Plockmatic BLM 35/50

Production Booklet Maker

Operator Manual

Please read this manual carefully before you use this product and keep it handy for future reference.

For safety, please follow the instructions in this manual.

Doc no: X04107E

Date: 26 June 2017

Electromagnetic compliance

This product complies with EU Standard EN 55032:2015, Class A.

Operation of this equipment in a residential environment could cause radio interference.

NOTE:

The domestic environment is an environment where the use of broadcast radio and

television receivers may be expected within a distance of 10m of the apparatus concerned.

Introduction

This manual contains instructions on the operation and maintenance of this machine. To

get maximum versatility from this machine all operators should carefully read and follow

the instructions in this manual. Keep this manual in a handy place near the machine.

Please read the Safety Information before using this machine. It contains information

related to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

How to read this manual

Notation conventions

Whenever necessary, the following points for attention are indicated in this manual.

WARNING

Indicates a potentially hazardous situation which, if instructions are not followed,

could result in death or serious injury.

CAUTION

Indicates a potentiality hazardous situation which, if instructions are not followed, may

result in minor or moderate injury or damage to machine or property.

NOTE:

This sign refers to:

• Remarks for making the operation much easier. You get practical hints or knowledge to

assist you in the machine operation such as:

• Preparations required before operating

• How to prevent papers from being misfed or damaged

• Precautions required or actions to take after misoperation

• Limitations like numerical limits, functions that cannot be used together or conditions,

under which a particular function cannot be used or obtained.

• Information.

[ ]

Keys that appear on the machine’s display panel.

Safety Information

When using this machine, following safety precautions should always be followed.

Safety during operation

WARNING

• To avoid hazardous situations like for instance electric shock or danger while exposed

to moving, rotating or cutting devices, do not remove any covers, guards or screws

other than those specied in this manual.

• Turn off the power and disconnect the power plug (by pulling the plug, not the cable) if

any of the following conditions exists:

• You drop objects or spill something into the equipment.

• You suspect that your equipment needs service or repair.

• Your equipment’s covers has been damaged.

• You notice unusual noises or odours when operating the equipment.

• If the power cable or plug becomes worn out or otherwise damaged.

• Before cleaning and care (unless otherwise specically instructed).

• Electromagnetic compliance:

• This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

• The product (System) which is connected to this machine will be class A.

General safety

WARNING

• Always connect the equipment to a properly grounded power source (wall outlet). If in

doubt, have the power source checked by a qualied electrician.

• Improper grounding of the equipment can result in electrical shock. Never connect the

machine to a power source that lacks a ground connection terminal. This machine is

destined for specic purpose only. Any use going beyond this specic purpose is regarded as beyond the determination. The manufacturer will not be liable for damages

resulting from any use beyond the determination, unallowed operation, respectively.

The user alone bears the risk.

• Do not make arbitrary changes or modications to the machine. The manufacturer will

not be liable for modications made at the machine on your own and damages resulting thereof. EC declaration of conformity and the mark CE will be invalidated, if you

make changes at the machine or at the individual components.

• Do not override or bypass electrical or mechanical interlock devices.

• The machine is to be used only by authorized and instructed persons. The responsibilities on operating the machine have to be strictly laid down and observed so that there

are no unclear competences regarding safety aspects.

• Vent holes serve for air circulation to protect the machine from overheating. Make sure

that the holes are not covered.

• Do not expose ngers or other parts of the body to moving, rotating or cutting devices

such as for instance between upper and lower trimmer knives.

• Always locate the equipment on a solid support surface with adequate strength tor the

weight of the machine.

General safety, continued

CAUTION

• The machine and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

• Always follow all warnings marked on, or supplied with, the equipment.

• When you disconnect the power plug from the wall outlet, always pull the plug (not the cable).

• Disconnect the power cord before you move the machine. While moving the machine, always

exercise care and make sure that the power cord will not be damaged under the machine.

• Always contact service if relocating the equipment.

• Do not move the machine while the machine is running.

• Do not open covers while the machine is running.

• Do not switch off the power while the machine is running. Make sure the machine cycle has

ended.

• Lay the power cord in a way that nobody will stumble over it. Do not place things on the cord.

• Never attempt any maintenance function that is not specically described in this

documentation.

• Always keep magnets and all devices with strong magnetic elds away from the machine.

• If the place of installation is air-conditioned or heated, do not place the machine where it will be:

• Subject to sudden temperature changes.

• Directly exposed to cool air from an air-conditioner.

• Directly exposed to heat from a heater.

• If the machine is not used over an extended period of time it should be unplugged to prevent

damage in the case of overload.

NOTE:

• The indications like front and rear, left and right refer to the paper transport direction.

• The operator manual always has to be available at the place of use of the machine.

• In the interest of technical development the company reserves the right to make

alterations to specications without prior notice!

Page intentionally blank.

TABLE OF CONTENTS

What You Can Do With This Machine ............................................................................. 11

Guide to Components ...................................................................................................... 13

Booklet Maker ............................................................................................................................. 13

User Interface ............................................................................................................................. 16

Control Panel.........................................................................................................................................16

Options .............................................................................................................................. 19

Rotate Crease Trim Module ........................................................................................................ 19

Booklet Maker ............................................................................................................................. 24

Alive Logo..............................................................................................................................................24

Cover Feeder ........................................................................................................................................25

BookFold Module ........................................................................................................................ 26

Trimmer ....................................................................................................................................... 28

BST4000-1 Belt Stacker Module ................................................................................................ 30

BST4000-1 Principle of Operation.........................................................................................................31

1. Basics ............................................................................................... 33

Turning On / Off the Main Power ..................................................................................... 33

RCT, Booklet Maker, BookFold Module, Trimmer & BST Module ............................................... 33

Change staple cartridges and Check Stapler ................................................................ 34

Change left/right staple cartridge(s) ............................................................................................ 34

Check left/right stapler ................................................................................................................ 35

Cover Feeder..................................................................................................................... 35

Loading covers ........................................................................................................................... 35

Emptying the trim waste bin ............................................................................................ 36

Belt Stacker ....................................................................................................................... 37

Setting up Belt Stacker for right-angled mode ............................................................................ 37

Setting up Belt Stacker for straight mode ................................................................................... 38

2. Making Booklets .............................................................................. 39

Guided Start ...................................................................................................................... 39

Guided Start, step by step .......................................................................................................... 39

Changing settings ............................................................................................................ 42

General procedure ...................................................................................................................... 42

Basic settings ................................................................................................................... 42

Input Sheet Size ......................................................................................................................... 42

Selecting standard paper sizes ............................................................................................................. 42

AUTO sheet size ...................................................................................................................................43

Custom input sheet size ........................................................................................................................ 43

Finished Booklet Size ................................................................................................................. 43

Auto trimming ........................................................................................................................................ 43

Custom booklet size .............................................................................................................................. 44

Customizing settings ....................................................................................................... 45

Staple .......................................................................................................................................... 45

Selecting stapling On or Off ..................................................................................................................45

Adjusting staple position........................................................................................................................45

Fold position ............................................................................................................................... 46

Adjusting fold position ...........................................................................................................................46

Cover .......................................................................................................................................... 46

General..................................................................................................................................................46

Cover ..................................................................................................................................................... 47

Air Separation........................................................................................................................................47

Double Sheet Detection ........................................................................................................................47

Purge Cover .......................................................................................................................................... 48

BookFold ..................................................................................................................................... 48

General..................................................................................................................................................48

Selecting BookFold pressure setting ..................................................................................................... 49

Crease ........................................................................................................................................ 50

Crease Mode ......................................................................................................................................... 50

Crease position .....................................................................................................................................50

Fine-tuning booklet appearance ..................................................................................... 51

Set registration (ne adjustment) ..........................................................................................................51

Bleed Trimmer - Asymmetric Side Trim ................................................................................................. 52

Bleed Trimmer - Cover Adjust ............................................................................................................... 52

Hand-feeding ..................................................................................................................... 53

Hand feed mode ......................................................................................................................... 53

3. Tools ................................................................................................. 55

The Tools screen ......................................................................................................................... 55

Stacker full detection .................................................................................................................. 55

Units ............................................................................................................................................ 55

Software version ......................................................................................................................... 56

Paper path light ........................................................................................................................... 56

Language .................................................................................................................................... 56

Service mode .............................................................................................................................. 57

Fold delay ................................................................................................................................... 57

Sheet feeder ............................................................................................................................... 57

Auto Rotate ................................................................................................................................. 58

BookFold offset ........................................................................................................................... 58

4. Jobs .................................................................................................. 59

Handling jobs .................................................................................................................... 59

Saving a Job ............................................................................................................................... 59

Opening and handling stored Jobs ............................................................................................. 60

5. Clearing Misfeed(s) ......................................................................... 61

Clearing misfeed(s) .......................................................................................................... 61

General ....................................................................................................................................... 61

RCT Module ....................................................................................................................... 62

Clearing misfeed(s) ..................................................................................................................... 62

Infeed “A” area and exit “D” area...........................................................................................................62

Registration and creaser area ............................................................................................................... 63

Booklet Maker ................................................................................................................... 64

Clearing misfeed(s) ..................................................................................................................... 64

Inside the Booklet Maker ....................................................................................................................... 64

Clearing misfeed in infeed area.............................................................................................................65

Clearing misfeed in folder area .............................................................................................................66

Cover Feeder..................................................................................................................... 67

Clearing misfeed(s) in vertical transport area ............................................................................. 67

BookFold Module ............................................................................................................. 68

Clearing misfeed(s) ..................................................................................................................... 68

Inside the BookFold Module .................................................................................................................. 68

Trimmer .............................................................................................................................69

Clearing misfeed(s) ..................................................................................................................... 69

Clearing misfeed in input area...............................................................................................................69

Clearing misfeed in exit area ................................................................................................................. 70

Belt Stacker ....................................................................................................................... 71

Clearing misfeed(s) ..................................................................................................................... 71

Clearing misfeed on belt stacker ........................................................................................................... 71

6. Troubleshooting .............................................................................. 73

Fault codes........................................................................................................................ 73

General ....................................................................................................................................... 73

RCT fault codes .......................................................................................................................... 73

Booklet Maker fault codes .......................................................................................................... 74

Cover Feeder fault codes ........................................................................................................... 75

BookFold Module fault codes ..................................................................................................... 76

Trimmer fault codes .................................................................................................................... 77

Belt stacker fault codes ............................................................................................................... 77

General fault codes ..................................................................................................................... 78

Clear Misfeed(s) .................................................................................................................................... 78

Close cover(s) ....................................................................................................................................... 78

Empty stacker!.......................................................................................................................................78

7. REMARKS ........................................................................................ 79

Do’s And Don’ts ................................................................................................................ 79

Where to put Your Machine ............................................................................................. 80

Machine environment ................................................................................................................. 80

Power connection ....................................................................................................................... 80

Access to machine ...................................................................................................................... 81

Maintaining Your Machines ............................................................................................. 82

Cover Feeder .............................................................................................................................. 82

Cleaning feed rollers and paper separator pad ..................................................................................... 82

BookFold Module ........................................................................................................................ 83

Cleaning feed belts................................................................................................................................83

Pressure springs ...................................................................................................................................84

RCT Module ................................................................................................................................ 85

Cleaning the paper path transportation nip rollers (12x) ....................................................................... 85

Cleaning the xing rollers (3x) ............................................................................................................... 86

Cleaning the registration cross roller (4x) & friction tires (4X) ............................................................... 87

Cleaning the rotator rollers (2x) ............................................................................................................. 88

Cleaning the paper path sensors (5x) ................................................................................................... 88

Cleaning of creaser tools (2x) ...............................................................................................................90

Adjustment of Bleed Trimmer registration angle (parallel cut)............................................................... 91

Adjustment of Creaser registration angle .............................................................................................. 92

Best practices for the BLM 35/50 system....................................................................... 93

Limitations of the BLM 35/50 system ............................................................................. 94

8. Specication ................................................................................... 97

Machine Specications .................................................................................................... 97

Rotate Crease Trim Module (option) ........................................................................................... 97

Booklet Maker ............................................................................................................................. 98

Cover Feeder Module ................................................................................................................ 99

Trimmer Module .......................................................................................................................... 99

BookFold Module ..................................................................................................................... 100

BST4000-1 Belt Stacker Module .............................................................................................. 100

System Set Size Guide ............................................................................................................. 101

Cables, plugs and jumpers ....................................................................................................... 105

INDEX.................................................................................................. 106

Page intentionally blank.

10

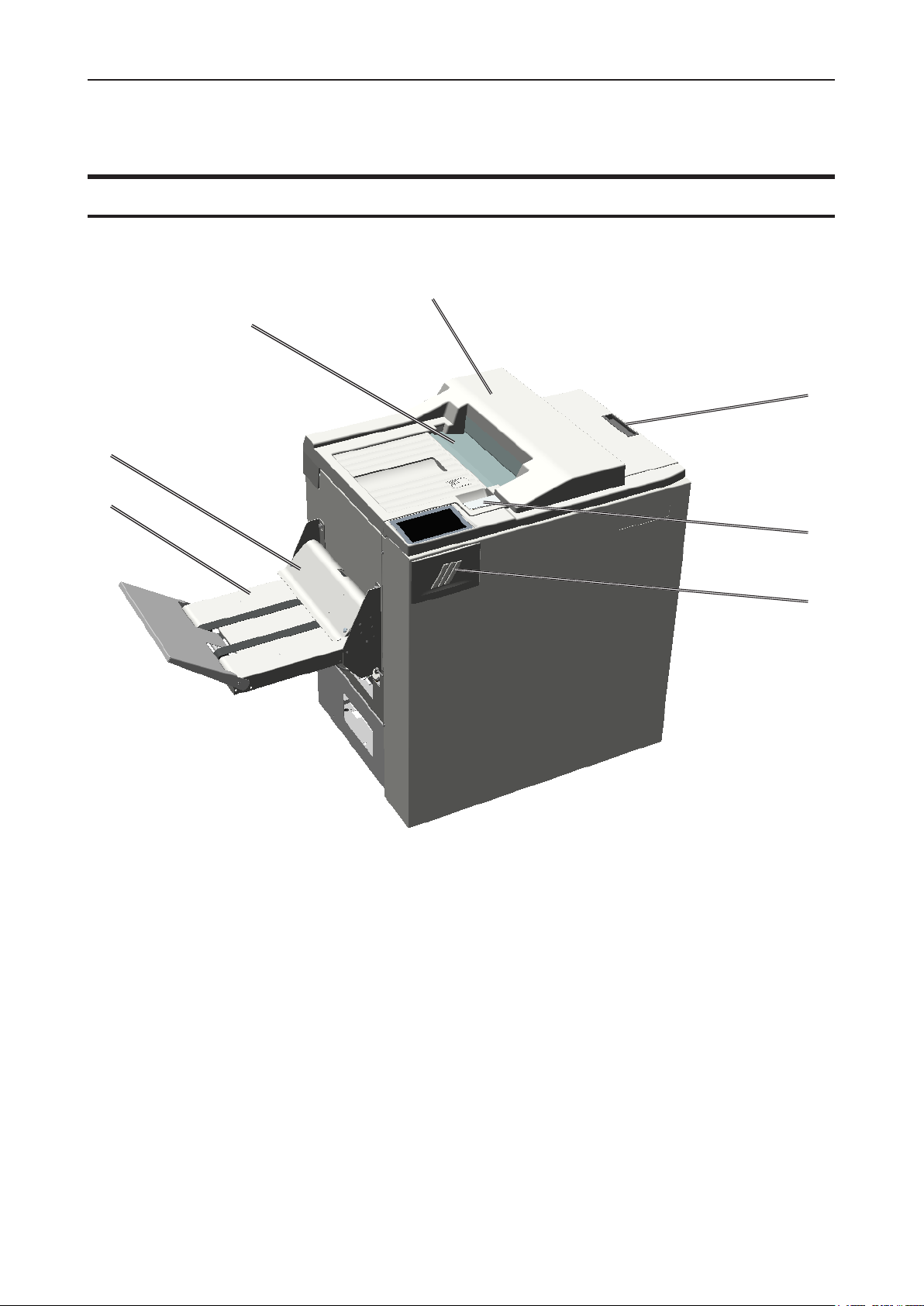

What You Can Do With This Machine

BF50 BookFold

Module (option)

Belt Stacker

FTR50 Trimmer Module

(option)

BLM50 upgrade kit

(option) incl. Alive Logo

BLM35/50 Production

Booklet Maker

CF50 Cover Feeder

Module (option)

RCT50 Rotate Crease

Trim Module (option)

The Plockmatic BLM50 or the Plockmatic BLM35 Production Booklet Maker System

consists of:

Rotate Crease Trim Module (optional), also referred to as the RCT Module or the RCT

Cover Feeder Module (optional), also referred to as the Cover Feeder or the CF

BookFold Module (optional), also referred to as the BookFold or the BF

Trimmer Module (optional), also referred to as the Trimmer or the TR

BST4000-1 Belt Stacker Module (optional), also referred to as the BST Module or the BST

Together they form a system that allows full bleed booklet making online with the Printer.

A capacity enhancement is the BLM50 upgrade kit. This kit increases the capacity of the

BLM35 Booklet maker from 35 sheets to 50 sheets. This means that instead of 140 page

booklets, 200 page booklets are now possible. The BLM50 upgrade kit also includes the

Live logo feature. The logo below the user interface will be illuminated, allowing the user to

monitor the system status from a distance.

The print-outs rst enter the Rotate Crease Trim Module. The RCT Module is able to

rotate small(er) sheets from long edge feed to short edge feed to maintain high printer

productivity. In order to avoid toner cracking at the spine when folded, the RCT can be

programmed to crease the cover sheet. The RCT can also trim the long sides of the

booklet sheets to deliver booklets in the desired size. To enable full bleed booklets, a

Trimmer Module must be installed after the Booklet Maker, see below.

From the RCT, the printed sheets are transported into the BLM50 or BLM35 Production

Booklet Maker where they are compiled in the stapler area.

If a Cover Feeder Module is installed in the Booklet Maker, it can add any type of cover, in

colour or black and white, to the printed set. The Booklet Maker jogs and staples the set.

continued on next page

11

continued from previous page

The set is then transported further into the Booklet Maker to the folding area where the set

is folded into a booklet and delivered out to the belt stacker or a downstream module.

After the Booklet Maker, an optional BookFold Module can be attached. The stapled and

folded books will be fed into the BookFold Module where the spine of the booklets are

attened square. The booklets will now have the look of a perfect bound book. Finally, the

booklets are fed out to the optional Trimmer or directly to a Belt Stacker.

When a larger number of sheets are folded, an effect called creeping occurs. In order to

eliminate creep, an optional Trimmer Module can be attached after the Booklet Maker

or BookFold Module. The booklets are transported from the Booklet Maker or BookFold

Module into the Trimmer where the front edge will be cut off. The Trimmer combined with

an RCT Module in front of the Booklet Maker creates the possibility to create full bleed

booklets.

To allow longer, unattended runs there is an optional high capacity belt stacker available.

The BST4000-1 Belt Stacker Module will stack up to 1000 A4 or 8,5 × 11” booklets of 4

pages.

In addition to producing booklets inline, it is possible to use the Booklet Maker System for

hand-feeding.

The user interface/control panel is of

touch screen type. Point at the screen

and press the button or function you

wish to make changes to.

In this sample screen shot, the Staple

button is pressed.

A sub screen is shown.

Make your changes and conrm by

pressing the green check mark or

exit without making any changes

by pressing the red X. Pressing the

home symbol takes you back to the

main or home screen.

12

Guide to Components

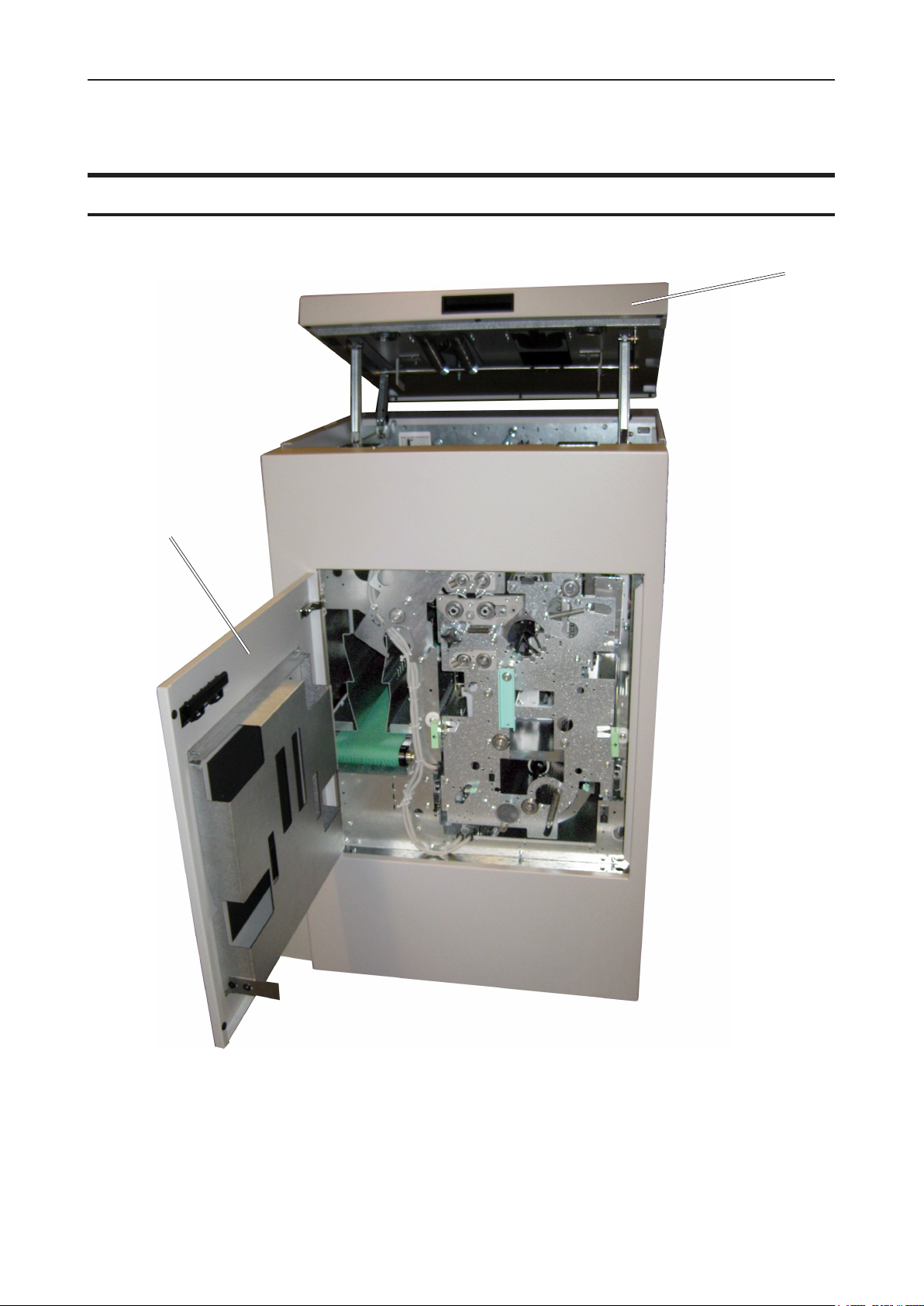

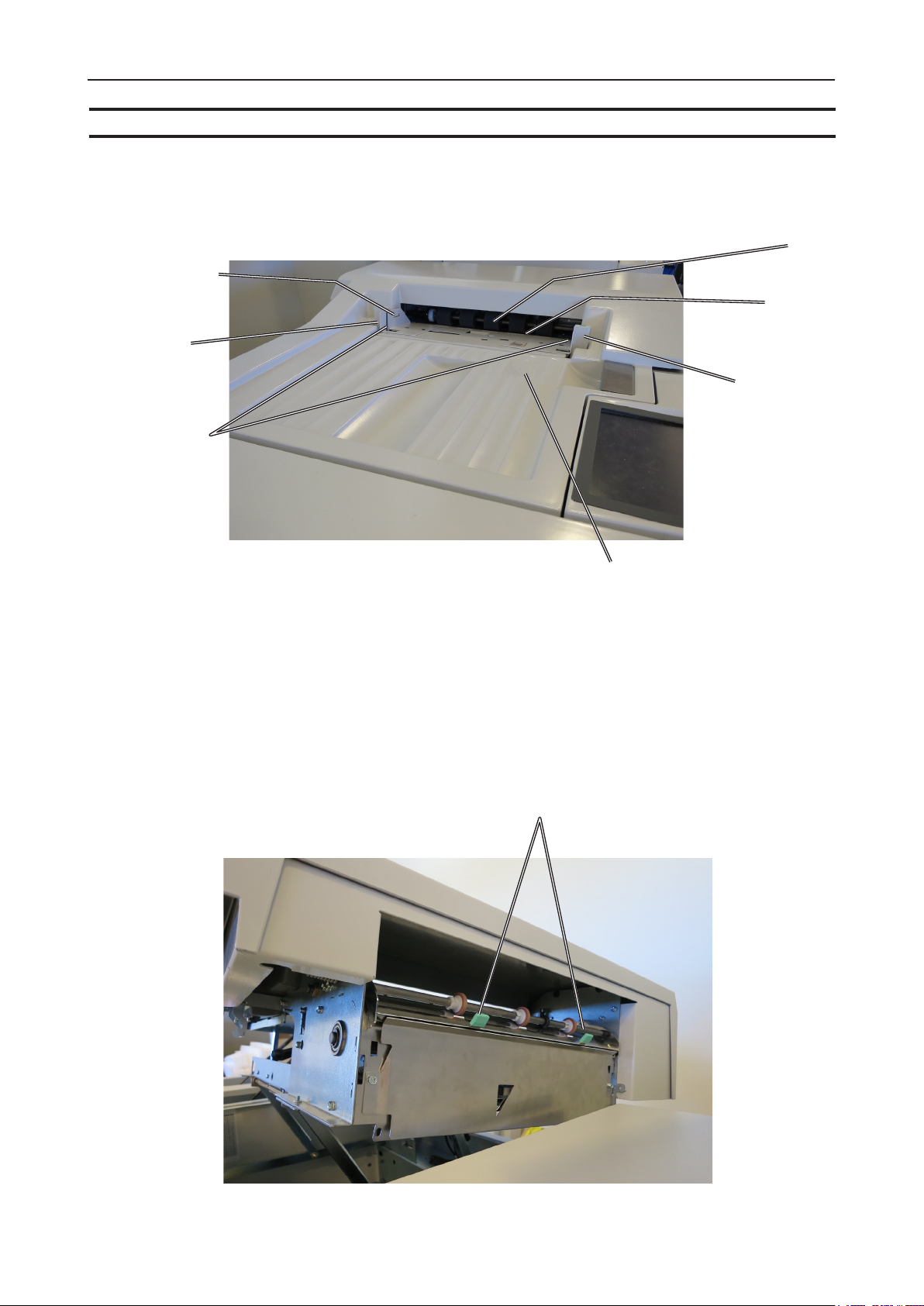

Booklet Maker

7

6

5

1

2

3

1. Top cover

2. Cover for Hand Feed

3. Latch handle

4. Live Logo, only on 50 sheet option

5. Belt Stacker

6. Belt Stacker Cover

4

7. Slot for optional Cover Feeder

13

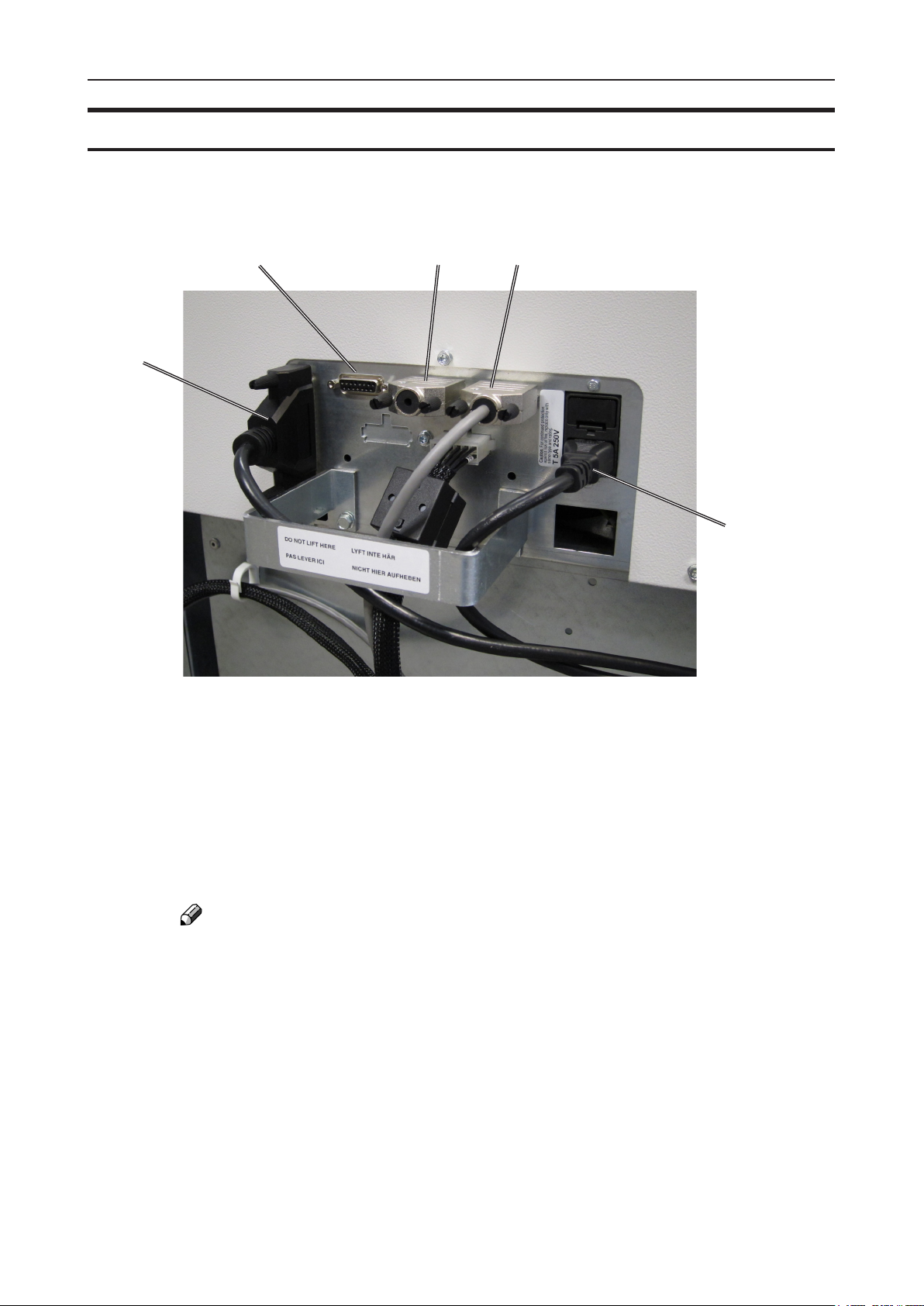

Booklet Maker, continued

1

5

2 3

4

1. Belt Stacker Connector

2. Upstreams Communication

3. Downstreams Communication

4. Power Connection

5. Printer interface

NOTE:

How to connect cables, plugs and jumpers is described at the end of this manual.

14

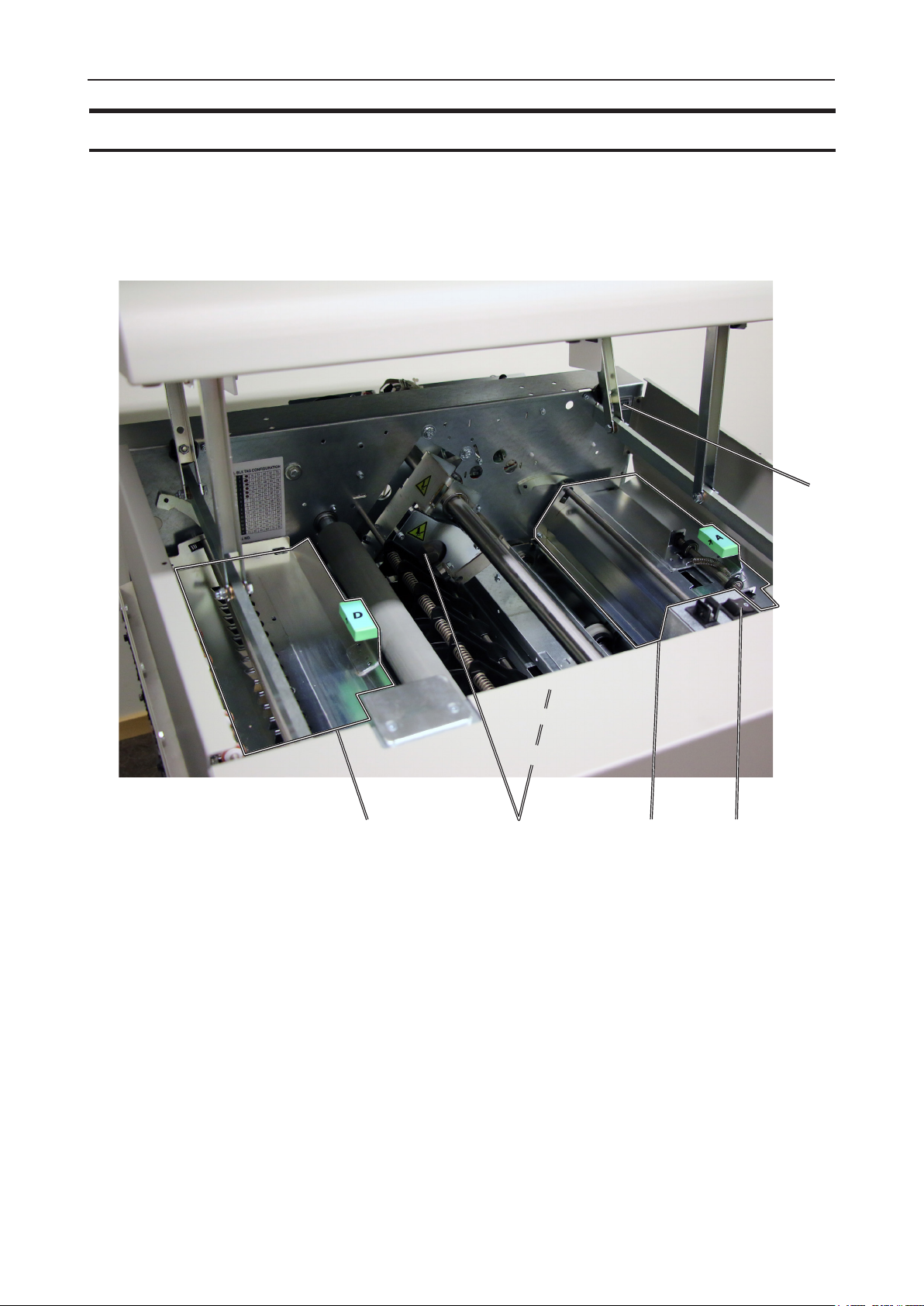

Booklet Maker, continued

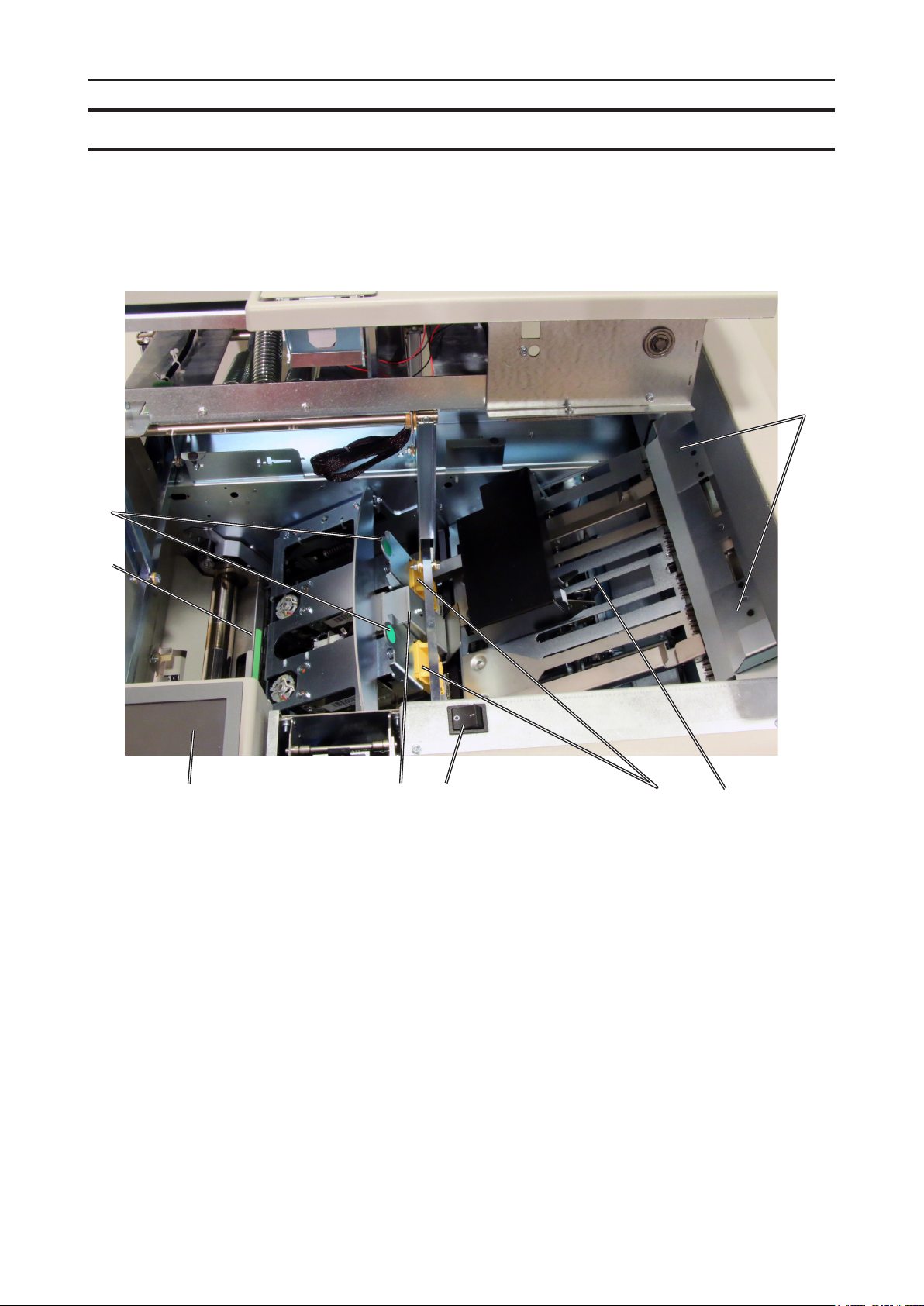

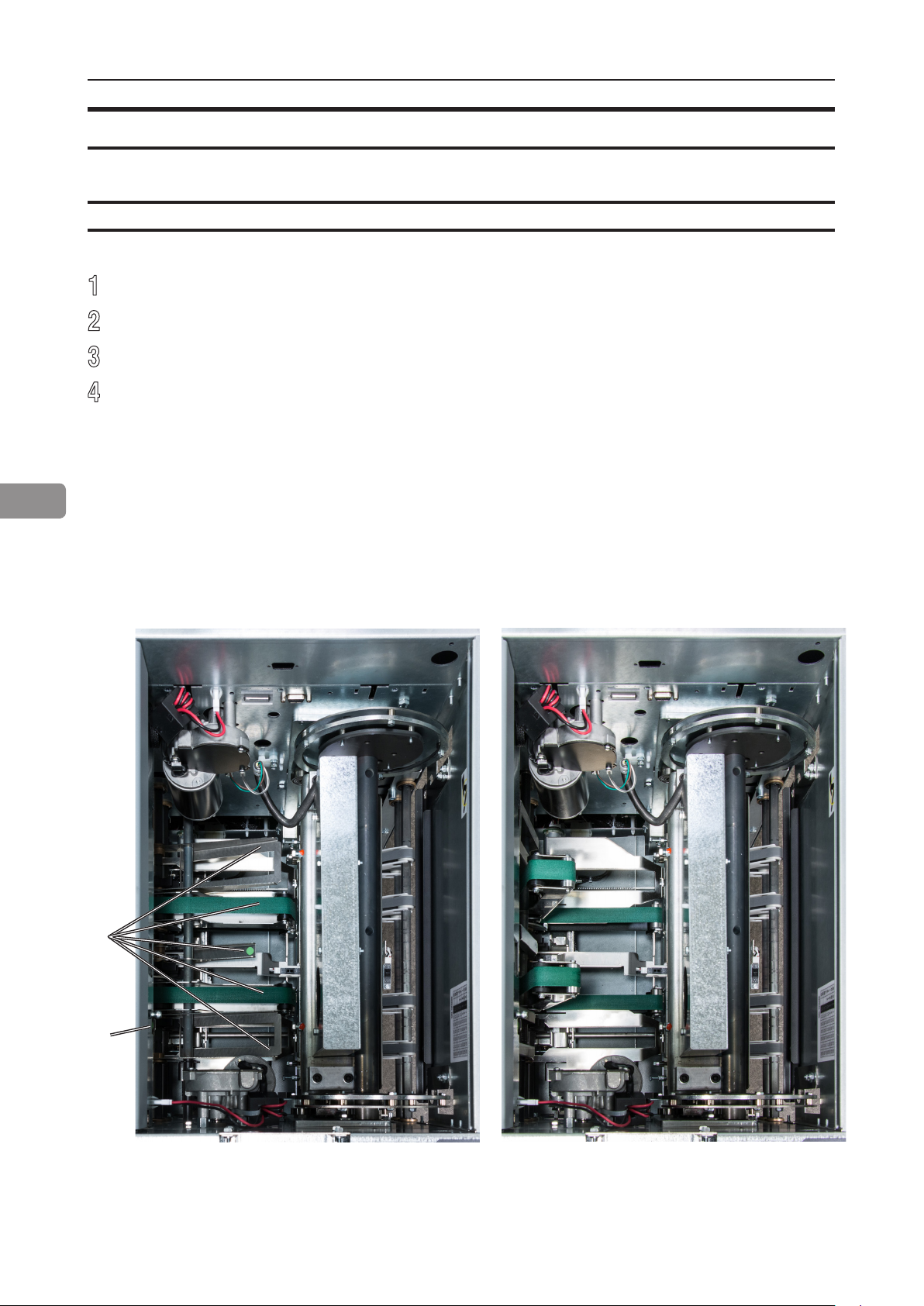

Parts that are important for setup, adjustments, troubleshooting or maintenance are highlighted below.

8

7

1

1. Hand feeding paper guides

2. Compiler area

3. Staple cartridges (incl. stapler heads)

4. Main power switch

5. Set thickness sensor

6. Control panel

7. Fold roller guide

8. Staple cartridge ejection lever

23456

15

User Interface

The Plockmatic BLM50 or BLM35 Production Booklet Maker System is controlled from a panel

located on the Booklet Maker. The control panel will allow you to set up, adjust and operate the

complete system. An optional “Alive logo” makes the state of system visible from a distance.

NOTE:

Depending on modules and features installed, the screen may look different from what you

see here. Some functions are greyed out or not visible at all and remaining buttons may

stretch to t the screen. This manual will most often show a fully congured system.

Control Panel

The control panel is of touch screen type. Point at the screen and press the “button” to

reach the desired function or change the desired setting.

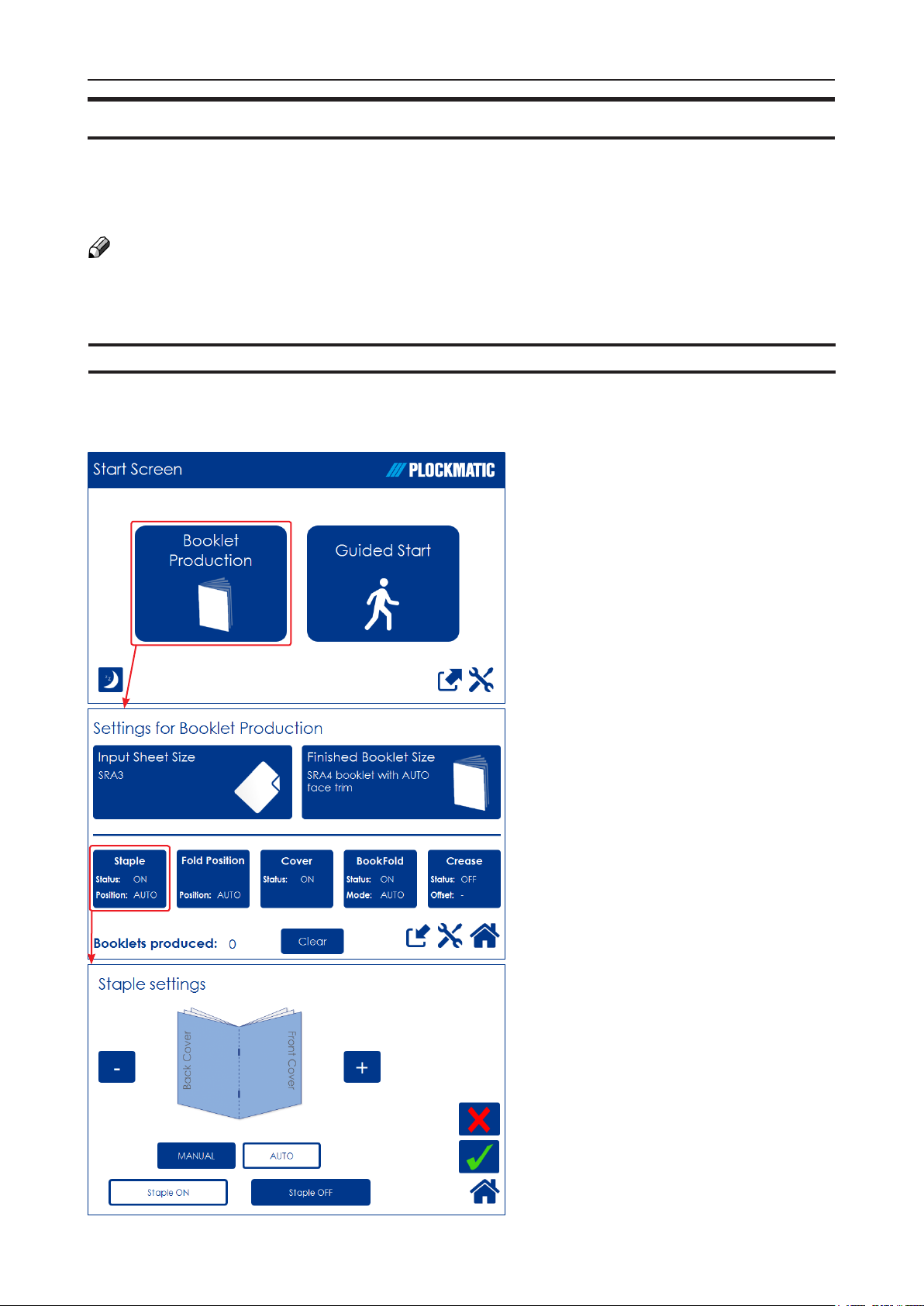

The Start Screen

When the system power is switched

on, the Start screen will be shown.

From here you can choose to set

up Booklet Production, perform a

Guided Start, retrieve stored jobs or

access the General System Settings.

Settings for Booklet Production

Pressing the [Booklet Production]

button in the Start Screen opens

the Settings for Booklet Production

screen. From here you can reach all

detailed settings for setting up the job.

A counter shows the number of

booklets produced. Clear will reset.

Detailed Settings

Pressing, for example, the [Staple]

button in the Settings for Booklet

Production screen opens the Staple

settings screen. Here you can

perform detailed settings concerning

stapling. Explore this and other

settings more thoroughly in section 2,

“Making Booklets.”

16

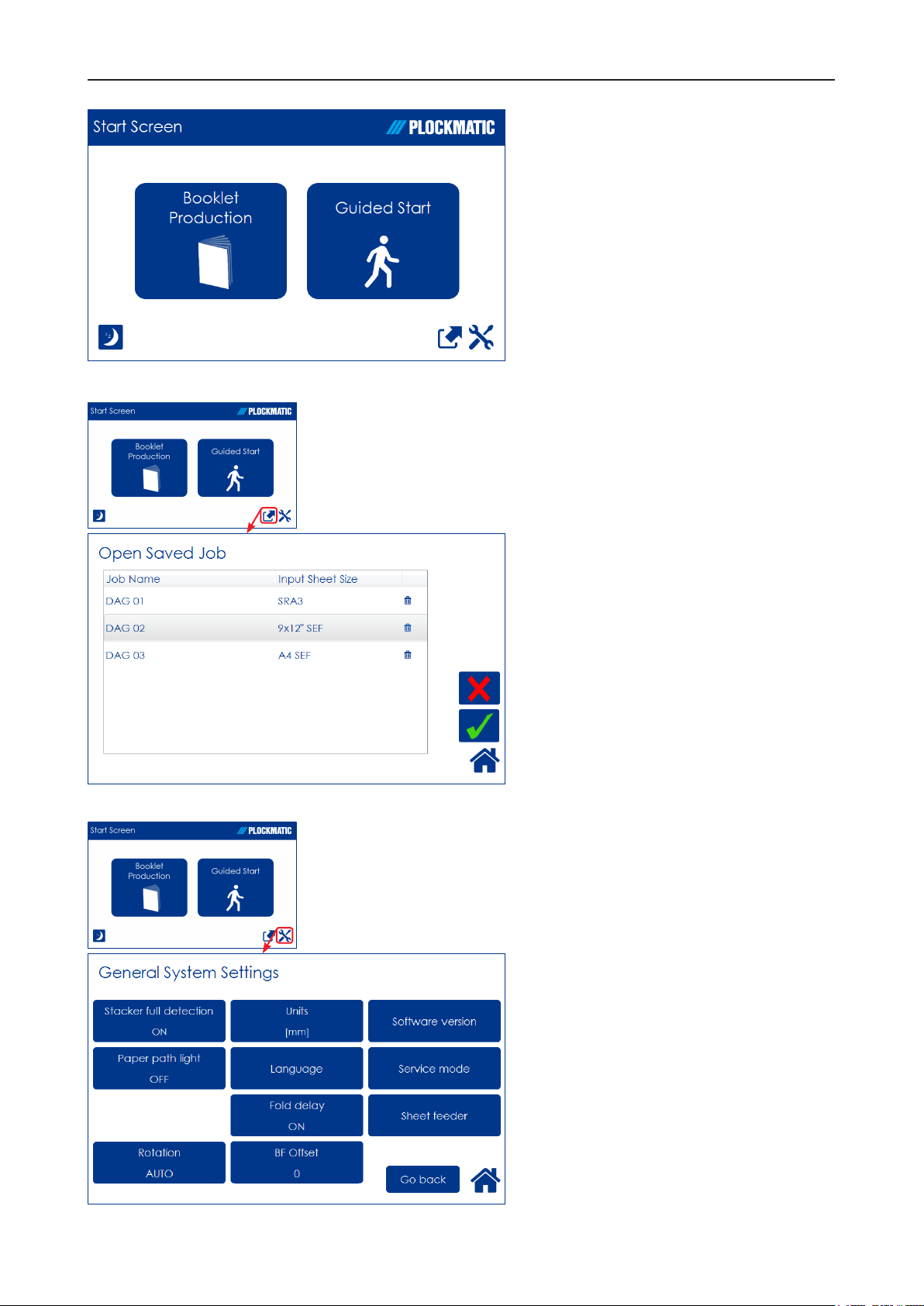

Guided Start

Guided Start is a function that takes

you through all the basic settings

the Booklet Maker System needs

for booklet production in eight easy

steps.

See “Guided Start” in section 2

“Making Booklets” for details.

The Jobs Screen

Pressing the [Open Jobs] button in

the Start screen opens the Open

saved Job screen. From here you

can open a saved job. Jobs can

be stored, deleted, customized etc.

Handling jobs is described in section

4, “Jobs”.

General System Settings

Pressing the [Tools] button opens the

General Systems Settings screen.

From here you can change basic

settings like the display language,

setting units from millimeters to

inches and more. See section 3,

”Tools” for how to work with the Tools

screen.

17

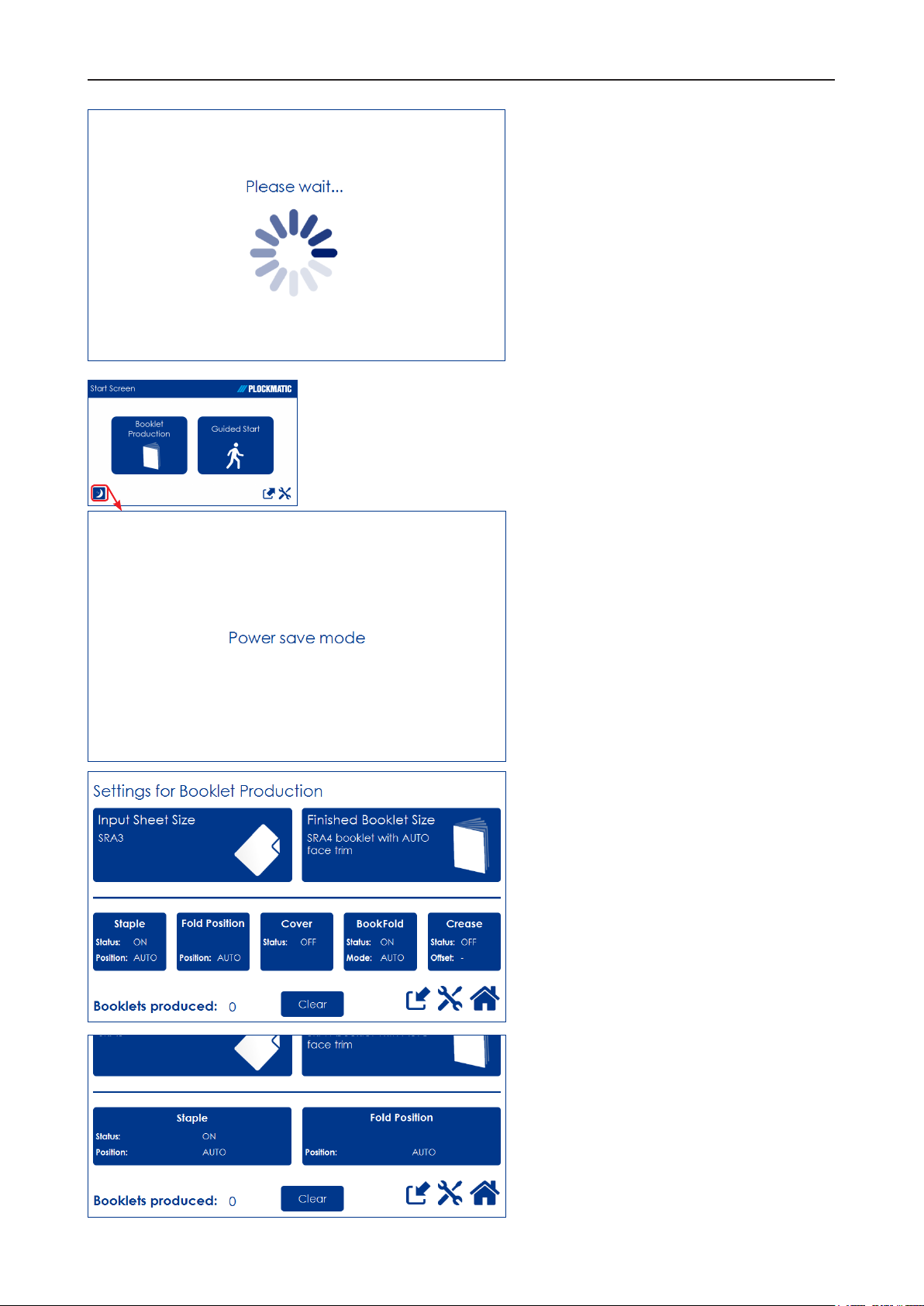

The Please wait screen

While the machine sometimes needs

time to perform changes in settings,

the Please wait screen will be shown.

Power save mode

When the Booklet Maker System is

in a ready state, it will enter power

save mode after 20 minutes of

inactivity.

To recover from Power save mode,

touch the screen or send a print job

to the Booklet Maker System.

The Booklet Maker System can also

be forced into Power save mode

by pressing the [Power save mode]

button.

When the Booklet Maker system is

processing or when there is a jam

state it will not enter power save

mode.

Information on screen

Depending on how the system is

congured, the information on the

screen changes and the size of the

buttons will adapt to t the screen.

This sample screen shows a fully

congured Booklet Maker system

with RCT, Cover Feeder, BookFold

Module and Trimmer.

18

This sample screen shows exactly

the same screen as above but this

time the system is congured only

with a Trimmer.

Options

Rotate Crease Trim Module

2

1

1. Top cover

2. Side door

19

Rotate Crease Trim Module, continued

Connections bracket

1

4

1. Exit slot

2

3

2. Trim waste transport

3. Waste container

4. Cable protector

NOTE

How to connect cables, plugs and jumpers is described at the end of this manual.

20

Rotate Crease Trim Module, continued

Parts that are important for setup, adjustments, troubleshooting or maintenance are highlighted below.

5

1. Exit section “D”

2. Bleed trimmer circular knives

3. Infeed Section “A”

4. Main switch

5. Counter

2

31 4

21

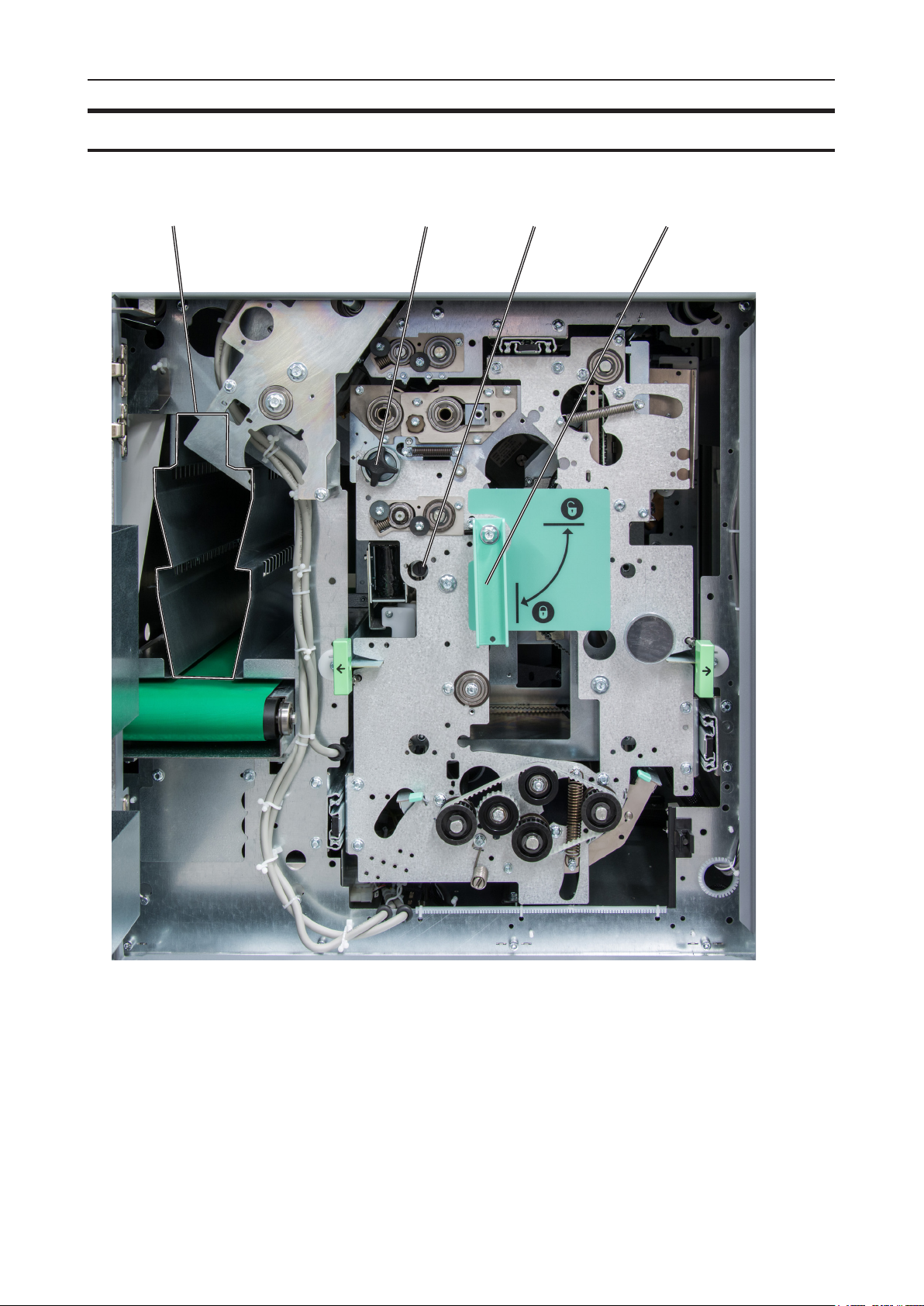

Rotate Crease Trim Module, continued

1

2 3 4

1 Waste chute(s)

2 Creaser registration adjustment

3 Bleed trimmer registration adjustment

4 Latch handle, slide

22

Rotate Crease Trim Module, continued

1

2

4

3

1 Creaser tools

2 Jam clearance bafe, ne registra-

tion, section “C”

3 Jam clearance bafe, coarse regis-

tration, section “B”

4 Rotator

23

Booklet Maker

Alive Logo

Alive Logo

With a BLM50 upgrade kit installed, the three

stripes below the user interface will signal status

as follows:

Not illuminated - System in power save mode or

switched off.

Steady blue - System is on and ready.

Alternating blue/yellow - Soft stop (staples low,

cover low, stacker full, waste bin full).

Alternating blue/red - Jam or malfunction

24

Cover Feeder

Parts that are important for setup, adjustments, troubleshooting or maintenance are highlighted below.

3

1

4

2

5

7

1 Loading capacity mark

2 Rear side guide

3 Feed roller assembly

4 Paper separator pad

6

5 Front side guide

6 Paper orientation indicator

7 Air nozzle (2x)

8 Jam clearance bafe

8

25

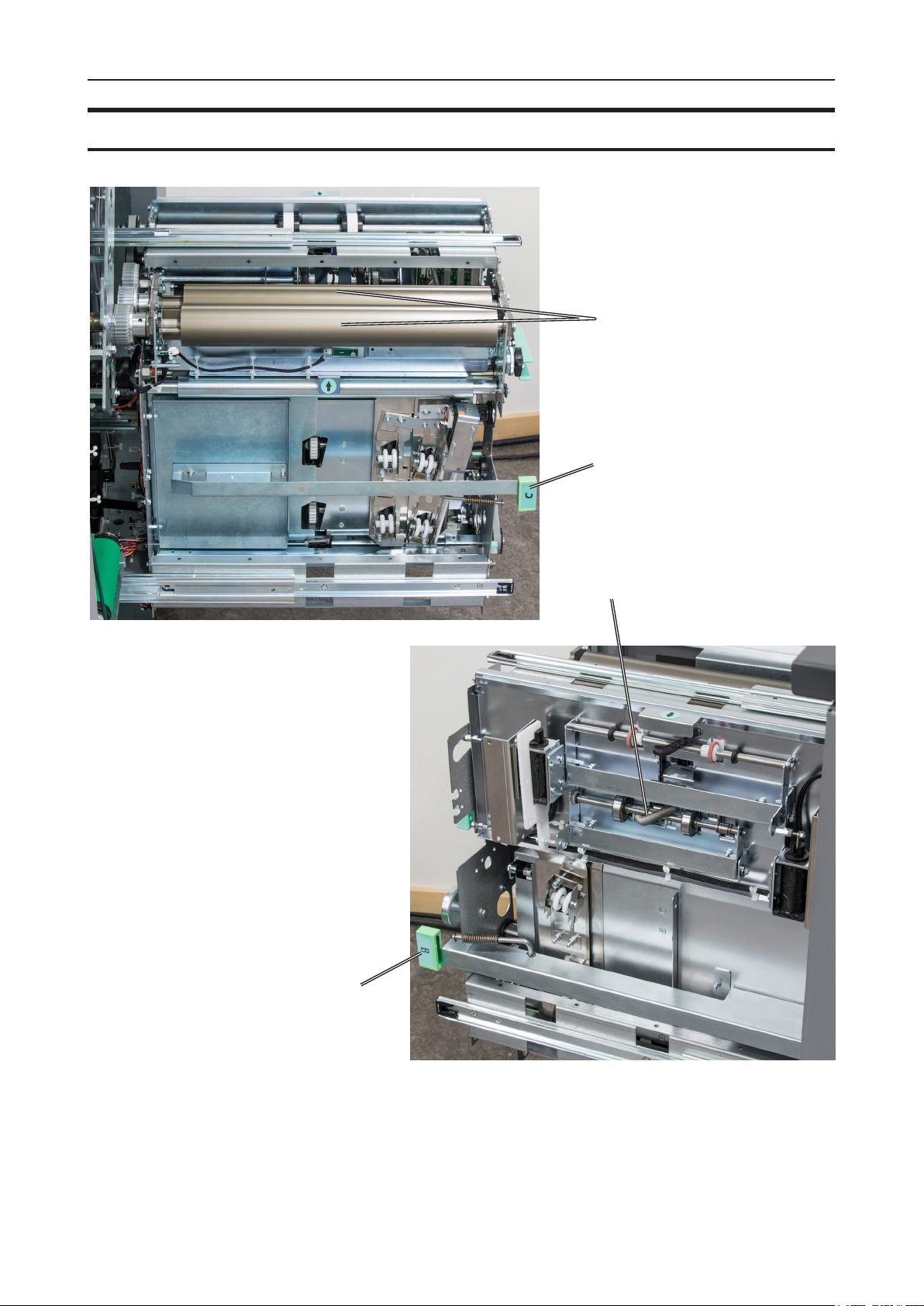

BookFold Module

1

3

2

1. Top cover

2. Base

3. Connections

4. Cable protector

NOTE:

How to connect cables, plugs and jumpers is described at the end of this manual.

4

26

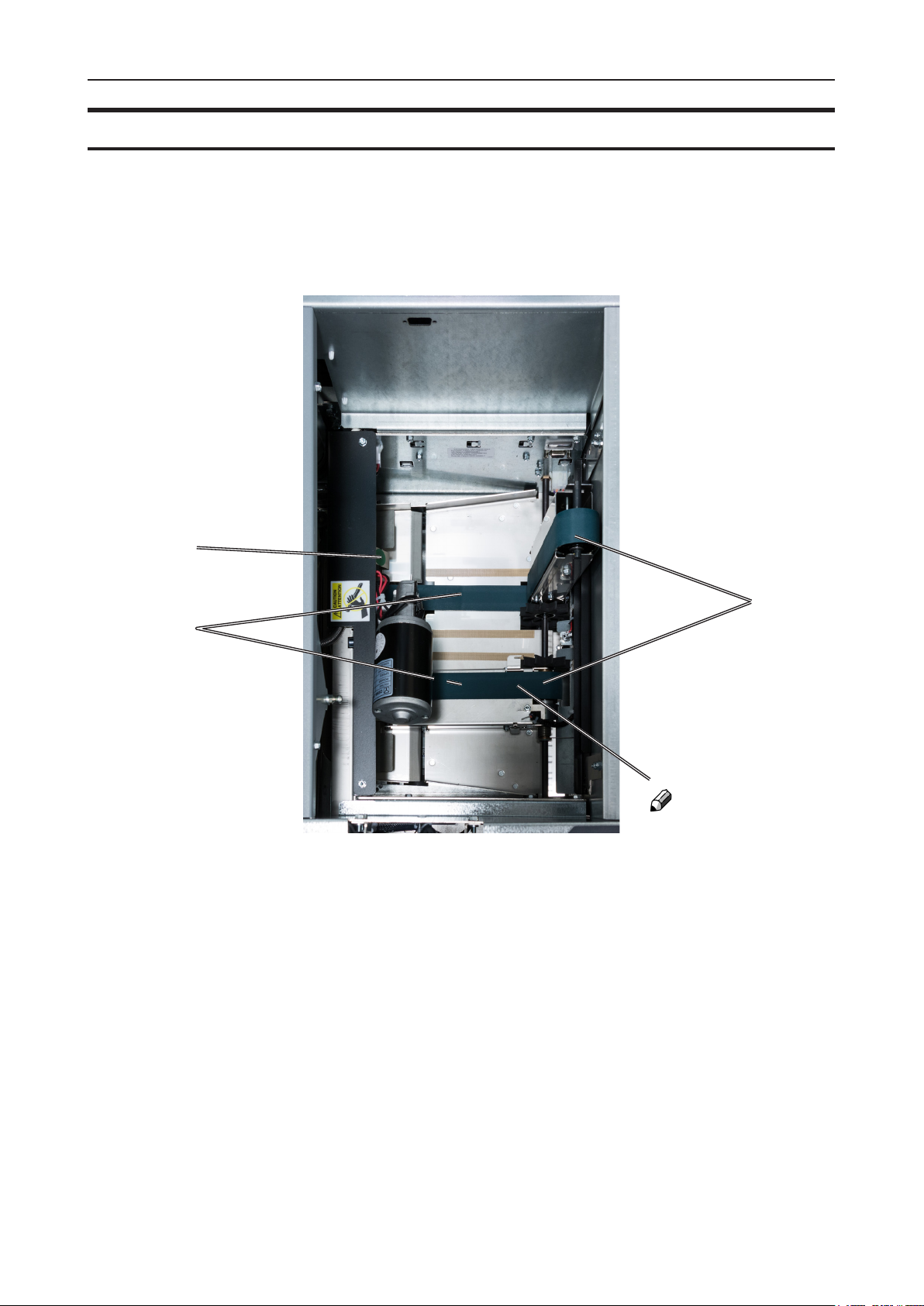

BookFold Module, continued

Parts that are important for setup, adjustments, troubleshooting or maintenance are highlighted below.

1

3

2

NOTE:

Upper feed belt on

operator side cannot

be lifted fully

BookFold Module, top view,

non operator side upper feed

belts lifted up

1 Upper feed belt release latch

2 Lower feed belts

3 Upper feed belts

27

Trimmer

1

2

4

3

1. Top cover

2. Trim bin

3. Base

4. Connections

5. Cable protector

NOTE:

How to connect cables, plugs and jumpers is described at the end of this manual.

5

28

Trimmer, continued

Parts that are important for setup, adjustments, troubleshooting or maintenance are highlighted below.

1

6

7

2

3

4

Trimmer, top view

1 Set counter

2 Exit drive lifting lever

3 Trimmer stop

4 Exit drive release

5 Exit compressing brackets

8

9

5

6 Infeed roller shaft

7 Trimmer fan

8 Transport belt

9 Upper trim knife

29

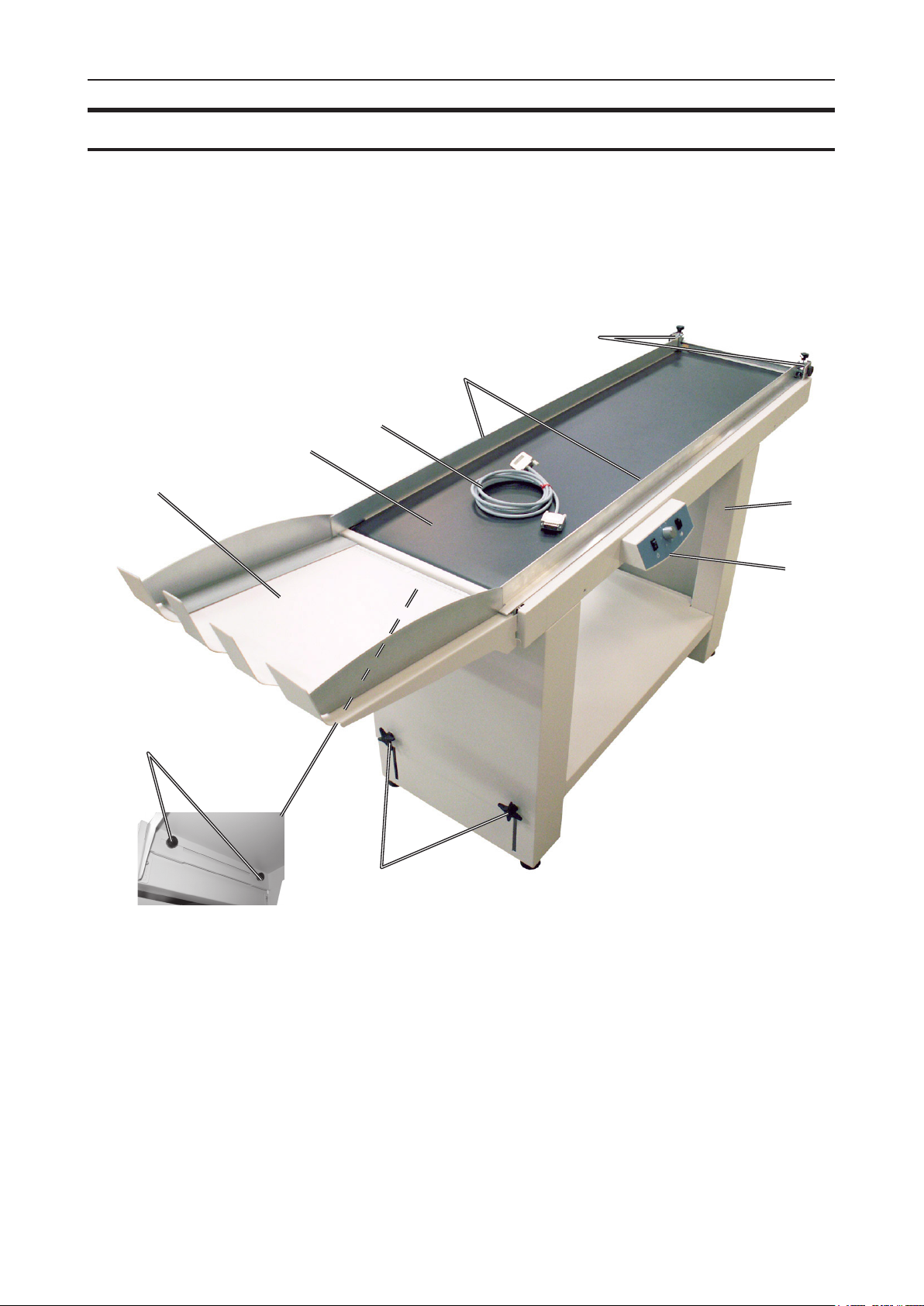

BST4000-1 Belt Stacker Module

The BST4000-1 High Capacity Belt Stacker Module is an option available for the

Plockmatic BLM50 or BLM35 Production Booklet Maker System. The stacker can be

congured in a straight line after the booklet maker system or at a 90 degree angle.

Parts that are important for setup, adjustments, troubleshooting or maintenance are highlighted below.

5

4

3

2

1

1

9

1 Control panel

2 Conveyor belt

2

6

7

30

8

1 Stacking tray

2 Conveyor belt

3 COM-cable

4 Side guides

5 Front end side guide adjustment knobs

6 Leg assembly

7 Control panel box

8 Height adjustment knobs (two on each leg)

9 Rear end side guide adjustment knobs (underneath)

BST4000-1 Control Panel

BST4000-1 Belt Stacker Module, continued

(1)

1 Power switch (on/off)

2 Belt speed selector

3 Run-out button (full speed)

BST4000-1 Principle of Operation

The belt is triggered by a signal from the Booklet Maker and will run for a set time.

The belt speed can be adjusted in order to optimize the stacking function for various

materials.

The Run-out button is used to gather the material after a job is nished.

The belt then moves at the highest speed, independent of the speed setting.

The power switch is also used to reset the unit after an overload situation.

(3)

(2)

31

Page intentionally blank.

1. Basics

Turning On / Off the Main Power

RCT, Booklet Maker, BookFold Module, Trimmer & BST Module

1

Make sure that the Booklet Maker, RCT

module (optional) and BST power cords are

plugged into the wall outlet.

NOTE:

BookFold (optional) and/or Trim (optional)

Modules are both powered from the Booklet

Maker.

2

Open the Booklet Maker top cover [A].

[A] [B]

[C] [D]

3

Set main power switch [B] on Booklet Maker

to ON position. If a BookFold Module and

Trimmer are attached, they will be powered

on via the Booklet Maker main power switch.

4

Close the Booklet Maker top cover.

5

Open the top cover of the RCT [C].

6

Set the main power switch [D] to ON position.

7

Close the RCT top cover.

[E]

8

Set main power switch [E] on the BST

Module to ON position.

33

Change staple cartridges and Check Stapler

The staple cartridges contains approximately 5000 staples each. Each cartridge includes

all wearable parts. The cartridges may need to be removed either for replacement or for

jam clearance.

1

Change left/right staple cartridge(s)

The Booklet Maker will indicate “Replace left/

right/left and right staple cartridges” when there

are approximately 20 staples left in the stapler

cartridge. Replace the indicated staple cartridge

by doing the following:

1

Open the Booklet Maker top cover.

2

Remove one or both staple cartridges by

lifting the lever [A], pressing either or both

levers [B] and pulling either or both staple

[B]

cartridges [C] out using the grip [E] at both

sides of the staple cartridge.

NOTE:

Lever [A] controls the stapler guides [D]. It is kept

in place by a magnet and can be hard to release.

Pressing either lever [B] makes it a bit easier to

overcome the force of the magnet.

[A]

[C]

[D]

3

Replace by pushing a new staple cartridge

into stapler until it snaps into position.

4

Put the stapler guides [D] back in position so

that lever is locked by the magnet.

5

Close booklet maker top cover and restart the

job.

[E]

34

Check left/right stapler

If the Booklet Maker indicates “Check right/left/

right and left stapler”, it means that there is a

jam in the indicated stapler. Remove the stapler

cartridge as described above.

1

Open the Booklet Maker top cover.

2

Remove either or both staple cartridge(s) as

described above.

3

Remove any sheets left in the Booklet Maker

and look for jammed staples stuck in the sheets.

4

Look inside the staple cartridge for jammed

staples and remove them if any.

5

Look at the clinchers [A] and remove any

jammed staples.

6

Push the staple cartridge(s) into stapler until

it snaps into position and lock stapler guides

in position as described above.

1

Cover Feeder

Loading covers

[A]

[A]

7

Close Booklet Maker top cover and restart job.

NOTE:

If the error message persists for no reason or if

staple jam reoccurs, replace the staple cartridge

as described above.

1

Make sure the cover sheets are well fanned

to avoid misfeeds or double-feeds.

2

Align the cover sheets well to achieve a

reliable feeding operation and good nishing

results.

3

Make sure that the ink has completely dried,

to avoid smearing.

4

Press on top of either air nozzle [A] to

lower the paper bin. Load the covers facing

downwards into the paper bin.

[B]

5

Adjust side guides [B] up against the cover

sheets until there is no clearance.

NOTE:

Make sure covers are same size as sheets fed

to booklet maker. When using an RCT, see Note

under “Changing settings, Finished Booklet Size,

Custom booklet size”.

35

Emptying the trim waste bin

Remove the trim waste bin by lifting it and pulling it out.

1

Trim bin

36

2

The Stacker can be used in either right-angled or in-line conguration with the Booklet

Maker. In-line mode is preferred if running heavy and large booklets.

Setting up Belt Stacker for Right-Angled Mode

Tighten the Side Guides at both

Move the inner Side Guide [A]

as far as possible towards the

Setting up Belt Stacker BST4000-1

Belt Stacker

Setting up Belt Stacker for right-angled mode

Follow these steps to correctly set up the Stacker

1

[B]

[A]

Move the inner Side Guide [A] as

far as possible towards the Booklet

Maker.

Booklet Maker.

2

Adjust the outer Side Guide [B] to

give at least 5mm (1/4”) play.

Adjust the outer Side Guide [B]

Tighten the Side Guides at both

to give at least 5 mm play.

ends.

3

Adjust the stacking with belt speed

ends.

selector.

Adjust the stacking with belt

speed selector. See page

11.

1

5 mm

37

Setting up Belt Stacker for Straight Mode

Adjust the stacking with belt speed

Adjust Side Guides to their

outermost position by loosening

Setting up Belt Stacker for straight mode

1

1 Adjust Side Guides to their

outermost position by loosening

knobs [A].

knobs [A].

2 Adjust the stacking with belt speed

selector [B].

selector.

[A]

[A]

[B]

38

2. Making Booklets

Guided Start

Guided Start is a function that takes you through all the basic settings the Booklet Maker

System needs to start booklet production in a few easy steps. Customizing settings and

ne adjustments are described later in this chapter.

Guided Start, step by step

Guided Start

Press the [Guided Start] button to

enter the Guided Start procedure.

Guided Start 1/8

This is the rst of up to 8 screens.

Depending on how the system is

congured and your selections

during this procedure, the number of

screens may be less than 8.

Conguration of the system also

affects the information shown and

button size will adapt to t screen.

To proceed from one screen to

another, press the [Next] button.

Guided Start 2/8

Select the sheet size loaded for the

job by pressing the corresponding

button.

For other sizes, follow “Custom sheet

size” described in section “Basic

Settings” below.

39

2

Guided Start 3/8

Choose either of two suggested

formats (except for B4 which only

has one suggested format).

When Face Trim is set to Auto,

a minimum trim, based on the

information from Set Thickness

Sensor, is calculated.

To set the trim manually, follow

“Finished Booklet size” described in

section “Basic Settings” below.

Guided Start 4/8

Select whether the Cover Feeder

is to be used or not and press the

corresponding button.

Guided Start 5/8

Load the covers face down.

NOTE:

Make sure covers are same size as

sheets fed to the Booklet Maker.

When using the bleed trim function

and feeding covers at the same time,

make sure covers loaded in Cover

Feeder are same size as sheets fed

from RCT to the Booklet Maker.

Guided Start 6/8

Select whether or not the booklet

should have a square formed spine

and press the corresponding button.

NOTE:

If the job includes a small number

of lighter weight sheets, the square

forming action will be switched off

and the BookFold Module will be

bypassed.

40

Guided Start 7/8

Select whether the booklets should

have a creased cover or not. This

feature is used to avoid high area

coverage toner cracking on the spine

on booklets containing less than 6

sheets.

Press the corresponding button.

After you are done, press the [Finish]

button to conclude the Guided Start.

Guided Start 8/8

All settings needed to begin

producing booklets are now set.

Start production by sending the print

job from the printer.

After the job has been sent to the

Booklet Maker System, the “Settings

for Booklet Production” screen is

shown.

2

From here you can customize and

ne-tune settings, save the job and

access the Tools screen.

Customizing and ne-tuning settings

is described below in this section.

How to save jobs is described in

section 4, “Jobs.”

Tools are described in section 3,

“Tools.”

Press Home to return to the “Start

Screen”.

41

Changing settings

General procedure

Settings can changed in one of two ways. “Temporary”, which means that the changes will remain

until a new job is loaded or “Permanent”, which means that the changes will be stored as a job.

This job can later be recalled.

Procedure for temporary changes:

From the Settings for Booklet Production screen, select the option you wish to alter and make your

2

selection. Conrm by pressing the green [check] button. You will be returned to the Settings for

Booklet Production screen

Procedure for permanent changes:

To keep your new settings, press the [Save current settings] button. Follow on screen instructions

to save your current settings as a new job or to an existing job.

NOTE:

Choose either of the above mentioned procedures when changing size, stapling, trimming, covers

or square forming as follows.

Depending on how the system is congured, the number of settings that can be selected varies.

The information on the screen and the size of the buttons will adapt to t the screen. Examples

below shows a fully congured system.

Basic settings

Input Sheet Size

Selecting standard paper sizes

From the Settings for Booklet Production screen, press the [Input Sheet Size]

button.

Select any standard paper size by

pressing the corresponding button and

save choice by pressing the green

[check] button.

Depending on conguration, available

standard paper sizes may differ. The

LEF paper sizes are only available if

there is a RCT installed.

For other paper sizes, follow “Custom

input sheet size” as described on the

next page.

42

NOTE:

Change of paper size will set Staple

position, Fold position, BookFold and

Crease to Auto and Cover to Off.

Any Fine-tuning (see section below) and

the “Booklets produced” counter will

also be reset.

AUTO sheet size

AUTO means that the Booklet Maker will adjust to the paper size information sent from the printer.

Auto Rotate will be turned on and a nished booklet size will be chosen from a predened list i.e.

the [Finished Booklet Size] button will be greyed out. No other settings will be affected.

Custom input sheet size

From the Input sheet size screen, press any

of the Custom size buttons and then press the

[Edit] button.

NOTE:

Changing to a Custom input sheet size will NOT

change Staple position, Fold position, Cover,

BookFold, Crease or Fine adjustment settings.

The “Booklets produced” counter will still be

reset.

Select Length and/or Width and key in the

desired value. Save the custom size format by

pressing the [check] button.

2

Finished Booklet Size

Auto trimming

Three different custom paper sizes can be stored.

NOTE:

A full number (incl. decimal point and fractions

of an inch/mm) must be entered before the

green [check] button appears.

Save setting by pressing the green [check] button.

From the Settings for Booklet Production

screen, press [Finished Booklet Size].

Trimming can now be set to either of two

suggested formats (except for B4 which only

has one suggested format) or Custom Booklet

Size.

When Face Trim is set to Auto, a minimum trim,

based on the information from Set Thickness

Sensor, is calculated.

For custom sized booklets, see below.

43

Custom booklet size

2

To set the trim manually, press [Custom Booklet

Size] and then [Edit].

To adjust the amount of face trim, press the

number on the [Length] button and type in the

desired length of the booklet, decimals included.

Also, the [plus] and [minus] buttons can be used

to change the numbers. The amount of face trim

is displayed in the box.

Press the green [check] button to conrm or

continue adjusting the amount of bleed trim.

To also adjust the amount of bleed trim, press

the number on the [Width] button and type in the

desired width of the booklet, decimals included.

Also the [plus] and [minus] buttons can be used

to change the numbers. The amount of bleed

trim is displayed in the box.

Press the green [check] button to conrm.

Back in the Finished Booklet size screen, the

size of the nished booklet and the amount of

face and bleed trim is displayed.

Press the green [check] button to conrm.

NOTE:

When using the bleed trim function and

feeding covers at the same time, make sure

covers loaded in Cover Feeder are the same

size as sheets fed from the RCT. According

to the example on the left, covers must be

300x450mm.

44

Customizing settings

Staple

Selecting stapling On or Off

From the Settings for Booklet Production

screen, press the [Staple] button.

2

Select On or Off by pressing the corresponding

button and save setting by pressing the green

[check] button.

Adjusting staple position

From the Settings for Booklet Production

screen, press the [Staple] button.

Set to Manual, the staple position can be altered

up to 3 mm (0.12”) on either side of the fold.

Press the [+] button move position closer to the

lead edge and press the [-] button move position

closer to the trail edge. Save setting by pressing

the green [check] button.

NOTE:

This change can be performed during run.

Set to Auto, the Booklet Maker uses the set

thickness sensor to adjust the staple position.

Press the [Auto] button and save setting by

pressing the green [check] button.

45

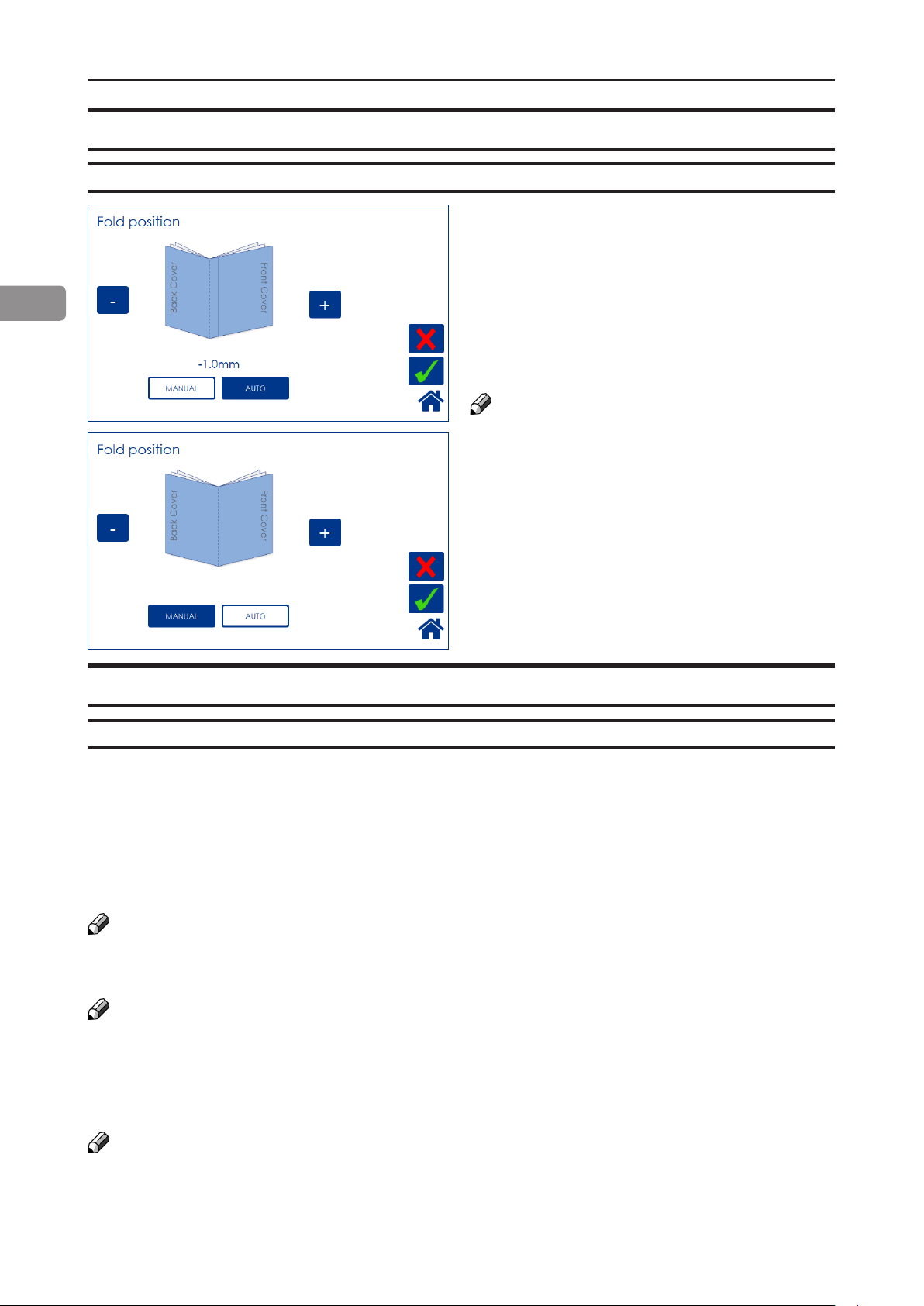

Fold position

Adjusting fold position

2

From the Settings for Booklet Production

screen, press the [Fold position] button.

The position of the fold can be changed up to 3

mm (0.12”) on either side of the center of the set.

Press the [+] button move position closer to the

lead edge and press the [-] button move position

closer to the trail edge. Save setting by pressing

the green [check] button.

NOTE:

This change can be performed during run.

You may want to turn off trimming to see the

result more clearly when you move the fold

position.

Set to Auto, the Booklet Maker uses the set

thickness sensor to adjust the fold position.

Press the [Auto] button and save setting by

pressing the green [check] button.

Cover

General

If the optional Cover Feeder is installed, the [Cover] button will be visible in the control panel. If

enabled, the cover feeder will automatically feed one sheet to each set from the printer, or one

sheet to each manually, hand-fed set.

A higher paper weight, pre-printed cover is fed to the set waiting in the compiler. The set and the

cover are then stapled and folded together.

Depending of system conguration, the booklet is then fed to the Belt Stacker, BookFold Module or

Trimmer.

NOTE:

Make sure sheets fed from Cover Feeder are the same size as sheets fed to booklet maker from

printer or by hand. When using an RCT, see Note under “Changing settings, Finished Booklet Size,

Custom booklet size”.

NOTE:

After selecting Cover [Yes], when the green [check] button is pressed, the Cover Feeder will try to

move the rst sheet into feeding postion. Therefore, load covers before pressing the green [check]

button to avoid the error message “Load covers” from being shown. See section 1, “Basics” for

how to load covers.

The Cover Feeder can also be used as a regular feeder. See section 3, “Tools”.

NOTE:

In case of a cover feeding jam/error, it is difcult to remove a stuck cover due to the very strong

separation nip. Removing the stack of sheets and then using the purge button on the stuck sheet

is the easiest way to remove a cover that is stuck.

46

Cover

Air Separation

From the Settings for Booklet Production

screen, press the [Cover] button. Press the

[Yes] button and conrm by pressing the green

[check] button.

2

You may want to increase the Air ow when

running thick, heavy covers. From the Cover

screen, press the [Air separation] button.

Set the desired amount of air ow by pressing

the corresponding button and save setting by

pressing the green [check] button. Default setting is 40%.

Double Sheet Detection

From the Cover screen, press the [Double

sheet detection] button.

Set the detection to On or Off by pressing

the corresponding button and save setting by

pressing the green [check] button.

Normally, double sheet detection should be set

to “On” when you are feeding covers. However,

if you experience “false double sheet feeds”,

for example when running covers that are thick,

with dark print or with mixed prints on the

covers, the double sheet detection can be set

to Off.

NOTE:

Misfeed detection will work regardless of how

Double Sheet detection is set.

47

Purge Cover

The Purge mode is used when you want to

completely empty the Cover Feeder from covers.

1 Remove all cover sheets from the bin.

2 Press the [Purge Cover] button and conrm

by pressing the green [check] button. The

2

NOTE:

If you open and close the top cover without removing the cover sheet, the cover sheet will be

stapled and folded and then fed to the stacker.

pre-fed cover sheet will now be fed into the

Booklet Maker to the stapling area, but will

not be stapled.

3 Open top cover and remove the cover sheet.

BookFold

General

The BookFold Module has three different settings - Manual, Auto and Off.

In Manual mode, there are eight different modes of BookFold pressure to choose from.

Set to Auto, information from the set thickness sensor in the Booklet Maker is used to calculate the

most appropriate mode between 1 and 7. See guidance table below.

Select Off to bypass the BookFold Module without any square forming action.

NOTE:

When the BookFold Module is set to Auto and the booklet has less than approximately 6 sheets/

booklet, the BookFold Module will bypass the square forming action.

For some jobs, Auto mode may not provide the optimum result. In this case, ne tune by selecting

a mode in Manual mode - see the table below.

Mode 8 is a heavy duty setting in case of extra demanding media. Mode 8 is not included in the

Auto setting and therefore must be selected manually.

Use the manual modes to override the auto function. There are eight different manual modes to

select from.

Table below is approximate numbers and is based on 80 gsm / 20 lb Bond sheets.

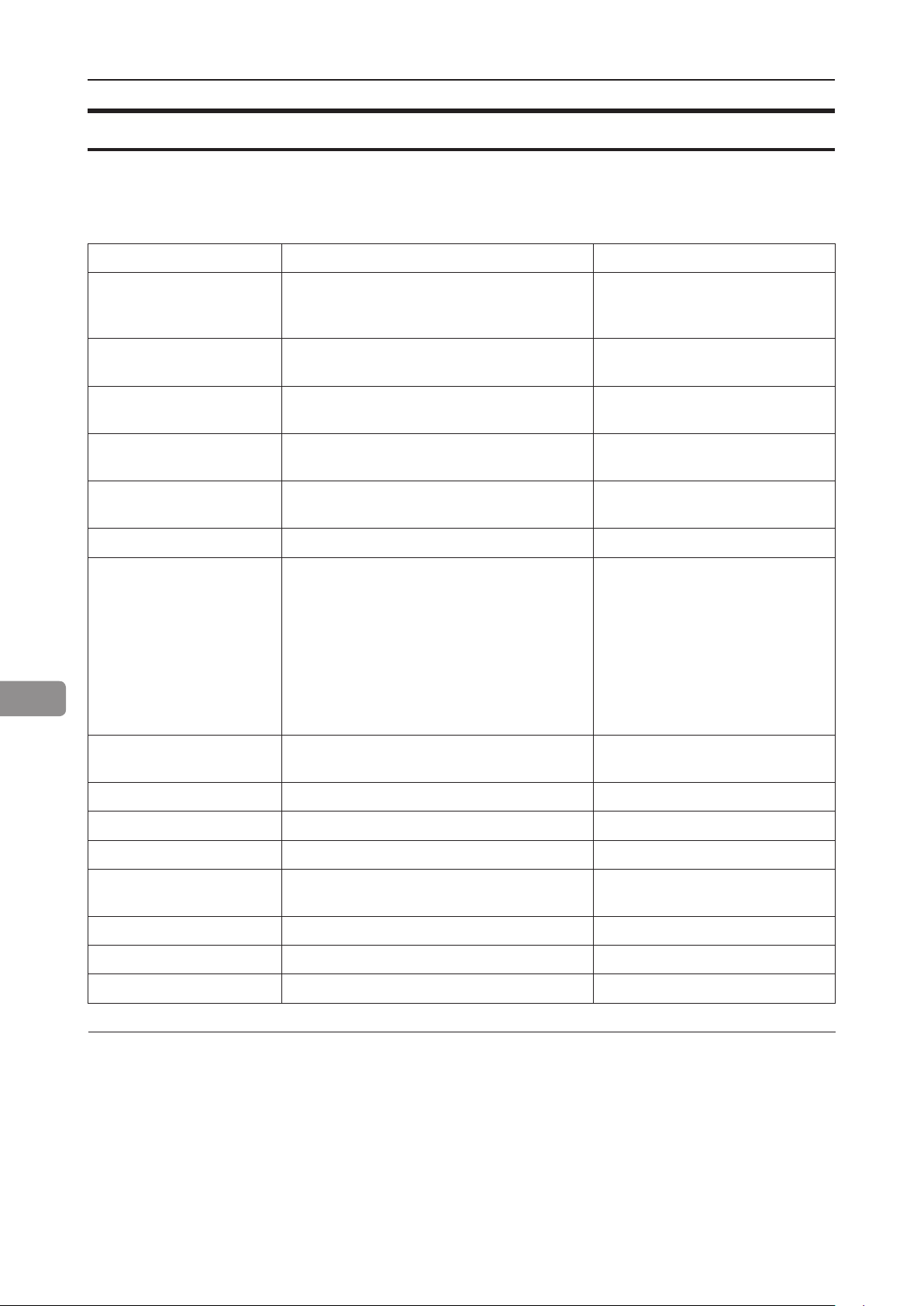

Mode Number of sheets in the set Notes

1 Approximately 6 to 10

2 Approximately 11 to 16

3 Approximately 17 to 22

4 Approximately 23 to 29

5 Approximately 30 to 35

6 Approximately 36 to 43

7 Approximately 44 to 50

8 Heavy duty setting in case of

extra demanding media.

BookFold pressure settings guidance table

continued on next page

48

The table below shows highest supported BookFold pressure settings on BLM35 and BLM50 Production Booklet Maker systems.

NOTE:

The following table indicates maximum BookFold pressure setting that can be used on the

Production Booklet Maker systems without slowing the printer down.

Number of sheets A4 A3 SRA3 8.5x11" 11x17" 12x18"

1-5 2 4 7 1 4 7

6-10 4 7 8 4 7 8

11-15 7 8 8 7 8 8

16-20 7 8 8 7 8 8

21-30 8 8 8 8 8 8

31-50 8 8 8 8 8 8

NOTE:

When square forming thick booklets with a thin cover, the cover sheet may be spaced away from

the body of the book and/or it may be crushed in the square forming process.

This phenomenon is eliminated/reduced by using a heavier media as the cover. If using a heavier

cover is not an option, using a lower BookFold pressure setting in the square forming process may

improve booklet appearance.

Selecting BookFold pressure setting

2

From the Settings for Booklet Production

screen, press the [BookFold] button.

Press the [Manual] button and select the desired amount of pressure using the [+] and [-]

buttons. Save setting by pressing the green

[check] button.

49

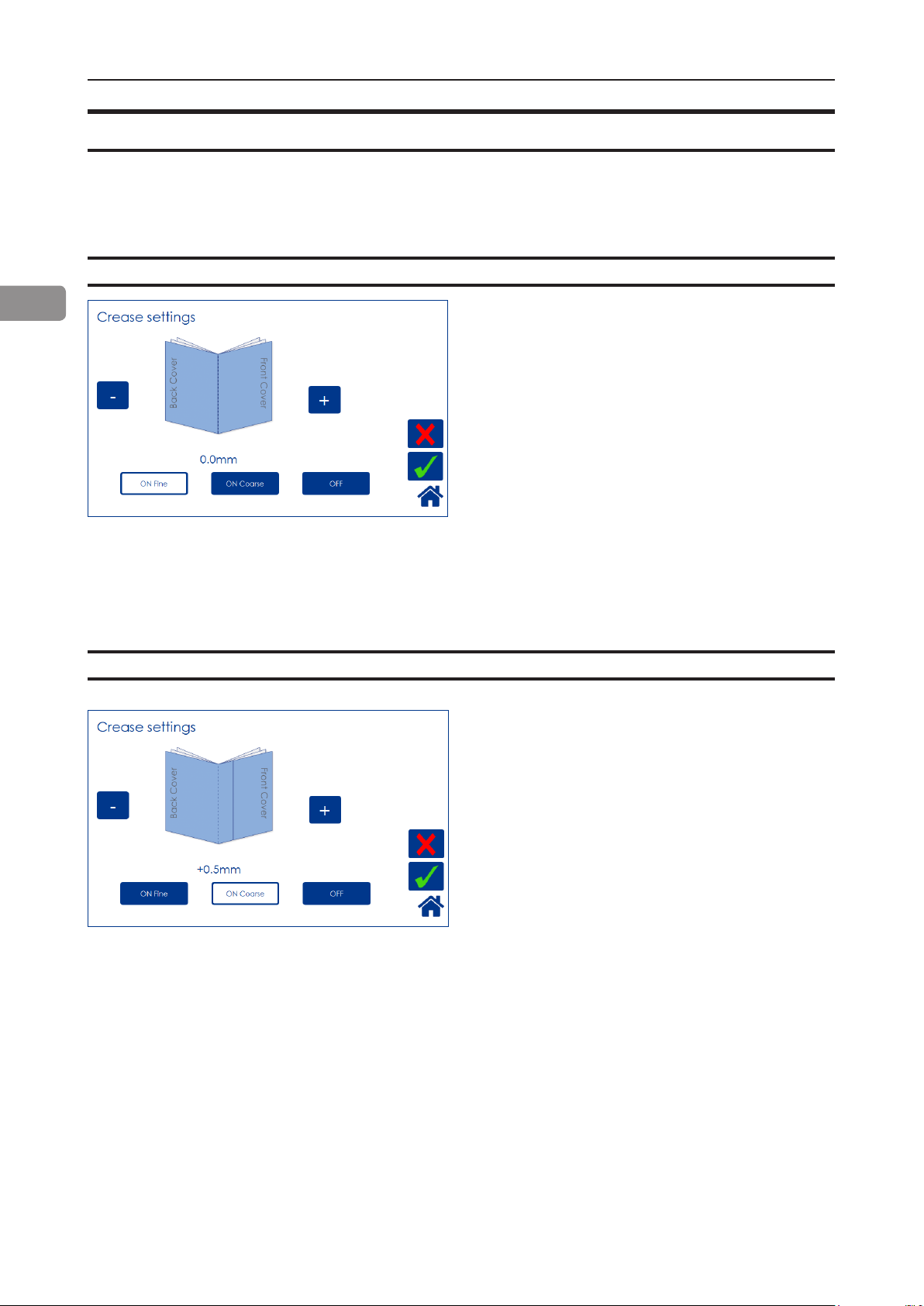

Crease

The Crease function makes it possible to crease the cover sheet of the booklet in order to avoid

toner cracking or aking at the fold.

Crease Mode

2

Crease position

From the Settings for Booklet Production

screen, press the [Crease] button.

Press the corresponding button to choose [On

Fine], [On Coarse] or [OFF].

Fine is recommended for cover sheets less than

120 gsm / 32 lb Bond.

For sheets heavier than that, select Coarse.

When you want to turn the Creaser off, select

Off.

Press the green [check] button to conrm.

The crease is initially set to the center of the

sheet. Operators have the option to offset the

position of the crease using the [+] or [-] buttons.

Press the [+] button move position closer to the

lead edge and press the [-] button move position closer to the trail edge. Regardless if you

chose Fine or Coarse creasing, each press of a

button will move the crease 0.1 mm / 0.004”.

50

When done, press the green [check] button to

conrm.

The illustration shows that the crease is offset

0.5 mm towards the trail edge.

Fine-tuning booklet appearance

Set registration (ne adjustment)

You can ne-tune the booklet quality by adjust-

ing the joggers in the booklet maker.

From the Settings for Booklet Production

screen, press the [Finished Booklet Size] button.

From the Finished Booklet size screen, press

the [Set registration (ne adjustment)] button.

2

Press the [-] and [+] buttons to alter either or

both registration values.

Negative value means a tighter registration.

NOTE:

Too tight of a setting may worsen the result.

After setting registration value, press the [Check

set registration] button and follow the instructions on screen.

If you are satised with the registration, conrm

by pressing the green [check] button.

If not, press the [-] and [+] buttons to enter new

value. Check out the new value by pressing the

[Verify adjustments] button.

Press the green [check] button when you are

satised.

51

Bleed Trimmer - Asymmetric Side Trim

From the Finished Booklet size screen, press

the [Asymetric Side Trim] button.

2

Choose Asymmetric Side Trim if you want to

offset the bleed trim. Move using the [+] and [-]

buttons and press the green [check] button to

save setting.

Settings as in the example above would result

in a booklet with trim settings shown in the im-

age to the left.

Bleed Trimmer - Cover Adjust

52

From the Finished Booklet size screen, press

the [Cover Adjust] button.

Choose Cover Adjust to compensate for different

shrinkage of body- and booklet cover stock. This

can occur under some conditions and can be

caused by different paper stocks shrinking due to

the heat and pressure of the fusing process.

Adjusting these settings can improve booklet

appearance, especially if the cover is dark and

the body sheets are bright.

The shown example will make the cover sheet

0.7mm bigger than the body stock.

Hand-feeding

The Booklet maker can be operated in two modes. On-line mode, when used together with

the printer, or off-line mode, working as a stand-alone unit.

Hand feed mode

[A] [C][B]

1

Setup the Booklet Maker to the correct

paper size.

2

Open the Hand Feed Cover [B].

3

Adjust the hand feeding paper guides

[A] to the correct paper size.

4

Start hand feeding sets [C] when the

text [Ready to feed!] is shown in the

user interface.

2

5

To stop hand feeding, close the Hand

Feed Cover.

NOTE:

RCT features will not be available.

53

Page intentionally blank.

3. Tools

The Tools screen

From the Start screen or the Settings

for Booklet Production screen, press the

[Tools] button to get to the General System

Settings screen. Select the setting you want to

change by pressing the corresponding button.

Press the green [check] button to save your

changes.

Stacker full detection

Units

Set Stacker Full Detection to ON if you want

the system to stop and cycle down when the

stacker is full.

Select millimeters or inches by pressing the cor-

responding button.

55

Software version

3

Paper path light

Select module by pressing the corresponding

button to display the software version. Press

[Exit] button to go back to the Settings screen.

This function is for service purposes.

To turn the paper path light on, press [ON 5 min]

button and save by pressing the [OK] button.

Language

Select desired language by pressing the corresponding button.

56

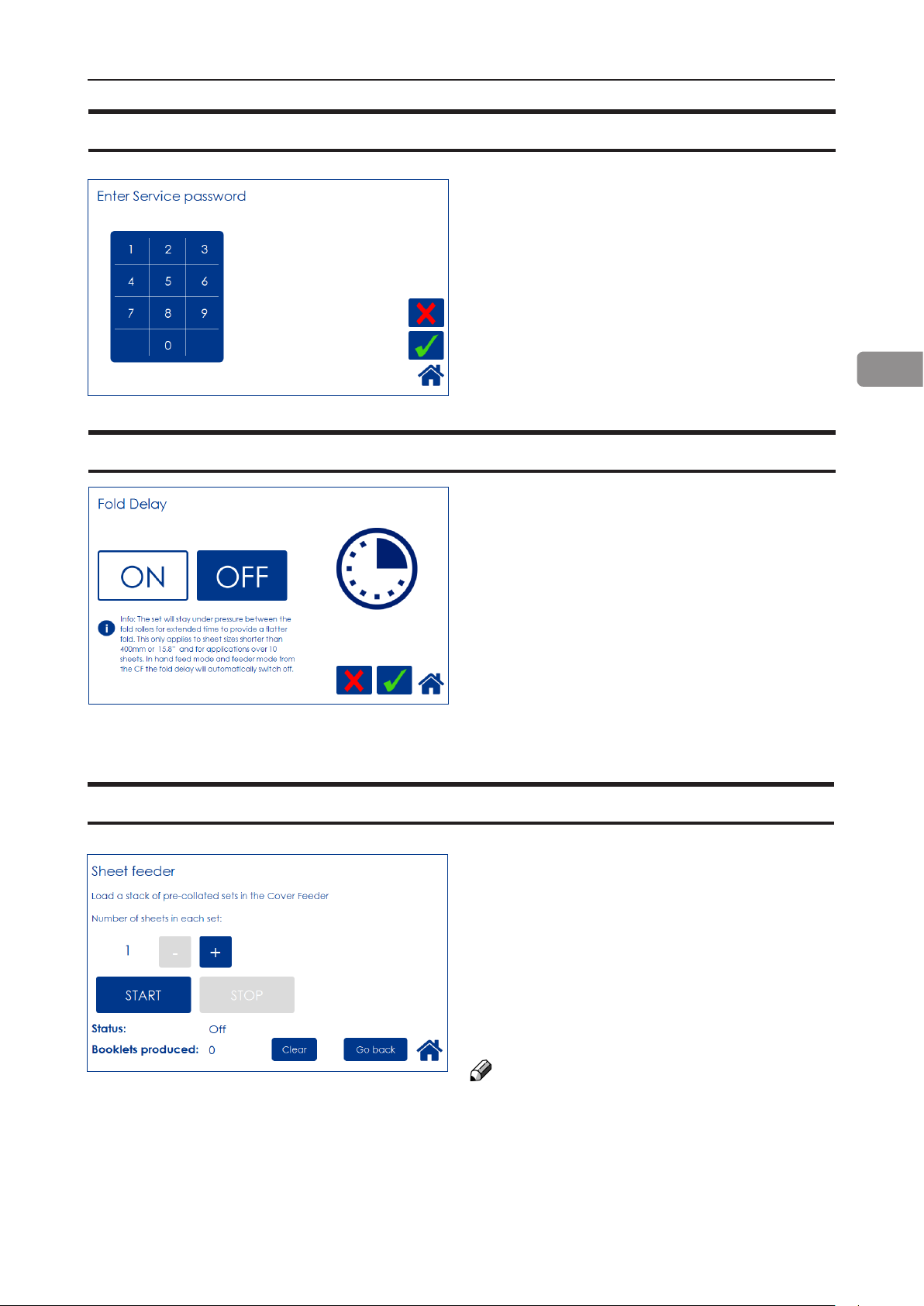

Service mode

Fold delay

This function is for authorized service personnel

only and is password protected.

3

With this feature, the set will stay under pressure between the fold rollers for an extended

time to provide a atter fold. This only applies

to sheet sizes shorter than 400mm or 15.8”

and for applications over 10 sheets. In hand

feed mode and feeder mode from the CF, the

fold delay will automatically switch off.

Sheet feeder

This function allows you to use the Cover Feed-

er as a regular Feeder. Load the Cover Feeder,

enter the desired number of sheets in each set

and press the [Start] button to begin folding.

Press the [Stop] button to stop.

See section 1, “Basics”, for how to load the

cover feeder.

See section 2, “Making Booklets” for how to ad-

just Air Separation and Double sheet detection.

NOTE:

To avoid the error message “Load covers”, load

covers before pressing the [START] button.

57

Auto Rotate

If your system includes the optional RCT mod-

ule, you can select whether you want Auto

Rotate function to be ON or OFF by pressing

the corresponding button.

It is recommended to keep this ON.

When turned on, the Rotator will automatically

rotate all sheet sizes sent from the printer in

long edge feed, enabling higher printer productivity.

3

Selecting OFF will prevent sheets from being

rotated when possible. Sheet length has to

exceed 275mm / 10.6”. Otherwise Auto Rotate

will automatically be changed to ON and sheets

will be rotated.

BookFold offset

The BookFold pressure setting is set to a standard that should suit most applications.

Operators have the option of sharpening or softening the square edges based on application or

preference. Customizing this setting will affect modes 1 to 7 but not mode 8.

Select sharper edges by pressing the [+] button

or softer edges by pressing the [-] button.

NOTE:

BookFold Offset affects modes 1 -7 only.

58

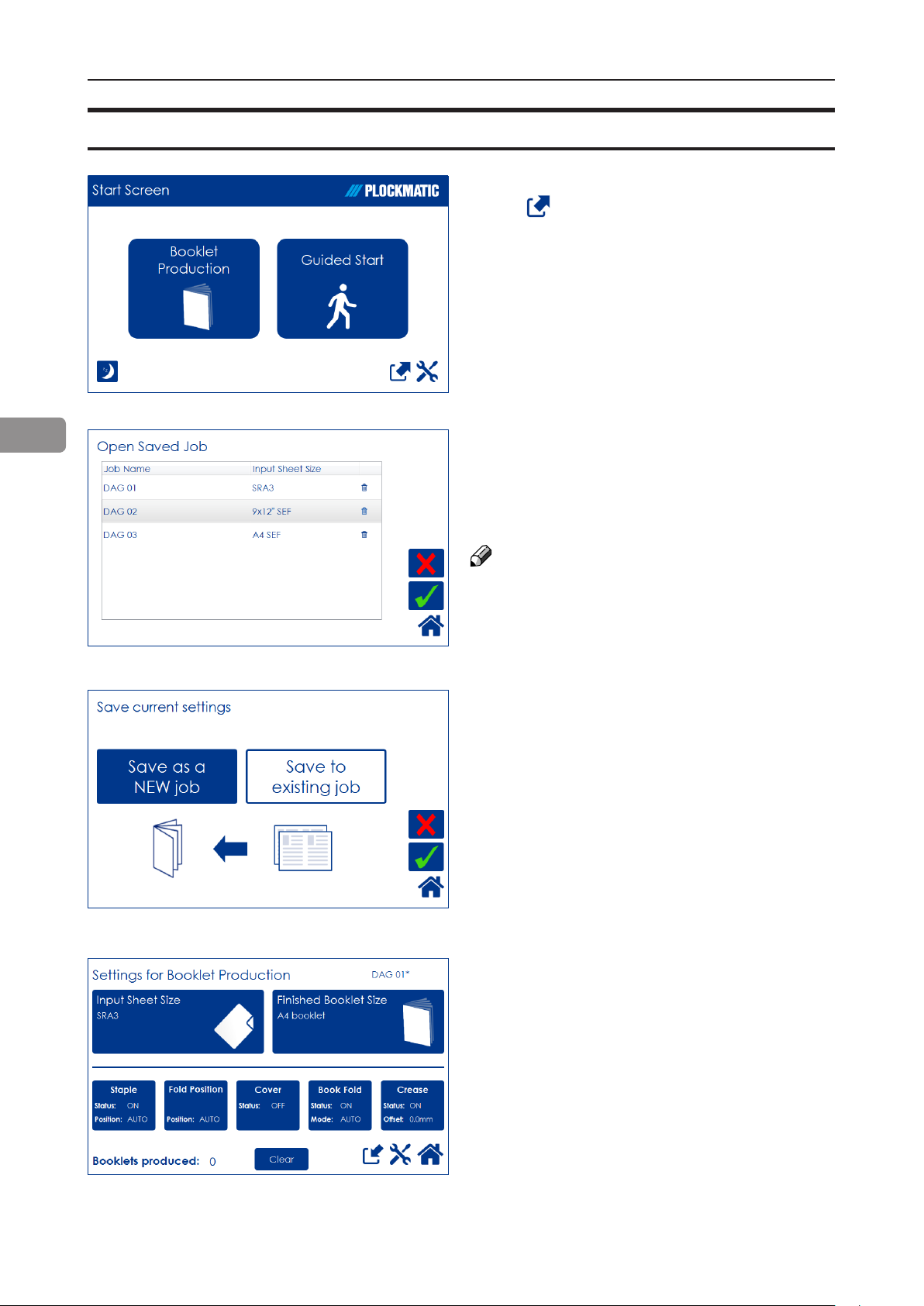

4. Jobs

Handling jobs

The Booklet Maker has a maximum storage capacity of 20 different jobs. To make

temporary changes in the actual job settings or temporary changes of a stored job, see

section 2, “Making Booklets.”

From the Start screen, press the [Jobs] button to be able to store, change or delete jobs.

Saving a Job

To store a job, press from the Settings for

Booklet Production screen.

Press the [Save as a NEW job] button and then

press the green [check] button to continue.

The [Save to existing job] button is only available if a job is currently loaded.

Enter a job name and save by pressing the

green [check] button.

To delete last character, press the [←] button

59

Opening and handling stored Jobs

To access already stored jobs,

press from the Start Screen.

4

Open (load) any stored job by pressing the job

and conrm by pressing the green [check] mark.

Delete any stored job by pressing the job but-

ton, the waste bin symbol and then conrm by

pressing the [Yes] button.

NOTE:

The currently loaded job cannot be deleted.

The button [Save to existing job] is only available if a saved job is currently loaded. Press

the [Save to existing job] button to overwrite the

currently loaded job.

Press the green [check] button to conrm.

60

The name of the currently loaded job is shown

in the upper right corner. An asterisk next to the

name shows that changes to the job have been

made and that the changes have not yet been

saved.

5. Clearing Misfeed(s)

Clearing misfeed(s)

General

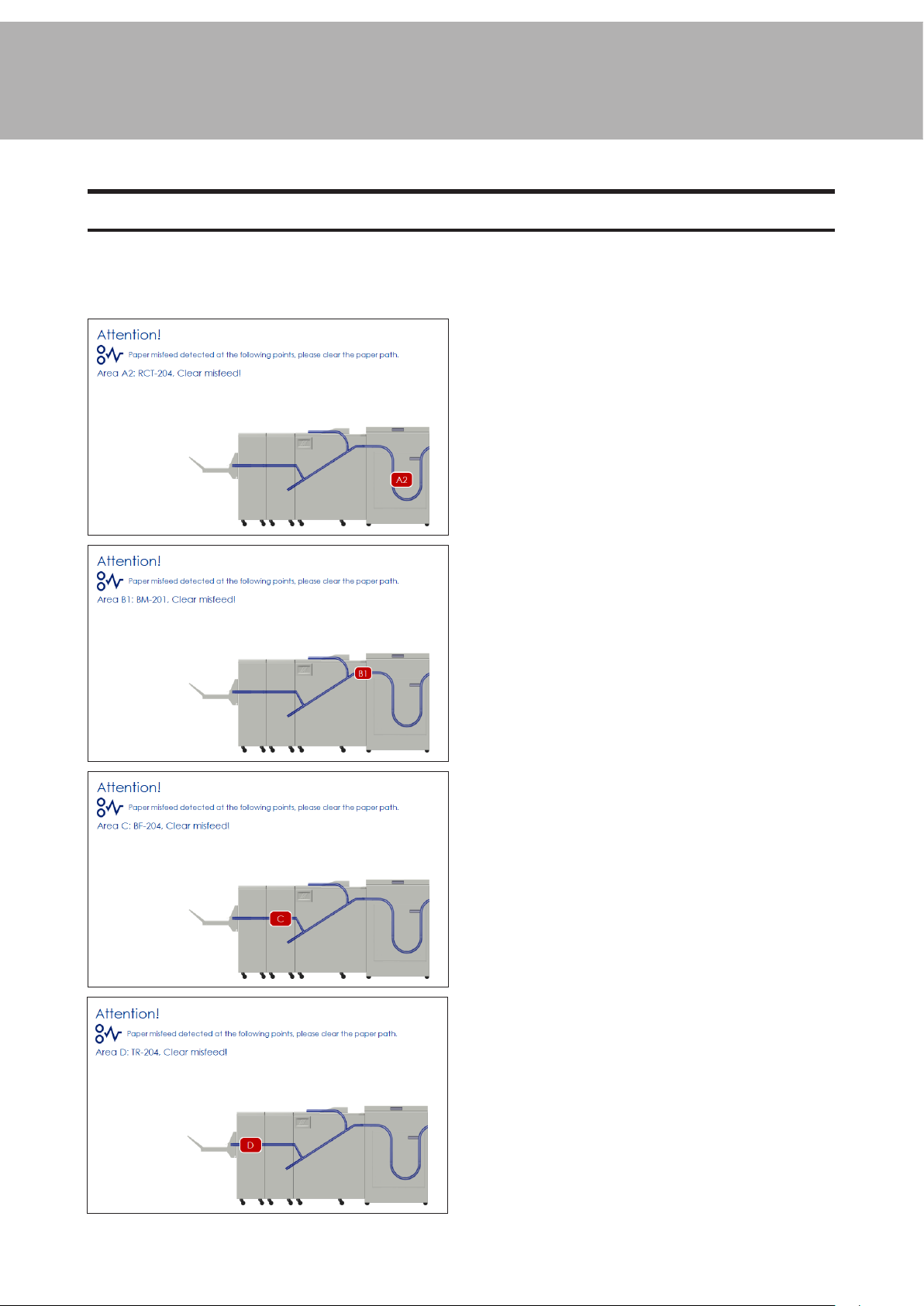

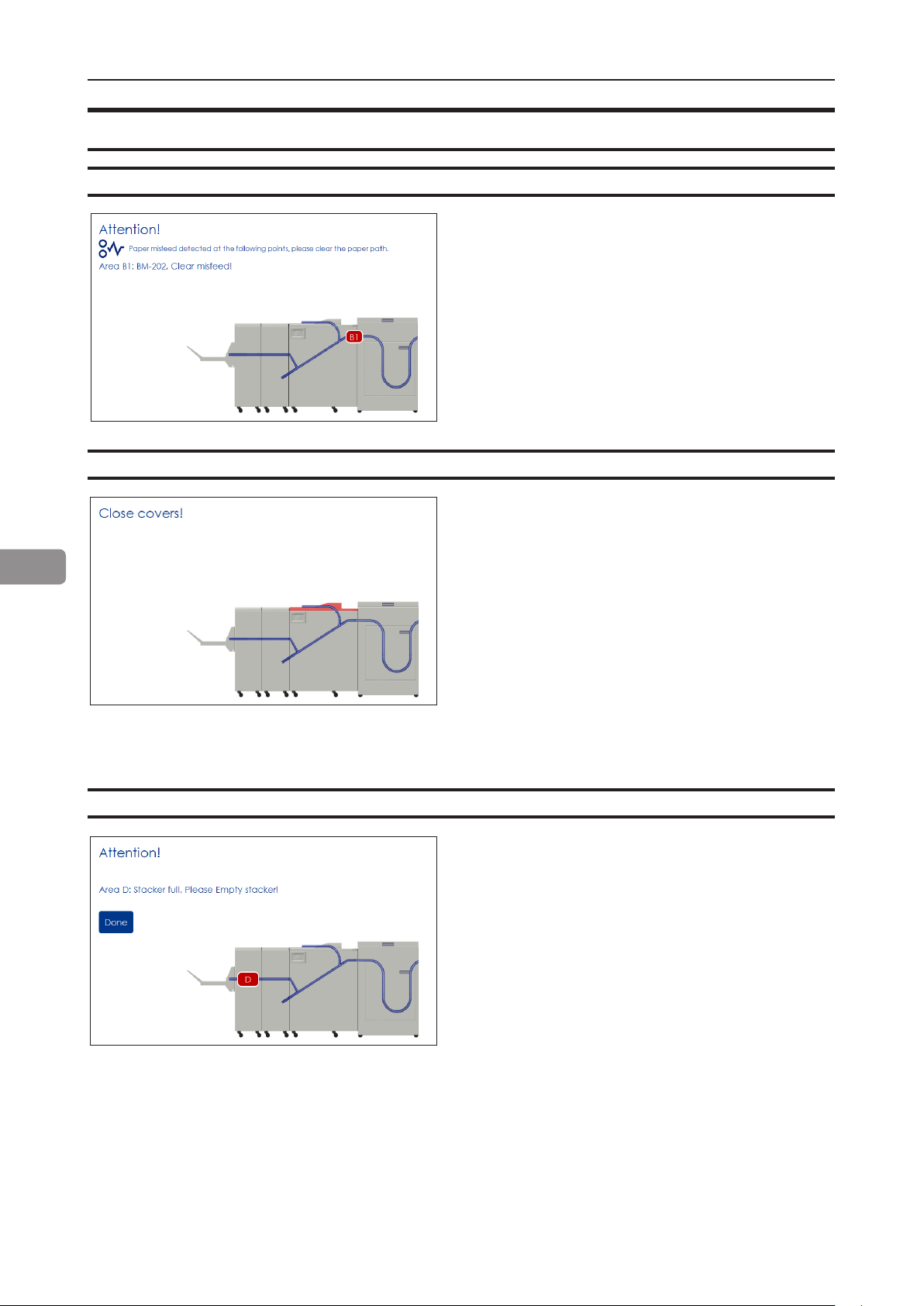

If a misfeed condition should occur, it is indicated on the Booklet Maker display. The

message “Clear Misfeed(s)”, an error code and the location of the misfeed is displayed.

See examples below.

Misfeeds in the Rotate Crease Trim Module

are indicated by the error code RCT-XXX.

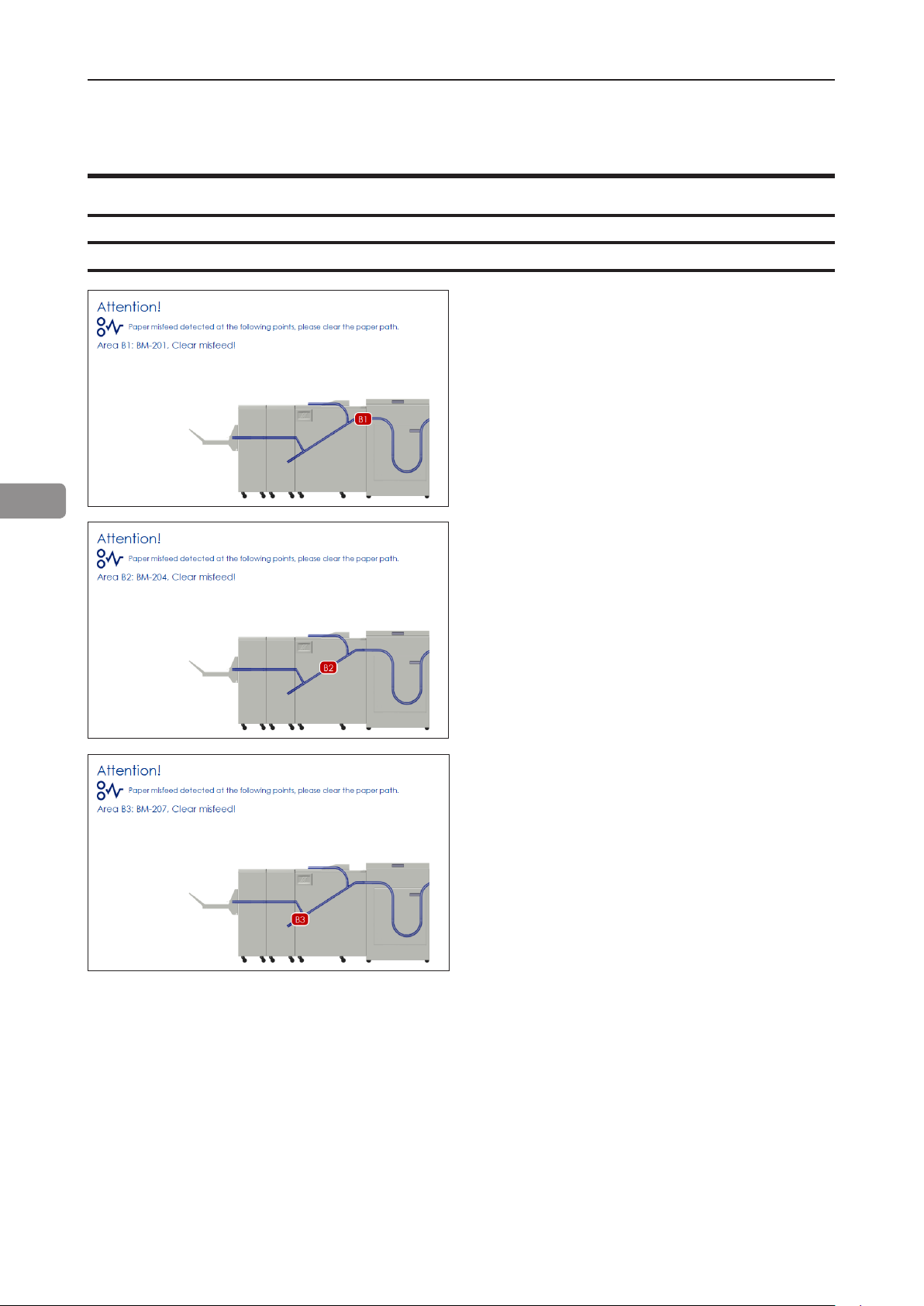

Misfeeds in the Booklet Maker are indicated

by the error code BM-XXX and visually

where in the Booklet Maker (B1, B2 or B3)

the misfeed occurred.

Misfeeds in the BookFold Module are

indicated by the error code BF-XXX.

Misfeeds in the Trimmer are indicated by

the error code TR-XXX.

61

RCT Module

Clearing misfeed(s)

Infeed “A” area and exit “D” area

1

Open the RCT top cover.

2

Lift up bafes “A” and “D” if needed.

3

Remove any misfeed(s).

4

Lower bafes “A” and “D” to normal position

5

Misfeed(s) in the trimmer area are rolled out by rotating the rubber surfaced pinch

roller [A].

5

6

Close the top cover.

WARNING

Do not put your ngers within knife protections (B).

Doing so may result in injury.

62

Bafe D

[A]

[B]

Bafe A

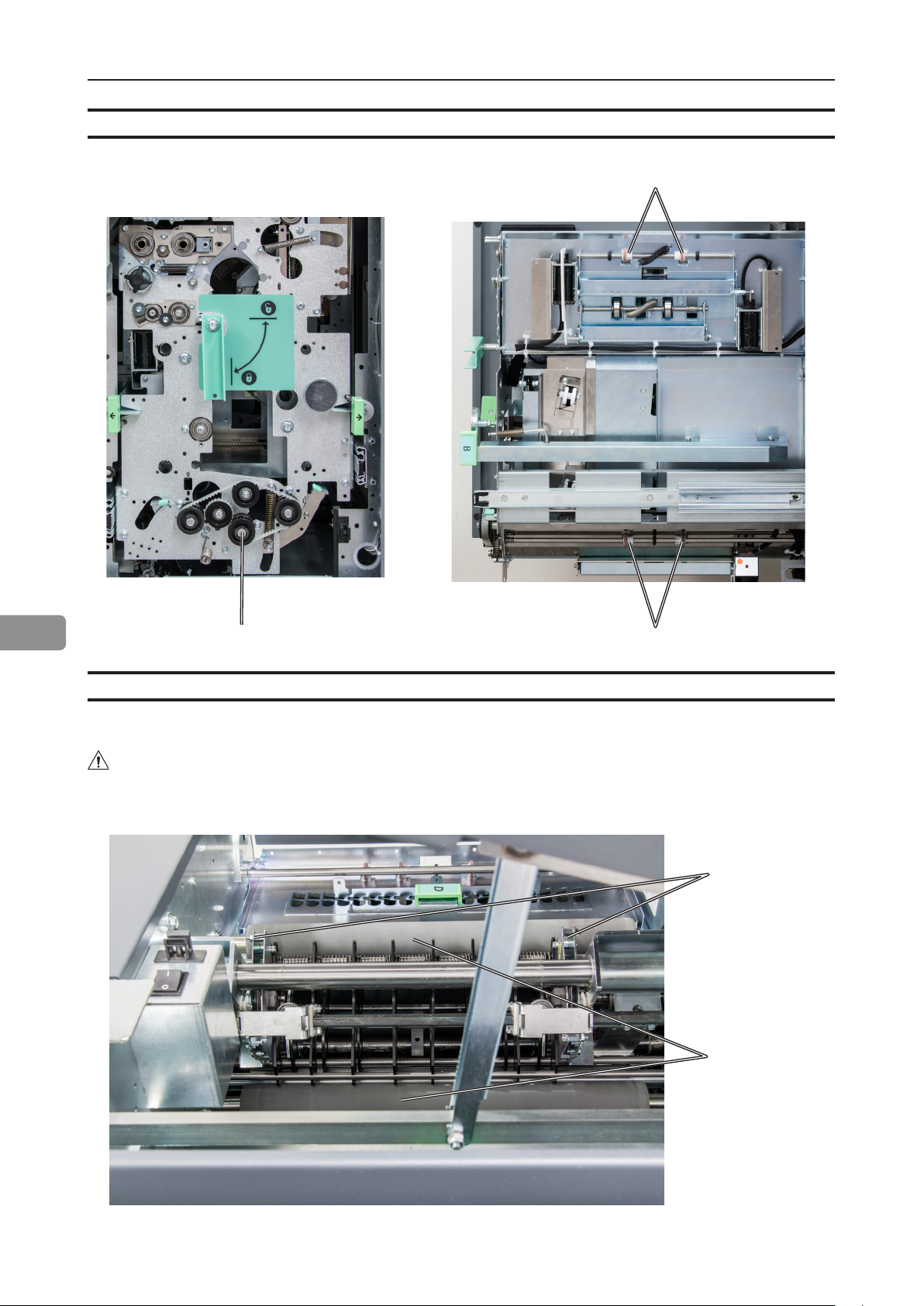

Registration and creaser area

1

Open the slide door [A].

2

Unlatch and pull out the slide [B].

3

Open bafes “B” and “C” if needed.

4

Remove any misfeed(s).

5

Close bafes “B” and “C”.

6

Push in and latch the slide.

7

Always remove any residual waste from waste channel and waste [C] belt before

closing the slide door.

8

Close the slide door.

Clearing jams in the waste transport

The waste transport is easily accessible through the slide door. Shreds jammed in or wrapped

around the knife assembly are also accessible through the slide door.

CAUTION

Under no circumstances should jams around the trimmer blades be cleared using metallic

tools. The edges are very fragile and easily damaged.

5

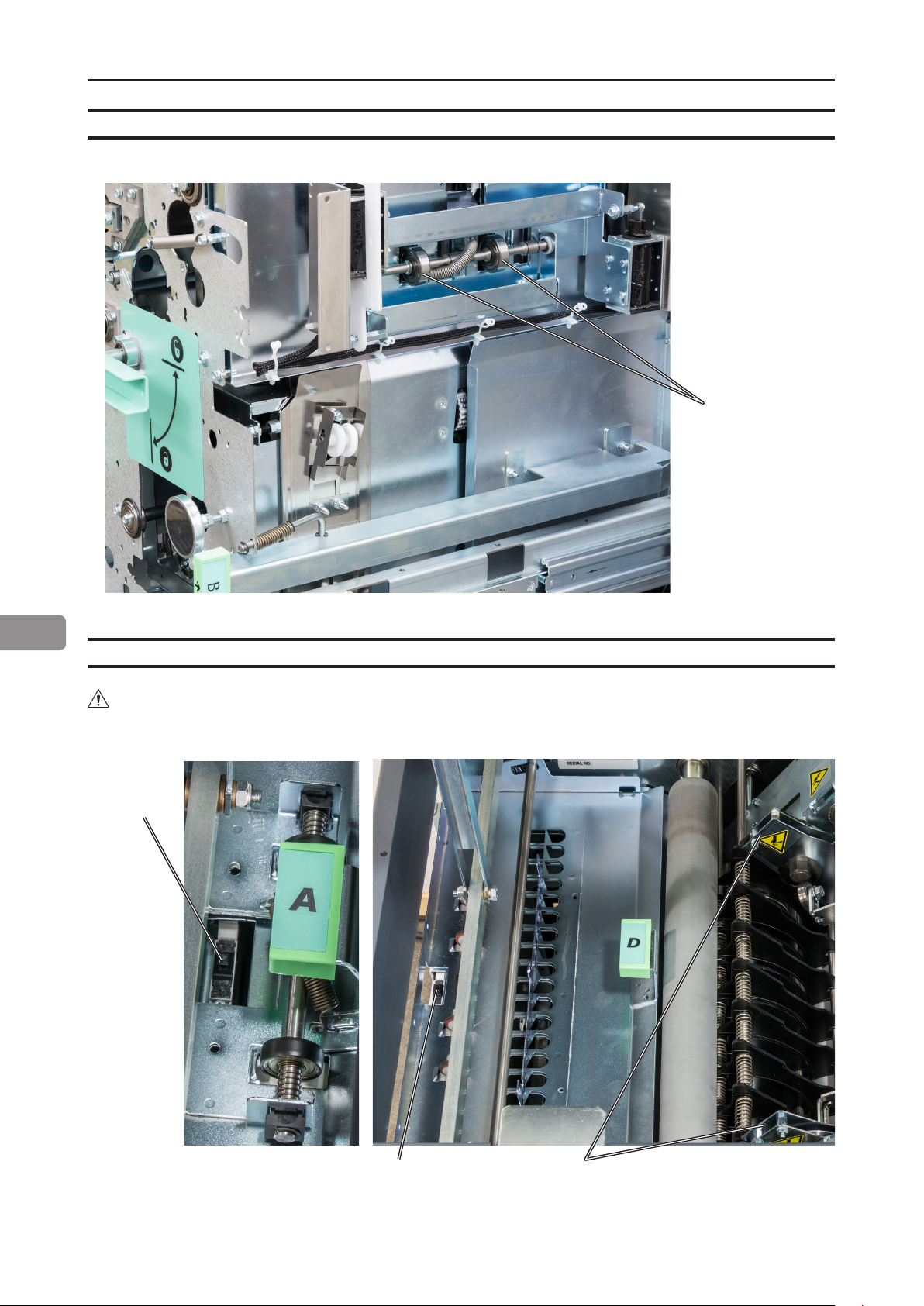

[A] [C] [B]Bafe C Bafe B

63

Booklet Maker

Clearing misfeed(s)

Inside the Booklet Maker

5

To clear a misfeed indicated in Area B1

1 Open the top cover.

2 Remove misfed sheets.

3 Close the top cover.

To clear a misfeed indicated in Area B2

1 Open the top cover.

2 Close top cover.

If system does not purge, open top cover and

remove misfed sheets manually.

To clear a misfeed indicated in Area B3

1 Open the top cover.

2 Close top cover.

If misfeed condition remains:

1 Switch off the main power.

2 Switch on the main power.

64

Clearing misfeed(s), continued

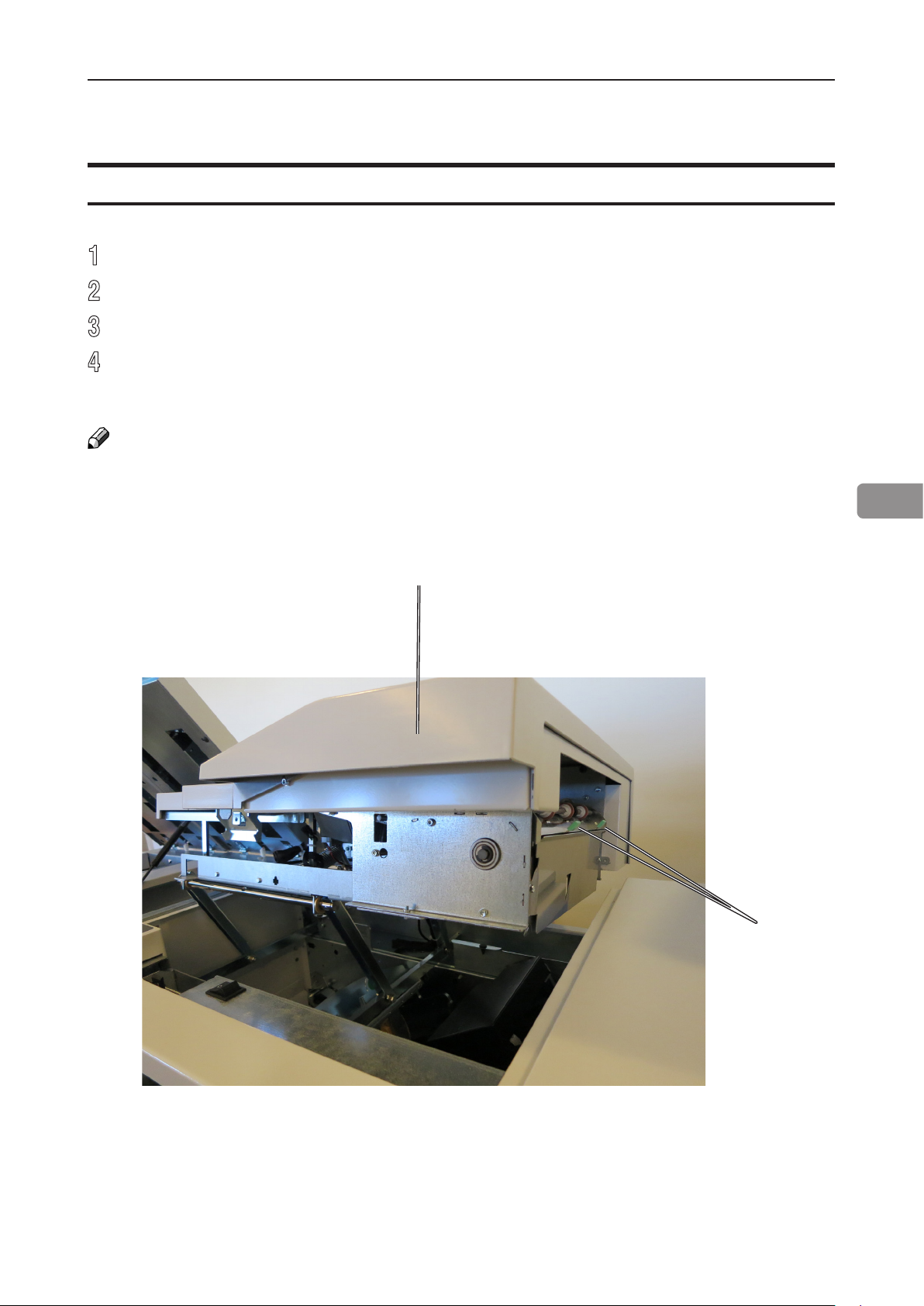

Clearing misfeed in infeed area

1

Open the top cover.

2

Lift the paper guide [A] as shown in picture.

3

Remove misfed sheets.

4

Close top cover.

5

[A]

65

Clearing misfeed(s), continued

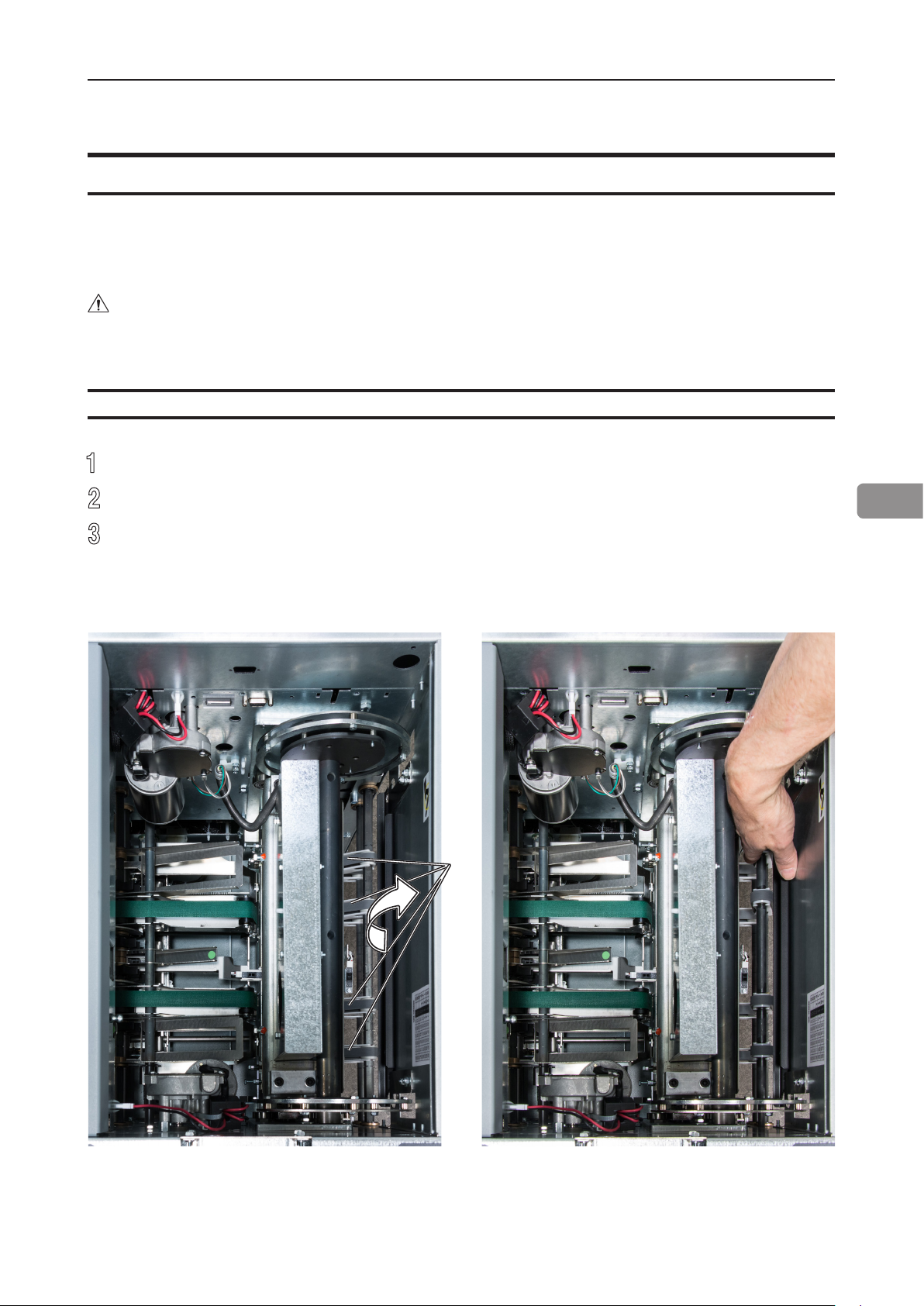

Clearing misfeed in folder area

1

Open the top cover.

2

Open the fold roller paper guide [A] by pushing (arrow 1), lifting (arrow 2) and pivoting

(arrow 3) to access any misfed or jammed sheets/booklets between the lower and

upper pair of fold rollers.

3

Remove sheets/booklets in folder area between fold rollers.

4

In reversed manner, place the fold roller paper guide back in operating position.

NOTE:

Make sure the fold roller paper guide is locked in operating position [B] at both sides.

5

5

Close top cover.

[A]

66

2

1

3

Fold roller

paper guide

locks here

[B]

Cover Feeder

Clearing misfeed(s) in vertical transport area

1

Open the top cover [A].

2

Lift the jam clearance bafe [B].

3

Remove the misfed sheet.

4

Put the jam clearance bafe back in normal position.

NOTE:

In case of a cover feeding jam/error, it is difcult to remove a stuck cover due to the very strong

separation nip. Removing the stack of sheets and then lifting the jam clearance bafe is the

easiest way to remove a cover that is stuck.

[A]

5

[B]

67

BookFold Module

Clearing misfeed(s)

Inside the BookFold Module

1

Open the top cover.

2

Lift up upper feed belts (A) to access jammed/misfed booklets.

NOTE:

Press the green dots (B) (only one visible in picture) on the latches to release.

3

Remove the jammed/misfed booklets.

4

Place the upper feed belts in normal position.

5

5

Close the top cover.

B

A

B

NOTE:

The upper feed belt on the

operator side cannot be lifted fully.

68

Trimmer

Clearing misfeed(s)

The upper trimmer blade on the trimmer is protected by a knife protection plate that moves

away during the cutting stroke.

WARNING

Never put ngers or other body parts between the upper and lower trimmer knives.

Clearing misfeed in input area

1

Raise the rightmost side of the infeed roller shaft assembly (A).

2

Remove the misfed sheets in the infeed area.

3

After the misfed sheets are removed, place the infeed roller shaft assembly into

operating position.