Page 1

Transient Fault Locaon for Energized Dedicated Circuit Breakers

TFT100 User Manual

Toll Free: 800-749-5783

www.planumtools.com

Page 2

Toll Free: 800-749-5783

www.planumtools.com

This product should only be used by and connected/

disconnected from a circuit to be tested by qualified

service personnel or certified electricians

Introduction

Fault Trapper™ is a new class of tester intended to locate the

distance to a circuit anomaly that is either intermittently causing a

change in the circuit’s characteristics or blowing the circuit breaker.

Fault Trapper™ can capture and save up to two events (open and/

or short) per test session and save them separately. If the circuit

breaker trips, the backup battery powers the Fault Trapper™ to allow

for an orderly shutdown. The last faults can be viewed using the

battery power. An In-Line Adapter is used to isolate the circuit being

monitored from the breaker panel and all other breakers.

Key Features

• Unattended in-line monitoring of energized dedicated circuits up

to 300 VAC and 40 amps

• Fault Location reported as distance from Fault Trapper™

• Detects a fault whether or not it trips the circuit breaker

• Timer logs elapsed time of tests

• Back-up battery allows capture of breaker trips/Unpowered

display of results

Page 2 of 24

Page 3

Toll Free: 800-749-5783

www.planumtools.com

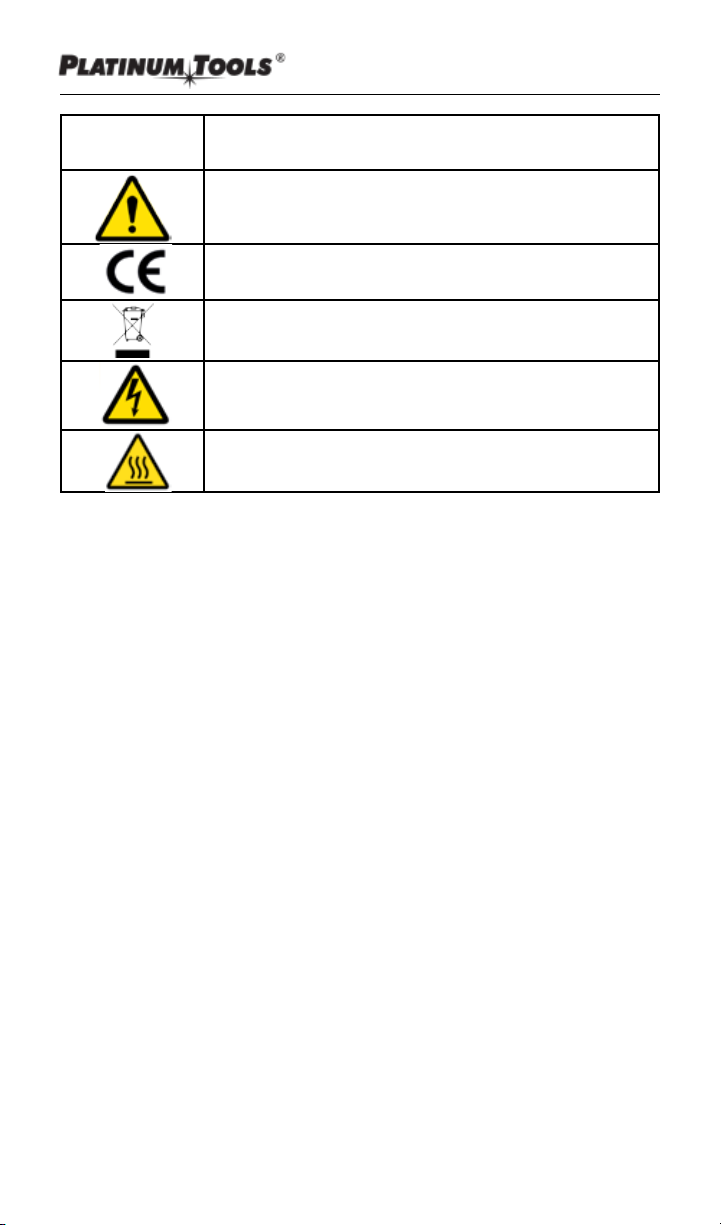

Safety Alert

Symbols

Definition

Warning: Potential for personal injury

Caution: Potential for damage to or destruction of

equipment

Conformité Européenne.

Conforms to European Economic Area directives.

Disposal Information

Warning: Electricity - High Voltage

Warning: Hot Surface

Safety Information

To ensure safe operation of the Fault Trapper™, follow instructions

carefully when using the unit and observe warning and caution

messages listed in this manual. Failure to observe warnings can

result in severe injury or death and can damage the unit.

• Fault Trapper™ is for use only by persons qualified to work in

and around breaker panels.

• Do not use the Fault Trapper™ or cables if they appear damaged

or the unit is not working properly.

• Do not use with voltages and currents higher than what the Fault

Trapper™ is rated for. The Fault Trapper is rated for 110/120VAC

to 230/240VAC branch circuits at a maximum of 40 amps.

• Turn off circuit breaker prior to attaching Fault Trapper™ and inline adapter to circuit to be monitored.

• Do not use around explosive or flammable gas.

• Use only test leads provided for connecting the Fault Trapper™

to the 40A In-Line Adapter Module.

• Before opening the battery door, remove cables from Fault

Trapper™.

• Always wear personal protective equipment when working with

the Fault Trapper™

• Do not open case of either the Fault Trapper or the In-Line

Adapter (when changing the fuse) with any cables connected to

it.

Page 3 of 24

Page 4

Contents:

Toll Free: 800-749-5783

www.planumtools.com

Fault Trapper

Main Unit

40 Amp In-Line

Adapter

Two Plug-in 2-Wire

Terminal Block

Connectors - 8 to 24

AWG (0.2 to 10 mm)

Banana Plug Leader Cable

Page 4 of 24

Page 5

Toll Free: 800-749-5783

www.planumtools.com

Insulated 1/8” Screwdriver

(1000V Rated)

Contents (cont.) :

• Duracell® 9 Volt Alkaline Battery. (Note - Do not use “Heavy

Duty” Carbon batteries or generic budget batteries.)

• User Instruction Sheet

• Warranty Card

Orderable Accessories and Replacement Parts:

Part Number Description

6075 Spare Plug-in 2-Wire Terminal Blocks (Set of 2)

6076 Replacement Banana Plug Leader Cable

19202 Insulated 1/8” Screwdriver (1000V Rated)

TCA008 Hanging Strap with Carabineer

Page 5 of 24

Page 6

Toll Free: 800-749-5783

www.planumtools.com

Fault Trapper™ Front Panel and Connections:

1. Load Terminal Jack (L1/L2)

2. Source Terminal Jack (S1/S2)

3. Banana Plug Leader Cable Jacks

4. Backlit LCD Display

5. Display Button (View Faults)

6. Ignore Button

7. Test Button (Start/Stop Monitoring)

8. Distance Buttons (Press & Hold to change to Feet or

Meters)

Page 6 of 24

Page 7

Toll Free: 800-749-5783

www.planumtools.com

Front Panel and Connections (Cont.):

1. Load Terminal Jack (L1/L2) - Wire or wires removed from

load attaches here using supplied Plug-in Termninal Block

Connectors

2. Power Source Terminal Jack (S1/S2) - Usually attached to

circuit breaker terminal or terminals, using the supplied plug-in

terminal blocks. Screw on terminal block should be tightened to

7 in/lbs.

3. Banana Plug Leader Cable Jacks - Supplied Banana Plug

Leader Cable connects 40A In-Line Adaper Module to Fault

Trapper™.

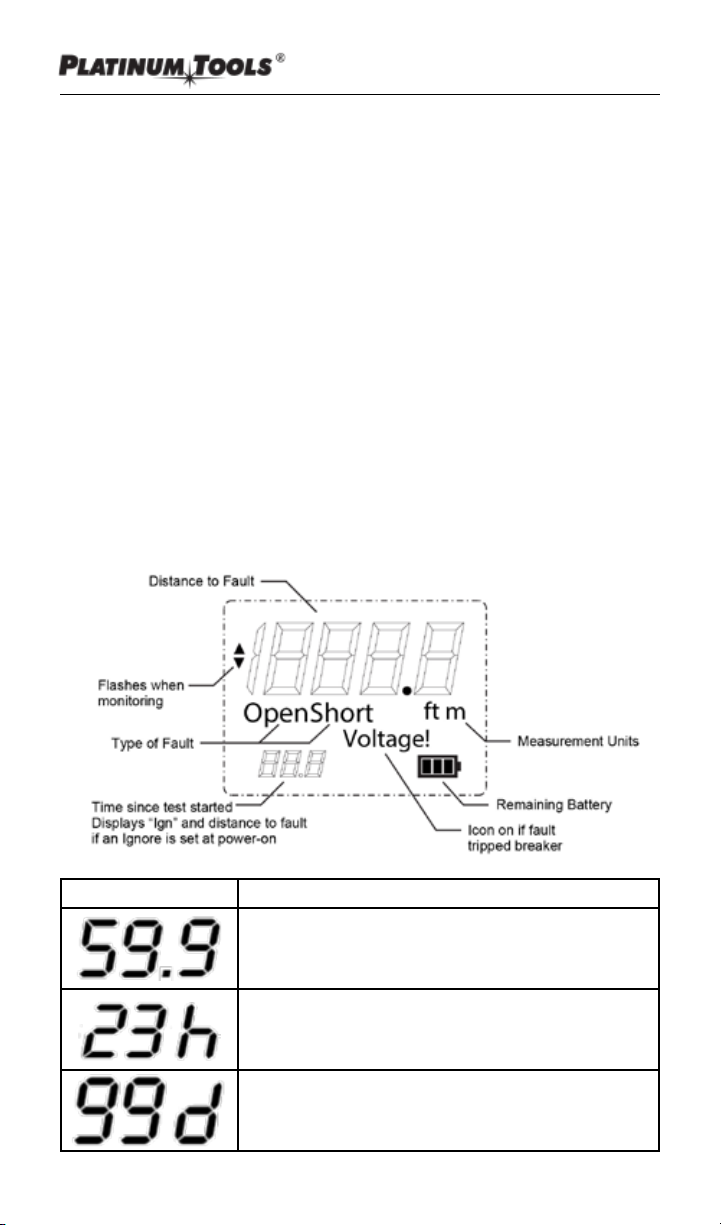

4. Backlit LCD Display - Shows Distance to Fault, Elapsed Time to

Fault, Fault Type (Short/Open) , and Battery Status

5. Display Button - Used to power unit on briefly to view faults

when not powered by AC and to toggle between a breaker trip

fault and a non-breaker trip fault, if there is one.

Displayed Elapsed Time of Test

From the first 0.1 min to 59.9 mins:

The elapsed time will be displayed in minutes

and tenths of a minute (0.1 equals 6 seconds)

From the first hour until 23 hours:

The elapsed time will be displayed as hours

(1h to 23h)

From the first day until the 99th day:

The elapsed time will be displayed as time in

days (1d to 99d)

Page 7 of 24

Page 8

Toll Free: 800-749-5783

www.planumtools.com

6. Ignore Button - Press to ignore events that are part of the

circuit’s normal operation.

7. Test Button - Press Button to start a monitoring session. Press

during a monitoring session to stop a test if running.

8. Distance/Units Button - Press and hold the Display and Ignore

buttons for 3 seconds. The “ft” or “m” icons will flash denoting

the new unit used for measurement.

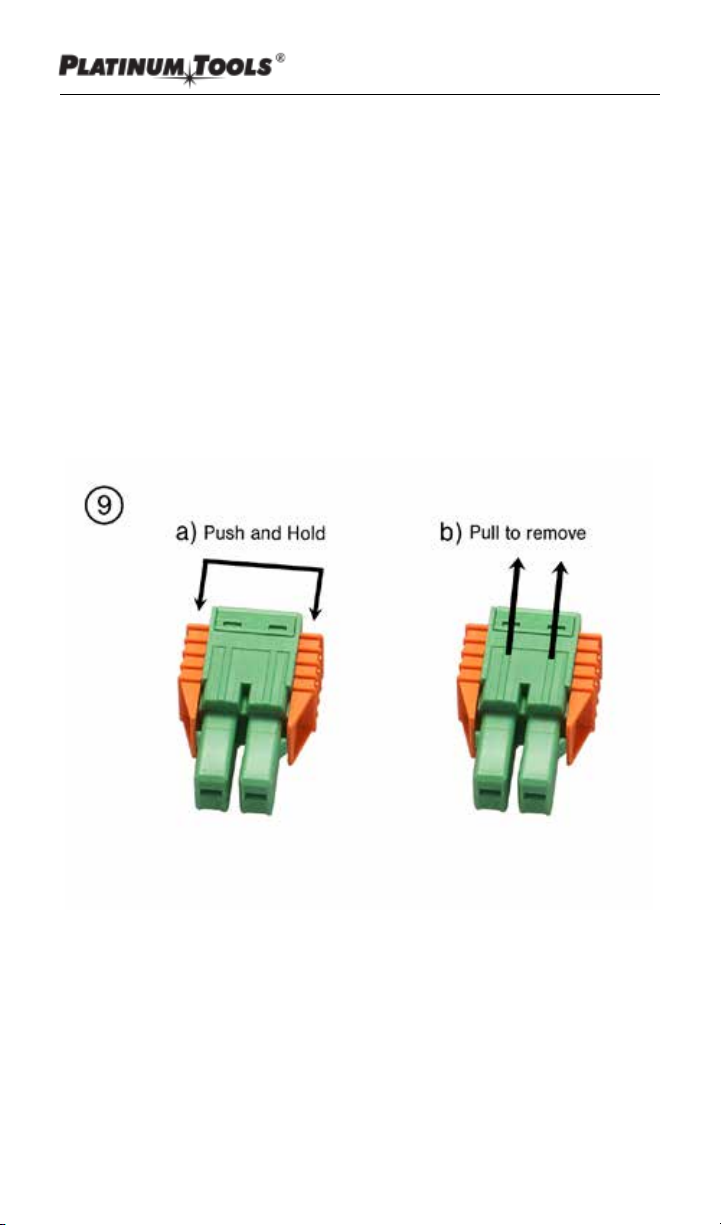

9. Terminal Block Connectors - Insert the circuit wires or jumpers

into these blocks and insert the blocks into the designated jacks.

To remove the Terminal Block Connectors:

a.) push and hold the orange side tabs towards the jack

b.) then pull the block connector out.

Page 8 of 24

Page 9

Toll Free: 800-749-5783

www.planumtools.com

Details and Functions of the Fault Trapper™

40A In-Line Adapter Module

Caution - Turn off power to the circuit the In-Line

Adapter is being connected to!

The Fault Trapper measures the wired pair impedance in the circuit

to sense an electrical event as a fault. The 40A In-line Adapter

Module is positioned between the Power Source and the Load at the

breaker. Power for Main Unit is tapped off a coil in the 40A In-line

Adapter Module through a fuse (Littelfuse® p/n 0215.250) via the

Banana Plug Leader Cable.

Page 9 of 24

Page 10

Toll Free: 800-749-5783

www.planumtools.com

40A In-Line Adapter Module Connections

LOAD (WIRING TO LOAD) SOURCE (CIRCUIT BREAKER)

VOLTAGE

L1 L2 S1 S2

110/120

VAC

230/240

VAC

BLACK WHITE BLACK

BLACK RED BLACK RED

NO

CONNECTION

GFI/AFCI BLACK WHITE BLACK WHITE

Page 10 of 24

Page 11

Toll Free: 800-749-5783

www.planumtools.com

Note! Use only on Energized Dedicated Circuits, Max 40 Amps.

Caution - Turn off power to the circuit the InLine Adapter is being connected to!

Connecting the Fault Trapper 40A In-Line Adapter

Module to Circuit Breakers (USA)

To connect to a 120VAC Standard Breaker (up to 40 Amps)

All connections to the Fault Trapper 40A In-Line Adapter Module are

made using plug-in terminal block connectors; torque screws to 7inlbs:

1. Noting the alignment of the Terminal Block Connector relative

to the Load Terminal Jack on the 40A In-Line Adapter Module,

remove the hot wire from the breaker being tested and insert it

into the Terminal Block Connector so that it is matched with Load

Terminal “L1”. Torque down the fastening screw to 7 in-lbs.

2. Strip the ends off a white jumper wire and connect one end

to the neutral/ground bus bar and insert the other end into

the Load Terminal Block Connector so that it is matched with

Terminal “L2”. Torque down the fastening screw to 7 in-lbs.

120VAC Connection Diagram

Page 11 of 24

Page 12

Toll Free: 800-749-5783

www.planumtools.com

3. Insert the Load Terminal Block Connector into the Load Terminal

Jack until it is seated firmly and lock tabs are fully engaged.

4. Strip the ends of another jumper wire and connect one end to

the Circuit Breaker (where the wire was removed in Step 1) and

the other end to the Source Terminal Block Connector so that it

is matched with Source Terminal “S1”.

5. Connect the Fault Trapper meter to the module using the

included Banana Plug Leader Cable.

To connect to 220VAC Standard Breaker (up to 40amps):

All connections to the Fault Trapper 40A In-Line Adapter Module are

made using supplied Plug-in Terminal Blocks Connectors, torque

screws to 7in-lbs:

1. Remove the two hot wires

from the breakers for the load

being tested and attach them

to the Load side of the Fault

Trapper 40A In-Line Adapter

Module with the black in Load

Terminal “L1” and the red wire

in Load Terminal “L2” using

the Plug-in Terminal Block

Connector.

2. Strip the ends of a black

jumper wire and connect

one end of the wire using

the Source Terminal Block

Connector Source at Source

Terminal “S1” and the other

end to the breaker terminal

where the black wire was

removed from in Step 1.

3. Strip the ends of a red jumper wire and connect one end of

the wire to the Source Terminal Block Connector at “S2” and

the other end to the breaker terminal where the red wire was

removed from in Step 1.

4. Insert the Load Terminal Block Connector into the Load Terminal

Jack until it is seated firmly and lock tabs are fully engaged.

5. Connect the Fault Trapper meter to the module using the

included Banana Plug Leader Cable.

Page 12 of 24

Page 13

Toll Free: 800-749-5783

www.planumtools.com

To connect to a 120VAC GFI or AFCI breaker (up to

40amps):

All connections to the Fault Trapper 40A In-Line Adapter Module are

made using supplied Plug-in Terminal Blocks Connectors, torque

screws to 7in-lbs:

1. Remove the hot and neutral from the breaker and attach them to

the load side of the Fault Trapper 40Amp Adapter Module with

the black wire at “L1” and white neutral at “L2”.

2. Keep the curly pigtail neutral white wire from the GFI/AFCI

breaker connected to the Neutral/GND Bus bar.

3. Connect a black jumper wire from the HOT port of the GFI/AFCI

breaker to the Source Terminal “S1”

4. Connect a white jumper wire from the NEUTRAL port of the GFI/

AFCI breaker to the Source Terminal “S2” and connect the Fault

Trapper meter to the module using the included Banana Plug

Leader Cable.

Page 13 of 24

Page 14

Toll Free: 800-749-5783

www.planumtools.com

Instructions for Use

After connecting in one of the configurations above and switching on

the breaker(s).

1. Powering on Unit – Once the unit is powered by the AC power

connection the battery level will be shown

on the display. The unit will be ready at this

point to run a test.

If there is no AC power connection the

Display button can be used to power the

unit on using battery power to show the

results from a previous test.

2. Starting a Test

– While powered by the AC power connection press the Test

button. The Fault Trapper will not run a test under battery power.

The velocity of propagation used for distance measurement is 70%

the speed of light, a nominal value for power wiring, and is not

configurable.

Before you start, note the time.

The Fault Trapper displays the elapsed time from when you start

the monitoring to when the fault occurs. You will need to know

the starting time to determine when the fault occurred.

3. Test Running – When a test is started “zero’s” will be scrolling

left to right in the test results area and the up down arrows on the

left side will be flashing until a fault is shown.

Once a fault is found the up down arrows will continue to flash while

the test is running while the distance to the last fault found is shown.

The lower left portion of the screen denotes the time. Before a

fault is found the time will show how long it has been since the test

started. Once a fault is found the last fault will be shown and the time

will show how long the time was between the beginning of the test

and the last fault found.

Page 14 of 24

Page 15

Toll Free: 800-749-5783

www.planumtools.com

4. Stopping a Test – The three ways a test can stop are:

a. When the AC power goes down,

b. The Test button is pressed

c. The Ignore button is pressed.

When the AC power goes down the unit will run on battery power for

long enough to finish scanning for the fault which may have caused

the AC to power off (breaker trip). If a fault occurred within the last

several seconds before the AC went down it will be classified as the

“Breaker Trip Fault”, the “Voltage!” icon will be displayed when this

occurs.

A non-breaker trip fault (if found earlier during the test) will also

be saved. When the Test button is pressed during a test any fault

found will be saved as a “Non-Breaker Trip Fault” and testing halted.

A second press of the Test button will

restart testing.

5. Ignore Feature – The ignore function

allows for ignoring a fault location that is

being reported under normal operation

of the circuit. The primary use would be

when a load which causes “faults” during

testing that are not important and should

be ignored to make it easier to find real

wiring issues. One example would be an

air conditioning compressor cycling on

and off.

A fault that trips the breaker will be

shown in the results regardless of

whether or not the fault was ignored.

If the displayed fault is

to be ignored, press the

IGNORE button briefly.

The test will stop running

and alternate between

displaying the current

fault to ignore and

displaying “IGN” until the

Setting an Ignore - To save an ignore

test is restarted.

location press the Ignore Button for a

short time. When an ignore is set the

Fault Trapper will alternate showing the distance to be ignored and

“IGN” until testing is resumed. If the Ignore Button is pressed while

a test is running the test will be stopped and the last fault found will

be saved. If the test is not running the fault to be ignored must be

chosen using the Display Button to toggle to the fault to be ignored

and then a short press of the Ignore Button will save that location.

The ignored location will continue through power cycles of the

Page 15 of 24

Page 16

Toll Free: 800-749-5783

www.planumtools.com

Fault Trapper. When powered on with

AC power the ignore location will be

shown on the screen and “IGN” will be

displayed in the lower left corner of the

screen.

Clearing an Ignore – To clear an

ignore location press and hold the

Ignore Button until “CLR” is displayed

on the screen.

6. Test Results - The Display button is used to show test results.

If the AC power connection is off the unit will use the 9 volt battery

to power on the display and show

the results from the last test. There

can be a “Breaker Trip” fault and a

“Non-Breaker Trip” fault. The voltage

icon will flash indicating that the fault

shown caused the breaker to trip. Tap

the Display button to cycle between

the two faults (if there are more than

one). Ft and M units can be toggled by

holding down the Display and Ignore

buttons for 3 seconds.

Page 16 of 24

Page 17

Toll Free: 800-749-5783

www.planumtools.com

Displaying Results using DISPLAY Button

Testing Stopped with No Results

7. Battery Remaining – In the lower right portion of the screen is a

battery icon with bars showing how much remains for the 9V battery.

Three bars shows a full battery, two bars is between 33% and 66%,

one bar is between 33% and 10%. A flashing battery outline icon

shows that there is less than 10% battery life remaining.

Since the test runs for a short time after the AC power shuts off it is

recommended to replace the 9V battery (with no AC power present)

once the battery indicator shows one bar or a flashing battery

outline icon.

Page 17 of 24

Page 18

Toll Free: 800-749-5783

www.planumtools.com

Maintenance

Changing the Battery

Warning! Remove any cables attached to the

Fault Trapper™ before opening any battery

compartment!

1. Remove screw on rear of unit near the middle with a #1 Philips

head screwdriver.

2. Remove battery and disconnect from battery snaps.

3. Attach a new 9 volt alkaline battery to the battery snaps and

return to battery compartment.

4. Place battery cover in slot and rotate shut. Fasten shut with

screw removed. Do not over tighten!

Replacing the Fuse in the 40A In-Line Adapter Module

The 40A In-Line Adapter Module contains a fuse used to protect

Fault Trapper cabling and circuitry.

Warning! To avoid electrical shock, remove

any cables attached to the 40A In-Line Adapter

Module before opening the case!

Replace fuse with same type and rating! The fuse is a special type

capable of interrupting high current circuits.

1. Remove four case screws using

a T-15 Torx® driver and open the

case.

2. Remove Fuse cover and fuse.

Replacement fuse is Littelfuse®

p/n 0215.250, 5x20 mm, time-lag,

0.25Amp, 250VAC.

3. Replace fuse cover, reassemble

case, replace 4 screws and tighten.

Warning! Never operate 40A In-Line Adapter

Module without the connector side panel being

installed! After servicing the fuse, verify safe state

of case and operation of unit.

Page 18 of 24

Page 19

Toll Free: 800-749-5783

www.planumtools.com

Specifications

Physical Dimensions

Fault Trapper Main Unit

Size: 15.25 x 7.6 x 3.8 cm (6.0 x 3.0 x 1.5 inches)

Weight: 255 grams (9 oz.) with battery

40A In-Line Adapter Module

Size: 11.5 x 7.6 x 5.85 cm (4.5 x 3.0 x 2.3 inches)

Weight: 312 grams (11 oz.)

Input Rating:

Fault Trapper Main Unit: 90 to 265 Volts AC RMS 50/60 Hz,

4 Watts max.

40 Amp In-Line Adapter: 300 Volts AC RMS, 40 Amp circuits

maximum, supplies power to main unit

Measurement Method: Spread Spectrum Time Domain Reflectometry

(SSTDR)

Accuracy: +/-10% of reading

Maximum Length: 300 ft on NM-B or Wire in Conduit

Battery is used to review results when not AC powered

Battery Low Level: Approximately 5.5 volts

Battery Life (9 Volt Alkaline battery, typical)

Standby: 2 years

Active: 4 hours typical

Environmental

Temperature

Operating: 0° to 50°C (32° to 122°F)

Storage temperature: -20° to 60°C (-4° to 140°F)

Long Term Storage w/ battery: 35°C maximum (95°F)

Humidity: 10% to 90%, Non-Condensing

Altitude: 2,000 meters (6,561ft) maximum

Patents / Intellectual Property

Platinum Tools product: Fault Trapper may be covered by one or

more of the following patents: US Patent No. 6868357, US Patent

No. 6937944, US Patent No. 7069163, US Patent No. 7215126,

US Patent No. 7250772, US Patent No. 7271596, US Patent No.

7165200, US Patent No. 7495450, US Patent No. 7075309, US

Patent No. 7282922, US Patent No. 7634012, US Patent No.

7622931, US Patent No. 7548071.

Page 19 of 24

Page 20

Toll Free: 800-749-5783

www.planumtools.com

Fault Trapper™ FAQ

Does the Fault Trapper Require Batteries?

- Yes, the Fault Trapper requires a 9V battery in the event of Power

Loss from the wires under test. The Fault Trapper requires a

high quality welded cell 9V battery such as Duracell®. Generic

budget batteries may not be sufficient to power the Fault Trapper.

The Fault Trapper main unit does not power up when it is

connected to AC power.

- Check that the Fault Trapper is connected correctly.

- Check the fuse in the 40A Adapter Module. If the fuse is blown, a

replacement can be ordered from Digi-Key® at www.digikey.com,

P/N F4603-ND.

The Fault Trapper does not see a fault when I short the wires to

trip the breaker intentionally.

- If the ignore button has been pressed, the Fault Trapper will

ignore the fault. Press and hold the Ignore button until the LCD

displays “clr”, this clears the ignore feature.

Does the Fault Trapper and 40 Amp Adapter Module work in wet

environments?

- No, the Fault Trapper and 40 Amp Adapter module must be

operated in dry environments.

Can I use my own longer or shorter Banana Jack leader cable

between the Isolation module and main unit?

- No. The impedance, length and voltage rating is critical to safe

and correct operation of the unit.

My unit seems to work fine, but doesn’t save the last event

detected.

- The battery must have enough energy to run the unit for 5

seconds on battery power alone. If your battery is low or poor

quality, the unit may not be powered on long enough to save the

results.

The Fault Trapper doesn’t report the breaker tripping because

of sustained over-current loads; I thought it would tell me where

the fault is.

- The Fault Trapper does not measure current. The Fault Trapper is

designed to locate actual wiring faults. If the over-current event is

Page 20 of 24

Page 21

Toll Free: 800-749-5783

www.planumtools.com

from a wiring short (not just the load at the end of the run) it will

be detected as a short at the event distance.

How can I get the latest information on my Fault Trapper?

- Go to www.platinumtools.com for manual updates, more FAQs,

and other important information.

Will the Fault Trapper detect series and or Parallel arc faults?

- It depends on the nature of the connection/parallel arc

event. When the Fault Trapper detects an open or loose wire

connection for 5 half AC cycles in a row (33mS) it will be

reported as an open fault. Parallel arc detection takes 5 half AC

cycles with low impedance to be detected as a short fault. In

the case of parallel arcing, if the shorting material is blown out,

blown apart, vaporized or someway removed before the 5 half

cycles, it may not be detected as a fault.

How far down a daisy-chained branch circuit would the Fault

Trapper be able to detect faults?

- The Fault Trapper is optimized for monitoring homerun circuits.

Using it to monitor circuits that extend beyond a homerun may

detect a fault but the accuracy of displayed distance to the fault

maybe affected.

Sometimes the circuit breakers are due to ground faults, will the

Fault Trapper detect this?

- The Fault Trapper is capable of detecting electrical events due to

shorts and opens between hot and neutral lines. It will not detect

events due to ground-faults.

Most circuits in a breaker box use dedicated neutrals for each

line, however, there are cases where two hot wires may share

a common neutral. Would this compromise the Fault Trappers

ability to detect a fault?

- The two hot wires have to be different phases, effectively a 240V

line using 120V to the neutral from each phase instead of using

the 240 available across the two hot wires. This should not be

a problem for Fault Trapper. Connect Fault Trapper to Hot line

to be monitored and the neutral bus as shown in 120V hook up

section.

Page 21 of 24

Page 22

Toll Free: 800-749-5783

www.planumtools.com

Snap Shot™ Cable Fault Finder

Platinum Tools recommends the Snap Shot™ Cable Fault Finder for

a great companion tool with your Fault Trapper!

With the Fault Trapper you are able to find the approximate location

of a fault in a dedicated circuit. To find the length to the fault to

within 1% accuracy or better you need a cable fault locator time

domain reflectometer tool that is fast, accurate and easy to use to

see down the wire and show the exact conditions that exist. The

Snap Shot™ is that tool.

The Snap Shot™ accurately finds cable length, impediments in the

cable and conditions at the end of every wire in your data, power,

or communications/video system up to 3,000 ft. Calibrate it for your

specific cable for the most accurate length measurements available.

Advanced Spread Spectrum TDR technology works in all wire

environments and is immune to voltage, current, or data stream

disruptions. See the true picture of your wiring and cable systems

with the Snap Shot™ cable fault detector and length measurement

tool today.

Page 22 of 24

Page 23

Notes

Toll Free: 800-749-5783

www.planumtools.com

Page 23 of 24

Page 24

Toll Free: 800-749-5783

www.planumtools.com

Toll Free: 800-749-5783

www.platinumtools.com

IS TFT100 REV A 11/15

Loading...

Loading...