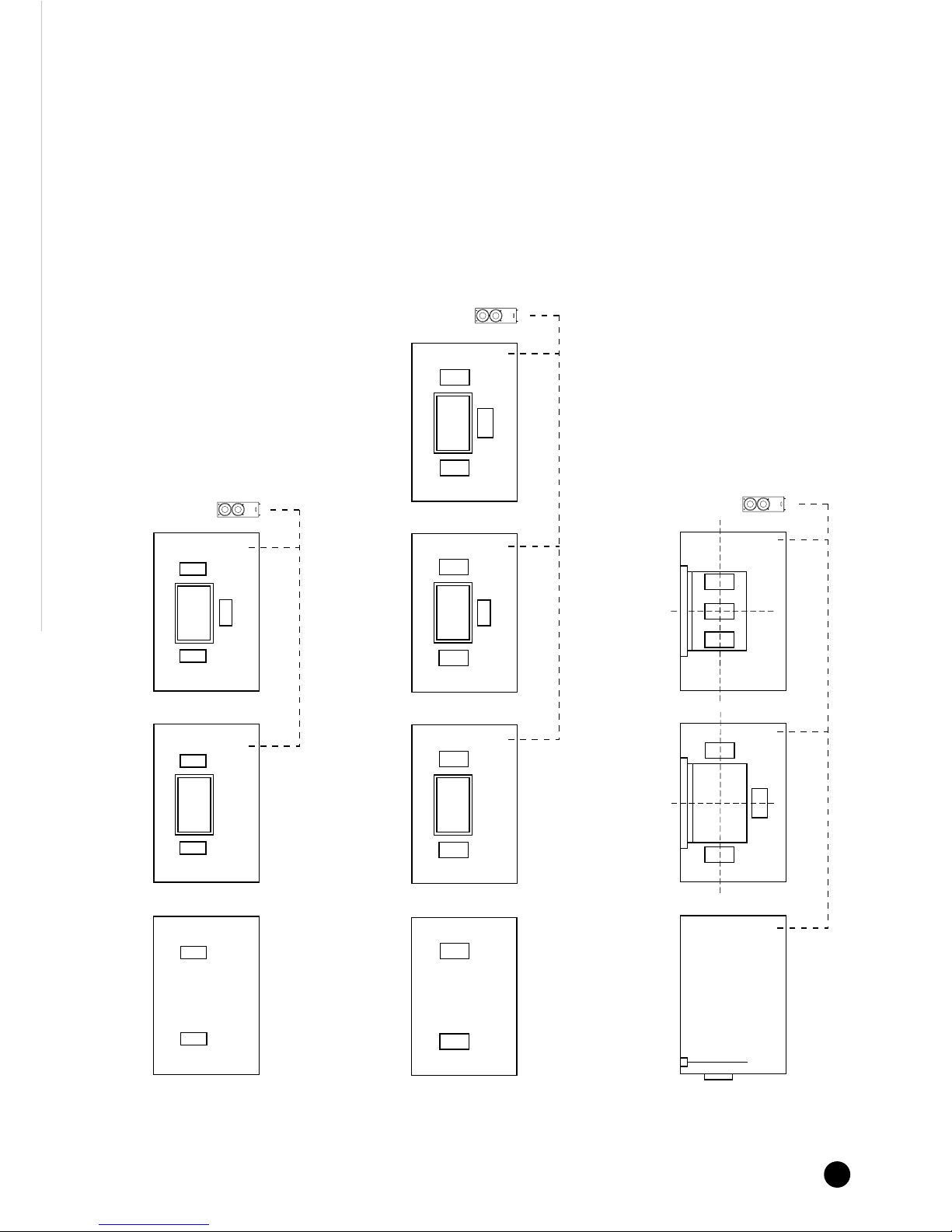

Switch position set to vertical

Shading denotes

functioning drivers

Beams/Joists

wafer-iw

™

in-ceiling Installation examples

Depending on the direction of the woodwork e.g. beams or joists that form the ceiling

structure, it will be necessary to orientate the wafer-iw

“

in the following manor to

ensure the highest quality response.

These diagrams are a view from the floor looking directly up at the ceiling.

An identical view if you were lying on your back in bed. Not that we are insinuating

you are lazy, but it is a view you will be familiar with.

Page 17

wafer-iw

™

Loudspeaker User-Guide

17

control

Switch position set to horizontal

Shading denotes

functioning drivers

Beams/Joists

NB

If the wafer-iw’s

“

have been installed within the ceiling of a large room or the

listening position is more than 20 feet away; experiment with those distant speakers

using the beam-up function. If the acoustics of the room allow, the image will be

more obvious in this setting.

wafer-iw™in-ceiling Installation examples (Cont.)

Page 18

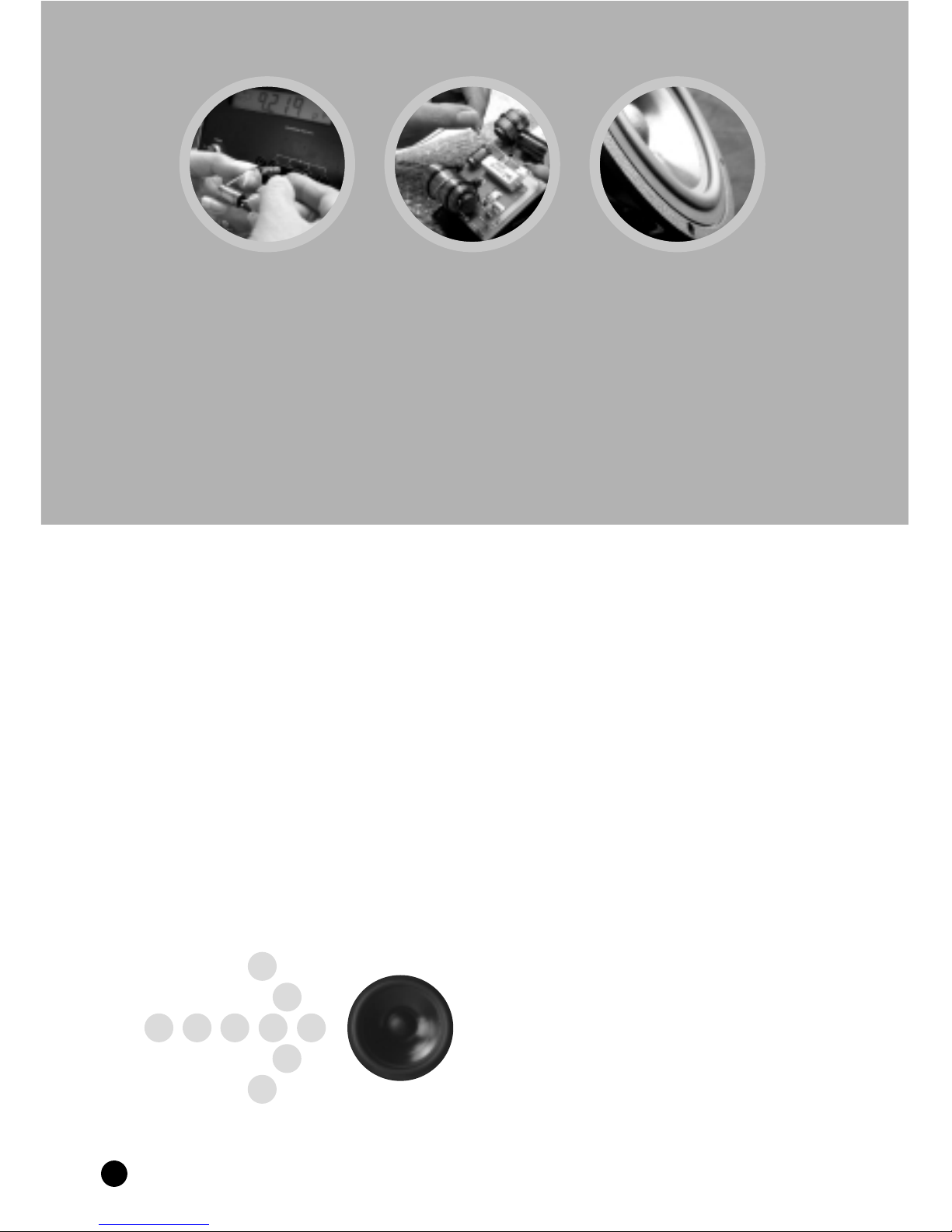

Connections

To avoid potential damage, please ensure that your power amplifier(s) or receiver is

turned off before making or breaking any loudspeaker connections.

When selecting cables for use with your PMC loudspeakers, ensure that their

construction is of a high enough quality to withstand the rigours of everyday use and

comply with local regulations.

Bare, tinned, or 4mm banana plug terminated cable can be accommodated by the

wafer-iw

“

sprung binding posts.

To use the spring terminal function - push the terminal lightly until the two 4.3mm holes

of the inner and outer housings correspond. Place the cable through the hole and

release the terminal. Then test the cable is secure and there is no loose cable strand

protruding that may cause shorting.

It is of vital importance to observe the polarity markings and

maintain positive-to-positive and negative-to-negative

connections from amplifier or receiver to the wafer-iw“.

The wafer-iw

“

terminals are colour-coded to aid in their

identification, positive terminals are red, negative

terminals are black.

Customisation

Both the bezel & grille can be repainted to match the desired interior scheme.

When painting ensure the paint is applied as a thin coat and does not reduce the

pore size of the grille. Failure to do so will inhibit the performance of the wafer-iw

“

.

While painting, or when there is dust in the atmosphere, leave the Paint/Dust mask

in place not forgetting to remove it before operation.

NB: Do not attempt to paint the main cabinet or front baffle of the wafer-iw

“

.

-

+

-

+

wafer™ back panel

wafer-iw

™

Loudspeaker User-Guide

18

Page 19

wafer-iw

™

Loudspeaker User-Guide

19

Service

We are confident that your wafer-iw“loudspeakers will afford many years of troublefree listening of the highest order, but in the unlikely event that one or more requires

repair, our unique manufacturing procedure, wherein the precise value of each

component together with the response of the system as a whole is recorded, will

ensure that any replaced parts will exactly match the performance of those originally

included within each individual loudspeaker.

For any issues that might arise or for advice and service requirements, the primary point

of contact should be your knowledgeable and authorised PMC dealer/distributor.

If you do not have a local representative please see www.pmc-speakers.com and

click on distribution.

Important Note: Please do not return any products to PMC directly without first

contacting our support department and obtaining a Return Authorisation Number.

Page 20

wafer-iw

™

Loudspeaker User-Guide

20

wafer1-iw

™

wafer2-iw

™

Freq response 50Hz-25kHz 40Hz-25kHz

Sensitivity 87dB 1w 1m 90dB 1w 1m

Impedance 8 Ohms 8 Ohms

Drive Units LF 140mm (5.5 inches) LF 170mm (6.5 inches)

HF 2 x 27mm Soft dome HF 2 x 27mm Soft dome

Input connectors 1 pair - Sprung & 4mm sockets 1 pair - Sprung & 4mm sockets

Dimensions H x W x D H x W x D

Cabinet 500 x 235 x 100mm 575 x 355 x 100mm

(19.7 x 9.3 x 4 inches) (22.6 x 14 x 4 inches)

Cabinet with grille 550 x 285 x 107mm 625 x 405 x 107mm

(21.65 x 11.22 x 4.21 inches) (24.61 x 15.94 x 4.21 inches)

Weight 5.5kg (12.1 lbs) 7.1kg (15.62 lbs)

Grille & frame/bezel White, satin, RAL 9016 "

Cabinet colour Black, satin, RAL 9005 "

Suggested cutout Suggested cutout

Specifications

www.pmc-speakers.com

Positioning Template

Cut Out (max.)

Height 504mm - (19.84")

Width 239mm - (9.40")

Cabinet Dimensions

Height 500mm - (19.69")

Width 235mm - (9.25")

Depth 100mm - (3.94")

Spring lug protrudes 25mm/1"

from the cabinet side

Frame Dimensions

Height 550mm - (21.65")

Width 285mm - (11.22")

Spring lug position

protrudes by

25mm/1 inch

239mm - 9.40"

504mm

19.84"

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

50mm

1.97"

50mm

1.97"

www.pmc-speakers.com

Positioning Template

Cut Out (max.)

Height 579mm - (22.80")

Width 359mm - (14,13")

Cabinet Dimensions

Height 575mm - (22.64")

Width 355mm - (13,98")

Depth 100mm - (3.94")

Spring lug protrudes 25mm/1"

from the cabinet side

Frame Dimensions

Height 625mm - (24.61")

Width 405mm - (15.94")

Spring lug position

protrudes by

25mm/1 inch

359mm - 14.13"

579mm

22.80"

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

Spring

lug bolt

50mm

1.97"

50mm

1.97"

Page 21

wafer-iw

™

Loudspeaker User-Guide

21

405mm/19.94"

625mm

24.61"

550mm

21.66"

285mm/11.22"

wafer 1-iw

™

Front

wafer 1-iw

™

Rear

wafer 2-iw

™

Front

wafer 2-iw

™

Rear

120mm/4.72"

140mm/5.51"

235mm/9.25"

81mm

3.19"

142mm

5.59"

500mm

19.69"

50mm

1.97"

50mm

1.97"

50mm

1.97"

142mm

5.59"

81mm

3.19"

167mm/6.57"

187mm/7.36"

355mm/13.98"

575mm

22.64"

50mm

1.97"

100mm

3.94"

96mm

3.78"

Page 22

wafer-iw

™

Loudspeaker User-Guide

22

Suggested Associate Loudspeakers

PMC manufacture a large selection of loudspeakers and sub-woofers to meet a range

of budgets and uses, from compact, audiophile designs to large studio monitors.

The following products make ideal companions to create an unbeatable

surround system.

DB1M-C+

(Magnetically screened

Horizontal centre channel)

TB2M-C+

(Larger, Magnetically

screened Horizontal centre)

TB2+

(Larger, Two way monitor)

DB1+

(Compact two way monitor)

wafer1-iw

™

(Two Way in-wall monitor)

wafer 2-iw

™

(Larger Two way in-wall monitor)

TLE1

(Active Subwoofer)

FB1+

(Two Way, Floorstanding monitor)

GB1

(Compact, Two Way,

Floorstanding monitor)

OB1

(Larger, Three Way

Floorstanding monitor)

wafer 1

™

(Two way on-wall monitor)

wafer 2

™

(Larger, Two way on-wall monitor)

Page 23

wafer-iw

™

Loudspeaker User-Guide

23

Inspection Certificate

Every component that appears in a PMC product is measured, tested, matched and

recorded by hand. This analysis also applies to the final product with the addition of

the ultimate test of the human ear. We simply listen to every product we make to

ensure you receive an identical replica of the reference model.

Enclosure finish

Assembly & Wiring

Driver Installation

Enclosure seal test

Level - Frequency test

Impedance - frequency test

Listening test 1

Listening test 2

Final inspection

Paint/Dust mask included

Grille hook included

User Guide included

all above checked by

Date

Page 24

GUARANTEE CERTIFICATE - Part 1

Your Copy

Please complete and retain this page

Thank you for purchasing a PMC product. Please read all points carefully before sending any

product to PMC Limited.

If a product is returned to us and subsequently is found to have no fault it will be subject to a

minimum testing and labour charge of £50.00 plus an additional £18.00 carriage for its return.

(UK customers only)

Proof of purchase is required for any claim covered by this guarantee.

This product is guaranteed for a period of 5 years from the date of purchase or date of receipt if

received by mail, provided that the bottom section of this form is detached and returned to PMC

within ten days of purchase or receipt. The guarantee covers defects due to faulty materials or

workmanship but does not cover defects arising from accidental damage, misuse or wear and

tear. The guarantee is void if any attempt has been made by persons not authorised by PMC to

dismantle or repair any part of the product.

Should you have a claim under this guarantee, you can either send the product to the address at

the bottom of this form or return it to the dealer from whom the product was purchased.

Please ensure that it is properly packaged as this guarantee does not cover damage in transit.

Please note that the cost of the carriage to PMC is not covered by the guarantee.

Returned products that are defective will be repaired or replaced at the discretion of PMC

and returned free of charge.

Please allow 14 working days for return of guarantee repairs.

This guarantee does not effect your consumer rights under statutory law.

This guarantee certificate is only valid in the United Kingdom.

Type of product

Serial Nos

Date of purchase

Dealers Name

Address

Town

County

Postcode

Dealers Telephone No

PMC LIMITED 43-45 Crawley Green Road Luton LU2 0AA UK T +44 (0) 870 4441044 F +44 (0) 870 4441045

wafer-iw

™

Loudspeaker User-Guide

24

Page 25

wafer-iw

™

Loudspeaker User-Guide

25

Help us improve

our products

see over

GUARANTEE CERTIFICATE - Part 2

Our Copy

Please complete and return this section -

or complete the on-line version at www.pmcloudspeaker.com/guarantee

Product

Serial Nos

Date of purchase

Your name

Address

Town

County

Zip/Postcode

Dealers Name

PMC Limited 43-45 Crawley Green Road Luton UK LU2 0AA

T (0)870 4441044 F (0)870 4441045

Page 26

wafer-iw

™

Loudspeaker User-Guide

26

We value all our client s comments. Please take a moment to help us improve:

If there is one thing we should change, what would it be?

Is there a product/finish missing from our range? If so, what would it be?

If you wish to write your very own review of your PMC product, please attach it with the

guarantee certificate - CD/Floppy/Hard copy. We will include as many as we can on our

website page - Clients Reviews. See www.pmc-speakers.com

Many thanks

Help us Improve - Your Comments

Page 27

notes

Page 28

PMC LIMITED

43-45 CRAWLEY GREEN ROAD LUTON LU2 0AA UK

T +44 00 (0)870 4441044 F +44 00 (0)870 4441045

email sales@promonitor.co.uk web www.pmc-speakers.com

PMC USA LLC

17932 SKY PARK CIRCLE DR., SUITE A IRVINE, CA 92614

T 949-861-3350 F 949-861-3352

email sales@pmc-speakers.us web www.pmc-speakers.com

Loading...

Loading...