Pleasurecraft marine Pleasurecraft 302/2A, Pleasurecraft 351/4, Pleasurecraft 302/4 Owner's Manual

STATEMENT OF LIMITED WARRANTY

The Pleasurecraft Marine Engine Co warrants its new products to be free from defects in material and workmanship under normal use and

service conditions, to the first registered owner or user. Covered under the Pleasurecraft warranty are all Pleasurecraft supplied components, except for

those components warranted by Pleasurecraft Suppliers. The obligation of Pleasurecraft shall be limited to the repair or replacement, at its option, of

any part or parts which have failed during the period of warranty and which Pleasurecraft's examination shall disclose to have failed due to defective

material and/or workmanship.

WARRANTY PERIOD

This warranty shall be valid to the first registered owner or user only, for the period specified below.

All components, other than those itemized below, are warrantied for a period of one (1) year from the date of delivery to the first registered

owner, or until the expiration of 200 hours of operation, whichever occurs first, in non-commercial use. In case of commercial use, said warranty shall

be for a period of six (6) months from the date of delivery to the first user or registered owner or until the expiration of 200 hours of use or whichever

occurs first.

Exceptions to the one (1) year/200 hour warranty;

(A) Water pump impellers not covered by warranty.

(B) Electrical system and fuel system warranty is for a period of 90 days from the date of delivery or first use.

(C) Seals, gaskets, o-rings and other material affected by time are not covered by this warranty if their effectiveness is reduced by an

extended storage period prior to sale and/or use.

(D) Components supplied by the Ford Motor Co. are warrantied by the Industrial Engine Division of the Ford Motor Co.

MANNER OF PERFORMANCE OF WARRANTY

Service under the terms of this warranty must be performed by an authorized Pleasurecraft Marine dealer or distributor without charge for

replacement parts or established flat rate labor, excepting miscellaneous items not considered as warranty defects, such as, but not limited to,

lubricants, spark plugs, points, and other items which are normally frequently replaced as part of normal maintenance. Charges for additional nonwarranty work and/or additional dealer charges relative to warranty work in excess of flat rate must be paid for by the owner.

Prior authorization in writing must be obtained for any warranty repairs over $50.00 and in all cases where customer fails to establish purchase

and warranty expiration date with the Warranty Identification Card sent the owner upon receipt of his warranty registration form by Pleasurecraft. The

product warranty is not in effect and, therefore, cannot be honored until the product purchase date can be confirmed by Pleasurecraft.

FAILURE EXCLUDED FROM WARRANTY

This Warranty will not apply to any failure which results from accidents, sinking, fire, neglect, abuse, or abnormal service, such as racing,

towing or operating in water of insufficient depth, or to any failure resulting from improper installation, improper adjustments or improper delivery

service, or to any failure resulting from the use of parts, fuels, oils or lubricants not suitable for use with the product and/or material not approved by

Pleasurecraft Marine Engine Co. This warranty does not apply to any engine or drive which has been modified, or altered, or repaired in such a

manner as, in the opinion of Pleasurecraft Marine Engine Co., to affect its stability, reliability, or performance. Also, excluded from warranty are all

consequential and/or subsequent losses including but not limited to, loss of use, loss of income, inconvenience, trailering, towing, haul out, launch

and/or any other in and out of water expenses, storage charges, dockage charges, expenses to deliver or pick-up the product being warrantied to and

from the warranty dealer, telephone expenses, telegraph expenses, lodging expenses, travel expenses, mechanics travel time and mileage, personal

property damage, damage caused by any occurrence of an insurable nature, rental of substitute equipment of any type, removal and replacement and/or

modification of any boat parts to facilitate repairs, moving of furniture, carpets, cleaning, painting, carpenter work, pre-delivery services, repairs

resulting from modifications or improper repairs performed by authorized or unauthorized facility or from use of non-approved parts. Failures due to

use of non-recommended lubricants or fuels, or failure to follow maintenance or lubrication schedules. Failures caused or contributed to by

contaminated fuel, failures caused by improper installation or misapplication of the engine or drive, failures resulting from owners or operators failure

to exercise due or normal care and precaution, components and/or assemblies that are warrantied by Pleasurecraft Marine Engine Co. suppliers.

OWNER'S RESPONSIBILITY

The above Warranty shall be conditional upon owner's compliance with the following conditions:

1. Owner shall verify that the pre-delivery service has been performed, all requested information is recorded and that the selling dealer has

signed the warranty registration.

2. Owner shall promptly mail the warranty registration to Pleasurecraft Marine Engine Co. after accepting delivery.

3. Owner shall follow the instructions in the owner's manual regarding operation, break-in, lubrication, and fuel.

4. Owner shall follow maintenance schedule, operating, limits, and lay-up instructions, as outlined in the owner's manual.

NO OTHER WARRANTY GIVEN

No other warranty, whether of mercantability, fitness or otherwise, express or implied in fact or by law, is given by Pleasurecraft Marine Engine

Co. with respect to any product of the Pleasurecraft Marine Engine Co., and no other or further obligation or liability shall be incurred by Pleasurecraft

Marine Engine Co. by reason of manufacture, sale, lease or use of any such product.

The obligations of Pleasurecraft Marine Engine Co. set forth in the first paragraph above shall be the exclusive remedy for any breach of

warranty hereunder. In no event shall Pleasurecraft Marine Engine Co. be liable for general, consequential or incidental damages, including without

limitation, any damages for personal injury, property damage, loss of use or loss of profits. Pleasurecraft Marine Engine Company's policy is one

continued improvement of its products and reserves the right to improve and change its design and production of any of its products without assuming

any obligation to modify products previously manufactured and/or sold.

No distributor, dealer, agent or employee of Pleasurecraft Marine Engine Co. is authorized to grant any other or further warranty or incur any

additional warranty obligation on Pleasurecraft Marine Engine Co.'s behalf, in connection with the sale of its products. There are no warranties which

extend beyond those printed herein. Except that any qualification or restriction contained herein which is prohibited by any law where the product is

sold is changed to conform with that law making that qualification and/or restriction only null and void. All other qualifications and/or restrictions of

this warranty remain in full force and effect.

GENERAL INFORMATION

IMPORTANT: read this manual carefully and thoroughly, particularly WARNING,

CAUTION and IMPORTANT information in bold type, such as this paragraph.

WARNING: It is recommended that the battery

cables be removed from the battery when the boat

is placed in storage, on display or in transit. This

will eliminate the possibility of the engine

accidentally starting and causing damage to the

engine due to lack-of water.

Installation of the propeller shaft and associated mounting

parts is not outlined in this manual. The propeller shaft angle

and propeller location must be determined by the boat

builder to meet the requirements of the boat design.

Propeller shaft diameter should be of sufficient size for the

type of application. The following propeller shaft couplings

are available from PMC.

Part No. For

1:1, 1.51 and 2:1

Shaft Size

1 " (25.4mm)

1-1 /8 "

(28.6mm)

1-1/4" (31.8mm)

1-3/8" (34.9mm)

1-1/2" (38.1 mm)

1-3/4" (44.5mm)

2" (50.8mm)

2-1/2"

Transmissions

R148010

R148011

R148012

R148013

R148018

The engine drawings should be used when determining

engine space requirements and engine bed location. The

horizontal angle of the installed engine at rest must be

between 0° to 15°.

#1. CAUTION: Some engines use a different

dipstick for 0° installation than a 15° installation.

Be certain that the proper dipstick is installed to

prevent damage due to overfilling or underfilling of

the crankcase. If in doubt contact your dealer or

PCM.

Part No. For

2.5:1 and 3:1

Transmissions

R 148001

R 148002

R148003

R 148004

R148005

R148007

R148008

R148009

Engine and Transmission Identification

The engine model and serial number are located on the

intake manifold at the rear.

The transmission model, serial number and ratio is located

on the transmission case.

Except for V drives on some applications the propeller shaft

rotation -with the transmission in forward gear on engines

equipped with 1:1, 1.5:1, 2.5:1 and 3:1 transmissions - is the

same as engine rotation.

Propeller shaft rotation - with the transmission in forward

gear on engines equipped with 1.9:1 transmissions - is the

opposite of engine rotation.

On V drive engines both engines may turn the same

direction and have the propeller rotation changed in the V

Drive.

On all engines the Serial # plate indicates both engine and

propeller shaft rotation. Example: PLD-WV-R20 and

PLD-WV-L20. The L following the P indicates the engine

rotation. The R and L following the V and preceding the 20

indicates the Propeller Shaft Rotation. The engines must be

installed accordingly to insure proper propeller rotation.

1

CAUTION: The Warner Gear shift lever MUST BE IN

FORWARD; that is, positioned over the letter "F"

which is embossed in the case casting for

FORWARD gear. Likewise, the shift lever must be

positioned over the letter "R" for REVERSE gear

on all gear models.

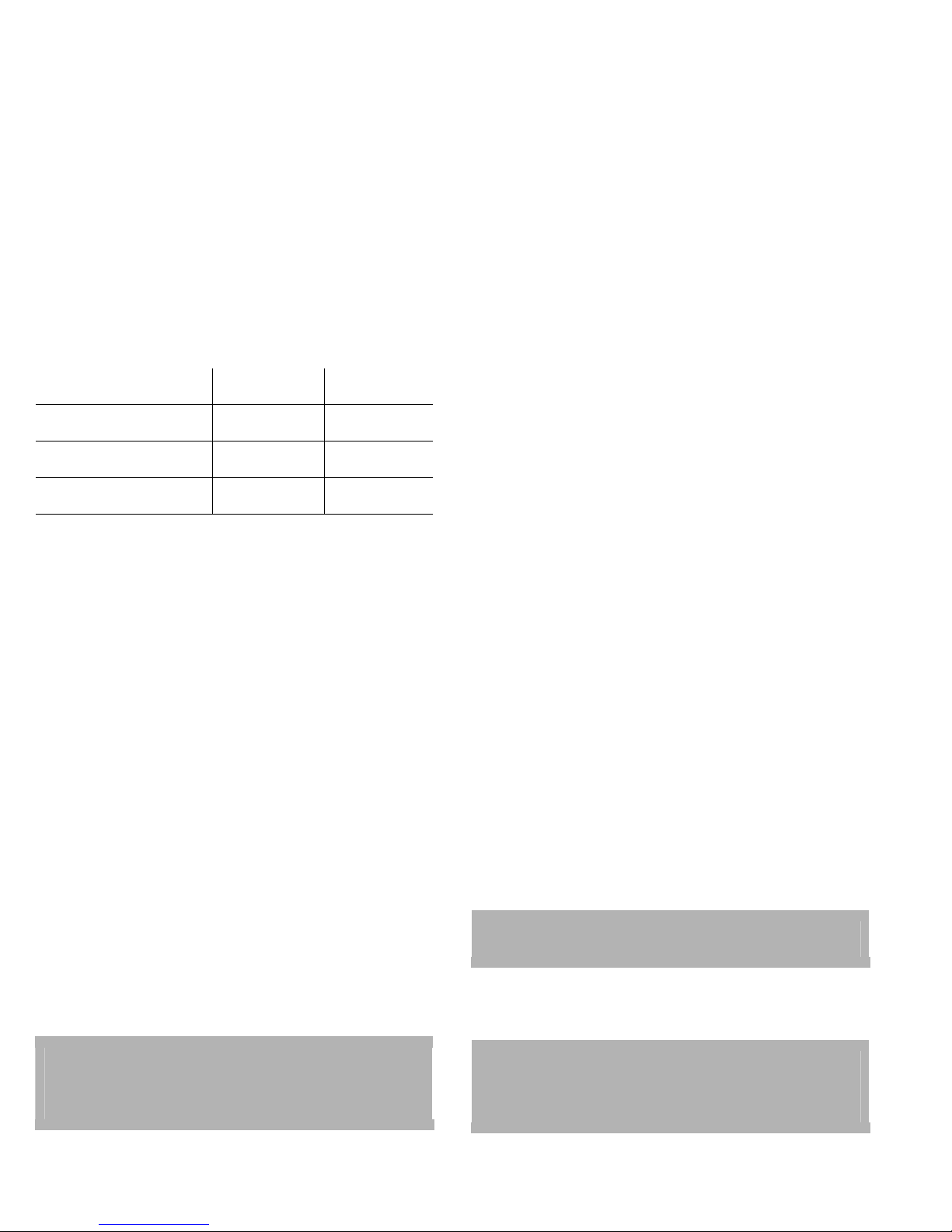

Engine Alignment and Mounting Adjustments

The engine must be aligned to the propeller shaft within

.003' (.076mm) or less when measured between the mating

surfaces of the transmission coupling flange and the

propeller shaft coupling flange. To obtain correct engine

alignment, insert a feeler gauge between the coupling mating

faces and adjust engine position as required to place the

mating surfaces parallel to each other within .003' (.076mm).

This clearance must be maintained at all times and at all

positions of the coupling. To complete alignment turn the

shaft coupling 180* from the starting point after the engine

and shaft are aligned to within .003'. Test for proper

clearance. If out readjust the engine to proper clearance.

Retest by turning coupling 90' at a time and testing to insure

alignment at all points through the 360' circle.

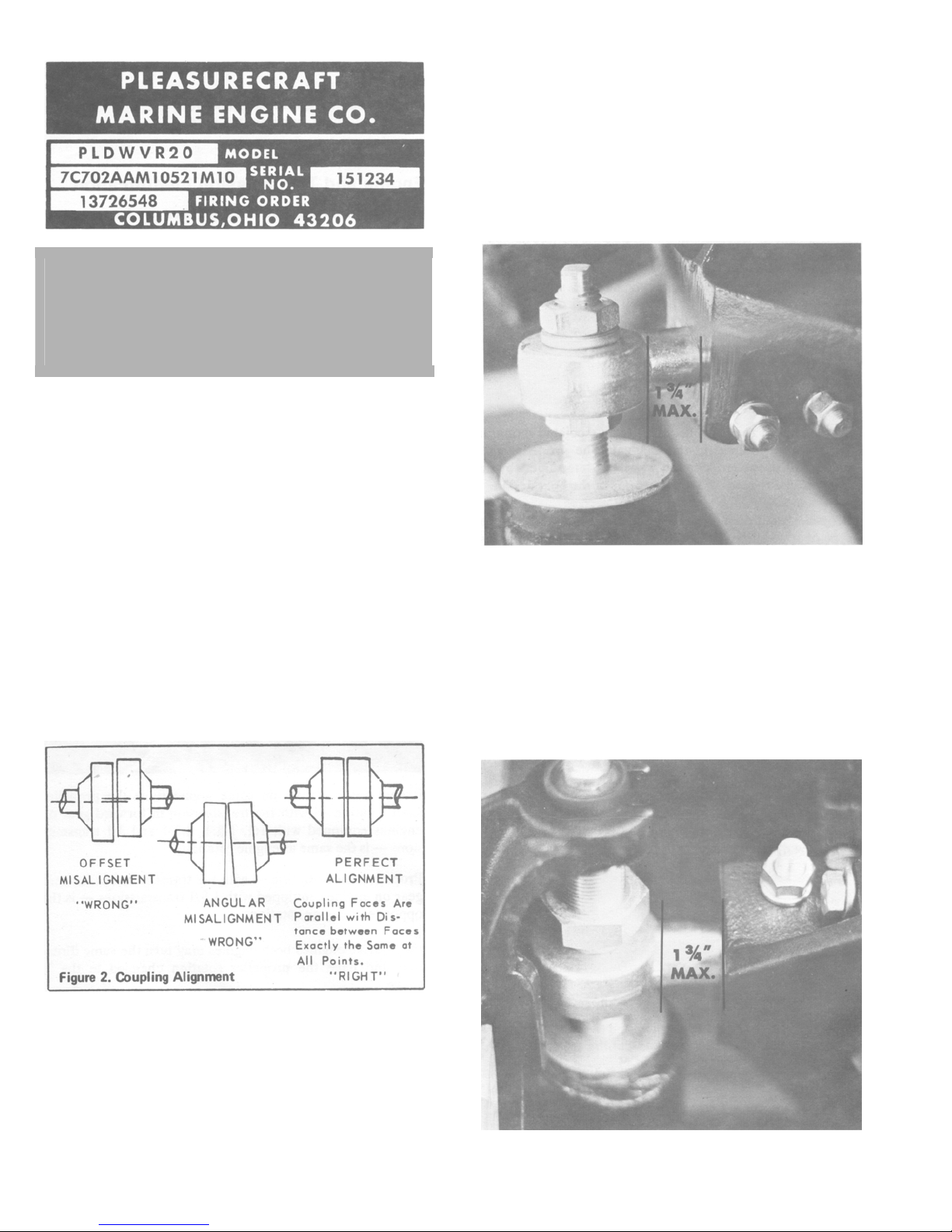

Front mounts are adjusted by loosening the upper lock nut

on the mount stud and trunion locking stud nuts and tapping

on the nuts to loosen the studs on the trunion The mount can

then be raised or lowered by screwing the lower nut up or

down in the desired direction and side to side by prying

against the block. CAUTION: Side to side adjustment must

be limited to a maximum 1-3/4: extension of the trunion

from the mount bracket. Extension of more can cause

bending of the trunion or possible mount failure.

Rear mount adjustment is made by loosening the stud lock

nut and turning the stud in the proper direction for vertical

adjustment and by loosening and tapping the nut on the lock

studs to free the rear trunions and adjust in the same manner

as the front for side to side adjustment. CAUTION: Be

certain to lock the lock nuts on the adjusting and lock studs

when adjustment is completed.

After alignment is complete lag and/or cross bolt mounts

securely to the stringers.

The engine mounts are adjustable to permit raising or

lowering the engine and also moving the engine to the right

or left. It is recommended that, when the engine bed is

installed in the boat, it is positioned so that engine alignment

is as close as possible. After engine mounts have been

fastened to the engine bed, final alignment should be done

by adjusting the mounts as follows:

2

Water Pick-Up Installation

Water pickup must be large enough to permit sufficient

water flow to engine seawater pump in order to provide

adequate engine cooling. Pleasurecraft Marine recommends

that a sea strainer be installed on all boats equipped with

transom or thru-hull water pickups to prevent foreign

material from entering and clogging engine cooling systems.

Engine damage that results from a clogged cooling system,

will not be covered by Pleasurecraft's Warranty.

In the interest of safety, it is recommended that a sea cock be

installed between water pickup and sea strainer.

Water pickup should be located as close to seawater pump

inlet as possible and in an area where an uninterrupted, solid

stream of water will flow past it when boat is underway.

Seawater pump inlet is designed for I' I.D. hose. Hose must

have adequate wall thickness to prevent collapsing caused

by pump suction. Hose should be fastened securely at

connections with hose clamps.

EXHAUST SYSTEM

When designing the exhaust system, it is very important that

the following points are taken into consideration:

1. System must not cause an excessive amount of back

pressure. Back pressure must not exceed 4' (10.2cm) of

mercury when measured with a mercury manometer at

the exhaust manifold outlets. Minimum exhaust hose

sizes are as follows:

Dual Exhaust - 3' I.D. (7.6cm)

Single Exhaust - 3-1/2' I.D. (8.9cm)

2. System layout and construction must prevent cooling

system discharge water from flowing back into the

engine and also prevent sea water from entering the

engine via the exhaust system.

Exhaust Hose Installation

The exhaust hose, which connects to the exhaust manifold

riser should be connected so that it does not restrict the flow

of discharge water from the elbow.

Both exhaust manifolds are water-cooled, and all cooling

system water is discharged thru openings which are located

inside the risers. To prevent discharge water from flowing

back into the engine, the exhaust piping must not be higher

than the manifold outlet at any point.

It is the obligation of the boat manufacturer or installing

dealer to correctly locate the engine for installation.

Therefore, if water is present in the exhaust manifolds or

combustion chambers of the engine, the product has not

caused the problem, unless there is a defective part.

Hoses, which are connected in a manner to bend in front of

the exhaust outlet, will prevent discharge water from flowing

around the entire inside diameter of the hose and will cause a

hot spot that may burn through the hose.

The exhaust system should have no sags or low spots to

accumulate water. Sharp bends of more than 45 degrees in

the exhaust lines should be avoided. The exhaust lines

should slope toward the transom at a rate of at least 1/2 in.

per foot with vessel at rest. Exhaust pipe size should not be

restricted. Exhaust back pressure will create poor

performance, high fuel consumption, and severe engine

damage.

Exhaust transom flanges should be above the water line, and

the exhaust lines should be self-draining.

The system should be periodically inspected for leaks and

general condition to prevent leakage of water and exhaust

gases into the hull. Flapper valves are suggested to be used

on all exhaust systems.

Fuel System Installation

Coast Guard Regulations must be observed when installing

fuel system. Fuel systems should be installed in accordance

with the standards of industry associations and applicable

federal standards.

Engine Compartment Air Intake

The engine compartment must be properly vented to provide

a sufficient amount of air for engine breathing. Air intake

and exhaust openings must be large enough to provide an

unrestricted volume of air under all operating conditions.

Engine compartment ventilation also should conform to

Coast Guard Regulations.

Control Cable Adjustments

After installation of controls and cables proceed with the

following adjustments.

Shift Cable

1. Set control lever in neutral position.

2. Position shift selector on the warner gear into neutral

position. In moving the selector from neutral to forward

to reverse to neutral three distinct detent positions will

be felt.

3. Adjust the connector on the control cable so the

connector slips freely into the hole in the selector arm.

4. Remove the connector from the selector arm and move

the selector and control lever into the forward position.

In this position the shift lever must cover the "F" cast

into the transmission case. The connector should slip

freely into the hole in the selector arm.

3

5. Repeat step #4 with the selector and control levers in

reverse position.

If the movement of the connector does not correspond with

the movement of the selector lever it will be necessary to

readjust the remote control head to provide the proper

direction of control cable travel.

CAUTION: Transmissions operated in reverse to

propel the boat forward will fail early. Engine and

propeller rotation must be matched according to

the Serial Plate.

Throttle Cable

1. Place control lever on single lever control into forward

gear without advancing the throttle and on a twin lever

control in the fully closed position.

2. Adjust the connector so that it slips freely into the

connector socket and lock into place.

3. Position throttle into the full throttle position after

blocking the choke open. Check to see if the throttle

valves are in the full open position on both the primary

and secondary side if so equipped.

If valves do not open fully make necessary adjustments

at either control head or cable connector to insure full

opening. Repeat steps #1 and 2 to insure proper idle

settings and adjust if necessary.

Battery Specifications

Battery Specifications Must Be as Follows:

12 volt marine type

Tapered post connectors

70 amp-hr. minimum rating

Battery Cable Size Specifications

Cable Length Cable Size Required

Up to 3 Ft. 6 In. #4 Gauge

3 Ft. 6 In. to 6 Ft. #2 Gauge

6 Ft. to 7 Ft. 6 In. #1 Gauge

7 Ft. 6 In. to 9 Ft. 6 In. #0 Gauge

9 Ft. 6 In. to 12 Ft. #00 Gauge

12 Ft. to 15 Ft. 1 #000 Gauge

15 Ft. to 19 Ft. 2 #0000 Gauge

1 In. (I n c h) = 2.54cm 1 Ft. (Foot) = 30.5cm

NOTE: Cable sizes apply both to positive (+) and

negative (-) cables. Terminals must be

soldered to cable ends to provide adequate

contact.

Battery and Battery Cable Installation

1. Battery should be positioned as close to engine as

possible and should be securely mounted in boat.

2. Connect negative (-) battery cable to ground on engine,

connect positive (+) battery cable to solenoid.

3. Connect positive battery cable to positive post on

battery and negative battery cable to negative (-) post on

battery.

IMPORTANT: Engine electrical system is negative ground.

Failure to connect battery leads, as outlined, will damage

system.

MISCELLANEOUS INSTALLATION INSTRUCTIONS

WARNING: Before starting engine always ventilate

engine compartment by opening engine hatch or, if

equipped, operate bilge blower a sufficient amount

of time to remove any gas fumes from engine

compartment. It is doubly important to check for

fuel spillage or leaks after repair, refueling or

maintenance before starting engine. Remove

battery cable from battery before attempting any

maintenance, repairs or when boat is placed in

storage or in transit.

Check Before Running

1. Engine oil level.

2. Transmission lubricant level.

3. Engine drain plugs installed.

4. Leakage (fuel and water lines and connections).

5. Throttle shutters full close at idle (neutral).

Check While Running (See "Caution", Below)

1. Oil pressure 35 to 40 PSI (2.5 to 2.8kg/cm2) (Approx.)

at 2000 RPM.

2. Water temperature 1401-1600 R/W and 180'-2000 F/W

3. Idle RPM (550-600) in gear

4. Maximum forward RPM 4,400

5. Shifting linkage (forward, neutral and reverse) for shift

lever in detent and proper direction.

6. Leakage (water, oil and fuel)

Check After Initial Run

1. Engine alignment

2. Engine mounting fasteners are tight.

3. Engine oil level

4. Transmission oil level and shift connections.

CAUTION: Do Not Operate Engine without Cooling

Water Flowing thru Water Pump, or Neoprene

Water Pump Impeller Will Become Damaged.

Attach Water Hose to Pump Inlet. Run Engine

Slowly (650-700 RMP) in Neutral to Circulate Water.

Watch Water Temperature Gauge to Prevent

Overheating.

4

Operating Limits (See Specifications for

Your Model)

Maximum RPM at wide open throttle under normal load

conditions can be controlled only by propeller pitch,

diameter, and design. It is essential that the propeller

selected does not overload or underload the engine. Extreme

overloading resulting in low RPM's at wide open throttle

will deliver poor performance, poor fuel economy, and

eventually result in engine damage. Underloading will result

in high RPM, poor fuel economy, and engine damage, if

operated above recommended maximum RPM's.

Do not operate at high RPM's in neutral. Operation in

extremely shallow water can cause sand, silt, and gravel to

be pulled into the cooling system. This can create excessive

water pump wear, and in extreme cases may deposit in the

engine block water jackets and seriously damage the engine

from improper cooling. Heavy weed growth can plug oil

coolers and water intakes and cause damage. If operation

under these conditions is necessary, a good quality sea water

strainer or filter should be installed. The installation of a

fresh water cooling system can reduce the danger of engine

damage from this cause.

ALWAYS OBSERVE HIGH SAFETY STANDARDS

AND COURTESY AFLOAT.

Propellers

Propellers can affect the performance of your boat in many

ways. Selection of the proper propeller for your application

is vital. In most cases, the selection is made by the

Boatbuilder for best over-all performance; however, many

variable factors, such as heavy loads, high altitude, hull

balance, etc., can contribute toward rendering the "standard"

propeller unsuitable, since the application is no longer

"standard."

Many undesirable results can occur from a propeller not

properly matched to the specific application; high RPM's,

low RPM's, cavitation, vibration, steering torque (stem

drives), drumming or rumbling noise, high fuel

consumption, poor efficiency, and even electrolysis damage

(stem drive). When changing propellers, extreme care should

be taken to select a propeller which allows the maximum

engine RPM's with normal load to be within the proper

range for the particular model. See the engine specification

chart in this book for "Maximum RPM."

The use of brass or bronze propellers on stern drives in salt

water or water with high mineral or acid content is not

recommended, due to the possibility of electrolytic attack

and corrosion of the outdrive housings.

If the propeller is bent, broken, out of balance, or otherwise

damaged, limit operation to bare necessity until the propeller

is repaired or replaced.

Directional References

Directional references are given as they appear when

viewing boat from stern, looking toward bow. Front of boat

is bow; rear is stern. Starboard side is right side; port side is

left side.

Service Recommendations

This manual includes operating and maintenance

instructions that are usually required in normal service. Do

not attempt any repairs which are not specifically covered in

this manual. Strict compliance to the recommendations for

lubrication, maintenance, operation, etc., will assure you of

superior performance and dependable service.

Literature

To obtain service and/or parts literature for your PCM

Engine(s) contact your dealer or write:

PCM

P.O. Box 130

Canal Winchester, Ohio 43110

Serial Number Locations

Serial number of your PCM Engine is located at rear of

engine on the Intake Manifold. Transmission serial number

is located on the transmission case.

5

Service Information Request

When contacting the factory, include the following

information:

1. Engine and transmission serial and model numbers.

2. Date purchased.

3. Name of selling dealer.

4. Boat manufacturer, model and length.

5. Number of hours unit has been operated.

6. Date of previous correspondence.

For your convenience there is a form which can be used

when writing PCM.

Record These Numbers from the Serial Number Plates on

the engine and transmission.

Engine Model

Engine Serial No

Transmission Model

Transmission Serial No.

.

Port Starboard

Marine Engine Description

PCM engines are 4-cycle, overhead valve, V-8 engines.

Lubrication is provided by a rotor-type oil pump which

provides full pressure lubrication to all bearings. Valve

rocker arms are lubricated by oil which passes thru the

hydraulic value lifters and up thru hollow push rods. All

lubricating oil is filtered by a full-flow filter system.

PCM Installation and Delivery Inspection

The selling dealer must check the items listed below prior to

delivery of your PCM Engine. Check with him to be sure

that these checks have been completed.

Check and Adjust as Necessary

1. Engine oil level and transmission oil level

2. Battery condition

3. All mounting bolts

4. Engine Alignment

Start Engine and, While Running, Check

CAUTION: DO NOT operate engine without cooling

water flowing through water pump, or water pump

will be damaged, and subsequent engine damage

may result.

(With Engine Warmed-Up at Fast Idle to Normal Operating

Temperature)

1. Oil pressure and cooling water flow

2. Ammeter or voltmeter function

3. Exhaust, oil and fuel system for leaks

4. Idling speed (adjust as necessary)

5. Operation of throttle and shift controls

Test Run Boat and Check (in water)

1. Recommended engine RPM (as stated under

"Specifications")

2. Operation of throttle and shift controls

3. General operation of craft

MAINTENANCE AND

TUNE-UP

Fuel Requirements

Use any good grade automotive regular or premium gasoline

with a minimum average octane rating of 88* (93 research)

in your PCM engine.

An 86* average octane (90 research) gasoline may be used if

the gasoline described above is not available; however, the

ignition timing MUST BE retarded 41 to prevent harmful

detonation.

*New U.S. Regulation requires posting average of

research and motor octane.

PCM reserves the right to refuse warranty on parts which are

damaged -when using improper gasolines.

Replacing Fuel Filter

PCM recommends the use of a Remote Mounted fuel filter

and/or water separator and fuel filter on all its engines. Fuel

filters are not standard with PCM engines, however, we do

offer them as an option to all Boat Builders and Dealers. If

your Boat is not equipped with a fuel filter see your PCM

Dealer. He can provide you with the proper parts and

installation service to protect your engine's fuel system.

When replacing the fuel filter element, follow the

manufacturer's instructions and the following cautions.

CAUTION: Be careful of spilled fuel. Gas vapor

buildup is explosive.

NOTE: DO NOT re-use; always replace with new filter and

gasket.

CAUTION: DO NOT operate engine without cooling

water flowing thru water pump, or water pump

impeller will be damaged, and subsequent engine

damage may result.

6

7

Cleaning Carburetor Inlet Filter

Transmission

Fluid Type

Use only automatic transmission fluid type "A", suffix "A"

in this transmission. This fluid is trade named Dexron.

Change Frequency

Change transmission fluid once each year.

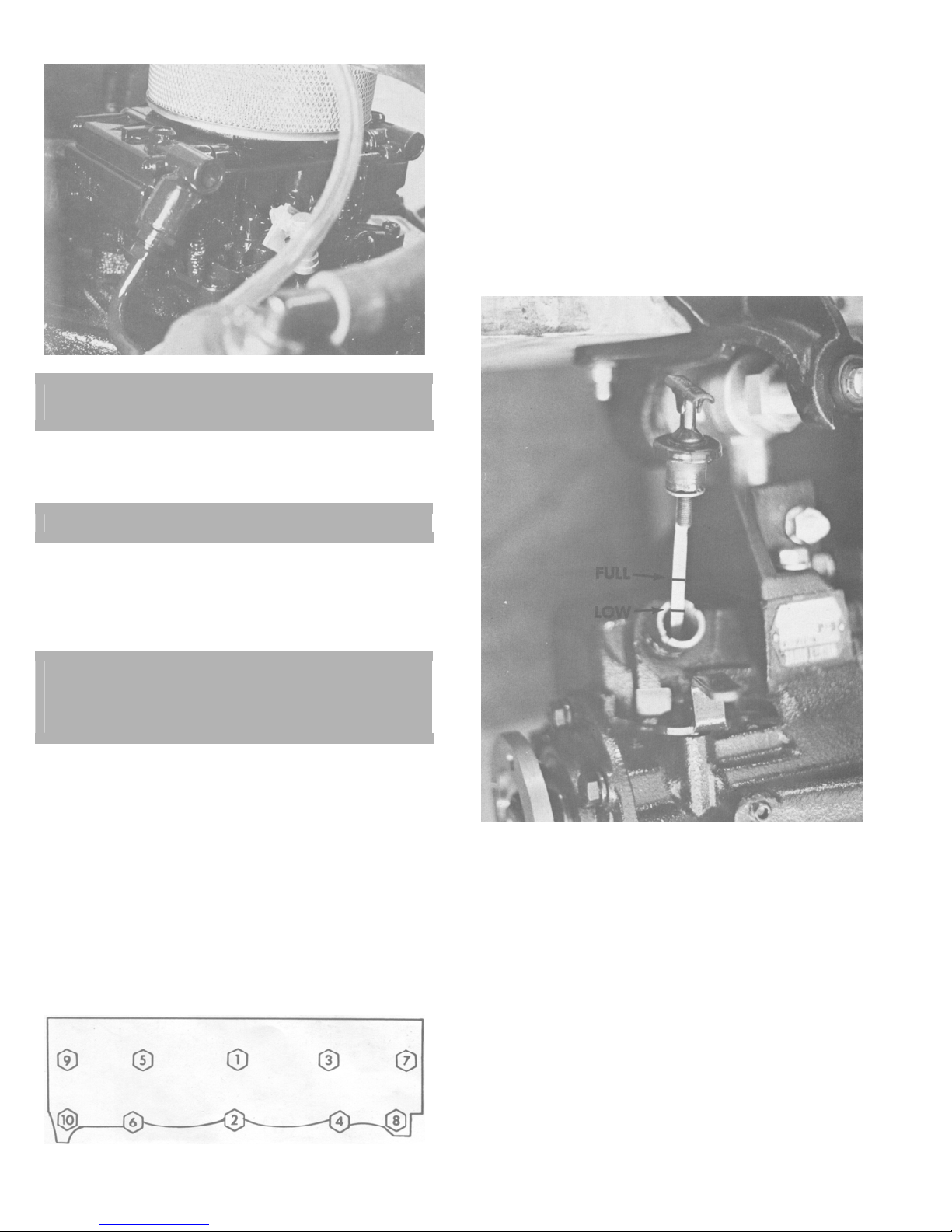

Maintaining Transmission Fluid Level

Transmission fluid level should be checked frequently and

fluid added if necessary. Level must be maintained between

the two marks on dipstick.

CAUTION: Be careful of spilled fuel. Gas vapor

buildup is explosive.

1. Carburetor inlet filter is located in primary float bowl in

fuel inlet fitting.

CAUTION: Use care so fuel is not spilled.

2. Remove fuel line and fuel inlet fitting from carburetor.

3. Wash filter in solvent. Dry with compressed air.

4. Install new gasket on fuel inlet fitting. Install fitting into

carburetor and tighten. Install fuel line.

CAUTION: DO NOT operate engine without cooling

water flowing thru water pump, or water pump

impeller will be damaged, and subsequent engine

damage may result.

5. Run engine and check for gasoline leaks.

Valve Adjustment

Hydraulic valve lifters require little attention. Lifters are

extremely simple in design, readjustments are not necessary

and servicing requires only that care and cleanliness are

exercised in the handling of parts. The best preventive

maintenance for valves is frequent changes of engine oil.

Cylinder Head Torque and Sequence

Cylinder head bolts are tightened in 3 progressive steps.

Torque all bolts in sequence and finally to 100 ft. on 351

engines and 70 ft. lb. on 302 engines.

Maintain fluid level as follows:

1. Boat must be at rest in the water and engine running.

2. Turn dipstick "T" handle counterclockwise and remove

dipstick.

3. Wipe fluid off dipstick and set in position in

transmission fill hole.

4. Remove plug and note level indicated on dipstick. Add

fluid, if required, to bring level up to the top mark.

5. Reinstall dipstick and turn "T" handle clockwise to

tighten.

6. Shut off engine.

Transmission Information Plate

Transmission serial number is located on the transmission

case.

8

SPECIFICATIONS SECTION

Model 351/4 302/2, 302/4

Bore 4.00” 4.00”

Stroke 3.50” 3.00”

Cubic Displacement 351 cubic inches 302 cubic inches

Horsepower 240@4400 RPM 175@4400 302 2/V

220@4400 302 4/V

Intermittent Service 4400 4400

Continuous Cruise 3600 3600

NOTE: Do not cruise at high limits of above range unless propped to turn at or near maximum RPM's at full throttle.

Idle Speed, in forward gear 600 RPM 600 RPM

Timing 10 degrees BTC

@ 600 RPM

Breaker Point Gap .018” .018”

Breaker Point Dwell 24 to 29 degrees 24 to 29 degrees

Spark Plug Gap .035 .035

Spark Plug Type*

*These numbers have been corrected

when copied from original document

Firing Order See engine identification tag* See engine identification tag*

Recommended Fuel Regular grade, leaded

NOTE: Low lead fuel of proper octane rating may be used intermittently. Unleaded fuel should not be used.

Recommended Oil – See Engine Lubrication Section for further information.

Engine 10W30 or 10W40

Warner Drives and

Vee Drives

Carburetor Holley 4 bbl 175 – 2 bbl Holley

Fuel Pump Marine approved,

Electrical System 12 Volt, Negative ground 12 Volt, Negative ground

WARNING: DO NOT reverse battery cables on battery terminals. DO NOT spark battery cables against terminals to

check polarity. Damage to charging system components may result if these precautions are not observed.

Alternator Marine approved, 35 AMP. Marine approved, 35 AMP.

Regulator Sealed solid state

Battery Recommended Marine type of

Oil Capacity 4 quarts and 1 for filter 4 quarts and 1 for filter

* L.H. Rotation

Firing Order

1-3-7-2-6-5-4-8 LC & LD

1-5-4-2-6-3-7-8 LE

Motorcraft BTF3M or

Autolite 124 or

Champion F10. 18MM

Motorcraft ARF32M or

Autolite 24 or

Champion RBL11Y. 14MM

93 octane minimum

(Research method)

premium grade

Automotive Transmission

Fluid (ATF),

Type A, Suffix A. Dexron

double diaphragm,

with safety sight tube

transistorized

70 AMP. hr. minimum

R.H. Rotation

Firing Order

1-8-4-5-6-2-7-3 RC & RD

1-8-7-3-6-2-4-5 RE

10 degrees BTC

@ 600 RPM or lower

Motorcraft BTF3M or

Autolite 124 or

Champion F10. 18MM

Motorcraft ARF32M or

Autolite 24 or

Champion RBL11Y. 14MM

Regular grade, leaded

93 octane minimum

(Research method)

10W30 or 10W40

premium grade

Automotive Transmission

Fluid (ATF),

Type A, Suffix A. Dexron

220 – 4 bbl Holley

Marine approved,

double diaphragm,

with safety sight tube

Sealed solid state

transistorized

Marine type of

70 AMP. hr. minimum

9

Loading...

Loading...