Page 1

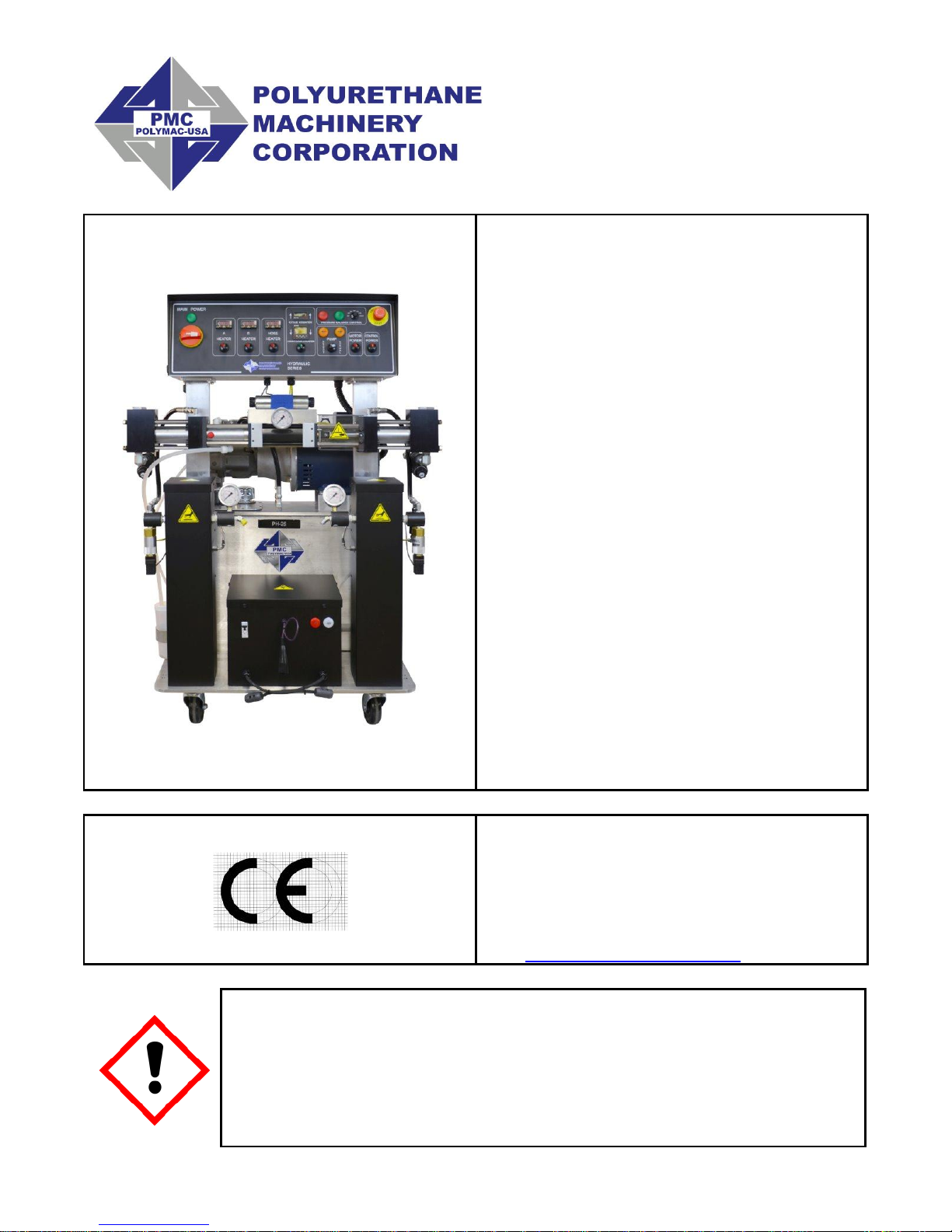

Classic

PH/PHX-25

PH/PHX-40

Proportioners

Hydraulic, Heated, Plural Component

Proportioner

For spraying Polyurethane Foam and

Coatings

For Professional Use Only

Not approved for use in explosive

atmosphere locations

Service Manual

Ref. # MN-04014

Revision 3.3

September 23, 2016

Polyurethane Machinery Corp.

Corporate: 1 Komo Dr, Lakewood, NJ 08701

Manufacturing: 2 Komo Dr, Lakewood, NJ 08701

Phone: 732-415-4400

Fax: 732-364-4025

URL: http://www.polymac-usa.com

Before installing the PH Series Proportioner and start-up, carefully

read all the technical and safety documentation included in this

manual. Pay special attention to the information in order to know and

understand the operation and the conditions of use of the PH Series

Proportioner. All of the information is aimed at improving user safety

and avoiding possible breakdowns from the incorrect use of the PH

Series Proportioner.

Page 2

TABLE OF CONTENTS

WARRANTY ............................................................................................................................ 1

SAFETY AND HANDLING ...................................................................................................... 3

CHARACTERISTICS .............................................................................................................. 5

PRINCIPAL HEATING SYSTEM ......................................................................................... 5

HOSE HEATING SYSTEM .................................................................................................. 5

DOUBLE ACTING OPPOSED PISTON METERING PUMPS ............................................. 5

PRESSURE BALANCE CONTROL SYSTEM ..................................................................... 6

PH(X)-25 TECHNICAL SPECIFICATIONS ............................................................................. 7

ELECTRICAL ....................................................................................................................... 7

MECHANICAL ..................................................................................................................... 7

PH(X)-40 TECHNICAL SPECIFICATIONS ............................................................................. 8

ELECTRICAL ....................................................................................................................... 8

MECHANICAL ..................................................................................................................... 8

DESCRIPTION ........................................................................................................................ 9

INSTALLATION ................................................................ .................................................... 13

HEATED HOSE INSTALLATION ....................................................................................... 15

TRANSFORMER SETTINGS ............................................................................................ 17

PROPORTIONER PURGING ................................................................................................ 19

PRESSURE BALANCE CONTROL ...................................................................................... 21

OPERATION ...................................................................................................................... 21

DIGITAL TEMPERATURE CONTROLLER .......................................................................... 22

START-UP ............................................................................................................................ 23

SHUT-DOWN ........................................................................................................................ 25

Short Term ......................................................................................................................... 25

Long Term.......................................................................................................................... 25

TROUBLESHOOTING .......................................................................................................... 26

HEATERS .......................................................................................................................... 27

HYDRAULIC DRIVE SYSTEM ........................................................................................... 31

METERING PUMP LINE .................................................................................................... 33

HOSE HEATING ................................................................................................................ 37

Page 3

TABLE OF CONTENTS

PRESSURE BALANCE CONTROL ................................................................................... 41

MAINTENANCE .................................................................................................................... 42

INLET MATERIAL SCREENS ............................................................................................ 43

ISO LUBRICATION SYSTEM ............................................................................................ 44

HYDRAULIC DRIVE SYSTEM ........................................................................................... 45

METERING PUMP LINE .................................................................................................... 46

Pump Base Service .................................................................................................................... 46

Pump Seal Replacement ............................................................................................................ 47

METERING PUMP REMOVAL ................................................................................................... 47

MATERIAL HEATER ......................................................................................................... 48

Thermocouple Replacement ....................................................................................................... 48

Heating Rod ............................................................................................................................... 49

REPLACEMENT KITS .......................................................................................................... 50

HYDRAULIC OIL SPECIFICATIONS ................................................................................... 56

List of Manufacturers: ........................................................................................................ 56

PART IDENTIFICATION ....................................................................................................... 57

PUMPLINE ASSEMBLY .................................................................................................... 57

HYDRAULIC CYLINDER COMPLETE .............................................................................. 58

HYDRAULIC CYLINDER ASSEMBLY ............................................................................... 59

HYDRAULIC SEAL ASSEMBLY ........................................................................................ 60

HYDRAULIC PISTON ASSEMBLY .................................................................................... 61

“R” PUMP ASSEMBLY; SIZE 120 & 80 ............................................................................. 62

“A” PUMP ASSEMBLY; SIZE 120 ...................................................................................... 64

“A” PUMP ASSEMBLY; SIZE 80 ........................................................................................ 66

PISTON ASSEMBLY ......................................................................................................... 68

PUMP BASE ASSEMBLY .................................................................................................. 69

PH(X)-25 HEATER ASSEMBLY ................................ ........................................................ 70

PH(X)-40 HEATER ASSEMBLY ................................ ........................................................ 73

PRESSURE TRANSDUCER ASSEMBLY ......................................................................... 76

TRANSFORMER COVER ASSEMBLY ............................................................................. 77

Y-STRAINER ASSEMBLY ................................................................................................. 79

FRAME/TANK ASSEMBLY ................................................................................................ 80

MOTOR LINE ASSEMBLY ................................................................................................ 82

Page 4

TABLE OF CONTENTS

PH-SERIES PROPORTIONER .......................................................................................... 84

LUBE BOTTLE COMPONENTS ........................................................................................ 87

HOSES .............................................................................................................................. 88

BLEED SYSTEM ............................................................................................................... 89

Page 5

WARRANTY

Polyurethane Machinery Corporation (hereinafter “PMC”) provides this LIMITED WARRANTY

(hereinafter “Warranty”) to the original purchaser (hereinafter “Customer”) covering this

equipment and the original PMC manufactured accessories delivered with the equipment

(hereinafter “Product”) against defects in material or workmanship of the Product (hereinafter

“Defect” or “Defective”) for a period of one (1) year from the date of first purchase as shown on

the original PMC invoice (hereinafter “Warranty Period”).

If during the Warranty Period under normal use, the Product is suspected by Customer to be

Defective in material or workmanship, it is Customer’s responsibility to contact PMC and return

the Product to PMC as directed by PMC, freight prepaid. If PMC determines that the Product is

Defective and that such Defect is covered by this Warranty, PMC will credit Customer for the

reasonable freight charges incurred by Customer in returning the Defective Product to PMC,

and PMC (or its authorized agent) will, at PMC’s option, repair or replace the Product, subject to

the following:

Original Invoice: The original invoice must be kept as proof of the date of first sale and the

Product serial number. The Warranty does not cover any Product if the Original Invoice appears

to have been modified or altered, or when the serial number on the Product appears to have

been altered or defaced.

Product Maintenance: It is the Customer’s responsibility to maintain the Product properly. See

your maintenance schedule and owner’s manual for details. The Warranty does not cover an

improperly maintained Product.

Non-PMC Components and Accessories: Non-PMC manufactured components and accessories

that are used in the operation of the Product are not covered by this Warranty. Such

components and accessories shall be subject to the warranty offered to the Customer, if any, by

the original manufacturer of such component or accessory.

Other Warranty Exclusions: The Warranty does not cover any Product that PMC determines has

been damaged or fails to operate properly due to misuse, negligence, abuse, carelessness,

neglect, or accident. By way of example only, this includes:

Normal wear and tear.

Improper or unauthorized installation, repair, alteration, adjustment or modification of the

product.

Use of heating devices, pumping equipment, dispensers, or other parts or accessories

with the product that have not been approved or manufactured by PMC.

Failure to follow the operating instructions and recommendations provided by PMC.

Cosmetic damage.

Fire, flood, “acts of God,” or other contingencies beyond the control of PMC.

1

Page 6

WARRANTY

THE WARRANTY DESCRIBED HEREIN IS THE EXCLUSIVE REMEDY FOR THE

CUSTOMER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED,

STATUTORY OR OTHERWISE, AND THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND ALL

OTHER WARRANTIES ARE HEREBY DISCLAIMED. TO THE FULLEST EXTENT

PERMITTED BY LAW, PMC SHALL NOT BE RESPONSIBLE, WHETHER BASED IN

CONTRACT, TORT (INCLUDING, WITHOUT LIMITATION, NEGLIGENCE),

WARRANTY OR ANY OTHER LEGAL OR EQUITABLE GROUNDS, FOR ANY

CONSEQUENTIAL, INDIRECT, INCIDENTAL, LOST PROFITS, SPECIAL, PUNITIVE

OR EXEMPLARY DAMAGES, WHETHER TO PERSON OR PROPERTY, ARISING

FROM OR RELATING TO THE PRODUCT, EVEN IF PMC HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH LOSSES OR DAMAGES.

Non-Warranty Service by PMC: If PMC determines that the suspected Defect of the Product is

not covered by this Warranty, disposition of the Product will be made pursuant to the terms and

conditions of PMC’s written estimate on a time and materials basis.

Continuing Warranty for Products Repaired or Replaced under Warranty: Following the repair or

replacement of a Product covered by this Warranty, such Product will continue to be subject to

the original Warranty for the remainder of original Warranty Period or for three (3) months from

the repair or replacement date, whichever is longer.

No Rights Implied: Nothing in the sale, lease or rental of any Product by PMC shall be

construed to grant any right, interest or license in or under any patent, trademark, copyright,

trade secret or other proprietary right or material owned by anyone; nor does PMC encourage

the infringement of same.

Exclusive Warranty: This writing is the final, complete, and exclusive expression of the Warranty

covering the Product. Any statements made by PMC, its employees or agents that differ from

the terms of this Warranty shall have no effect. It is expressly understood that Customer’s

acceptance of this Warranty, by performance or otherwise, is upon and subject solely to the

terms and conditions hereof, and any additional or different terms and conditions proposed or

expressed by Customer or anyone, whether in writing or otherwise, are null and void unless

specifically agreed to in writing by an Officer of PMC.

2

Page 7

Before installing the PH Series Proportioner and start-up,

carefully read all the technical and safety documentation

included in this manual. Pay special attention to the

information in order to know and understand the operation and

the conditions of use of the PH Series Proportioner. All of the

information is aimed at improving user safety and avoiding

possible breakdowns from the incorrect use of the PH Series

Proportioner.

SAFETY AND HANDLING

This chapter contains important information on the safety, handling, and use of your

PH Series Proportioner.

Classic

WARNING! Presents information to alert of a situation that

might cause serious injuries if the instructions are not

followed.

CAUTION! Presents information that indicates how to avoid damage

to the equipment or how to avoid a situation that could cause minor

injuries.

NOTE! Is relevant information of a procedure being carried out.

Careful study of this manual will enable the operator to know the characteristics of the PH

Series Proportioner and the operating procedures. By following the instructions and

recommendations contained herein, you will reduce the potential risk of accidents in the

installation, use or maintenance of the PH Series Proportioner; you will provide a better

opportunity for incident-free operation for a longer time, greater output and the possibility of

detecting and resolving problems quickly and simply.

Keep this Operations Manual for future consultation of useful information at all times. If you lose

this manual, ask for a new copy from your PMC Distributor or go online and visit our web site at

www.polymac-usa.com.

The

Classic

polyurea chemical systems, polyurethane foam chemical systems, and some two-component

epoxy systems.

PH Series Proportioner has been designed and built for the application of

3

Page 8

SAFETY AND HANDLING

To prevent possible injury caused by incorrect handling of the raw

materials and solvents used in the process, carefully read the

Material Safety Data Sheet (MSDS) provided by your supplier.

Deal with the waste caused according to current regulations.

To avoid damage caused by the impact of pressurized fluids, do

not open any connection or perform maintenance work on

components subject to pressure until the pressure has been

completely eliminated.

Use suitable protection when operating, maintaining or being

present in the area where the equipment is functioning. This

includes, but is not limited to, the use of protective goggles,

gloves, shoes and safety clothing and breathing equipment.

The equipment includes components that reach high temperatures

and can cause burns. Hot parts of the equipment must not be

handled or touched until they have cooled completely.

To prevent serious injury through crushing or amputation, do not

work with the equipment without the safety guards installed on the

moving parts. Make sure that all the safety guards are correctly

reinstalled at the end of the repair or maintenance work of the

equipment.

WARNING! The design and configuration of the PH Series

Proportioner does not allow its use in potentially explosive

atmospheres, or the pressure and temperature limits

described in the technical specifications of this manual to be

exceeded.

Always use liquids and solvents that are compatible with the unit. If in doubt, consult your PMC

Distributor.

When working with the PH Series Proportioner, it is recommended that the operator wear

suitable clothing and elements of personal protection, including, without limitation, gloves,

protective goggles, safety footwear, and face masks. Use breathing equipment when working

with the PH Series Proportioner in enclosed spaces or in areas with insufficient ventilation. The

introduction and follow-up of safety measures must not be limited to those described in this

manual. Before starting up the PH Series Proportioner, a comprehensive analysis must be

made of the risks derived from the products to be dispensed, the type of application, and the

working environment.

4

Page 9

100% circumferential coverage produces the most

uniform distribution of heat available.

CHARACTERISTICS

The

Classic

polyurea chemical systems, polyurethane foam chemical systems, and some specific twocomponent epoxy systems.

PH Series Proportioner has been designed and built for the application of

PRINCIPAL HEATING SYSTEM

The Proportioners consist of two (2) independent Material Heaters without internal seals. Each

heater for the PH(X)-25 Proportioner has four (4) Heating Elements rated at 1,000, 1,250 or

1,500 watts, each giving the Proportioner a total heat of 8,000, 10,000, or 12,000 watts. Each

heater for the PH(X)-40 Proportioner has six (6) Heating Elements rated at 1,250 1,500 or 1,750

watts each, giving the Proportioner a total heat of 15,000, 18,000 or 21,000 watts. The Material

Heater systems for all PH Series Proportioners contain the necessary control and safety

components for their precise operation. The Material Heater design allows a temperature

differential (ΔT) of 90ºF (32ºC) and material application temperatures of up to 190ºF (88ºC)

under normal ambient temperatures.

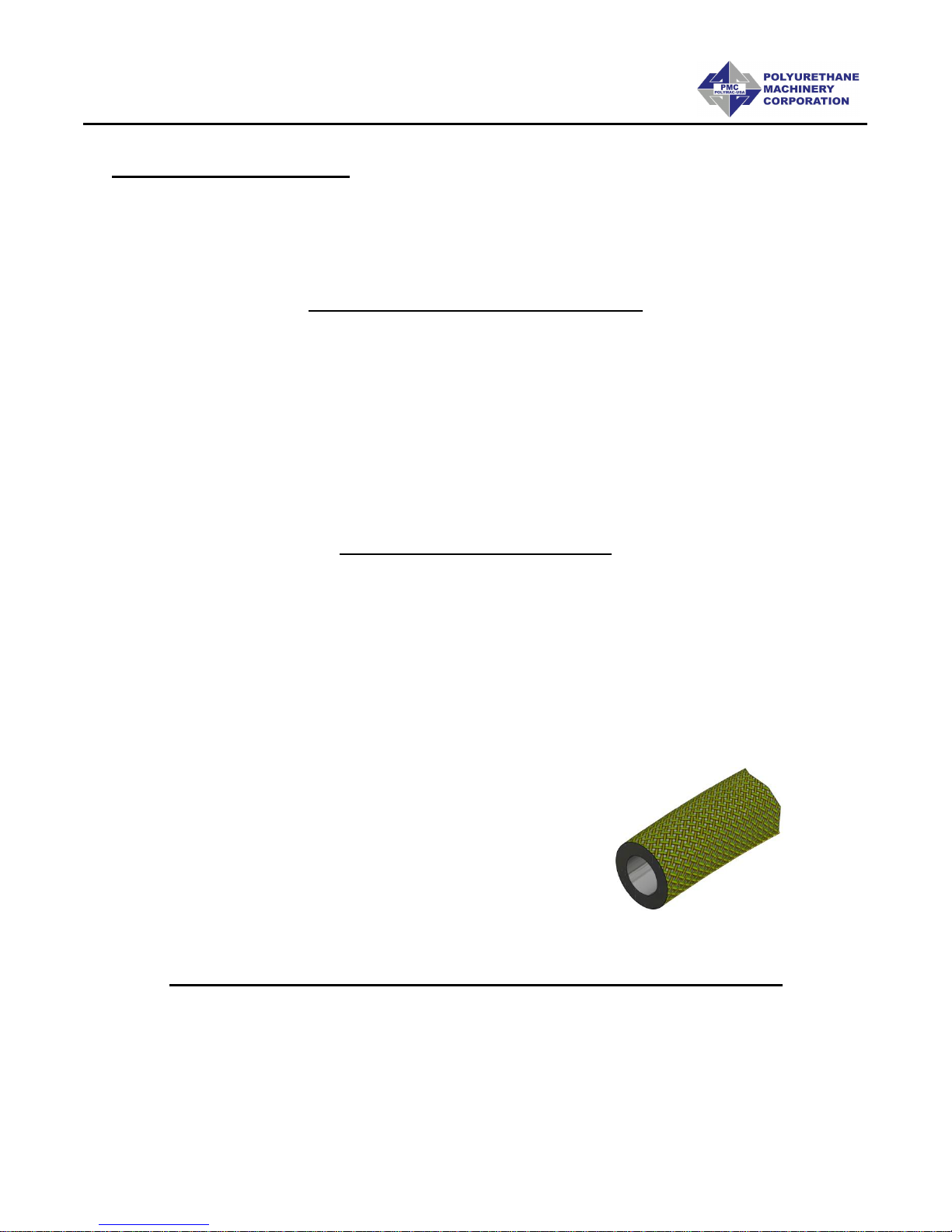

HOSE HEATING SYSTEM

The PH(X)-25 Proportioner is designed with a 3 KVA (90 V) Isolation Transformer that enables

effective heating of up to a total hose length of 310 feet (94 meters). The PH(X)-40 Proportioner

is designed with a 5 KVA (120 V) Isolation Transformer that enables effective heating of up to a

total hose length of 410 feet (123 meters). Both systems include an innovative hose heating

concept in which the continuous braid tinned-copper jacket is distributed evenly around the

circumference of the hose providing a uniform heating watt density and precise control of the

material application temperature. This hose heating element design is extremely resistant to

fatigue failure.

DOUBLE ACTING OPPOSED PISTON METERING PUMPS

The opposed double acting Pump Line is driven by a dual rod Hydraulic Cylinder. The in-line

pump system with opposed piston pumps provides a constant volume and guarantees uniform

pressures in both directions of pump movement. Different sized pumps allow for various

volumetric ratios to be achieved (1:4 to 1:1 to 4:1) between the chemical components used in

the process.

5

Page 10

CHARACTERISTICS

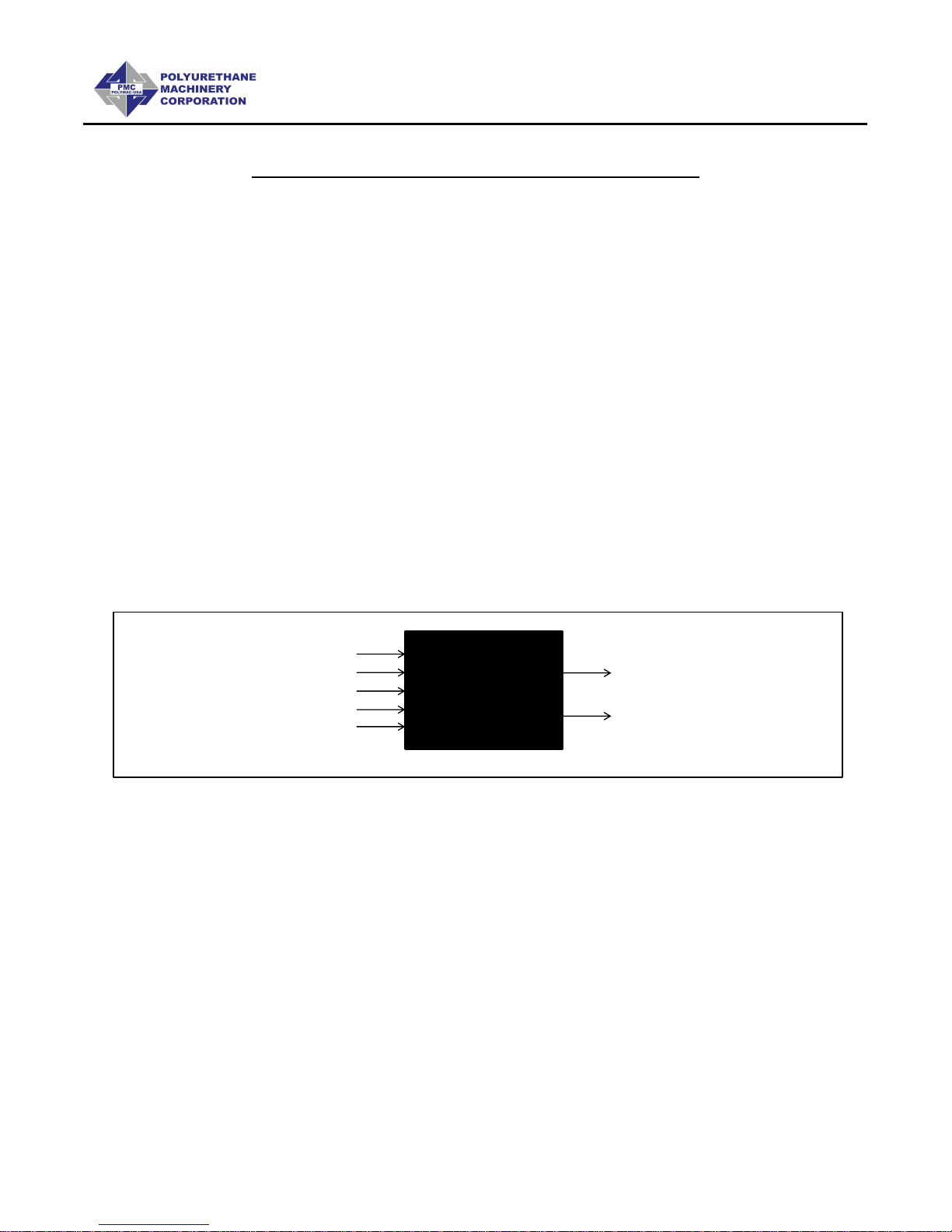

1. Power supply

2. “A” side pressure reading

3. “R” side pressure reading

4. Maximum pressure

5. Maximum allowable

pressure differential

Logic Box

1. Continue pumping material

OR

2. Shut off pumps

PRESSURE BALANCE CONTROL SYSTEM

The Pressure Balance Control (PBC) system provides better control over a chemical pressure

imbalance. When the system is turned off, the Proportioner will perform as if there is no PBC

system and will continue pumping material. When the system is turned on, it will continually

monitor the pressure between the two chemicals (known as the pressure differential). If the

pressure differential becomes equal to or greater than the maximum allowable pressure

differential, the pumps will be shut off.

The Pressure Balance Control system can be simplified into a logic box diagram with inputs and

outputs. There are five inputs: the power supply from the main console, the pressure readings

from each chemical, the maximum pressure, and the maximum allowable pressure differential.

Inside the logic box, the actual pressure differential of the chemicals is compared to the

maximum allowable pressure differential. Depending on the circumstances of all five inputs,

there are only two possible outputs: either the pumps will continue to pressurize and move

material, or the pumps will shut off and flow will be lost.

Logic Box Repre sent ation

6

Page 11

CAUTION! Inside the console is a Terminal Strip for

connecting the main power (wire not supplied) to the

PH Series Proportioner. This electrical connection

must be made only by a qualified electrician.

PH(X)-25 TECHNICAL SPECIFICATIONS

ELECTRICAL

Main Voltage: ______________________________________ 3 x 208-230V, 50/60Hz

Electrical Consumption: (2 x 4 kW Heaters) _____________________ 40 A @ 3 x 230V

Electrical Consumption: (2 x 5 kW Heaters) _____________________ 49 A @ 3 x 230V

Electrical Consumption: (2 x 6 kW Heaters) _____________________ 57 A @ 3 x 230V

Main Voltage: _________________________________________ 1 x 208-230V, 60Hz

Electrical Consumption: (2 x 4 kW Heaters) _____________________ 61 A @ 1 x 230V

Electrical Consumption: (2 x 5 kW Heaters) _____________________ 70 A @ 1 x 230V

Electrical Consumption: (2 x 6 kW Heaters) _____________________ 78 A @ 1 x 230V

Material Heater Power: (2 x 4 kW) ______________________________________ 8 kW

Material Heater Power: (2 x 5 kW) _____________________________________ 10kW

Material Heater Power: (2 x 6 kW) _____________________________________ 12kW

Hose Transformer Power: _____________________________________ 3 KVA (90 V)

Electrical Motor Power: ______________________________________________ 3 HP

Frequency: (Single Phase) ___________________________________________ 60 Hz

Frequency: (Three Phase) _________________________________________ 50/60 Hz

MECHANICAL

Maximum working pressure (with 120 pumps): _________________ 2,000 psi (138 bar)

Maximum working pressure (with 80 pumps): __________________ 3,000 psi (207 bar)

Maximum production ratio 1:1 (with 120 pumps): ____________ 25 lbs/min (12.5 kg/min)

Maximum production ratio 1:1 (with 80 pumps): ________________ 1.4 GPM (5.6 L/min)

Minimum production: ______________________________________ 2 lb/min (1kg/min)

Maximum hose length: _________________________________________ 310 ft (93 m)

Approximate weight (Hydraulic Tank empty): _____________________ 420 lbs (190 kg)

Approximate weight (Hydraulic Tank full @ 20 gal, 76 liters): ________ 594 lbs (269 kg)

Dimensions: _______________________________________ 30in W x 26in D x 45in H

Dimensions (Metric): ____________________________ 76cm W x 66cm D x 114cm H

7

Page 12

CAUTION! Inside the console is a Terminal Strip for

connecting the main power (wire not supplied) to the

PH Series Proportioner. This electrical connection

must be made only by a qualified electrician.

PH(X)-40 TECHNICAL SPECIFICATIONS

ELECTRICAL

Main Voltage: ______________________________________ 3 x 208-230V, 50/60Hz

Electrical Consumption: (2 x 7.5 kW Heaters) ___________________ 75 A @ 3 x 230V

Electrical Consumption: (2 x 9.0 kW Heaters) ___________________ 89 A @ 3 x 230V

Electrical Consumption: (2 x 10.5 kW Heaters) _________________ 103 A @ 3 x 230V

Main Voltage: _________________________________________ 1 x 208-230V, 60Hz

Electrical Consumption: (2 x 7.5 kW Heaters) __________________ 130 A @ 1 x 230V

Material Heater Power: (2 x 7.5 kW) ___________________________________ 15 kW

Material Heater Power: (2 x 9.0 kW) ___________________________________ 18 kW

Material Heater Power: (2 x 10.5 kW) __________________________________ 21 kW

Hose Transformer Power: ____________________________________ 5 KVA (120 V)

Electrical Motor Power: ______________________________________________ 5 HP

Frequency: (Single Phase) ___________________________________________ 60 Hz

Frequency: (Three Phase) _________________________________________ 50/60 Hz

MECHANICAL

Maximum working pressure (with 120 pumps): _________________ 2,000 psi (138 bar)

Maximum working pressure (with 80 pumps): __________________ 3,500 psi (241 bar)

Maximum production ratio 1:1 (with 120 pumps): _____________ 40 lbs/min (20 kg/min)

Maximum production ratio 1:1 (with 80 pumps): ________________ 2.5 GPM (1.0 L/min)

Minimum production: _________________________________________ 2 lb/min (1 kg)

Maximum hose length: ________________________________ _______ 410 ft (123 m)

Approximate weight (Hydraulic Tank empty): _____________________ 420 lbs (190 kg)

Approximate weight (Hydraulic Tank full @ 20 gal (76 liters) ________ 594 lbs (269 kg)

Dimensions: _______________________________________ 30in W x 26in D x 45in H

Dimensions (Metric) ____________________________ (76cm W x 66cm D x 114cm H)

8

Page 13

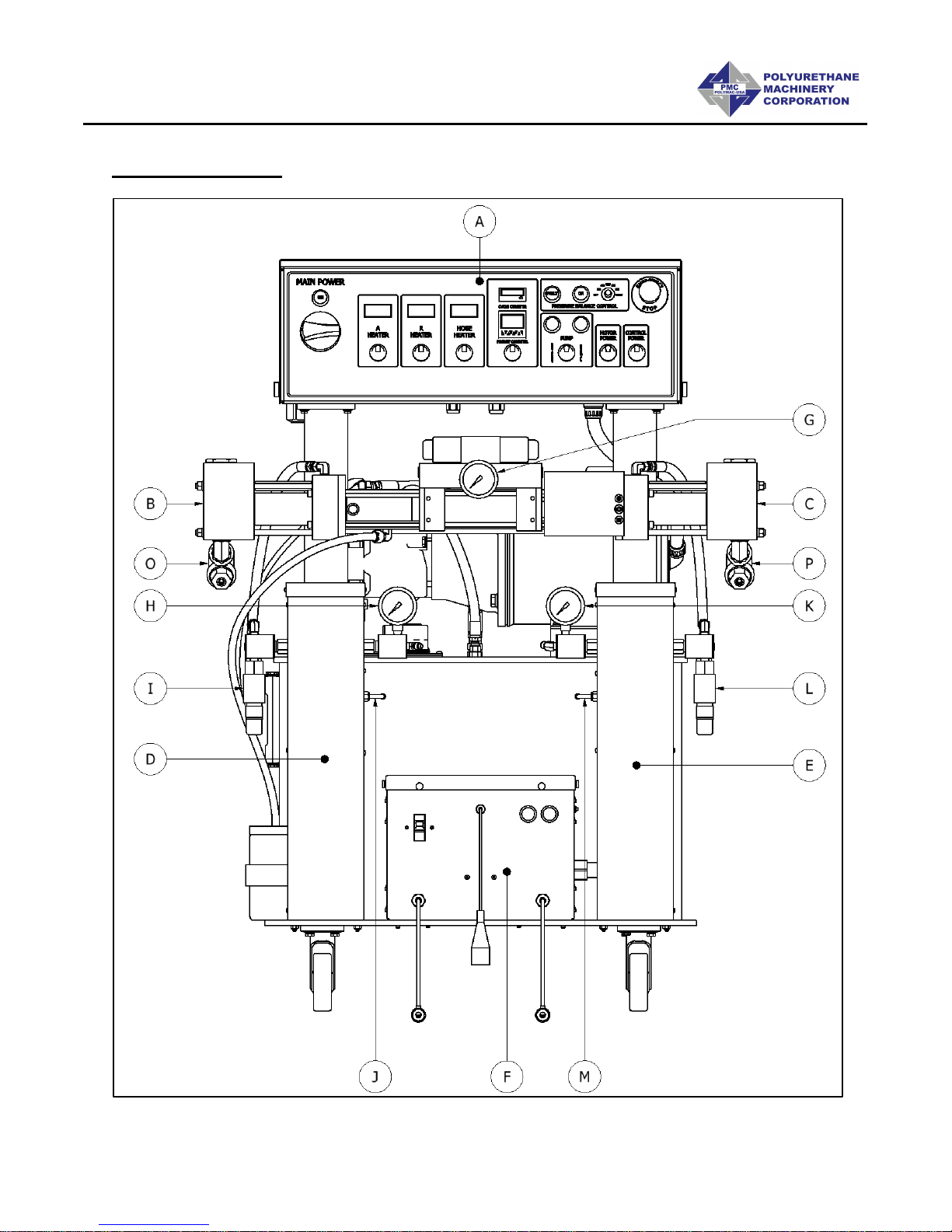

DESCRIPTION

CLASSIC PH-SERIE S

PROPORTIONER

9

Page 14

DESCRIPTION

A. Control Panel

Controls and regulates the operation of the PH Series Proportioner.

B. Isocyanate (Iso, A) Metering Pump

Meters the Isocyanate material.

C. Polyol (Poly, R) Metering Pump

Meters the Polyol material.

D. Isocyanate (Iso, A) Heater

Heats the incoming Isocyanate to a temperature set by the operator.

E. Polyol (Poly, R) Heater

Heats the incoming Polyol to a temperature set by the operator.

F. Hose Heating Transformer

Supplies the required voltage for material Heated Hoses.

G. Hydraulic Pressure Gauge

Indicates the pressure in the Hydraulic Drive System.

H. Isocyanate (Iso, A) Pressure Gauge

Indicates the pressure in the Isocyanate system.

I. Isocyanate (Iso, A) Safety Pressure Switch

Disables the pump circtuit in the event of excessive pressure in the Isocyanate

system.

J. Isocyanate (Iso, A) Thermocouple

Provides temperature information of the Isocyanate to its Temperature Controller.

K. Polyol (Poly, R) Pressure Gauge

Indicates the pressure in the Polyol system.

L. Polyol (Poly, R) Safety Pressure Switch

Disables the pump circuit in the event of excessive pressure in the Polyol system.

M. Polyol (Poly, R) Thermocouple

Provides temperature information of the Polyol to its Temperature Controller.

N. Hydraulic Pressure Control

Allows the pressure of the hydraulic system to be increased

or decreased. Turn clockwise to increase the pressure and

counterclockwise to decrease. To regulate the pressure of

the hydraulic system, the NORMAL or RETRACT Pump

Switch position must be selected.

O. Isocyanate (Iso, A) Inlet Material Strainer

Screens (60 mesh) material from bulk supply.

P. Polyol (Poly, R) Inlet Material Strainer

Screens (60 mesh) material from bulk supply.

10

Page 15

DESCRIPTION

PUMP SIZE

CYCLES PER GAL (3.79 L)

120

16

80

24

R

CLASSIS PH-SERIE S

CONTROL PANEL

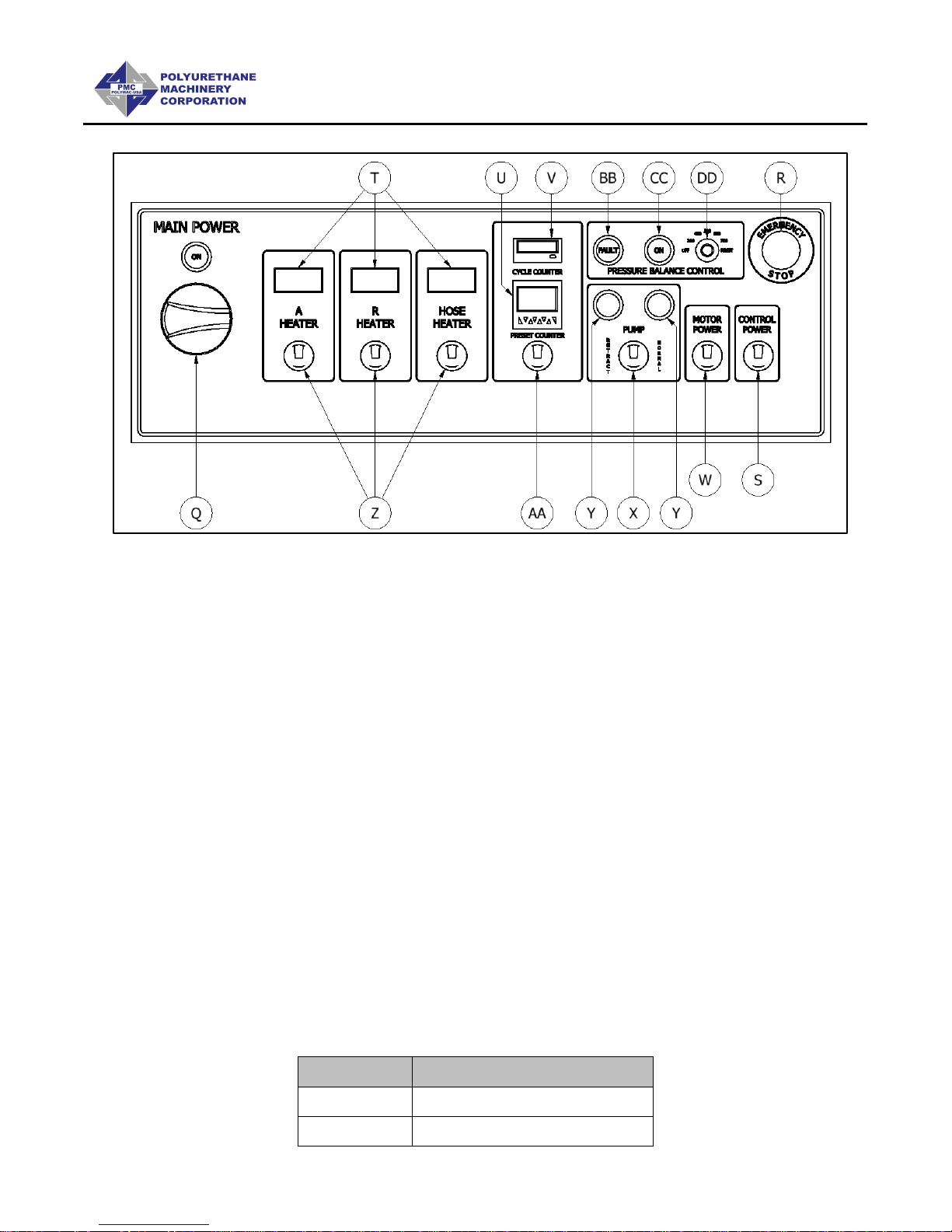

Q. Main Power - Turns ON and OFF main power to the control panel. It must be

turned ON for any operation to be performed with the unit. When turned ON, the

green pilot light will be lit.

R. Emergency Stop - Interrupts the PH Series control power circuit to stop all motion

and heating.

S. Control Power - Turns ON and OFF the control power to the complete electrical

circuit including Heaters and Hose Heater.

T. Heater Temperature Zones, A (Iso), R (Poly), HOSE - Turns ON and OFF power

to the specific Heaters. See page 22 for detailed Temperature Controller

instructions.

The Hose Heater Controller automatically controls the Hose Heater only when

using the TSU (Temperature Sensing Unit) probe.

U. Count Down Counter – Used to set the amount of cycles required to prevent the

chemical drums from running dry, the machine will shut down when the preset

cycles expires. There is an on/off switch to either activate this feature or deactivate

and not use it.

V. Cycle Counter – Indicates the number of pump cycles to calculate material usage.

11

Page 16

DESCRIPTION

W. Motor Switch - Turns ON and OFF the Electric/Hydraulic Motor. When turned ON

the switch will be lit. In the event of an overload of the Motor, pilot light will turn

OFF and Motor will stop.

X. Pump Switch

Off - Removes power from the pump circuit. The directional indicator lights will not

be lit.

Normal - Activates the normal operation of the machine. When the switch is ON,

the directional light corresponding to the stroke direction will light.

Retract - Sets the Piston Rod of the Iso (A) metering pump to the retract position

and prevents the crystallization of Iso (A) on the Piston Rod. Turn the switch to

RETRACT position every time the unit is stopped by the operator (see Shut-Down,

page 25).

Y. Direction Indicator Light - Indicates the direction of movement of the Metering

Pumps. If excessive pressure occurs in the system, the pump circuit will be

disabled and the directional lights will be OFF.

Z. Heater Temperature Switch – A (Iso), R (Poly), HOSE – Turns ON and OFF

power to the specific Heaters and Hose.

AA. Auto Shut Down Switch - Turns ON and OFF power to the Auto Shut Down unit.

BB. Pressure Balance Control “FAULT” Light – Indicates that the pressure

differential is equal to or greater than the maximum allowable pressure differential.

CC. Pressure Balance Control “ON” Light – Indicates that the Pressure Balance

Control system is on and functioning.

DD. Pressure Balance Control Knob – Used to set the maximum allowable pressure

differential (in PSI) between the A (Iso) and R (Poly) pumps. See page 21 for more

information.

12

Page 17

L1

L2

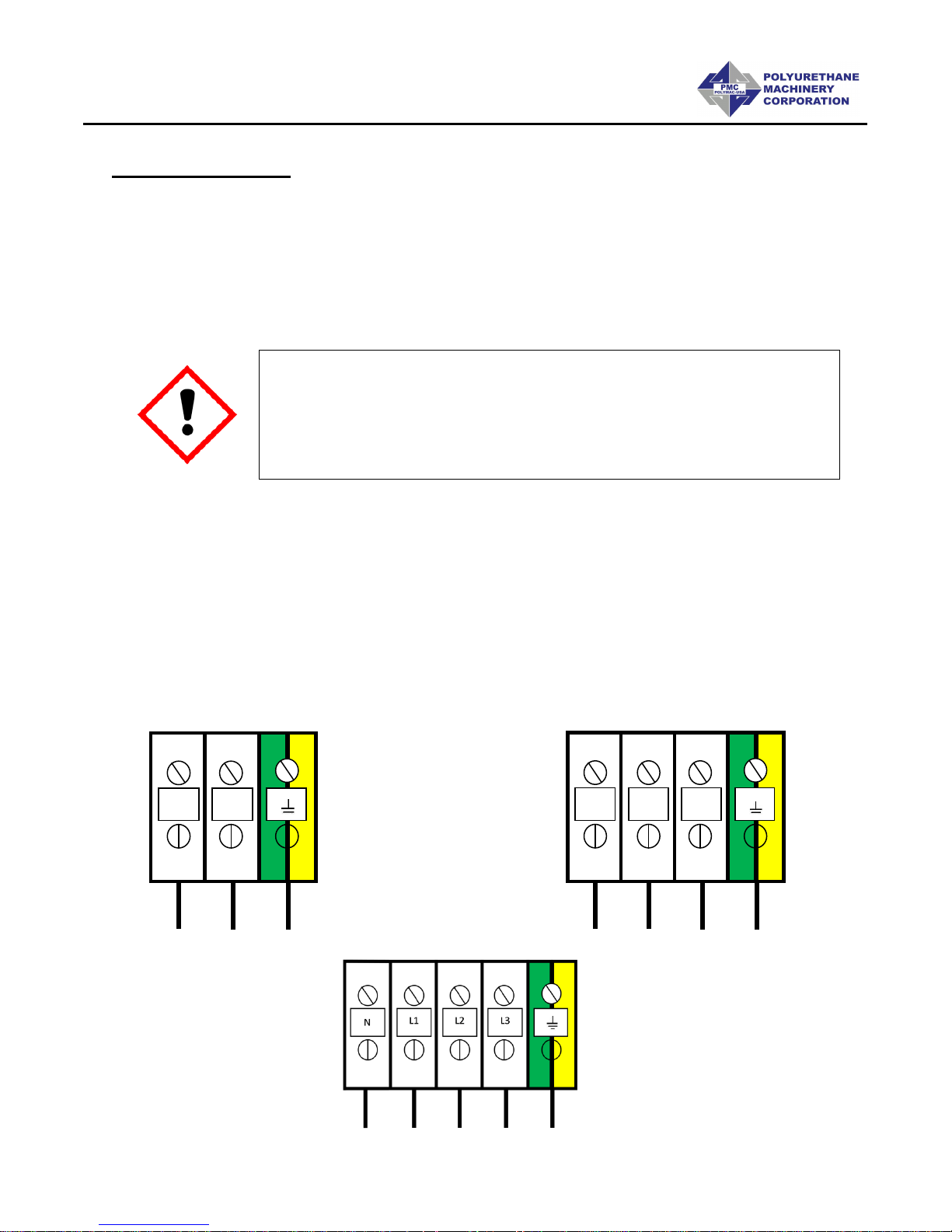

CAUTION! Inside the console is a Terminal Strip for

connecting the main power (wire not supplied) to the

PH Series Proportioner. This electrical connection

must be made only by a qualified electrician.

1 phase x 230 Volt

L3

L2

L1

3 phase x 380 Volt

3 phase x 230 Volt

INSTALLATION

WARNING! Use suitable protection and follow the

recommendations in the Safety Information enclosed and

provided by material suppliers when installing or working

with the Proportioner.

CAUTION! Make sure the power cable is disconnected from the main

power source before connecting to the Terminal Strip in the Console.

NOTE! To ensure the PH Series Proportioner works correctly, the electrical

supply must meet the specifications indicated on the Serial Number

Placard affixed to the Electrical Console.

13

Page 18

INSTALLATION

Follow the recommended procedure in the indicated order to install the Proportioner:

1. Insert the main power cable by passing it through the strain relief at the bottom of the

Electrical Console and connect as shown in the above diagram.

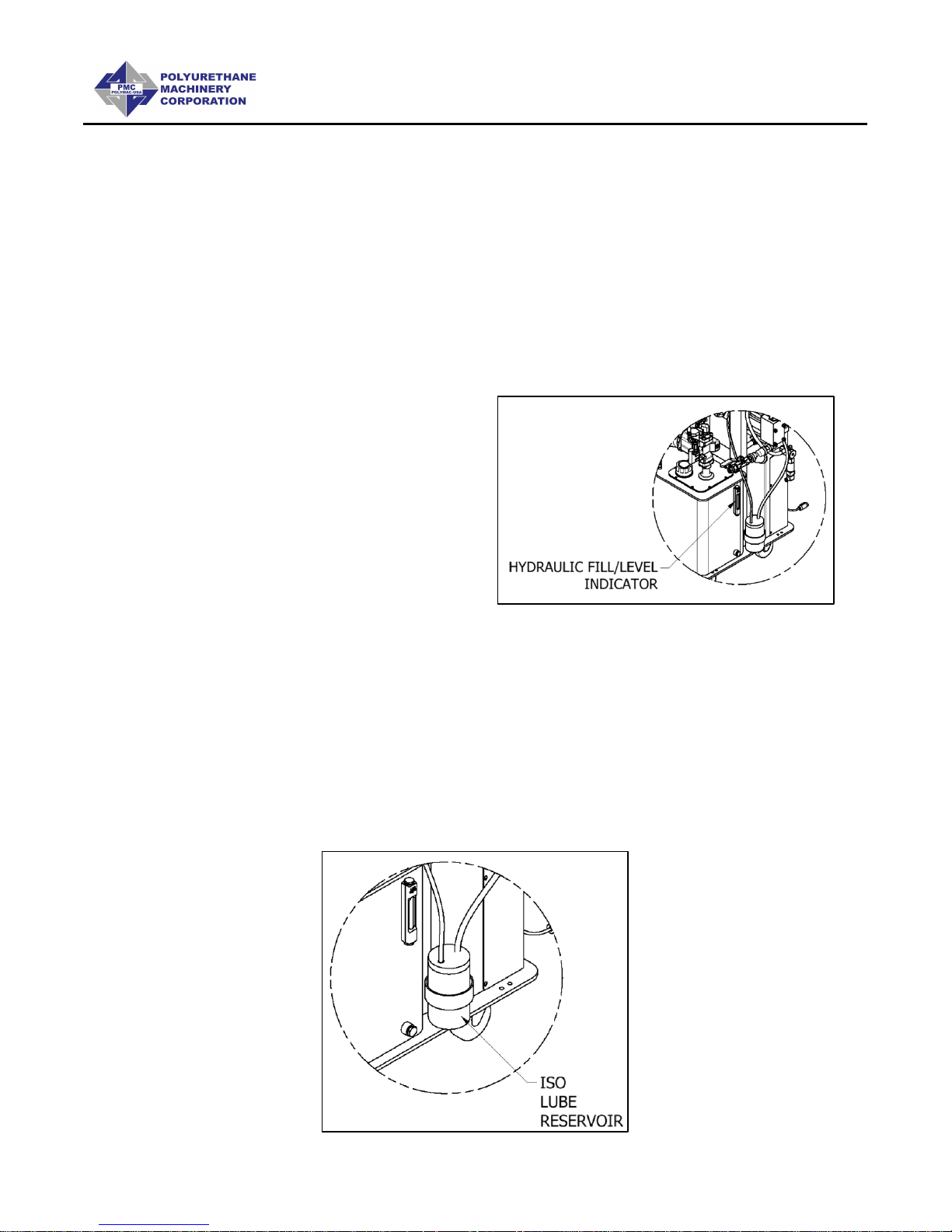

2. Fill the Hydraulic Reservoir with 20 gallons (76 Liters) of approved hydraulic fluid. See

page 56 for specifications.

NOTE! Do not fill the tank to maximum capacity; use the Visual Level

Indicator on the tank to make sure the amount of hydraulic fluid is not more

than 20 gallons (76 liters) or 80% of the tank max capacity.

3. Check the level of the hydraulic fluid in

the Hydraulic Pump Case: Disconnect

the Hydraulic Hose from the 90 fitting

and remove the Fitting from Hydraulic

Case. Add fluid as required to the top of

threaded hole. Reattach Fitting and

Hydraulic Hose.

NOTE! Ensure that the Emergency

Stop is not engaged.

4. Three-phase Proportioner Only: Check the Electric Motor to ensure rotation is

clockwise when viewing the end of the Electric Motor. A counter clockwise rotation

indicates two of the incoming power leads need to be reversed. Recheck rotation before

proceeding with Installation.

CAUTION! Ensure Main Power Switch is OFF and incoming power is

locked OFF before reversing power leads.

5. Fill the Lube Reservoir with PMC Pump Lube or suitable diluents. It is not necessary to

prime the system.

14

Page 19

INSTALLATION

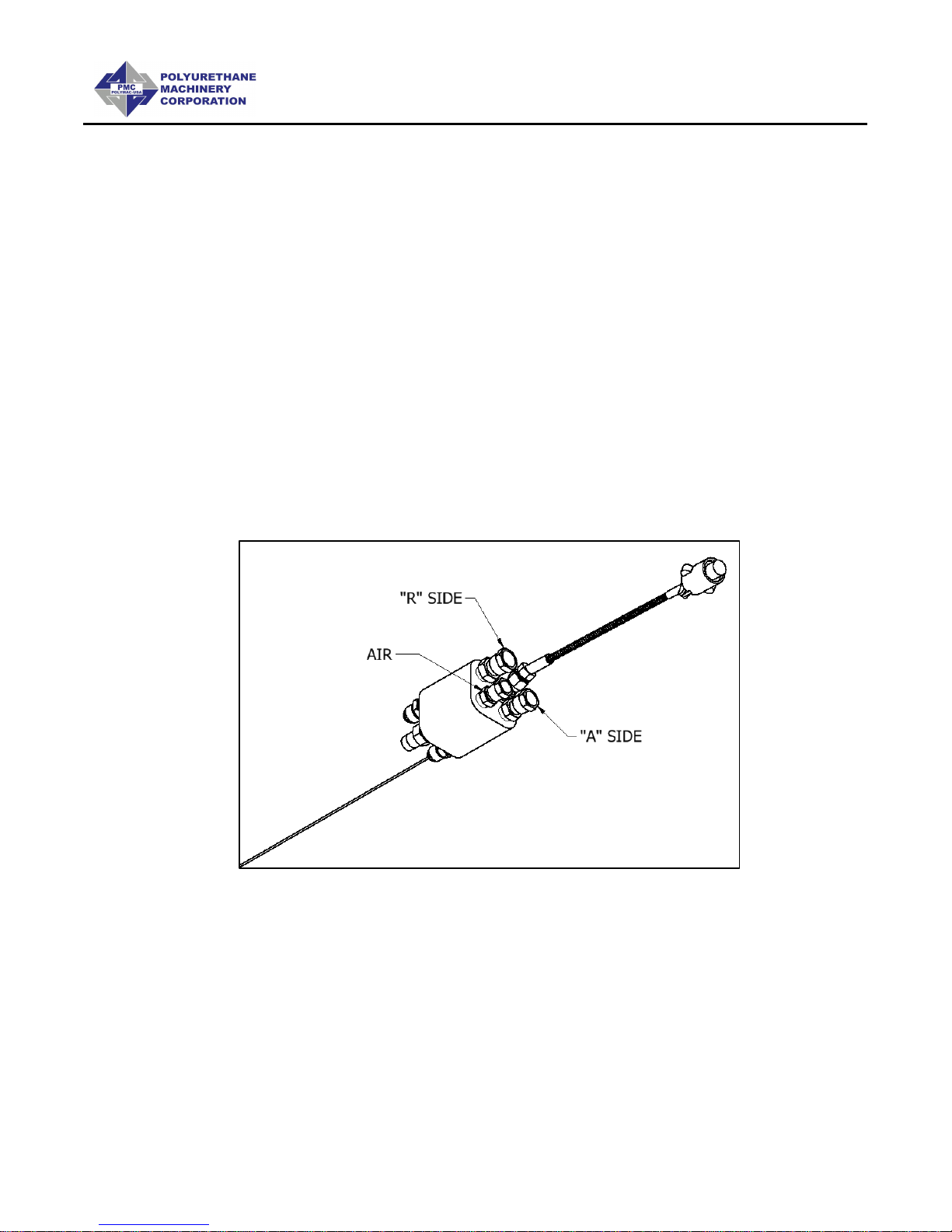

HEATED HOSE INSTALLATION

CAUTION! The material delivery Heated Hoses are color coded Red

and Blue allowing the user to recognize them. The Red corresponds

to the Isocyanate (Iso, A) and the Blue to the Polyol (Poly, R). To avoid

connection errors the Coupling Connections of the Iso (A) and Poly

(R) Heated Hoses are also different sizes, which makes it difficult to

swap connections.

NOTE! The material delivery Heated Hoses are capped at the ends to

prevent absorbing moisture. Do not remove caps until the Heated Hoses

are going to be installed on the Proportioner.

1. Lay out all the Heated Hose assemblies end to end aligning the Iso “A” (red) and Poly

“R” (blue) and connect the respective Coupling Connections using the appropriate sized

open-end wrench after ensuring Heated Hose assemblies lay flat.

CAUTION! Take care to not cross-thread or over-tighten the Coupling

Connections. Thread seal tape or compound is not required for this

tapered seat Coupling Connections.

2. Connect the material Heated Hoses to the outlets of the respective Heaters i.e. Iso (A)

Heated Hose to the Iso (A) Heater and the Poly (R) Heated Hose to the Poly (R) Heater

ensuring Heated Hose assemblies lay flat.

a. For half inch hose assemblies, all required fittings and instructions are included in

kit 200212

3. Connect Air Hose Coupling Connections.

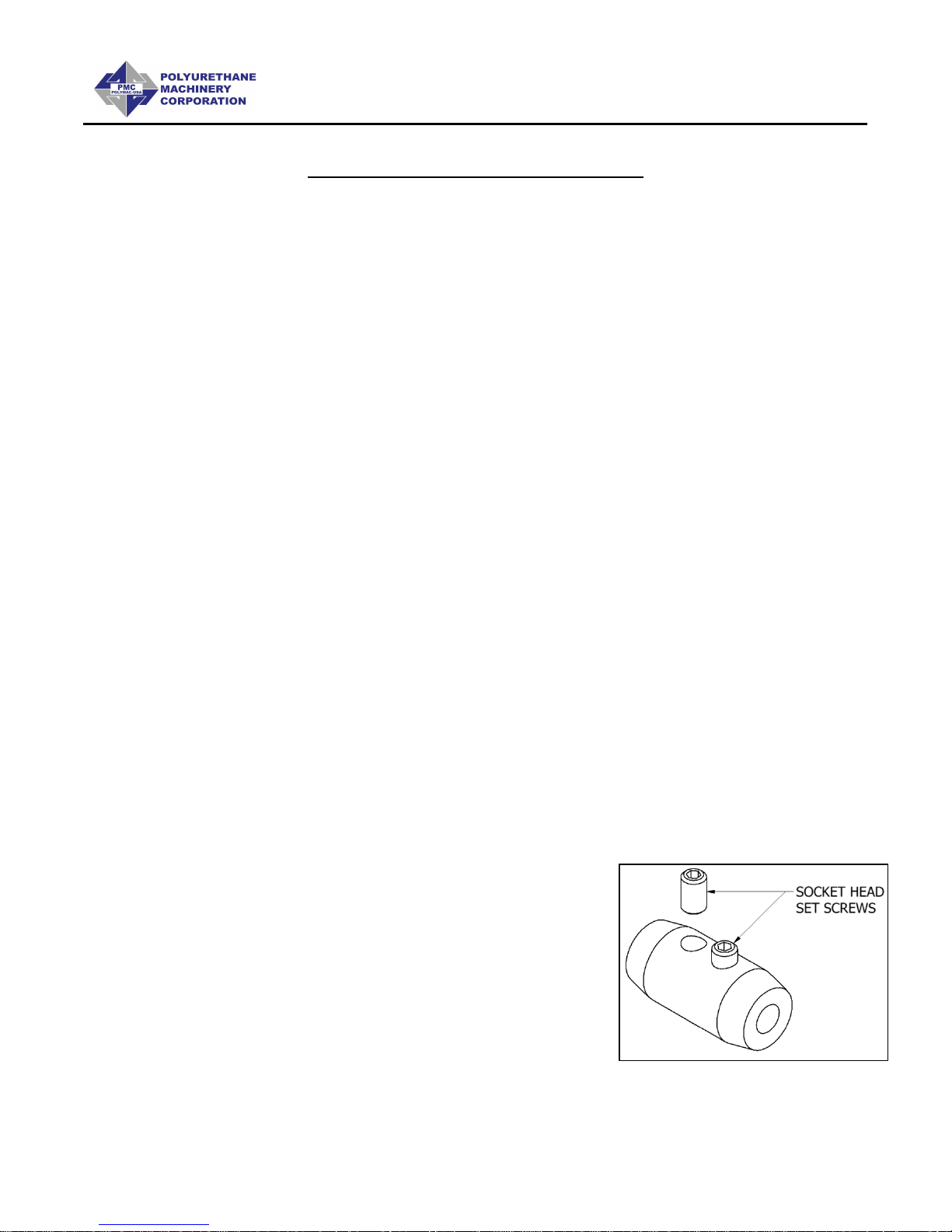

4. Connect the Heated Hose power wires to the “Fast-Lock” Connector (Part # KT-00029A)

coming from the Hose Heat Transformer as follows:

a. Loosen the Socket Head Set Screw to allow

insertion of the Heated Hose electrical wire

Terminal.

b. Insert the Terminal into the “Fast-Lock”

Connector Body.

c. Securely tighten the Socket Head Set Screw.

d. Install electrical tape around Connector Body.

NOTE! A good practice is to add some dielectric grease (Permatex 67VR

or equivalent) to the outside of the Terminal prior to insertion.

15

Page 20

INSTALLATION

5. Repeat the above steps to connect the “Fast-Lock” Connectors that you will find on all

Heated Hose power wire.

CAUTION! Ensure the proper mechanical and electrical connections

of the Heated Hoses are made to avoid possible material leakage and

Hose heat problems.

6. It is recommended the TSU be installed between the last section of Heated Hose and

the Gun Whip. Carefully straighten the sensing wire, inserting it in the Iso (A) Heated

Hose and tighten fluid fittings with appropriate sized open-end wrenches.

CAUTION! To protect the TSU sensor, pay special attention not to

kink or excessively bend the Heated Hoses. Do not coil the Heated

Hoses with a diameter of less than 4 feet (1.22 meters).

Replacement Sensor Part # EL -51A-2

CAUTION! Connecting the TSU between the first and second section

of Heated Hose results in the TSU sensing the material temperature

exiting the Heater and not the inside of the Heated Hose near the

Spray Gun.

Temperature Sensin g Un it

(TSU) Part # EL- 51A -4

16

Page 21

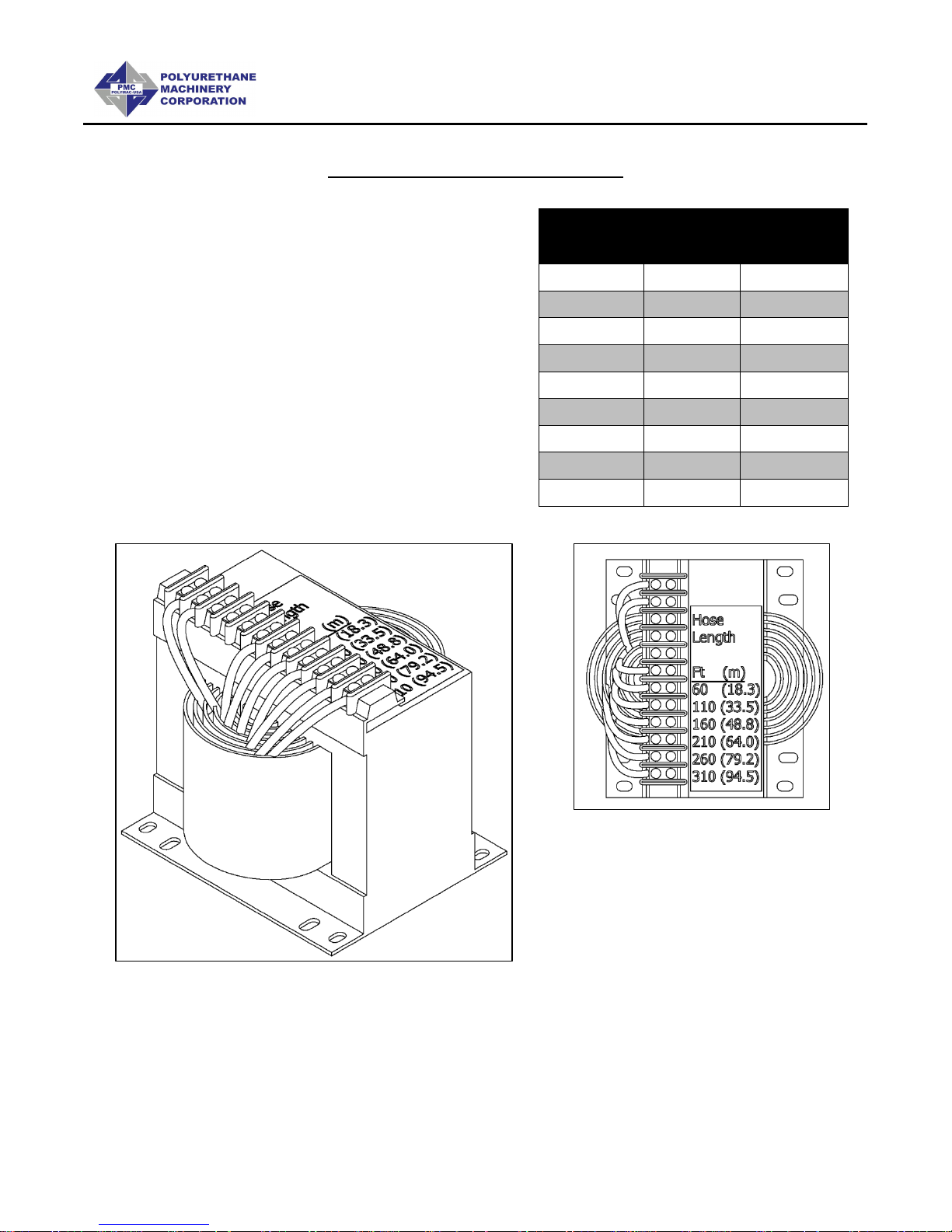

INSTALLATION

RECOMMENDED TAP

SETTINGS

1

Tap

Feet

Meters

120V

410

125.0

105V

360

109.7

90V

310

94.5

75V

260

79.5

60V

210

64.0

45V

160

48.8

30V

110

33.5

18V

60

18.3

TRANSFORMER SETTINGS

The Hose Heat Transformer offers the ability of

connecting to different output voltages depending

on the total length of the Heated Hose in use,

maximizing the heating ability of the Heated Hose.

The factory setting is 18 volts for use with 60 feet

(18 Meters) of Heated Hose1. Before starting the

Proportioner, ensure the setting matches the

Heated Hose length installed. If Heated Hose

sections are added or removed, the Tap setting

must be changed to a setting which will limit the

maximum amperage in the Heated Hose to 52

amps. The suggested tap settings are tabled

below2:

1

90V transformers (shown above) allow for a maximum hose length of 310 ft (94.5 m). 120V

transformers allow for a maximum hose length of 410 ft (125 m).

2

90V Transformers (shown above) are standard on all PH(X)-25 Proportioners. 120V

Transformers are standard for all PH(X)-40 Proportioners, and are also optional for PH(X)-25

Proportioners

17

Page 22

INSTALLATION

7. Ensure the Manual Valves are CLOSED and connect the Coupling Block to the Heated

Gun Whip.

CAUTION! Excessive force closing or opening the Manual Valves may

result in damage to the Manual Valves and/or Coupling Block.

8. Connect the Transfer Pump/Heated Hose Assemblies air supply and air dryer systems

as required. Review the Installation Instructions for each to ensure proper set-up and

operation.

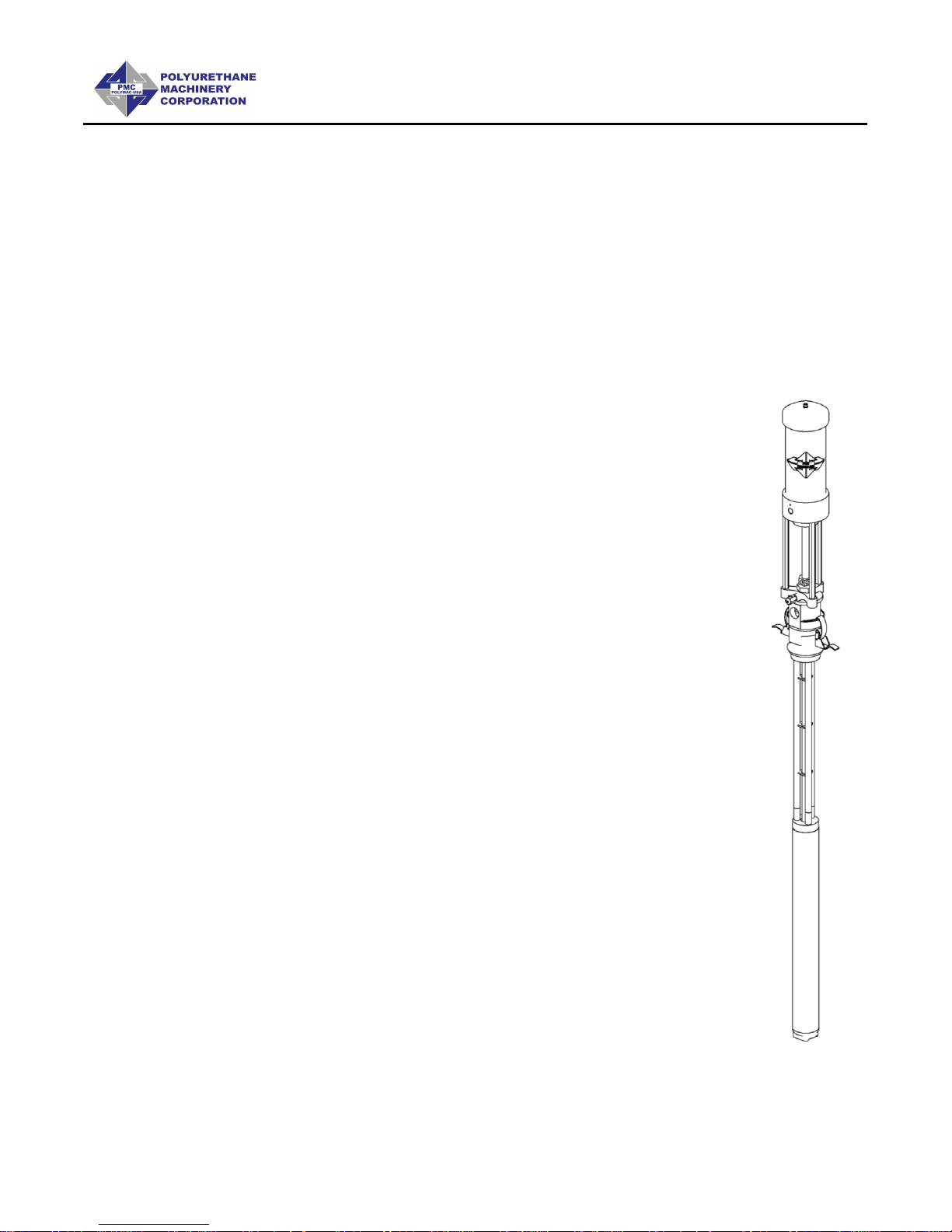

9. Install the Material Transfer Pumps as follows:

WARNING! If Transfer Pumps have been previously

used, pay special attention to connect each Pump to

“its” specific material. Inadvertently changing the

Transfer Pumps will cause a chemical reaction

rendering them useless.

NOTE! Placing tape of the same color as of the Material Delivery

Hoses (red for the Iso (A), blue for the Poly (R)) on each Transfer

Pump would be a good method for minimizing errors in

connection.

a. Make sure that the Inlet Valves on the Proportioner are closed.

b. Connect one end of the Polyol (R) Material Delivery Hose (¾” thread) to

the Proportioner Polyol (R) Inlet Valve and the other end to the Polyol

(R) Transfer Pump.

c. Connect one end of the Iso (A) Material Delivery Hose (½” thread) to the

Proportioner Iso (A) Inlet Valve and the other end to the Iso Transfer

Pump.

d. Connect the air hose to the Transfer Pumps after ensuring each Transfer

Pump Shut-Off Valve is CLOSED.

NOTE! To avoid errors in connection, the Coupling connections of

the Iso (A) and Poly (R) Material Delivery Hoses are different

sizes, making it difficult to swap connections.

10. Ground the Transfer Pump as recommend by the material supplier. The

movement of product inside the Hoses can cause static electricity and

produce electrical discharges.

18

Page 23

PROPORTIONER PURGING

WARNING! Use suitable Personal Protection Equipment

(PPE) and follow the recommendations in the Safety

Information provided by product suppliers when installing or

working with the unit.

NOTE! Before using the Proportioner it is necessary to purge the entire

system, including Heated Hoses of mineral oil and air left over from Quality

Control testing. The following procedure is also followed to purge air

entrapped by running out of material in the supply Drum/Reservoirs

resulting in a significant material pressure imbalance as indicated by the

Pressure Gauges and sprayed material.

1. Ensure the following before proceeding:

a. Air supply to Transfer Pumps is 90 - 110 psi (6-8 Bar).

b. Proportioner Inlet Valves are CLOSED.

c. All connections are tight.

d. Material should be stored to the material suppliers' recommended temperatures.

2. Slowly OPEN the Poly (R) Transfer Pump Air Shut-Off Valve allowing Pump to cycle

slowly as it fills the Material Delivery Hose to the Proportioner. Check for leaks.

3. OPEN Poly (R) Coupling Block Manual Valve over a waste container.

4. Slowly OPEN Proportioner Poly (R) Inlet Valve allowing the Transfer Pump to move

material through the system. When all air spitting stops and all traces of mineral oil have

disappeared, CLOSE Poly (R) Coupling Block Manual Valve. Clean Coupling Block.

5. Repeat steps 2 to 4 for Iso (A) side.

CAUTION! Properly dispose of all waste chemicals in accordance with

all applicable local, state and federal codes.

NOTE! Do not turn on the Count Down Counter.

6. Turn Hydraulic Pressure Control (N, page 10) full COUNTERCLOCKWISE.

7. Turn ON Main Power (Q, page 11). Green pilot will light.

8. Turn ON Control Power (S, page 11). Switch will light.

9. Turn ON Motor Power (W, page 12). Switch will light.

19

Page 24

PROPORTIONER PURGING

10. Set Pump Switch (X, page 11) to NORMAL. Turn Hydraulic Pressure Control

CLOCKWISE (N, page 10) increasing material pressure to 400 psi (27 bar). Both

Material Pressure Gauges (H, K, page 10) should read the same.

11. Check all connections for leaks.

12. Bundle all Heated Hose Connections ensuring that there are NO kinks in the TSU Cable

or Air Hose. Wrap with Electrical Tape to securely hold all components in place and

minimize places for bundle to snag onto job site protrusions.

20

Page 25

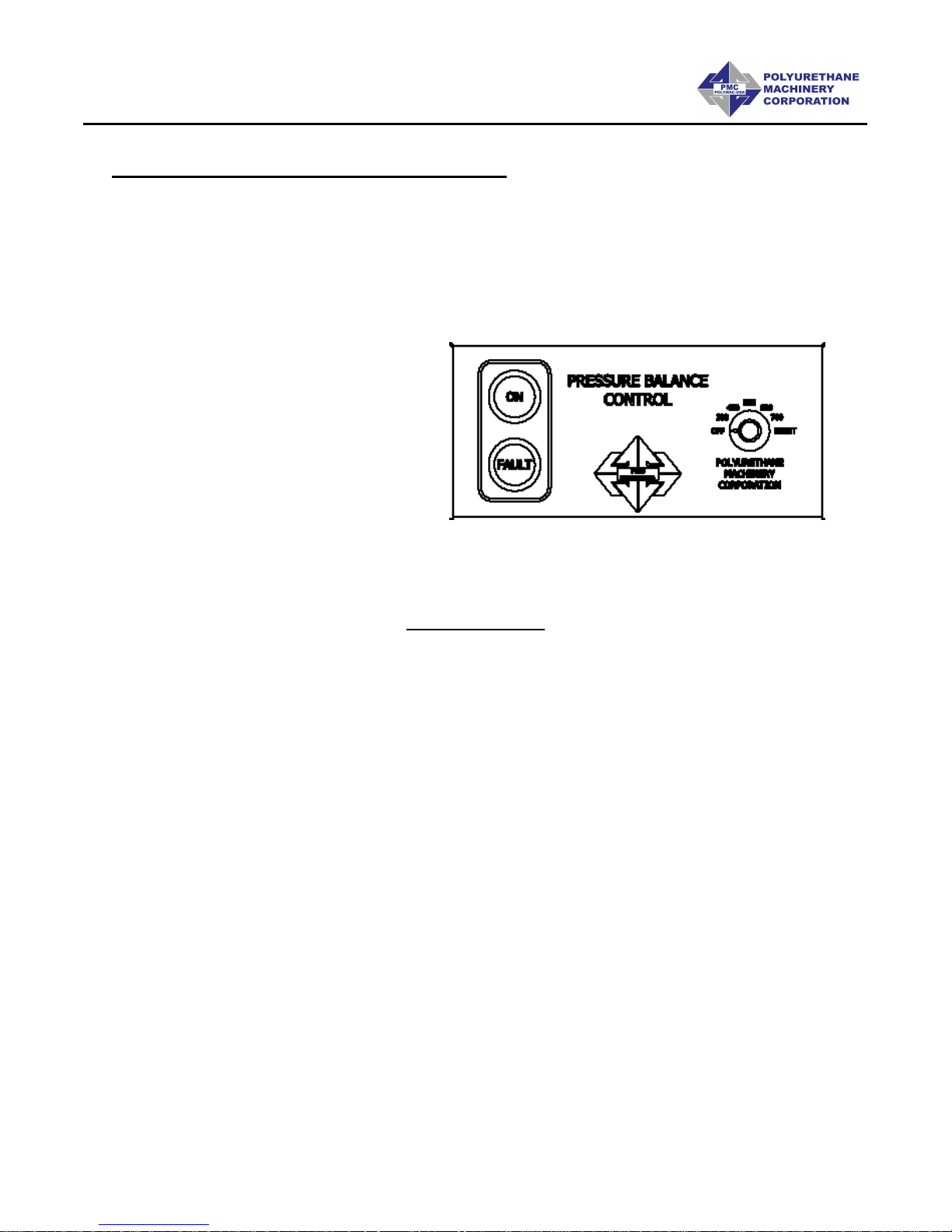

PRESSURE BALANCE CONTROL

The PH Series Proportioner has been designed with a pressure balance control system.

This system will give the operator of this machine the ability to control a pressure

imbalance within certain predetermined parameters.

The system consists of:

Selector Switch

Fault Light

On Light

Control Unit

Pressure Transducers

Relay

OPERATION

Position the selector switch on one of the three options:

Pressure differential number – these consist of 300, 400, 500, 600, and 700

PSI. Selecting any of these numbers with the switch will activate the green ON

light. While the pressure differential numbers are selected, the control box will

continually monitor pressure on both sides of the Proportioner. In the event that

the pressure differential between both sides of the Proportioner is equal to or

larger than the selected number, a fault is given (the red fault light is turned on

and the active green light is turned off) and shuts down.

Off – if the selector switch is placed in this position, the Proportioner will operate

as though there is NO PRESSURE BALANCE CONTROL SYSTEM (neither the

red fault light nor the active green light will be lit). The over pressure system will

remain active for the machine and personnel protection.

Reset – in the event of a pressure imbalance, resolve the Proportioner

imbalance, position the selector switch on reset to clear the fault light and restore

power to the Proportioner. After the fault has been cleared, position the switch in

either a Pressure Differential number or in the Off Position to continue

operations.

21

Page 26

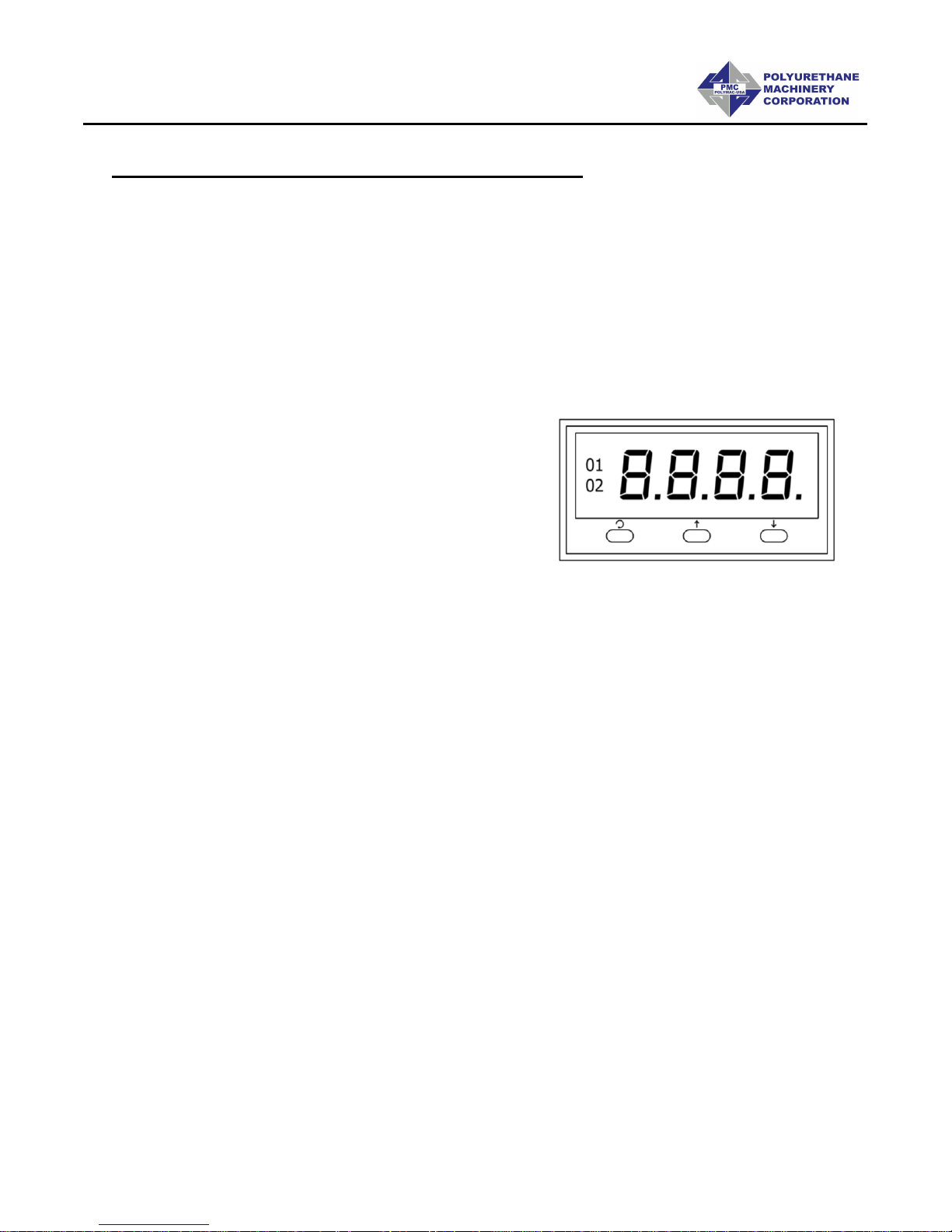

DIGITAL TEMPERATURE CONTROLLER

The PH Series has three Digital Temperature Controllers to manage the temperatures for the

Primary Heaters (Iso (A), Poly (R)) and the Heated Hose. The Hose Heater Controller is

programmed different from the Iso (A) and Poly (R) Controllers and therefore not

interchangeable with them.

WARNING! Do not turn the Temperature Controllers ON until

the Proportioner Purging procedure is complete and the

Primary Heaters and Heated Hoses are filled with material.

1. Ensure Main Power (Q, page 11) is ON,

Control Power (S, page 11) is ON, and 01

Display light is lit.

2. Press and release button. The display will

read SP1.

3. Press and release or button to display the current material temperature set-point.

4. Press and hold the or to increase or decrease the material temperature set-point to

the desired value as determined by the material supplier or application conditions.

5. Press and release and together to return to the actual material temperature in the

Primary Heater/Hose Heater.

WARNING! The Controllers are factory programmed and are

not field re-programmable. If a problem is encountered,

contact your PMC Distributor. Do not attempt to change any

of the programmed parameters. Do not substitute a

Controller from an alternate supplier as its use may result in

equipment damage and/or bodily injury.

NOTE! The Temperature Controller normally displays the actual material

temperature. When lit, the “01” display in the upper left indicates power is

sent to the designated heating system. The “01” display goes out when the

material temperature has reached its set-point. The “01” display will

continue to cycle on and off indicating the Controller is maintaining the

material temperature set-point.

22

Page 27

START-UP

NOTE! Follow the recommended procedures in the order shown.

CAUTION! The Start-up procedures assume that all of steps in

Proportioner purging have been performed and no problems found.

1. Check the condition of the PMC pump lube in the Iso (A) Lube Reservoir (page 14).

Replace the PMC pump lube if you see significant changes in the color or signs of

solidification. Ensure inside of Reservoir is wiped clean.

2. Check the hydraulic fluid level and service as required.

3. Make sure the materials have been stored at the manufacturer's recommended

temperature. Ask your material supplier for information (Material Data Sheet) on the

minimum storage temperature.

4. Connect air supply to the two Transfer Pumps and ensure Air Valves are in the full

OPEN position. OPEN both Proportioner Material Inlet Ball Valves.

CAUTION! Remove all Heated Hose sections from coiled storage and

lay flat to eliminate heat build-up and possible Heated Hose failure.

5. Turn ON Main Power (Q page 11).

6. Turn ON Control Power (S, page 11).

7. Turn ON Hose Heater (T, page 11) and confirm material set-point temperature as

recommended by the material supplier or application conditions.

CAUTION! To avoid excessive pressure in the Proportioner, wait for

the Hose Heater to reach its set-point temperature before continuing.

8. Turn ON each Primary Heater and confirm material set-point temperature as required by

the material supplier or application conditions has been reached.

9. Turn ON Motor Power (W, page 12).

10. Set Pump Switch (X, page 11) to NORMAL. One of the Directional Indicator Lights (Y,

page 12) will light indicating Metering Pump direction and the Metering Pump Shafts will

begin to move.

NOTE! The Material Pressure Gauges (H, K, page 10) should be

approximately equal and remain constant throughout the Metering Pump

cycle. If not, refer to Trouble Shooting section.

23

Page 28

START-UP

120 Pumps

80 Pumps

16 cycles = 1 gal (3.79 L)

24 cycles = 1 gal (3.79 L)

NOTE! Directional Indicator Lights must indicate Metering Pump direction

when Pump Switch is in the NORMAL position. If not, refer to Trouble

Shooting section.

11. Using the Hydraulic Pressure Control, adjust to the required stall pressure1 and check

each Material Pressure Gauge.

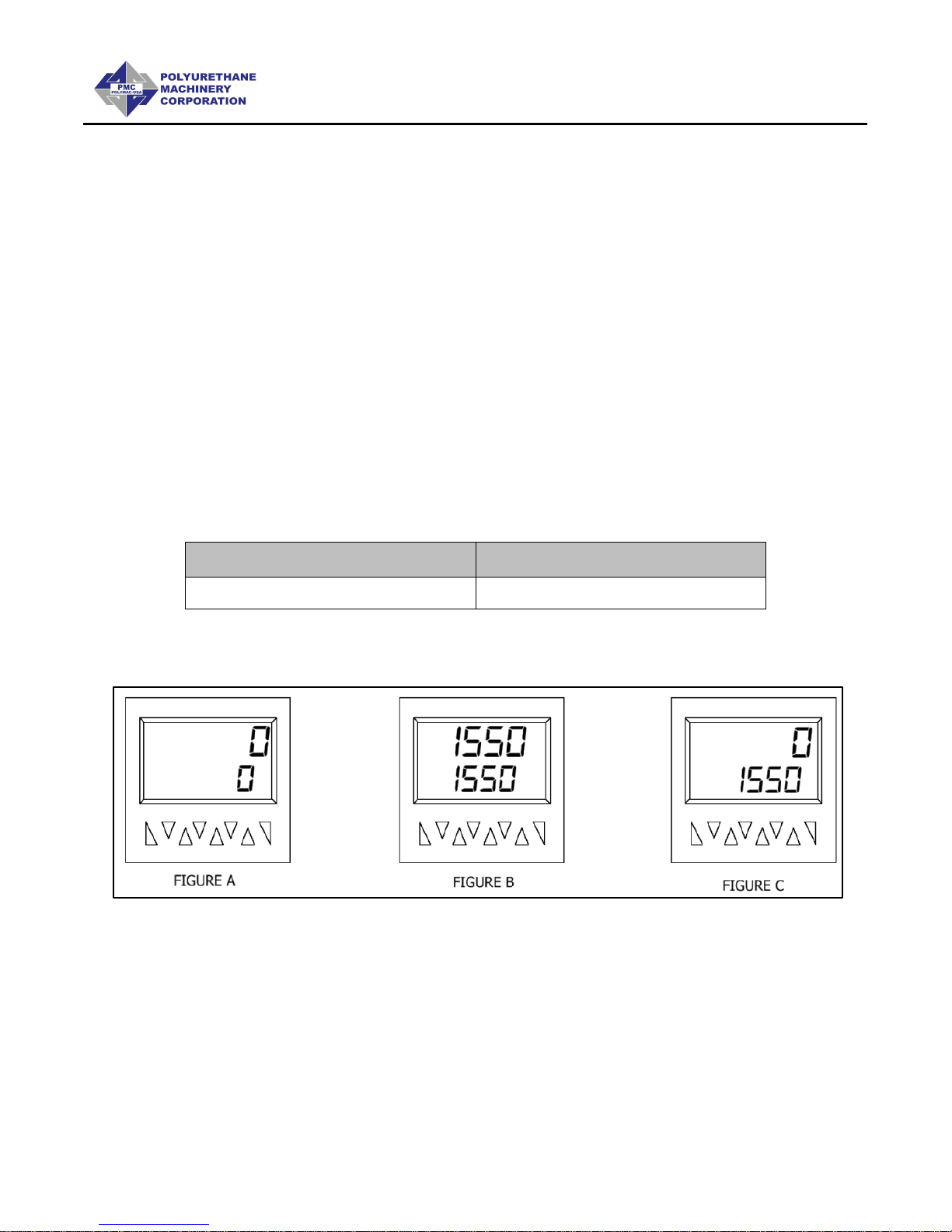

12. COUNT DOWN COUNTER

NOTE! If this function is not needed, leave it in the off position.

To set the Auto Shut Down Counter:

a. Turn the switch to the on position, the green light will illuminate.

b. Insert the number of cycles desired to disable the pump circuit by pushing in on

the white triangles to set the cycle count. Push in on the red button until the data

is replicated on the top row, the top row will count down. Figure B

c. When the counter counts down to zero the machine will stop and the pump

directional light will be off, push in on the red button to reset. Figure C

13. Proceed with Installation and Start-up of the Spray Gun as per the Gun manual.

1

Stall pressure: When materials are at recommended application temperature and Metering

Pumps are pressurized but not moving. This pressure is normally 100 – 200 psi (7-14 Bar)

greater than the developed spray pressure as recommended by the material supplier.

24

Page 29

SHUT-DOWN

Short Term

Follow the procedure below for temporary shut-downs, such as lunch breaks:

1. Set Pump Switch (X, page 11) to OFF position.

2. Turn each Heater OFF. Hose Heater should remain ON. Never leave Proportioner ON if

unattended.

3. CLOSE Spray Gun Manual Valves.

CAUTION! Excessive force opening or closing the Manual Valves may

result in damage to the Manual Valves and/or Coupling Block.

Long Term

Follow the procedure below for shut-downs when work is stopped for the day:

1. Set the Pump Switch (X, page 11) to RETRACT.

2. Spray off the application surface until Material Pressure Gauges (H, K, page 10)

readings begin to fall.

CAUTION! To avoid possible Proportioning Pump Seal seepage and

moisture vapor drive into the Heated Hoses, the system pressure

should not be reduced to zero. It is recommended to lower the system

pressure to a minimum of 400 psi (27 Bar).

3. CLOSE the Spray Gun Coupling Block Manual Valves.

CAUTION! Excessive force opening or closing the Manual Valves may

result in damage to the Manual Valves and/or Coupling Block.

4. Turn OFF Motor Power (W, page 12).

5. Turn OFF the A and R Heaters and Hose Heater (T, page 11).

6. Turn OFF the Auto Shut down switch.

7. Turn OFF the Control Power (S, page 11).

8. Turn OFF the Main Power (Q, page 11).

9. Disconnect the air supply to the two Transfer Pumps and CLOSE the Proportioner

Material Inlet Valves.

25

Page 30

To prevent possible injury caused by incorrect handling of the raw

materials and solvents used in the process, carefully read the

Material Safety Data Sheet (MSDS) provided by your supplier.

Deal with the waste caused according to current regulations.

To avoid damage caused by the impact of pressurized fluids, do

not open any connection or perform maintenance work on

components subject to pressure until the pressure has been

completely eliminated.

Use suitable protection when operating, maintaining or being

present in the area where the equipment is functioning. This

includes, but is not limited to, the use of protective goggles,

gloves, shoes and safety clothing and breathing equipment.

The equipment includes components that reach high temperatures

and can cause burns. Hot parts of the equipment must not be

handled or touched until they have cooled completely.

To prevent serious injury through crushing or amputation, do not

work with the equipment without the safety guards installed on the

moving parts. Make sure that all the safety guards are correctly

reinstalled at the end of the repair or maintenance work of the

equipment.

TROUBLESHOOTING

The PH Series Proportioner has been designed and built to withstand severe working conditions

with a high degree of reliability, provided that it is used in a suitable application by a properly

trained operator. This chapter contains information on possible faults that may interrupt the

operation of the PH Series Proportioner. The information provided will serve as a guideline to

detect and resolve problems. In any case, feel free to contact your authorized PMC Distributor,

where a qualified technician will advise you.

CAUTION! All repairs performed by unqualified personnel or the use

of spares other than originals may cause damage to the unit and put

the operator at risk.

26

Page 31

TROUBLESHOOTING

HEATERS

WARNING! Before troubleshooting make sure the Main

Power Switch is OFF and incoming power is locked OFF.

NEVER access the inside of the Control Panel with the

Proportioner power supply ON. The Heaters are components

that reach high temperatures; you must wait until they cool

before handling.

NOTE! The Thermal Limit Switch is a safety switch in contact with the

Heater body. If the surface temperature exceeds 220 F (109 C), the Limit

Switch will shut off the Heater power. The Limit Switch will not re-set until

the temperature in the Heater is below 190 F (88 C). The system is

designed that in case of an over temperature a contactor will open,

disabling power to both Heaters and the Hose.

27

Page 32

TROUBLESHOOTING

Follow the recommended procedure in the indicated order to solve the problem and avoid

unnecessary repairs. Make sure all Switches are in the correct position and Indicator Lights ON

before determining the existence of a fault.

PROBLEM

Primary heater does not heat and the display on the controller shows ambient

temperature.

SOLUTIONS

1. Check that the light on the on/off switch is lit when the heater is turned on, if

not replace the switch.

If the light is on, move to the next step.

2. Check the heater breaker in the main console, reset the breaker, if it

continues to trip, wrap an Amp Clamp around one of the wires coming off the

breaker. If the Amperage reading does not exceed the rating of the breaker,

the breaker needs to be replaced. If the breaker draws more than its rating

the most likely cause is that one or more of the fire rods are shorted. Remove

the heater cover, disconnect the wires and check each rod for resistance.

Refer to page 30.

If the breaker is not tripped, move on to the next step.

3. Open the console top and locate the solid state relays for the heaters, looking

over the console top from the front of the machine. There are two relays to

the left bottom of the console, the one to the far left is for the “A” heater and

the one to the right is for the “R” heater. With the heater on look to see if a

LED light is lit on the relay.

If there is no LED light on the solid state relay, move to the next step.

4. With a DC volt meter read across position A1 and A2 on the solid state relay

(smaller wires) if you have a reading of 4-6 volts DC and the AC reading

across L1 and L2 (Heavy wires) reads 208-230 volts AC replace the solid

state relay. With 24 volt DC at A1 and A2 the proper reading should be 1 volt

AC across L1 and L2. If the AC reading across L1 and L2 is .025 volts check

the over temperature switches in the heaters. A defective over temperature

switch will open a contactor disabling both Heaters and the Hose.

If there is no DC voltage to the relay, move to the next step.

5. Using a DC volt meter measure across position 5 and 6 on the back of the

heater controller this is the output of the controller and sends power to the

solid state relay, your reading will be 4-6 volts DC. If there is no reading check

to make sure that the set temperature on the controller is above the actual

temperature reading on the controller. Before replacing the controller read

28

Page 33

TROUBLESHOOTING

across position 1 and 2 to make sure that the controller is powered up, your

reading will be 208 to 230 volts AC. If no voltage is present check for loose

wires or a malfunction of the heater circuit breaker.

PROBLEM

Primary heater does not heat and the display on the controller shows a flashing error

message SbEr.

SOLUTIONS

1. Check position 9 and 10 on the heater controller for loose wires.

If the wires are tight, move to the next step.

2. Remove the heater cover and check that the thermocouple wires are secure to

the harness going up to the controller.

If there are no loose connections, replace the thermocouple.

PROBLEM

Primary heater controller shows excessive temperature and the circuit has turned off.

CAUTION! The heater must be allowed to cool down before

continuing.

SOLUTIONS

1. Set the controller set point at least 20F (7C) lower than the temperature shown

on the controller. Briefly turn on the heater and look for the LED light on the solid

state relay to be on.

If the light is on, replace the controller.

If the light is off, replace the solid state relay.

PROBLEM

Primary Heater Temperature drops excessively while spraying.

POSSIBLE CAUSE

1. Temperature of the chemical in the containers is too cold.

2. Exceeding the flow rate specification of the machine.

CAUTION! Disconnect power to the machine before proceeding.

29

Page 34

TROUBLESHOOTING

INDIVIDUAL OHMS MEASUREMENT

1000 WATT

45.9 Ω

1250 WATT

39.0 Ω

1500 WATT

32.4 Ω

1750 WATT

27.5 Ω

3. One or more of the fire rods in the heater have malfunctioned. Remove the

heater cover and disconnect the wires to measure the resistance across each

rod. Installing a smaller mixing chamber in the gun may allow you to spray until a

new rod(s) is installed.

CAUTION! If the rod that is used in conjunction with the thermocouple

is defective, do not operate the heater until the rod is replaced.

30

Page 35

TROUBLESHOOTING

HYDRAULIC DRIVE SYSTEM

Follow the recommended procedure in the indicated order to solve the problem and avoid

unnecessary repairs. Make sure all Switches are in the correct position and Indicator Lights ON

before determining the existence of a fault.

WARNING! Before correcting any kind of defect, make sure

the Main Power Switch is OFF and the incoming power is

locked OFF. NEVER access the inside of the Control Panel

with the Proportioner power supply ON. The Hydraulic Unit is

a component that works under pressure. Do not open any

connection or carry out maintenance on components subject

to pressure until all pressure has been bled to zero.

CAUTION! Do not attempt to reset the Motor Contactor more than

twice. Failure of the Motor Contactor safety mechanism will occur and

the Contactor will become inoperable and/or the Motor will be

damaged. The cause of the problem must be determined and

corrected.

PROBLEM:

Motor does not run and Hydraulic Pump does not develop pressure.

SOLUTIONS:

1. The Electric Motor is protected from excessive current by

an Overload Safety Switch. After allowing the Motor to

cool, open the Control Panel and reset Motor Contactor

Safety.

31

Page 36

TROUBLESHOOTING

PROBLEM:

Motor runs but Hydraulic Pump does not develop pressure

SOLUTIONS:

NOTE! Hydraulic pressure is not generated if the Motor Power Switch (W,

page 12) is OFF or the Pump Switch (X, page 11) is in the OFF position.

With the Pump Switch in the NORMAL position, the failure of the Hydraulic Pump

to develop pressure is loss of pump suction (prime). To ensure positive prime,

check the following:

1. Motor rotation (page 14).

2. Hydraulic Reservoir is filled to the correct level (page 14).

3. Hydraulic Pump Case is filled with the proper hydraulic fluid (page 56).

4. Loose Inlet Plumbing: Check that all inlet plumbing to the Hydraulic Pump

is tight ensure there is no air leakage into the hydraulic system.

PROBLEM:

Low or zero hydraulic pressure with unusual Hydraulic Pump noises.

SOLUTION:

The use of an incorrect hydraulic fluid can result is unusual noises from the pump,

excessive wear and moisture absorption. Ensure the hydraulic oil used is from the list

on page 56. In addition to the above, continuous excessive hydraulic oil temperature as

well as failure to change the hydraulic oil on a yearly basis will cause the oil to fail and

result in excessive Hydraulic Pump wear and unusual noises.

1. Loose Inlet Plumbing: Check that all inlet plumbing to Hydraulic Pump is tight

ensuring no air leakage into the hydraulic system.

NOTE! Hydraulic Pressure will not be developed in the off position if the

pump switch is in the off position or if there is a malfunction in the pump

circuit.

32

Page 37

TROUBLESHOOTING

METERING PUMP LINE

Follow the recommended procedures in the indicated order to solve the problem and avoid

unnecessary repairs. Make sure all Switches are in the correct position and Indicator Lights ON

before determining the existence of a fault.

PROBLEM:

Metering pumps do not change direction and the pressures on both of the

chemical gauges are lower than normal.

SOLUTIONS:

1. The Metering Pump Line has a Reversing Plate which actuates two Proximity Switches,

one at each end of the stroke. The Prox Switches in turn actuate the appropriate

Directional Valve Solenoid. Failure to make contact with either PROX Switch may be

caused by:

a. Deformation of the Reversing Plate.

b. Foreign material preventing the Reversing Plate from contacting the Prox

Switches. If this is not the problem, go to the next step

2. Passing of the Reversing Plate beyond the Prox Switch may be caused by:

a. Failure of the Prox Switch and related components on the side of the over-run.

b. Failure of a component of the Directional Valve.

c. Mounting Plate and/or Prox Switch is out of adjustment.

NOTE! IF THE DIRECTIONAL INDICATOR LIGHT IS ON CHECK THE

REVERSING VALVE COIL ON THE SIDE THAT THE LIGHT IS ON. IF

YOU HAVE 24 VOLTS DC AT THE PLUG CHECK THE OHM’S

RESISTANCE OF THE COIL, IT SHOULD READ APPROXIMATELY 19

OHM’s, IF NOT REPLACE THE COIL OR REVERSING VALVE.

33

Page 38

TROUBLESHOOTING

NOTE! IF THE DIRECTIONAL LIGHT IS OFF PROCEED BELOW

NOTE! BEFORE TROUBLESHOOTING, THE REVERSING SWITCH

PLATE MUST BE MOVED AWAY FROM THE SWITCH.

d. Bleed down the chemical pressures.

e. Ensure Pump Switch (X, page 11) is OFF.

f. Turn on the motor (W, page 12).

g. Go to the Directional Valve and locate the Actuation Coils. Located in the middle

of each coil is a small round tab that can be pushed in to manually shift the spool

to move the pumps. If the Reversing plate is all the way to the left, push in on the

right side coil. If it’s all the way to the right, push in on the left side coil.

WARNING! THE MOTOR MUST BE OFF AND THE PUMP

SWITCH IN THE NORMAL POSITION.

h. Take a small screw driver or a thin piece of metal and move it across the front of

each Prox switch. A red light on the back of the switch should illuminate. If not,

replace the switch that does not light.

i. If the Prox switches light up, turn off all power and check for continuity on both

over pressure switches, pin 1 and 2. If the pressure switches are good, go to the

two solid state relays inside the console and interchange them (they can be

pulled from their housing). With the motor OFF and the pump switch in the

normal position, power-up the unit. If the directional light comes on replace the

defective solid state relay. If not, replace the Latching relay.

34

Page 39

TROUBLESHOOTING

MATERIAL CONDITION

“A” GAUGE

“R” GAUGE

NORMAL

LACK OF ISO (A)

LACK OF POLY (R)

RESTRICTION OF ISO (A)

RESTRICTION OF POLY (R)

2. Safety Pressure Switch - Each Metering Pump has a Safety Pressure Switch (I, L,

page 10). For PH-25 and PH-40 Proportioners, the Safety Pressure Switch is set to

2,200 PSI (152 bar). For PH(X)-25 Proportioners, the Safety Pressure Switch is set to

3,200 PSI (221 bar). For PH(X)-40 Proportioners, the Safety Pressure Switch is set to

3750 PSI (221 bar). When the material system reaches this pressure, the Safety

Pressure Switch will remove power from the Directional Valve and Direction Indicator

Lights (Y, page 12). Lack of Direction Indicator Lights along with high pressure indicated

on one or both of the material Pressure Gauges (H, K) is an indication of a overpressure condition. The Safety Pressure Switches are a momentary design; when the

pressure bleeds off the Metering Pump Line will resume normal operation. However, the

cause of the over-pressure should be determined and corrected. The three most

common causes are:

a. Cavitation of the Metering Pump on the low pressure side causing high pressure

on the opposite side.

b. A restriction in the Spray Gun on the high pressure side.

c. Hydraulic pressure set too high for Spray Gun Mixing Chamber.

3. Pressure/Material Imbalance - In summary troubleshooting this problem requires the

applicator to:

a. Know what the NORMAL spray pressures are for the application in progress.

b. Determine what material is NOT exiting the Mixing Chamber.

c. Read the Pressure Gauge on the problem side and interpret the reading.

35

Page 40

TROUBLESHOOTING

Left Directional Indicator

Light ON

Right Directional Indicator

Light ON

Iso Pressure Gauge

FALLS

Iso Inlet Ball does not

seat properly

Iso Discharge Ball does

not seat properly

Poly Pressure Gauge

FALLS

Poly Discharge Ball does

not seat properly

Poly Inlet Ball does not

seat properly

4. Cavitation - Cavitation occurs when the Metering Pump (B, or C, page 10) requires a

larger volume of material than the supply system (Transfer Pump) can furnish. This

creates a "void" of material in the Metering Pump. The most common causes of

cavitation are:

a. Material temperature too low causing increased material viscosity resulting in the

inability of the Transfer Pump to maintain sufficient supply to the Metering Pump.

This is most common with today's blown systems. Ensure the material

temperature in the drums is no lower than the material suppliers'

recommendation.

b. Failure to vent the material drum while drawing material out with the Transfer

Pump causes a vacuum and cavitation in the Transfer Pump. Ensure the drum is

vented to the atmosphere or a Desiccant Air Dryer Kit is installed as

recommended by the material supplier.

c. Air volume is insufficient for the Transfer Pump or if the Transfer Pump Air Valve

is partially closed, this will limit the ability of the Transfer Pump to operate at its

maximum capability.

d. Inlet Material Screen (O) obstructed (See MAINTENANCE section).

e. Metering Pump Inlet Ball does not seat properly allowing material to flow back

into the Material Delivery Hose when the Metering Pump is on the "Discharge"

stroke. This causes the volume of material on that Metering Pump to be less on

the discharge stroke resulting in intermittent off-ratio material and Pressure

Gauge fluctuation.

5. Pressure Loss: Discharge/Inlet Ball - Simultaneous observation of the material

Pressure Gauge (H, K, page 10) and Directional Indicator Light (Y page 12) is necessary

to determine which direction the Metering Pump fails to maintain pressure. Refer to the

chart to determine the problem:

In most cases the cause of a leaking Inlet/Discharge Ball is foreign material preventing

the Ball from seating properly. If the above steps do not resolve the problem, replace the

appropriate Ball, Ball Seat, Ball Seat Gasket and the O-ring on the cage.

For service see MAINTENANCE/Metering Pump Line (Page 46).

36

Page 41

TROUBLESHOOTING

HOSE HEATING

WARNING! Before correcting any kind of defect, make sure

the Main Power Switch is OFF and incoming power is locked

OFF. NEVER access the inside of the Control Panel with the

Proportioner power supply ON. The Heated Hoses are

components which reach high temperatures. Wait until they

have cooled before handling.

CAUTION! All electrical testing must be done by a qualified

electrician.

Follow the recommended procedure in the indicated order to solve the problem and avoid

unnecessary repairs. Make sure all Switches are in the correct position and Indicator Lights ON

before determining the existence of a fault.

PROBLEM:

A-Heated hose does not heat and the display on the controller shows ambient

temperature.

SOLUTIONS:

1. Check that the light on the on/off switch is lit when the heater is turned on, if not

replace the switch.

If the light is on, move on to the next step.

2. Check the Hose Heat Breaker in the main console reset the breaker. If it

continues to trip wrap an Amp Clamp around one of the wires coming off the

breaker. If it does not draw more than the rated value of the breaker, the breaker

needs to be replaced.

If the breaker is not tripped, move on to the next step.

3. Check the circuit breaker mounted on the transformer and reset the breaker if

necessary. If it continues to trip wrap an Amp Clamp around one of the wires

from the transformer going to the heated hose. If it does not draw more than the

rated value of the breaker, the breaker needs to be replaced.

If the AMP draw is less than the rated value, move on to the next step.

4. Check that the tap setting on the transformer is set for the proper hose length.

If it is set correctly, move to the next step.

37

Page 42

TROUBLESHOOTING

5. Look at the two lights located on the front of the transformer. If the voltage light is

lit and the AMP light is off the problem could in the heated hoses. If the voltage

light is on there is power to the primary side of the transformer. To check the

secondary side of the transformer you must take an AC volt reading across the

two leads coming out of the transformer that are connected to the “A” and “R”

hose leads. If you are reading voltage (your voltage reading will vary depending

on what tap setting is used) most likely the problem is in the heated hose. Either

a connector has come loose or there is a broken wire.

6. Remove one of the wires coming out of the transformer that is connected to

either the “A” or “R” side of the heated hose. Using an ohms meter perform a

continuity reading across the two lead wires coming off the machine end of the

heated hose. If there is no continuity through the hose check for loose or broken

connection between each section of hose. If all the connections are secure and

there are no visible broken wires it is possible that the element on the hose or the

lead wire has broken at its connection. Each hose must be checked individually

for continuity. Because the gun whip takes the most abuse it is most likely that

the problem is in the hose whip up at the gun end.

If no voltage is coming out of the transformer to the heated hose, move on

to the next step.

7. Open the console top and locate the solid state relay for the hose circuit (see

page 34), looking over the console top (front of machine) it is the relay to the

right. With the hose turned on and there is a LED light lit on the relay, take a volt

meter set on DC and measure across position A1 and A2 your reading should be

24 volts, then take an AC volts measurement across position L1 and L2 (heavy

wires). With the relay functioning properly you should have a 1 volt reading, if the

reading is 18 to 90 volts AC the relay has malfunctioned and needs to be

replaced. If the AC Reading across L1 and L2 is .025 volts check the over

temperature switches in the heaters. A defective over temperature switch will

open a contactor disabling both Heaters and the Hose.

If there is no light on the solid state relay, move to the next step.

8. Using a DC volt meter measure across position 5 and 6 on the back of the hose

controller, this is the output of the controller and sends power to the solid state

relay, your reading will be 4-6 volts DC. If there is no voltage check to make sure

that the set temperature of the controller is above ambient temperature. Before

replacing the controller read across position 1 and 2 to make sure that the

controller is powered up, your reading will be 208 to 230 volts AC.

38

Page 43

TROUBLESHOOTING

PROBLEM:

Hose does not heat and the display on the controller shows a flashing error message

“SbEr.”

SOLUTIONS:

1. Check position 9 and 10 on the heater controller for loose wires.

If the wires are tight, move to the next step.

2. Remove the transformer cover and check that the thermocouple wires are secure

to the harness going up to the controller. If there are no loose connections,

disconnect the wire from the TSU and connect it directly to the thermocouple

harness coming out of the hose transformer.

If the controller still shows the error code, replace the hose thermocouple.

If the error code goes away and temperature is now shown on the display of the

controller, then all the TSU harnesses from the TSU to the transformer need to be

checked for loose connectors or one or more of the harnesses are defective.

PROBLEM:

Heated hose controller shows excessive temperature.

SOLUTIONS:

1. Set the controller set point at least 20F (7C) lower than the temperature shown

on the controller. Briefly turn on the Hose Heater Switch and look for the LED

light on the solid state relay to be lit.

If the light is on, replace the controller.

If the light is off, replace the solid state relay.

PROBLEM:

Hose will heat but does not come up to set temperature.

SOLUTIONS:

1. Check the tap setting on the transformer to ensure that the correct position has

been selected for the length of hose being used. Depending on the machines

incoming voltage, you may have to move the tap setting higher (up one).

CAUTION! Do not exceed the trip value of the transformer hose

breaker.

39

Page 44

TROUBLESHOOTING

WARNING! Before correcting any kind of defect, make sure

the Main Power Switch is OFF and incoming power is locked

OFF. NEVER access the inside of the Control Panel with the

Proportioner power supply ON.

NOTE! In the event an equipment problem cannot be solved after following

the detailed instructions contained in this manual, please contact your PMC

authorized distributor and they have direct contact with PMC Technical

Service Department.

NOTE! For all parts and field service, contact your PMC authorized

distributor.

40

Page 45

TROUBLESHOOTING

PRESSURE BALANCE CONTROL