Plymovent Junior LM-2 Product Manual

Product manual

Junior LM-2

Table of contents: Page:

Technical description........................................ 2

Delivery .......................................................... 2

Advantages ..................................................... 2

Technical data ................................................. 2

Construction and function ................................. 2

Handling ......................................................... 2

Hood operation ................................................ 2

Mounting example............................................ 3

Working area ................................................... 3

Pressure loss................................................... 3

Alternative system layouts................................. 4

Complementary products and accessories.......... 5

Mounting instruction ..................................... 6 - 9

Maintenance instruction ............................ 10 - 11

Spare part drawing ..................................... 12-13

Thank you for buying a PlymoVent product.

Before you unpack and put it into operation please read

this product manual, and follow the instructions.

THIS MANUAL SHOULD BE HANDED OVER

AND KEPT BY THE SERVICE DEPARTMENT

AFTER THE INSTALLATION!

PlymoVent Canada Inc.

6615 Ordan Drive, Unit # 3

Mississauga, Ontario L5T 1X2, Canada

Tel: +1 (905) 564 4748

Fax: +1 (905) 564 4609

USA/CAN

PlymoVent Corp.

375 Raritan Center Parkway,

Edison New Jersey 08837, USA

Tel: +1 (732) 417 0808

Fax: +1 (732) 417 1818

TECHNICAL DESCRIPTION

Junior

LM-2

Junior LM-2

The PlymoVent Junior, LM-2, is an efficient and versatile fume extractor, especially designed for

benchwork. Perfect for schools, small working booths and any area with a low ceiling height.

The extraction arm is based on a telescopic tube, allowing it to be extended to give a 2 m, 6,6'

working radius and compressed to 1m, 3,3'. The spring-balancing together with the external

counter-weight ensures that the hood stays exactly where you position it. The arm is fitted with a

spring-balance which enables it to be moved from a vertical to a horizontal position in one easy

movement.

The arm can be turned through 300° due to PlymoVent's renow-ned ball-bearing joint. This is fitted

together with an adjustable friction brake in the wall mounting bracket. All movement of the arm

is controlled from the hood. Extension hoses (FSL-1, SLE-20 or SLE-30) can easily be connected to

the arm after releasing the simple catch and removing the hood.

Delivery

The LM-2 is delivered complete with wall mounting bracket, arm, hose and hood with damper.

Advantages

• Precise and easy positioning thanks to the counterweight

system which balances the hood.

• Spring assisted vertical movement.

• Flexible working radius due to the ”telescopic” operation.

• Small and compact. Ideal for confined working areas

and low ceiling heights.

• The one and only benchwork extractor.

• Wide coverage – can easily be turned through 300°.

BSAB no: T0.31

Ser.no: LM/TB

Date: Sept-97

Replace: Jan-95

Technical data

Construction and function

A Wall mounting bracket with

ball-bearings and inlet spigot Ø160 mm, 6,3".

B Counterweight and counterweight tube.

C Arm bracket.

D Tensioned spring.

E Three-part square-section telescopic tube with plastic bushes.

F Joints with friction pads for adjustment of tension.

G Flame-proof double skin flexible hose of PVC coated woven polyamide

with internal steel spiral. (Resistant to 85°C when in continous use).

H Universal joint.

I Hood collar with manual shut-off damper.

J Hood constructed from sheet steel, with safety mesh and quick-fit coupling.

Hood opening Ø300 mm, 11,8". Large comfortable circular handle Ø300

mm, 11,8".

Prod.

no:

LM-2

Max

Length

Min

Length

1,0 m,3,3'2,0 m, 6,6'

Hose

Diameter

Handling

1. 360° ring handle for positioning of the

hood. Can be reached from all sides.

2. Damper control knob.

3. Quick-fit catch for simple exchange

of extension hose and hood.

4. Switch for light cartridge

(seeaccessories HL-20/24).

5. Switch for manual start/stop

of fan or damper (see accessories

SA-24, ES-90 or ASE-12).

Recommended Airflow at

the Hood in m3/h/ cfm

800-1200 m3/h, 470-706 cfm160 mm,6,3"

Hood operation

The black enamelled ano-dised metal

hood can be angled 110° forwards,

backwards and to the sides. Large,

360°, ring handle, Ø300 mm, 11,8".

LM/USA/CAN/2/13

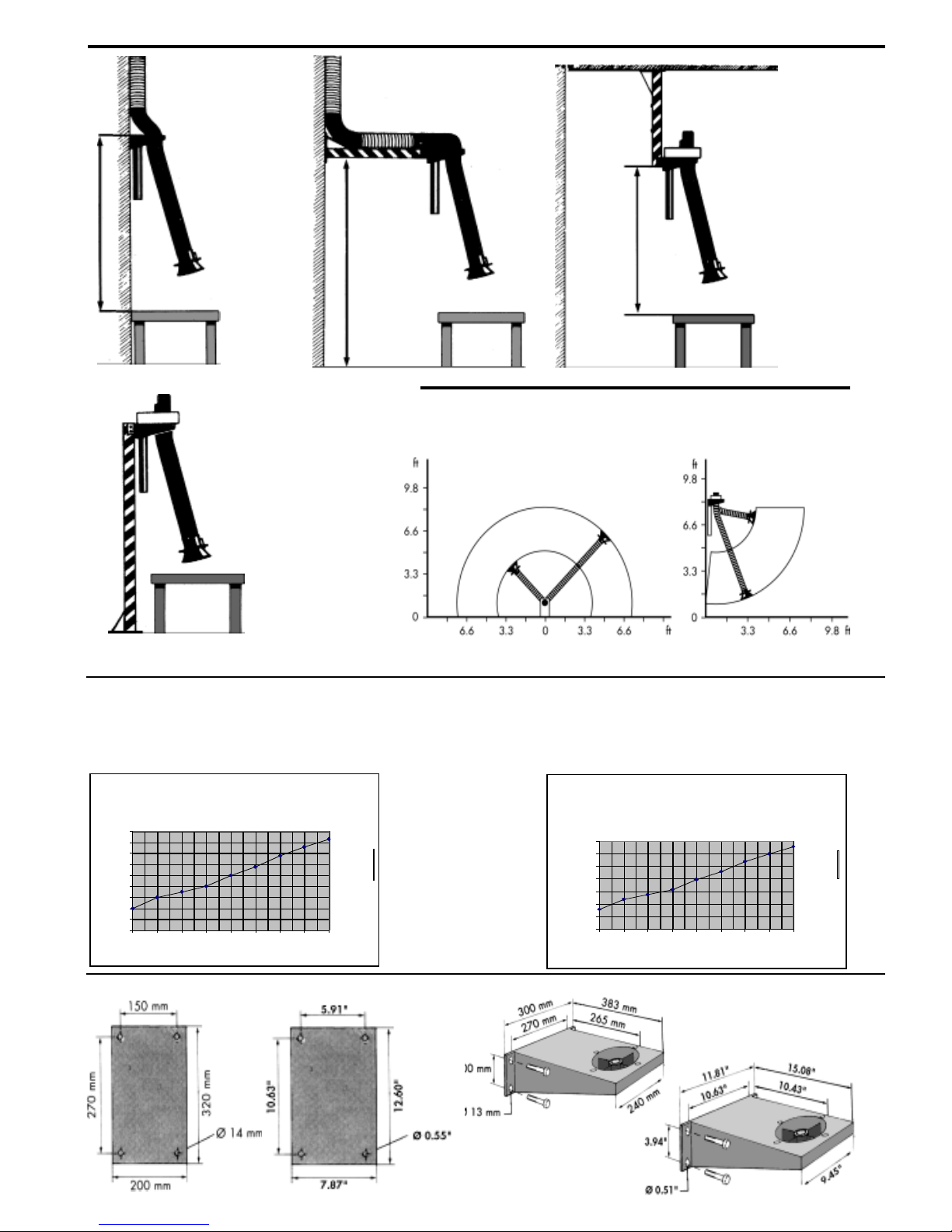

Mounting Example

h

Wall mounted LM-2 with

standard mounting bracket.

Floor mounted LM-2 with

stanchion PA-220 and separate fan.

Wall mounted LM-2

with stanchion PA-110

or PA-220.

LM-2 Working Area

Ceiling mounted LM-2

with stanchion PA-110 or

PA-220 and separate fan.

Pressure Loss

The pressure loss diagram below shows

the average

pressure loss through the LM-2.

Welding: 800-1200 m3/hr.

Pressure loss diagram

900

800

700

600

500

400

300

200

100

0

700 800 900 1000 1100 1200 1300 1400 1500

Air flow m◊/

PA-110 and PA-220 mounting plate

The following aspects

affect the pressure loss

in PlymoVent's LM-2.

:

1. The air volume.

2. The number of bends

Welding: 470-706 cfm.

and the extent of

these.

3,5

3

2,5

2

1,5

1

0,5

0

200 300 350 400 500 580 680 760 830

LM-2 wall mounting bracket dimensions

Pressure loss diagram

Air flow cfm

LM/USA/CAN/3/13

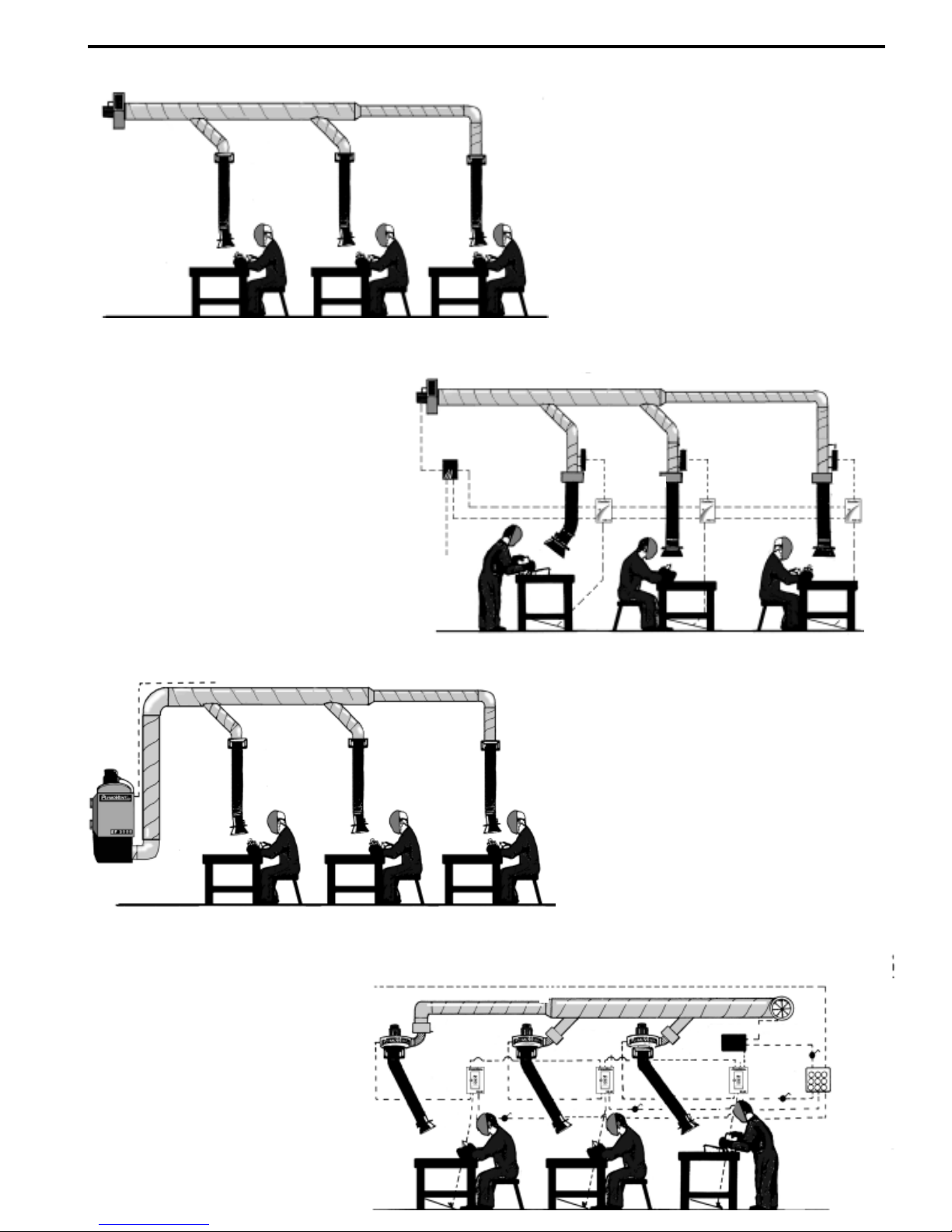

Alternative System Layouts

Alt. 1

Central system: 3 X LM-2 with one

central FS-4700 fan.

Recommended fan per no of arms:

FS-3000: 2-3 arms.

FS-4700: 3-4 arms.

FA-6000: 4-5 arms.

Alt. 2

Central system: 3 X LM-2 fitted with ASE-12

automatic dampers, M-1000 control unit

and one central fan.

Recommended fan per no. of arms:

FS-2100: 2-4 arms.

FS-3000: 3-6 arms.

FS-4700: 4-8 arms.

FA-6000: 4-8 arms.

As every working-place is unique, the above

recommendations are only applicable for

theoretically calculated examples.

Alt. 3

AC 230/400 V 3~

Central fan

Control unit

M-1000

AC 230 V 1~

AC 230/400 V 3~

Interlink 12V

Motorised

damper 24 V

ASE-12

ASE-12

Central system: 3 X LM-2 connected

to one electrostatic filter EF type.

Recommended filter per no. of arms:

EF-2000: 1-2 arms*

EF-3000: 1-3 arms*

EF-5000: 2-5 arms*

When more stations are required the system

can be fitted with ASE-12 automatic dampers.

ASE-12

Alt. 4

Central system: 3 X LM-2 fitted with separate

fans and ES-90 energy savers, interlinked to

a control unit M-1000 for switching the

centralised low pressure fan.

See technical data sheet on energy

saver ES-90 for further information.

Back draught damper

Interlink 12 V

ES

90

*For continuous use.

ES

90

AC 230/400 V 3

´Low pressure fan

Control unit M 1000

ES

90

LM/USA/CAN/4/13

Main

fuse

box

Loading...

Loading...