BOOKLET MAKER SR90

Operating instruction

Stapler folder reference

Read this manual carefully before you use this product and keep it handy for future

reference.

For safety, please follow the instructions in this manual.

Page intentionally blank

TABLE OF CONTENTS

What You Can Do with This Machine ............................................................................... 5

Guide To Components ...................................................................................................... 7

Booklet Maker ............................................................................................................................... 7

Options ............................................................................................................................. 10

Trimmer ...................................................................................................................................... 10

Cover Feeder .............................................................................................................................. 12

Control Panel ...................................................................................................................13

1. Basics ............................................................................................... 15

Docking / Undocking ...................................................................................................... 15

Docking the Booklet Maker ......................................................................................................... 15

Undocking the Booklet Maker...................................................................................................... 16

Turning On / Off the Main Power .................................................................................... 17

Booklet Maker and Trimmer........................................................................................................ 17

Staple cartridge and stapler head .................................................................................. 18

Removing staple cartridge .......................................................................................................... 18

Installing staple cartridge ............................................................................................................ 18

Removing stapler head ............................................................................................................... 19

Installing stapler head / clearing staple jam ................................................................................ 19

Emptying the trim bin ...................................................................................................... 20

2. Making Booklets .............................................................................. 21

Changing settings ........................................................................................................... 21

General procedure ...................................................................................................................... 21

Setting Paper Size ...................................................................................................................... 21

Selecting standard paper sizes ............................................................................. 21

Custom paper size .................................................................................................. 22

Fine adjustments of selected paper size .............................................................. 22

Stapling ....................................................................................................................................... 23

Selecting stapling On or Off ................................................................................... 23

Trimming..................................................................................................................................... 24

Selecting trimming On or Off .................................................................................. 24

Adjusting the cutting margin.................................................................................. 24

Covers ........................................................................................................................................ 25

Selecting Cover Feeder On or Off .......................................................................... 25

Loading covers ....................................................................................................... 25

On-line/Off-line ................................................................................................................. 26

Off-line mode .............................................................................................................................. 26

On-line mode .............................................................................................................................. 26

Begin On-line Production ............................................................................................... 27

3. Tools ................................................................................................. 29

The Tools Screen ............................................................................................................ 29

Units ........................................................................................................................................... 29

Software version ......................................................................................................................... 29

Language .................................................................................................................................... 30

Air Separation Fan ...................................................................................................................... 31

Double Sheet Detection .............................................................................................................. 31

Service access ........................................................................................................................... 32

3

4. Jobs .................................................................................................. 33

Storing and deleting jobs ............................................................................................... 33

Storing a new Job ....................................................................................................................... 33

Recalling a Job ........................................................................................................................... 34

5. Clearing Misfeed(s) ......................................................................... 35

Booklet Maker .................................................................................................................. 35

Clearing misfeed(s) .................................................................................................................... 35

Inside the Booklet Maker ........................................................................................ 35

Trimmer ............................................................................................................................ 36

Clearing misfeed(s) .................................................................................................................... 36

Clearing misfeed in input area ............................................................................... 36

Clearing misfeed in exit area .................................................................................. 37

Cover Feeder ................................................................................................................... 38

Clearing misfeed(s) in vertical transport area ............................................................................. 38

6. Troubleshooting .............................................................................. 39

Fault codes ...................................................................................................................... 39

General fault codes..................................................................................................................... 39

Misfeed..................................................................................................................... 39

Booklet maker fault codes .......................................................................................................... 40

Check staples.......................................................................................................... 40

Trimmer fault codes.................................................................................................................... 40

Trim bin full .............................................................................................................. 40

Cover feeder fault codes ............................................................................................................ 40

Misfeed..................................................................................................................... 40

Double feed ............................................................................................................. 40

Load covers ............................................................................................................ 40

7. REMARKS ........................................................................................ 41

Do’s And Don’ts ............................................................................................................... 41

Where to put Your Machine............................................................................................ 42

Machine environment .................................................................................................................. 42

Power connection ....................................................................................................................... 42

Access to machine ..................................................................................................................... 43

Maintaining Your Machines............................................................................................. 44

Cover Feeder .............................................................................................................................. 44

Cleaning feed rollers and paper separator pad .................................................... 44

8. Specification .................................................................................... 45

Machine Specifications ................................................................................................... 45

Booklet Maker SR90 ................................................................................................................... 45

Trimmer TR90 (option) ............................................................................................................... 46

Cover Feeder CF90 (option) ....................................................................................................... 46

INDEX.................................................................................................... 47

4

What You Can Do with This Machine

CF90 Cover Feeder

(option)

TR90 Trimmer

(option)

SR90 Booklet Maker

Rail (option)

The Booklet Maker SR90, Trimmer TR90 and Cover Feeder CF90 forms a booklet making

system that works online with the Bellini C2a/b, Martini and Bellini C1a/b.

The print-outs from the Bellini C2a/b are collected in the finisher and then transported into

the SR90 Booklet Maker to the staple area. From the CF90 Cover Feeder (optional), if

present, any type of covers, colored or black and whites, can be added to the printed set. The

Booklet Maker now jogs and then staples the set. The set is then transported further to the

folding area where the set is folded to a booklet and then fed onto the belt stacker. When a

larger number of sheets are folded an effect called creeping occurs. In order to rectify creep,

the TR90 Trimmer (optional) can be attached after the Booklet Maker. The booklets are then

transported from the Booklet Maker into the Trimmer where the trail edge will be cut off. The

booklets are then fed onto the Belt Stacker.

To facilitate undocking, a Rail (optional) can be installed under the Booklet Maker. Undocked,

or off-line, the Booklet Maker can be used as a stand-alone unit for hand feeding.

5

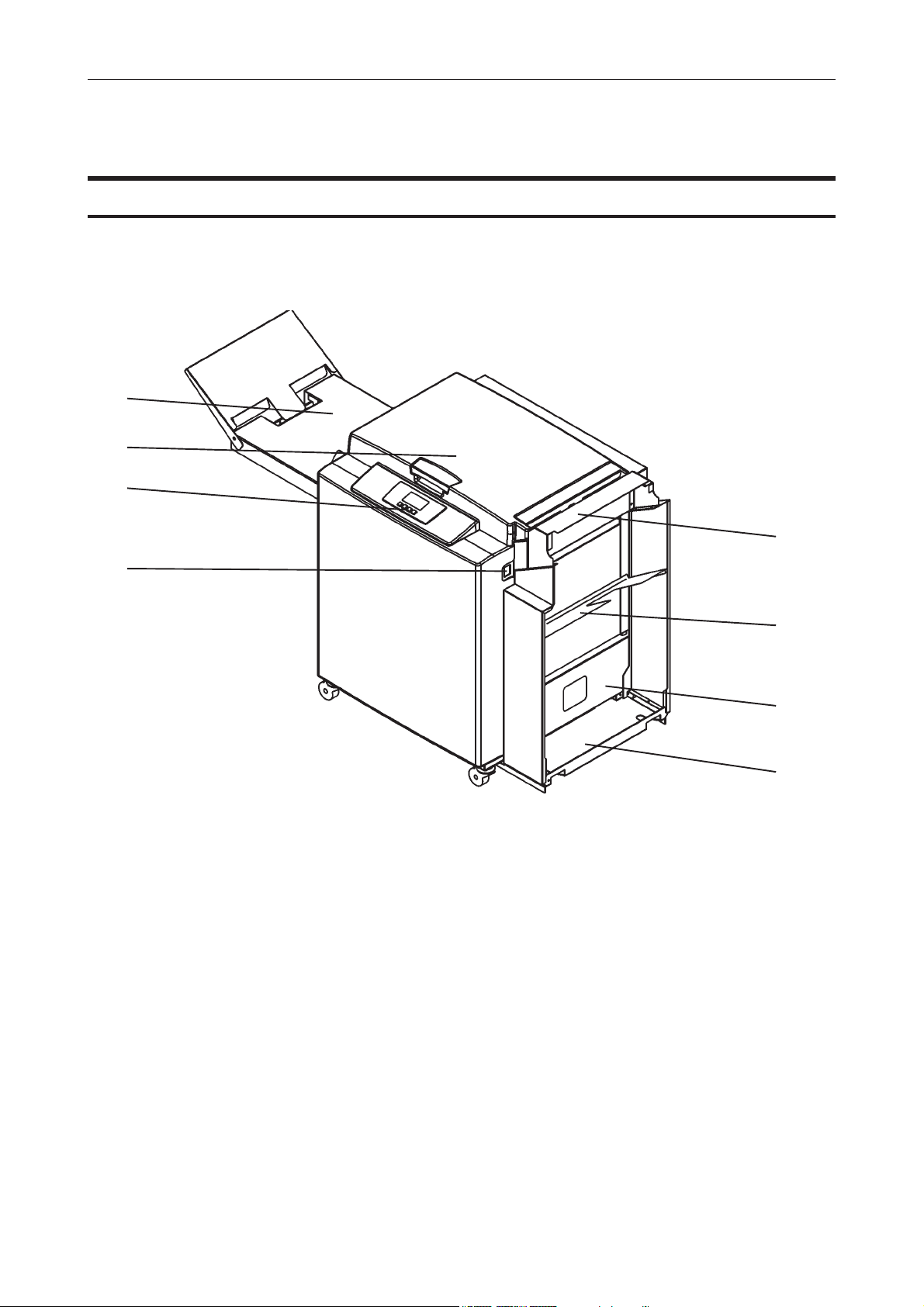

The booklet making system is controlled from a single control panel on the Booklet Maker.

The control panel has only four buttons which will allow you to easely set up, adjust and

operate the complete system.

The Ready screen.

When the system power is switched on the Ready

screen will be shown. Here you will find information

showing the actual set up. From this screen you can

also access other screens, that will help you operate

the complete booklet making system.

arrow button

change button

tools button

jobs button

Changing settings.

To change or adjust settings; Select an item in the

Ready screen with the [arrow] button and press the

[Change] button. For example you can change the

paper size, fine adjust the trimming or turn off the

cover feeder. Explore all settings more thoroughly in

section 2. Making Booklets.

The Tools screen.

Pressing the [Tools] button in the Ready screen takes

you to the tools screen. Here you will find all the

necessary tools for a troublefree operation. From

here you can change the display language, set units

from millimeters to inches and more. See section 3.

Tools. for how to get around in the Tools screen.

The Jobs screen.

Pressing the [Jobs] button in the Ready screen opens

the Jobs screen. From here you can load, customize

and save job settings. These procedures are

described in section 4. Jobs.

6

The Processing screen.

This screen is shown when the machine is busy working.

If the machine is used in off-line mode you do not have

to wait for the Ready screen before handfeeding the

next set.

The Please wait screen.

While the machine sometimes needs time to perform

changes in settings, the Please wait screen will be

shown. The machine will automatically return to the

Ready screen after changes has been implemented.

7

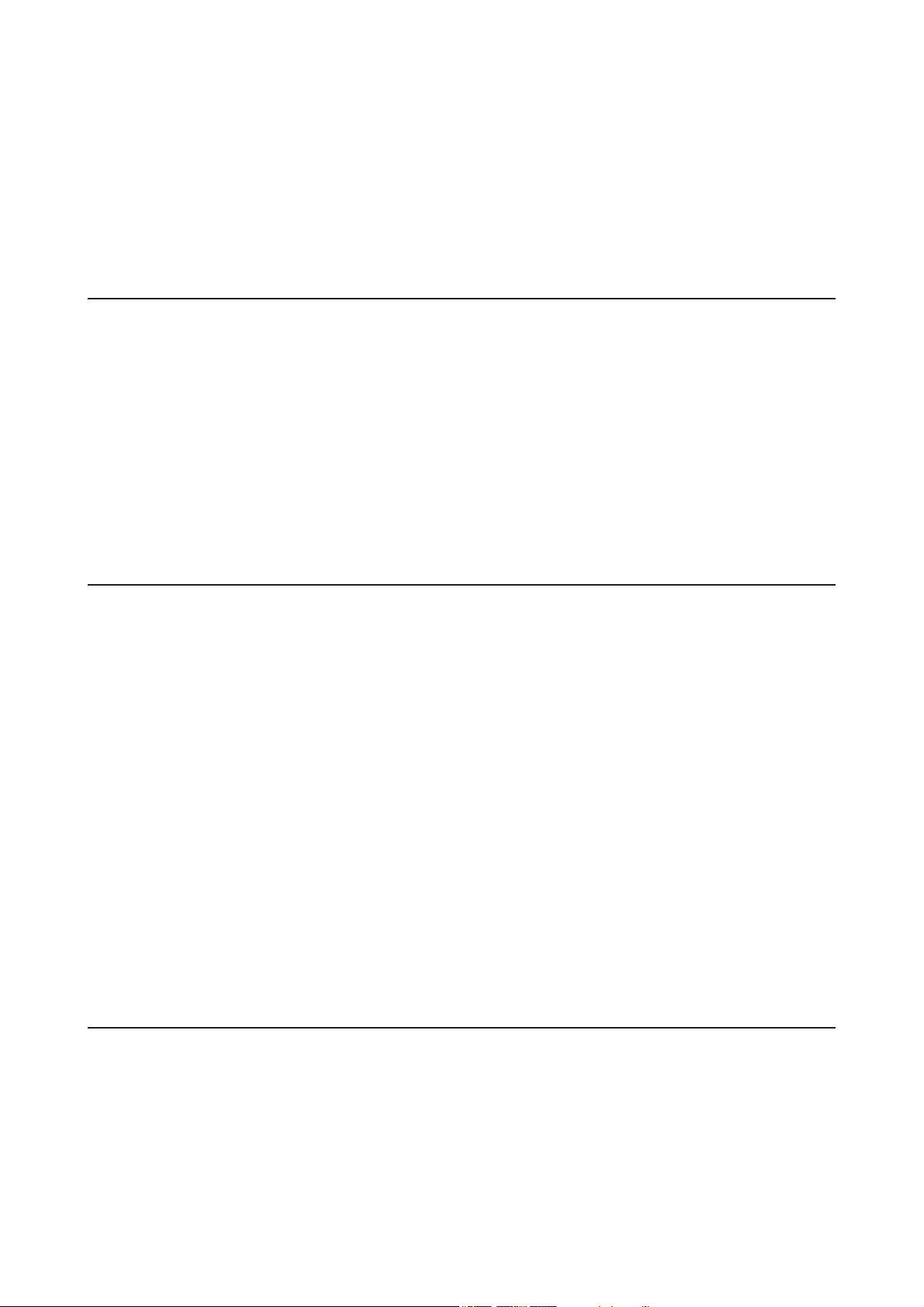

Guide To Components

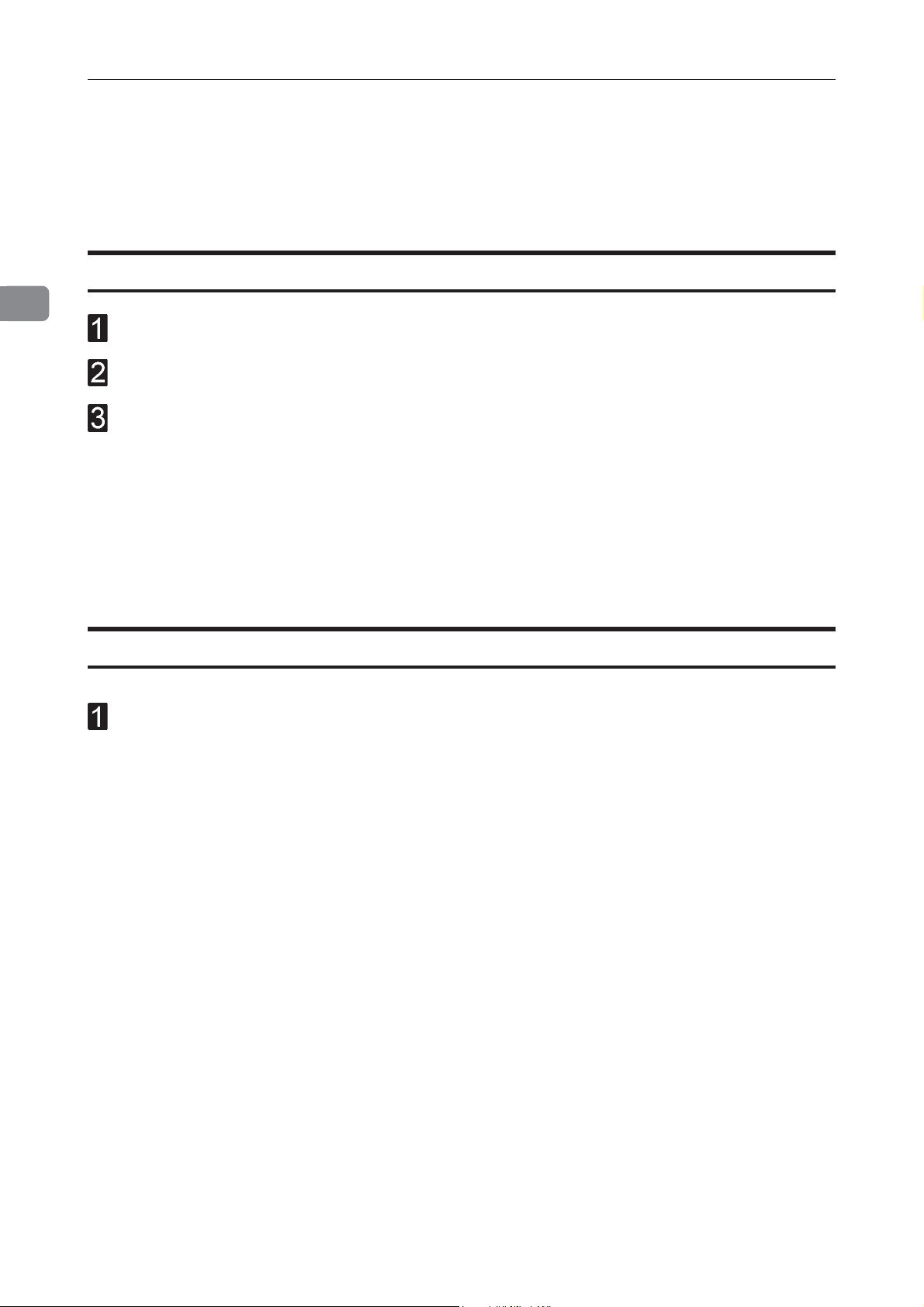

Booklet Maker

1

2

3

5

4

1 Belt stacker

2 Top cover

3 Control panel

4 Infeed assembly

6

7

8

5 Main power switch

6 Shift tray storing shelf

7 Base

8 Docking assembly

8

Booklet Maker, continues

8

9

8 Connections

9 Fold stop gate

Main Power

Stacker

POW CF90 POW TR90

COM TR90COM CF90

COM Copier

9

Booklet Maker, continues

1

6

2

3

4

5

1 Stapler head (2x)

2 Staple cartridge (2x)

3 Cartridge locking lever

4 Stapler release latch

5 Staple detection lead

6 Hand feeding paper guides

10

Options

Trimmer

1

2

3

4

1 Top cover

2 Connections

3 Trim bin

4 Base

Stacker

POW TR90

TerminatorCOM TR90

11

Trimmer, continues

The Trimmer interior has parts that you will come in contact with if a misfeed occur.

1234

5

12

67 89 10

1 Exit compressing brackets

2 Outfeed latch

3 Transport belt

4 Trimmer stop

5 Set counter

6 Infeed latch

7 Upper knife

8 Upper knife beam

9 Outfeed paper path

10 Infeed roller shaft

Cover Feeder

1

2

3

4

5

6

1 Rear side guide

2 Paper separator pad

3 Bin extension plate

4 Adjustable air nozzle

5 Paper orientation label

7

8

9

6 Length adjustment handle

7 Feed roller assembly

8 Loading capacity mark

9 Adjustable side guide and

Loading handle

1110 14 15

12 13

10 Terminator

11 COM CF90

12 Bin extension plate connector

13 POW CF90

14 Upper paper path

15 Jam clearance baffle

13

Control Panel

Button: 1 2 3 4

The booklet making system is operated from a single

control panel on the Booklet Maker. All settings are

done using the four buttons below the LCD display

panel. These buttons are multi functional, meaning that

the function of each button depends on the information

displayed. For example: Pressing button 3 from the

Ready screen takes you to the Tools screen.

Example 2: In this screen, button 3 has no function.

Button: 1 2 3 4

Button: 1 2 3 4

Example 3: Pressing button 3 here will load the stored

Job (4).

Example 4: In this screen pressing button 3 will save

the current settings for job No 1. The asterisk on the

first row shows that the settings for Job (1) has been

changed, but not yet saved.

14

1. Basics

Docking / Undocking

Docking the Booklet Maker

Turn the Copier off.

Make sure the Booklet Maker is turned off.

Lift up the exit arm catcher and set the exit paper

arm in the upper position.

Turn the Copier on, the shift tray will now go down

to the lower position.

Remove the shift tray from the Finisher and put it on

the shelf on the Booklet Maker

Turn the Copier off.

Move the Booklet Maker up to the copier and dock it.

First turn the Booklet Maker on then turn the Copier

on.

Note

It is important to turn the machines on in the right

order.

The Copier is now in booklet maker mode and a staple

icon is now present in the Copier display panel.

15

Basics

Undocking the Booklet Maker

First turn the Booklet Maker off, then turn the

Copier off.

1

Push in the latch on the docking assembly.

Move the Booklet Maker away from the Copier.

Note

Be careful not to damage the communication cable

Lift up the exit arm catcher and move the exit paper

arm to the lower position.

Take the shift tray from the shelf on the Booklet

Maker, and install it on the Finisher .

Turn the Copier on, the shift tray will now go up to

the upper position.

The Copier is now in standard Copier mode.

16

Turning On / Off the Main Power

Turning On / Off the Main Power

Booklet Maker and Trimmer

Plug the Booklet Maker into the wall outlet.

Set ON/OFF switch (1) on Booklet Maker to ON

position.

1

1

The main power switch also controls the Trimmer

(optional) and the Cover Feeder (optional) since they

are powered from the Booklet Maker.

17

1

Basics

Staple cartridge and stapler head

Removing staple cartridge

The staple cartridges, containing approximately 5000

staples per cartridge, can be replaced without

removing the stapler head. Cartridge may be removed

either for renewal or for jam clearance.

Open the booklet maker top cover.

Remove the set of paper.

A

Installing staple cartridge

Raise the handle (A) on the staple cartridge locking

lever.

Remove the staple cartridge from the stapler head

by sliding it away from the stapler head.

Renewing or reinstalling the staple cartridge, pull

25 mm (1 inch) of staples out of the cartridge and

tear the staples downward starting at one side

pulling away from you. The staple tear line is indicated by an arrow on the side of the cartridge.

Insert the cartridge into the stapler head with the

end of the staples facing toward the head of the

stapler mechanism. Push it firmly ahead.

18

Hold the staple cartridge firmly in place and push

down the cartridge locking lever.

Note

Keep holding (pushing) the staple cartridge in place

while pushing down the cartridge locking lever.

Close the top cover. Hand feed a four sheet set of

paper. The booklet maker will automatically cycle

and advance staples until both stapler heads are

driving staples. If not and/or error message persists, remove and reinstall stapler head according

to procedure (see next page).

Staple Cartrigde and Stapler Head

Removing stapler head

Open the top cover.

Disconnect the staple indication lead (A) from the

socket.

Hold the stapler head in place, press the release

latch (B) to release the rear end of the stapler head

and lift up this end.

Lift out the head, allowing it to rotate around the

front end. The stapler assembly is spring loaded

and will follow the rotation of the stapler.

AB

Installing stapler head / clearing staple jam

Remove stapler cartridge. Look inside stapler

head to locate jammed staples by eject point.

Remove staples if any.

Position the stapler head on the edge of a firm

surface (for example the top of a table).

1

While securely holding the head, actuate the Stapler

up and down through full travel. Perform this operation first without staple cartridge then with staple

cartridge. Repeat this a few times to ensure that the

staples are ejected at each down movement.

Reinstall the stapler head by inserting the pin at the

top of the stapler head into the stapler retraction

swing arm (C).

While rotating the stapler head, insert the pin

located at the rear end of the stapler head into the

slots in the frame of the stapler head assembly.

Press down the rear end of the stapler head until

the release lever snaps into place, locking the

stapler head in position.

Press down the front end of the stapler head until it

snaps in position under the frame assembly.

C

Reconnect the staple indication lead (A).

Close the top cover. Hand feed a two sheet set.

The booklet maker will automatically cycle and

advance staples until both stapler heads are driving

staples. If not and/or error message persists,

repeat procedure.

19

1

Basics

Emptying the trim bin

Remove the trim bin by lifting it and pulling it out.

20

trim bin

2. Making Booklets

Changing settings

General procedure

Changing of settings can be performed in two ways. Temporary, which means that the

changes will remain until a new job is loaded or permanent, which means that the changes

will be stored as a job. This job can later be recalled.

Procedure for temporary changes:

From the Ready Screen, select the option you wish to change and press the [Change] button.

Confirm changes by pressing the [OK] button.

Procedure for permanent changes:

From the Ready Screen, press the [Jobs] button to reach the Jobs screen. Select the Job you

want to change by pressing the [Next] button and then press the [Change] button. Select the

option you wish to change and press the [Change] button. After confirming your changes by

pressing the [OK ]button you can press the [Save] button to store your job settings.

Note

Choose either of the above mentioned procedures when changing size, stapling, trimming or

covers as follows.

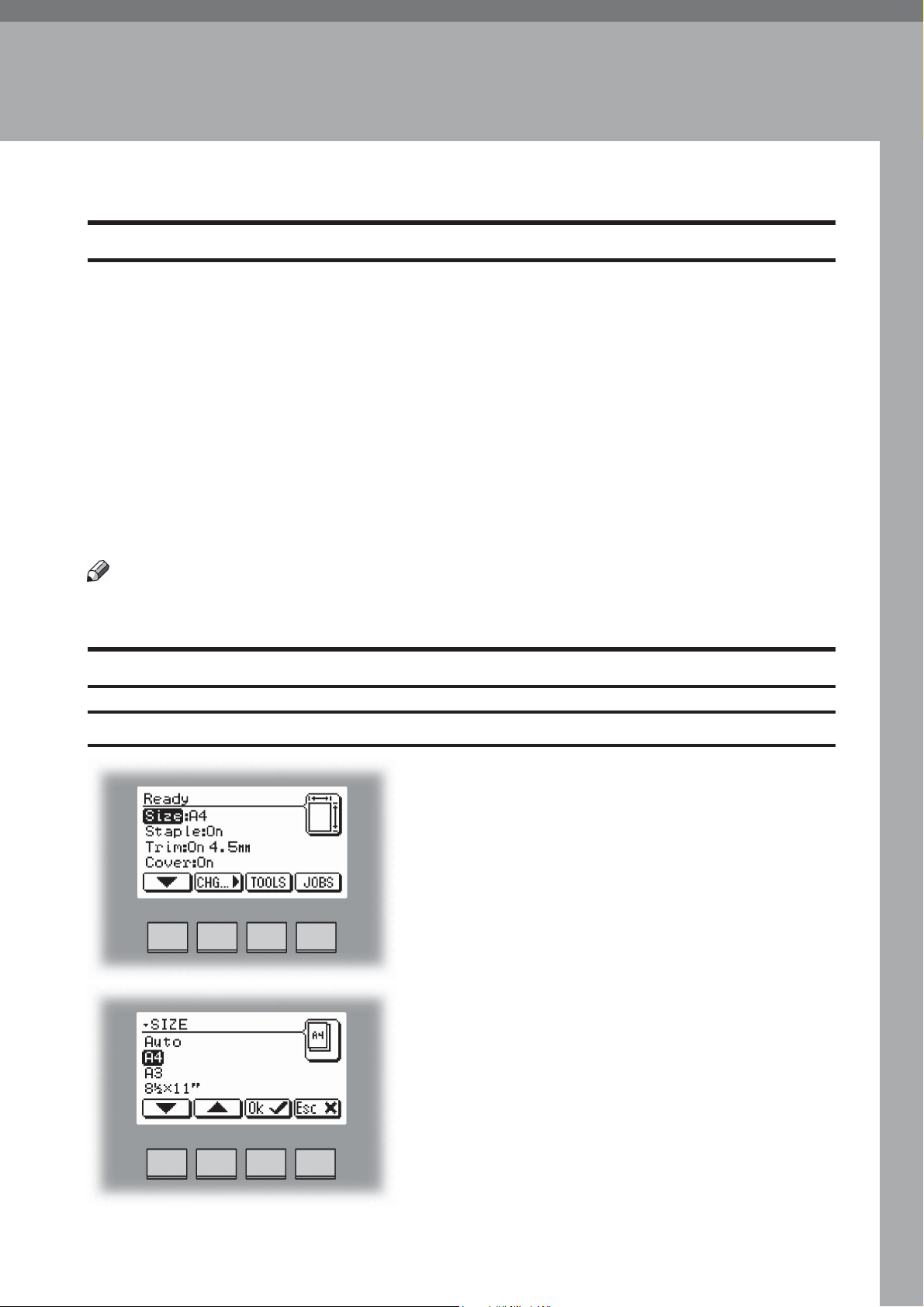

Setting Paper Size

Selecting standard paper sizes

From the Ready screen, select Size and press the

[Change] button.

Select Auto or any standard paper size with the [arrow]

button and press the [OK] button. Selecting Auto

means that the booklet maker will automatically adjust

to the same paper size (A4, A3, 8.5”x11” or 11”x17”) as

the copier.

For other paper sizes, follow “Custom paper size” as

described on the next page.

21

2

Making Booklets

Custom paper size

Select Size and press the [Change] button to display

the preprogrammed paper sizes.

Scroll down to Custom sizes, by pressing the [arrow]

button, and press the [OK] button. Select the custom

paper size you want to use and press the [OK] button.

If you want to adjust, select the custom paper size you

want to change and press the [Change] button. Select

Width or Length with the [arrow] button and press the

[Change] button.

The paper size can now be changed in increments of 1

mm or 0.08 inches. Press the [OK] button to confirm.

Two different custom paper sizes can be stored.

Fine adjustments of selected paper size

Select Size and press the [Change] button to display

the preprogrammed paper sizes. Scroll down to Fine

adjust, by pressing the [arrow] button, and then

pressing the [OK] button.

22

Changing settings

Fine adjustments of selected paper size, continues

Select Width or Length with the [arrow] button and

press the [Change] button.

Press the [+] or [-] buttons to fine adjust in increments

of 0.1 mm or 0.01 inches. Press the [OK] button to

confirm.

2

Stapling

Selecting stapling On or Off

Fine adjustment can be made while the machine is

running.

From the Ready screen, select Staple and press the

[Change] button.

If stapling was On, the first choice will be Off and vice

versa.

Select On or Off with the [arrow] button and press the

[OK] button.

23

2

Making Booklets

Trimming

Selecting trimming On or Off

From the Ready screen, select Trim and press the

[Change] button.

If trimming was On, the first choice will be Off and vice

versa.

Select On or Off with the [arrow] button and press the

[OK] button.

Adjusting the cutting margin

Select Trim and press the [Change] button. Select Trim

length and press the [OK] button. Press the [+] or [-]

buttons to fine adjust in increments of 0.5 mm or 0.02

inches. The trimmed booklet size and waste are

displayed. Press the [OK] button to confirm.

24

Changing settings

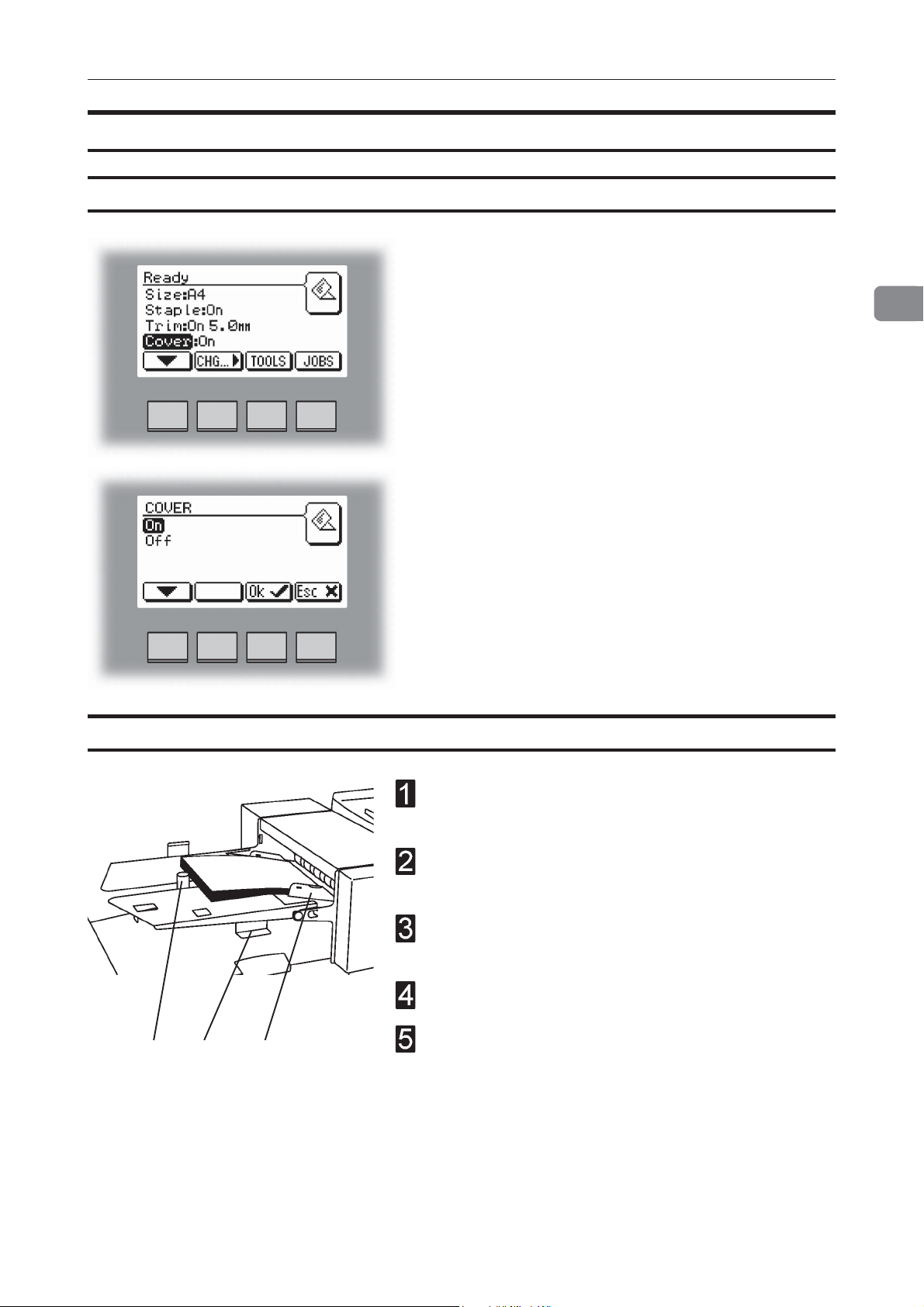

Covers

Selecting Cover Feeder On or Off

From the Ready screen, select Cover and press the

[Change] button.

Select On if you want the cover feeder to automatically

feed one cover to each set from the copier. Select Off if

no covers are to be fed. Press the [OK] button to

confirm.

2

Loading covers

ACB

Make sure that the cover sheets are well fanned to

avoid misfeeds or double-feeds.

Align the cover sheets well to achieve a reliable

feeding operation and good finishing results.

When using printed covers make sure that the ink

has completely dried, to avoid smearing.

Load the covers into the paper bin.

Move the adjustable side guide (C) up against the

sheets until there is no clearance. Move the adjustable air nozzle (A) using the length adjustment

handle (B), so that the green stripe on the air nozzle

bracket is level with the paper stack.

25

2

Making Booklets

On-line/Off-line

The booklet maker can be operated in two modes. On-line mode, when used together with

the copier, or off-line mode, working as a stand-alone unit.

Off-line mode

Follow “Undocking the Booklet maker” in section 1. Basics.

Adjust the hand feeding paper guides to the correct paper size.

Turn on the booklet maker.

The booklet maker is now in stand-by and will start automatically when a set is fed into the

booklet maker. If settings need to be changed, follow “Changing settings” earlier in this

section.

On-line mode

Follow “Docking the Booklet maker” in section 1. Basics.

26

Begin On-line Production

Begin On-line Production

Make sure that the [staple icon] is present on the copier control panel.

If not, turn the copier and the booklet maker Off. First turn the booklet maker On and then

turn the copier On.

Make sure that the booklet maker is set to auto paper size. Selecting Auto means that the

booklet maker will automatically adjust to the same paper format (A4, A3, 8.5”x11” or

11”x17”) as the copier.

Select [Paper tray] (A).

Select [Staple icon] (B).

Select [Dup / Combine / Series] (C).

Select [Book] (D).

2

Select [1 Sided] (E) if your originals are only printed on one side or [2 Sided] (F) if they

are printed on both sides.

Select [Magazine] (G).

Press the Start key (H).

A. Paper tray

B. Staple icon

C. Dup / Combine / Series

D. Book

E. 1 Sided

F. 2 Sided

G. Magazine

H. Start key

27

Page intentionally blank

3. Tools

The Tools Screen

The Tools screen.

From the Ready screen, press the [Tools] button to get to the Tools screen. Here you will find

all the necessary tools for a troublefree operation.

Units

From this screen you can change units between

millimeters and inches. Select Units with the [arrow]

button and press the [OK] button.

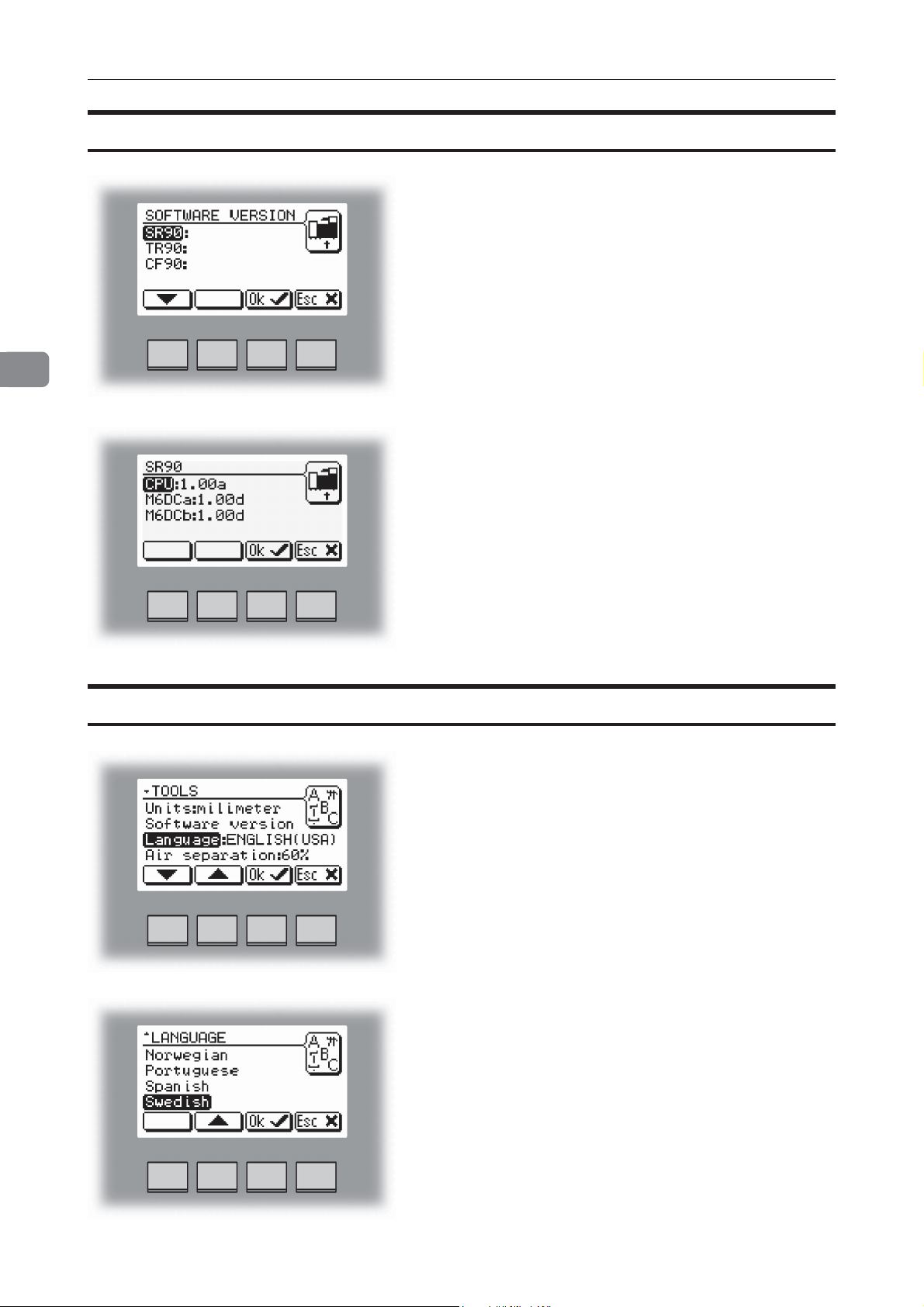

Software version

Select the millimeters or inch units and then press the

[OK] button.

Select Software version with the [arrow] button and

press the [OK] button. This screen, and sub screens

show the software version for the different modules in

the booklet making system.

29

3

Tools

Software version, continues

Select the module in the system for which you want to

check the software version and press the [OK] button.

This screen will show software version(s) in the

selected module.

Language

From this screen you can change the language in the

user interface.

Select Language with the [arrow] button and press the

[OK] button.

Select desired language with the [arrow] button and

press the [OK] button.

30

The Tools Screen

Air Separation Fan

From this screen you can change the speed of the air

separation fan. This screen will only be shown if a

cover feeder is present. Select Air separation with the

[arrow] button and press the [OK] button.

3

You might want to increase the speed of the air

separator fan when running thick, heavy covers.

Set the desired speed in increments of 10% with the

[+] or [-] buttons and press the [OK] button. Normal user

(default) setting is 60%.

Double Sheet Detection

From this screen you can turn the double sheet

detection On or Off. Select Double sheet det. with the

[arrow] button and press the [OK] button.

Normally double sheet detection should be set to On.

However, if you experience “false double sheet feeds”,

for example when running covers that are thick, with

dark print or with mixed prints on the covers, the double

sheet detection can be set to Off.

31

3

Tools

Service access

This screen is for authorized service personnel only

and is password protected.

32

4. Jobs

Storing and deleting jobs

The booklet maker has a maximum storage capacity of 10 different jobs. It is not possible to

delete jobs, therefore when you need to store a new job, an old job must be overwritten. To

make temporary changes in the actual job settings or temporary changes of a stored job, see

section 2 Making Booklets.

Storing a new Job

To store a new job or add new settings to an existing

job you need to start from the Jobs screen. From the

ready screen press the [Jobs] button to enter the Jobs

screen.

Select an already stored job by pressing the [Next]

button. Then press the [Change] button.

Select the option you want to change with the [arrow]

button and then press the [Change] button. See section

2. Making Booklets for how to set up each separate

option.

After changing the options press the [OK] button to

accept the changes you just made.

Continued on next page.

33

Jobs

Storing a new Job, continues

To store the job, press the [Save] button.

4

If you want to run the actual job, press the [Load] button.

The booklet maker will then automatically setup that

specific job and return to the Ready screen.

Recalling a Job

To recall a stored job press the [Jobs] button from the

Ready screen to enter the Jobs screen.

Select the desired job by pressing the [Next] button.

Then press the [Load] button. The booklet maker will

then automatically setup that specific job and return to

the Ready screen.

34

5. Clearing Misfeed(s)

Booklet Maker

Clearing misfeed(s)

Inside the Booklet Maker

To clear a misfeed indicated in Area A

Open the top cover.

Remove misfed sheets.

Close the top cover.

To clear a misfeed indicated in Area B

Open the top cover.

Close top cover.

If misfeed condition remains:

Switch off the main power.

Switch on the main power.

If misfeed condition remains:

Switch off the main power.

If a Trimmer is installed, first remove the trim bin to

get access to the fold stop. By hand, pull down the

fold stop (page 8, item 9).

Remove misfed sheets.

Push the fold stop back into the upper position.

Switch on the main power.

35

5

Clearing Jams

Trimmer

Clearing misfeed(s)

The upper trimmer blade on the trimmer is protected by a knife protection plate that moves

away during the cutting stroke. Jams can occur in the input area or the exit area.

WARNING:

Never put fingers or other parts of the body between the upper and lower trimmer knives.

Clearing misfeed in input area

Lift up the infeed roller shaft (A).

Secure under latch (B)

Remove the misfed sheets in the infeed area.

After the misfed sheets are removed, lift up the latch (B) and place the infeed roller

shaft into operating position.

A

B

36

Trimmer

Clearing misfeed(s), continues

Clearing misfeed in exit area

Lift the exit compressing brackets (A).

Secure them under the latch (B).

Remove the misfed sheets from the exit area.

After the misfed sheets are removed, lift up the latch (B) and place the compressing

brackets in operating position.

5

A

B

37

5

Clearing Jams

Cover Feeder

Clearing misfeed(s) in vertical transport area

Undock the Bookletmaker.

Lift up the upper paper path (spring loaded) (A).

Release the jam clearance baffle (B). If neccessary, the jam clearance baffle can be

removed.

Remove the misfed cover.

Put the jam clearance baffle back in normal position (C) and lock it with the upper paper

path.

Upper paper path

Jam clearance baffle

38

A: Lift upper paper path

B: Upper paper path lifted and

releasing jam clearance baffle

C: Normal

position

6. Troubleshooting

Fault codes

When there is a misfeed or fault condition in the booklet maker system, a message will be

displayed on the booklet maker. In case there is a problem that can be rectified by the

operator, a fault code and an explanation will be displayed.

Fault codes that can be rectified by the operator:

Booklet maker: BM-201 to BM-210 and BM-401

Trimmer: TR-201 to TR-204 and TR-401

Cover feeder: CF-201 to CF-205, CF-401 and CF-501

Note

If procedures in this manual do not rectify the problem an authorized technician will be

needed.

General fault codes

Misfeed

In general, fault codes indicate a misfeed condition.

When a misfeed occurs, the message “Clear

Misfeed(s)”, a code and the jam area will be displayed.

See section 5. Clearing Misfeeds, for how to clear a

misfeed.

39

Troubleshooting

Booklet maker fault codes

Check staples

This message will be displayed when a staple cartridge is empty or when stapling could not

be performed. Check in the following order:

– If a staple cartridge is empty, replace according to section 1. Basics.

– If staple cartridges are OK; remove the set and check that the number of sheets is within

specifications.

– If staple cartridges are OK and set is within specifications; remove and check stapler head

according to section 1. Basics.

Trimmer fault codes

6

Trim bin full

This message will be displayed when the trim bin is full or when a trim strip, due to static

electricity, is prevented from falling down into the trim bin. Empty the trim bin and remove

loose trim strips from inside the Trimmer. See section 1. Basics for how to remove the trim

bin.

Cover feeder fault codes

Misfeed

This message will be displayed when the cover feeder could not feed a cover from the paper

bin. Check cover loading according to section 2. Making Booklets. If problem persists, clean

separator pad according to section 7. REMARKS.

Double feed

This message will be displayed when the Cover Feeder detects that more than one cover

was fed from the cover bin. If more than one cover was fed, check cover loading according to

section 2. Making Booklets. If the covers that are fed are thick, with dark print or with mixed

prints on the covers, double feeding may be displayed even if that is not the case. Turn off

double sheet detection according to section 3. Tools.

Load covers

This message will be displayed when the paper bin is running low or is empty. Reload paper

bin according to section 2. Making Booklets.

40

7. REMARKS

Do’s And Don’ts

• Always follow all warnings marked on, or supplied with, the equipment.

• Always exercise care in moving or relocating the equipment.

CAUTION:

• Unplug the powercord from the wall outlet and machine before you move or relocate

the equipment.

• Do not remove the covers or guards that are fastened with screws.

• Do not override or bypass electrical or mechanical interlock devices.

• Do not operate the equipment if you notice unusual noises or odours. Disconnect the

powercord from the power source and call your authorized technician to

correct the problem.

WARNING:

• Do not put fingers or other parts of the body between the upper and lower trimmer

knives.

• Do not switch off the main power switch while machine is running. Make sure machine

cycle has ended.

• Do not open covers while machine is running.

• Do not move machine while machine is running.

41

REMARKS

Where to put Your Machine

Machine environment

• Always locate the equipment on a solid support surface with adequate strength for the

weight of the machine.

• Always keep magnets and all devices with strong magnetic fields away from the

machine.

If the place of installation is air-conditioned or heated, do not place the machine where it

will be:

• Subjected to sudden temperature changes.

7

• Directly exposed to cool air from air-conditioner.

• Directly exposed to heat from heater.

Power connection

• Always connect the equipment to a properly grounded power source. If in

doubt, have the power source checked by a qualified electrician.

• WARNING: Improper grounding of the equipment can result in electrical shock.

• Never connect the machine to a power source that lacks a ground connection terminal.

42

Where to put Your Machine

Access to machine

Place the machine near the power source, providing clearance as shown.

1

2

1. Left: more than 400 mm / 15 3/4”.

2. Front: more than 555 mm / 21 7/8”

3. Right: more than 400 mm / 15 3/4” (off-line use).

3

7

43

REMARKS

Maintaining Your Machines

Never attempt any maintenance function that is not specifically described in this documentation.

Cover Feeder

Cleaning feed rollers and paper separator pad

The Feed rollers need to be cleaned regularly when in use, and if the unit has not been used

for a period of time. How often this should be done, depends on the paper type and print

quality.

An increasing number of misfeeds, or double feeds, is one indication of the need to clean.

Remove the feed roller assembly by pressing it to the front of unit (A). The left end of

the feed roller assembly will now be released (B) and the assembly can be removed.

7

Clean the Feed rollers and the Paper separator pad with water and a clean lint free

cloth.

Lift out this

side

Press toward front.

A

Paper separator pad

44

B

Feed rollers

8. Specification

Machine Specifications

Booklet Maker SR90

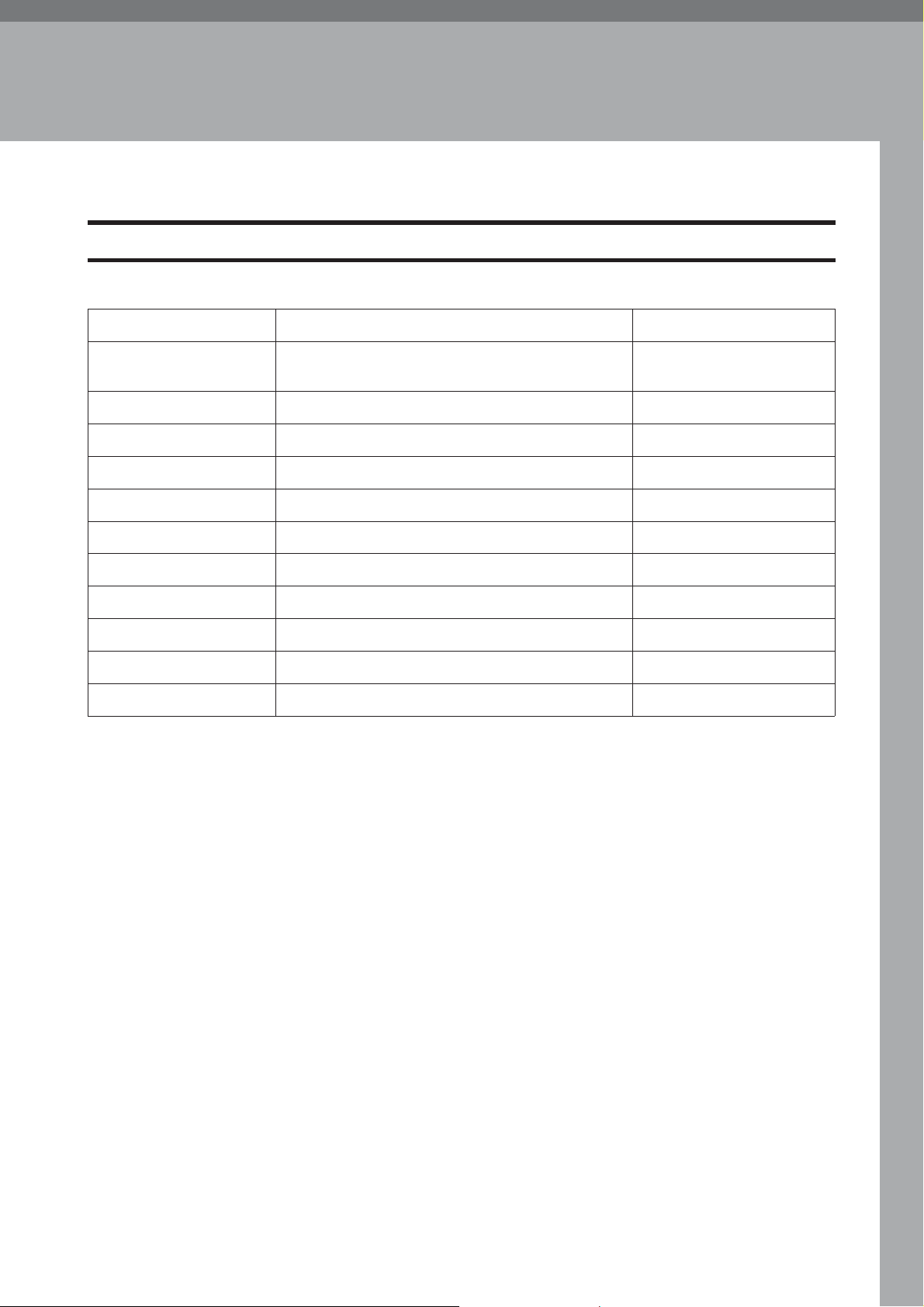

snoitacificepsrojaM

snoitacificepSskrameR

deepSmumixaM(enihcamdetcennocfotuptuosehctaM

)mpp501

seziSrepaPdradnatS"71x11&"41x5.8,"11x5.8,3A,4A elbaliavaerasezismotsuC

)muminiM(thgieWrepaPdnoB.bl71/msg46

)mumixaM(thgieWrepaPrevoC.bl09/xednI.bl531/msg042

steehStuptuO/tupnI )tnelaviuqe,dnoB.bl02/msg08(steehS02-2delpatS

steehStuptuO/tupnIsteehS2gnidloFdelpatSnoN

esUenil-ffOelbissoP )selpats2(dloF/elpatS

thgieWsselro.bl6.871/gk18

)DxHxL(snoisnemiD 61/742x8/713x61/5135/mm026x018x0731rekcatSdnaesaB.lcnI

ecruoSrewoPzH06-05032/022/721/511/011/001%01±

noitpmusnocrewoPsselroW052snoitarepOsuounitnoC

deepsenigneniatniaM

45

Specification

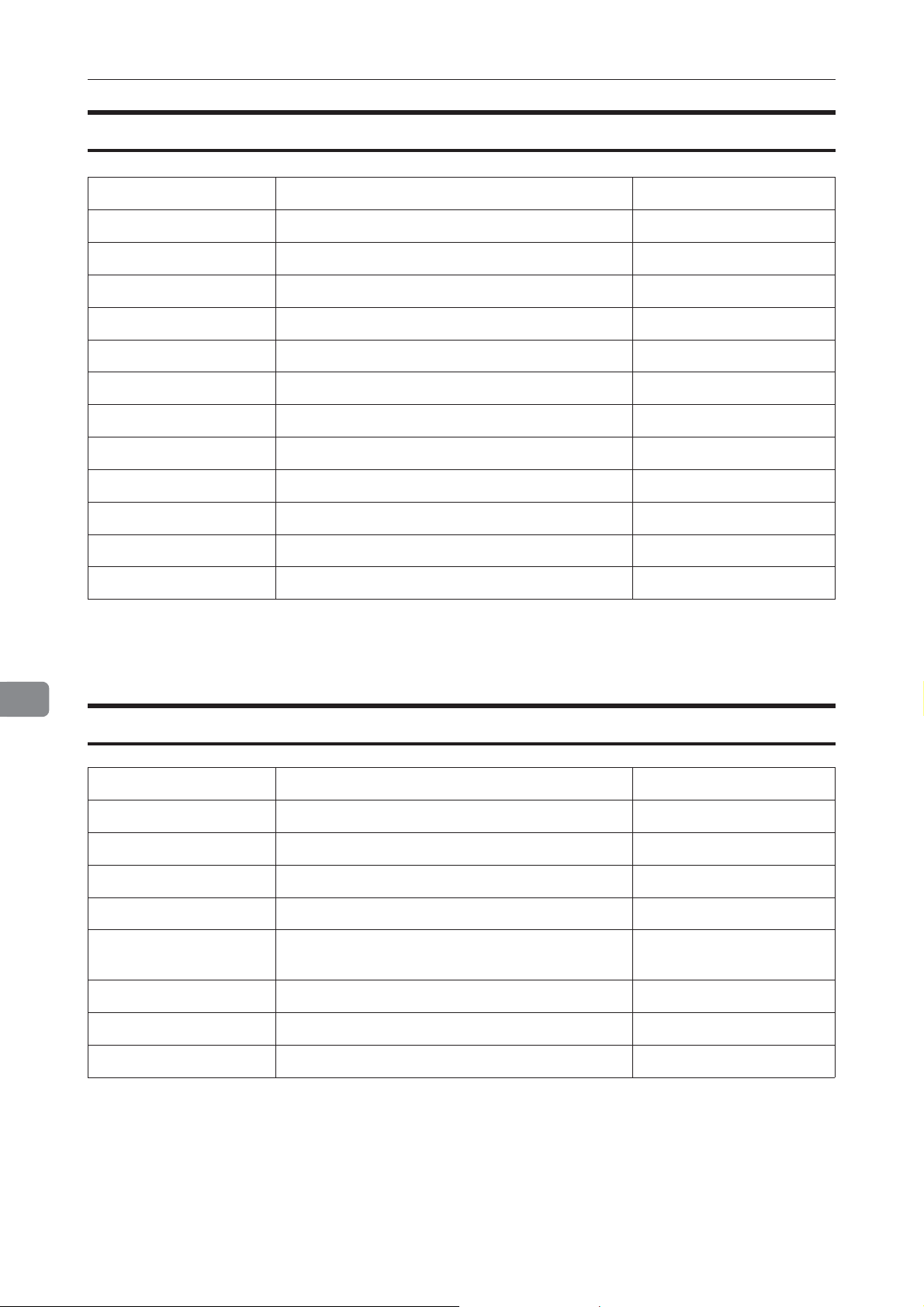

Trimmer TR90 (option)

deepS09RSsaemaS

seziSrepaPdradnatS09RSsaemaS elbaliavaerasezismotsuC

htgnelmirttluafeD)"46/11(/mm5,4elbatsujdA

gnimmirtmuminiM)"46/1(/mm5,0

gnimmirtmumixaM)"2/1(/mm5,21

)muminiM(thgieWrepaP09RSsaemaS

)mumixaM(thgieWrepaP09RSsaemaS

steehStuptuO/tupnI09RSsaemaS

steehStuptuO/tupnI09RSsaemaS

esUenil-ffOrekaMtelkooBotdetcennocnehw,seY )selpats2(dloF/elpatS

snoitacificepSskrameR

8

thgieWsselro.bl7.521/gk75

)DxHxL(snoisnemiD "8/513x8/543x61/341/mm026x088x063ylnoremmirT

Cover Feeder CF90 (option)

snoitacificepSskrameR

deepSmumixaM09RSsaemaS

seziSrepaPdradnatS09RSsaemaS

)muminiM(thgieWrepaPdnoB.bl81/msg07

)mumixaM(thgieWrepaP09RSsaemaS

yticapaCredeeFrevoC2m/rg08fosteehs002.xorppA.)"61/31(mm02

)dnoB.bl02fosteehs002(

esUenil-ffOrekaMtelkooBotdetcennocnehw,seY )selpats2(dloF/elpatS

46

thgieWsselro.bl65.72/gk5.21

snoisnemiD61/122x61/77x8/352/mm065x881x546ylnoredeefrevoC

INDEX

A

Access to machine 43

Air Separation Fan 31

B

Basics 15

Begin On-line Production 27

Booklet Maker 35, 45

C

Changing options 10

Changing settings 21

Check staples 40

Cleaning feed rollers and paper separator pad 44

Clearing Misfeed(s) 35

Clearing misfeed(s), Booklet Maker 35

Clearing misfeed(s), Cover Feeder 38

Clearing misfeed(s), Trimmer 36

Components, guide to 7

Cover Feeder 44, 46

Cover Feeder On or Off 25

Covers 25

Custom paper size 22

D

Docking / Undocking 15

Docking the Booklet Maker 15

Do's and Don'ts 41

Do’s And Don’ts 41

Double Feed 40

Double Sheet Detection 31

F

Fault codes 39

Fault codes, Booklet Maker 40

Fault codes, Cover Feeder 40

Fault codes, general 39

Fault codes, Trimmer 40

Feed rollers 44

G

Guide To Components 7

Guide To Components, Booklet Maker 7

Guide To Components, Control Panel 13

Guide To Components, Cover Feeder 12

Guide To Components, Trimmer 10

I

Inches to millimeters 29

J

Job, recalling 34

Job, storing a new 33, 34

Jobs 33

Jobs, storing and deleting 33

L

Language 30

Load covers 40

M

Machine environment 42

Machine, positioning 42

Machine Specifications 45

Main power. See Turning On / Off the Main Power

Maintaining Your Machines 44

Major specifications 45

Making Booklets 21

Millimeters to inches 29

Misfeed 39, 40

Misfeed(s), clearing 35

O

Off-line mode 26

On-line mode 26

On-line/Off-line 26

Options. See Changing options

P

Paper Size, custom 22

Paper Size, fine adjustments 22

Paper Size, setting 21

Paper Sizes, selecting standard 21

Power connection 42

R

REMARKS 41

S

Separator pad 44

Service access 32

Setting Paper Size 21

Software version 29

Specification 45

Standard paper sizes, selecting 21

Staple cartridge, installing 18

Staple cartridge, removing 18

Stapler Cartrigde 18, 19

Stapler Head 19

Stapler head, installing 19

Stapler head, removing 19

Stapling 23

Stapling On or Off 23

T

Tools 29

Tools Screen 29

Trim bin, emptying 20

Trim bin full 40

Trimme 46

Trimmer 36

Trimming 24

Trimming On or Off 24

Troubleshooting 39

Turning On / Off the Main Power 17

U

Undocking 15

Undocking the Booklet Maker 16

Units 29

W

What You Can Do with This Machine 5

Where to put Your Machine 42

47

Page intentionally blank

Loading...

Loading...