Platinum Tools HPH48, HPH32W, HPH16, HPH48W, HPH64W Installation Instructions Manual

...

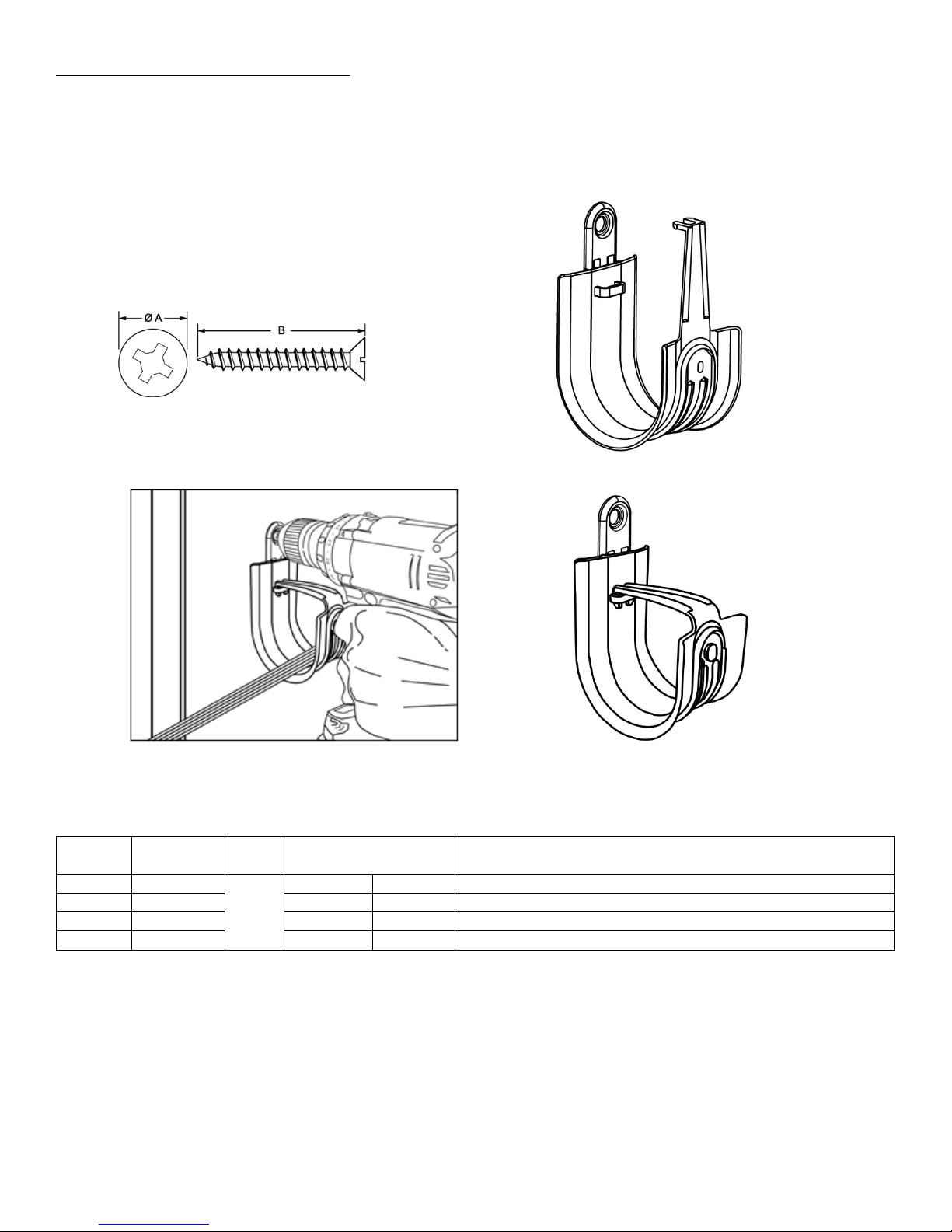

HPH Series J-Hook Installation Instructions

1

Mounting to a vertical surface: HPH16, HPH32, HPH48 and HPH64

Part

Hook

Fig.

UL Load Rating

Description

HPH16

1"

20

88.96

1” Standard HPH J-Hook, size 16

HPH32

2”

17

75.62

2” Standard HPH J-Hook, size 32

HPH48

3”

20

88.96

3” Standard HPH J-Hook, size 48

HPH64

4”

17

75.62

4” Standard HPH J-Hook, size 64

Use a nail*, bolt* or screw* with a minimum head diameter of 0.329” (Fig.1-A) and an

appropriate length for the substrate (Fig.1-B) to fasten the HPH J-Hook (Fig.2) to the vertical

surface (Fig.3). Insert the cables and close the latch as shown in Fig.3. The latch must be in the

closed position as shown in Fig.4 to secure the cables and complete the installation.

Fig.1 Fig.2

Fig.3 Fig.4

No.

Size

No.

2 & 4

LBS. | N

2

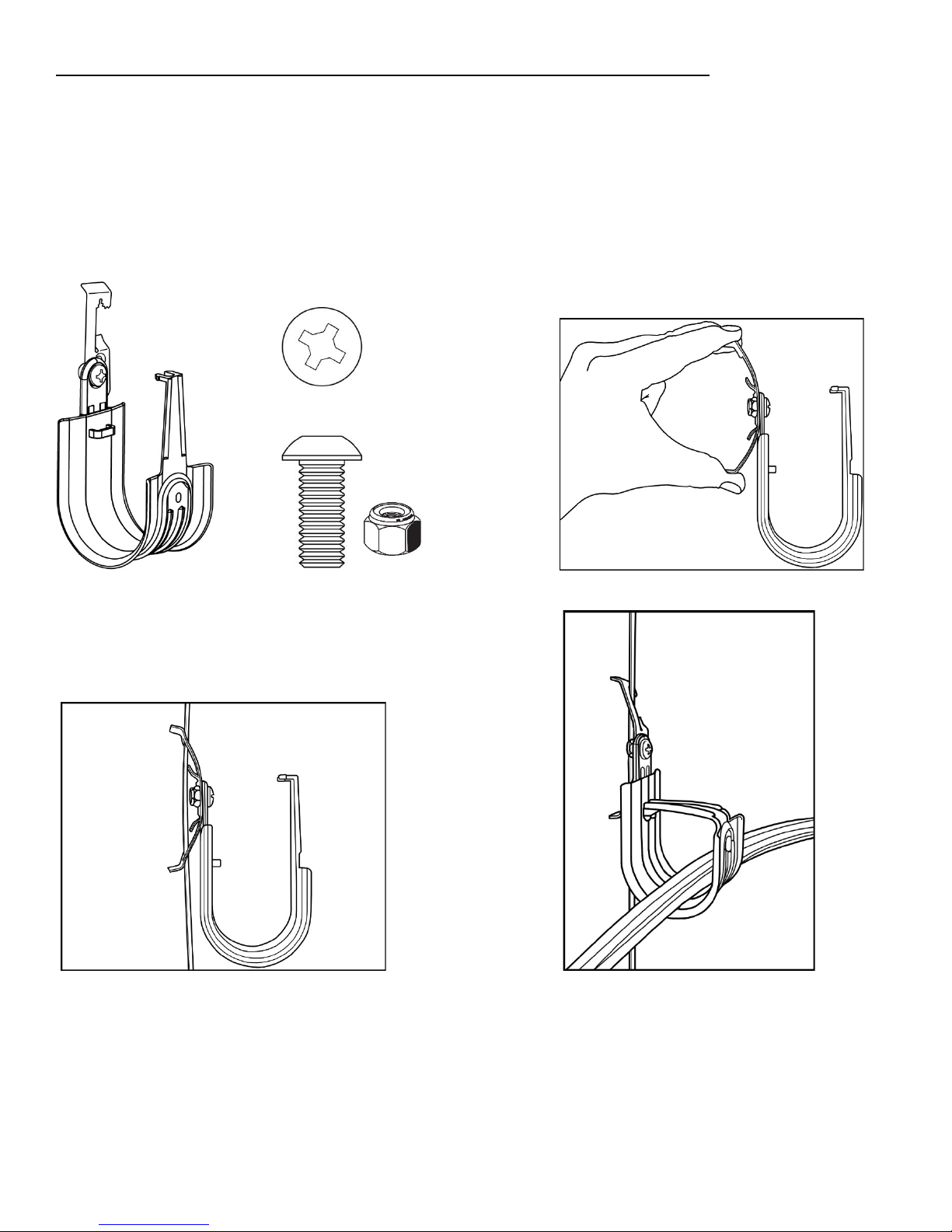

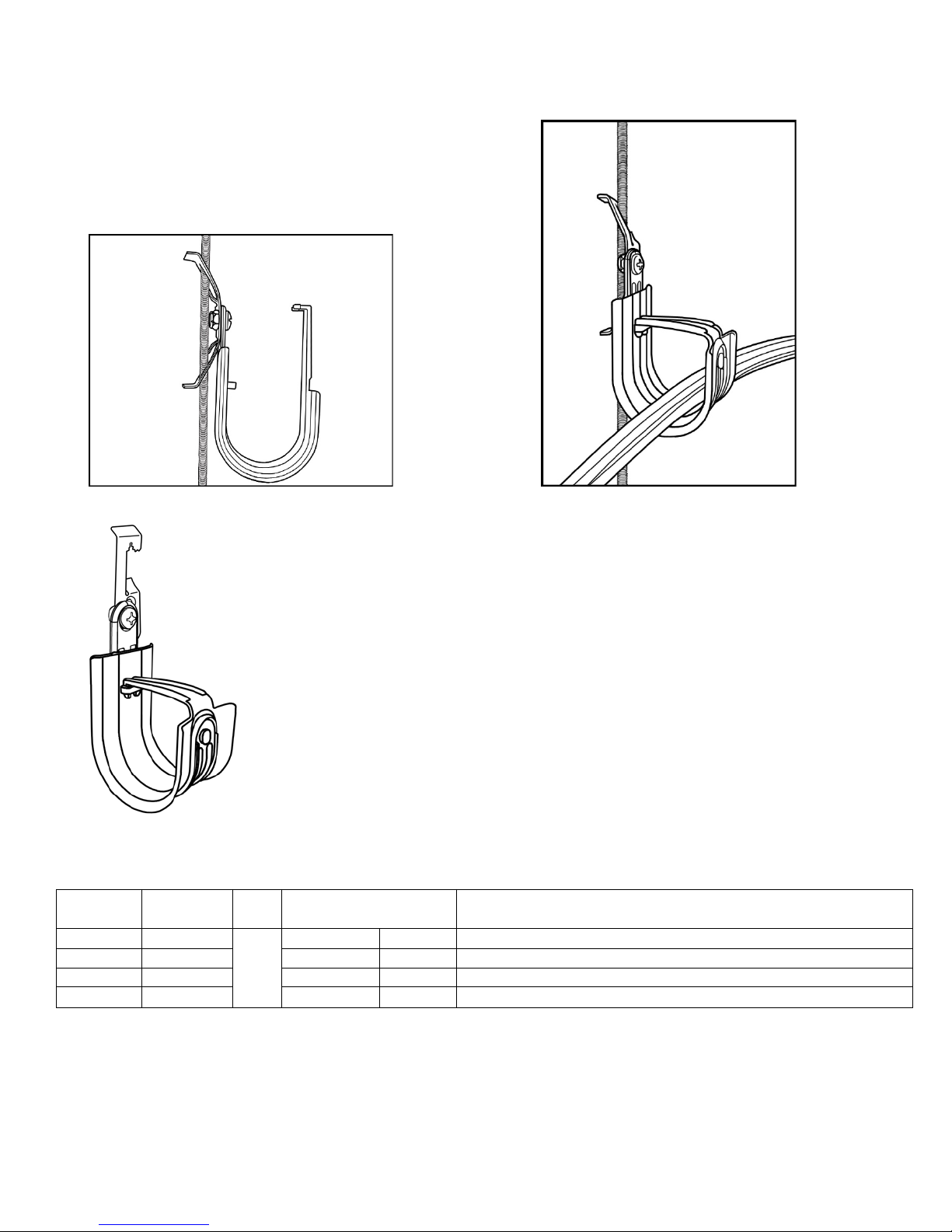

Mounting to a rod or ceiling wire with a Multi-Function Clip-Batwing: HPH16W,

HPH32W, HPH48W and HPH64W

HPHXXW J-Hooks (Fig.1) are pre-assembled to Multi-Function Clip-Batwings at the factory using

a fastener such as a rivet or a zinc plated ¼-20 x 3/8” pan head Phillips machine bolt and a

grade A ¼-20 hex Nylon locknut (Fig.2). A plain HPH J-Hook may be assembled to a UL listed

batwing clip in the field with the use of a similar fastener. Depress the batwing between your

fingers (Fig. 3). Attach the HPHXXW to 12 gauge ceiling wire or 1/4" threaded rod (Fig.4 and

Fig.6).

position as shown in Fig.8 to secure the cables and complete the installation.

Insert the cables and close the latch (Fig.5 and Fig.7). The latch must be in the closed

Fig. 1 Fig. 2 Fig. 3

Fig. 4 Fig. 5

3

Part No.

Hook

Fig.

UL Load Rating

Description

HPH16W

1"

20

88.96

1” Batwing HPH J-Hook, size 16

HPH32W

2”

20

88.96

2” Batwing HPH J-Hook, size 32

HPH48W

3”

20

88.96

3” Batwing HPH J-Hook, size 48

HPH64W

4”

20

88.96

4” Batwing HPH J-Hook, size 64

Fig. 6 Fig. 7

Fig. 8

Size

No.

1

&

8

LBS. | N

4

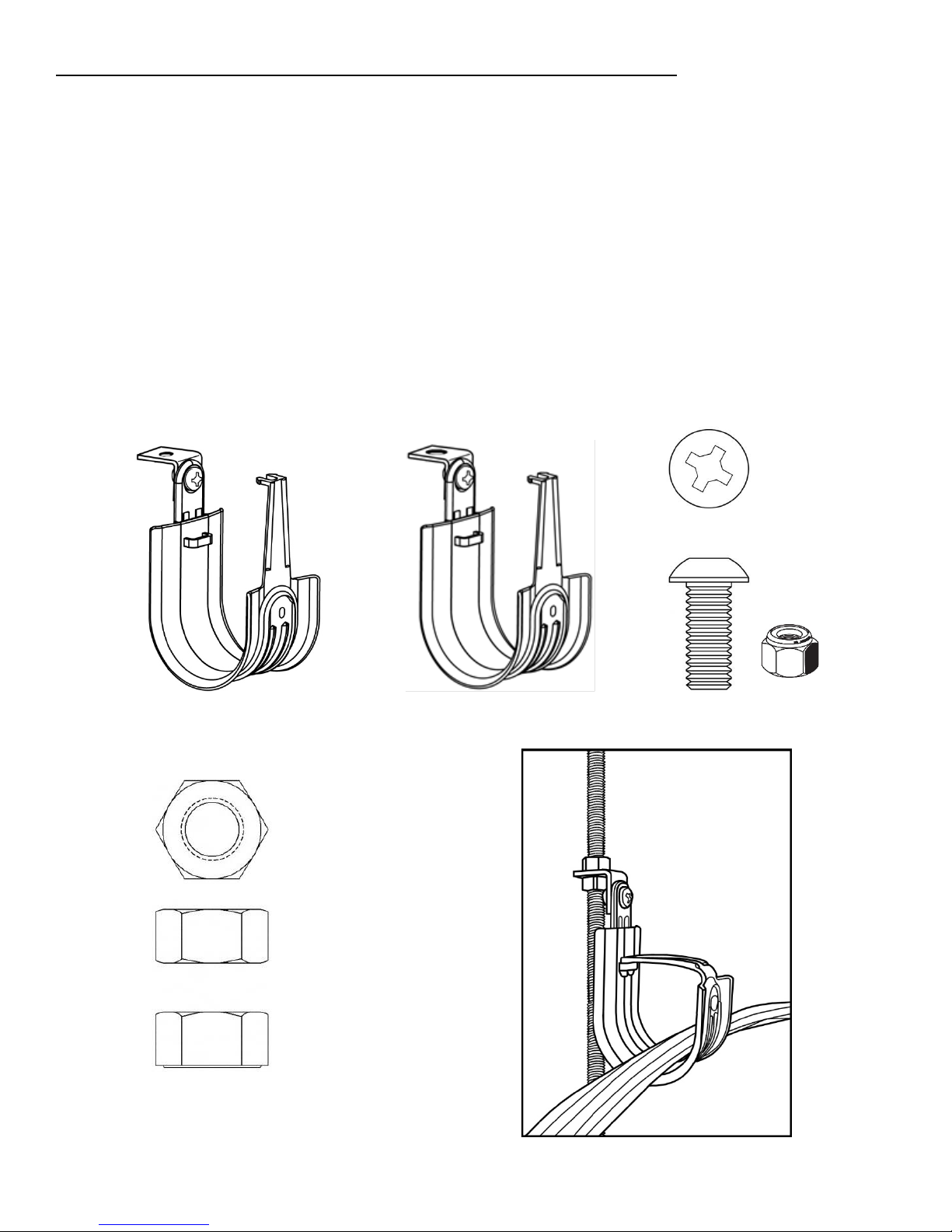

Mounting to a rod or a horizontal surface with an Angle Clip 90°: HPH16AC, HPH16AC6

HPH32AC, HPH32AC6, HPH48AC, HPH48AC6, HPH64AC & HPH64AC6

HPHXXAC and HPHXXAC6 J-Hooks (Fig.1 and Fig.2) are pre-assembled to Angle Clips 90° at the

factory using a fastener such as a rivet or a zinc plated ¼-20 x 3/8” pan head Phillips machine

bolt and a grade A ¼-20 hex Nylon locknut (Fig.3). A plain HPH J-Hook may be assembled to a

Platinum Tools Angle Clip 90° in the field using a similar fastener. Fasten the HPHXXAC or

HPHXXAC6 to 1/4" or 3/8” threaded rod using two standard hex nuts (Fig.4). Thread a single nut

up to the desired location of the threaded rod. Guide the HPHXXAC or HPHXXAC6 onto the

threaded rod. Thread a second nut onto the threaded rod and tighten to the first nut, thereby

sandwiching the Angle Clip 90° between the two nuts (Fig.5). An HPHXXAC or an HPHXXAC6

may be fastened directly to the underside of a horizontal surface using an appropriate fastener*

(Fig.6). Use a fastener with an appropriate head diameter (Fig.7-A) and an appropriate length

for the substrate (Fig.7-B). Place the cables in the hook and close the latch as shown in Fig.5

and Fig.6. The latch must be in the closed position as shown in Fig.8 and Fig.9 to secure the

cables and complete the installation.

Fig.1 Fig.2 Fig. 3

Fig. 4 Fig. 5

5

Loading...

Loading...