Page 1

TM

JackAX Instructions

Instruction Sheet: P/N 13210, 13211C, 13212C

®

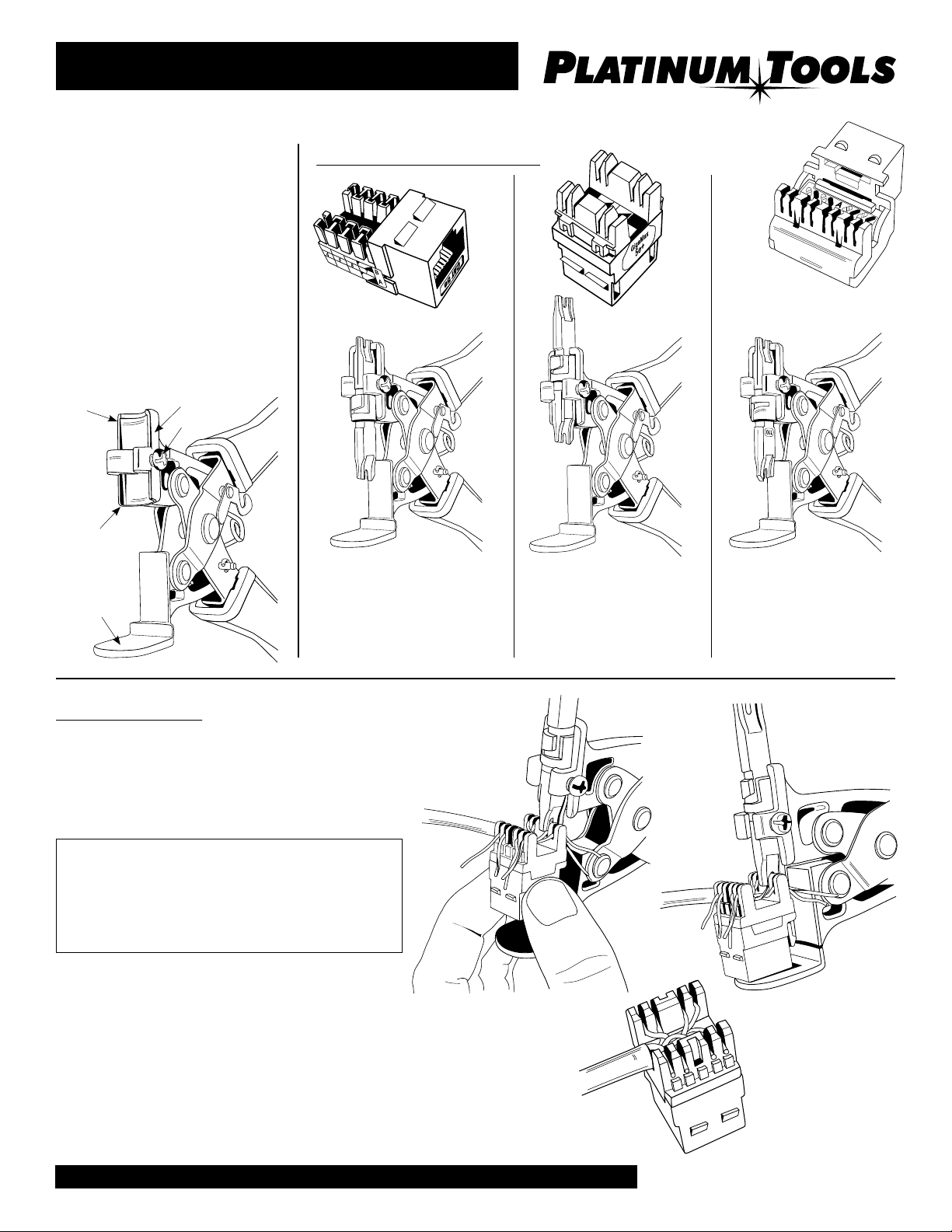

Using either a Philips or slotted

screwdriver, back the holding screw

off enough to insert and seat the

110 blade. The type of jack used will

determine how to position the 110

blade in the holding xture of the

JackAX. Install the blade as shown

below to correspond to the jack.

Once properly seated, hold the blade

rmly in place & tighten the screw

down securely. Be careful not to

over tighten.

JackAX: Tool only, no blade.

Upper Position

Lower

Position

Base

Holding Fixture

Screw

Jacks and Blade Positions:

90° Jack

90° Jacks: Insert the 110 blade

in the

lower

holding xture, with the cutting

knife of the blade facing the tool.

position of the

180° Jacks: Insert the 110

blade in the

of the holding xture, with

the cutting knife of the blade

facing the tool.

upper

180° Jack Single Row

Pairing Jack

Single Row Pairing Jacks:

position

Insert the 110 blade in the

lower

position of the holding

xture, with the cutting knife

of the blade facing away from

the tool.

Prep & Terminate:

1) Strip cable jacket.

2) Prep all 4 pairs (8 conductors or wires).

Choose your wiring scheme, A or B, and

insert each conductor into the proper IDC

slot per the color code chart on the jack.

Inserting the conductors into the IDC, choose what

works best for you:

n All 4 pairs & terminate.

n 2 pairs per side & terminate one side at a time.

n 2 pairs at the front end & terminate.

Repeat on the back end.

3) Position the prepared jack into the blade (Fig 1)

lining up the IDC with the blade. Squeeze the tool

until the jack and the base come together.

4) Once the jack ts snugly on the tool’s base (Fig 2),

continue to squeeze slowly, seating the conductor until

it is seated & cut. Once cut, release handles.

Do not over squeeze!

5) Repeat steps 3 & 4 until all conductors are terminated

as shown in Fig 3.

Fig 2

Fig 1

Fig 3

www.platinumtools.com

©2010 Platinum Tools Inc. All rights reserved. 7/10

Loading...

Loading...