Page 1

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 1 of 14

Installation Instructions

Playworld Systems® Models XX0193 and XX0193S

Unity Rocker

Installation Preparation

Recommended Crew: ...........................Two (2) adults

Installation Time (In-Ground): ................4 man-hours

Installation Time (Surface Mount): ........2.5 man-hours

Concrete Required: ............................... 0.39 cubic yard (0,30 cubic meters)

Use Zone: .............................................. Refer to the information below

User Group Age (years): ....................... ASTM/CSA: 2-12, EN: 2-14

Assembly View (representative structure)

Equipment Use Zone

A - (ASTM) 72 in. (1830 mm)

(CSA) 1800 mm

(EN) 1000 mm

A

A

Refer to the Elevation View for the specifi c Critical Fall Height for the component.

ICON KEY

Fully Tighten

Hardware

Add 1 Drop of

Thread Locking Adhesive

Do Not Fully Tighten

Hardware

Pour Concrete

Drill Dig Footing Holes

Hammer Critical Fall Height

Page 2

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 2 of 14

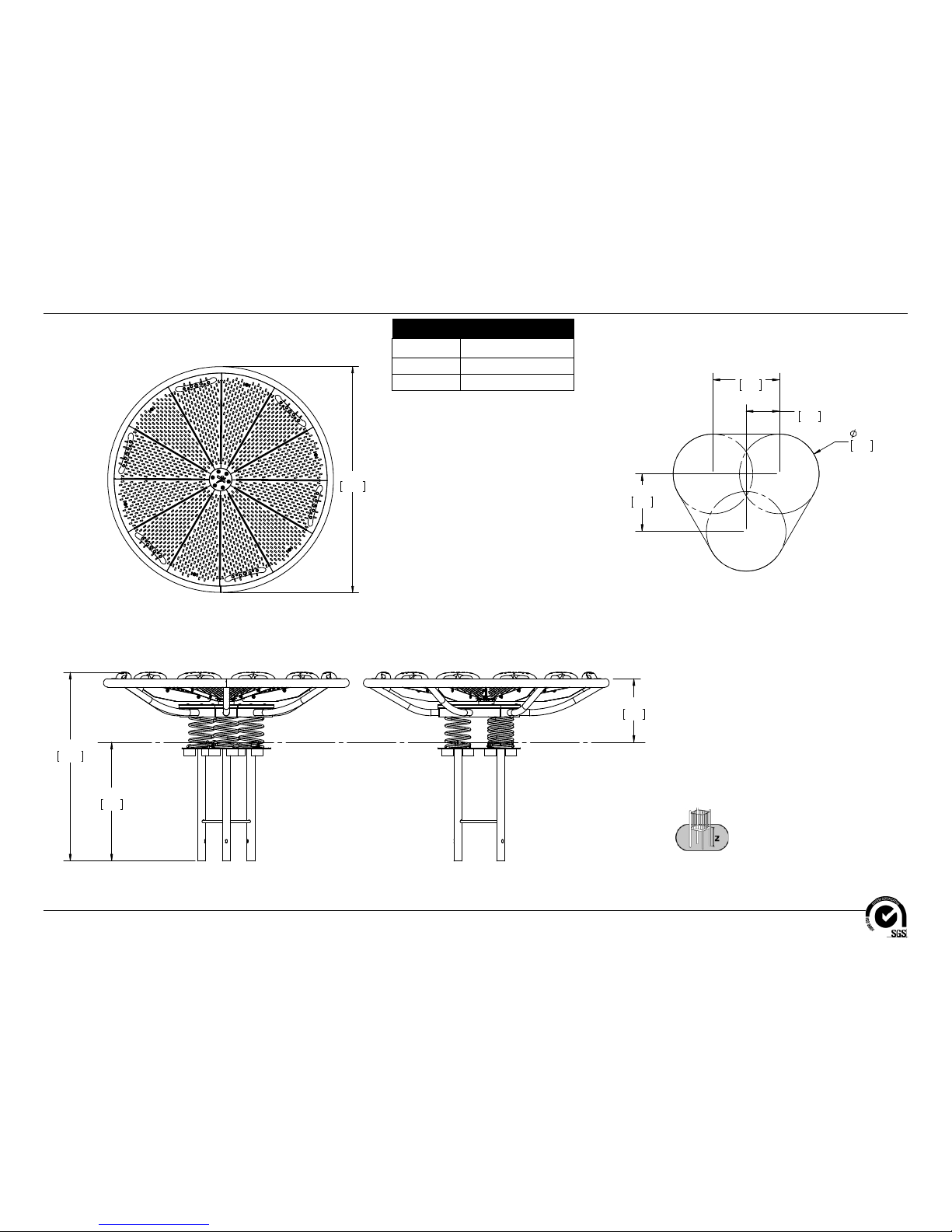

Top View

Elevation Views

XX0193 In-Ground

Footing Diagram

19.3"

(491 mm)

KEY

Position

Unit of Measurement

Top #

Inches

Bottom #

[Millimeters]

685)$&,1*/(9(/

Page 3

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 3 of 14

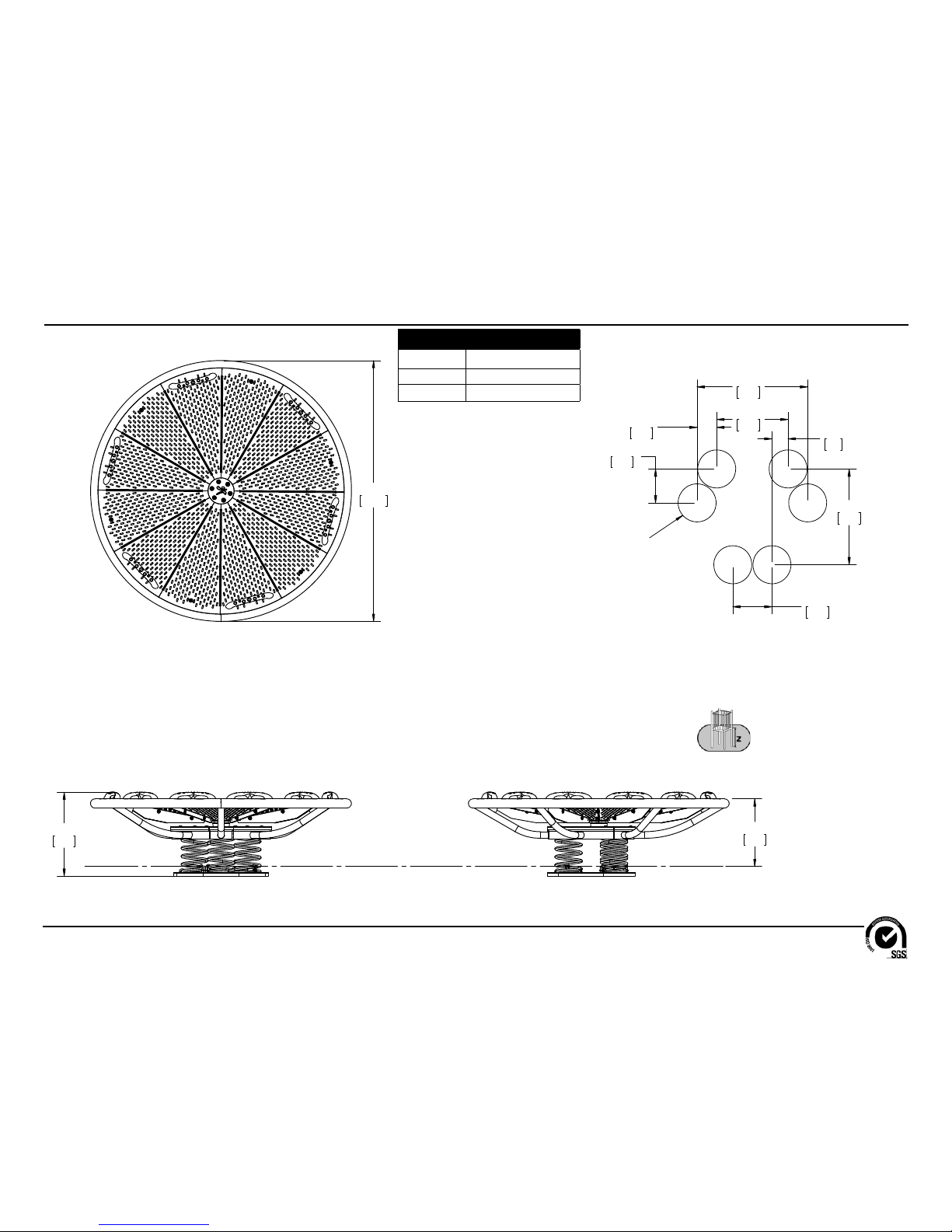

Elevation Views

XX0193S Surface Mount

Top View

KEY

Position

Unit of Measurement

Top #

Inches

Bottom #

[Millimeters]

Footing Diagram

$1&+25/2&$7,216

685)$&,1*/(9(/

19.3"

(491 mm)

Page 4

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 4 of 14

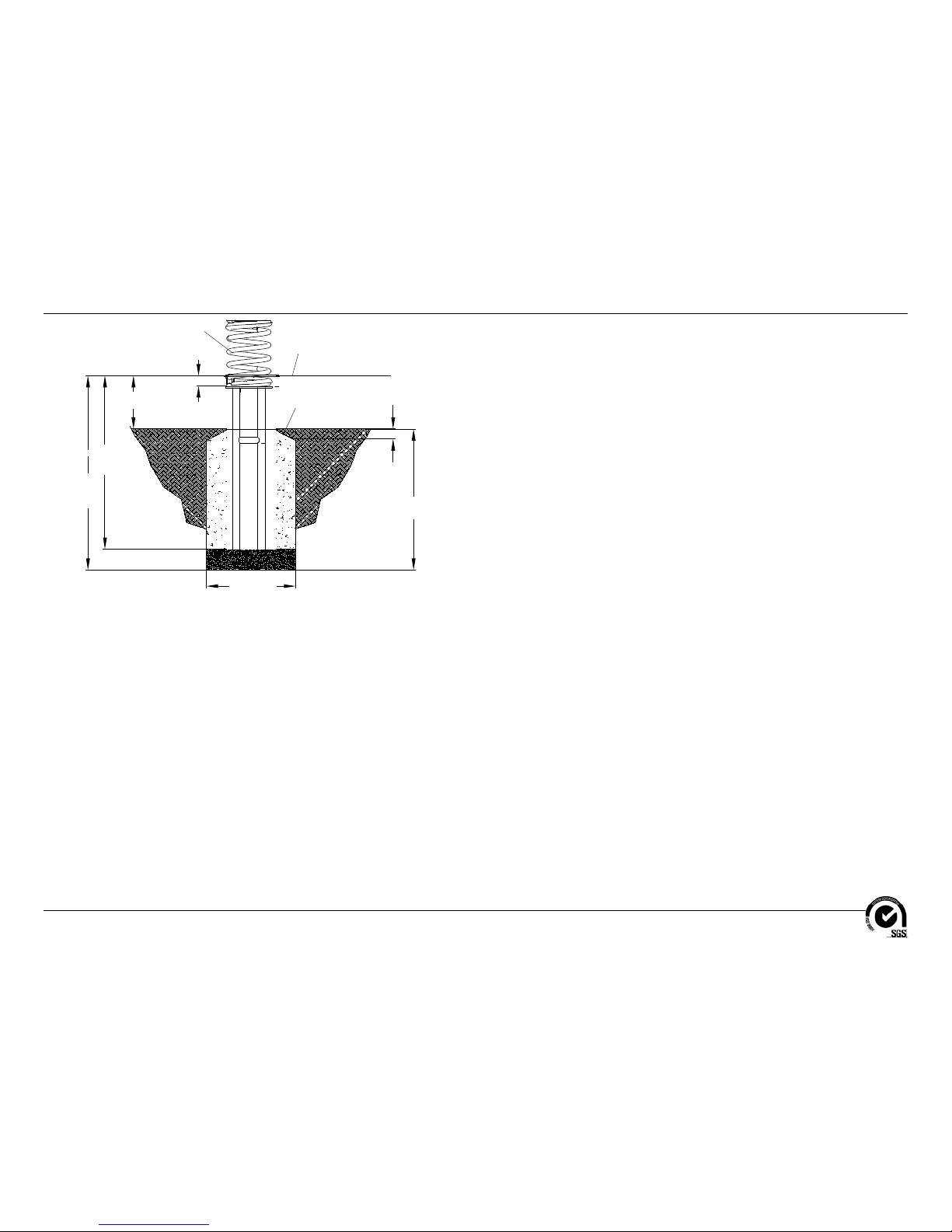

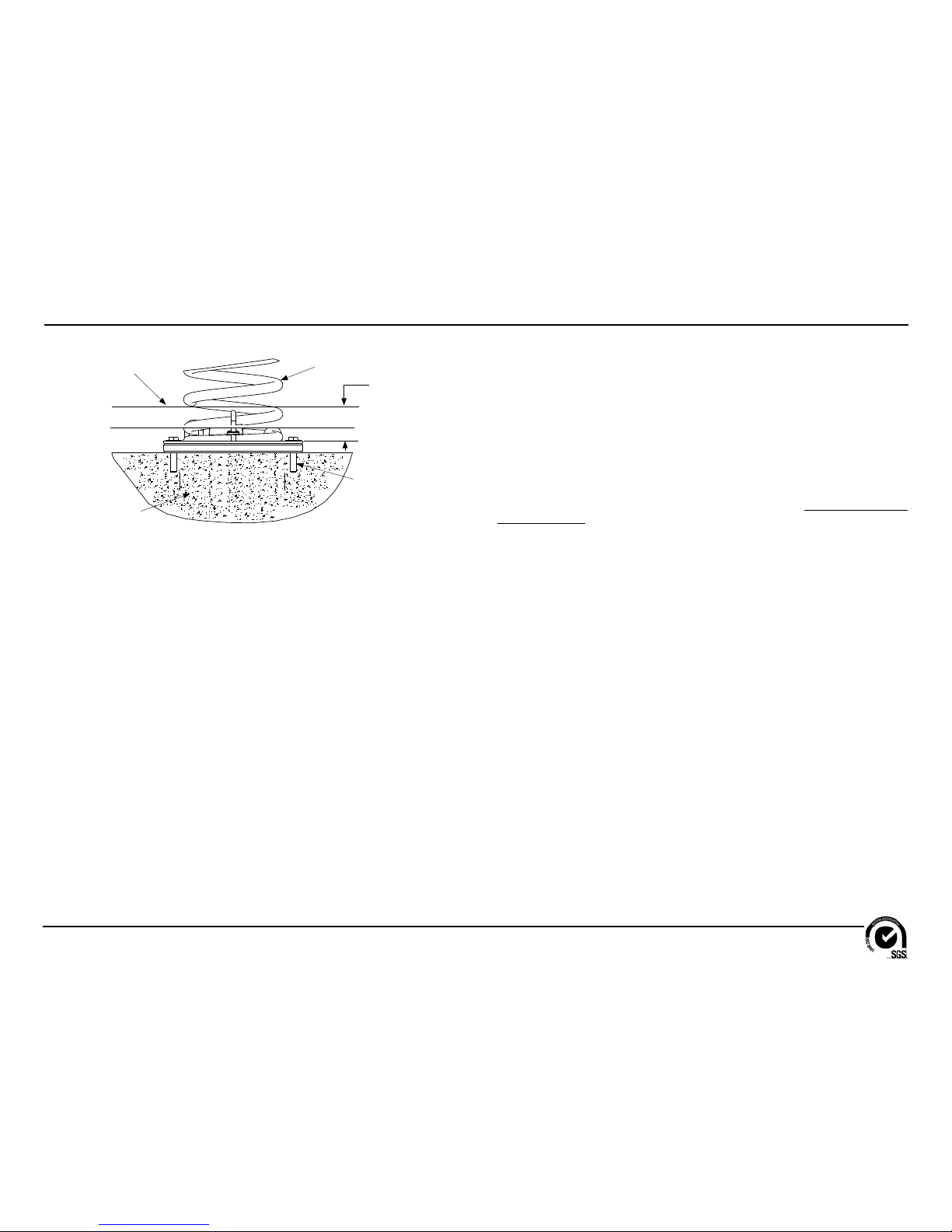

Coil Spring Footing Detail

2" (51 mm)

Protective Surfacing Level

Spring Rider

Spring

Bevel Edge

of Concrete

2" (51 mm)

18"

(457 mm)

Diameter

36"

(914 mm)

42"

(1067 mm)

Varies

Varies

FOOTING NOTES

• Coil Spring Footing post footing depth equals 42 in. (1067 mm) less the depth of the

protective surfacing material. The post is designed to have 24" (610 mm) in concrete.

Example: If 12 in. (305 mm) of wood mulch is used for surfacing, the footing depth would

be 30 in. (762 mm).

• Some support posts and component support legs may have either a factory-applied

sticker with line, or factory-applied mark designating protective surfacing level on a clear

and level installation site.

• If play structure is installed on uneven terrain, maintain support post mark at protective

surfacing level at lowest grade. Adjust other footings accordingly. Support posts and all

attaching decks and play components must be plumb and level.

• Do not encase bottom of support post in concrete. Place post directly on packed stone

or porous block.

• The footings shown on Playworld Systems’ documentation are recommendations based

on historical performance in average soil conditions. Footing dimensions may be modifi ed

by the owner based on actual soil conditions.

For example:

- If local soil is loose or unstable, a larger footing may be required.

- If local soil is considered stable, such as bedrock, clay or hard packed earth, a smaller

footing may be used. Before changing footing dimensions, we strongly recommend that

the footings be reviewed and approved by a registered engineer.

• Base of footing must be below frost line.

• Assemble the entire structure before pouring concrete unless specifi cally instructed to

do so in the individual component installation instructions.

Page 5

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 5 of 14

Concrete Base

Anchor Bolts

Supplied By

Customer

Protective

Surfacing Level

Coil Spring

2" in. (51 mm)

Coil Spring Surface Mount Footing Detail

FOOTING NOTES

• All support posts and component support legs may have either a factory-applied sticker

with line, or factory-applied mark designating protective surfacing level on a clear and

level installation site.

• If play structure is installed on uneven terrain, maintain support post mark at protective

surfacing level at lowest grade. Adjust other footings accordingly. Support posts and

all attaching decks and play components must be plumb and level.

• Footing size may vary due to local soil and weather conditions.

• Base of footing must be below frost line.

• Comparison of protective surfacing materials is available in Handbook for Public

Playground Safety published by U. S. Consumer Product Safety Commission.

Surface mount hardware is not supplied. Customer is responsible for

concrete base and providing surface mount hardware as specifi ed by a

registered structural engineer for each specifi c project application.

Page 6

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 6 of 14

Follow the details in alphabetical order. For clarifi cation, each detail references the

step description. The step descriptions start on page 10.

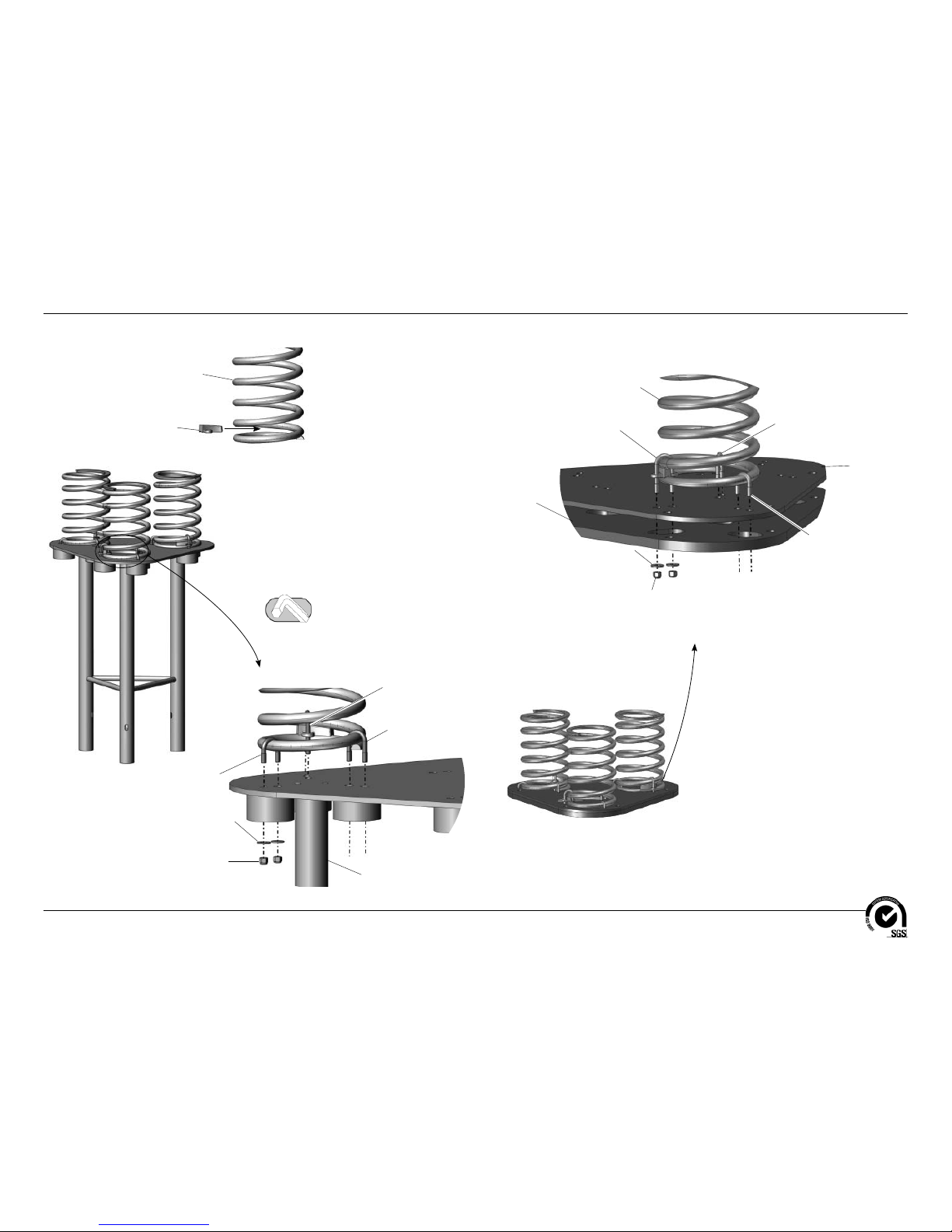

Detail A-1

Step 4

Insert the spring wedge into the

bottom of the spring until secure

Detail A-2

Step 4

(In-Ground Model Only)

Attach the springs to the anchor

frame

Spring Wedge Casting

AAU0062

(3 Total)

Spring

ATM0093

(3 Total)

3/8" Hex Nut

w/ Locking Ring

BAE0621

(18 Total)

1" O.D. Flat Washer

BAE0600

(18 Total)

Anchor Frame

AFR1701

(1 Total)

3/8" x 3.25" U-Bolt

BAE1798

(3 Total)

3/8" x 2.50" U-Bolt

BAE0029

(3 Total)

3/8" x 1.75" U-Bolt

BAE0036

(3 Total)

1" O.D. Flat Washer

BAE0600

(18 Total)

3/8" Hex Nut

w/ Locking Ring

BAE0621

(2 Total)

3/8" x 3.25" U-Bolt

BAE1798

(3 Total)

Spring

ATM0093

(3 Total)

3/8" x 2.50" U-Bolt

BAE0029

(3 Total)

3/8" x 1.75" U-Bolt

BAE0036

(3 Total)

Anchor Plate

APL2238

(1 Total)

Sheet Plastic

BFC3624

(1 Total)

Detail A-3

Step 4

(Surface Mount Models Only)

Attach the springs to the base plate

Note: The side of the anchor

plate with "TOP" on it should be

facing up.

Page 7

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 7 of 14

Note: The frame is shown

transparent for ease of viewing

the connection.

3/8" Lock Nut

BAE0620

(6 Total)

1" O.D. Flat Washer

BAE0600

(12 Total)

3/8" x 1-3/4"

Button Head Bolt

BAE0665

(6 Total)

Plate

APL2268

(1 Total)

Sheet Plastic

BFC3625

(1 Total)

3/8" Lock Nut

BAE0620

(3 Total)

1" O.D. Flat Washer

BAE0600

(6 Total)

Hub Casting

AAU0843

(1 Total)

Detail C

Step 6

Attach the sheet plastic and plate

to the frame

Detail D

Step 7

Attach the hub casting to the

assembly

3/8" x 2-1/4"

Button Head Bolt

BAE06675

(3 Total)

Spring Wedge Casting

AAU0062

(3 Total)

Detail B-1

Step 5

Insert the spring wedge into the

top of the spring until secure

Detail B-2

Step 5

Attach the springs to the Unity

Rocker frame

3/8" Hex Nut

w/ Locking Ring

BAE0621

(18 Total)

1" O.D. Flat Washer

BAE0600

(18 Total)

3/8" x 3.25" U-Bolt

BAE1798

(3 Total)

3/8" x 2.50" U-Bolt

BAE0029

(3 Total)

3/8" x 1.75" U-Bolt

BAE0036

(3 Total)

Unity Rocker Frame

AFR1702

(1 Total)

Note: The frame is shown

transparent for ease of viewing

the connection.

Page 8

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 8 of 14

3/8" x 1"

Button Head Bolt

BAE0664

(36 Total)

1" O.D. Flat Washer

BAE0600

(72 Total)

3/8" Lock Nut

BAE0620

(36 Total)

Detail F

Step 9

Attach the perf sheets together

1" O.D. Flat Washer

BAE0600

(6 Total)

3/8" Lock Nut

BAE0620

(6 Total)

3/8" x 1"

Button Head Bolt

BAE0664

(12 Total)

1" O.D. Flat Washer

BAE0600

(6 Total)

Right Perf Sheet

BPM0323

(6 Total)

Detail E-1

Step 8

Attach the Right Perf Sheets to

the frame on alternating tabs

Left Perf Sheet

BPM0322

(6 Total)

Detail E-2

Step 8

Place the Left Perf Sheets on the

frame on alternating tabs

1" O.D. Flat

Washer

BAE0600

(6 Total)

Note: An alignment pin may be

needed to line up holes before

securing the planks together

Page 9

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 9 of 14

3/8" x 1"

Button Head Bolt

BAE0664

(6 Total)

3/8" Flat Washer

BAE0595

(6 Total)

Casting Cover

AAU0844

(1 Total)

3/8" x 1"

Button Head Bolt

BAE0664

(18 Total)

1" O.D. Flat Washer

BAE0600

(18 Total)

Handhold

AAU0845

(6 Total)

Detail H

Step 11

Attach the handholds

Detail G

Step 10

Attach the casting cover

Page 10

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 10 of 14

Notes Before You Begin: Do not over tighten bolts during assembly, only snug

tighten them until assembly is complete.

Carefully read and understand these installation instructions before you

begin.

Step 1: Before attempting to assemble your equipment, please review all

installation information carefully. Should you experience any diffi culty during the

installation process, please call us at the phone number shown on the last page

of these instructions.

Step 2: Separate and identify all components and hardware.

Step 3: Excavate or prepare footings as shown in the Annex at the end of this

document. Use the Coil Spring Footing Detail (In-Ground) on page 4.

Step 4: Attach the springs to the anchor frame. See Details A-1, A-2 and A-3.

Insert the spring wedge into the bottom of the spring and rotate until secure. See

Detail A-1. Place the U-bolts over the bottom of the spring and attach to the

anchor frame as shown. See Detail A-2.

For Surface Mount Only: Place the anchor plate over the sheet plastic base

with TOP facing up, aligning the holes, and attach as shown. See Detail A-3.

Note: The 3.25" U-Bolt attaches through the spring wedge.

Step 5: Attach the springs to the frame. See Details B-1 and B-2. Insert the

spring wedge into the top of the spring and rotate until secure. See Detail B-1.

Place the U-bolts over the top of the spring and attach to the frame as shown.

See Detail B-2. Note: The 3.25" U-Bolt attaches through the spring wedge.

Step 6: Attach the sheet plastic and plate to the frame. See Detail C. Place the

sheet plastic on the frame fi rst, then place the plate on top, aligning the holes.

Select the appropriate hardware and attach as shown, there are six connections.

Fully tighten these connections as per the Torque Specifi cations, see Final Details.

Step 7: Attach the hub casting to the assembly. See Detail D. Align the holes

in the casting with the holes on the assembly, and attach as shown. There are

three connections.

Step 8: Attach the perf sheets to the frame. See Details E-1 and E-2. Select

the six Right Perf Sheets (BPM0323), align the holes on the top and bottom of

the sheet with the frame and align the right side of the sheets with the left side

of the tabs on the frame. See Detail E-1. Select the appropriate hardware, and

attach as shown, alternating tabs. Do not fully tighten the connection. Select

the six Left Perf Sheets (BPM0322), align the holes on the top and bottom of the

sheet with the frame, and place on the frame. See Detail E-2.

Note: The hardware connections for the left perf pieces will be made in Steps

10 and 11.

Step 9: Attach the perf sheets together. See

Detail F. Select the appropriate

hardware, and attach as shown.

Note: An alignment pin may be needed to keep the perf pieces in line with the

holes to make your connections underneath.

Step 10: Attach the casting cover to the assembly. See Details G. Align the

holes on the casting cover to the open holes on the perf sheets. Select six bolts

and washers, apply a drop of thread locking adhesive to the bolt threads, and

attach the casting as shown. Fully tighten these connections as per the Torque

Specifi cations, see Final Details.

Step 11: Attach the handholds. See Detail H. Place the handholds over the

three holes on the Left Perf Sheet pieces, select the appropriate hardware, apply

a drop of thread locking adhesive to the bolt threads, and attach as shown.

Final Details.

Step 12: Plumb and level the component. Tighten all fasteners. Fully tighten all

fasteners according to tightening torque specifi cations.

Torque Specifi cations:

Bolts and nuts - Snug tighten and then tighten an additional one half turn.

(In-Ground Only): Block and brace for concrete. Pour concrete after all equipment

has been assembled. Allow 72 hours for concrete to completely cure.

(Surface Mount Only): Bolt down all surface mount supports in accordance with

specifi cations provided by your registered structural engineer.

Important Note: Surface mount hardware is not supplied. Customer is responsible

for concrete base and for providing surface mount hardware as specifi ed by a

registered structural engineer for each specifi c project application.

Step 13: Apply the Surfacing Warning labels to a visible area on the component.

Page 11

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 11 of 14

Bill of Materials

XX0193 - UNITY ROCKER

PART NO. DESCRIPTION QTY.

AAU0062 CASTING - 7.09" O.D. SPRING WEDGE 6

AAU0843 HUB - 7.00" O.D. x 1.72" - CAST 1

AAU0844 COVER - 7.50" O.D. x 1.04" - CAST 1

AAU0845 UNITY ROCKR HAND HOLD 6

AFR1701 ANCHOR - 34.38" x 27.00" x 24.99" 1

AFR1702 FRAME - UNITY ROCKR 1

APL2268 PLATE - 28.84" x 24.99" x 12 GA 1

ATM0093 SPRING - 300MM 3

BAD0085 THREAD LOCKING ADHESIVE 1

BAE0029 BOLT - .38"-16 x .89" x 2.50" - U 6

BAE0036 BOLT - .38"-16 x .89" x 1.75" - U 6

BAE0595 WASHER - 3/8" SAE FLAT 6

BAE0600 WASHER - 1" O.D. FLAT 162

BAE0620 NUT - 3/8"-16 LOCK w/NYLON CAP 51

BAE0621 NUT - 3/8"-16 ZINC HEX w/LOCKING RING 36

BAE0664 BOLT - 3/8"-16 x 1.00" BUTTON HEAD - SS 72

BAE0665 BOLT - 3/8"-16 x 1.75" BUTTON HEAD - SS 6

BAE0922 TOOL - TT 45 L WRENCH 1

BAE1798 BOLT - 3/8"-16 x .89" x 3.25" - U 6

BAE06675 BOLT - 3/8"-16 x 2.25" BUTTON HEAD - SS 3

BFC3625 SHEET - 28.84" x 24.99" x .75" 1

BPM0322 ROCKR PERF SHEET - LEFT 6

BPM0323 ROCKR PERF SHEET - RIGHT 6

ALB0025 LABEL - AGE APPROPRIATE SHEET 1

1000 Buffalo Road • Lewisburg, PA 17837

www.playworldsystems.com

For Customer Service, Call

800-233-8404 or

570-522-9800

OUTSIDE U.S.

XX0193S - UNITY ROCKER SURFACE MOUNT

PART NO. DESCRIPTION QTY.

AAU0062 CASTING - 7.09" O.D. SPRING WEDGE 6

AAU0843 HUB - 7.00" O.D. x 1.72" - CAST 1

AAU0844 COVER - 7.50" O.D. x 1.04" - CAST 1

AAU0845 UNITY ROCKR HAND HOLD 6

AFR1702 FRAME - UNITY ROCKR 1

APL2238 PLATE - 27.00" x 24.99" x .38"- ANCHOR 1

APL2268 PLATE - 28.84" x 24.99" x 12 GA 1

ATM0093 SPRING - 300MM 3

BAD0085 THREAD LOCKING ADHESIVE 1

BAE0029 BOLT - .38"-16 x .89" x 2.50" - U 6

BAE0036 BOLT - .38"-16 x .89" x 1.75" - U 6

BAE0595 WASHER - 3/8" SAE FLAT 6

BAE0600 WASHER - 1" O.D. FLAT 162

BAE0620 NUT - 3/8"-16 LOCK w/NYLON CAP 51

BAE0621 NUT - 3/8"-16 ZINC HEX w/LOCKING RING 36

BAE0664 BOLT - 3/8"-16 x 1.00" BUTTON HEAD - SS 72

BAE0665 BOLT - 3/8"-16 x 1.75" BUTTON HEAD - SS 6

BAE0922 TOOL - TT 45 L WRENCH 1

BAE1798 BOLT - 3/8"-16 x .89" x 3.25" - U 6

BAE06675 BOLT - 3/8"-16 x 2.25" BUTTON HEAD - SS 3

BFC3624 SHEET - 27.00" x 24.99' x .75" 1

BFC3625 SHEET - 28.84" x 24.99" x .75" 1

BPM0322 ROCKR PERF SHEET - LEFT 6

BPM0323 ROCKR PERF SHEET - RIGHT 6

ALB0025 LABEL - AGE APPROPRIATE SHEET 1

Page 12

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 12 of 14

This page is

intentionally left blank.

Page 13

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 13 of 14

Fasteners

• Inspect for loose fasteners.

Tightening torque specifi cations are:

Bolts and Nuts: Snug tighten and tighten an additional

one-half turn.

• If during the maintenance process a bolt needs to be

removed from a part or parts, it will be necessary to apply

a drop of liquid thread lock to the bolt before reinstallation.

• Inspect for missing, worn or broken fasteners. If any

missing, worn or broken fasteners are found, refer to the

installation instructions for proper replacement fastener.

If any damage is detected, barricade equipment to

prevent use until repair is completed. Contact your sales

representative immediately for a replacement part.

Plastic Parts

• Inspect all plastic surfaces for sharp points, cracks

or jagged edges. If any damage is detected and is

determined to be unsafe, barricade equipment to prevent

use until repair is completed. Minor burrs or sharp edges

may be removed by using a sharp utility knife or block

plane to remove sharp burr.

Castings

• Inspect the aluminum castings to insure they are properly

secured to the component.

• Visually inspect the castings for cracks or breakage. If

any damage is detected, barricade the equipment to

prevent use until repair is completed. Contact your sales

representative immediately for a replacement part.

Welds

• Inspect all welded joints. If any broken welds are detected,

barricade equipment to prevent use until repair is

completed. Contact your sales representative immediately

for a replacement part.

Equipment Maintenance

Playworld Systems

®

Models XX0193 and XX0193S

Unity Rocker

Finish

• Inspect metal parts for fi nish damage.

To repair painted surfaces, sand damaged area with

sandpaper and wipe clean. Mask area and paint with

primer and allow to dry. Paint primed area with colormatching paint and allow to dry. Recoat area with colormatching paint if required. Drying time is approximately

8 hours between coats.

To repair the perf sheet coating, contact the Playworld

Systems’ Customer Service Department for a coating

repair touch-up kit.

Springs

• Inspect the springs to insure they are properly secured to

the anchor and frames. Check spring U-bolts to ensure

secure connections. If any damage is detected, barricade

equipment to prevent use until repair is completed.

Contact your sales representative immediately for a

replacement part.

Footings

• Inspect component to be solid in footing and secure. If

any damage is detected, barricade equipment to prevent

use until repair is completed.

Surfacing

• Refer to the specifi c surfacing maintenance detail sheet

for additional information.

Replacement Parts

• Refer to your installation instructions to obtain replacement

part number.

• Contact your sales representative or call Playworld

Systems’ Customer Service for a replacement part.

1000 Buffalo Road • Lewisburg, PA 17837

www.playworldsystems.com

For Customer Service, Call

800-233-8404 or

570-522-9800

OUTSIDE U.S.

Page 14

Installation Instructions

Models XX0193 and XX0193S

ECN2716

Page 14 of 14

Inspection Form

• Be sure that you are using a copy of this Inspection Form and not your original.

• Use the Inspection Codes listed below and record condition of equipment at time of

examination on the Inspection Checklist.

• Document any item from the Inspection Checklist that will require maintenance along with

any corrective action on the Maintenance Schedule.

• Be sure to include appropriate dates and signatures on each section to properly document

maintenance procedure.

Preventive Maintenance

. . . for Safety's Sake!

Repairer: Name (Please Print) __________________________________ Signature:________________________________________ Date:___ /___ /___

MAINTENANCE SCHEDULE

Item in Question Description of Problem Corrective Action Date

Inspector: Name (Please Print) __________________________________ Signature:_________________________________________ Date:___ /___ /___

Inspection Codes

P = Pass F = Fail

NA = Not Applicable

INSPECTION CHECKLIST Frequency

Inspection

Code Date

Date Repairs

Completed

Inspect plastic parts for damage. Medium

Inspect spring connections for tightness. High

Inspect metal parts for structural and fi nish damage. Medium

Inspect for loose, missing, worn, or broken fasteners. High

Inspect footing to insure support is secure and footing is not damaged. Low

Inspect surfacing to insure proper depth and distribution. High

Page 15

Guidelines & Information (fs RS_st) Annex Page 1

Guidelines

Rocking/Springing Equipment

Intended for Sitting Use Zones

A = ASTM: 72 in. (1829 mm)

CSA: 1800 mm

EN: 1000 mm

Important ! Please Read Completely Before Beginning Installation. According

to a report published by the U. S. Consumer Product Safety Commission (C.P.S.C.)

72% of all playground injuries result from accidental falls. With this in mind, this

equipment is designed to ll the need for safe yet challenging play. In conjunction

with design efforts to reduce the possibilities of injuries, this equipment must be

installed "Step by Step" per our installation instructions. As a new owner you

are responsible for the correct installation, safe use, and maintenance of your

equipment.

Installation Guidelines

• Identify all parts and thoroughly read the assembly instructions before

beginning construction.

• Refer to your playground equipment plan and footing diagram to assure

the equipment purchased will t into your selected site area. The use and no-

encroachment zones around the play equipment shall be obstacle-free areas

designated for unrestricted circulation.

• ASTM compliance: For rocking/springing equipment intended for sitting,

the use zone should extend on all sides a minimum distance of 72 inches (1829

mm). This use zone may be overlapped by the use zone of other rocking/springing

intended for sitting or stationary equipment when the seat or designated play

surface is 30 inches (762 mm) or less from the protective surfacing level. See

diagram.

• CSA compliance: For rocking/springing equipment intended for sitting,

the use zone should extend on all sides a minimum distance of 1800 mm. The

designated play surface, or seating surface must be 700 mm or less from the level

of the protective surfacing. This use zone may be overlapped by the use zones

of adjacent play equipment. See diagram.

• EN Compliance: For rocking/springing equipment intended for sitting, the

use zone should extend on all sides a minimum distance of 1000 mm. This use

zone may be overlapped by the use zone of other rocking/springing equipment.

• Site layout is a critical part of the overall installation. Footings must be

measured and marked accurately according to the footing diagram. A level and

clear installation site is ideal.

• Good drainage around the structure and its supports is important. Inquire

with local contractors for appropriate recommendations.

• After laying out all footings and before digging holes, be sure to inquire about

underground utilities that may exist.

• Do not leave the job site unattended without making sure that all fastening

hardware on all components are tightened according to tightening torque

specications listed on every installation guide. We also recommend roping off

construction area and covering all holes that do not contain a piece of equipment

with plywood or other suitable material.

• Excavate holes as shown in the footing detail. If a level and clear site cannot

be obtained, adjust the depth of footing to maintain a level footing base. If soil

conditions are loose or unstable, a larger diameter footing may be required. Inquire

with local contractors for appropriate recommendations. Be sure concrete that

might have splashed onto the unit is washed off before it dries. Allow concrete to

harden 72 hours before allowing your structure to be used. Assemble the entire

structure before pouring concrete unless specically instructed to do so in

the installation instructions.

Placement of multiple Spring Riders

A

A

Page 16

Guidelines & Information (fs RS_st) Annex Page 2

• Insure that Age Appropriate and Hard Surface Warning/Playworld Systems

identication labels are properly afxed to the play equipment. Labels are to be

plainly visible according to current playground equipment guidelines.

• IMPORTANT! Because accidental falls around your playground equipment

can occur, Playworld Systems recommends that the area under and around the

structure be covered with a resilient material such as sand, bark mulch, or wood

chips. If loose ll surfacing materials are used, Playworld Systems recommends

a depth of 12 in. (305 mm). An approved rubber safety matting can also be

used. Many protective surfacing materials can become compacted due

to weather and use, which reduces their shock absorbency. It is strongly

recommended that the surfacing be checked weekly and material added

or replaced as necessary. Hard surfaces, such as asphalt, concrete and

packed earth are not acceptable for use under playground equipment.

• The entire area, under and around the playground equipment, must be

covered with protective surfacing material. The impact attenuation of the

protective surfacing under and around playground equipment should be rated to

have a critical height value of at least the height of the highest accessible part

of the equipment. The critical height for surfacing is to be rated in accordance

with A.S.T.M. standard, designated F1292, A Standard Specication for Impact

Attenuation of Surface Systems Under and Around Playground Equipment.

Contact the manufacturer of unitary surfacing materials (rubber matting) for the

critical height rating for their products.

Tools Required: Playworld Systems supplies a service kit that contains commonly

used hex key wrenches required to assemble your equipment. You may also

need: shovel, digging iron, post hole digger, steel rake, wheelbarrow, garden hoe,

water hose, tape measure, level, alignment tool, 3/8" ratchet with 9/16" socket,

and 9/16" combination wrench.

Maintenance

• Inadequate maintenance of equipment has resulted in injuries on the

playground. Because the safety of playground equipment and its stability depends

on good inspection and maintenance, a comprehensive maintenance program

must be developed for each playground and strictly followed. All equipment

must be inspected frequently for any potential hazards. Special attention must

to be given to moving parts and other components that can be expected to wear.

Inspections must to be carried out in a systematic manner by trained personnel.

Any damaged or worn parts, or any other hazards identied during inspections

must be repaired or replaced immediately. Complete documentation of all

maintenance inspections and repairs must be retained.

Supervision Guidelines

• Playworld Systems strongly recommends close supervision of the children as

they play as well as intensive classroom and home instruction about safe behavior

on playground equipment.

• Playground supervisors should be aware that not all playground equipment is

appropriate for all children who may use the playground. Signs should be posted

near the equipment indicating the recommended age of the users. Supervisors

should direct children to equipment appropriate for their age.

• It is important that playground supervisors recognize that preschool-age

children require more attentive supervision on playgrounds than older children.

• Do not permit the use of wet playground equipment. Wet equipment will

inhibit necessary traction and gripping capabilities. Slips or falls could occur.

• Do not permit too many children on the same piece of equipment at the same

time. It is suggested that children take turns.

• Constantly observe play patterns to discover possible hazardous play and

suggest changes in equipment use or play patterns.

Page 17

Guidelines & Information (fs RS_st) Annex Page 3

FINAL INSPECTION

• Playworld Systems® insists on the installation of protective surfacing within the

use zone of each play structure in accordance with the applicable standard or

specications appropriate for the fall height of each structure.

• Playworld Systems® strongly recommends close supervision of children as

they play. The owners of playground equipment and the parents or guardians

of children are responsible for this proper supervision.

• As the owner of playground equipment, you are responsible for the maintenance

of the equipment and surrounding play area. A comprehensive maintenance and

inspection schedule must be developed and all equipment inspected frequently.

Refer to the inspection and maintenance schedule in the back of this booklet.

• Perform a thorough final check on the installed equipment to insure all

equipment is installed as specied by manufacturer’s installation instructions.

• Review all Installation Instructions for specied dimensions. Make sure

dimensions called for in instructions agree with actual installation.

• Double check height dimensions. Height measurements are taken from the

top of the protective surfacing material.

• Insure all fasteners are tightened according to tightening torque specications

listed on your installation instructions.

• Insure all exposed pipe ends have properly installed end caps. Insure that

drive rivets are secure.

• Clean dried concrete off of components and any other affected surface.

• Touch-up any scratches or installation damage to powder coated nish with

color-matched spray paint.

• Allow adequate time for proper curing, both for concrete and urethane

cement if rubber safety surfacing tiles have been installed.

• Insure that protective surfacing is properly installed according to C.P.S.C.

(or other appropriate body) recommendations. Footings must not be exposed.

• Insure that hard surface warning/Playworld Systems® identication labels are

properly afxed to the play equipment. Labels are to be plainly visible according

to current playground equipment guidelines. For locations complying with ASTM

F1487 or CSA Z-614, Age Appropriate labels must also be applied in a visible

location.

• Dispose of all packaging material properly. These materials which include

large plastic bags and sheets can be a suffocation hazard. Dispose of these

materials out of reach or contact of small children.

Surfacing Warning Label

Loading...

Loading...