Platinum Access Systems BLSW1016 Installation Instruction And Owenrs Manual

BLSW1016

3

Installation Instructions & Safety Information Manual

BLSW1016

Installation Instructions and Safety Information Manual:

Vehicular Gate Operator

Class I, Class II, Class III, and Class IV

Safety Information

Installation

Inductive Loops

Alarm Reset Switch

Plan of Installation

Electrical

Limit Switches

Primary/Secondary Connections

Loop Rack

Accessory Connections

Selectable Features

Maintenance

Gate Operator Trouble Shooting Procedure

Part

...............................................4-8

.............................................9-10

...........................................11-12

................................................13

..........................................14-17

..........................................18-19

...............................................20

...............................................22

...............................................23

..........................................24-27

..........................................28-30

...............................................31

...........................................32-33

...............................................34

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 3

4

SAFETY INFORMATION

1. READ AND FOLLOW ALL INSTRUCTIONS MANUAL BEFORE ATTEMPTING ANY INSTALLATION.

2. Should never let children play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. “NO ONE SHOULD CROSS THE PATH OF

THE MOVING GATE”.

4. Check and test the gate operator monthly. The gate MUST reverse on contact with a rigid object

or when an object activates the non-contract sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the gate operator properly can increase

the risk of injury or death.

5. 7KHJDWHV\VWHP0867EHPDLQWDLQHGSURSHUO\+DYHDTXDOL¿HGVHUYLFHSHUVRQLQVSHFWUHSDLURU

adjust your system if any unusual behavior is observed or suspected.

6. Some companies offer a scheduled preventive maintenance service.

7. '2127(;&(('WKHHTXLSPHQWVSHFL¿FDWLRQV

8. Insure a safe and proper installation.

9. ,QVWDOOWKLVHTXLSPHQWLQDFFRUGDQFHZLWKWKH8/VSHFL¿FDWLRQV

10. All installation MUST have secondary protection devices against entrapment, such as edge sensors and photo beams especially in places where the risk of entrapment is more likely to occur.

11. Gate is for vehicles only, a separate entrance for pedestrians is required.

12. SAVE THESE INSTRUCTIONS

SAFETY DEVICES:

1. Remove the Power Harness for the control board.

2. Check that all mounting hardware of the gate operator is properly tightened.

3. Ensure that the gate moves freely.

4. Check the battery for the following:

Battery connections must be free of corrosion.

Battery voltage must be 26.5 VDC minimum (fully charged battery).

5. Reconnect the Power Harness for the control board.

6. Make sure every installation has a minimum of one safety device (such as photo beams or loop

detector).

7. Check for Reverse Sensitivity.

8. Make sure that all areas around the gate are safe and secure.

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 4

5

SAFETY INFORMATION

GENERAL SAFETY PRECAUTIONS WITH THE END-USER:

1. Instruct the end-user on how to safely operate all functions of the operator.

2. Instruct the end-user on how to safely use the Back-drive/ Emergency Release Options.

3. Clearly label and identify the circuit breaker for the operator and show the End-User the location of

the circuit breaker for the operator.

4. Thoroughly explain any and all warranties associated with the operator and installation.

5. These instructions must be kept for reference and forwarded to all possible future users of the system.

6. Provide the End-User with the “Home Owner’s Manual Guide”.

7. The Manufacturer cannot be held responsible for possible damage caused by improper, erroneous or

unreasonable use.

8. $OOFOHDQLQJPDLQWHQDQFHRUUHSDLUZRUNPXVWEHFDUULHGRXWE\TXDOL¿HGSHUVRQQHO

9. Failure to comply with the above may create a situation of danger.

10. All installation, maintenance and repair work must be documented and made available to the user.

Signature:

Contact:

Date:

Installer:

11. When gate is moving, do not:

a. Allow any children to play near the moving gate.

b. Attempt to obstruct the moving gate.

c. Allow any one get close to the moving gate.

12. Keep remote control, or any other gate operator remote devices away from the children.

13. If operator breakdown, or mulfunction, please disconnect the operator from the main power source.

Do not attempt to repair, or intervene directly by any one except a qualify personnel.

IMPORTANT INSTALLATION INSTRUCTIONS BY UL STANDARDS:

1. Install the vehicular gate operator only when:

a. The gate operator is appropriate for the construction of the gate and the usage class of the

gate.

b. All exposed pinch points are eliminated or guarded.

2. The gate operator is intended for installation only on gates used for vehicles. Pedestrians must be

supplied a separate access opening.

a. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate

such that persons will not come in contact with the vehicular gate during the entire path of travel of

the vehicular gate.

3. The gate must be installed in a location so that enough clearance is supplied between the gate and

adjacent structures when opening and closing to reduce the risk of entrapment. Swinging gates shall

not open into public access areas.

(CONTINUED ON NEXT PAGE...)

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 5

6

SAFETY INFORMATION

IMPORTANT INSTALLATION INSTRUCTIONS BY UL STANDARDS:

(CONTINUED FROM PREVIOUS PAGE)

4. The gate must be properly installed and work freely in both directions prior to the installation of

the gate operator. Do not over-tighten the arm clamp to compensate for a damaged or poorly

maintained gate.

5. The gate operator controls must be placed so that the user has full view of the gate area when

the gate is moving and away from the gate path perimeter.

6. Controls intended for user activation must be located at least six feet (6’) away from any moving

part of the gate and where the user is prevented from reaching over, under, around or through

the gate to operate the controls and shall be at least (5’) from the ground as to be out of reach of

children. Outdoor or easily accessible controls shall have a security feature to prevent unauthorized use. Also:

7. Ensure the Stop and/or Reset button must be located in the line-of-sight of the gate following

rules above. Activation of the reset control shall not cause the operator to start.

8. A minimum of two (2) Warning Placards shall be mounted, one on each side of the gate where

easily visible.

9. A gate operator utilizing a non-contact sensor such as an Photo beam or like in accordance

with section 31.1.1 of the UL325 standard:

a. Reference owner’s manual regarding placement of non-contact sensor for each type of ap plication.

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips

the sensor while the gate is still.

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction

exists, such as the perimeter reachable by a moving gate or barrier.

d. We recommend (EMX IRB-325) use as a fail safe photoeye to comply with UL325.

10. A gate operator utilizing a contact sensor such as an edge sensor or like in accordance with

section 31.1.1 of the UL325 standard:

a. A hard wired contact sensor shall be located and its wiring arranged so the communication

between the sensor and the gate operator is not subject to mechanical damage.

b. A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the

gate operator for entrapment protection functions shall be located where the transmission of

the signals are not obstructed or impeded by building structures, natural landscaping or simi lar obstruction. A wireless contact sensor shall function under the intended end-use condi tions.

c. One or more contact sensors shall be located on the inside and outside leading edge of a

swing gate. Additionally, if the bottom edge of a swing gate is greater than 6 inches (152 mm)

above the ground at any point in its arc of travel, one or more contact sensors shall be lo cated on the bottom edge.

d. The following model(s) are comply with UL 325: Miller Edge model MGR20 or MGS20 edge

sensor.

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 6

7

gate operator class categories and examples

CAUTION: To Reduce the Risk of Fire or Injury to Persons

Use only the type and size of batteries provided on an AC powered system: OUTDO-OT7-12

'RQRWGLVSRVHRIWKHEDWWHULHVLQ¿UH7KHFHOOVPD\H[SORGH&KHFNZLWKORFDOFRGHVIRUSRVVLEOH

disposal instructions.

Do not open or mutilate the operator batteries. Released electrolyte is corrosive and may cause

damage to the eyes or skin. It may be toxic if swallowed.

Exercise care in handling batteries in order not to short the battery with conducting materials such

as metal parts, rings, bracelets and keys.

Do not mix batteries of different sizes, from different manufacturers or of different ages in this

product. Replace both batteries as a set.

Observe proper polarity orientation between the batteries and charging circuit.

&KDQJHWKHRSHUDWRUEDWWHULHVSURYLGHGZLWKRULGHQWL¿HGIRUXVHZLWKWKLVSURGXFWRQO\LQDFFRU-

GDQFHZLWKWKHLQVWUXFWLRQVDQGOLPLWDWLRQVVSHFL¿HGLQWKLVRSHUDWRUPDQXDO

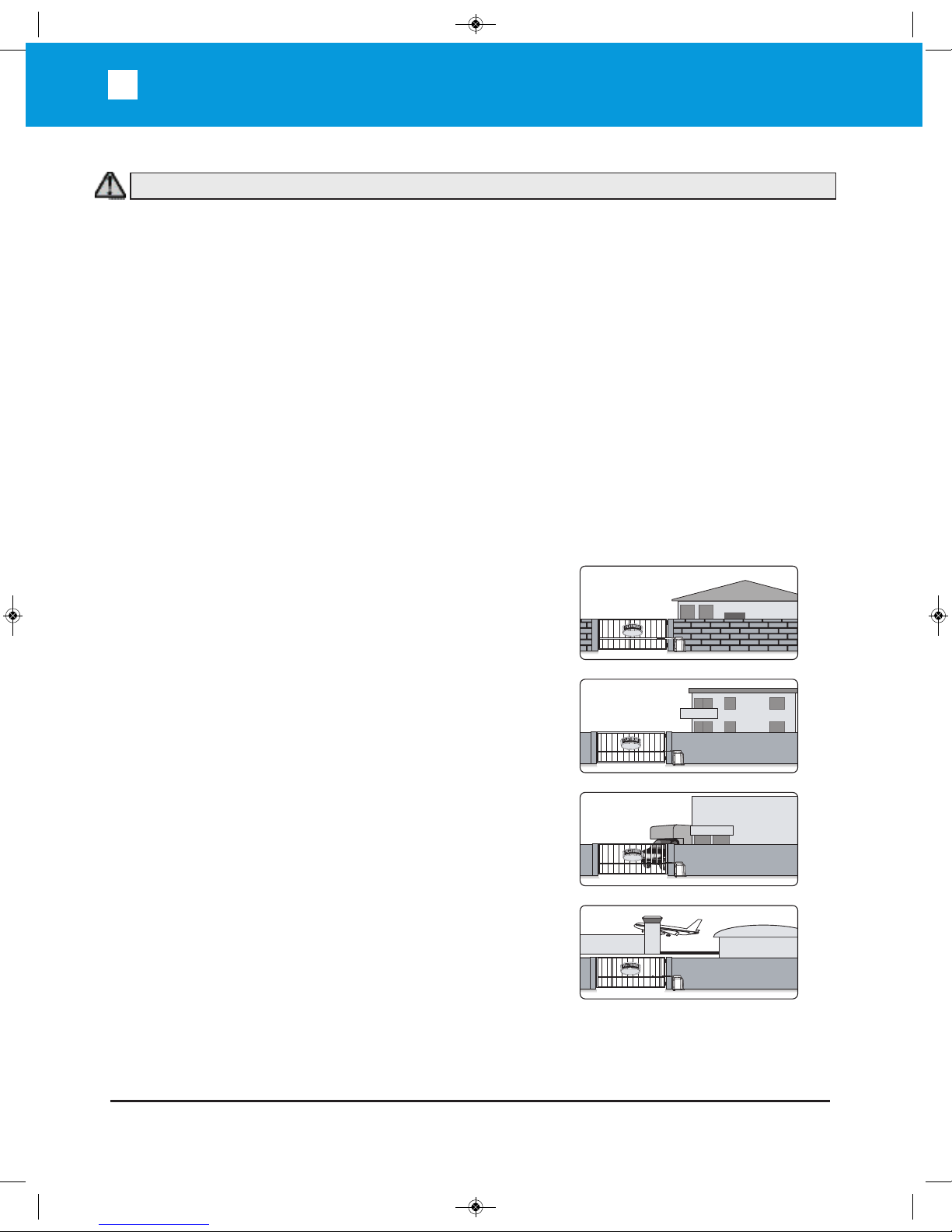

8/*DWH2SHUDWRU&ODVVL¿FDWLRQ

Install the gate operator only when: The operator is appropriate for the construction of the gate and the

Usage Class of the gate.

RESIDENTIAL VEHICULAR GATE OPERATOR

CLASS I – A vehicular gate operator (or system) intended for use In

a home of one-to four single family dwelling, or a garage or parking

area associated there with.

COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

CLASS II – A vehicular gate operator (or system) intended for use in

a commercial location or building such as a multi-family housing unit

¿YHRUPRUHVLQJOHIDPLO\XQLWVKRWHOJDUDJHVUHWDLOVWRUHRURWKHU

building servicing the general public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

CLASS III – A vehicular gate operator (or system) intended for use

in an industrial location or building such as a factory or loading dock

area or other locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR

CLASS IV – A vehicular gate operator (or system) intended for use in

a guarded industrial location or building such as an air port security

area or other restricted access locations not servicing the general

public, in which unauthorized access is prevented via supervision by

security personnel.

HOTEL

FACT ORY

DOCK

HANGAR 00

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 7

8

SAFETY INFORMATION

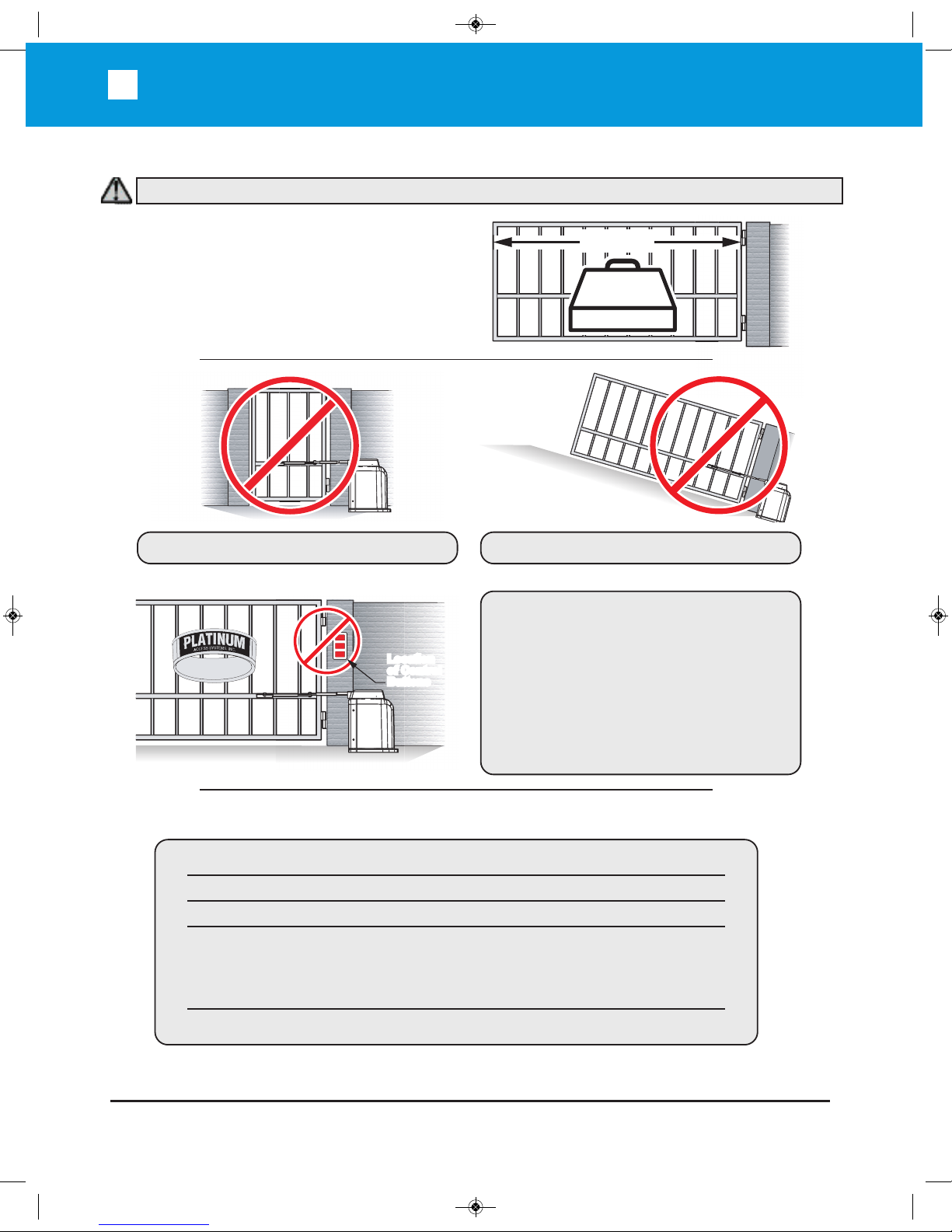

FOR USE WITH GATES OF A

MAXIMUM OF 16 FT IN LENGTH

AND 1000 LBS. IN WEIGHT

Specifications

This is NOT a pedestrian gate operator

Do NOT Install the gate operator to lift gates

Control Buttons Location:

1. Within sight of the gate,

2. At a minimum height of 5 feet so

small children are not able to

reach it, and make sure it is

away from all moving parts of

the gate.

1000 lb.

MAX.

16'-0"

CLOSE

STOP

OPEN

Location

of Control

Buttons

Location

of Control

Buttons

Maximum Gate Length:

Maximum Gate Weight:

Maximum Aperture Angle:

Power Requirements:

Operating Temperature:

16 feet

1000 lbs

120 deg.

120 VAC Single Phase at 2 Amps

or

220 VAC Single Phase at 1 Amp

-20°C (-4°F) to 70°C (158°F)

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 8

9

INSTALLATION

Contact Sensor (Edge) Installation:

Secondary Entrapment Protection

One or more contact sensors shall be located on the inside and outside leading edge of a swing gate.

Also if the bottom edge of a swing gate is more than 6” (152mm) above the ground at any point in its

travel on or more sensors shall be located to protect from the bottom edge.

A wireless contact sensor such as one that transmits radio frequency signals to the gate

operator for entrap-ment protection functions shall be located where the transmission of the

signals are not obstructed or im-peded by building structures, natural landscaping or similar

obstruction. A wireless contact sensor shall function under the intended end-use conditions.

A hardwired contact sensor shall be located and its wiring arranged so that the communica-

tion between the sensor and the gate operator is not subjected to mechanical damage.

Use only Miller Edge 3-sided activation type MGR20 or MDS20 to comply with UL325

3-Sided Edge Sensor

3-Sided Edge Sensor

When manual operation is required:

1. Remove the Hat

2. Lift the Locking Handle.

3. Remove the Clutch Key

To reengage the gate operator:

1. Align the Clutch and the notches on the

Output Shaft.

2. Insert the Clutch Key.

3. Push down the Locking Handle.

4. Reattach the Hat.

Attention: Lock and release operations MUST

be performed with motor NOT RUNNING.

Manual Release

Locking Handle

(in Unlocked

Position)

Note: This type of installation DOES NOT reverse the gate all the way back to its limits when the photobeam is obstructed. This installation is only to protect against entrapment and to comply with UL325.

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 9

10

INSTALLATION

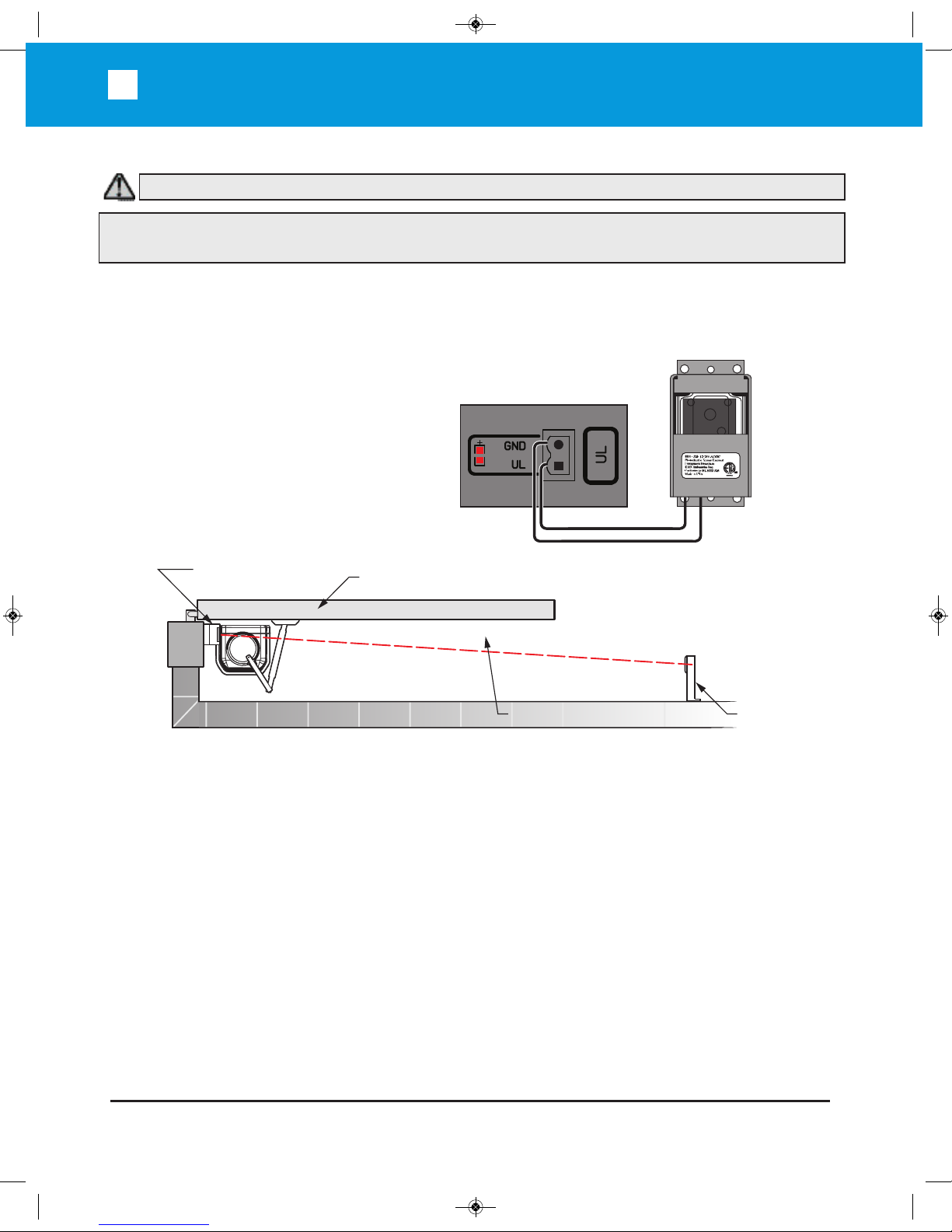

Non-Contact Sensors (Photoelectric Sensors) Installation:

One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists,

such as the perimeter reachable by a moving gate or barrier.

Install photoelectric sensors to protect

against any entrapment or safety conditions

encountered in your gate application.

We recommend the use of EMX IRB-325

photoeyes to comply with UL325.

Open Position

Photo Beam Device

Reflector

Potential Entrapment Area

Consult the UL325 device installation manual for more detail information about the usage,

installation and maintenance of this device.

Note: This type of installation DOES NOT reverse the gate all the way back to its limits when the photobeam is obstructed. This installation is only to protect against entrapment and to comply with UL325.

TX

EMX Model

IRB-325

Shown

Connection ‘1’ (C1)

Connection ‘2’ (NC1)

WARNING – To reduce the risk of severe injury or death to person, please to follow these instructions:

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 10

11

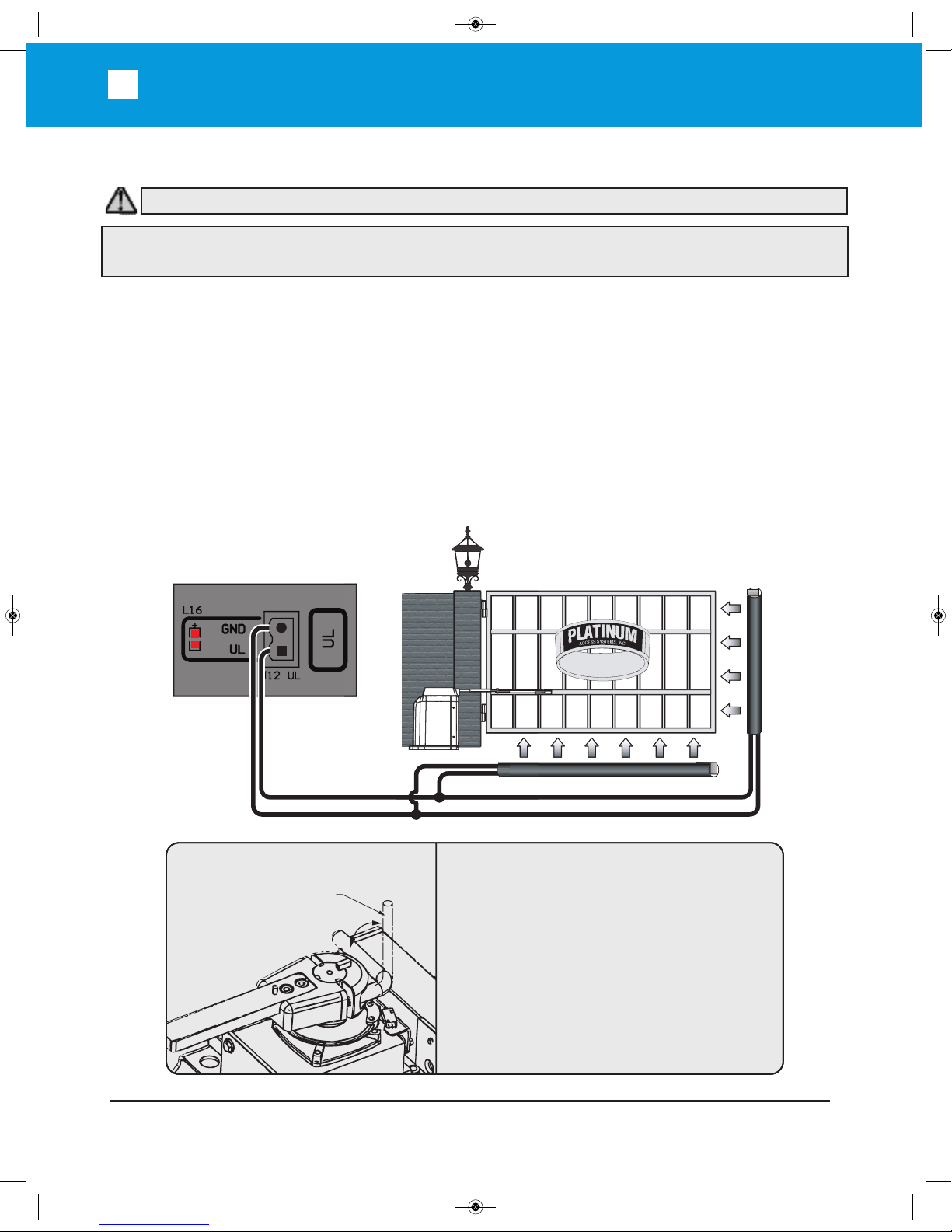

Installation: Inductive Loops

Inductive Loops Installation:

Safety loops allows the gate to stay open when vehicles are obstructing the gate path.

If the gate is longer than the vehicles that pass through it a center loop is recommended and should

be installed. A center loop prevents the gate from closing when a vehicle is between the safety loops.

Safety loops are required when using a center loop. See Loop Wiring.

Outside

Inside

Outside Safety

Loop

Center

Loop

Inside Safety

Loop

Exit

Loop

5'

5' 5'

XX

5'

Gate in Open Position

Even with Open Gate

Outside

Safety

Loop

Outside Inside

Center

Loop

Inside

Safety

Loop

Exit

Loop

Check with local regulations and accepted best practice requirements for every installation.

S

WARNING – Consult the installation instructions from the loop detector manufacturer. The following

statements are provided as a guide but different requirements may be required by the vehicular loop

detector manufacturer.

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 11

12

Installation: inductive loops

WARNING – This product is an accessory or part of a system. Always read and follow the manufacturer’s instructions for the equipment before connecting this product. Comply with all applicable codes

and safety regulations. Failure to do so may result in damage, injury or death.

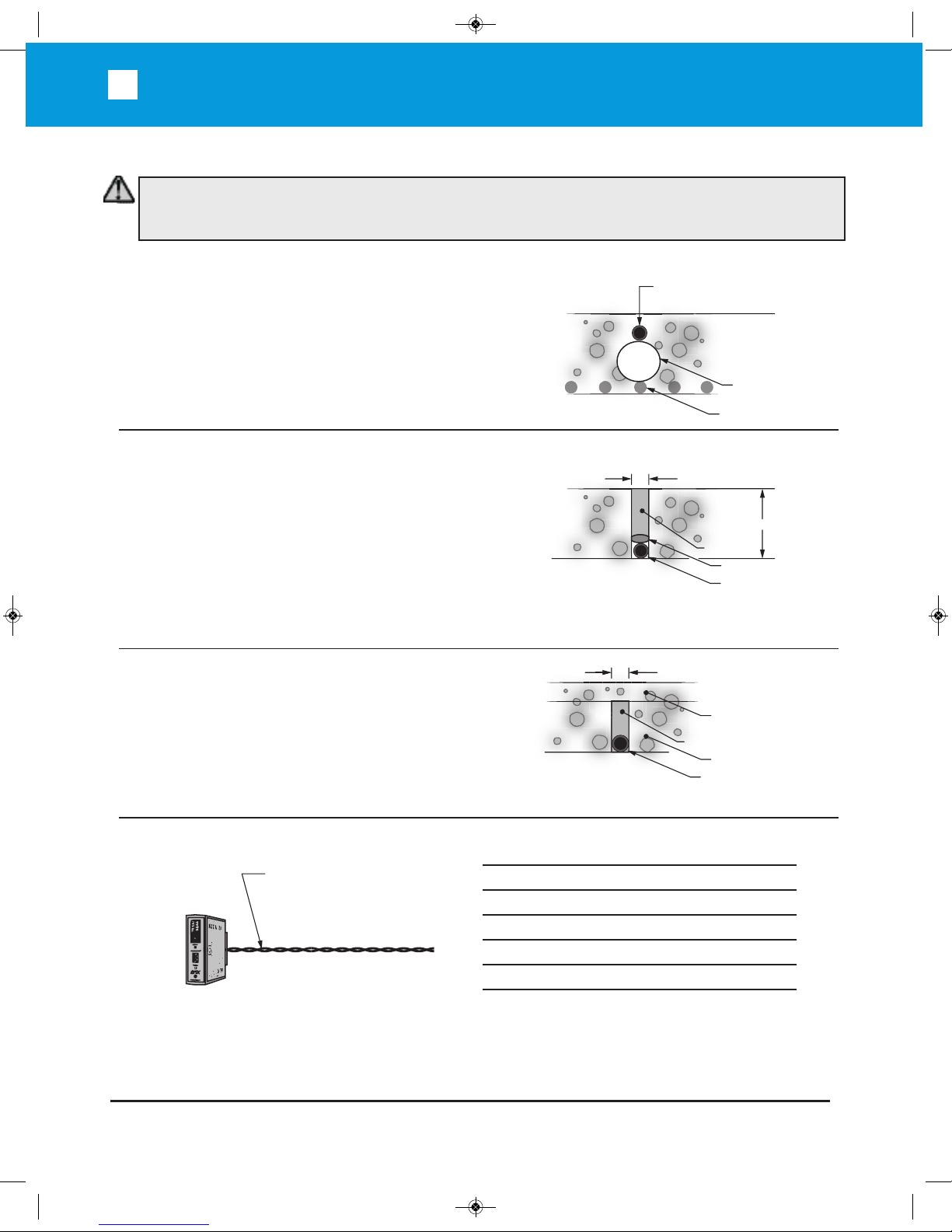

Inductive Loops Installation:

Recommended # of Turns

Perimeter in Feet # of Turns

10 5

20 4

30-40 3

50-100 2

General Installation Guidelines

Lead-in wire (wire from loop to

detector) must be must be twisted

a minimum of 6 turns/ foot to

avoid the effects of noise or other

interference.

Detection height is approximately 70%

of the shortest side of the loop.

1" Min.

Backer-Rod

Vehicular Loop

Detector Wire

Sealant

Saw Cut

Concrete Slab Cross View

1 - 1 1/4in. PVC Pipe

Steel Rebar

Concrete Slab Cross View

Vehicular Loop

Detector Wire

Existing Surface

Vehicular Loop

Detector Wire

Sand filled Saw Cut

Saw Cut

Asphalt Re-surface

New Asphalt

New Slab Pour

Ty-wrap 1 1/4” PVC Pipe to the top of the rebar in the

size and configuration of the loop (i.e. 4ft x 8ft). Then

ty-wrap the loop to the top of the PVC frame. This

stabilizes the loop during the pour and separates it

from the rebar.

Saw Cut Existing Surface

Cut “ deep into the existing surface, place a 45° cut

at the corners to prevent sharp edges from damaging

the loop wire. Notch out for the ”T” connection where

the lead wire connects to the loop. Remove all debris

from the finished cut with compressed air. Place the

loop into the saw cut. Place backer material into the

saw cut over the loop wire and pack tightly. Place a

high quality sealer over the saw cut to seal the

surface.

Resurface Asphalt

Saw cut the existing surface 3/4” deep and place a

45° cut at the corners to prevent sharp edges from

damaging the loop wire. Remove all debris from the

finished cut with compressed air. Place sand over the

loop wire to the surface and pack tightly. Lay new

asphalt.

BLSW1016 Manual_Layout 1 5/8/2015 5:06 PM Page 12

Loading...

Loading...