Page 1

KS 94 / DP

PROFIBUS-DP option for KS 94

PROFIBUS-DP Slave

Cyclic transmission of up to

16 input and 16 output values

Free definition of data content

Transmission of process and parameter data

Inputs and outputs as decentral IO

advanced line

DESCRIPTION

The PROFIBUS-DP option enables the

KS 94 to be connected to PROFIBUS-DP

networks. This allows de-centralized and

independent industrial and process controllers to be integrated into PLC or PC

systems. The PLC/IPC transfers

set-points and control information to the

KS 94, and polls process values cyclically.

All control functions and the associated

scaling and monitoring tasks are executed independently. This ensures high

process safety together with short times

for engineering and commissioning.

DISPLAY AND OPERATION

Via its “day & night” display, the KS 94

shows all process data locally and easily

readable. If required, one line of the dis

play can be used to show a

freely-definable message.

Furthermore, the controller can be

switched to local operation, e.g. for com

missioning the control loop without any

previous programming of the PLC or the

supervisory system. In addition, the En

gineering Tool ET/KS 94 is available as a

useful device. It is connected via a

front-panel socket of the KS 94, and

serves for configuration, parameter set

ting, and operation of the controller.

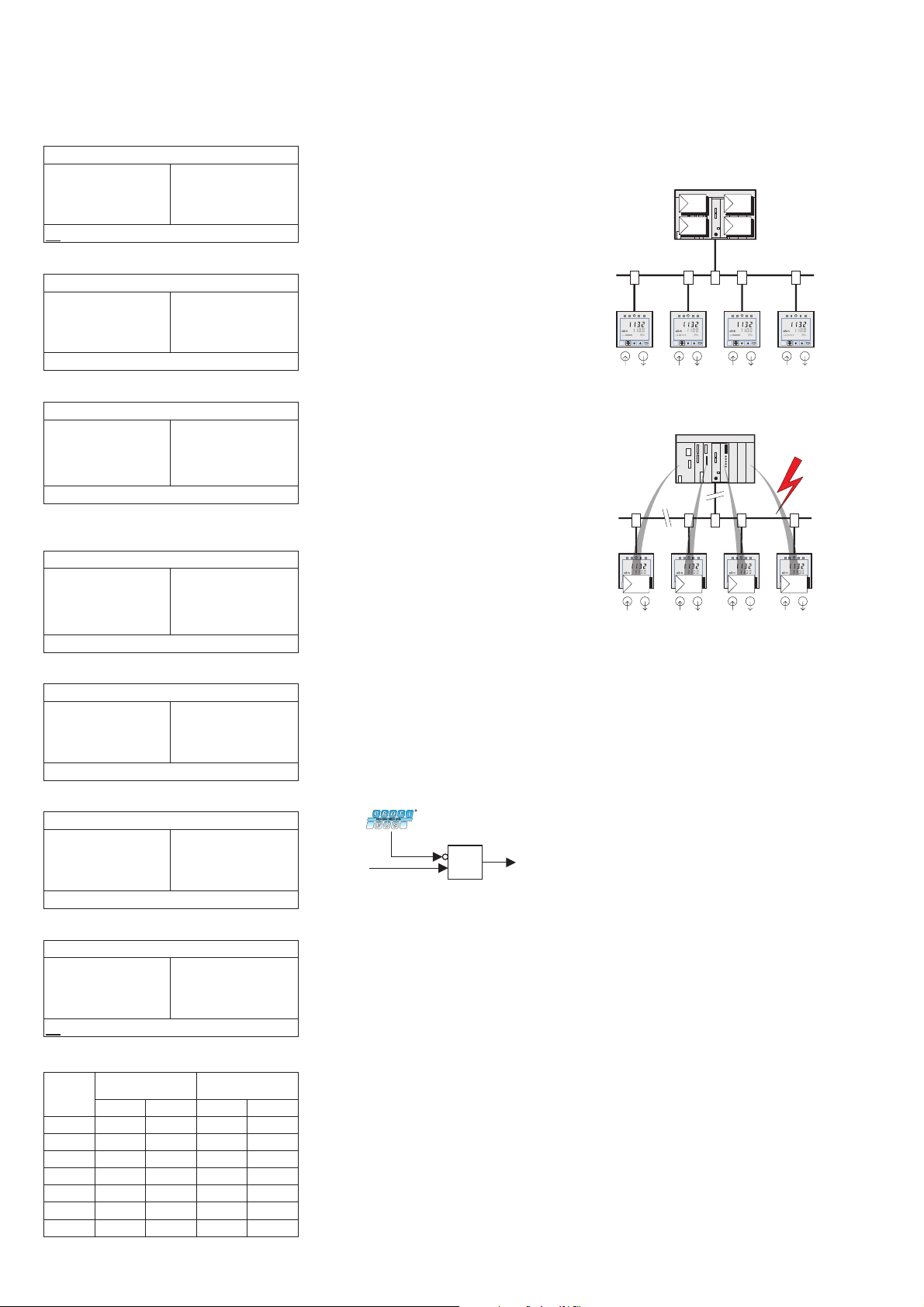

DE-CENTRALIZED I/O

Apart from the control function of the

KS 94, it is possible to access all inputs

and outputs directly. In this way, all the

controller’s I/O are also available to the

PLC/IPC.

756.0

756.0

qm/h

y:ууууу 55

-

The basic functions of the KS 94 / DP,

such as inputs/outputs, control

functions, etc. are described in the data

sheet (9498 737 28213) for the KS 94.

-

-

Technical data

According to EN 50170 Vol. 2

Reading and writing of all process data,

parameters and configuration data.

DATA FORMAT

Real values such as set-points and process data are transmitted in the IEEE

format (REAL) or in the 16-bit fiexed

point format (FIX) with one digit behind

the decimal point (configurable).

PARAMETER CHANNEL

Process data and selected parameter

data are written and read cyclically. All

process-, parameter- and configuration

can be transmitted via parameter chan

nel. These data are transmitted over

several cycles on request.

-

The standard graphical trend display al

lows a qualitative evaluation of the

control results.

-

Page 2

CONFIGURABLE PROCESS DATA

MODULES

Module a (I/O):

process data

process value (xeff)

output value (yeff)

set-point (weff)

read

status

parameter channel

no

Module b (I/O + parameter channel):

process data

process value (xeff)

output value (yeff)

set-point (weff)

read

status

parameter channel

Module c (extended I/O + parameter):

process data

process value (xeff)

output value (yeff)

set-point (weff)

read

status

inputs (INP+di)

parameter channel

Module d (ext.. I/O + forcing +

parameter):

process data

process value (xeff)

output value (yeff)

set-point (weff)

read

status

inputs (INP+di)

parameter channel

Module e (variabel + para. channel):

process data

status word1+2

IN1...IN16

read

parameter channel

set-point (w)

output value (yman)

write

auto/manual

set-point (w)

output value (yman)

write

auto(manual

set-point (w)

output value (yman)

write

auto(manual

outputs (OUT+do)

set-point (w)

output value (yman)

write

auto(manual

inputs (INP+di)

control word 1+2

OUT1...OUT16

write

Writing of inputs/outputs can be acti

vated individually for each input and

output.

DATA CONTENTS (MODULES

E,F,G)

Status words 1 and 2

Reading the digital inputs

·

Sensor break/short-circuit status

·

Error and status information

·

Alarms and controller outputs

·

Automatic or manual operation

·

Control words 1 and 2

Automatic/Manual switch-over

·

Controller off/Set-point switch-over

·

Forcing of digital inputs

·

Forcing/enabling of digital outputs

·

Local/Remote switch-over

·

Inputs IN1...IN16

The data to be read from the KS 94 can

be defined by means of the Engineering

Tool ET/KS 94 (Version 4.0 upwards).

It is possible to access all signals and pa

rameters (ð Fig.4).

Outputs OUT1...OUT16

The data to be transmitted to the KS 94

can be defined by means of the Engineering Tool ET/KS 94 (Version 4.0

upwards). It is possible to access all signals and parameters (ð Fig.4).

FUNCTIONS

Enabling the controller outputs

The control word allows you to en

able/disable the digital controller outputs.

-

Back-up controller mode

During “normal” operation, the control

output is computed by the master. The

KS 94 is used to measure the process

values, to generate the control output

signal, and for display.

If the master or the bus communication

should fail, the KS 94 takes over auto

matically and bumplessly.

-

CONNECTION

AMP flat-pin terminals 1 x 6,3 mm or

2 x 2,8 mm.

By needs of an adapter (ðAccessories)

Sub-D connectors or screw terminals

can be used.

-

Module f (variabel + para. channel):

process data

status word1+2

IN1...IN6

read

parameter channel

control word 1+2

OUT1...OUT6

write

Module g (multiplex transmission):

process data

status word1+2

Index IN (1...16)

read

IN

no

parameter channel

control word 1+2

Index OUT (1...16)

write

OUT

Memory requirements (byte):

Module read write

FIX REAL FIX REAL

a 814610

b 16221418

c 30462028

d 30462640

e 44764476

f 24362436

g 810810

controller

&

digital output

(do, OUT)

De-centralized I/O

All inputs and outputs of the KS 94 are

directly accessible via the I/O memory

area. In this way it is possible to make

use of additional input/output functions

apart from the control function. Analog

values are transmitted in the scaled for

-

mat.

Input forcing

All physical inputs can be overwritten via

the PROFIBUS-DP. In this way it is pos

sible e.g. to define individual elements of

a multi-element control loop via the bus,

or to let the PLC compute corrections for

process value/set-point.

2 KS 94 PROFIBUS

Page 3

DIAGNOSIS/BEHAVIOR ON ERROR

If the master fails or the bus connection

is interupted (communication error) the

last setpoint remains active and the

KS 94 works independently. If the mas

ter PLC is switched in stop-mode the

Clear Data Signal will be suppressed and

the last setpoint remains active, too! In

case of a fault on the bus, the KS 94 can

activate an alarm relay.

Plain-text display on the controller front:

Master missing

·

Parameter error

·

Configuration error

·

Loss of master

·

CABLE

According to EN 50170 Vol. 2

TRANSMISSION SPEEDS AND

CABLE LENGTHS

Automatic transmission speed detection

Speed Max. cable length

9,6 kbit/s 1200 m

31,25 kbit/s 1200 m

45,45 kbit/s 1200 m

187,5 kbit/s 1200 m

500 kbit/s 400 m

1,5 Mbit/s 200 m

3 Mbit/s * 100 m

6 MBit/s * 100 m

12 Mbit/s * 100 m

*

Sub-D adapter 9407-998- 00031 required!

Fig. 1 Connection diagram KS 94/DP:

90...250V

-

24VUC

OUT2

-

.

24 V

+

+

di8( )

+

di9( )

+

di 10 ( )

+

di 11 ( )

+

di 12 ( )

Option C

do 5

do 6

GND

+

}

_

+

}

_

+

_

galvanic isolation

C

oder

or

24 V

-

di1( )

+

di2( )

+

+ Volt

+mA

_

Volt/mA

-

24 V

+

+

di 3 ( )

+

di 4 ( )

+

di 5 ( )

+

di 6 ( )

+

di 7 ( )

do 1

do 2

do 3

do 4

VP (5V)

GND

RxD/TxD-N

RxD/TxD-P

Option B

Adapter

PROFIBUS-DP

ADDRESSES

0...126 (factory setting: 126)

Remote setting of address allowed

OTHER FUNCTIONS

Sync and Freeze

TERMINATING RESISTORS

Internally selectable with wire-hook

switches

Required Accessories

ENGINEERING SET

Content:

·

GSD-file

·

Manual, data description

·

Function blocks for Step5, Step7 used

for reading and writing of parameter

and configuration data via parameter

channel.

Universal S5 Function Block for

Parameter Channel

By needs of this FB the parameter chan

nel can be used in P- and Q-tiles,

extended P-area and together with the

special function block FB IM380C.

Fig. 2 Sub-D adapter:

Fig. 4 Selection of data content by means of the Engineering Tool (process data module e, f, g):

Fig. 3 Dimensions (in mm):

96 105

160

8.8.8.8

96

M3/h

8.8.8.8

Y:ыыыыыо 55%

96

min. 0 C

60 Cmax.

-

1...16

92

max.

95% rel.

+0,8

%

+0,8

92

KS 94 PROFIBUS 3

Page 4

g

ORDERING INFORMATIONS

940

Flat pin connectors

Screw terminal connectors

9

7

8

KS 94 2

KS 94 with transmitter power supply 3

90...250V AC 4 relays

90...250V AC 3 relays + current output

3

4

24VUC4relays 7

24V UC 3 relays + current output 8

no interface 0

TTL-interface + di/do 1

RS422+di/do+clock

PROFIBUS-DP + di/do

IB+di/do

NTER US

2

3

4

no extension 0

INP3, INP4, OUT3, di/do 1

OUT3 5

no additional functions 0

measurement correction 1

measurement correction + programmer 2

Standard configuration 0

2-point controller

3-point controller

continuous controller

3-point controller (Logic/relays) 4

3-point stepping controller for 3-element control 5

continuous controller for 3-element control 6

uration to specification 9

confi

1

1

2

3

Accessory Equipement Order no..

Engineering Set German 9407-999-05201

Engineering Set Englisch 9407-999-05101

Adapter, screw terminals (max. 1,5Mbit/s) 9407-998-00021

Adapter, Sub-D 9407-998-00031

Universal S5 function block for parameter channel 9407-999-05301

Germany

PMA

Prozeß- und Maschinen-Automation GmbH

Miramstraße 87, D-34123 Kassel

Tel.: +49 561 505 - 1403

Fax: +49 561 505 - 1661

E-mail: export@pma-online.de

Internet: http://www.pma-online.de

Printed in Germany - Edition 0306 Data subject to alteration without notice 9498-737-37213

Your local distributor

Loading...

Loading...