EQP-102

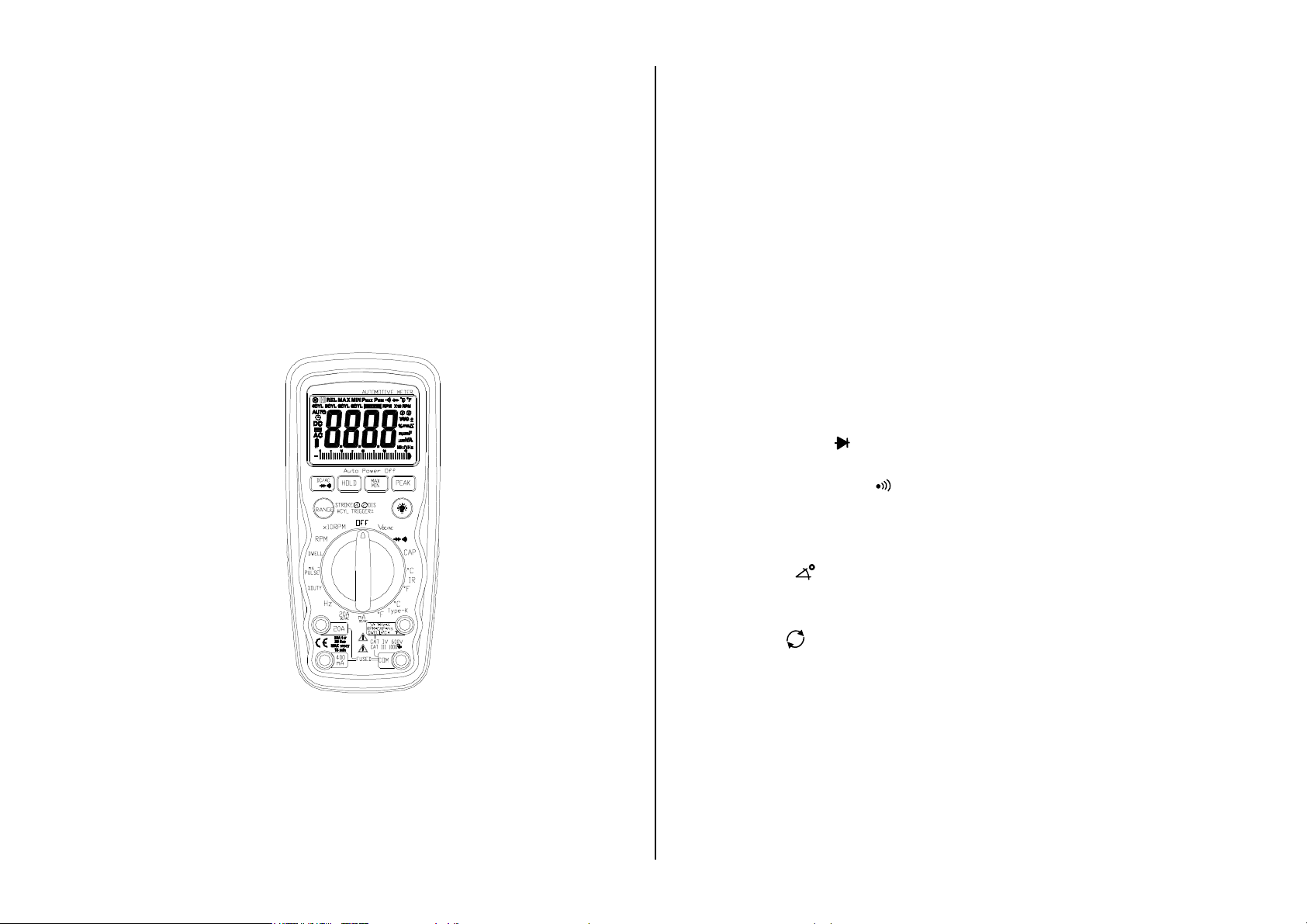

AUTOMOTIVE MULTIMETER

Ω

Ω

USER MANUAL

Contents

Introduction……………………………………………………………………….1

Safety………………………………………………………………………………2

Getting Started…………………………………………………………………6

Digital LCD Display………………………………………………………………7

Front Panel Description…………………………………………………………7

LCD Symbols……………………...…………………………………………………8

Push-button Functions……………………………………………………9

Mode Button…………………………………………………………9

Manual range & Stroke 4/2,Hz,%,ms,CYL Button………………………… 9

Data Hold /Backlight Button………………………………………………9

Relative Button………………………………………………………………11

Meter Functions

Voltage (V)……………………………………………………………………12

Resistance (Ω) ………………………………………………………………13

Diode Check( )……………………………………………………………14

Capacitance(CAP) …………………………………………………………15

Audible Continuity ( )……………………………………………………16

AC or DC Current (A) ………………………………………………………17

Temperature (0C /0F) ………………………………………………………18

Frequency (Hz) ……………………………………………………………19

Dwell ( )…………………………………………………………………20

Duty Cycle (%)………………………………………………………………21

Ms – PULSE……………………….………………………………………22

RPM ( ) ……………………………………………………………………24

IR Temperature Probe……………………………………………………….25

General Specifications…………………………………………………………30

Electrical Specifications…………………………………………………………31

Replacing the Battery…………………………………………………………34

Battery Installation…………………………………………………………35

Replacing the Fuses………………………………………………………………35

Trouble Shooting…………………………………………………………………36

-1 0

his chapter covers brief, introductory information, You will find:

Safety precautions

Ω

Safety

DANGER

Engines produce carbon monoxide which

is odourless, cause’s slower reaction time,

and can lead to serious injury. When the

engine is operating, keep service areas

WELL VENTILATED or attach the vehicle

exhaust system to the shop exhaust

removal system.

Set the parking brake and block the

wheels before testing or repairing the

vehicle. It is especially important to block

the wheels on front-wheel drive vehicles;

the parking brake does not hold the drive

wheels.

Ω

Wear an eye shield when testing or

repairing vehicles.

Exceeding the limits of this meter is

dangerous. This will expose you to serious

or possibly fatal injury. Carefully read and

understand the cautions and the

specification limits of this meter.

Voltage between any terminal and ground

must not exceed 600V DC or 600V AC.

Use caution when measuring voltage above 25V DC or 25V AC.

Circuit tested must be protected by a 20A fuse or circuit breaker.

Do not use the meter if it has been damaged.

Do not use the test leads if the insulation is damaged or if metal

is exposed.

1 2

Safety Cont’d…

Function

TEMP. Adaptor,

Safety Cont’d…

Danger

Avoid electrical shock: do not touch the test

leads, tips or the circuit being tested.

Do not try a voltage measurement with the

test leads in the 20A or the mA terminal.

When testing for the presence of voltage or current, make sure

the meter is functioning correctly. Take a reading of a known

voltage or current before accepting a zero reading.

Choose the proper range and function for the measurement. Do

not try voltage or current measurements that may exceed the

ratings marked on the Function/Range switch or terminal.

When measuring current, connect the meter in series with the

load.

Never connect more than one set of test leads to the meter.

Disconnect the live test lead before disconnecting the common

test lead.

The mA and the 20A terminals are protected by fuses. To avoid

possible injury or damage, use only in circuits limited to 400mA

or 20A for 30 seconds.

See also…

Fuse Replacement

IMPORTANT

To maintain accuracy of the meter, replace the discharged

battery immediately when the battery symbol “BAT”

appears on the meter display.

Avoid measuring error from outside interference. Keep the

meter away from spark plug or coil wires.

Avoid damaging the meter when testing voltage. Disconnect

the test leads from the test points before changing functions.

Do not exceed the limits shown in the table below:

Terminal Input limit

DC/AC Volts,

Ohm/Continuity

/Diode,CAP.,IR-

V-Ω-RPM

Type-K

TEMP.,Hz,%Duty,

Ms Dwell, RPM

AC/DC μA mA μA / mA 400mA DC/AC

AC/DC20A 20A *20A DC/AC

* 20Amp measurement for 30 seconds maximum.

① Ohms can not be measured if voltage is present, ohms

can be measured only in a non-powered circuit. However,

the meter is protected to 600 volts.

600VoltsAC DC

3 4

Notes:

Getting Started

his chapter will help you get started. It describes the basic

functions of the Meter.

Ω

Ω

5 6

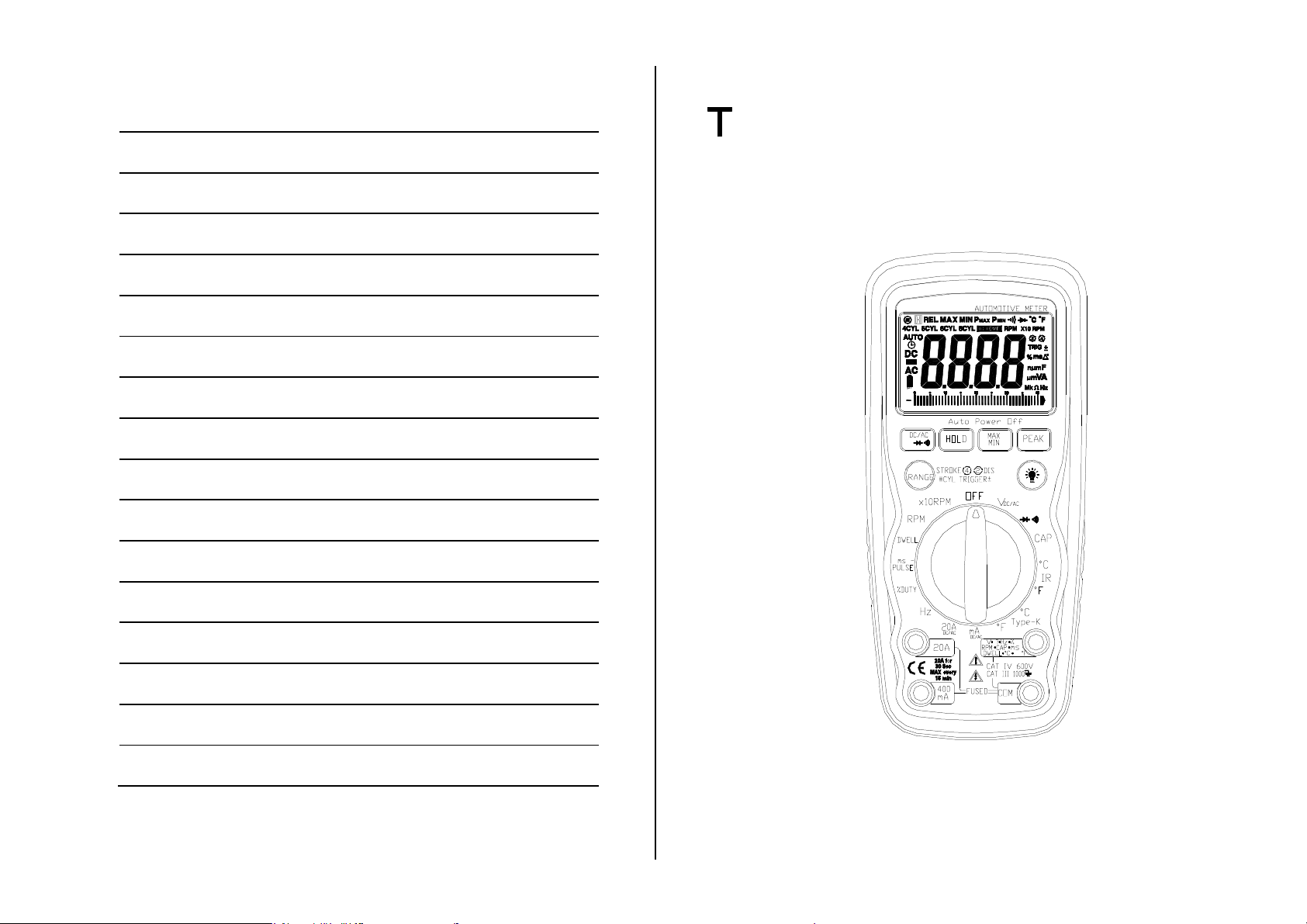

Meter Basics

1.Digital LCD display

Display features:

1a. Symbols to identify function

1b. Four character digital display

The digital display is best for

stable input. The bar graph is best

for rapidly changing input.

2.Function buttons

Press the button to select a

function. A symbol will display to

verify your choice.

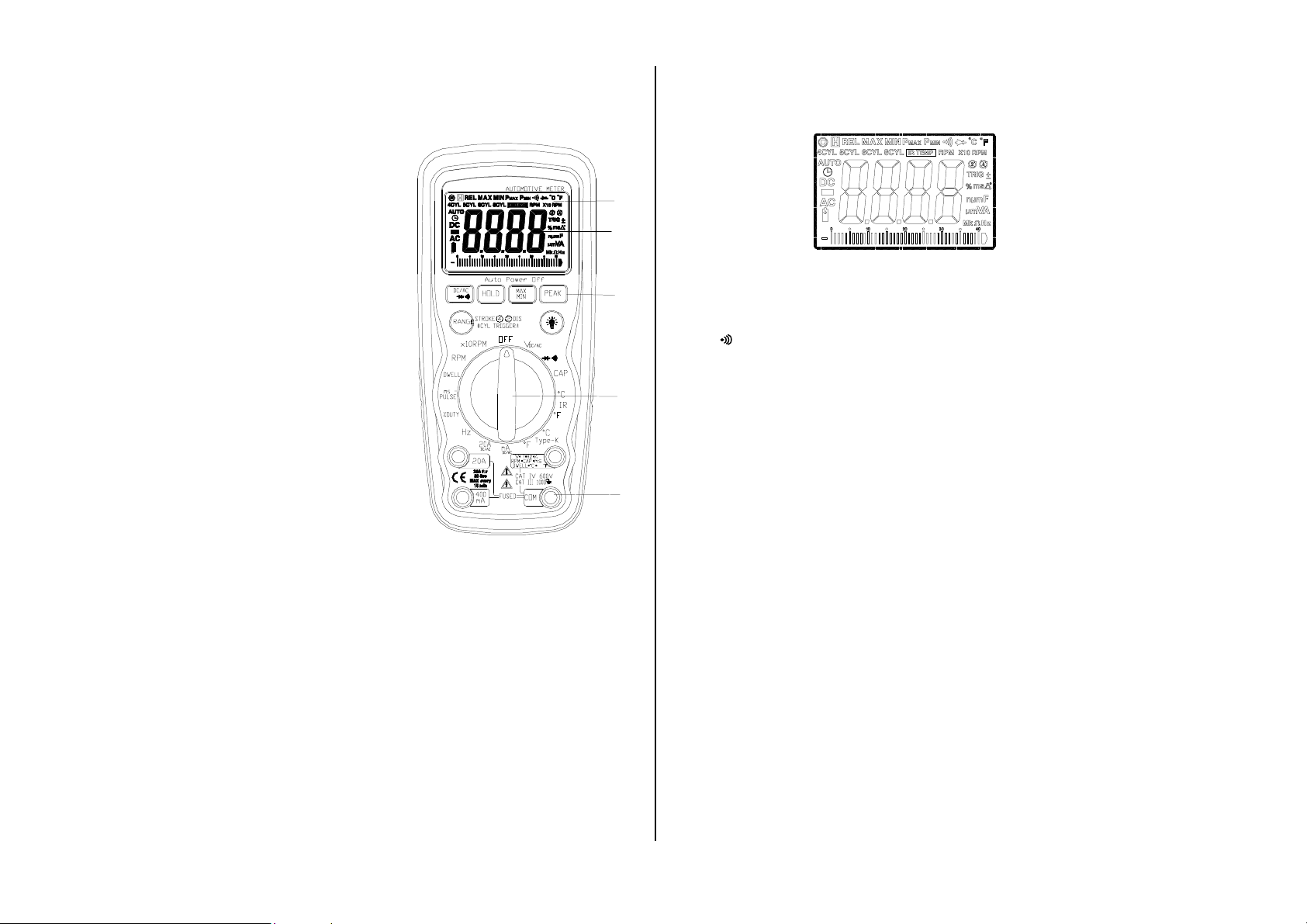

LCD DISPLAY SYMBOLS AND ANNUNCIATORS

1a

1b

Ω

Ω

2

-8.8.8.8 LCD display reading

Continuity

BAT Low Battery

3

DATAHOLD Data Hold

AUTO Auto Ranging

Diode

3.Rotary Selector Switch

Turn this switch to select a

function or turn the meter OFF.

4.Volts Terminal

The Red test lead is used to

measureAmps, Volts, Ohms,

TEMP, Hz, RPM, Cap, mS and

Dwell.

The Black test lead is used in the

Common (COM) terminal for

all tests

7 8

4

AC Alternating Current or Voltage

DC Direct Current or Voltage

n nano (10-9) (capacitance)

µ micro (10-6) (amps, cap)

m milli (10-3) (volts, amps) A Amps

k kilo (103) (ohms) F Farads (capacitance)

M mega (106) (ohms) Ohms

Hz Hertz (frequency) V Volts

% Percent (duty ratio)

ºF Degrees Fahrenheit

ºC Degrees Centigrade

IR TEMP Infrared Temperature

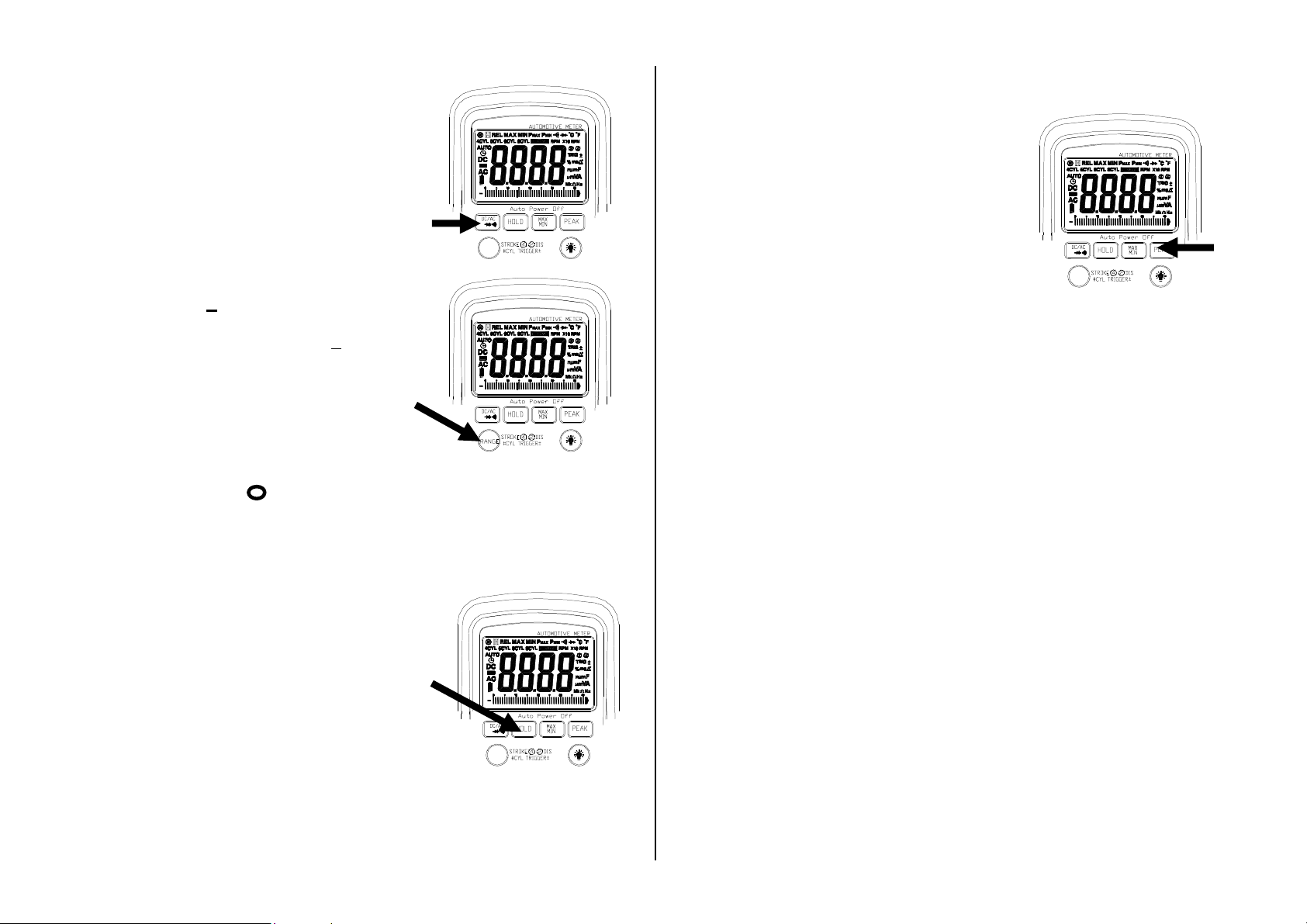

Push–button Functions

Mode Button

Press the mode pushbutton to select

the following functions;

DC/AC Voltage, DC/AC Current

Resistance, Diode, Continuity &

Capacitance

Manual Range & Stroke 4/2(DIS),

Hz, %, ms +, CYL Button

Press to this button to select;

STROKE 4, 2DIS, Hz ,%, ms+ ,

CYL range & V/A/ Resistance

manual Range

Manual Ranging

The meter turns on in the auto ranging mode.

Press the Range button to go to manual ranging.

The display icon " " will appear. Each press of the range button

will step to the next range as indicated by the units and decimal

point location. Press and hold the Range button for two seconds to

return to auto ranging.

Ω

Ω

Peak Hold

The Peak Hold function captures

the peak AC or DC voltage or current.

The meter can capture negative

or positive peaks as fast as

1 millisecond in duration.

Ω

1. Turn the function switch to the A or V position.

2. Press and Hold the PEAK button until “CAL” appears

in the display. This procedure will zero the range

selected & meter go to manual ranging.

3. Press the PEAK button, Pmax will display.

4. The display will update each time a higher positive

peak occurs.

5. Press the PEAK button again, Pmin will display. The

display will now update and indicate the lowest

negative peak.

Data Hold

The Data Hold function allows the

meter to "freeze" a measurement for

later reference.

1. Press the DATA HOLD button to

“freeze” the reading on the indicator.

The indication of “HOLD” will appear

in the display.

2. Press the DATA HOLD button

again to return to normal operation.

9 10

6. To return to normal operation, press and hold the

PEAK button until the Pmin or Pmax indicator

switches off.

Note: If the Function switch position is changed after a

calibration the Peak Hold calibration must be repeated for the

Ω

new function selected.

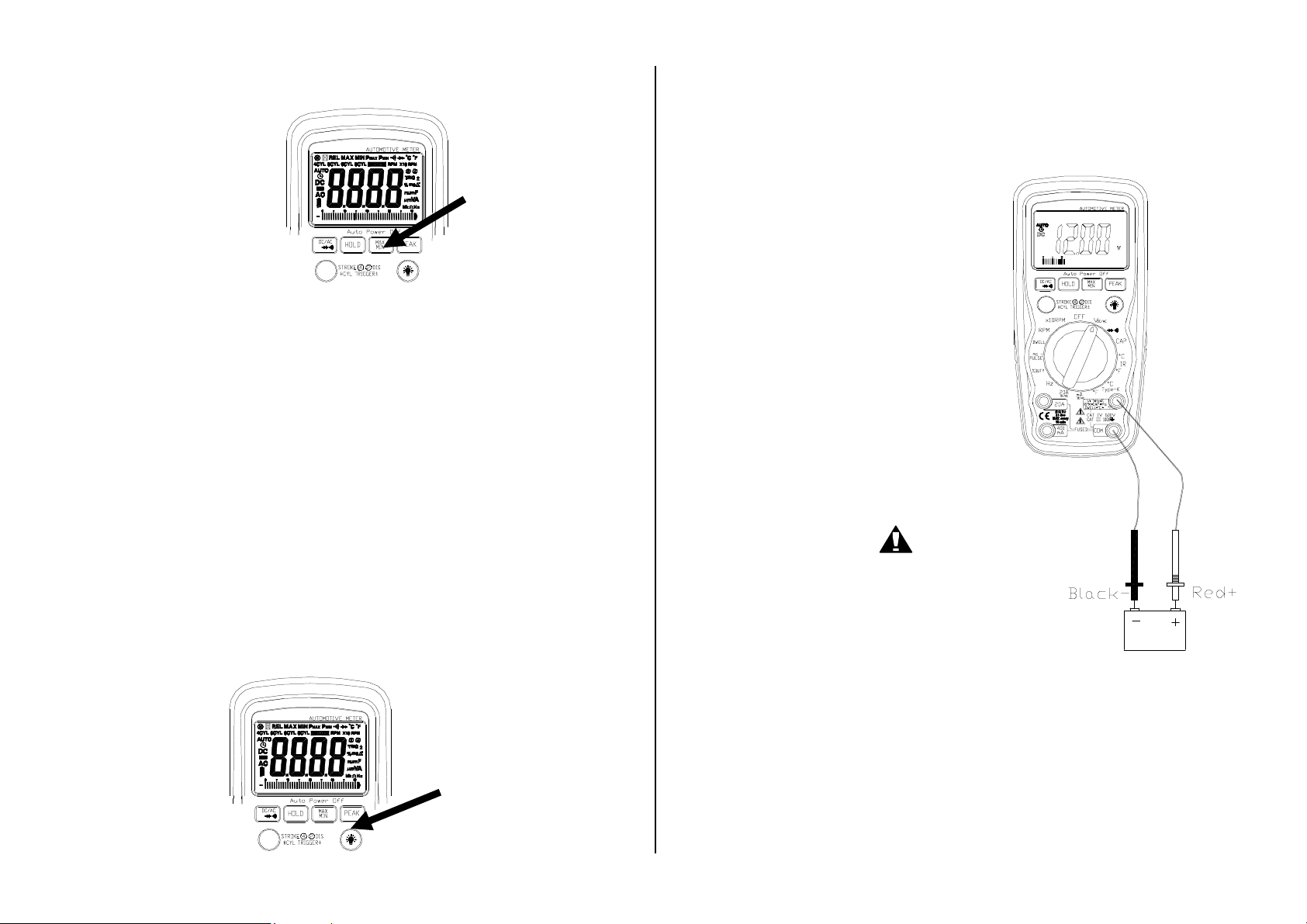

MAX/MIN

WARNING

measuring voltage,

be sure the Red test lead is

in the terminal marked “V”.

If the test lead is in an Amp

terminal, you may be

injured or the meter

Ω

1. Press the MAX/MIN key to activate the MAX/MIN

recording mode. The display icon "MAX or MIN" will

appear. The meter will go to manual ranging & display and

hold the maximum or minimum reading and will update

only when a new “max or min” occurs.

2. Press the MAX/MIN key and a blinking “MAX MIN” will

appear. The meter will display the present reading, but will

continue to update and store the max and min readings.

To exit MAX/MIN mode press and hold the MAX/MIN key for 2

seconds.

Meter Functions - Voltage (V)

Select the Volts “ V” range with

the rotary switch.

The meter will automatically

select the best voltage (V) range.

Select DCV or ACV with the

MODE button.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal

Touch the Black probe to ground or

to the negative (-) circuit

Touch the Red probe to the circuit

coming from the power source

IMPORTANT: Voltage must be

measuring in parallel (Red probe

measuring circuit from power

source).

When

Ω

Ω

Backlight Button

1. Press the BACKLIGHT button to turn the backlighting ON.

2. Press the BACKLIGHT button again to turn the backlighting

OFF.

(A) or Milliamp (mA)

damaged.

Ω

11 12

Meter Functions – Resistance (Ω)

IMPORTANT: If you are testing

an application that has capacitors

in the circuit, be sure to turn the

power OFF on the test circuit and

discharge all capacitors. Accurate

measurement is not possible if

external or residual voltage is

present.

Select the Resistance “ Ω”

range with the rotary switch.

Ω

Meter Functions –Diode Check ( )

IMPORTANT: Turn the power OFF to

the test circuit

Select the Diode Check “ “

function with the rotary switch and

mode button.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal.

Ω

Touch the Black test probe to the

negative (-) side of the diode.

Touch the Red test probe to the positive

(+) side of the diode. Reverse the probes:

Black to the positive

(+) side and Red to the negative (-) side.

Ω

Ω

Select the Resistance “Ω”

function with the Mode button.

Please note the unit defaults to

resistance.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal.

Touch the test lead probes across

the resistor to be tested.

13 14

Note:

A “good” diode will read low in one

`direction and high in the other direction

when the probes are reversed (or vice

versa).

A defective diode will have the same

reading in both directions or read

between 1.0 to 3.0 V. in both directions

Reverse

Probes

Diode - to +

Good

.4 to .9V OL

OL .4 to .9V

OL 1.0 to 3.0V

1.0 to 3.0V OL

.4 to .9V .4 to .9V

Bad

OL OL

.000V .000V

+ to -

Meter Functions – Capacitance ( CAP )

IMPORTANT: Turn the power OFF to

the test circuit

select the Capacitance “ CAP “

function with the rotary switch and

mode button

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal

CAUTION: When checking in-circuit

capacitance, be sure

that the circuit has all power

removed and all capacitors are

fully discharged.

Touch the test lead probes across the

capacitance circuit to be tested.

Read the measured value from the

LCD display.

Note:

1. The bar graph is disabled in capacitance measurement mode.

However, since the measurement time of 4mF and 40mF

modes is quite long (3.75s and 7.5s respectively,

to be precise,) the bar graph is used to display

the time rest to accomplish the measurement.

2. In order to obtain an accurate reading,

a capacitor must be discharged before measurement begins. The meter has a

built-in discharge mode to automatically discharge the capacitor. In discharge

mode, the LCD displays “DIS.C”

3. Discharging through the chip is quite slow. We recommend the user to

discharge the capacitor with some other apparatus.

Ω

Ω

Meter Functions –Audible Continuity ( )

IMPORTANT: Turn the power

OFF on the test circuit

Select the Audible Continuity

“ “ function with the rotary

switch and mode button.

Insert:

Black lead in COM terminal.

Red lead in V-Ω-RPM terminal.

Connect one test probe to each

end of the circuit to be tested.

Circuit complete, the meter will

beep continuously.

Circuit open, there is no beep

and the display shows to OL

(over limit).

Ω

Ω

15 16

Meter Functions –AC or DC Current (A)

N

ote:

Current must always be

measured with the meter test

probes connected in series,

IMPORTANT: All current measured

flows through the meter.

It is important that you do not:

Measure current greater than

600 Volts AC or DC, with

respect to ground.

Do Not Exceed 30 seconds

when measuring continuous

current between 1A-20A.

Allow five minutes for cool

down before continuing.

Select the “20A” or “mA”

range with the rotary switch.

Ω

Meter Functions –Temperature (0C/0F )

IMPORTANT: To avoid heat

damage to the meter, keep

it away from sources of

very high temperature. The

life of the Temperature

Probe is also reduced

when subjected to very

high temperatures. Probe

operating range is

–58oto 482oF.

Ω

Select the Temperature

“0C or0F” function with the

rotary switch.

Ω

Ω

Press the Mode button to

select AC or DC.

Insert:

Black lead in COM terminal.

Red lead in the 20A or mA

terminal (select 20A if you are

unsure of the current draw).

IMPORTANT: Turn OFF all power

to the circuit or disconnect the

circuit from the power source.

Connect:

The Red probe to the side of the

circuit closest to the power

source.

The Black probe to the side of

the circuit to ground.

Turn the power ON and test.

Insert the temperature probe

connector into the K-type

thermocouple adapter.

Insert the adapter into the

front of the meter as shown.

Touch the end of the

temperature sensor to the area

or surface of the object to be

measured.

as described.

17 18

Meter Functions –Frequency (Hz)

Meter Functions-Dwell ( )

Selectthe “Hz” Frequency

function with the rotary

switch.

Insert:

Blackleadin COM terminal.

Red leadinV-Ω-RPM terminal.

Connect the Black test probe

to ground.

Connect the Red test probe to

the “signal out” wire of the

sensor to be tested.

Select the “DWELL”

function with the rotary

switch.

Insert:

Auto Power Off

Ω

4 2

V

Ω

Black lead in COM terminal.

Red lead in V-Ω-RPM

terminal.

Connect the Black test probe to

ground.

Ω

Ω

Connect the Red test probe to

V

the wire that connects to the

breaker points (see illustration).

Black-

"Signal Out"

Side

"Voltage In"

Red+

Ground

Side

19 20

Meter Functions-Duty Cycle (%)

Meter Functions- ms-PULSE (Pulse Width) &

Select the “% Duty” Cycle

function with the rotary switch.

Insert:

Black lead in COM terminal.

Red leadin V-Ω-RPM terminal.

Connect the Black test probe to

ground.

Connect the Red test probe to

the signal wire circuit.

The illustration for a mixture

control solenoid is shown with the

metering rod in the closed

position. The meter will display

the percentage of time the

plunger is in the closed position.

(low duty cycle) during one duty

cycle.

ms- PERIOD (Period)

Pulse Width is the length of time an actuator is energized. For

example, fuel injectors are activated by an electronic pulse from

the Engine Control Module (ECM).

This pulse generates a magnetic field that pulls the injectors nozzle

Ω

Ω

valve open.

The pulse ends and the injector nozzle is closed.

This open to close time is the Pulse Width and is measured in

milliseconds( ms).

The most common automotive application for measuring pulse

width is on fuel injectors.

You can also measure the pulse width of the fuel mixture control

solenoid and the idle air control motor.

This exercise shows how to measure Pulse Width on Port Fuel

injectors.

(continued on next page)

21 22

To measure pulse width (mS):

242

Select the “mS-Pulse”

function with the rotary

switch.

Press the ±TRIG button for 2

seconds until the negative (-)

trigger slope is displayed on

the upper left side of the

display.

NOTE: The applied time for

most fuel injectors is

displayed on the

negative (-) slope.

Insert:

Black lead in COM jack.

Red lead in V-Ω-RPM jack.

Ω

Meter Functions-RPM/×10RPM

Select the RPM range with the

rotary switch.

OR

Select the×10RPM range with

the rotary switch (1,000 to

12,000 RPM). Multiply the

displayed reading by ten to get

actual RPM.

Ω

Press STROKE / DIS

button to select through

4

RPM for 4-stroke, RPM

for 2-stroke and DIS ignitions.

Insert the inductive pickup

connecting terminal into the

meter.

Black lead in COM terminal.

Ω

Ω

Connect:

Jumper wires between the fuel

injector and the harness

connector.

Black test probe to a good

ground at the fuel injector or the

negative (-) vehicle battery post.

Red test probe to the fuel

injector solenoid driver input on

the jumper cable.

Startthe engine. A pulse width in

milliseconds should be read.

Note: Initially, the unit will read

“OL”, then readings will descend

and stabilize to the actual pulse

width. If “OL” remains,

re-check your connections.

23 24

Red lead in V-Ω-RPM

terminal.

Connect the inductive pickup to

a spark plug wire. If no reading

is received, unhook the clamp,

turn it over and connect again.

Note:

Position the inductive pick-up as far away from the distributor and the

exhaust manifold as possible.

Position the inductive pick-up to within six inches of the spark plug or move

it to another plug wire if no reading or an erratic reading is received.

RPM 4 : For RPM of 4-stroke engines which have 1 ignition on

every 4 engine strokes

RPM 2: For RPM of DIS (Distributor less ignition System) &

2-stroke engines which Have 1 ignition on every 2

engine strokes

PLEASE NOTE- THE RPM PICK-UP HAS AN ADJUSTABLE SENSITIVITY

SWITCH THAT CAN ALSO BE USED TO CORRECT AN

UNSTABLE READING.

Meter Functions – Non-contact Infrared

Infrared Temperature Probe Introduction

Temperature (0C /0F )measurements

Ω

Ω

Infrared

Temperature

Probe

The Infrared Temperature Probe is a noncontact temperature measurement

accessory for use with a test instrument capable of measuring DC volts in the

millivolt range (200mV/400mV/600mV/2V/4V/6V range). The probe has a

temperature range of -30°C to 550°C (-22°F to 1022°F), with a basic accuracy

of 2% of reading, and an output of 1 mV dc per °C or °F.

Temperature is measured by pointing the probe at the surface to be measured,

and reading the temperature on the test instrument display.

Compatibility

The probe is compatible with all DC millivolt measuring instruments or this

automotive meter. Infrared Temperature (0C/0F ) ranges measuring

instruments that have a minimum of 1 MΩ input impedance and accept safety

shrouded, standard diameter 0.16 in. (4 mm) banana plugs

Field of View

The meter’s field of view is 8:1, meaning that if the meter is 8 inches from the

target, the diameter of the object under test must be at least 1 inch. Other

distances are shown below in the field of view diagram. Refer to the chart

printed on the meter for more information.

Field of View

Make sure that the target is larger than the unit’s spot size. The smaller the

target, the closer you should be to it. When accuracy is critical, make sure the

target is at least twice as large as the spot size

25 26

SAFETY

Use extreme caution when the laser beam is turned on.

Do not let the beam enter your eye, another person’s eye or the eye of

an animal.

Be careful not to let the beam on a reflective surface strike your eye.

Operation

To take a measurement, perform the following steps:

1. Plug the red connector into the V mV dc input jack and the black connector

into the common or ground input jack on the test instrument.

2. Select Infrared Temperature (0C /0F ) or mV dc range on the test

instrument.

3. Press the probe button laser, the Infrared Temperature Probe ON

4. Point the tip of the probe as close as possible to the object being measured

without touching the object.

5. Read the test instrument display.

C

F

C

¡ã

F¡ã

¡ã¡ã

Additional considerations are:

Release the probe button laser and the Infrared Temperature Probe OFF

the DMM display will show 0°C or 0°F or 0mV.

The temperature scale can be changed to °C or °F by removing the

battery from the battery compartment and moving the internal °C/°F

switch to the desired position.

9V

If the test instrument displays an overload condition, switch the DMM

range from mV dc to V dc. Increasing the range to V dc moves the

decimal position three places to the left (500°F displays as 0.500V).

Note: Measurement considerations

Holding the meter by its handle, point the IR Sensor toward the

object whose temperature is to be measured. The meter

automatically compensates for temperature deviations from

ambient temperature. Keep in mind that it will take up to 30

minutes to adjust to wide ambient temperatures are to be

measured followed by high temperature measurements,

sometime (several minutes) is required after the low (and

before the high) temperature measurements are made.

This is a result of the cooling process which must take place for the IR

sensor.

27 28

C) whichever is

Note: Accuracy is specified for the following

64 to 82°F (18 to

General Specifications

Response rate 0.5 second approx.

Operating Temperature

32°F to 122°F (0°C to 50°C)

Operating Humidity Max. 80% RH.

Power Supply 9V battery

Weight 182g

Size 164 x 50 x 40mm

Infrared Thermometer Specifications

Range -30 to 550oC/-22 to 1022oF

Output 1mV=1oC or 1oF

Accuracy ± 2% of reading or ± 4oF (2

greater.

ambient temperature range:

28°C)

Emissivity 0.95 fixed value

Field of View D/S = Approx. 8:1 ratio (D = distance, S = spot)

(Has 90% encircled energy at the focal point)

Laser power Less than 1mW

Spectral response 6 to 14 µm (wavelength)

BATTERY REPLACEMENT

② As battery power is not sufficient, LED show will “ ON ” replacement with

one new battery type 9V is required.

o

General Specifications

General Specifications

The instrument complies with: IEC 1010-1 EN61010-1.

Insulation: Class2, Double insulation.

Overvoltage category: CATIII1000V/CATIV600V.

Display: 4000 counts LCD display with function indication.

Polarity:Automatic, (-) negative polarity indication.

Overrange: “OL” mark indication.

Low battery indication: The “BAT” is displayed when the battery

voltage drops below the operating level.

Measurement rate: 2 times per second, nominal.

Auto power off: Meter automatically shuts down after approx. 30

minutes of inactivity.

Operating environment: 0oC to 50oC (32oF to 122oF) at <

70 % relative humidity.

Storage temperature: -20oC to 60oC (-4oF to 140oF) at < 80 %

relative humidity.

For inside use, max height: 2000m

Pollution degree: 2

Power: One 9V battery , NEDA 1604, IEC 6F22.

Dimensions: 182 (H) x 82 (W) x55 (D) mm

Weight: Approx.: 375g.

② Open battery cover, then take out the battery from instrument and replace

with a new 9-Volt battery and place the battery cover back.

29 30

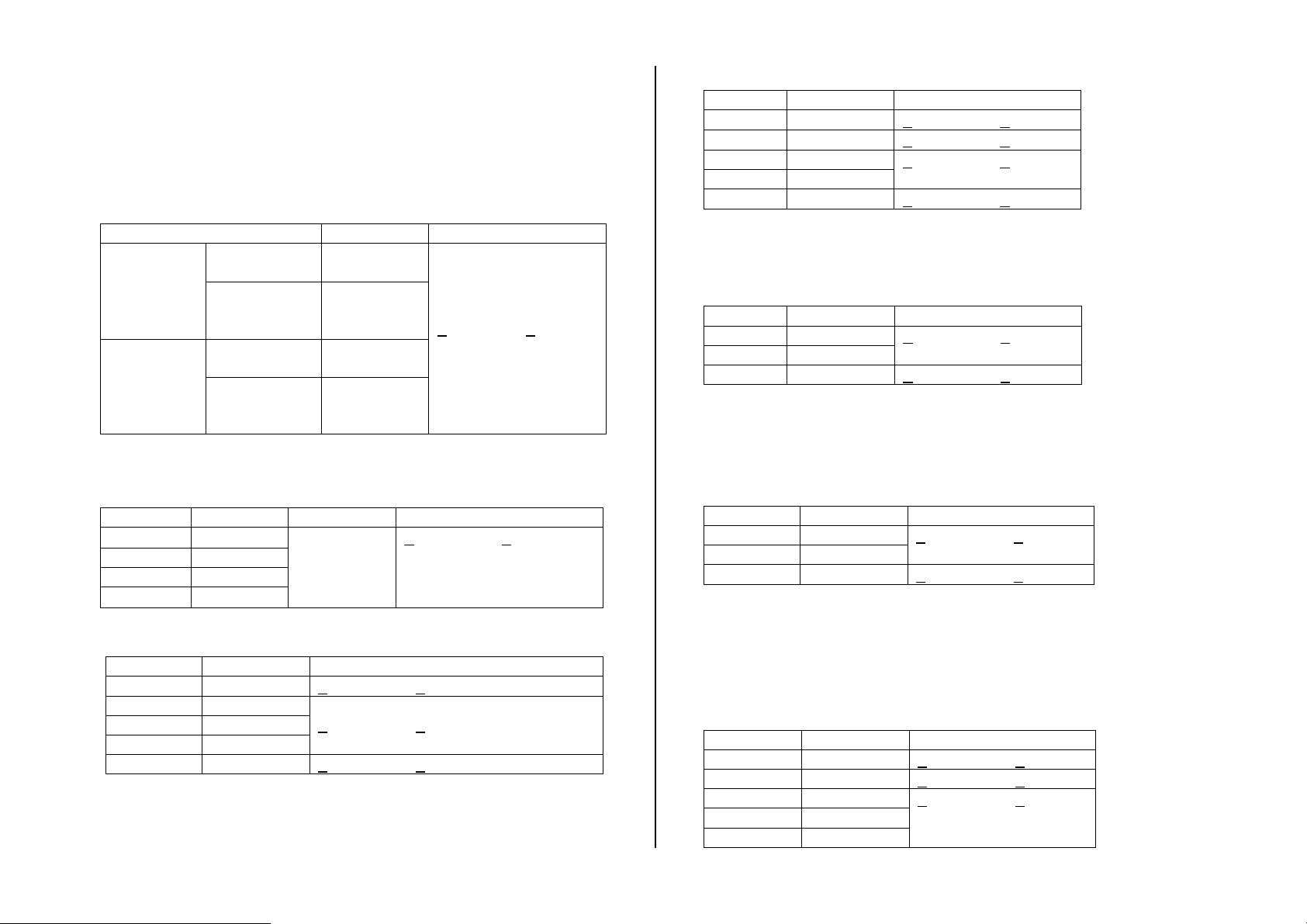

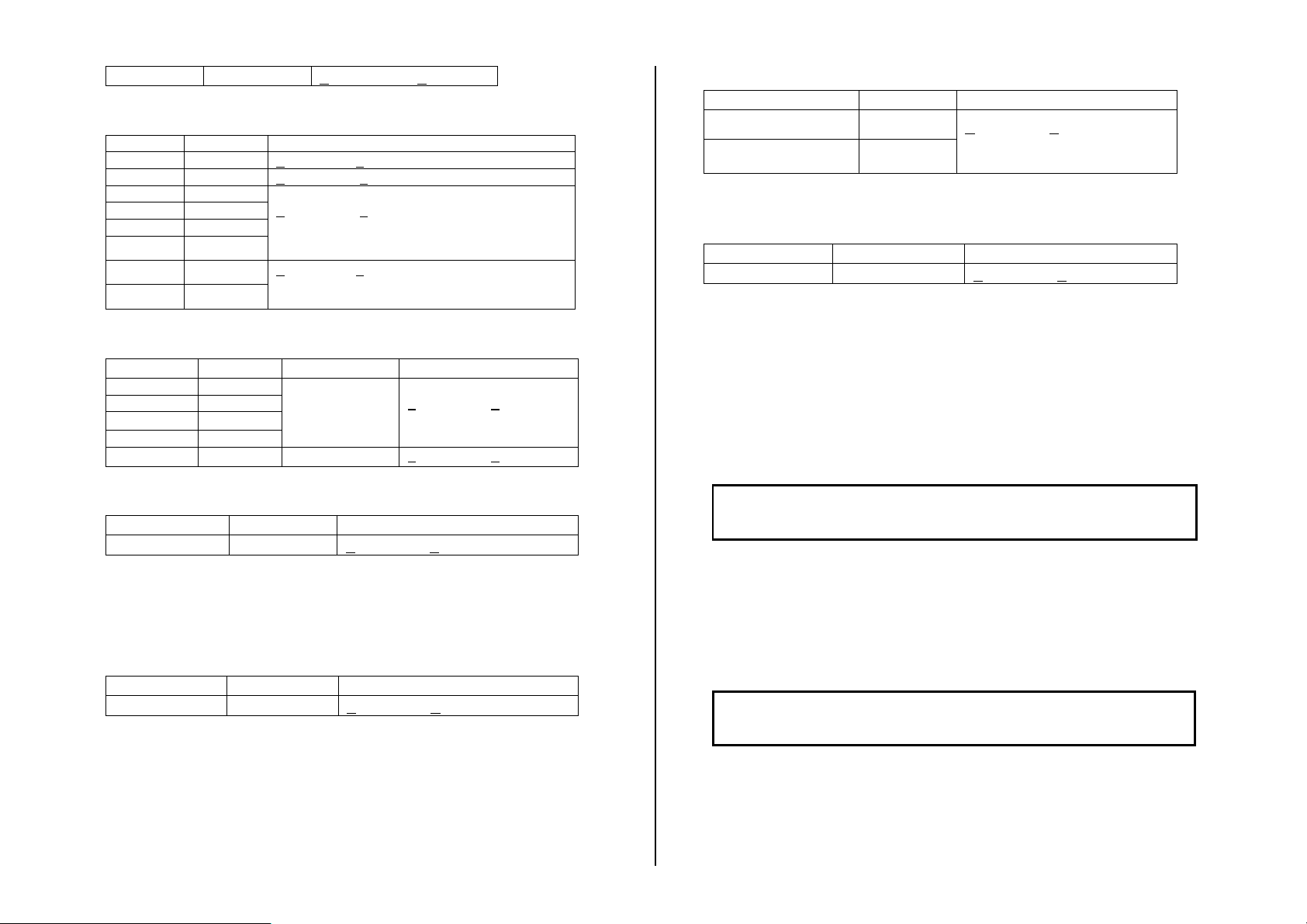

Electrical Specifications

Electrical Specifications

*Accuracy is given as ± ([% of reading] + [number of least

significant digits]) at 18 to 28℃ (65F to 83F), with relative

humidity up to 70%.

RPM (Tach)

Range Resolution Accuracy

600~4000

RPM 4

RPM 2/DIS 300~4000

Effect Reading: >600 RPM

RPM

1000~12000

RPM

(X10 RPM)

RPM

1000~6000

RPM

(X10 RPM)

1 RPM

10 RPM

+2 % of rdg + 4 dgts

1 RPM

10 RPM

AC Voltage

Range Resolution Accuracy

400.0mV 0.1mV +1.5% of rdg + 5 dgts

4.000V 1mV +1.0% of rdg + 3 dgts

40.00V 10mV +1.5% of rdg + 3 dgts

400.0V 100mV

600V 1V +2.0% of rdg + 4 dgts

Input Impedance: 10MΩ.

Frequency Range: 50 to 60Hz

DC Current

Range Resolution Accuracy

40.00mA 10uA +1.5% of rdg + 3 dgts

400.0mA 100uA

20A 10mA +2.5% of rdg + 5 dgts

Overload Protection: 0.5A / 250V and 20A / 250V Fuse.

Maximum Input: 400mA dc or 400mA ac rms on uA / mA

ranges,20Adc or ac rms on 20A range.

DEWLL ANGLE

Cylinder Range Resolution Accuracy

4CYL 0~90.0° 0.1° +2.0% of rdg + 4 dgts

5CYL 0~72.0°

6CYL 0~60.0°

8CYL 0~45.0°

DC Voltage

Range Resolution Accuracy

400.0mV 0.1mV +0.5% of rdg + 3 dgts

4.000V 1mV

40.00V 10mV

400.0V 100mV

600V 1V +1.8% of rdg + 2 dgts

Input Impedance: 10MΩ

+1.5% of rdg + 2 dgts

31 32

AC Current

Range Resolution Accuracy

40.00mA 10uA +1.8%of rdg + 5 dgts

400.0mA 100uA

20A 10mA +3.0% of rdg + 7 dgts

Overload Protection: 0.5A / 250V and 20A / 250V Fuse.

Frequency Range: 50 to 60 Hz

Maximum Input: 400mA dc or 400mA ac rms on uA / mA ranges,

20A dc or ac rms on 20A range.

Resistance

Range Resolution Accuracy

400.0Ω 0.1Ω +1.2% of rdg + 4 dgts

4.000kΩ 1Ω +1.0% of rdg + 2 dgts

40.00kΩ 10Ω +1.2% of rdg + 2 dgts

400.0kΩ 100Ω

4.000MΩ 1kΩ

40.00MΩ 10kΩ +2.0% of rdg + 3 dgts

Capacitance

Range Resolution Accuracy

4.000nF 1pF +5.0% of rdg+50 dgts

40.00nF 10pF +5.0% of rdg + 7 dgts

400.0nF 0.1nF

4.000uF 1nF

40.00uF 10nF

400.0uF 0.1uF

4.000mF 0.001mF +10% of rdg + 10 dgts

40.00mF 10.00mF

+3.0% of rdg + 5 dgts

Type-K Temperature

Range Resolution Accuracy

-30oC~ 1000oC 1oC +3% of rdg +5oC/8oF

-22oF~1832oF 1oF

(Meter only, probe accuracy

not included)

Sensor: Type K Thermocouple

Diode Test

Test current Resolution Accuracy

1.0mA typical 1 mV +5% of rdg +15 dgts

Open circuit voltage: 3.0V dc typical

Frequency

Range Resolution

4.000kHz 1Hz

40.00kHz 10Hz

400.0kHz 100Hz

4.000MHz 1000Hz

40.00MHz 1kHz

Sensitivity

>5V RMS

>15V RMS

Accuracy

+1.5% of rdg + 3 dgts

+2.0% of rdg + 4 dgts

Duty Cycle

Range Resolution Accuracy

0.5%~99.0 % 0.1% +2% of rdg + 5 dgts

Pulse width: >100us, <100ms;

Frequency width: 5Hz – 100kHz

Sensitivity: >5V RMS

Pulse Width

Range Resolution Accuracy

1.0~ 20.0ms 0.1ms +2% of rdg +20 dgts

Audible continuity

Audible threshold: Less than35Ω Test current: <1mA dc typical

Maintenance

REPLACING THE BATTERY

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the battery door.

1. When the batteries become exhausted or drop below the

operating voltage, “BAT” will appear in the right-hand side of the

LCD display.The battery should be replaced.

2. Follow instructions for installing battery. See the Battery

Installation section of this manual.

3. Dispose of the old battery properly.

WARNING: To avoid electric shock, do not operate your meter

until the battery door is in place and fastened securely.

33 34

9V Battery

Rear cover screws

BATTERY INSTALLATION

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the battery door.

1. Disconnect the test leads from the meter.

2. Open the battery door by loosening the screw using a Phillips

head screwdriver.

3. Insert the battery into battery holder, observing the correct

polarity.

4. Put the battery door back in place. Secure with the two screws.

WARNING: To avoid electric shock, do not operate your meter until

the fuse door is in place and fastened securely.

9V Battery Door Screws

9V Battery Door

WARNING: To avoid electric shock, do not operate the meter

until the battery door is in place and fastened securely.

NOTE: If your meter does not work properly, check the fuses and

battery to make sure that they are still good and that they are

properly inserted.

REPLACING THE FUSES

WARNING: To avoid electric shock, disconnect the test leads

from any source of voltage before removing the rear cover (fuse

door).

1. Disconnect the test leads from the meter and any item under

test.

2. Open the fuse door by loosening the screws on the rear cover

using a Phillips head screwdriver.

3. Remove the old fuse from its holder by gently pulling it out.

3. Install the new fuse into the holder.

4. Always use a fuse of the proper size and value (0.5A/250V -φ5

x 20, fast blow for the 400mA range, 20A/250V –φ6.3 x 32 fast

blow for the 20A range).

5. Put the fuse door back in place. Insert the screw and tighten it

securely.

Rear cover screws

F1 500mA/250 FUSE

F2 20A/250V FUSE

Trouble Shooting

1. Meter will not turn ON.

Check the battery contacts for a tight fit.

Check for a minimum battery voltage of 8.0 volts.

2. Ampere reading is erratic or there is no reading at all.

Disassemble the meter back cover as per the fuse

replacement instructions on page 36 and test the fuses for

continuity with another meter.

3. Meter reading is erratic.

Printed circuit board damaged from handling with hands.

Low battery.

“Blown” fuse.

Open circuit in a test lead (frayed or broken wire).

4. Meter readings do not change.

“Hold” feature is still toggled ON.

35 36

Loading...

Loading...