Hub

OPERATING MANUAL

®

™

HUB MANUAL

Thank You

We at Pliant® Technologies want to thank you for purchasing CrewCom®. Pliant brings our experience, expertise, and commitment

to quality technology with the new CrewCom System. In order to get the most out of your new CrewCom product, please take a few

moments to read this manual completely so that you better understand the operation of this product. For questions not addressed in

this manual, feel free to review the additional support documentation provided on our website or contact Pliant’s Customer Support

Department:

Pliant Technologies, LLC

205 Technology Parkway

Auburn, AL 36830 USA

www.plianttechnologies.com

Phone: +1.334.321.1160

Toll-Free: 1.844.475.4268 or 1.844.4PLIANT

Fax: +1.334.321.1162

Copyright © 2018–2019 Pliant Technologies, LLC. All rights reserved. The Pliant®, CrewCom®, and CrewNet™ word marks and the

Pliant “P” logo are trademarks of Pliant Technologies, LLC. Any and all other trademark references within this document are property

of their respective owners.

Model Information

This document applies to model CHB-8C, CHB-8C-02, and CHB-8F.

Document Reference: 2019.11 D0000217_G

ii

Table of Contents

HUB MANUAL

Table of Contents

Safety Information ................................................................................................................................................1

Safe Operation Recommendations ...................................................................................................................1

Safe Installation Recommendations .................................................................................................................1

Power Information .........................................................................................................................................2

Introduction .........................................................................................................................................................3

What’s in the box? ..........................................................................................................................................3

Additional Items Required ...............................................................................................................................3

Optional Item(s) ..............................................................................................................................................3

Firmware Release Notes ..................................................................................................................................3

CrewCom Overview ........................................................................................................................................3

CrewCom Conguration File Overview .............................................................................................................5

About Network Power .....................................................................................................................................5

Product Overview ..................................................................................................................................................6

CrewCom Copper Hub ....................................................................................................................................6

CrewCom Fiber Hub ........................................................................................................................................8

Setup and Installation ...........................................................................................................................................9

Determining the Device Location .....................................................................................................................9

Connecting to CrewNet ...................................................................................................................................9

Powering the Device .....................................................................................................................................10

Activating the Device ....................................................................................................................................10

Operation ............................................................................................................................................................11

Understanding the Hub LEDs .........................................................................................................................11

Product Specications .........................................................................................................................................12

Product Support ..................................................................................................................................................13

Returning Equipment for Repair or Maintenance ...........................................................................................13

Maintenance and Storage ...................................................................................................................................14

Cleaning .......................................................................................................................................................14

Temperature and Humidity ............................................................................................................................14

License Information ...........................................................................................................................................15

CrewCom Compliance Numbers ....................................................................................................................15

Warranty Information ..........................................................................................................................................16

Limited Warranty ...........................................................................................................................................16

Parts Limited Warranty ..................................................................................................................................16

Glossary ............................................................................................................................................................17

Index ..................................................................................................................................................................18

iii

Safety Information

HUB MANUAL

Safety Information

The following section details important safety information related to the ownership and operation of the CrewCom Hub.

WARNING: Indicates a situation, which, when not avoided, has the potential to result in death or severe injury.

CAUTION: Indicates a situation, which, when not avoided, results or has the potential to result in minor

injury or product failure or damage.

1. Read these instructions.

2. Follow all instructions.

3. Heed all warnings.

Safe Operation Recommendations

• Install and operate in accordance with manufacturer’s instructions.

• Do not submerge the Hub in water.

• Do not set food, water, or other beverage containers on or near the unit.

• Do not place unit in areas where it will be exposed to weather.

• Ensure the device’s cord remain free from areas of foot trafc. Do not allow cords to become crimped, twisted, or frayed.

• Clean only with a dry cloth. Do not spray household cleaners or water onto the cloth. Never spray household cleaners or

water onto any part the Hub.

• Use only attachments/accessories that are specically made for or certied by Pliant Technologies with the Hub. Any

attempt to modify ports in order to use cables or wires that are not manufactured specically for or certied for use on

this system will void the product warranty.

• Unplug the Hub during periods of inclement weather and after use.

• Refer all Hub service to qualied Pliant Technologies service personnel. There are no user-serviceable parts

inside the Hub. Opening the product may expose dangerous electrical components, which will result in product failure.

Any attempt to self-service or self-repair the unit will void the product warranty.

• Service is required if the Hub receives any type of damage to any of its parts or if it does not operate normally. For

example, if water or any other type of liquid has been spilled on the Hub or if it has been exposed to rain or moisture,

then service is necessary. Service is also required if debris or other objects have fallen into the unit or if it has been

dropped.

Safe Installation Recommendations

• Elevated Operating Ambient Temperature - If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than room ambient. Therefore, consideration should be

given to installing the equipment in an environment compatible with the maximum ambient temperature (Tma) specied

on page 12.

• Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air ow required for safe

operation of the equipment is not compromised.

• Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

1

Safety Information

• Circuit Overloading - Consideration should be given to the connection of the equipment to the supply circuit and the

effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate consideration

of equipment nameplate ratings should be used when addressing this concern.

• Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention should be

given to supply connections other than direct connections to the branch circuit (e.g., use of power strips).

HUB MANUAL

Power Information

WARNING – DANGER! Users should exercise extreme care when working with electricity. Additional care

should be used when working with electricity outdoors in inclement weather. When working

outdoors or near water, always connect the system into a ground-fault interrupting circuit.

AC Power Connection Safety

• When using local power to power the Hub, always connect the power cord to the CrewCom Hub’s external power supply

before connecting to the outlet.

• CrewCom Hubs may be powered by an external power supply. The cord to connect the external power supply to the

mains supply must conform to the following specications:

» The mains power cord shall have an IEC C13 connector at one end and a mains power plug at the opposite end.

» An IEC C13 plug has three pins. The center pin carries the earth/ground. The remaining two pins carry neutral and

live circuits.

» The conductors of the mains cords shall have adequate cross-sectional area for rated current consumption of the

equipment.

» The mains plug that connects to the mains supply must be approved for use in the country in which the equipment

will be used.

» The mains power cord must be an IEC mains 3-Wire grounding power cord complying with standard IEC60320;

IEC320/C13.

» Mains power cords used in the U.S. must also comply with standard UL817.

2

Introduction

What’s in the box?

Introduction

HUB MANUAL

• CrewCom Copper Hub (1) OR CrewCom Fiber Hub (1)

• USB A to Micro B Cable

• Cat 5e Cable, 6 ft. (1.8 m)

• Fiber Cable, 6 ft. (1.8 m) (Fiber Hub Only)

*Note: Power Supplies vary by CrewCom Hub model, and they are not interchangeable. Always ensure your

Hub uses a compatible power supply:

**Note: A one year product warranty is standard with CrewCom products. Follow the product registration

instructions on the Warranty Extension Registration Card and visit www.plianttechnologies.com/

customer/account/login to extend your product warranty to two years. See page 16 for more

information about Pliant warranties.

PPS-48V-02 with CHB-8C-02 and CHB-8F; PPS-48V with CHB-8C.

• Rubber Feet

• 48VDC External Power Supply*

• Product Overview Guide

• Warranty Extension Registration Card**

Additional Items Required

In addition to your Copper or Fiber Hub, at least one of each of the devices listed below is required to complete your CrewCom

System (sold separately with included components):

• Control Unit (includes AC Power Cord; USB A to Micro B Cable; Cat 5e cable, 15 ft. (4.6 m); and USB Flash Drive)

• Radio Transceiver (includes USB A to Micro B cable; Cat 5e cable, 15 ft. (4.6 m); Mounting Hardware/Bracket; and 2 OmniDirectional Antennas)

• Radio Pack (includes Lithium-Polymer Rechargeable Battery, USB A to Micro B Cable, Multi Blade Worldwide Battery, and

Charger/Power Supply)

• Headset

Optional Item(s)

• CrewCom-Hub-compatible rack ears (PAC-RMK-S and PAC-RMK-D) are available for purchase separately if needed.

Firmware Release Notes

Find the latest CrewCom rmware release notes on the Pliant Technologies website at www.plianttechnologies.com/media/

resources/releasenotes/crewcom_release_notes.pdf

Download the latest rmware release from https://plianttechnologies.com/downloads.

CrewCom Overview

CrewCom is a versatile yet straightforward communications solution built on an intelligent wireless and wired network-based

distributed system architecture. Innovative technologies have been specically developed to facilitate intercom system growth

and effortless adaptation, along with unparalleled digital wireless reliability for consistent operation, even in the most demanding

production environments.

3

Introduction

HUB MANUAL

Decentralized Network Architecture

The CrewCom system utilizes a proprietary network backbone, known as CrewNet™, to coordinate and transport all system timing,

audio, signaling, and controls. This efcient, decentralized resource network delivers increased exibility over that of traditional

technologies, using a distributed network-to-device intelligence within a modular building block structure. System components can

easily be placed where they are needed or scaled to facilitate system growth, reconguration, and effortless adaptation to changing

environments. For increased infrastructure exibility, the CrewNet network is capable of operating over standard Cat 5e (or greater)

and/or Single Mode Fiber (SMF) lines.

Flexible RF Platform

CrewCom’s RF platform is vast and exible to meet the needs of virtually any wireless communication challenge facing production

and entertainment professionals worldwide. Each CrewCom wireless product is available in the 2.4GHz and 900MHz (North

America, Australia, and New Zealand only) ISM bands and any combination of these frequency ranges may be simultaneously

used on the same CrewCom system. CrewCom makes it easy to operate in challenging RF environments by combining support for

multiple simultaneous frequency bands, while also allowing for simple system setup without the need for an RF engineer.

In addition, a more robust RF link enhances RF range and reliability through a newly developed dual carrier double-send

transmission scheme that minimizes the adverse effects of inter-symbol interference. This innovation allows increased useful RF

range and improved performance, especially in large, reective environments.

Intuitive User Experience

CrewCom’s family of products is designed around a system architecture that offers a high density of users with a more manageable

infrastructure and lower cost per user than typically found in large-scale wireless installations. The CrewCom system not only

consists of a range of wired and wireless hardware products but also incorporates an intuitive software application, known as

CrewWare, working together with the system hardware to enhance the experience of system administrators, designers, integrators,

and users. Each device’s user interface allows a quick learning curve with high functionality, and its ease of use is consistent across

all frequency bands, types of users, and applications.

CrewCom Devices

The following is a list of available CrewCom devices. For more information on each of these products and their conguration

capabilities, visit our website at: www.plianttechnologies.com

• Control Unit (CU) – the 1RU foundational element of the CrewCom system that establishes the CrewNet-based

infrastructure while also providing external connections to common established intercom systems. Unlike traditional

BaseStations, the CU contains no radio and is frequency agnostic, which sets the groundwork for a multi-frequency

capable system. For maximum exibility, any CU can access, control, and monitor any active device across CrewNet. The

CU is available in a “CCU-22” or “CCU-44” model, which simultaneously support up to (2) 2-Wire and (2) 4-Wire or (4)

2-Wire and (4) 4-Wire intercom connections, respectively.

• Radio Transceiver (RT) – a CrewCom radio device that houses a radio (2.4GHz or 900MHz) and its corresponding

antennas, enabling RF communications to CrewCom Radio Packs. Using the CrewNet network as the system’s backbone,

RTs can be positioned throughout a wide coverage area by being linked back to a Control Unit either directly or through

a Hub(s). Connectivity is accomplished using either Cat 5e (or greater) or Single Mode Fiber (SMF).

• Radio Pack (RP) – the direct portable wireless communication device connecting individual CrewCom users to the

CrewCom system. Each RP provides full duplex audio communications and, through customized function buttons, GPO

control and event logging. The RP requires a connected headset and access to a Radio Transceiver on the CrewCom

system. Devices are available in 2.4GHz and 900MHz bands as well as two and four volume/talk button congurations.

• Copper Hub – a CrewNet-based device with eight ports to allow extended interconnection for a variety of CrewCom

hardware. Ports one through seven are copper (RJ-45, Cat 5e, or greater); port eight can be either an additional copper

port or a duplex LC Single Mode Fiber port, but only one may be used at a time. The Hub provides for extensive system

expansion and exibility.

4

Introduction

• Fiber Hub – a CrewNet-based device with eight ports to allow extended interconnection for a variety of CrewCom

hardware. Ports two through eight are duplex LC Single Mode Fiber ports; port one can be either an additional ber port

or a copper port (RJ-45, Cat 5e, or greater), but only one may be used at a time. The Hub provides for extensive system

expansion and exibility.

HUB MANUAL

CrewCom Conguration File Overview

The CrewCom system operates using a CrewCom Conguration File (CCF) to coordinate the processes and data that make up the

system’s operation. A default CCF is available for your CrewCom system out of the box to provide your initial settings. You can use

CrewWare to customize your conguration to meet your specic needs beyond the default settings. The CCF stores the settings for

your Conferences and Proles, intercom settings, and connection information for your 2-Wire, 4-Wire, and CrewCom devices.

Conferences and Proles work together to create channels of communication between CrewCom users. They are dened for each

user, stored in the CCF, and available each time you set up. For more information about Conferences and Proles, continue reading

the following sections for their denition.

About Conferences

A CrewCom Conference is an administrator-dened grouping of audio entities (inputs such as Radio Packs, wired intercom ports,

etc.). Audio outputs are then created dynamically by mixing one or more audio entities and routing them to Conference subscribers

accordingly. This method of subscription-based audio using Conferences is very powerful. Point-to-point associations may also be

easily constructed using this method. Each association requires a separate, unique Conference. Conferences in CrewCom are full

duplex (i.e. bidirectional) and there can be a maximum of 64.

Default Conferences are included as part of a system’s default conguration. New Conferences can be created using CrewWare.

About Proles

Each CrewCom Radio Pack has a Prole that contains a variety of system settings that are dened as either global prole settings

or user settings. A Radio Pack Prole assigns functionality to an RP’s local controls, knobs, and buttons (including Conference

assignments), and allows customization for user preferences and roaming

• Global Prole Settings - These settings are part of the CrewCom Conguration File and are usually assigned by

a system administrator through customization in CrewWare during setup. Find a full list of the global prole settings

available for each Radio Pack in the CrewWare Operating Manual or the Radio Pack Operating Manual.

• User Settings - A user setting is one that is classied as being adjustable by the Radio Pack user and is limited to local

device settings that do not alter the CrewCom Conguration File. The Prole can be used to determine these settings, but

they can also be customized directly from a Radio Pack after a Prole is loaded.

About Network Power

Power-Over-CrewNet (PoC) is a proprietary network protocol that provides operating voltage and current to CrewNet-compatible

devices connected to the Control Unit via RJ-45 connections (Cat-5e or greater). Control Units must receive AC power via the

supplied power cord in order to operate and provide necessary PoC to connected CrewNet-compatible devices.

To ensure best performance, especially with larger CrewCom congurations and longer cable lengths, Pliant recommends utilizing

the supplied 48VDC power supply to locally power each Hub. However, powering a Hub and the devices connected to it via PoC

may be advantageous in some smaller congurations. Fiber connections will not transfer power to the Hub. The supplied

48VDC Power Supply (PPS-48V-02 with CHB-8C-02 and CHB-8F, PPS-48V with CHB-8C) must be used in conjunction with a ber

connection in order for the Hub to operate.

PoC can be supplied to devices downstream from a locally powered CrewCom Copper Hub. Under optimal conditions, connected

CrewCom devices may be powered from a locally powered Hub; however, this number can vary greatly depending on the line

lengths and the number and conguration of those connected devices.

5

Product Overview

C D E F G

A

B

®

Front

Rear

HUB MANUAL

Product Overview

The CrewCom Hub operates on CrewNet and allows a variety of CrewCom devices to be interconnected. The Hub consists of

CrewNet ports that enable users to add more CrewCom devices, such as Radio Transceivers, in order to extend the connection of

their CrewCom system.

The Hub is a 1RU half-rack-mount capable device. A maximum of 32 hubs (within up to four Hub layers) can be on a CrewCom

system. See “About Hub Layers” on page 10 for more information.

There are two types of CrewCom Hubs: the Copper Hub and the Fiber Hub.

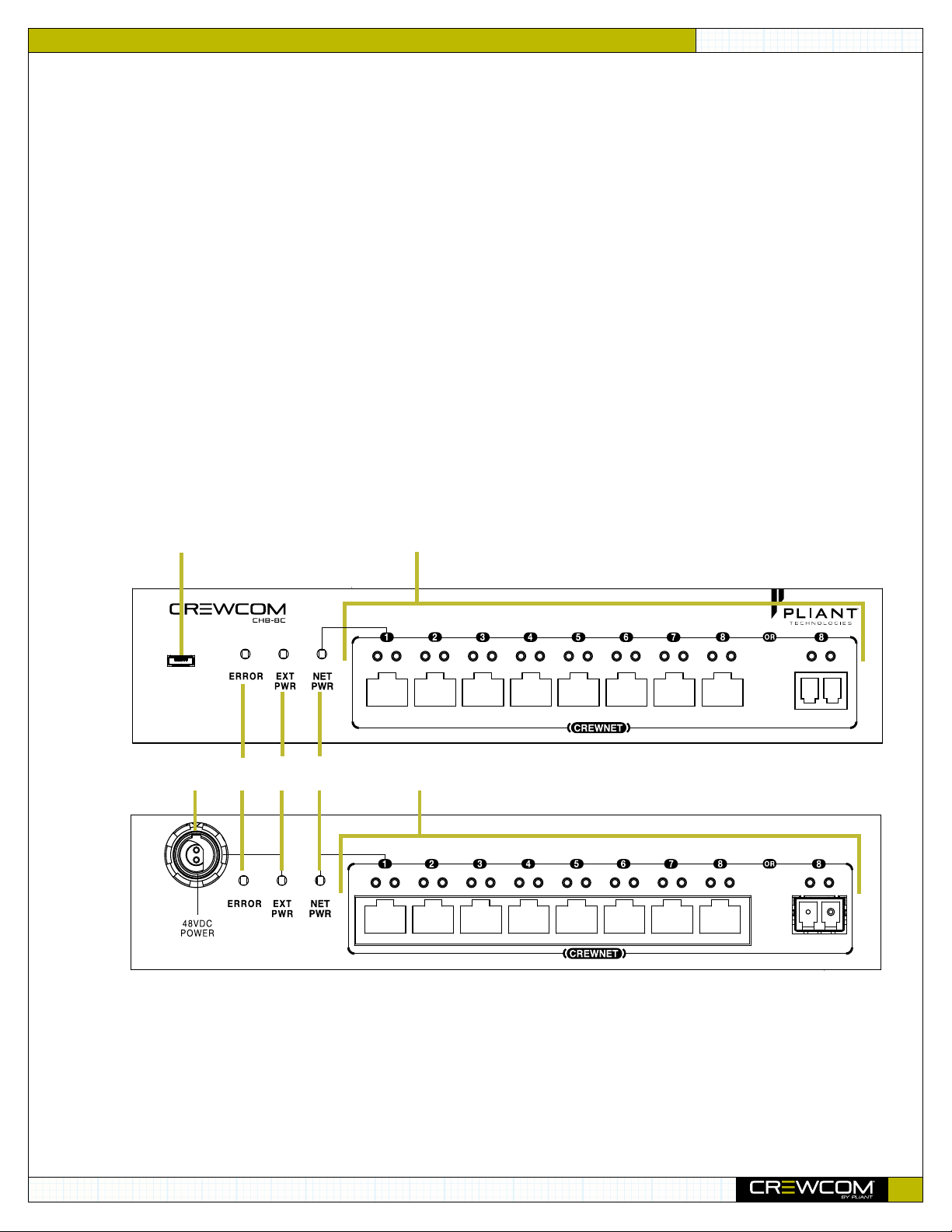

CrewCom Copper Hub

The Copper Hub (CHB-8C-02) has eight ports for copper connections and one ber-optic port.

Port 8 is an “either/or” connection. The eighth copper port and the ber port cannot operate simultaneously; the user must choose

one or the other. See “Connecting to CrewNet” on page 9 of this manual for more information about choosing between copper

and ber.

Note: The front and rear Copper Hub labels and LEDs are identical and display identical alerts. This allows for both

front and/or rear face mounting. See Figure 1:

Figure 1: Copper Hub Front and Rear View

6

Product Overview

HUB MANUAL

(A) USB Connection

Connects Hub to a computer to update rmware. See the

CrewWare Manual

for more information on updating rmware.

(B) CREWNET Port Labels and Status LEDs for Ports 1–8

The front and rear Copper Hub labels and LEDs are identical and display identical alerts. The port status LEDs indicate the CrewNet

connection status. See the Operation section on page 11 for more LED information.

(C) 48VDC Power Connection

Power connection for the Pliant 48VDC Power Supply (PPS-48V-02 included with CHB-8C-02 and CHB-8F, PPS-48V included with

CHB-8C PPS-48V-02), which allows the Hub to receive external (local) power.

To ensure best performance, especially with larger CrewCom congurations and longer cable lengths, Pliant recommends utilizing

the supplied 48VDC power supply to locally power each Hub. However, powering a Hub and the devices connected to it via PoC may

be advantageous in some smaller congurations.

(D) ERROR LED

Device error status indicator. This LED function is currently not available. See the Operation section on page 11 of this manual for

more LED information.

(E) External (Local) Power (EXT PWR) LED

Indicates that external (local) power is being provided via a Pliant 48VDC Power Supply. See the Operation section on page 11 of

this manual for more LED information.

(F) Network Power (NET PWR) LED

Indicates the Hub is receiving PoC via Port 1. The LED indicates the presence and strength of this PoC.

The Hub must be connected to Port 1 via a Cat 5e (or greater) copper cable in order for it to receive PoC. If PoC is not used, the Hub

must be powered externally by a Pliant 48VDC Power Supply.

(G) CREWNET Ports 1–8 and Status LEDs

The CrewNet ports allow the Hub to connect to the CrewCom Control Unit and Radio Transceivers, supporting a proprietary network

design where all devices are part of a CrewCom Conguration File that shares data, timing synchronization, and audio. Ports 1

through 7 are copper (RJ-45, Cat 5e or greater); Port 8 can be either the last copper port or the separate duplex LC Single Mode

Fiber port, and only one may be used at a time.

Note: Port 1 cannot power devices. It can only accept power, and this power is indicated with the NET PWR LED.

Since Port 1 cannot source power to downstream devices, even if the Hub is locally powered, any device

connected to this port will require its own local power supply. To ensure best performance, especially with

larger CrewCom congurations and longer cable lengths, Pliant recommends utilizing the supplied 48VDC

power supply to locally power each Hub. However, powering a Hub and the devices connected to it via PoC

may be advantageous in some smaller congurations.

Each port’s status LEDs indicate the status of the CrewNet connection. See the Operation section on page 11 of this manual for

more LED information.

7

Product Overview

Front

Rear

B

A

HUB MANUAL

CrewCom Fiber Hub

The Fiber Hub (CHB-8F) functions identically to the Copper Hub, except it has eight ports for ber optic connections and one copper

port.

Port 1 is an “either/or” connection, and use of Port 1 is required for downstream operation of ports 2–8. The rst ber port and the

copper port cannot operate simultaneously; the user must choose one or the other. See “Connecting to CrewNet” on page 9 of

this manual for more information about choosing between copper and ber.

Note: The front and rear Fiber Hub labels and LEDs are identical and display identical alerts. See Figure 2:

Figure 2: Fiber Hub Front and Rear View

(A) CREWNET Port Labels and Status LEDs for Ports 1–8

The front and rear Fiber Hub labels and LEDs are identical and display identical alerts. The port status LEDs indicate the CrewNet

connection status. See the Operation section on page 11 for more information.

(B) CREWNET Ports 1–8 and Status LEDs

The CrewNet ports allow the Hub to connect to the CrewCom Control Unit and Radio Transceivers, supporting a proprietary network

design where all devices are part of a CrewCom Conguration File that shares data, timing synchronization, and audio. Ports 2

through 8 are duplex LC Single Mode Fiber ports; Port 1 can be either the rst ber port or the copper (RJ-45, Cat 5e or greater)

port, and only one may be used at a time.

Note: Port 1 (copper only) is only capable of PoC input, and Port 1 cannot supply PoC output. Either copper or

ber use of Port 1 is required for downstream operation of ports 2–8.

Each port’s status LEDs indicate the status of the CrewNet connection. See the Operation section on page 11 of this manual for

more LED information.

8

Setup and Installation

HUB MANUAL

Setup and Installation

Determining the Device Location

Determine a location for your CrewCom Hub.

• If rack-mounting, secure using its rack-mounting hardware. They can be mounted either single or two side by side.

(Mounting hardware, PAC-RMK-S and PAC-RMK-D, sold separately).

• Or place the device on a clean, at surface. For your convenience, stick-on rubber feet are included with the Hub.

Connecting to CrewNet

After securely placing the Hub, connect it to other CrewCom devices via its available CrewNet ports. Device port connections must

match the CCF in order to operate. Pliant recommends making all cable connections between devices prior to powering on the

system. Adding and removing devices in live mode (often referred to as “hot-plugging” or “hot-swapping”) may cause system errors

to occur.

• RJ-45 Ports – For an RJ-45 copper CrewNet port, use the supplied 6.6 ft. (2 m) Cat 5e cable, or your own Cat 5e (or

greater) cable (up to 330 ft. (100 m) in length). Any CrewCom device connected to CrewNet via a Cat 5e (or greater)

cable can receive Power-over-CrewNet (PoC) via the CrewNet port. In some situations, there may be too many connected

devices or the cable lengths may be too long for the PoC to adequately power all devices, and this will be indicated

with the NET PWR LED lighting red. To ensure best performance, especially with larger CrewCom congurations and

longer cable lengths, Pliant recommends utilizing the supplied 48VDC power supply to locally power each Hub. However,

powering a Copper Hub and the devices connected to it via PoC may be advantageous in some smaller congurations.

• Fiber (Optical) Ports - For a ber CrewNet port, a Single Mode Fiber cable (duplex LC connector) will be required

(up to 32,800 ft. (10 km) in length). Any CrewCom device connected to CrewNet via ber port must receive power via a

Pliant 48VDC power supply (PPS-48V-02 included with CHB-8C-02 and CHB-8F, PPS-48V included with CHB-8C; power

supply sold separately with all other devices).

9

Setup and Installation

HUB MANUAL

About Hub Layers

Any additional Hub cascaded from a previous Hub is considered a new Hub layer. Cascading can be direct from a previous Hub or

through another CrewNet device. (See a diagram of some possible Hub congurations in Figure 3.) A helpful way of determining

Hub layers is to count how many Hubs you pass through to reach the Master CU, including the starting Hub.

Hub Layer 1 Hub Layer 2 Hub Layer 3 Hub Layer 4

44 Master

CU

CCU_44_001

44 Secondary

CU

CCU_44_002

44 Tertiary

CU

CCU_44_003

Figure 3: Hub Layer Examples

HB

HB

Copper

CHB_8C_001

Copper

CHB_8C_003

HB

HB

Copper

CHB_8C_002

Copper

CHB_8C_004

HB

Fiber

CHB_8F_001

HB

Legend

Copper

Fiber

Fiber

CHB_8F_002

Powering the Device

After connecting your CrewCom devices, power everything on and verify that your Hub is receiving power by checking that the

applicable Power LED is green. PoC can be supplied to devices downstream from a locally powered CrewCom Copper Hub. Under

optimal conditions, 7–9 connected CrewCom devices may be powered from a locally powered Copper Hub; however, this number

varies greatly depending on the line lengths and the number and conguration of those connected devices.

Once the CU is powered on, you can tell that a conguration error has occurred with the Hub if a connected RT’s TX LED is not

lit and its RPs do not log in. The conguration error may be present in the RT or other device upstream. If you are connected to

CrewWare, it will alert you of any rmware or conguration errors needing resolution.If a device does not have compatible rmware,

follow the instructions provided in the

CrewWare Manual

to update to the correct version

.

Note: See the Connecting to CrewNet section above for more information on how power is distributed for all

connected CrewCom devices.

Activating the Device

If you need to add additional CrewCom devices (e.g., a Hub, RT, or additional Control Units) after you’ve applied your CrewCom

Conguration File, you’ll need to power down your system and add the devices while powered down and ofine.

Connect the additional CrewCom device(s) to CrewNet via an available CrewNet RJ-45 Copper or duplex LC Fiber port. Add the

device(s) to your system diagram in CrewWare, then save the Conguration File change and apply the new Conguration File to

your system.

Advanced device settings and system conguration and customization can be done via CrewWare. Refer to the separate

Operating Manual

for more information on this process.

CrewWare

10

Operation

HUB MANUAL

Operation

Understanding the Hub LEDs

Each LED on the Front and Rear of the Hub display identical connection and power status information, allowing the user to monitor

the device easily from both a free-standing or rack mount conguration.

Table 1: Hub LED Descriptions

Connection/LED Description

ERROR LED This LED function is currently not available.

EXT PWR LED Green – External (local) power is present.

Off – No external (local) power is present.

NET PWR LED Green – Power-over-CrewNet (PoC) is adequate for operation with current connections.

Amber – PoC is approaching the minimum threshold with current connections.

Off – No PoC is present.

CREWNET Status LEDs Left Green – CrewNet connection is good.

Off – No CrewNet connection detected.

Right On (Green) – 1000 Mbps link is detected.

Blinking (Green) – Activity is detected.

Off – No CrewNet connection detected.

11

Product Specifications

Product Specications

Table 2: Hub Product Specications

Specication* CHB-8C-02 CHB-8F

CrewNet Ports (8 total connections) (7) RJ-45 for copper; (1) RJ-45 for

copper or duplex LC for Single Mode

Fiber

Maximum CrewNet Line Length Copper 330 ft. (100 m); Fiber 32,800 ft.

(10,000 m)

External Power In 48VDC Power Supply 48VDC Power Supply

Power-over-CrewNet (PoC) In Port 1 (RJ-45) Port 1 (RJ-45)

Power-over-CrewNet (PoC) Out Sourced by PoC: Ports 2–8;

Sourced by external power: Ports 2–8

Dimensions (L × W × H) 8.62 in. × 1.73 in. × 8.68 in. (21.9 cm ×

4.4 cm × 22 cm)

Weight 1.75 lbs (794 g) 1.75 lbs (794 g)

Operating Environment -20° to 50° C (-4° to 122° F); 10% to

90% Humidity.

Maximum Altitude 6,562 ft. (2,000 m) 6,562 ft. (2,000 m)

RoHS Yes Yes

(7) duplex LC for Single Mode Fiber; (1) RJ45 for copper or duplex LC for Single Mode

Fiber

Copper 330 ft. (100 m); Fiber 32,800 ft.

(10,000 m)

N/A

8.62 in. × 1.73 in. × 8.68 in. (21.9 cm × 4.4

cm × 22 cm)

-20° to 50° C (-4° to 122° F); 10% to 90%

Humidity.

HUB MANUAL

*Notice About Specications: While Pliant makes every attempt to maintain the accuracy of the information contained in this

manual, this information is subject to change without notice, and published device/system functions and features are subject to

rmware version. . Please check our website for the latest system specications and certications.

12

Product Support

HUB MANUAL

Product Support

Pliant offers technical support via phone and email from 07:00 to 19:00 Central Time (UTC−06:00), seven days per week.

1.844.475.4268 or +1.334.321.1160

technical.support@plianttechnologies.com

Visit www.plianttechnologies.com for product support, documentation, and live chat for help. (Live chat available 08:00 to 17:00

Central Time (UTC−06:00), Monday–Friday.)

Returning Equipment for Repair or Maintenance

All questions and/or requests for a Return Authorization Number should be directed to the Customer Service department

(customer.service@plianttechnologies.com). Do not return any equipment directly to the factory without rst obtaining a Return

Material Authorization (RMA) Number. Obtaining a Return Material Authorization Number will ensure that your equipment is

handled promptly.

All shipments of Pliant products should be made via UPS, or the best available shipper, prepaid and insured. The equipment should

be shipped in the original packing carton; if that is not available, use any suitable container that is rigid and of adequate size to

surround the equipment with at least four inches of shock-absorbing material. All shipments should be sent to the following address

and must include a Return Material Authorization Number:

Pliant Technologies Customer Service Department

Attn: Return Material Authorization #

205 Technology Parkway

Auburn, AL 36830-0500

13

Maintenance and Storage

HUB MANUAL

Maintenance and Storage

Cleaning

Generally, the CrewCom hardware should be cleaned only with a dry cloth. A soft cloth with rubbing alcohol may be used to wipe

the devices if needed, but you should avoid using rubbing alcohol on plastic components. Never spray solvents or chemicals onto

the devices.

All electronic devices can be susceptible to particulate contamination. If yours are exposed to an extremely dusty environment,

contact Pliant’s Customer Service for internal cleaning.

Temperature and Humidity

CrewCom components are designed to be very durable and can tolerate a wide range of environmental conditions; however, you

should take all necessary precautions to keep your system devices safe, dry, and out of extreme conditions.

The Radio Transceiver is weather-resistant, including gaskets intended to prevent moisture entry from the top and sides. The Cat 5e

cable connection on the bottom is not water tight. If it is to be used in an outdoor environment, protect the RT with a protective

enclosure that will not interfere with the RF.

The Radio Packs are designed to work wherever people work. While the Radio Pack design is weather-resistant, Radio Packs should

not be submerged in liquids unnecessarily. Protect the battery compartment from water when changing batteries. The battery

compartment offers a route to the electronic circuitry.

14

License Information

HUB MANUAL

License Information

Warning: Changes or modications to this device not expressly approved by Pliant could void the user’s authority

to operate the equipment.

1. FCC Notices

1.1. This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

2. Canada, Industry Canada (IC) Notices

2.1. This Class A digital apparatus meets all requirements of the Canadian Interference Causing Equipment

Regulations. Cet appareillage numérique de la classe A répond à toutes les exigencies de l’interférence canadienne

causant des règlements d’équipment.

CrewCom Compliance Numbers

Table 3: Hub Compliance Model Numbers

Model Numbers Compliance Model No.

CHB-8C HB2520

CHB-8C-02 HB2520

CHB-8F HB2521

15

Warranty Information

HUB MANUAL

Warranty Information

Limited Warranty

CrewCom products are warranted to be free from defects in materials and workmanship for a period of two years from the date of

sale to the end user, under the following conditions:

• First year of warranty included with purchase.

• Second year of warranty requires product registration on the Pliant website.

Tempest professional products will carry a two-year product warranty.

All accessories carry a one-year warranty.

The sole obligation of Pliant Technologies, LLC during the warranty period is to provide, without charge, parts and labor necessary to

remedy covered defects appearing in products returned prepaid to Pliant Technologies, LLC. This warranty does not cover any defect,

malfunction, or failure caused by circumstances beyond the control of Pliant Technologies, LLC, including but not limited to negligent

operation, abuse, accident, failure to follow instructions in the Operating Manual, defective or improper associated equipment,

attempts at modication and/or repair not authorized by Pliant Technologies, LLC, and shipping damage. Products with their serial

numbers removed or effaced are not covered by this warranty.

Pliant device IP ratings are dependent upon device design and assembly; therefore, unauthorized disassembly or device

modications may impair or negate the IP rating for the device, and therefore any associated damage or malfunction is not covered

under this warranty.

This limited warranty is the sole and exclusive express warranty given with respect to Pliant Technologies, LLC products. It is the

responsibility of the user to determine before purchase that this product is suitable for the user’s intended purpose. ANY AND

ALL IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY, ARE LIMITED TO THE DURATION OF

THIS EXPRESS LIMITED WARRANTY. NEITHER PLIANT TECHNOLOGIES, LLC NOR ANY AUTHORIZED RESELLER WHO SELLS PLIANT

PROFESSIONAL INTERCOM PRODUCTS IS LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

Parts Limited Warranty

Replacement parts for Pliant Technologies, LLC products are warranted to be free from defects in materials and workmanship for

120 days from the date of sale to the end user.

This warranty does not cover any defect, malfunction, or failure caused by circumstances beyond the control of Pliant Technologies,

LLC, including but not limited to negligent operation, abuse, accident, failure to follow instructions in the Operating Manual,

defective or improper associated equipment, attempts at modication and/or repair not authorized by Pliant Technologies, LLC, and

shipping damage. Any damage done to a replacement part during its installation voids the warranty of the replacement part.

This limited warranty is the sole and exclusive express warranty given with respect to Pliant Technologies, LLC products. It is the

responsibility of the user to determine before purchase that this product is suitable for the user’s intended purpose. ANY AND

ALL IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY, ARE LIMITED TO THE DURATION OF

THIS EXPRESS LIMITED WARRANTY. NEITHER PLIANT TECHNOLOGIES, LLC NOR ANY AUTHORIZED RESELLER WHO SELLS PLIANT

PROFESSIONAL INTERCOM PRODUCTS IS LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

16

Glossary

HUB MANUAL

Glossary

Audio Output: Outputs are created by mixing one or more audio entities. This could be for use at any headset connection or for

output to a wired connection.

Conference: A grouping of audio entities. Wireless Radio Packs (or other CrewCom I/O) may be subscribed to one or more of 64

available Conferences.

Control Unit (CCU-22 and CCU-44): A CrewCom device that is used to establish a CrewNet system and provides initial system

audio I/O. It is compatible with all levels of wireless Radio Packs.

CrewCom Conguration File (CCF): A le that stores all of the device setup and conguration parameters for a CrewCom system.

CrewNet: The digital proprietary network used to move audio and to control data, timing, and other functional signals used in

CrewCom.

CrewWare: Software tool developed to incorporate all the necessary mechanisms for facilitating graphically based system

construction and full system control, monitoring, and diagnosis.

Firmware: (As it relates to CrewCom.) The embedded code that exists in any CrewCom device. All of this embedded code, including

radio code, is upgradeable easily by the end user. It is required that all CrewCom devices operate on the same version of rmware.

Hub: A device that provides routing and expansion capabilities to a CrewNet infrastructure allowing the connection of multiple

CrewCom devices.

Hub Layer: The combining of multiple Copper and/or Fiber Hubs on a CrewCom system. Each additional Hub cascaded from a

previous Hub is a new layer. Cascading can be direct from a previous Hub or routed through another CrewNet compatible device. A

maximum of 32 hubs can be connected across four layers.

ISM Bands: Industrial, Scientic, and Medical Bands. A part of the radio spectrum that can be used for any purpose without a

license in most countries.

Power-Over-CrewNet: A proprietary network protocol that provides operating voltage and current to devices that are connected to the

CrewCom Control Unit.

Prole: A Radio Pack (RP) Prole assigns functionality to a RP’s local controls, knobs, and buttons as well as what Conferences it subscribes to.

Radio Pack: The direct portable wireless communication device connecting individual CrewCom users to the CrewCom system. Sometimes

commonly referred to as a BeltPack.

Radio Transceiver: A device used to remotely locate a radio and its corresponding antenna to provide an expanded coverage area.

System Administrator: A CrewCom top-level user who has conguration knowledge and capabilities. Certain system changes

should be performed by the administrator.

Wired Intercom: Any hard wired duplex audio port for getting audio in or out of a system.

17

Index

HUB MANUAL

Index

Symbols

2-Wire 4, 5

4-Wire 4, 5

A

AC Power 2

Audio Output 5

C

Cat 5e. SeeCopper

Conference 5

Control Unit 4, 7

Overview 4

Copper 3, 4, 6, 7, 8, 9, 12

CrewCom Conguration File 5, 7, 10

CrewNet 4, 5, 7, 8, 9, 10, 11, 12

CrewWare 4, 5, 7, 10

S

Subscriber 5

Subscription 5

System Administrator 5

W

Warranty 3, 15

Wired Intercom 5

F

Fiber 3, 4, 5, 6, 7, 8, 9, 10, 12

Firmware 7

H

Hub 4, 10

Operation 11

Safety 1

Specications 12

Hub Layer 10, 17

I

ISM Bands 4

L

LED 6, 7, 8, 11

P

PoC. SeePower-over-CrewNet

Power-over-CrewNet 5, 7, 9, 11, 12

Prole 5

R

Radio Pack 3, 4, 5

Radio Transceiver 4, 10

RJ-45 9, 10, 12

18

HUB MANUAL

Pliant Technologies, LLC

205 Technology Parkway

Auburn, AL 36830 USA

www.plianttechnologies.com

Phone +1.334.321.1160

Toll-Free 1.844.475.4268 or 1.844.4PLIANT

Fax +1.334.321.1162

Copyright ©2018–2019 Pliant Technologies. All rights reserved. The Pliant®, CrewCom®, and CrewNet™ word marks and the Pliant “P”

logo are trademarks of Pliant Technologies, LLC. Any and all other trademark references within this document are property of their respective

owners.

Loading...

Loading...