MEFI 4 / 4B

DIAGNOSTIC

MANUAL

5.0/5.7/6.0/8.1L

L510005P

11/05

This page left

intentionally

blank

Marine Electronic Fuel Injection (MEFI 4 / 4B)

Contents

Section 1 - General Information ........................................................................................................................Page 1-1

Section 2 - ECM and Sensors ..........................................................................................................................Page 2-1

Section 3A - Fuel Metering System (5.0/5.7L) ................................................................................................ Page 3A-1

Section 3B - Fuel Metering System (6.0L) .....................................................................................................Page 3B-1

Section 3C - Fuel Metering System (8.1L) .................................................................................................... Page 3C-1

Section 4A - Ignition System (5.0/5.7L) ..........................................................................................................Page 4A-1

Section 4B - Ignition System (6.0/8.1L) ..........................................................................................................Page 4B-1

Section 5 - Diagnosis ........................................................................................................................................Page 5-1

Section 6 - PCV System ...................................................................................................................................Page 6-1

Section 7 - Symptoms .......................................................................................................................................Page 7-1

Section 8 - Master Specifi cations ......................................................................................................................Page 8-1

This page left

intentionally

blank

5.0/5.7/6.0L/8.1L General Information 1 - 1

Marine Electronic Fuel Injection (MEFI)

Section 1

General Information

Contents

General Description .............................................Page 2

Visual/Physical Inspection ...............................Page 2

Basic Knowledge and Tools Required .............Page 2

Electrostatic Discharge Damage ..................... Page 2

Engine Wiring................................................... Page 2

Engine Control Module (ECM)

Self-Diagnostics............................................... Page 2

Malfunction Indicator Lamp (MIL) ................... Page 2

Intermittent Malfunction Indicator Lamp

(MIL) ......................................................... Page 3

Reading Diagnostic Trouble Codes

(DTCs) ......................................................Page 3

Service Mode ............................................Page 3

Normal Mode.............................................Page 3

MEFI On-Board Diagnostic (OBD)

System Check.................................................. Page 3

DLC Scan Tools ............................................... Page 3

Scan Tool Use With Intermittents..................... Page 4

How Diagnostic Trouble Codes Are Set........... Page 4

Clearing Diagnostic Trouble Codes

(Non-Scan) ...................................................... Page 4

Clearing Diagnostic Trouble Codes (Scan) ......Page 5

Non-Scan Diagnosis of Driveability Concerns

(No DTCs Set) .................................................Page 5

Aftermarket (Add-On) Electrical and

Vacuum Equipment...........................................Page 5

Use of Circuit Testing Tools...............................Page 5

Tools Needed to Service the System ...............Page 5

Service Precautions..........................................Page 6

Test Light Amperage Draw Test........................Page 6

Special Tools (1 of 3) .......................................Page 7

Special Tools (2 of 3) .......................................Page 8

Special Tools (3 of 3) .......................................Page 9

Abbreviations.......................................................Page 10

Diagnosis .............................................................Page 11

On-Board Service ................................................Page 11

Wiring Harness Service..................................Page 11

Wiring Connector Service...............................Page 12

Metri-Pack Series 150 Terminals..............Page 12

Weather-Pack Connectors........................Page 13

Micro-Pack 100/W Series Connectors .....Page 14

MEFI 4 - PCM

1 - 2 General Information 5.0/5.7/6.0/8.1L

near a highly charged object and momentarily touches

General Description

Visual and Physical Inspection

Important: This visual and physical inspection is

very important. Perform this inspection carefully and

thoroughly. Perform a careful visual and physical

inspection when performing any diagnostic procedure.

This can often lead to repairing a problem without further

steps. Use the following guidelines when performing a

visual and physical inspection:

• Inspect all vacuum hoses for the following

conditions:

– Correct routing

– Pinches

ground. Charges of the same polarity are drained off,

leaving the person highly charged with the opposite

polarity. Static charges of either type can cause damage.

Therefore, it is important to use care when handling and

testing electronic components.

Engine Wiring

When it is necessary to move any of the wiring, whether

to lift wires away from their harnesses or move harnesses

to reach some component, take care that all wiring is

replaced in its original position and all harnesses are

routed correctly. If clips or retainers break, replace them.

Electrical problems can result from wiring or harnesses

becoming loose and moving from their original positions,

or from being rerouted.

– Cuts

– Disconnects

• Inspect all wires in the engine compartment for the

following conditions:

– Proper connections

– Burned or chafed spots

– Pinched wires

– Contact with sharp edges

– Contact with hot exhaust manifolds

Basic Knowledge and Tools Required

To use this manual most effectively, a general

understanding of basic electrical circuits and circuit

testing tools is required. You should be familiar with wiring

diagrams, the meaning of voltage, ohms, amps and the

basic theories of electricity. You should also understand

what happens if a circuit becomes open, shorted to ground

or shorted to voltage.

To perform system diagnostics, several special tools and

equipment are required. Please become acquainted with

the tools and their use before attempting to diagnose the

system. Special tools that are required for system service

are illustrated in this section.

Electrostatic Discharge Damage

Electronic components used in control systems are often

designed to carry very low voltage, and are very susceptible

to damage caused by electrostatic discharge. It is possible

for less than 100 volts of static electricity to cause damage

to some electronic components. By comparison, it takes

as much as 4,000 volts for a person to feel the zap of

a static discharge.

There are several ways a person can become statically

charged. The most common methods of charging are by

friction and by induction. An e xample of charging b y friction

is a person sliding across a seat, in which a charge of as

much as 25,000 volts can build up. Charging by induction

occurs when a person with well insulated shoes stands

Engine Control Module (ECM) SelfDiagnostics

The Engine Control Module (ECM) performs a continuous

self-diagnosis on certain control functions. This diagnostic

capability is complemented by the diagnostic procedures

contained in this manual. The ECM’s language for

communicating the source of a malfunction is a system of

Diagnostic Trouble Codes (DTC’s). The DTC’s are two digit

numbers that can range from 12 to 81. When a malfunction

is detected by the ECM, a DTC is set and the Malfunction

Indicator Lamp (MIL) is illuminated.

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) is part of the Marine

Diagnostic Trouble Code (MDTC) tool, or it can be a dash

mounted warning light on some boat models.

If present, it informs the operator that a problem has

•

occurred and that the boat should be taken for service

as soon as reasonably possible.

It displays DTC’s stored by the ECM which help the

•

technician diagnose system problems.

As a bulb and system check, the light will come “ON” with

the key “ON,” engine “OFF.” When the engine is star ted,

the light will turn “OFF.” If the light remains “ON,” the

self-diagnostic system has detected a problem. If the

problem goes away, the light may go out, but a DTC will

remain stored in the ECM.

When the light remains “ON” while the engine is running,

or when a malfunction is suspected due to a driveability

problem, the MEFI “On-Board Diagnostic (OBD) System

Check” must be performed as the fi rst step. These checks

will expose malfunctions which may not be detected if other

diagnostics are performed prematurely.

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 3

Intermittent Malfunction Indicator Lamp (MIL)

In the case of an “intermittent” problem, the Malfunction

Indicator Lamp (MIL) will light for 10 seconds, and then

go out. However, the corresponding DTC will be stored

in the memory of the ECM. When DTC’s are set by an

intermittent malfunction, they could be helpful in diagnosing

the system.

If an intermittent DTC is cleared, it may or may not reset. If

it is an intermittent failure, consult the “Diagnostic Aids” on

the facing page of the corresponding Diagnostic Procedure.

Symptoms section also covers the topic of “Intermittents.”

A physical inspection of the applicable sub-system most

often will resolve the problem.

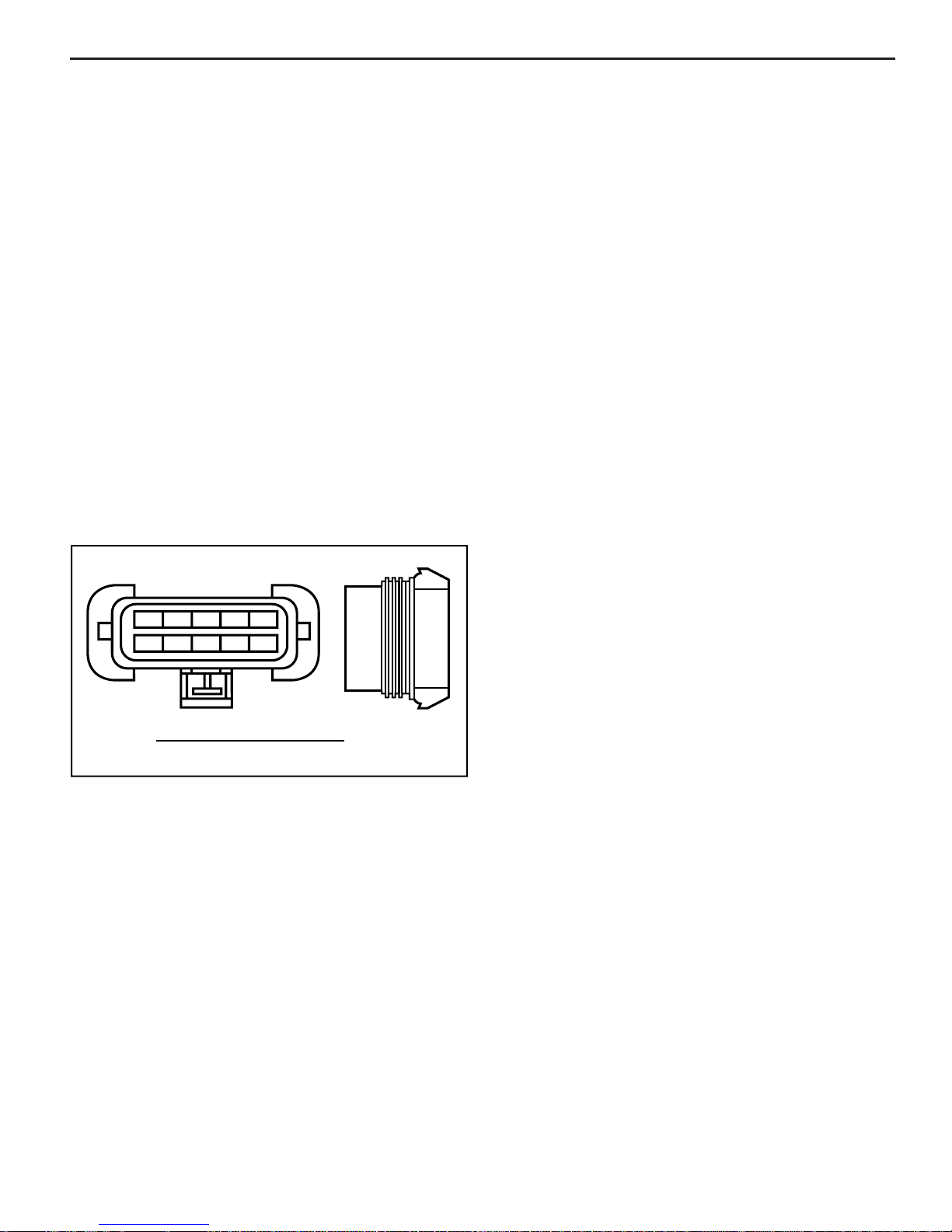

Reading Diagnostic Trouble Codes (DTC’s)

The provision for communicating with the ECM is the Data

Link Connector (DLC) (Figure 1-1). It is part of the MEFI

engine wiring harness, and is a 10-pin connector, which

is electrically connected to the ECM. It is used in the

assembly plant to receive information in checking that the

engine is operating properly before it leaves the plant. The

DTC(s) stored in the ECM’s memory can be retrieved two

different ways. One way is with a Diagnostic Trouble Code

(DTC) tool. The other way is through a scan tool,

A

A B C D E

K J H G F

DATA LINK CONNECTOR (DLC)

B

C

D

E

6-18-93

MS 13554

times. At the end of the DTC’s, the ECM will simply go

back and start over with fl ashing DTC 12.

Service Mode

When the DTC tool is installed at the DLC and “service

mode” or “ON” is selected, the system will enter what is

called the “Service Mode.” In this mode, the ECM will:

• Display a DTC 12 by fl ashing the MIL, indicating that

the diagnostic system is working.

• Display any stored DTC’s by fl ashing the MIL. Each

DTC will be fl ashed two times, then DTC 12 will be

fl ashed again.

Normal Mode

When the DTC tool is in the “normal mode” or “OFF,” it has

no affect on the engine operation.

MEFI On-Board Diagnostic (OBD) System

Check

After the visual/physical inspection, the “On-Board

Diagnostic (OBD) System Check” is the starting point for all

diagnostic procedures. Refer to Diagnosis section.

The correct procedure to diagnose a problem is to follow

two basic steps:

1. Are the on-board diagnostics working? This is

determined by performing the “On-Board Diagnostic

(OBD) System Check.” Since this is the starting point

for the diagnostic procedures, always begin here. If

the on-board diagnostics are not working, the OBD

system check will lead to a Diagnostic Procedure

in the Diagnosis section to correct the problem. If

the on-board diagnostics are working properly, the

next step is:

2. Is there a DTC stored? If a DTC is stored, go directly to

the number DTC procedure in the Diagnosis section.

This will determine if the fault is still present.

Figure 1-1 - Marine Data Link Connector (DLC)

a hand-held diagnostic scanner, plugged into the DLC.

Once the DTC tool has been connected, and “service

mode” or “ON” selected, the ignition switch must be mov ed

to the key “ON,” engine “OFF” position. At this point, the

MIL should fl ash DTC 12 two times consecutively. This

would be the following flash sequence: “flash, pause,

fl ash-fl ash, long pause, fl ash, pause, fl ash-fl ash.” DTC 12

indicates that the ECM’s diagnostic system is operating.

If DTC 12 is not indicated, a problem is present within

the diagnostic system itself, and should be addressed

by consulting the “On-Board Diagnostic (OBD) System

Check” in the Diagnosis section.

Following the output of DTC 12, the MIL will indicate a

DTC two times if a DTC is present, or it will continue to

fl ash DTC 12. If more than one DTC has been stored in

the ECM’s memory, the DTC’s will be fl ashed out from the

lowest to the highest, with each DTC being fl ashed two

DLC Scan Tools

The ECM can communicate a variety of information through

the DLC. This data is transmitted at a high frequency which

requires a scan tool for interpretation.

With an understanding of the data which the scan tool

displays, and knowledge of the circuits involved, the scan

tool can be very useful in obtaining information which

would be more diffi cult or impossible to obtain with other

equipment.

A scan tool does not make the use of Diagnostic Procedures

unnecessary, nor do they indicate exactly where the

problem is in a particular circuit. Some Diagnostic

Procedures incorporate steps with the use of a scan

tool (scan diagnostics), or with the DTC tool (non-scan

diagnostics).

MEFI 4 - PCM

1 - 4 General Information 5.0/5.7/6.0/8.1L

Scan Tool Use With Intermittents

The scan tool provides the ability to perform a “wiggle test”

on wiring harnesses or components with the engine not

running, while observing the scan tool display.

The scan tool can be plugged in and observed while

driving the boat under the condition when the MIL turns

“ON” momentarily, or when the engine driveability is

momentarily poor. If the problem seems to be related to

certain parameters that can be checked on the scan tool,

they should be checked while driving the boat. If there

does not seem to be any correlation between the problem

and any specifi c circuit, the scan tool can be checked on

each position, watching for a period of time to see if there

is any change in the readings that indicates intermittent

operation.

The scan tool is also an easy way to compare the operating

parameters of a poorly operating engine with those of a

known good one. For example, a sensor may shift in value

but not set a DTC.

The scan tool has the ability to save time in diagnosis

and prevent the replacement of good parts. The key to

using the scan tool successfully for diagnosis lies in the

technicians ability to understand the system they are trying

to diagnose, as well as an understanding of the scan tool

operation and limitations. The technician should read the

tool manufacturer’s operating manual to become familiar

with the tool’s operation.

How Diagnostic Trouble Codes (DTC) Are Set

The ECM is programmed to receive calibrated voltage

signals from the sensors. The voltage signal from the

sensor may range from as low as 0.1 volt to as high

as 4.9 volts. The sensor voltage signal is calibrated for

engine application. This would be the sensor’s operating

parameter or “window.” The ECM and sensors will be

discussed further in the ECM and Sensor section.

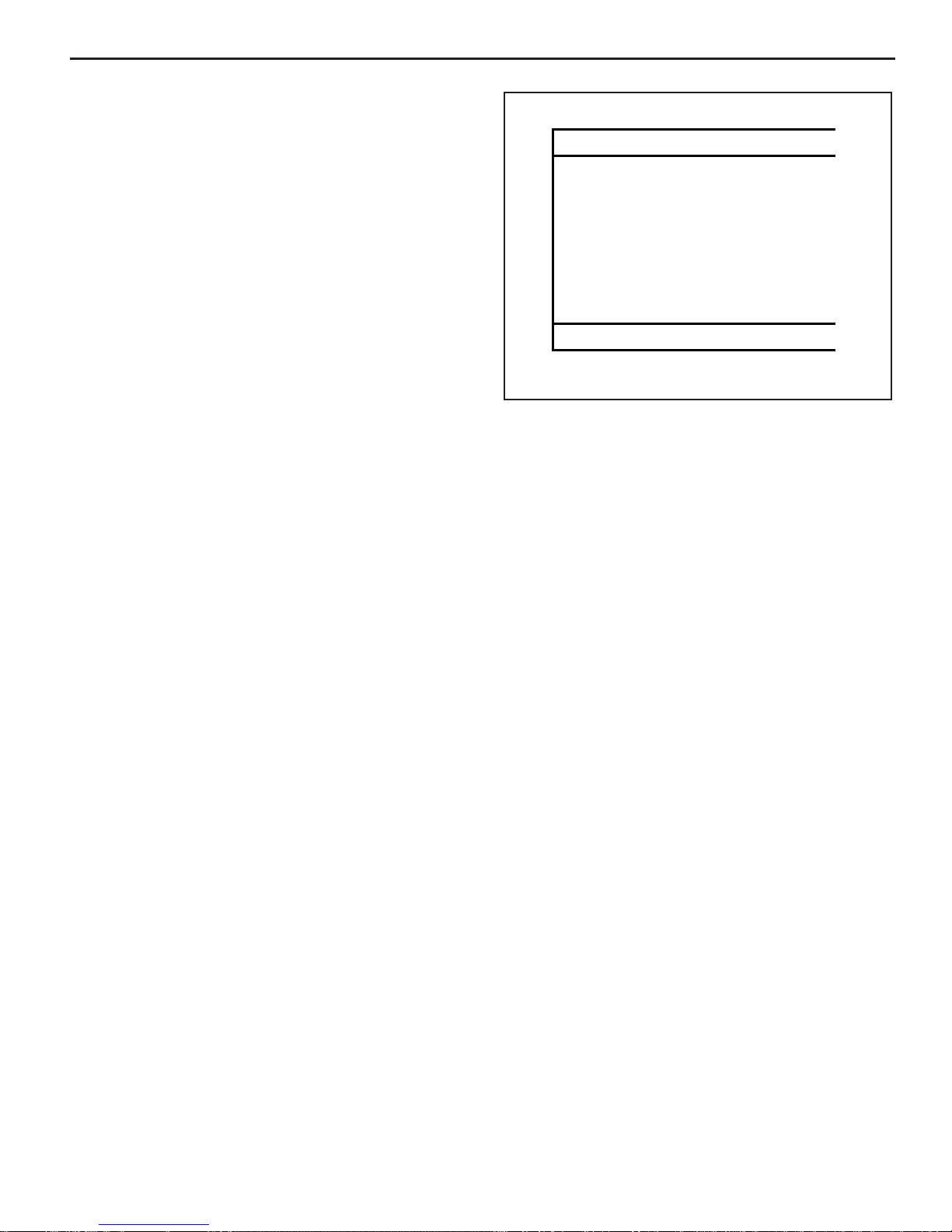

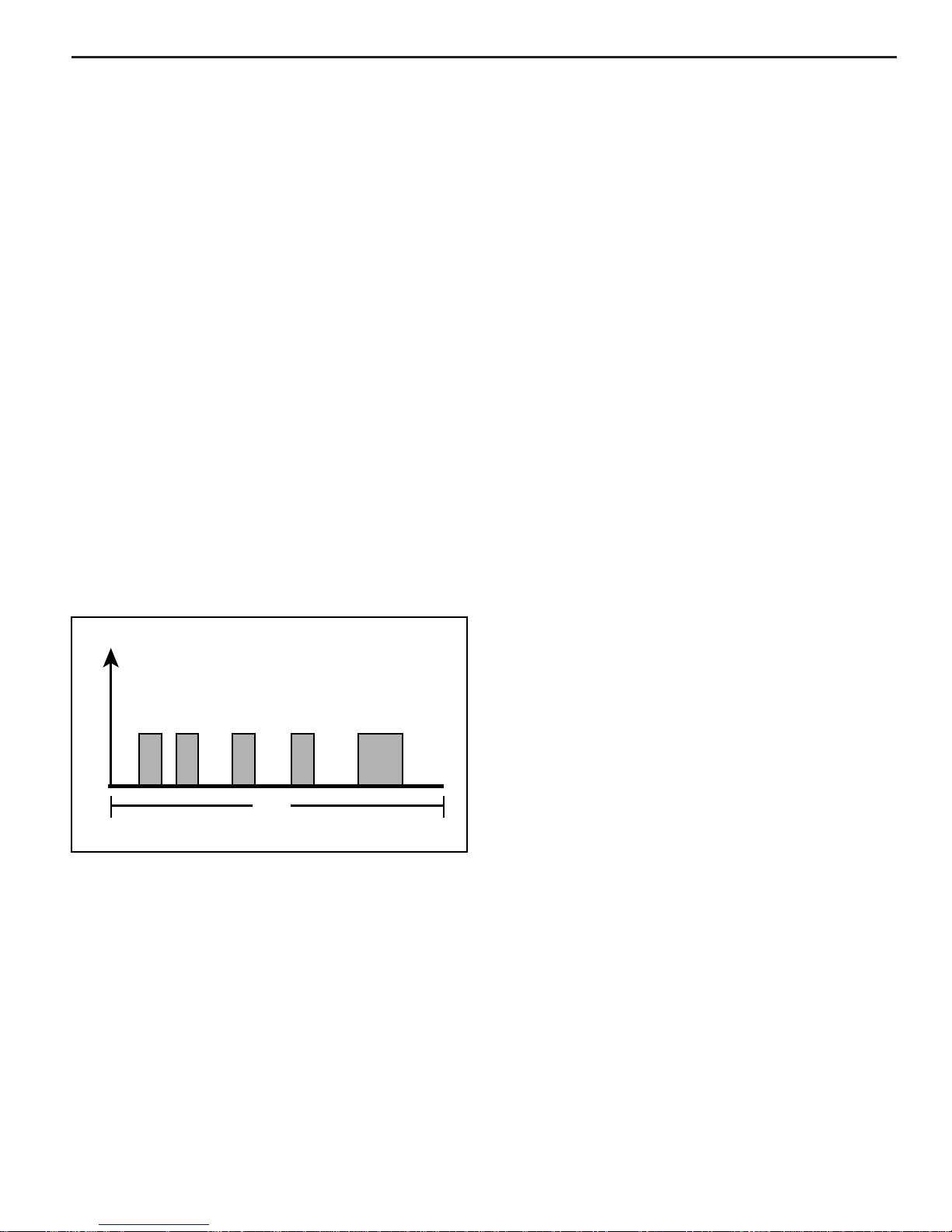

If a sensor is within its operating or acceptable parameters

(Figure 1-2), the ECM does not detect a problem. When a

sensor voltage signal falls out of this “window,” the ECM

no longer receives a signal voltage within the operating

“window.” When the ECM does not receive the “window”

voltage for a calibratible length of time, a DTC will be

stored. The MIL will be illuminated and a known default

value will replace the sensor value to restore engine

performance.

Clearing Diagnostic Trouble Codes (NonScan)

1. Install Diagnostic Trouble Code (DTC) tool.

2. Ignition “ON,” engine “OFF.”

3. Switch DTC tool to “service mode” or “ON.”

4. Move the throttle from 0% (idle) to 100% (WOT) and

5. Switch DTC tool to “normal mode” or “OFF.” (If this

6. Turn ignition “OFF” for at least 20 seconds.

7. Ignition “ON,” engine “OFF.”

8. Switch DTC tool to “service mode” or “ON” and verify

9. If original DTC(s) are still present, check “Notice” below

10. If new DTC(s) are displayed, perform the OBD system

NOTICE: When clearing DTC’ s with or without the use of a

scan tool, the ignition must be cycled to the “OFF” position

or the DTC’s will not clear.

5 VOLTS

XXXXXXXXXXXXXXX DEFAULTXXXXXXXXXXX

4.6V

V

O

L

T

A

G

E

XXXXXXXXXXXXXXX DEFAULTXXXXXXXXXXX

0 VOLTS

Figure 1-2 - Example of Sensor Normal Operation

TYPICAL SENSOR RANGE

“WINDOW”

0.7V

6-5-93

back to 0%.

step is not performed, the engine may not start and

run).

DTC 12 only. Remove DTC tool.

and repeat the DTC clearing procedure.

check.

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 5

Clearing Diagnostic Trouble Codes (Scan)

1. Install scan tool.

2. Start engine.

3. Select “clear DTC’s” function.

4. Clear DTC’s.

5. Turn ignition “OFF” for at least 20 seconds.

6. Turn ignition “ON” and read DTC’s. If DTC’s are still

present, check “Notice” below and repeat procedure

following from step 2.

NOTICE: When clearing DTC’ s with or without the use of a

scan tool, the ignition must be cycled to the “OFF” position

or the DTC’s will not clear.

Non-Scan Diagnosis Of Driveability

Concerns (No DTC’s Set)

If a driveability concern still exists after following the OBD

system check and reviewing the Symptoms section, an

out of range sensor may be suspected. Because of the

unique design of the MEFI system, the ECM will replace

sensed values with calibrated default values in the case of

a sensor or circuit malfunction. By allowing this to occur,

limited engine performance is restored until the boat

is repaired. A basic understanding of sensor operation

is necessary to be able to diagnose an out of range

sensor.

If the sensor is out of range, but still within the operating

“window” of the ECM, the prob lem will go undetected by the

ECM and may result in a driveability concern.

A good example of this would be if the coolant sensor was

reading incorrectly and indicating to the ECM that coolant

temperature was at 50°F, but actual coolant temperature

was at 150°F (Figure 1-3). This would cause the ECM to

deliver more fuel than what was actually needed by the

engine. This resulted in an overly rich condition, causing

rough running. This condition would not have caused

a DTC to set, as the ECM interprets this as within the

operating “window.”

To identify a sensor that is out of range, you may unplug

the sensor electrical connector while the engine is running.

After about 2 minutes, the DTC for that sensor will set,

illuminate the MIL, and replace the sensed value with

a calibrated default value. If at that point, a noticeable

performance increase is observed, the non-scan DTC

table for that particular sensor may be followed to correct

the problem.

NOTICE: Be sure to clear each DTC after disconnecting

and reconnecting each sensor. Failure to do so may result

in a misdiagnosis of the driveability concern.

Aftermarket (Add-On) Electrical And Vacuum

Equipment

Aftermarket, add-on electrical and vacuum equipment is

defi ned as any equipment installed on a vehicle after

leaving the factory that connects to the vehicles electrical

or vacuum systems.

Notice: Do not attach add-on vacuum operated

equipment to this engine. The use of add-on vacuum

equipment may result in damage to engine components

or systems.

Notice: Connect any add-on electrically operated

equipment to the vehicle’s electrical system at the battery

(power and ground) in order to prevent damage to the

vehicle.

Add-on electrical equipment, even when installed to

these strict guidelines, may still cause the powertrain

system to malfunction. This may also include equipment

not connected to the vehicle’s electrical system such as

portable telephones and radios. Therefore, the fi rst step

in diagnosing any powertrain problem, is to eliminate all

aftermarket electrical equipment from the vehicle. After

this is done, if the problem still exists, diagnose the

problem in the normal manner.

Use of Circuit Testing Tools

Do not use a test lamp in order to diagnose the engine

electrical systems unless specifi cally instructed by the

diagnostic procedures. Use the J 35616-A connector

test adapter kit whenever diagnostic procedures call for

probing any connectors.

LOW TEMP - 5 VOLTS

XXXXXXXXXXXXXXX DEFAULTXXXXXXXXXXX

T

------50 -4.2V OUT OF RANGE SENSOR

E

M

P

E

R

A

T

U

R

E

------150 -1.7V ACTUAL COOLANT TEMPERATURE

XXXXXXXXXXXXXXX DEFAULTXXXXXXXXXXX

HIGH TEMP - 0 VOLTS

Figure 1-3 - Example of Shifted Sensor Operation

6-5-93

MS 13552

Tools Needed To Service The System

Refer to Special Tools in this section for engine control

tools for servicing the system.

MEFI 4 - PCM

1 - 6 General Information 5.0/5.7/6.0/8.1L

Service Precautions

The following requirements must be observed when

working on MEFI equipped engines.

1. Before removing any ECM system component,

disconnect the negative battery cable.

2. Nev er start the engine without the battery being solidly

connected.

3. Never separate the battery from the on-board electrical

system while the engine is running.

4. Never separate the battery feed wire from the charging

system while the engine is running.

5. When charging the battery, disconnect it from the

vehicle’s electrical system.

6. Ensure that all cable harnesses are connected solidly

and the battery connections are thoroughly clean.

7. Never connect or disconnect the wiring harness at the

ECM when the ignition is switched “ON.”

8. Before attempting any electric arc welding on the

vehicle, disconnect the battery leads and the ECM

connector(s).

9. When steam cleaning engines, do not direct the nozzle

at any ECM system components. If this happens,

corrosion of the terminals or damage of components

can take place.

10. Use only the test equipment specifi ed in the diagnostic

procedures, since other test equipment may either giv e

incorrect test results or damage good components.

11. All measurements using a multimeter must use a digital

meter with a rating of 10 megaohm input impedance.

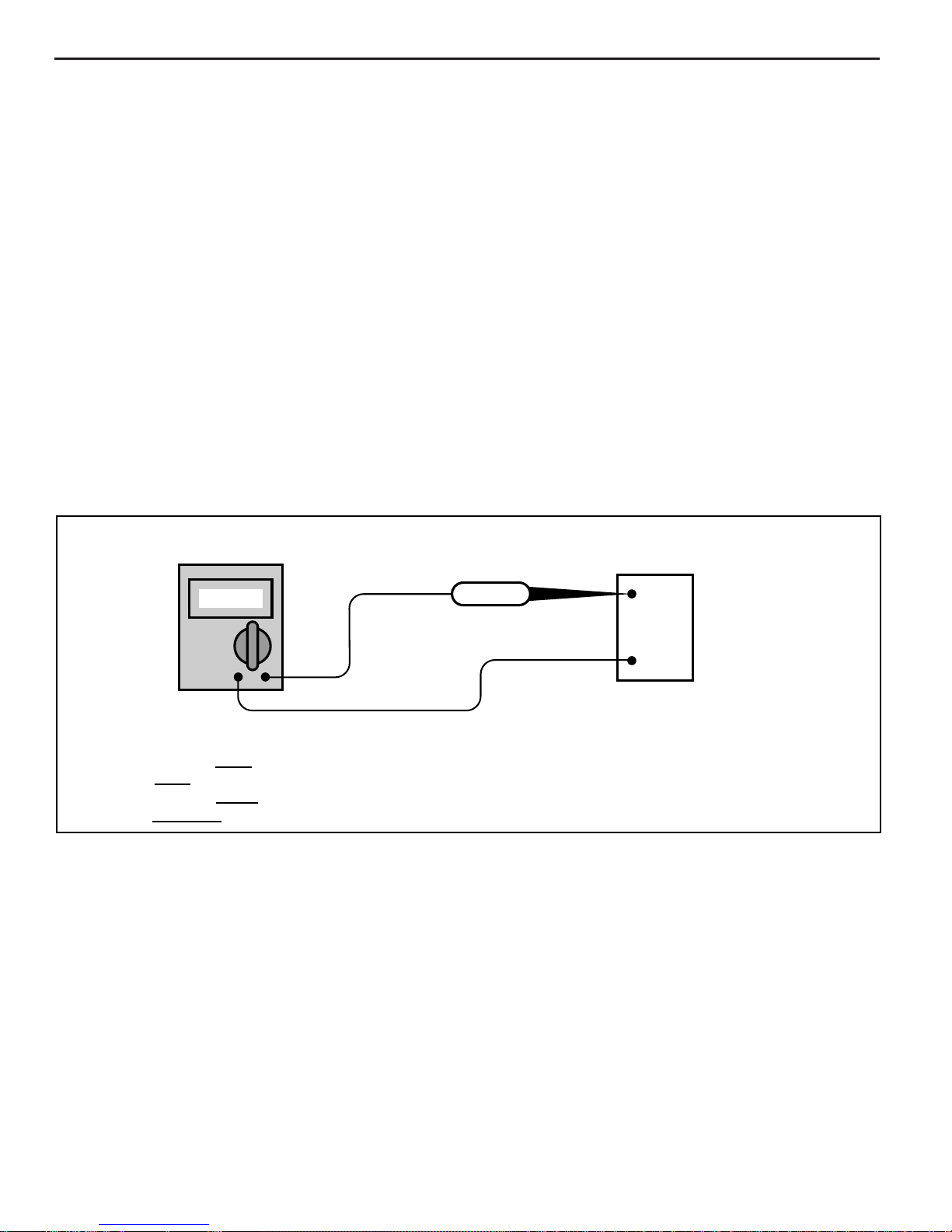

12. When a test light is specifi ed, a “low-power” test light

must be used. Do not use a high-wattage test light.

While a particular brand of test light is not suggested,

a simple test on any test light will ensure it to be safe

for system circuit testing (Figure 1-4). Connect an

accurate ammeter (such as the high-impedance digital

multimeter) in series with the test light being tested,

and power the test light ammeter circuit with the

vehicle battery.

DC Amps

If the ammeter indicates

the testlight is

If the ammeter indicates

the testlight is

safe

to use.

not safe

less

than 3/10 amp(.3A) current flow,

more

than 3/10 amp(.3A) current flow,

to use.

Figure 1-4 - Test Light Amperage Draw Test

testlight

*

+

BATTERY

-

I 22307

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 7

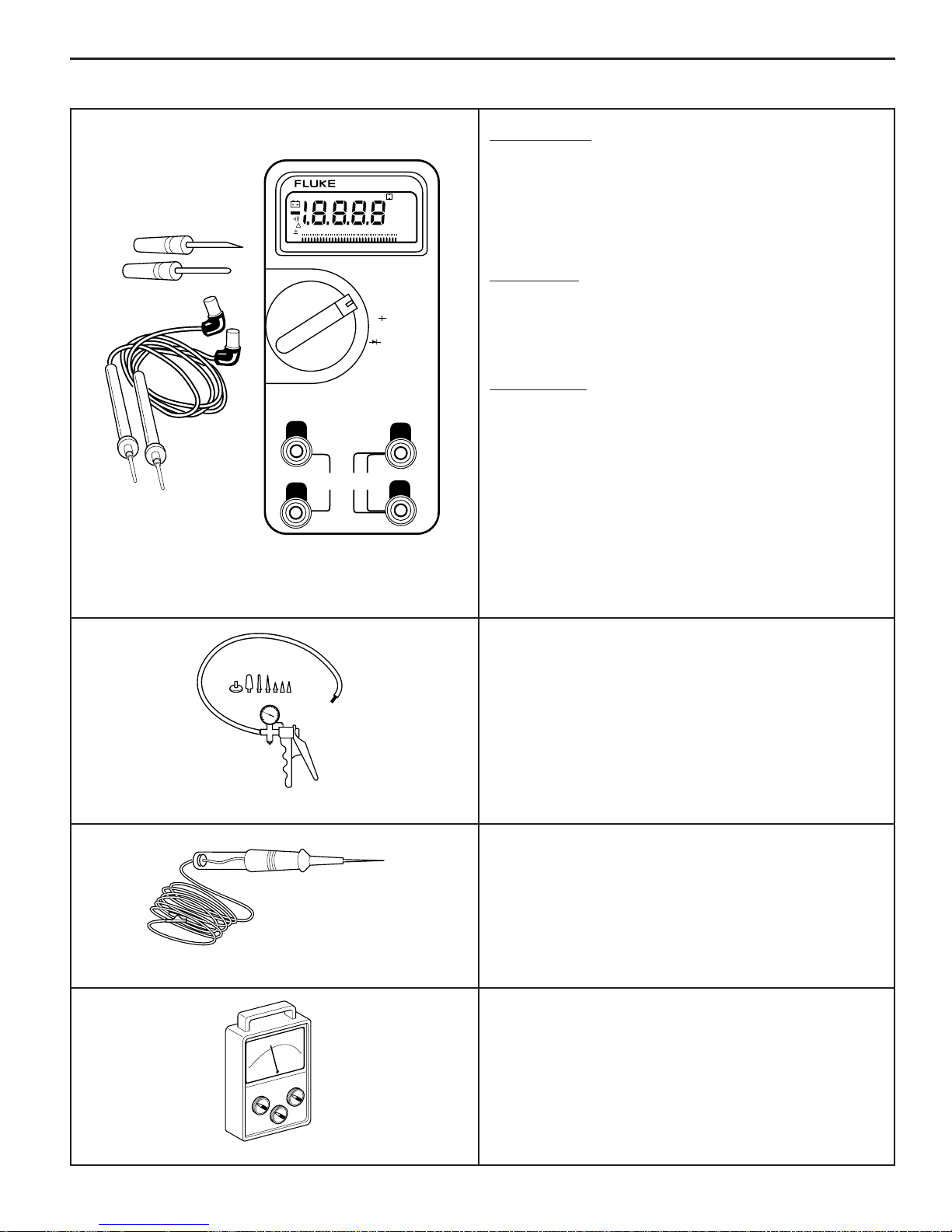

Special Tools (1 of 3)

VOLTMETER - Voltage position measures magnitude of

voltage when connected in parallel to an existing circuit.

A digital voltmeter with a 10 megohm input impedance

is used because this type of meter will not load down

the circuit and result in faulty readings. Some circuits

require accurate low voltage readings because they have

a very high resistance.

AMMETER - When used as an ammeter, this meter

accurately measures extremely low current fl ow. Refer to

meter instructions for more information.

AUTO 100

OFF

0

1234

ms

TRUE RMS MULTIMETER

87

RECORD MAX MIN AVG

5678 90

~

V

_

…

V

…

mV

AC DC

µ

m V A

n F S %

M k Ω Hz

4000

mV

_

(

Ω

• Selector must be set properly for both function and

_

mA

…

~

A

_

…

µ

A

~

range. DC is used for most measurements.

OHMMETER - Measures resistance of circuit directly in

ohms. Refer to meter instructions for more information.

• OL display in all ranges indicates open circuit.

• Zero display in all ranges indicates a short circuit.

400mA MAX

FUSED

10A MAX

FUSED

• An intermittent connection in a circuit may be indicated

by a digital reading that will not stabilize on the

circuit.

• Range Switch - Automatic and Manual.

200ý - Reads ohms directly

2K, 20K, 200Ký - Reads ohms in thousands

J 39978

2M, 20M, 200Mý - Reads ohms in millions

3

➤

2

1

0

TACHOMETER

VACUUM PUMP WITH GAUGE (20 IN. HG. MINIMUM)

Use the gauge to monitor manifold engine vacuum and

use the hand pump to check vacuum sensors, solenoids

and valves.

J 23738-A

UNPOWERED TEST LIGHT

Used for checking wiring for a complete circuit, voltages

and grounds.

J 34142-B

TACHOMETER

4

5

Must have inductive trigger signal pick-up.

NS 14574

MEFI 4 - PCM

1 - 8 General Information 5.0/5.7/6.0/8.1L

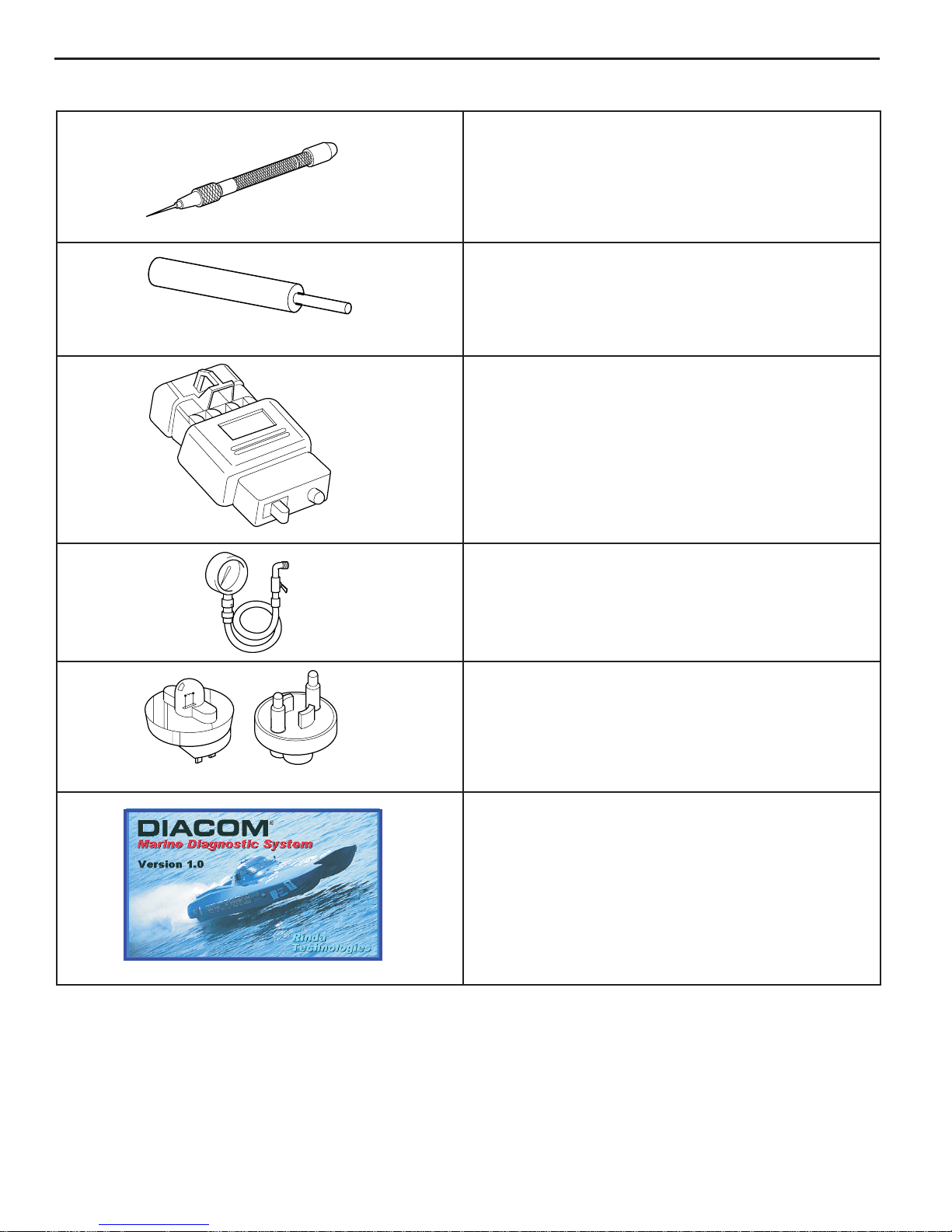

Special Tools (2 of 3)

METRI-PACK TERMINAL REMOVER

Used for removing 150 series Metri-Pack “pull-to-seat”

terminals from connectors. Refer to wiring harness

service in MEFI General Information Section for removal

procedure.

J 35689

WEATHER PACK TERMINAL REMOVER

Used for removing terminals from Weather P ack connectors.

Refer to wiring harness service in MEFI General Information

Section for removal procedure.

J 28741-A/BT-8234-A

DIAGNOSTIC TROUBLE CODE (DTC) TOOL

A hand held diagnostic tool that plugs into the DLC

connector for various diagnostics.

TA 06075

RTK0078

J 34730-2C & J 34730-350/BT 8329

RT0086

FUEL PRESSURE GAUGE

Used for checking fuel system pressure on MFI and PFI

engines.

INJECTOR HARNESS TEST LIGHT

A specially designed light used to visually indicate injector

electrical pulses from the ECM.

DIACOM SCAN TOOL

A hand held diagnostic tool that plugs into the DLC

connector for various diagnostics. It will display various

parameters.

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 9

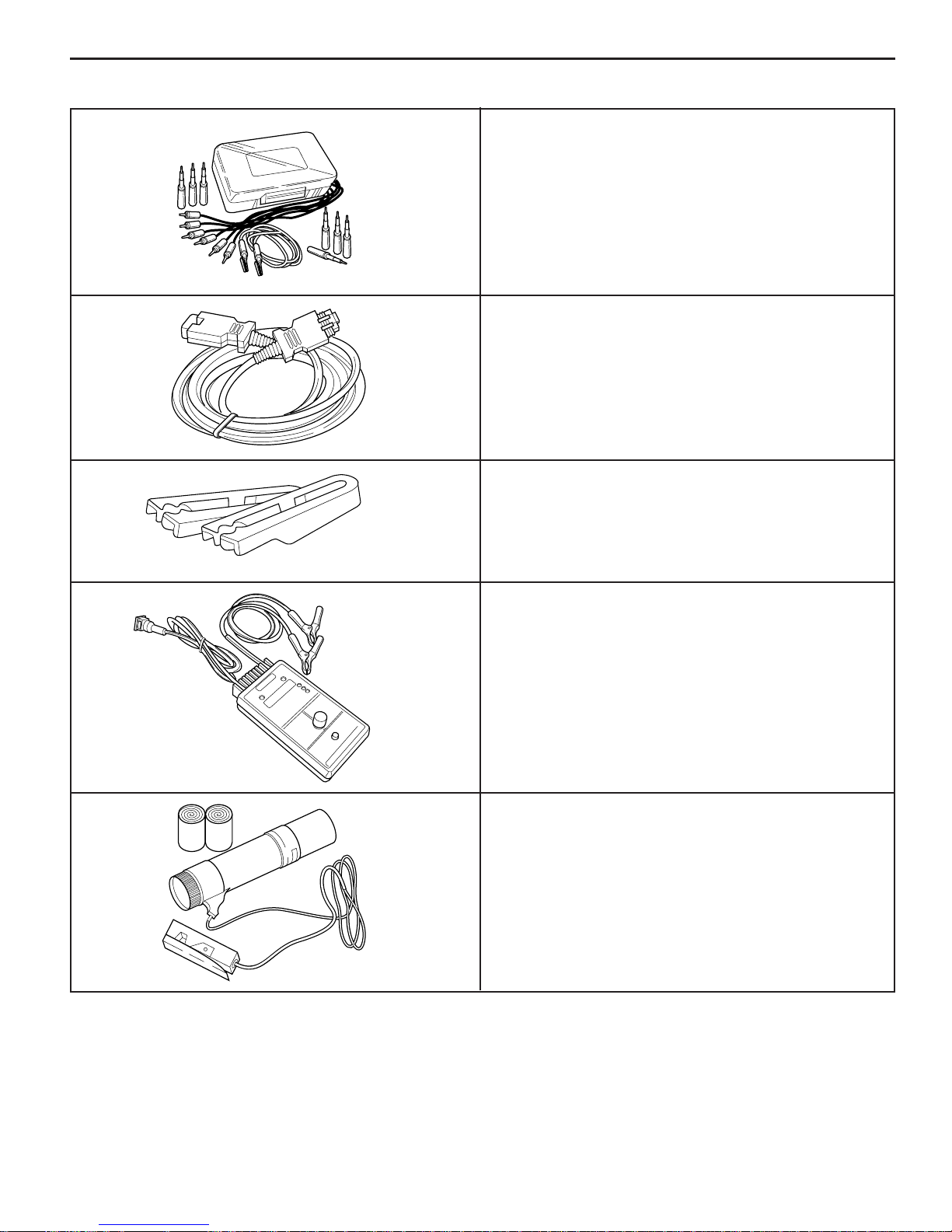

Special Tools (3 of 3)

HARNESS TEST ADAPTER KIT

Used to make electrical test connections in current W eather

Pack, Metri-Pack and Micro-Pack style terminals.

J 35616

20’ DIAGNOSTIC CONNECTOR EXTENSION CABLE

Extension cable to go between the scan tool and the DLC

on the engine harness.

TA 06076

FUEL LINE QUICK-CONNECT SEPARATOR

Used to release fuel line quick-connect fi ttings.

J-39021

J 37088-A/BT-9171

INJECTOR TESTER

Separately energizes each injector to compare for equal

fuel pressure drops over a constant time interval.

+

INJECTOR

VOLTS

-

LOWBATTERY

READYTO TEST

MP

TESTIN PROGRESS

AMP

4AMP

2.5 AMP

PUSHTO TEST

6.5 AMP

KENT-MOORE

J 39021

TIMING LIGHT

Must have inductive signal pickup.

J 34186

MEFI 4 - PCM

1 - 10 General Information 5.0/5.7/6.0/8.1L

ABBREVIATIONS

BARO - BAROMETRIC PRESSURE

BAT - BATTERY, BATTERY POSITIVE

TERMINAL, BATTERY OR SYSTEM

VOLTAGE

B+ - BATTERY POSITIVE

CKP - CRANKSHAFT POSITION SENSOR

CKT - CIRCUIT

CMP - CAMSHAFT POSITION SENSOR

CONN - CONNECTOR

CYL - CYLINDER

DEG - DEGREES

DIAG - DIAGNOSTIC

DLC - DATA LINK CONNECTOR

DMM - DIGITAL MULTIMETER

DTC - DIAGNOSTIC TROUBLE CODE

ECM - ENGINE CONTROL MODULE

ECT - ENGINE COOLANT TEMPERATURE

SENSOR

EEPROM - ELECTRONIC ERASABLE

PROGRAMMABLE READ ONLY

MEMORY

EI - ELECTRONIC IGNITION

EMI - ELECTROMAGNETIC

INTERFERENCE

ENG - ENGINE

GND - GROUND

GPH - GALLONS PER HOUR

HVS - HIGH-VOLTAGE SWITCH

IAC - IDLE AIR CONTROL

IAT - INTAKE AIR TEMPERATURE

IC - IGNITION CONTROL

KS - KNOCK SENSOR SYSTEM

KV - KILOVOLTS

MAP - MANIFOLD ABSOLUTE PRESSURE

MEFI - MARINE ELECTRONIC FUEL

INJECTION

MFI - MULTIPORT FUEL INJECTION

MIL - MALFUNCTION INDICATOR LAMP

MSEC - MILLSECOND

N/C - NORMALLY CLOSED

N/O - NORMALLY OPEN

OBD - ON-BOARD DIAGNOSTIC SYSTEM

CHECK

OPT - OPTIONAL

PFI - PORT FUEL INJECTION

PROM - PROGRAMMABLE READ ONLY

MEMORY

RAM - RANDOM ACESS MEMORY

REF HI - REFERENCE HIGH

REF LO - REFERENCE LOW

ROM - READ ONLY MEMORY

SLV - SLAVE

SW - SWITCH

TACH - TACHOMETER

TBI - THROTTLE BODY INJECTION

TERM - TERMINAL

TP - THROTTLE POSITION SENSOR

V - VOLTS

VAC - VACUUM

WOT - WIDE OPEN THROTTLE

“ HG - INCHES OF MERCURY

IGN - IGNITION

INJ - INJECTOR

I/O - INPUT/OUTPUT

kPa - KILOPASCAL

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 11

T endency f or connectors to come apart due to vibration

Diagnosis

The diagnostic tables and functional checks in this manual

are designed to locate a faulty circuit or component through

logic based on the process of elimination. The tables are

prepared with the requirement that the system functioned

correctly at the time of assembly and that there are no

multiple failures.

Engine control circuits contain many special design features

not found in standard vehicle wiring. Environmental

protection is used extensively to protect electrical contacts.

Proper splicing methods must be used when necessary.

The proper operation of low amperage input/output circuits

depend upon good continuity between circuit connectors. It

is important before component replacement and/or during

normal troubleshooting procedures that a visual inspection

of any questionable mating connector is performed. Mating

surfaces should be properly formed, clean and likely to

make proper contact. Some typical causes of connector

problems are listed below:

Improperly formed contacts and/or connector

•

housing.

Damaged contacts or housing due to improper

•

engagement.

Corrosion, sealer or other contaminants on the contact

•

mating surfaces.

Incomplete mating of the connector halves during

•

initial assembly or during subsequent troubleshooting

procedures.

•

and/or temperature cycling.

Terminals not fully seated in the connector body.

•

Inadequate terminal crimps to the wire.

•

On-Board Service

Wiring Harness Service

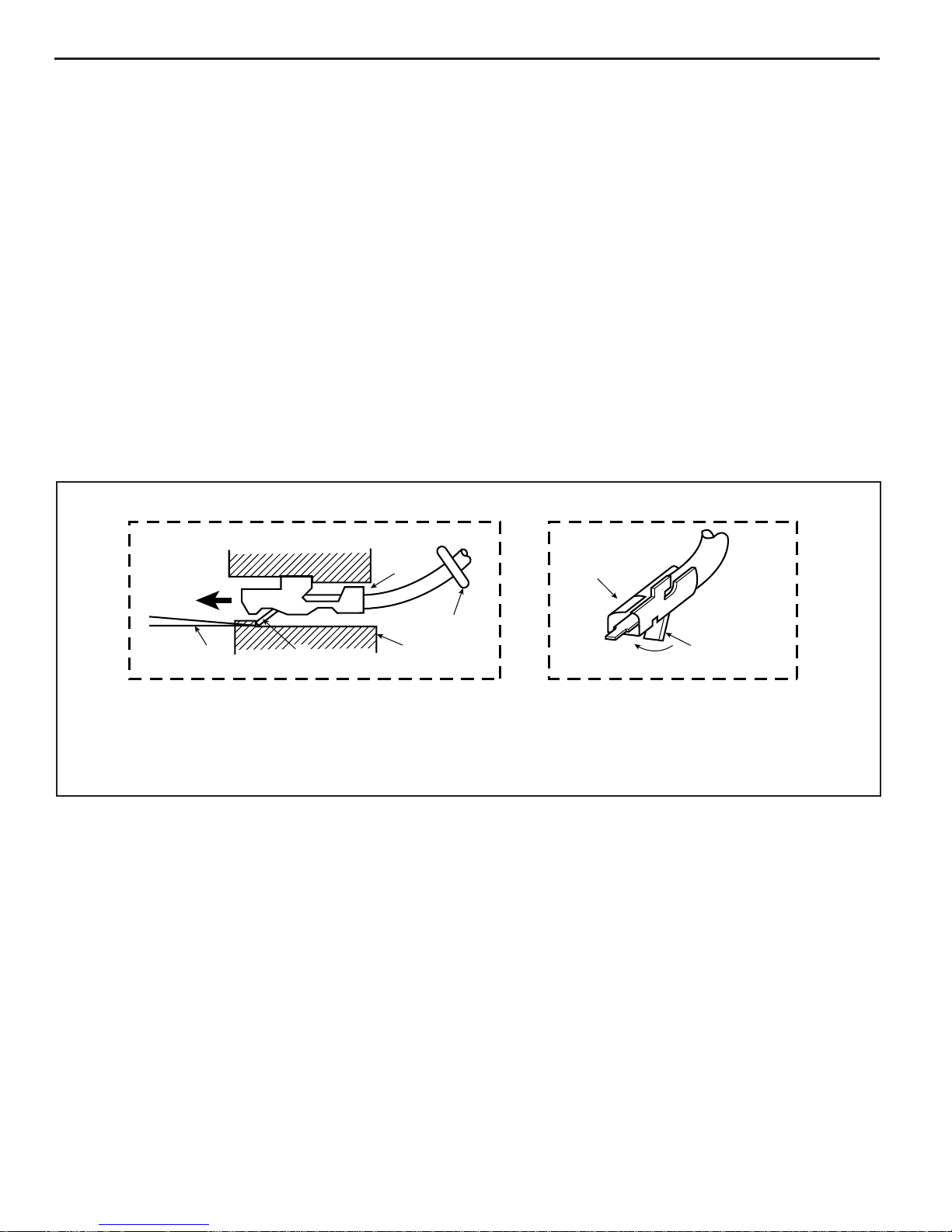

Figure 1-5

Wiring harnesses should be replaced with proper part

number harnesses. When wires are spliced into a harness,

use the same gauge wire with high temperature insulation

only.

With the low current and voltage levels found in the

system, it is important that the best possible bond be

made at all wire splices by soldering the splices as shown

in Figure 1-5.

Use care when probing a connector or replacing a connector

terminal. It is possible to short between opposite terminals.

If this happens, certain components can be damaged.

Always use jumper wires with the corresponding mating

terminals between connectors for circuit checking. NEVER

probe through connector seals, wire insulation, secondary

ignition wires, boots, nipples or covers. Microscopic

damage or holes may result in water intrusion, corrosion

and/or component failure.

DRAIN WIRE

OUTER JACKET

MYLAR

1REMOVE OUTER JACKET.

2UNWRAP ALUMINUM/MYLAR TAPE. DO NOT

REMOVE MYLAR.

3UNTWIST CONDUCTORS. STRIP INSULATION AS

NECESSARY.

DRAIN WIRE

4SPLICE WIRES USING SPLICE CLIPS AND ROSIN CORE

SOLDER. WRAP EACH SPLICE TO INSULATE.

5WRAP WITH MYLAR AND DRAIN (UNINSULATED) WIRE.

6TAPE OVER WHOLE BUNDLE TO SECURE AS BEFORE.

1LOCATE DAMAGED WIRE.

2REMOVE INSULATION AS REQUIRED.

3SPLICE TWO WIRES TOGETHER USING SPLICE

CLIPS AND ROSIN CORE SOLDER.

4COVER SPLICE WITH TAPE T O INSULA TE

FROM OTHER WIRES.

5RETWIST AS BEFORE AND TAPE WITH

ELECTRICAL TAPE AND HOLD IN PLACE.

8-24-94

RS 22186

Figure 1-5 - Wiring Harness Repair

MEFI 4 - PCM

1 - 12 General Information 5.0/5.7/6.0/8.1L

Wiring Connector Service

Most connectors in the engine compartment are protected

against moisture and dirt which could create oxidation

and deposits on the terminals. This protection is important

because of the very low voltage and current levels found

in the electronic system. The connectors have a lock

which secures the male and female terminals together.

A secondary lock holds the seal and terminal into the

connector.

When diagnosing, open circuits are often diffi cult to locate

by sight because oxidation or terminal misalignment are

hidden by the connectors. Merely wiggling a connector on

a sensor, or in the wiring harness, may locate the open

circuit condition. This should always be considered when

an open circuit or failed sensors is indicated. Intermittent

problems may also be caused by oxidized or loose

connections.

Before making a connector repair, be certain of the type of

connector. Some connectors look similar but are serviced

differently.

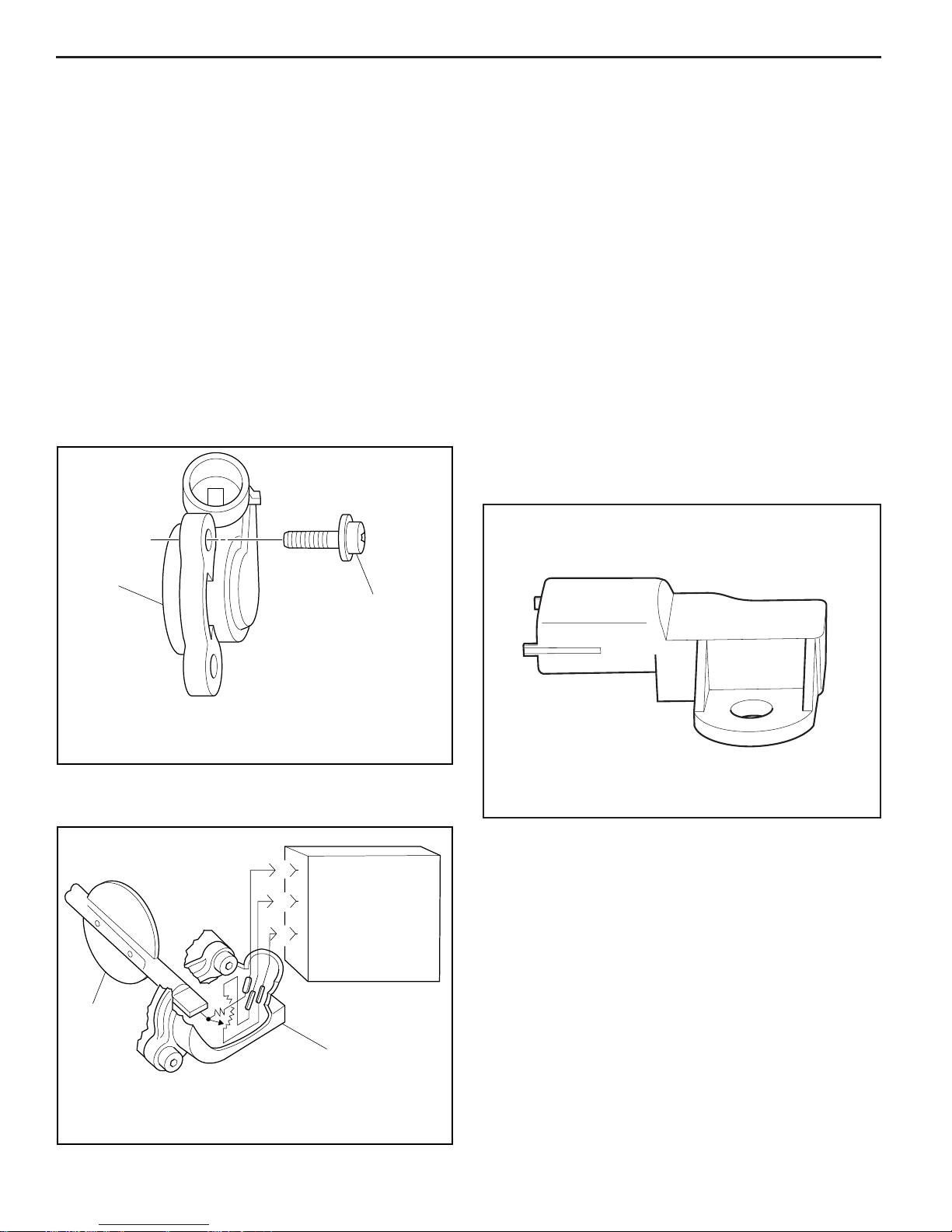

Metri-Pack Series 150 Terminals

Figure 1-6

Some ECM harness connectors contain terminals called

Metri-Pack (Figure 1-6). These are used at some of the

sensors and the distributor connector.

Metri-Pack terminals are also called “Pull-To-Seat”

terminals because, to install a terminal on a wire, the wire is

fi rst inserted through the seal and connector. The terminal

is then crimped on the wire, and the terminal is pulled back

into the connector to seat it in place.

To remove a terminal:

1. Slide the seal back on the wire.

2. Insert tool J 35689 or equivalent, as shown in Figure

1-6, to release the terminal locking tang.

3. Push the wire and terminal out through the connector.

If the terminal is being reused, reshape the locking

tang.

AB

1

5

3

1. METRI-PACK SERIES

150 FEMALE TERMINAL.

2. LOCKING T ANG.

RS 22187

2

Figure 1-6 - Metri-Pack Series 150 Terminal Removal

4

3. TOOL J35689 OR BT-8446.

4. CONNECTOR BODY.

5. SEAL.

1

2

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 13

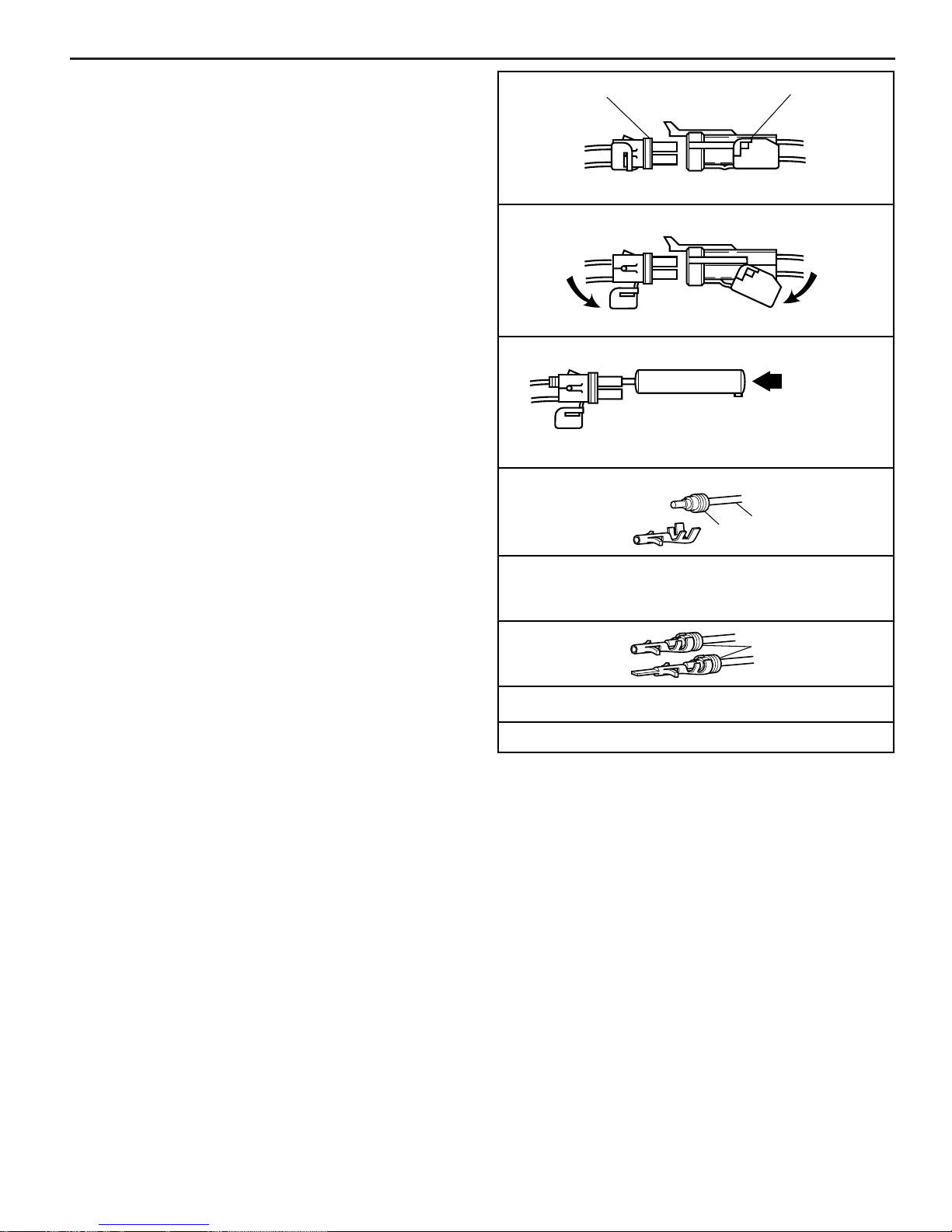

Weather-Pack Connectors

Figure 1-7

Figure 1-7 shows a Weather-Pack connector and the

tool (J 28742 or equivalent) required to service it. This

tool is used to remove the pin and sleeve terminals. If

terminal removal is attempted without using the special

tool required, there is a good chance that the terminal

will be bent or deformed, and unlike standard blade type

terminals, these terminals cannot be straightened once

they are bent.

Make certain that the connectors are properly seated and

all of the sealing rings in place when connecting leads.

The hinge-type fl ap provides a secondary locking feature

for the connector. It improves the connector reliability by

retaining the terminals if the small terminal lock tangs are

not positioned properly. Weather-Pack connections cannot

be replaced with standard connections.

MALE

CONNECTOR

BODY

1. OPEN SECONDARY LOCK HINGE ON CONNECTOR

2. REMOVE TERMINAL USING TOOL

TERMINAL REMOVAL TOOL

J 28742, J 38125-10 OR BT-8234-A

3. CUT WIRE IMMEDIATELY BEHIND CABLE SEAL

SEAL

FEMALE

CONNECTOR

BODY

PUSH TO

RELEASE

WIRE

4. REPLACE TERMINAL

A. SLIP NEW SEAL ONTO WIRE

B. STRIP 5mm (.2") OF INSULATION FROM WIRE

C. CRIMP TERMINAL OVER WIRE AND SEAL

SEAL

5. PUSH TERMINAL INTO CONNECTOR

UNTIL LOCKING TANGS ENGAGE

6. CLOSE SECONDARY LOCK HINGE

RS 22188

Figure 1-7 - Weather-Pack Terminal Repair

MEFI 4 - PCM

1 - 14 General Information 5.0/5.7/6.0/8.1L

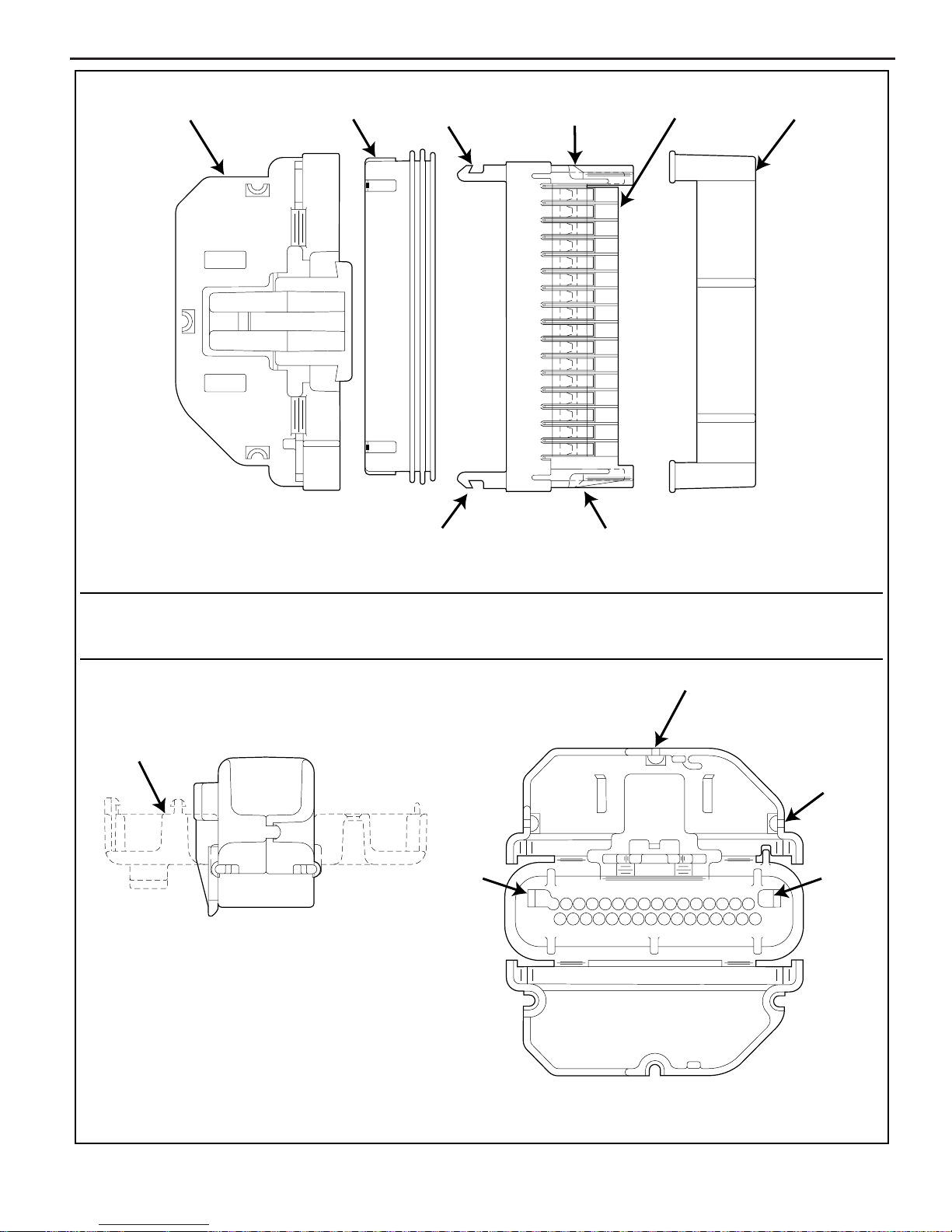

Micro-Pack 100/W Series Connectors

Figure 1-8

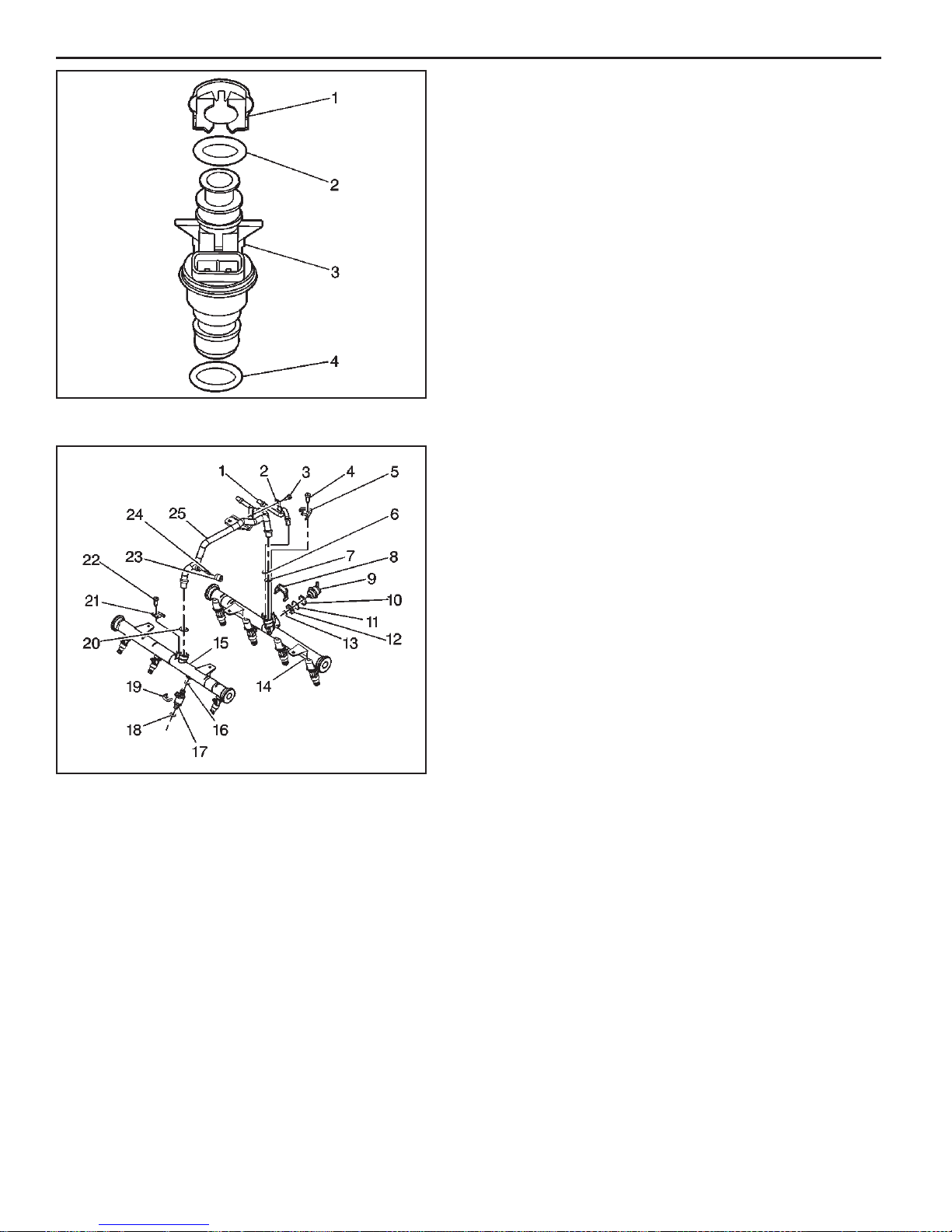

The harness connectors used with the ECM “J1” and “J2”

connectors are Micro-Pack 100/W Series. It is used for its

ruggedized construction, capable of carrying more current

and provides good sealing ability. The connector is made

up of fi ve different parts (refer to Figure 1-8 View A): Str ain

Relief (1), Seal (2), Connector (3), Index Cover (4) and

Ter minals (not shown).

Remove or Disconnect

1. Negative battery cable.

2. Connector from ECM by lifting up locking tab with

thumb and pulling on connector body.

Inspect

Check strain relief for being cracked or locking tab

•

damaged.

Check index cover for being cracked.

•

Check seal for being torn, twisted or out of shape from

•

improper installation.

Check terminals for being corroded, out of position,

•

bent or stretched out.

Use a wire gauge .038 for checking terminal

–

internal fi t. Wire gauge should slide with smooth

feel and not be loose.

Notice: If you are only going to clean terminals, complete

disassembly is not necessary. Remove index cover from

the connector by pushing on Tab C on both sides and

sliding off cover. Care m ust be tak en not to mov e terminals

out of their position. The index cover locks the terminals

in position. If repair or replacement of parts is needed, DO

NOT remove index cover at this time.

3. With a small screwdriver, move Tabs A on strain relief

(1) to unlock position.

4. Open strain relief as shown in View B.

5. Release Tabs B (View C) on connector (3) by pushing

inward with both thumbs or small screwdriver.

6. Push Tabs B through strain relief (1) with thumbs or

small screwdriver while in released position.

Important

Where there are not wires in strain relief, small plugs

•

are installed. DO NO T lose the plugs, they are important

to help keep connector assembly sealed.

7. Remove plugs where there are not any wires.

8. Slide strain relief off of seal and back on wires.

9. Slide seal off of connector and back on wires.

Important

To ensure proper engine operation after repair of

•

connector assembly , wires must be in proper connector

location. Before removing index cover, note if there

are any wires of the same color. Mark these wires from

the location that they were remov ed. For the remaining

wires, their location can be found by ref erring to “Wiring

Diagrams” in the Diagnosis section. The strain relief is

numbered for identifying wire location.

10. Index cover (4) by pushing in on Tabs C with a small

screwdriver.

11. Ter minals by pulling out of connector.

12. Seal (2) from wires.

13. Strain relief (1) from wires.

Clean and Inspect

Terminals for corrosion.

•

– Use spray electrical contact cleaner.

Loose crimps on terminals.

•

Broken wires at terminals.

•

Notice: For terminal replacement, refer to instructions

found with terminal repair kit and crimper tool.

Install or Connect

1. Align index cover (4) on connector (3) and lock into

position. Make sure Tabs C are locked.

2. Align seal (2) on connector (3) and slide all the way

on.

DO NOT install strain relief (1) onto connector (3)

•

yet.

3. One wire with terminal installed, through strain relief

(1) in location that it was removed.

Start with the lowest numbered wire position for

•

that connector.

4. Terminal through seal (2), connector (3) and into inde x

cover (4) until it locks in place.

5. Remaining wires one at a time per same method.

• Keep wires straight.

DO NOT kink wires.

•

6. Strain relief (1) onto seal (2) and connector (3).

7. Lock Tabs B into strain relief (1).

8. Plugs into strain relief (1) where there are not any

wires.

9. Fold strain relief (1) together and lock Tabs A.

10. Connector assembly to ECM.

11. Negative battery cable.

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L General Information 1 - 15

1

2

TAB B

TAB B

TAB C

TAB C

34

FIGURE A - EXPLODED VIEW OF CONNECTOR ASSEMBLY

1 STRAIN RELIEF

2 SEAL

TAB A

FIGURE B - STRAIN RELIEF CLOSED

TAB B

3 CONNECTOR

4 INDEX COVER

TAB A

21 3 4 5 6 7 8 9 10111213141516

1817 1920212223242526272829303132

TAB A

TAB B

FIGURE C - STRAIN RELIEF OPENED

PS 19745

Figure 1-8 - Micro-Pack 100/W Series

MEFI 4 - PCM

1 - 16 General Information 5.0/5.7/6.0/8.1L

This page left

intentionally

blank

MEFI 4 - PCM

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 1

Marine Electronic Fuel Injection (MEFI)

Section 2

Engine Control Module (ECM) and Sensors

This section will describe the function of the Engine Control Module (ECM) and the sensors. The section explains

how voltages reflect the inputs and outputs of the ECM. The sensors are described how they operate and how

to replace them.

Contents

General Description .............................................Page 2

Computers and Voltage Signals.......................Page 2

Analog Signals.................................................Page 2

Three-Wire Sensors ..................................Page 2

Two-Wire Sensors .....................................Page 2

Digital Signals..................................................Page 3

Switch Types..............................................Page 3

Pulse Counters..........................................Page 3

Engine Control Module (ECM).........................Page 4

ECM Function............................................Page 4

Memory .....................................................Page 4

ROM..........................................................Page 4

RAM...........................................................Page 4

EEPROM...................................................Page 4

Speed Density System ....................................Page 5

Speed........................................................Page 5

Density.......................................................Page 5

ECM Inputs and Sensor Descriptions..............Page 5

Input Components............................................Page 5

Output Components.........................................Page 5

MEFI Inputs and Outputs ..........................Page 6

Engine Coolant Temperature (ECT)

Sensor.......................................................Page 7

Manifold Absolute Pressure (MAP)

Sensor.......................................................Page 7

Throttle Position (TP) Sensor....................Page 8

Intake Air Temperature (IAT) Sensor.........Page 8

Ignition Control (IC) Reference..................Page 8

Knock Sensor............................................Page 9

Discrete Switch Inputs...............................Page 9

Diagnosis ............................................................Page 10

Engine Control Module (ECM).......................Page 10

On-Board Service ...............................................Page 10

Engine Control Module (ECM)

Replacement..................................................Page 10

System Relay.................................................Page 11

Fuel Pump Relay ...........................................Page 11

Starter Relay..................................................Page 11

Engine Coolant Temperature (ECT)

Sensor............................................................Page 12

Manifold Absolute Pressure (MAP)/Intake Air

Temperature (IAT) Sensor (5.0/5.7L).............Page 13

Manifold Absolute Pressure (MAP)

Sensor (6.0/8.1L)...........................................Page 14

Throttle Position (TP) Sensor.........................Page 16

Idle Air Control (IAC) Valve............................Page 17

Knock Sensor (KS) (5.0/5.7L)........................Page 18

Knock Sensors (KS) (6.0L)............................Page 18

Torque Specifi cations ........................................Page 20

MEFI 4 - PCM

2 - 2 ECM and Sensors 5.0/5.7/6.0/8.1L

General Description

The Marine Electronic Fuel Injection (MEFI) system is

equipped with a computer that provides the operator with

state-of-the-art control of fuel and spark delivery. Before

we discuss the computers on the Marine applications,

let’s discuss how computers use voltage to send and

receive information.

Computers and Voltage Signals

Voltage is electrical pressure. Voltage does not flow

through circuits. Instead, voltage causes current. Current

does the real work in electrical circuits. It is current, the fl ow

of electrically charged particles, that energizes solenoids,

closes relays and illuminates lamps.

Besides causing current fl ow in circuits, voltage can be

used as a signal. Voltage signals can send information by

changing levels, changing waveform (shape) or changing

the speed (frequency( at which the signal switches from

one level to another. Computers use voltage signals to

communicate with one another. The different circuits

inside computers also use voltage signals to talk to each

other.

There are two kinds of voltage signals, analog and digital.

Both of these are used in computer systems. It is important

to understand the difference between them and the different

ways they are used.

Analog Signals

An analog signal is continuously variable. This means that

the signal can be any voltage within a certain range.

An analog signal usually gives information about a condition

that changes continuously over a certain range. For

example, in a marine engine, temperature is usually

provided by an analog signal. There are two general types

of sensors that produce analog signals, the 3-wire and

the 2-wire sensors.

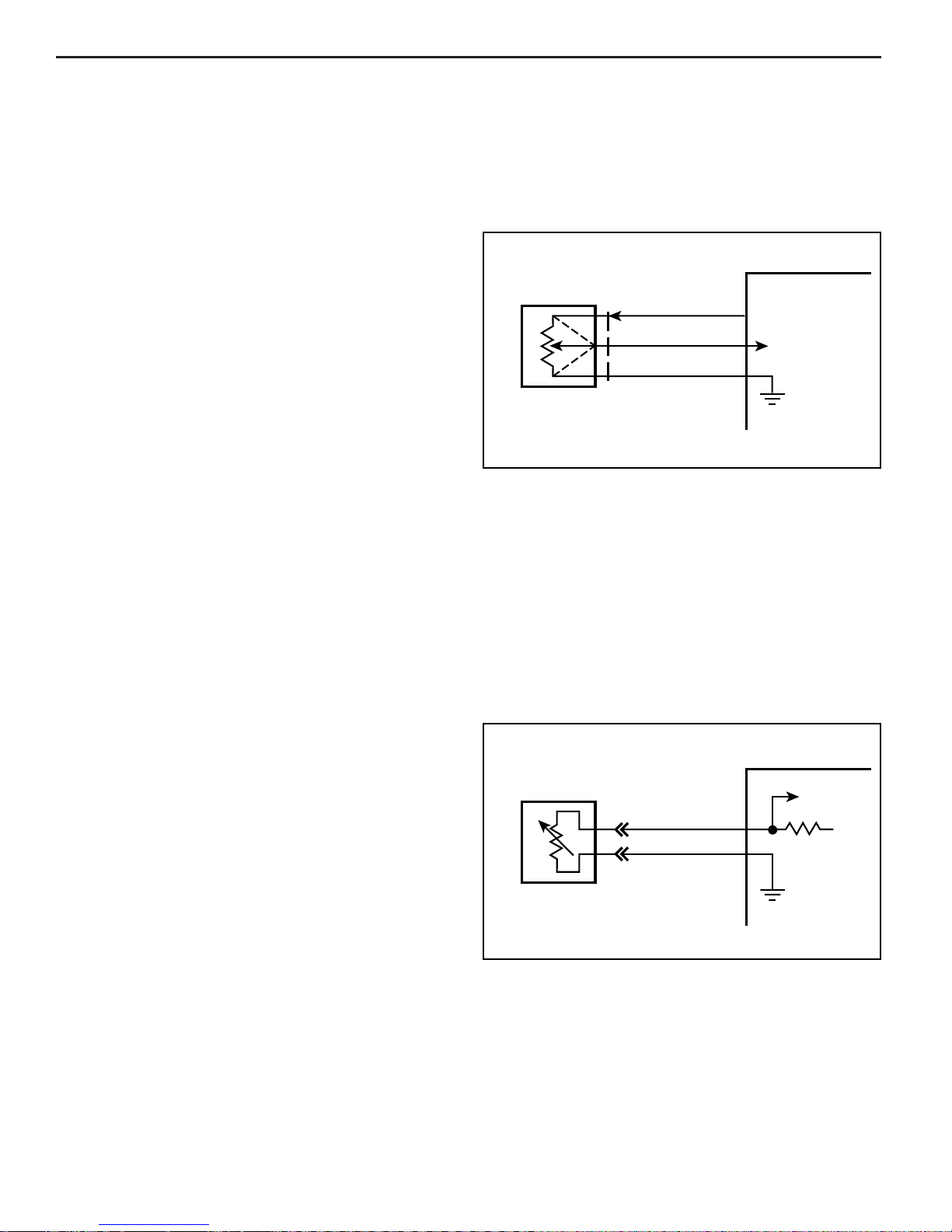

Three-Wire Sensors

Figure 2-1 shows a schematic representation of a 3-wire

sensor. All 3-wire sensors have a reference voltage, a

ground and a variable “wiper.” The lead coming off of the

“wiper” will be the signal to the Engine Control Module

(ECM). As this “wiper” position changes, the signal voltage

to the ECM also changes.

ECM

TYPICAL

SENSOR

Figure 2-1 - Three-Wire Sensors

VOLTAGE OUT

SIGNAL INPUT

4-24-91

MS 11697

Two-Wire Sensors

Figure 2-2 shows a schematic representation of a 2-wire

sensor. This sensor is basically a variable resistor in series

with a known-fi xed resistor within the ECM. By knowing

the values of the input voltage and the v oltage drop across

the known resistor, the value of the variable resistor can

be determined. The variable resistors that are commonly

used are called thermistors. A thermistor’s resistance

varies with temperature.

ECM

TYPICAL

SENSOR

SENSOR

SIGNAL

5V

MEFI 4 - PCM

SENSOR

GROUND

4-24-91

MS 11698

Figure 2-2 - Two-Wire Sensors

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 3

Digital Signals

Digital signals are also variable, but not continuously. They

can only be represented by distinct voltages within a range .

For example, 1V, 2V or 3V would be allowed, but 1.27V or

2.56V would not. Digital signals are especially useful when

the information can only refer to two conditions: “YES” and

“NO,” “ON” and “OFF” or “HIGH” and “LOW.” This would

be called a digital binary signal. A digital binary signal is

limited to two voltage lev els . One lev el is a positiv e voltage ,

the other is no voltage (zero volts). As y ou can see in Figure

2-3, a digital binary signal is a square wave.

The ECM uses digital signals in a code that contains only

ones and zeros. The high voltage of the digital signal

represents a one (1), and no voltage represents a zero (0).

Each “zero” and each “one” is called a bit of information,

or just a “bit.” Eight bits together are called a “word.”

A word, therefore, contains some combination of eight

binary code bits.

Binary code is used inside the ECM and between a

computer and any electronic device that understands the

code. By stringing together thousands of bits, computers can

communicate and store an infi nite varieties of information.

To a computer that understands binar y, 11001011 might

mean that it should turn an output device “ON” at slow

speed. Although the ECM uses 8-bit digital codes internally

and when talking to another computer, each bit can have

a meaning.

Switch T ypes

Switched inputs (also known as discretes) to the ECM can

cause one bit to change, resulting in information being

communicated to the ECM. Switched inputs can come

in two types: “pull-up” and “pull-down” types. Both types

will be discussed.

With “pull-up” type switch, the ECM will sense a voltage

when the switch is CLOSED. With “pull-down” type switch,

the ECM will sense a voltage when the switch is OPEN.

Pulse Counters

For the ECM to determine frequency information from a

switched input, the ECM must measure the time between

the voltage pulses. As a number of pulses are recorded in

a set amount of time, the ECM can calculate the frequency.

The meaning of the frequency number can have any

number of meanings to the ECM.

An example of a pulse counter type of input is the

Crankshaft Position (CKP) sensor input. The ECM can

count a train of pulses, a given number of pulses per

engine revolution. In this way, the ECM can determine

the RPM of the engine.

V

O

L

T

A

G

E

DIGITAL BINARY SIGNAL

TIME

4-18-91

MS 11696

Figure 2-3 - Digital Voltage Signal

MEFI 4 - PCM

2 - 4 ECM and Sensors 5.0/5.7/6.0/8.1L

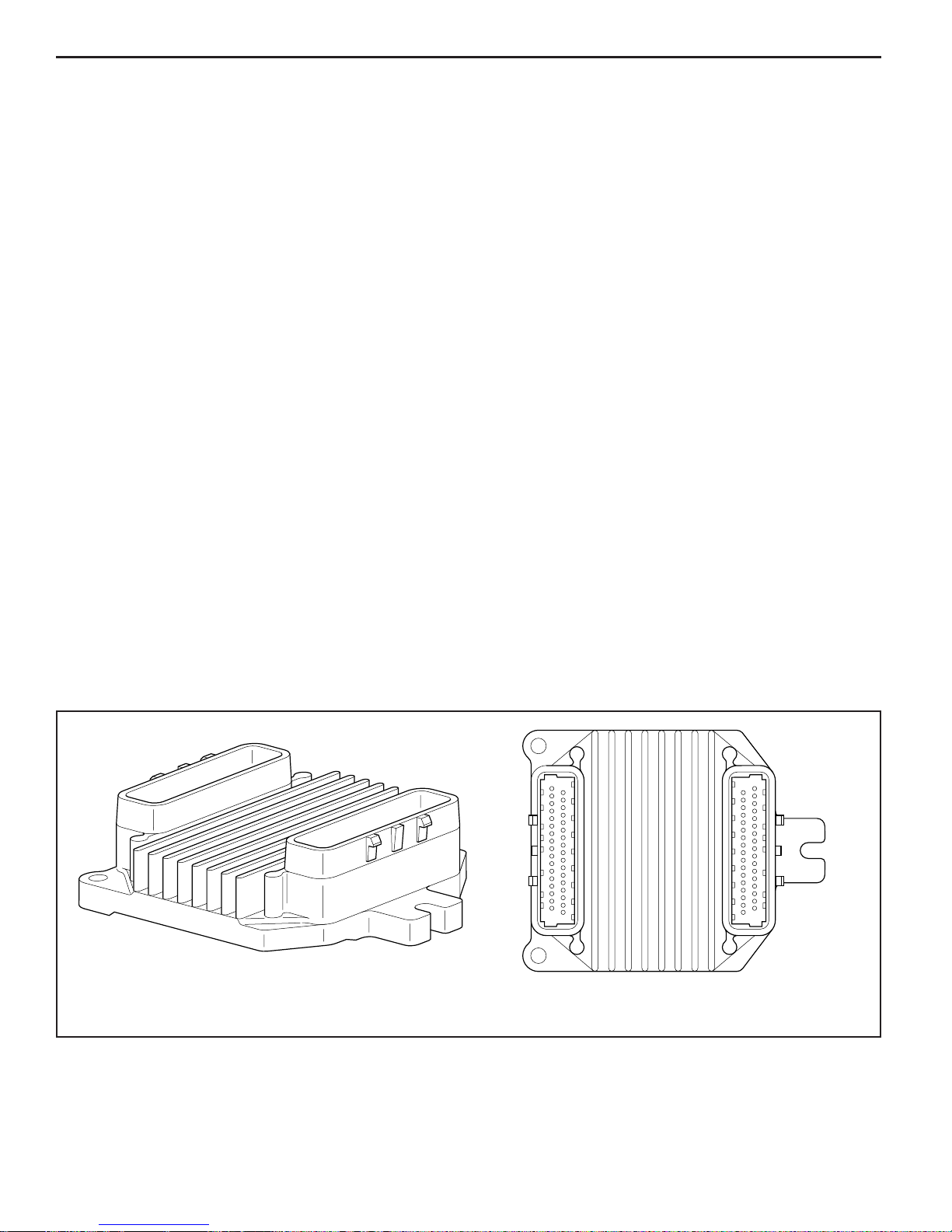

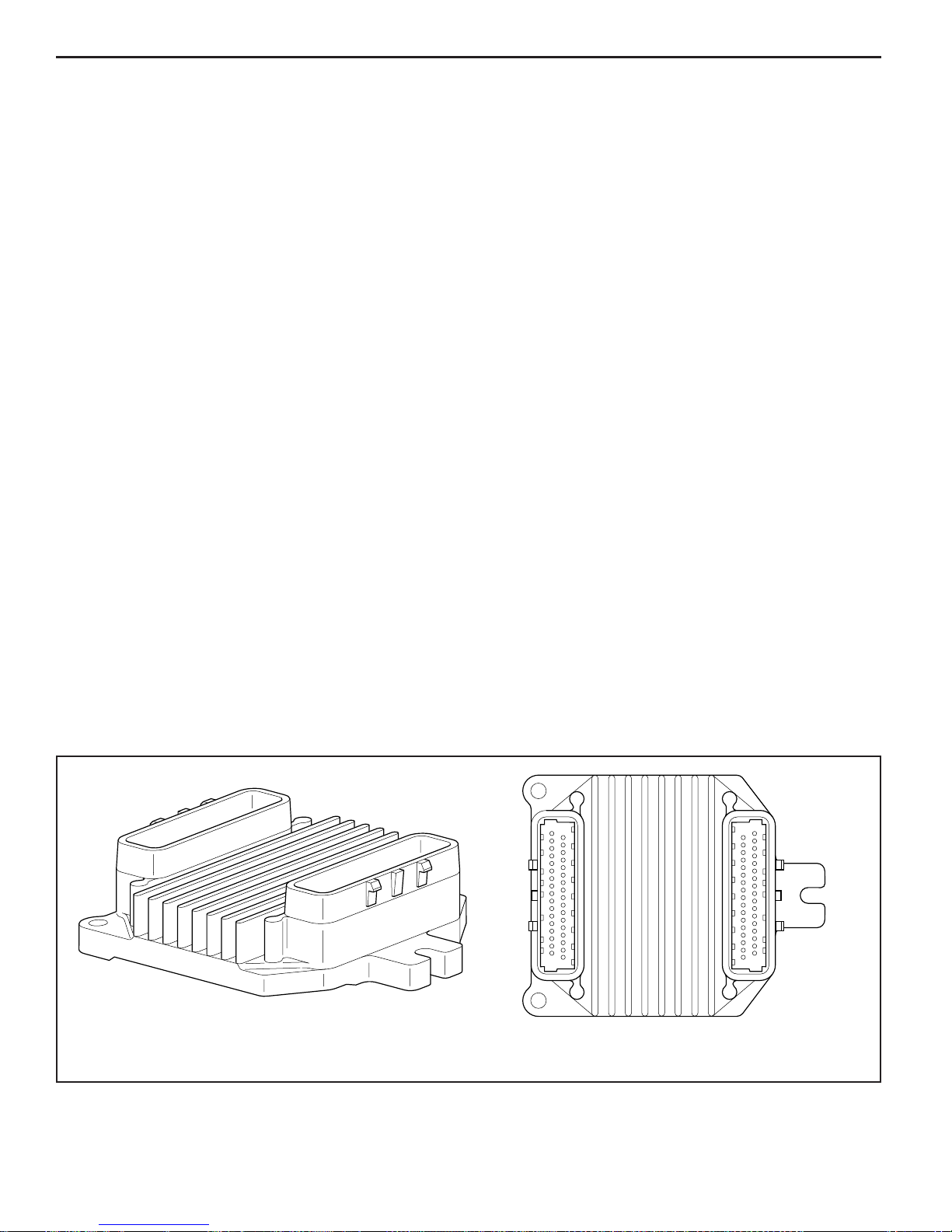

Engine Control Module (ECM)

The Engine Control Module (ECM), located on the engine,

is the control center of the fuel injection system. It controls

the following:

• Fuel control circuit

• Ignition control circuit

• Idle Air Control (IAC)

• Knock Sensor (KS) system

• On-board diagnostics for engine functions

It constantly looks at the information from various sensors,

and controls the systems that affect engine performance.

The ECM also performs the diagnostic function of the

system. It can recognize operational problems, alert the

operator through the MIL (Malfunction Indicator Lamp)

and store diagnostic trouble codes, or logged warnings,

which identify the problem areas to aid the technician

in making repairs. Refer to General Information section

for more information on using the diagnostic function

of the ECM.

ECM Function

The ECM supplies either 5 or 12 volts to power various

sensors or switches. This is done through resistances in

the ECM which are so high in value that a test light will

not light when connected to the circuit. In some cases,

even an ordinary shop voltmeter will not give an accurate

reading because its resistance is too low. Therefore, a

digital voltmeter with at least 10 megohms input impedance

is required to ensure accurate voltage readings. Tool J

39978 meets this requirement.

The ECM controls output circuits such as the injectors,

IAC, relays, etc. by controlling the ground or power feed

circuit.

Memory

There are three types of memory storage within the ECM.

They are ROM, RAM and EEPROM.

ROM

Read Only Memory (ROM) is a permanent memory that is

physically soldered to the circuit boards within the ECM.

The ROM contains the overall control programs. Once

the ROM is programmed, it cannot be changed. The ROM

memory is non-erasable, and does not need power to

be retained.

RAM

Random Access Memory (RAM) is the microprocessor

“scratch pad.” The processor can write into, or read from

this memory as needed. This memory is erasable and

needs a constant supply of voltage to be retained. If the

voltage is lost, the memory is lost.

EEPROM

The Electronically Erasable Programmable Read Only

Memory (EEPROM) is a permanent memory that is

physically soldered within the ECM. The EEPROM contains

program and calibration information that the ECM needs

to control engine operation.

The EEPROM is not replaceable. If the ECM is replaced,

the new ECM will need to be programmed by the engine

manufacturer with the calibration inf ormation that is specifi c

to each marine application.

MEFI 4 - PCM

J2J1

MEFI3004

Figure 2-4 - Engine Control Module (ECM)

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 5

Speed Density System

The Marine Electronic Fuel Injection (MEFI) system is a

speed and air density system. The system is based on

“speed density” fuel management.

Sensors provide the ECM with the basic information for

the fuel management portion of its operation. Signals

to the ECM establish the engine speed and air density

factors.

Speed

The engine speed signal comes from the CKP sensor to

the ECM. The ECM uses this information to determine the

“speed” or RPM factor for fuel and spark management.

Density

One particular sensor contributes to the density factor,

the Manifold Absolute Pressure (MAP) sensor. The MAP

sensor is a 3-wire sensor that monitors the changes in

intake manifold pressure which results from changes in

engine loads. These pressure changes are supplied to the

ECM in the form of electrical signals.

As intake manifold pressure increases, the vacuum

decreases. The air density in the intake manifold also

increases, and additional fuel is needed.

The MAP sensor sends this pressure information to the

ECM, and the ECM increases the amount of fuel injected,

by increasing the injector pulse width. As manifold pressure

decreases, the vacuum increases, and the amount of

fuel is decreased.

These two inputs, MAP and RPM, are the major

determinants of the air/fuel mixture delivered by the fuel

injection system. The remaining sensors and switches

provide electrical inputs to the ECM, which are used for

modifi cation of the air/fuel mixture, as well as for other

ECM control functions, such as idle control.

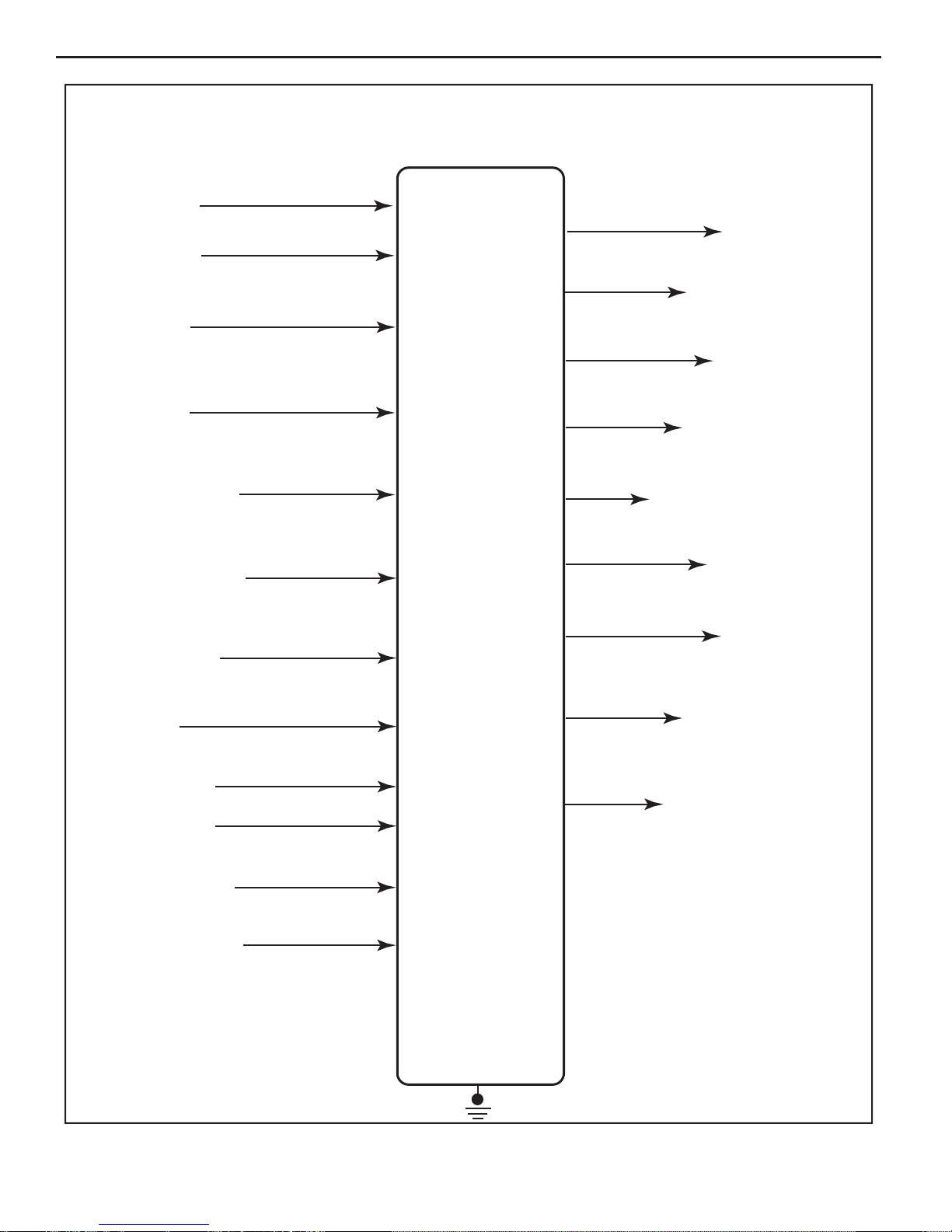

ECM Inputs and Sensor Descriptions

Figure 2-5 lists the data sensors, switches, and other inputs

used by the ECM to control its various systems. Although

we will not cover them all in great detail, there will be a

brief description of each.

Input Components

The ECM monitors the input components for circuit

continuity and out-of-range values. This includes

performance checking. Performance checking refers to

indicating a fault when the signal from a sensor does not

seem reasonable, such as a throttle position (TP) sensor

that indicates high throttle position at low engine loads or

MAP voltage. The input components may include, but are

not limited to, the following sensors:

• Intake air temperature (IAT) sensor (5.0/5.7L only)

• Crankshaft position (CKP) sensor

• Camshaft position (CMP) sensor

• Knock sensor(s) (KS)

• Throttle position (TP) sensor

• Engine coolant temperature (ECT) sensor

• Manifold absolute pressure (MAP) sensor

Output Components

Diagnose the output components for the proper response

to ECM commands. Components where functional

monitoring is not feasible, will be monitored for circuit

continuity and out-of-range values, if applicable.

Output components to be monitored include, but are not

limited to, the following circuits:

• The malfunction indicator lamp (MIL) control

• The check gauges lamp control

• The general warning 2 (low oil pressure) lamp

control

MEFI 4 - PCM

2 - 6 ECM and Sensors 5.0/5.7/6.0/8.1L

MEFI INPUTS AND OUTPUTS

INPUTS

BATTERY 12V

IGNITION 12V

CRANKSHAFT

POSITION

SENSOR (RPM)

CAMSHAFT

POSITION

SENSOR

THROTTLE POSITION

(TP) SENSOR

MANIFOLD ABSOLUTE

PRESSURE(MAP)

(TYPICAL)

E

L

E

C

T

R

O

N

I

C

OUTPUTS

FUEL INJECTORS

MULTIPLE

IGNITION CONTROLS (IC)

FUEL PUMP RELAY

IDLE AIR CONTROL (IAC)

OPERATOR INFORMATION

LAMPS/BUZZERS

SERIAL DATA (ECM

COMMUNICATION)

ENGINE COOLANT

TEMPERATURE (ECT)

SENSOR

INTAKE AIR

TEMPERATURE (IAT) (5.0/5.7L only)

KNOCK SENSOR 1

KNOCK SENSOR 2

(6.0/8.1L only)

DIAGNOSTIC ENABLE

GENERAL WARNING 2

(OIL PRESSURE)

C

O

N

T

R

O

L

M

O

D

U

L

E

V- REFERENCE

(5 VOLT OUTPUT

TO SENSORS)

MALFUNCTION INDICATOR

LAMP (MIL)

DEPSPOWER

(12 VOLT OUTPUT

TO SENSORS)

Figure 2-5 - ECM Inputs and Outputs (Typical)

MEFI 4 - PCM

2-13-04

MS 11699

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 7

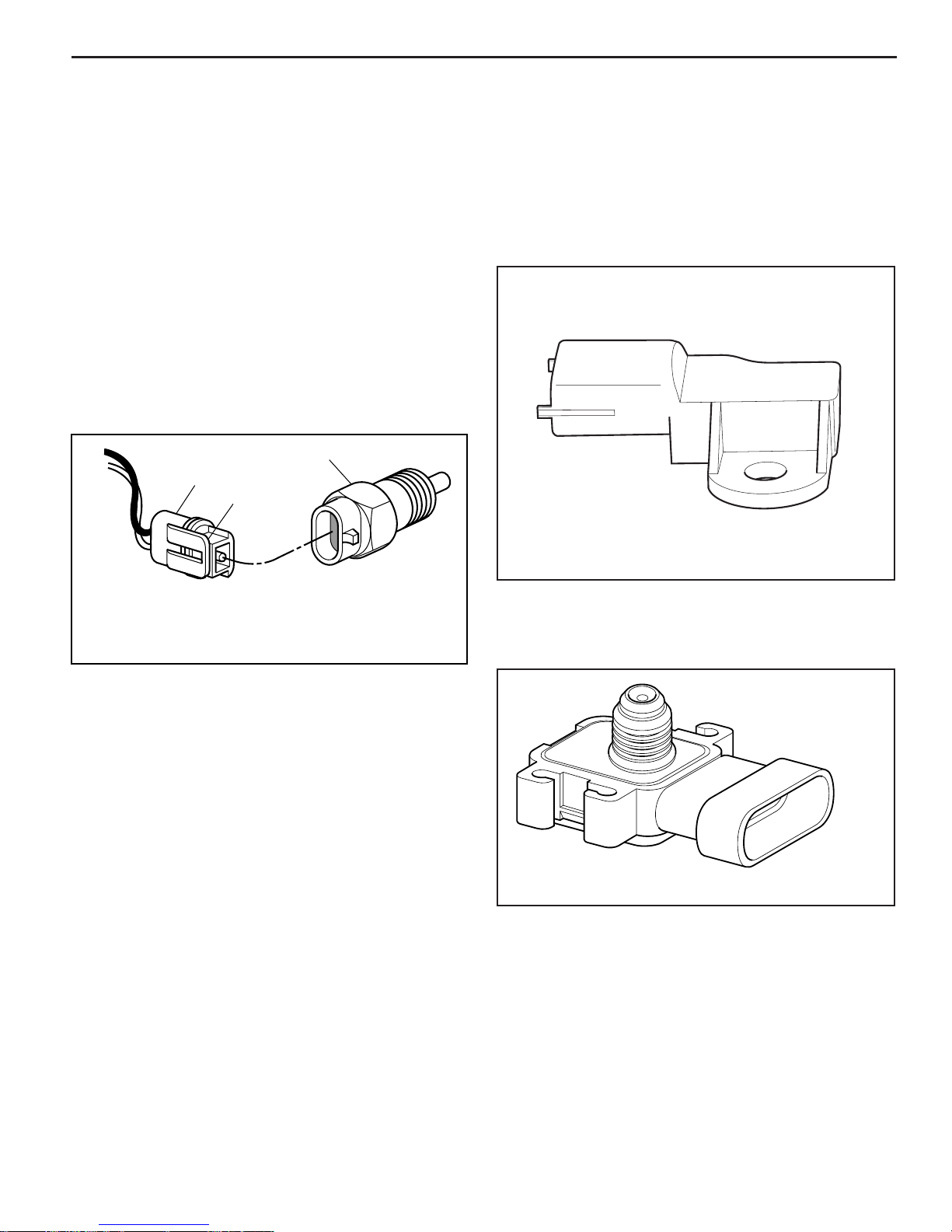

Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature (ECT) sensor is a

thermistor (a resistor which changes value based on

temperature) mounted in the engine coolant stream. Low

coolant temperature produces a high resistance (100,000

ohms at -40°C/-40°F) while high temperature causes low

resistance (70 ohms at 130°C/266°F).

The ECM supplies a 5 volt signal to the ECT sensor

through a resistor in the ECM and measures the voltage.

The voltage will be high when the engine is cold, and low

when the engine is hot. By measuring the v oltage, the ECM

calculates the engine coolant temperature. Engine coolant

temperature affects most systems the ECM controls.

A hard fault in the engine coolant sensor circuit should

set DTC 14 or DTC 15; an intermittent fault may or may

not set a DTC. The DTC “Diagnostic Aids” also contains

a chart to check for sensor resistance values relative

to temperature.

3

1

2

The ECM supplies a 5 volt reference voltage to the MAP

sensor. As the manifold pressure changes, the electrical

resistance of the MAP sensor also changes. By monitoring

the sensor output voltage, the ECM knows the manifold

pressure. A higher pressure, low vacuum (high voltage)

requires more fuel. A lower pressure, high vacuum (low

voltage) requires less fuel. The ECM uses the MAP sensor

to control fuel delivery and ignition timing. A failure in the

MAP sensor circuit should set a DTC 33 or DTC 34.

1HARNESS CONNECTOR

2LOCKING TAB

3SENSOR

Figure 2-6 - Engine Coolant Temperature (ECT) Sensor

8-24-94

RS 22189

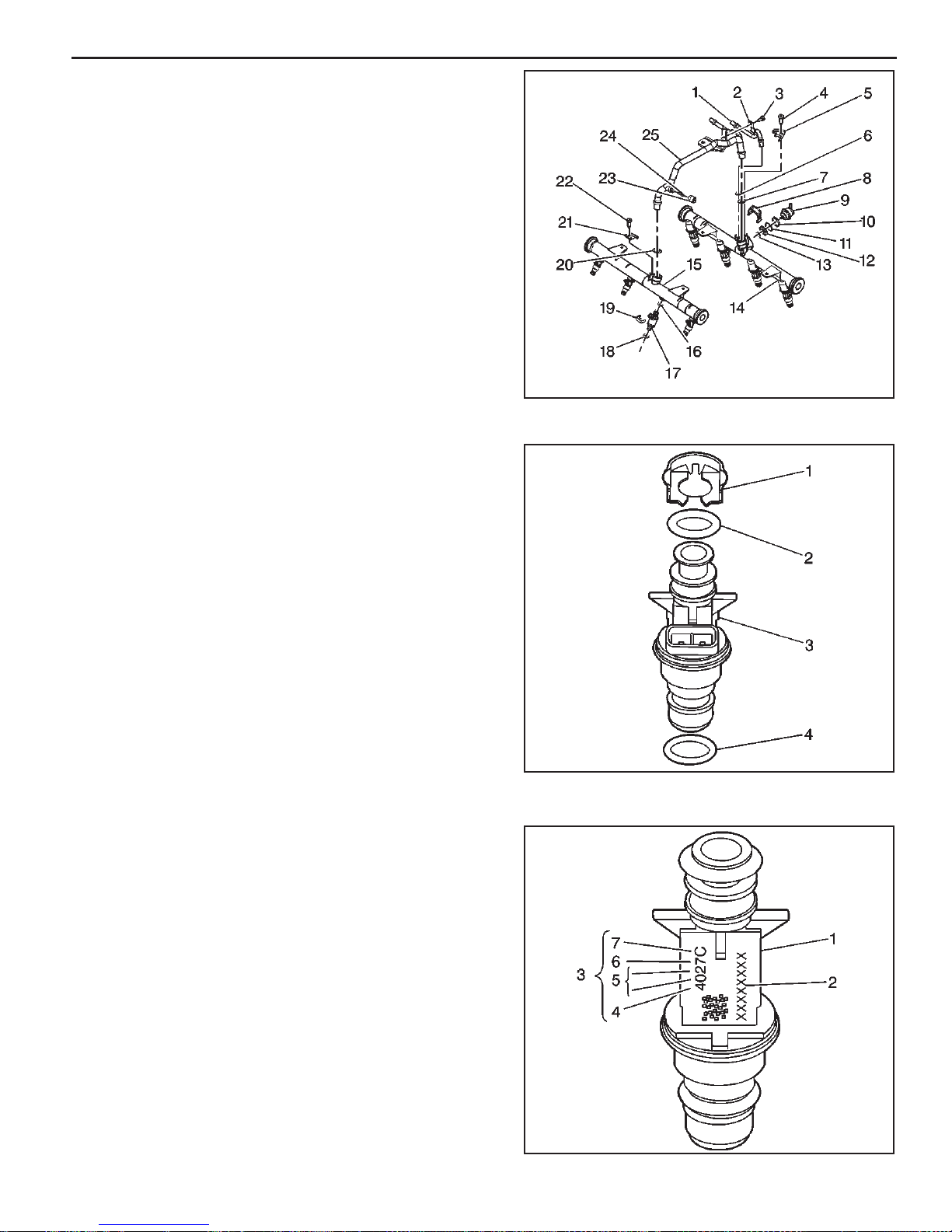

Manifold Absolute Pressure (MAP) Sensor

The Manifold Absolute Pressure (MAP) sensor is a

pressure transducer that measures the changes in the

intake manifold pressure. The pressure changes as a result

of engine load and speed change, and the MAP sensor

converts this into a voltage output.

A closed throttle on engine coastdown would produce

a relatively low MAP output voltage, while a wide open

throttle would produce a high MAP output voltage. This

high output voltage is produced because the pressure

inside the manifold is almost the same as outside the

manifold, so you measure almost 100% of outside air

pressure. MAP is the opposite of what you would measure

on a vacuum gauge. When manifold pressure is high,

vacuum is low, causing a high MAP output voltage.

The MAP sensor is also used to measure barometric

pressure under certain conditions, which allows the ECM

to automatically adjust for different altitudes.

Figure 2-7 - Manifold Absolute Pressure (MAP) Sensor/

Intake Air Temperature (IAT) Sensor

(Used On 5.0/5.7L Engines)

I 22312

Figure 2-8 - Manifold Absolute Pressure (MAP) Sensor

(Used On 6.0/8.1L Engines)

MEFI 4 - PCM

2 - 8 ECM and Sensors 5.0/5.7/6.0/8.1L

Throttle Position (TP) Sensor

The Throttle Position (TP) sensor is a potentiometer

connected to the throttle shaft on the throttle body.

By monitoring the voltage on the signal line, the ECM

calculates throttle position. As the throttle valve angle is

changed (accelerator pedal moved), the TP sensor signal

also changes. At a closed throttle position, the output of the

TP sensor is low. As the throttle valve opens, the output

increases so that at Wide Open Throttle (WOT), the output

voltage should be above 4 volts.

The ECM calculates fuel delivery based on throttle valve

angle (driver demand). A broken or loose TP sensor

may cause intermittent bursts of fuel from an injector

and unstable idle because the ECM thinks the throttle is

moving. A hard failure in the TP sensor circuit should set

either a DTC 21 or DTC 22. Once a DTC is set, the ECM

will use a calibratible default value for throttle position and

some engine performance will return.

Intake Air Temperature (IAT) Sensor (5.0/5.7L)

The Intake Air Temperature (IAT) sensor is a thermistor

which changes value based on the temperature of air

entering the engine (Figure 2-12). Low temperature

produces a high resistance (100,000 ohms at -40°C/-40°F)

while high temperature causes low resistance (70 ohms

at 130°C/266°F).

The ECM supplies a 5 volt signal to the sensor through a

resistor in the ECM and measures the voltage. The voltage

will be high when the incoming air is cold, and low when

the incoming air is hot. By measuring the voltage, the

ECM calculates the incoming air temperature. The IAT

sensor signal is used to determine spark timing based on

incoming air density.

The scan tool displays temperature of the air entering the

engine, which should read close to ambient air temperature

when engine is cold, and rise as engine compartment

temperature increases. If the engine has not been run for

several hours (overnight), the IAT sensor and ECT sensor

temperatures should read close to each other. A failure in

the IAT sensor circuit should set DTC 23 or DTC 25.

1

2

1 THROTTLE POSITION (TP) SENSOR

2 TP SENSOR ATTACHING SCREW

Figure 2-10 - Throttle Position (TP) Sensor (Typical)

C

B

A

2

CONTROL

MODULE

1

RS 22191

Figure 2-12 - Manifold Absolute Pressure (MAP) Sensor/

Intake Air Temperature (IAT) Sensor

(Used On 5.0/5.7L Engines)

Ignition Control (IC) Reference

The Ignition Control (IC) reference (RPM signal) is supplied

to the ECM by way of the crankshaft position sensor. This

pulse counter type input creates the timing signal for the

pulsing of the fuel injectors, as well as the IC functions.

This signal is used for a number of control and testing

functions within the ECM.

1 THROTTLE POSITION (TP) SENSOR

2 THROTTLE VALVE

Figure 2-11 - Throttle Position (TP) Sensor (Typical)

MEFI 4 - PCM

RS 22192

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 9

Knock Sensor (KS) System Description

Purpose:

To control spar k knock (detonation), a knock sensor

(KS) system is used. This system is designed to retard

spark timing when excessive spark knock is detected

in the engine. The KS system allows the engine to use

maximum spark advance for optimal driveability and fuel

economy under all operating conditions.

Operation:

The ECM uses a knock sensor(s) to detect abnormal

vibration in the engine (detonation/spark knock).

Mounted on the engine block, the knock sensor(s)

produces an AC voltage signal at all engine speeds and

loads. The ECM then adjusts the spar k timing based on

the amplitude and frequency of the KS signal. The ECM

uses the KS signal to calculate an average voltage.

Then, the ECM assigns a voltage range above and

below the average voltage value. The ECM checks the

KS and related wiring by comparing the actual knock

signal to the assigned voltage range. A normal KS

signal should vary outside the assigned voltage range

as shown in the NORMAL KS fi gure. If the ECM detects

a KS signal within the assigned voltage range as shown

in the ABNORMAL KS fi gure, the applicable DTC will

set.

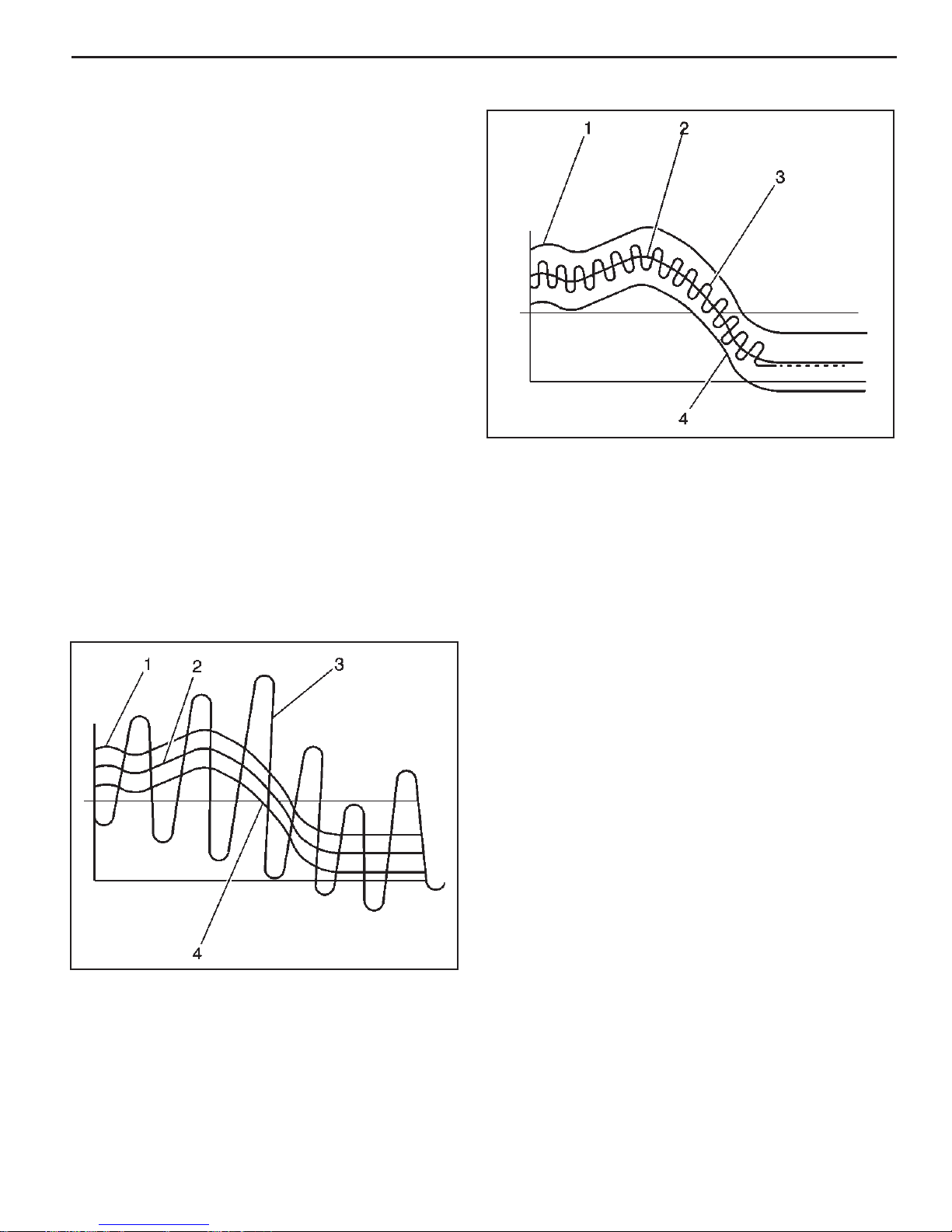

Abnormal Knock Sensor Signal

Legend

1. Upper fail region

2. Knock sensor calculated average

3. Knock sensor signal

4. Lower fail region

245257

Normal Knock Sensor Signal

245253

Discrete Switch Inputs

Several discrete switch inputs are utilized by the MEFI

system to identify abnormal conditions that may affect

engine operation. Pull-up and pull-down type switches are

currently used in conjunction with the ECM to detect critical

conditions to engine operation.

If a switch changes states from its normal at rest position,

that is, normally closed to open, or normally open to closed,

the ECM senses a change in voltage and responds by

entering Power reduction mode.

This engine protection feature allows the operator normal

engine operations up to 2500 RPM, but disables half the

fuel injectors until the engine drops below 1200 RPM.

Then normal engine operation is restored until the RPM

limit is exceeded. This feature allows the operator a safe

maneuvering speed while removing the possibility of high

RPM engine operation until the problem is corrected.

Switches that may be used with the MEFI system to detect

critical engine operation parameters are:

• Oil Pressure

MEFI 4 - PCM

2 - 10 ECM and Sensors 5.0/5.7/6.0/8.1L

Diagnosis

Engine Control Module (ECM)

To read and clear diagnostic trouble codes, use a scan tool

or Diagnostic Trouble Code (DTC) tool.

Important: Use of a scan tool is recommended to clear

diagnostic trouble codes from the ECM memory . Diagnostic

trouble codes can also be cleared by using the DTC tool.

Since the ECM can have a failure which may affect more

than one circuit, following the diagnostic procedures will

determine which circuit has a problem and where it is.

If a diagnostic procedure indicates that the ECM connections

or ECM is the cause of a problem and the ECM is replaced,

but does not correct the problem, one of the following

may be the reason:

• Check for good ECM power and grounds.

• There is a problem with the ECM terminal connections.

The diagnostic table will say ECM connections or

ECM. The terminals may have to be removed from the

connector in order to check them properly.

• EEPROM program is not correct for the application.

Incorrect components may cause a malfunction and

may or may not set a DTC.

• The problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the Symptoms portion

of the manual and make a careful physical inspection

of all portions of the system involved.

• Shorted relay coil or harness. Relays are turned

“ON” and “OFF” by the ECM using internal electronic

switches called drivers. A shorted relay coil or harness

may not damage the ECM but will cause the relay

to be inoperative.

On-Board Service

Engine Control Module (ECM) Replacement

Notice: When replacing the ECM, the ignition must be

“OFF” and disconnect the battery before disconnecting or

reconnecting the ECM “J1” and “J2” connectors to prevent

internal damage to the ECM.

Notice: T o prev ent possible electrostatic discharge damage

to the ECM, do not touch the connector pins. The ECM is

an electrical component. Do Not soak in any liquid cleaner

or solvent, as damage may result.

Remove or Disconnect

1. Negative battery cable.

2. “J1” and “J2” connectors from ECM.

3. The ECM mounting screws.

4. ECM from mounting bracket.

Important

• Make sure the new ECM has the same part number

and service number as the old ECM, to insure proper

engine performance.

Install or Connect

1. New ECM to mounting bracket.

2. The ECM mounting screws. Torque to 10-14 N•m

(88-124 lb in).

3. “J1” and “J2” connectors to ECM.

4. Negative battery cable.

MEFI 4 - PCM

J2J1

MEFI3004

Figure 2-13 - Engine Control Module (ECM)

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 11

System Relay Replacement

Removal Procedure

1. Tur n the ignition OFF.

2. Remove the retainer.

3. Disconnect the system relay electrical connector.

4. Remove the system relay.

Important: The system relay is an electrical component.

Do Not soak in any liquid or solvent as damage may

result.

Installation Procedure

1. Install the system relay.

2. Reconnect the system electrical connector.

3. Install the retainer clip.

mefi 4337

Fuel Pump Relay Replacement

Removal Procedure

1. Turn the ignition OFF.

2. Remove the retainer.

3. Disconnect the fuel pump relay electrical connector.

4. Remove the fuel pump relay.

Important: The fuel pump relay is an electrical

component. Do Not soak in any liquid or solvent as

damage may result.

Installation Procedure

1. Install the fuel pump relay.

2. Reconnect the fuel pump relay electrical connector.

3. Install the retainer clip.

mefi 4337

Starter Relay Replacement

Removal Procedure

1. Turn the ignition OFF.

2. Remove the retainer.

3. Disconnect the star ter relay electrical connector.

4. Remove the starter relay.

Important: The starter relay is an electrical component.

Do Not soak in any liquid or solvent as damage may

result.

Installation Procedure

1. Install the starter relay.

2. Reconnect the star ter relay electrical connector.

3. Install the retainer clip.

mefi 4337

MEFI 4 - PCM

2 - 12 ECM and Sensors 5.0/5.7/6.0/8.1L

Engine Coolant Temperature (ECT) Sensor

Replacement

Notice: Care must be taken when handling the ECT

sensor. Damage to the sensor will affect proper operation

of the MEFI system.

Remove or Disconnect

1. Turn OFF the ignition.

2. Drain the cooling system below the level of the ECT

sensor (if necessary).

3. Disconnect the ECT electrical connector.

4. Remove the ECT sensor.

mefi 4333

Installation Procedure

Important: Coat ECT sensor threads with Tefl on tape

sealant prior to installation.

1. Install the ECT sensor.

Tighten

Tighten the ECT sensor to 20 N•m (15 lb ft).

2. Reconnect the ECT electrical connector.

3. Refi ll the cooling system (if necessary).

MEFI 4 - PCM

mefi 4333

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 13

Manifold Absolute Pressure (MAP) / Intake

Air Temperature (IAT) Sensor Replacement

(5.0/5.7L)

Removal Procedure

1. Remove the MAP sensor retaining stud.

2. Remove the MAP sensor from the intake manifold.

3. Inspect the MAP sensor seal for wear or damage and

replace as necessary.

map rr

Installation Procedure

Important: Lightly coat the MAP sensor seal with rubber

lubricant before installing the sensor. The lubricant should

be applied with a sponge or brush. To prevent blockage,

avoid dipping the sensor port directly into the lubricant.

1. Install the MAP sensor.

2. Install the MAP sensor retaining stud.

Tighten

Tighten the MAP sensor retaining stud to 12 N•m

(106 lb in).

3. Connect the manifold absolute pressure (MAP) sensor

electrical connector.

map rr

MEFI 4 - PCM

2 - 14 ECM and Sensors 5.0/5.7/6.0/8.1L

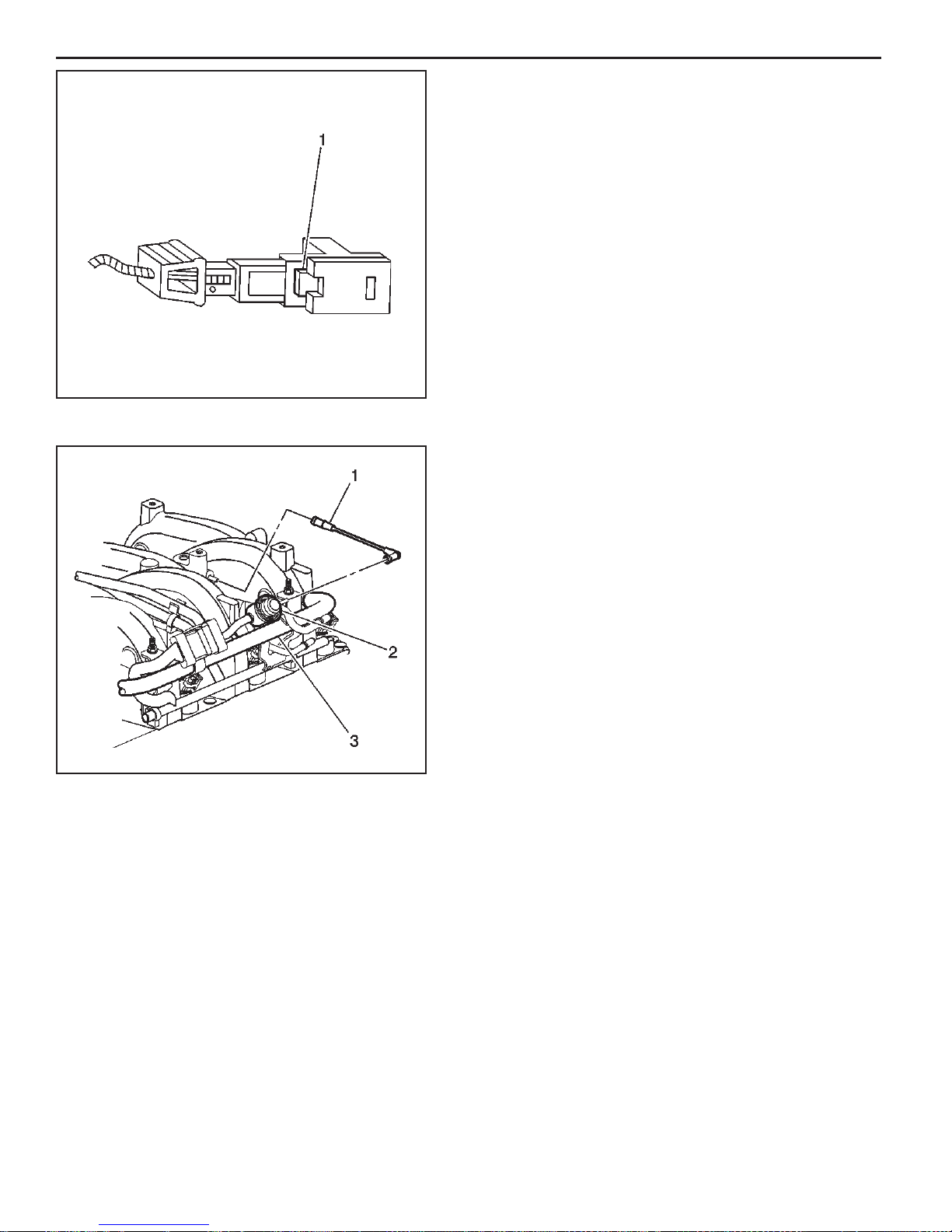

Manifold Absolute Pressure (MAP) Sensor

Replacement (6.0/8.1L)

1

684798

Removal Procedure

1. Disconnect the manifold absolute pressure (MAP)

sensor electrical connector (1).

2. Remove the MAP sensor retaining bolt and washer

(1).

3. Remove the MAP sensor (3) from the intake manifold

(2).

4. Inspect the MAP sensor seal for wear or damage and

replace as necessary.

MEFI 4 - PCM

684801

Installation Procedure

Important: Lightly coat the MAP sensor seal with rubber

lubricant before installing the sensor. The lubricant should

be applied with a sponge or brush. To prevent blockage,

avoid dipping the sensor port directly into the lubricant.

1. Install the MAP sensor (3).

2. Install the MAP sensor retaining bolt and washer (1).

Tighten

Tighten the MAP sensor retaining bolt to 12 N•m

(106 lb in).

684801

5.0/5.7/6.0L/8.1L ECM and Sensors 2 - 15

3. Connect the MAP sensor electrical connector (1).

1

684798

MEFI 4 - PCM

2 - 16 ECM and Sensors 5.0/5.7/6.0/8.1L

Throttle Position (TP) Sensor

Remove or Disconnect

1. Flame arrestor.

2. TP sensor electrical connector.

3. TP sensor attaching screws (1).

4. TP sensor (2).

1

Important

• The TP sensor is an electrical component. Do Not

soak in any liquid cleaner or solvent, as damage

may result.

• If replacing TP sensor, install new screws that are

2