BAIndustrie_UK | Version 1.0 | 2016.04.12 ENGLISH

Operating manual industrial motors

operating manual BAIndustrie_UK 2

List of contents

List of contents ............................................................................. 2

1. Notes regarding this document .............................................. 3

Legal provisions .................................................................... 3

Scope of valitidy .................................................................... 4

Target group .......................................................................... 4

Updated additional information .............................................. 4

Symbols ................................................................................ 4

Nomenclature ........................................................................ 4

2. Savety ................................................................................... 5

Intended use ......................................................................... 5

Savety information ................................................................. 5

3. Product overview ................................................................... 8

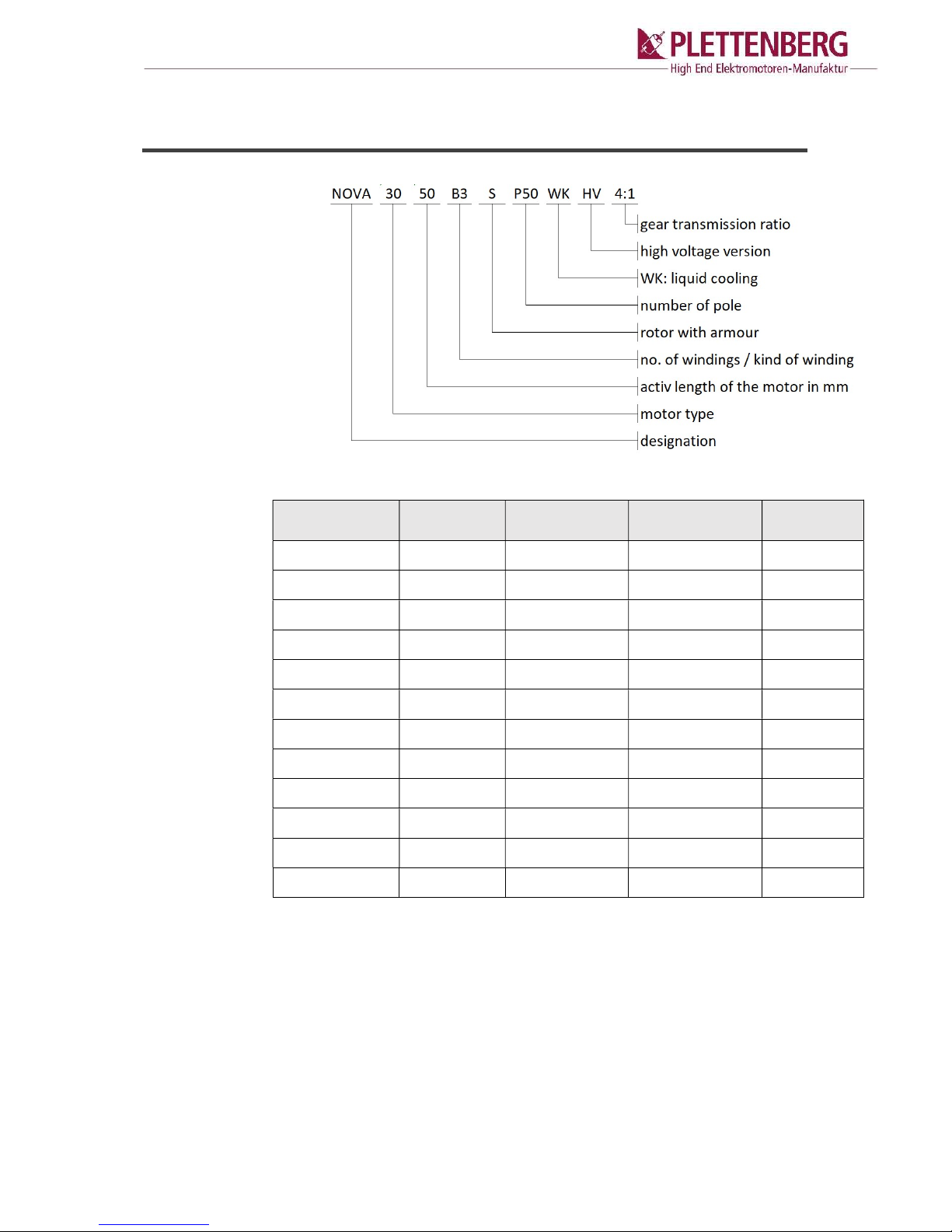

Type designation ................................................................... 8

Technical data ....................................................................... 8

Environmental and climatic conditions ................................... 8

Structure of internal rotor ....................................................... 9

4. Commissioning .................................................................... 10

Safety during commissioning ............................................... 10

Assembly ............................................................................. 10

Nova 15 ............................................................................... 11

Nova 30 ............................................................................... 12

HP 370 ................................................................................ 14

HP 505 ................................................................................ 17

HP 600 / HP 620.................................................................. 19

Cable connections ............................................................... 21

Settings ............................................................................... 22

Visual inspection and mechanical inspection ....................... 22

5. Troubleshooting ................................................................... 23

6. Repetetive handling ............................................................. 23

Care .................................................................................... 23

7. Disposal .............................................................................. 23

8. Service / Contact ................................................................. 24

9. EU-Declaration of Conformity .............................................. 25

operating manual BAIndustrie_UK 3

1. Notes regarding this document

The information contained in this document is the sole property of

Plettenberg Elektromotoren GmbH & Co. KG. Publication, in whole

or in part, requires the express written consent of Plettenberg

Elektromotoren GmbH & Co. KG. An internal company duplication,

which is intended for the evaluation of the product or for the

appropriate assignment, is permitted and not subject to approval

Plettenberg Elektromotoren GmbH & Co. KG

Rostocker Straße 30

D-34225 Baunatal – Großenritte

GERMANY

Telefon: +49 (0) 56 01 / 97 96-0

Fax: +49 (0) 56 01 / 97 96-11

Internet: www.Plettenberg-Motoren.com

E-Mail: Info@Plettenberg-Motoren.com

© 2016 Plettenberg Elektromotoren GmbH & Co. KG. All rights

reserved.

Legal provisions

operating manual BAIndustrie_UK 4

This document applies for the following device types:

Motor type

Nova 15

Nova 30

HP 370

HP 505

HP 600

HP 620

The activities described in this document may only be executed by

qualified, skilled workers. The qualified, skilled workers must

possess the following qualifications:

Knowledge regarding the functional methods and operation for

the product

Knowledge and observation of these instructions with all safety

notes

Links regarding updated additional information can be found under

www.Plettenberg-Motoren.com.

Symbols Clarification

Warning, the non-observance of

which leads directly to death or

serious injury

Warning, the non-observance of

which may result in serious injury

Warning, the non-observance of

which may result in minor or

moderate injury

Warning, non-observance of

which may result in damage to

property

Information which is important for

a specific subject or goal, but not

relevant to safety

Complete designation Designation in this document

Speedcontroller Controller

Scope of valitidy

Target group

Updated additional

information

Symbol

s

Nomenc

latur

e

operating manual BAIndustrie_UK 5

2. Savety

The motor series of the validity range are intended for this purpose:

As drive unit

Unapproved use in the sense of a foreseeable misuse shall be

deemed to be improper use:

the drive unit in man-bearing devices

the drive unit in public transport and means of transport

the drive unit for toys

use in potentially explosive atmospheres

use by children under 14 years of age

any use other than those provided for

This chapter contains safety instructions which must always be

observed when working on and with the product. In order to prevent

personal injury and property damage and to ensure continuous

operation of the product, always read this chapter carefully and

follow all safety instructions at all times.

Intended use

Savety information

Slight, moderate or severe injuries

Malfunction due to electromagnetic interference. Communication

equipment and other devices in the surroundings must not be

exposed to impermissible electromagnetic interference.

The control and phase cables must not be extended more

than 20 cm. The product must be inspected and the fastening

must be controlled again before commissioning

Modifications to the product are not permitted

The supply and return cables must be laid together

Always shield all cables

operating manual BAIndustrie_UK 6

Cut injuries, loss of eyesight

Parts can be ejected from the housing by rotation.

It must be therefore be ensured that the product is only used

in the closed place of destination. It must also be ensured that

no magnetic or non-magnetic parts get into the motor during

transport and assembly.

The product must always be protected against heat, dirt and

moisture, otherwise the adhesive strength of the components

may be lost.

Always ensure proper handling.

The product must never be contaminated with foreign bodies

/ adhesives / paint during assembly.

Modifications to the product are forbidden

Always ensure that the motor is properly fastened.

Always ensure that the controller settings are correct.

The product must be sufficiently cooled.

Operation of the motor at idling speed without load is

prohibited.

Electric shock, burns, fire

caused by energised parts.

The product must always be protected against overheating,

dirt and moisture, otherwise the components will be

damaged. This can cause short circuits.

The product as well as the contacts must be inspected for

overheating, soiling, deformation, fire and moisture before

commissioning.

Modifications to the product are not permitted.

The maximum bending radius of the connecting cables must

not be undershot. 6 x outer diameter.

To prevent high-impedance connections, only gold contact

plugs from Multi-Contact, Plettenberg or Schnepp are

permitted.

Assembly and/or dismantling only when de-energised.

operating manual BAIndustrie_UK 7

Injuries due to crushing, being caught up

Malfunction due to electromagnetic interference.

The control and phase cables must not be extended. The

product must be inspected and the fastening must be

controlled again before commissioning.

Modifications to the product are not permitted.

The supply and return cables must be laid together.

Cables must be shielded.

Danger from magnetic radiation

Malfunction / destruction of magnetically sensitive parts.

The motor must never come into contact with magnetically

sensitive parts such as pacemakers or data carriers. The

strong magnets can lead to damage and/or malfunction or

extinction of these.

Crushing, pulling in / being caught up

Caused by careless touching and too small a distance from

rotating parts.

There must be sufficient distance retained to the motor so that

no people or objects can be caught up or drawn in.

Burns

Caused by carelessly touching hot surfaces.

After operation of the product, the surfaces may still be hot.

Always allow the product to cool down.

Thermal overload / destruction

Always ensure sufficient cooling for the motor (air or water

cooling).

A high load on the motor is only permissible in short

operation. Under no circumstances may the motor exceed

the temperature of 100°C.

After each use, the motor must cool down again to ambient

temperature.

Only control systems and regulators approved by us may be

used. You will find an overview on our homepage.

operating manual BAIndustrie_UK 8

3. Product overview

type

weight

:

[kg]

voltage: [V]

max.RPM:

[1/min]

Ø

shaft

:

[mm]

Nova 15 (HV)

2,5 – 3,1 30 – 80 (120) 5000 18

Nova 15 „S“ (HV)

2,5 – 3,1 30 – 80 (120) 11000 18

Nova 30

5 – 6,5 30 - 140 5000 30 C=1:10

Nova 30 „S“

5 - 6,5 30 - 140 7000 30 C=1:10

Nova 30 WK

5 – 6,5 30 - 140 5000 32

Nova 30 „S“ WK

5 - 6,5 30 - 140 7000 32

HP 370

0,57 – 0,95 10-60 10000 5 oder 12

HP 370 „S“

0,57 – 0,95 10-60 20000 5 oder 12

HP 505

1,4 – 1,5 10-60 10000 12

HP 600 „S“

1,7 – 2,7 10-80 20000 15

HP 620

1,7 – 2,5 10-80 7000 15

HP 620 „S“

1,7 – 2,5 10-80 12000 15

Ambient temperature: -20°C up to +40°C

Permissible humidity: Non-condensing

Protection class depending on type IP 21 / IP53

Type

designation

Technical data

Environmental and

climatic conditions

operating manual BAIndustrie_UK 9

The windings are located in the motor housing. Permanent

magnets are attached to the axis and rotate in the magnetic field

of the windings.

Type: Nova 30 mit Wasserkühlung

1: motor phase 1 (red)

2: motor phase 2 (yellow)

3: motor phase 3 (blue)

4: sensor wire

5: shaft

6: cooling (optionally)

Structure of

in-running motor

1 2

3

4

5

6

operating manual BAIndustrie_UK 10

4. Commissioning

The motor phases must not be shortened without prior

consultation. Crimping of connections may also not be

executed without previous consultation.

The motor phases must not be shortened without prior consultation.

Crimping of connections may also not be executed without previous

consultation.

Test runs should only be executed outdoors in principle.

During motor operation, it is essential to ensure that no people are

located to the side or in front of the rotation plane.

Destruction / damage of the motor

.

Always use suitable screws or bolts.

Sawed or ground screws or bolts can destroy the thread in the

motor's bearing shield.

After each use, the motor must cool down again to ambient

temperature.

Only control systems and regulators approved by us may be

used. You will find an overview on our homepage.

Never exceed the maximum screw-in depth. Screws or bolts

which are screwed in too far will damage or destroy the motor.

Only use original screws or bolts.

Always position distance spacers between the screw or bolt

and the head frame of the model.

Safety during

commissioning

Severe, moderate or minor injuries.

Destruction or damage to the product.

Safety instructions from Chapter 2 must be complied with!

Assembly

operating manual BAIndustrie_UK 11

Nova 15/xx

(30 = 77mm; 40 = 87mm; 50 = 97mm)

The motor is fixed with 6 M5 bolts.

Maximum screw-in depth: 9 mm

Maximum tightening torque: 6 Nm

Nova 15/xx WK

(40 = 87mm; 50 = 97mm)

The motor is fixed with 6 M5 bolts.

Maximum screw-in depth: 9 mm

Maximum tightening torque: 6 Nm

Nova 15

operating manual BAIndustrie_UK 12

Nova 30/50

The motor is fixed with 6 M6 bolts.

Maximum screw-in depth: 10 mm

Maximum tightening torque: 10 Nm

Nova 30

operating manual BAIndustrie_UK 13

Nova 30/50 WK

The motor is fixed with 6 M6 bolts.

Maximum screw-in depth: 10 mm

Maximum tightening torque: 10 Nm

operating manual BAIndustrie_UK 14

HP 370/xx

(30 = 73 mm; 40 = 83 mm; 50 = 93 mm)

The motor is fixed with 6 M4 bolts.

Maximum screw-in depth: 8 mm

Maximum tightening torque: 3 Nm

HP 370

operating manual BAIndustrie_UK 15

HP 370/XX MKR

(30 = 73 mm; 40 = 83 mm; 50 = 93 mm)

The motor is fixed with 6 M4 bolts.

Maximum screw-in depth: 8 mm

Maximum tightening torque: 3 Nm

operating manual BAIndustrie_UK 16

HP 370/50 WK

The motor is fixed with 6 M4 bolts.

Maximum screw-in depth: 8 mm

Maximum tightening torque: 3 Nm

operating manual BAIndustrie_UK 17

HP 505

The motor is fixed with 6 M4 bolts.

Maximum screw-in depth: 8 mm

Maximum tightening torque: 3 Nm

HP

505

operating manual BAIndustrie_UK 18

HP 505/50 WK

The motor is fixed with 6 M4 bolts.

Maximum screw-in depth: 8 mm

Maximum tightening torque: 3 Nm

operating manual BAIndustrie_UK 19

HP 600/xx / HP 620/xx

(30 = 100,5 mm; 37 = 110,5 mm; 40 = 110,5 mm; 50 = 118,5 mm)

The motor is fixed with 4 M6 bolts.

Maximum screw-in depth: 12 mm

Maximum tightening torque: 10 Nm

HP 6

00 / HP 620

operating manual BAIndustrie_UK 20

HP 600/xx WK; HP 620/xx WK

(40 = 108,5 mm; 50 = 118,5 mm)

The motor is fixed with 4 M6 bolts.

Maximum screw-in depth: 12 mm

Maximum tightening torque: 10 Nm

operating manual BAIndustrie_UK 21

Only control systems and regulators approved by us may be

used. You can read about them in the catalogue or on our

current homepage. If other control systems or regulators are used,

then we cannot assume any guarantee or liability in the event of

destruction of the motor, regulator or the controller.

Motor connection cables must never be shortened or extendeds:

Firma Plettenberg Elektromotoren GmbH & Co. KG

The three motor phases must be connected to the controller

according to the manufacturer's instructions:

The sensor cable must be connected to the controller in accordance

with the regulator manufacturer's specifications.

The brush-free Plettenberg motors with sensors are either equipped

with 3 hall sensors or with 3 fork light barriers with 120° electrical

angle. The sensors have open-collector outputs with pull-up

resistors. 6.2K Ohm pull-up resistors are normally installed, but

older motors can also have 10k Ohm or 12k Ohm pull-up resistors.

For motors with fork light barriers, no additional external pull-up

resistors may be used otherwise the output will not switch cleanly

to 0 V. The pull-up resistance can be easily determined by

measuring the resistance of the sensor VCC (red) against sensor

A (green) with an ohmmeter.

Phase A: red, Phase B: white, Phase C: blue/black

Sensor A: green, Sensor B: white, Sensor C: orange, VCC = 5 V:

red, GND = 0 V: black.

Temperature sensor NTC47K optional: blue

The shield of the sensor cable should be connected to the sensor

GND. The shield should not be connected to the motor housing or

motor control housing.

Commutation sequence forwards

Step1 Step2 Step3 Step4 Step5 Step6 Error1 Error2

Phase A(U)

+ Z - - Z + Z Z

Phase B(V)

Z + + Z - - Z Z

Phase C(W)

- - Z + + Z Z Z

Sensor A

1 1 0 0 0 1 0 1

Sensor B

0 1 1 1 0 0 0 1

Sensor C

0 0 0 1 1 1 0 1

Cable connections

operating manual BAIndustrie_UK 22

Commutation sequence backwards

Step1 Step 2 Step 3 Step 4 Step 5 Step 6 Error1 Error2

Phase A(U)

- - Z + + Z Z Z

Phase B(V)

Z + + Z - - Z Z

Phase C(W)

+ Z - - Z + Z Z

Sensor A

1 1 0 0 0 1 0 1

Sensor B

0 0 0 1 1 1 0 1

Sensor C

0 1 1 1 0 0 0 1

Z: High impedance, +:Plus, -:Minus, 1:>3 V, 0:<2 V

The motor speed must be controlled with a revolution speed

measuring device.

All fastening screws or bolts for the motor must be checked for

tightness before commissioning.

It must always be ensured that all energised cables or plugs and

sockets are insulated so that unintentional switching on of the motor

by cable contact is impossible.

The position of the water cooling ring and its tightness must be

inspected before the initial commissioning of water-cooled motors.

All indicated dimensions are in mm.

Settings

Visual inspection

and mechanical

inspection

operating manual BAIndustrie_UK 23

5. Troubleshooting

It is absolutely necessary to install the receiver as far away as

possible from the motor, regulator, controller and/or its currentcarrying cables. The aerial must not be laid past the motor and its

current-carrying cables. If this is not possible for structural reasons,

then these elements must be shielded with sheet steel or foil.

6. Repetetive handling

The housing surfaces can be cleaned with compressed air and a

dry, lint-free cloth.

The motor must never be oiled. If this is not observed, then the

correct functioning of the motor cannot be guaranteed or irreparable

damage may occur.

7. Disposal

A motor with exceeded service life is electronic scrap. E-scrap

consists on the one hand of valuable materials which can be

recovered as secondary raw materials and, on the other hand, it

contains environmentally hazardous substances.

Information regarding optimum material recycling is available from

commercial waste disposal companies.

Care

operating manual BAIndustrie_UK 24

8. Service / Contact

Should, despite proper handling and sufficient care, problems

should still occur or the motor will be damaged, then please send

the motor back to our address stating the problem, defect or

damage.

Plettenberg Elektromotoren GmbH & Co. KG

Rostocker Straße 30

34225 Baunatal – Großenritte

GERMANY

Phone: +49 (0) 56 01 / 97 96-0

Fax: +49 (0) 56 01 / 97 96-11

Internet: www.Plettenberg-Motoren.com

E-Mail: Info@Plettenberg-Motoren.com

operating manual BAIndustrie_UK 25

9. EU-Declaration of Conformity

In the sense of the EU Directives

EMC Directive 2014/30/EU Appendix IV

Low Voltage Directive 2014/35/EU Appendix IV

RoHS Directive 2011/65/EU Appendix I

Plettenberg Elektromotoren GmbH & Co. KG

Rostocker Straße 30

34225 Baunatal – Großenritte

hereby declares, as the manufacturer, that the articles and objects described below

comply with the provisions of the relevant community harmonisation legislation referred

to above.

Motor type Motor type

Nova 15 HP 600/30

Nova 30 HP 600/37

HP 600/40

HP 370/30 HP 600/50

HP 370/40

HP 370/50 HP 620/30

HP 620/40

HP 505 HP 620/50

Interference emission EMC Directive Article 6 Appendix I.1.a

DIN EN 61000-6-3:2011-09

Electromagnetic Compatibility (EMC)- Part 6-3:

Generic standards - Interference emission for residential

areas, business and commercial areas as well as small

businesses

(IEC 61000-6-3:2006 + A1:2010); German Edition

EN 61000-6-3:2007 + A1:2011

Interference immunity EMC Directive Article 6 Appendix I.1.b

DIN EN 61000-6-1:2007-10

Electromagnetic Compatibility (EMC)- Part 6-1:

Generic standards - Immunity for residential

environments, business and commercial areas as well

as small businesses

(IEC 61000-6-1:2005);

operating manual BAIndustrie_UK 26

Device safety Low Voltage Directive 2014/35/EU Anhang I

DIN EN 60335-1:2012-10

Household and similar electrical appliances - Safety Part 1: General requirements

(IEC 60335-1:2010, modified);

Safety of machinery

DIN EN 60335-1:2012-10

Household and similar electrical appliances - Safety Part 1: General requirements

(IEC 60335-1:2010, modified);

DIN EN ISO 12100:2010

General principles for design - Risk assessment and

risk mitigation ISO 12100:2010 (): German Edition EN

ISO 12100

DIN EN 60204-11:2014-10

Safety for Machinery ‒ Electrical Equipment for

Machinery ‒ Part 1: General requirements

(IEC 44/709/CDV:2014); German Edition

FprEN 60204-1:2014

Maximum permissible

concentrations in

homogeneous materials

in % by weight

RoHS Directive Appendix II

Lead 0,1%

Cadmium 0,01%

Polybrominated biphenyl (PBB) 0,1%

Polybrominated diphenyl ether (PBDE) 0,1%

Mercury 0,1%

Hexavalent chromium 0,1%

Note:

The sole responsibility for drawing up this declaration of conformity lies with the manufacturer. This declaration of

conformity will lose its validity when the product is converted, extended or altered in any other manner without the

express consent of Plettenberg Elektromotoren GmbH & Co. KG and when components, not belonging to Plettenberg

Elektromotoren GmbH & Co. KG, or accessories are installed in the product as well as in the event of improper

connection or improper use of the product.

Baunatal, 12 April 2016 .........................................................................

(Uwe Plettenberg, Director)

Loading...

Loading...