Page 1

98

KS

KS98

S98K

98KS

8KS9

K

S

9

8

&

LimL

LimH

Xsd

Fnc

y0

a

c

b

d

TS.D

TS.H

TS.Mi

TE.D

TE.H

TE.Mi

t

Operating instructions

9499-040-44311

Valid from: 8432

PMA Prozeß- und Maschinen-Automation GmbH

KS 98 and KS98Plus

Page 2

Symbols used on the device

à EU conformity mark

a Attention, follow the operating instructions!

All rights reserved. No part of this document may be

reproduced or published in any form or by any means without prior written permission

from the copyright owner.

A publication of

û

PMA

Prozeß- und Maschinen-Automation GmbH

P.O.Box 310 229

D-34058 Kassel

Germany

Content

1. Operation ..........................3

2. Important technical data .................3

3. Versions ...........................4

4. Front view ..........................5

5. Mounting ..........................5

6. Electrical connections ..................6

7. Menus ...........................11

8. Maintenance .......................14

9. Scaling and calculation functions ...........15

10. Non-linear functions ...................17

11. Trigonometric functions .................17

12. Logic functions ......................19

13. Signal converters .....................21

14. Time functions ......................23

15. Selection and storage ..................26

16. Limit signalling and limiting ..............28

17. Visualization........................30

18. Communication ......................34

19. KS98+ I/O extension ...................36

20. Cross communication KS 98plus - KS98plus .....43

21. KS 800 and KS 816 connection .............45

22. Description of KS98 CAN bus extension........48

23. Programmer ........................51

24. Controllers .........................54

25. Inputs ............................61

26. Outputs ...........................63

27. Zusatzfunktionen .....................64

28. KS98 I/O extension modules...............66

29. Modular I/O extension modules ............68

30. Function management ..................74

Page 3

a

Change notice!

The Functionblock SOUT has changed since operating version 7. Eventually you must adjust your engineering when

updating Soft- or Hardware (see Page 27).

1 Operation

1.1

Description

KS 98 is a freely structurable compact automation unit. Each unit contains a function library from which selection, configuration, parameter setting and combination of up to 450 function blocks is possible by means of an engineering tool. This permits realization of complex mathematical calculations, multi-channel control structures and sequencing in one instrument.

Various pages are displayed by means of an LCD (64x128 dots): input and output for analog and digital signals, bargraphs

and trends. Communication with other instruments and systems is possible via an optional digital interface.

2 Important technical data

2.1

Analog inputs r sections 6 and 25.1

INP 1: universal input, configurable for thermocouples, resistance thermometers, temperature difference, resistance

transducer, DC current and DC voltage

INP 3 (option C): DC current or -50...1300 mV, INP 4 (option C): DC current, INP 5: DC current and

DC voltage, INP 6: resistance transducer and DC current

2.2 Digital inputs

Opto-coupler for 24 V DC, current sink to IEC 1131 type1, logic 0 = -3...5 V, logic 1 = 15...30 V, approx.

5mAdi1 and di2: in all versions, di3...di7: in option B, di4...di12: in option C.

2.3 Outputs r section 26.1

Relay contact rating: 500 VA, 250 V, 2 A at 48...62 Hz

OUT1, OUT2, OUT4, OUT5: relay or logic dependent of version, OUT 3 (option C): current

2.4 Control outputs

Opto-coupler, grounded load with common positive control voltage, power 18...32 V DC ß 100 mA.

do1...do4: in option B, do5 and do6: in option C

2.5 Supply voltage

90...260V AC, 48...62 Hz, power consumption approx. 10 VA (equipped with all possible options)

For detailed technical data, see data sheet KS98 9498 737 32113

KS98+ 9498 737 37933

9499-040-44311 Operation

3 Description

SOFTWARE/ENGINEERING

HARDWARE

Option B

Option C

Standard

INP3

INP4

di8

di9

di10

di11

di12

di3

di4

di5

di6

di7

INP1

INP5

INP6

di1

di2

OUT3

do5

do6

do1

do2

do3

do4

Interface

OUT1

OUT2

OUT4

OUT5

HARDWARE

Standard

Option B

Option C

Page 4

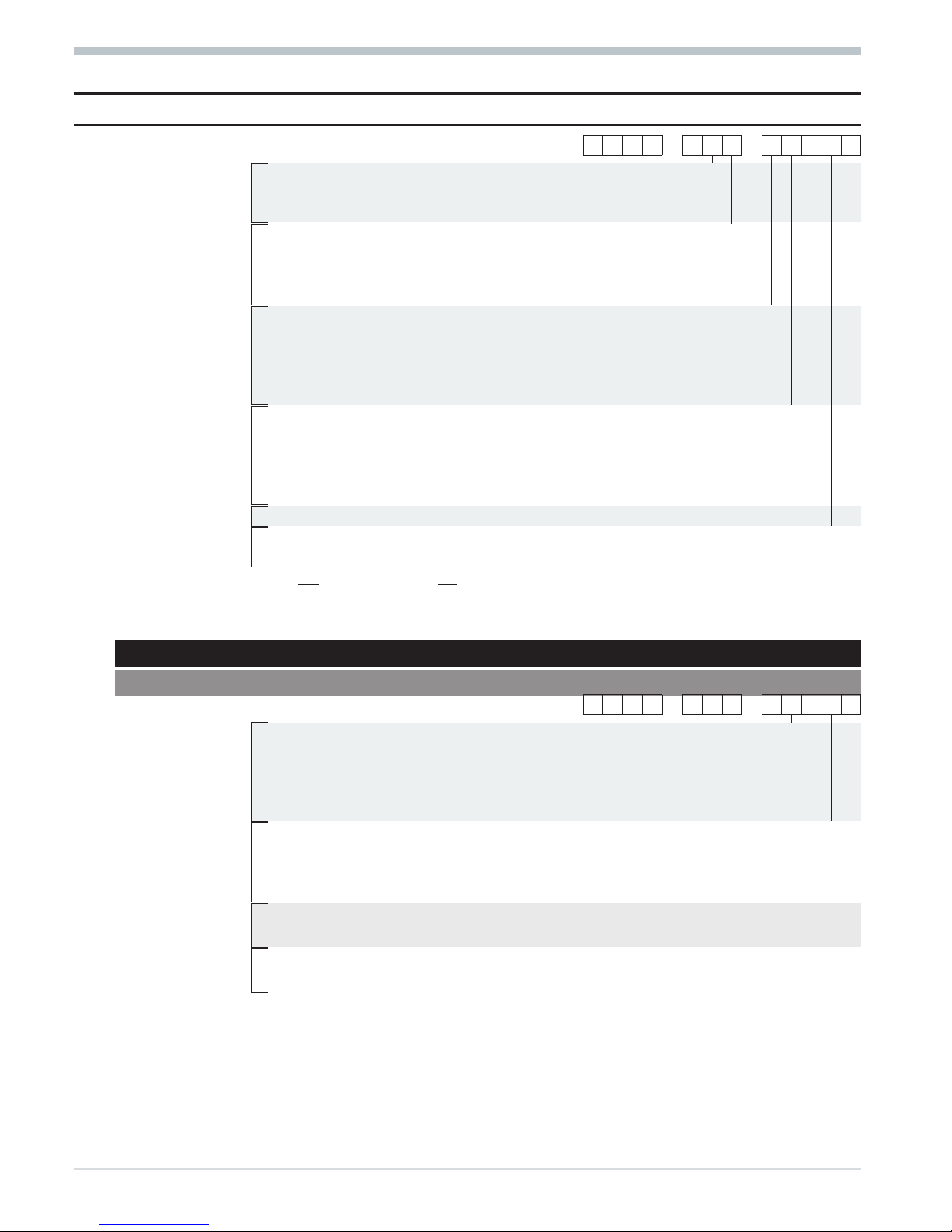

3 Versions

Order no.

9407-9 - 0 1

Basic unit

Standard

6

with integrated supply voltage

7

KS98+ with CANopen I/O

8

90...250 V AC with 4 relays

3

Power supply and

90...250 V AC with 2 relays + 2 current outputs

5

process outputs

24 V UC with 4 relays

7

24 V UC with 2 relays + 2 current outputs

9

Option B

no option B

0

TTL interface + di3...7 / do1...4

1

RS 422 + di3...7 / do1...4 + real-time clock

2

PROFIBUS-DP + di3...7 / do1...4

3

INTERBUS + di3...7 / do1...4

4

Option C

no option C

0

INP3 / INP 4 / OUT 3 / di8...12 / do5 / do6

1

INP3

*2)

/ INP 4 / OUT 3 / di8...12 / do5 / do6

2

Modular option C basic card

*1)

3

Modular option C basic card with modules

*1)

4

Engineering

single-channel controller (basic unit)

0

Setting

standard setting

0

setting to specification

9

*1)

Combination KS98+ (CANopen I/O) and modular option C is not possible. Either KS98+ or modular option C!

*2)

INP3: With Type = 0...20 mA, the input is designed for -50...1300 mV. For further use of the output of INP3 with this scaling,

an x0 of -50 and an x100 of 1300 must be adjusted.

3.1 I/O modules

- for installation in units with modular option C basic card

Order no.

9407-998-00 1

Position

Separate order

0

Fitted in KS98 socket 1

1

Fitted in KS98 socket 2

2

Fitted in KS98 socket 3

3

Fitted in KS98 socket 4

4

Module type-

Analog inputs

Pt100 / 1000, Ni 100 /1000, resistance, potentio

-

meter

20

Thermocouple, mV, 0/4...20mA

21

-50...1500mV, 0...10V

22

Module type-

Analog outputs

0/2...10V, 0..._10V

30

0/4...20mA, 0..._20mA

31

Module type-

Digital inputs/outputs

Digital I/O (universal)

40

Frequency/counter input

41

Versions 9499-040-44311

I/O modules 4

Page 5

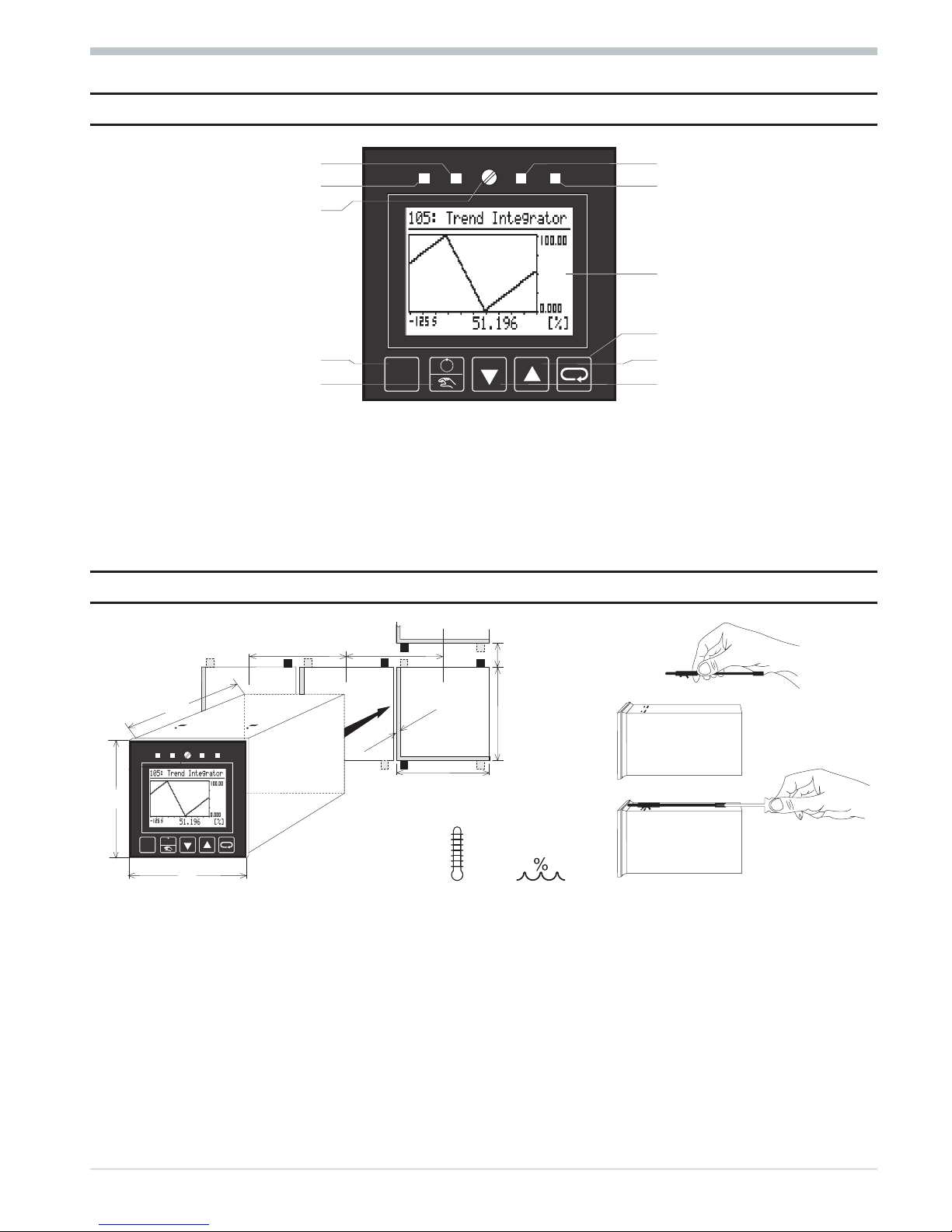

4 Front view

LED 2 e.g. cooling LED 3 e.g. alarm 1

LED 1 e.g. heating LED 4 e.g. alarm 2

Locking screw

Display e.g. trend

Selector key

PC interface Increment key (z)

Manual/automatic key Decrement key (u)

q

Locking screw: locks the controller module in the housing.

q

LEDs: indicate the statuses of the LED function (r section 27.1).

q

Display: LCD dot matrix with (64x128 dots, back lighting). The relevant display is shown in sections

7 Menus, 17 Visualization, 23 Programmer and 24 Controller.

q

Keys HDIM: The relevant function is described in section 7 Menus.

q

PC interface: PC connection for structuring/wiring/configuring/parameter setting/operating with the engineering tool.

5 Mounting

a

Mount the unit with min. 2 fixing clamps

(diagonally at top and bottom).

a

Protection type IP65:

Use 4 fixing clamps. Insert the controller module firmly and block it using the locking screw.

9499-040-44311 Front view

5 I/O modules

2

1

96 96

92

+0,8

92

?24

+0,8

1...16

min. 0°C

60°C

max.

max.

95% rel.

96

96

160

l

Page 6

Wire-hook switch S: Its switching status is signalled by function STATUS

and can be used in the engineering. After delivery, the switch is open.

For closing, release the locking screw, withdraw the controller module from the

housing, close the Wire-hook switch. Insert the unit and lock it with the

screw.

Wire-hook switch DP: The bus termination resistor can be activated by 2

S.I.L.

switches (DP) in KS98. Both S.I.L. switches must always be open or closed

(terminating resistor active).

Wire-hook switch CAN: for bus terminating resistor r see page36

a

Ensure tightness!

l

Caution! The instrument contains electrostatically sensitive components.

6 Electrical connections

6.1

Safety hints

a

Following the enclosed safety hints 9499 047 07101 is indispensable! The instrument insulation meets

standard EN 61 010-1 (VDE 0411-1) with contamination degree 2, overvoltage category III, operating

voltage range 300 V and protection class I.

a

With horizontal installation, the following rule is applicable additionally: with the instrument module

withdrawn, a facility which prevents conducting parts from dropping into the open housing must be

provided.

a

If the unit is switched to off-line, the outputs keep their status from the time of switch-over!!!

6.2 Electromagnetic compatibility

European guide line 89/336/EEC. The following European generic standards are met:

Electromagnetic radiation: EN 50081-2 and Electromagnetic immunity: EN 50082-2. The unit is suitable for use in

industrial areas (in residential areas, RF interference may occur). The electromagnetic radiation can be reduced

decisively by installing the unit in a grounded metal switch cabinet.

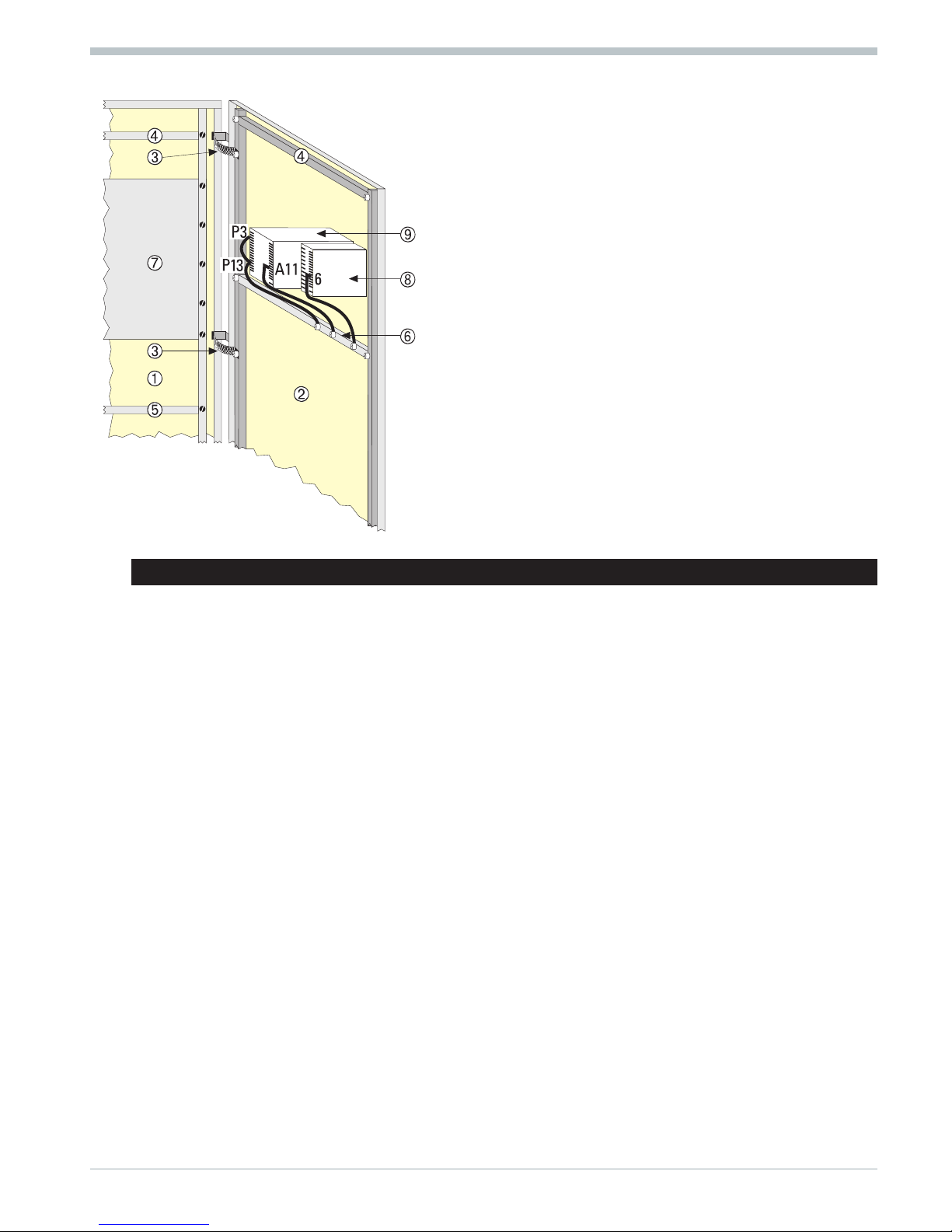

6.3 Measurement earth (for grounding interferences)

a

If outside interference voltages act on the instrument, functional troubles may be caused

(concerns also high-frequency interferences). For grounding the interference voltages and ensuring the

electromagnetic immunity, a measurement earth must be connected. Terminal A 11 must be connected to

ground potential by means of a short cable (approx. 20 cm, e.g. to switch cabinet ground)! This cable must

be kept separate from mains cables.

6.4 Störschutzbeschaltung

Load current free connections between the ground potentials must be realized so that they are suitable

both for the low-frequency range (safety of persons, etc.) and the high-frequency range (good EMC valu

-

es).

The connections must be made with low impedance. All metal grounds of the components installed in the cabinet Ü

or in the cabinet door * must be screwed directly to the sheet-metal grounding plate to ensure good and durable

contact. In particular, this applies to earthing rails ä, protective earth rail #, mounting

Electrical connections 9499-040-44311

Safety hints 6

CAN

S

DP

Page 7

plates for switching units > and door earthing strips <.Control

-

lers KS40/50/90 y and KS92/94 x are shown as an example for

earthing. The max. length of connections is 20 cm (see relevant ope

-

rating instructions).

Generally, the yellow/green protective earth is too long to

provide a high-quality ground connection for high-frequency

interferences.

Braided copper cables Ö provide a high frequency conducting,

low-resistance ground connection, especially for connecting cabinet

Ü and cabinet door *.

Because of the skin effect, the surface rather than the cross

section is decisive for low impedance. All connections must

have large surfaces and good contact. Any lacquer on the

connecting surfaces must be removed.

Due to better HF properties, zinc-plated mounting plates and

compartment walls are more suitable for large-surface grounding

than chromated mounting plates.

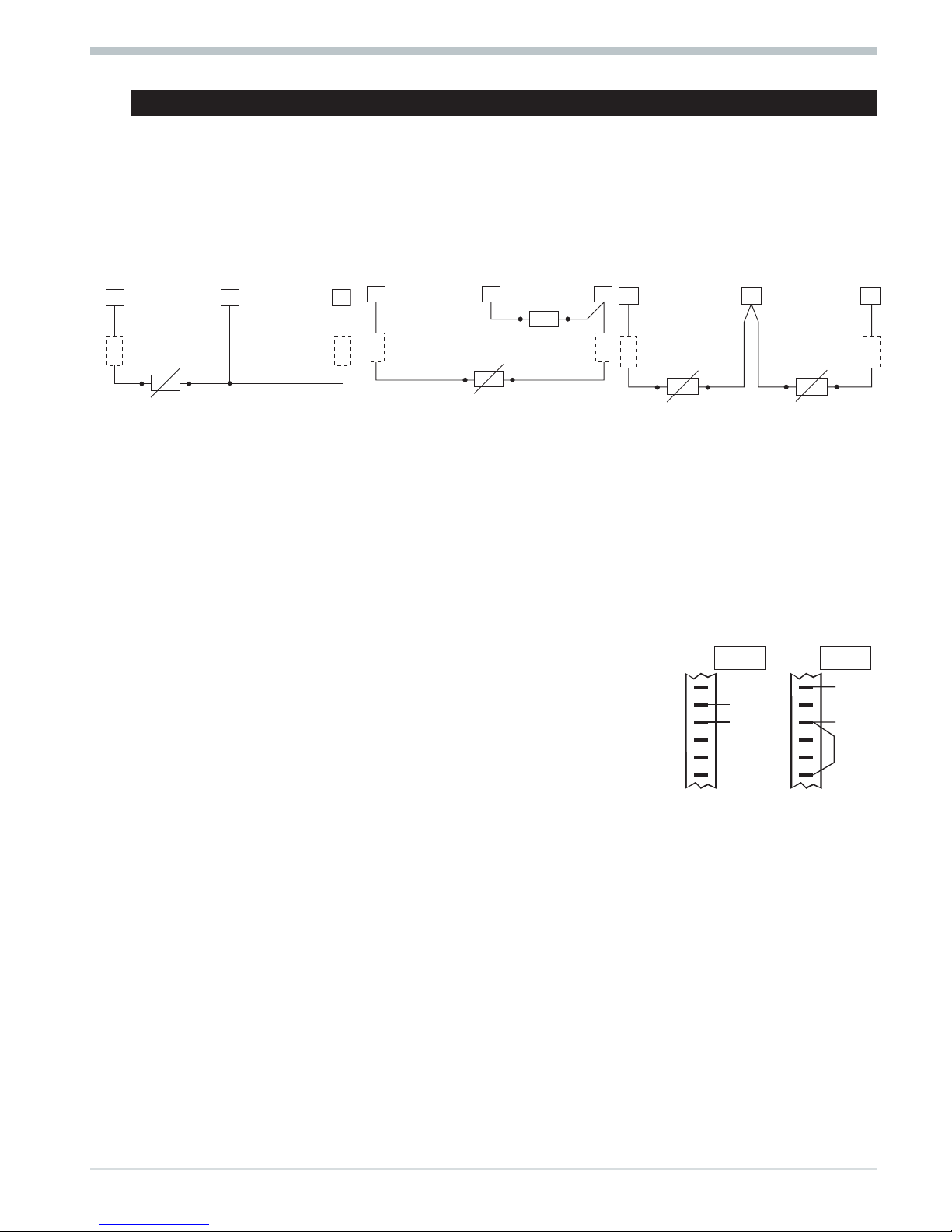

6.5 Connecting diagram

w

Power supply cables must be kept separate from signal and measuring cables.

w Twisted and screened measuring cables have to be used (screening connected with measurement earth).

w

Connected final elements must be equipped with protective circuits to manufacturer specifications.

This avoids voltage peaks which can cause trouble to the instrument.

w

The instruments must be protected additionally by an individual or common fuse for a max. power consumption of 10

VA per unit (standard fuse ratings, min. 1 A)!

a

Signal and measurement circuits may carry max. 50 Vr.m.s. against ground,

mains circuits may carry max. 250 V r.m.s between terminals.

9499-040-44311 Electrical connections

7 Connecting diagram

Page 8

galvanic isolations

Bei Geräten mit Modularer Option C

r siehe Anschlußbild Seite 67

* Versions with integrated supply voltage only

** With 24 V DC or AC, protective earth must also be connected. With 24 DC, the polarity is uncritical.

Electrical connections 9499-040-44311

Connecting diagram 8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 V

di8( )

di9( )

di 10 ( )

di 11 ( )

di 12 ( )

do 5

do 6

GND

+

_

+

_

+

_

-

+

+

+

+

+

+

.

C

INP4

INP3

OUT3

0/4...20mA

0/4...20mA

0/4...20mA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

P

OUT4

OUT5

OUT2

OUT1

0/4...20mA

+

_

ßßß500VA, 250V, 2A

ßßß500VA, 250V, 2A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

di (-) CAN-GND

di 1 (+) CAN-H

di 2 (+) CAN-L

+ Volt

+mA

_

Volt/mA

Volt

mA

A

INP5

INP6

INP1

0/4...20mA

100%

0%

0%

100%

}}2

1

+

_

+

_

+

_

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

B

-

+

+

+

+

+

+

24 V

di3( )

di4( )

di5( )

di6( )

di7( )

do 1

do 2

do 3

do 4

RXD-B

GND

RXD-A

TXD-B

TXD-A

RS422 RS485 TTL PROFIBUS

+5V

GND

TRE

TXD

RXD

VP

GND

RxD/TxD-N

RxD/TxD-P

RGND

DATA B

DATA A

100 [

abcd efg

ABCP

1

16

1

16

(Option)

(Option)

-

OUT

IN

INTERBUS

AB

0/4...20mA

+

_

*

_

+

*

_

+

**

Ra

Page 9

6.6 Analog inputs (r connecting diagram)

Thermocouples (a)

No lead resistance adjustment.

Internal temperature compensation: compensating lead up to the instrument terminals. With AINP1,

STK = int.CJC must be configured.

External temperature compensation: Use separate cold junction reference with fixed reference temperature.

Compensating lead is used up to the cold junction reference. Copper lead between reference and instrument. With

AINP1, STK = ext.CJC and TKref = reference temperature must be configured.

Resistance thermometer Pt 100 in 3-wire connection (b)

No lead resistance adjustment is necessary, if RL1 = RL2.

Resistance thermometer Pt 100 in 2-wire connection (c)

Lead resistance adjustment is necessary: Ra must be equal to RL1 + RL2.

Two resistance thermometers Pt100 for difference measurement (d)

Lead resistance compensation: proceed as described on page13 - 7.7.

Resistance transducer (e)

Measurement calibration: proceed as describedon page13 - 7.7..

Standard voltage signals 0/2...10V (g)

Input resistance: ? 100 k[, configure scaling and digits behind the decimal point.

INP5 is a difference input, the reference potential of which is connected to

terminal A9. With voltage input, A6 must always be connected to A9.

Standard current signals 0/4...20 mA (f)

Input resistance: 50 [, configre scaling and digits behind the decimal point.

DC voltage -50...1300 mV

(only for INP3 in instruments with order no. 9407-9xx-x2xx1):

With Type = 0...20 mA, the input is designed for -50...1300 mV. For further use of the output of INP3 with this scaling,

an x0 of -50 and an x100 of 1300 must be adjusted.

a

The inputs INP1 / INP6 are interconnected. This must be taken into account if both inputs must be used for standard

current signal. If necessary, galvanic isolation should be used.

9499-040-44311 Electrical connections

9 Analog inputs (r connecting diagram)

RL2

14

16

15

RL1 = RL2

RL1

}

b

RL2

14

16

15

Ra = RL1+RL2

Ra

c

RL1

}

RL2

14

16 15

RL1

xeff = 1 - 2}}

}1 }2

d

4

5

6

7

8

9

mAmA+

-

4

5

6

7

8

9

Volt

Volt

+

-

INP5 INP5

Page 10

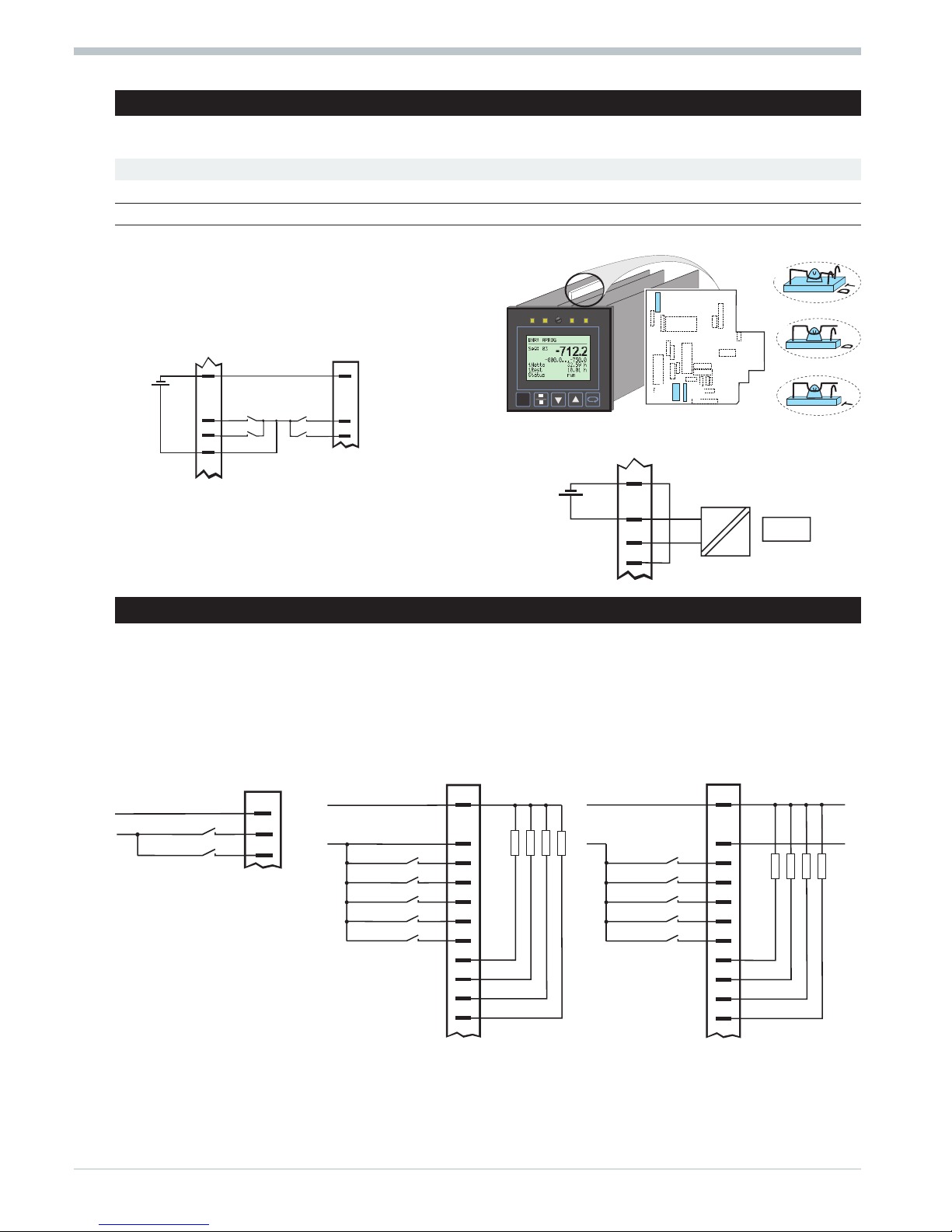

6.7 Versions with integrated supply voltage

The potential-free supply voltage can energize a 2-wire transmitter or max. 4 control inputs. Its output connectors are

selectable by means of 3 S.I.L. switches:

Connectors Ü* Ö Remarks

14 (+) 12 (-) T open closed

Only available with INP1 configured for current or thermocouple

4 (+) 1 (-) D closed open

The voltage input of INP5 is not available

Factory setting: Ü =T,* = open, Ö = closed (T). For chan

-

ging the switch positions, the instrument must be with

drawn from its housing. The S.I.L switches are

accessible on the circuit board indicated below

Connecting a 2-wire transmitter (e.g. INP1)

* If A14/A12 is used for di1/di2, A12 muß be linked

with A1.

6.8 Digital inputs and outputs (r connecting diagram)

The digital inputs and outputs must be energized from one or several external 24 V DC sources. Power consumption is

5 mA per input. The max. load is 0,1 A per output. Examples:

Digital inputs (connector A) Digital inputs and outputs at one Digital inputs and outputs at two

voltage source (e.g. connector B) voltage sources (e.g. connector B)

Electrical connections 9499-040-44311

Versions with integrated supply voltage 10

13

15

+

_

+

_

+

_

1 (12)

4 (14)

A

INP1

Connection 2-wire-transducer (e.g. INP1)

Ö

*

Ü

*

Ö

Ü

di 1

di 2

2

3

+

_

1 (12)

4 (14)

A

*

B

1

3

4

di 3

di 4

(Option)

Energizing digital inputs (e.g. di1...di4)

()()-

+

()()-

+

24V

(ext.1)

24V

(ext.2)

Imax. 70 m A

Imax. 6 mA

Imax. 6 mA

Imax. 6 mA

Imax. 6 mA

Imax. 6 mA

Imax. 70 m ARLImax. 70 m A

Imax. 70 m A

B

1

2

3

4

5

6

7

8

9

10

11

do 1

do 2

do 3

do 4

di 3

di 4

di 5

di 6

di 7

()()-

+

24V (ext.1)

Imax. 0,1 A

Imax. 5 mA

Imax. 5 mA

Imax. 5 mA

Imax. 5 mA

Imax. 5 mA

Imax. 0,1 ARLImax. 0,1 A

Imax. 0,1 A

B

1

2

3

4

5

6

7

8

9

10

11

do 1

do 2

do 3

do 4

di 3

di 4

di 5

di 6

di 7

()()-

+

24V (ext.)

Imax. 5 mA

Imax. 5 mA

A

1

2

3

di 1

di 2

Page 11

7 Menus

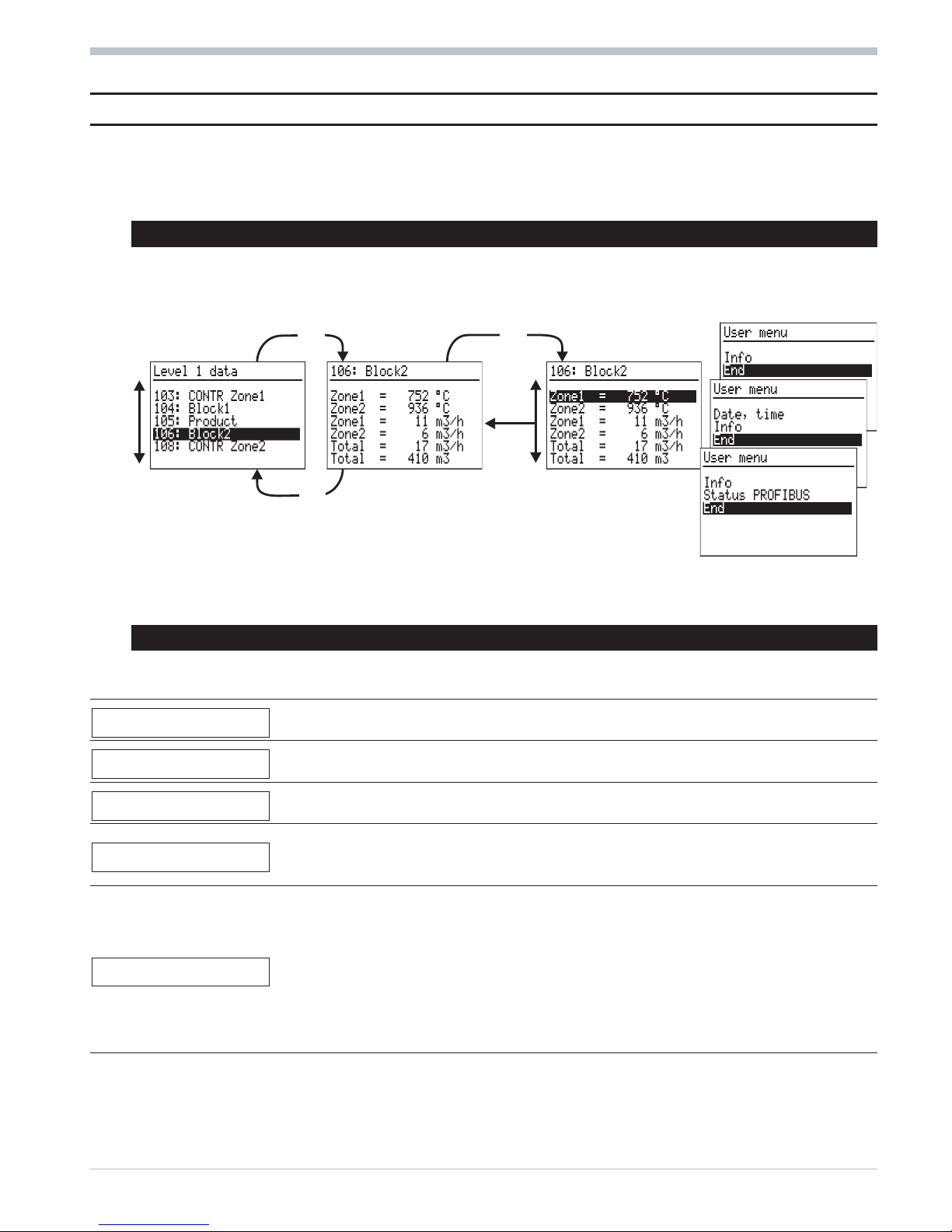

Instrument operation is menu-guided. Distinction of complete dialog and short-form dialog is made. In the complete dialog,

the main menu with its sub-menus is displayed, i.e. all permitted settings are selectable. During short-form dialog, the main

menu is switched off, i.e. unauthorized or accidental access is prevented and only the operating page menu with the permit

-

ted operating pages is selectable. The short form dialog is available from operating version 2.

7.1 Short-form dialog

Available from operating version 2. The main menu is switched off via interface (m-hide) or function STATUS

(m-hide). The operating page menu with the permitted operating pages is selectable. Selecting, marking lines

and value adjusting are done as described below.

When pressing key M during>3s,auser menu which is different dependent of

instrument version (standard / real-time clock / PROFIBUS) is displayed:

Line Info: hardware order no., software order no., software version and operating version.

Line Date, time: display and adjustment of date and time.

Line Status PROFIBUS: status of bus access, parameter setting, configuration and data communication.

7.2 Complete dialog

A main menu for selecting the five sub-menus, using which an application-dependent number of pages can be selected.

Sub-menu Contents of pages

Level 1 data

The operating pages VWERT, VPARA, VBAR, VTREND, APROG, DPROG, CONTR, CONTR+

and PIDMA are displayed: display and adjust the operating values.

Parameter

A page is provided for each function used with which parameters are adjustable:

display and adjust parameters.

I/O data

A page is provided for each function used:

display of input and output data

Configuration

A page is provided for each function used, which must be configured:

display and adjust configurations. For changing the configuration, the instrument must be

set to ‘Offline’ (r Operating modes).

Miscellaneous

Page Date, time: display and adjust date and time. Ü

Page Device data: display and adjust interface, mains frequency and language.

Page Online/Offline: on-line i off-line, cancel configuration.

Page Calibration: display and calibrate all signals to be calibrated.

Page Info: display hardware / software order no., software version no. *

Page Status CAN-BUS: status of any connected CAN nodes. Ö

Page Status PROFIBUS/INTERBUS: display status of bus access and data

communication. ä

Ü

Only with option B with real time clock

*

From operating version 2, the operating version is also displayed.

Ö

Only with option KS98+ with CAN I/O extension (r 19 KS98+ I/O extension with CANopen interface)

ä

Only with option B with PROFIBUS/I

NTERBUS

9499-040-44311 Menus

11 Short-form dialog

D

I

D

I

M

M

D

Page 12

Prior to operating version 2, KS 98: was displayed additionally in the headers of the main menu and the five

sub-menus. Example: KS 98: Main menu

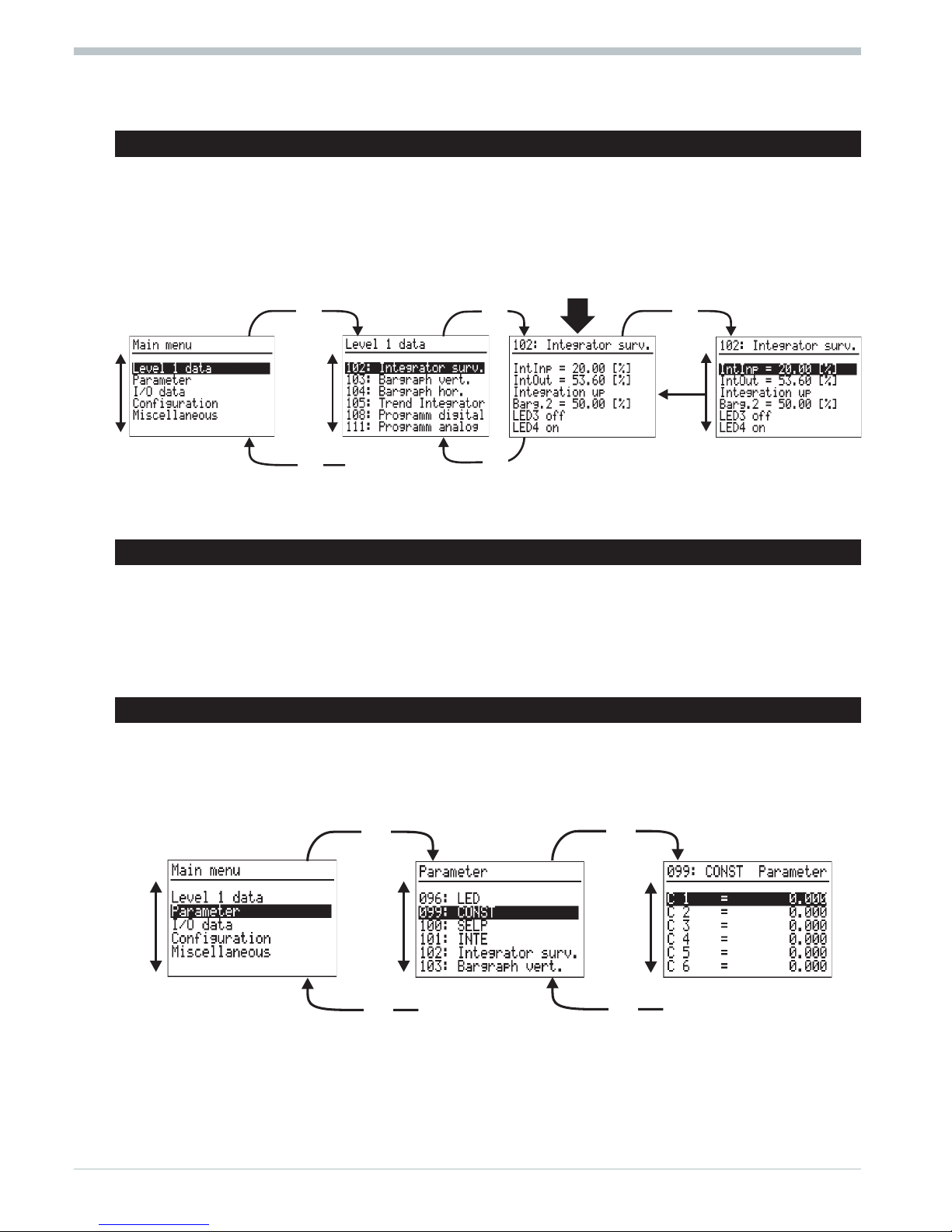

7.3 Selection (switching on and operating pages)

After power switch-on, the instrument starts up with a logo and Main menu wait! and then the main

menu is displayed during several seconds. Unless a selection is made during this time, the first operating page

entered in the sub-menu without marked line is displayed. Pressing keys I / D marks one line at a time (inverse

display). When reaching the page without marked line again by means of keys I / D, return to the sub-menu is by

pressing key M. When reaching the End in the sub-menu by pressing keys I / D, return to the main menu is

possible by pressing the M key.

Keys I / D scroll the marked line up to the start or down to the menu end. When pressing the key again, the

marked line changes from the start to the end, or vice versa.

7.4 Language selection

English: Mark Allgemeine Daten r Gerätedaten r Sprach = deutsch.

Press M: deutsch blinks. Press I: english blinks. Press M: Main menu is indicated.

German: Mark Miscellaneous r Device data r Langu. = english.

Press M: english blinks. Press D: deutsch blinks. Press M: Hauptmenü is indicated.

French: Mark Divers r Donn er d´appar. r Langu. = francais.

Press M: francais blinks. Press D 2x:francais blinks. Press M: Menu principal is indicated.

7.5 Selection (other pages)

Select sub-menu (inverse display) in the main menu with IDand open it with M. Select page with IDand

open it with M. The first line is marked (inverse, r Adjusting values). When reaching End with ID, return to

the sub-menu is with M. When reaching End in the sub-menu with ID, return to the main menu is with M.

Example: parameters

Keys I / D scroll the marked line up to the start or down to the menu end. When pressing the key again, the mar

-

ked line changes from the start to the end, or vice versa.

Menus 9499-040-44311

Selection (switching on and operating pages) 12

End

.

.

.

D

I

D

I

M M

M

D

I

M

D

D

I

D

I

End

.

.

.

D

I

End

.

.

.

M

M

M

M

Page 13

7.6 Adjusting values

Values in marked lines of pages can be adjustable. For this, the required line or value is marked with ID (inverse

display). When confirming the value with M, it starts blinking and can be adjusted with ID. When reaching the

required value, confirm it with M. Now, ID can be pressed to mark another line.

Example: bargraph vertical Example: parameter CONTR+

7.7 Calibration

Select (ID) item Calibration in sub-menu KS98: Miscellaneous and open it (M). Mark the

bottommost line (inverse display, e.g. Quit) by pressing I. Continue as follows:

Transducer input (INP1 or INP6) 2 resistance thermometers in difference (INP1)

Calibration of transducer start and end: Calibration of lead resistance effect:

Ü

Set transducer to start (r section Operating modes)

Ü

Short-circuit both thermometers in the connecting head

*

Press M

r

Quit blinks *

*

Press M

r

Quit blinks *

Ö

Press I

r

Set 0% blinks

Ö

Press I

r

Set Dif blinks

ä

Wait until the input has settled (min. 6 s)

ä

Wait until the input has settled (min. 6 s)

#

Press M

r

0% done is displayed

#

Press M

r

Cal done is displayed

<

Set transducer to end (r section Operating modes) Lead resistance adjustment is finished. Remove both

short circuits. For exit from calibration press D until

nothing is marked and then press M.

* if another word blinks, press key I or D as many

times as necessary, until the required dialogue

blinks.

>

Press M

r

0% done blinks

y

Press I 3xrSet 100% blinks

x

Wait until the input has settled (min. 6 s)

c

Press M

r

100% done is displayed

Calibration is finished. For exit from calibration

press D until nothing is marked and then press M.

7.8 Operating modes

q

Online/Offline

For configuration changing, switch the unit to ‘Offline’ and back to ‘Online’ ( Miscellaneous,

Online/Offline).

q

Manual/automatic operation

When using controllers, automatic or manual operation may be requested by several points. The controller leaves the

manual mode, when all control signals request automatic operation.

Example: INP6 is provided for potentiometric transducer and connected accordingly (position feed-back). When it is

calibrated, the controller can be switched to manual mode on the calibrating page (by means of H, Man. is

displayed on the bottom left). Line Y can be marked by pressing I and M and the actuator can be driven to its

limits with I / D. After calibration, the manual mode must be switched off on this page (press H again).

9499-040-44311 Menus

13 Adjusting values

D

I

M

M

D

I

M

M

Page 14

8 Maintenance

8.1

Behaviour in case of trouble

The unit needs no maintenance. In case of trouble, check:

w

the unit for on-line operation,

w

the power supply for correct voltage, correct frequency and correct connection,

w

all connections for correctness,

w

sensors and final elements for correct function,

w

the engineering for correctness,

w

the configuration for required operation and

w

the adjusted parameters for required effects.

If the unit does not function correctly after these checks, it must be shut down and replaced. A defective unit can be

returned to the supplier for repair.

8.2 Shut-down

Disconnect the supply voltage completely and protect the unit against accidental operation. Before switching off,

check that other equipment in the same signal loop is not affected. If necessary, appropriate measures must be

taken.

8.3 Cleaning

Housing and front panel can be cleaned using a dry, lint-free cloth. No use of solvents or cleansing agents!

8.4 Further information

Order no.

For a structured single-channel controller

operating instructions 9499-040-51001

For the Engineering-Tool

operating instructions 9499-040-45701

For the digital interface (ISO1745)

interface description 9499-040-45111

For the PROFIBUS

interface description 9499-040-52711

For the I

NTERBUS

interface description 9499-040-57011

Engineering manual

manual 9499-040-44911

This manual includes the operating instructions 9499-040-45701 for the engineering tool and the manual

9499-040-50611 for KS 98 Multi Function Unit.

Maintenance 9499-040-44311

Behaviour in case of trouble 14

Page 15

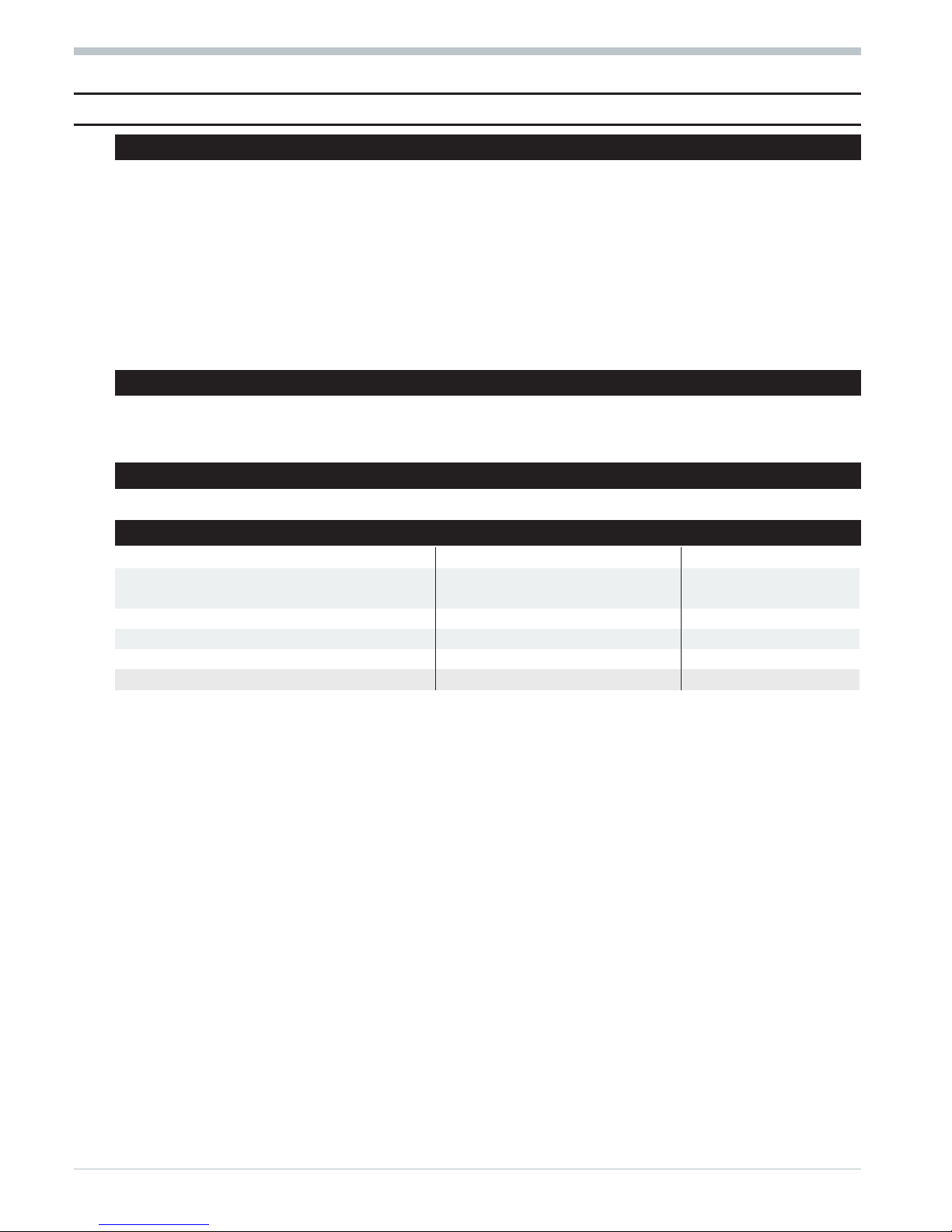

Software functions

The function blocks are described basically. Analog inputs are described with x, digital inputs with d, analog outputs

with y and digital outputs with z. Range “Real” is within -29 999 and 200 000. The max. permissible length of the

value is 6 digits (inclusive of minus sign and decimal point), with max. 3 digits behind the decimal point. With time

adjustment, negative values are not permissible.

To prevent engineering errors which would result in operating error, we recommend making own engineerings by

means of the KS98 engineering tool only. It offers a graphic user interface, manages function blocks and scanning

times and permits parameter setting and configuration by means of the relevant short-form descriptions. Text entry is

also possible (block title, units and other user-specific texts).

9 Scaling and calculation functions

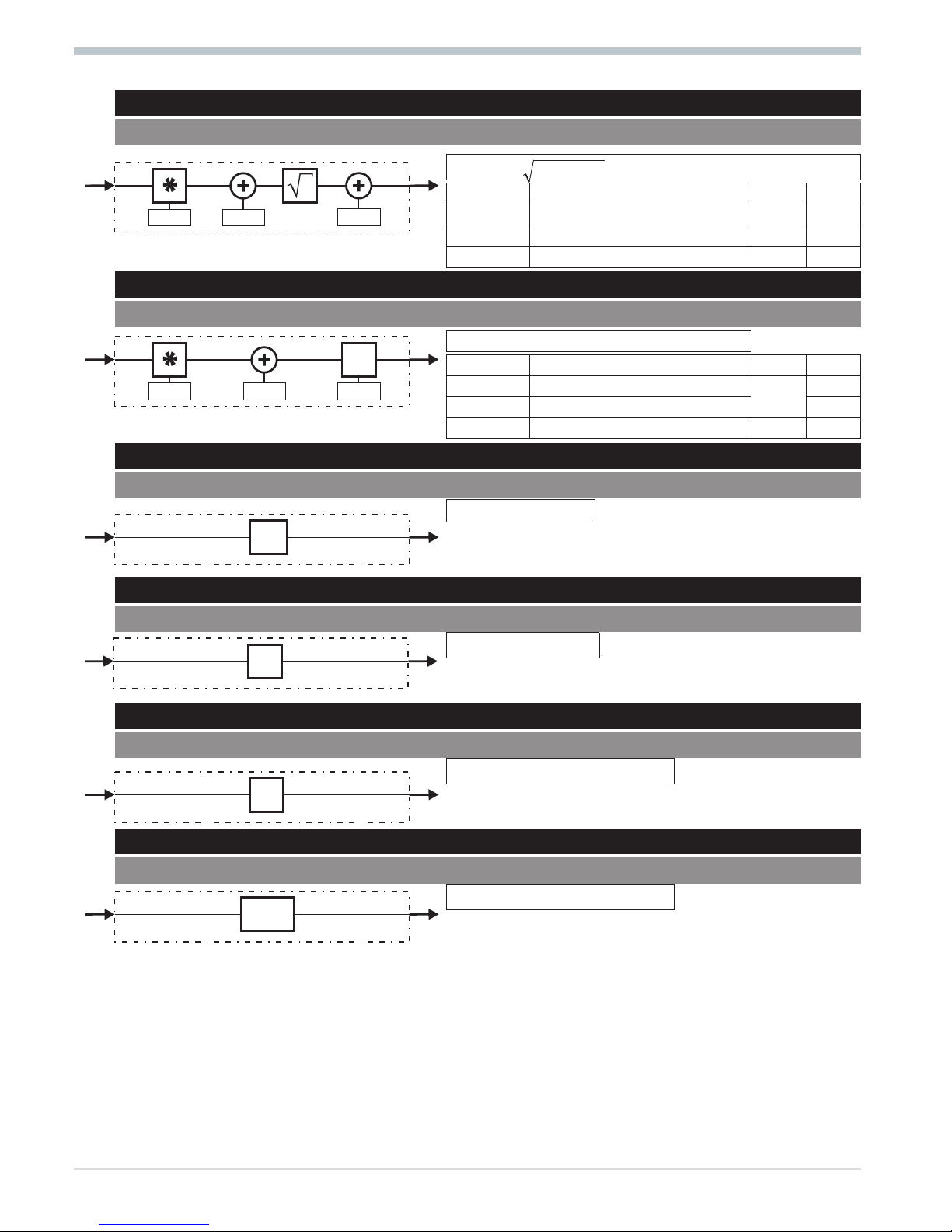

9.1

ABSV

(absolute value - no. 01)

||

yaxa

110

=× +

Parameter Description Values Default

a

Multiplication factor

Real

1

a0

Offset 0

9.2 ADSU

(addition / subtraction - no. 03)

yaxbxcxdxy

1123 40

=× +× +× +× +

Parameter Description Values Default

a...d

Multiplication factor

Real

1

y0

Offset 0

9.3 MUDI

(multiplication / division - no. 05)

y

AB

C

ax a bx b

cx c

1

10 20

30

=

×

=

×+ ××+

×+

()()

Parameter Description Values Default

a...c

Multiplication factor

Real

1

a0...c0

Offset 0

9499-040-44311 Scaling and calculation functions

15 ABSV

x1

A

y1

a0a

A

x1

x2

x3

x4

y1

y0

a

c

b

d

x1

x2

x3

y1

A

B

C

a0

b0

c0

a

c

b

A*B

C

Page 16

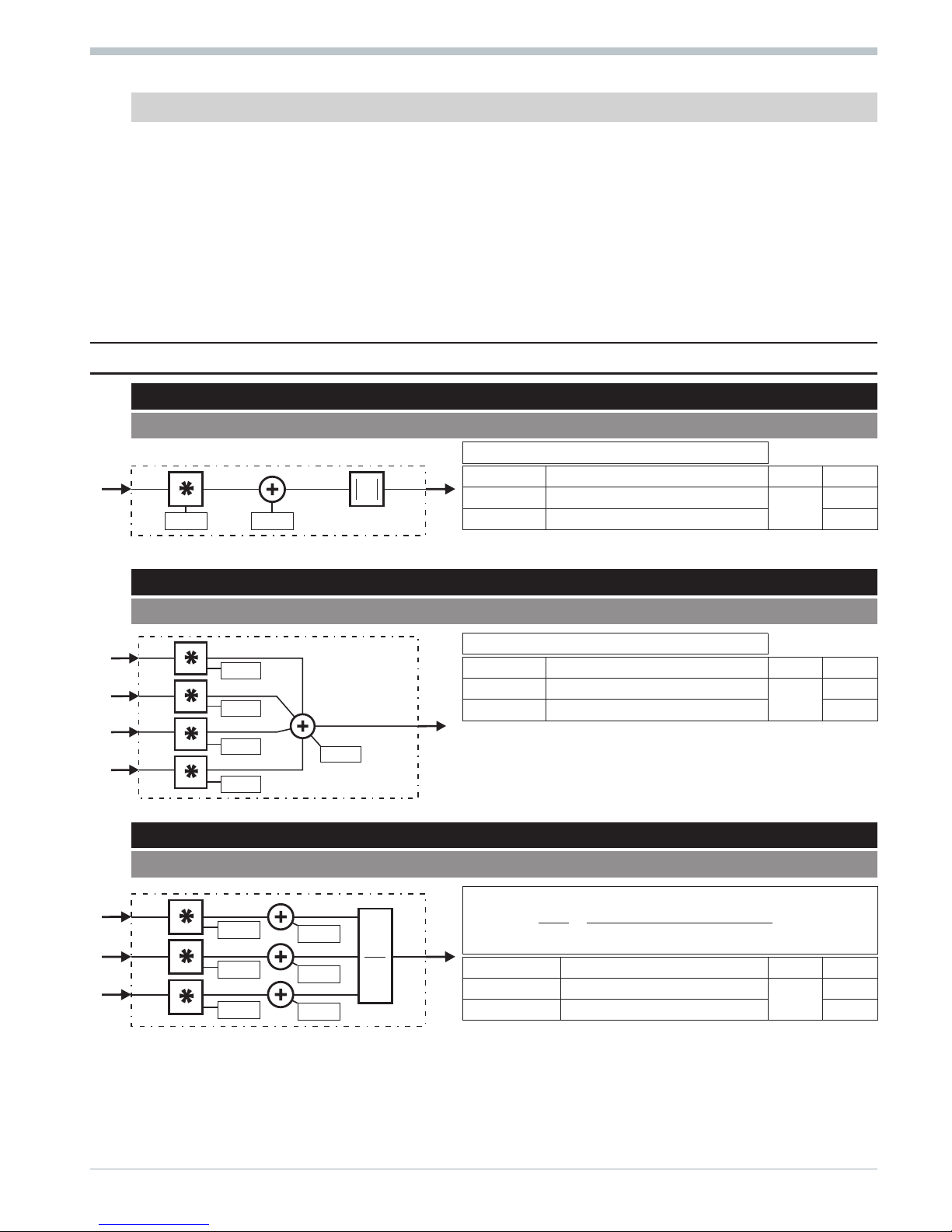

9.4 SQRT

(square root function - no. 08)

yaxa y

1100

=×+ +

Parameter Description Values Default

a

Multiplication factor Real 1

a0

Input offset 0

y0

Output offset 0

9.5 SCAL

(scaling - no. 09)

yaxa

Exp

110

=× +()

Parameter Description Values Default

a

Multiplication factor

Real

1

a0

Offset 0

Exp

Exponent -7...+7 1

9.6 10EXP

(10s exponent - no. 10)

y

x11

10=

9.7 EEXP

(e function - no. 11)

ye

x11

=

9.8 LN

(natural logarithm - no. 12)

yx

1

ln 1)= (

9.9 LG10

(10s logarithm - no. 13)

yx

1

log 1)= (

Scaling and calculation functions 9499-040-44311

SQRT 16

x1 y1

a0

y0

a

x1 y1

a0a Exp

EXP

x1 y1

10

x1

x1 y1

e

x1

x1 y1

ln

x1 y1

log

10

Page 17

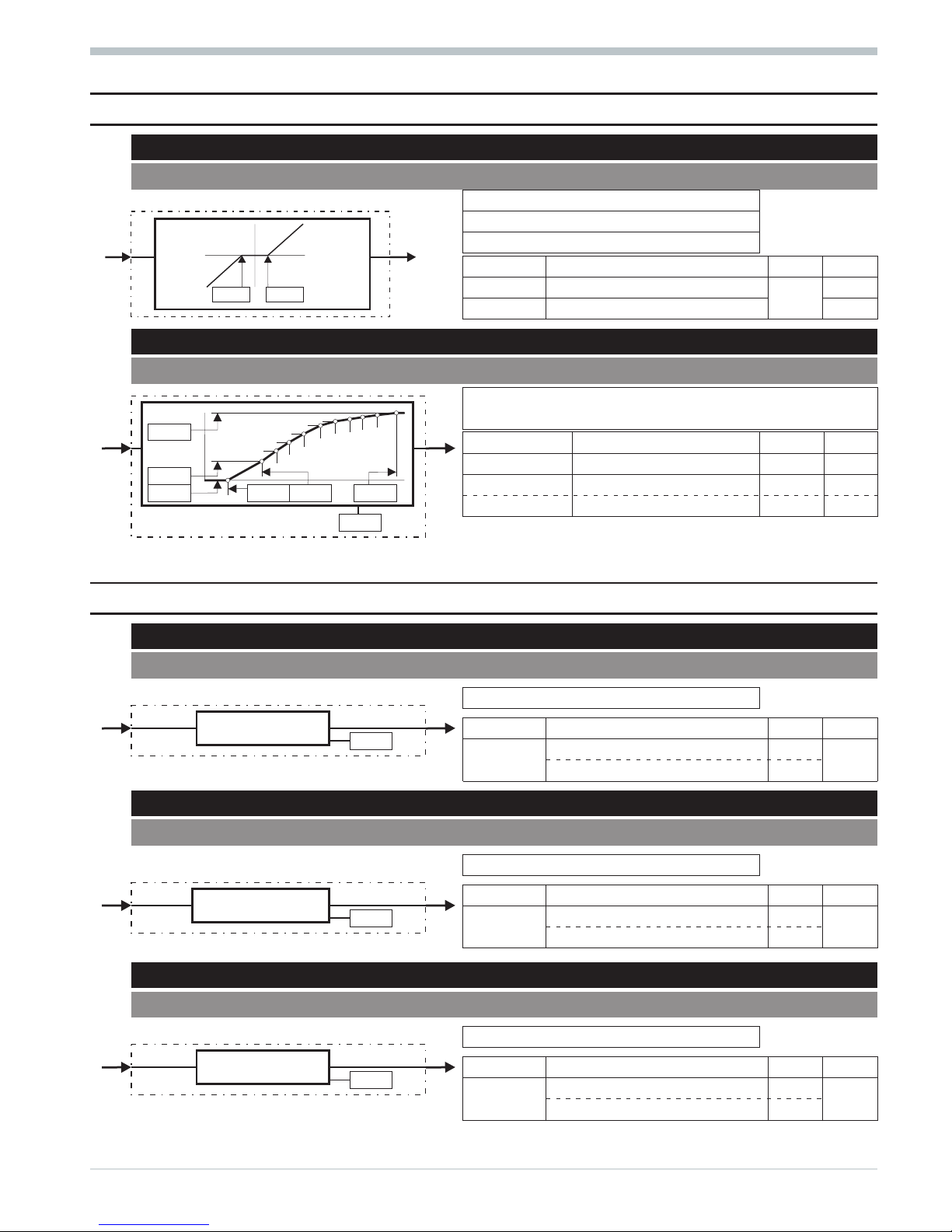

10 Non-linear functions

10.1

GAP

(dead band - no. 20)

yxL

1

1= \

with x1 < L

y

1

0=

with x1 = L...H

yxH

1

1= \

with x1 > H

Parameter Description Values Default

Low

Lower limit value

Real

0

High

Upper limit value 0

10.2 CHAR

(function generator - no. 21)

With max. 11 value pairs (input / output) non-linear functions

are simulated or linearized.

Configuration Description Values Default

Seg

Number of segments 1...10 1

x(1...11)

Input value for curve point Real *

y(1...11)

Output value for curve point 0

* 0 for x1, x3...x11 and 1 for x2

11 Trigonometric functions

11.1

SIN

(sinus function - no. 80)

yx

1

sin 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0 0

Unit: arc measure 1

11.2 COS

(cosinus function - no. 81)

yx

1

cos 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0 0

Unit: arc measure 1

11.3 TAN

(tangent function - no. 82)

yx

1

tan 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0 0

Unit: arc measure 1

9499-040-44311 Non-linear functions

17 GAP

x1 y1

y

x

y=x-High

y=x-Low

Low

High

x1 y1

y

x

( 10)ß

1

2

3

4

5

6

7

8

9

10

y1

y2

y11

x1 x2 x11

...

...

Seg

x1 y1

Select

(y1) = sin (x1)

x1 y1

Select

(y1) = cos (x1)

x1 y1

Select

(y1) = tan (x1)

Page 18

11.4 COT

(cotangent function - no. 83)

yx

1

cot 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0 0

Unit: arc measure 1

11.5 ARCSIN

(arcus sinus function - no. 84)

yx

1

arcsin 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0 0

Unit: arc measure 1

11.6 ARCCOS

(arcus cosinus function no. 85)

yx

1

arccos 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0 0

Unit: arc measure 1

11.7 ARCTAN

(arcus tangent function - no. 86)

yx

1

arctan 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0

0

Unit: arc measure 1

11.8 ARCCOT

(arcus cotangent function - no. 87)

yx

1

arccot 1)= (

Parameter Description Values Default

Select

Unit: degree of angle 0

0

Unit: arc measure 1

Trigonometric functions 9499-040-44311

COT 18

x1 y1

Select

(y1) = cot (x1)

x1 y1

Select

(y1) = arcsin (x1)

x1 y1

Select

(y1) = arccos (x1)

x1 y1

Select

(y1) = arctan (x1)

x1 y1

Select

(y1) = arccot (x1)

Page 19

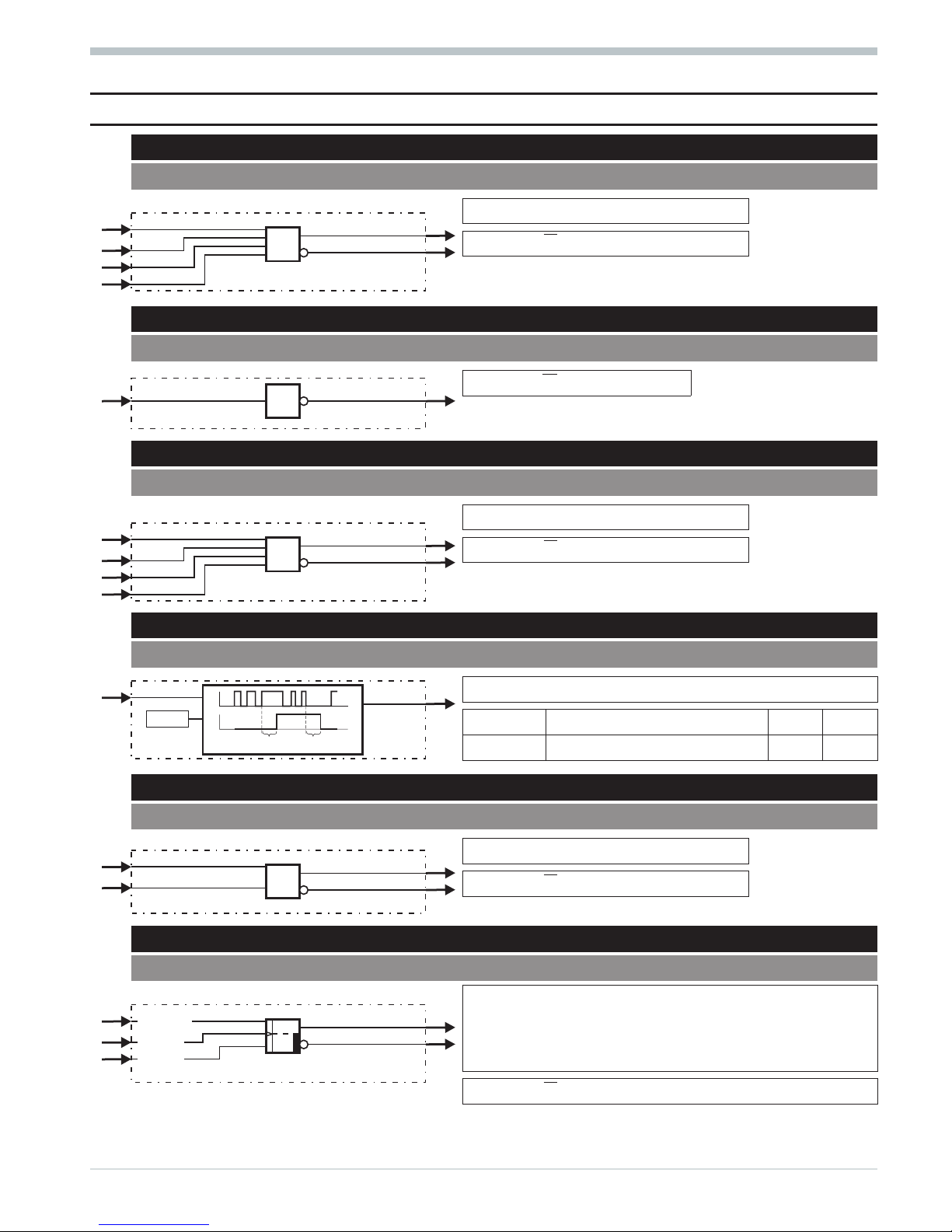

12 Logic functions

12.1

AND

(AND gate - no. 60)

z d AND d AND d AND d

11234

=

zz

21

=

12.2 NOT

(inverter - no. 61)

zd

11

=

12.3 OR

(OR gate - no. 62)

z d OR d OR d OR d

11234

=

zz

21

=

12.4 BOUNCE

(debouncer - no. 63)

for de-bouncing a logic signal

Parameter Description Values Default

Delay

Switch-on and off delay time [s] Real 0

12.5 EXOR

(exclusive OR gate - no. 64)

zdEXORd

11 2

=

zz

21

=

12.6 FLIP

(D flipflop - no. 65)

The status of d1 is transferred to z1, when

- d2 changes from 0 to 1 (positive flank) and

- d3 is logic 0.

If d3 is logic 1, z1 is logic 0.

zz

21

=

9499-040-44311 Logic functions

19 AND

d1

d2

d3

d4

z1

z2

&

d1 z1

1

d1

d2

d3

d4

z1

z2

?1

d1

z1

Delay

Delay Delay

d1

d2

z1

z2

=1

signal

clock

reset

d1

d2

d3

z1

z2

Page 20

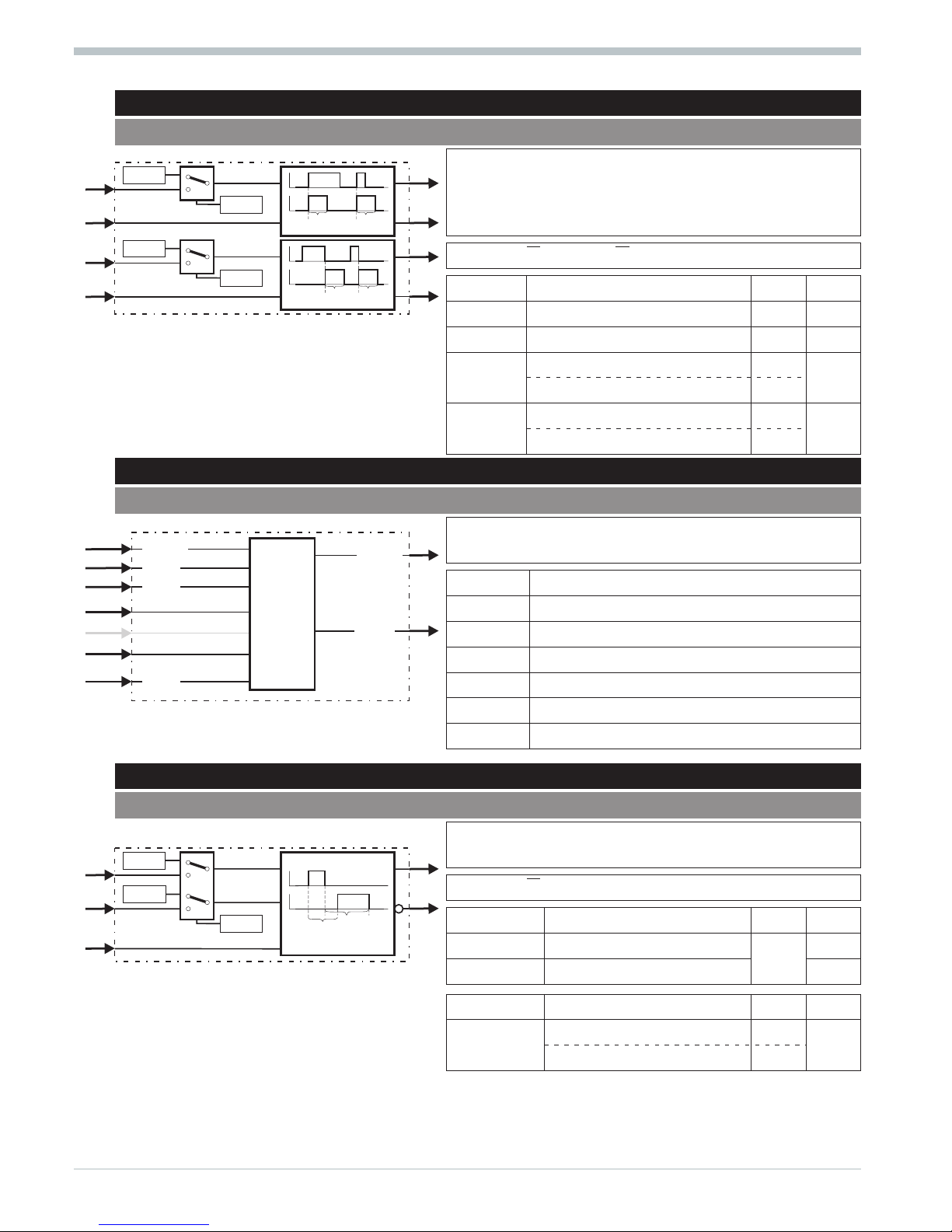

12.7 MONO

(monoflop - no. 66)

Positive pulse of length T1 at z1, if a positive flank is detected

at d1 (0 r 1) and

Positive pulse of length T2, when a negative flank is detected at

d2 (1 r 0).

zzandzz

21 43

==

Parameter Description Values Default

Ti1

Pulse duration in s (d1,Mode1=0) Real 1

Ti2

Pulse duration in s (d2,Mode2=0) Real 1

Mode1

Source of pulse duration T1= Ti1 0

0

Source of pulse duration T1 = x1 1

Mode2

Source of pulse duration T2= Ti2 0

0

Source of pulse duration T2 = x2 1

12.8 STEP

(step function for sequencing - no. 68)

For conditional switch-on or as a ring counter. The STEP function can be cascaded.

d1...d10 Condition inputs for switching on

x1 Input for cascading

d11=1 reset (y1 is set to 1 or to x1)

d12=1 stop (y1 and z1 remain unchanged)

d13 skip (switch-on with positive flank)

y1 Active step number (or + x1)

z1 1 = STEP function is active or in reset

12.9 TIME1

(timer - no. 69)

The status change of d1 is output with delay at z1. The delay is

T1 or x1 for the positive flank, T2 or x2 for the negative flank.

zz

21

=

Parameter Description Values Default

T1

Delay time in s (d1=0r1)

Real

0

T2

Delay time in s (d1=1r0) 0

Configuration Description Values Default

Mode

Delay times = T1/T2 0

0

Delay times = x1/x2 1

Logic functions 9499-040-44311

MONO 20

x1

d1

x2

d2

z1

z2

z3

z4

Ti1

Mode1

Ti2

Mode2

T1

T1

T1

T2T2T2

d11

d12

d13

reset

stop

skip

Casc

activ

Step

d1

d10

...

x1

z1

y1

STEP

x1

x2

d1

z1

z2

Mode

T1

T1

T2

t

t

T2

T1

T2

Page 21

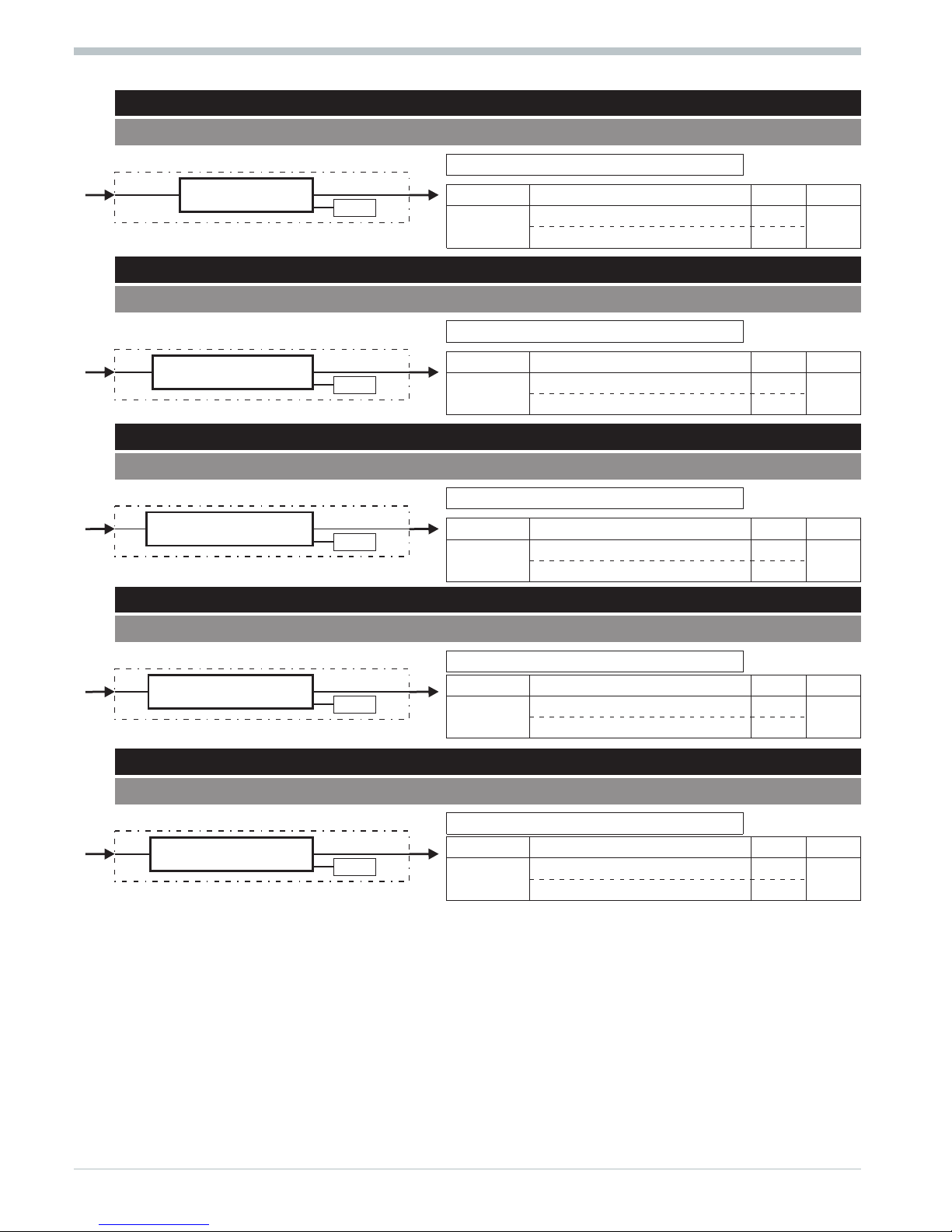

13 Signal converters

13.1

AOCTET

data type conversion

Function AOCTET converts an analog value (X1) into the individual bytes (Ooct1-4) of a data

type as used e.g. for transmission via the CAN bus ( see CPREAD / CPWRIT ). In the CAN

notation, the bytes are transmitted in Intel format. Unless connected instruments are in

compliance with this notation, word or bytewise echange of the bytes may be necessary.

The function works in both directions simultaneously ( analog > bytes / bytes > analog )

with separate data type adjustment in the parameters.

Analog inputs:

X1 analog input value

Ioct1..4 analog input byte value 1

Analog outputs:

Y1 analog output value

Ooct1..4 analog output byte value 1

Parameters:

Ioct data type of analog > byte conversion

Ooct data type of byte > analog conversion

The following data types

are available

0: Uint8

1: Int8

2: Uint16

3: Int16

4: Uint32

5: Int32

6: Float

13.2 ABIN

(analog i binary convertion - no. 71)

Converts analog value x1 into digital value z1...z8 and converts digital

value d1...d8 into analog value y1. Either binary: z1/d1 = LSB or BCD:

z1...z4/d1...d4 = LSD, z1/z5/d1/d5 = LSB or 1 of 8: z1/d1 = 1

Configuration Description Values Default

Select

analog r binary and vice versa 0

0analog r BCD and vice versa 1

analog r 1 of 8 and vice versa 2

13.3 TRUNC

(integer portion - no. 72)

Provides the integer portion of x1 (not rounded!) to y1.

yINTx

11

= ()

13.4 PULS

(analog-pulse convertion - no. 73)

Value x1 is converted into a number of pulses/h.

n Puls h

xx

xx

=×

10

100 0

\

\

n

max.

= 18 000/h with ts=100 ms Parameter Description Values Default

n

max.

= 9 000/h with ts=200 ms

x0

Start

Real

0

n

max.

= 4 500/h with ts=400 ms

x100

End 1

nmax. = 2 250/h with ts=800 ms

Puls/h

Pulses/h 0...nmax. 0

9499-040-44311 Signal converters

21 AOCTET

x1

d1

d8

...

z1

z8

y1

...

1 aus 8

BCD

Binär

2

2

2

0

1

7

1 aus 8

BCD

Binär

2

2

2

0

1

7

.

.

.

.

.

.

.

.

Select

0...255

0...255

x1 y1

x

y

x1 z1

x0 x100

Puls/h

Page 22

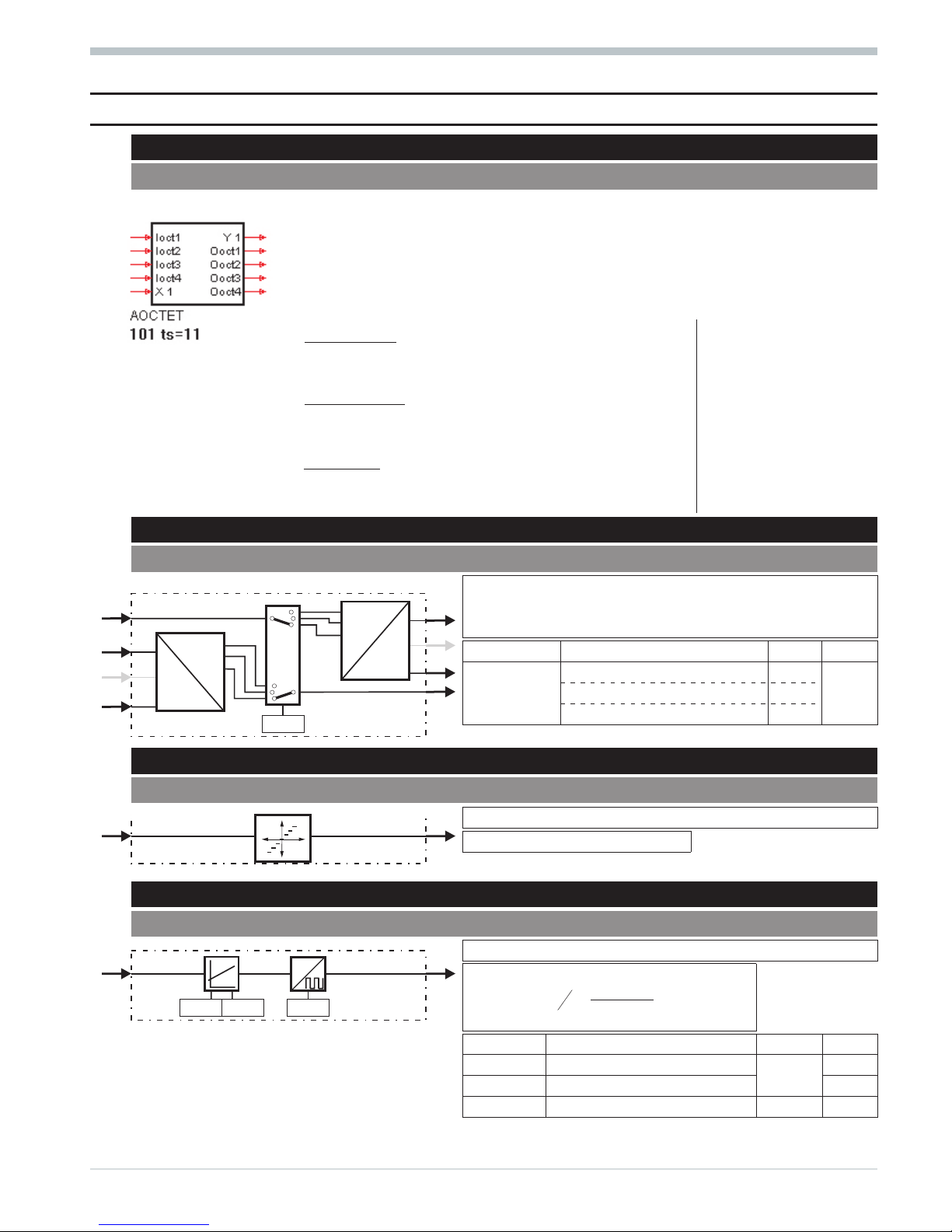

13.5 COUN

(up/down counter - no. 74)

The events (0 r 1) at d1 are counted up and the events at d2 are

counted down. Condition: the non-counting input is not connected,

or connected to 1. During carry or borrow, the relevant output is 0.

Parameter Description Values Default

y0

Preset value 0

Max

Max. limit Real 9999

Min

Min. limit 0

Mode

Source of preset = y0 0

0

Source of preset = x1 1

reset (di4) preset (di3) Mode

Count = counter output (counter value) 0 0 GO (Default)

carry = positive carry 0 1 PRESET

borrow = negative carry 1 0 RESET (first-Run)

1 1 RESET (first-Run)

13.6 MEAN

(mean value formation - no. 75)

y1 = arithmetic mean value from the number (ValNo)ofx1

values sampled last. The interval between the individuel samples is adjustable with Sample and Unit. Sampling is

also possible at a positive flank at d3 (sample).

Sampling is interrupted with d1=1(disabl),

the mean value is deleted with d2 = 1 (reset).

Configuration Description Values Default

After sampling of the required number of

Sample

Value for interval Real 1

values (ValNo), z1 goes to 1 during 800 ms.

ValNo

Number of values to be sampled 1...100 100

This signal can be used at the sample input (d3)

Unit

Time unit for interval: s 0

0of a second MEAN function for cascading. Time unit for interval: min 1

Time unit for interval: h 2

Example 1: Mean value of the last minute with one sample every second.

Sample:1 Unit:0 r one sample every second.

ValNo: 60 r the mean value is calculated from the last 60 values (1 minute).

Example 2: Mean value of the last day with one sample every hour.

Sample:1 Unit:2 r one sample every hour.

ValNo:24 r the mean value is calculated from the last 24 values (1 day).

Example 3: Mean value of the last day with one sample every 15 minutes.

Sample:15 Unit:1 r one sample every 15 minutes.

ValNo:96 r the mean value is calculated from the last 96 values (1 day).

Signal converters 9499-040-44311

COUN 22

>Tr

>Tr

reset

preset

Preset

down

up

Count

carry

borrow

d4

d3

x1

d2

d1

y1

z1

z2

&

&

&

y0

Mode

Min

0000

Max

9999

d2

d1

d3

x1

z1

y1

reset

disabl

sample

Unit

ValNo

Sample

]

ValNo

ready

Mean

Page 23

14 Time functions

14.1

LEAD

(differentiator - no. 50)

{}

yt

T

Tt

y tt a xtxtt y

1

s

1s 1 1s 0

() [ ( \ ) ()\ ( \ ) ]=

+

×+× +

ts calculation cycle time x1(t) instantaneous x1

T time constant x1(t-ts) previous x1

a

gain y1(t) instantaneous y1

reset = reset to start condition

y0

Output offset y1(t-ts) previous y1

Parameter Description Values Default

a

Description

Real

1

y0

Output offset 0

T

Time constant in s 1

Configuration Description Values Default

Mode

Differentiating all changes 0

0Differentiating only pos. changes 1

Differentiating only neg. changes 2

14.2 INTE

(integrator - no. 51)

yt y tt

t

T

xt x

11

s

s

10

() ( \ ) [ () ]=+×+

ts calculation cycle time x1(t) instantaneous x1

T integration constant y1(t) y1 aftert=n.ts

n number of calcul. cycles y1(t-ts) previous y1

x0 input offset

Parameter Description Values Default

T

Time constant in s

Real

60

x0

constant 0

reset (d2 = 1, priority over preset and stop)

y0

Preset value 0

preset (d3 = 1, priority over stop)

Min

Min. limiting -9999

stop (d1 = 1)

Max

Max. limiting 9999

z1 = 1 with max. limiting exceeded

Mode

Source of Preset = y0 0

0

z2 = 1 with min. limiting exceeded Source of Preset = x2 1

14.3 LAG1

(filter - no. 52)

With d1 = 0, x1 is transmitted to y1 with delay after a 1st order

e-function (d1 = 1: without delay).

yt

T

Tt

ytt

t

Tt

xt

1

s

1

s

s

s

1

() ( \ ) ()=

+

×++×

ts calculation cycle time x1(t) instantaneous x1

d1 = 0: delay effective (default) T time constant y1(t) y1 aftert=n.ts

d1 = 1: delay ineffective n no. of calculation cycles y1(t-ts) previous y1

Parameter Description Values Default

T

Time constant in s Real 1

9499-040-44311 Time functions

23 LEAD

a

T

d1

x1

reset

y1

y0

Mode

+

+-

-

/

preset

reset

stop

x2

d3

d2

x1

d1

z1

z2

y1

y0

Mode

?1

T

ò

MAX

MIN

MAX

MIN

Min

Max

x0

Preset

T

d1

x1

y1

Page 24

14.4 DELA1

(delay time 1 - no. 53)

Delay time with TT = n.ts (d3 not wired) or shift register of

depth n (d3: 0 r 1 as clock).

Parameter Description Values Default

n

Delay factor 0/1/...255 0

reset (d1 = 1, priority over preset and clock)

preset (d2 =1, priority over clock)

ts = calculation cycle time

clock (d3, as specified above)

14.5 DELA2

(delay time 2 - no. 54)

Value x1 is output with delay of Td (y1).

yt xtTd

11

() ( \ )=

Parameter Description Values Default

Td

Delay in s Real 0

Td max =25,5 s with ts=100 ms

reset (d1 = 1, priority over preset)

Td max =51,0 s with ts=200 ms preset (d2 = 1, delay (d1=0andd2=0)

Td max =102,0 s with ts=400 ms

Td max =204,0 s with ts=800 ms

14.6 FILT

(filter with tolerance band - no. 55)

With the difference between x1 and y1 below Diff and d1 =

0, y1 is delayed as follows:

yt

T

Tt

ytt

t

Tt

xt

1

s

1

s

s

s

1

() ( \ ) ()=

+

×++×

Outside the tolerance band or with d1 = 1 the output fol

-

lows the input directly

Parameter Description Values Default

T

Time constant in s

Real

1

Diff

Tolerance band 1

Time functions 9499-040-44311

DELA1 24

d1

d2

d3

x1

x2

y1

0

n

t

reset

preset

clock

X1

Preset

Y1

d1

d2

x1

x2

y1

0

Td

t

reset

preset

X1

Preset

Y1

T

d1

x1

y1

?1

Diff

reset

Page 25

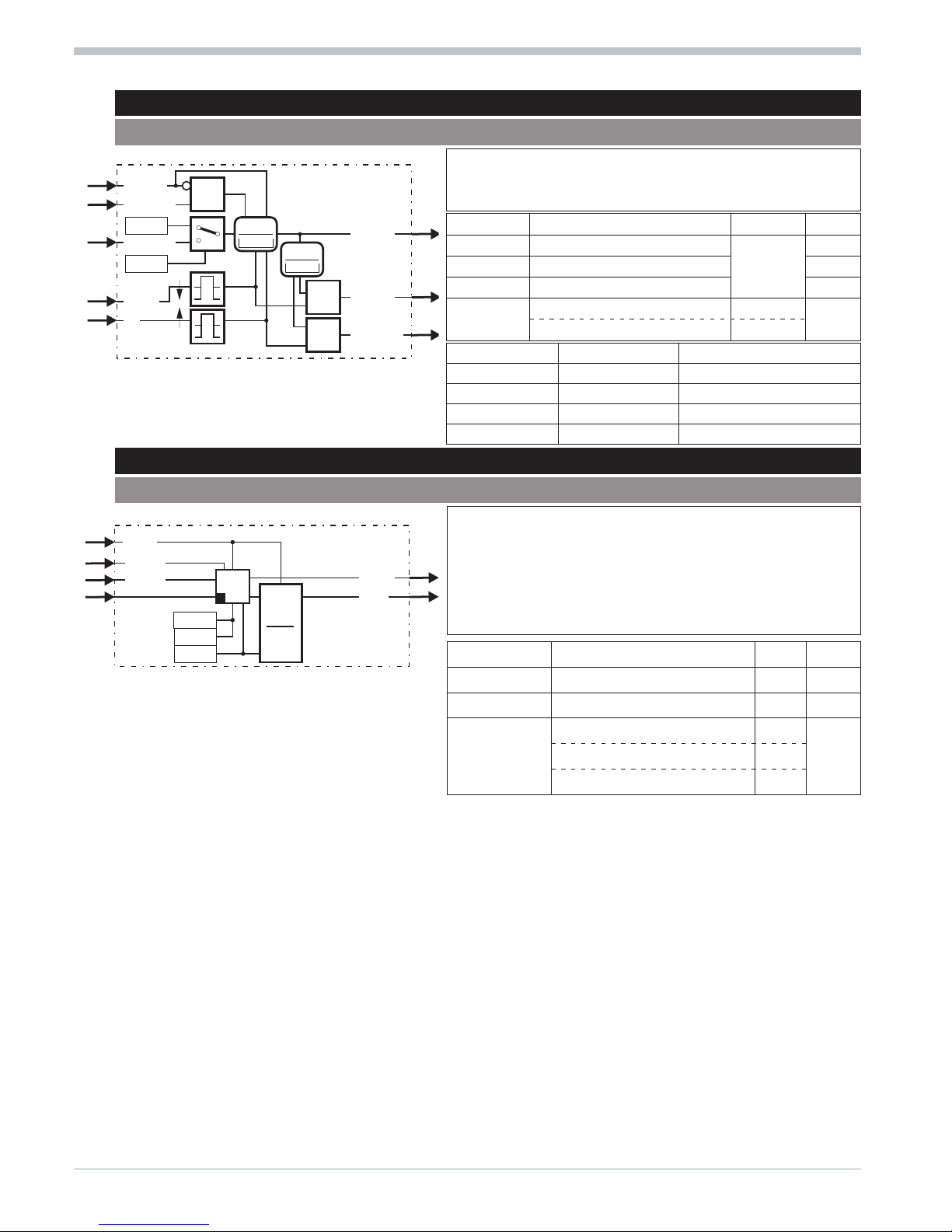

14.7 TIMER

(time switch 1 - no. 67)

z1 is switched on at absolute time TS (Mo=month, D=day,

H=hour, Mi=minute) and switched off again TE later

(D=days, H=hours, Mi=minutes). Switching can be done once

or cyclically, and suppressed with d1 = 1.

y1 indicates the actual weekday (0...6 = Su...Sa)

Parameter Description Values Default

TS.Mo

Switch-on time, month 0...12

0

TS.D

Switch-on time, day 0...31

TS.Mo=0andTS.D = 0 means ‘actual day’ When

time defined with TS.H / TS.Mi has elapsed,

the 1st switching operation occurs on the following

day.

With TS.Mo = 0 and TS.D < actual day the 1st

switching operation occurs in the following month.

With TS.Mo ß actual month and TS.D < act.

day the 1st switching operation occurs in the following year.

TS.H

Switch-on time, hour 0...23

TS.Mi

Switch-on time, minute 0...59

TE.D

Time duration, days 0...255

TE.H

Time duration, hours 0...23

TE.Mi

Time duration, minutes 0...59

Configuration Description Values Default

Func1

Function runs cyclically 0

0

Function runs once 1

Func2

Function runs daily 0

0

Function runs from Mo...Fr 1

Function runs from Mo...Sa 2

Function runs weekly 3

14.8 TIME2

(time switch 2 - no. 70)

z1 is switched on TS (D=days, H=hours, Mi=minutes) after a

positive flank of d3 and switched off again TE later (D=days,

H=hours, Mi=minutes). If end is fed back to start, the

switching operation is cyclical. The operation is suppressed

with d1 = 1, d2 = 1 finishes an instantaneously running swit

-

ching operation immediately. y1 indicates the actual weekday

(0...6 = So...Sa)

Parameter Description Values Default

z2=1atswitching operation end

TS.D

Switch-on delay, days 0...255 0

TS.H

Switch-on delay, hours 0...23 0

TS.Mi

Switch-on delay, minutes 0...59 0

TE.D

Time duration, days 0...255 0

TE.H

Time duration, hours 0...23 0

TE.Mi

Time duration, minutes 0...59 0

9499-040-44311 Time functions

25 TIMER

disabl

d1 z1

y1

Func 1

Func 2

TS.Mo

TS.D

TS.H

TS.Mi

TE.D

TE.H

TE.Mi

t

disabl

start

reset

ende

d1

d3

d2

z1

y1

z2

TS.D

TS.H

TS.Mi

TE.D

TE.H

TE.Mi

t

Page 26

15 Selection and storage

15.1

EXTR

(extreme value selection - no. 30)

The values of x1...x3 are output sorted according to height at

y1...y3. y4...y6 indicate the relevant input number. With equality

the distribution is at random. If an input is not wired or >0,5 . 10

37

or <-0,5 . 1037, it is not taken into account during selection.

15.2 PEAK

(peak value memory - no. 31)

y1 follows the max. and y2 follows the min. value of x1. With

stop (d1 = 1, d2 = 0) both values remain stable.

reset (d2 = 1, priority over stop): y1 = x1

stop (d1 = 1, d2 = 0): as described above

go (d1 = 0 and d2 = 0): as described above

15.3 TRST

(hold amplifier - no. 32)

y1 follows x1, when d1 = 0.

With d1 = 1 the momentary value of x1 is stored.

15.4 SELC

(constant selection - no. 33)

Either parameters C1.1...C1.4 (with d1 = 0) or C2.1...C2.4 (with

d1 = 1) are connected with y1...y4.

Parameter Description Values Default

C1.1...4

Constant group1

Real

0

C2.1...4

Constant group2 1

15.5 SELP

(parameter selection - no. 34)

y1=C1(d1=0,d2=0)

y1=C2(d1=0,d2=1)

y1=C3(d1=1,d2=0)

y1=x1(d1=1,d2=1)

Parameter Description Values Default

C1...C3

Constants Real 0

Selection and storage 9499-040-44311

EXTR 26

Max

MaxNo

Mid

MidNo

Min

MinNo

y1>y2>y3

x1

x2

x3

y3

y6

y2

y5

y1

y4

y1

y2

d1

d2

x1

xmax

xmin

&

x<y

x>y

stop

reset

d1

x1

y1

hold

y1

y2

y3

y4

d1

C1.1

C1.2

C1.3

C1.4

I

C2.1

C2.2

C2.3

C2.4

II

d1

d2

x1

001

012

103

114

y1

C2

C3

C1

Page 27

15.6 SELV1

(variable selection - no. 35)

y1=x1(d1=0,d2=0)

y1=x2(d1=0,d2=1)

y1=x3(d1=1,d2=0)

y1=x4(d1=1,d2=1)

15.7 SOUT

(selection of output - no. 36)

y1=x1(d2=0,d1=0)

y2=x1(d2=0,d1=1)

y3=x1(d2=1,d1=0)

y4=x1(d2=1,d1=1)

This functionblock has changed from operating

version 6 to7. Old truthtable:

15.8 REZEPT

(recipe management - no. 37)

The block contains 5 groups each with 4 parameters. x5 selects,

which group is available at y1...y4. With x5 <1 or >5 or with d2

=1(manual), x1...x4 are through-connected directly to

y1...y4. With d1 = 0 r 1 the values at x1...x4 are written to the

group selected with x5 (store).

manual (d2 = 1): as described above

store (d1=0r 1): as described above

15.9 2OF3

(2-out-of-3 selection with mean value formation - no. 38)

y1 = arithmetic mean value of x1, x3 and x5. y2 = number of values used for mean value formation. The difference of x1, x3 and x5

is formed and compared with Diff. Inputs, the value of which va

-

ries by > Diff, are not used for mean value formation. When ap

plying the fail signals of AINP (z1) to d1...d3, faulty inputs are not

taken into account either during mean value formation. z1=1in

dicates, that 1 input has failed and was not used for mean value

formation. z2 = 1 indicates, that there was no mean value forma

tion, because min. 2 inputs had failed.

Parameter Description Values Default

Diff

Difference limit value Real 1

15.10 SELV2

(cascadable selection of variables - no. 39)

y1 = x1 (x5 < 1,5)

y1 = x2 (x5 = 1,5...<2,5)

y1 = x3 (x5 = 2,5...<3,5)

y1 = x4 (x5 = 3,5...Î)

9499-040-44311 Selection and storage

27 SELV1

001

102

013

114

d1

d2

x1

x2

x3

x4

001

012

103

114

y1

d1

d2

x1

001

012

103

114

y1

y2

y3

y4

y1

y2

y3

y4

y5

d2

d1

x1

x2

x3

x4

x5

-5

manual

store

SetNo Casc

Set1.1

Set1.2

Set1.3

Set1.4

1

Set2.1

Set2.2

Set2.3

Set2.4

2

Set3.1

Set3.2

Set3.3

Set3.4

3

Set4.1

Set4.2

Set4.3

Set4.4

4

Set5.1

Set5.2

Set5.3

Set5.4

5

d1

d2

d3

d4

x1

x2

x3

x4

x5

x6

z1

z2

y1

y2

]

err1

err2

Difffail1

fail2

fail3

off

X1

X1mult

X2

X2mult

X3

X3mult

Y1

Casc

y2

y1

x5-3

Casc

Select

x5

x1

x2

x3

x4

<1,5 1

1,5...<2,5 2

2,5...<3,5 3

3,5... 4Î

Page 28

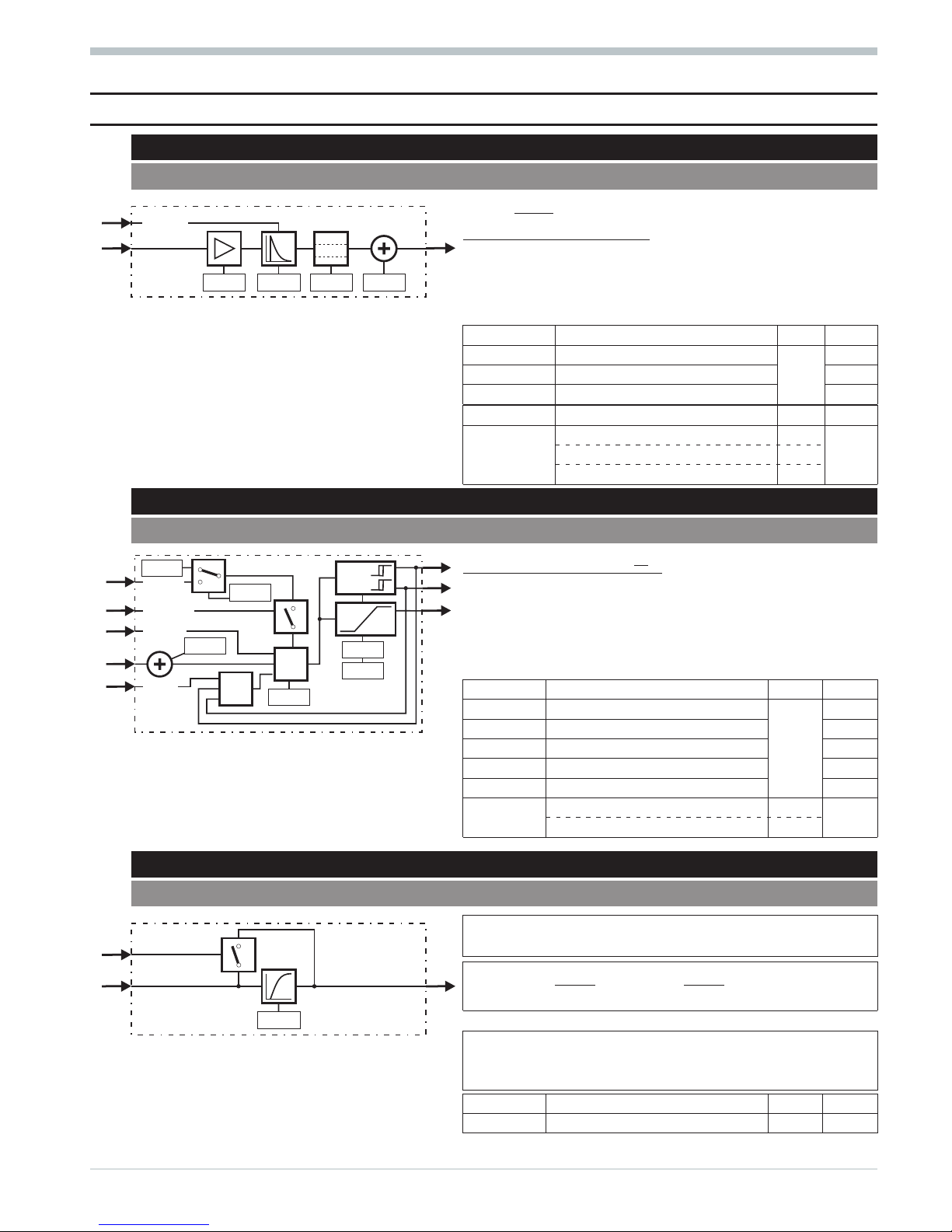

16 Limit signalling and limiting

16.1

ALLP

(alarm and limiting with fixed limits - no. 40)

Signal x1 is monitored for 2 low (L1, L2) and 2 high limit values

(H1, H2). Additionally min. and max. limiting is applied to the sig

-

nal (L1, H1). The signal can be x1 or dx1/dt or x1 - x0.

Parameter Description Values Default

H1

Max. alarm 1 or max. limit

Real

9999

L1

Min. alarm 1 or min. limit -9999

H2

Max. alarm 2 9999

y1 = signal limited to L1 and H1

z1 = 1 with signal > H1

z2 = 1 with signal > H2

z3 = 1 with signal < L1

z4 = 1 with signal < L2

L2

Min. alarm 2 -9999

x0

offset 0

xsd

switching hysteresis 1

Configuration Description Values Default

Select

Monitored variable: x1 0

0

Monitored var.: dx1/dt [1/s] 1

Monitored var.: x1 - x0 2

16.2 ALLV

(alarm and limiting with variable limits - no. 41)

Signal x1 is monitored for 2 low (x2, L2) and 2 high limit values

(x3, H2). Additionally min. and max. limiting is applied to the

signal (x2, x3). The signal can be x1 or dx1/dt or x1 - x0.

Parameter Description Values Default

H2

Max. alarm 2

Real

9999

L2

Min. alarm 2 -9999

y1 = signal limited to L1 and H1

x0

offset 0

z1 = 1 with signal > H1

xsd

switching hysteresis 1

z2 = 1 with signal > H2 Configuration Description Values Default

z3 = 1 with signal < L1

Select

Monitored variable: x1 0

0z4 = 1 with signal < L2 Monitored variable: dx1/dt [1/s] 1

Monitored variable: x1 - x0 2

16.3 EQUAL

(comparison - no. 42)

Checking, whether x1 is smaller, equal or higher than x2

(+/- tolerance Diff).

zwithxx

312

1=<\ e zz

63

=

zwithxx x

2122

1== +(\)( )eeK zz

52

=

zwithxx

112

1=>+e zz

41

=

Parameter Description Values Default

Diff

Tolerance limit Real 0

Mode

Source tolerance limit: Diff 0

0

Source of tolerance limit: x3 1

Limit signalling and limiting 9499-040-44311

ALLP 28

Select

H1 H2

L2

L1

x1

y1

z1

z2

z3

z4

Y1

h1

h2

l1

l2

Xsd

x0

Select

H2

L2

x1

x2

x3

y1

z1

z2

z3

z4

Y1

h1

h2

l1

l2

Xsd

X0

X1

H1

L1

Mode

Diff

x1

x2

x3

z1

z4

z2

z5

z3

z6

X1

X2

Diff

X1>X2

X1=X2

X1<X2

Page 29

16.4 VELO

(rate-of-change limiting - no. 43)

x1 is passed through to y1, however, its rate of change is limited to a

positive and / or a negative maximum value (gradient).

Parameter Description Values Default

GrX+

Positive gradient (1/s)

Real

Î

GrX-

Negative gradient (1/s) Î

Mode+

Source of pos. gradient: GrX+ 0

0

d1 = 0: positive gradient is effective

d2 = 0: negative gradient is effective

d1 / d2 = 1: relevant gradient is ineffective

Source of pos. gradient:x2 1

Mode-

Source of neg. gradient: GrX- 0

0

Source of neg. gradient: x3 1

16.5 LIMIT

(multiple alarm - no. 44)

x1 is checked for 8 alarm values. Mode determines the opera

-

tion of the relevant alarm (max. / min.).

Parameter Description Values Default

L1...L8

Alarm values

Real

0

Xsd

Switching hysteresis 0

z1...z8:0=noalarm 1 = alarm

Configuration Description Values Default

Mode1...

Mode8

Operation: max. alarm 0

0

Operation: min. alarm 1

16.6 ALARM

(alarm processing - no. 45)

x1 is checked for a low and a high alarm value. Additionally the digital

alarm input can be switched to d1. With d2 = 1 the alarms are sup

pressed. After removal of this signal, suppression is maintained, until

the monitored value returns within the limits.

z1:0=noalarm 1 = alarm Parameter Description Values Default

d1 can come e.g. from the fail output of an AINP

LimL

Low alarm value

Real

10

LimH

High alarm value 10

Lxsd

Switching difference 0

Configuration Description Values Default

Fnc

Alarm function: meas. value 0

0Alarm function: meas. value + d1 1

Alarm function: d1 2

9499-040-44311 Limit signalling and limiting

29 VELO

d2

d1

x1

x2

x3

y1

Mode+

GrX+

GrX+

Mode-

GrX-

GrX-

Î

Î

x1

L2 L8

L1

...

Mode1

Mode2 Mode8

...

z1

...

z8

Xsd

stop

fail

LimL

LimH

Xsd

d2

x1

d1

z1

Fnc

alarm

Page 30

17 Visualization

17.1

VWERT

(display / definition of process values - no. 96)

For display or alteration of 6 analog or digital values in 6

display lines. With d1 = 1 the operating page is not displayed.

With d2 = 1 the values are not adjustable by means of keys

ID. With a positive flank at d9 (0r1) the input values are

stored as output values.

Parameter Description Values Default

z1...z

6

Start values digital at po

-

wer-on

0/1 0

Y1...Y

6

Start values analog at po

-

wer-on

Real 0

Configurati

-

on

Disp1

...

Disp6

Display line, value adjustable 0

1Only display line 1

Line = Empty line 2

Mode1

...

Mode6

Display line analog 0

0

Display line digital 1

Dp1...

Dp6

Digits behind dec. point 0...5 0

Text entry is possible only via the engineering tool.

Header

The following values or texts are displayed in the lines:

Ü

Block number 3 digits

*

Fixed text or space (no access)

Ö

First 16 characters of ‘title’’

Analog line

ä

With analog lines: parameter name (dependent

of line

the first 6 characters of ‘text 1a’...’text 6a’)

#

With analog lines: value x1...x6 dependent of line

<

With analog lines: unit (the first 6 characters

Digital line

of ‘text 1b’...’text 6b’ dependent of line)

>

With digital lines: dependent of signal and line

the first 16 characters of ‘text 1a’...’text 6a’ (Signal=0)

the first 16 characters of ‘text 1b’...’text 6b’ (Signal=1)

Visualization 9499-040-44311

VWERT 30

x1

d3

x2

d4

x3

d5

x4

d6

x5

d7

x6

d8

d9

d2

d1

.

.

.

.

.

.

.

.

.

y1

z1

y6

z6

Mode 1

Mode 2

Mode 4

Mode 3

Mode 5

Mode 6

Dp1

z2

z3

z4

z5

z6 Y6

Dp2

Dp4

Dp3

Dp5

Dp6

Disp 1

A.A

?1

store

lock

hide

Disp 2

Disp 3

Disp 4

Disp 5

Disp 6

Y5

Y4

Y3

Y2

Y1z1

x1

x2

x3

x4

x5

x6

d1

d2

d3

d4

d5

d6

:

Ü* Ö

=

ä#<**

>*

Page 31

17.2 VBAR

(bargraph display - no. 97)

For display of 4 analog values, 2 thereof as bargraphs. The bar

graphs can be horizontal or vertical. The values of x1 and x2 can

also be altered. With d1 = 1 this operating page is not displayed.

With d2 = 1 the values are not adjustable using keys ID.

Parameter Description Values Default

Y1, Y2

display x1 / x2, variable Real 0

Configuration Description Values Default

Disp 1

Disp 2

display x1 / x2, variable 0

1only display x1 / x2 1

empty field x1 / x2 2

Dp1, DP2

Digits behind dec. point 0...3 0

Type

Both bargraphs horizontal 0

0

Both bargraphs vertical 1

Scaling bargraph 1 (x3)

X3 0

Left or bottom Real 0

X3 100

Right or top Real 100

X3 mid

Start value middle Real 0

Scaling bargraph 2 (x4)

X4 0

Left or bottom Real 0

X4 100

Right or top Real 100

X4 mid

Start value middle Real 0

Text entry is possible only via the engineering tool.

Bargraphs

horizontal

The following values or texts are displayed:

Ü

Block number 3 digits

*

Fixed text or space (no access)

Ö

First 16 characters of ‘title’

ä

Parameter name for x1 (first 6 characters of ‘name 1’)

#

Parameter name for x2 (first 6 characters of ‘name 2’)

<

Value x1

vertical

>

Value x2

y

Unit for x1 (first 6 characters of ‘unit 1’)

x

Unit for x2 (first 6 characters of ‘unit 2’)

9499-040-44311 Visualization

31 VBAR

x1

x3

x4 x2

x1

x3

x4

x2

x1

x2

x3

x4

d2

d1

y1

X4 0 X4 100

Typ

X3 100

y2

Y2

Dp2

Dp1

Disp 1

?1

Y1

X3 0 X3 mid

X4 mid

lock

hide

A.A

Disp 2

:

Ü* Ö

ä<y

#

>

x

:

Ü* Ö

ä

<>

yx

#

Page 32

17.3 VPARA

(parameter operation - no. 98)

For common display and adjustment of max. 6 parameters of ot

her function blocks on 6 display lines. When value 0 is specified

as block number, the corresponding line is a text line. With in

-

put (x) connected, keys ID are without effect but display and

output follow the input with positive edge at d3 (0r1). With d2

= 1, the values are not adjustable by means of keys ID. With

d1 = 1, the operating page is not displayed

Configuration Description Values Default

Block1...

Block6

Block number of

displayed parameter

**

Num1...

Num6

Parameter number

**

* To prevent confusion and thus operator errors, we

recommend adjusting block numbers and parameters

exclusively via the engineering tool, which is also used

for entry of the parameters with short-form descriptions

Text entry is possible only via the engineering tool.

The following values or texts are displayed in the lines:

Ü

Block number 3 digits

*

Fixed text or space (no access)

Ö

First 16 characters of ‘title’

ä

With parameter lines: parameter name (depend. of line

the first 6 characters of ‘text 1’...’text 6’)

Parameter line

#

With parameter lines: the parameter value

<

With parameter lines: unit (the first 6 characters

of ‘unit 1’...’unit 6’ dependent of line)

>

With text lines: the first 16 characters of

Text line

‘text 1’...’text 6’ dependent of line

Visualization 9499-040-44311

VPARA 32

x1

x2

x3

x4

x5

x6

d3

d2

d1

y1

y6

.

.

.

.

.

.

.

.

.

z1

z6

store

lock

hide

Block1

Num1

Num3

Num5

Num2

Num4

Num6

Block2

Block3

Block4

Block5

Block6

(1)

(2)

(3)

(4)

(5)

(6)

:

Ü* Ö

=

ä#<**

>*

Page 33

17.4 VTREND

(trend display - no. 99)

For collection and display of the last 100 analog values of x1.

These values are displayed in a trend curve. Sampling interval

(Sample) and time unit (Unit) are adjustable. With d1 = 1

the operating page is not displayed. With d2 = 1 sampling is in

terrupted. With d3 = 1 trend sampling is reset. Sampling can be

done automatically or with a positive pulse at d4.

Configuration Description Values Default

Unit of sampling interval

Unit

seconds ( s)0

0Minutes( m)1

Hours ( h)2

Sample

Value of sampling interval Real 1

Dp

Digits behind decimal point 0...3 0

X0

Display scaling 0%

Real

0

X 100

Display scaling 100% 100

Y1 is the value from 100 samples ago (X-100)

z1=1 when buffer memory full (ready)

The following values or texts are displayed:

Trend display

Ü Block number 3 digits

* Fixed text or space (no access)

Ö

First 16 characters of ‘title’

ä

X 100

#

X0

<

Instantaneous value x1

>

Unit for x1 (first 6 characters of ‘unit’)

y

-100*Sample, Unit

Text entry is possible only via the engineering tool.

9499-040-44311 Visualization

33 VTREND

X1

X1

Unit

-100

.

Sample

X0

x1

d3

d1

Y1

z1

d4

d2

Unit

Sample

sample

disabl

X-100

ready

reset

hide

...

98

99

100

1

2

3

4

X0 X 100

X 100

Dp1

A.A

:

Ü* Ö

ä

<

y

#

>

Page 34

18 Communication

ISO 1745

Max. 20 functions L1READ and L1WRIT are configurable (blocks 1...20), whereby any combination is possible. In the

functions, any data can be used.

18.1 L1READ

(read level1 data - no. 100)

Any 7 analog process values (x1...x7) and any 12 digital status

informations (d1...d12) of the engineering are composed into a

data set for the digital interface. With code 00, function num

ber 0, the digital interface can read the data set as overall

block or the individual values with codes 01...09, function

number 0.

18.2 L1WRIT

(write level1 data - no. 101)

With codes 31...39, function number 0, the digital interface

writes into EEPROM cells. The data set comprises 8 analog

process values (y1...y8) and 15 digital status informations

(z1...z15), which are thereby made available to the enginee

-

ring.

Communication 9499-040-44311

L1READ 34

Interface

x1

x7

...

Statusbyte1

Code 01

Code 02

Code 00

Code 03

Code 04

Code 05

Code 06

Code 07

Code 08

Code 09

6543210

d6

d1

...

Statusbyte2

6543210

d12

d7

...

Code 31

Code 32

Code 33

Code 34

Code 35

Code 36

Code 37

Code 38

Code 39

EEPROM

987654321043210

z1

z15

...

y1

.

.

.

.

.

.

.

y8

Interface

Page 35

PROFIBUS INTERBUS

Max. 4 functions DPREAD and 4 functions DPWRIT are configurable (blocks 1...4 or 11...14), whereby any combination

is possible. In the functions, any data can be used.

18.3 DPREAD

(read level1 data via PROFIBUS / INTERBUS - no. 102)

Block numbers 1...4. Any 6 analog process values (x1...x6) and

any 16 digital process values (d1...d16) of the engineering are

grouped for reading via a PROFIBUS/I

NTERBUS data channel.

Block number 1 provides the data for channel 1 etc. The

PROFIBUS/ I

NTERBUS module reads the data of two channels at

intervals of 100 ms. z1...z4 indicate the PROFIBUS/I

NTERBUS sta

-

tus.

z1 = bus access not successful

z2 = faulty parameter setting

z3 = faulty configuration

z4 = no data communication

18.4 DPWRIT

(write level1 data via PROFIBUS / INTERBUS - no. 103)

Block numbers 11...14. The data of a PROFIBUS/INTERBUS

data channel are transmitted into the memory. Block number

11 transmits the data of channel 1 etc. The

PROFIBUS/I

NTERBUS module writes the data of two channels

at intervals of 100 ms. The data set comprises 6 analog process values (y1...y6) and 16 digital status informations

(z1...z16), which are available to the engineering. z17...z21

indicate the PROFIBUS/I

NTERBUS status.

z17 = bus access not successful

z18 = faulty parameter setting

z19 = faulty configuration

z20 = no data communication

z21 = data OK

9499-040-44311 Communication

35 DPREAD

Interface

Statusbyte1

(0)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

76543210

d8

d1

...

Statusbyte2

76543210

d16

d9

...

x1

.

.

.

.

.

x6

z1

z2

z3

z4

b-err

p-err

c-err

d-err

z1

z16

...

y1

.

.

.

.

.

y6

Interface

(0)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

76543210

76543210

z17

z18

z19

z20

z21

b-err

p-err

c-err

d-err

valid

Page 36

19 KS98+ I/O extension

with CANopen interface

The additional CANopen interface extends the multi

-

function unit functionality already in the basic version by

w

Extension of the number of local I/O by means of

the modular PMA RM 200 I/O system

w

connection of PMA multi-temperature controllers

KS800 / KS 816 with CANopen interface

w

on-site data exchange with other KS98+ units (cross

crommunication)

a

These functions are available only in KS98+

versions from operating version 5.

BUS terminating resistor

Both ends (first and last unit) of the CANopen bus must be

fitted with a bus terminating resistor. For this purpose, the

bus terminating resistor provided in each KS98+ can be used.

With the S.I.L. switch closed, the terminating resistor is

connected. By default , the S.I.L. switch is open

(see opposite).

Status display : CAN bus status

Character Value Signification

1, 2 1...42 Node number

3, 4 : Separator

5, 6 NC NoCheck:

Node existence so far unchecked / node not provided.

Ck Check:

Check for node existence is busy.

NR NoResponse:

No response from this node. However, node is required.

OK Ready:

Node has responded and was identified.

ES EmStart:

Node has output an emergency message.

7, 10, 13 - Separator

8, 9 NA NotAvailable:

Node status is unknown.

PO PreOperation:

Node is in status PreOperational.

Er Error:

Node is in error condition.

Op Operational