Page 1

Installation and user guide

Inverter

3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

As at 10/2013, Material no. 747 405-AD

EN

Page 2

2

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Page 3

3

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Contents

1 Introduction 5

1.1 PLATINUM® TL 5

1.2 About this manual 5

1.3 Symbols used 5

1.4 Symbols on product and packaging 6

2 Safety 7

2.1 Intended usage 7

2.2 Improper usage 7

2.3 Personnel requirements 7

2.4 General safety instructions 7

3 Installation 8

3.1 Scope of delivery 8

3.2 Unpacking 8

3.3 Assembly 9

3.4 Connection 13

4 Placing into operation 22

4.1 Switch on 22

4.2 Initial operation 22

4.3 Initial operation menu 23

5 Operation 27

5.1 Display 27

5.2 Operation display 28

5.3 Isolation from the generator field 30

6 Menu 31

6.1 Operate and navigate in the menu 31

6.2 Menu tree 32

6.3 SETTINGS menu 33

6.4 INFORMATION menu 35

6.5 Service menu 36

Contents

Page 4

4

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

7 Maintenance and cleaning 41

7.1 Maintenance 41

7.2 Cleaning 41

8 Errors and troubleshooting 42

8.1 Error display 42

8.2 Event list 44

9 Technical data 48

10 Taking out of operation 52

11 Disposal 53

Contents

Page 5

5

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Introduction

1 Introduction

1.1 PLATINUM® TL

The inverters in the PLATINUM® TL series are single-phase feed-in inverters for different power ranges, see “Technical data” on page 48.

With the aid of the PLATINUM® network (EIA485), up to 50 PLATINUM® inverters can

be connected to form a system.

Options

The following options are available to enhance an inverter or inverter system:

▪ Remote monitoring or remote readouts with the PLATINUM® WebMaster

▪ Evaluation of plant data with the PLATINUM® PV monitor

▪ Remote-controlled AC power reduction via an external monitoring device

1.2 About this manual

This installation and operating manual describes the installation

and operation of the PLATINUM® inverters of the types

3800 TLD, 3801 TLD, 4300 TLD, 4800 TLD, 5300 TLD, 6300 TLD, 7200 TLD.

Additional documents

The following additional documents are available in the download area of our website

www.platinum-nes.com:

▪ Detailed installation and user guide

▪ Information on fault current protection devices

▪ Detailed event list for detecting/eliminating errors

▪ Overview of country and grid codes

▪ Declaration of conformity and certificates

▪ Manufacturer’s warranty

1.3 Symbols used

1.3.1 Structure of warnings

WARNING WORD

Type, source and consequence of the hazard!

f Measures to avoid the hazard.

Page 6

6

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Introduction

1.3.2 Hazard levels in warnings

Symbol Warning

word

Probability of occurrence Consequences of non-obser-

vance

DANGER Imminent danger Death, serious injury

WARNING Potential danger Death, serious injury

CAUTION Potential danger Minor injury

– CAUTION Potential danger Damage to property

1.3.3 Notes

Notes give tips on how to work easily and safely or contain further information.

1.4 Symbols on product and packaging

The following sticker is attached to the inverter:

Page 7

7

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Safety

2 Safety

2.1 Intended usage

▪ Inverters are to be used solely for the purpose of feeding photovoltaically generated

solar energy into the public grid.

▪ All other usage does not comply with the regulations.

2.2 Improper usage

▪ The inverters are not to be used in off grid PV plants.

▪ The inverters are not to be used in vehicles.

▪ The inverters are not to be used in areas at risk of explosion (flour dust, sawdust, etc.).

▪ The inverters are not to be exposed to direct sunlight.

▪ The inverters are not to be used in areas in which the ammonia content of the air

exceeds 20 ppm.

▪ All warranty claims will be rendered null and void in the event of failure to comply

with the warranty terms or the information provided in this operating and installation

manual.

2.3 Personnel requirements

The inverter may only be installed and put into operation in accordance with this

installation and user guide by trained specialist personnel, for example:

▪ Service partners authorised by PLATINUM GmbH

▪ Authorised specialist personnel with knowledge of the applicable guidelines and

standards

2.4 General safety instructions

▪ The inverters are to be used in their original state without independent modifications

and in a technically perfect condition.

▪ Steps must be taken to ensure that the following are adhered to when assembling

and connecting the inverter and the PV system:

– Guidelines and regulations valid in the respective country

– Provisions of the trade associations, TÜV, VDE (Association for Electrical, Electronic

& Information Technologies)

– Technical connection conditions of the energy supplier responsible

– National and international regulations and provisions

▪ Ensure that all protection devices are working correctly.

▪ Observe the operating conditions; see “Technical data” on page 48.

Page 8

8

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3 Installation

3.1 Scope of delivery

▪ Inverter

▪ Wall bracket

▪ Brief guide

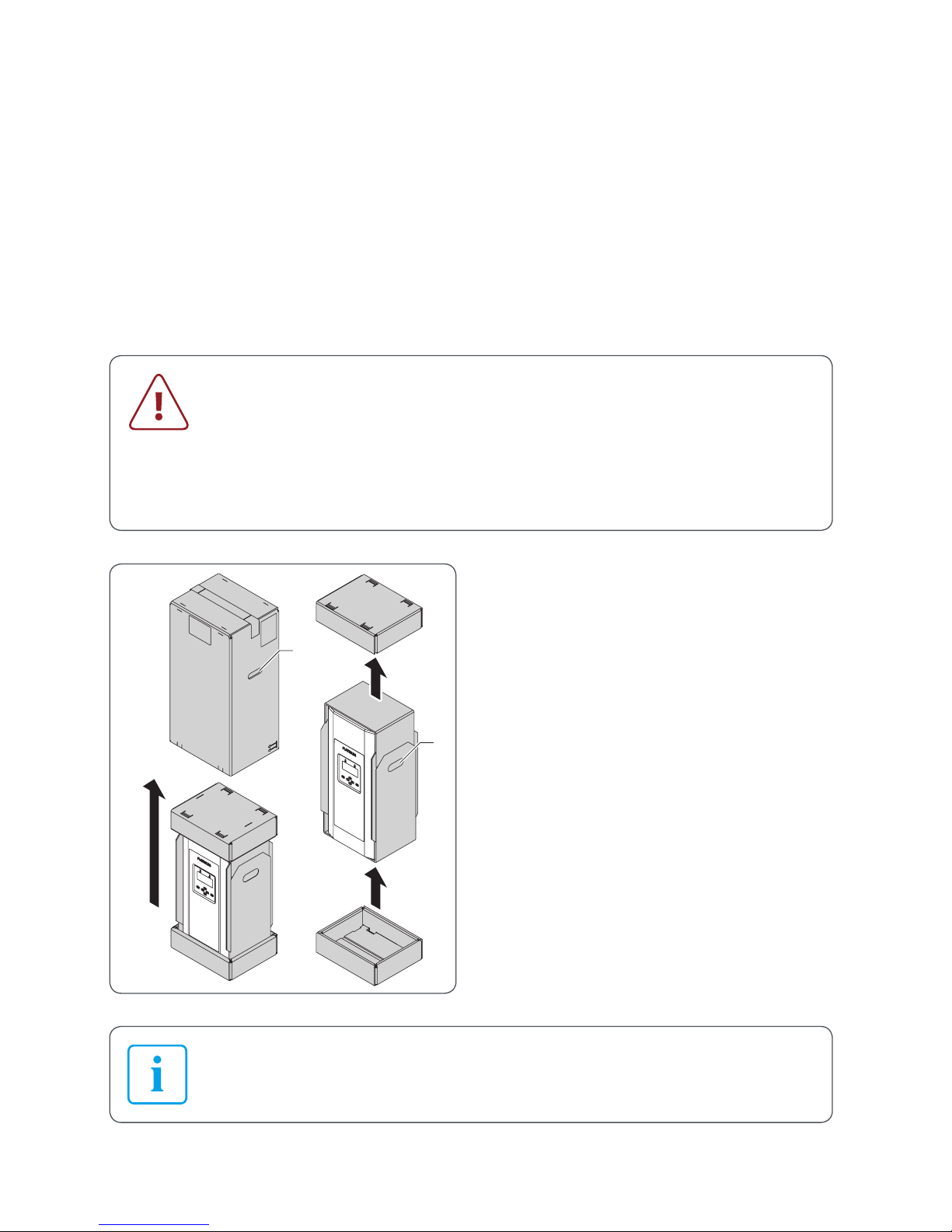

3.2 Unpacking

CAUTION

The inverter is heavy!

f Ask another person to help you unpack and lift it.

f Wear safety shoes when unpacking the inverter and during

installation.

f Ensure that the inverter is positioned securely.

3.

4.

5.

2

1

1. Place the box upright (note the

lettering on the box).

2. Cut the retaining straps without

damaging the box.

3. Grab the handle openings (1) on the

outer jacket of the box and lift it up

and off.

4. Take off the cover from the box.

5. Lift the inverter by the handle

openings (2) out from the bottom of

the box.

6. Set down the inverter.

The supplied brief guide is located underneath the protector; see 13.

Page 9

9

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.3 Assembly

3.3.1 Safety instructions

WARNING

Injury may result if the inverter falls!

f Use fixing materials suited to the assembly wall and the weight of the

inverter.

f Get a second person to help with assembly and disassembly.

f Wear safety shoes during assembly and disassembly.

f Ensure that the inverter is positioned securely.

CAUTION

Material damage due to excessive build-up of dust!

The protection class IP66 does not apply to the communication interface.

f Avoid excessive build-up of dust.

f Avoid build-up of dust with electrically conductive dust particles.

In order to comply with the requirements of standard IEC-62109, a

possibility must be provided for tool-free isolation of the solar generator.

If the design does not feature an integrated DC isolator then an external

isolation device is mandatory; this must be easily accessible.

PLATINUM GmbH recommends that the inverter should not be installed

in living quarters.

Page 10

10

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.3.2 Disassemble the wall bracket from the inverter.

4

3

1. Loosen but do not remove the safety

screws on the sides (3).

2. Grab the wall bracket (4) at the bottom

and lift it up off the inverter.

Page 11

11

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.3.3 Mounting the inverter

The upper cutout in the wall bracket corresponds to the position of the

display and buttons on the mounted inverter.

≥191

≥177

Ø9

≥500

344

125125

≥232

115

≥494

≥920

285

Dimensions in mm

1. Choose a suitable location for assembly. Take into account dimensions and

distances.

2. Fix the wall bracket to the assembly wall with suitable fixing materials.

Page 12

12

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3

5

5

3

3

4

5

1. Working from underneath, hook the

hanger of the inverter (5) at the top in

the slotted piece of the wall bracket

(4).

2. Ensure that the inverter is fitted

correctly on the wall bracket.

3. Secure the inverter by tightening the

safety screws (3) on the sides.

Page 13

13

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.4 Connection

3.4.1 Preparatory work

On devices with a DC disconnect

t Move the switch knob of the DC

disconnect on the underside of the

device to the “0” position.

On devices without a DC disconnect

t Disconnect the DC voltage side with

the external isolation device from the

solar generator.

6

7

1. Grab the protector (6) by its underside

and pull it off the inverter.

2. Take out the brief guide (7).

3. Hang the protector in one of the

holders on the sides of the inverter.

Page 14

14

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.4.2 Connect the AC voltage

DANGER

Risk of death due to high AC voltage!

f Switch off the mains voltage supply (AC side) before connecting the

inverter (safety device).

f Make sure that the central isolation device can be accessed freely.

f Only connect the inverter to TN or TT networks (see IEC 60364-1) with

230 V.

f Observe max. fuse protection permitted on the AC voltage side, see

“Technical data” on page 48.

f Make the AC voltage connection with a cable isolator switch.

PLATINUM GmbH recommends a type C cable isolator switch.

f If an external residual current protective device is required, PLATINUM

GmbH recommends using a residual current protective device (RCD)

of type A.

CAUTION

Destruction of the inverter!

f Never connect inverters between two phases.

f Never mix up the phases with PE or N.

f Distribute the inverters across the three phases in such a way that the

differences between the AC power levels on the different phases do

not exceed the maximum permitted unbalanced load of the network

operator.

Prepare the connection cable for the AC voltage

Dimensioning the wire cross section is the responsibility of the

electrician and depends on the cable length and installation situation.

▪ Min. cross section 4 mm

2

▪ Max. cross section 16 mm

2

1. Protect the AC voltage connection lines with appropriate fuses, see “Technical data”

on page 48.

2. Strip 18 mm of insulation from the AC voltage connection lines and add wire-end

sleeves.

Page 15

15

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

Connect

8

1. Take off the cover (8) from the AC

voltage connection by removing

4 screws.

2. Put the screws in the row of holes.

3. Unfasten the AC screw connection (9)

with seal from the underside of the

inverter.

The cable entry is sealed with a thin

protective layer (10) against external

influences. This protective layer needs to

be removed.

4. Direct the prepared AC voltage

connection line through the AC screw

connection and seal.

5. Feed the AC voltage connection line

into the housing from below.

6. Tighten the AC screw connection.

Page 16

16

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

L N PE 1 2

LNPE 12

7. Connect the AC voltage connection

cable to the inverter:

– Open the terminal with a

screwdriver.

– Insert the conductor.

– Remove the screwdriver.

Terminal Assignment

L Feed phase L1

N Neutral

PE Potential equalisation

1 Monitoring phase L2,

for 3-phase ENS only

2 Monitoring phase L3,

for 3-phase ENS only

8. Refit the cover of the AC voltage

connection using the 4 screws

3.4.3 Connect DC voltage

DANGER

Risk of death due to high DC voltage! A voltage is present at the

PV modules when it is bright.

f Before connecting the inverter, check whether voltage is applied to

the generator’s DC voltage connection.

f Before connecting the inverter, check whether the polarity of the

DC voltage is correct.

f If voltage is applied, wear insulating protective clothing and face

protection.

f Ensure that the cable plug has engaged completely with the socket.

f Detach the DC voltage cable only if the inverter is not in operation.

f Make sure that the DC isolator or a central isolation device can be

accessed freely.

f Do not ground the poles of the PV modules. The inverter does not

have a transformer.

Page 17

17

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

WARNING

Risk of electric shock and material damage!

f Use only the original DC voltage Multi-Contact MC4 cable plug.

f Only connect PV modules that meet the requirements of

IEC 61730 class A.

f Ensure that the max. DC voltage permitted is not exceeded.

f Ensure that the max. direct current permitted per string is not

exceeded.

If more than one string is connected, make sure that the quantity and

type of solar modules and the voltage of strings to be connected in

parallel are the same.

–

+

–

+

1. Fit original Multi-Contact MC4 connectors to each string of the DC voltage

cable. Make sure that the polarity is

correct here.

2. Take off the protective caps from the

required DC voltage connections.

3. Insert the prepared DC voltage

connectors into the DC voltage

connections. In the process, make

sure that the connectors lock in place

correctly.

Fit protective caps to plug connectors that are not used on the inverter.

Page 18

18

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.4.4 Connection to the PLATINUM® network (EIA 485)

Up to 50 PLATINUM® inverters can be connected with monitoring

devices into a network with an overall length of up to 1000 m.

Network cable

▪ CAT 5 shielded twisted pair cable with pre-assembled RJ45 plugs (pin 3 = B and

pin 6 = A)

– or –

▪ Twisted pair of wires of a CAT 5 cable

Connect

11

1. Take off the cover (11) from the terminal strip.

Page 19

19

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

shield

EIA 485

12

EIA 485

ABA

B

0 V

+ 12 V / max. 30

N.C.

optional Input (m

24V

2. Connect the network cables in the

inverter.

CAT 5 cable with RJ45 plug

▪ Incoming cable: Socket 1

▪ Outgoing cable: Socket 2

CAT 5 cable with 2 twisted wires

▪ Incoming cables:

Left-hand terminals A, B

▪ Outgoing cables:

Right-hand terminals A, B

▪ Shielding: Shield

t Ensure that signal lines A and B are

not connected incorrectly.

Termination

An integrated terminating resistor can be activated at both open ends of the network (at

the first and last inverters).

Terminating ensures that the network functions correctly.

12

1. Remove the terminating plug (12)

from the protector.

2. Connect the terminating plug to

socket 1 of the first and last inverter.

Page 20

20

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.4.5 Further connections on the terminal strip

On the terminal strip, there are further terminals for the connection of a potential-free

alarm contact, an external consumer and an input.

shieldABAB

0 V

+ 12 V /

N.C.

optional

1234567

(1) Alarm contact (NC contact)

(2) Alarm contact (centre contact)

(3) Alarm contact (NO contact)

(4) Not used

(5) Input, 12 V max. (optional)

(6) Supply voltage for external

consumer, 12 V, 300 mW max.

(7) Supply voltage for external

consumer, 0 V

Alarm contact

In the event of a fault, the contact closes and activates the alarm system (visual or

acoustic) if required.

t For the supply voltage, only use a safety extra-low voltage (SELV) with a maximum

voltage of 24 V.

The alarm contact can be configured in the menu

SETTINGS –> ALARM FUNCTION; see 34.

Page 21

21

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Installation

3.4.6 Final tasks

6

1. Refit the cover on the terminal strip.

2. Take off the protector (6) from the side

position.

3. Place the upper part of the protector

on the upper holder and gently press

it onto the housing.

4. Slide the lower part of the protector

into the lower holder.

Page 22

22

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Placing into operation

4 Placing into operation

4.1 Switch on

1. Switch on mains voltage supply (safety device).

2. Switch on the DC voltage via the DC disconnect

on the underside of the device or via the external

isolation device.

The inverter type appears on the display along

with the prompt “START?”.

4.2 Initial operation

▪ To transfer all settings correctly, initial operation must be conducted in

full once.

▪ When installing several inverters that are linked with each other via the

PLATINUM® network (EIA485), initial operation can be performed on

any inverter (master programming). For this to be possible, all inverters

in the network must be switched on.

▪ The inverter automatically transfers the setting values to the other

inverters via the PLATINUM® network (EIA485).

▪ Every inverter is allocated a number automatically during initial

operation. This number can be changed and freely assigned in a further

step.

▪ The inverters on which no data is entered display different screen

content depending on the menu. If data cannot be entered, the

inverter displays the start screen.

▪ During initial operation, all inverters connected to the PLATINUM®

network are blocked.

Page 23

23

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Placing into operation

4.3 Initial operation menu

4.3.1 Overview

The initial operation menu distinguishes between the initial operation of a device

in a new PLATINUM® network to be configured and modifications to an existing

PLATINUM® network (exchange inverter, reconfiguration).

Initial operation Exchange inverter/reconfiguration

Start Start

Language Language

Network scan Network scan

Change device number Exchange inverter

Reassign numbers

Country code * Country code *

Date Date

Time Time

* The country code can only be changed for a period of four hours after

initial operation and feed-in starts. This menu will not be displayed later.

Page 24

24

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Placing into operation

4.3.2 Description of the initial operation menu

Changing the date and time can cause saved data to be overwritten or

lead to gaps in data logging.

During initial operation, the date and time must be entered completely

once.

Initial operation menu

Start

Confirm prompt with OK.

Language

Select the language required using the / buttons and confirm

with OK.

Network scan

The inverter scans the PLATINUM® network connected and then

displays the number of participants and inverters in the network.

▪ If the number of participants and inverters is correct, confirm with

OK.

▪ If the number of participants and inverters displayed is not

correct:

– Check the wiring.

– Select REPEAT using the / buttons and confirm with OK.

The inverter recognises only those network participants that are

correctly connected via the PLATINUM® network.

Change

device

number/

reassign

numbers

During initial operation, the inverter numbers are assigned

automatically in the network.

▪ If the numbers set automatically are to be retained, confirm

with NO and continue to the next menu option. The automatic

numbers for all inverters in the network are transferred.

Page 25

25

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Placing into operation

Initial operation menu

Change

device

number/

reassign

numbers

▪ If different numbering is required, choose YES using the

/buttons and choose OK to open the menu for changing

device numbers. The following screen appears on all inverters in

the network.

– On the desired first inverter, confirm NEXT NUMBER? with

OK. The number 1 will be assigned to the inverter.

– Confirm NEXT NUMBER? with OK for every inverter in the

network in the order desired. The next number in each case will

be assigned to the inverter.

Exchange

inverter

This menu option appears only if a new inverter is detected in an

existing network. In this case, the numbers of the inverters replaced

can be used.

This must be configured on every inverter replaced.

▪ If the number displayed (of the inverter replaced) is to be used,

confirm with YES and continue to the next menu.

▪ If different numbering is required, choose NO using the /

buttons and choose OK to open the menu for changing device

numbers.

Page 26

26

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Placing into operation

Initial operation menu

Country code

Select the country required using the / buttons and confirm

with OK.

Further settings may be required depending on the country. These

settings depend on the network operator.

The country code is automatically applied to all network participants.

The country code can only be changed for a period of four hours after

initial operation and feed-in starts. This menu will not be displayed later.

Date

Enter the current date.

▪ Use the / buttons to set the digits.

▪ Use the / buttons to continue to the next digit.

▪ Choose OK to confirm the date entered.

Time

Enter the current time.

▪ Use the / buttons to set the digits.

▪ Use the / buttons to continue to the next digit.

▪ Choose OK to confirm the time entered.

The date and time are automatically applied to all network

participants.

The date and time must be confirmed with OK, otherwise initial

operation cannot be completed.

Once the date and time have been entered, the TIME SETTINGS screen appears; see

“SETTINGS menu” on page 33.

Depending on the requirements of the utility company, the following

additional settings need to be made in the service menu; see “Service

menu” on page 36:

▪ Phase balancer*

▪ Grid support

▪ Power reduction *

* These menus can only be changed 4 hours after initial configuration.

Page 27

27

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Operation

5 Operation

5.1 Display

1

11

10

9

876

23 45

(1) Time in 24-hour format

(2) Alarm LED (red)

(3) Title of the current screen

(4) Operation LED (green)

(5) Date

(6) OK button

(7) Navigation buttons

(8) ESC button

(9) Inverter number

(10) Scroll arrows (vertical and horizontal)

(11) Week day

The scroll arrows show which navigation buttons can be used to navigate

on the current screen.

Meaning of the LEDs

Alarm LED (2) (red)

LED off ▪ Normal operation

LED flashes ▪ Error

Operation LED (4) (green)

LED lit up ▪ Feed-in mode

LED flashes ▪ Preparation for feed-in

LED off ▪ Inverter not in feed-in mode

Both LEDs flash at same time

The inverter is running a network scan or making parameter settings.

Page 28

28

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Operation

5.2 Operation display

I

During normal operation, the operating mode is displayed. The power data is shown in

a table and graph. In this way, the operation display provides an overview of the feed-in

process and the yield of the PV system.

5.2.1 Navigating in the TODAY operation display

/ buttons Switch between “TODAY” and “ACTUAL” operation displays

/ buttons Switch between time periods in the operation display TODAY

5.2.2 TODAY operation display

1

2

3

4

5

(1) Current power

(2) Total energy fed in today

(3) Total feed-in rebate generated today

(4) Total CO

2

saving today

(5) Feed-in progress today

The values displayed by the inverter may differ from those displayed on

calibrated electricity meters.

Display of other time periods

The inverter stores the power data for the total operating time. The following periods

can be displayed:

▪ Today

▪ Current week

▪ Current month

▪ Current year

▪ Since initial operation

▪ Yesterday

▪ Previous week

▪ Previous month

▪ Previous year

Page 29

29

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Operation

Differing display in other time periods

▪ The current power value (W ) is only displayed for the TODAY period and if energy

is currently being fed in. In all other periods, and when energy is not being fed in, the

maximum value (W ) is displayed.

▪ Feed-in rebate >999,000 is displayed exponentially.

– Example: EUR 1,234,567 is displayed as 1.234E6 (=1.234 x 10

6

)

▪ The progress of the power feed-in is only displayed for the periods TODAY and

YESTERDAY. In all other periods, the energy fed in is displayed for each time interval.

– Each day is represented by one bar in the weekly display (Mon. – Sun.).

– Each day is represented by one bar in the monthly display (1st – 31st).

– Each month is represented by one bar in the yearly display (Jan. – Dec.).

5.2.3 ACTUAL operation display

This display shows the actual (current) values for the

voltage, current and power on the DC side and on

the AC side.

Page 30

30

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Operation

5.3 Isolation from the generator field

On devices with a DC disconnect

The DC disconnect on the underside of the device allows the solar generator to be

switched on and off.

Position 0: Solar generator switched off

Position 1: Solar generator switched on

▪ PLATINUM GmbH recommends activating the DC isolator once a year

to prevent the contacts from fusing together.

▪ PLATINUM GmbH recommends switching off the mains voltage (AC)

before switching off the DC isolator to minimise wear to the contacts.

On devices without a DC disconnect

t Disconnect the DC side from the solar generator using the external isolation device.

Page 31

31

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6 Menu

6.1 Operate and navigate in the menu

6 .1.1 Call up menu

1. Press ESC on the operation display.

The main menu is displayed.

OPERATION DISPLAY is selected.

2. Use the / buttons to select the menu

required, e.g. SETTINGS.

3. Open the menu selected by choosing OK.

The associated submenus are displayed.

6.1.2 Menu operation

The scroll arrows available in the current menu are shown in the black

bar on the left.

Button Meaning

/ ▪ Select from a list

▪ If entering information: increase/decrease value

/ ▪ Switch between alternatives, e.g. YES/NO, BACK/SELECT

▪ To the next/previous/higher-level parameter

▪ If entering information: to the next/previous digit

ESC

▪ Return to the higher-level menu without making any changes

OK

▪ Adopt setting and return to the higher-level menu

▪ Open selected submenu

Page 32

32

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.2 Menu tree

Operation

display

See “Display” on page 27

Settings

Time settings

Date / time

Date format

DD-MM-YYYY, MM-DDYYYY, YYYY-MM-DD

Daylight saving Manually, automatically

Language Deutsch, English, Italiano, Español, Nederlands,

Français

Alarm volume

0 ... 3

Alarm function Off, Interval, Continuous, Test

LCD Contrast 0 ... 63

Brightness 0 ... 9

Rebate

System

Plant size

Meter 2

Information

Operating data

System data

Inverter type

Inverter version

The menu options are described in tables below.

Page 33

33

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.3 SETTINGS menu

Time settings

Date / time ▪ Enter date and time in the format shown.

▪ If changing to daylight savings time manually, the following

prompt appears: DAYLIGHT SAVING YES/NO.

– YES One hour is added to the time set.

– NO The time already set is used.

▪ Before the new values are selected, a security prompt is shown.

Date format ▪ Select date format.

Possible date formats: DD-MM-YYYY, MM-DD-YYYY, YYYY-MM-DD

Daylight saving MANUALLY Manually switch between daylight saving/

winter time.

When the date and time are next entered, the

DAYLIGHT SAVING YES/NO prompt appears.

AUTOMATICALLY Automatically switch to daylight saving/winter

time according to the selected country.

▪ Changing the date and time can cause saved data to be

overwritten or lead to gaps in data logging.

▪ The inverter transfers the time settings to all network participants

automatically.

Language

Deutsch

English

Italiano

Español

Nederlands

Français

▪ Select the language required.

The inverter transfers the language set to all network participants

automatically.

Volume

0 ... 3 ▪ Set the alarm volume for the built-in buzzer on this inverter.

Possible values: 0 ... 3

Factory setting: 0 (alarm off)

Page 34

34

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

Alarm function

Off The alarm contact (NO contact) remains constantly open in the

event of a safety-related or blocking fault.

Interval The alarm contact (NO contact) opens and closes periodically in the

event of a safety-related or blocking fault.

Duration The alarm contact (NO open contact) is constantly closed if a safety-

related or blocking fault occurs until the fault has been rectified.

Test Briefly closes the alarm contact for testing purposes if the menu

item is selected.

LCD

Contrast ▪ Set the display contrast.

Possible values: 0 ... 63

Brightness ▪ Set the display brightness.

Possible values: 0 ... 9

Feed-in rebate

Currency ▪ Enter currency of the country, max. three characters.

Value / kWh ▪ Enter rebate per fed-in kWh in the format shown.

System

Name ▪ Assign the system (network with several inverters) one name

(max. 18 characters).

Description ▪ Specify the system further by means of a description

(max. 18 characters).

Plant size

Power system ▪ Enter power installed in the entire network.

A security prompt appears: “Plant size ...”

Meter 2

Meter 2 counts the energy fed in since the last reset.

Back ▪ Do not reset meter 2.

Reset ▪ Reset meter 2.

Page 35

35

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.4 INFORMATION menu

The INFORMATION menu offers the following information screens:

1 2

(1) Total energy since initial operation

date and number of operating hours

(2) Energy since the last reset and

number of operating hours

3

4

(3) Name and description (if available) of

the system

(4) Number of participants and inverters

in the PLATINUM® network

5

6

8

7

(5) Type information

(6) ENS version *

(7) Serial number

(8) Configured standard

9

10

(9) Firmware version

(10) PLATINUM® Network version

* ENS = Device for monitoring the network with allocated control elements

Page 36

36

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.5 Service menu

6.5.1 Call up service menu

1. Call up the main menu with the ESC button.

2. Select the SETTINGS menu with the / buttons and confirm with OK.

3. Hold both the and buttons down together for around three seconds.

The service menu is displayed and the EVENT LIST menu option is selected.

4. Select the menu required using the / buttons.

6.5.2 Overview of the service menu

Event list

See section 8.2

Parameters

See section 6.5.3

Initial op. date

Show initial operation date

Energy meter

Show energy fed in since initial operation

Reconfiguration

See section 4.3

MPP mode

See section 6.5.4

Grid support

See section 6.5.5

Phase balancer*

See section 6.5.6

Power reduction *

See section 6.5.7

* These menus can only be changed for a period of 4 hours after initial

configuration.

Page 37

37

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.5.3 Service menu PARAMETERS

In some supply areas, the values for supply voltage and frequency sometimes or always

differ from the factory settings. PLATINUM® inverters can be adapted to these values.

For more information, contact the PLATINUM® service.

The PARAMETERS service menu shows the parameters set, the country code and the

valid guidelines. The parameters are structured in several levels, with the specific value

displayed on the lowest level.

Parameters can only be modified by certified persons with the

PLATINUM® service tool.

Example: Parameter 1007 VoltMon (voltage monitoring)

Parameter 1007

Parameter 1007

▪ with submenus 1007.0 and 1007.1

Parameter 1007,

▪ with submenus 1007.0 and 1007.0.0

▪ with the current value for 1007.0.0

Page 38

38

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.5.4 Service menu MPP MODE

MPP mode

Default ▪ Default MPP mode for free module surface

Shadow mode ▪ For systems with shadowing (e.g. through trees), the MPP area is

frequently subject to complete scans.

▪ Shaded systems should also be run initially in the MPP mode

NORMAL.

▪ In the MPP SHADOW mode, the ideal yield may not be achieved

because only a low level is fed in during the MPP search.

6.5.5 Service menu GRID SUPPORT

Grid support

Remote In this setting, grid support is set by a remote device

(e.g. PLATINUM® WebMaster).

Cosine Phi Enter cosine phi.

▪ Cosine Phi 0.707 ... 1

▪ Type Capacitive* (over-excited),

inductive* (under-excited)

▪ Phi Associated angle

Reactive power Enter the reactive power.

▪ % P_Nom 0 ... 50

▪ Type Capacitive* (over-excited),

inductive* (under-excited)

▪ Reactive power Associated reactive power

Cosine Phi(P) In this setting, cosine phi is configured according to the

specifications defined in the PLATINUM® inverter.

Q(U) Voltage-dependent reactive power Centre voltage

▪ Typically 102.0%

Q(U) hysteresis Q(U) closed-loop control according to the curve saved in the inverter.

The curve can be parametrised via the PLATINUM® service tool.

* from the perspective of a meter system

Page 39

39

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

6.5.6 Service menu PHASE BALANCER

The unbalanced load is the difference between the instantaneous AC power levels

on the three network phases. Energy providers and network operators specify the

maximum permissible unbalanced load for the installation of inverters in different

phases of the supply network.

The phase balancer function ensures that the maximum permissible unbalanced load is

not exceeded in the following scenarios:

▪ Failure of an inverter module

▪ Load-dependent variations in AC power levels

▪ This menu can only be changed for a period of 4 hours after initial

configuration.

▪ A special phase balancer cable is required in order to adjust the phase

balancer; this cable is available as an optional accessory.

▪ The phase balancer monitors the three different inverters that are

connected with the phase balancer cable. Further information can be

found in the guide for the phase balancer cable.

▪ PLATINUM GmbH recommends setting the phase balancer to “Off”

(factory setting) and to only activate it at the express request of the

energy supplier.

Phase Balancer

Off The phase balancer is switched off. The unbalanced load is not

limited.

Power Control Configuring the phase balancer.

▪ Max. power Enter max. permissible unbalanced load in W.

Possible settings: 0 W ... max. power

▪ Reaction time Enter the reaction time in seconds.

Possible settings: 0 ... 3600 seconds

Factory setting: 300 seconds

▪ Power control Checking and confirmation of the previously

chosen settings. The inverter transmits the data

to the other two inverters connected to the

phase balancer cable. The red and green LEDs

flash while the data is being saved.

Page 40

40

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Menu

Phase Balancer

Error Off In the event of failure of an inverter, the other two inverters

connected via the phase balancer are also isolated from the

network.

Error Reduce In the event of failure of an inverter, the other two inverters

connected via the phase balancer limit the AC power level to the set

unbalanced load.

If the feed-in power of an inverter is reduced due to unbalanced load, no

status message is displayed on the inverter.

6.5.7 Service menu POWER REDUCTION

This menu can only be changed for a period of 4 hours after initial

configuration.

Power reduction

Maximum

power

Enter the maximum power for this inverter according to the

specifications of the network operator.

Page 41

41

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Maintenance and cleaning

7 Maintenance and cleaning

DANGER

Risk of death due to electric shock!

f Only allow inverters to be opened by the PLATINUM® service

department or by service partners authorised by PLATINUM GmbH.

DANGER

Risk of death due to high DC and AC voltages!

f Wear insulating protective clothing and face protection.

f Maintenance and cleaning is to be performed only by trained

specialist personnel.

The trained specialist personnel must be granted permission by the

energy provider responsible.

Before every maintenance or cleaning task:

f Switch off mains voltage supply (safety device).

f Set the switch knob of the DC isolator to 0.

f Wait at least 40 minutes until the capacitors are discharged.

f Make sure that no voltage is applied to the DC cables.

7.1 Maintenance

The inverter is maintenance-free.

7.2 Cleaning

CAUTION

Destruction of the inverter!

f The inverters must not be cleaned with a steam cleaner.

To ensure cooling, clean the ventilation slots regularly with

▪ a vacuum cleaner

▪ soft brush

▪ pressured air

Page 42

42

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Errors and troubleshooting

8 Errors and troubleshooting

8.1 Error display

Three different types of error are displayed on the inverter:

▪ Serious errors

▪ Blocking errors

▪ Non-blocking errors

As long as an error is displayed, the event list can be called up by

pressing the button; see 36.

8 .1.1 Serious errors

WARNING

Destruction of the inverter due to serious error!

f Switch off AC voltage.

f Switch off DC voltage: Set DC isolator to 0.

f Inform the PLATINUM® service department. Have the error code and

serial number to hand.

Example of a serious error

When a serious error is displayed:

1. Follow the instructions on the inverter.

2. To exit the error display, press the button.

The event list is displayed.

3. Exit the event list by pressing the ESC button.

Page 43

43

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Errors and troubleshooting

8.1.2 Blocking errors

DANGER

Risk of death due to electric shock!

f Blocking errors are only to be rectified by service partners authorised

by PLATINUM GmbH.

Example of a blocking error

▪ The inverter is permanently switched off.

▪ The inverter raises a visual alarm (red LED

flashes).

▪ The inverter raises an acoustic alarm.

When a blocking error is displayed:

1. Follow the instructions on the inverter.

2. To stop the acoustic alarm, press any button.

3. To exit the error display, press the button.

The event list is displayed.

4. Exit the event list by pressing the ESC button.

The initial operation screen is displayed. The red LED continues to flash as long as

the error remains.

8.1.3 Non-blocking errors and warnings

Non-blocking errors occur temporarily (e.g. overvoltage on the grid). The inverter

switches off automatically and remains switched off until the cause of the error no

longer exists. Once the error has been rectified, the inverter automatically reverts to

normal operation.

Example of a non-blocking error

The red LED flashes at the same time as long as

the error exists.

Stop alarm

1. To exit the error display, press the button.

The event list is displayed.

2. Exit the event list by pressing the ESC button.

Page 44

44

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Errors and troubleshooting

8.2 Event list

The “Event List” in the service menu (see “Service menu” on page 36) displays the

last 100 events detected.

Structure of the event list

1 2 3 4

(1) Sequential numbers

(2) Date

(3) Time

(4) Event code

The complete event list can be downloaded from our website

www.platinum-nes.com.

When making contact with the PLATINUM® service department, have

the serial number and event code to hand.

No. Meaning Measure

Serious errors

900 AC voltage too high ▪ Isolate inverter from network

▪ Check AC voltage connection

910 DC voltage too high ▪ Isolate inverter from network

▪ Isolate inverter from DC voltage connection

▪ Check inverter for damage

▪ Check the module connections

920 Reverse polarity at DC

voltage connection

▪ Set DC disconnect to 0

▪ Check DC voltage connection

930 Isolation error between PV+

and earth / PV– and earth

▪ Check isolation of PV modules

▪ Check isolation of PV cables

▪ AC installation (check N and PE)

Page 45

45

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Errors and troubleshooting

No. Meaning Measure

Blocking errors

1000

...

1030

Blocking system error ▪ Isolate inverter from network and from DC

generator

▪ Put inverter back into operation

If measures prove unsuccessful:

▪ Inform service

1040 DC voltage too high ▪ Check module connection

1050 Reverse polarity at DC

voltage connection

▪ Set DC disconnect to 0

▪ Check DC voltage connection

1060

...

1290

Blocking system error ▪ Isolate inverter from network and from DC

generator

▪ Put inverter back into operation

If measures prove unsuccessful:

▪ Inform service

1300 L and N connections mixed up ▪ Check L and N at the AC voltage connection

1310

...

1990

System error ▪ Isolate inverter from network and from DC

generator

▪ Put inverter back into operation

If measures prove unsuccessful:

▪ Inform service

Non-blocking errors

2010 Amplitude limit for feed-

in phase exceeded or

undershot

▪ Arrange for voltage amplitude of feed-in

phase to be checked

2020

...

2040

Grid amplitude error phaseto-phase voltage

▪ Ensure that all safety devices are switched

on

▪ Ensure that all three phases are connected

2080 Network fault on feed-in

phase (voltage peak)

If this occurs frequently:

▪ Arrange for all contacts and safety devices

to be checked, from the service connection

to the inverter

▪ Arrange for the network quality to be

checked

Page 46

46

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Errors and troubleshooting

No. Meaning Measure

2100

2110

Mains frequency limit

exceeded or undershot

If the inverter is supplied with emergency

power from a different mains frequency:

▪ No measures required

2120

...

2190

Diagnosis support in service

situation

▪ Inform service of error code if required

2200

...

2240

Measured temperature too

high

▪ Check ventilation openings

2300

...

2330

Temperature sensor

defective

▪ Inform service

2340

...

2890

Diagnosis support in service

situation

▪ Inform service of error code if required

2900 Subsequent error during

network fault or excess

temperature

▪ No measures required

2910

...

2990

Diagnosis support in service

situation

▪ Inform service of error code if required

Warnings

3000

...

3990

Diagnosis support in service

situation

The inverter stores the

warning in the event list

▪ Inform service of error code if required

Information

4000

...

4990

Diagnosis support in service

situation

The inverter stores the

warning in the event list

▪ Inform service of error code if required

Page 47

47

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Errors and troubleshooting

Page 48

48

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Technical data

9 Technical data

Input variables 3800 TL 3801 TL

Max. PV power 4,300 Wp 4,000 Wp

Max. DC power (cos ϕ = 1) 3,800 Wp 3,480 Wp

MPPT voltage range 350 – 710 V 349 – 710 V

Max. input voltage 880 V

Max. MPPT input current 11.5 A 10.5 A

Number of string inputs 1 1

Number of MPP trackers 1

Short circuit current 16 A 15 A

Output variables 3800 TL 3801 TL

Nominal power (cos ϕ = 1) 3,680 W 3,330 W

Nominal current 16.0 A 14.5 A

Max. apparent power 3,680 VA 3,330 VA

Max. AC current 16.0 A 14.5 A

Fuse protection on the AC side 20 A 20 A

Min. start power 7 W 7 W

Mains output voltage / mains frequency 230 V (+/– 20%) / 50 Hz (+/– 5%)

Feed-in / monitoring phases 1 / 1 or 3

Max. network impedance permitted (Z

max

) n/a

Standby consumption <2 W

Short-circuit strength Yes

Power factor (cos ϕ) 0.7 ind. ... 0.7 cap.

Max. short circuit current (max. duration 5 ms) <100 A

Max. switch-on current <20 A

Efficiency 3800 TL 3801 TL

Max. efficiency 97.7% 97.7%

Euro efficiency 97.4% 97.4%

Type name 3800 TLD 3801 TLD

Page 49

49

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Technical data

4300 TL 4800 TL 530 0 TL 6300 TL 7200 TL

4,900 Wp 5,400 Wp 6,000 Wp 7,100 Wp 8,000 Wp

4,300 Wp 4,800 Wp 5,300 W 6,300 W 7,200 W

351 – 710 V 348 – 710 V 349 – 710 V 350 – 710 V 351 – 710 V

880 V

13 A 14.5 A 16.0 A 18.5 A 21.0 A

1 1 1 2 2

1

18 A 20 A 22 A 26 A 29 A

4300 TL 4800 TL 530 0 TL 6300 TL 7200 TL

4,120 W 4,600 W 5,000 W 6,000 W 6,900 W

17.9 A 20.0 A 21.7 A 26.1 A 30.0 A

4,120 VA 4,600 VA 5,000 VA 6,000 VA 6,900 VA

17.9 A 20.0 A 21.7 A 26.1 A 30.0 A

25 A 25 A 32 A 32 A 32 A

7 W 7 W 7 W 8 W 8 W

230 V (+/– 20%) / 50 Hz (+/– 5%)

1 / 1 or 3

424 mW 379 mW 349 mW 290 mW 253 mW

<2 W

Yes

0.7 ind. ... 0.7 cap.

<100 A

<20 A

4300 TL 4800 TL 530 0 TL 6300 TL 7200 TL

97.7% 97.7% 97.7% 98.0% 98.0%

97.4% 97.4% 97.4% 97.5% 97.5%

4300 TLD 4800 TLD 5300 TLD 6300 TLD 7200 TLD

Page 50

50

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Technical data

Interfaces ... TL

DC isolation device Optional switch integrated in device for

isolation from generator field

DC input DC connector, Multi-Contact MC4

AC output Spring terminal

PLATINUM® Network EIA 485, 2 x RJ45 Western Modular, screw

terminals

Service interface EIA 232, D-sub 9-pin socket

Potential-free contact 1 changeover contact, max. 24 V AC / 2 A,

screw terminals

Ambient conditions ... TL

Operating temperature range –20 °C to +60 °C

Max. temperature for rated power +45 °C

Storage temperature –20 °C to +80 °C

Rel. Humidity Max. 95%

Protection class (with the exclusion of

the digital interface)

IP66 in accordance with DIN EN 60529

Level of contamination II, external and internal use possible

Page 51

51

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Technical data

Inverter data ... TL

Weight

▪ 3800 TL, 3801 TL, 4300 TL

▪ 4800 TL, 5300 TL

▪ 6300 TL, 7200 TL

27 kg

28 kg

29 kg

Dimensions (H x W x D) 720 x 320 x 250 mm

Overvoltage category DC side: II

AC side: III

Reverse voltage protection (DC) Yes

Ground fault monitoring DC side: Isolation check

AC side: AFI

Protection class / overvoltage

protection

I / III

Optical display Full graphic LCD, 170 x 76 pixels

Integrated datalogger Storage capacity sufficient for operating time

of 30 years

Switching concept Transformerless, DIVE, RAC-MPP®

technology

Cooling concept

▪ 3800 TL, 3801 TL, 4300 TL, 4800 TL

▪ 5300 TL, 6300 TL, 7200 TL

Convection cooling

Fan

The technical data is valid for a maximum height of 2,000 m above sea

level.

Page 52

52

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Taking out of operation

10 Taking out of operation

DANGER

Risk of death due to high DC and AC voltages!

f Wear insulating protective clothing and face protection.

f Inverters are only to be uninstalled by trained specialist personnel.

The trained specialist personnel must be granted permission by the

energy provider responsible.

f Switch off mains voltage supply (safety device).

f Set the switch knob of the DC isolator to 0.

f Wait at least 40 minutes until the capacitors are discharged.

f Make sure that no voltage is applied to the DC cables.

WARNING

Injury may result if the inverter falls!

f Get a second person to help with assembly and disassembly.

f Wear safety shoes during assembly and disassembly.

f Ensure that the inverter is positioned securely.

The procedure for taking inverters out of operation is the reverse of that

for installation and assembly.

Page 53

53

Installation and user guide for PLATINUM® inverters 3800 TL, 3801 TL, 4300 TL, 4800 TL, 5300 TL, 6300 TL, 7200 TL

Disposal

11 Disposal

▪ Packaging and replaced parts are to be disposed of in accordance with

the regulations of the country in which the inverter was installed.

▪ Do not dispose of PLATINUM® inverters in household waste.

▪ PLATINUM® inverters can be fully returned to PLATINUM GmbH at

the end of their service life.

▪ PLATINUM® inverters can be disposed of via municipal waste

management for electrical devices.

Page 54

PLATINUM GmbH

Pfannerstraße 75

88239 Wangen im Allgäu, Germany

Tel.: +49 7522 9738-0

Fax: +49 7522 9738-100

info@platinum-nes.com

www.platinum-nes.com

PLATINUM® Service

Tel.: +49 7522 9738-400

Fax: +49 7522 9738-410

service@platinum-nes.com

Loading...

Loading...