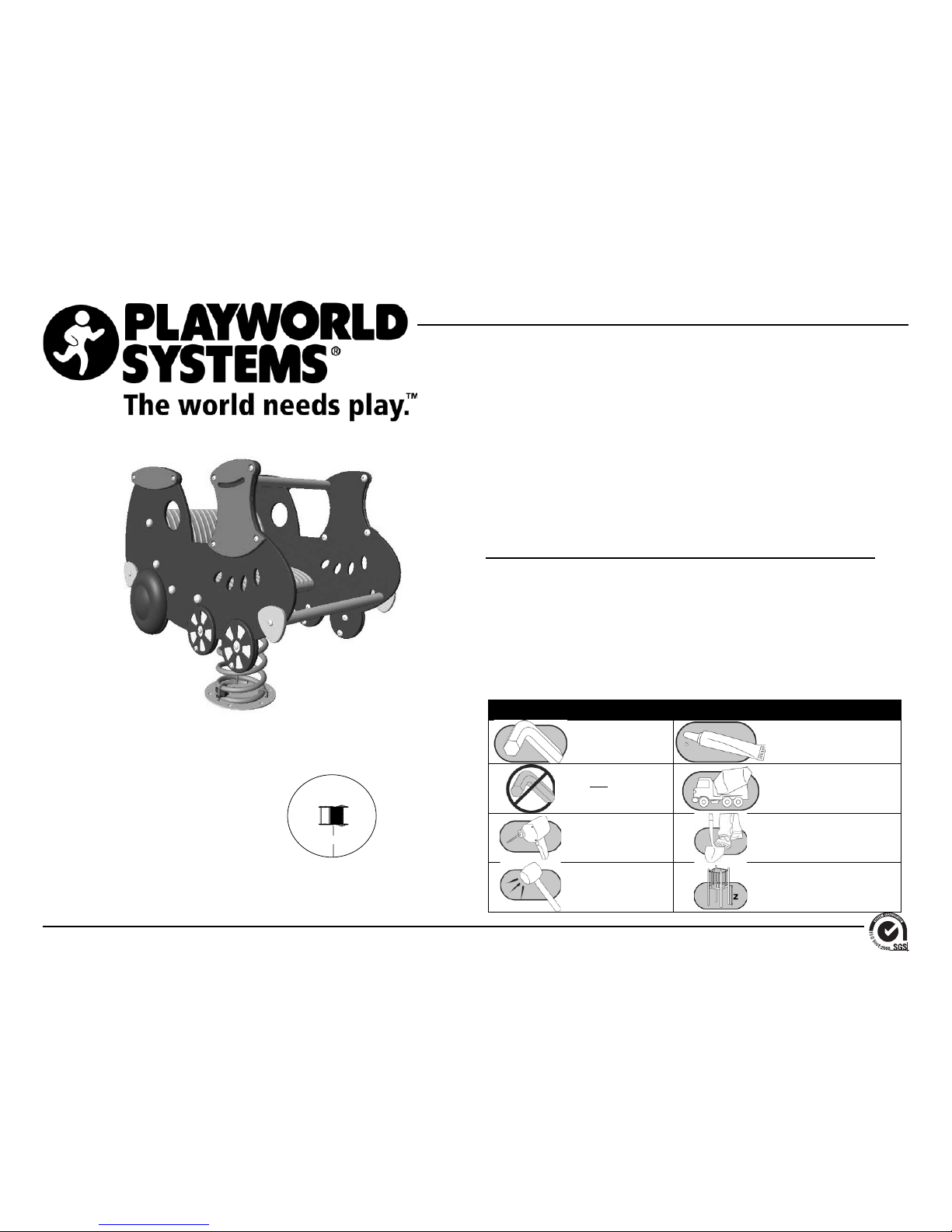

Playworld Systems XX0549, XX0550 Installation Instructions Manual

Installation Instructions

Models XX0549 & XX0550

ECN 1867

Page 1 of 12

Installation Instructions

Playworld Systems® Models XX0549 & XX0550

Train Spring Rider & Train Spring Rider w/ Sound

Installation Preparation

Recommended Crew: ...........................Two (2) adults

Installation Time: ...................................2 man-hours

Weight: ..................................................100.9 Lbs. (45,8 Kilos)

Use Zone: ..............................................Refer to the information below

User Group Age (years): .......................ASTM/CSA: 2-12, EN: 2-14

Assembly View (representative structure)

Refer to the Elevation View for the specifi c Critical Fall Height for the component.

ICON KEY

Fully Tighten

Hardware

Add 1 Drop of

Thread Locking Adhesive

Do Not Fully Tighten

Hardware

Pour Concrete

Drill Dig Footing Holes

Hammer Critical Fall Height

Spring Rider Use Zones

A = ASTM: 72 in. (1829 mm)

CSA: 1800 mm

EN: 1000 mm

A

Installation Instructions

Models XX0549 & XX0550

ECN 1867

Page 2 of 12

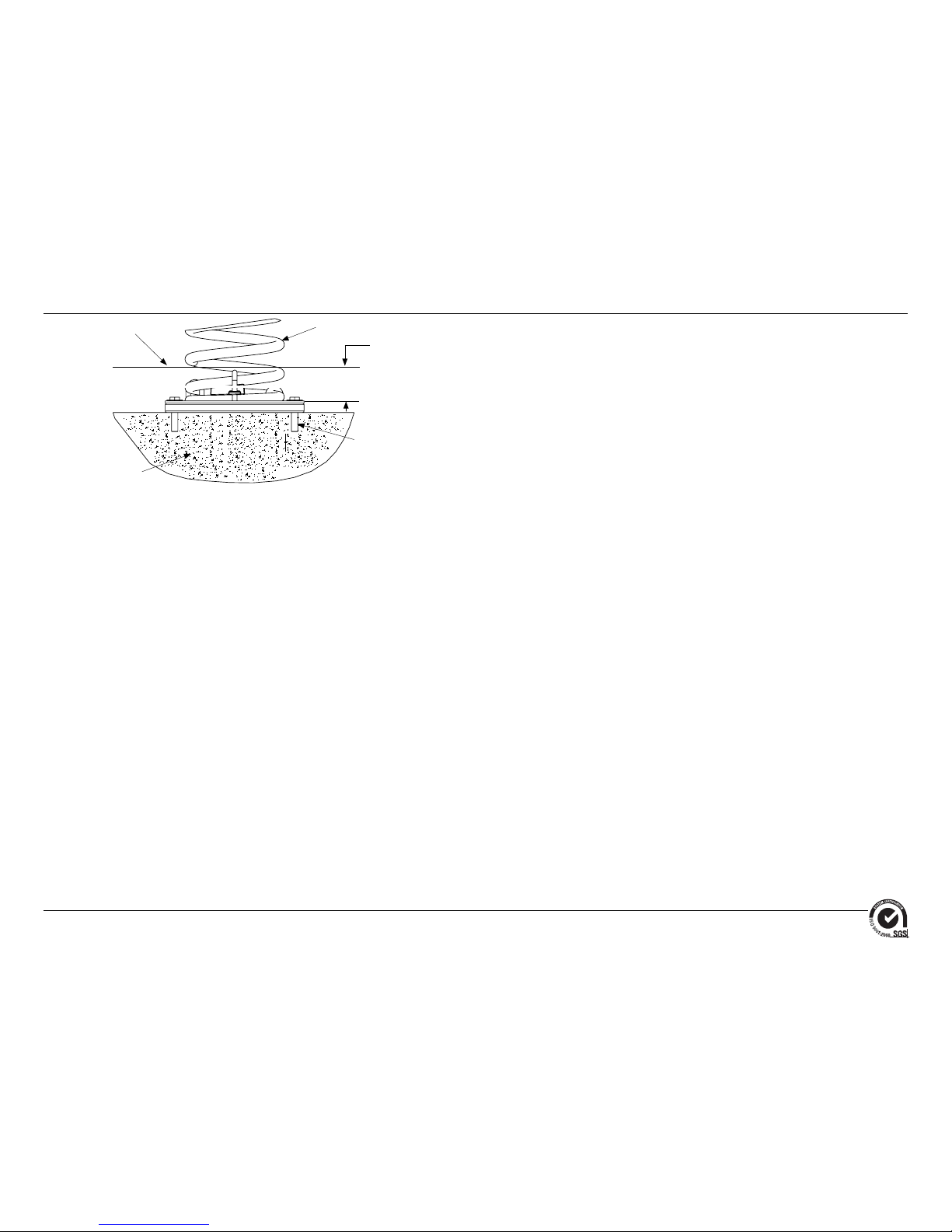

FOOTING NOTES

• Footing size may vary due to local soil and weather conditions.

• The base of the footing must be below frost line.

Surface mount hardware is not supplied. Customer is responsible for

concrete base and providing surface mount hardware as specifi ed by a

registered structural engineer for each specifi c project application.

Concrete Base

Anchor Bolts

Supplied By

Customer

Protective

Surfacing Level

Coil Spring

2" in. (51 mm)

Coil Spring Surface Mount Footing Detail

Installation Instructions

Models XX0549 & XX0550

ECN 1867

Page 3 of 12

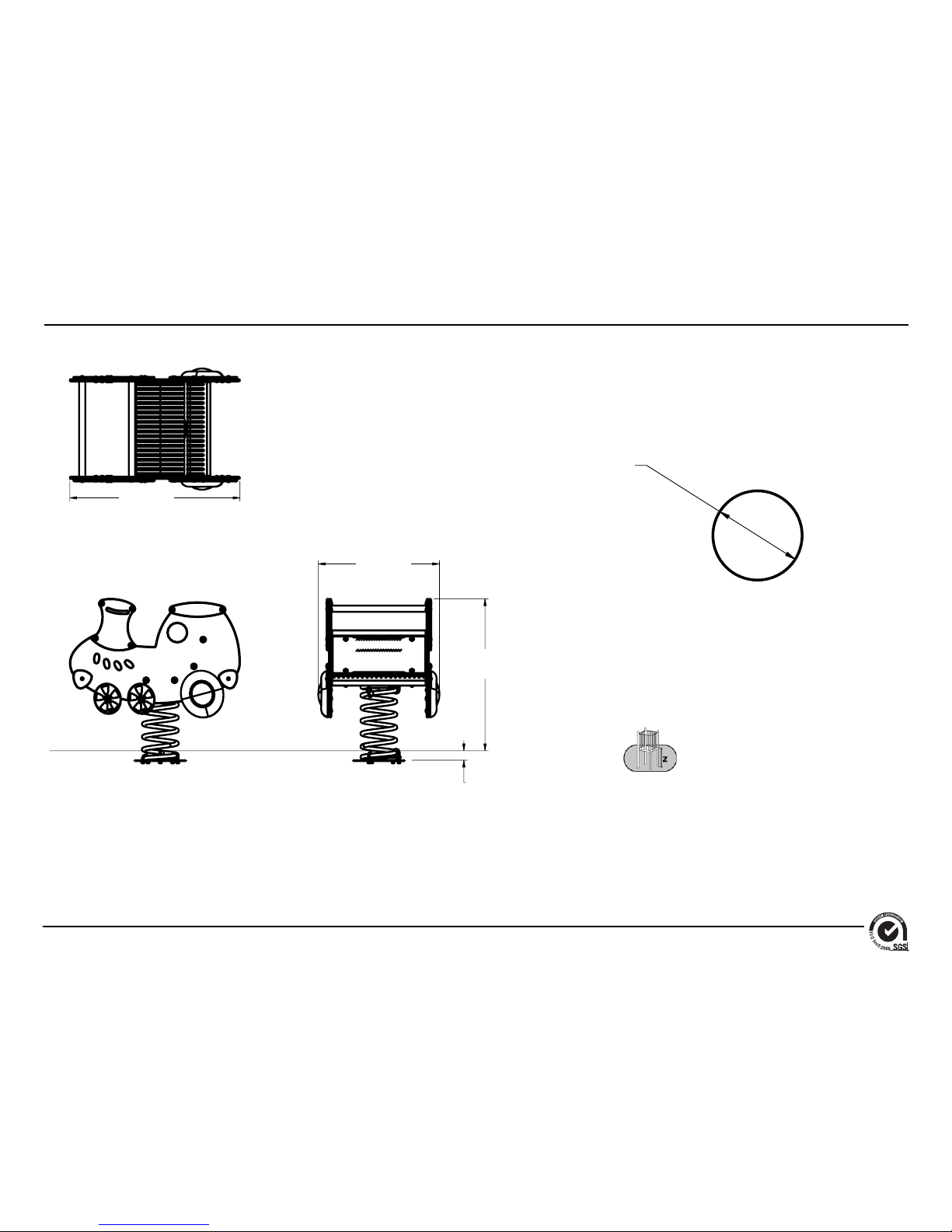

Top View

Elevation Views

XX0549 & XX0550

Footing Diagram

EN: 432 mm

36"

(914 mm)

25.6"

(651 mm)

32.2"

(817 mm)

2"

(51 mm)

Surfacing Level

12"

(305 mm)

Diameter

Installation Instructions

Models XX0549 & XX0550

ECN 1867

Page 4 of 12

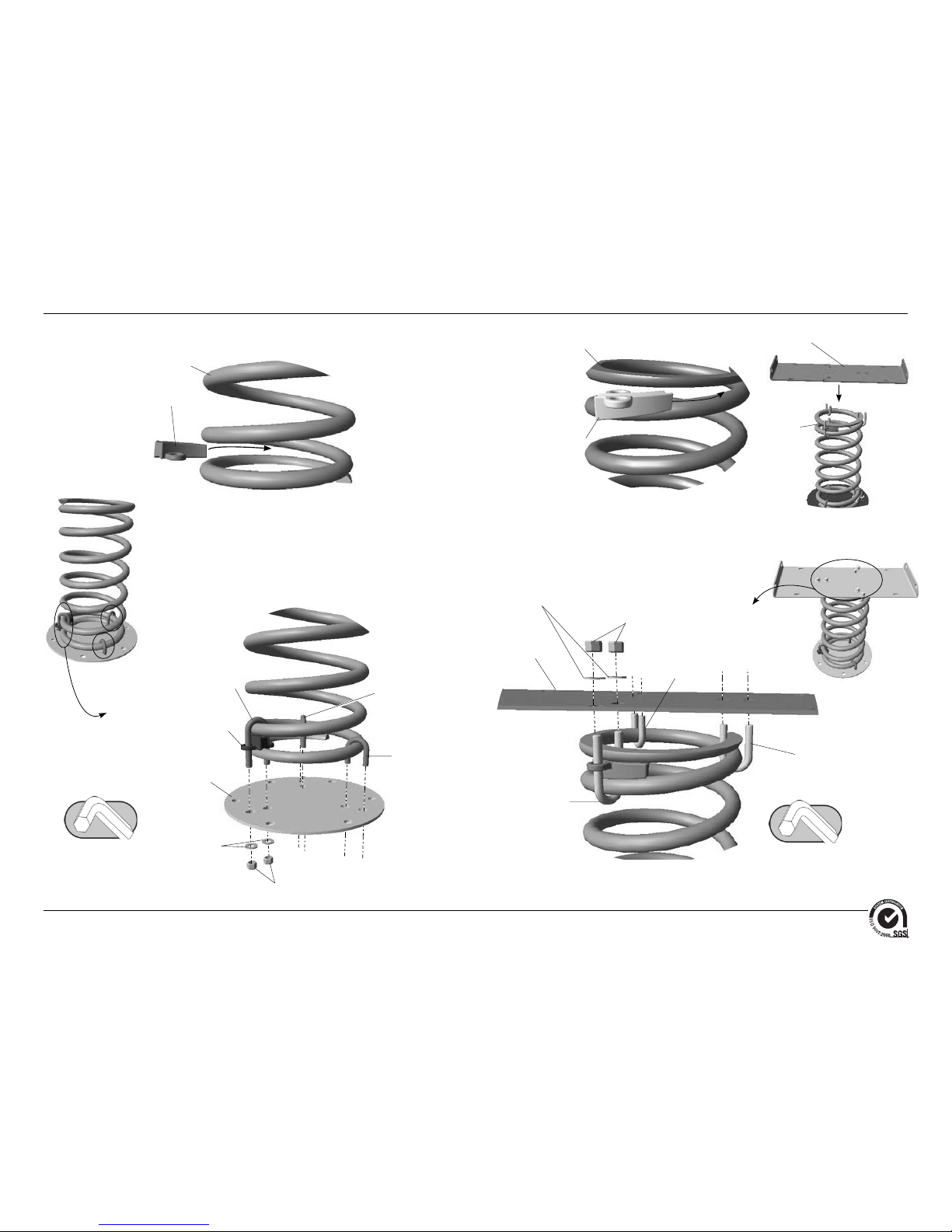

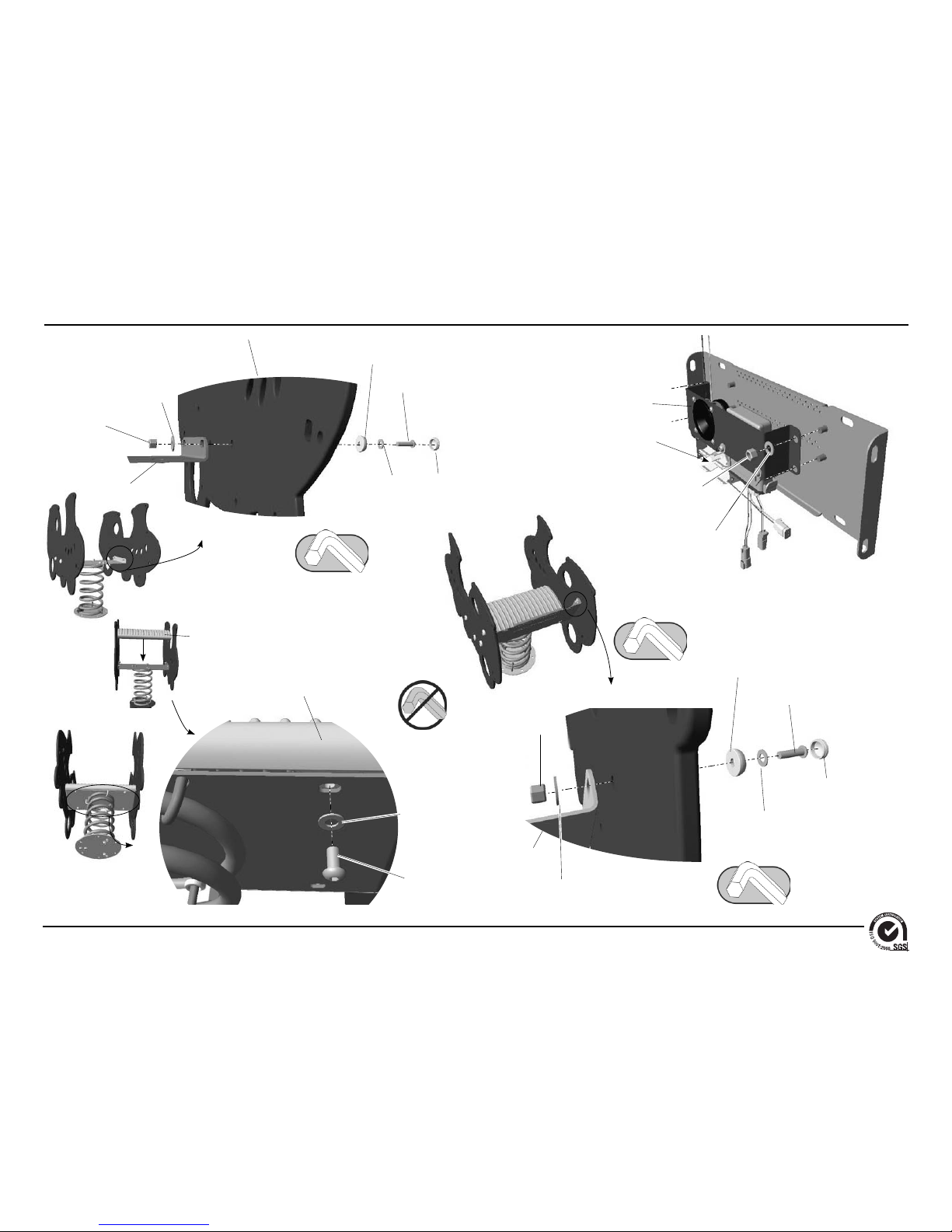

Follow the details in alphabetical order. For clarifi cation, each detail references the

step description. The step descriptions start on page 8.

Detail B-1

Step 5

Detail B-2

Step 5

Detail B-3

Step 5

Spring Wedge Casting

AAU0062

Spring

ATM0014

Spring Wedge Casting

AAU0062

Spring

ATM0014

Metal Platform

ABC0499

Metal Platform

ABC0499

Spring

ATM0014

3/8" x 2"

U-Bolt

BAE0028

3/8" x 1-1/2"

U-Bolt

BAE0027

Hex Nut

w/ Locking Ring

BAE0621

Detail A-2

Step 4

Spring Wedge

AAU0062

Anchor Plate

APL1238

3/8" x 2" U-Bolt

BAE0028

Hex Nut w/ Locking Ring

BAE0621

3/8" x 2-3/4" U-Bolt

BAE0047

3/8" Flat Washer

BAE0595

3/8" Flat Washer

BAE0595

Detail A-1

Step 4

3/8" x 2-3/4" U-Bolt

BAE0047

3/8" x 1-1/2" U-Bolt

BAE0027

Installation Instructions

Models XX0549 & XX0550

ECN 1867

Page 5 of 12

Hex Nut w/ Locking Ring

BAE0621

3/8" Flat Washer

BAE0595

Detail D

Step 7

Detail E

Step 8

3/8" x 1-1/2"

Button Head Bolt

BAE06645

3/8" Flat Washer

BAE0595

3/8" Hex Nut

w/ Locking Ring

BAE0621

1" O.D. Flat Washer

BAE0600

Metal Platform

ABC0499

Train Side Panel

BFC1223

Bolt Cap

BPL0300

Plastic Washer

BPL0300

Important Note: Do Not install bolt caps

until the entire structure is assembled.

3/8" x 3/4"

Button Head Bolt

BAE0659

3/8" Flat Washer

BAE0595

Rider Seat

BPL0266

Rider Seat

BPL0266

Detail C

Step 6

Detail F

Step 9

Note: Skip this step for model XX0549.

Sound Electronics

ASY0149

Note: Sound electronics are factory

ready. No electrical connections will

need to be made.

Insert D-Cell

Batteries Here

(Customer Supplied)

Seat Bracket

ABC0498

3/8" Hex Nut

w/ Locking Ring

BAE0621

1" O.D. Flat Washer

BAE0600

Plastic Washer

BPL0300

3/8" x 1-1/2"

Button Head Bolt

BAE06645

Bolt Cap

BPL0300

3/8" Flat Washer

BAE0595

Loading...

Loading...