IntelliPlex

TM

1000 πCode Processor

User Manual

PlexBio Co., Ltd.

PlexBio Co., Ltd.

6F-1, No. 351, Yangguang St., Neihu Dist.,

Taipei City 11491, Taiwan

Tel: +886-2-2627-5878.Fax: +886-2-2627-5979

http://www.plexbio.com

A04-016 V01 (RUO)

Standard Terms and Conditions for the Use of Products

Contract

The terms and conditions herein (hereinafter referred to as the “Standard Terms”) apply to all of

the products and services provided or will be provided by PlexBio Co., Ltd. (hereinafter referred

to as “PlexBio”). Any changes to the Standard Terms shall have no binding effect on PlexBio unless

the same has been agreed upon by an authorized representative of PlexBio in writing. The “Dealer”

referred to herein represents PlexBio (if the products are purchased from PlexBio directly), or the

distributor licensed by PlexBio. PlexBio expressly disagrees with any terms or conditions made by

the buyer in the purchase order or any of such which is different from or not included in this

Standard Terms.

The buyer’s acceptance, unpacking, or use of the products or services shall constitute his/her

acknowledgment and acceptance of the Standard Terms unconditionally. Once the buyer opens

the packaging of PlexBio products or uses the products or services in any manner, the buyer

acknowledges and accepts the Standard Terms unconditionally, and also agrees that the

Standard Terms constitute the contract which has binding effect on the buyer under law. Where

the buyer disagrees with the Standard Terms, he/she shall contact PlexBio immediately to

return the products before using the products or services in any manner, and he/she shall not

use the products or services in any manner. PlexBio has the right to amend the terms and

conditions regarding specification and service without notifying the buyer in advance if no

specification or service has been specified and identified in writing before.

Warranty

The warranty terms and conditions in this Standard Terms (the “Warranty”) apply to any

instruments, spare parts and services (collectively, the “Products”) purchased by the buyer from

PlexBio directly and situated in the territory of Taiwan. The Warranty excludes any activities other

than calibration, certification and maintenance. PlexBio will not provide any Warranty toward the

sale and use of the Products outside the territory of Taiwan. The Products distributed outside the

territory of Taiwan will be sold “As is”. PlexBio will provide the buyer with quality assurance

toward the spare parts purchased from PlexBio and that are used to maintain PlexBio instruments

under the same terms and conditions herein in any countries/territories other than Taiwan

around the world.

Particularly, the Warranty provided herein excludes any products, software or hardware provided

not by PlexBio. If the product is purchased from a PlexBio’s distributor, the Warranty shall be

provided by the distributor to the buyer in writing directly.

Quality Assurance

Products: Regardless of whether or not the buyer accepts said terms and conditions, for any

Products purchased from PlexBio directly, PlexBio will ensure that the performance of all the

Products meets the product specifications provided by PlexBio within 12 months from the

delivery date on (hereinafter referred to as the quality assurance period). PlexBio is entitled to

take one of the following actions against any defects found and reported during the quality

assurance period: (1) payment refund, or (2) defect repairs or spare parts replacements. The

expenses derived from said actions shall be borne by PlexBio.

Software: PlexBio ensures that all the installed software substantially meets the functions

described in the software documentation provided by PlexBio. Notwithstanding, PlexBio does

not guarantee that the software is error-free or may not be attacked by hackers or viruses. The

quality assurance period of the software is identical with that of the PlexBio product in which the

software is installed.

Service: PlexBio ensures that, where the buyer finds any inconformity of related services and

notifies PlexBio of the same in writing within 30 days after the related services are performed;

PlexBio shall be obligated to provide necessary services, assistance and consultation to correct

the inconformity.

General clauses: The Warranty and quality assurance provided are subject to the following

limitations, including (1) the said quality assurance does not apply to consumable materials,

accessories, normal wear and tear, damageable parts and fragile parts; (2) when the buyer asks

PlexBio to provide quality assurance work beyond normal working hours, PlexBio shall be entitled

to charge the buyer additional expenses; (3) the said quality assurance does not apply to the

following circumstances: accidents, modifications, unfair use, abuse, destruction, or disassembly

without authorization, or if the buyer fails to keep or operate in the manner as required, and(or)

do unauthorized maintenance, installation or service, and(or) incorporates or integrates any

product without permission from PlexBio into the PlexBio Products, or integrates the PlexBio

Products into the buyer’s environment or products, and(or) uses other software or user interface

provided by the buyer/vendor without PlexBio’s permission; (4) for the Products sold by PlexBio

but produced by another manufacturer, the quality assurance provided by PlexBio is only valid in

the residual period in which the manufacturer provides its quality assurance; (5) once any

Products is maintained and repaired by PlexBio, the buyer acknowledges that the maintenance

work will not extend the quality assurance period or derive any new quality assurance period.

Other than the Warranties and quality assurance explicitly provided in writing in this Standard

Terms, PlexBio does not provide any other warranties, including but not limited to the warranty

toward fitness for a specific purpose, explicitly or implicitly. If the dealer determines, on the basis

of its own judgment, that the buyer has misused the Products or failed to follow the instructions

to use the Products, the warranty provided by the dealer toward the sale of the Products shall be

invalid.

PlexBio shall not be liable for any direct or incidental damage caused by the use of or failure to

use the Products, including but not limited to, the loss in the process of operation, shutdown,

loss of revenue or profit, loss of the buyer’s product or other products, in addition to the liability

to be borne by the buyer to the supplier, or by the supplier due to such loss, and the labor or

other expenses, damages or losses caused by such Products, including personal injury or loss of

property, unless the personal injury or loss of property is caused by the PlexBio’s willful conduct

or gross negligence.

Maintenance: This maintenance clause applies to Products provided by PlexBio within the

territory of Taiwan only. The maintenance includes correction, verification, and regular

maintenance works only. PlexBio does not provide any warranty to the sales outside of Taiwan.

The Products sold outside Taiwan shall be labeled “original manufactured” and provided “as-is”.

In regards of any spare parts placed outside Taiwan and used for the purpose of maintaining the

PlexBio Products, PlexBio shall provide the quality assurance hereunder.

For any Products situated outside the territories of Taiwan for which maintenance is required:

(i) The buyer shall notify PlexBio in writing of the issue of the Products immediately and also

provide the details about the issue verified.

(ii) The buyer shall contact PlexBio or the service maintenance engineers trained and qualified

by PlexBio to evaluate the problems and verify the issues, and might need to bear the related

expenses derived from the maintenance or transportation of the Products.

(iii) The buyer shall return the Products at issue to PlexBio or the distributor as per PlexBio’s

request. PlexBio might analyze the Products returned. Upon verifying that no defects exist,

PlexBio will send the Products back to the buyer and the buyer shall bear the related

expenses and freight. Notwithstanding, if PlexBio verifies that some issues exist, PlexBio will

bear the freight. The buyer is not entitled to return the Products without PlexBio’s prior

written consent.

Notice to User

The use of this instrumentation and its associated software is covered by one or more

pending US and foreign patents owned by PlexBio Co., Ltd. The purchase of this instrument

and software includes nontransferable rights to use the instrument and software to practice

the methods described therein. No general patent or other license of any kind other than

this specific right of use from purchase is granted. For further information on purchasing

licenses for other applications can be obtained from PlexBio Co., Ltd. 6F-1, No. 351,

Yangguang St., Neihu District, Taipei City 11491, Taiwan.

Trademarks

, ,DeXipherTM, IntelliPlexTM, DigiPlexTM, πCode

trademarks or registered trademarks of PlexBio Co., Ltd. All other product names and any

registered and unregistered trademarks mentioned are used for identification purposes only

and remain the exclusive property of their respective owners.

Copyright

© 2017 PlexBio Co., Ltd. All rights reserved.

TM

, PlexBioTM, are

I

IntelliPlexTM 1000 Code User Manual - Jul-17

Table of Contents

Chapter 1. Instruction .......................................................................................................................... 1

Overview .......................................................................................................................................................... 1

Warnings .......................................................................................................................................................... 1

Symbols ............................................................................................................................................................ 2

Chapter 2. Safety and Regulatory Issues ............................................................................................ 3

Intended Use ................................................................................................................................................... 3

Regulatory Labels ............................................................................................................................................ 3

Testing and Certifications ....................................................................................................................................................... 4

Safety Precautions .................................................................................................................................................................... 4

Chapter 3. IntelliPlex 1000 πCode Processor Technical Overview ................................................... 6

Introduction ..................................................................................................................................................... 6

Main Characteristics ....................................................................................................................................... 7

Shaking and Incubation .......................................................................................................................................................... 7

Washing ......................................................................................................................................................................................... 7

Fluorescence Labeling ............................................................................................................................................................. 7

System Technical Specification ...................................................................................................................... 8

Chapter 4. Installation Procedure ....................................................................................................... 9

Inspect the Instrument ................................................................................................................................... 9

Instrument Unpacking ................................................................................................................................. 10

Unpack Procedures................................................................................................................................................................ 10

List of Accessories .................................................................................................................................................................. 13

Instrument Assembling ............................................................................................................................... 14

Removing the Shipping Brackets...................................................................................................................................... 14

Place the Solution Trays ....................................................................................................................................................... 16

Connecting the Components............................................................................................................................................. 17

Chapter 5. Operation Procedure ...................................................................................................... 18

Initial Startup ................................................................................................................................................ 18

Touchscreen Introduction ........................................................................................................................... 19

Predefined Assay Protocols......................................................................................................................... 20

RUN the Built-in Assay Kit ................................................................................................................................................... 20

II

IntelliPlexTM 1000 Code User Manual - Jul-17

Create a Custom Program ........................................................................................................................... 24

Procedure Introduction ....................................................................................................................................................... 25

How to Create a Customized New Program ................................................................................................................ 29

How to Overwrite a Program ............................................................................................................................................ 32

Special Applications ..................................................................................................................................... 33

Silicone Pad Assembly (Optional) .................................................................................................................................... 33

SAPE Solution Supplement ................................................................................................................................................. 36

Chapter 6. System Setting ................................................................................................................. 37

Maintenance................................................................................................................................................. 38

Renew Tank ............................................................................................................................................................................... 39

Clean Manifold ........................................................................................................................................................................ 41

Machine Reset .............................................................................................................................................. 42

Rinse Time .................................................................................................................................................... 43

Fluid Path ...................................................................................................................................................... 44

System Update ............................................................................................................................................. 45

Assay Update ................................................................................................................................................ 45

Date/Time ..................................................................................................................................................... 46

Language ....................................................................................................................................................... 46

Service Mode ................................................................................................................................................ 47

Log Status ...................................................................................................................................................... 47

Shutdown ...................................................................................................................................................... 48

Chapter 7. Maintenance ................................................................................................................... 49

Recommended Maintenance Schedule ..................................................................................................... 49

As Needed Maintenance ............................................................................................................................. 50

Long-term Shutdown Situation ........................................................................................................................................ 50

Fuse Replacement .................................................................................................................................................................. 50

Chapter 8. Contact Information ....................................................................................................... 51

Customer Service and Sales ........................................................................................................................ 51

1

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 1. Instruction

Overview

Read this manual carefully before using IntelliPlex 1000 πCode Processor. It provides essential

information about the following aspects of IntelliPlex 1000 πCode Processor:

• Safety and Regulatory Issues

• Labeling

• Technical Information

• Installation

• Operation Procedures

• Setting

• Routine Maintenance

Warnings

When operated in a safe environment according to the instructions in this user

manual, there are no known hazards associated with the instrument. However,

the operator should be aware of certain situations that could result in serious

injury or possible damage of the instrument. The protection provided by the

instrument may be impaired if it is used in a manner not specified in this

instruction.

2

IntelliPlexTM 1000 Code User Manual - Jul-17

Symbols

General cautions and

warnings

Caution: pinch point

Warning: Biohazard

Warning: Hot Surface

Manufacturer

Date of Manufacture

Batch code

Serial number

Waste Electrical and

Electronic Equipment

Consult instructions for

use

ETL Mark

Federal Communications

Commission (FCC) Mark

The following symbols may appear throughout this manual with safety warnings, identification,

conditions, instructions and regulatory agencies.

Table 1. List of symbols

3

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 2. Safety and Regulatory Issues

Please read the safety information in this chapter before using IntelliPlex 1000 πCode Processor.

The system contains electrical and mechanical components which may result in injury and damage

of the instrument if handled improperly. Do not perform procedures on IntelliPlex 1000 πCode

Processor that are not specifically described in the user manual.

Intended Use

IntelliPlex 1000 πCode Processor is a unique, user-friendly 4-in-1 workstation and is intended to

use for 96-well plate washing, shaking, incubation and automated fluorescence labeling. The

workstation is specifically designed for πCodeTM MicroDisc during the hybridization, washing and

labeling steps required before fluorescent detection by PlexBioTM 100 Fluorescent Analyzer to get

optimized results. Additionally, this workstation can also be applied for ELISA washing only.

Regulatory Labels

The following label appears on the IntelliPlex 1000 πCode Processor. It displays the model, serial

number, lot number, power requirements, electrical safety certification and information of

manufacturer.

Figure 1. Label of IntelliPlex 1000 πCode Processor

4

IntelliPlexTM 1000 Code User Manual - Jul-17

The following symbols may appear as necessary on the instrument and user manual which

Electrical

Cautions

General

Cautions

indicate the information notes and warnings.

Testing and Certifications

IntelliPlex 1000 πCode Processor has been tested and complies with the safety requirements. The

following agency mark will be on the label.

(ETL mark) (FCC mark)

Safety Precautions

In any situation in which user may encounter following symbols, please read and understand all

the safety precaution notes before the system operation.

This message is used to provide general caution information.

Please handle with extreme care when moving or relocating system as mishandling may

damage the system.

Lift the unit from the base only. DO NOT lift by or put excessive force on the plastic case.

DO NOT put excessive force on the stage or it may become tilted or bent. This will severely

interfere with the performance of the system.

This message is provided to avoid electric shock or possible damage

to the system.

DO NOT open or remove the covers on the system peripherals.

Use only power cords supplied with the system or cords with grounded outlets properly rated

for the system.

Ensure the power cord is connected to properly grounded AC outlets only.

Users should not perform any maintenance or cleaning of the electrical components in the

system.

If any malfunction happens, please turn off the power button and then disconnect the power

cable. The main plug is used as main disconnection device, not to position the equipment so

that it is difficult to unplug the mains plug.

5

IntelliPlexTM 1000 Code User Manual - Jul-17

Waste Electrical

And Electronic

Equipment

(WEEE)

Pinch

Point

Hot Surface

The IntelliPlex 1000 πCode Processor has modules that move during the operation. The risk

of pinching hazards are presents. Please keep hands away from the moving part and do not

put your hands under the moving part.

Please do not touch the heating thermos plate surface until it has cooled.

Biohazard

Human and animal samples in the 96-well plate may contain biohazardous, infectious

materials. Please use personal protective equipment (PPE) including gloves and laboratory

coats. Please handle with extreme care when loading the plate onto the stage to prevent

spilling.

Within the European Union, the Waste Electrical and Electronic Equipment Directive

2002/96/EC requires the properly dispose of electrical and electronic equipment when it

reaches the end of its lifecycle.

If you are disposing of a IntelliPlex 1000 πCode Processor, please contact PlexBio Technical Support

for a Return Material Authorization (RMA) number at +886-2-2627-5878.

6

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 3. IntelliPlex 1000 πCode Processor

Technical Overview

This chapter describes the technology introduction, module characteristics and technical

specifications of IntelliPlex 1000 πCode Processor.

Introduction

IntelliPlex 1000 πCode Processor is the workstation specifically designed for πCode MicroDisc

during the hybridization, washing and labeling steps required before fluorescent detection by

PlexBio 100 Fluorescent Analyzer which minimizes user’s hands-on time. Users could also create

their own custom protocols from hybridization to fluorescence labeling by adjusting the related

parameters.

Features Include:

Easy to use: User-friendly interface with imbedded processing modes for PlexBio assays or

customization.

Multifunctional: Combines aspiration, buffer dispensing, shaking, rinsing, heating, and the

magnetic force application to minimize πCode MicroDiscs loss during washing steps.

Applicability: Designed for both molecular and immunoassays.

Touchscreen: Includes a 7-inch industrial touch panel.

7

IntelliPlexTM 1000 Code User Manual - Jul-17

Main Characteristics

The multifunctions of IntelliPlex 1000 πCode Processor are including shaking , incubation, washing

and automated fluorescence labeling optimized for πCode MicroDisc. The characteristics are

provided as follows:

Shaking and Incubation

This function is designed for shaking standard 96-well microplates in thermostatic mode.

Features:

Easy to control time and temperature for operation

Simultaneous display of set and actual time, and temperature

Heating platform for standard 96-well microplates

Built-in PlexBio assay programs with no further setting needed

Washing

This function is designed to reduce hands-on time and human error during the πCode MicroDiscs

washing process.

Features:

Combines aspiration, buffer dispensing, shaking, automatic rinsing, and a magnetic plate for

minimizing πCode MicroDiscs loss during washing steps

Simultaneous display of the current washing cycles and status

Convenience: easy for operation and maintenance

Fluorescence Labeling

This function is designed to reduce hands-on time for the fluorescence labeling process. IntelliPlex

1000 πCode Processor can work with all types of Cy3 fluorescence readers. Use of SA-PE for πCode

MicroDiscs fluorescence labeling is most recommended.

8

IntelliPlexTM 1000 Code User Manual - Jul-17

System Technical Specification

Model

IW100

PERFORMANCE

Processing time

(full plate)

3~6.5 min (one time wash)

Shaking

Timing setting range: 1min~23 hr59 min59 sec

Max. rate: 1200rpm

Incubator

Temperature range from RT+5℃ to 60℃

Safety

Plate position sensor and door sensor

Temperature accuracy

± 0.5°C

Temperature uniformity

1°C

Shaking accuracy

≤ 10%

Dispensing accuracy

≤ ± 6%, Measured under following conditions:

8-way manifold, 150 μL, PlexBio Wash Buffer (PBST)

Dispensing uniformity

≤ 4% CV, Measured under following conditions:

8-way manifold, 150 μL, PlexBio Wash Buffer (PBST)

MicroDisc loss

Around ≥ 75% of microdiscs retained after whole processes,

Measured under following condition:

500~1500 discs/well in 150μL PlexBio Wash Buffer

Residual volume

≤ 5μl /well, Measured under following conditions:

8-way manifold, 150 μL, PlexBio Wash Buffer

OPERATION CONDITIONS

Temperature/ Humidity

18℃~32℃/ 20~80%RH, non-condensing

Altitude

Up to 2000 meters (6561 ft) above mean sea level

Others

Reliability tests

STORAGE CONDITIONS

Temperature/ Humidity

-10℃~70 ℃/ 10~80% RH non-condensing

Others

Reliability tests

PHYSICAL CHARACTERISTICS

Power

100-240V, 50-60Hz, 250W

Dimensions

Without Bottle Carrier: (W)540mm*(D)408mm*(H)456mm

With Bottle Carrier: (W)540mm*(D)554mm*(H)456mm

Weight

38 kg

Fuse rating

T 5A H 250V

OTHERS

Pollution degree

2

Method of disposal

Electronic waste

Table 2. System Technical Specification

9

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 4. Installation Procedure

Cautions

Fig 2. The inside package of IntelliPlex 1000 πCode Processor

This chapter provides the detailed installation procedures. Note that IntelliPlex 1000 πCode

Processor should be installed and serviced by PlexBio’s qualified service engineers only. Before

setting up and unpacking the processor, please make sure the operation environmental

requirements:

Environmental Conditions

Indoor use only

Operating temperature: 18°C to 32°C

Operating relative humidity: 20% to 80%, non-condensing

Operating altitude: up to 2000m (6561 ft) above mean sea level

Storage temperature: -10°C to 70°C

Inspect the Instrument

IntelliPlex 1000 πCode Processor arrives in a large, corrugated cardboard overpack on skids.

Inspect the shipping box, packaging, instrument and accessories for signs of damage.

The package of IntelliPlex 1000 πCode Processor may be too heavy to

lift. Please lift the instrument from the bottom and do not pull, push,

or bend the case from the side.

IntelliPlex 1000 πCode Processor needs an operation area of 0.36

square meters. The system also needs to be placed at least 10

centimeters from the wall for components connection and for

efficient cooling.

10

IntelliPlexTM 1000 Code User Manual - Jul-17

Instrument Unpacking

The following information provides the assembling process of the instrument.

Unpack Procedures

To set up IntelliPlex 1000 πCode Processor (Fig. 3 to Fig. 8):

1. Remove the carton buckle from the package box.

2. Remove the boxes containing IntelliPlex 1000 πCode Processor. The instrument is inside a

plastic bag and surrounded by foam inserts attached to a corrugated cardboard insert.

3. Remove the surrounded foam inserts and plastic bag.

4. Place the instrument on a stable and flat bench.

5. Remove two black cushions affixed on the frame of the front door.

Fig 3. Remove the carton buckle from the package box

11

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 4. Remove the upper carton from its package

Fig 5. Remove accessories first then remove the foam inserts from its package

12

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 6. Pulling out IntelliPlex 1000 πCode Processor from its package

Fig 7. The unpacked IntelliPlex 1000 πCode Processor

Fig 8. Remove two black cushions on the front door frame

13

IntelliPlexTM 1000 Code User Manual - Jul-17

List of Accessories

Tubes*3

Manual*1

Accessory

box *1

Waste

bottle*1

Bottle

holder*1

Buffer

bottle*2

U tray*10

V tray*10

AC fuse*2

Silicon

pad*3

Power

cord*1

Silicon

pad

fixture*1

Before proceeding with the installation, please check the accessories provided with the

accessories list.

Table 3.1 Accessories in Top EPE

Table 3.2 Accessories in the box

14

IntelliPlexTM 1000 Code User Manual - Jul-17

Instrument Assembling

Cautions

Removing the Shipping Brackets

Users must remove the shipping brackets before connecting the

components and before operating the moving manifold.

To remove the shipping brackets, please follow the steps 1 to 6.

Step1. Open the left side access door by loosening the screws on it (Fig.9).

Fig 9. Open the left side access door

Step 2. Remove the four screws (two small ones and two large ones) of the bracket A.

Step 3. Remove the five screws of the bracket B (Fig.10).

Fig 10. Remove the screws of bracket A and B

15

IntelliPlexTM 1000 Code User Manual - Jul-17

Step 4. Remove the two screws of bracket C (Fig. 11).

Cautions

Fig 11. Remove the screws of pipette bracket

Step 5. Check all the removed brackets and screws.

Please be careful not to lose and save all removed brackets and

screws for future re-packaging and transporting.

Fig 12. All removed brackets

16

IntelliPlexTM 1000 Code User Manual - Jul-17

Place the Solution Trays

Once complete removing the shipping brackets, please place the U-Tray and V-Tray in the

dedicated proper positions before connecting the components (Fig.13) and put the left side

access door back.

Fig 13. The positions of solution trays

17

IntelliPlexTM 1000 Code User Manual - Jul-17

Connecting the Components

To connect the components:

1. Take out all the accessories including bottles, tubes and the AC power cord.

2. Plug the power cord into the back of the instrument.

3. Ensure that the on/off switch in the rear panel of the instrument is in the off position.

4. Fill up the wash buffer bottle with wash buffer and fill up the ddH2O bottle with distilled

water.

5. Connect the buffer tubes (Wash buffer and Distilled water) to the inlet connectors on the rear

panel of the instrument and to the corresponding bottle as well. See the Fig 14 for the

connected diagrams.

Fig 14. Connected diagrams

18

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 5. Operation Procedure

Before operation, please connect the power cord and the corresponding bottles and tubes. Make

sure the dedicated U Tray tank for washing buffer and V Tray tank for SAPE solution are placed

accordingly. Please make sure the bottles contain enough water and enough wash buffer.

Initial Startup

After setting up preparation, turn on the power at the backside of the instrument. The system will

run a system self-test every time users turn on the power. Please make sure buffer bottles are

filled with corresponding buffer and the waste bottle is empty. Click on the OK to complete system

self-test process.

Fig 15. Interface of system self-test

19

IntelliPlexTM 1000 Code User Manual - Jul-17

Touchscreen Introduction

1.

2.

3.

4.

There are 4 main portions on the user interface homepage: (1) Main functions; (2) Menu; (3)

Date/Time; (4) Software version.

(1) There are 4 main function buttons for users to run the operation.

- Built-in PlexBio Molecular Assay

- Built-in PlexBio Immunoassay

- Built-in PlexBio Assays in Applied Science

- Custom Program

(2) Menu is for users to run the settings and maintenance procedures.

(3) Current date and time display.

(4) General information of certifications and software versions.

Fig 16. Homepage of the user interface

20

IntelliPlexTM 1000 Code User Manual - Jul-17

Predefined Assay Protocols

IntelliPlex 1000 πCode Processor is installed with the predefined assay protocols from PlexBio’s

assay kits. There is no need to reset the protocol conditions each time before assay starts.

RUN the Built-in Assay Kit

For running the PlexBio assay kit, please see the Fig 17 to 22 for step 1 to 6.

Step 1. Select the built-in Plexbio assay types (Molecular Assay, Immunoassay or Applied

Science).

Step 2. Select the desired rows on the interface for processing and click on the Next ( ).

Step 3. Select the corresponding assay to operate.

Step 4. Confirm the shown procedure conditions are correct and click on the button START.

Step 5. Make sure the pop-up window notices are followed and click on the START to run the

assay.

Step 6. The interface will show the real-time status on the touchscreen until the assay is

finished.

Fig 17. Select the assay types

21

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 18. Select the desired rows for processing

Fig 19. Select the corresponding assay

22

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 20. Procedures confirmation

Fig 21. Pop-up window confirmation

23

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 22. Real-time display of the assay operation status

24

IntelliPlexTM 1000 Code User Manual - Jul-17

Create a Custom Program

This section describes how users can create and edit assay procedures based on their needs. See

the following information for the editable parameters.

Fig 23. Interface of custom program

25

IntelliPlexTM 1000 Code User Manual - Jul-17

Procedure Introduction

Incubation: Users can edit the desired incubation temperature and time on this program. The

parameters for setting are listed as below.

(A) Heating temp.: Set up the desired heating temperature by sliding the setting bar or directly

key in the number into the screen square frame. Please note the temperature setting range

are limited from RT+5°C to 60°C .

(B) Heating period: Set up the desired heating period by directly key in the number into the

screen square frame by the order of Hour (H): Minute (M): Second (S). Please note the

temperature setting range are limited from 1min to 23hr59 min59 sec.

(C) Close lid before heating: The function is designed for users to incubate the plate in the

confined incubation space for the thermostatic environment. Please click to fill the square

if necessary. Note that the function should be used with silicone pad.

(D) Shake before reaching temp.: If the function is clicked to open, the plate will be shaken for

seconds to be mixed evenly once reaching the set temperature.

Fig 24. Parameters of custom incubation procedure

26

IntelliPlexTM 1000 Code User Manual - Jul-17

Washing: Users can setup various conditions listed below during the washing step (Fig. 25).

(A) Washing Cycles: Setup the washing cycles for maximum 4 cycles.

(B) Washing Dispensing Volume: Users can either setup the 150 uL wash buffer dispensed for

the πCode system wash or use ELISA wash function for 200 uL washing.

(C) Last Dispense Volume: This is designed for users who want to dispense the buffer of 50 uL

into wells as the final step for dispersing πCode before decoding. It is usually used before

decoding analysis, but no need for ELISA assays.

(D) Magnetic Function: Users can choose to turn on the magnetic function to separate πCode

Microdiscs to peripheral bottom of the well from supernatant. The magnetic function is no

need for the ELISA assays.

(E) Clean Tip: When dealing with different samples in one 96-well microplate, to prevent any

carryover contamination between each sample placed in different rows, Clean Tip can do

the tip cleaning every time right before the next row approach. The tip cleaning will only be

performed in the 1st cycle during the washing procedure.

Fig 25. Parameters of custom washing procedure

27

IntelliPlexTM 1000 Code User Manual - Jul-17

SAPE Reaction: This procedure is used for the fluorescence labeling step with automated SAPE

dispensing. The dispensed SAPE is fixed with 50uL per single well at 37°C

incubation for the desired incubation time and continues with the 4 washing

cycles. The heating period could be adjusted from 1min to 23hr59min59sec.

Fig 26. Parameters of custom SAPE procedure

28

IntelliPlexTM 1000 Code User Manual - Jul-17

Disperse: This function is used to minimize the πCode MicroDiscs aggregates before decoding.

Pause: Pause is used to pause the process in progress for checking well status. The system will

be stopped during the pause and a warning window will be popped up, once users want

to restart the process, click to confirm restarting the process.

Fig 27. Disperse and Pause Procedure

29

IntelliPlexTM 1000 Code User Manual - Jul-17

How to Create a Customized New Program

Users can create a program to perform the customized assay procedures sequentially in one run.

Please see the Fig 28 to 32 for step 1 to 7.

Step 1. Click on the Custom Program on the homepage.

Step 2. Select the desired rows on the interface for the processing and click on the Next.

Step 3. Select one program for editing from Custom 1 to 6.

Step 4. Click on ADD PROCESS, and choose the desired procedure from the drop-down menu

on the right side.

Step 5. Set detailed parameters for each procedure like temperature, time, washing cycles, etc,

and save the procedure.

Step 6. Repeat Step 4 and 5 to combine all procedures in order as the custom program steps.

Step 7. Confirm all the procedures and order are correct and then click on to save the

program and run the custom assay process.

NOTE:

1. Force touch the process on the touchscreen, users could delete the specific process with the

confirmation by the pop-up notice window.

2. Before operating processes, please make sure wash buffer and SAPE solution are supplemented

to the dedicated containers.

3. During the process operation, the touchscreen will real-time display the current status.

30

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 28. Custom Program Homepage and Row Selection

Fig 29. Custom Program 1 to 6

31

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 30. Select desired procedures to set up a process

Fig 31. Set detailed parameters for each process

32

IntelliPlexTM 1000 Code User Manual - Jul-17

Custom Program1

Fig 32. Custom Program Process and Real-time Display

How to Overwrite a Program

IntelliPlex 1000 πCode Processor has the default for 6 programs for users to save.

Step 1. Select the Custom Program on the homepage.

Step 2. Select the desired rows on the interface for the processing and click on to Next step.

Step 3. Select one program for editing from Custom 1 to 6 to overwrite the program.

33

IntelliPlexTM 1000 Code User Manual - Jul-17

Special Applications

Yellow Circle: Anchor

points for silicone pad

Red Triangle: Anchor

points for thermal lid

Yellow Circle: Anchor

points for silicone pad

Red Triangle: Anchor

points for thermal lid

This section describes the applications of necessary accessories before or during the assay

procedures.

Silicone Pad Assembly (Optional)

If users concern with the designed assay conditions such as contamination possibilities and

heating environments, the usage of silicone pad could be optionally applied.

During the incubation procedures of IntelliPlex 1000 πCode Processor, the microplate sealing tape

is replaced by silicone pad (Fig 33). The holding fixture (Fig 34) is used as a tool to assist users to

connect the silicone pad and reduce the contamination possibilities.

Fig 33. Silicone Pad

Fig 34. Holding Fixture

34

IntelliPlexTM 1000 Code User Manual - Jul-17

Please follow the operation steps listed below to connect the silicone pad:

Step 1. Take out one silicone pad without touching the inner side (bump on the inner side)

which will cover on the 96-well plate directly.

Step 2. Let the inner side of silicone pad face to the holding fixture and connect the four anchor

points (Fig 35) together. Make sure the silicone pad is snap-fit with the holding fixture

(Fig 36).

Fig 35. Direction of assembling silicone pad to the holding fixture

Fig 36. Assembled silicone pad on the holding fixture

35

IntelliPlexTM 1000 Code User Manual - Jul-17

Step 3. Let the holding fixture, which assembled with silicone pad, face to thermal lid and

connect another four anchor points (Fig 37) together.

Fig 37. Connect silicone pad via holding fixture to the thermal lid

Step 4. Remove the holding fixture and make sure the silicone pad is snap-fit to the thermal lid

(Fig 38).

Fig 38. Remove holding fixture and silicone pad is connected

Note: It is not recommended to reuse the silicone pad under different assay procedures though it

could be cleaned with 70% alcohol and tolerated the temperature for up to 200℃.

36

IntelliPlexTM 1000 Code User Manual - Jul-17

SAPE Solution Supplement

The SAPE solution supplement is necessary for the built-in PlexBio assays or the customized assays

which need SAPE reaction process. The SAPE solution tank (V Tray) position is shown as Fig. 39.

The tank can be filled with SAPE solution directly followed by the desired SAPE solution volume

calculation. Please note that the dead volume of the SAPE solution of IntelliPlex 1000 πCode

Processor is 500 µL and the minimum usage of SA-PE is one row. Normally, the needed SAPE

solution for assay reaction per well is 50 µL.

Calculation Example:

For 3 rows reaction, the SA-PE solution needed is

400 µL x 3 rows + 500 µL = 1.7mL (at least).

In order to ensure the instrument has sufficient solution to dispense, pipet extra volume into the

solution tank is recommended.

Note: It is suggested to supplement the SAPE solution by pipetting and reuse the SAPE solution

leftover are not recommended.

Fig 39. The positions of two types of tanks (modules)

37

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 6. System Setting

This section describes the tool menu for users to do the settings. Each setting function (Fig 40)

will be described in details as follows.

Fig 40. The menu setting list

38

IntelliPlexTM 1000 Code User Manual - Jul-17

Maintenance

This section describes the maintenance of the buffer tank renew and manifold cleaning (Fig 41).

Fig 41. Maintenance from tool menu

39

IntelliPlexTM 1000 Code User Manual - Jul-17

Renew Tank

Wash buffer (U Tray)

SAPE solution (V Tray)

Periodically renewing the wash buffer and SAPE solution tanks helps to keep the tanks clean and

reduce the possibility to have the salts crystals and contamination. Users could renew the tanks

manually. There are two types of tanks including the wash buffer tank (U Tray) and the SAPE

solution tank (V Tray), please see Fig 42.

Fig 42. The position of two types of tanks (modules)

There is no need to take out the fixed white modules from the instrument to renew the wash

buffer and SAPE solution tanks, the transparent tanks can be taken out from the fixed modules

directly and manually.

For the wash buffer tank (U Tray) renew, please follow the steps described below:

Step 1. Select the Setting on the menu page.

Step 2. Click on the Maintenance button.

Step 3. Choose the Renew Tank and the manifold will move backwards to reveal the tanks for

users to replace manually (Fig 43).

Note: It is recommended to renew wash buffer tank (U Tray) once a week to reduce the possibility

of contamination or the crystal clogging.

For the SAPE solution tank (V Tray) renew, users could renew the tank directly without any setting

procedures. It is recommended to renew SAPE solution tank (V Tray) every time prior to use.

40

IntelliPlexTM 1000 Code User Manual - Jul-17

Fig 43. Renew wash buffer tank

41

IntelliPlexTM 1000 Code User Manual - Jul-17

Clean Manifold

Regular rinsing helps to keep the manifold clean and reduce the possibility to have the salts

crystals. If the crystals block the manifold tips or any visible dust on the manifold tips, users could

clean the manifold manually by using the fine needles or thin iron wire. Please follow the steps

described below (Fig 44) to do the clean manifold:

Step 1. Select the Menu on the homepage.

Step 2. Click on the Maintenance button.

Step 3. Choose the Clean Manifold and the dispensing and sucking module will move forward

to reveal the manifold for users to clean manually.

Note: It is not recommended to disassemble the manifold tips by users. If there is any crystals or

dust on manifold tips which cannot cleaning away, please contact PlexBio Co., Ltd. or local

distributors for service.

Fig 44. Clean the manifold

42

IntelliPlexTM 1000 Code User Manual - Jul-17

Machine Reset

Users can use this function to return the manifold, the thermal lid, and the magnetic plate back

to their original setting positions.

Step 1. Select the Setting on the menu.

Step 2. Choose the Machine Reset to reset the all modules

Fig 45. IntelliPlex 1000 machine reset

43

IntelliPlexTM 1000 Code User Manual - Jul-17

Rinse Time

The rinse function is used to keep pumps and tubes wet to prevent clogging during the instrument

processing. Otherwise, the pump may fail due to the salt crystals formation from wash buffer.

Hence, users can setup the rinse time for system to do rinsing automatically.

Step 1. Select the Rinse Time on the setting menu.

Step 2. Set up the Rinse Time. If it is set as 2hr, the system will do the auto-rinse when it has

been stopped running for 2 hours.

Note: After the auto-rinse procedure, users could operate the prime step by confirming the pop-

up window, if necessary.

44

IntelliPlexTM 1000 Code User Manual - Jul-17

Fluid Path

This function is used to rinse or prime the fluid path after the system experiences an abnormal

stop such as a crash. When an abnormal stop happens and the system reboots again, some

contamination from the fluid path may affect following procedures. It is crucial for priming or

rinsing the fluid path first. There are three options in this function including RINSE (ddH2O), PRIME

(wash buffer) and RINSE & PRIME.

Step 1. Select the Menu on the homepage.

Step 2. Select the Fluid Path on the tool menu.

Step 3. Choose RINSE, PRIME or RINSE/PRIME.

Step 4. Press OK to start running.

Fig 46. Fluid path process

45

IntelliPlexTM 1000 Code User Manual - Jul-17

System Update

Upgrade the software in the instrument for the new versions through USB drive. If you need more

information, please contact PlexBio Co., Ltd.

Assay Update

Upgrade the assay software to renew the built-in assay protocols through USB drive. If you need

more information, please contact PlexBio Co., Ltd.

Fig 47. Update Assay Protocols

46

IntelliPlexTM 1000 Code User Manual - Jul-17

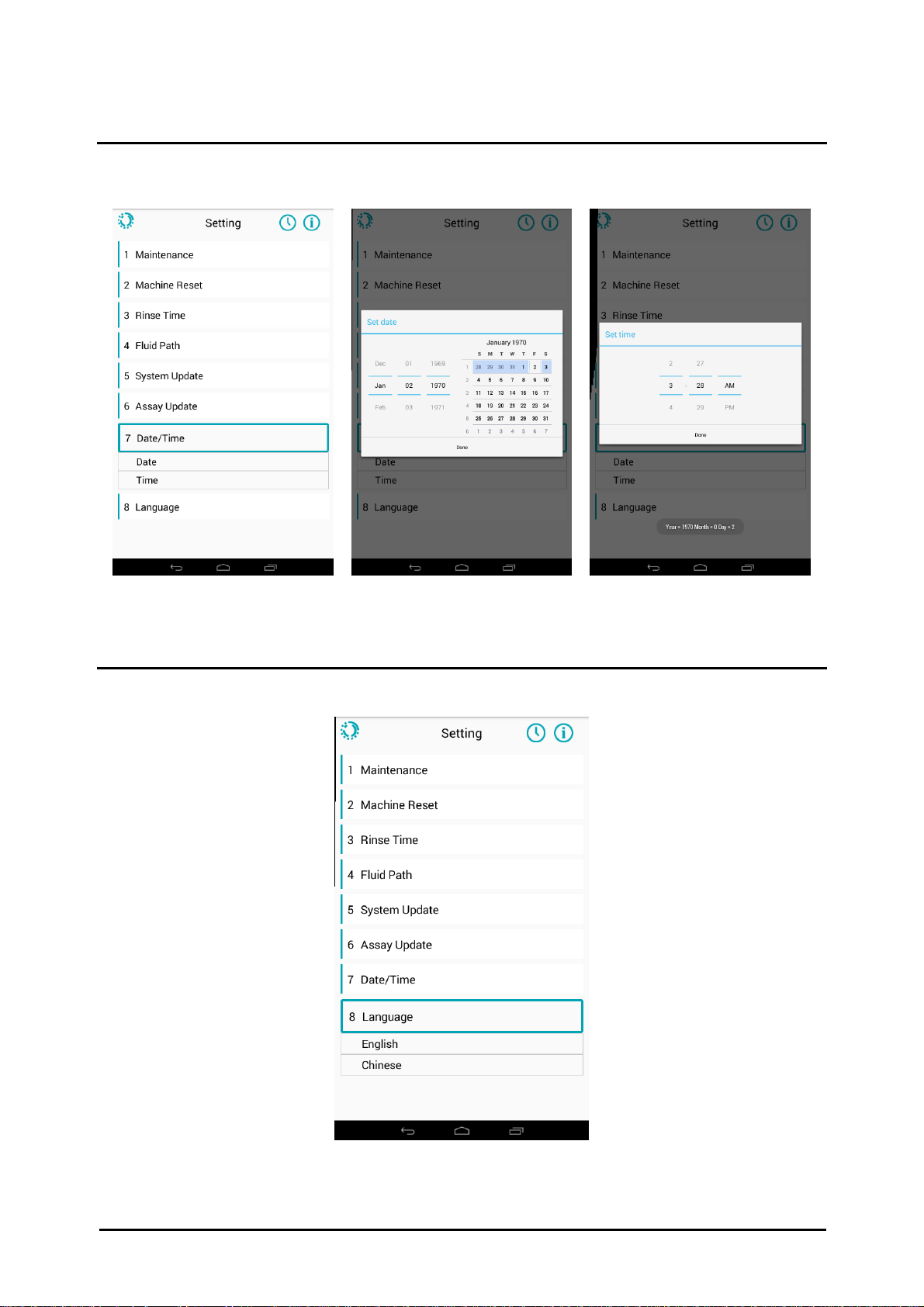

Date/Time

Setup the current Date and Time for the instruments.

Fig 48. Date and time setting

Language

Set up the language of the user interface for English or Simplified Chinese.

Fig 49. Language setting

47

IntelliPlexTM 1000 Code User Manual - Jul-17

Service Mode

The Service Mode is mainly for the factory to do the instrument service. Do not access the service

mode without any instructions.

Fig 50. Service Mode

Log Status

Users could check the system log history through the Status on the homepage.

Step 1. Select the Status on the menu.

Step 2. Choose the date to check the detailed log.

Step 3. Choose the procedure to check the detailed log.

48

IntelliPlexTM 1000 Code User Manual - Jul-17

Shutdown

After the operation of system, users should run the program of Shutdown every time to do the

pump and tubes rinsing followed by the instrument close. Users should not turn off the power on

the instrument backside directly in case of salt crystals formation without rinsing.

Step 1. Select the Shutdown on the menu.

Step 2. Press OK to run the auto-rinse followed by the system turn-off.

Step 3. After the system is off, switch off the power button and unplug the power cord to

totally disconnect the instrument.

Fig 51. System shutdown program

49

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 7. Maintenance

Action

Daily

Weekly

Monthly

Yearly

Check/ Empty waste bottles

✔

Clean bottles

✔

Clean external surface

✔

Clean fluid path tubes with 70% alcohol

✔

Lubricate the stage guideway to prevent

stage positioning error or motor failure.

✔

Replace the plastic tips

✔

Replace the fluid path tubes

✔

Re-position all axes of moving modules

✔

General

Cautions

Biohazard

Please observe the following general maintenance precautions:

Personnel that use, maintain, or clean IntelliPlex 1000 πCode Processor should be trained in

standard laboratory safety practices and should follow those practices when handling the

instrument.

Samples and waste fluid may contain biohazardous material. Where

exposure to biohazardous material exists, follow appropriate biosafety procedures, use personal protective equipment, and use

ventilation devices.

Users should not perform any maintenance or cleaning of the

electrical components in the system without training.

Recommended Maintenance Schedule

In spite of the IntelliPlex 1000 πCode Processor has been systematically tested and calibrated

before shipment, preventative actions are required to maintain the properly functions. The

recommended maintenance schedule should be checked and calibrated periodically by a qualified

service technician. See the specified section of the instruction manual for further details.

For more information on Preventive Maintenance or Extended Warranties, please contact

Technical Services Department of PlexBio Co., Ltd. or qualified local distributors.

Important: The affecting factors associated with users’ assays may require performing some or all

of the procedures more frequently than recommended in the schedule.

50

IntelliPlexTM 1000 Code User Manual - Jul-17

As Needed Maintenance

Long-term Shutdown Situation

If the IntelliPlex 1000 πCode Processor has been known not to operate for long time, it is

recommended to clean the fluid path, as procedures listed as follows, to reduce the possibility of

salt crystals formation in the fluid path.

Step 1. Use another buffer bottle contained 70% alcohol to replace the ddH

connect the ddH2O tube.

Step 2. Run the Rinse of Fluid Path on the setting menu for four times.

Step 3. Connect the 70% alcohol buffer to the wash buffer tube.

Step 4. Run the Prime of Fluid Path on the setting menu for four times.

Step 5. Remove all the buffer bottles to disconnect with tubes.

Step 6. Run the Rinse/Prime of Fluid Path on the setting menu for three times to empty the

tubes with volatile of alcohol.

Step 7. Run the Shutdown to turn off the instrument.

O bottle and

2

Fuse Replacement

If the fuse in the instrument is broken, please follow the next steps to replace it.

Step 1. Pull out the fuse holder from the power socket.

Step 2. Take out the broken fuse and replace it with a new one from the accessory box.

Step 3. Push the fuse holder back to its original place.

Fig52. A Fuse holder Fig53. B Fuse in the fuse holder

51

IntelliPlexTM 1000 Code User Manual - Jul-17

Chapter 8. Contact Information

PlexBio Co., Ltd.

6F-1, No. 351, Yangguang St., Neihu Dist.,

Taipei City 11491, Taiwan

Customer Service and Sales

Web: http://www.plexbio.com

Phone: +886-2-2627-5878

Fax: +886-2-2627-5979

Order info: order@plexbio.com

General info: marketing@plexbio.com

Loading...

Loading...