Page 1

Air Purge

Spray & Pour Gun

AP-3

For use with non-flammable Foam and

Polyurea

For professional use only

Not for use in explosive atmospheres

Service Manual

Ref. # MN-04030

Revision 1.4

November 21, 2018

Subscribe to our channel,

Polyurethane Machinery

Corporation PMC, for

video instructions.

Polyurethane Machinery Corp.

Corporate: 1 Komo Drive, Lakewood, NJ 08701

Manufacturing: 2 Komo Drive, Lakewood, NJ 08701

Phone: 732-415-4400

Fax: 732-364-4025

URL: http://www.polymacusa.com

Before installing the AP-3 Gun and start-up, carefully read all the

technical and safety documentation included in this manual. Pay

special attention to the information in order to know and understand

the operation and the conditions of use of the AP-3 Gun. All of the

information is aimed at improving user safety and avoiding possible

breakdowns from the incorrect use of the AP-3 Gun.

Page 2

Table of Contents

WARRANTY ........................................................................................................................................ 1

SAFETY AND HANDLING ................................................................................................................... 3

CHARACTERISTICS ........................................................................................................................... 5

TECHNICAL SPECIFICATIONS .......................................................................................................... 5

GENERAL DESCRIPTION .................................................................................................................. 6

INSTALLATION AND START UP ........................................................................................................ 7

SHUTDOWN PROCEDURES ............................................................................................................. 8

LOSS OF AIR PRESSURE/EMERGENCY SHUT-OFF ....................................................................... 8

MAINTENANCE .................................................................................................................................. 9

Gun Block and Mixing Chamber Removal ...................................................................................... 11

Screen Screw and Component Maintenance ................................................................ ................. 13

Air Cylinder Maintenance ............................................................................................................... 15

Cartridge Valve Removal ............................................................................................................... 17

GUN OPERATION ............................................................................................................................ 18

Triggered Off ................................................................................................................................. 18

Triggered On ................................................................................................................................. 19

TROUBLE SHOOTING GUIDE ......................................................................................................... 20

REFERENCE GUIDE ........................................................................................................................ 21

Chamber Kits ................................................................ ................................................................. 21

PCT Kits ................................ ................................................................................................ ........ 22

Chamber/PCT Kits ......................................................................................................................... 25

Soft Chamber Kits .......................................................................................................................... 25

Spare Parts Kit AP2 ................................ ................................................................ ....................... 26

AP2/3-000 Spare Parts Kit (200445) .............................................................................................. 26

AP2/3-00 Spare Parts Kit (200446) ................................................................................................ 27

AP2/3-00X Spare Parts Kit (200447) ............................................................................................. 27

AP2/3-01 Spare Parts Kit (200448) ................................................................................................ 28

AP2/3-01X Spare Parts Kit (200449) ............................................................................................. 28

AP2/3-02 Spare Parts Kit (200450) ................................................................................................ 29

AP2/3-02X Spare Parts Kit (200451) ............................................................................................. 29

AP2/3-03 Spare Parts Kit (200452) ................................................................................................ 30

AP2/3-04 Spare Parts Kit (200453) ................................................................................................ 30

AP2/3-05 Spare Parts Kit (201173) ................................................................................................ 31

AP2/3-05 Package Drill Bits (201174) ............................................................................................ 31

Page 3

TABLE OF CONTENTS

Air Cylinder Rebuild Kit .................................................................................................................. 32

AP-3 O-Ring Kit ............................................................................................................................. 32

PMC Recommended O-Ring Grease ............................................................................................. 32

Screen Sizes ................................................................................................................................. 32

A & R Screen Screw Assembly Kits ............................................................................................... 33

Recommended Spare Parts ........................................................................................................... 33

Optional Parts ................................ ................................................................................................ 34

Check Valve Assembly ................................ ................................................................ .................. 34

1/4” Unheated Stainless Steel Hose Assy. ..................................................................................... 34

Flush Tanks ................................................................................................................................... 35

PARTS IDENTIFICATION ................................................................................................................. 36

Manual Valve Assembly ................................................................................................................. 36

Coupling Block Assembly .............................................................................................................. 37

Gun Assembly ............................................................................................................................... 38

Gun Block Assembly ...................................................................................................................... 40

Screen Screw Assembly ................................................................................................................ 41

List of Tools ................................................................................................................................... 42

APPENDIX ........................................................................................................................................ 43

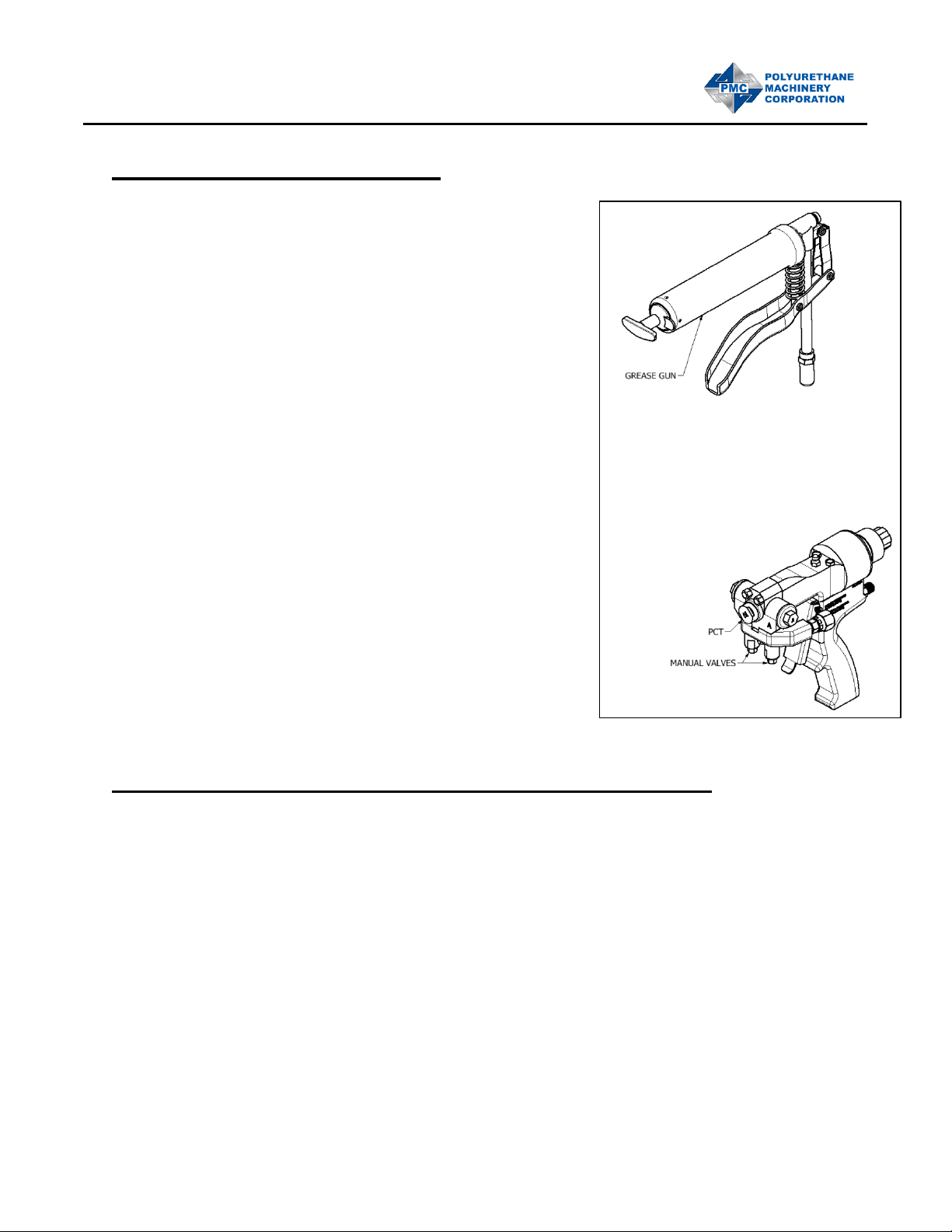

Grease Gun Assembly ................................................................................................................... 43

Mixing Chamber Flow Rates ................................................................................................ .......... 44

Chamber/Orifice Comparison Chart ............................................................................................... 44

Page 4

1

WARRANTY

Polyurethane Machinery Corporation (hereinafter “PMC”) provides this

LIMITED

WARRANTY

(hereinafter “Warranty”) to the original purchaser (hereinafter “Customer”) covering

this equipment and the original PMC manufactured accessories delivered with the equipment

(hereinafter “Product”) against defects in material or workmanship of the Product (hereinafter

“Defect” or “Defective”) for a period of one (1) year from the date of first purchase as shown on

the original PMC invoice (hereinafter “Warranty Period”).

If during the Warranty Period under normal use, the Product is suspected by Customer to be

Defective in material or workmanship, it is Customer’s responsibility to contact PMC and return the

Product to PMC as directed by PMC, freight prepaid. If PMC determines that the Product is

Defective and that such Defect is covered by this Warranty, PMC will credit Customer for the

reasonable freight charges incurred by Customer in returning the Defective Product to PMC, and

PMC (or its authorized agent) will, at PMC’s option, repair or replace the Product, subject to

the following:

Original Invoice:

The original invoice must be kept as proof of the date of first sale and the

Product serial number. The Warranty does not cover any Product if the Original Invoice appears to

have been modified or altered, or when the serial number on the Product appears to have been

altered or defaced.

Product Maintenance:

It is the Customer’s responsibility to maintain the Product properly. See

your maintenance schedule and owner’s manual for details. The Warranty does not cover an

improperly maintained Product.

Non-PMC Components and Accessories:

Non-PMC manufactured components and accessories

that are used in the operation of the Product are not covered by this Warranty. Such components and

accessories shall be subject to the warranty offered to the Customer, if any, by the original

manufacturer of such component or accessory.

Other Warranty Exclusions:

The Warranty does not cover any Product that PMC determines has

been damaged or fails to operate properly due to misuse, negligence, abuse, carelessness,

neglect, or accident. By way of example only, this includes:

•

Normal wear and tear.

•

Improper or unauthorized installation, repair, alteration, adjustment or modification of

the Product.

•

Use of heating devices, pumping equipment, dispensers, or other parts or accessories with

the Product that have not been approved or manufactured by PMC.

•

Failure to follow the operating instructions and recommendations provided by PMC may cause

loss or damage to personnel, equipment, or work area.

•

Fire, flood, “acts of God,” or other contingencies beyond the control of PMC.

Page 5

WARRANTY

2

THE WARRANTY DESCRIBED HEREIN IS THE EXCLUSIVE REMEDY FOR THE

CUSTOMER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED,

STATUTORY OR OTHERWISE, AND THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND ALL OTHER

WARRANTIES ARE HEREBY DISCLAIMED. TO THE FULLEST EXTENT PERMITTED BY

LAW, PMC SHALL NOT BE RESPONSIBLE, WHETHER BASED IN CONTRACT, TORT

(INCLUDING, WITHOUT LIMITATION, NEGLIGENCE), WARRANTY OR ANY OTHER

LEGAL OR EQUITABLE GROUNDS, FOR ANY CONSEQUENTIAL, INDIRECT,

INCIDENTAL, LOST PROFITS, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES,

WHETHER TO PERSON OR PROPERTY, ARISING FROM OR RELATING TO THE

PRODUCT, EVEN IF PMC HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

LOSSES OR DAMAGES.

Non-Warranty Service by PMC: If PMC determines that the suspected Defect of the Product is not

covered by this Warranty, disposition of the Product will be made pursuant to the terms and

conditions

of PMC’s written estimate on a time and materials bas

is.

Continuing Warranty for Products Repaired or Replaced under Warranty: Following the repair

or replacement of a Product covered by this Warranty, such Product will continue to be subject

to the original Warranty for the remainder of original Warranty Period or for three (3) months from

the repair or replacement date, whichever is longer.

No Rights Implied: Nothing in the sale, lease or rental of any Product by PMC shall be construed

to grant any right, interest or license in or under any patent, trademark, copyright, trade secret or

other proprietary right or material owned by anyone; nor does PMC encourage the infringement

of same.

Exclusive Warranty: This writing is the final, complete, and exclusive expression of the Warranty

covering the Product. Any statements made by PMC, its employees or agents that differ from

the

terms of this Warranty shall have no effect. It is expressly understood that Customer’s

acceptance of

this Warranty, by performance or otherwise, is upon and subject solely to the

terms and conditions hereof, and any additional or different terms and conditions proposed or

expressed by Customer or anyone, whether in writing or otherwise, are null and void unless

specifically agreed to in writing by an Officer of PMC.

Page 6

3

SAFETY AND HANDLING

This chapter contains important information on the safety, handling and use of your AP-3 Gun.

Before installing the AP-3 Gun and start-up, carefully read all the

technical and safety documentation included in this manual. Pay

special attention to the information in order to know and

understand the operation and the conditions of use of the AP-3

Gun. All of the information is aimed at improving user safety and

avoiding possible breakdowns from the incorrect use of the AP3 Gun.

WARNING!

Presents information to alert of a situation that

might cause serious injuries if the instructions are not

followed.

CAUTION! Presents information that indicates how to avoid damage

to the AP-3 Gun or how to avoid a situation that could cause injuries.

NOTE! Is relevant information of a procedure being carried out.

Careful study of this Manual will enable the operator to know the characteristics of the Gun and

the operating procedures. By following the instructions and recommendations contained, you will

reduce the potential risk of accidents in the installation, use or maintenance of the AP-3 Gun;

you will provide a better opportunity for incident-free operation for a longer time, greater

productivity and the possibility of detecting and resolving problems fast and simply.

Keep this Service Manual for future reference to useful information. If you lose this Manual, ask

for a new copy from your PMC Service Center or go to the company website

(www.polymacusa.com).

The AP-3 Gun has been designed and built for the application of polyurea chemical systems,

polyurethane foam chemical systems and some two-component epoxy systems.

Page 7

SAFETY AND HANDLING

4

WARNING! The design and configuration of the AP-3 Gun

does not allow its use in potentially explosive atmospheres

or exceeding the pressure and temperature limits described

in the Technical Specifications of this Manual to be

exceeded.

Always use liquids and solvents that are compatible with the AP-3 Gun. If in doubt, consult PMC

Technical Service.

When working with the AP-3 Gun, it is recommended that the operator wear suitable clothing and

elements of personal protection, including, without limitation, gloves, protective goggles,

safety footwear and face masks. Use breathing equipment when working with the Gun in

enclosed spaces or in areas with insufficient ventilation. The introduction and follow-up of safety

measures must not be limited to those described in this Manual. Before beginning to work with

the Gun, a comprehensive analysis must be made of the risks derived from the products to be

dispensed, the type of application and the working environment.

To prevent possible injury caused by incorrect handling of the

materials and solvents used in the process, carefully read the

Material Safety Data Sheet (MSDS) provided by your supplier.

To avoid damage caused by the impact of pressurized fluids, do

not open any connection or perform maintenance work on

components subject to pressure until the pressure has been

completely eliminated.

Use suitable protection when operating, maintaining or being

present in the area where the equipment is functioning. This

includes, but is not limited to, the use of protective goggles,

gloves, shoes and safety clothing and breathing equipment.

The equipment includes components that reach high

temperatures and can cause burns. Hot parts of the equipment

must not be handled or touched until they have cooled

completely.

The equipment sprays high pressure fluids that can lead to fluid

being injected under the skin or eyes. Severe injury could be

incurred. Proper personal protective equipment should be used

in conjunction with training and situational awareness of all

personnel on the job.

Page 8

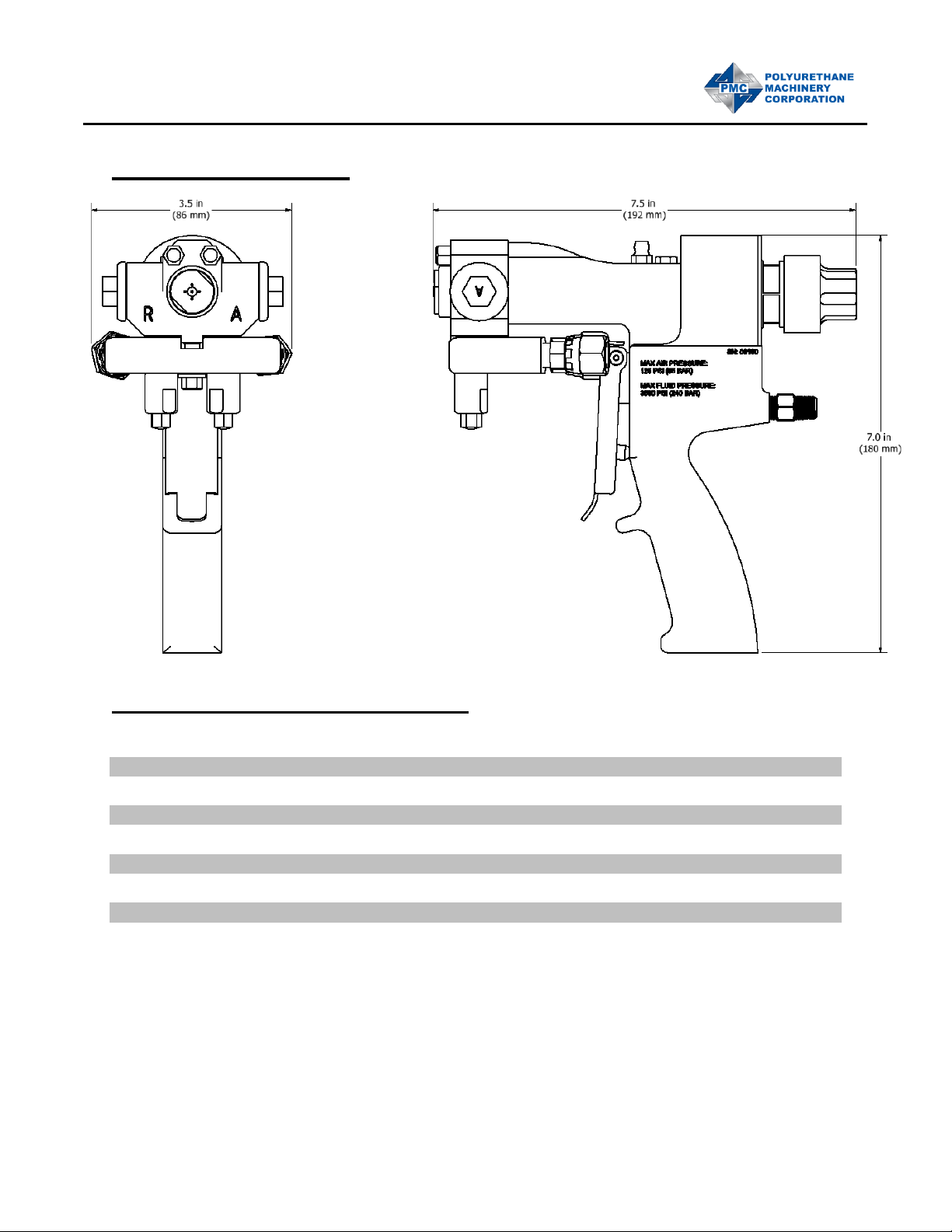

5

CHARACTERISTICS

TECHNICAL SPECIFICATIONS

Maximum Working Pressure: _______________________________ 3,500 psi (245 Bar)

Air Pressure: _________________________________________________ 90-125 psi (6.2-8.6 Bar)

Maximum Output (1:1 ratio): ____________________________________ 50 lb/min (22.7 L/min)

Minimum Output (1:1 ratio): ____________________________________ 3.3 lb/min (1.55 L/min)

Opening Force @ 110 psi (8 Bar): ____________________________________ 200 lb (91 kg)

Closing Force @ 110 psi (8 Bar): ________________________________________ 200 lb (91 kg)

Weight (Not including Coupling Block): _____________________________ 2.4 lbs (1.1 kg)

Weight (Including Coupling Block): _________________________________ 3.1 lbs (1.4 kg)

Page 9

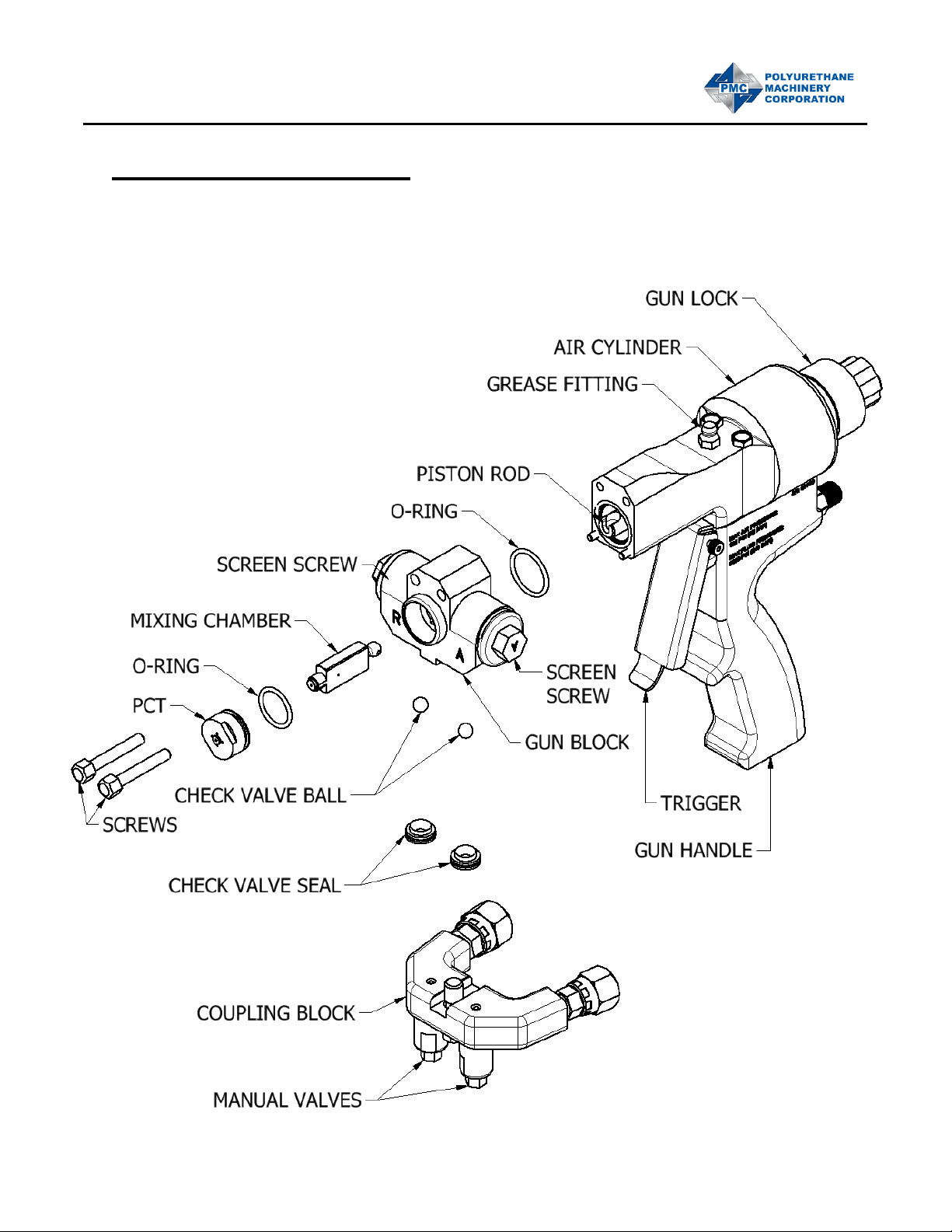

6

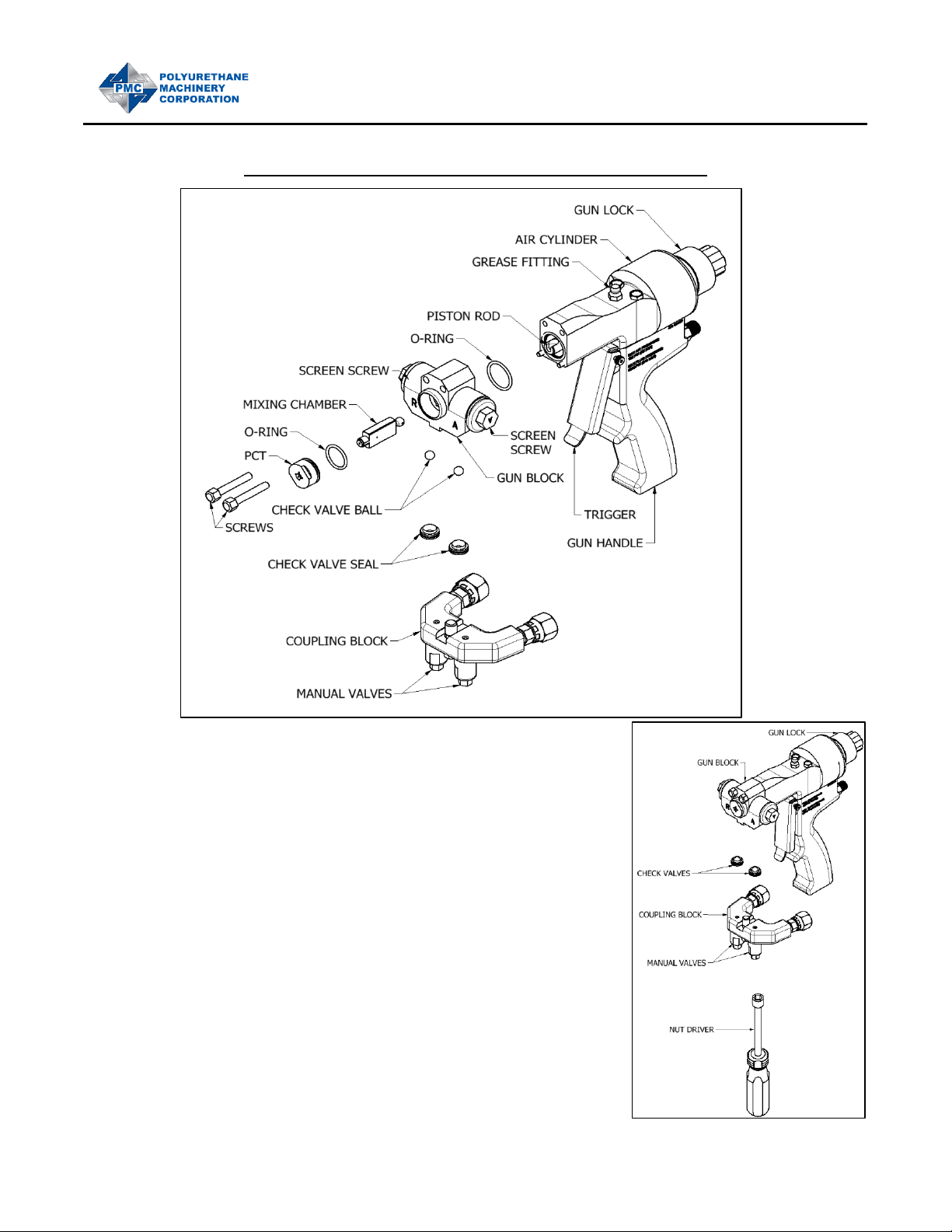

GENERAL DESCRIPTION

For better knowledge of the AP-3 Gun, the main components and their description are shown.

For a more precise identification, see the Parts Identification section.

Page 10

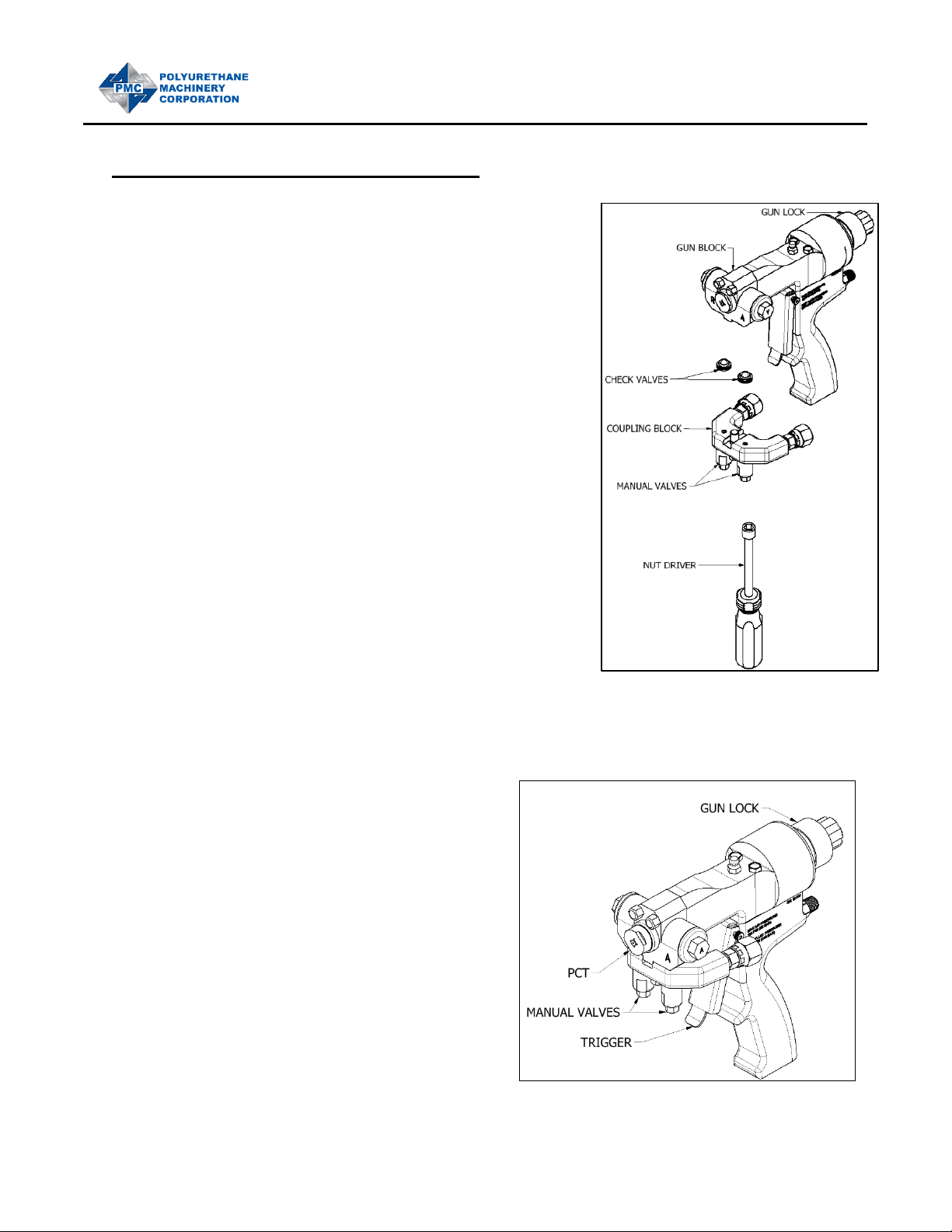

INSTALLATION AND START UP

7

INSTALLATION AND START UP

CAUTION!

When working with the AP-3 Gun or

performing maintenance work, wear suitable

safety protection in accordance with the

recommendations and specifications

provided by the product suppliers.

1. Install Coupling Block to the hose.

2. Ensure the Manual Valves are CLOSED by turning them to

the full clockwise position.

CAUTION!

Excessive force closing or opening

the Manual Valves may result in damage to the

Manual Valves and/or Coupling Block.

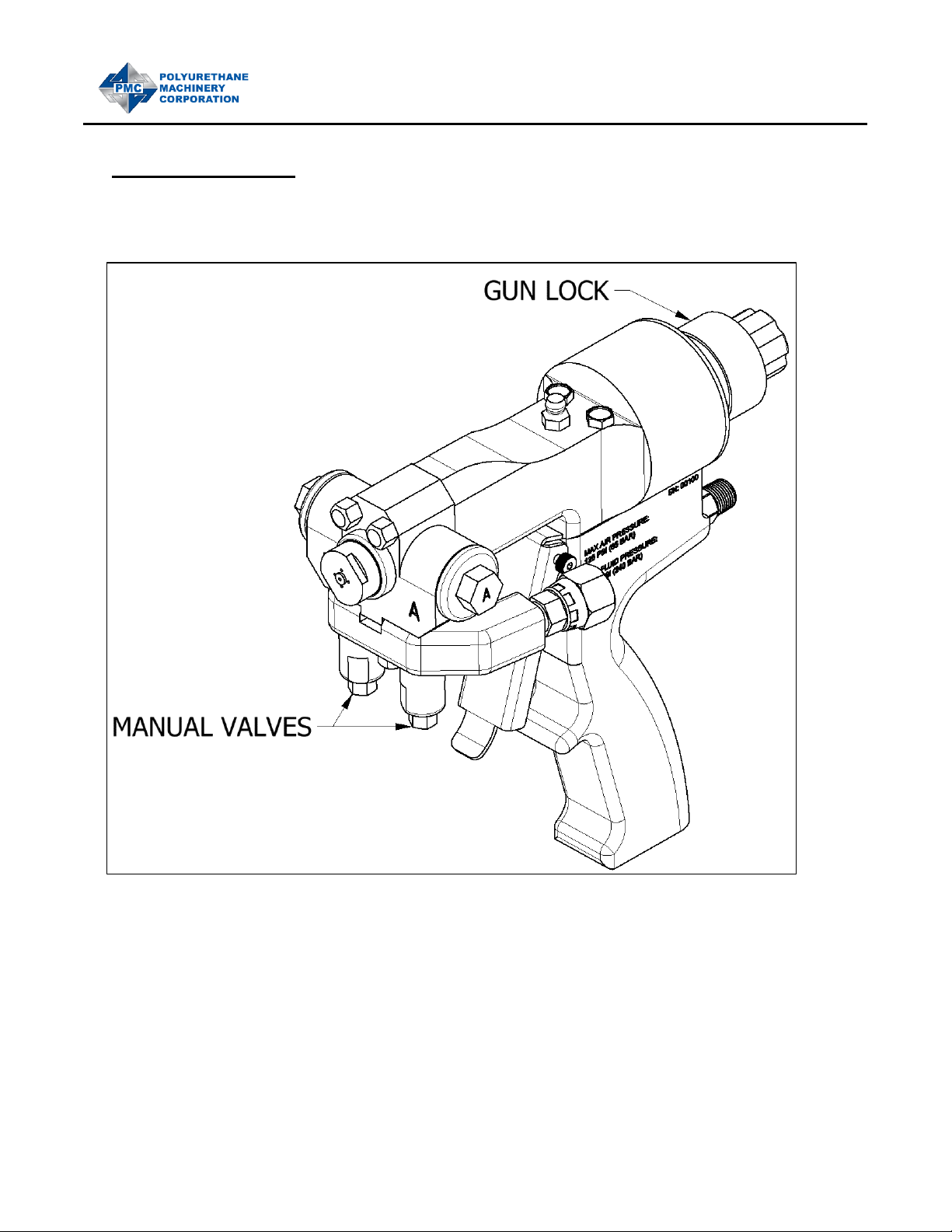

3. Set the Gun Lock to the LOCKED position.

4. Ensure Check Valve Assemblies are properly installed in the

Gun Block.

5. Connect the Coupling Block to the Gun Block using the Nut

Driver provided (Pg. 42). Tighten Coupling Block until there

is a hand tight seal.

6. Connect the air supply with 90 to 125 psi (6.2 to 8.6 bar) to the gun.

NOTE!

The material delivery hoses are color coded Red and Blue. The Red corresponds to the Isocyanate (A) and

the Blue to the Polyol (R). To avoid connection errors, the (A) and (R) hoses have connections with different sizes

to avoid incorrect connections. [

Set the Gun Lock to the OPEN position.]

7. Pull the Trigger several times to check for correct

movement of the Mixing Chamber and PCT.

8. Ensure the Proportioner and supply system are in

the ready position and the material pressures and

temperatures are set as recommended by the

chemical supplier (see Machine Service Manual).

9. OPEN each Manual Valve by turning three (3) full

turns counter clockwise.

10. Perform a test spray.

Page 11

8

SHUTDOWN PROCEDURES

1.

CLOSE the Manual Valves by turning them to the full

clockwise position.

CAUTION!

Excessive force closing or

opening Manual Valves may result in damage

to the Manual Valves and/or Coupling Block.

2. Using the supplied Grease Gun (Pg. 42), lubricate the

Mixing Chamber through the Grease Fitting until a

fine mist of grease is sprayed from the gun (Pg. 43 for

Grease Gun Assembly Instructions). This action will

help prevent Isocyanate from crystallizing on the mixing

chamber which may cause damage to the internal parts.

NOTE! The injection of grease supplied with the

Gun at the end of the day will minimize

maintenance time and can eliminate the need to

remove the Mixing Chamber each day to clean it.

Use of grease with high moisture content will

not achieve the desired results. PMC Grease is

recommended. Use of incorrect grease will

cause blockage in the mixing chamber.

3. Disconnect the air supply.

LOSS OF AIR PRESSURE/EMERGENCY SHUT-OFF

1. SHUT OFF air supply to gun.

2. Using the palm of your hand, push in on the Gun Lock and rotate clockwise to set it to

the LOCKED position.

3. CLOSE each Manual Valve.

CAUTION!

Excessive force closing or opening Manual Valves may result in

damage to the Manual Valves and/or Coupling Block. Emergency shut off

if trigger sticks – disconnect air line.

Page 12

MAINTENANCE

9

MAINTENANCE

To obtain maximum performance from your AP-3 Gun, it is necessary to periodically perform

certain maintenance operations.

WARNING! Before proceeding with any maintenance work on

the AP-3 Gun, trigger the gun to remove internal material

pressure, ensure the Manual Valves are CLOSED, ensure the

Gun Lock is in the LOCKED position, and SHUT

OFF/DISCONNECT the air supply. It is recommended to

remove the Gun from the Coupling Block.

Page 13

MAINTENANCE

10

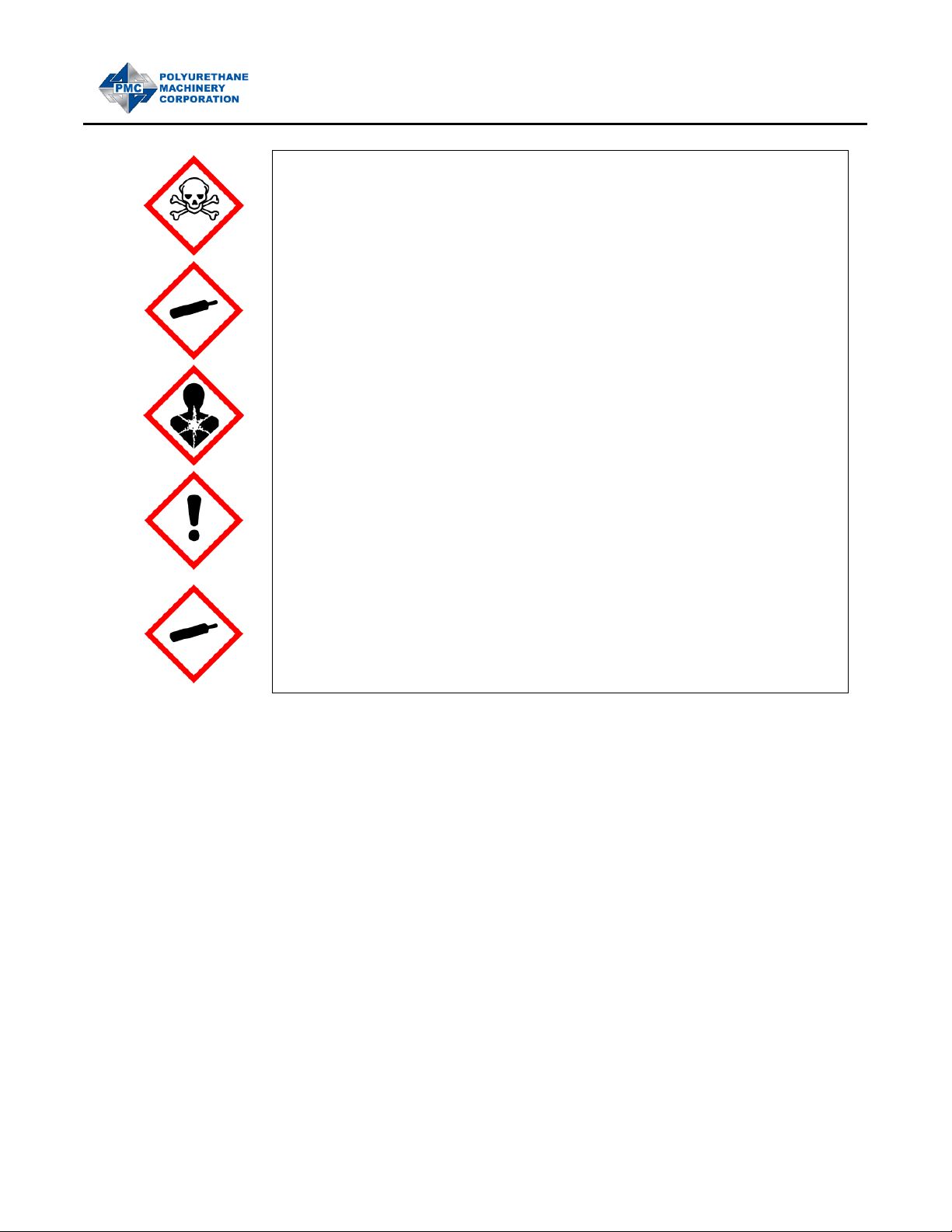

To prevent possible injury caused by incorrect handling of the

materials and solvents used in the process, carefully read the

Material Safety Data Sheet (MSDS) provided by your supplier.

To avoid damage caused by the impact of pressurized fluids,

do not open any connection or perform maintenance work on

components subject to pressure until the pressure has been

completely eliminated.

Use suitable protection when operating, maintaining or being

present in the area where the equipment is functioning. This

includes, but is not limited to, the use of protective goggles,

gloves, shoes and safety clothing and breathing equipment.

The equipment includes components that reach high

temperatures and can cause burns. Hot parts of the equipment

must not be handled or touched until they have cooled

completely.

The equipment sprays high pressure fluids that can lead to

fluid being injected under the skin or eyes. Severe injury could

be incurred. Proper personal protective equipment should be

used in conjunction with training and situational awareness of

all personnel on the job.

Page 14

MAINTENANCE

11

Gun Block and Mixing Chamber Removal

1. CLOSE the Manual Valves by turning them to the full

clockwise position.

CAUTION!

Excessive force opening or closing

Manual Valves may result in damage to the

Manual Valves and/or Coupling Block.

2. Point the gun over a waste container and pull the Trigger to

relieve pressure.

3. Using the Nut Driver provided (Pg. 42), remove the

Coupling Block from the Gun Block.

4. Flush the Gun Block to remove any residue. Use the

recommended Flush Tank (Pg. 35)

5. Shut off air to the gun.

Page 15

MAINTENANCE

12

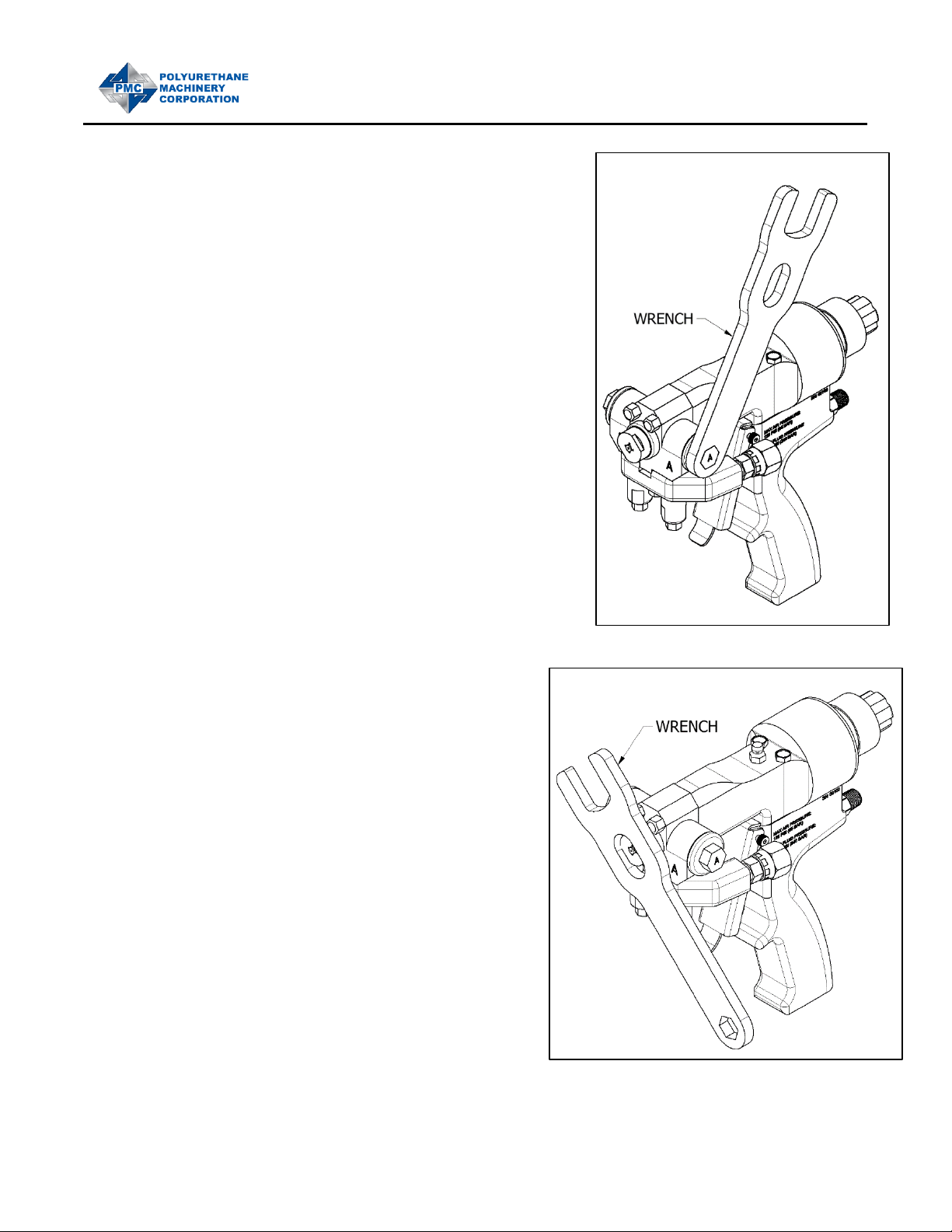

6. .Using the Wrench provided (Pg. 42) or a ½”

wrench, loosen or remove both Screen Screws to

facilitate easy removal of the Mixing Chamber, as

shown below.

7. Loosen the PCT, but do not remove.

8. Using the Nut Driver (Pg. 42) provided, remove the

gun block screws mounting screws. (see page 6,

item O)

9. Disconnect the Gun Block from the Cylinder.

10. Remove the Mixing Chamber and PCT from the Gun

Block.

11. Clean or replace the Mixing Chamber as required.

12. When reassembling in reverse order, it is

recommended to screw the PCT onto the Mixing

Chamber first, then insert the Mixing Chamber

into the front of the Gun Block. This helps to

reduce wear on the PCT O-ring.

NOTE! A small amount of PMC grease applied

to the Mixing Chamber and Side Seals upon

assembly is recommended.

CAUTION!

Use wooden or plastic tools

or a brass brush for cleaning. Do not use

metal or abrasive tools that can scratch

or damage the contact surfaces.

Page 16

MAINTENANCE

13

Screen Screw and Component Maintenance

CAUTION!

To avoid possible contamination by the residual chemical

inside the Gun do not interchange the Isocyanate (A) parts with the

Polyol (R) parts. The Isocyanate (A) side is identified with an (A) on the

Screen Screw Head and the Polyol (R) side is marked with an (R) on the

Screen Screw Head. The Gun Block is also marked with (A) and (R)

designation.

1. CLOSE the Manual Valves by turning them to the full clockwise position.

CAUTION!

Excessive force opening or closing Manual Valves may

result in damage to the Manual Valves and/or Coupling Block.

2. Point the gun over a waste container and pull the Trigger to relieve pressure.

3. Using the Nut Driver provided (Pg. 35), remove the Coupling Block from the Gun Block.

4. Flush the gun block

to remove any residue. Use the recommended Flush Tank (Pg. 35)

5.

SHUT OFF

air supply to the gun.

6.

Set the Gun Lock to the LOCKED position.

Page 17

MAINTENANCE

14

7.

Use the Wrench provided (Pg. 42) or a ½” wrench to remove the Screen Screw.

8.

To clean or replace the Screens, remove the larger O-Ring and Back Up Ring.

9. Remove the Side Seal and Spring from the Screen Screw. Inspect all components and O-

rings. Clean or replace as required.

10.

Inspect for damage and apply PMC lubrication to all O-rings and threads and reassemble in

reverse order

.

11.

The gun is now ready for service

.

NOTE! When replacing O-rings, replace ALL O-rings included in the

appropriate Kit.

Page 18

MAINTENANCE

15

Air Cylinder Maintenance

1. CLOSE the Manual Valves by turning them to the full clockwise

position.

CAUTION!

Excessive force opening or closing

Manual Valves may result in damage to the

Manual Valves and/or Coupling Block.

2. Point the gun over a waste container and pull the Trigger to

relieve pressure.

3. DISCONNECT air supply to gun.

4. Set the Gun Lock to the LOCKED position.

5. Flush the gun block to remove any residue. Use the

recommended Flush Tank (Pg. 35)

6. Loosen the Screen Screws using the Wrench provided

(Pg. 42) a ½” wrench.

7. Disconnect Coupling Block from Gun Block using the Nut

Driver provided (Pg. 42).

Page 19

MAINTENANCE

16

8. Using the Nut Driver provided, remove

the gun block mounting screws and

disconnect the Gun Block.

9. Using an 11/16” Wrench, remove the

End Cap.

10. Push on the front of the Piston to

remove the Piston from the rear of the

Air Cylinder.

11. Inspect the O-rings on the Piston and

Shaft and replace as required.

12. Inspect the O-ring on the End Cap

and replace as required.

NOTE! When replacing O-rings,

replace ALL O-rings included in the

Rebuild Kit.

13. Coat the inside of the Cylinder and all O-rings with PMC grease to facilitate reassembly.

14. Reassemble the Air Cylinder in reverse order.

CAUTION!

Use wooden or plastic tools or a brass brush for cleaning.

Do not use metal or abrasive tools that can scratch the contact

surfaces.

Page 20

MAINTENANCE

17

Cartridge Valve Removal

1. Remove the trigger from the handle.

2. Remove Push On Cap.

3. Remove the Split Ring from in front of the Cartridge Valve.

4. Eject the Cartridge Valve by pushing it out through the hole indicated by the arrow above.

Page 21

18

GUN OPERATION

Triggered Off

1. Compressed dry air enters through the rear or bottom of the Gun Handle.

2. The air is directed through the cartridge valve and into the Rear of the Piston in the Air

Cylinder, moving the Piston (and Mixing Chamber) forward to the CLOSED position.

3. In the CLOSED position, the orifices in the Mixing Chamber are NOT aligned with the Side

Seal ports. The orifices in the Mixing Chamber are exposed to the air/grease chamber in the

Gun Block.

4. Purge air passes through the Spool Valve and the Check Valve, and into the Air Cylinder and

Gun Block.

5. Purge air and residual grease enter the Mixing Chamber and pass through the Mixing

Chamber and PCT, expelling mixed material out of the chamber area in the process.

6. Purge air is also expelled from the PCT in a circular trajectory to keep the tip clean.

Compressed

Shop Air

90 – 120 PSI

(6.2 – 8.3 Bar)

Page 22

GUN OPERATION

19

Triggered On

1. Compressed dry air is directed through the cartridge valve and into the front, filling the cavity

and pushing the Piston and Chamber backwards.

2. The orifices in the Chamber are now aligned with the Side Seals and exposed to high pressure

chemical.

3. High pressure chemical enters the chamber from the opposing orifices. The high pressure

chemicals mix by impingement, and the mixture then travels down the chamber and out the

PCT.

NOTE! While the trigger is pulled, the purge air is shutoff during spraying and

the PCT will be retracted to the point of being flush with the front surface of

the Gun Block.

Compressed

Shop Air

90 – 120 PSI

(6.2 – 8.3 Bar)

Page 23

20

TROUBLE SHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

SOLUTION

PCT not flush with

Gun Block when Gun

is triggered

Insufficient air pressure (minimum 90 psi, 6.2 bar)

Ensure 90 psi (6.2 Bar)

Failed cartridge valve

Replace, see page17

Air Passages plugged

Clean, See page 18-19

Material does not

spray when Gun is

triggered

Lock is in “Locked” position

Unlock gun

Air supply is not on

Turn on air supply

Manual Valve CLOSED

OPEN, see page 7

Mixing Chamber Inlet Orifices plugged

Clean, see page 11

Side Seal Orifices plugged

Clean, see page 13

Check Valve plugged

Replace

Mixing Chamber

moves slowly

Failed Cartridge Valve

Replace, see page 38

Insufficient Gun air pressure (minimum 90 psi, 6.2

Bar)

Ensure 90 psi (6.2 Bar) of air

pressure

Piston Assembly requires service

Rebuild, see page 15

Air Passages plugged

Clean, see page 18-19

Mixing Chamber

moves slowly, then

normally

Reacted material around Side Seals

Inspect Side Seals, Mixing

Chamber and clean, see

pages 11, 13

Pattern deformation

Incorrect chemical temperature

See Proportioner Manual

Mixing Chamber Nozzle and/or PCT dirty

Inspect and clean

Material spray

pressure imbalance

Mixing Chamber Inlet Orifices plugged

Clean

Side Seal Orifices plugged

Clean, see page 13

Dirty screens

Replace

Material temperatures not as recommended by

material supplier

Adjust, see Proportioner

Operating Manual

Iso and/or Resin in

Gun Air Passages

Side Seal damaged

Replace, see page 13

Mixing Chamber damaged

Replace, see page 11

Side Seal/ Screen Screw O-rings damaged

Replace, see page 13

Material mist from

Mixing Chamber or

PCT

Side Seal damaged

Replace, see page 13

Mixing Chamber damaged

Replace, see page 11

Side Seal/Screen Screw O-rings damaged

Replace, see page 13

Excessive

overspray

Material temperatures and/or spray pressures not as

recommended by material supplier

Adjust, see Proportioner

Operating Manual

Buildup of material

on PCT

Plugged air passages in PCT and Gun Block

Clean, see page 11

Air leakage from

Handle

Air Cylinder O-rings damaged

Replace, see page 38

Cartridge Valve Damaged

Replace, see page 17

Page 24

21

REFERENCE GUIDE

Chamber Kits

KIT

NUMBER

PART

NUMBER

QTY

DESCRIPTION

(INCH)

FOR USE WITH

ILLUSTRATION

GU-814-000

200476

1

#63 DRILL

(.0370)

MIXING

NOZZLE

GU-03031

1

#70 DRILL

(.0280)

MIXING

CHAMBER

PORT

RM-814-000

1

CHAMBER #000 - -

GU-814-00

200477

1

1.25mm DRILL

(.0492)

MIXING

NOZZLE

GU-03027

1

#69 DRILL

(.0292)

MIXING

CHAMBER

PORT

RM-814-00

1

CHAMBER #00 - -

GU-814-00X

200478

1

1.35mm DRILL

(.0531)

MIXING

NOZZLE

GU-03032

1

#61 DRILL

(.0390)

MIXING

CHAMBER

PORT

RM-814-00X

1

CHAMBER

#00X

-

-

GU-814-01

200479

1

1.45mm DRILL

(.0571)

MIXING

NOZZLE

GU-03021

1

#59 DRILL

(.0410)

MIXING

CHAMBER

PORT

RM-814-01

1

CHAMBER #01 - -

GU-814-01X

GU-03053

1

#52 DRILL

(.0635)

MIXING

NOZZLE

GU-03052

1

#57 DRILL

(.0430)

MIXING

CHAMBER

PORT

RM-814-01X

1

CHAMBER #01X

-

-

GU-814-02

GU-03024

1

#51 DRILL

(.0676)

MIXING

NOZZLE

GU-03023

1

#56 DRILL

(.0465)

MIXING

CHAMBER

PORT

RM-814-02

1

CHAMBER #02 - -

GU-814-02X

200480

1

2mm DRILL

(.0787)

MIXING

NOZZLE

GU-03050

1

#55 DRILL

(.0520)

MIXING

CHAMBER

PORT

RM-814-02X

1

CHAMBER #02X

-

-

Page 25

REFERENCE GUIDE

22

Chamber Kits (Continued)

KIT

NUMBER

PART

NUMBER

QTY

DESCRIPTION

(INCH)

FOR USE WITH

ILLUSTRATION

GU-814-03

GU-03028

1

#44 DRILL

(.0860)

MIXING

NOZZLE

GU-03035

1

#54 DRILL

(.055)

MIXING

CHAMBER

PORT

RM-814-03

1

CHAMBER #03 - -

GU-814-04

200481

1

2.4mm DRILL

(.0945)

MIXING

NOZZLE

GU-03054

1

#50 DRILL

(.0700)

MIXING

CHAMBER

PORT

RM-814-04

1

CHAMBER #04 - -

200920

GU-03028

1

#44 Drill

(.0860)

MIXING

NOZZLE

201120

1

#33 DRILL

(0.1130)

MIXING

CHAMBER

PORT

RM-814-05

1

CHAMBER #05 -

PCT Kits

KIT NUMBER

PART

NUMBER

QTY

DESCRIPTION

FOR USE

WITH

ILLUSTRATION

GU-815-000

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

2000476

1

#63 DRILL

(.0370)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-000

1

PATTERN

CONTROL TIP

000

-

GU-815-00

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

200477

1

1.25mm DRILL

(.0492)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-00

1

PATTERN

CONTROL TIP

00

-

Page 26

REFERENCE GUIDE

23

PCT Kits (Continued)

KIT NUMBER

PART

NUMBER

QTY

DESCRIPTION

FOR USE

WITH

ILLUSTRATION

GU-815-00X

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

200478

1

1.35mm DRILL

(.0531)

PCT PURGE

AND NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-00X

1

PATTERN

CONTROL TIP

00.X

-

GU-815-01

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

200479

1

1.45mm DRILL

(.0571)

PCT PURGE &

NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-01

1

PATTERN

CONTROL TIP

01

-

GU-815-01X

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

GU-03053

1

#52 DRILL

(.0635)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-01X

1

PATTERN

CONTROL TIP

01X

-

GU-815-02

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

GU-03024

1

#51 DRILL

(.0676)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-02

1

PATTERN

CONTROL TIP

02

-

Page 27

REFERENCE GUIDE

24

PCT Kits (Continued)

KIT

NUMBER

PART

NUMBER

QTY

DESCRIPTION

FOR USE

WITH

ILLUSTRATION

GU-815-02X

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

200480

1

2mm DRILL

(.0787)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-

02X

1

PATTERN

CONTROL TIP

02X

-

GU-815-03

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

GU-03028

1

#44 DRILL

(.0860)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-03

1

PATTERN

CONTROL TIP

03

-

GU-815-04

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

200481

1

2.4mm DRILL

(.0945)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

RM-815-04

1

PATTERN

CONTROL TIP

04

-

200919

GU-03033

1

#65 DRILL

(.0350)

PCT PURGE

PORT

GU-03035

1

#54 DRILL

(.055)

PCT PURGE

PORT

201093

1

2.9mm DRILL

(.114)

PCT NOZZLE

PORT

OR-00042A

2

PCT FLAT TIP

O-RING .016

-

200918

1

PATTERN

CONTROL TIP

05

-

Page 28

REFERENCE GUIDE

25

Soft Chamber Kits

PART NUMBER

QTY

DESCRIPTION

GU-814-S00

1

CHAMBER SOFT 00

GU-814-S000

1

CHAMBER SOFT 000

GU-814-S0000

1

CHAMBER SOFT 0000

GU-814-S01

1

CHAMBER SOFT 01

GU-814-S02

1

CHAMBER SOFT 02

GU-814-S03

1

CHAMBER SOFT 03

GU-814-S04

1

CHAMBER SOFT 04

*FOR USE WITH PLASTIC SIDE SEALS (GU-817-90D)

NOT COMPATIBLE WITH STANDARD SIDE SEALS

Chamber/PCT Kits

KIT NUMBER

PART NUMBER

QTY

DESCRIPTION

KT-814-000

GU-814-000

1

CHAMBER 000 W/ DRILLS

GU-815-000

1

PCT 000 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-00

GU-814-00

1

CHAMBER 00 W/ DRILLS

GU-815-00

1

PCT 00 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-00X

GU-814-00X

1

CHAMBER 00X W/ DRILLS

GU-815-00X

1

PCT 00X W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-01

GU-814-01

1

CHAMBER 01 W/ DRILLS

GU-815-01

1

PCT 01 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-01X

GU-814-01X

1

CHAMBER 01X W/ DRILLS

GU-815-01X

1

PCT 01X RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-02

GU-814-02

1

CHAMBER 02 W/ DRILLS

GU-815-02

1

PCT 02 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-02X

GU-814-02X

1

CHAMBER 02X W/ DRILLS

GU-815-02X

1

PCT 02X RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-03

GU-814-03

1

CHAMBER 03 W/ DRILLS

GU-815-03

1

PCT 03 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

KT-814-04

GU-814-04

1

CHAMBER 04 W/ DRILLS

GU-815-04

1

PCT 04 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

201119

200920

1

CHAMBER 05 W/ DRILLS

200918

1

PCT 05 RND W/ DRILLS

OR-00042A

1

PCT FLAT TIP O-RING .016

Page 29

REFERENCE GUIDE

26

Spare Parts Kits AP2/

PART NUMBER

DESCRIPTION

REFERENCE PAGE

200445

AP2/3-000 SPARE PARTS KIT

26

200446

AP2/3-00 SPARE PARTS KIT

27

200447

AP2/3-00X SPARE PARTS KIT

27

200448

AP2/3-01 SPARE PARTS KIT

28

200449

AP2/3-01X SPARE PARTS KIT

28

200450

AP2/3-02 SPARE PARTS KIT

29

200451

AP2/3-02X SPARE PARTS KIT

29

200452

AP2/3-03 SPARE PARTS KIT

30

200453

AP2/3-04 SPARE PARTS KIT

30

201173

AP2/3-05 SPARE PARTS KIT

31

201174

AP-2/3-05 PACKAGE DRILL BITS

31

AP2/3-000 Spare Parts Kit (200445)

PART NUMBER

QTY

DESCRIPTION

KT-814-000

1

CHAMBER/PCT ROUND 000 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

O-RING #013 80D AFLAS

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

2

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200592

1

AP2/3-000 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

Page 30

REFERENCE GUIDE

27

AP2/3-00 Spare Parts Kit (200446)

PART NUMBER

QTY

DESCRIPTION

KT-814-00

1

CHAMBER/PCT ROUND 00 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

O-RING #013 80D AFLAS

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200593

1

AP2/3-00 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

AP2/3-00X Spare Parts Kit (200447)

PART NUMBER

QTY

DESCRIPTION

KT-814-00X

1

CHAMBER/PCT ROUND 00X W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200598

1

AP2/3-00X PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

Page 31

REFERENCE GUIDE

28

AP2/3-01 Spare Parts Kit (200448)

PART NUMBER

QTY

DESCRIPTION

KT-814-01

1

CHAMBER/PCT ROUND 01 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

KT-830

1

AP2/3-01 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

AP2/3-01X Spare Parts Kit (200449)

PART NUMBER

QTY

DESCRIPTION

KT-814-01X

1

CHAMBER/PCT ROUND 01X W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200596

1

AP2/3-01X PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

Page 32

REFERENCE GUIDE

29

AP2/3-02 Spare Parts Kit (200450)

PART NUMBER

QTY

DESCRIPTION

KT-814-02

1

CHAMBER/PCT ROUND 02 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

KT-829

1

AP2/3-02 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

AP2/3-02X Spare Parts Kit (200451)

PART NUMBER

QTY

DESCRIPTION

KT-814-02X

1

CHAMBER/PCT ROUND 02X W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-90

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200597

1

AP2/3-02X PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

Page 33

REFERENCE GUIDE

30

AP2/3-03 Spare Parts Kit (200452)

PART NUMBER

QTY

DESCRIPTION

KT-814-03

1

CHAMBER/PCT ROUND 03 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-180

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200594

1

AP2/3-03 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

AP2/3-04 Spare Parts Kit (200453)

PART NUMBER

QTY

DESCRIPTION

KT-814-04

1

CHAMBER/PCT ROUND 04 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-180

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

200595

1

AP2/3-04 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

Page 34

REFERENCE GUIDE

31

AP2/3-05 Spare Parts Kit (201173)

PART NUMBER

QTY

DESCRIPTION

201164

1

CHAMBER/PCT ROUND 05 W/DRILLS

GU-020

1

MANUAL VALVE ASSY.

GU-04007

2

SCREEN SCREW SEAL

GU-818-80

4

FILTER SCREEN; 80 MESH

OR-801A

2

BACK UP RING; #013

OR-00043B

10

O-RING; #10 AFLAS

SP-04005

2

SPRING; SIDE SEAL

GU-817-180

2

SIDE SEAL

OR-00042A

4

O-RING; #16

KT-850

1

CHECK VALVE KIT

KT-020

1

MANUAL VALVE SOFTWARE KIT

GP-LUBEGREASE

1

GREASE; TUBE

GP-00101

1

PIN VICE

201174

1

AP2/3-05 PKG DRILL BITS

200459

2

O-RING; #018

OR-804

3

O-RING 2MMX4MM BUNA

OR-800

2

#013 BACK UP RING

OR-00026A

2

O-RING #129 VITON

OR-805

8

O-RING #108 VITON

AP2/3-05 Package Drill Bits (201174)

PART NUMBER

QTY

DESCRIPTION

GU-03028

1

#44 DRILL (.0860)

201120

1

#33 DRILL (.1130)

GU-03033

1

#65 DRILL (.0350)

GU-03035

1

#54 DRILL (.055)

201093

1

DRILL BIT, 2.9MM, .114

Page 35

REFERENCE GUIDE

32

Air Cylinder Rebuild Kit

(KT-801)

PART NUMBER

QTY

DESCRIPTION

OR-00026A

2

O-RING #129 VITON

OR-00043B

2

O-RING #010 80D AFLAS

OR-804

3

O-RING 2mmx4mm BUNA

OR-00037B

2

QUAD RING #011 VITON

OR-00042A

1

#016 O-RING

GU-829

1

A/P CHECK VALVE

GU-830

1

AIR CYLINDER BUSHING

200459

1

#018 O-RING

AP-3 O-Ring Kit

(201118)

PART NUMBER

QTY

DESCRIPTION

OR-800

2

#013 BACK UP RING

OR-801A

2

O-RING #013 80D AFLAS

OR-804

3

O-RING 2MMX4MM BUNA

OR-00026A

2

O-RING #129 VITON

OR-00043B

4

O-RING -010 80D AFLAS

OR-00042A

1

#016 O-RING

200459

1

#018 O-RING

PMC Recommended O-Ring Grease

PART NUMBER

QTY

DESCRIPTION

GP-LUBEGREASE

1

LUBRIPLATE GREASE

TL-04003

1

GREASE TUBE FOR USE W/ GREASE GUN

Screen Sizes

PART NUMBER

QTY

DESCRIPTION

GU-818-80

1

FILTER SCREEN, 80 MESH (STANDARD)

GU-818-60

1

FILTER SCREEN, 60 MESH

GU-818-40

1

FILTER SCREEN, 40 MESH

KT-818-80

1

FILTER SCREEN, 80 MESH (PKG 10)

KT-818-60

1

FILTER SCREEN, 60 MESH (PKG 10)

KT-818-40

1

FILTER SCREEN, 40 MESH (PKG 10)

Page 36

REFERENCE GUIDE

33

A & R Screen Screw Assembly Kits

KIT NUMBER

PART NUMBER

QTY

DESCRIPTION

KT-819-R

GU-819-R

1

R SCREEN SCREW

GU-04007

1

SCREEN SCREW SEAL

OR-800

1

#013 BACK UP RING

OR-801A

1

O-RING #013 80D AFLAS

KT-819-A

GU-819-A

1

A SCREEN SCREW

GU-04007

1

SCREEN SCREW SEAL

OR-800

1

#013 BACK UP RING

OR-801A

1

O-RING #013 80D AFLAS

Recommended Spare Parts

PART NUMBER

QTY

DESCRIPTION

PAGE

KT-801

1

AIR CYLINDER REBUILD KIT

32

KT-817-90

1

SIDE SEAL KIT

-

GU-818-40

4

FILTER SCREEN 40 MESH

32

GU-818-60

4

FILTER SCREEN 60 MESH

32

GU-818-80

4

FILTER SCREEN 80 MESH (STANDARD)

32

GU-04007

2

SCREEN SCREW SEAL

13

OR-00043B

8

O-RING #010 80D AFLAS

13

OR-801A

8

O-RING #013 80D AFLAS

13

SP-04005

2

SPRING; SIDE SEAL

13

GU-020

1

MANUAL VALVE ASSEMBLY

36

KT-850

2

CHECK VALVE ASSEMBLY

34

OR-00042A

2

#016 O-RING

32

GU-829

1

A/P CHECK VALVE

34

TL-04003

1

GREASE TUBE

43

OR-800

8

#013 BACK UP RING

13

201118

1

AP-3 O-RING KIT

32

Page 37

REFERENCE GUIDE

34

Optional Parts

PART NUMBER

QTY

DESCRIPTION

GU-815-50-509

1

BLASTER TIP .059

GU-815-50

1

BLASTER TIP 3.5

GU-815-51

1

POUR TIP

GU-815-53

1

POUR NOZZLE

GU-815-52

1

PCT FLAT TIP RETAINER ASSEMBLY

* GU-815-52-1

1

PCT FLAT TIP BODY

* GU-815-52-2

1

PCT FLAT TIP GASKET

* GU-815-52-3

1

PCT FLAT TIP RETAINER

* OR-00042A

1

#016 O-RING

GU-817-90D

1

SIDE SEAL; DELRIN

*DENOTES PARTS IN THE GU-815-52

NOTE: SPRAY TIP NOT INCLUDED WITH PART NUMBER GU-815-52

Check Valve Assembly

(KT-850)

PART NUMBER

QTY

DESCRIPTION

GU-851

4

CHECK VALVE SEAT

GU-852

2

CHECK VALVE SPRING

GU-853

2

¼” CHECK VALVE BALL

Manual Valve Software Kit

(KT-020)

PART NUMBER

QTY

DESCRIPTION

GU-LOCTITE

1

LOCTITE #242

GU-015

4

O-RING #007 AFLAS

GU-016

4

#007 VITON CURVED BACKUP RING

1/4” Unheated Stainless Steel Hose Assy.

PART NUMBER

DESCRIPTION

MA-41

HOSE PACKAGE KIT, UNHEATED

MA-41A

REPLACEMENT HOSE, “A” SIDE

MA-41R

REPLACEMENT HOSE, “R” SIDE

Page 38

REFERENCE GUIDE

35

Flush Tanks

Optional 2.5 Gallon Flush Tank (200426, 200427) and 1QT Mini Flush Tank (200216, 200217)

shown.

2.5 Gallon Flush Tank 1 QT Mini Flush Tank

FLUSH TANKS

2.5 Gallon Flush Tank

1 QT Mini Flush Tank

200426 – Solvent Flush Kit, 2.5 Gal, AP

200216 – Solvent Flush Kit, Quart, AP

200427 – Solvent Flush Kit, 2.5 Gal, F-AP

200217 – Solvent Flush Kit, Quart, F-AP

Page 39

PARTS IDENTIFICATION

36

PARTS IDENTIFICATION

Manual Valve Assembly

(GU-020)

NOTE: The orientation of the back-up ring is

important. The concave face must point towards the

O-Ring.

MANUAL VALVE ASSEMBLY (GU-020)

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

GU-022

MANUAL VALVE HOUSING

2

1

GU-021

MANUAL VALVE STEM

3

1

GU-023

MANUAL VALVE SEAT

4

1

OR-016

007 VITON CURVED

BACKUP RING

5

1

OR-015

#007 AFLAS O-RING

Page 40

PARTS IDENTIFICATION

37

Coupling Block Assembly

(GU-04001)

COUPLING BLOCK ASSEMBLY (GU-04001)

ITEM

QTY

PART NUMBER

DESCRIPTION

1 1 GU-04001-01

COUPLING BLOCK BODY

2 2 TN-04192

1/8 NPT PIPE PLUG

3 2 GU-020

MANUAL VALVE ASSY

4 1 RA-00005A

1/8 NPT X #5 JIC SWIVEL

5 1 RA-00006A

1/8 NPT X #6 JIC SWIVEL

6 1 TN-04193

COUPLING BLOCK MOUNTING SCREW

Page 41

PARTS IDENTIFICATION

38

Gun Assembly

(200631)

Page 42

PARTS IDENTIFICATION

39

GUN ASSEMBLY

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

200459

O-RING, VITON, -018

2

1

200507

PIPE PLUG, 1/16, NPT , STEEL

3

1

200634

VALVE, CARTRIDGE, 4-WAY

4

1

200637

HANDLE, AP-3

5

1

200638

PISTON, AP-3

6

1

201092

CYLINDER, PINNED, AP-3

7

2

201109

10-24 X 1-3/4 HEX MACH SCREW, STEEL, ZINC

8

2

201110

STEP AP203

9

1

201111

RETAINING RING, INT, 1/2 ID

10

1

201124

CAP, PUSH-ON, 7/64 OD, EPDM

11

1

201139

TRIGGER, AP-3 W/STUD

12

1

201562

AIR CYLINDER BUSHING

13

1

GU-803

CYLINDER END CAP

14

1

GU-804

LOCK KNOB

15

1

GU-806

SPRING

16

1

GU-807

TWO POSITION STOP

17

1

GU-829

A/P CHECK VALVE

18

1

GU-831

STEP AP203

19

2

OR-00026A

O-RING #129 VITON

20

2

OR-00043B

O-RING #010 80D AFLAS

21

3

OR-804

O-RING; 2MMX4MM BUNA

22

1

TN-04186

GREASE FITTING

23

1

TN-04187

SHCS 10-32 x 3/16 PORT PLUG

24

1

TN-04192

1/8 NPT PIPE PLUG

Page 43

PARTS IDENTIFICATION

40

Gun Block Assembly

GUN BLOCK COMPONENTS

ITEM

QTY

PART NUMBER

DESCRIPTION

1 2 201108

SCREW, HEX CAP, 10-32 CUSTOM

2

1

200635

ALUMINUM GUN BLOCK, AP-3

200636

STEEL GUN BLOCK, AP-3

3 2 GU-04007

SCREEN SCREW SEAL

4 2 GU-818-80

FILTER SCREEN, 80 MESH

5 2 GU-817-90

SIDE SEAL

6 2 SP-04005

SPRING; SIDE SEAL

7 2 OR-800

#013 BACK UP RING

8 2 OR-801A

O-RING #013 80D AFLAS

9 2 OR-00043B

O-RING #010 80D AFLAS

10 1 GU-819-R

R-SCREEN SCREW

11 1 GU-819-A

A-SCREEN SCREW

12 2 GU-851

CHECK VALVE SEAT, AP-2/3

13 2 GU-852

CHECK VALVE SPRING, AP-2/3

14 2 GU-853

1/4" CHECK VALVE BALL, AP-2/3

15 1 OR-00042A

#016 O-Ring

Page 44

PARTS IDENTIFICATION

41

Screen Screw Assembly

SCREEN SCREW COMPONENTS

ITEM

QTY

PART NUMBER

DESCRIPTION

22

1

GU-819-R *

“R” SCREEN SCREW

1

GU-819-A *

“A” SCREEN SCREW

23

1

GU-04007 *

SCREEN SCREW SEAL

24

1

GU-818-40

FILTER SCREEN; 40 MESH

1

GU-818-60

FILTER SCREEN; 60 MESH

1

GU-818-80

FILTER SCREEN 80 MESH (STANDARD)

25

1

OR-801A *

O-RING #013 80D AFLAS

26

1

OR-800 *

#013 BACK UP RING

27

1

OR-00043B

O-RING #010 80D AFLAS

28

1

SP-04005

SPRING; SIDE SEAL

29**

1

GU-817-90

SIDE SEAL

1

GU-817-180

SIDE SEAL (FOR CHAMBERS 03,04,05)

*Included in KT-819-R and KT-819-A (Pg. 33)

**Available in plastic (GU-817-90D) for soft chambers

Page 45

PARTS IDENTIFICATION

42

List of Tools

LIST OF TOOLS

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

GU-04019

AIR HOSE

2

1

TL-00002

GREASE GUN

3

1

GU-04021

QUICK DISCONNECT; FEMALE

4

1

GU-04022

QUICK DISCONNECT; MALE

5

1

TL-04003

GREASE TUBE

6

1

TL-09

OPEN END WRENCH

7

1

TL-04001

5/16 SPINTITE; NUT DRIVER

8

1

GP-00101

DOUBLE ENDED PIN VISE

9

1

TL-10

CHECK VALVE REMOVAL TOOL

Page 46

43

APPENDIX

Grease Gun Assembly

1. Screw the rod (2c) into the top of the

grease gun (2a) so that the final

assembly represents the assembled

grease gun (2, Pg. 41).

2. Unscrew the top of the grease gun

(2a) from the bottom of the grease

gun (2b).

3. Pull the handle (2e) on the bottom of

the grease gun (2b) so that it

resembles the picture.

4. Remove the tape and cap from the

grease tube (5) and insert the

uncapped end of the grease tube (5)

into the bottom of the grease gun

(2b).

5. Remove the foil from the grease

tube (5).

6. Screw the top of the grease gun (2a)

back on to the bottom of the grease

gun (2b).

7. Push down on the latch (2d) to

release the plunger and push

plunger completely back in.

Page 47

44

Mixing Chamber Flow Rates

Chamber

Lbs/Min

@ 1000 PSI

KG/Min

@ 69 Bar

Lbs/Min

@ 2000 PSI

KG/Min

@ 138 Bar

GU-814-000

4 2 6

3

GU-814-00

7 3 11

5

GU-814-00X

8

3.5

13.5

6

GU-814-01

9 4 16

7

GU-814-01X

10.5

4.5

19

8.5

GU-814-02

12 5 22

10

GU-814-02X

15

7.5

27

12

GU-814-03

18 8 32

14

GU-814-04

25

11

47

21

200920

28

20

50

23

*Flow rates will vary depending on viscosity, hose length and machine efficiency.

Chamber/Orifice Comparison Chart

Competitive Air Purge

PMC Air Purge

Chamber

Number

Orifice Size

Chamber

Number

Orifice Size

000 (AR2020)

0.0200

000

0.0280

00 (AR2929)

0.0290

00

0.0350

NOT AVAILABLE

00X

0.0380

01 (AR4242)

0.0420

01

0.0410

NOT AVAILABLE

01X

0.0440

02 (AR5252)

0.0520

02

0.0520

NOT AVAILABLE

02X

0.0550

03 (AR6060)

0.0600

03

0.0610

04 (AR7070)

0.0700

04

0.0690

05 (AR8686)

0.0860

05

0.0860

Loading...

Loading...