PLS PLS5 Operating Manual

NEW

PLS5

PACIFIC LASER

SYSTEMS

The Professional Standard

OPERATING MANUAL

Table of Contents

Welcome to PLS laser tools. We believe you have chosen the finest laser tool in

the world. We are committed to the highest quality standards in workmanship and

materials.

PLS laser tools were developed by contractors to provide every trade with accurate and

efficient alignment information. Thousands of our customers will attest to the savings of

time and money through the performance, convenience and versatility of PLS laser

tools.You can be confident of prompt service to your laser, should the need arise.

CONTENTS

Introduction ...................................

About The Company...............1A,1B

Maintenance .................................

Warranty..........................................

Features..........................................

Safety Labeling & Instructions.......

Beams.............................................

1

B

2

2

3

4

5

Plumb...........................................6

Level.............................................

Square.........................................

Check Calibration..............

Magnetic Bracket........................

Target..........................................

PLS5 Exterior System...........

PLS5 & PLS3 Specifications......16

9,10,11

14,15

1

7

8

12

13

About Pacific Laser Systems

The PLS family of laser tools was developed to give contractors the ability to

transfer critical layout reference points for any job site task. All are self-leveling,

compact and durable laser alignment tools.

What sets PLS•Pacific Laser Systems apart from the rest? Built by contractors

for contractors, PLS tools were developed out of necessity by professionals with

over 50 years of experience in commercial and residential interior and exterior

layout. PLS founders were contractors first before becoming manufacturers of

the finest point-to-point alignment tools in the world.

Point-to-point reference means you can plumb with a PLS5 or PLS3 literally

from floor to ceiling or from 50 feet off the ground. With our PLS5, squaring or

layout of 90° angles can be done faster than ever before.

1A

About Pacific Laser Systems

Our target market is the professional contractor who needs a dependable alignment tool that will speed production and save money. General Contractors and

project managers use the PLS laser to check existing conditions before work

begins. They also use it to judge the work performed by subcontractors.

Subcontractors use PLS lasers for layout on the job site. As much as 25% of the

work day can be spent on layout. The PLS5 system gives square reference easily and quickly. No more 3-4-5. The unique PLS cantilever design allows easy

sight of the opposing reference points and is proven to be effective in installing

curtain walls, foundations, columns, skylights, doors, cabinetry and much more.

The portability and utility of PLS lasers make them attractive alignment tools

when bubble vial levels or rotary lasers are too cumbersome or too limited to do

the job.

The PLS5 and PLS3 are registered trademarks of PLS•Pacific Laser Systems.

The PLS5 utilizes our patented technology, U.S. Patent No. 5,144,487.

1B

Maintenance

Good care of the PLS3or PLS5is primarily common sense care. Remove the batteries from unit

if the laser is to be stored for a considerable period of time. Keep the optic windows clean using a

soft cloth or photographic grade cleaning tissue. Avoid storage conditions of prolonged heat or cold.

Warranty

Thisproduct is warranted by PLS • Pacific Laser Systems to the original purchaser to be free from

defects in material and workmanship under normal use for a period of three years from the date of

purchase. During the warranty period, and upon proof of purchase, the product will be repaired or

replaced (with the same or similar model at our option), without charge for either parts or labor

through PLS. The purchaser shall bear all shipping, packing and insurance costs. Upon completion of the repair or replacement, the unit will be returned to the customer, freight prepaid. The warranty will not apply to this product if it has been misused, abused or altered. Without limitingthe

foregoing, battery leakage, dents or gouges to the plastic housing, broken optic windows, damage

to the switch/LED membrane are presumed to result from misuse or abuse. Tampering with or

removal of the caution or certification labels voids this warranty.

Neither this warranty or any other warranty, express or implied, includingimpliedwarranties of merchantability, shall extend beyond the warranty period. No responsibility is assumed for any incidental or consequential damages. This warranty gives you specific legal rights, and you may have other

rights which vary from state to state.

There is nothing an owner can do in the way of service or maintenance on PLS tools. Contact

PLS or your local service center for repairs.

2

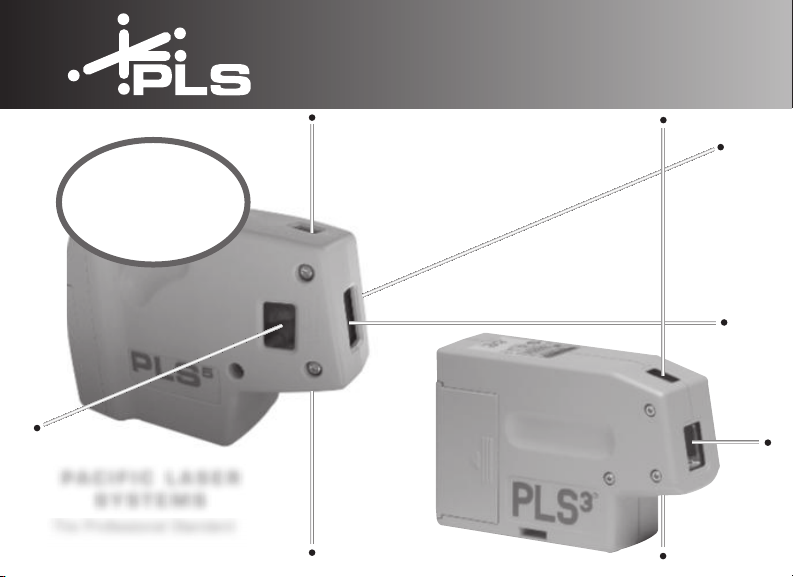

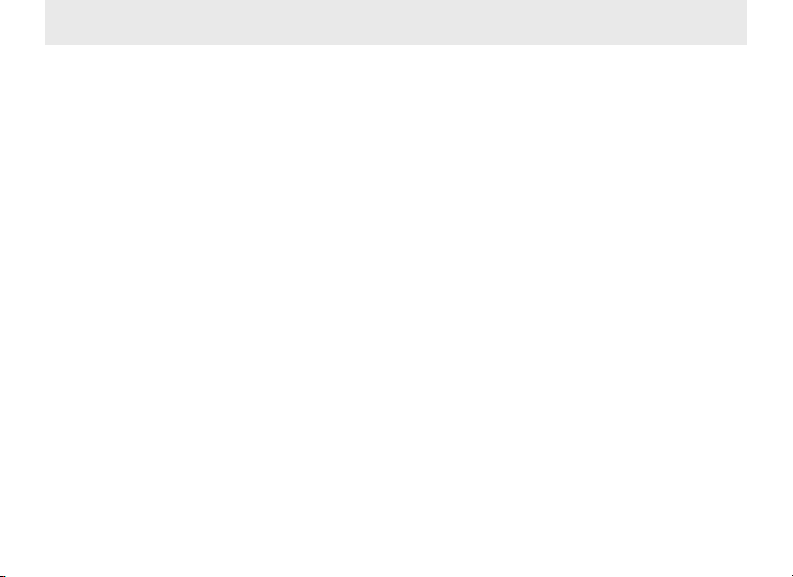

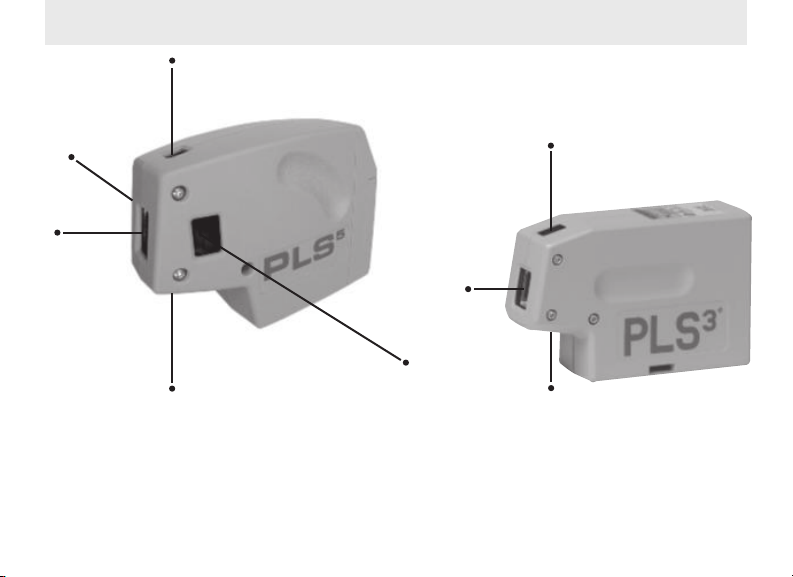

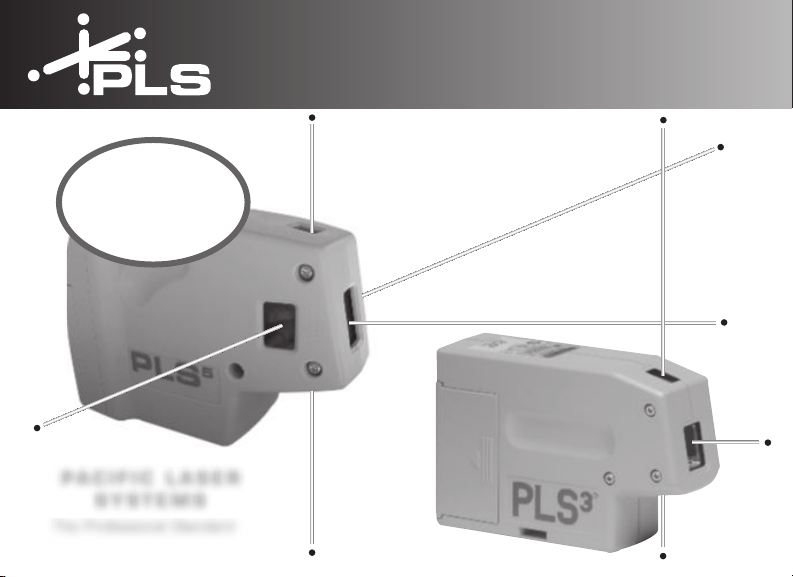

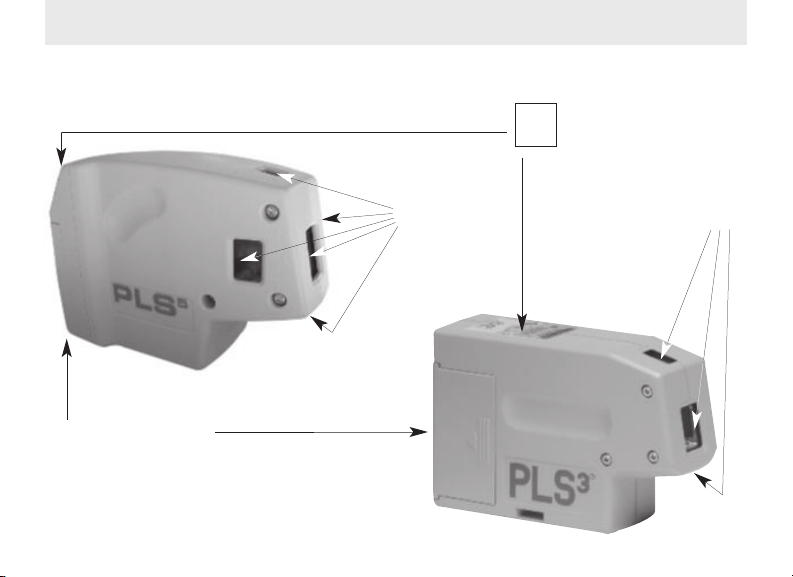

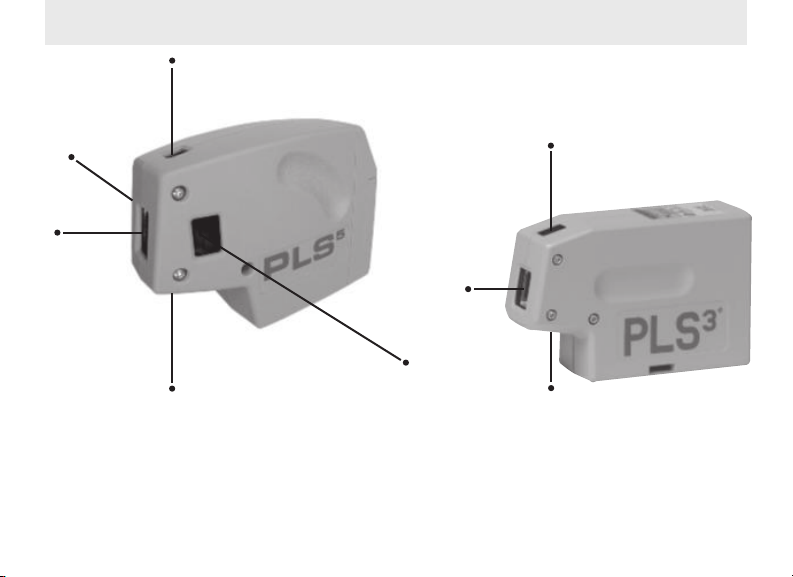

Features

1/4 X 20 ACCESSORY MOUNT IN BASE OF EACH UNIT

BATTERY DOOR

USE EITHER 3AA 1.5V

ALKALINE OR NICAD

BATTERIES

3

OPTIC WINDOWS

(5)

INDICATOR LED

ON: GREEN

ON

TILT: RED

OFF

BATTERY LOW: AMBER

OPTIC WINDOWS

(3)

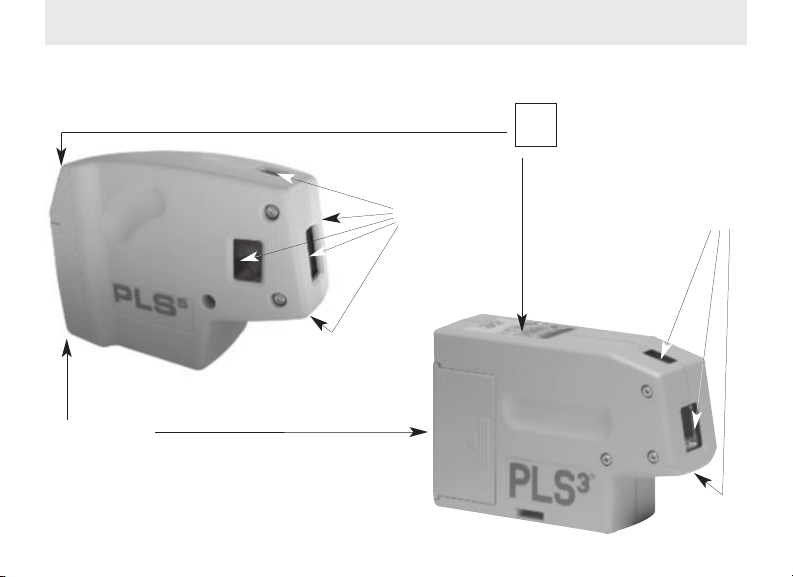

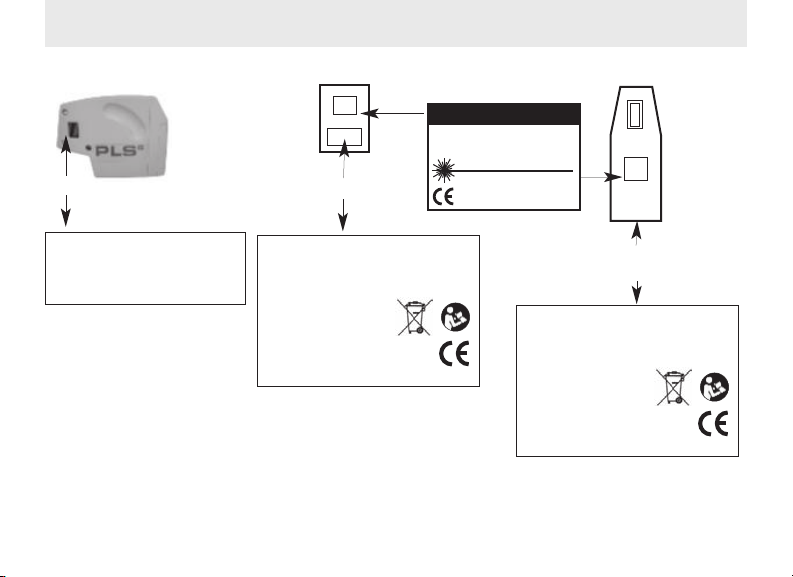

Safety Labeling & Instructions

PLS5 SIDE

PLS5 BACK

PLS3 TOP

WARNING LABEL

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM OR VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS

APERTURE LABEL

AVOID EXPOSURE

LASER RADIATION EMITTED

FROM THIS APERTURE

5

PLS

and PLS3comply with

US FDA performance standards,

21 CFR, Subchapter J.

5

The PLS

a semiconductor laser diode

and PLS3contain

with a wavelength of 635 nanometers.

The continuous output of any single beam never exceeds 1.0 milliwatts.

Never stare directly into the laser beam or view the beam with optical

instruments. Turn the laser off when not in use.

CAUTION: USE OF CONTROLS, ADJUSTMENTS OR PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

These labels are attached to every PLS laser. These are not to be removed or defaced.

ID# CERTIFICATION LABEL

GLOBALLY SOURCED. FINALASSEMBLY IN U.S.A.

PATENT #6,938,360 1-800-601-4600

PLS 2550 KERNER BLVD., SAN RAFAEL, CA 94901

S/N:

CLASS 2 LASER PRODUCT

PLS5COMPLIES WITH FDA STDS. 21. CFR.,

CHAP. J 1040.10 & 11 EXCEPT FOR DEVIATION

PURSUANT TO LASER NOTICE .60 OF 7/26/2006

REGISTERED U.S. PATENT OFFICE.

DATE:

MAX OUTPUT POWER <1mW

WAVELENGTH 635-670nm

CLASS 2 LASER PRODUCT

ID# CERTIFICATION LABEL

GLOBALLY SOURCED. FINALASSEMBLY IN U.S.A.

PATENT #6,938,360 1-800-601-4600

PLS 2550 KERNER BLVD., SAN RAFAEL, CA 94901

S/N:

CLASS 2 LASER PRODUCT

PLS3COMPLIES WITH FDA STDS. 21. CFR.,

CHAP. J 1040.10 & 11 EXCEPT FOR DEVIATION

PURSUANT TO LASER NOTICE .60 OF 7/26/2006

DATE:

4

#3

Beams

#5

#1

PLS

#2

5

The five beams of the PLS5are: #1 Forward Beam, #2 Down Beam, #3 Up Beam,

#4

#3

#1

#2

#4 Left Beam, #5 Right Beam. All PLS5 beams have the same brightness and are

square to each other.

3

PLS

The three beams of the PLS3are: #1 Forward Beam, #2 Down Beam, #3 Up Beam.

5

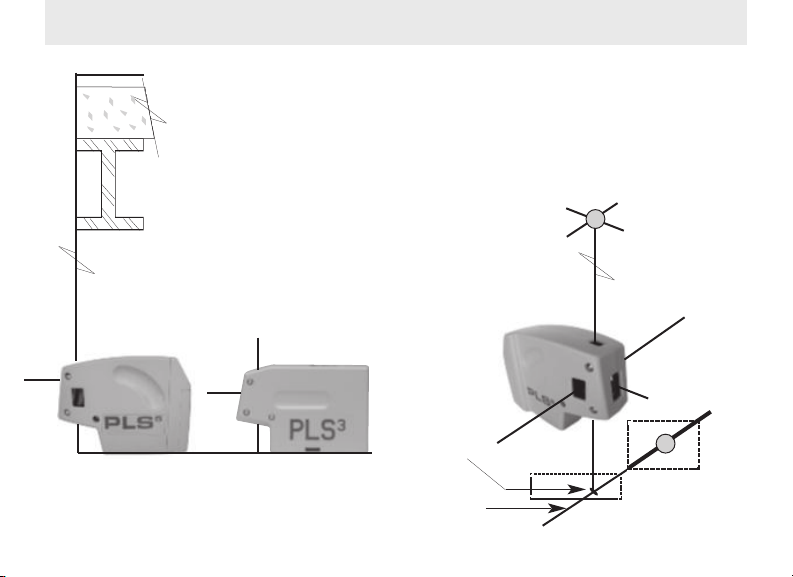

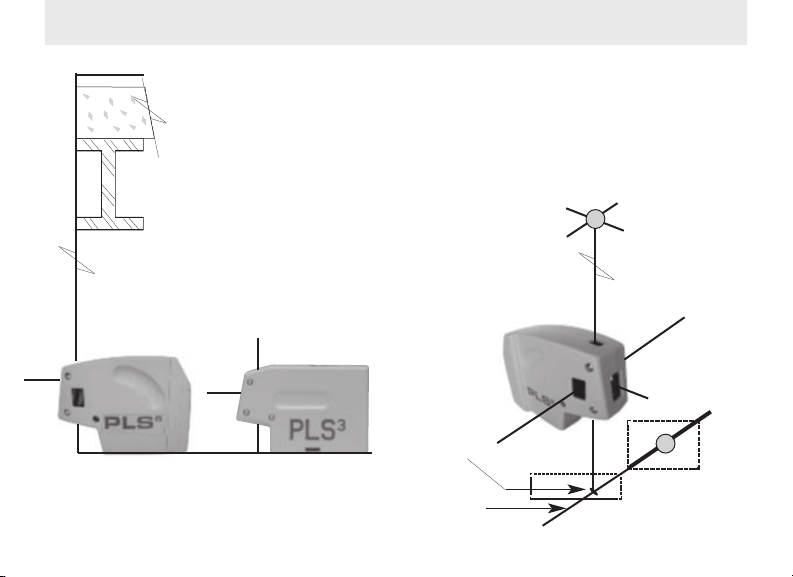

Plumb

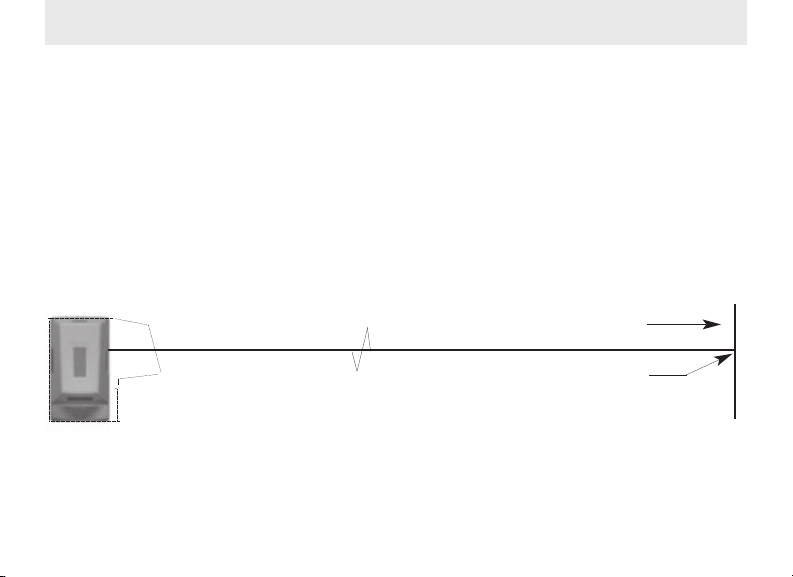

To establish plumb with the PLS5and PLS3, place the #2 down beam over the mark to be

transposed. See Fig.1. The #3 up beam is exactly plumb within specification. You can

shoot plumb marks down and up, or cantilevered over the edge of a building/shaft opening

or floor track, etc. See Fig.2. Use the floor stand with your PLS5or PLS3to increase the

sight angle of the #2 down beam.

The PLS3and PLS5can quickly survey existing conditions for plumb. Use a tape

and #3 up beam. Position the laser near the structure.

Check any distance up or down the structure. It is also

possible to transpose marks from a roof or ceiling down to

the floor. Move the laser until the #3 up beam hits the edge or

center of the ceiling component to be transposed. Mark the

floor at the #2 down beam. See Fig. 2 and 3.

#3

FIG. 2

FIG. 3

PLUMB

POINT

FLOOR

LAYOUT

FIG. 1

#2

CENTER BEAM

ON LAYOUT

6

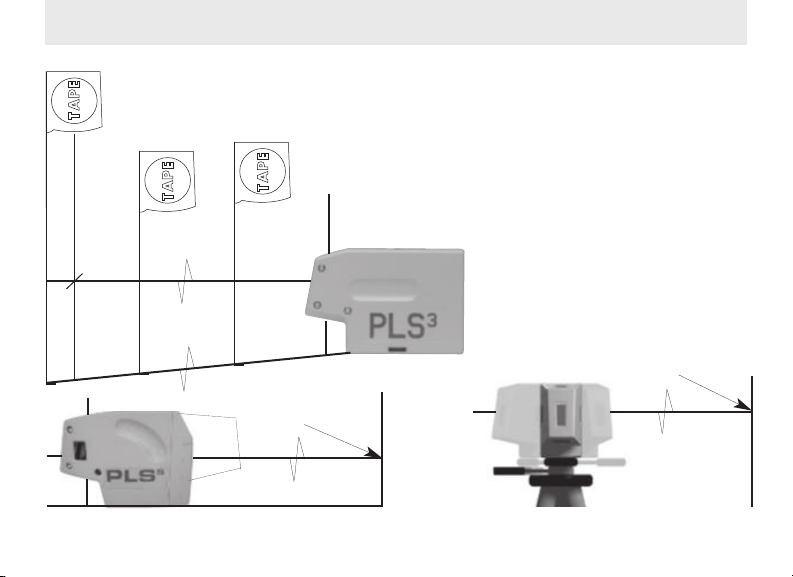

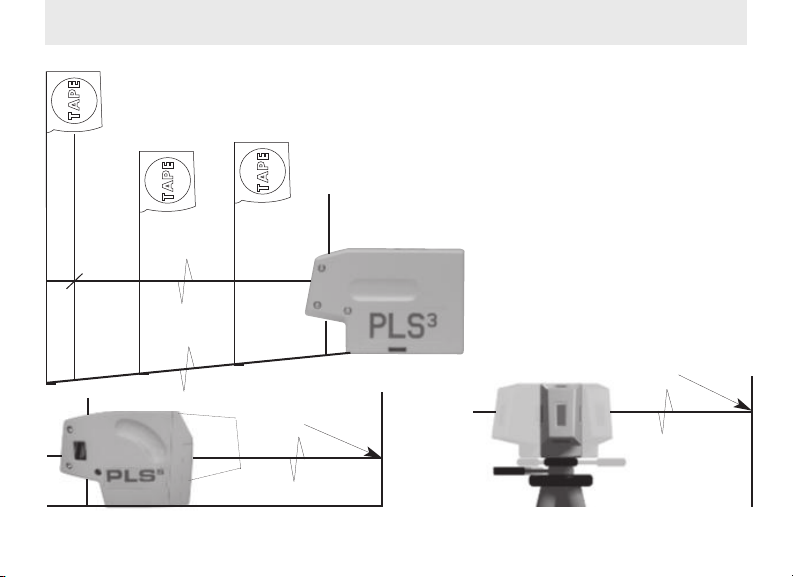

Level

Precise level and grade marks are easily established with the PLS5and PLS3. Swivel the

unit about its center, stopping to mark the desired level or grade points. See Fig. 4. Any

TAPE

stable surface can be used. When mounted on a tripod or wall mount, swivel and mark.

TAPE

20’

10’

See Fig. 5.When turning your PLS

be sure tripod head is perfectly level. Error in marks can

result with tripod out of level.

TAPE

To survey existing conditions for level,

point in the direction to survey. Using

a tape or rod with a bench mark, the

variations in level or grade can be

noted quickly at various distances.

See Fig. 6.

5

or PLS3on a tripod

FIG.6

MARK

MARK

FIG. 4

FIG. 5

7

Square

To establish square, place the PLS5with the #2 down beam over the layout reference line. See Fig.

7. Place the pendulum target on that line, and center #1 forward beam on the center of the target.

Once centered, move the pendulum target to square on #4 left beam or #5 right beam. Make a

mark on the floor or surface near the laser and the second mark at the desired distance from the

laser. See Fig. 7.

BEAM #5

C

L

MARK

C

L

MARK

BEAM #1

FIG. 7

LAYOUT OR REFERENCE LINE

8

Checking Calibration

There are several easy methods to check the calibration and accuracy of the PLS5and PLS3.

We recommend that you check this periodically.

5

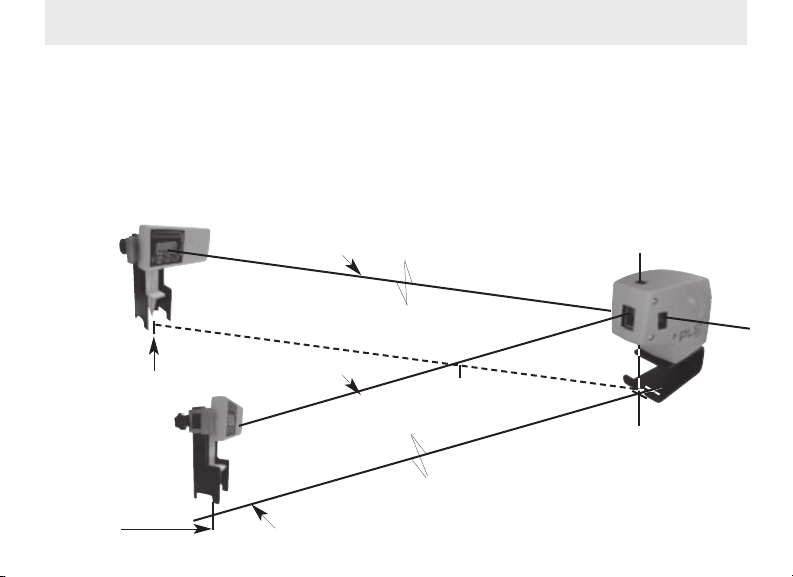

METHOD 1 (PLS

surface 25’-0” or more from a suitable wall or target. See Fig. 8. Point the #1 forward beam at

the wall or target and carefully mark the center of elevation. Swivel the PLS590° on its center

until the #5 right beam is over the first mark. Check to see if there is any difference in elevation

from the center of #1 forward beam and the center of #5 right beam. Repeat to check #4 beam.

At 50’-0” the difference should not be greater than 1/8.” At 25’-0” the difference should not be

greater than 1/16.”

only) Quick Check of Performance Accuracy. Place the PLS5on a stable

WALL OR TARGET

MARK

FIG. 8

9

Checking Calibration

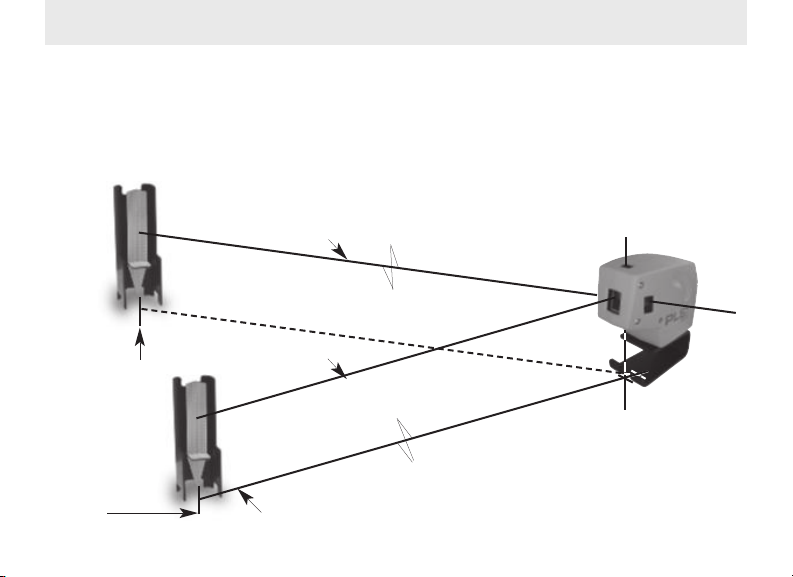

METHOD 2 (both PLS5and PLS3) Exact Check of Level Accuracy. Find a fairly level site line

(preferably a concrete slab) 25’-0” or greater with two opposing walls. You can also use scrap

2 x 4s, for example, as targets. See Fig. 9. Place the laser about 6” from target #1, and carefully

mark the elevation of #1 forward beam on the target. Swivel the laser 180° on its center. Mark

the elevation center of #1 forward beam on target #2. Move the laser to target #2. At 6” from the

target, mark the center of elevation of #1 forward beam on target #2. Swivel the laser on its center and mark center of elevation at target #1. You now have two centers of elevation at each target. Carefully measure the distance between centers of each set of marks. If the distance is the

same, the laser is exactly level. If there is a difference, subtract one measurement from the other.

This method magnifies any error by a factor of two. Therefore, divide this difference by two to find

the exact error of level. The maximum error for the PLS

maximum error for the PLS3is 1/8” at 25’-0” or 1/4” at 50’-0.”

5

is 1/16” at 25’-0” or 1/8” at 50’-0.” The

TARGET #1

FIG. 9

TARGET #2

10

Checking Calibration

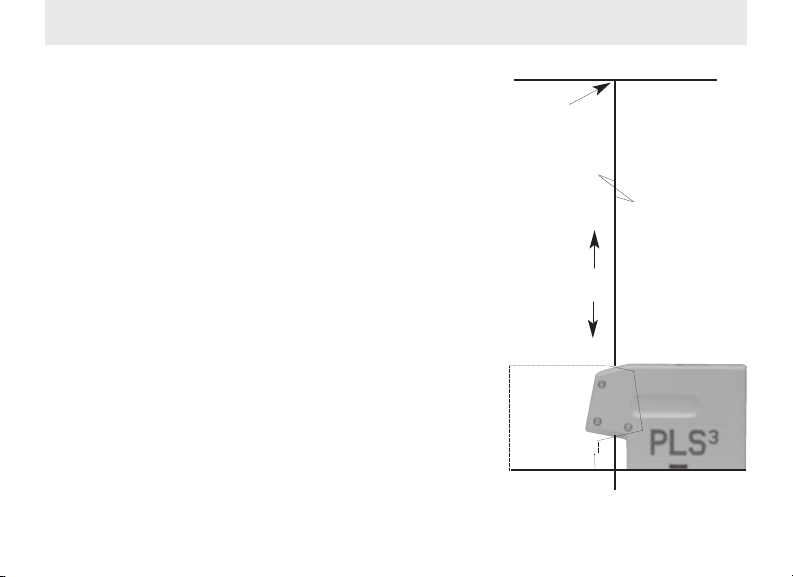

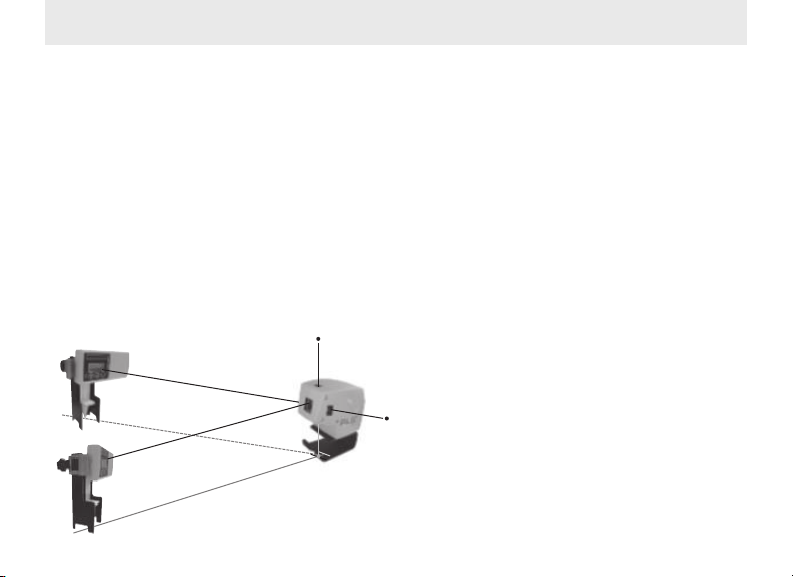

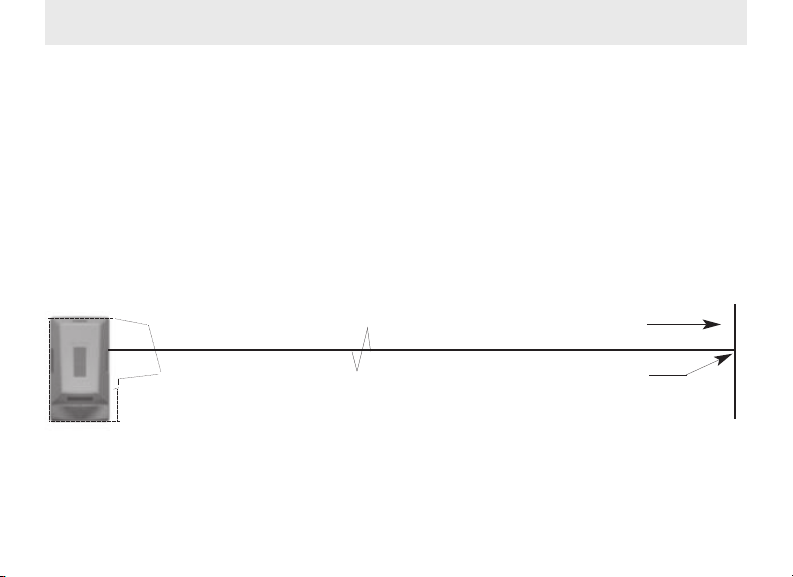

METHOD 3 (both PLS5and PLS3) Exact Check of Plumb

Accuracy. This requires significant vertical height (minimum 10’-0”) and the ability to mark at that height. Place

the unit with the #2 down beam exactly centered on both

axes over a cross mark. See Fig. 10. At the surface

above, mark both axes of #3 up beam. Rotate the laser

180° and place the #2 down beam exactly centered on the

same mark. The #3 up beam should be exactly over the

first mark.

MARK

If there is a difference between mark #1 and mark #2,

the error of the plumb beam is one half that difference.

11

DISTANCE

FIG. 10

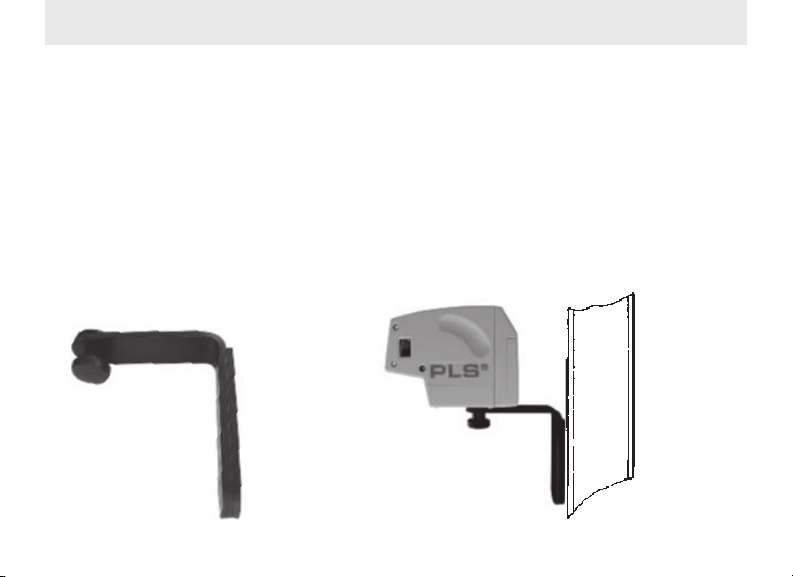

Magnetic Bracket Instructions

To use the magnetic bracket with the PLS laser:

1. Screw the 1/4 x 20 threaded knob to the mount on the base of the PLS laser.

2. Mount the PLS laser and bracket to steel studs, steel door frame, I-beams, carpenter’s

square, etc.

3. Rotate the PLS laser to desired point and make your mark.

Combine the PLS laser, the magnetic bracket, a standard steel carpenter’s framing square and one

or more clamps and you have the ability to mount the laser in unlimited ways. Clamp carpenter’s

square to concrete forms, ladders, wood studs, etc. Attach the PLS laser with magnetic mount as

described above. If you drill two small holes centered on the long section of the carpenter’s square,

the square can be attached to unfinished drywall partitions with screws or removable nails. Slide

the PLS laser up and down the mounted carpenter’s square to the precise desired height.

STEEL STUD

FIG. 11

FIG. 12

12

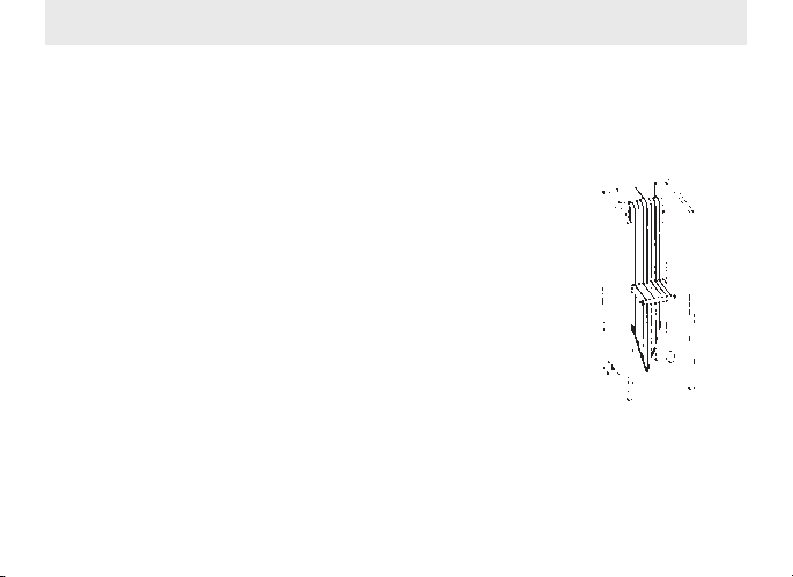

Pendulum Target

Use the PLS5pendulum target for a variety of time saving alignment tasks. For square: For consistent accuracy in establishing or checking square, use the PLS5target to transfer the laser

beam to the floor surface. To establish square, see page 8 of this manual. Always mount the

5

laser on the floor stand when establishing square. The pendulum target is designed so the

PLS

beams are best seen at this height.

For transfer of vertical lines:

To transfer vertical marks quickly and accurately to a wall:

1. Place the front of the PLS

forward beam on the mark to be transferred. (If the mark is on the

floor, place the #2 down beam over the mark.)

2. Place the target with its back flat against the wall at the desired

height and move the target until the #3 up beam is centered on

the plastic lined target.

3. Mark the top or bottom of the target arrow pins.

5

laser against the wall with the #1

PENDULUM TARGET

FIG. 13

13

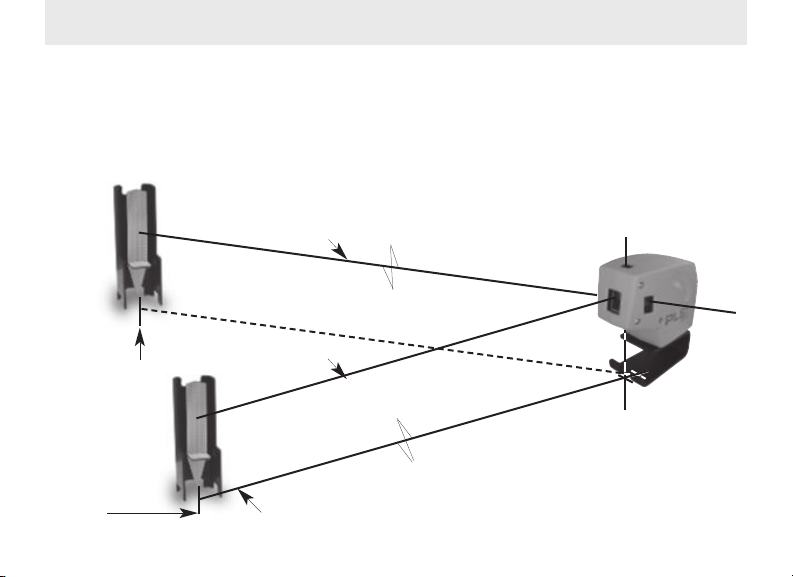

PLS5 System Interior - Exterior System

The PLS5 is the only point-to-point layout tool for use on both indoor and outdoor job

sites. Bright sunshine has traditionally limited the use of visible beam lasers to interior

projects. The PLS5 partnered with our laser receiver gives the contractor the ability to

accurately lay out a job site up to 250 + feet, even in the brightest outdoor conditions.

The PLS5 can also be used inside, without the receiver, for all point-to-point

alignment tasks.

“Beep

Beep”

C

L

MARK

“Beep

Beep”

C

L

MARK

BEAM #5

BEAM #1

FIG. 7

LAYOUT OR REFERENCE LINE

14

PLS5 Exterior Applications

CONCRETE CONSTRUCTION

• Layout of batter boards

• Layout & alignment for masonry projects

• Layout for saw cutting (control joints)

• Alignment of anchor & J bolts

• Layout & alignment of piers and

column footings

• Layout of form boards for concrete

flatwork

“Beep Beep”

“Beep Beep”

15

ELECTRICAL AND MECHANICAL

CONSTRUCTION

• Rough-in of conduit

• Rough-in of waste and supply lines

• Rough-in of natural gas supply lines

FRAMING CONSTRUCTION

• Layout of control lines on concrete

slabs, decking and sub-floors

• Alignment of exterior heavy gauge

steel framing

• Layout & alignment for commercial &

residential wood framing

GLAZING CONSTRUCTION

• Layout & install of curtain walls &

storefront projects.

Specifications

5

Light Source: Semiconductor laser diode Semiconductor laser diode

Working range: +/- 100 feet +/-100 feet

Accuracy: < 1/8” @ 100 feet < 1/4” @ 100 feet

Leveling: Automatic Automatic

Leveling range: +/- 6° +/- 6°

Power supply: 3 AA batteries, alkaline or 3 AA batteries, alkaline or

Operating time: + 30 hrs. continuous use + 30 hrs. continuous use

Operating temp.: 0° F to 122° F 0° F to 122° F

Storage temp.: -40° F to 158° F -40° F to 158° F

Indicators: Green light: ON Green light: ON

Environmental: Water resistant; not Water resistant; not

Dimensions: 2” X 4” X 4 3⁄4 “ 1 3/4” x 5” x 3 1/4”

Weight (with batteries): 1.13 lbs. ( .52 kg. ) 12 oz. (.33 kg.)

PLS

510-650nM, visible 510-650nM, visible

(<3mm @ 30 meters) (<6mm @ 30 meters)

rechargeable rechargeable

(-18° C to 50° C) (-18° C to 50° C)

(-40° C to 70° C) (-40° C to 70° C)

Red light: EXCEEDS Red light: EXCEEDS

TILT TILT

Amber light: BATTERY Amber light: BATTERY

LOW LOW

submersible submersible

PLS

3

16

PLS Lab Technicians

PLS•Pacific Laser Systems

2550 Kerner Blvd., San Rafael, CA 94901

www.plslaser.com • 800 601 4500

NUEVO

PLS5

PACIFIC LASER

SYSTEMS

The Professional Standard

MANUAL DE INSTRUCCIONES

ÍNDICE

Bienvenido a las herramientas láser PLS. Creemos que ha seleccionado la mejor herramienta láser en el mundo. Estamos comprometidos con las más altas normas de calidad en mano de obra y materiales.

Las herramientas láser PLS fueron creadas por contratistas a fin de proporcionar a cada

comercio información precisa y eficaz sobre alineación. Miles de nuestros clientes darán

fe del ahorro de tiempo y dinero que se logra a través del rendimiento, la conveniencia

y la versatilidad de las herramientas láser PLS. Además, en el caso de que surja la

necesidad, puede confiar en un servicio inmediato para su láser.

CONTENIDO

Introducción ............................................1

Mantenimiento ....................................... 2

Garantía.................................................. 2

Características........................................ 3

Etiquetas de seguridad e instrucciones.. 4

Haces......................................................5

Plomada...................................................6

1

Nivel................................................... 7

Escuadra............................................ 8

Verificar calibración................. . 9,10.11

Soporte magnético............................12

Objetivo..............................................13

PLS 5 sistema exterior.................14,15

Especificaciones de PLS5 y PLS3....16

Mantenimiento

Un buen mantenimiento del PLS3 o PLS5 requiere principalmente cuidado sensato. Retire las

baterías de la unidad si guardará el láser durante un tiempo considerable. Mantenga las ventanas

ópticas limpias. Use un paño suave o papel de limpieza fotográfico. Evite guardarlo en lugares con

calefacción o frío prolongado.

Garantía

PLSoPacific Laser Systems garantiza al comprador original que este producto no tendrá defectos

de materiales ni mano de obra en circunstancias de uso normal durante un período de un año a

partir de la fecha de compra. Durante el período de garantía y presentando prueba de compra, el

producto será reparado o reemplazado (por un modelo igual o similar según nuestro criterio), sin

cobro por los repuestos o la mano de obra, a través de PLS. El comprador se hará cargo de todos

los costos de envío, empaque y seguro. Una vez completada la reparación o el reemplazo, la

unidad será devuelta al cliente, con flete previamente pagado. La garantía no se aplicará si el producto ha sido mal utilizado, maltratado o alterado. Además de lo anterior, el derrame de la pila, las

abolladuras o gubias en la cubierta plástica, la rotura de las ventanas ópticas, el daño del interruptor o la membrana del indicador luminoso se consideran consecuencia del mal uso o maltrato.

Alterar o retirar las etiquetas de precaución o certificación anula esta garantía.

Ni esta garantía, ni ninguna otra, expresa o implícita, incluidas las garantías implícitas de comerciabilidad, se extenderá más allá del período estipulado. No se asume ninguna responsabilidad por

daños imprevistos o consecuentes. Esta garantía le otorga derechos legales específicos y usted

podría tener otros derechos que varían según el estado.

El usuario no puede hacer nada para realizar servicio o mantenimiento en las herramientas

PLS. Comuníquese con PLS en su centro de servicio local para reparaciones.

2

Características

MONTAJE PARA ACCESORIOS DE 1/4 X 20 EN LA BASE DE CADA UNIDAD

VENTANAS ÓPTICAS

PUERTA PARA LA BATERÍA

UTILICE 3 PILAS ALCALINAS

AA DE 1.5 V O NICAD

3

(5)

ILED INDICADOR

ENCENDIDO: VERDE

ON

INCLINACIÓN: ROJO

OFF

BATERÍA BAJA ÁMBAR

VENTANAS ÓPTICAS

(3)

Etiquetas de seguridad e instrucciones

LADO DEL PLS5

PARTE POSTERIOR DEL PLS5

ETIQUETA DE ADVERTENCIA

PARTE SUPERIOR DEL PLS3

PRECAUCIÓN

RADIACIÓN LÁSER

NO MIRE DIRECTAMENTE AL HAZ DE

LUZ NI CON AYUDADE

INSTRUMENTOS ÓPTICOS

POTENCIA MÁX. DE EMISIÓN <1MW

ETIQUETA DE ABERTURA

EVITE EXPOSICIÓN

EMISIÓN DE RADIACIÓN LÁSER

DESDE ESTA ABERTURA

PLS5 y PLS3 cumplen con las

normas de rendimiento de la

FDA de Estados Unidos, 21

CFR (Código de Regulaciones

Federales), Subcapítulo J.

PLS5 y PLS3 contienen un diodo láser semiconductor

con una longitud de onda de 635 nanometros. La salida continua de un haz

único nunca excede 1.0 miliwatts. Nunca mire directamente en el haz láser ni

lo mire con instrumentos ópticos. Apague el láser cuando no lo use.

N.º DE ETIQUETA DE CERTIFICACIÓN

GLOBALLY SOURCED. FINALASSEMBLY IN U.S.A.

PATENT #6,938,360 1-800-601-4600

PLS 2550 KERNER BLVD., SAN RAFAEL, CA 94901

S/N:

CLASS 2 LASER PRODUCT

PLS5COMPLIES WITH FDA STDS. 21. CFR.,

CHAP. J 1040.10 & 11 EXCEPT FOR DEVIATION

PURSUANT TO LASER NOTICE .60 OF 7/26/2006

REGISTRADO EN LA OFICINA DE PATENTES DE EE.UU.

DATE:

LONGITUD DE ONDA 635-670NM

PRODUCTO LÁSER DE CLASE II

N.º DE ETIQUETA DE

CERTIFICACIÓNCERTIFICACIÓN

GLOBALLY SOURCED. FINALASSEMBLY IN U.S.A.

PATENT #6,938,360 1-800-601-4600

PLS 2550 KERNER BLVD., SAN RAFAEL, CA 94901

S/N:

CLASS 2 LASER PRODUCT

PLS3COMPLIES WITH FDA STDS. 21. CFR.,

CHAP. J 1040.10 & 11 EXCEPT FOR DEVIATION

PURSUANT TO LASER NOTICE .60 OF 7/26/2006

DATE:

PRECAUCIÓN: EL USO DE CONTROLES, AJUSTES O PROCEDIMIENTOS DIFERENTES A LOS AQUÍ

ESPECIFICADOS PUEDE ORIGINAR UNA EXPOSICIÓN PELIGROSA A LA RADICACIÓN.

Estas etiquetas están adheridas a todos los láseres PLS. No deben retirarse ni dañarse.

4

#3

Haces

#5

#1

#2

5

PLS

Los cinco haces del PLS5 son: N.º 1 Haz de avance, N.º 2 Haz hacia abajo, N.º 3 Haz hacia

#4

#3

#1

#2

arriba, N.º 4 Haz izquierdo, N.º 5 Haz derecho. Todos los haces del PLS5 tienen el mismo brillo y

están en escuadra entre sí.

3

PLS

Los tres haces del PLS3 son: N.º 1 Haz de avance, N.º 2 Haz hacia abajo, N.º 3 Haz

hacia arriba.

5

Plomada

Para establecer la plomada con el PLS5 y PLS3, coloque el haz hacia abajo N.º 2 sobre la marca que

debe transponer. Consulte la Fig.1. El haz hacia arriba N.º 3 está a plomada exacta según las especificaciones. Puede efectuar marcas de plomada hacia abajo y arriba, o en voladizo sobre el borde de la abertura de un edificio/eje o pista del piso, etc. Consulte la Fig.2. Use la base del piso con el PLS5 o PLS3

para aumentar el ángulo de visualización del haz hacia abajo N.º 2.

El PLS3 y PLS5 pueden sondear rápidamente condiciones existentes para plomada. Use una cinta

y el haz hacia arriba N.º 3. Coloque el láser cerca de la estructura.

Compruebe la distancia hacia arriba o hacia abajo de la estructura.

También es posible transponer marcas desde un techo hacia el

piso. Mueva el láser hasta que el haz hacia arriba N.º 3 dé con el borde o

el centro del componente del techo que debe transponer. Marque el

piso en la marca del haz hacia abajo N.º 2. Consulte las Figs. 2 y 3.

#3

FIG. 2

FIG. 3

PLOMADA

PUNTO

PISO

REPLANTEO

FIG. 1

#2

HAZ CENTRAL

EN REPLANTEO

6

Nivel

PLS5 y PLS3 permiten establecer marcas precisas de nivel y de nivel en tierra. Gire la

unidad sobre su centro y deténgase para marcar el nivel deseado o los puntos de nivel en

tierra. Consulte la Fig. 4. Se puede usar cualquier superficie estable. Cuando se use sobre

TAPE

20’

TAPE

10’

un trípode o montaje en la pared, gire y marque. Consulte la Fig.

5. Cuando utilice el PLS5 o PLS3 sobre un trípode,

asegúrese de que la cabeza del trípode esté perfectamente nivelada. Un trípode mal nivelado puede producir

TAPE

FIG.6

errores en las marcas.

Para sondear condiciones existentes

en relación con el nivel, apunte en la

dirección para sondear.Use una cinta

o varilla con un punto de referencia

para anotar rápidamente las variaciones en el nivel o el nivel a tierra a

diferentes distancias. Consulte la

Fig. 6.

MARCA

MARCA

FIG. 4

FIG. 5

7

Escuadra

Para establecer la escuadra, coloque el PLS5 con el haz hacia abajo N.º 2 sobre la línea de referencia del replanteo. Consulte la Fig. 7. Coloque el objetivo del péndulo en esa línea y el haz de

avance N.º central en el centro del objetivo. Una vez centrado, mueva el objetivo del péndulo

en escuadra en el haz izquierdo N.º 4 o el haz derecho N.º 5. Haga una marca en el piso o la

superficie cerca del láser y una segunda marca en la distancia deseada desde el láser. Consulte

la Fig. 7.

HAZ N.º 5

C

L

MARCA

C

L

MARCA

HAZ N.º 1

FIG. 7

LÍNEA DE REPLANTEO O REFERENCIA

8

Verificación de la Calibración

Hay varios métodos fáciles que le permiten verificar la calibración y exactitud del PLS5 y PLS3.

Le recomendamos que realice estas verificaciones periódicamente.

Método 1 (sólo PLS5) Verificación rápida de la exactitud de rendimiento.

Coloque el PLS5 en una superficie

estable a 25'-0” o más de distancia de una pared u objetivo adecuado. Consulte la Fig. 8.

Coloque el haz de avance N.º 1 en

la pared u objetivo, y marque detenidamente el centro de elevación. Gire el PLS5 90° sobre su centro hasta que el haz derecho N.º 5 esté sobre la primera marca. Compruebe si hay alguna diferencia en la elevación desde el centro del haz de avance N.º 1 y el centro del haz derecho N.º 5.Repita

para verificar el haz N.º 4. A 50'-0”, la diferencia no debe ser superior a 1/8”. A 25'-0”, la diferencia

no debe ser superior a 1/16”.

PARED U OBJETIVO

MARCA

FIG. 8

9

Loading...

Loading...