Plasti-Bond, a RobRoy Company Corrosion Protection Comparison Guide

Corrosion Protection

Corrosion and Harsh Environment Protection

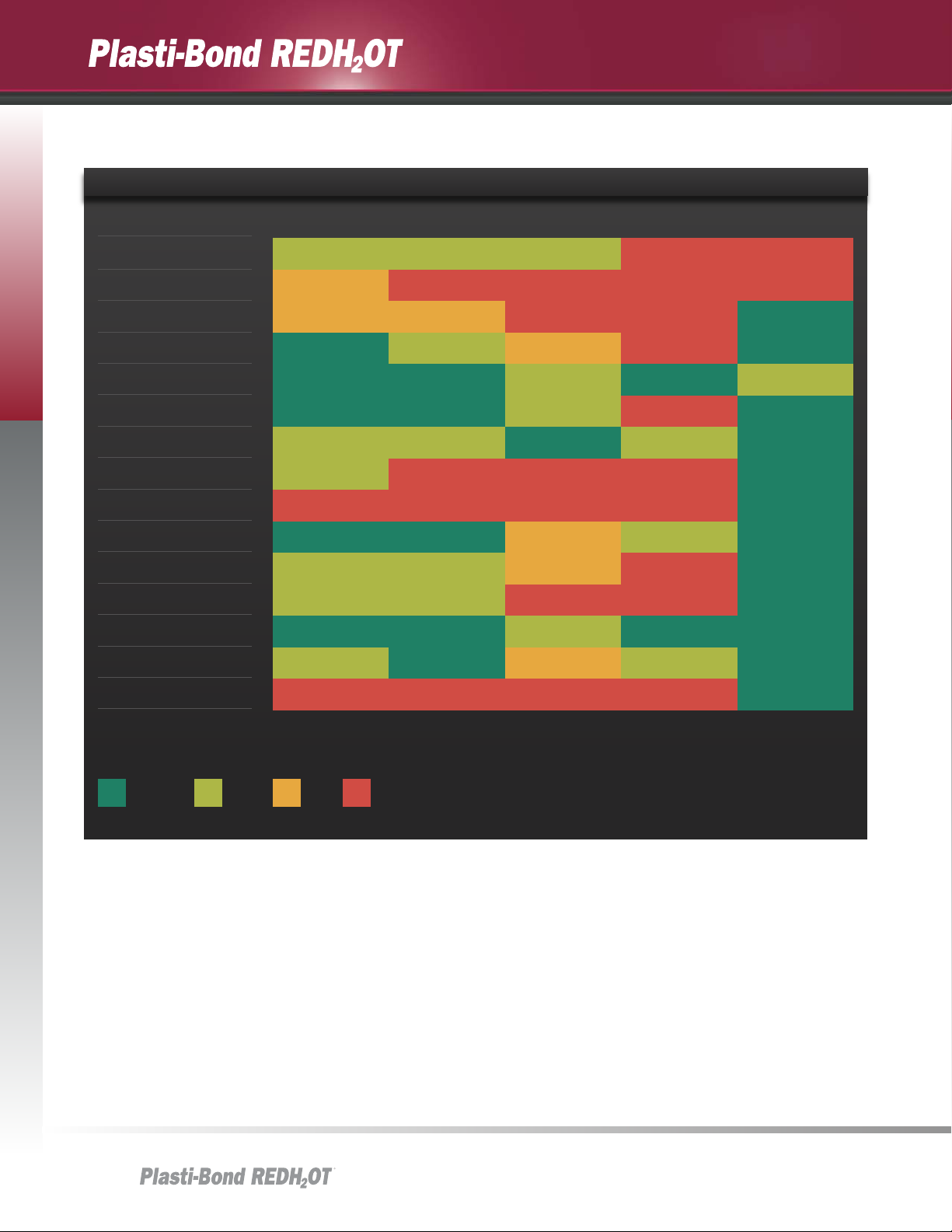

CHEMICAL RESISTANCE PERFORMANCE RATING

Overview

Harsh Chemicals

Acetic Acid (20%)

Chlorine, Anhydrous Liquid

Chorine Water

Citric Acid

Diethylene Glycol

Fruit Juice

Hydrogen Peroxide (30%)

Phosphoric Acid (Crude)

Phosphoric Acid (>40%)

Sodium Carbonate

Sodium Chloride

Sodium Hydroxide (50%)

Sodium Metasilicate

Sodium Silicate

316

STAINLESS STEEL

B B B d d

C d d d d

C C d d A

A B C d A

A A B A B

A A B d A

B B A B A

B d d d A

d d d d A

A A C B A

B B C d A

B B d d A

A A B A A

B A C B A

304

STAINLESS STEEL ALUMINUM

CAST

IRON

PVC

COATED

Sulfuric Acid (10-75%)

d d d d A

Chemical Resistance

Performance Rating Key

Excellent Good Fair Not Recommended

A B C d

The chart above will guide you in the selection of

the best anti-corrosion products for your specic

applications. There is a direct correlation between

every corrosive environment and products installed

to protect against the high cost of corrosion

damage. Consequently, product performance and

uct life cycles are critical to successful

prod

protection. In that regard not all PVC-coated

galvanized rigid conduit is created equal.

All such conduit is authorized to carry an identical

UL listing label related to safety, but only some

manufacturers, such as Plasti-Bond have earned

the right to carry the ETL-Veried PVC-001 label

based on independent product performance tests

proving that ETL-Veried PVC-

coated galvanized

rigid conduit provides reliable protection against

corrosion 10 or more times longer than brands

that have not been ETL-Veried.

16

1100 US Highway 271 South

Gilmer, Texas 75644

Phone: 903.843.5591

Fax: 903.843.5595

Loading...

Loading...