KS 98-2 Multi-function unit

Engineering manual

9499-040-94411/V1.0

Description

A publication of:

û PMA

Prozeß- und Maschinen-Automation GmbH

P.O.Box 310 229 • D-34058 Kassel • Germany

All rights reserved.

No part of this document may be reproduced or

published in any form or by any means without prior

written permission from the copyright owner.

Symbols used on the instrument

à EU conformity marking

a Caution, Follow the operating instructions!

Symbols in the text

a Danger of injury

! Danger for the instrument, or of faulty function.

Liability and warranty

Any information and notes in these operating

instructions were composed under consideration of the

applicable regulations, the present state of the art and

our extensive know-how and experience.

With special versions, additional ordering options or due

to the latest technical modifications, the actual scope of

delivery may vary from the descriptions and drawings in

this manual.

For questions, please, contact the manufacturer.

a Before starting to work with the instrument

and before commissioning, in particular,

these operating instructions must be read

carefully!

The manufacturer cannot be held

responsible for damage and trouble

resulting from failure to comply with the

information given in this manual.

This product may be subject to change due

to improvements of the product features in

the course of further development.

Ý Danger of destroying electronic components due

to electrostatic discharge (ESD).

g Additional information or reference to further

sources of information.

+ Important hint for avoiding frequent operator

faults.

Copyright

This operating manual should be considered as

confidential information, intended only for persons who

work with the instrument.

Contraventions are subject to payment of damages.

Further claims reserved.

E/A-Module 2

Description

Content

1. Operating description ........................................................................................................................................... 10

1.1. Description ....................................................................................................................................................... 10

1.2. Safety notes ..................................................................................................................................................... 11

1.3. Technical data .................................................................................................................................................. 13

1.4. Achievements ................................................................................................................................................... 20

1.4.1. E/A-Module .................................................................................................................................................. 21

1.5. Mounting .......................................................................................................................................................... 22

1.5.1. Internel switches ......................................................................................................................................... 23

1.5.2. Retro-fitting and modific. of I/O-ext. (watch connecting diagram)............................................................ 23

1.5.3. I/O extension with CANopen ...................................................................................................................... 23

1.6. Electrical connections ...................................................................................................................................... 24

1.6.1. Safety hints .................................................................................................................................................. 24

1.6.2. Electromagnetic compatibility ..................................................................................................................... 24

1.6.3. Galvanic isolation ........................................................................................................................................ 25

1.6.4. General connecting diagram ....................................................................................................................... 26

1.6.5. Connection Diagram I/O Modules .............................................................................................................. 27

1.6.6. Analog inputs ............................................................................................................................................... 28

1.6.7. Digital inputs and outputs ........................................................................................................................... 29

1.7. Commissioning ................................................................................................................................................. 29

1.8. Operation .......................................................................................................................................................... 30

1.8.1. Front view .................................................................................................................................................... 30

1.8.2. Touch features ............................................................................................................................................. 31

1.9. Menues ............................................................................................................................................................. 32

1.9.1. Short-form dialog ......................................................................................................................................... 32

1.9.2. Complete dialog ........................................................................................................................................... 33

1.9.3. Selection of operating pages ...................................................................................................................... 33

1.9.4. Language selection ...................................................................................................................................... 34

1.9.5. Navigation, page selection ......................................................................................................................... 34

1.9.6. Adjusting values .......................................................................................................................................... 35

1.10. Device settings in the main menu ................................................................................................................... 36

1.10.1. Date, Time .................................................................................................................................................... 36

1.10.2. Device data .................................................................................................................................................. 36

1.10.3. Online/Offline .............................................................................................................................................. 36

1.10.4. Calibration .................................................................................................................................................... 36

1.10.5. Info ............................................................................................................................................................... 37

1.10.6. Status I / O ................................................................................................................................................... 37

1.10.7. CAN-Status .................................................................................................................................................. 38

E/A-Module 3

Description

1.10.8. Profibus-Status ............................................................................................................................................ 38

1.10.9. USB Menü .................................................................................................................................................... 38

1.11. Operating pages ............................................................................................................................................... 39

1.11.1. List display ................................................................................................................................................... 39

1.11.2. Bargraph display .......................................................................................................................................... 39

1.11.3. Alarm display ............................................................................................................................................... 39

1.11.4. Graphic trend curve ..................................................................................................................................... 40

1.11.5. Programmer .................................................................................................................................................. 41

1.11.6. Controller ..................................................................................................................................................... 44

1.11.7. Cascade controller ....................................................................................................................................... 49

1.12. Maintenance, test, trouble shooting ............................................................................................................... 51

1.12.1. Cleaning ....................................................................................................................................................... 51

1.12.2. Behaviour in case of trouble ....................................................................................................................... 51

1.12.3. Shut-down .................................................................................................................................................... 51

1.12.4. Default engineering as basic equipment .................................................................................................... 51

2. Engineering-Tool ................................................................................................................................................... 52

2.1. Survey ............................................................................................................................................................... 52

2.1.1. Scope of delivery ......................................................................................................................................... 52

2.2. Installation ........................................................................................................................................................ 52

2.2.1. Hardware and software prerequisites ........................................................................................................ 52

2.2.2. Software installation ................................................................................................................................... 52

2.2.3. Licencing ...................................................................................................................................................... 52

2.2.4. Software start .............................................................................................................................................. 53

2.3. Engineering tool operation............................................................................................................................... 54

2.3.1. Fundamentals of the engineering tool operation ....................................................................................... 54

2.3.2. Load projects and put them into operation ................................................................................................ 54

2.3.3. Navigate in the editor.................................................................................................................................. 54

2.3.4. Parameterization of function blocks ........................................................................................................... 54

2.3.5. Change / create program logic.................................................................................................................... 54

2.3.6. Function block placement ............................................................................................................................ 55

2.3.7. Function block shifting................................................................................................................................. 55

2.3.8. Creating connections ................................................................................................................................... 55

2.3.9. Online-operation .......................................................................................................................................... 57

2.3.10. Trend function .............................................................................................................................................. 57

2.4. Overview of all menu functions ....................................................................................................................... 60

2.4.1. Menu ‘File’ ................................................................................................................................................... 60

2.4.2. Menu ‘Edit’ ................................................................................................................................................... 63

2.4.3. Menu ‘Functions’ ......................................................................................................................................... 64

2.4.4. Menu ‘Fixed-funct.’ ...................................................................................................................................... 64

2.4.5. Menu ‘Device’ .............................................................................................................................................. 65

E/A-Module 4

Description

2.4.6. Menu ‘Online’ .............................................................................................................................................. 66

2.4.7. Menu ‘Extra’ ................................................................................................................................................. 67

2.4.8. Menu ‘Window’ ........................................................................................................................................... 68

2.4.9. Menu ‘Help’ ................................................................................................................................................. 69

2.4.10. Attachment .................................................................................................................................................. 69

3. Function blocks ..................................................................................................................................................... 73

3.1. Scaling and calculating functions .................................................................................................................... 75

3.1.1. ABSV (absolute value (No. 01)) ................................................................................................................... 75

3.1.2. ADSU ( addition/subtraction (No. 03)) ........................................................................................................ 75

3.1.3. MUDI ( Multiplication / division (No. 05)) .................................................................................................. 76

3.1.4. SQRT ( square root function (No. 08)) ......................................................................................................... 76

3.1.5. SCAL ( scaling (No. 09)) ............................................................................................................................... 77

3.1.6. 10EXP (10s exponent (No. 10)) .................................................................................................................... 77

3.1.7. EEXP (e-function (No. 11)) ........................................................................................................................... 78

3.1.8. LN (natural logarithm (No. 12)).................................................................................................................... 78

3.1.9. LG10 (10s logarithm (No. 13)) ...................................................................................................................... 79

3.2. Non-linear functions ........................................................................................................................................ 80

3.2.1. LINEAR (linearization function (No. 07)) ..................................................................................................... 80

3.2.2. GAP (dead band (No. 20)) ............................................................................................................................ 82

3.2.3. CHAR (function generator (No. 21)) ............................................................................................................ 83

3.3. Trigonometric functions ................................................................................................................................... 84

3.3.1. SIN (sinus function (No. 80)) ....................................................................................................................... 84

3.3.2. COS (cosinus function (No. 81))................................................................................................................... 84

3.3.3. TAN (tangent function (No. 82)) .................................................................................................................. 85

3.3.4. COT (cotangent function (No. 83)) ............................................................................................................... 86

3.3.5. ARCSIN (arcus sinus function (No. 84)) ...................................................................................................... 87

3.3.6. ARCCOS (arcus cosinus function (No. 85)) ................................................................................................. 88

3.3.7. ARCTAN (arcus tangent function (No. 86)) ................................................................................................. 89

3.3.8. ARCCOT (arcus cotangent function (No. 87)) .............................................................................................. 89

3.4. Logic functions ................................................................................................................................................. 90

3.4.1. AND (UND-gate (Nr. 60)) ............................................................................................................................. 90

3.4.2. NOT (inverter (No. 61))................................................................................................................................. 90

3.4.3. OR (OR gate (No. 62))................................................................................................................................... 91

3.4.4. BOUNCE (debouncer (No. 63)) ..................................................................................................................... 92

3.4.5. EXOR (exclusive OR gate (No. 64)) .............................................................................................................. 92

3.4.6. FLIP (D flipflop (No. 65)) ............................................................................................................................... 93

3.4.7. MONO (monoflop (No. 66)) .......................................................................................................................... 94

3.4.8. STEP (step function for sequencing (No. 68)) ............................................................................................. 95

3.4.9. TONOFF (timer (No. 69)) .............................................................................................................................. 96

3.5. Signal converters.............................................................................................................................................. 97

E/A-Module 5

Description

3.5.1. A2BYTE (data type conversion (No. 02)) ..................................................................................................... 97

3.5.2. ABIN (analog i binary conversion (No. 71)) ................................................................................................. 99

3.5.3. TRUNC (integer portion (No. 72)) .............................................................................................................. 101

3.5.4. PULS (analog pulse conversion (No. 73)) .................................................................................................. 102

3.5.5. COUN (up/down counter (No. 74)) ............................................................................................................ 104

3.5.6. MEAN (mean value formation (No. 75)).................................................................................................... 106

3.6. Time functions ................................................................................................................................................ 108

3.6.1. LEAD ( differentiator (Nr. 50) )................................................................................................................... 108

3.6.2. INTE (integrator (No. 51)) .......................................................................................................................... 110

3.6.3. LAG 1 (filter (No. 52) ) ................................................................................................................................ 112

3.6.4. DELA1 (delay time (No. 53) ) .................................................................................................................... 113

3.6.5. DELA 2 (delay time (No. 54)) ..................................................................................................................... 114

3.6.6. FILT (filter with tolerance band (No. 55)) .................................................................................................. 115

3.6.7. TIMER (timer (No. 67)) ............................................................................................................................... 116

3.6.8. TIME 2 (timer (No. 70)) .............................................................................................................................. 117

3.7. Selecting and storage .................................................................................................................................... 118

3.7.1. EXTR (extreme value selection (No. 30))................................................................................................... 118

3.7.2. PEAK (peak value memory (No. 31)) .......................................................................................................... 119

3.7.3. TRST (hold amplifier (No. 32) ) .................................................................................................................. 120

3.7.4. SELC (Constant selection (No. 33)) ........................................................................................................... 121

3.7.5. SELD (selection of digital variables - function no. 06)) ............................................................................ 122

3.7.6. SELP (parameter selection (No. 34) ) ........................................................................................................ 123

3.7.7. SELV1 (variable selection (No. 35)) ........................................................................................................... 124

3.7.8. SOUT (Selection of output (No. 36)) .......................................................................................................... 125

3.7.9. REZEPT (recipe management (No. 37)) ..................................................................................................... 126

3.7.10. 2OF3 ( 2-out-of-3 selection with mean value formation (No. 38)) ........................................................... 128

3.7.11. SELV2 (cascadable selection of variables (No. 39)) ................................................................................. 130

3.8. Limit value signalling and limiting................................................................................................................. 131

3.8.1. ALLP (alarm and limiting with fixed limits(No. 40)) .................................................................................. 131

3.8.2. ALLV (alarm and limiting with variable limits (No. 41)) ........................................................................... 133

3.8.3. EQUAL (comparison (No. 42)) .................................................................................................................... 135

3.8.4. VELO (rate-of-change limiting (No. 43)) .................................................................................................... 136

3.8.5. LIMIT (multiple alarm (No. 44)) ................................................................................................................. 137

3.8.6. ALARM (alarm processing (No. 45)) .......................................................................................................... 138

3.9. Visualization ................................................................................................................................................... 139

3.9.1. TEXT (text container with language-dependent selection (No. 79)) ........................................................ 139

3.9.2. VWERT (display / definition of process values (No. 96)) ......................................................................... 141

3.9.3. VBAR (bargraph display (No. 97)) .............................................................................................................. 146

3.9.4. VPARA (parameter operation (No. 98)) ..................................................................................................... 149

3.9.5. VTREND (trend display(No. 99)) ................................................................................................................ 151

E/A-Module 6

Description

3.10. Communication ............................................................................................................................................... 154

3.10.1. L1READ (read level1 data(No. 100)) .......................................................................................................... 154

3.10.2. L1WRIT (write level1 data (No. 101)) ........................................................................................................ 155

3.10.3. DPREAD (read level1 data via PROFIBUS (No. 102)) ................................................................................ 156

3.10.4. DPWRIT (write level1 data via PROFIBUS (No. 103)) ............................................................................... 157

3.10.5. MBDATA (read and write parameter data via MODBUS - no. 104)) ....................................................... 158

3.11. I/O extensions with CANopen ....................................................................................................................... 159

3.11.1. RM 211, RM212 and RM213 basic modules ............................................................................................ 159

3.11.2. C_RM2x (CANopen fieldbuscoupler RM 201 (No. 14)) ............................................................................ 160

3.11.3. RM_DI (RM 200 - (digital input module (No. 15))..................................................................................... 161

3.11.4. RM_DO (RM 200 - digital output module (No. 16)) .................................................................................. 161

3.11.5. RM_AI (RM200 - analog input module (No. 17)) ...................................................................................... 162

3.11.6. RM_AO (RM200 - analog output module (No. 18)) .................................................................................. 164

3.11.7. RM_DMS (strain gauge module (No. 22)) ................................................................................................ 165

3.12. KS 98-1- KS 98-1 cross communication (CANopen) ..................................................................................... 167

3.12.1. CRCV (receive mod. block no's 22,24,26,28 (No.56) ................................................................................. 167

3.12.2. CSEND (Send mod. blockno.'s 21, 23, 25, 27 - (No. 57)) .......................................................................... 168

3.13. Connection of KS 800 and KS 816 ................................................................................................................. 169

3.13.1. C_KS8x (KS 800 and KS 816 node function - (No. 58)) ............................................................................ 170

3.13.2. KS8x (KS 800/ KS 816 controller function - (No. 59)) ............................................................................... 171

3.14. Description of KS 98-1 CAN bus extension................................................................................................... 173

3.14.1. CPREAD (CAN-PDO read function (No. 88)) .............................................................................................. 177

3.14.2. CPWRIT (CAN-PDO write function (No. 89)) ............................................................................................. 178

3.14.3. CSDO (CAN-SDO function (No. 92)) .......................................................................................................... 179

3.15. Programmer .................................................................................................................................................... 184

3.15.1. APROG ( analog programmer (No. 24)) / APROGD ( APROG data (No. 25)) ............................................. 184

3.15.2. DPROG ( digital programmer (No. 27)) / DPROGD ( DPROG data(No. 28)) ............................................... 202

3.16. Controller ........................................................................................................................................................ 206

3.16.1. CONTR (Controller with one parameterset (No. 90)) ................................................................................ 206

3.16.2. CONTR+ (Controller with six parametersets (Nr. 91)) .............................................................................. 207

3.16.3. Parameter and configuration for CONTR, CONTR+ .................................................................................. 209

3.16.4. Control behaviour ...................................................................................................................................... 211

3.16.5. Controller characteristics (CONTR und CONTR+) ..................................................................................... 223

3.16.6. Empirical optimization CONTR / CONTR+ ................................................................................................ 224

3.16.7. Self-tuning r controller adaptation to the process ................................................................................ 225

3.16.8. PIDMA (Control function with particular self-tuning behaviour (Nr. 93)) ................................................ 229

3.16.9. Parameter and configuration for PIDMA .................................................................................................. 232

3.16.10. Controller characteristics and self-tuning with PIDMA ........................................................................... 234

3.16.11. Controller applications: ............................................................................................................................. 238

3.16.12. Setpoint functions ..................................................................................................................................... 242

E/A-Module 7

Description

3.16.13. Process value calculation .......................................................................................................................... 247

3.16.14. Small controller ABC ................................................................................................................................. 252

3.17. Inputs / outputs .............................................................................................................................................. 255

3.17.1. UNI_IN (analog universal input-Modul U) ................................................................................................ 256

3.17.2. TC_IN (analog input card TC, mV, mA) ..................................................................................................... 262

3.17.3. R_IN (analog input card) ........................................................................................................................... 264

3.17.4. U_IN (analog input card -50...1500mV, 0...10V) ....................................................................................... 266

3.17.5. TPS_IN ....................................................................................................................................................... 267

3.17.6. I_OUT (analog output card 0/4…20mA, +/- 20mA) ................................................................................. 269

3.17.7. U_OUT (analog output card 0/2…10V, +/- 10V) ...................................................................................... 270

3.17.8. REL_OUT (Relais output) ........................................................................................................................... 271

3.17.9. SSR_OUT (Solid-State-Relais Ausgang) ................................................................................................... 272

3.17.10. DIDO (digital input/output card) ................................................................................................................ 273

3.17.11. DINPUT (digital inputs (Nr. 121)) ............................................................................................................... 274

3.17.12. DIGOUT (digital outputs (No. 122)) ........................................................................................................... 275

3.18. Additional functions ....................................................................................................................................... 276

3.18.1. LED (LED display (No. 123)) ....................................................................................................................... 276

3.18.2. CONST (constant function (No. 126)) ........................................................................................................ 277

3.18.3. INFO (information function (No. 124)) ....................................................................................................... 278

3.18.4. STATUS (status function (No. 125)) .......................................................................................................... 279

3.18.5. CALLPG (Function for calling up an operating page (no. 127)) ................................................................. 282

3.18.6. SAFE (safety function (Nr. 94) ) ................................................................................................................. 283

3.18.7. VALARM (display of all alarms on alarm operating pages (function no. 109)) ....................................... 284

3.18.8. F_Inp (Frequenz-/ Zählereingang) ............................................................................................................. 286

3.19. Function management .................................................................................................................................... 287

3.19.1. Memory requirement and calculation time .............................................................................................. 287

3.19.2. Sampling intervals ..................................................................................................................................... 288

3.19.3. EEPROM data ............................................................................................................................................. 288

3.20. Examples ........................................................................................................................................................ 289

3.20.1. Useful small engineerings ......................................................................................................................... 289

3.20.2. Controller applications .............................................................................................................................. 290

3.20.3. Programmer fragments .............................................................................................................................. 290

E/A-Module 8

Description

Foreword

This manual consists of three descriptive units:

1. Operating instructions

2. Engineeringtool description

3. Function block description

Section 1 holds the required information for identification, mounting, connection and electrical commissioning of

the unit under consideration of safety notes of the application and environmental conditions.

The basic principles of operation are explained: Controls and indicators, menu structure and navigation with the

cursor, selection of sub-menus and properties as well as adjustment of e.g. s and parameters.

Section II comprises the handling of the engineering-tool, the building of a simple engineering and transmission

to the KS 98-2.

Section 3 presents the particular function blocks in detail.

+ For functional commissioning, additional descriptions are required; please, order them separately or load

them from the PMA homepage: www.pma-online.de.

+ As the functions provided in KS 98-2 are composed individually for each application using an Engineering

Tool ET/KS 98, entire comprehension of the operating functions requires the relevant Project description

with the Engineering

Supplementary documentation:

PROFIBUS-protocoll (GB) 9499-040-82811

ISO 1745-protocoll (GB) 9499-040-82911

E/A-Module 9

Description

1. Operating description

1.1. Description

The device is a compact automation unit.

The function can be freely structured via function blocks.

Dependent on version, the basic unit (standard) contains analog and digital outputs as well as relays.

Additional inputs and outputs are available as plug-in modules. The basic unit has at least 2 slots. The number of

slots can be increased by up to 12 using additional cards (for terminal blocks B and C).

An additional optional communication card provides interfaces to communicate with other devices and systems

available.

The instrument is a compact automation unit the function of which can be configured and linked together freely

by means of function blocks. Each unit contains a comprehensive function library.

The function blocks can with an engineering tool selected, configured, parameterized and linked together.

I.e. complex mathematical calculations, multi-channel control structures and sequence controllers

can be realized in a single unit.

Indication of various operating pages with max. 10 lines is via a full-graphic color display (320 x 240 dots) e.g.

numeric input and output of analog and digital signals, values and parameters as well as full-graphic display of

barographs, controllers, programmers and trends.

The display color can be switched over dependent on events, or by operation (engineering).

E/A-Module 10

Safety notes

1.2. Safety notes

This section provides a survey of all important safety aspects:

optimum protection of personnel and safe, trouble-free

operation of the instrument.

Additionally, the individual chapters include specific safety

notes for prevention of immediate hazards, which are marked

with symbols. Moreover, the hints and warnings given on

labels and inscriptions on the instruments must be followed

and kept in readable condition continuously.

General

Software and hardware are programmed or developed in

compliance with the state of the art applicable at the time of

development, and considered as safe.

Before starting to work, any person in charge of work at the

product must have read and understood the operating

instructions.

The plant owner is recommended to request evidence for

knowledge of the operating instructions by the personnel.

Correct use for intended application

The operating safety is only ensured when using the products

correctly for the intended application. The instrument can be

used as a multiple function controller for open and closed

control loops in industrial areas within the limits of the

specified technical data and environmental conditions.

Any application beyond these limits is prohibited and

considered as non-compliant.

Claims of any kind against the manufacturer and /or his lawful

agents, for damage resulting from non-compliant use of the

instrument are precluded, liability is limited to the user.

User responsibility

The user is responsible:

for keeping the operating manual in the immediate

vicinity of the instrument and always accessible for the

operating personnel.

for using the instrument only in technically perfect and

safe condition.

The operator of the system is recommended to have the

operating personnel demonstrably confirm their

knowledge of the operating instructions.

Apart from the work safety notes given in these operating

instructions, compliance with the generally applicable

regulations for safety, accident prevention and environment

protection is compulsory.

The user and the personnel authorized by the user are

responsible for perfect functioning of the instrument and for

clear definition of competences related to instrument operation

and maintenance. The information in the operating manual

must be followed completely and without restrictions!

The user is responsible that the instrument is operated only by

trained and authorized persons. Maintenance and repair may

be done only by trained and specialized persons who are

familiar with the related hazards.

Operation and maintenance of the instrument are limited to

reliable persons. Any acts susceptible to impair the safety of

persons or of the environment have to be omitted. Any persons

who are under effect of drugs, alcohol or medication affecting

reaction are precluded from operation of the instrument.

Instrument Safety

This instrument was built and tested according to VDE 0411 /

EN61010-1 and was shipped in safe condition. The unit was

tested before delivery and has passed the tests required in the

test plan.

In order to maintain this condition and to ensure safe

operation, the user must follow the hints and warnings given in

these safety notes and operating instructions.

The unit is intended exclusively for use as a measuring and

control instrument in technical installations.

The insulation meets standard EN 61010-1 with the values for

overvoltage category, degree of contamination, operating

voltage range and protection class specified in the operating

instructions / data sheet.

The instrument may be operated within the specified

environmental conditions (see data sheet) without impairing its

safety.

The instrument is intended for mounting in an enclosure. Its

contact safety is ensured by installation in a housing or switch

cabinet.

Unpacking the instrument

Remove instrument and accessories from the packing. Enclosed

standard accessories:

– operating notes or operating instructions

– fixing elements.

Check, if the shipment is correct and complete and if the

instrument was damaged by improper handling during

transport and storage.

! Warning!

If the instrument is so heavily damaged that safe operation

seems impossible, the instrument must not be taken into

operation.

We recommend to keep the original packing for shipment in

case of maintenance or repair.

E/A-Module 11

Safety notes

Mounting

Mounting is done in dustfree and dry rooms.

The ambient temperature at the place of installation must not

exceed the permissible limits for specified accuracy given in

the technical data. When mounting several units with high

packing density, sufficient heat dissipation to ensure perfect

operation is required.

For installation of the unit, use the fixing clamps delivered with

the unit. The sealing devices (e.g. sealing ring) required for the

relevant protection type must also be fitted.

Electrical connections

All electrical wiring must conform to local standards (e.g. VDE

0100 in Germany). The input leads must be kept separate from

signal and mains leads.

The protective earth must be connected to the relevant

terminal (in the instrument carrier). The cable screening must

be connected to the terminal for grounded measurement. In

order to prevent stray electric interference, we recommend

using twisted and screened input leads.

The electrical connections must be made according to the

relevant connecting diagrams.

See electrical safety, page 241.6.4

Electrical safety

The insulation of the instrument meets standard EN 61

010-1 (VDE0411-1) with contamination degree 2,

overvoltage category II, working voltage 300 V r.m.s. and

protection class I.

Commissioning

Before instrument switch- on, ensure that the rules given

below were followed:

Ensure that the supply voltage corresponds to the

specification on the type label.

All covers required for contact safety must be fitted.

Before instrument switch- on, check if other equipment

and / or facilities connected in the same signal loop is /

are not affected. If necessary, appropriate measures

must be taken.

The instrument must be operated only when mounted in

its enclosure.

Shut- down

For permanent shut- down, disconnect the instrument from all

voltage sources and protect it against accidental operation.

+ Before instrument switch- off, check that other

equipment and / or facilities connected in the

same signal loop is / are not affected. If

necessary, appropriate measures must be taken.

Maintenance and modification

The instrument needs no particular maintenance.

Modifications, maintenance and repair may be carried out only

by trained, authorized persons. For this, the user is invited to

contact the service.

For correct adjustment of wire-hook switche (page 23) and for

installation of modular option cards, the unit must be

withdrawn from the housing.

a Warning!

When opening the instruments, or when removing

covers or components, live parts or terminals can be

exposed.

Before carrying out such work, the instrument must be

disconnected from all voltage sources.

After completing such work, re- shut the instrument and re-fit

all covers and components. Check, if the specifications on the

type label are still correct, and change them, if necessary.

Explosion protection

Non-intrinsically safe instruments must not be operated in

explosion-hazarded areas. Moreover, the output and input

circuits of the instrument / instrument carrier must not lead

into explosion-hazarded areas.

Operation

Switch on the supply voltage. The instrument is now ready for

operation. If necessary, a warm-up time of approx. 1.5 min.

should be taken into account.

E/A-Module 12

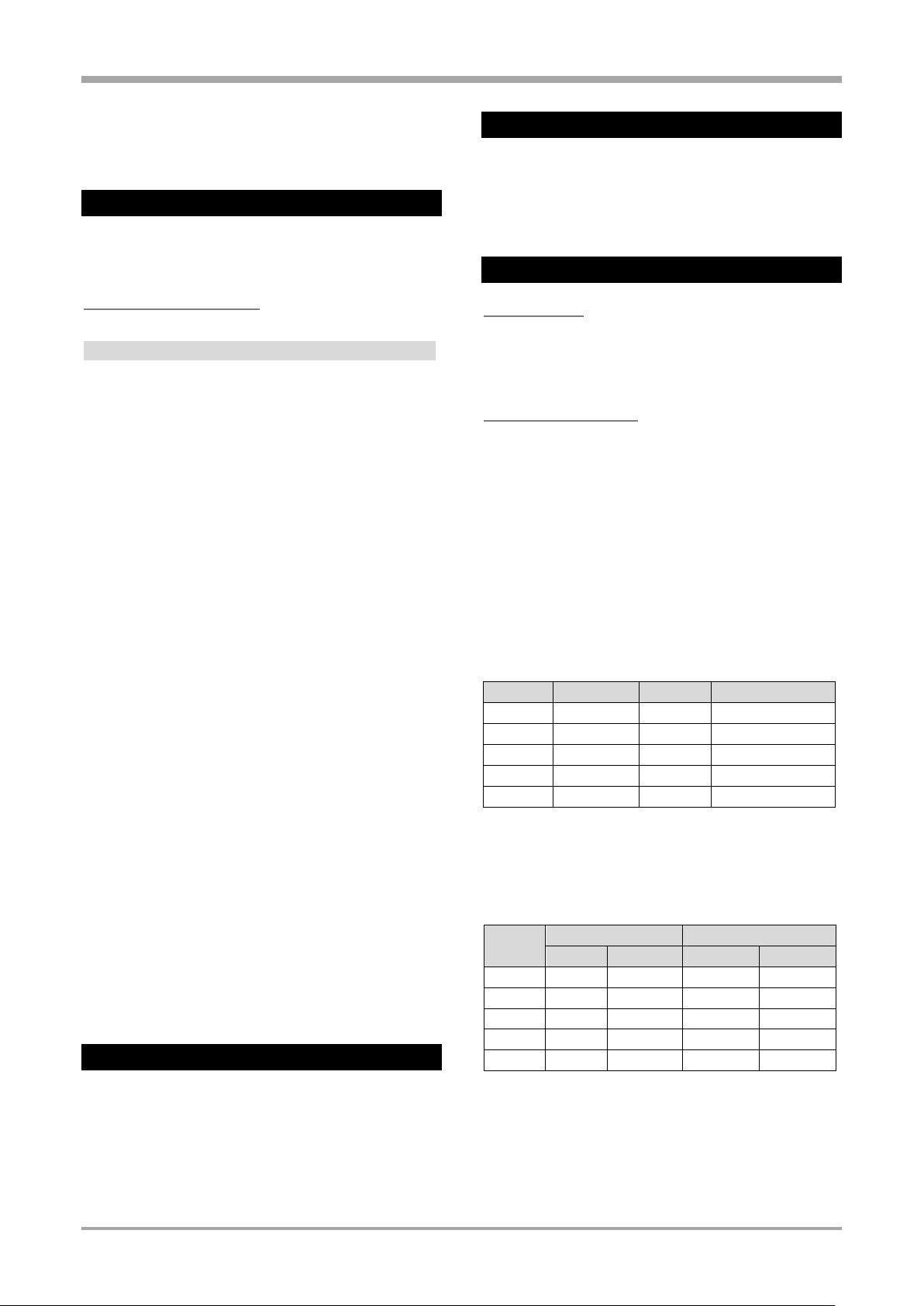

Technical data

Typ

Range

Error

Resolution

L 1)

–200...900°C

≤ 2K

0,05 K

J 1)

–200...900°C

≤ 2K

0,05 K

K 1)

–200...1350°C

≤ 2K

0,072 K

N 1)

–200...1300°C

≤ 2K

0,08 K

S

–50...1760°C

≤ 3K

0,275 K

R

–50...1760°C

≤ 3K

0,244 K

B 2)

(25)400...1820°C

≤ 3K

0,132 K

T 1)

–200...400°C

≤ 2K

0,056 K

C 3)

0...2300°C

≤ 2K

0,18 K

E 1)

–200...900°C

≤ 2K

0,038 K

Range

Error

Resolution

–200,0...250,0 °C

≤ 0.5K

0,024 K

–200,0...850,0 °C

≤ 1.0K

0,05 K

2x –200,0...250,0 °C

≤ 0.5K

0,024 K

2x –200,0...250,0 °C

≤ 0.1K

0,05 K

Range

Error

Resolution

0...500 Ω

1 )

≤ 0.1 %

0.02Ω

Range

Error

Resolution

0...250 Ω

≤ 0.25Ω

≤ 0.01Ω

0...500 Ω

≤ 0.5Ω

≤ 0.02Ω

Range

Error

Resolution

0/4...20 mA

≤ 0.1 %

≤ 0.8µA

Range

Error

Resolution

0/2...10 V

≤ 0.1 %

≤ 0.4mA

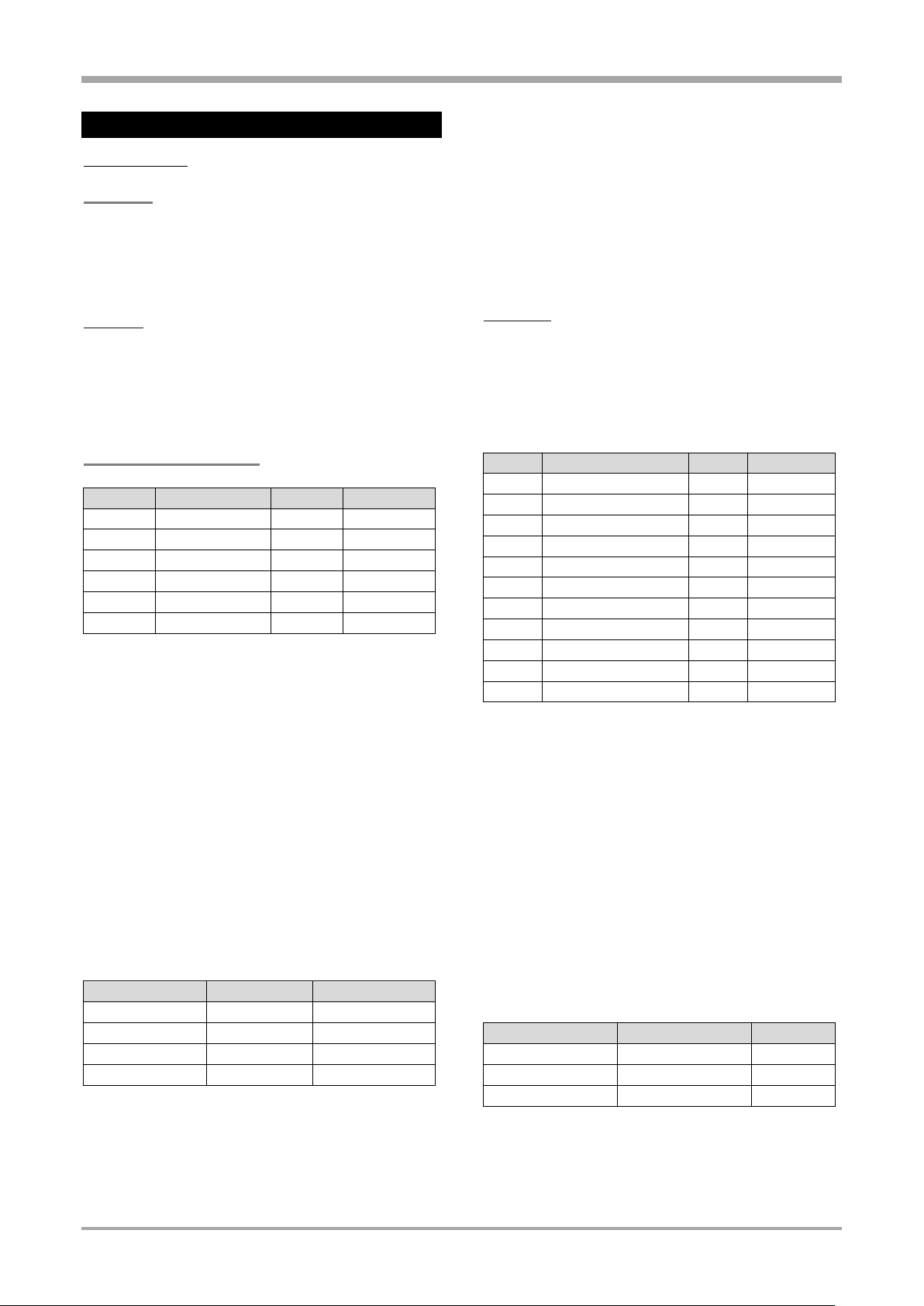

1.3. Technical data

In-/Outputs Base Unit

Arrangement of In- and Outputs

Depending on the version and option, the following

inputs and outputs are available:

Analog Inputs

Universal Input (Terminal A, Sect. 4)

Resolution: 16bit; Measurement cycle: 100ms

External CJC

selectable: 0...60 °C bzw. 32...140 °F

Resistance thermometer

Pt 100 DIN IEC 751 and Temperature difference 2 x Pt 100

Linearisierung in °C oder °F

3-wire connection

Lead resistance ß 30 [ per lead

Sensor current ß 1 mA

Input circuit monitoring for sensor/lead break and short

circuit.

Potentiometers

1)

Rgesamt inkl. 2 x RL

Resistance linear

Sensor current ß 1 mA

Adjustment/scaling with sensor connected.

Input circuit monitoring for sensor/lead break and short

circuit.

Resistance measurement

Thermocouples

According to DIN IEC 584

1)

accuracy valid from -100 °C

1)

accuracy valid from 400 °C

2)

W5Re/W26Re

Temperature linear in °C or °F)

Input resistance: ? 1 M[

Cold junction compensation internal/external

Sensor monitoring:

Current through sensor ß 1 A

Reverse polarity detection triggered at 30 °C below start

of range. Sensor status information is available to be

used in the application program.

Direct current 0/4...20 mA

Input resistance: 5 [

Input circuit monitoring 4...20 mA: I ß 2 mA

Direct voltage

Input resistance ? 50 k[

Transmitter-Supply

to energize a 2-wire transmitter Galvanically isolated,

Short-circuit proof,

Output: 22 mA / ≥ 17,5 V

Influence of internal CJC

ß 0,5 K per 10 K terminal temperature

E/A-Module 13

Technical data

Digital Inputs

Logic Inputs (Terminal A, Sect. 1)

Opto-coupler

Nominal voltage 24 V DC external

Residual ripple: ≤ 5%pp

Current sink (IEC 61131 Typ 1)

Logic „0“= –3...5 V

Logic „1“ = 15...30 V

Current approx. 6 mA

Galvanic isolation or connections see

section 1.6.3 page 25

Outputs

Outputs (Terminal P, Sect. 1..4)

Depending on version 4 Relays or 2 Relays and 2 option

module slots

Relay outputs

Relays have potential free change-over contacts

Contact rating:

Max. 500 VA, 250 V, 2 A at 48...62 Hz, cos 0,

Min. 12 V, 10 mA AC/DC

Switching cycles:

electrical for I = 1A/2A (resistive load)

≥ 800.000 / 500.000 at 250V.

If the relays operate external contactors, these must be

fitted with RC snubber circuits to prevent excessive

switch-off voltage peaks! Varistor protection is not

recommended!

Modular I/O Extension

Option module carrier board for terminals B, C

Option slots (Terminal B)

Behind terminal strip B an optional module carrier board

with 4 slots can be installed.

All module types are supported. Each module is

galvanically isolated from the rest of the unit. Details of

available modules see chapter „In-/Output Extension

Modules”

Option slots (Terminal C)

Same specification as terminal B

Digital In--/Output board

for terminals B, C

Control inputs di1...di10

Current sink (IEC 61131 Type 1)

Nominal voltage 24 V DC external

Residual ripple: ≤ 5%ss

Logic „0“= -3...5 V

Logic „1“ = 15...30 V

Current approx. 6 mA

Control outputs do1...do4

Galvanically isolated opto-coupler outputs. Grounded

load (common positive control voltage)

Switching capacity: 18...32 VDC; 70mA

Internal voltage drop: 0,7V

Refresh-Rate: 100 ms

Protective circuit: thermal against short circuit; Overload

cut-off.

Nominal voltage 24 V DC external

Residual ripple 5%ss

Option slots base unit

Option slots (Terminal A, Sect. 2,3)

Option slots for sections A2 and A3 are providing 4

terminals each and can support all available option

modules. Option modules are galvanically isolated from

the base unit. Details of available modules see chapter

„In-/Output Extension Modules”.

Limitations to take into account

To avoid inadmissible self-heating the number of output

extension modules is limited. The following rule applies:

• A maximum of 6 current outputs or transmitter power

supplies are allowed per unit!

Exceedances are checked by the engineering tool.

Option slots (Terminal P, Sect. 3,4)

(optional instead of relays)

Option slots for sections P3 and P4 are providing 3

terminals each. They support input modules for standard

signals (0/4..20mA, 0/2..10V) and SSR driver modules.

Dual channel modules share a common reference

terminal. Option modules are galvanically isolated from

the base unit. Details of available modules see chapter

„In-/Output Extension Modules”.

E/A-Module 14

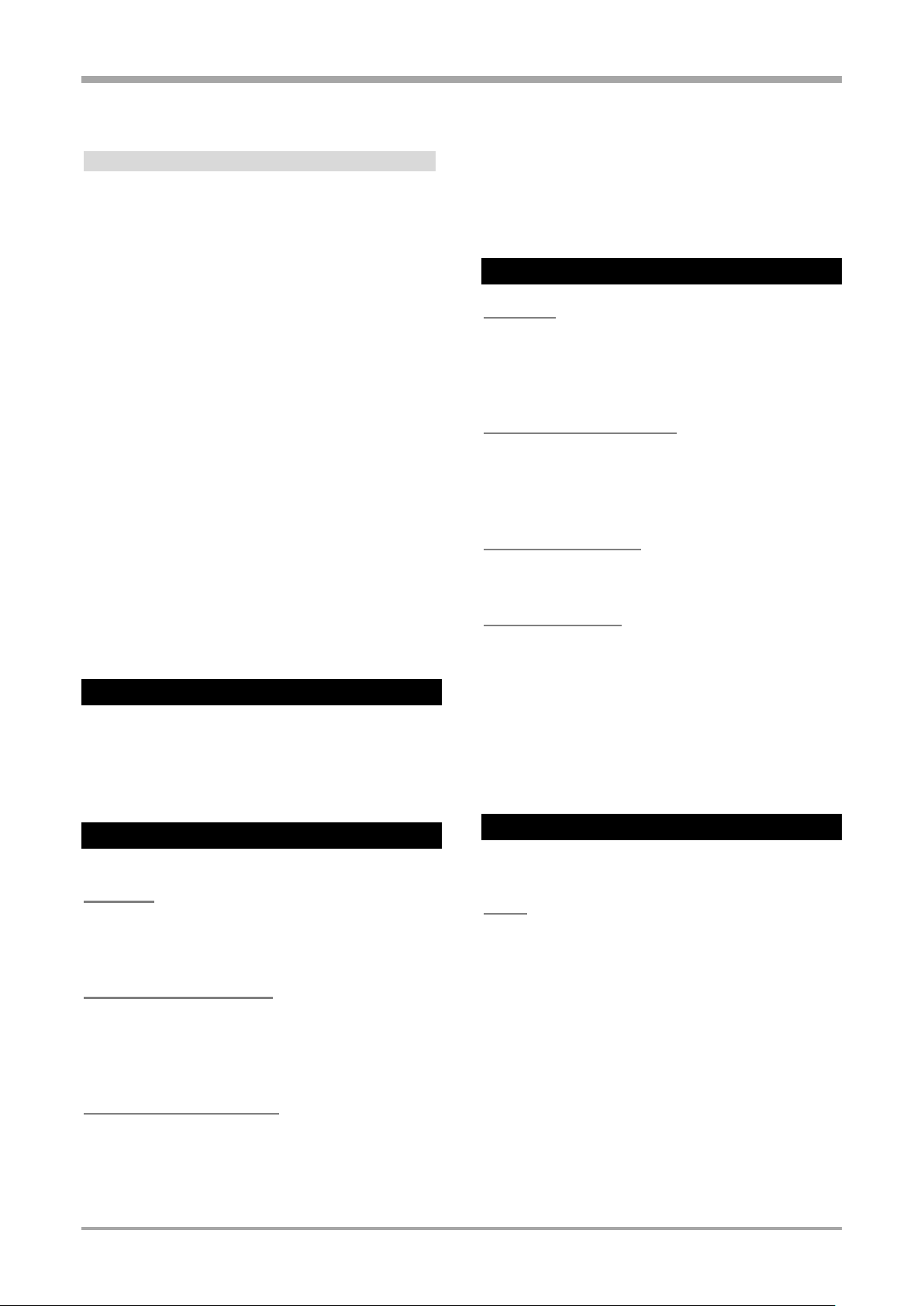

Technical data

Typ

Range

Error

Resolution

Pt100

-200...850°C

≤ 1 K

0,071

Pt100

-200...100°C

≤ 0,5 K

0,022

Pt1000

-200...850°C

≤ 1 K

0,071

Pt1000

-200...100°C

≤ 0,5 K

0,022

Ni100

-60...180°C

≤ 1 K

0,039

Ni1000

-60...180°C

≤ 0,5 K

0,039

Range

Error

Resolution

0...160 Ω

≤ 1%

0,012

0...450 Ω

≤ 1%

0,025

0...1600 Ω

≤ 1%

0,089

0...4500 Ω

≤ 1%

0,025

Typ

Range

Error

Resolution

L

1)

-200...900°C

≤ 2 K

0,080

J

1)

-200...900°C

≤ 2 K

0,082

K

1)

-200...1350°C

≤ 2 K

0,114

N

1)

-200...1300°C

≤ 2 K

0,129

S

-50...1760°C

≤ 3 K

0,132

R

-50...1760°C

≤ 3 K

0,117

B

2)

(0) 400...1820°C

≤ 3 K

0,184

T

1)

-200...400°C

≤ 2 K

0,031

C

3)

0...2300°C

≤ 2 K

0,277

D

0...2300°C

≤ 2 K

0,260

E

1)

-200...900°C

≤ 2 K

0,063

Range

Error

Resolution

0...30 mV

≤ 45 µV

1,7 µV

0...100 mV

≤ 150 µV

5,6 µV

0...300 mV

≤ 450 µV

17 µV

In-/Output Extension Modules

Analog Inputs

U-Module

Universal input module

No of channels: 1

The technical design corresponds to the universal input

of the basic unit.

R-Modul

RTD module (resistance thermometer)

No of channels: 2 (with 3- or 4-wire- connection just one).

Type of sensor can be selected separately for each

channel!

Sensor current: 0,25 mA

Resistance thermometers

Connection: 2-, 3- or 4-wire

Cable compensation or Calibration (0%/100%) can be

carried out via the user interface with sensor connected.

• 0% calibration for 2-wire resistor measurement

• 0% and 100% calibration for potentiometer

Influence of lead resistance:

negligible with 3 or 4-wire connection.

Input circuit monitoring for break of sensor or lead and short

circuit

T-Module

Thermo coupler module (TC, mV, mA)

No of channels: 2 (Differential input).

Type of sensor can be selected separately for each channel!

Thermocouples

According to DIN IEC 60584

(not Typ L, W(C) und D)

Linearization: in °C or °F

Lead resistance

Pt (-200...850°C): ≤ 30 Ω per lead

Pt (-200...100°C), Ni: ≤10 Ω per lead

Lead resistance compensation:

not necessary with 3- and 4-wire connection.

For 2-wire connection with short-circuited sensor via the

front user interface.

Influence of lead resistance:

negligible with 3 or 4-wire connection

Input circuit monitoring for break of sensor or lead and

short circuit.

Short circuit: reacts at 20K below measurement range

Resistance measurement / Potentiometers

2-, 3- or 4-wire connection

Potentiometer 2-wire connection

1)

accuracy valid from -100°C

2)

accuracy valid from 400°C

3)

C(W) W5RE/W26Re

Linearization in °C or °F

Linearity error: negligible

Input resistance: ≥ 1M

Internal temperature compensation (CJC)

Error: ≤ 0,5K/10K

External JCC possible: 0...60 °C or 32...140 °F

Effect of source resistance: 1mV/k

Sensor monitoring:

Sensor current: ≤ 1

Reverse polarity detection triggers at 30K below range min.

mV- Input

Characteristic linear

E/A-Module 15

Input resistance: 1M

Sensor break monitoring: built in Sensor current: ≤ 1A

Technical data

Range

Error

Resolution

0/4...20 mA

≤ 40 µA

2 µA

Range

Error

Resolution

-50...1500 mV

≤ 1,5 mV

0,09

0...10 V

≤ 10 mV

0,56

mA- Input

Input resistance: 5

Sensor alarm: << 2 mA (with 4...20 mA)

Over range alarm: >>22mA

V-Module

High impedance voltage input module

No. of channels: 2

Range can be selected separately for each channel!

Voltage linear characteristic

Input resistance: >>1G

Effect of source resistance: 0,25mV/M

Sensor monitoring: not available

P-Modul

Input module with transmitter supply

No of channels: 1

The technical design of the input corresponds to the TModule

Transmitter-Supply

to energize a 2-wire transmitter or up to 4 opto-coupler

inputs.

Galvanically isolated, Short-circuit proof,

Output: 22 mA / ≥ 17,5 V

Analog Outputs

L-Module

Linear output module

No of channels: 2

Resolution: 16 Bit

Refresh-Rate: 100ms

Signal ranges: 0/4...20mA, -20...20mA

(configurable by channel)

Resolution: approx. 5 A/Digit

Error: ≤ 0,2%

Load: ≤ 500 Ω / ≤ 150 Ω (selectable)

Influence of load: ≤ 0,05%/100 Ω

Used as logic signal

0 / ≤ 20 mA

B-Module

Bipolar linear output module

No of channels: 2

Resolution: 16 Bit

Refresh-Rate: 100ms

Signal ranges: 0/2...10V, -10...10V

(configurable by channel)

Resolution: approx. 5 mV/Digit

Error: ≤ 0,2%

Load: ≥ 2k

Influence of load: ≤ 0,05%/100

Used as logic signal

0 / ≥ 10 V

Digital In-/Outputs

D-Module

Digital I/O module

No of channels: 2 (configurable as input or output per

channel)

Reverse polarity protection.

Input

Current sink IEC 61131 Type 1)

Nominal voltage 24 V DC external

Residual ripple: ≤ 5%pp

Logic „0“: -3...5V

Logic „1“: 15...30V

Cycle time: 100 ms

Galvanically isolated

Input resistance: 5 k

Output

Grounded load (common positive control voltage)

Switching capacity: 18...32 VDC; ≤ 70mA

Internal voltage drop: ≤ 0,7V

Refresh-Rate: 100 ms

Galvanically isolated

Protective circuit: thermal against short circuit; Overload

cut-off.

Nominal voltage 24 V DC external

Residual ripple 5%ss

A-Module

SSR driver module

No of channels: 2

Logic „0“: 0V

Logic „1“: ≥10 V

Load: 500

Galvanic Separation

Galvanically isolated areas are visualized in the diagram

underneath. In general, each of the I/O modules is

galvanically isolated from the rest of the unit. Channels

inside a module are not separated.

Signal- and measurement circuits

Functional isolation up to a voltage of 33VAC/70VDC

against each other and against ground (according EN

61010-1).

E/A-Module 16

Technical data

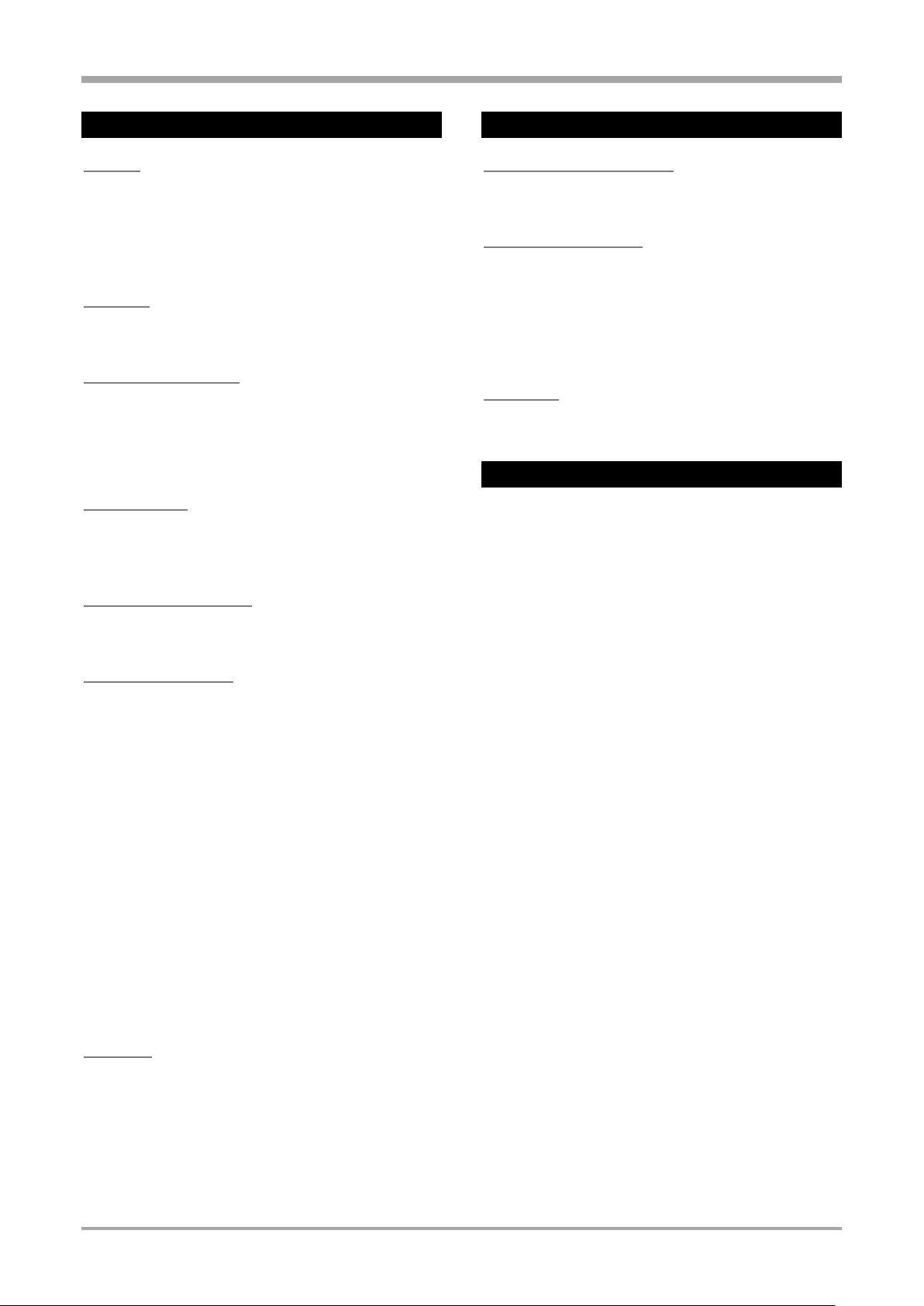

Com. speed

max. cable length

10 kbit/s

1200 m

20 kbit/s

1000 m

50 kbit/s

1000 m

100 kbit/s

500 m

125 kbit/s

250 m

250 kbit/s

250 m

500 kbit/s

100 m

800 kbit/s

50 m

1000 kbit/s

25 m

Modul

DPREAD

DPWRIT

Parameterchannel

a 1 1 - b 1 1 x c 2 2 x d 3 3 x e 4 4

x

Modul

Read

Write

FIX

REAL

FIX

REAL

a

18

26

18

26 b 26

34

26

34 c 44

60

44

60 d 62

86

62

86 e 80

112

80

112

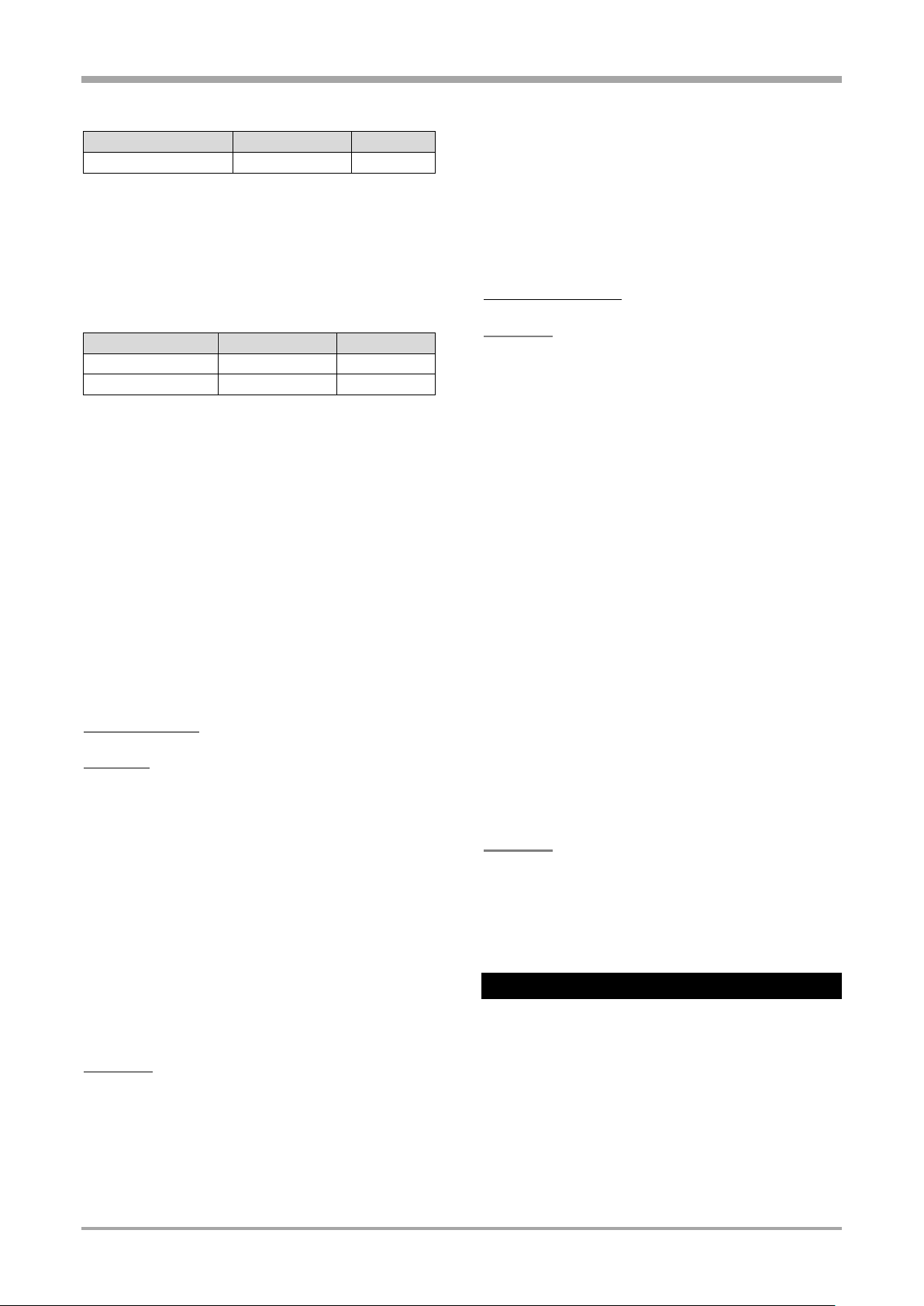

Mains circuits 90...250 VAC, 24V UC

Safety isolation up to a voltage of 3kV against each other

and against ground (according EN 61010-1).

Remote I/O-Extension

Detailed technical data and functional descriptions of

remote I/O systems can be found in the related

documents.

CAN Interface (CANopen)

Transmission speeds:

Termination resistor

Internal resistor connectable by switch

Transmission mode:

cyclic

Error detection:

Automatic node monitoring

(“node guarding“).

Front Interface

(Standard)

The front accessible USB interface uses a standard USB

cable.

It provides access for the programming and diagnosis

tool ET/KS98-2 even with the unit not connected to

power.

Fieldbus Interfaces

(Optional)

RS485-Module

Galvanically isolated RS 485

Anzahl der Regler pro Bus

max 32 interface modules without repeater.

PROFIBUS-DP Module

According to EN 50170 Vol. 2 (DIN 19245 T3)

Read/write access to all process values parameters

and configuration data.

Configurable process data modules

Max. 4 DPREAD and 4 DPWRIT functions with six analog

and sixteen logic variables each can be selected with the

Engineering Tool. By suitable internal connections with

inputs and outputs of these functions, any internal signal

can be routed to the PROFIBUS-DP interface.

The parameter channel provides non-cyclical access to all

parameters and configuration data.

Addressing:

KS 98-X: 1...24 (Default =1)

RM 200: 2...42 (Default =32)

Refresh times:

Depending on the selected transmission speed and the

number of CAN-nodes connected.

• RM 200: typical 100ms

• Cross communication: ≥ 200ms

Maximum Setup RM 200

16 Analog Inputs and ≤16 Analog Outputs per RM200-Rack!

Digital I/O is only limited by the size of the rack.

Examples: 72 digital In- /Outputs (without analog

modules!), or 16 analog Inputs plus 16 analog Outputs

plus 8 digital In- /Outputs.

Engineering Tools

KS98-2 units can be programmed and maintained with

the following tools:

ET/KS98: from Version 7.0

SIM/KS98-2: from Version 1.0

OEM/KS98-2: from Version 1.0

Data format

Values are transmitted using the IEEE-format (REAL) or in

a 16-Bit-fixpoint notation (FIX) with one decimal digit

(configurable).

I/O memory requirements (Byte)

Diagnosis/behavior on error

The functions DPREAD and DPWRIT are providing status

outputs to indicate error conditions.

E/A-Module 17

Technical data

Speed

max. cable length

9,6 kbit/s

1200 m

187,5 kbit/s

1000 m

500 kbit/s

400 m

1,5 Mbit/s

200 m

12 Mbit/s

100 m

Transmission speeds and cable lengths

Automatic speed detection

Addresses

0...126 (Factory setting: 126)

Remote addressing supported.

Other functions

Sync and Freeze

Connection

9pin. Sub-D connector

Termination resistor

By selecting a corresponding connector.

Cable

according EN 50170 Vol. 2 (DIN 19 245T3)

Acessories

Engineering Set KS98/PROFIBUS consisting of:

• GSD-file, Type-file

• PROFIBUS-Manual

• Function blocks for S5 / S7

Display

3,5“ color TFT display with

LED backlight

Resolution: 320 x 240 (QVGA)

Capacitive Touch

Working data of functions (Programmer, Integrator,

Counters, ...

Stored in a capacitor buffered RAM

(typically >> 15 Minutes).

Real Time Clock

Backed up with a Lithium battery.

Environmental Conditions

Protection

Front: IP 65

Housing: IP 20

Terminals: IP 00

according DIN EN 60529 (VDE 0470-1

Ambient Temperature range

Operation: 0...55 °C

Storage/Transport: –20...60 °C

Humidity: ≤ 75% RH yearly average,

non-condensing

Temperature influence

Reference temperature 25°C

Temperature influence << 0.05 %/ 10 K

Shock and vibration

Vibration test according to DIN EN 60068-2-6

Frequency: 10...150 Hz

Unit in operation: 1 g / 0,075 mm,

Unit not in operation.: 2 g / 0,15 mm

Shock test according to DIN EN 60068-2-27

Shock: 15 g,

Duration: 11 ms

Power Supply

depending on order code:

AC Supply

Voltage: 90...250 VAC (48...62 Hz)

Power consumption: approx. 18 VA

(fully equipped)

Electromagnetic Compatibility

Complies with EN 61326-1

“continuous, non-monitored operation”

Safety

According EN 61010-1 (VDE 0411-1)

• Overvoltage category II

• Contamination class 2

Low voltage supply 24 V UC

AC voltage: 20.4….26.4 VAC (48...62 Hz)

DC voltage: 18...31 VDC

Power consumption: approx. 18 VA

(fully equipped)

Behavior with power failure

User program, configuration, parameter and active

setpoints

• Working voltage range 300 V

• Protection class II

Are permanently stored in EEPROM

E/A-Module 18

Technical data

General

Housing

Plug-in unit, inserted from the front

Material: Makrolon 9415, flame retardant, self extinguishing. Flammability class:: UL 94 VO

Weight:

approx. 750 g (fully equipped)

Mounting

Panel mounting with 2 fixing elements at top and bottom.

Close mounting possible Orientation as desired.

Electrical connections

depending on order code:

• Screw terminals for conductor cross-section 0,5-2,5mm2

• Flat pin connectors 1 x 6,3mm or 2 x 2,8mm according

DIN 46244

CE Compliance

Meets the European Directives regarding

„Electromagnetic Compatibility“ and „Low-voltage

equipment“

DIN EN 14597 Certificate

The device is certified to be used as temperature control

and limiting equipment according to DIN EN 14597.

Supporting Software

Engineering Tool ET/KS98-2

Graphical function block editor for programming and

maintenance of KS98-2 units

Simulation SIM/KS98-2

Program to simulate KS 98-2 on a PC screen with full

functionality of the device plus:

• Simulation of In- and Outputs

• Trend diagrams

• „Turbo“-Mode (time laps)

USB-Cable

To connect PC with programming utility to the unit.

(KS 98-2 Front USB Interface)

Delivered Condition

Every unit is coming with a test-engineering that allows

to check the in- and outputs of the basic unit.

UL & cUL Compliance

(Type 1, indoor use)

File: E 208286

For compliance with UL certificate, the following

information must be considered:

• Use only Screw Terminal variant

• Use only 60/75°C copper (Cu) conductors.

• Tighten the terminal-screws with a torque

of 0.5 – 0.6 Nm.

• The instrument shall be mounted on a flat surface of a

“Type 1 Enclosure” for “Indoor use” only.

• Ambient temperature: ≤ 50 °C

• Power supply: ≤ 250 VAC

• Max. ratings of relay contacts:

250 VAC, 2 A, 500 W (resistive)

250 VAC, 2 A, 360 VA (inductive)

In the box

• Device according to order code

• Concise manual (DE/EN/FR)

• 4 fixing clamps

E/A-Module 19

Achievements

KS98 - 2 x x - x x x x x - x 0 0

Base Models

Universal Input, 2 digital Inputs, TPS, RTC

with Fast-On Terminals

0

with Screw Terminals

1

Power Supply & Outputs [P]

90…250V (2 Relays, 2 option module slots)

0

24V UC (2 Relays, 2 Option Slots)

1

90…250V (4 Relays)

2

24V UC (4 Relays)

3

Communication Options [D]

none / for stand-alone applications

0

Standard Interfaces (Ethernet/USB) and CAN for Remote I/O

1

Standard Interfaces plus RS485 / Modbus

2

Standard Interfaces plus Profibus

3

Standard Interfaces plus Profinet

4

Options

none

0

Datalogger

1

I/O Extensions [B]

not fitted

0

Digital-I/O Extension (10 DI, 4 DO)

1

Modular Extension (4 option module slots)

2

I/O Extensions [C]

not fitted

0

Digital-I/O Extension (10 DI, 4 DO)

1

Modular Extension (4 option module slots)

2

Configuration

Default settings; No option modules installed

0

Default settings; Option modules according to additional order line

1

Preset to specification; No option modules installed

8

Preset to specification; Option modules according to additional order line

9

Certification

Standard (CE certified)

0

UL / cUL certified

U

DIN3440 / EN 14597

D

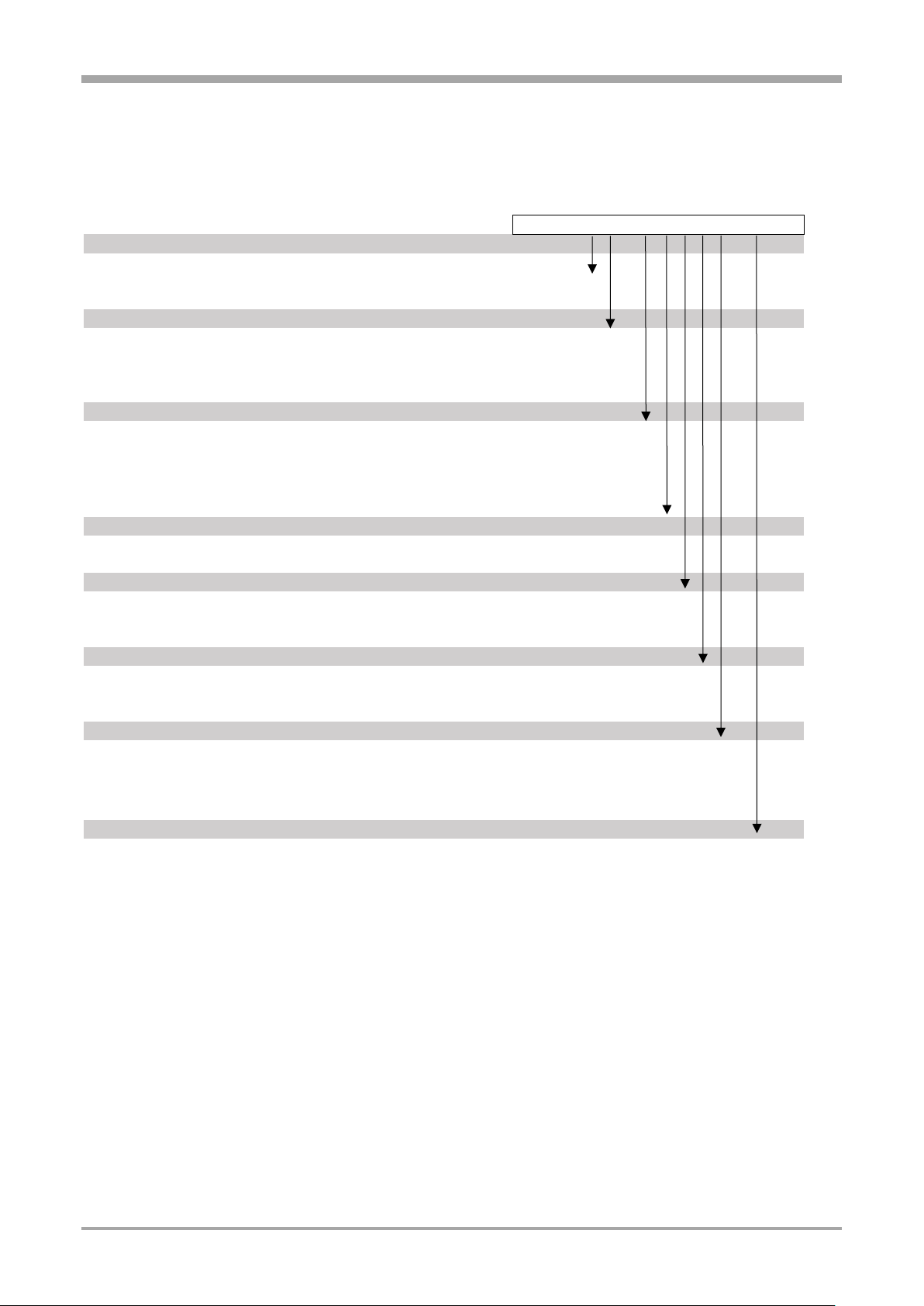

1.4. Achievements

The versions of the device result from the combination of different variants according to the following scheme.

E/A-Module 20

Achievements

Extended order code for factory installed option modules

Separate

module

orders:

Position of digit within the order code defines the positioning of

the module and assignment to output terminals Positions at

terminal strips B and C require extension cards

Strip P, Segment 3

Strip P, Segment 4

Strip A, Segment 2

Strip A, Segment 3

Strip B, Segment 1

Strip B, Segment 2

Strip B, Segment 3

Strip B, Segment 4

Strip C, Segment 1

Strip C, Segment 2

Strip C, Segment 3

Strip C, Segment 4

A98 - F - x x x x x x x x x x x

x A98 - M - x

Modules and possible positions

nicht vorhanden

0 0 0 0 0 0 0 0 0 0 0 0 Universaleingang

- - U U U U U U U U U

U

U Zweifach Pt100/1000, Ni100/1000, Widerstand

- - R R R R R R R R R R

R

Zweifach Thermoelement, mV, 0/4...20mA

- - T T T T T T T T T T

T

Zweifach -50...1500mV (z.B. Lamda-Sonde), 0...10V

- - V V V V V V V V V V

V

0/4...20mA Eingang mit Sensorspeisung

- - P P P P P P P P P P P Zweifach SSR-Ausgang

A A A A A A A A A A A

A

A

Zweifach Linearer Ausgang (0/4...20mA)

L L L L L L L L L L L L L Zweifach Linearer Ausgang (-10V…10V)

B B B B B B B B B B B

B

B Zweifach Digital I/O

- - D D D D D D D D D D

D

1.4.1. E/A-Module

E/A-Module 21

Mounting

1.5. Mounting

The figure shows the necessary dimensions of the outbreak in the Cabinet wall and the minimum distances to additional

devices. For installation, the device is inserted into the outbreak of the Panel or the control panel door from outside.

A rubber seal is molded on the front frame of the appliance. This rubber seal must be intact.

The delivery scope includes four fasteners. These be inserted from the inside of Panel on the device, each 2 top and

bottom. The threaded rods of fixtures are then screwed from the inside against the Cabinet.

a The instrument is mounted by means of four fixing clamps. Insert the module firmly and mount it safely by means of

the locking screw.

a UL/cUL: Note section “Certificates and approvals”!

a Ensure tightness!

! A rubber seal is fitted on the rear of the instrument front panel (in mounting direction). This rubber seal

must be in perfect condition, flush and cover the cut-out edges completely to ensure tightness. Only

then is the tightness guaranteed!

UL & cUL

+ For compliance with cUus certificate, the technical data at the beginning must be taken into

account (see technical data, page Fehler! Textmarke nicht definiert.)

E/A-Module 22

Mounting

Bus termination CAN-Bus:

Position of the swich „ON”

Both ends of the CAN bus must be terminated. To get a bus termination on the KS98-2,

an internal terminating resistor can be connected via a slide switch behind the CAN

connector plug.

1. Stecken Sie das Modul in die

vorgesehene Position

2. Prüfen Sie den korrekten Sitz der

Steckverbindung:

3. Drücken Sie den Abstandshalter in die

entsprechende Bohrung der Träger-

karte bis er einrastet.

1.5.1. Internel switches

Ý The unit contains electrostatically sensitive components. Comply with rules for protection against ESD during

mounting.

1.5.2. Retro-fitting and modific. of I/O-ext. (watch connecting diagram)

Ý The instrument contains electrostatically sensitive components. Original packing protects against electrostatic

discharge (ESD), transport only in original packing.

Connection:

KS 98-1 engineering must be taken into account, because it determines pin allocation and signification of connections!

Moreover, the rules for the performance limits must be followed.

Installing Option Modules

The design of the product enables option modules to be installed to enhance functionality. The instrument is removed

from the rear case by pressing the lugs at the top & bottom of the case whilst withdrawing the front bezel forward from

the housing

1.5.3. I/O extension with CANopen

The unit offers a CANopen-compliant interface port for connection of the RM 200 system, KS 800 or additional KS 98 units

with max. five CAN nodes. See installation notes in the CANopen system manual (9499-040-62411).

Internel switches 23

Electrical connections

1.6. Electrical connections

1.6.1. Safety hints

a Die dem Gerät beiliegenden Sicherheitshinweise und die Hinweise ab Seite Fehler! Textmarke nicht definiert. sind

unbedingt zu beachten! Die Isolierung des Gerätes entspricht der Norm EN 61 010-1 (VDE 0411-1) mit

Verschmutzungsgrad 2, Überspannungskategorie II, Arbeitsspannung ß 300 V effektiv und Schutzklasse II.